Page 1

VOYAGER® 570G

USER MANUAL

RADION 8140

USER MANUAL

Automatic Sprayer Control

Software Version 1.06

Page 2

Copyrights

© 2017 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced, copied,

photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without prior written

consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

Limitation of liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED.

NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF

BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE.

Safety information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety requirements. As

the operator of the vehicle, you are responsible for its safe operation. The Radion 8140 in combination with any assisted/auto steering

device is not designed to replace the vehicle’s operator. Do not leave a vehicle while the Radion 8140 is engaged. Ensure the area around the

vehicle is clear of people and obstacles before and during engagement. The Radion 8140 is designed to support and improve efciency while

working in the eld. The driver has full responsibility for the quality and work related results. Disengage or remove any assisted/auto steering device

before operating on public roads.

Page 3

Radion 8140 Automatic Sprayer Control

Table of Contents

CHAPTER 1 – INTRODUCTION 1

Product Upgrades Available .......................................................................................................................................................................1

SYSTEM COMPONENTS 1

Radion8140 Console.....................................................................................................................................................................................1

Additional Information .................................................................................................................................................................................1

Power On ..................................................................................................................................................................1

Power Off ..................................................................................................................................................................1

Simulated Speed Alert ............................................................................................................................................... 1

BASIC SCREEN USE 2

Home screen .............................................................................................................................................................2

Options Tab ...............................................................................................................................................................3

Console Screen Colors..............................................................................................................................................3

Options Menus ..........................................................................................................................................................4

Next Page .................................................................................................................................................................4

Keyboard Entry Screen .............................................................................................................................................4

Warnings and Information Pop-ups ............................................................................................................................4

Setup Option Information...........................................................................................................................................4

CHAPTER 2 – OPERATION 6

Operation Menu ..............................................................................................................................................................................................6

Information Bar ...............................................................................................................................................................................................7

INTRODUCTION

OPERATIONDATA APPENDIX SETTINGSTOOLS CONSOLE

REGULATION MODES 7

Manual Regulation Mode ............................................................................................................................................................................ 8

INFORMATION BAR 8

Selectable Information ................................................................................................................................................................................. 8

Selecting a Job Number ............................................................................................................................................9

Application Rate ..............................................................................................................................................................................................9

Select Target Application Rate ...................................................................................................................................9

Change Preset Target Application Rate ...................................................................................................................10

Target Rate Percentage Increase/Decrease ............................................................................................................10

Change Application Rate Step .................................................................................................................................11

TIP SELECTION 11

Selecting the Current Tip ......................................................................................................................................... 11

Presetting Tips ........................................................................................................................................................ 11

TANK 12

ALARM WARNING 13

PRESSURE GAUGE 13

BOOM SECTIONS & SWITCHES 14

98-05311-ENUS R2

i

Page 4

Radion 8140 Automatic Sprayer Control

CHAPTER 3 – SETTINGS 15

INTRODUCTION

JOB PARAMETERS 16

Establish Preset Target Application Rates ...............................................................................................................16

MACHINE 17

OPERATION DATA APPENDIXSETTINGS TOOLSCONSOLE

Filling ................................................................................................................................................................................................................ 18

Operation ....................................................................................................................................................................................................... 20

Implement Parameters .............................................................................................................................................................................. 21

Section Configuration ..............................................................................................................................................21

Establish Number of Tips ........................................................................................................................................22

Tip Preset Setup .....................................................................................................................................................22

Establish Tip Presets ...............................................................................................................................................23

Regulation Parameters ............................................................................................................................................24

Calibrations .................................................................................................................................................................................................... 25

Implement Speed Sensor ........................................................................................................................................26

Implement Speed Sensor Automatic Calibration ......................................................................................................26

Flow Sensor ............................................................................................................................................................26

Flow Sensor Automatic Calibration ..........................................................................................................................27

Liquid Pressure Sensor ...........................................................................................................................................27

Maximum Pressure Automatic Calibration................................................................................................................28

Maximum Pressure Manual Calibration ...................................................................................................................29

Fill Flow Sensor ......................................................................................................................................................29

Fill Flow Sensor Automatic Calibration ....................................................................................................................29

Tank Level Sensor ...................................................................................................................................................30

Alarms .............................................................................................................................................................................................................. 33

Active Alarms on Operation Screen ...........................................................................................................................33

OEM 34

Sensor Presence ........................................................................................................................................................................................... 35

Implement Parameters .............................................................................................................................................................................. 36

Sections on Operation Screen .................................................................................................................................36

Valve Setup .................................................................................................................................................................................................... 37

Tank Setup ......................................................................................................................................................................................................38

Regulation Details ....................................................................................................................................................................................... 39

Clear Totals ..................................................................................................................................................................................................... 40

Import/Export data ..................................................................................................................................................................................... 41

DIAGNOSTICS 42

Test Inputs ...................................................................................................................................................................................................... 43

Test Outputs .................................................................................................................................................................................................. 44

Test BoomPilot .............................................................................................................................................................................................. 45

Alarm Log ....................................................................................................................................................................................................... 46

Save Alarm Log ....................................................................................................................................................... 46

SETTINGS MENU OPTIONS 47

CHAPTER 4 – DATA 49

Jobs ................................................................................................................................................................................................................... 49

Job Data Report ......................................................................................................................................................50

Campaign ....................................................................................................................................................................................................... 50

Clear All Campaign Counters ..................................................................................................................................50

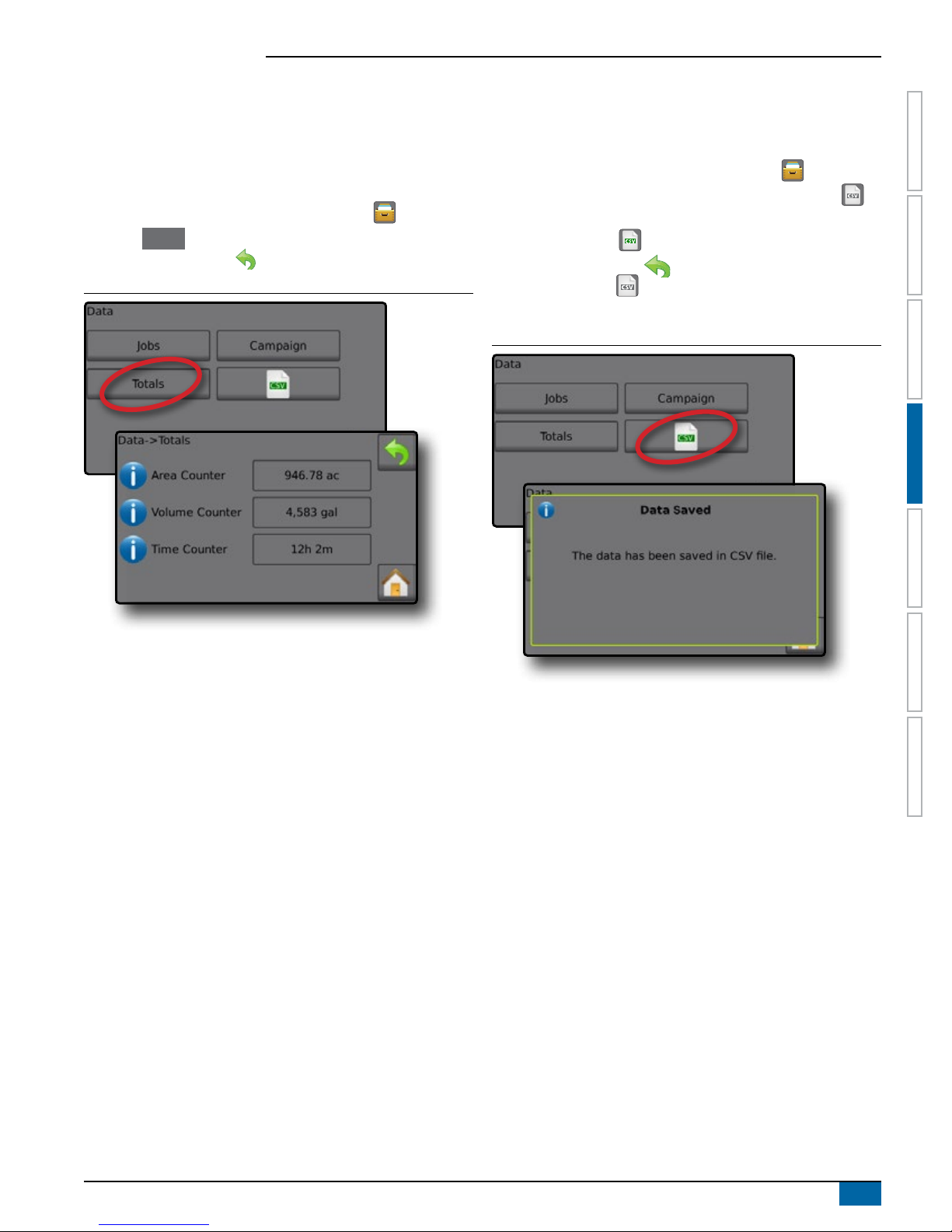

Totals ................................................................................................................................................................................................................ 51

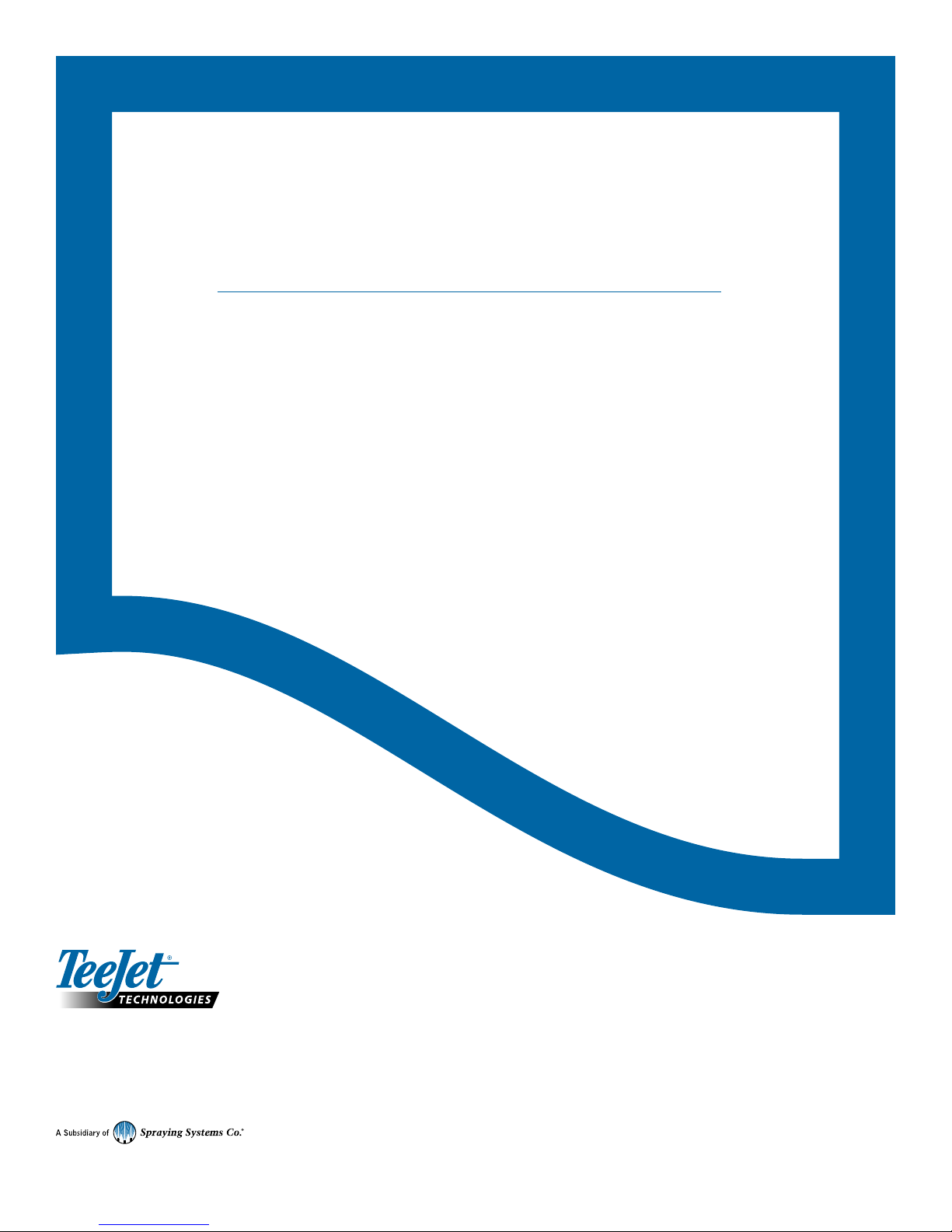

CSV Report ..................................................................................................................................................................................................... 51

ii

www.teejet.com

Page 5

Radion 8140 Automatic Sprayer Control

CHAPTER 5 – CONSOLE 52

Display ............................................................................................................................................................................................................. 52

Cultural ............................................................................................................................................................................................................ 53

Language Selection.................................................................................................................................................53

Sound ............................................................................................................................................................................................................... 54

Unlock .............................................................................................................................................................................................................. 54

About ............................................................................................................................................................................................................... 54

INTRODUCTION

CHAPTER 6 – TOOLS 55

APPENDIX A – SYSTEM CONFIGURATIONS AND CONNECTIONS 56

CONFIGURATIONS 56

CONNECTIONS 56

Radion Console Connections .................................................................................................................................................................. 56

Miscellaneous Connections .................................................................................................................................................................... 57

APPENDIX B – USER SETTING NOTES 58

APPENDIX C – ALARM CONFIGURATIONS 60

APPENDIX D – UNIT SPECIFICATIONS 61

OPERATIONDATA APPENDIX SETTINGSTOOLS CONSOLE

98-05311-ENUS R2

iii

Page 6

Page 7

Radion 8140 Automatic Sprayer Control

CHAPTER 1 – INTRODUCTION

Designed with simplicity in mind, Radion 8140 offers spraying advantages not found in other controllers. Setting the target application

rate and the unique VisiFlo® display on the controller helps select the right TeeJet tip for the application. Once spraying begins, the large

display shows application rate, volume sprayed, system pressure, sprayer speed, and area covered. Radion 8140’s built-in planning tool

automatically displays the available speed range for the target rate and spray tip that have been selected. Radion 8140 may be used as an

individual controller or in combination with CAN bus technology using Matrix® Pro and BoomPilot® to add automated boom section control.

Product Upgrades Available

Matrix Pro Guidance and BoomPilot Automated Boom Section Control.

SYSTEM COMPONENTS

Radion8140 Console

The Radion 8140 is designed to provide years of service under typical agricultural operating conditions. A tight tting enclosure, combined with

rubber covers for all connectors means that typical dusty environments will not cause operational problems. While occasional splashing of water

will not damage the unit, the Radion 8140 is not designed for direct exposure to rain. Take care not to operate the Radion 8140 in wet conditions.

Figure 1-1: Radion 8140 Console Front And Back

Power Button

Bright Touch Screen

USB Port With Rubber Cover

Speed Cable Connection

INTRODUCTION

OPERATIONDATA APPENDIX SETTINGSTOOLS CONSOLE

Main Cable Connection

Available in 5, 7 and 9 switch models

The 9 switch model supports up to 13 Boom

Boom Section Controls

Master Switch

Sections (9 switch model shown)

CAN Connection

Integrated RAM Mount

(assembly required)

Serial Connection

Additional Information

All changes are saved automatically. The console needs to be cycled off and back on when changing or attaching equipment to the

Radion 8140 system.

Power On

Press the POWER button to power on the console. Upon power

up, a TeeJet screen appears while Radion 8140 initiates a start up

sequence. Once start up is complete, the Operation screen appears.

Power Off

Press the POWER button until a pop-up screen appears.

Press Yes to power off the console.

Simulated Speed Alert

An alert will sound at start-up if Simulated Speed is activated.

98-05311-ENUS R2

1

Page 8

Radion 8140 Automatic Sprayer Control

INTRODUCTION

BASIC SCREEN USE

The basic screen functions are:

• Home button accesses the Home screen with setup buttons for Operation, Settings, Data, Console settings and Tools

• Options tab on the Operation screen accesses the Home button and Application Rate options

OPERATION DATA APPENDIXSETTINGS TOOLSCONSOLE

• Warnings and information pop-ups inform of console activities and details on setup or application functions

• Setup options can be applied using option menus or keyboard entry screens

NOTE: There is a Settings Menu Structure Chart, at the end of the Chapter 1 – Overview.

When a Job is active some setup options are unavailable.

Home screen

The Home screen gives access to Jobs, Setup Options and Application Control.

Tools

Operation

Settings

Data

Console Settings

Figure 1-2: Home Button from the Operation Screen

Man

reg

0%

Figure 1-3: Home Button from the Settings Screen

5%

5%

2

www.teejet.com

Page 9

Radion 8140 Automatic Sprayer Control

Options Tab

The Options tab is always available on the Operation screen.

This tab opens the Operation menu which accesses the Home

button and regulation controls.

Operation menu settings buttons

Home

Auto

reg

0%

Figure 1-4: Options Tab – Automatic Regulation Mode

Man

reg

5% 5%

Automatic/Manual Regulation Mode

Return to Target Rate

Target Rate Percentage Boost Increase/Decrease

Regulation Valve Manual Open/Close

Close Menu

Console Screen Colors

The console is available in six (6) color schemes. From the

Home screen , press the CONSOLE button and

choose Display . Press the current selection to access color

scheme options and select a color style.

Figure 1-6: Color Schemes

INTRODUCTION

OPERATIONDATA APPENDIX SETTINGSTOOLS CONSOLE

Man

reg

0%

Figure 1-5: Options Tab - Manual Regulation Mode

Auto

reg

5%

5%

NOTE: When changing screen Styles, there is a slight delay in the

screen displaying the new selection.

98-05311-ENUS R2

3

Page 10

Radion 8140 Automatic Sprayer Control

Options Menus

INTRODUCTION

Press the current selection to access options. Select an appropriate

option, or use a next page arrow to access additional options. To close

the list without changing the current option, reselect the current option.

Figure 1-7: Example of Option Menu

OPERATION DATA APPENDIXSETTINGS TOOLSCONSOLE

Metric Imperial US

Next Page

Some screens have more information/options that are visible beyond

the current screen. Use the Next Page arrow to access additional

options/information not currently visible on the screen.

Keyboard Entry Screen

Some screens offer keyboard entry. Press the current selection to

access the keyboard. Use the numeric keypad to enter a value.

Press the ACCEPT icon to save the settings or the

CANCEL icon to leave the keypad without saving.

Figure 1-9: Example of Keyboard

Application Rate (l/ha)

0.0

1 2 3 Clear

4 5 6 <--

7 8 9

0 . +/-

Warnings and Information Pop-ups

A pop-up warning or information box will display for approximately ve

(5) seconds. To remove the pop-up box, tap anywhere on the screen.

Figure 1-10: Information Screens

Figure 1-8: Example of Accessing Additional Options Screen

Setup Option Information

Press the option icon or option name, of any menu item, to display a

pop-up information screen with a denition of and range values for that

item. To remove the information box, press anywhere on the screen.

Figure 1-11: Example of Information Text Box

4

www.teejet.com

Page 11

Radion 8140 Automatic Sprayer Control

INTRODUCTION

OPERATIONDATA APPENDIX SETTINGSTOOLS CONSOLE

SETTINGS MENU STRUCTURE

| | | |

Job Parameters Machine OEM Diagnostics

Density Factor Tank sensor Flow Sensor

Application Rate Number Filling Sensor Presence Test Inputs

Application Rate Actual Content Flow Sensor Implement Wheel Sensor

Tip Type *Full Tank Liquid Pressure Sensor Tractor Wheel Sensor

Idle Pressure Density Type Fill Flow Sensor Supply Voltage

Desired Content Implement Parameters Fill Flow Sensor

Calibration Number Operation Circulation Tank Level Sensor

Automatic Calibration Section Conguration Display Rate Smoothing Remote Master Signal

Implement Speed Sensor Automatic Filling Number of Sections Liquid Pressure Sensor

*Flow Sensor Application Rate Step Section Number Valve Setup Master Switch

Tip Preset Setup Tank Setup Master Valve

Calibration Number Speed Source Number of Tips Regulation Valve Type Section Switches

Low Flow Limit Simulate Speed Copy Section Section Valve Type Test Outputs

High Flow Limit Minimum Speed Section Width Section Valve Behavior Liquid Valve PWM Duty Cycle

Automatic Calibration Implement Parameters

Calibrations Tip Preset Maximum tank content Fill Valve

No Pressure Calibration Minimum Tank Content Tip Capacity Automatic Filling Section Valve State

Maximum Pressure Section Output Low Low Pressure Limit Regulation Details Test BoomPilot

No pressure Alarms Tip Series Minimum Tank Content Section Number

*Liquid Pressure Sensor

Reference Pressure High Pressure Limit Minimum Regulation Pressure Connection

Maximum Pressure Flow/Pressure Cross Check Factory Settings Automatic Filling Offset All Sections Off

Automatic Calibration Reference Flow Maximum Regulation Pressure Mode

*Fill Flow Sensor Reference Pressure Regulation Valve Time Section Input

Calibration Number Regulation Parameters Minimum Regulation Voltage Alarm Log

Automatic Calibration Course Value Calibration Regulation Deadband Save Alarm Log

Automatic Calibration Regulation Mode Manual Regulation Speed

Empty Tank Tip Spacing Regulation Start Delay

*Tank Level Sensor Fine Value Calibration Regulation Valve Capacity

Minimum Tank Level Restrictor Plate Flow

Minimal Tank Level Default Valve Position

Automatic Calibration Clear Totals

Maximum Tank Level Area Counter

Maximum Tank Level Volume Counter

Automatic Calibration Time Counter

Tank Shape Clear All Total Counters

Maximum Tank Level Import/Export Calibrations

Start Calibration

Import/Export Calibrations

OEM menu is password protected.

*Menu settings directly related to fitted OEM equipment.

98-05311-ENUS R2

5

Page 12

Radion 8140 Automatic Sprayer Control

INTRODUCTION

CHAPTER 2 – OPERATION

Prior to operation, all settings and congurations must be established. Please contact a dealer or TeeJet Customer service

representative with questions about system operations. TeeJet Technologies is not responsible for misuse or incorrect operation of the

OPERATION

system. Settings are automatically saved when selected. Select functions may not be visible due to OEM settings, available equipment or

sensors.

Figure 2-1: Operation Screen Overview

Information Bar

Tank Contents / Filling Options

Current Tip

Application Rate Change

DATA APPENDIXSETTINGS TOOLSCONSOLE

Current Droplet Size

1. From the Home screen, press the OPERATION button .

2. Screen options include:

►Information Bar – displays application rates and selectable

information

►Current Tip – displays current tip and accesses ve (5) preset

tip types

►Application Rate Change – displays rate changes (if in

Automatic Regulation Mode)

►Tank – displays remaining tank contents and accesses lling

options

◄Filling – establishes actual/desired tank material/density

►Alarm Warning – displays active alarm conditions

►Options Tab – accesses the Operation menu

◄Displays Home button, Close Menu button, Regulation

Modes and Target Rate options

NOTE: Toggle between the Operation screen and

Operation menu using the Options tab and

the Close menu button .

►Pressure Gauge – displays current pressure range compared

with recommended pressure range

◄Droplet Size – displays selected droplet size

►Boom Sections – displays congured boom sections

◄Spray Status – displays active/inactive for section

Alarm Warning

Options Tab

Pressure Gauge

Boom Sections

Spray Status

Operation Menu

The Options tab is always available on the Operation screen.

This tab accesses the Operation menu where the Home button,

Regulation Modes and Target Rate options display.

Operation Menu Buttons

Home

Auto

Man

reg

Automatic Regulation Mode

Manual regulation mode

Change Between Automatic/Manual Regulation Modes

reg

5%

Target Rate Boost Percent Increase

5%

Target Rate Boost Percent Decrease

0%

Return to Target Rate

Regulation Valve Manual Open

Regulation Valve Manual Close

Close Menu

6

www.teejet.com

Page 13

Radion 8140 Automatic Sprayer Control

Figure 2-2: Options Tab – Automatic Mode

Boost/Step Percent Increase

Regulation Mode

Home

Man

reg

0%

Close Menu

Target Rate Reset

Boost/Step Percent Decrease

Figure 2-3: Options Tab – Manual Mode

Valve Open

Regulation Mode

Home

Auto

reg

5%

5%

REGULATION MODES

Automatic Regulation mode will automatically adjust the Application

Rate based on the current speed in reference to the Target Rate. The

Target Rate can be adjusted using the Boost/Step percent increase/

decrease buttons

Application Rates dene up to three (3) Target Rates for product being

applied per hectare/acre. These can be toggled using the Application

Rate section on the Information bar on the Operation screen.

Manual regulation mode will retain an established regulation valve

setting regardless of speed. The regulation valve setting can be

adjusted using the Regulation valve open/close buttons on

the Operation menu.

1. From the Operation screen, press the OPTIONS tab to

display the Operation menu.

2. Select from:

► Auto reg to change from Manual Regulation Mode to

Automatic Regulation Mode:

► Man reg to change from Automatic Regulation Mode to

Manual Regulation Mode:

NOTE: The Regulation button displays the regulation mode that may

be selected not the active regulation mode.

5%/5%

on the Operation menu. Preset

INTRODUCTION

OPERATION

DATA APPENDIX SETTINGSTOOLS CONSOLE

Close Menu

Valve Close

Information Bar

The Information Bar displays:

►Application Rate – displays the actual Application Rate or

Target Application Rate and accesses the Preset Target

Application Rates options menu.

►Selectable Information – displays user-selected information

including Volume Applied, Flow Rate, Flow Pressure, Speed,

Total Area Applied and Job Number.

Figure 2-4: Information Bar

Selectable Information Selectable Information

Application Rate

Figure 2-5: Regulation Options: Automatic / Manual

Man

reg

0%

Auto

reg

Man

reg

5%

5%

5%

Target Application Rate

Manual Mode

0%

98-05311-ENUS R2

5%

7

Page 14

Radion 8140 Automatic Sprayer Control

Manual Regulation Mode

INTRODUCTION

Manual Regulation Mode will retain an established regulation valve

setting regardless of speed.

To open/close the valve:

1. From the Operation screen, press the OPTIONS tab to

OPERATION

display the Operation menu.

2. Press the Regulation valve open/close buttons to

manually turn the valves on/off.

3. Press the Close menu button .

Figure 2-6: Manual Regulation Mode

INFORMATION BAR

The Information Bar displays user selected information and

application rate information.

Figure 2-7: Information Bar

Selectable Information Selectable Information

Application Rate

DATA APPENDIXSETTINGS TOOLSCONSOLE

Auto

reg

Selectable Information

Selectable Information displays user-selected information.

1. Press either the left or right Selectable Information section.

2. Select one (1) of six (6) available options to display for each side

(options depend upon equipment in use).

►Volume Applied – displays volume applied for the current

job number

►Flow Rate – displays current ow rate

►Flow Pressure – displays current ow pressure

►Speed – displays vehicle speed

►Area Applied – displays applied area for the selected job

number

►Job Number – displays the current job number

Figure 2-8: Selectable information

8

www.teejet.com

Figure 2-9: Selectable Information Options

Speed

9.0

km/h

Volume Applied

3450

l

50

ha

Area applied

Flow Rate

0.2

l/min

5

Job No.

Job number

Flow Pressure

20.0

bar

Page 15

Radion 8140 Automatic Sprayer Control

Selecting a Job Number

One of up to ten (10) jobs may be selected to view job information.

1. From the Operation screen, press the OPTIONS tab .

2. Press the HOME button .

3. From the Home screen, press the DATA button .

4. Press Jobs .

5. Press Job number to select current job number.

6. Press the HOME button .

7. From the Home screen, press the OPERATION button .

Figure 2-10: Selecting a Job Number

Man

reg

5%

Application Rate

Application Rate displays or give access to:

►Application Rate – while application is active, displays the

actual application rate

►Target Application Rate – while application is inactive, displays

the target rate of product to apply.

◄Automatic regulation mode – Target Application Rate

symbol will be active

Use the Boost/Step Percent Increase/Decrease

5%/5%

to adjust the Target Application Rate

buttons

◄Manual Regulation Mode – manual regulation symbol will

remain active

►Preset Target Application Rates Options Menu – denes the

target rate of product to apply for the selected number. These

settings will be the same for all active jobs. Range is 0 to

6,554 litres/hectare.

Select Target Application Rate

1. Press the Application Rate section.

2. Select one (1) of up to three (3) preset application rates.

Figure 2-11: Select target application rate

INTRODUCTION

OPERATION

DATA APPENDIX SETTINGSTOOLS CONSOLE

0%

5%

140

l/ha

225

l/ha

180

l/ha

98-05311-ENUS R2

9

Page 16

Radion 8140 Automatic Sprayer Control

Change Preset Target Application Rate

INTRODUCTION

The selected target rate can be changed either on the Operation

screen or in Settings->Job Parameters.

Operation

1. Press the Application Rate section.

OPERATION

2. Select the Target Application Rate to be changed.

3. Press KEYBOARD button .

4. Select an application rate.

NOTE: Value must be between 0 and 6,554 litres/hectare.

Figure 2-12: Application Rate Number

DATA APPENDIXSETTINGS TOOLSCONSOLE

140

l/ha

225

l/ha

180

l/ha

Settings

1. From the Home screen, press the SETTINGS button .

2. Press Job Parameters .

3. Select Application Rate Number 1 .

4. Select an application rate to be associated with Number 1.

5. Repeat steps 3 and 4 for Application Rate Numbers 2 and 3.

Figure 2-13: Establish Preset Target Application Rate 2

225

l/ha

50

l/ha

100

l/ha

Application Rate (l/ha)

140

l/ha

140

l/ha

225

l/ha

1 2 3

4 5 6 <--

7 8 9

0 . +/-

225

l/ha

165

180

l/ha

165

l/ha

Clear

Target Rate Percentage Increase/Decrease

Target Rate Boost/Step Percent Increase/Decrease buttons

increase/decrease the application target rate per the established

percentage set in the Settings->Machine->Operation setup screen

under Application Rate Step.

Figure 2-14: Target rate boost/step percent

Increase/Decrease Percentage

1. From the Operation screen, press the OPTIONS tab to

display the Operation menu.

2. Press the Boost/step percent increase/decrease

buttons

3. Press the Close menu button .

5%/5%

to adjust application rates.

10

www.teejet.com

Return to Preset Target Rate

1. From the Operation screen, press the OPTIONS tab to

display the Operation menu.

Page 17

Radion 8140 Automatic Sprayer Control

2. Press 0% to return to the preset target rate.

3. Press the Close menu button .

Figure 2-15: Application Rate Step

Man

reg

0%

5%

5%

TIP SELECTION

Tips must be preset to be available for current tip selection. Presets

allow saving of up to ve (5) tips for quick recall.

Selecting the Current Tip

1. From the Operation screen, press the CURRENT TIP to

display the Preset Tip menu.

2. Select a tip type from among ve (5) tip presets.

NOTE: Current Tip can also be selectable on the

Settings->Job Parameters screen.

Figure 2-17: Tip Type on Operation screen

XR11001

XR110015 XR8001

INTRODUCTION

OPERATION

DATA APPENDIX SETTINGSTOOLS CONSOLE

Change Application Rate Step

Application Rate Step is the percent of increase/decrease boost of

the active application rate at which the product is applied. Range is

1 to 20%.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Operation .

4. Press Application Rate Step value .

5. Select an Application Rate Step.

6. Press RETURN arrow to return to the Machine screen.

Figure 2-16: Operation

XR110025

TT11004

Presetting Tips

Tip Preset Setup establishes up to ve (5) sets of tip options setting

the tip type, capacity, low/high pressure limit, reference ow and

reference pressure. For more information see Settings->Machine>Implement Parameters->Tip Preset Setup.

1. From the Home screen , press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Press Tip Preset Setup .

5. Select Tip Preset Number 1 .

6. Select Tip Series .

7. Select Tip Capacity .

8. Repeat steps 5, 6 and 7 for Tip Preset Numbers 2 to 5.

9. OPTIONAL: Press NEXT PAGE arrow to adjust the

settings for Low Pressure Limit, High Pressure Limit, Reference

Flow and Reference Pressure. Each of these settings are specic

to the current tip preset number.

98-05311-ENUS R2

11

Page 18

Radion 8140 Automatic Sprayer Control

Figure 2-18: Establish Tip Presets

INTRODUCTION

TANK

OPERATION

DATA APPENDIXSETTINGS TOOLSCONSOLE

Tank displays or give access to:

►Actual Content – displays the current volume of content in

the tank. Manual adjustment is directly relate to OEM tted

equipment. The volume cannot be manually adjusted if a Tank

sensor is active.

►Tank Filling – establishes the amount of actual and desired

material in the tank and the density of that material. Options

displayed directly relate to OEM tted equipment. Different

options will be available depending upon if a Tank sensor or

Fill Flow Sensor is active. See Settings->Machine->Filling for

additional information.

1. Press TANK

2. Press setting value to adjust settings as needed:

◄Actual Content (unavailable when Tank sensor is active)

◄Full Tank (unavailable when Tank sensor or Fill Flow Sensor

is active)

◄Density Type

◄Density Factor (available when Density Type is Fertilizer)

◄Desired Content (available when Tank sensor or Fill Flow

Sensor is active)

◄Automatic Filling (available when Tank sensor or Fill Flow

Sensor is active)

3. Press RETURN arrow to return to the Operation screen.

100

.

Figure 2-19: Tank Filling

12

www.teejet.com

Page 19

Radion 8140 Automatic Sprayer Control

ALARM WARNING

If there is an active alarm, an Alarm warning icon will appear next to

the Tank. For a list of Alarm message codes see Appendix C – Alarm

Congurations.

1. Press ALARM WARNING icon to display a list all active

alarms.

Figure 2-20: Active Alarm Warning List

PRESSURE GAUGE

The Pressure Gauge displays current pressure compared with the

recommended pressure range. Pressure sensor options are used to

enter the sensor manufacturer maximum pressure rating and to set

high and low user-determined pressure alarms.

Figure 2-22: Pressure Gauge Example

Current Working

Current Droplet Size

Recommended Pressure Range

Pressure

Recommended Pressure Range

Displays the recommended pressure range for the selected tip. The

pressure range will change depending upon the selected tip, Target

Application Rate (including boost/step percent increase/decrease)

and Working Speed.

IMPORTANT! Always refer to the recommended pressure range as

failure to do so may result in uneven spray patterns.

Speed

Pressure

INTRODUCTION

OPERATION

DATA APPENDIX SETTINGSTOOLS CONSOLE

Set Up Alarms

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Alarms .

4. Press setting value to adjust settings as needed:

◄Minimum Tank Content

◄Flow/Pressure Cross Check (alarm active only when both a

Flow Sensor and Liquid Pressure Sensor are active)

◄Section Output Low

5. Press RETURN arrow to return to the Machine screen.

Figure 2-21: Alarms

Current Working Pressure

Displays the current working pressure.

NOTE: This pressure range should not exceed the recommended

pressure range.

IMPORTANT! Always refer to the recommended tip pressure values

when setting tip pressure.

Current Droplet Size

A single tip can produce different droplet size classications at

different pressures. The colors displayed in the recommended

pressure range are directly associated with the current droplet

sizes. The droplet size displays as one (1) of eight (8) classication

categories.

Table 2-1: Droplet Size Chart

Category Symbol Color Code

Extremely Fine XF Violet

Very ne VF Red

Fine F Orange

Medium M Yellow

Coarse C Blue

Very Coarse VC Green

Extremely Coarse XC White

Ultra Coarse UC Black

98-05311-ENUS R2

13

Page 20

Radion 8140 Automatic Sprayer Control

INTRODUCTION

BOOM SECTIONS & SWITCHES

The console operates with, nine (9), seven (7) or ve (5) section

switches (depending on console model) and one (1) Master Switch.

In the nine (9), seven (7) and ve (5) section switch models, each

section switch is associated with one of up to the same number of

OPERATION

sections on the boom and illustrated on the Operation screen.

Nine (9) switch consoles are capable of supporting up to 13 boom

sections. The boom sections are paired across the nine (9) switches

evenly but will work as individual sections in ASC mode.

NOTE: Although the Number of Sections range is up to 13, the max.

number of physical switches are still nine (9).

►Switches – control individual boom sections

◄On – Flip the switch up

◄Off – Flip the switch down

DATA APPENDIXSETTINGS TOOLSCONSOLE

►Master Switch – opens/closes the main product valves and

enables/disables power to individual boom section on/off

switches

◄cannot be activated outside of the Operation screen

►Boom Sections Spray Status – displays the status of the

section switches in association to the master switch. Number

of Sections shown is established in Settings-> OEM>Implement Parameters.

◄Section On, Master Switch On – spray is blue

◄Section Off, Master Switch On – spray is white

◄Master Switch Off – spray not shown

Figure 2-23: Master Switch, 9 Section Switches

Figure 2-24: Boom Sections

Boom Section Spray Status

Section On, Master Switch On Section Off, Master Switch On

Master Switch Off

Table 2-1: Pairing Key for 9 physical section switches operating with

10, 11, 12 and 13 Boom Sections

Section

Switches 1-9

1 1 1 1 1

2 2 2 2 2

3 3 3 3 3 and 4

4 4 4 and 5 4 and 5 5 and 6

5 5 and 6 6 6 and 7 7

6 7 7 and 8 8 and 9 8 and 9

7 8 9 10 10 and 11

8 9 10 11 12

9 10 11 12 13

Boom Section Pairing Greater Than 9 Boom Sections

10 Sections 11 Sections 12 Sections 13 Sections

Master SwitchSection Switchs

14

www.teejet.com

Page 21

Radion 8140 Automatic Sprayer Control

CHAPTER 3 – SETTINGS

The main settings menu contains four (4) options: Job Parameters, Machine, OEM and Diagnostics. Each option directly accesses

settings or additional menus. When a job is active some setup options are unavailable.

SETTINGS MENU STRUCTURE

| | | |

Job Parameters Machine OEM Diagnostics

Filling Sensor Presence Test Inputs

Operation Implement Parameters Test Outputs

Implement Speed Sensor Implement Parameters

*Flow Sensor

*Liquid Pressure Sensor Alarms Regulation Parameters Regulation Details Save Alarm Log

No Pressure Clear Totals

Maximum Pressure Import/Export Calibrations

*Fill Flow Sensor

*Tank Level Sensor

Empty Tank

Minimum Tank Level

Maximum Tank Level

Tank Shape OEM menu is password protected.

Import/Export Calibrations *Menu settings directly relate to fitted OEM equipment.

Calibrations Tip Preset Setup Tank Setup Alarm Log

1. From the Home screen, press the SETTINGS button .

2. Select from:

►Job Parameters – congures current target application rate

settings, current tip and idle pressure

►Machine – congures machine settings:

◄Filling – establishes the amount of actual and desired

material in the tank and the density of that material

◄Operation – establishes application rate step, speed source,

simulated speed and minimum speed

◄Implement Parameters – establishes the section

conguration, tip preset setup and regulation parameters

◄Calibrations – establishes either manual or automatic

settings of sensors

◄Alarms – establishes alarms on/off or sets trigger levels

►OEM – directly related to the tted OEM equipment and is

password protected.

◄Sensor Presence – establishes sensors for Flow, Liquid

pressure, Fill ow, and the Tank

◄Implement Parameters – establishes the number of

sections, circulation and display rate smoothing

◄Valve Setup – establishes the regulation valve type, section

valve behaviour and section valve type

◄Tank Setup – establishes maximum and minimum tank

content, auto-lling mode and auto-lling offset value

◄Regulation Details – adjusts control of the regulation valve

◄Clear Total – deletes the total count system counter for

area, volume and time and resets to the default settings

◄Import/Export – import or export settings

Section Conguration Valve Setup Test BoomPilot

►Diagnostic – troubleshoots input/output of the controller

(sensor or actuator) or BoomPilot

◄Test Inputs – displays the input high and low values on the

installed sensors

◄Test Outputs – sets the Liquid Valve PWM Duty Cycle

percentage and checks if Master Valve, Fill Valve and

Section Valves are on/off

◄Test BoomPilot – displays automatic boom section control

correction, mode and section input status (only available

when feature is unlocked)

◄Alarm Log – displays the last 50 alarms

◄Save Alarm Log – saves the alarm log

Figure 3-1: Settings Options

INTRODUCTION

OPERATIONDATA APPENDIX TOOLS CONSOLE

SETTINGS

98-05311-ENUS R2

15

Page 22

Radion 8140 Automatic Sprayer Control

INTRODUCTION

JOB PARAMETERS

Job Parameters congures the Target Application Rate, Current Tip and Idle Pressure Settings. Selections are also active on the Operation

screen.

SETTINGS MENU STRUCTURE

OPERATION DATA APPENDIXTOOLSCONSOLE

Application Rate Number

Application Rate

Tip Type

*Idle Pressure *Menu settings directly relate to fitted OEM equipment

SETTINGS

1. From the Home screen, press the SETTINGS button .

2. Press Job parameters .

3. Press a setting value to adjust settings as needed.

◄ Target Application Rate Number

◄ Target Application Rate

◄ Tip Type

◄ Idle Pressure (available when Liquid Pressure Sensor is active)

4. Press the RETURN arrow to return to the main Settings

screen.

Figure 3-2: Job Parameters

| | | |

Job Parameters Machine OEM Diagnostics

Establish tip presets under Settings->Machine->

Implement Parameters->Tip Preset Setup.

Idle Pressure

Idle Pressure value sets the minimum pressure when the master

valve is off when using a non-circulation system and a Liquid

Pressure Sensor is present. Range is 0.00 to 50.00 bar.

Establish Preset Target Application Rates

1. From the Home screen, press the SETTINGS button .

2. Press Job Parameters .

3. Select Application Rate Number 1 .

Target Application Rate Number

Target Application Rate Number species up to three (3) target

application rate presets from which to select.

Target Application Rate

Target Application Rate denes the target rate of product to apply for

the selected number. These settings will be the same for all active

jobs. Range is 0 to 700.6 gallons/acre / 6,554 liters/hectare.

Tip Type

Tip Type selects the current tip type from the ve (5) tip presets.

This selection is also active and adjustable on the Operation Screen.

This setting does not change with when the Target Application Rate

number changes.

4. Select an Application Rate to be associated with Number 1.

5. Repeat steps 3 and 4 for Application Rate Numbers 2 and 3.

Figure 3-3: Establish Preset Target Application Rate 2

225

l/ha

Application

Rate no. 1

The Target Application Rates are accessed on the Operation screen

by pressing the Application Rate Section of the Information bar.

50

l/ha

Application

Rate no. 2

100

l/ha

Application

Rate no. 3

16

www.teejet.com

Page 23

Radion 8140 Automatic Sprayer Control

MACHINE

Machine congures machine settings. Options include Filling, Operation, Implement Parameters, Calibrations and Alarms.

SETTINGS MENU STRUCTURE

| | | |

Job Parameters Machine OEM Diagnostics

Filling

Actual Content

Implement Speed Sensor *Full Tank Section Conguration

Calibration Number Density Type Section Number

Automatic Calibration Density Factor Number of Tips

*Flow Sensor Desired Content Copy Section

Calibration Number Automatic Filling Section Width

Low Flow Limit Operation Tip Preset Setup

High Flow Limit Application Rate Step Tip Preset

Automatic Calibration Speed Source Tip Series

*Liquid Pressure Sensor Simulate Speed Tip Capacity

No Pressure Minimum Speed Factory Settings

No Pressure Calibration Implement Parameters

Maximum Pressure

Maximum Pressure Alarms Reference Flow

Reference Pressure Minimum Tank Content Reference Pressure

Automatic Calibration Flow/Pressure Cross Check Regulation Parameters

*Fill Flow Sensor Section Output Low Course Value Calibration

Calibration Number Fine Value Calibration

Automatic Calibration Tip Spacing

*Tank Level Sensor Regulation Mode

Empty Tank

Automatic Calibration

Minimum Tank Level

Minimal Tank Level

Automatic Calibration

Maximum Tank Level

Maximum Tank Level

Automatic Calibration

Tank Shape

Maximum Tank Level

Start Calibration

Import/Export Calibrations

Calibrations High Pressure Limit

Low Pressure Limit

►Calibrations – establishes either manual/automatic settings

of the following sensors:

◄ Implement Speed Sensor

◄ Flow Sensor

◄ Liquid Pressure Sensor

◄ Fill Flow Sensor

◄ Tank Level Sensor

►Alarms – establishes alarms on/off and sets their trigger levels

INTRODUCTION

OPERATIONDATA APPENDIX TOOLS CONSOLE

SETTINGS

*Menu settings directly relate to

fitted OEM equipment

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Select from:

►Filling – establishes the amount of actual and desired material

in the tank and the density of that material

►Operation – establishes application rate step, speed source,

simulated speed and minimum speed

►Implement Parameters

◄ Section Conguration – sets the number of tips on the boom

which determines the spraying width during application

◄ Tip Preset Setup – establishes options for up to ve (5)

tips including series, capacity, low/high pressure limits,

reference ow and reference pressure

◄ Regulation Parameters – adjusts valve calibration and tip

spacing and selects a regulation mode

4. Press RETURN arrow to return to the main Settings screen.

Figure 3-4: Machine

98-05311-ENUS R2

17

Page 24

Radion 8140 Automatic Sprayer Control

Filling

INTRODUCTION

Filling establishes the amount of actual and desired material in the tank and the density of that material. Options displayed directly relate to

OEM tted equipment. Different options will be available depending upon if a Tank Sensor or Fill Flow Sensor is active.

SETTINGS MENU STRUCTURE

| | | |

OPERATION DATA APPENDIXTOOLSCONSOLE

SETTINGS

Job Parameters Machine OEM Diagnostics

Filling

Actual Content

*Full Tank

Density Type

Density Factor

Desired Content

Automatic Filling

Operation

Implement Parameters

Calibrations

Alarms *Menu settings directly relate to fitted OEM equipment.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Filling .

4. Press setting value to adjust settings as needed:

◄Actual Content (unavailable when Tank Sensor is active)

◄Full Tank (unavailable when Tank Sensor or Fill Flow Sensor

is active)

◄Density Type

◄Density Factor (available when Density Type is fertilizer)

◄Desired Content (available when Tank Sensor or Fill Flow

Sensor is active)

◄Automatic Filling (available when Tank Sensor or Fill Flow

Sensor is active)

5. Press RETURN arrow to return to the Machine screen.

NOTE: Maximum tank content is established in Settings->OEM->

Tank Setup.

When a Tank Sensor is active, the actual content can not be

changed manually.

If "Fertilizer" is selected, a Density Factor option is active.

Figure 3-5: Filling

18

www.teejet.com

Page 25

Radion 8140 Automatic Sprayer Control

Filling from Operation screen

All lling settings may be accessed from the Operation screen by

pressing the TANK

100

.

Figure 3-6: Filling from Operation Screen

Screen (1)

Actual Content

Actual Content displays the current volume of content in the tank.

Manual adjustment is directly relate to OEM tted equipment. The

volume cannot be manually adjusted if a Tank Sensor is active.

NOTE: Maximum Tank Content is established in Settings->OEM->

Tank Setup.

When available, this number repopulates when

the Full Tank option is pressed.

Full Tank

Full Tank returns the Actual Content volume value to the maximum

volume of the tank.

NOTE: When a Tank Sensor or Fill Flow Sensor is active, the Full

Tank option is not displayed.

Density Type

Density establishes the density of the material applied. It can be set

to either fertilizer or water.

NOTE: If Fertilizer is selected, a Density Factor option is active.

Density Factor

Density Factor establishes the weight per volume setting based on

the type of fertilizer used. Range is 6.676 to 16.691 lb./gal. / 0.8 to

2.0 kg/l.

The fertilizer’s ability to ow is affected by a number of factors.

These factors may vary with each batch and it may change due to

weather (humidity, etc.). In order to accommodate for this, the job

computer uses a density factor to compensate for the nature of the

applied fertilizer.

The default value of “1.00” corresponds with the specic gravity of

water and is correct for most pesticide applications. Occasionally

some spray solutions, such as fertilizer, have different densities. If

using such a material, a new value should replace the default value.

The chart to the below can help determine the specic gravity of

other solutions.

Table 3-1: Specific Gravity

Weight of Solution per litre/lb Specic Gravity

3.2 Kg 7.0 lb (UK) 0.84

3.6 Kg 8.0 lb (UK) 0.96

1 Kg/L - water 8.34 lb - water (UK) 1.00

4.5 Kg 10.0 lb (UK) 1.20

4.8 Kg - 28%N 10.65 lb - 28%N (UK) 1.28

4.9 Kg - 30%N 10.85 lb - 30%N (UK) 1.30

5.0 Kg 11.0 lb (UK) 1.32

5.4 Kg 12.0 lb (UK) 1.44

6.4 Kg 14.0 lb (UK) 1.68

NOTE: Water weighs 1 Kg/L or 8.34 lb/gal (UK)

The Specic Gravity can be calculated as follows:

Weight of Solution

Specic Gravity =

Weight of Water

Screen (2)

These options are only displayed when a Tank Sensor or Fill Flow

Sensor is active.

Desired Content

Desired Content establishes the desired maximum content volume.

The volume can be manually adjusted.

Actual Content

Actual Content displays the current volume of content in the tank.

The volume can be manually adjusted on the Filling (1) screen.

Automatic Filling

Automatic Filling starts and stops the automatic lling process.

INTRODUCTION

OPERATIONDATA APPENDIX TOOLS CONSOLE

SETTINGS

NOTE: If water is selected, a Density Factor option is inactive.

98-05311-ENUS R2

19

Page 26

Radion 8140 Automatic Sprayer Control

Operation

INTRODUCTION

Operation congures application rate steps and speed settings relating to operations. Options include Application Rate Step, Speed Source,

Simulate Speed and Minimum Speed.

SETTINGS MENU STRUCTURE

| | | |

OPERATION DATA APPENDIXTOOLSCONSOLE

SETTINGS

1. From the Home screen, press the SETTINGS button .

Job Parameters Machine OEM Diagnostics

Filling

Operation

Application Rate Step

Speed Source

Simulated Speed

Minimum Speed

Implement Parameters

Calibrations

Alarms

Figure 3-7: Application Rate Step on Operation Screen.

2. Press

Machine .

3. Press Operation .

4. Press setting value to adjust settings as needed:

◄Application Rate Step

◄Speed Source

◄Simulated Speed (available when Speed Source is Simulated)

◄Minimum Speed

5. Press RETURN arrow to return to the Machine screen.

Figure 3-8: Operation

Application Rate Step

Application Rate Step is the percent of increase/decrease boost of

the active application rate at which the product is applied. Range is

1 to 20%.

Application Rate Boost/Step Percent is used on the Operation

screen from the Options tab while in Automatic Mode.

Man

reg

0%

5%

5%

Speed Source

Speed Source selects whether to base the machine speed on input

from the CAN, an Implement or a Simulated source.

◄Implement – allows for speed to be supplied from an

Implement Speed Sensor. Calibration of the Implement Speed

Sensor is done.

NOTE: Calibration of the Implement Speed Sensor is

established in the Settings->Machine-> Calibrations

-

>Implement Speed Sensor options.

◄Simulated – allows for simulated speed to be entered

NOTE: An alarm will sound at start up when active.

◄CAN

– uses speed supplied by the CAN

Simulated Speed

Simulated Speed establishes a speed for using the Simulated Speed

source. Range is 0 to 62.1 miles/hour / 99.9 kilometers/hour.

Minimum Speed

Minimum Speed establishes the minimum forward speed at which

the system should automatically switch the main valve off. Range is

0 to 62.1 miles/hour / 99.9 kilometers/hour.

20

www.teejet.com

Page 27

Radion 8140 Automatic Sprayer Control

Implement Parameters

Implement Parameters establishes: the Section Conguration including the number of Tips per Section; Tip Conguration including up to

ve (5) presets; and Regulation Parameters including Valve Calibration, Tip Spacing and Regulation Mode.

SETTINGS MENU STRUCTURE

| | | |

Job Parameters Machine OEM Diagnostics

Filling

Operation

Implement Parameters

Calibrations Section Number

Alarms Number of Tips

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Select from:

►Section Conguration – sets the number of tips on

the boom which determines the spraying width during

application

►Tip Preset Setup – where up to ve (5) sets of tip options

can be established to set the tip series, capacity, low/high

pressure limit, reference ow and reference pressure

►Regulation Parameters – where adjustments to the valve

calibration, tip spacing and regulations mode can be

established

5. Press RETURN arrow to return to the Machine screen.

Figure 3-9: Implement Parameters

Section Conguration

Copy Section

Section Width

Tip Preset Setup

Tip Preset

Tip Series

Tip Capacity

Factory Settings

Low Pressure Limit

High Pressure Limit

Reference Flow

Reference Pressure

Regulation Parameters

Course Value Calibration

Fine Value Calibration

Tip Spacing

Regulation Mode

Section Configuration

Section Conguration sets the number of tips on the boom which

determines the spraying width during application.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Press Section Conguration .

5. Press setting value to adjust settings as needed:

INTRODUCTION

OPERATIONDATA APPENDIX TOOLS CONSOLE

SETTINGS

◄Section Number

◄Number of Tips

◄Copy Section

◄Section Width

6. Press RETURN arrow to return to the Implement Parameters

screen.

98-05311-ENUS R2

21

Page 28

Radion 8140 Automatic Sprayer Control

Figure 3-10: Section Configuration

INTRODUCTION

OPERATION DATA APPENDIXTOOLSCONSOLE

SETTINGS

Section Number

Section Number establishes the current section number to which

changes can be made. Sections are numbered from left to right while

facing in the machine forward direction.

NOTE: The number of available sections is established in the

OEM menu and limited by the sections available on the

console.

Number of Tips

The number of tips in the current section number. Range is 0 to 200.

Copy Section

Copy Section sets all Number of Tips counts to the same count for

all boom sections based upon the current Section Number.

Section Width

Section Width displays the width for the current section. The width

is calculated based on the number of tips established in the Number

of tip section and tip spacing established under: Settings->Machine>Implement Parameters->Regulation Parameters->Tip Spacing.

Figure 3-11: Establish Number of Tips

Tip Preset Setup

Tip Preset Setup establishes up to ve (5) sets of tip options setting

the Tip Type, Capacity, Low/High Pressure Limit, Reference ow and

Reference Pressure.

NOTE: Settings on both screen 1 and screen 2 are specific to the

currently selected Tip Preset number.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Press Tip Preset Setup .

5. Press setting value to adjust settings as needed:

◄Tip Preset (number)

◄Tip Series

◄Tip Capacity

◄Factory Settings

6. Press RETURN arrow to return to the Implement Parameters

screen.

Figure 3-12: Tip Preset Setup

◄Low Pressure Limit

◄High Pressure Limit

◄Reference Flow

◄Reference Pressure

Establish Number of Tips

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Press Section Conguration .

5. Select Section Number .

6. Set the Number of Tips for the selected section number.

7. Repeat steps 5 and 6 for additional Section Numbers as available.

8. OPTIONAL: If all sections have the same number of tips,

press Copy to set all sections to the current number of tips.

22

www.teejet.com

Page 29

Radion 8140 Automatic Sprayer Control

Screen (1)

Tip Preset

Tip Preset allows saving of up to ve (5) tips for quick recall. Each

preset tip can be selected to establish different tip options.

Tip Series

Tip Series selects the tip series from a general selection of

established tips or an optional user dened tip.

Tip Capacity

Tip Capacity selects the tip capacity from a list of established sizes.

When the tip series is user-dened, tip capacity will need to be

encoded manually.

Table 3-1: Tip Sizes and Associated Colors

Established Tip Capacities and Colors

Size Color Size Color

01 Orange 06 Gray

015 Green 08 White

02 Yellow 10 Light Blue

025 Purple

03 Blue 15 Light Green

04 Red 20 Black

05 Brown 30 Beige

12 Telemagenta

Reference Flow

Reference Flow establishes the value for the volume applied over a

specic time. Range is 0 to 26.42 gallons/minute / 100 liters/minute.

Reference Pressure

Reference Pressure establishes the pressure value at which

the target application rate is true (ISO = 2 bar). Range is1.2 to

1,450.2 psi / 0.10 to 99.99 bar.

Establish Tip Presets

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Press Tip Preset Setup .

5. Select Tip Preset number 1 .

6. Select Tip Series .

7. Select Tip Capacity .

8. Repeat steps 5, 6 and 7 for Tip Preset numbers 2 to 5.

9. OPTIONAL: Press NEXT PAGE arrow to adjust the

settings for Low Pressure Limit, High Pressure Limit, Reference

Flow and Reference Pressure. Each of these settings are specic

to the current tip preset number.

Figure 3-13: Establish Tip Presets

INTRODUCTION

OPERATIONDATA APPENDIX TOOLS CONSOLE

SETTINGS

Factory Settings

Factory Settings resets all tip settings (Low Pressure Limit, High

Pressure Limit, Reference Flow and Reference Pressure) to the

default settings for the selected tip capacity and series.

Screen (2)

When an established tip series and capacity is selected, the Low

Pressure Limit, High Pressure Limit, Reference Flow and Reference

Pressure elds automatically establishes standard settings for

the specic tip chosen. These settings can be manually adjusted.

Restore standard settings to all tips using the Factory Settings

Restore button on Screen (1).

IMPORTANT! Always refer to supplier recommended tip pressure

values when setting tip pressure.

Low Pressure Limit

Low Pressure Limit establishes the limit for the lowest allowed

operating pressure for the selected tip capacity. Range is 0.0 to

369.8 psi / 25.5 bar.

High Pressure Limit

High Pressure Limit establishes the limit for the highest allowed

operating pressure for the selected tip capacity. Range is0.0 to

369.8 psi / 25.5 bar.

98-05311-ENUS R2

23

Page 30

Radion 8140 Automatic Sprayer Control

Regulation Parameters

INTRODUCTION

Regulation Parameters establishes adjustments to the Valve

Calibrations, Tip Spacing and Regulations Mode.

NOTE: Adjusting the Valve calibration settings involves significant

changes so adjustments should be made in small steps.

OPERATION DATA APPENDIXTOOLSCONSOLE

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement Parameters .

4. Press Regulation Parameters .

SETTINGS

5. Press setting value to adjust settings as needed:

◄Coarse Valve Calibration

◄Fine Valve Calibration

◄Tip Spacing

◄Regulation Mode

6. Press the RETURN arrow to return to the Implement

Parameters screen.

Figure 3-14: Regulation Parameters

If the system is plumbed in a throttling mode, start with

valve setting number 3 and adjust the number according to

application requirements.

Low flow situations require a slower response time. Adjusting

agitation volumes, to accommodate the regulating valve

to work in a more fully open position, allows for a faster

response time with little to no searching.

NOTE: Adjust the setting valve to optimize system performance. If

the valve seems to “search” for the programmed application

rate by continuously cycling pressure up/down, reduce

the number until “searching” is minimized or eliminated.

Conversely, a higher number increases the valve response

time and “speeds up” the rate of adjustment.

Fine Valve Calibration

Fine regulation value calibration allows setting the regulating valve

to accommodate different application needs. Operating conditions

may necessitate a higher or lower response setting for the regulating

valve. Fine valve calibration adjusts the setting for the ne tune

adjustment in relation to a small percentage close to the target

application rate. Range is 0 to 9.

Coarse Valve Calibration

Coarse regulation value calibration allows regulating the setting of

the regulating valve to accommodate different application needs.

Operating conditions may necessitate a higher or lower response

setting for the regulating valve. This value adjusts the setting for

coarse adjustments in relation to a large percentage outside of the

target application rate. Range is 0 to 19.

►If the system is too slow in nding the correct rate, values

should be increased

►If the system is too unstable, values should be decreased

TIPS: If the system is plumbed in a bypass mode, valve setting

number 9 works very well in most applications.

►If the system is too slow in nding the correct rate, increase

values.

►If the system is too unstable, decrease values.

TIPS: If the system is plumbed in a bypass mode, valve setting

number 5 works very well in most applications.

If the system is plumbed in a throttling mode, start with a

valve setting number 3 and adjust the number according to

application requirements.

Low flow situations require a slower response time. Adjusting

agitation volumes to accommodate the regulating valve, to

work in a more fully open position, allows for faster response

time with little to no searching.

NOTE: This setting value can be adjusted to optimize system

performance. If the valve seems to “search” for the

programmed application rate by continuously cycling the

pressure up/down, reduce the number until “searching”

is minimized or eliminated. Conversely, a higher number

increases the valve response time and “speeds up” the rate

of adjustment.

Tip Spacing

Tip Spacing establishes the distance between the tips on the boom.

Range is 4 to 7,874 inches / 10 to 19,999 centimeters.

Regulation Mode

Regulation Mode determines if the rate control is pressure based or

ow based.

24

www.teejet.com

Page 31

Radion 8140 Automatic Sprayer Control

Calibrations

Calibrations congures sensor parameters including Implement Speed Sensor, Flow Sensor, Liquid Pressure Sensor, Fill Flow Sensor, and

Tank Level Sensor. Options displayed directly relate to OEM tted equipment.

SETTINGS MENU STRUCTURE

| | | |

Job Parameters Machine OEM Diagnostics

Filling

Operation

Implement Parameters

Calibrations

Alarms Calibration Number

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Calibrations .

4. Select from:

►Implement Speed Sensor

►Flow Sensor

►Liquid Pressure Sensor

◄Calibrate each option in the following order:

No pressure

Maximum Pressure

►Fill Flow Sensor

►Tank Level Sensor

◄Calibrate each option in the following order:

Empty Tank

Minimum Tank Level

Maximum Tank Level

Tank Shape

5. Press the RETURN arrow to return to the Machine screen.

Figure 3-15: Calibrations – Tank Level Sensor and Fill Flow Sensor

Implement Speed Sensor

Automatic Calibration

*Flow Sensor

Calibration Number

Low Flow Limit

High Flow Limit

Automatic Calibration

*Liquid Pressure Sensor

No pressure

No Pressure Calibration

Maximum Pressure

Maximum Pressure

Reference Pressure

Automatic Calibration

*Fill Flow Sensor

Calibration Number

Automatic Calibration

*Tank Level Sensor

Empty Tank

Automatic Calibration

Minimum Tank Level

Minimal Tank Level

Automatic Calibration

Maximum Tank Level

Maximum Tank Level

Automatic Calibration

Tank Shape

Maximum Tank Level

Start Calibration

Import/Export Calibrations

*Menu settings directly relate to fitted OEM equipment.

INTRODUCTION

OPERATIONDATA APPENDIX TOOLS CONSOLE

SETTINGS

98-05311-ENUS R2

25

Page 32

Radion 8140 Automatic Sprayer Control

Implement Speed Sensor

INTRODUCTION

The Implement Speed Sensor establishes the wheel pulses over

a specied distance. Establish the value manually or automatically

calibrate the value.

Figure 3-16: Implement Speed Sensor

OPERATION DATA APPENDIXTOOLSCONSOLE

SETTINGS

Flow Sensor

The Flow Sensor establishes the pulses per litre. Establish the value

manually or automatically calibrate the value.

Figure 3-17: Flow Sensor

Calibration Number

Automatic Calibration will determine the number of pulses counted

while driving 300 feet (100 meters in metric mode) and convert the

calibration number to the correct units. In manual calibration, enter

the calibration number in pulses per 300 feet (100 meters in metric

mode). Range is 0 to 65,000 pulses.

Automatic Calibration

Automatic Calibration establishes the pulses using the automatic

calibration function.

Implement Speed Sensor Automatic Calibration

1. Press Calibrate to start an automatic sensor calibration.

2. Drive a distance of 300 feet (100 meters in metric mode).

3. Press Done when complete.

To cancel the calibration, press Cancel , RETURN arrow or the

Home button .

The counted wheel pulses will be displayed during the automatic

calibration.

Calibration Number

Enter the amount of pulses counted while running 1 litre of

water through the ow sensor. Use Automatic Calibration to

calculate pulses automatically. Manual calibration establishes

the calibration and limits based on user-entered values. Range is

10 to 4,900 pulses.

Low Flow Limit

Enter the ow sensors low limit value.

Range is 0 to 26.39 gallons/minute / 99.9 liters/minute.

High Flow Limit

Enter the ow sensors high limit value.

Range is 0 to 264.17 gallons / 999.9 liters/minutes.

Automatic Calibration

Automatic Calibration establishes the calibration and limits if the

number of pulses per litre for the ow meter is unknown or to make

sure the value is correct.

Pulse Count

Shows the number of pulses during calibration. Minimum of

10 pulses needed to do a calibration.

Collected Volume