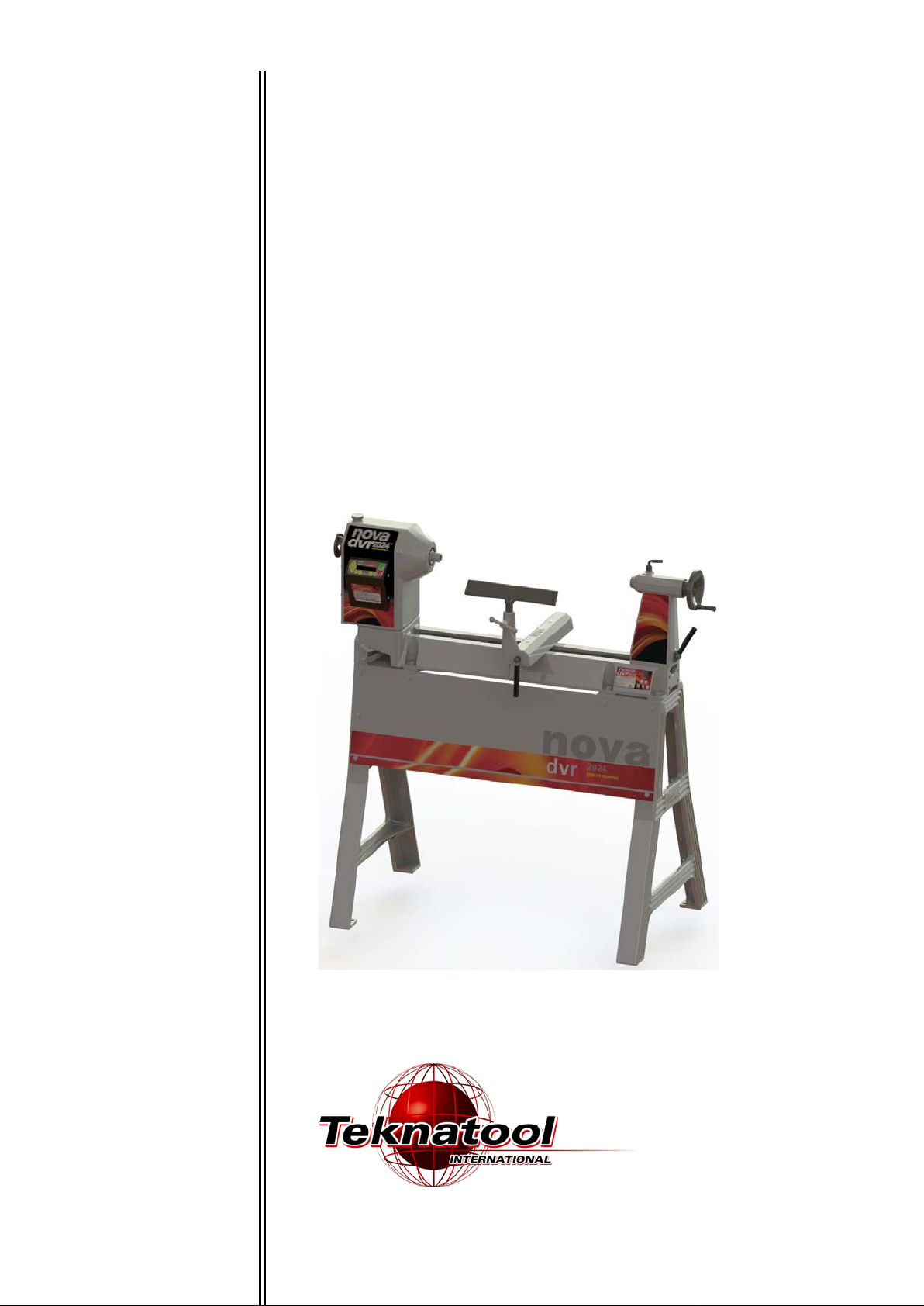

Teknatool DVR 2024 User Manual

I

M

NSTRUCTION

NOVA

TM

DVR 2024

WOOD LATHE

ANUAL

-1-

116-0712-006

Models

1) 57080 spindle thre a d 1 1/ 4" x 8 TPI 220v (USA)

2) 57081 spindle threa d 1 1/4" x 8 TPI 220v (Aus/NZ)

3) 57082 spindle thread 1 1/4" x 8 TPI 220v (UK)

4) 57083 spindle thread M33x3.5 220v (Europe)

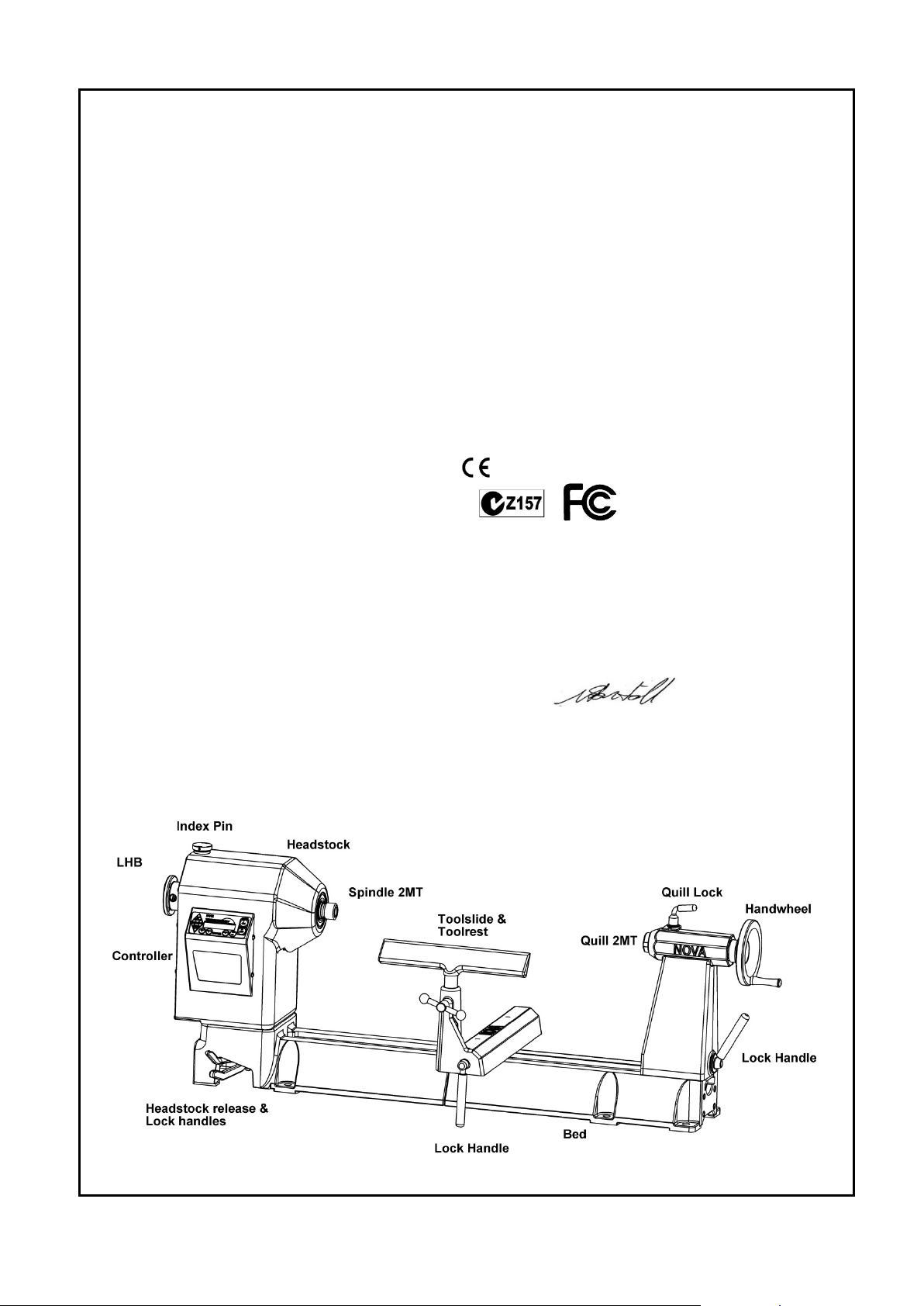

NOVA DVR 2024 Lathe Features at a glance

DVR Electronic drive

The Nova DVR lathes are unique. The DVR incorporates the motor built as part of the headstock, the

spindle and motor are one unit. The motor is almost maintenance free and designed with high

reliability. The Digital Variable Reluctance motor uses smart motor technology to provide an

incredibly smooth and powerful drive. This drive takes turning to a new level. The controller monitors

the spindle position constantly and maintains spindle speed very closely. Additional power is added

as it senses extra load from the tool.

Add on Bed System

A lathe that meets your woodturning needs your workshop space, and your pocket! Each segment is 20" or 510mm in length. This

feature appeals for many different reasons:

As a compact lathe (standard configuration) it is great for small turning workshop spaces.

• As an extended lathe for those wanting to do extra long spindles (beyond the traditional between center of most lathes) the Nova DVR

2024 delivers big turning capacity.

• As a bowl lathe for those just wanting to turn bowls.

Sophisticated Swivel Head

Swivel head lathes have many advantages:

• Space saving

• Allows the turner (not the machine!) to decide the most comfortable position for your turning (saving you from backstrain)

• Elimination of left-hand ‘outboard’ turning techniques and no extra outboard chucks and faceplates are necessary.

There are a number of swivel head lathes available, but Nova DVR have by far the most sophisticated, accurate and easy to use swivel

head on the market.

The Nova DVR lathes can be easily and quickly swiveled to any position (360 degrees). It can be solidly locked in any position plus it has

the added security of a detent pin lock at 0,22.5,45,90 degrees plus 315 (for left-hand use).

The swivel head turns, locks easily and has a very accurate detent position, to lock the spindle in line with the tailstock. The combination of

rigid Tailstock construction and detent pin delivers superb accuracy and is unique to the Nova DVR .

116-0712-006

-2-

Solid Construction

Well proven design, the Nova DVR 2024 is made from Cast Iron components for strength and rigidity. Added features like special webbed

bed design makes the lathe well equipped to take heavy turning stresses. The bed has been designed with vibration dampening qualities a solid 1/2" cross rib is positioned along the bed unit, quickly dissipating any vibration as it travels down the bed. The new powerful

trapezoidal bed design delivers even more vibration damping properties. All this combined with cosmeticall y appeali ng, smoot h fl owing

lines.

Cast iron has always been the material of choice for Woodlathe

construction for its inherent mass and an excellent modulus of

vibration.

Bed Extension Segment Main Bed Segment

New 10 Favourite Speeds Function

Pre-program your most favourite speeds for easy retrieval.

Trapezoidal Bed Design

Powerful with smooth flowing lines, Nova bed design delivers even more vibration dampening propert i es.

New Headstock Design

One piece design increases strength and vibration dampening properties. Micro analysed for optimum design. Same popular swivel

headstock as used in the older DVR and 3000 Lathe models, saves strain on your back.

Adaptive Control Software

Smart adaptive computer technology actually measures the weight of the work piece and adjusts its performance accordingly.

Safety Sensing Feature

Intelligent DVR computer controller senses abnormal turning conditions e.g. a chisel dig in or index left engaged – and instantaneously

shuts down power to the spindle. Normal safety precautions would still apply – see pages 7-8.

Energy Efficient

Unlike other ‘dumb’ electric motors, the Smart DVR Motor only inputs enough power to maintain the set speed – giving you potential for

power savings over conventional motors.

Wide Speed Range

100-5000 rpm, easy push button speed change.

DVR Direct Drive Motor

Driven by unique Direct Drive Variable Reluctance Motor Technology, with superior performance over AC or DC motors. Proven

technology, many thousands of users. No power loss through belts or transmission. Provides digital electronic push button variabl e speed

with no belt changes.

Ultra Smooth Cutting Power

Selected RPM is closely maintained and the DVR has no belt stretch or motor bounce which affects smooth cutting. The DVR motor runs

smooth with almost no vibration.

5 Year Warranty (limited)

On all castings, mechanical parts and components. 2 Year Warranty on all electronics and electrical components.

Plug and Play

Just bolt to stand or bench, plug it in and you are turning! No complex motor set ups or adjustments.

Low Mantainence

The motor is simple, brushless with no rotor windings (rotor is solid steel). The indust rial grade elect roni cs are bui lt to last. There are no

drive pulleys or belts to set up or come loose.

116-0712-006

-3-

Welcome

Thank you for choosing our NOVA DVR 2024 Wood Lathe and welcome to the Teknatool product family. Your

choice shows you want the best for your woodturning and you recognize the superb DVR drive technology and

the host of other unique features the Nova DVR offers.

We strive to achieve the best value for your money – providing quality, innovative features, a wide range of

accessories – plus comprehensive, ongoing support (latest manuals downloadable from our website,

newsletters, projects etc). We are only a phone call or email away with technical advice or assistance on the

operation of your lathe or your woodturnin g queries .

Please feel free to contact us about any aspect of our products or service – we regard our customers as our

best development and improvement team – we would love to hear from you!

Once again, welcome to the “Teknatool NOVA Family”. We trust that you enjoy our products and hope they

enhance the pleasure you experience from the wonderful craft of wood turning!

Best Regards

Brian Latimer

Marketing Director

Teknatool International Ltd

116-0712-006

-4-

Contact Teknatool

Website: http://www.baptist.nl

Email: info@hardwarecentre.co.za

New Zealand

Teknatool International Ltd

Phone: (+64) 9 477 5600

Fax: (+64) 9 477 5601

Email: service@teknatool.com

Website: www.teknatool.com

Carba-Tec NZ Ltd

Free Phone: 0800-444-329

Phone: 274-9454

Website: www.carbatec.co.nz

United States

Teknatool Service Center

Phone: 727-954-3433

Fax: 727-623-0902

Email: service@teknatool.com

Website: www.teknatool.com

Woodcraft Supply Corp

Technical Service: 1-800-535-4486

Orders: 1-800-225-1153

Website: www.woodcraft.com

Australia

Carbatec Australia

Phone: +61 7 3397 2577

Free Fax: +61 7 3390 5280

Email: sales@carbatec.com.au

Website: www.carbatec.com.au

Canada

KMS Tools and Equipment Ltd

Phone: (+1) 604-522-5599

Free Phone: 1-800-567-8979

Fax: (+1) 604-522-0638

Email: kmstools@kmstools.com

Website: www.kmstools.com

Netherlands

United Kingdom

Record Power

Phone: (+44) 0870 770 1777

Fax: (+44) 0870 770 1888

Website: www.recordpower.co.uk

Austria

Neureiter

Phone:+43 6244 202 99

Fax: +43 6244 202 9910

Email: kontakt@neureiter-maschinen.at

France

OTELO

Phone: 0.800 33 11 11

Fax: 01 39 72 16 60

Website: www.otelo.fr

MAISON DU TOURNAGE

Phone: +33-467-232-852

Fax +33-467-230-038

Email: relations.maison.du.tournage@wanadoo.fr

Norway

WWW VERKTOY AS

Phone: 0047-51-88-68-00

Fax: 0047-51-88-68-10

Email: post@verktoyas.no

Website: www.verktoyas.no

Belgium

Willy Vanhoutte BVBA

Phone +32 (50) 78 17 94

Fax + 32 (50) 78 19 64

Email: info@willyvanhoutte.be

Website: http://www.willyvanhoutte.beSouth Africa

The Hardware Centre

Phone: (27) 011 791 0844

Baptist voor Houtbewerkers

Tel: 026 445 16 44

-5-

Fax: (27) 011 791 0850

Website: www.hardwarecentre.co.za

116-0712-006

Table of Contents

GENERAL SAFETY RULES ..................................................................................................................... 7

ADDITIONAL SAFETY RULES FOR WOOD LATHES ............................................................................ 8

DVR 2024 Wood Lathe Specifications ................................................................................................... 9

Workshop Requirements ...................................................................................................................... 10

Assembling the Nova DVR 2024 ........................................................................................................... 11

Nova DVR Components After Unpacking ........................................................................................... 11

Adding an Extension Bed ..................................................................................................................... 12

Mounting the lathe to the Cast Iron Stand ............................................................................................ 13

Mounting the Skirt to the Stand ............................................................................................................ 16

Connecting to Power ............................................................................................................................ 17

Using the NOVA DVR 2024 .................................................................................................................... 18

DVR Drive Functions ............................................................................................................................ 19

Turning Tips .......................................................................................................................................... 21

Swiveling the Headstock ...................................................................................................................... 22

Spindle Index ........................................................................................................................................ 23

Headstock ............................................................................................................................................. 23

Spindle Thread Size ............................................................................................................................... 23

Toolrest ................................................................................................................................................. 25

Tailstock ............................................................................................................................................... 26

Learning Turning .................................................................................................................................. 27

CONTROLLER USER’S GUIDE ................................................................................................................... 28

Programming the Favorite Speeds ....................................................................................................... 33

Maintaining the NOVA DVR 2024 .......................................................................................................... 36

General Maintenance ........................................................................................................................... 36

Cleaning the Toolslide .......................................................................................................................... 37

Cleaning the Tailstock .......................................................................................................................... 37

Aligning the Tailstock ............................................................................................................................ 38

Troubleshooting Guide.......................................................................................................................... 39

Troubleshooting Guide continued ....................................................................................................... 41

NOVA DVR 2024 Wood Lathe Parts List .............................................................................................. 42

Accessories ............................................................................................................................................ 45

Accessories ............................................................................................................................................ 46

Index ........................................................................................................................................................ 48

Teknatool Warranty ................................................................................................................................ 49

© Copyright 2001-2012 by Teknatool International; All Rights Reserved.

Nova DVR is a trademark of Teknatool International Ltd.

The information and specifications contained herein are subject to change. Teknatool is not responsible for errors or

omissions herein or for incidental damages in connection with the furnishing or use of this information.

116-0712-006

-6-

GENERAL SAFETY RULES

Warning! Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE

MANUAL BEFORE OPERATING THE TOOL.

Learn the machine’s application and limitations

plus the specific hazards particular to it.

2. ALWAYS USE A FULL FACE SHIELDStrongly recommended (mus t comply with

ANSI STANDARD Z87.1 -USA) Everyday eyeglasses usually are only impact res istant and

safety glasses only protect eyes. A full face

shield will protect the eyes and face. A lso use

face or dust mask if cutting operation i s dusty.

3. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves , neckties, rings, bracelets or

other jewelry which may get caught in moving

parts. Non slip f ootwear is recommended. Wear

protective hair covering to contai n long hair.

4. USE EAR PROTECTORS. Use ear m uffs for

extended period of operation. Use muffs rated to

103 DBA LEQ (8 hour).

5. DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations,

or expose them to rain. Keep work ar ea well

lighted. The DVR Lat he is intended for indoor

use only. Failure t o do so may void the warr anty.

6. KEEP WORK AREA CLEAN. Cluttered ar eas

and benches invite accidents. Build up of

sawdust is a fire hazard.

7. KEEP CHILDREN AND VISITORS AWAY. The

Nova DVR is not recommended for children

and infirm. Such personnel and onlookers should

be kept a safe distance from work ar ea.

8. MAKE WORKSHOP CHILDPROOF with locks,

master switc hes, or by removing starter keys.

9. GROUND ALL TOOLS. If the t ool is equipped

with a three prong plug, it should be plugged into

a three hole electrical receptacle. If an adapter is

used to accommodate a two prong receptacle,

the adapter plug must be attached to a known

ground. Never remove the third prong.

10. MAKE SURE TOOL IS DISCONNECTED

FROM POWER SUPPLY while the mot or is

being mounted, c onnected, or reconnected.

11. DISCONNECT TOOLS from wall socket before

servicing and when changing acces sories such

as blades, bits, cutters and fuses etc.

12. AVOID ACCIDENTAL STARTING. Make sure

switch is in the Off position before pl ugging in

power cord.

13. NEVER LEAVE MACHINE RUNNING

UNATTENDED. Do not leave machine unless it

is turned off and has come to a complete stop.

14. KEEP GUARDS IN PLACE and in working

order.

15. USE CORRECT TOOLS. Do not use a tool or

attachment to do a job for which it was not

designed.

16. USE RECOMMENDED ACCESSORIES. The

use of improper accessories may cause

hazards.

17. DON’T FORCE THE TOOL. It will do t he job

better and be safer at the rate for which it was

designed.

18. MAINTAIN TOOLS IN TOP CONDITION. Keep

tools sharp and clean for best and safes t

performance. Follow instructi ons for lubricating

and changing acces sories.

19. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

accidentally contacted.

20. REMOVE ADJUSTING KEYS AND

WRENCHES. Form a habit of checking to see

that keys and adjusting wrenches are removed

from tool before turning it on.

21. DON’T OVERREACH. Keep proper footing and

balance at all tim es.

22. DIRECTION OF FEED. Feed wor k into a blade

or cutter against the direction of rotation of the

blade or cutter onl y.

23. ATTENTION TO WORK. Concentrate on your

work. If you become tired or frustr ated, leave it

for awhile and rest.

24. SECURE WORK. Use clamps or a vice to hold

work when practi cal. It’s safer than using your

hand and frees both hands to operate tool .

25. CHECK DAMAGED PARTS. Before fur ther use

of the tool, any part that is damaged should be

carefully checked to ensure that it will operate

properly and perform its intended function.

Check for ali gnm ent of moving parts, binding of

moving parts, m ounting, and any other

conditions that m ay affect its operation. Any

damaged part shoul d be properly repair ed or

replaced.

26. DRUGS, ALCOHOL, MEDICATION. Do not

operate machine whi le under the influence of

drugs, alcohol, or any medication.

27. DUST WARNING. The dust gen erated by

certain woods and wo od products can be

harmful to your healt h. Always operate

machinery in well-ventilated areas and provide

means for proper dus t removal. Use wood dus t

collection systems whenever possible.

116-0712-006

-7-

ADDITIONAL SAFETY RULES FOR WOOD LATHES

important information for you.

Warning! Failure to follow these rules may result in serious personal injury.

Important: ALWAYS BEFORE SWITCHING SPINDLE ON, CHECK SCREEN FOR

CORRECT SETTING

1. DO NOT MODIFY OR USE LATHE FOR USES

OTHER THAN FOR WHICH IT WAS DESIGNED.

2. SEEK INSTRUCTION. If you are not thoroughly

familiar wit h the operation of woodlat hes, obtain

advice from your supervisor, instructor, or other

qualified person. Instruction from a qualified person

is strongly recommended.

3. DO NOT OPERATE LATHE until it is completely

assembled and installed. Follow instructions and

recommendations.

4. FOLLOW ELECTRICAL CODES. M ake sure

wiring codes and recommended electrical

connections are followed and that the machine is

properly grounded.

5. WHEN REPLACING THE FUSE (on relevant

models), completely isolate power when removing

the fuse. It is im perative the plug is removed from

the mains supply before the fuse is r em oved.

Replace fuse cap before reconnecting to mains.

6. DVR ; Do not open the switch and rear covers.

Components can carry dangerous volt ages even

when isolated from m ains power.

7. DVR ; Always ensure spindle fixtures (e.g.

faceplates etc) are locked to spindl e in case

spindle reverse is en gaged. Otherwi se they will

unwind from spindle. See "Mounting a Faceplate to

a chuck" section.

8. WHEN SPINDLE REVERSE IS ENGAGED DO

NOT USE CHISELS OR CUTTING TOOLS - USE

FOR SANDING ONLY

9. KEEP WORK AREA CLEAN. Do not turn the

lathe on before clearing the lathe of all objects

(tools, scraps of wood, etc.). Keep the nearby area

and floor clear of debris.

10. CHECK SET-UP with spindle O ff. Examine the

set-up carefully and rotate the work piece by hand

to check clearance and check speed is correctly

selected before turning on spindle.

11. DO NOT MAKE ADJUSTMENTS when the lat he

or work piece is turning. Make all adjustments with

power Off.

12. TIGHTEN ALL CLAMP HANDLES on the

headstock, tailstock, and toolrest before operating

lathe.

13. EXAMINE WORK PIECE and glue joints before

turning to make sure it has no defects that would

cause it to break when turning.

14. DVR ; ALWAYS CHECK CORRECT SPEED IS

SELECTED BEFORE SWITCHING ON SPINDLE

15. USE LOWEST SPEED when tur ning a new or

unbalanced work piece.

16. TURN AT RECOMMENDED SPEED. Always

operate the lathe at the recommended speeds.

Consult this manual for suggested speeds.

17. ADJUST TOOLREST close to the work piece.

Before turning, r evolve the stock by hand to make

sure it clears t he rest. At intervals, stop the lathe

and readjust the toolrest.

18. KEEP TOOL ON TOOLREST. The lathe t ool or

chisel should be on the toolrest before the lathe is

turned On. Tools should remain on the toolrest

whenever the tool is engaged in contact with the work

piece REMOVE TOOLREST when sanding or

polishing so fi ngers do not get pinched.

19. USE CORRECT LATHE TOOLS. Do not use spindle

turning chisel s for faceplate mou nted work, and vice

versa. Spindle turning tools used f or faceplate

mounted work may grab the work piece and pull the

chisel from your control.

20. WHEN ROUGHING STOCK do not jam the lathe tool

or chisel into wor k piece or take too big a c ut.

21. DO NOT POUND WORK PIECE into headstock drive

(spur) center w hen turning between centers. Pound

the drive center i nto the work piece with a soft mallet

before installing it between center s in the lathe.

22. DO NOT USE TAILSTOCK to drive wor k piece into the

drive (spur) center when turning betw een centers.

Secure work between centers with light pressure fr om

the tailstock quill action.

23. FASTEN STOCK SECURELY BETWEEN CENTERS.

Make sure the tailstock is locked bef ore turning on the

power.

24. NEVER LOOSEN TAILSTOCK SPINDLE or tailstock

while work piece is turning.

25. CORRECT USE OF FACEPLATE. When faceplate

turning, make sure work piece is s ecurely fastened to

the faceplate and t hat appropriate size faceplate is

used to support the work piece. Any screw fasteners

must not interfere with the turning tool at the finished

dimension of the work piece. Rough-cut the work piece

as close as possible to finished shape before installing

on faceplate.

26. DO NOT OPERATE LATHE IF DAMAGED OR

FAULTY. If any part of your lathe is missing, damaged

or broken, in any way, or any electrical component fails,

shut off the lat he and disconnect the l athe from the

power supply. Replace missing, dama ged, or failed

parts before resuming operation.

27. ADDITIONAL SAFETY INFORMATION regar ding the

safe and proper operation of this product is available

from the National Safety Council, 444 N. Michigan

Avenue, Chicago, IL 60611 in the Acc ident Prevention

Manual of Industrial Operations and also in the Safety

Data Sheets provided by the NSC. Also refer to the

American National S tandards Institute ANSI 01.1

Safety Requirement s for Woodworking Machines and

the U.S Department of Labor OSHA 1910.213

Regulation.

Guidelines to symbols used in this manual:

Warning Symbol. Pay close attention!

Note/Information Symbol. Please read -

-8-

116-0712-006

DVR 2024 Wood Lathe Specifications

Size: 1100mm(L) x 240mm (W) x 412mm(H)

43 1/3"(L) x 9 1/2" (W) x 16 1/4"(H)

Weight: 88kg (194 LB) + Legs

Swing Over Bed: 508mm (20in.)

Distance Between Centers: 600mm (24in.);

extendable in 510mm (20in.) units with

add-on Bed sections.

Swing Outboard: 798mm (31in.) with headstock

at 90° using outrigger toolrest.

Headstock:

Spindle Thread: M33 x 3.5 RH

1-1/4 x 8 TPI RH

(2)

(1)

or

Headstock Bore: No. 2 Morse Taper (#2 MT)

Headstock Swivel: 0 to 360 degrees, with

detents at 0, 22.5, 45, and 90 degrees.

Outboard End Internal Thread: M20 x 1.5 LH

Spindle Index: 24 divisions (every 15 degrees)

15mm through-hole through Headstock

Tailstock:

Tailstock Bore: No. 2 Morse Taper (#2 MT)

Quill Travel: 85mm (3-1/4in.)

Hole Through Tailstock: 12mm (7/16in.)

Toolrest:

Length: 300mm (12in.)

Shaft Diameter: 25.4mm (1in.)

Speeds (rpm):

100 – 5000 (in 5rpm increments)

Favourite Speeds:

10 presets

Standard Equipment:

300mm (12in.) Toolrest, 150mm (6in.) Faceplate, Spur

Center, and Live Center. Outboard Handwheel, Cast

Iron Stand, NOVA DVR Wireless Remote.

Optional Accessories:

Precision Midi Chuck

G3 Chuck

SuperNova 2 Chuck

II

Chuck

Titan

80mm (3in.) Faceplate

100mm (4in.) Toolrest

Bowl Toolrest

Outrigger Toolrest Unit

Revolving Center System

Faceplate rings

Swing Away Bed Unit

Notes:

(1) Applicable to Europe (excluding the UK)

(2) Applicable to United States, Canada, United Kingdom,

Australia, New Zealand & South Africa.

For Europe, Australasia, UK and South Africa

Directives this equipment complies with:

Low voltage directive (LVD) 73/23/EEC + 93/68/EEC+2006/95/EC

Machinery directive (MD) 89/392/EEC + 91/368 EEC + 93/68/EEC+2006/42/EC

Electromagnetic compatibility directive (EMCD) 89/336/EEC + 92/31/EEC +

93/68/EEC+2004/108/EC

Harmonized Standards applied in order to verify compliance with Directives:

EN 61029-1:2009 Low Voltage Directive and Machinery Directive

EN 55014-1:2007

EN 55014-2:2009

EN 61000-3-2:Ed3 2006

EN 61000-3-3:1995 A1 + A2

Signed………………………………………..Dated 10/10/11

Nathan Stantiall

Development Manager

116-0712-006

-9-

Setting Up Your Workshop

Workshop Requirements

Consideration Recommendation

Lathe location Locate the Nova DVR 2024 close to a power source in an area with

good lighting. Leave enough clearance on all sides of the lathe;

allow for clearance when the headstock is swiveled. Other

machines in your shop should not interfere with the operation of the

lathe.

Lighting Your shop should have adequate lighting. The work area of the

lathe should be well lit; there should not be shadows cast on your

work. If possible, locate near a window. A portable spotlight may

be helpful.

Electrical The Nova DVR 2024 requires the appropriate power outlet nearby

to power the motor. Wiring and outlets should adhere to local

electrical codes. If in doubt, seek advice from an electrician.

Minimize use of extension cords. See "Connecting to power" section

for Surge Protector requirements.

Ventilation Your shop should be adequately ventilated. The degree of

ventilation will vary based on the size of the shop and the amount of

work done. The use of dust collectors and filters will minimize risks

to your health.

116-0712-006

-10-

Assembling the Nova DVR 2024

handle firmly in thread.

1. Unpack the lathe and components from the shipping container. This is best done by cutting down the

sides of the box to expose the lathe

Warning!

Have other people help when moving or lifting the Nova DVR 2024 Woodlathe; it

weighs 146.2kg (322.3 LB) including stand.

2. Clean any parts coated with rust preventative with a cloth moistened with a petroleum-based solvent or

cleanser, such as paint thinner. Coat the lathe bed with paste wax.

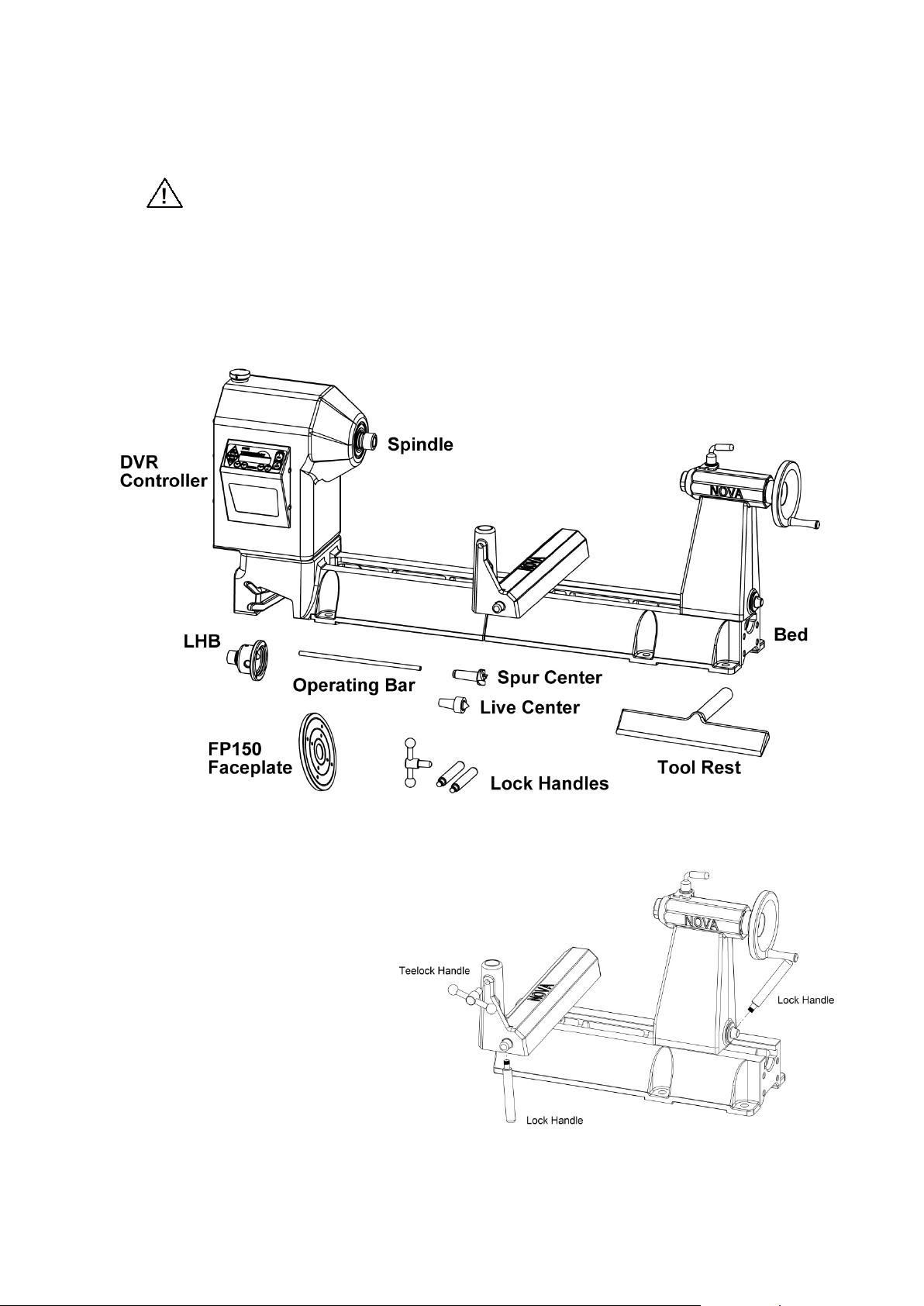

Nova DVR Components After Unpacking

5. Assemble the handles:

Note: Some handles may come pre-

assembled.

Toolrest Clamp Handle -

insert the rod through the handle

and screw the ball knobs onto each

end of the rod.

Toolslide Clamp Handle - screw the

rod lock handle into the Toolslide.

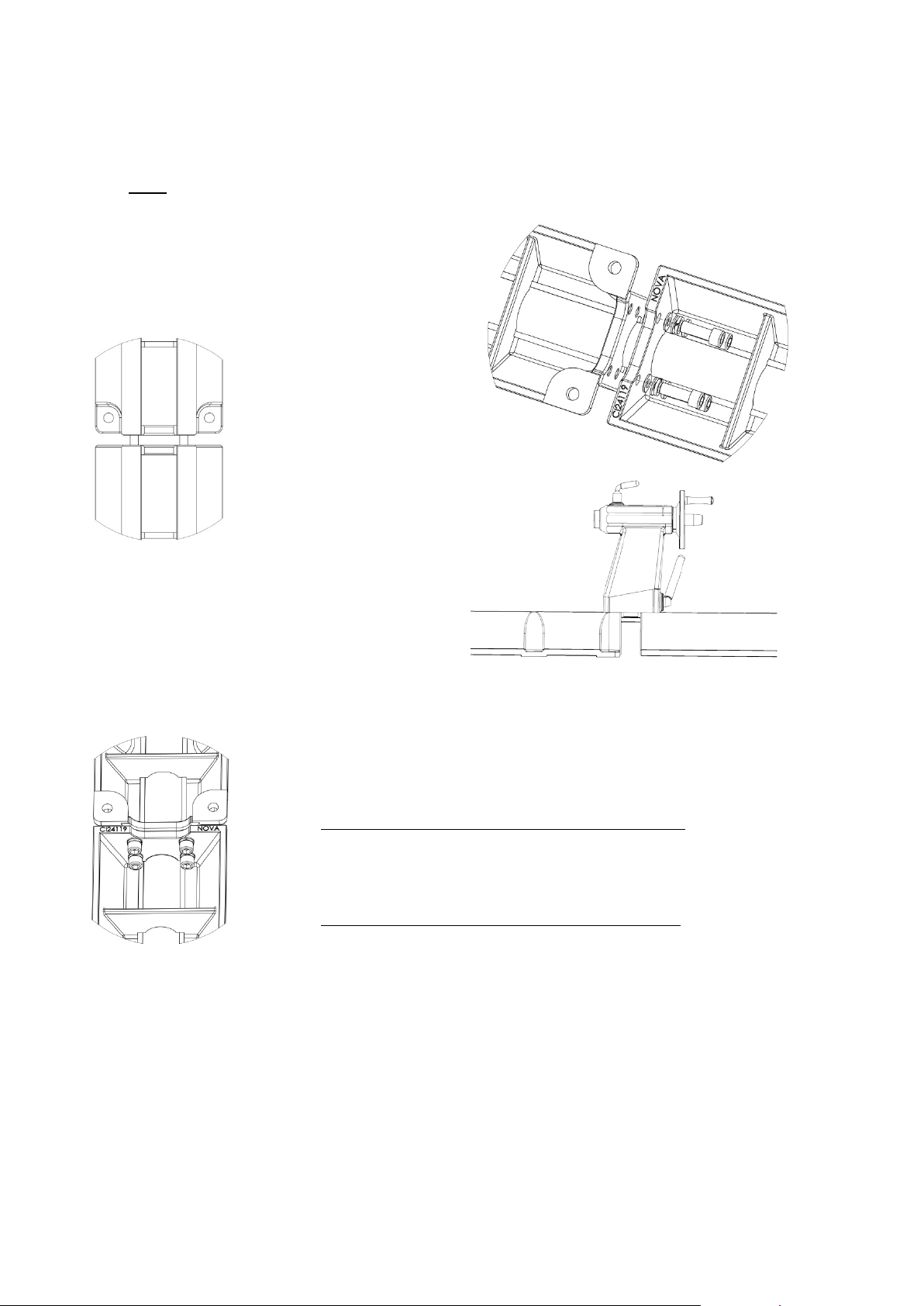

use a hex spanner to lock handle

firmly in thread.

Tailstock Clamp Handle -

screw the lock handle into the

tailstock. Use a hex spanner to lock

-11-

116-0712-006

Adding an Extension Bed

Also, wipe off any yellow rust protective, dirt etc (if applicable).

Allen key provided.

30 N-m (22 lb-ft).

and run over the join until the 'railroad clacking' sound disappears.

Each cast iron extension bed adds 510mm (20in.) to the lathe's capacity to turn between centers.

1. Ensure that the bed pieces are flat and the two faces of the bed (which are to be mated) are

clean, free of any burrs and dents.

Note: The end of the extension bed with no feet should be mated to the lathes end face.

2. Place the add on bed extension close to the

lathes end face, align the holes and screw

on the four M12 cap screws (with one spring

washer and flat washer on each)

four tapped holes with the help of the 10mm

Do NOT fully tighten the

cap screws at this stage,

but tighten enough so that

the add on bed extension

is secured

into the

3. Move the tailstock over the two joining extension

beds (tailstock approximately covering equal

length on either extension). Lock the tailstock

firmly over the joining faces

4. Now, use the 10mm Allen key to fully tighten all four cap screws. The torque required is approximately

5. Check that the tailstock runs smoothly over the mating joint, and also over the

full length of the extension. Although all components manufactured by

Teknatool International are made to closest possible tolerances, it is possible

for a difference of approximately 0.1mm to put the bed 'out of true'. The

tailstock can bind in any given area in two possible ways:

A) Jamming between slides (inside the wall of the bed)

Using a smooth flat file, run over the area a few times until the

tailstock frees itself. To maintain central running of the tailstock,

both sides must be filed evenly.

B) The Tailstock clips or appears to jump over the join

The machined flat surfaces may not be quite flush. Use a flat file

-12-

116-0712-006

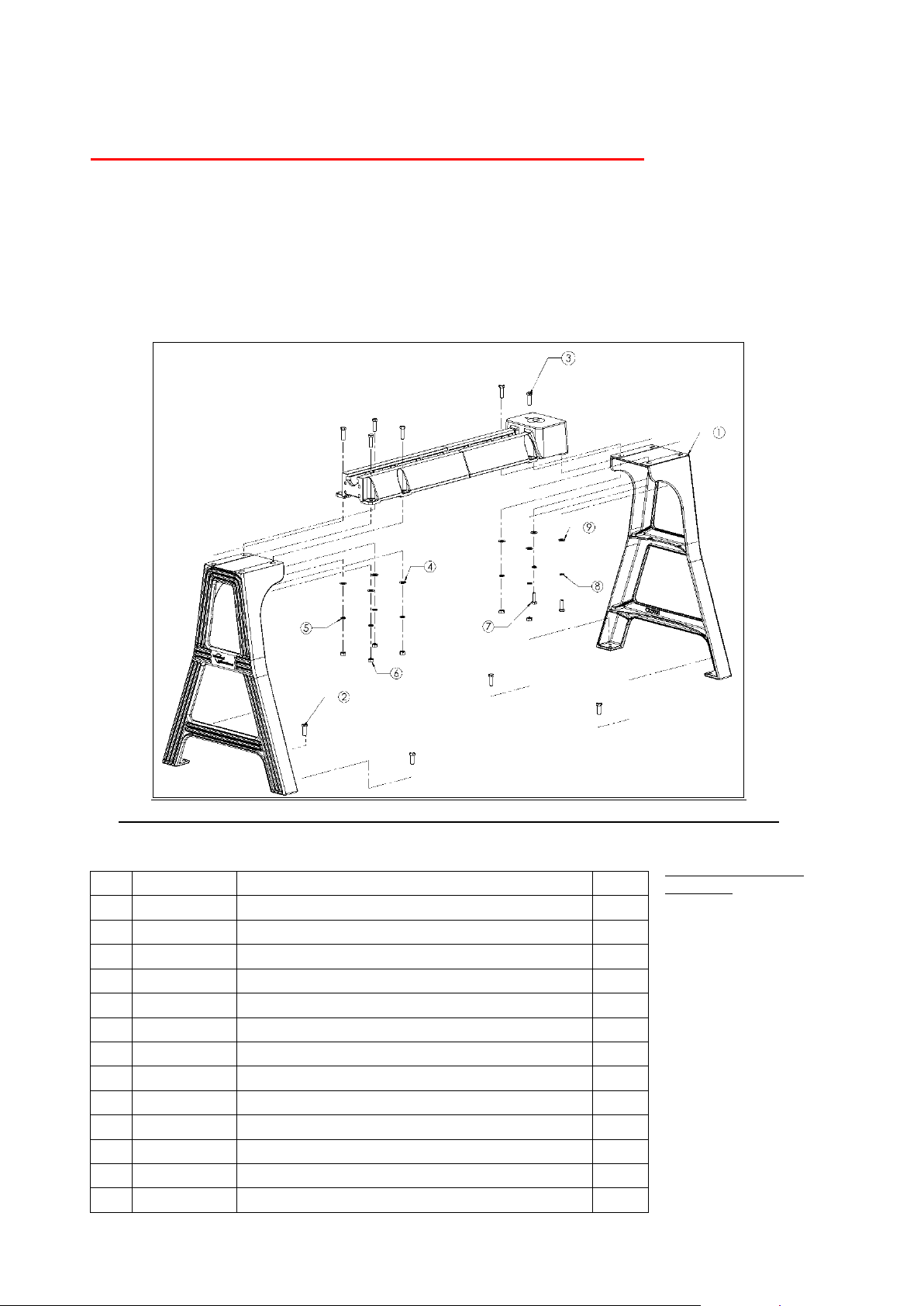

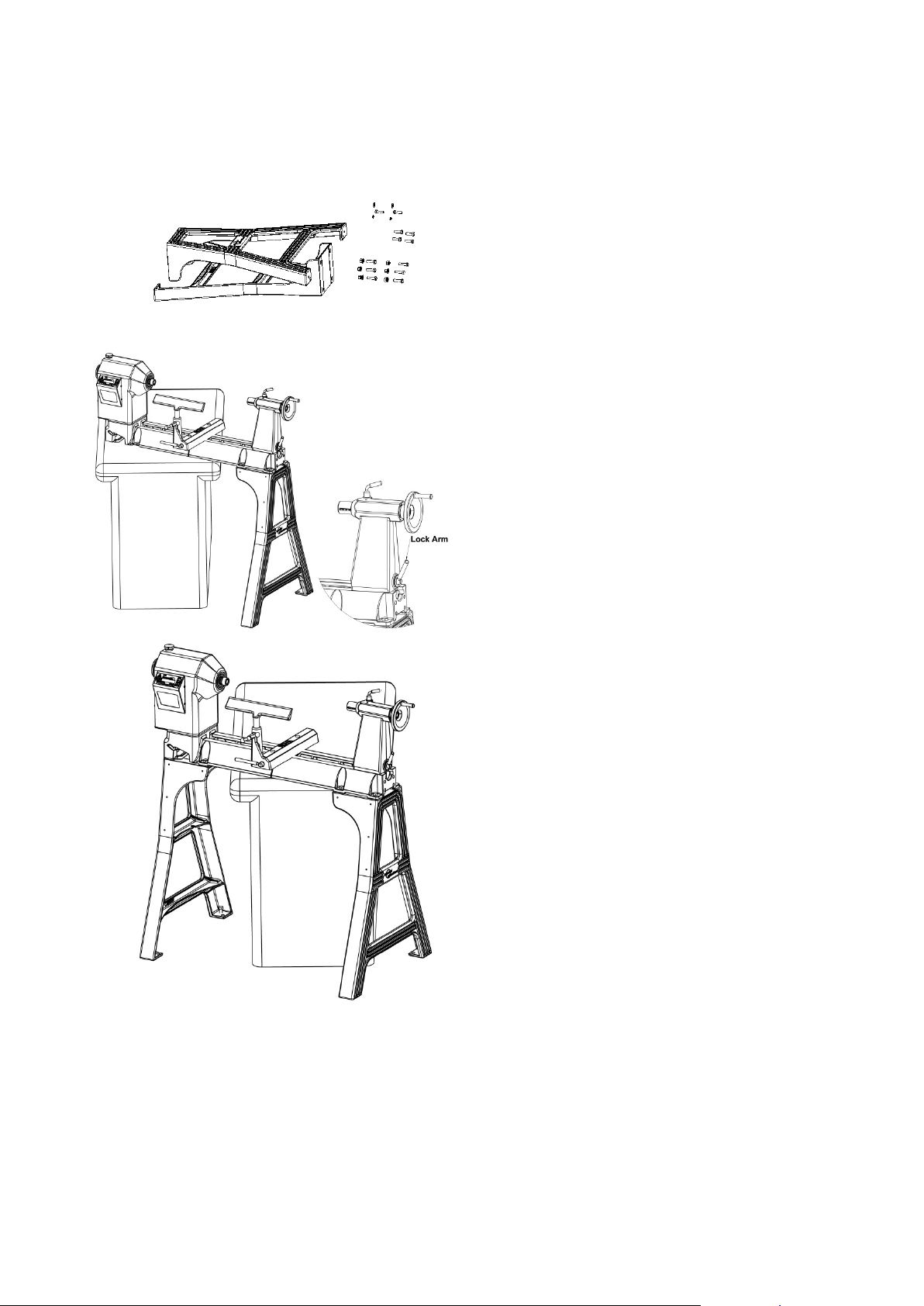

Mounting the lathe to the Cast Iron Stand

NB: Front Face (user side) of casting legs must have skirt fastening holes facing out. See page 16 for skirt fastening instruction.

Parts List

No.

Code

Description

Qty 1 57034

STAND MACHINED CAST IRON NOVA

2

2

BNMZ12030

BOLT ENG M12X30

4 3 BNMZ12050

BOLT ENG M12X50

6 4 FW12

WASHER FLAT M12

6 5 SW12

WASHER SPRING M12

6

6

NHZ12

NUT HEX M12

6

7

BNMZ10035

BOLT ENG M10X35

2 8 SW10

WASHER SPRING M10

2 9 FFW10

WASHER FLAT FENDER M10X32X1.6

2 57058

SKIRT (NOT SHOWN IN PICTURE)

1

NFW06

Nylon Shim (NOT SHOWN IN PICTURE)

8 FFW06

6 Washer C Degree (NOT SHOWN IN PICTURE)

8

MP30608

Screw (NOT SHOWN IN PICTURE)

8

For safety reasons please carefully read and understand these instructions.

The Nova Cast Iron Stand was designed to fit and be used only for Nova Lathes. Use of the stand on

other lathes could void the warranty, and risk personal injury.

The Nova Cast Iron Stand set comprises of two cast iron legs, one on either side, with skirt fastening

holes facing the user. The Stand pieces are cast from a high grade of cast iron with extremely good

section thickness and CAD generated internal gussets at all critical points to withstand extremely high

stresses with practically no distortion. Cast iron has always been the material of choice for wood lathe

construction because of its inherent mass and excellent modulus of vibration dampening.

Suggested Tools for

Assembly

• Ratchet and M10 socket

• At least one other

Person

• Saw benches or

workshop bench both

need to be greater than

860mm

(33 7/8”).

• 5/8” or 16mm Ring/

Open End Spanner

• 3/4” or 19mm

Ring/Open End Spanner

• 8” Adjustable Spanner

116-0712-006

-13-

Set up your workshop area before beginning assembly of the lathe stand.

assembly.

the lifting of the lathe.

ASSEMBLY INSTRUCTIONS

SAFETY: The stand and lathe elements are heavy, please ensure correct lifting techniques and equipment are

used and have someone to assist. Use correct tools and observe recommended practices.

1. Open the cardboard box and identify the parts

against the parts lists provided (above)

2. Stand the two legs uprig ht fac ing each other at

approximately the same distance apart as the

length of the lathe. The Stand legs will stand

upright on their two feet, although not very

stable, but this is enough to carry out the

3. For this step you will need a second person

and a table, saw horses or workshop bench of

suitable height. (If the table is not high enough

then you may need to put blocks underneath).

With the help of a second person, move the

lathe from the box and up to the bench or onto

the saw horses. It may be easier to cut the

box away in order to prevent any dangerous

loading on your back.

Notes:

• Check the tailstock is securely fastened by

tightening the lock arm.

Once the following checks have been made the

headstock and the tailstock can be used to assist in

4. Move the lathe on the bench so that the

tailstock end is overhanging and accessible.

Attach the legs sloping to the right on this

end. Drop the M12 x 50 hex bolts through the

holes and then fasten underneath with the

washer and nut.

5. Next do the headstock end. Note that the left

most fastenings are inserted upward into two

blind holes into the lathe bed.

116-0712-006

-14-

everywhere.

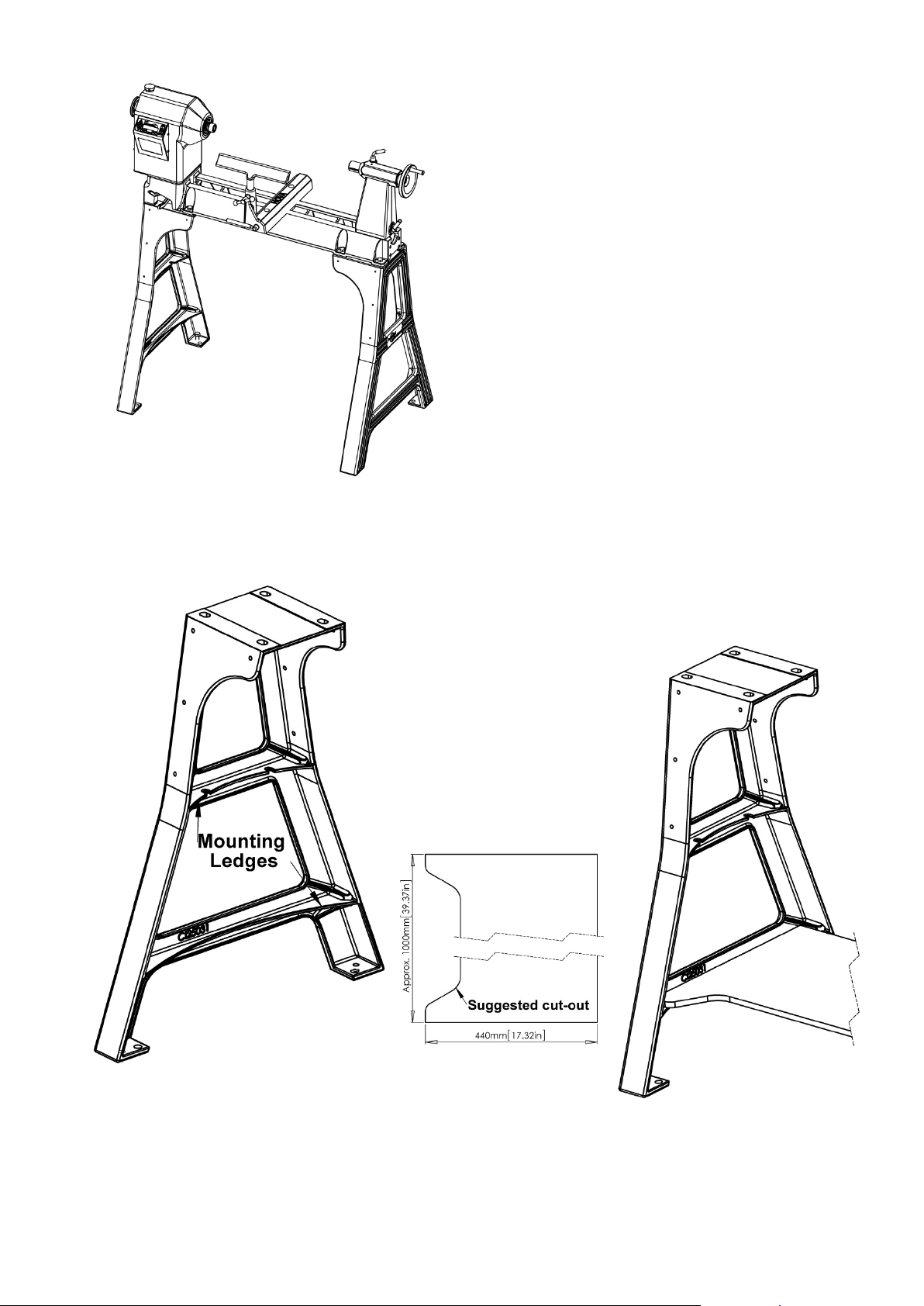

Stand Shelf

6. Now, with the help of a marker, mark the position for

drilling holes into concrete floor for securing the

construction bolts. On the feet of the Stand legs,

there are two holes , one is an M12 tap ped hole for

the jacking bolts, the other is a pla in 14mm hole f or

the construction bolts. T he position for construction

bolts has not been shown in the exploded view.

7. Once the hole posit ions ha ve be en marked, shift the

lathe aside and ins tall the construction bolts. Ref er

to your supplier on the size of drill recom m ended f or

the construction bolts you bu y.

8. Lift and position the complete unit over these

construction bolts. Tighten all nuts firmly.

9. Install all M12x30mm bolts (part 2) for jacking as

shown in the exploded view in the M12 tapped holes

on each of the feet of the Stand legs.

10. Level the lathe bed with the help of the above

jacking bolts with the help of a spirit level.

11. Once the lathe has been le veled tig hte n all

construction bolts firmly.

Re-inspect to ensure all fasteners are firmly secured

The Cast Iron stand has provision for customer shelving between the legs under the lathe. The exac t len gth of

the shelf will depend on how the legs have been setu p and adjusted .

If thicker wood is used, the edges of the shelf ends m ay need to

be relieved to allow the shelf to fit into the leg castings.

For the bottom shelf there

are example dimensions

below.

It is recommended that the

shelf has a cutout along the

front edge to enable free foot

movement around the lathe.

-15-

116-0712-006

Loading...

Loading...