Teknatool NOVA DVR XP, NOVA DVR 3000, 55016, 55077, 55078 Instruction Manual

115-0214-004 1

NOVA

DVR XP

TM (Xtra Performance)

WOODLATHE

Publication 115-0214-004

INSTRUCTION MANUAL

2 115-0214-004

Models

1)55175 spindle thread 1 1/4" x 8 tpi 115v

2) 55180 spindle thread M33x3.5 220-240v (Europe)

3) 55177 spindle thread 1 1/4" x 8 tpi 220-240v (Australasia)

4) 55178 spindle thread 1 1/4" x 8 tpi 220-240v (UK)

5) 55181 spindle thread 1 1/4" x 8 tpi 220-240v (South Africa)

Nova DVR XP Lathe Features at a glance

DVR Electronic drive

The Nova DVR XP lathe is unique. The DVR incorporates the motor built as part of the headstock,

the spindle and motor are one unit. The motor is almost maintenance free and designed with

high reliability. The Digital Variable Reluctance motor uses smart motor technology to provide

an incredibly smooth and powerful drive. This drive takes turning to a new level. The controller

monitors the spindle position constantly and maintains spindle speed very closely. Additional

power is added as it senses extra load from the tool.

Add on Bed System

A lathe that meets your woodturning needs your workshop space, and your pocket! Each segment is 20" or 510mmin length.

This feature appeals for many different reasons:

As a compact lathe (standard configuration) it is great for small turning workshop spaces.

As an extended lathe for those wanting to do extra long spindles (beyond the traditional between center of most lathes) the

Nova DVR XP delivers big turning capacity.

As a bowl lathe for those just wanting to turn bowls.

Sophisticated Swivel Head

Swivel head lathes have many advantages:

• Space saving

• Allows the turner (not the machine!) to decide the most comfortable position for your turning (saving

you from backstrain)

• Elimination of left-hand ‘outboard’ turning techniques and no extra outboard chucks and faceplates are necessary.

There are a number of swivel head lathes available, but the Nova DVR XP has by far the most sophisticated, accurate and easy

to use swivel head on the market.

The Nova DVR XP lathe can be easily and quickly swiveled to any position (360 degrees). It can be solidly locked in any position

plus it has the added security of a detent pin lock at 0,22.5,45,90 degrees plus 315 (for left-hand use).

The swivel head turns, locks easily and has a very accurate detent position, to lock the spindle in line with the tailstock. The

combination of rigid Tailstock construction and detent pin delivers superb accuracy and is unique to the Nova DVR XP.

DVR XP extended lathe (Standard model plus one bed segment)

115-0214-004 3

Solid Construction

Well proven design, the Nova DVR XP is made from Cast

Iron components for strength and rigidity. Added features

like the heavy duty TRIMAX triple bearing system and

special webbed bed design makes the lathe well equipped

to take heavy turning stresses. The bed has been

designed with vibration dampening qualities - a solid 1/2"

cross rib is positioned along the bed unit, quickly

dissipating any vibration as it travels down the bed. The

new powerful trapezoidal bed design delivers even more

vibration damping properties. All this combined with

cosmetically appealing, smooth flowing lines.

Cast iron has always been the material of choice for Woodlathe construction for its inherent mass and an excellent modulus of

vibration.

New 5 Favourite Speeds Function

Pre-program your most favourite speeds for easy retrieval.

New Trapezoidal Bed Design

Powerful with smooth flowing lines, new bed design delivers even more vibration dampening properties.

New Headstock Design

One piece design increases strength and vibration dampening properties. Micro analysed for optimum design. Same popular

swivel headstock as used in the older DVR and 3000 Lathe models, saves strain on your back.

Adaptive Control Software

Smart adaptive computer technology actually measures the weight of the workpiece and adjusts its performance accordingly.

Safety Sensing Feature

Intelligent DVR computer controller senses abnormal turning conditions e.g. a chisel dig in or index left engaged – and

instantaneously shuts down power to the spindle. Normal safety precautions would still apply – see pages 7-8.

Energy Efficient

Unlike other ‘dumb’ electric motors, the Smart DVR Motor only inputs enough power to maintain the set speed – giving you

potential for power savings over conventional motors.

Wide Speed Range

100-3500 rpm, easy push button speed change.

DVR Direct Drive Motor

Driven by unique Direct Drive Variable Reluctance Motor Technology, with superior performance over AC or DC motors. Proven

technology, many thousands of users. No power loss through belts or transmission. Provides digital electronic push button

variable speed with no belt changes.

Ultra Smooth Cutting Power

Selected RPM is closely maintained and the DVR has no belt stretch or motor bounce which affects smooth cutting. The DVR

motor runs smooth with almost no vibration.

Trimax Bearing System

Unique Trimax Bearing System is a triple bearing system to provide a smooth, heavy duty load bearing support for the spindle,

which can easily absorb turning stresses.

5 Year Warranty (limited)

On all castings, mechanical parts and components. 2 Year Warranty on all electronics and electrical components.

Plug and Play

Just bolt to stand or bench, plug it in and you are turning! No complex motor set ups or adjustments.

Low Mantainence

The motor is simple, brushless with no rotor windings (rotor is solid steel). The industrial grade electronics are built to last. There

are no drive pulleys or belts to set up or come loose.

Bed Extension Segment Main Bed Segment

4 115-0214-004

Welcome

Thank you for choosing our Nova DVR XP Woodlathe and welcome to the NOVA product family. Your

choice shows you want the best for your woodturning and you recognise the superb DVR drive

technology and the host of other unique features the Nova DVR XP offers.

We strive to achieve the best value for your money – providing quality, innovative features, a wide range

of accessories – plus comprehensive, ongoing support (latest manuals downloadable from our website,

newsletters, projects etc). We are only a phone call or email away with technical advice or assistance on

the operation of your lathe or your woodturning queries.

Please feel free to contact us about any aspect of our products or service – we regard our customers as

our best development and improvement team – we would love to hear from you!

Once again, welcome to the “NOVA Family”. We trust that you enjoy our products and hope they

enhance the pleasure you experience from the wonderful craft of woodturning!

Best Regards

Brian Latimer

Marketing Director

Teknatool International Ltd

115-0214-004 5

Contact NOVA

New Zealand and Rest of the World

Teknatool International Ltd

Phone: (+64) 9 477 5600

Email: service@teknatool.com

Website: www.teknatool.com

United States

NOVA Innovation and Customer Care Center

Phone: 727-954-3433

Email: service@teknatool.com

Website: www.teknatool.com

Or you can contact the retailer where you purchased your NOVA DVR XP Wood lathe, for the contact details please

see our website www.teknatool.com

6 115-0214-004

Table of Contents

GENERAL SAFETY RULES ...................................................................................................................... 7

ADDITIONAL SAFETY RULES FOR WOODLATHES .............................................................................. 8

DVR XP Woodlathe Specifications ............................................................................................................ 9

Workshop Requirements ...................................................................................................................... 10

Lathe Stand Recommendations ........................................................................................................... 10

Example of Shop-made Lathe Stand ....................................................................................................... 11

Assembling the Nova DVR XP ................................................................................................................. 12

Nova DVR XP Components After Unpacking ...................................................................................... 12

Installing the Headstock Lockpin .............................................................................................................. 13

Adding an Extension Bed ..................................................................................................................... 13

Mounting the Lathe to a Support Surface ............................................................................................. 15

Connecting to Power ............................................................................................................................ 15

Using the Nova DVR XP .......................................................................................................................... 16

DVR Drive Functions ............................................................................................................................ 17

Turning Tips .......................................................................................................................................... 19

Swiveling the Headstock ....................................................................................................................... 20

Spindle Index ........................................................................................................................................ 20

Headstock ............................................................................................................................................. 21

Spindle Thread Size ................................................................................................................................. 21

Toolrest ................................................................................................................................................. 22

Tailstock ............................................................................................................................................... 23

Learning Turning................................................................................................................................... 24

CONTROLLER USER’S GUIDE .............................................................................................................. 25

Programming the Favourate Speeds .................................................................................................... 29

Maintaining the Nova DVR3000 ............................................................................................................... 33

General Maintenance ........................................................................................................................... 33

Cleaning the Toolslide ....................................................................................................................... 34

Cleaning the Tailstock .......................................................................................................................... 34

Aligning the Tailstock ............................................................................................................................ 35

Voltage selection ...................................................................................................................................... 36

Troubleshooting Guide ............................................................................................................................. 38

Troubleshooting Guide continued ............................................................................................................ 40

DVR XP Woodlathe Parts List.................................................................................................................. 41

Accessories .............................................................................................................................................. 44

Accessories .............................................................................................................................................. 45

Index ........................................................................................................................................................ 46

© Copyright 2001-2013 by Teknatool International; All Rights Reserved.

Nova DVR XP is a trademark of Teknatool International Ltd.

115-0214-004

7

The information and specifications contained herein are subject to change. Teknatool is not responsible for errors

or omissions herein or for incidental damages in connection with the furnishing or use of this information.

GENERAL SAFETY RULES

!

Warning! Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE

MANUAL BEFORE OPERATING THE TOOL.

Learn the machine’s application and limitations

plus the specific hazards particular to it.

2. ALWAYS USE A FULL FACE SHIELD-Strongly

recommended (must comply with ANSI

STANDARD Z87.1 -USA) Everyday eye-glasses

usually are only impact resistant and safety

glasses only protect eyes. A full face shield will

protect the eyes and face. Also use face or dust

mask if cutting operation is dusty.

3. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets or

other jewelry which may get caught in moving

parts. Non slip footwear is recommended. Wear

protective hair covering to contain long hair.

4. USE EAR PROTECTORS. Use ear muffs for

extended period of operation. Use muffs rated to

103 DBA LEQ (8 hour).

5. DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations,

or expose them to rain. Keep work area well

lighted. The DVR XP Lathe is intended for indoor

use only. Failure to do so may void the warranty.

6. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents. Build up of

sawdust is a fire hazard.

7. KEEP CHILDREN AND VISITORS AWAY. The

Nova DVR XP is not recommended for children

and infirm. Such personnel and onlookers should

be kept a safe distance from work area.

8. MAKE WORKSHOP CHILDPROOF with locks,

master switches, or by removing starter keys.

9. GROUND ALL TOOLS. If the tool is equipped

with a three prong plug, it should be plugged into

a three hole electrical receptacle. If an adapter is

used to accommodate a two prong receptacle,

the adapter plug must be attached to a known

ground. Never remove the third prong.

10. MAKE SURE TOOL IS DISCONNECTED

FROM POWER SUPPLY while the motor is

being mounted, connected, or reconnected.

11. DISCONNECT TOOLS from wall socket before

servicing and when changing accessories such

as blades, bits, cutters and fuses etc.

12. AVOID ACCIDENTAL STARTING. Make sure

switch is in the Off position before plugging in

power cord.

13. NEVER LEAVE MACHINE RUNNING

UNATTENDED. Do not leave machine unless it

is turned off and has come to a complete stop.

14. KEEP GUARDS IN PLACE and in working

order.

15. USE CORRECT TOOLS. Do not use a tool or

attachment to do a job for which it was not

designed.

16. USE RECOMMENDED ACCESSORIES. The

use of improper accessories may cause

hazards.

17. DON’T FORCE THE TOOL. It will do the job

better and be safer at the rate for which it was

designed.

18. MAINTAIN TOOLS IN TOP CONDITION. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

19. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

accidentally contacted.

20. REMOVE ADJUSTING KEYS AND

WRENCHES. Form a habit of checking to see

that keys and adjusting wrenches are removed

from tool before turning it on.

21. DON’T OVERREACH. Keep proper footing and

balance at all times.

22. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of the

blade or cutter only.

23. ATTENTION TO WORK. Concentrate on your

work. If you become tired or frustrated, leave it

for awhile and rest.

24. SECURE WORK. Use clamps or a vice to hold

work when practical. It’s safer than using your

hand and frees both hands to operate tool.

25. CHECK DAMAGED PARTS. Before further use

of the tool, any part that is damaged should be

carefully checked to ensure that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, mounting, and any other

conditions that may affect its operation. Any

damaged part should be properly repaired or

replaced.

26. DRUGS, ALCOHOL, MEDICATION. Do not

operate machine while under the influence of

drugs, alcohol, or any medication.

27. DUST WARNING. The dust generated by certain

woods and wood products can be harmful to

your health. Always operate machinery in wellventilated areas and provide means for proper

dust removal. Use wood dust collection systems

whenever possible.

115-0214-004 8

ADDITIONAL SAFETY RULES FOR WOODLATHES

!

Warning! Failure to follow these rules may result in serious personal injury.

Important: ALWAYS BEFORE SWITCHING SPINDLE ON, CHECK SCREEN

FOR CORRECT SETTING

1. DO NOT MODIFY OR USE LATHE FOR USES

OTHER THAN FOR WHICH IT WAS DESIGNED.

2. SEEK INSTRUCTION. If you are not thoroughly

familiar with the operation of woodlathes, obtain

advice from your supervisor, instructor, or other

qualified person. Instruction from a qualified person

is strongly recommended.

3. DO NOT OPERATE LATHE until it is completely

assembled and installed. Follow instructions and

recommendations.

4. FOLLOW ELECTRICAL CODES. Make sure

wiring codes and recommended electrical

connections are followed and that the machine is

properly grounded.

5. WHEN REPLACING THE FUSE (on relevant

models), completely isolate power when removing

the fuse. It is imperative the plug is removed from

the mains supply before the fuse is removed.

Replace fuse cap before reconnecting to mains.

6. DVR XP; Do not open the switch and rear

covers. Components can carry dangerous

voltages even when isolated from mains power.

7. DVR XP; Always ensure spindle fixtures (e.g.

faceplates etc) are locked to spindle in case

spindle reverse is engaged. Otherwise they will

unwind from spindle. See "Mounting a Faceplate to

a chuck" section.

8. WHEN SPINDLE REVERSE IS ENGAGED DO

NOT USE CHISELS OR CUTTING TOOLS - USE

FOR SANDING ONLY

9. KEEP WORK AREA CLEAN. Do not turn the lathe

on before clearing the lathe of all objects (tools,

scraps of wood, etc.). Keep the nearby area and

floor clear of debris.

10. CHECK SET-UP with spindle Off. Examine the

set-up carefully and rotate the work piece by hand

to check clearance and check speed is correctly

selected before turning on spindle.

11. DO NOT MAKE ADJUSTMENTS when the lathe or

work piece is turning. Make all adjustments with

power Off.

12. TIGHTEN ALL CLAMP HANDLES on the

headstock, tailstock, and toolrest before operating

lathe.

13. EXAMINE WORK PIECE and glue joints before

turning to make sure it has no defects that would

cause it to break when turning.

14. DVR XP; ALWAYS CHECK CORRECT SPEED IS

SELECTED BEFORE SWITCHING ON SPINDLE

15. USE LOWEST SPEED when turning a new or

unbalanced work piece.

16. TURN AT RECOMMENDED SPEED. Always

operate the lathe at the recommended speeds.

Consult this manual for suggested speeds.

17. ADJUST TOOLREST close to the work piece.

Before turning, revolve the stock by hand to make

sure it clears the rest. At intervals, stop the lathe

and readjust the toolrest.

18. KEEP TOOL ON TOOLREST. The lathe tool or

chisel should be on the toolrest before the lathe is

turned On. Tools should remain on the toolrest

whenever the tool is engaged in contact with the work

piece REMOVE TOOLREST when sanding or

polishing so fingers do not get pinched.

19. USE CORRECT LATHE TOOLS. Do not use spindle

turning chisels for faceplate mounted work, and vice

versa. Spindle turning tools used for faceplate

mounted work may grab the work piece and pull the

chisel from your control.

20. WHEN ROUGHING STOCK do not jam the lathe tool

or chisel into work piece or take too big a cut.

21. DO NOT POUND WORK PIECE into headstock drive

(spur) center when turning between centers. Pound the

drive center into the work piece with a soft mallet

before installing it between centers in the lathe.

22. DO NOT USE TAILSTOCK to drive work piece into the

drive (spur) center when turning between centers.

Secure work between centers with light pressure from

the tailstock quill action.

23. FASTEN STOCK SECURELY BETWEEN CENTERS.

Make sure the tailstock is locked before turning on the

power.

24. NEVER LOOSEN TAILSTOCK SPINDLE or tailstock

while work piece is turning.

25. CORRECT USE OF FACEPLATE. When faceplate

turning, make sure work piece is securely fastened to

the faceplate and that appropriate size faceplate is

used to support the work piece. Any screw fasteners

must not interfere with the turning tool at the finished

dimension of the work piece. Rough-cut the work piece

as close as possible to finished shape before installing

on faceplate.

26. DO NOT OPERATE LATHE IF DAMAGED OR

FAULTY. If any part of your lathe is missing, damaged

or broken, in any way, or any electrical component fails,

shut off the lathe and disconnect the lathe from the

power supply. Replace missing, damaged, or failed

parts before resuming operation.

27. ADDITIONAL SAFETY INFORMATION regarding the

safe and proper operation of this product is available

from the National Safety Council, 444 N. Michigan

Avenue, Chicago, IL 60611 in the Accident Prevention

Manual of Industrial Operations and also in the Safety

Data Sheets provided by the NSC. Also refer to the

American National Standards Institute ANSI 01.1

Safety Requirements for Woodworking Machines and

the U.S Department of Labor OSHA 1910.213

Regulation.

Guidelines to symbols used in this manual:

!

Warning Symbol. Pay close attention!

Note/Information Symbol. Please read -

important information for you.

115-0214-004

9

DVR XP Woodlathe Specifications

Size: 1100mm(L) x 240mm (W) x 412mm(H)

43 1/3"(L) x 9 1/2" (W) x 16 1/4"(H)

Weight: 82kg (181 LB)

Swing Over Bed: 400mm (16in.)

Distance Between Centers: 600mm (24in.);

extendable in 510mm (20in.) units with

add-on Bed sections.

Swing Outboard: 740mm (29in.) with headstock

at 90° using outrigger toolrest.

Headstock:

Spindle Thread: M33 x 3.5 RH

(1)

or

1-1/4 x 8 TPI RH

(2)

Headstock Bore: No. 2 Morse Taper (#2 MT)

Headstock Swivel: 0 to 360 degrees, with

detents at 0, 22.5, 45, and 90 degrees.

Outboard End Internal Thread: M20 x 1.5 LH

Spindle Index: 24 divisions (every 15 degrees) 15mm

through-hole through Headstock

Tailstock:

Tailstock Bore: No. 2 Morse Taper (#2 MT)

Quill Travel: 85mm (3-1/4in.)

Hole Through Tailstock: 15mm (9/16in.)

Toolrest:

Length: 300mm (12in.)

Shaft Diameter: 25.4mm (1in.)

Speeds (rpm):

100 – 3500 (in 5rpm increments)

Favourite Speeds:

5 presets

Standard Equipment:

300mm (12in.) Toolrest, 80mm (3in.) Faceplate* (Not

all countries, see notes below), (Not all countries, see

notes below) Spur Center, and Live Center. Outboard

Handwheel.

Nova 3000 Bowl Lathe Version:

Specifically for bowl turning, does not include bed

extension, tailstock, and centers.

Optional Accessories:

Precision Midi, G3, SuperNova 2 & Titan Chuck

80mm (3in.) Faceplate

Vacuum Faceplate

100mm (4in.) Toolrest

Bowl Toolrest

Outrigger Toolrest Unit

Vacuum Coupler

Revolving Center System

Faceplate rings

Notes:

(1) Applicable to Europe (excluding the UK)

(2) Applicable to United States, Canada, United Kingdom,

Australia, New Zealand & South Africa.

* Note: Standard equipment varies from country to country, In

some markets, the faceplate is an optional accessory. Check with

your reseller if you are unsure.

For Europe, Australasia, UK and South Africa

Directives this equipment complies with:

Low voltage directive (LVD) 73/23/EEC + 93/68/EEC +2006/95/EC

Machinery directive (MD) 89/392/EEC + 91/368 EEC + 93/68/EEC +

2006/42/EC Electromagnetic compatibility directive (EMCD)

89/336/EEC + 92/31/EEC + 93/68/EEC + 2004/108/EC

Harmonized Standards applied in order to verify compliance with

Directives:

EN 61029-1:2009 (Low Voltage Directive and Machinery

Directive)

EN 55014-1:2007

EN 55014-2:2009

EN 61000-3-2: Ed3 2006

EN 61000-3-3:1995 A1 + A2

Signed………………………………………..Dated 10/12/2010

Nathan Stantiall

Development Manager

115-0214-004 10

Setting Up Your Workshop

Workshop Requirements

Consideration

Recommendation

Lathe location

Locate the Nova DVR XP close to a power source in an area with

good lighting. Leave enough clearance on all sides of the lathe;

allow for motor clearance when the headstock is swiveled. Other

machines in your shop should not interfere with the operation of the

lathe.

Lighting

Your shop should have adequate lighting. The work area of the

lathe should be well lit; there should not be shadows cast on your

work. If possible, locate near a window. A portable spotlight may be

helpful.

Electrical

The Nova DVR XP requires the appropriate power outlet nearby to

power the motor. Wiring and outlets should adhere to local electrical

codes. If in doubt, seek advice from an electrician. Minimize use of

extension cords. See "Connecting to power" section for Surge

Protector requirements.

Ventilation

Your shop should be adequately ventilated. The degree of

ventilation will vary based on the size of the shop and the amount of

work done. The use of dust collectors and filters will minimize risks

to your health.

Lathe Stand Recommendations

A sturdy and rigid stand is required so that the Nova DVR XP Woodlathe can deliver optimum

performance. A common flaw with many woodlathe installations is an inadequate stand for the lathe.

The larger the size of your turnings, the greater the importance of the lathe stand design.

Consideration

Recommendation

Lathe Height

from floor

The height of the stand should locate the centerline of the lathe

spindle at the elbow height of the turner.( illustration next page)

Stand Top

The stand top should be flat so the lathe does not twist when it

is bolted down. Check for any gaps between lathe feet and

stand top before bolting down. Shim and prepare stand as

necessary.

Stand Weight

The stand should have enough weight and mass so that it

doesn't move when turning large work pieces, and so that the

stand can absorb vibrations. A lathe stand's stability can be

improved by weighing it down with sand bags on a lower shelf.

Stand Legs

The stand should sit level on the floor and not rock.

115-0214-004

11

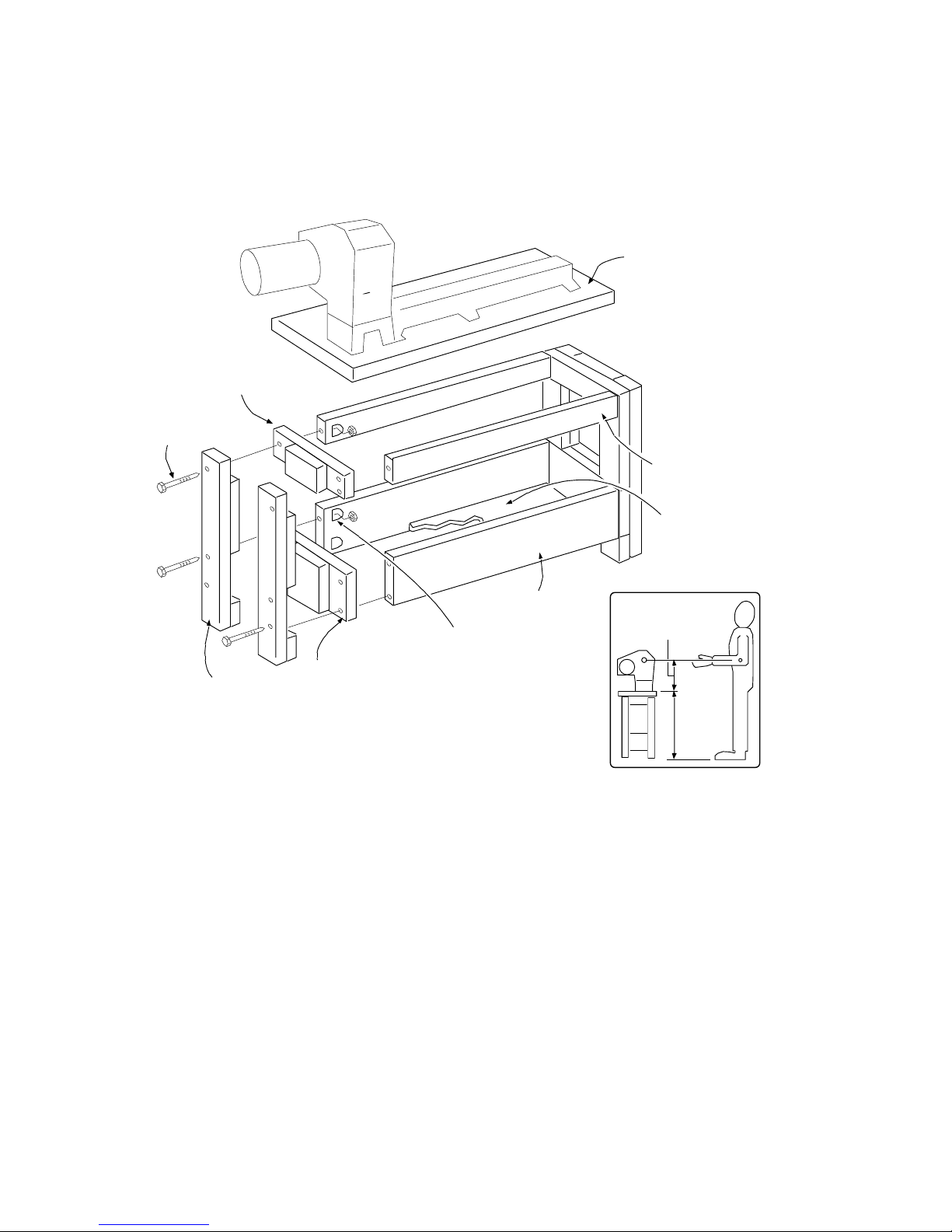

Example of Shop-made Lathe Stand

This has been designed with economy of space in mind. Heavier sections, wider rails and gussets on

the corners are encouraged. For stability and vibration dampening, it is highly recommended that the

base is filled with sand.

297 mm

(11-11/16 in.)

to suit

turner

Top

43 x 16 x 2 in.

plywood bottom

(compartment for sand)

Lower Rail (2)

1-1/2 x 7-1/2 x 33 in.

Leg (4)

1-1/2 x 3-1/2 in. x

height to suit turner

Upper Leg Brace (2)

1-1/2 x 3-1/2 x 13 in.

Lower Leg Brace (2)

1-1/2 x 7-1/2 x 13 in.

Upper Rail (2)

1-1/2 x 3-1/2 x 33 in.

Glue and screw leg pieces

Recessed Hole,

drill hole and chisel one

side square for nut.

Machine

Bolt (12)

115-0214-004 12

Assembling the Nova DVR XP

1. Unpack the lathe and components from the shipping container. This is best done by cutting down

the sides of the box to expose the lathe

!

Warning!

Have other people help when moving or lifting the Nova DVR XP Woodlathe; it

weighs about 82kg (181 LB).

2. Clean any parts coated with rust preventative with a cloth moistened with a petroleum-based

solvent or cleanser, such as paint thinner. Coat the lathe bed with paste wax.

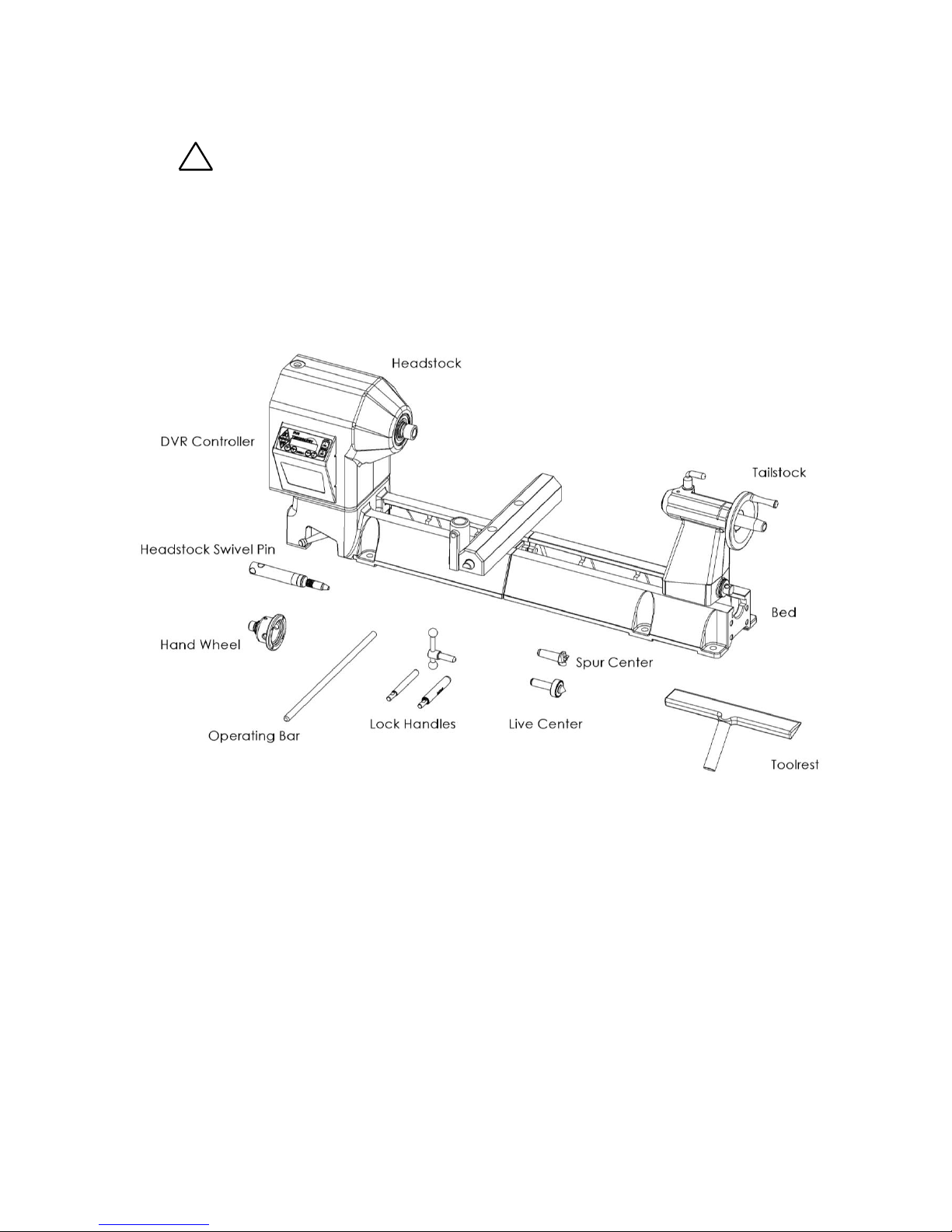

Nova DVR XP Components After Unpacking

115-0214-004

13

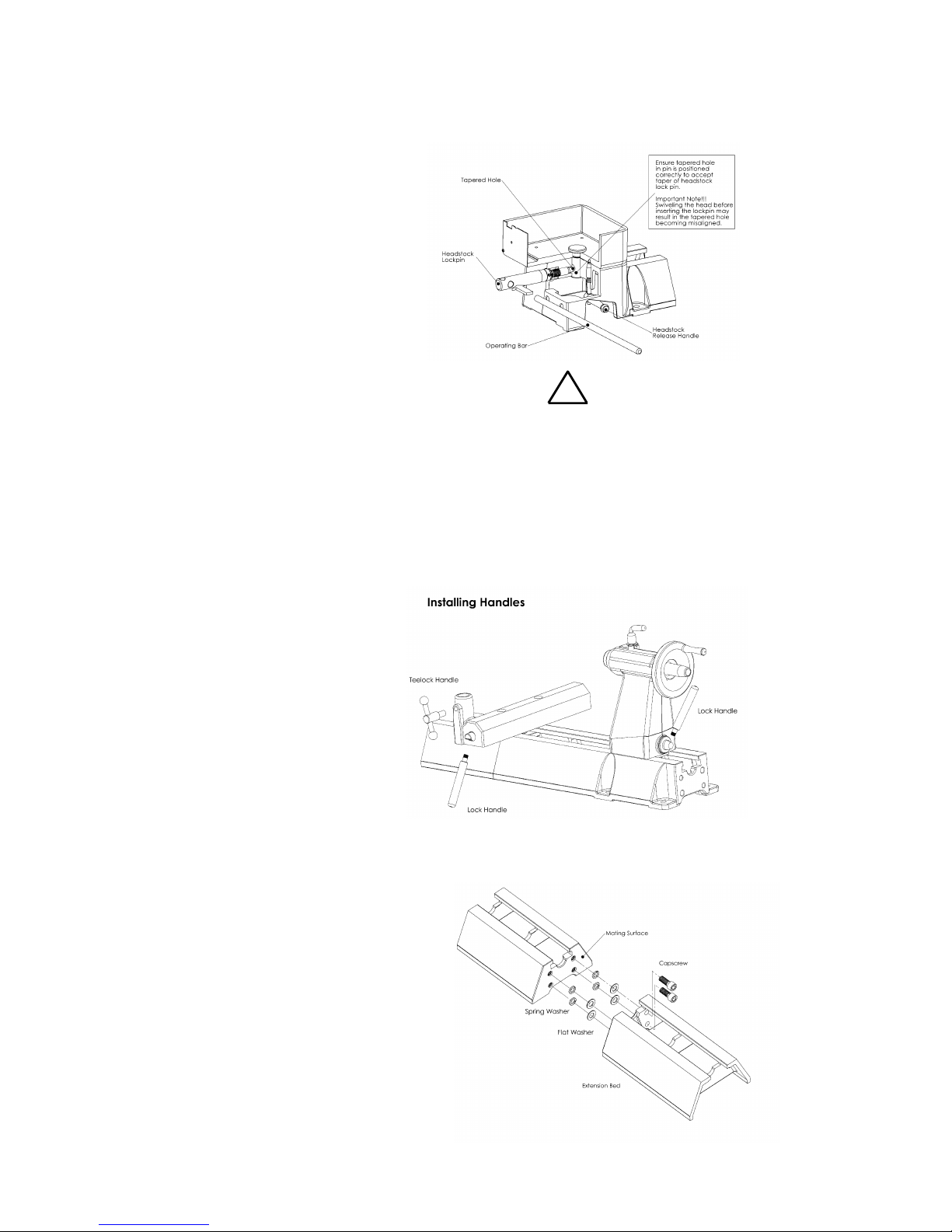

Installing the Headstock Lockpin

3. Remove the plastic shipping tube

from headstock base. Immediately

screw the Headstock Lockpin into

the threaded hole at the bottom of

the headstock. Insert the operating

bar into the hole in the Lockpin and

firmly tighten the Lockpin to lock the

headstock in position; then remove

the operating bar. NOTE: When the

pin is fully engaged the groove

machined into the pin furthest from

the thread should line up with the

edge of the hole in the casting. By

doing this the pin will be engaged in

the hole of the swivel pin.

4. Loosen the Lockpin 1 – 2 turns.

Push the Headstock Release

Handle down and rotate the

Headstock so the spindle points to

the tailstock and lines up parallel to

the lathe bed. Tighten lock pin

again.

Note: Do not use excessive force when

tightening the Lockpin.

!

Important note: Swiveling the head before inserting

the lock pin may result in the tapped hole on the

Swivel pin becoming mis-aligned.

5. Assemble the handles:

Note: Some handles may come pre-

assembled.

Toolrest Clamp Handle -

insert the rod through the handle

and screw the ball knobs onto

each end of the rod.

Toolslide Clamp Handle - screw

the lock handle into the toolslide.

Tailstock Clamp Handle -

screw the lock handle into the

tailstock.

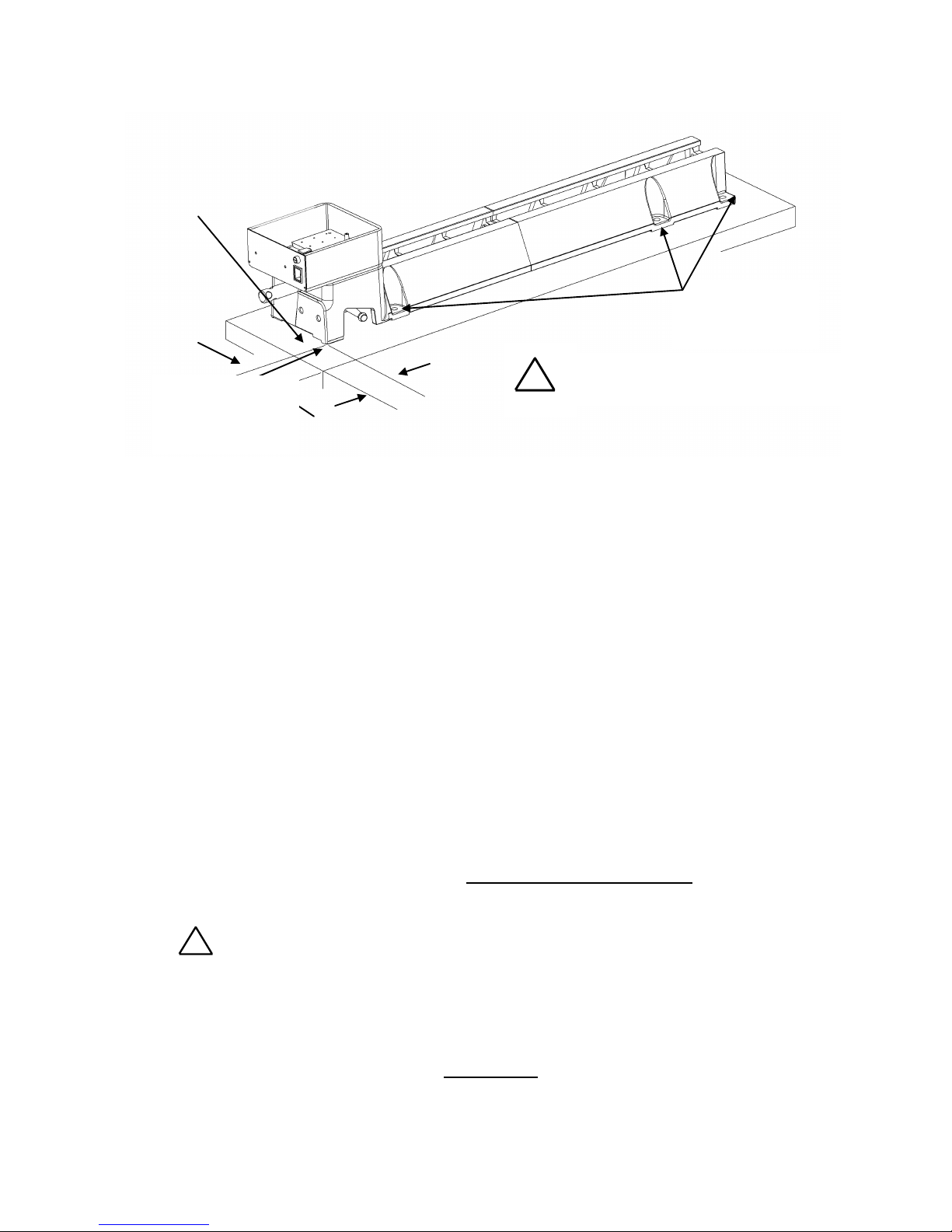

Adding an Extension Bed

Each cast iron extension bed adds 510mm

(20in.) to the lathe's capacity to turn between

centers.

1. Clean the joining ends of both bed sections

with a petroleum-based solvent. Make sure

there are no dents or burrs on either mating

surface. Remove burrs and high spots with

a smooth file.

2. Screw in cap screws tight

3. Secure the bed sections together with four

M12x30 cap screws using a 10mm Allen

wrench. It may be necessary to move the

lathe so the cap screws can be reached

115-0214-004 14

with the wrench from the bottom of the bed.

!

Warning!

Do not use a metal hammer to pound on the extension bed. This may damage the bed, affect

accuracy and tailstock action, and may prevent you from adding another extension bed.

4. Bring the Tailstock along until it is on top of the join area where the bed extension face meets the

lathe bed face. The bed extension may need to be manipulated up-and-down and sideways in

order for the Tailstock to fit.

5. Check that the toolslide and tailstock move freely over the mating joint and also over the full length

of the add-on extension. If there is a ridge between the two mating surfaces then repeat steps 1 - 4

again, use a smooth file to file the surfaces flush.

6. Follow the suggestions under "Mounting the Lathe to a Support Surface".

115-0214-004

15

Mounting the Lathe to a Support Surface

1. Place the lathe on the stand top. Locate the front and left corner of the lathe approximately 25mm

(1in.) from the corner edge of the stand top. This provides a comfortable reach when turning and

allows the optional outrigger unit to be easily installed.

2. If necessary, mark the six hole locations on the top and drill M12 holes.

3. Place a spirit level along the top of the lathe bed. Any movement of the bubble as the lathe is

secured, indicates a twist on the bed. For the lathe to operate correctly the bed must not twist; if

necessary, use shims between the bed and stand top.

4. Use bolts of suitable length (not included) to secure the lathe. Tighten the two headstock bolts first,

then the two tailstock bolts, and finally tighten the last two bolts on top.

5. The two M10 threaded holes underneath the outrigger end of headstock can be optionally used

(making a total of 8 bolt positions). Ensure that the bolt is a metric M10 x 1.5mm pitch and that the

length is correct to ensure that the bolt doesn't bottom in the threaded hole and potentially damage

casting.

Connecting to Power

The power cord should be 3-wire, having a grounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed and grounded in accordance with local

electrical codes.

The DVR XP can run on either 115v or 220v ~ 240v, but the voltage must be selected with an internal

jumper (see Voltage Selection page 36). If the lathe is purchased in USA, it will already be setup for

115v operation. All other countries are preset for 220v ~ 240v.

!

Warning!

Improper connection of the motor can result in a risk of electrical shock.

If it is necessary to use an extension cord, the cord should be grounded. Use the correct wire size for

the extension cord, for a given cord length, to avoid power loss and over-heating.

IMPORTANT: A Surge Protection Device rated to at least 15 amps - for USA and

Canada, other countries 10 or 15 amps - must be used to protect the DVR electronics from

electrical spikes or surges, similar to those used on most Home PC's.

Ground Fault Interrupters (GFI's) or Residual Current Detectors (RCD's) are helpful and are a

recommended protection device for any powertool. They can be used in conjunction with a DVR

lathe. Note some makes of GFI may not be compatible

The lathe must be fastened to a support

surface, such as a lathe stand or bench

Mounting Holes(6)

(M12 x 1.75 Bolts)

Maximum of 25mm (1in.)

(Required only for mounting

the Outrigger Unit option

!

Optional Mounting

Underneath lathe

2 x (M10 x 1.5)

Loading...

Loading...