Page 1

TASC-6100

LIQUID/GRANULAR

APPLICATION CONTROL SYSTEM

USER GUIDE

PN - 98-05018

Standard Rate

R2

®

MID-TECH

MPH

MIDWEST TECHNOLOGIES, INC.

Alt.-Rate

OFF

ON OPERATE INC.

OFF SET- UP

DEC.

%Rate

Product Vol.

Appl. Rate

Fan RPM

Total Applied

Area

Width

Speed

Distance

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

123 456789

BOOMS

Software Version 1.30

CE & STANDARD VERSION

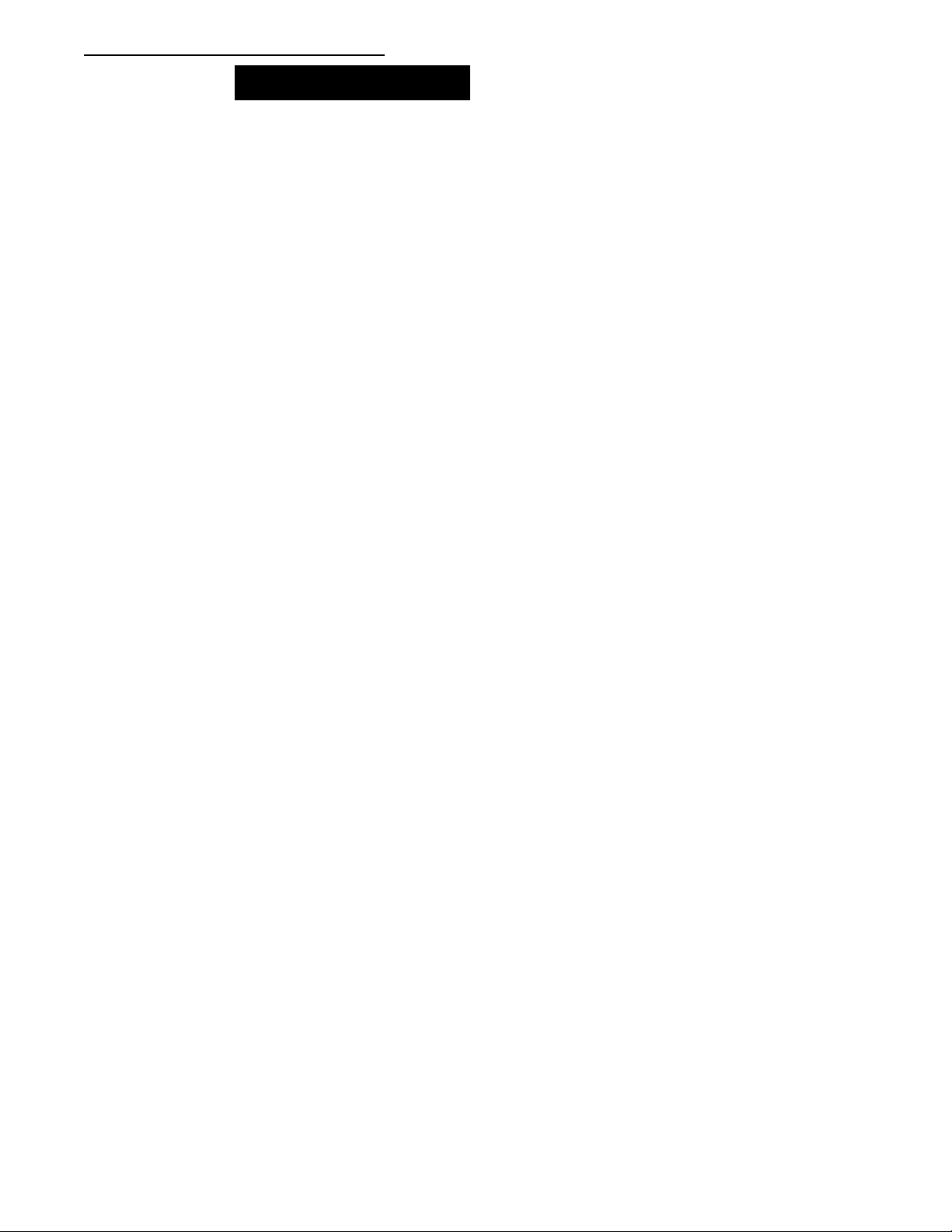

TASC-6100

Rate Controller

Midwest Technologies, Inc. of Illinois

Springfield, IL 62703

Page 2

TASC 6100

98-05018

R2

CHANGE LOG

DATE: DATE CODE: PAGES AFFECTED: SW VERSION

4/24/98 98114 New Manual(TASC-6100 w/Fan RPM) 1.20

10/1/98 98114 A-4 (No Revision Change) 1.20

5/15/00 00060 All - New Format/SW, CE Console 1.30

2/20/00 01110 Corrected graphic, updatedlogo & 1.30

warranty, cleaned up text

II

CE & S

TANDARD V ERSION

II

Page 3

TASC 6100

98-05018

R2

TABLE OF CONTENTS

CHANGE LOG II

TABLE OF C ONTENTS III

LIST OF I LLUSTRATIONS V

HOW TO USE THIS MANUAL VI

CHAPTER 1 SWITCHES AND C ONTROLS 1-1

CONSOLE SWITCHES AND INDICATORS 1-1

OWER SWITCH 1-1

P

M

ODE S ELECTOR SWITCH 1-1

INC / DEC SWITCH 1-2

BOOM SECTION “ON/OFF” INDICATORS 1-2

RATE S WITCH 1-2

ISPLAY SELECTOR SWITCH 1-2

D

I

MPLEMENT STA T U S I NPUT 1-6

GROUND SPEED OVERRIDE S WITCH (GSO) 1-7

CHAPTER 2 CALIBRATION 2-1

SELECTING THE A PPLICATION PROGRAM 2-1

SELECTING ENGLISH OR METRIC , UNITS 2-1

UNITS FOR E ACH DISPLAY SELECTOR SWITCH POSITION 2-2

UNITS FOR E ACH DISPLAY SELECTOR SWITCH POSITION 2-2

CHANGING UNITS 2-2

LIQUID/GRANULAR COMMON SETUP I TEMS 2-3

SETTING A PPLICATION RATES 2-3

SETTING THE % RATE CHANGE 2-3

SETTING BOOM W IDTHS 2-4

DISTANCE CALIBRATION - GROUND SPEED SENSOR 2-5

SETTING T HE HOLD/CLOSE R ESPONSE OF T HE FLOW CONTROL VALVE 2-7

SETTING THE GROUND SPEED O VERRIDE (GSO) VALUE 2-9

PRODUCT VOLUME (F ULL LOAD V ALUE) 2-10

RESETTING A CCUMULATORS 2-11

OPERATING UNDER E XTERNAL RATE COMMANDS 2-11

LIQUID ONLY SET-UP 2-12

SETTING THE C ORRECTION FACTOR 2-12

FLOW SENSOR C ALIBRATION 2-12

GRANULAR ONLY SET-UP 2-20

SETTING THE P RODUCT DENSITY 2-20

SETTING THE FAN TACH C AL. # 2-20

RATE S ENSOR CALIBRATION 2-21

SETTING A UTO POWER DOW N TIME 2-24

CHAPTER 3 OPERATION 3-1

NORMAL STA RT-UP AND OPERATION 3-1

CHANGING A CTIVE BOOM S ECTIONS 3-2

CHANGING A PPLICATION RATE 3-2

ALTERNATE APPLICATION RATE 3-2

% RAT E C HANGE 3-2

PRIMING THE MAIN PUMP AND BOOM 3-3

RAPID UNLOAD U SING T HE CONVEYOR 3-4

GROUND SPEED O VERRIDE (GSO) 3-5

III

CE & STANDARD V ERSION

Page 4

98-05018

R2

TASC 6100

CHAPTER 4 MAINTENANCE 4-1

FLUSHING AND CLEANING 4-1

C

ONTROL CONSOLE 4-1

ROUND SPEED SENSOR 4-2

G

F

LOW A ND PRESSURE SENSOR 4-2

CONVEYOR RAT E S ENSOR 4-3

LOW CONTROL V ALVE 4-3

F

W

IRING HARNESS 4-3

CHAPTER 5 TROUBLE SHOOTING - ERROR MESSAGES 5-1

LIQUID ERROR M ESSAGES 5-1

G

RANULAR ERROR M ESSAGES 5-5

CHAPTER 6 EMERGENCY OPERATION 6-1

GROUND SPEED S ENSOR FAILURE 6-1

LOW CONTROL V ALVE FAILURE 6-2

F

F

LOWMETER OR PRESSURE SENSOR F AILURE 6-4

APPENDIX A - SYSTEM DIAGRAMS A-1

APPENDIX B - SYSTEM OVERVIEW B-1

HOW THE TASC 6100 CONTROLS A PPLICATION RATE B-2

TASC 6100 S

YSTEM COMPONENTS B-3

AUTO TIP CONTROL B-7

XTERNAL RATE CONTROL B-7

E

APPENDIX C - GLOSSARY/TABLES C-1

GLOSSARY C-2

SEFUL FORMULAS C-4

U

E

NGLISH/METRIC CONVERSION C-4

MISCELLANEOUS NOTES C-6

CALIBRATION NUMBERS C-6

TANDARD V ERSION

IV

IVCE & S

Page 5

TASC 6100

List of Illustrations

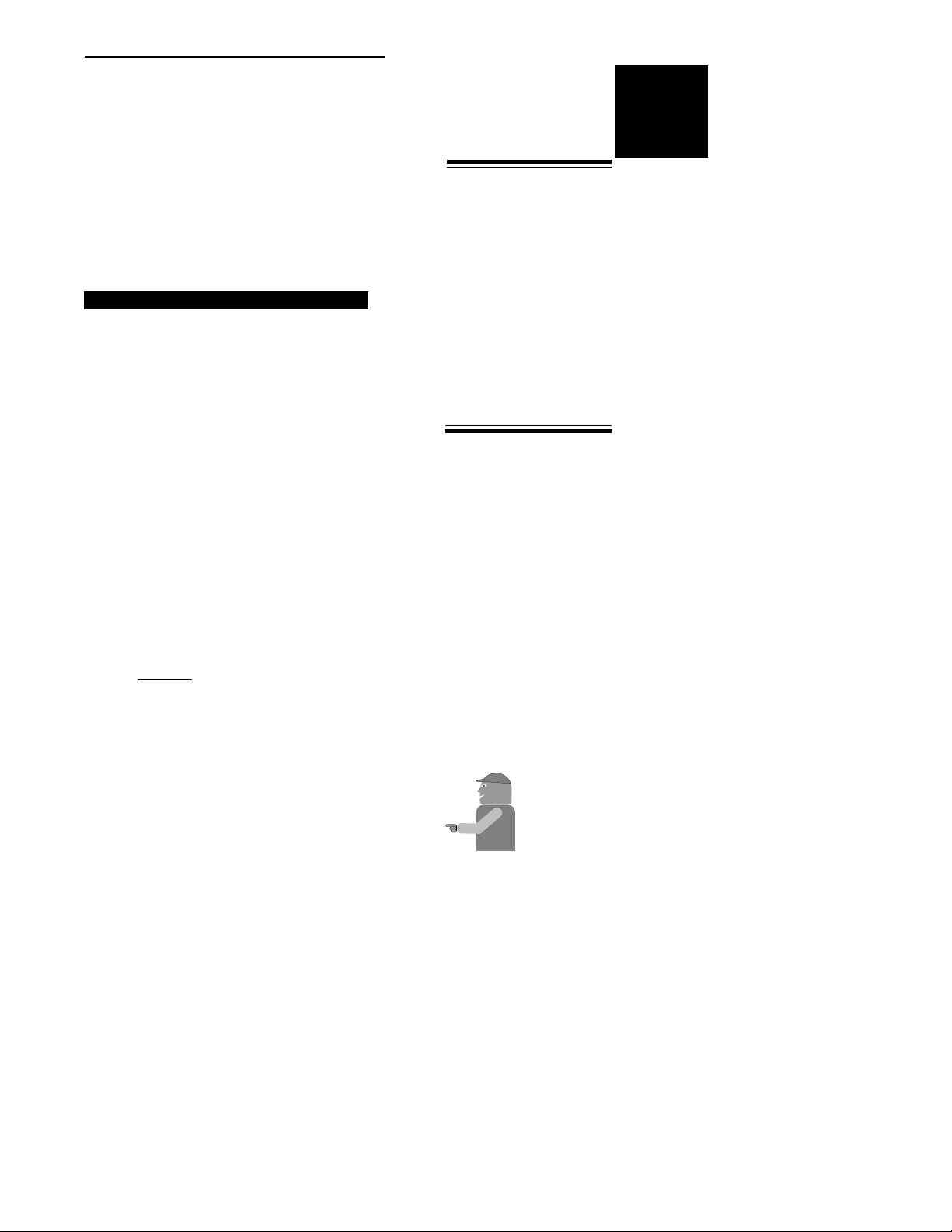

FIG. 1-1. TASC CONSOLE SWITCHES AND INDICATORS 1-1

IG. 1-2. DISPLAY SELECTO R FUNCTIONS - OPERATE MODE 1-3

F

F

IG. 1-3. DISPLAY SELECTOR FUNCTIONS - SET-UP MODE 1-4

IG. 1-4. TASC 6100 DEFAULT VALUES - LIQUID STANDARD MODE 1-8

F

F

IG. 1-5. TASC 6100 DEFAULT VALUES - LIQUID PRESSURE MODE 1-9

FIG. 1-6. TASC 6100 DEFAULT VALUES - GRANULAR MODE 1-10

IG. A1 - TYPICAL FLOW/PRESSURE B ASED WIRING DIAGRAM A-2

F

F

IG. A 2. TYPICAL FLOW/PRESSURE BASED PLUMBING D IAGRAM A-3

IG. A 3. TYPICAL TASC 6100 GRANULAR SYSTEM WIRING DIAGRAM A-4

F

F

IG. A 4. TASC 6100 W/AUTO TIP CONTROL WIRING DIAGRAM A-5

FIG. A 5. SERVICE FORM A-6

IG. B-1 TASC 6100 SYSTEM DATA FLOW B-2

F

F

IG. B-2. TASC 6100 CONSOLE B-3

IG. B-3. GROUND SPEED R ADAR B-4

F

F

IG. B-4. FLOWMETER B-5

FIG. B-6. 100 PULSE SENSOR B-5

IG. B-5. PRESSURE SENSOR B-5

F

F

IG. B-7. FLOW CONTROL V ALVE B-6

IG. B-8. BOOM CONTROL S WITCHBOX B-7

F

F

IG. B-10. DATA LINK B-7

FIG. B-9. AUTO TIP CONTROL BOX B-7

98-05018

R2

V

CE & STANDARD V ERSION

Page 6

98-05018

Mid-T

ech

R2

HOW TO USE THIS MANUAL

TASC 6100

his manual is designed to provide you with the basic

information needed to set up and operate the Mid-Tech

T

TASC 6100 control system. Actual procedures may vary

somewhat, depending on the configuration of your system.

When you see "Mitch", he is pointing out special information

that you should be aware of, regarding safety, preventing

console damage, an easier way to perform an operation, etc..

Below is a listing of the chapters in this manual, along with a

brief description of the information found in each chapter.

Chapter 1 - Switches and Controls - Lists each control switch,

on the face of the console, and gives a brief description of its

use.

Chapter 2 - Calibration and Setup - Takes you, step by step,

through the calibration of each sensor providing input to the

console, and entering other information the console needs to

perform the functions you require.

Chapter 3 - Operation - Briefly describes how to initiate the

application operation.

Chapter 4 - Trouble shooting - Lists possible causes and

remedies for the error codes that appear on the TASC display

if the console detects a problem.

®

M

id

-

T

e

c

h

Chapter 5 - Maintenance - Covers the basic maintenance

needed to keep your system operating at peak performance.

Chapter 6 - Emergency Operations - Suggests ways to operate,

under reduced accuracy, in the event of a major fault.

Appendix A - Sample system wiring and plumbing diagrams.

Appendix B - System Overview - Describes the major compo-

nents of the TASC system and their individual functions in

application control.

Appendix C - Glossary/Tables

Back Cover - Quick Start/Quick Set Up Guides

CE & STANDARD V ERSION

VI

Page 7

TASC 6100

CHAPTER 1 SWITCHES AND CONTROLS

everal switches and indicators serve as the

interface between the operator and the Mid-

S

Tech control system.

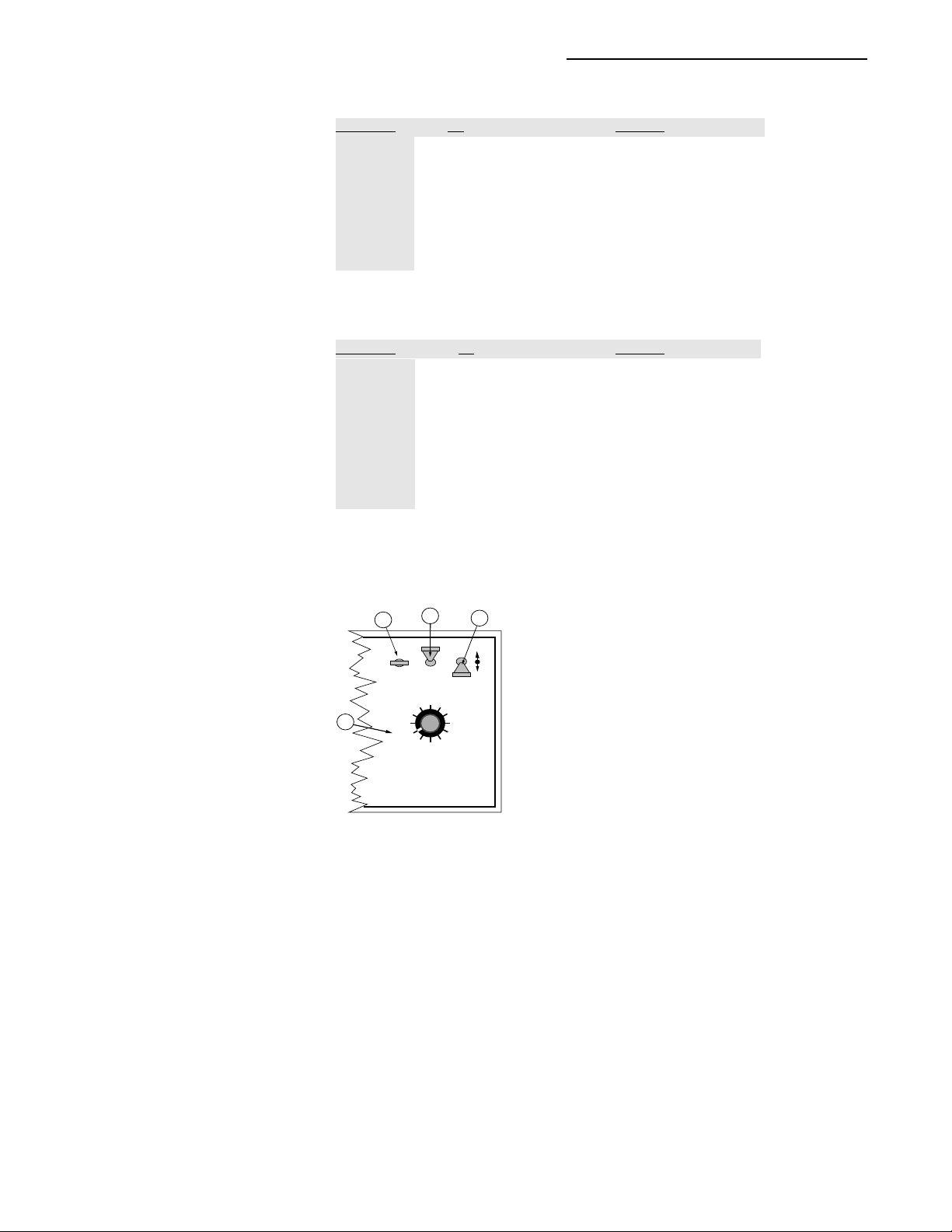

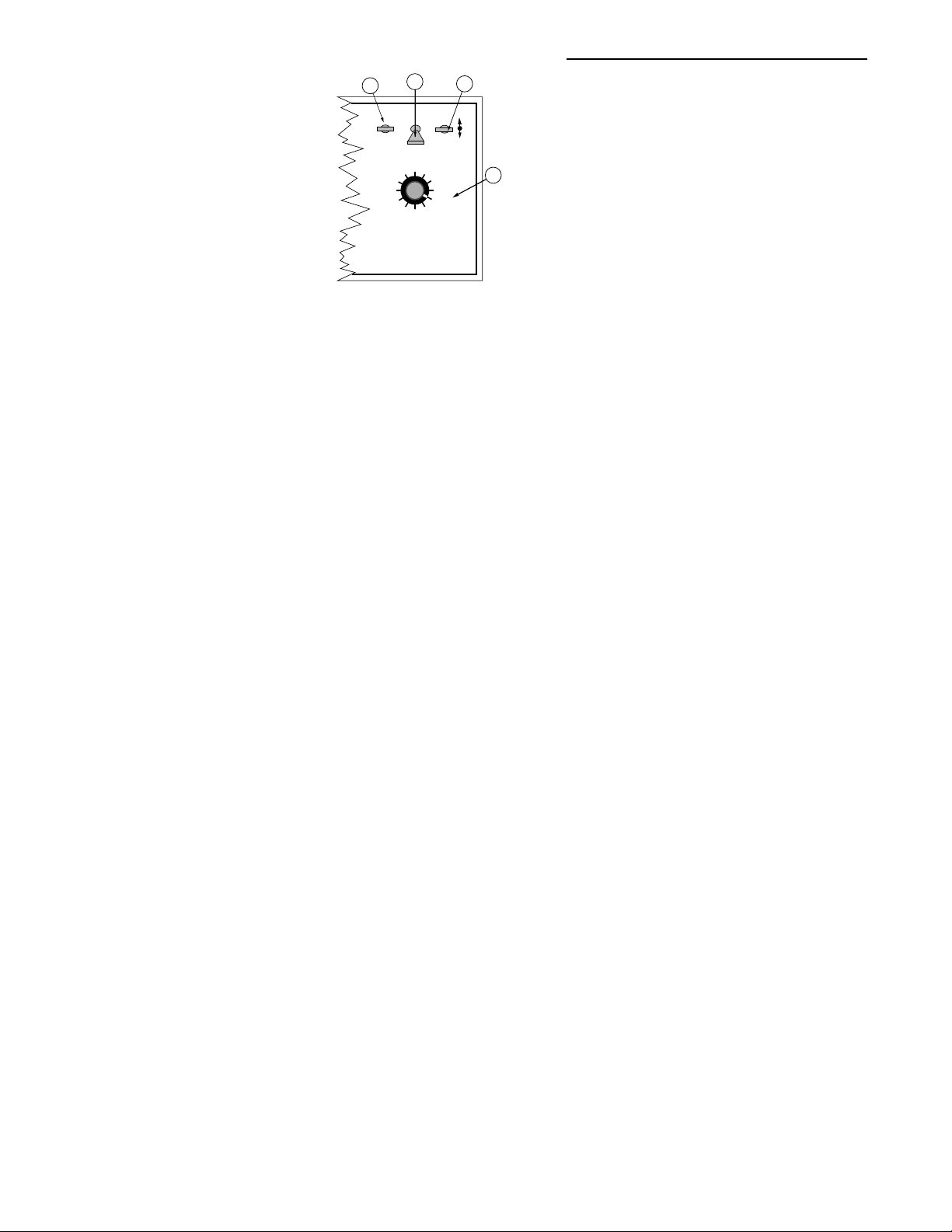

CONSOLE SWITCHES AND INDICATORS

his section shows the location of each switch

and indicator found on the TASC 6100 control

T

console and discusses its function in both the

Operate and Setup modes.

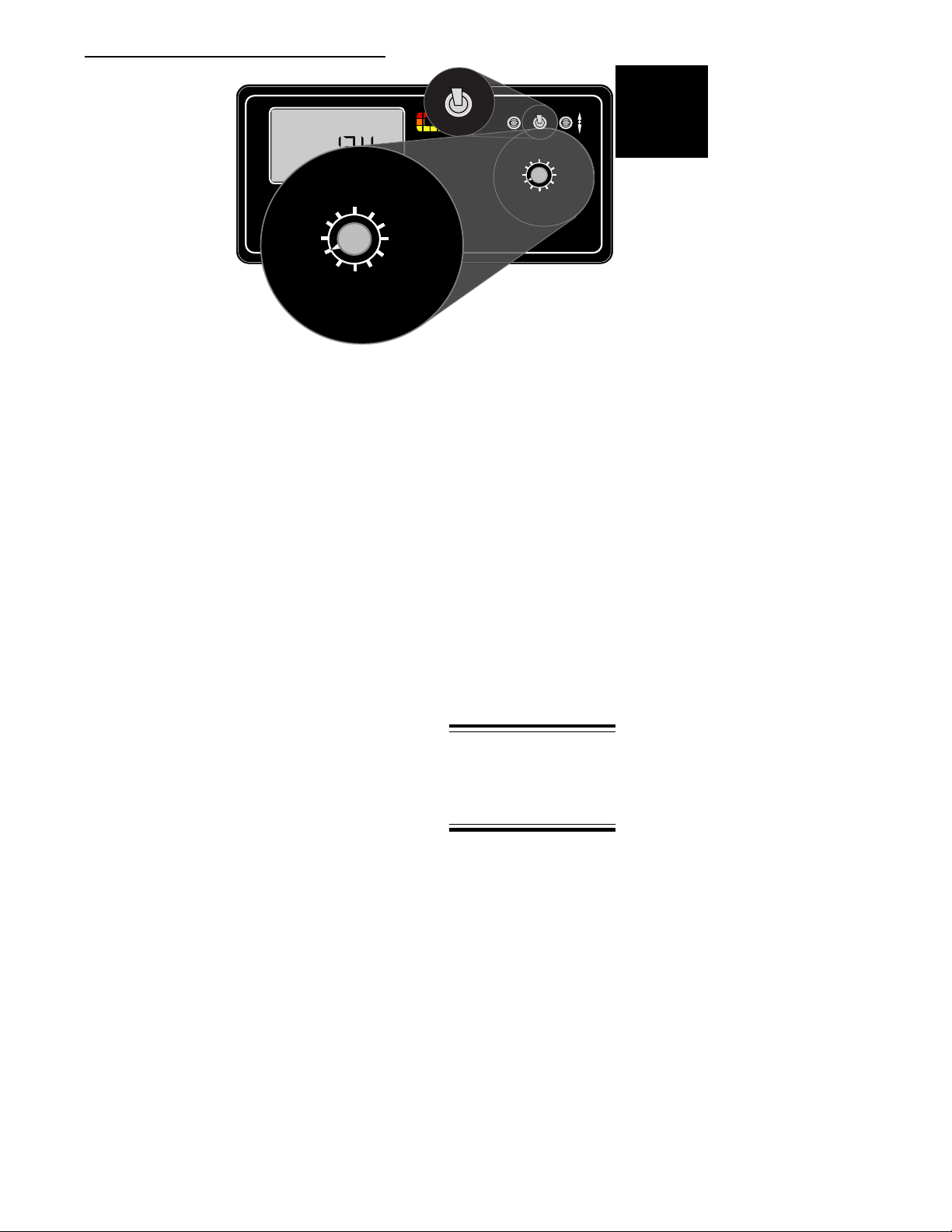

POWER SWITCH

The power switch (see #1 in Fig. 1-1) controls power

to the console. The CE console has an "Auto Power

Down" feature which

powers the console off

after a operator selectable

time has elapsed. The

console has a nonvolatile

memory so it "remembers"

the constants and data

previously entered, even

with the power removed.

NOTE: The “Auto Power Down Feature is only

available on the CE version of the console (CE

designation label on back of console).

Flow

TASC-6100

Rate Controller

Gal./

Standard Rate

Alt.-Rate

98-05018

R2

Switches

& Cont.

3

2

1

ON OPERATE INC.

MID-TECH

-Ac

MIDWEST TECHNOLOGIES, INC.

OFF

®

OFF SET- UP

DEC.

%Rate

Product Vol.

Appl. Rate

Fan RPM

Total Applied

Area

Width

Speed

Distance

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

123 4567 89

BOOMS

6

Fig. 1-1. TASC

Console Switches and

Indicators

4

5

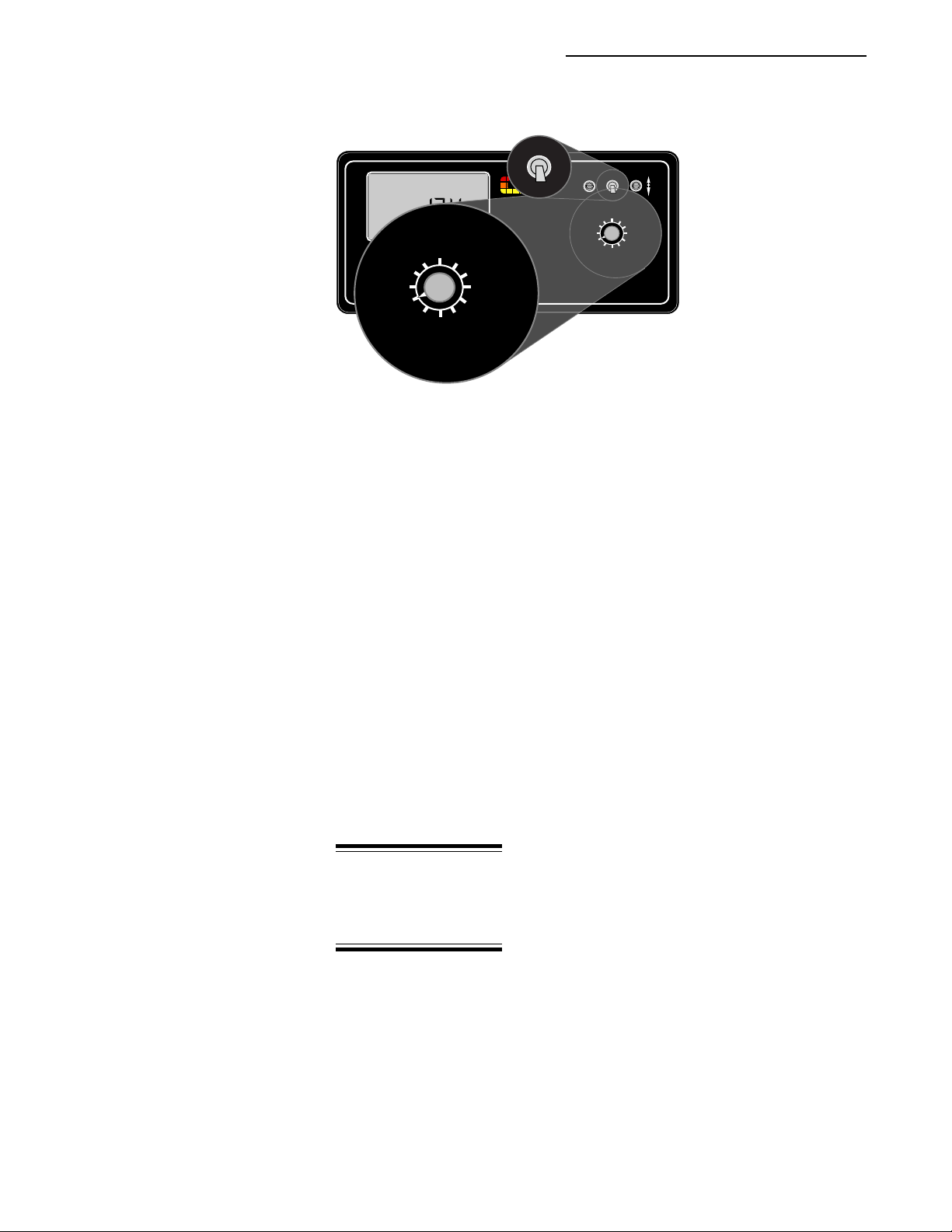

MODE SELECTOR SWITCH

The Mode Selector switch (see #2 in Fig. 1-1)

switches between the OPERATE and SET-UP modes

of the control console. This switch must be in the

“OPERATE” position when applying product. The

“SET-UP” position is used for entering set-up

information into the console. In the SET-UP Mode an

“Err” message appears if a position which can not be

programmed is selected.

1-1

CE & STANDARD V ERSION

Page 8

98-05018

R2

TASC 6100

INC / DEC SWITCH

The Increase/Decrease (INC/DEC) switch (see #3 in

Fig. 1-1) is used, in both the OPERATE and SET-UP

modes, to adjust the values appearing in the display.

BOOM SECTION “ON/OFF” INDICATORS

The boom section On/Off indicators (see #5 in Fig. 1-

1) indicate which boom sections the operator has

selected. When a boom is turned on, its indicator is lit.

There are a maximum of nine boom sections available.

RATE SWITCH

The Rate Selector switch (see #6 in Fig. 1-1) is a three

position switch that allows the operator to select

either a pre-selected standard rate, an alternate rate, or

stop the application.

DISPLAY SELECTOR SWITCH

The Display Selector (see #4, Fig. 1-1) is used to

choose which of the console functions is displayed on

the screen and is available for setting by the operator.

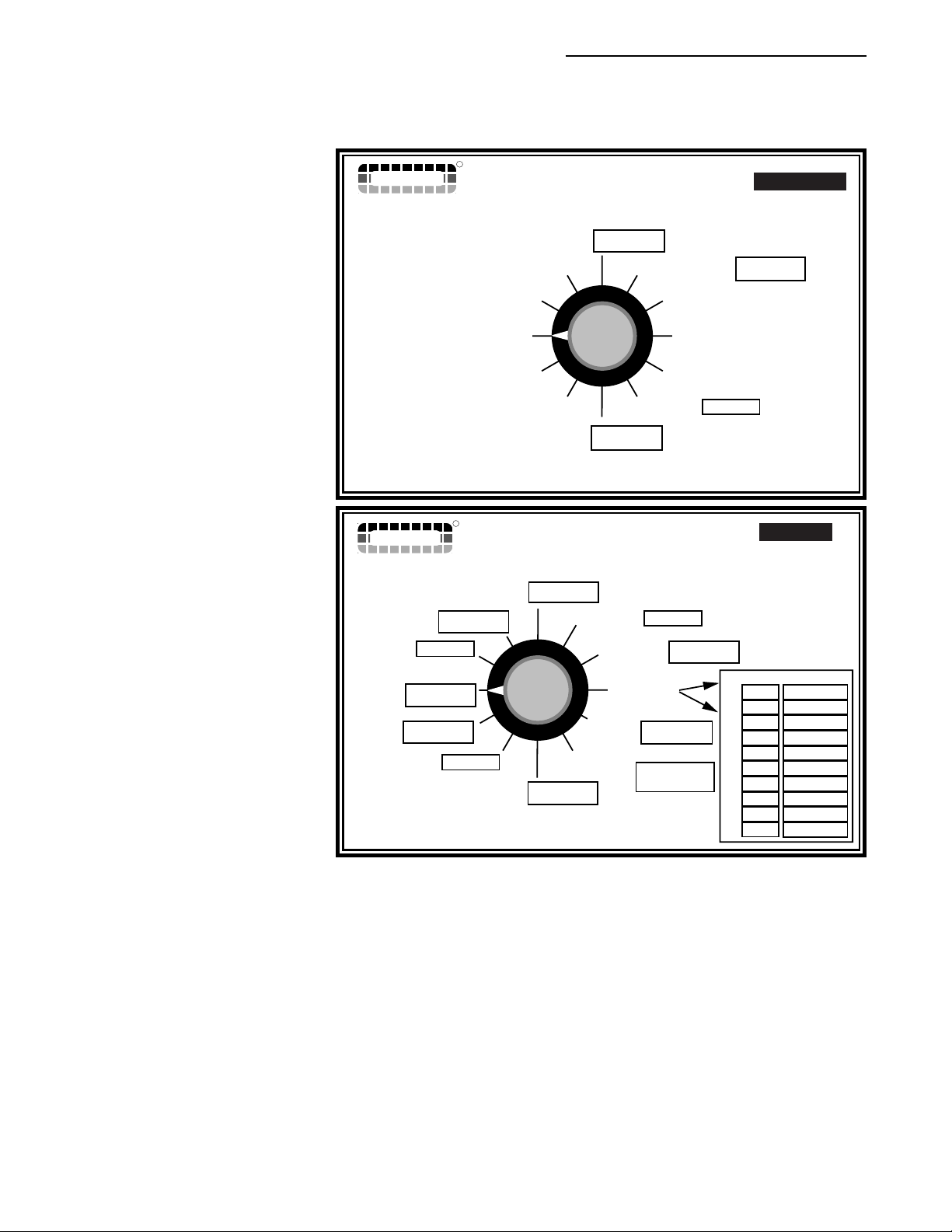

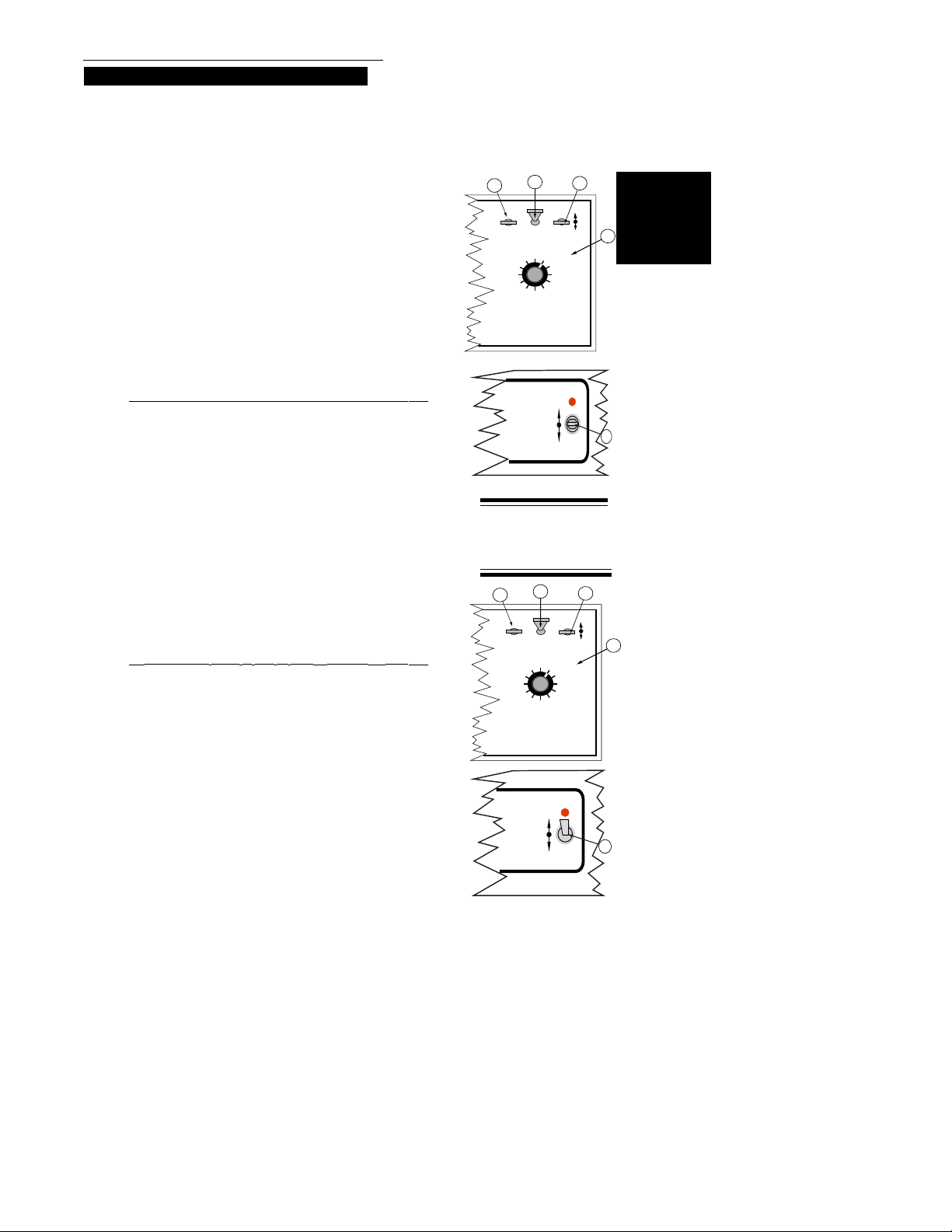

Display Selector - Operate Mode (Liquid)

(See Fig. 1-2)

Speed: The current vehicle speed.

Area: Area Accumulator #1. The total area treated

since the counter was last reset.*

Fan RPM: Not used in liquid mode.

Product Vol: Amount of product aboard the vehicle.

Value counts down as the product is applied and

alarm sounds when 10 % of the full load is left.**

CE & STANDARD V ERSION

1-2

Page 9

TASC 6100

®

OFF

567 89

MPH

123

BOOMS

OFF

DEC.

4

OFF

MIDWEST TECHNOLOGIES, INC.

% Rate: The percent

of programmed

application rate

at which the

MPH

system is applying product.***

Application Rate:

Displays the

target application

rate when the

ground speed is

zero or all booms

are OFF.** The

Product Vol.

TASC-6100

Fan RPM

Rate Controller

Speed

%Rate

Area

Scan

DISPLAY SELECTOR

Test

Speed

PSI/Prime

Appl. Rate

Total Applied

Width

Distance

actual application

rate is displayed

here once

application has started.

Total Applied: The total volume of product applied

since the last time the counter was reset, as

measured by the pressure sensor or flow meter.*

OPERATE

MID-TECH

SET- UP

MIDWEST TECHNOLOGIES, INC.

98-05018

R2

OPERATE

Scan

SET- UP

%Rate

Test

Speed

4

INC.

DEC.

Appl. Rate

Total Applied

Width

Distance

PSI/Prime

567 89

ON

®

OFF

Product Vol.

Fan RPM

Area

Speed

DISPLAY SELECTOR

123

BOOMS

Fig. 1-2. Display Selector

Functions - Operate Mode

Switches

& Cont.

Impl. Width: The active boom width, (total of all

boom sections turned ON).

Distance: The total distance traveled since the last

time the counter was reset.

PSI/Prime: Used to open the control valve during

product pump priming, for fast unload, and to

display boom pressure when operating in pressure

based mode.

Test Speed: The speed the console uses for stationary

tests of the sprayer.**

Scan: The display scans Speed, Area #1, Product

Vol., Application Rate, Total Applied, and Fan

RPM, stopping at each position for approximately

two seconds before automatically cycling to the

next.

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

1-3

CE & STANDARD V ERSION

Page 10

98-05018

R2

Product Vol.

Fan RPM

Fig. 1-3. Display Selector

Functions - Set-Up Mode

%Rate

TASC-6100

Rate Controller

Area

Speed

Scan

Test

Speed

DISPLAY SELECTOR

PSI/Prime

MPH

Appl. Rate

Total Applied

Width

Distance

TASC 6100

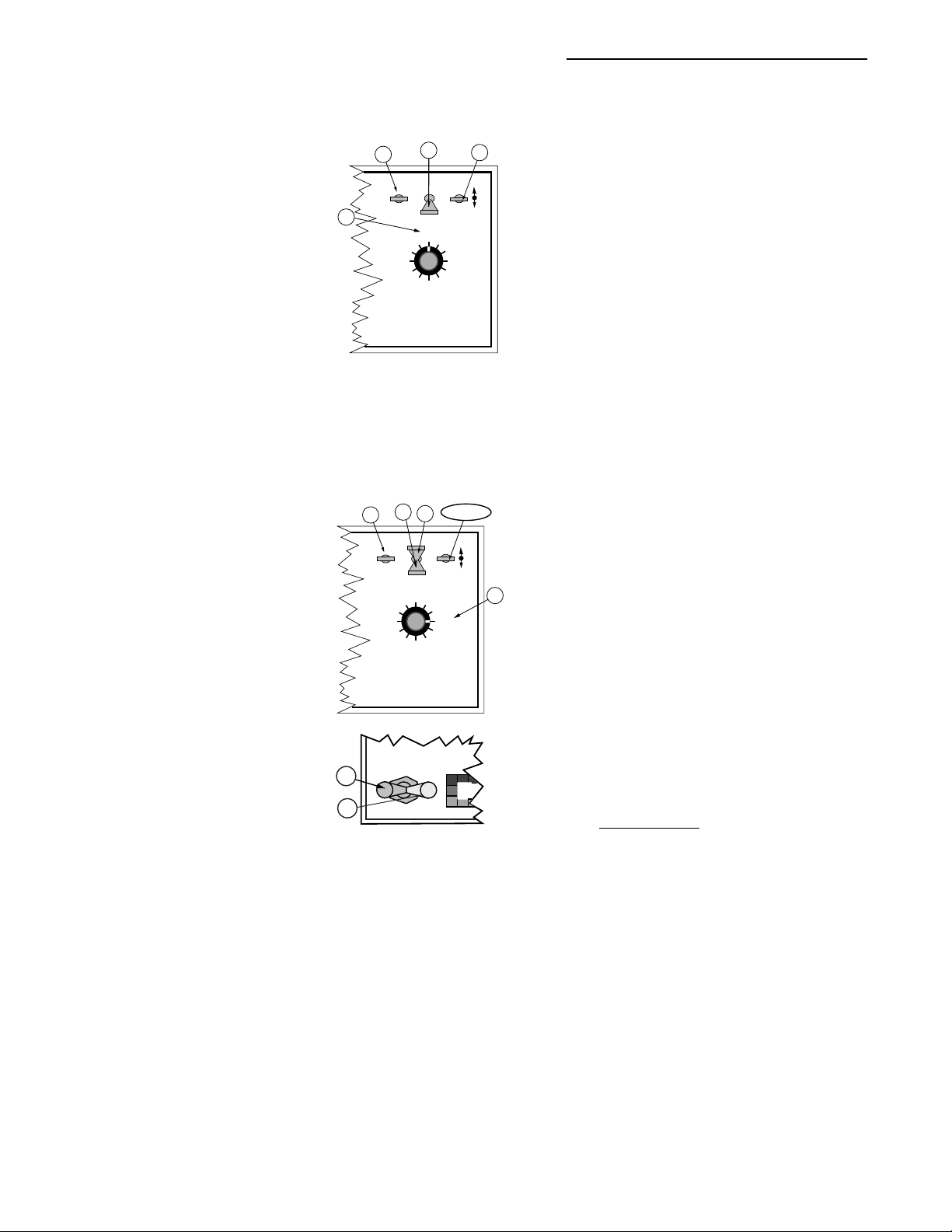

Display Selector - Setup Mode (Liquid)

(See Fig. 1-3)

Speed: Ground speed

OPERATE

INC.

ON

OPERATE

SET- UP

®

OFF

Product Vol.

Fan RPM

Area

Speed

Scan

DISPLAY SELECTOR

123

BOOMS

SET- UP

%Rate

Appl. Rate

Total Applied

Width

Distance

PSI/Prime

Test

Speed

567 89

4

DEC.

MID-TECH

MIDWEST TECHNOLOGIES, INC.

mode, can be set to zero to remove the fan

RPM reading from the scan feature.**

Product Volume: Used to set the full load value of the

vehicle.**

% Rate: The percent rate change value (the percent

by which the programmed application rate can be

changed with each activation of the INC/DEC

switch).**

override (GSO) value.**

Area: Area Accumulator

#2. The total area treated

since the counter was last

reset.*

Fan RPM: The current fan

RPM. calibration number.

Since not used in liquid

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

CE & STANDARD V ERSION

Application Rate: Psi mode - A flow sensor cal. #

correction factor that allows for corrections due to

differences in product viscosities without changing

the base cal. #. STnrd and rEFLO modes - ERR, No

function in this mode.

Total Applied: The pressure sensor or flow meter

calibration number. NOTE: Must have all booms

ON when in REFLOW Mode.**

Width: Individual boom section widths. The display

cycles through the individual boom sections, in

order, unless a particular boom switch is activated

and the boom master switch is ON.**

Distance: The current distance calibration number.**

PSI/Prime: The current console operating mode.**

Test Speed: The current test speed.**

Scan: ERR, No function in SETUP mode.

1-4

Page 11

TASC 6100

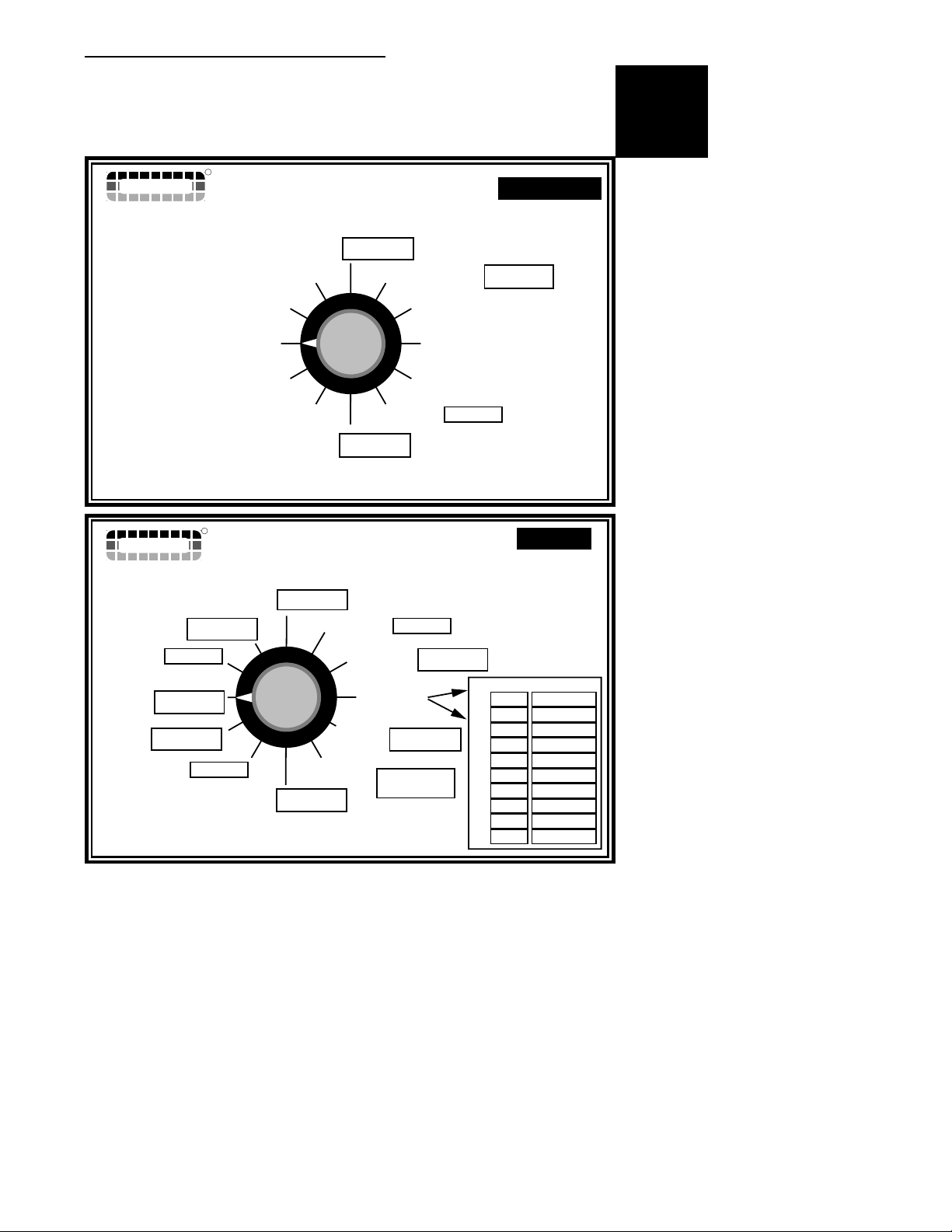

Display Selector - Operate Mode (Gran.)

(See Fig. 1-2)

Speed: The current vehicle speed.

Area: Area Accumulator #1. The total area treated

since the counter was last reset.*

Fan RPM: The current speed of the fan (spinners).

Product Vol.: Amount of product aboard the ve-

hicle.**

% Rate: The percent of programmed application rate

at which the product is being applied.***

Application Rate: Displays the target application rate,

when the ground speed is zero or all booms are

OFF. ** Once application begins, the actual

application rate is displayed here.

Total Applied: The total volume applied since the

accumulator was last reset, as measured by the rate

sensor.*

98-05018

R2

Switches

& Cont.

Impl. Width: The active spread width, (total of all

spreader sections turned “ON”).

Distance: The total distance traveled since the last

time the counter was reset.

Prime: Used to open the control valve. It can be used

in the granular application to unload the vehicle at

its maximum discharge rate.

Test Speed: The speed the console uses for stationary

tests of the spreader.**

Scan: The display scans Speed, Area #1, Product

Volume, Application Rate, Total Applied, and Fan

RPM (if Fan RPM Cal # not set to zero). The

display stops at each position for approximately

two seconds before automatically cycling to the

next.

1-5

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

CE & STANDARD V ERSION

Page 12

98-05018

R2

TASC 6100

Display Selector - Set-Up Mode (Gran.)

(See fig. 1-3)

Speed: Ground Speed Override (GSO) value.**

Area: Area Accumulator #2. The total area treated

since the counter was last reset.*

Fan RPM: The current fan RPM calibration

number. This cal # can be set to zero to remove the

fan RPM reading from the scan feature.**

Product Volume: Used to set the full load capacity of

the vehicle.**

% Rate: The percent rate change value (the percent

by which the programmed application rate can be

changed with each activation of the INC/DEC

switch).**

Application Rate: Product density.**

Total Applied: The rate sensor calibration number

[spreader constant].**

* Totals can be zeroed in

this mode.

** Values are programmable

in this mode.

*** Values changeable by a %

increase or decrease.

CE & STANDARD V ERSION

Width: Individual boom section widths.**

Distance: The current distance calibration number.**

Prime: The current console operating mode.**

Test Speed: The current test speed.**

Scan: Err, No function in the SETUP mode.

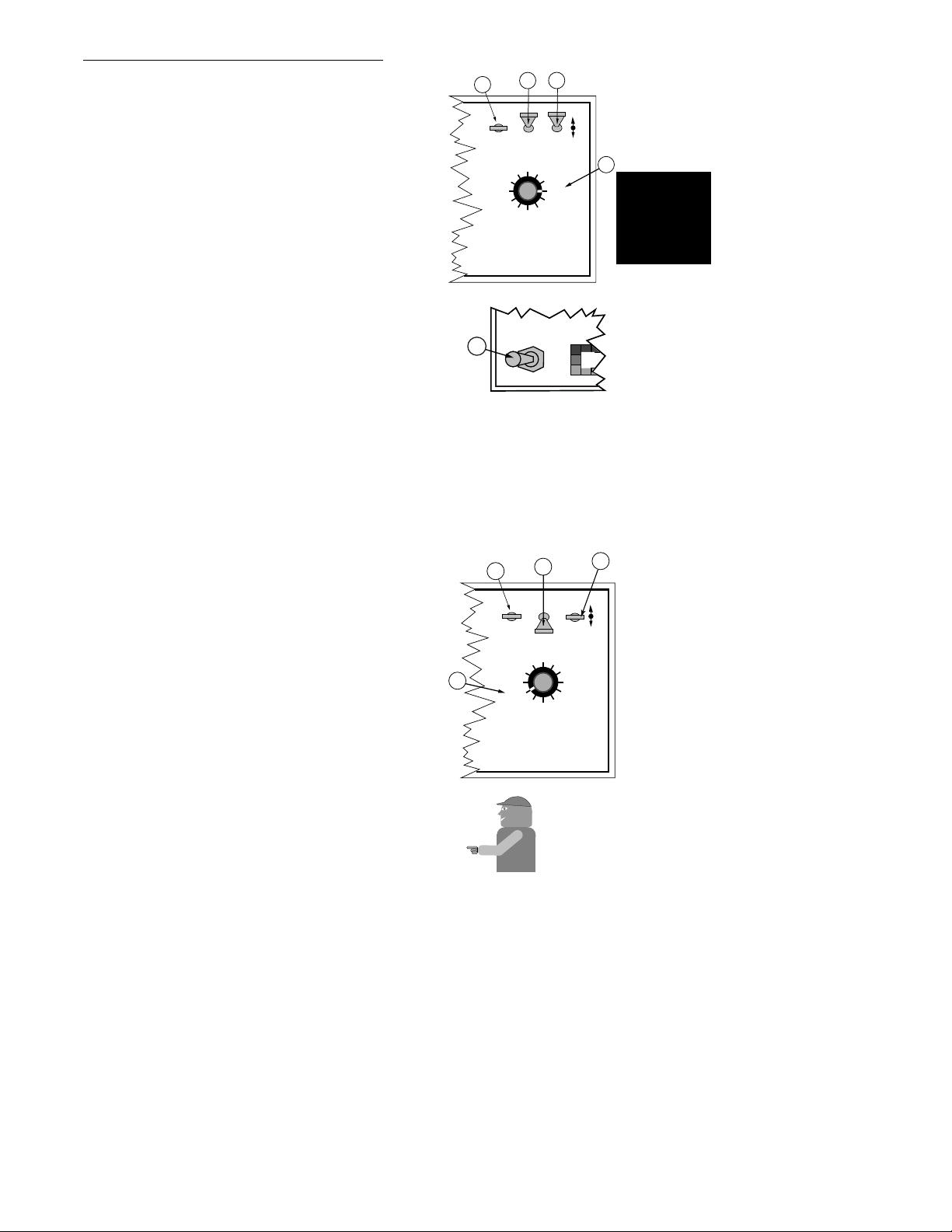

IMPLEMENT STATUS INPUT

n external “Implement Status” input can be

used to override the TASC control. The

A

VDC) on the boom interface cable sense line. As long

as this condition is present, the control console

operates normally. If the voltage is interrupted, the

control console automatically stops applying. At the

same time, the control console will either "HOLD" or

input must present a positive voltage (+12.0

1-6

Page 13

TASC 6100

Mid-T

ech

"CLOSE" the control valve, depending on the

response selected by the operator. (See Page 2-7).

This feature allows the operator to control the

operation of the control valve through the normal

operation of the vehicle. The implement status input

can be used to sense the ON/OFF condition of the

main vehicle pump switch, a separate Master switch,

or, an external switch sensing an implement "UP"/

"DOWN" condition.

GROUND SPEED OVERRIDE SWITCH (GSO)

f your TASC system includes an optional MIDTECH® Boom Control Switch Box, the GSO

I

switch is already installed. An optional, externally

mounted, GSO switch can be used to temporarily

operate the vehicle using a pre-selected GSO minimum speed rather than the actual speed registered by

the ground speed sensor. The override feature is used

to allow the vehicle to reach the application rate

quickly when starting from a complete stop or to

maintain a good application pattern when the vehicle

is moving at very low ground speeds. It can also be

used to allow the operator to flush or empty the tank

of a sprayer, or empty the bed of a spreader, from the

cab, with the vehicle stopped.

98-05018

R2

Fig. B-8, in Appendix B,

shows a “Boom Control

Switch Box” which incorporates the Implement Status

Switch and the GSO function

into one switch. The “OFF”

position provides a Status

Switch “OFF” condition,

“AUTO” furnishes Status

Switch ON, and “GSO”

activates the GSO function.

Other methods of controlling

these functions are also

available. This switchbox

also includes an individual

ON/OFF switch for each

boom section.

Switches

& Cont.

The control console operates normally as long as the

GSO switch condition is open (OFF). Whenever the

override switch is closed (ON) and the actual ground

speed is

less than the GSO Speed, the control console

automatically uses the GSO Speed to control application rate. As soon as the switch reverts to its normally

open (OFF) condition, or the actual ground speed

increases above the preset GSO speed, the control

console will adjust the rate based on the actual ground

speed.

CAUTION: Controlling application rates based on

a GSO Speed is not as accurate as using the actual

ground speed. When GSO is being used and the true

ground speed is less than the GSO speed", the

console sounds an alarm and the display flashes a

"Too Slow" message to warn the operator of over

application.

1-7

M

id

-T

e

c

h

CE & STANDARD V ERSION

Page 14

98-05018

R2

TASC 6100

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

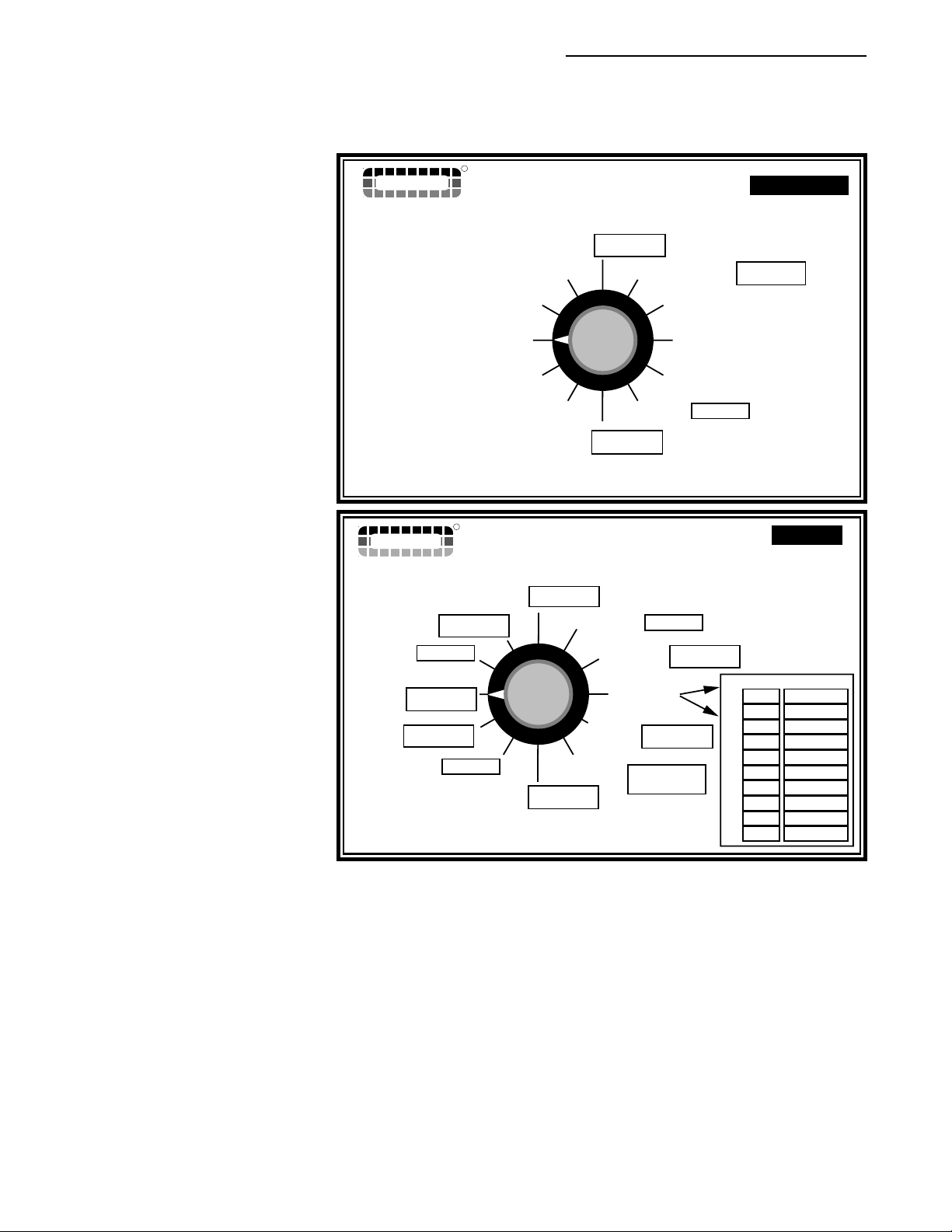

TASC 6100, DISPLAYED VALUES WHEN IN

Use INC switch to set full load,

INC/DEC to change

Product Vol.

Fan RPM

Area

Use DEC switch to zero display

Speed

Test Speed

Default values shown in upper left of boxes.

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

Product Vol.

Fan RPM

Full Load Amount

500

2.00

R

TASC 6100, DISPLAYED VALUES WHEN IN

Rate Change Increment

10

% Rate

Use INC/DEC switch to change up or down

100

% Rate

Scan

10.0

Use INC/DEC switch to change up or down

Application Rate

Total Applied

Application Rate

Use INC/DEC switch to change up or down

Total Applied

Use DEC switch to zero display

Impl. Width

Distance

PSI/Prime

Correction factor

1.00

Hold increase switch to drive valve OPEN

-----

Rate Sensor Cal#

71.0

OPERATE

SOFTWARE VER. 1.30

LIQUID STD MODE

Preset #1

10.0/12.0

SET-UP

SOFTWARE VER. 1.30

LIQUID STD MODE

Preset #1

0.0

Area

Ground Speed Override

7.0

Speed

Scan

Err

Test Speed

Default values shown in upper left of boxes.

Use the INC/DEC switch to change values.

CE & STANDARD V ERSION

Impl. Width

Distance Sensor Cal#

Distance

PSI/Prime

10.0/

1000

DEC sets to granular

INC sets to liquid

Stnrd L

Fig. 1-4. TASC 6100 Default Values

- Liquid Standard Mode

1-8

Default Custom

960

C

120

1

2

200

3

320

4

200

5

120

6

7

0

8

0

9

0

0

99362

Page 15

TASC 6100

98-05018

R2

Switches

& Cont.

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

TASC 6100, DISPLAYED VALUES WHEN IN

Use INC switch to set full load,

INC/DEC to change

Product Vol.

Fan RPM

Use DEC switch to zero display

Area

Speed

Test Speed

Default values shown in upper left of boxes.

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

Product Vol.

Fan RPM

Full Load Amount

500

2.00

R

TASC 6100, DISPLAYED VALUES WHEN IN

Rate Change Increment

10

% Rate

Use INC/DEC switch to change up or down

100

% Rate

Scan

10.0

Use INC/DEC switch to change up or down

Application Rate

Total Applied

Application Rate

Use INC/DEC switch to change up or down

Total Applied

Use DEC switch to zero display

Impl. Width

Distance

PSI/Prime

Correction factor

1.00

Hold increase switch to drive valve OPEN

Ps---

Rate Sensor Cal#

10.0/12.0

OPERATE

SOFTWARE VER. 1.30

LIQUID PSI MODE

Preset #1

10.0

SET-UP

SOFTWARE VER. 1.30

LIQUID PSI MODE

Preset #1

Area

0.0

Ground Speed Override

7.0

Speed

Scan

Default values shown in upper left of boxes.

Use the INC/DEC switch to change values.

Err

Test Speed

10.0

Fig. 1-5. TASC 6100 Default Values

Impl. Width

Distance Sensor Cal#

Distance

PSI/Prime

1000

DEC sets to granular

INC sets to liquid

PSi

- Liquid Pressure Mode

1-9

Default Custom

960

C

120

1

2

200

3

320

4

200

5

120

6

7

0

8

0

9

0

0

99362

CE & STANDARD V ERSION

Page 16

98-05018

R2

TASC 6100

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

R

TASC 6100, DISPLAYED VALUES WHEN IN

Use INC switch to set full load,

INC/DEC to change

Product Vol.

Fan RPM

Use DEC switch to zero display

Area

Speed

Test Speed

Default values shown in upper left of boxes.

MID-TECH

MIDWEST TECHNOLOGIES, INC.

Specialists In Control System Electronics Since 1983

Product Vol.

Fan RPM

Full Load Amount

10750

2.00

R

TASC 6100, DISPLAYED VALUES WHEN IN

Rate Change Increment

10

% Rate

Use INC/DEC switch to change up or down

100

% Rate

Scan

10.0

Use INC/DEC switch to change up or down

Application Rate

Total Applied

Application Rate

Use INC/DEC switch to change up or down

Total Applied

Use DEC switch to zero display

Impl. Width

Distance

Hold increase switch to drive valve OPEN

PSI/Prime

Density

65.0

-----

Rate Sensor Cal#

1630.0

OPERATE

SOFTWARE VER. 1.30

GRANULAR MODE

Preset #1

200/250

SET-UP

SOFTWARE VER. 1.30

GRANULAR MODE

Preset #1

0.0

Area

Ground Speed Override

7.0

Speed

Scan

Err

Test Speed

Default values shown in upper left of boxes.

Use the INC/DEC switch to change values.

CE & STANDARD V ERSION

Impl. Width

Distance Sensor Cal#

Distance

PSI/Prime

10.0

1000

DEC sets to granular

INC sets to liquid

Stnrd C

Fig. 1-6. TASC 6100 Default Values

- Granular Mode

1-10

Default Custom

720

C

360

1

2

360

3

0

4

0

5

0

6

7

0

8

0

9

0

0

99362

Page 17

TASC 6100

Mid-T

ech

CHAPTER 2 CALIBRATION

NOTE: PLEASE READ THROUGH THE FOLLOWING SECTIONS COMPLETELY BEFORE YOU

BEGIN CALIBRATION!

pecific information about your applicator (i.e.

application rates, boom widths, test speed, etc.)

must be programmed into the control console and

S

the flow/rate and ground speed sensors must be calibrated

before the system is ready to use. The calibration and set

up procedures are not difficult but must be followed

precisely in order to get the maximum possible accuracy

out of the system.

SELECTING THE APPLICATION PROGRAM

erify that the proper console application pro

gram is selected.

8

To view the program currently selected, set the Mode switch

to Setup and the Display Selector to PSI/Prime.

M

id

-

T

e

c

h

98-05018

R2

Setup

& Cal.

Pump L PSi(bAr) is LIQUID PRESSURE application (normal pressure based spraying)

Pump L STnrd is STANDARD LIQUID application (normal flow based spraying)

Pump L rEFLO is LIQUID REFLOW application (for use on some European sprayers)

Pump C STnrd is standard GRANULAR application (single conveyor spreaders)

Pump C SPLit is GRANULAR SPLIT DRIVE application (dual conveyor spreaders)

To change programs, hold the INC. switch up to set LIQUID

and cycle between standard, reflow, and pressure. Hold the

DEC. switch down to set GRANULAR and cycle between

standard and split drive. The display changes about every

ten seconds. The program being displayed, when the INC./

DEC. switch is released, is the program selected. If you have

a question about which application to use, check with your

dealer or call MID-TECH Customer Service.

SELECTING ENGLISH OR METRIC, UNITS

he control console is capable of displaying either

US or Metric units of measure.

T

2-1

CE & StandardVersion

Page 18

98-05018

R2

TASC 6100

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION

(Liquid Mode)**

POSITION US METRIC

Speed Miles/Hour (mph) Kilometers/Hour (kmph)

Field Area Acres (acre) Hectares (ha)

Total Area Acres (acre) Hectares (ha)

Product Vol. US Gallons (gal.) Liters (l)

Appl. Rate US Gallons/acre (gpa) Liters/Hectare (l/ha)

Total Applied US Gallons (gal.) Liters (l)

Impl. Width Inches - Feet (in., ft.) Meters (m)

Distance Feet - Miles (ft.-miles)* Meters - Kilometers (m-km)*

Test Speed Miles/Hour (mph) Kilometers/Hour (kmph)

UNITS FOR EACH DISPLAY SELECTOR SWITCH POSITION

(Granular Mode)**

POSITION US METRIC

Speed Miles/Hour (MPH) Kilometers/Hour (KPH)

Field Area Acres (Ac) Hectares (-Ha)

Total Area Acres (Ac) Hectares (-Ha)

Product Vol. Pounds (lb) Kilograms

Appl. Rate pounds/Acre (lb/Ac) Kilograms/Hectare (-Ha)

Total Applied Pounds-Tons (lb -Tons) Kilograms-Metric Tons

Impl. Width Inches-Feet (In.-Ft.) Meters (Meters)

Distance Feet-Miles (Ft.)* Meters-Kilometers (Meters)*

Test Speed Miles/Hour (MPH) Kilometers/Hour (KPH)

Prod. Density Pounds/Cubic Ft. (Cu Ft.) Kilograms/Tenths Meter3 (Meters Cu)

* No units displayed after roll over of feet to miles or meters to kilometers

** Items in parenthesis are the abbreviations that appear on the screen.

A-1

ON

OFF SET- UP DEC.

Product Vol.

Fan RPM

A-3

CE & S

Area Impl. Width

Speed

Scan

DISPLAY SELECTOR

123456789

BOOMS

TANDARD V ERSION

A-2

OPERATE INC.

% Rate

Application Rate

Total Applied

Distance

PSI/Prime

Test

Speed

CHANGING UNITS

A. Set the console switches to the following positions:

B

1. Power ON

2. Mode Selector OPERATE

3. Display selector Speed

The display shows the current speed units.

B. Hold down the INC./DEC. switch for approximately

5 sec. The display alternates between MPH (US) and

KPH (Metric). Release the switch when the mode

that you desire is being displayed.

2-2

Page 19

TASC 6100

LIQUID/GRANULAR COMMON SETUP ITEMS

SETTING APPLICATION RATES

98-05018

R2

he TASC 6100 system is designed to maintain a

constant, pre-selected application rate. In order for

T

the control console to do this, the operator must

enter the desired application rate. Two, switch selectable,

rates can be pre-programmed into the console.

Standard Rate

A. Set the console switches to the following positions:

1. Power ON

2. Mode Selector OPERATE

(APPLICATION RATE IS SET IN THE OPERATE MODE!!!)

3. Display Selector Application Rate

4. Rate switch Standard Rate

The display shows the current application rate.

B. Use the INC./DEC. switch to set the desired rate.

Alternate Rate

C. Set the console switches to the following positions:

1. Power ON

2. Mode Selector OPERATE

(APPLICATION RATE IS SET IN THE OPERATE MODE!!!)

3. Display Selector Application Rate

4. Rate switch Alt.- Rate

The display shows the current application rate.

D. Use the INC./DEC. switch to set the desired rate.

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

Alt.-Rate

Standard Rate

Application Rate

Total Applied

Distance

PSI/Prime

OFF

B

Setting the APPLICATION RATE to 0.0 will

turn off the flow

control function.

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Speed

DISPLAY SELECTOR

123456789

BOOMS

Test

Application Rate

Total Applied

Distance

PSI/Prime

B

A-3

Setup

& Cal.

A-4

A-3

SETTING THE % RATE CHANGE

his feature allows the operator to change the

application rate “ON THE GO” with a simple

T

actuation of the INC./DEC. switch. The amount of

change each switch actuation makes is proportional to

the value programmed into this position, (e.g. 20 =20%

2-3

Alt.-Rate

Standard Rate

OFF

A-4

CE & StandardVersion

Page 20

98-05018

R2

A-2

A-1

ON

OPERATE INC.

A-3

A-4

E

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

A-2

A-1

Fan RPM

123456789

BOOMS

OFF

E

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

MASTER

ON

Application Rate

Total Applied

Distance

PSI/Prime

B, C, D, E

Application Rate

Total Applied

Distance

PSI/Prime

MI

TASC 6100

change in the target rate). For example, with the application rate set to 10.0 gallons per acre, a single actuation of

the INC. switch causes the system to control flow at the

rate of 12.0 gallons per acre (10.0 + 20% = 12.0).

B

A. Set the console switches to the following positions:

1. Power ON

2. Mode Selector SET-UP

3. Display Selector % Rate

The display shows the current % change value.

B. Use the INC./DEC. switch to set this number to the

desired % change value.

SETTING BOOM WIDTHS

he MID-TECH control console is designed to

automatically compensate for changes in the swath

T

width, caused by turning boom sections on or off.

To accurately respond to changes in swath width, the

console must know the length of each boom section. Use

the following procedure to set boom section widths.

A. Set the console to the following positions;

A-3

1. Power ON

2. Mode Selector SET- UP

3. Display Selector Impl. Width

4. Boom switches OFF

(or Master switch)

The display cycles through each boom position (1

through 9) and displays its current width in inches

(meters).

B. As each boom position appears on the display, use

the INC./DEC. switch to set the display to the

number of inches (meters) covered by that boom.

Repeat for each section.

CE & S

TANDARD V ERSION

C. Set all unused boom sections to a width of zero “0”

inches (meters). This insures that accidentally

turning a boom switch ON doesn’t affect the control

console. (An ERROR 0 Boom # will then result if an

unused boom gets accidentally turned on)

2-4

Page 21

TASC 6100

D. Finally, let the boom width display cycle through the

boom sections until it shows “Boom C”. When the

“C” width is displayed, set it to the normal operating

width of the entire sprayer, in inches (meters), using

the INC./DEC. switch.

E. The boom width is now set. Turn all booms ON and

return to the OPERATE mode. The new total boom

width will be displayed in feet (meters). If this does

not agree with your total applicator width, check the

individual boom widths, ( steps B and C).

Record these calibration numbers

on last page of manual.

DISTANCE CALIBRATION - GROUND SPEED SENSOR

General Considerations and Initial Calibration

Numbers

he control console must be calibrated for the

ground speed sensor installed to ensure accurate

T

application rates. The procedure involves physically measuring an accurate distance along a road or

field, driving the vehicle through that distance, mathematically comparing the distance computed by the

control console to the actual measured distance, and

making any necessary adjustments to the distance

calibration number. Follow the recommended procedure

below to ensure accuracy of operation.

98-05018

R2

Boom widths are

entered in inches in

the US system. For

example; for a liquid

boom with 7 nozzles

on 30" spacings, enter

210 for that boom.

There is no need to

convert to feet, the

control console does

that automatically

when it is switched

back to the Operate

Mode. (In metric, all

widths are entered in

meters.)

Setup

& Cal.

The distance calibration should be checked periodically

to maintain its accuracy. This is especially important if

the sensor mounting has become loose or has been

repositioned, or if the tires have been changed.

Use the following initial calibration numbers. It is

important to field calibrate the distance sensor to

insure maximum accuracy!

MID-TECH® COMPACT RADAR - 780

Dj RADAR - 1000

WHEEL SENSOR - 3500

SPEEDOMETER SENSOR - 3500

2-5

CE & StandardVersion

Page 22

98-05018

R2

A-1

ON

OFF SET- UP DEC.

Product Vol.

Fan RPM

Area Impl. Width

Speed

DISPLAY SELECTOR

A-2

OPERATE INC.

% Rate

Scan

Test

Speed

Application Rate

Total Applied

Distance

PSI/Prime

TASC 6100

B

A. Set the control console switches to the following

settings:

1. Power ON

2. Mode Selector SETUP

3. Display Selector Distance

A-3

The display shows the current distance calibration

value.

123456789

BOOMS

B. Use the INC./DEC. switch to enter the initial

distance calibration number suggested.

You can now perform the distance calibration.

Distance Calibration Procedure

The following procedure is recommended by MIDWEST

TECHNOLOGIES for establishing an accurate distance

calibration. NOTE: All boom switches should remain

OFF during the entire procedure.

A. Fill the vehicle 1/2 full of material (unless it is a pull

type unit with the speed sensor mounted on the tow

vehicle), to approximate average load conditions.

B. Measure a known distance of at least 400 ft. in a

field or roadway (preferably in terrain similar to that

being treated). A longer distance, allows for a more

accurate calibration.

C. Record the current distance cal. #, which can be

viewed using the switch settings shown in the

“G

ENERAL C ONSIDERATIONS AND INITIAL CALIBRATION

NUMBERS” section above. For this example assume

an initial cal. # of 760.

CE & S

TANDARD V ERSION

D. Move the vehicle to the starting point of the

measured distance.

E. Reset the distance accumulator to zero (see page 2-

11)

F. Drive the vehicle to the other end of the measured

distance at a speed of between five and ten miles per

hour. Distance will accumulate on the display.

2-6

Page 23

TASC 6100

G. Stop the vehicle at the measured distance end marker.

Compare the distance indicated by the console to the

actual measured distance, to determine how much

correction is necessary. For example: if the indicated

distance is 396 Ft. after driving over a 400 foot

range, the error in the distance calibration is 1.0%.

H. Calculate the new distance calibration number using

the following formula:

Measured distance

Indicated distance

Example:

400

x 760 = 768, the New DC#

396

NOTE: Use the same equation, regardless of the type of

distance sensor .

I. Enter the corrected cal. # using the switch settings

shown in the “GENERAL CONSIDERATIONS AND INITIAL

CALIBRATION NUMBERS” section above. Switch back to

the OPERATE mode. The distance accumulator

should now agree with the measured distance that

you traveled. If it doesn't , recheck your calculations.

x Old DC# = New DC#

98-05018

R2

Setup

& Cal.

RECORD THIS CALIBRATION NUMBER

LAST PAGE OF MANUAL.

ON

SETTING THE HOLD/CLOSE RESPONSE OF THE FLOW

CONTROL VALVE

he operator can select a "Hold" or "Close" response

of the flow control valve to both “Implement

T

Status switch” and “All Booms OFF" conditions.

These responses are independent of each other, allowing

the operator to select a "Hold" condition for one and a

"Close" for the other. Careful consideration should be

given to both conditions and the response selected for

your application.

Implement Status Switch

When the operator selects the "Hold" condition, deactivation of the Implement Status switch (open circuit) hold’s

the flow control valve in its current position. When

2-7

CE & StandardVersion

Page 24

98-05018

R2

TASC 6100

turning on the Implement Status switch (closed circuit)

the flow control valve is already open and product flow

is instantaneous. This response assumes that some other

device, such as a boom section valve, has stopped the

product flow.

When the operator selects the "Close" condition,

deactivation of the Implement Status Switch (open

circuit) automatically causes the flow control valve to

close. This response is preferred when it is necessary to

use the flow control valve to stop the product flow.

Use the following procedure to set the Status switch

response.

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

123456789

BOOMS

B

OFF

Application Rate

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

MASTER

ON

Total Applied

Distance

Area Impl. Width

Speed

C

A. Set the console to the following positions;

1. Power ON

2. Mode Selector OPERATE

A-3

3. Display Selector Total Applied

4. Boom switches OFF

(or Master switch)

B. Hold the INC./DEC. switch up to display the current

setting (Hold or Close). Continuing to hold the INC.

switch up will cause the display to alternate

between the two options at about three to ten

second intervals. The option appearing in the

display when the INC. switch is released is the

MI

response selected.

All Booms Off

When the operator selects a "Hold" condition, an “All

Booms OFF" condition (either all Boom switches or the

Master switch OFF) hold’s the flow control valve in its

current position. When the boom valves are turned ON

again the flow control valve is already open and product

flow is instantaneous.

CE & S

TANDARD V ERSION

When the "Close" condition is selected, an “All Booms

OFF" condition automatically causes the flow control

valve to close. This response is preferred when it is

necessary to use the flow control valve to stop the

product flow.

2-8

Page 25

TASC 6100

Mid-T

ech

Use the following procedure to set the “All Booms OFF”

response.

A. Set the console to the following positions;

1. Power ON

2. Mode Selector OPERATE

3. Display Selector Impl. Width

4. Boom switches OFF

(or Master switch)

B. Hold the INC./DEC. switch up to display the current

setting (Hold or Close). Continuing to hold the

switch up causes the display to alternate between the

two options at about three to ten second intervals.

The option appearing in the display when the INC.

Switch is released is the response selected.

SETTING THE GROUND SPEED OVERRIDE (GSO)

VALUE

o use the GSO feature, set the GSO value to the

minimum ground speed you want to control to

T

when the GSO switch is activated. This should be

the lowest speed at which the vehicle can dispense

material satisfactorily. If you do not intend to use this

feature, set this value to zero (0.0). (See page 1-7 for a

more complete description of GSO operation.)

Use the following procedure to set the GSO Speed.

A. Set the console to the following positions;

1. Power ON

2. Mode Selector SET-UP

3. Display Selector Speed

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

MASTER

B

OFF

A-1

A-3

A-2

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Speed

DISPLAY SELECTOR

123456789

BOOMS

98-05018

R2

C

Application Rate

Total Applied

Distance

PSI/Prime

ON

Application Rate

Total Applied

Distance

PSI/Prime

Test

MI

A-3

B

Setup

& Cal.

B. Use the INC./DEC. switch to set the GSO speed to the

desired value.

CAUTION: When traveling at a speed slower than the

GSO speed setting, this feature will cause the product to

be applied at a rate consistent with the GSO speed,

rather than the true ground speed, possibly resulting in

serious over application. When Ground Speed Override is being used, and the true ground speed is less

2-9

M

id

-T

e

c

h

CE & StandardVersion

Page 26

98-05018

R2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

A-3

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

DISPLAY SELECTOR

123456789

BOOMS

MASTER

B

OFF

A-2

% Rate

Test

Speed

ON

Application Rate

Total Applied

Distance

PSI/Prime

MI

than the pre-selected GSO Speed, the console will sound

an alarm and the display will flash a “Too Slow”

message to warn the operator of possible over application.

PRODUCT VOLUME (FULL LOAD VALUE)

Setting the Full Load Value

C

The Full Load Value of the vehicle can be preset into the

console and automatically recalled when the vehicle is

reloaded.

Use the following procedure to set the Full Load Value

into the console.

A. Set the console to the following switch settings:

1. Power ON

2. Mode Selector SET-UP

3. Display Selector Product Vol.

4. Boom switches OFF

(or Master switch)

TASC 6100

Recall & Set

Recall & Set

CE & S

TANDARD V ERSION

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Application Rate

Total Applied

Area Impl. Width

Distance

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

Recall

Recall & Set

Product Vol.

Fan RPM

Speed

123456789

BOOMS

The display shows the current Full Load Value.

B. Use the INC./DEC. switch to set the desired Full Load

Set

Value.

Recalling the Full Load Value

When Product Vol. and OPERATE mode are selected,

the Full Load Value of the vehicle can be recalled by

holding the INC. switch up for at least three seconds.

Setting a Load Value Less than Full Load

If a full load is not taken aboard the vehicle, the actual

amount loaded can be set without changing the Full Load

Value. First recall the Full Load Value as explained in the

previous section, then use the INC./DEC. switch to set the

actual volume loaded into the tank.

2-10

Page 27

TASC 6100

Low Product Alarm

The Low Product Alarm alerts the operator when the

Product Vol., displayed on the console, reads 10% of the

Full Load Capacity. The console beeps for three seconds

and displays the message "LO” - ”PROD". Console

control functions are not affected by this alarm. To

disable the alarm, do not recall the Full Load Capacity.

98-05018

R2

Setup

& Cal.

RESETTING ACCUMULATORS

se the following method to reset the Area,

Distance, and Total Applied accumulators to

U

zero:

A. Set the Console to the following switch settings:

1. Power ON

2. Mode Selector OPERATE

3. Display Selector Area / Total

Applied /Distance

B. Hold the INC./DEC. Switch to DEC. until the display

reads zero (Approximately 3 sec.)

NOTE: There is also an Area/SET-UP accumulator.

OPERATING UNDER EXTERNAL RATE COMMANDS

hen the TASC 6100 console is operating under

external rate commands, it must be connected

W

program through a Mid-Tech Data Link. Minimum and

maximum anticipated rates must be programmed into the

Standard Rate and Alt.-Rate positions of the Rate switch

respectively and the Rate switch must be placed in the

Alt.-Rate position. The instructions, received with the

Data Link, explains in more detail how to set up the

TASC 6100 and Data Link.

to the computer running the field mapping

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Application Rate

Fan RPM

123456789

BOOMS

Total Applied

Area Impl. Width

Speed

Distance

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

B

A-3

2-11

CE & StandardVersion

Page 28

98-05018

R2

2

1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

123456789

BOOMS

Application Rate

Area Impl. Width

Speed

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

Total Applied

Distance

LIQUID ONLY SET-UP

SETTING THE CORRECTION FACTOR

(Pressure based (Pump L Psi (br)) only)

NOTE: The Correction Factor is locked at 1.00 when in

STnrd and rEFLO modes

f you are spraying water solutions, the correction

factor should be set to 1.00. If you are spraying a

I

solution with a specific gravity different than that of

water, adjust the correction factor according to the following

chart.

Weight of Solution Correction Factor

7.0 lbs/gal .92

8.0 lbs/gal .98

8.34 lbs/gal - Water 1.00

9.0 lbs/gal 1.04

10.0 lbs/gal 1.10

10.65 lbs/gal - 28% Nitrogen 1.13

11.0 lbs/gal 1.15

12.0 lbs/gal 1.20

4

To enter the correction factor, set the console to the

following switch settings:

3

14.0 lbs/gal 1.30

1. Power ON

2. Mode Selector SET-UP

3. Display Selector Application Rate

4. Use the INC./DEC. switch to adjust the correction

factor.

TASC 6100

CE & S

TANDARD V ERSION

FLOW SENSOR CALIBRATION

Determining The Initial Calibration Number

The control console must be calibrated for the flow sensor

being used. The calibration number required by the control

console is the actual number of electrical pulses per unit

volume generated by the sensor, or, for the pressure sensor,

the gallons per acre rating of the nozzles being used. If you

have any doubts as to the accuracy of the application rate,

2-12

Page 29

TASC 6100

a field calibration/catch test should be performed. (see

page 2-16)

Verify that the correct application program is selected.

(see page 2-1)

Check the Correction Factor, to ensure that it is set

correctly. (see page 2-11)

FLOWMETER

(for Pump L STnrd applications)

Flowmeters are calibrated for water at the factory and the

suggested calibration numbers are listed below. These numbers are meant to be initial cal. #’s since actual flow characteristics may differ, due to plumbing variations or other

factors.

STANDARD FLOWMETERS

SIZE SUPPLIER CAL. # SIZE SUPPLIER CAL. #

.75 inch (Mid-Tech) 396.9 3.00 inch (Mid-Tech) 5.0

1.00 inch (Mid-Tech) 153.1

1.50 inch (Mid-Tech) 38.8 1.25 inch (Raven) 75.0*

2.00 inch (Mid-Tech) 23.8 3.00 inch (Raven) 16.4*

98-05018

R2

Setup

& Cal.

MID-TECH RAPID CHECK FLOWMETERS

SIZE RANGE CAL. # SIZE RANGE CAL. #

1.00 inch 0.75 - 5 gpm 3200 1.50 inch 2.5 - 25 gpm 612.4

1.00 inch 2.5 - 16 gpm 800 1.50 inch 2.6 - 53 gpm 361.9

* Raven flow meters, use the factory calibration number divided by 10. All other

flowmeters use the manufacturers' supplied information regarding the pulses per

gallon (usually provided on a tag on the flowmeter).

2.00 inch 20.0 - 195 gpm 94.5

Once the initial calibration number is entered into the

console, per page 2-14, proceed to page 2-16 to fine tune

the flowmeter for maximum accuracy.

Pressure Sensor (U.S. Units)

(for Pump L Psi "US" applications)

The Pressure Sensor calibration number can be found by

determining the "Gallons per Acre" rating for the type of

nozzles being used. Find the chart that represents the

nozzle series you are using and the nozzle spacing of

your boom. Then find the nozzle size needed for the

2-13

CE & StandardVersion

Page 30

98-05018

R2

TASC 6100

range of speeds and the rate needed. When the nozzle is

selected, find the column of nozzle ratings in "Gallons per

Acre" at 10 MPH. Then, on the left of the chart, find the

horizontal line representing the ratings at 30 PSI. Where

the column and row intersect you will find the "Gallons

per Acre" rating of your nozzles at 10 MPH and 30 PSI.

This is the value to enter into the console as the pressure

sensor cal. #. For example, in the following chart, for a

floodjet K-SS10 nozzle, the row for 30 PSI and column

for 10 MPH intersect at 26 gallons per acre, the pressure

sensor cal. number for this particular nozzle.

NOTE: You must use the 30 PSI / 10 MPH value

regardless of the speed and pressure at which you are

operating.

Type Gallons per Acre

Liquid Capacity 40” Spacing

Floodjet Floodjet Pressure in 6 8 10 12

Tip No. Nozzle in PSI GPM MPH MPH MPH MPH

10 1.0 25.0 16.6 14.9 12.4

TK-SS10 K-SS10 20 1.4 35.0 26.0 21.0 17.5

30 1.7 43.0 32.0 26.0 21.0

40 2.0 50.0 37.0 30.0 25.0

10 1.5 37.0 28.0 22.0 18.6

TK-SS15 K-SS15 20 2.1 53.0 39.0 32.0 26.0

30 2.6 64.0 48.0 39.0 32.0

40 3.0 74.0 56.0 45.0 37.0

CE & S

TANDARD V ERSION

Use the circled number for the flowmeter cal. number in

this example.

Pressure Sensor (Metric Units)

(for Pump L bAr "Metric" applications)

The pressure sensor calibration number can be found by

determining the "Liters per Hectare" rating for the type of

nozzles being used. First find the chart that represents the

nozzle series you are using and the nozzle spacing of

your boom. Then find the nozzle size needed for the

range of speeds and the rate needed. When the nozzle is

selected find the column of nozzle ratings in "Liters per

Hectare" at 10 KPH. Then, on the left of the chart, find the

horizontal line representing the ratings at 2.0 BAR.

Where the column and row intersect you will find the

"Liters per Hectare" rating of your nozzles at 10 KPH and

2-14

Page 31

TASC 6100

2.0 BAR. This is the value to enter into the console as the

pressure sensor cal. #. For example, in the following chart,

for a 8002-SS nozzle, the row for 2.0 BAR and column

for 10 KPH cross at 78.0 Liters per Hectare, the pressure

sensor cal. # for this particular nozzle.

NOTE: You must use the 2.0 BAR / 10 KPH value

regardless of the speed and pressure at which you are

operating.

Liters per Hectare

Liquid Capacity 50 cm Spacing

Pressure in 7 8 10 12

Tip No. in bar l/min km/h km/h km/h km/h

2.0 0.65 111 97.5 78.0 65.0

TP8002-SS 2.5 0.72 123 108 86.4 72.0

3.0 0.79 135 119 94.8 79.0

Use the circled number for the pressure sensor calibration number.

Entering The Flow Sensor Calibration Number

98-05018

R2

Setup

& Cal.

Use the following procedure to enter the flow sensor

calibration number.

A. Set the console to the following positions;

1. Power ON

2. Mode Selector SET- UP

3. Display Selector Total Applied

4. Master switch OFF (ON If using

/Booms Pump L rEFLO)

B. Use the INC./DEC. switch to set the desired flow

sensor calibration number.

NOTE: If the console is in Reflow Mode (Pump L

rEFLOW), the flowsensor cal. # can only be viewed

or changed when all programmed booms are on.

2-15

Application Rate

PSI/Prime

Test

ON

B

A-3

Total Applied

Distance

MI

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Speed

DISPLAY SELECTOR

123456789

BOOMS

If using "Pump L STnrd"

or "Pump L PSi"

A-4

If using "Pump L rEFLO"

MASTER

OFF

CE & StandardVersion

Page 32

98-05018

R2

A-4

1 234567 89

BOOMS

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

Application Rate

Total Applied

Distance

PSI/Prime

TASC 6100

Pressure Sensor High/Low Calibration

B

The pressure sensor's Zero and High Set Point values must

be set to match the readings from your manual pressure

gauge. To do this, follow the procedure below.

A-3

Setting The Zero Set Point

BOOM CONTROL SWITCHES

A-4

MASTER

A-5

OFF

ON

MID-TECH

MIDWEST TECHNOLOGIES, INC.

A-8

MPH / KPH

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

Alt.-Rate

Standard Rate

OFF

A-5

MASTER

OFF

ON

A-7

MPH / KPH

GSO

®

AUTO

Application Rate

Total Applied

Distance

PSI/Prime

MI

A-6

A. Set the console to the following positions;

A-6

OFF

1. Power switch ON

2. Mode Selector OPERATE

3. Display Selector switch PSI/Prime

4. At least one Boom switch ON

A-7

5. Master switch ON

(to release any trapped pressure)

6. GSO switch OFF

MT 1000

7. Supply Pump OFF

8. Zero ground speed (vehicle not moving)

NOTE: Before adjusting the Zero Set Point, make sure

there is no pressure in the boom. It may be necessary to

loosen the diaphragm check valves on the boom to

B

achieve this.

B. Hold INC./DEC. switch to DEC. until console

reads “PSi 0” (“br 0”).

A-3

Setting The High Set Point

A. Set the console to the following positions;

A-4

MT 1000

1. Power Switch ON

2. Mode Selector OPERATE

3. Display Selector Switch PSI/Prime

4. Rate Switch Standard Rate

5. Master Switch ON

6. Supply Pump ON

7. Zero ground speed (Vehicle not moving)

B. Hold INC./DEC. switch to INC. for about 3

seconds. Display will read "OPEN". Release the INC

as soon as the “OPEN” message appears. Slowly

increase the engine RPM to adjust the pressure

reading, on the pressure gauge, to a maximum of no

CE & S

TANDARD V ERSION

2-16

Page 33

TASC 6100

Mid-T

ech

more than 100 PSI (6.8 br). Push INC. switch again

and hold for about 3 seconds. Display reads "PSi (br)

xxx". The xxx is a pressure reading. The INC./DEC.

switch can now be used to adjust the pressure reading

on the console to match the reading on the pressure

gauge. If no switch changes are detected for 3

seconds, the console display reverts to "OPEN"

again. Actuating the DEC. switch when the console

reads "OPEN" causes the console to read "CLOSE"

and the valve closes.

Note: A display reading of "PSi (br) - - " indicates that the

pressure sensor is not connected. A reading of "PSi (br) 0" indicates a reading of less than 0 PSI (br). This

suggests that the sensor may need to be recalibrated to 0

pressure. (See "Setting The Zero Set Point" on the

previous page.)

Fine Tuning The Flow Sensor Sensor Cal. #

NOTE: We recommend that these tests be done using

water, and only after neutralizing the tank and system.

M

id

-T

e

c

h

98-05018

R2

Setup

& Cal.

Once the initial calibration number is determined and

entered into the console, a calibration run should be

made to adjust the number for maximum accuracy.

The most critical part of the calibration procedure is

accurately measuring the discharge of large volumes of

liquid. Increased accuracy of measurement means

increased calibration accuracy. Since each operator's

facilities are different, it is not possible to prescribe a

standard method of measuring discharge. Successful

methods include using a second, calibrated flow meter,

using a truck scale and calculating volumes based on

weight and density of the liquid discharged, and by

discharging into a calibrated tank.

It will be necessary to pump and measure at least 100

gallons and as much as 300 gallons, depending on the

accuracy required. Larger volumes allow greater accuracy.

2-17

CE & StandardVersion

Page 34

98-05018

R2

TASC 6100

A method similar to the following is recommended.

1. If using Pump L Psi, enter the appropriate "Correction Factor" for the material that you will be using

for the test (Use factor of 1.00 for Pump L STnrd

applications) (see page 2-11).

2. Enter the desired application rate (see page 2-3).

3. Verify that the boom switches are OFF.

4. Verify that the correct initial flow sensor calibration

number is entered into the console (See pages 2-12

through 2-14). Use the INC./DEC. switch to adjust

as necessary.

5. Reset the Total Applied accumulator to zero (see

page 2-11).

6. Make sure there is enough liquid in the main tank

to perform the test. Weigh the sprayer and load of

water. Position the sprayer in the test area.

7. Start the main carrier pump. Set the Display

Selector switch to Test Speed and the Rate Switch

to “Standard Rate”. Turn ON the Master switch

and the Boom switches. The sprayer starts to spray.

Allow the sprayer to run until the desired amount

of liquid is discharged. Turn OFF the booms

8. Weigh the sprayer again and calculate the amount

of water discharged.

9. View the total amount of dispensed liquid as

measured by the console (Total Applied/OPER-

ATE). If the total shown on the console agrees

with the total amount actually discharged, no

further action is necessary. The pressure sensor, or

flowmeter, is now calibrated.

10. If the indicated volume pumped does not agree

with the actual volume pumped, calculate a new

calibration # as follows:

CE & S

TANDARD V ERSION

2-18

Page 35

TASC 6100

Pressure Sensor:

New Cal. # =

MEASURED A MOUNT

INDICATED A MOUNT

X OLD C AL. #

If the measured amount is more than the indicated

amount, the new cal# should be larger.

If the measured amount is less than the indicated

amount, the new cal# should be smaller.

Flow Meter:

New Cal. # =

INDICATED A MOUNT

MEASURED A MOUNT

X OLD C AL. #

If the measured amount is more than the indicated

amount, the new cal. # should be smaller.

If the measured amount is less than the indicated

amount, the new cal# should be larger.

11. Correct the cal. # in the console. Return the mode

selector to OPERATE. The amount displayed

should now match the amount measured. The flow

sensor is now calibrated.

98-05018

R2

Setup

& Cal.

11a. An alternate method, of correcting the cal. #, at

this point, is to switch back and forth, between

OPERATE/Total Applied and SET-UP/ Total

Applied, changing the cal. # until the Total

Applied display, in operate mode, equals the

amount actually dispensed.

12. Write this number down for future reference. This

is the number to use for this specific combination

(material and applicator configuration).

Another method of fine tuning the sensor cal. # is to

weigh the sprayer with a full tank of water, reset the Total

Applied to zero (see page 2-11), set the GSO speed to 10

MPH, and start spraying while watching the Total

Applied accumulate. When the Total Applied reaches at

least 100 gallons, re-weigh the sprayer and determine the

actual amount dispensed as compared to that indicated

by the console. Use the method described in step 9 and

10 above to correct the Cal. #.

2-19

CE & StandardVersion

Page 36

98-05018

R2

L Psi (bAr) Mode - Material left over - Adj. Cal. # down slightly

L STnrd Mode - Material left over - Adj. Cal. # up slightly

A-1

A-2

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

123456789

BOOMS

Application Rate

Area Impl. Width

Speed

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

Total Applied

Distance

The calibration number can also be calibrated based on

field experience.

- Short of material - Adj. Cal. # up slightly

- Short of material - Adj. Cal. # down slightly

GRANULAR ONLY SET-UP

erify that the correct application program has

been selected. (see page 2-1)

V

SETTING THE PRODUCT DENSITY

(for granular applications only.

he Product Density must be entered into the

TASC 6100 for the console to accurately control

6

Product density is entered as pounds per cubic foot (Lb /

Ft3) in US units and kilograms per tenths of a cubic meter

(Kg / 0.1m3) in Metric units. Product Density should be

measured and entered frequently to ensure accurate

B

application.

A-3

the application rate.

A. Set the console to the following positions:

1. Power ON

2. Mode Selector SET-UP

3. Display Selector Application Rate

The current product density is displayed.

B. Use the INC./DEC. switch to set the display to the

desired density.

TASC 6100

CE & S

TANDARD V ERSION

SETTING THE FAN TACH CAL. #

he TASC 6100 console includes a Tach port that

allows you to monitor the speed of the fan (spin

T

ner) on a granular spreader. For the console to

accurately measure the fan (spinner) RPM, the number of

pulses generated by the fan RPM sensor for each revolu-

2-20

Page 37

TASC 6100

tion of the fan (spinner) must be entered using the

following procedure:

A. Set the console to the following positions;

1. Power ON

2. Mode Selector SET- UP

3. Display Selector Fan RPM

The current Fan Calibration number is displayed.

B. Use the INC./DEC. switch to set this number to the

desired value.

RATE SENSOR CALIBRATION

Calculating The Initial Rate Sensor Cal. #

(Spreader Constant)

It is necessary to enter a Spreader Constant in TASC 6100

to ensure an accurate output from the conveyor. The

spreader constant represents the number of sensor pulses

per cubic foot of material discharged. The constant is

different for different gate settings on adjustable spreaders. Constants relating to particular gate settings should

be calibrated and recorded for the spreader.

98-05018

R2

A-1

A-2

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

123456789

BOOMS

Application Rate

Area Impl. Width

Speed

Total Applied

Scan

PSI/Prime

Test

Speed

DISPLAY SELECTOR

Distance

B

A-3

Setup

& Cal.

Calculation of the initial spreader constant requires the

following information:

1) Gate height (H) and width (W) in inches

2) Number of sensor pulses for each revolution of the

spreader rate sensor (P)

3) The distance the conveyor moves during one

revolution of the spreader rate sensor (D), in inches.

Calculate the initial spreader constant as follows:

Where: Ft

D x W x H

1728

3

is the volume discharged during each

r

= Ft

3

r

revolution of the spreader rate sensor, in Cubic Feet.

Continue as follows:

P

= Initial Calibration Number (Spreader Constant)

3

Ft

r

2-21

CE & StandardVersion

Page 38

98-05018

Mid-T

ech

Mid-T

ech

R2

A-2

A-1

ON

OPERATE INC.

OFF SET- UP DEC.

% Rate

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

If using "Pump C STnrd"

A-4

If using "Pump C rEFLO"

MASTER

OFF

ON

B

Application Rate

Total Applied

Distance

PSI/Prime

MI

ech

Mid-T

TASC 6100

Entering The Rate Sensor Calibration Number

Enter this calibration number into the console using the

procedure that follows.

A-3

A. Set the console to the following positions:

1. Power ON

2. Mode Selector SET-UP

3. Display Selector Total Applied

4. Booms ON

(If Split Drive option is active)

The current Spreader Constant is displayed.

NOTE: If you have a single conveyor bed, the

"Pump C STnrd" application program must be

selected in order to view or set the Spreader

Constant (See page 2-1)

ech

Mid-T

NOTE: If the console is in Split Drive Mode (Pump

C SPLit), the Spreader Constant can only be viewed

or changed when all programmed booms are on.

B. Use the INC./DEC. switch to set the display to the

calculated Spreader Constant.

Fine Tuning The Rate Sensor cal. #

The accuracy of the Spreader Constant should be verified

and adjusted as necessary. The following procedure is

suggested as a simple means of testing the calibration of

the spreader constant. BE SURE THE PROPER PRODUCT DENSITY HAS BEEN ENTERED BEFORE PERFORMING THE CALIBRATION OR THE RESULTS

WILL BE INACCURATE.

A. Verify the current Spreader Constant (see previous

page). Record this number for reference.

B. Enter the desired application rate (see page 2-3).

C. Load the vehicle with product of known density.

Be sure the Density is properly entered in the

TASC 6100 (see page 2-20). Use enough material

CE & S

TANDARD V ERSION

2-22

Page 39

TASC 6100

to get an accurate measurement but be careful to

keep the conveyor running full. As an example: if

the truck scale reads in 20 lb. (10 Kg.) increments,

at least 1000 lbs. (500Kg.) must be discharged to

be able to calibrate within 2%.

D. Weigh the truck and load and record this weight.

Back up to a location where you can safely unload

the material through the conveyor.

E. Reset the Total Applied accumulator (see page 2-

11).

98-05018

R2

Setup

& Cal.

F. Dispense the desired amount of material by setting

the console switches as follows:

1. Power ON

2. Mode Selector OPERATE

3. Display Selector Test Speed

4. Rate Switch Standard Rate

5. Programmed Booms ON

6. Master Switch ON

The conveyor will start to discharge. Allow the

conveyor to run until the desired amount has been

discharged.

7. Turn OFF the Master switch.

G. Rotate the Display Selector to Total Applied.

TASC 6100 displays the INDICATED AMOUNT

discharged by the conveyor in lbs (Kg.) or tons if

over 20,000 lbs. (metric tons if over 10,000 Kg.).

H. Weigh the truck and load (be sure the driver's

weight is included if he was on the truck when it

was weighed the first time). The difference

between the starting weight and the ending weight

is the ACTUAL AMOUNT discharged by the

conveyor. (This procedure assumes fuel use is

minimal during the test).

F-1

ON

OFF SET- UP DEC.

Product Vol.

Fan RPM

Area Impl. Width

Speed

Scan

DISPLAY SELECTOR

F-4

1 23456789

BOOMS

Standard Rate

F-7

MASTER

OFF

F-2

OPERATE INC.

% Rate

Application Rate

PSI/Prime

Test

Speed

Alt.-Rate

OFF

F-6

ON

B

Total Applied

Distance

F-3

F-4

MI

I. To adjust the Spreader Constant, use the following

formula:

Indicated Amount

Actual Amount

X Current Spreader Constant = New Spreader Constant

2-23

CE & StandardVersion

Page 40

98-05018

Mid-T

ech

R2

TASC 6100

If the weight displayed on the console is greater than

the weight actually measured, the calibration number

will increase.

J. Turn the Mode Selector to SET-UP and use the

INC./DEC. switch to change the Spreader Constant. (REMEMBER, IF SPLIT DRIVE IS ACTIVE,

THE BOOMS MUST BE ON.) Turn the booms

OFF and switch the Mode Selector back to

OPERATE, the corrected Indicated Amount will

be displayed. If this number does not match the

actual amount, check the calculation.

If it is not convenient to conduct an actual test, field