Page 1

98-05086

R1

PRODUCT WARRANTY

MIDWEST TECHNOLOGIES ILLINOIS, LLC (also known as Mid-Tech & TeeJet) warrants to the

original purchaser that the product purchased shall be free of defect in material or workmanship. If the

product proves to be defective within the warranty period the purchaser must return, freight prepaid, said

product to Midwest Technologies within thirty (30) days after such defect is discovered. Upon inspection

and examination by Midwest Technologies, and at its option, the product shall be repaired or replaced,

with a new or comparable product. No product will be considered defective if it substantially fulfills the

performance specifications. Purchaser shall be responsible for all required maintenance service in accordance

with procedures outlined in Midwest Technologies’ product operator manual or service bulletins.

All product(s) replaced or repaired under warranty shall carry the remainder of the warranty left on the

original purchase. All out of warranty product(s) serviced for fee or goodwill will have ninety (90) days

of warranty. The ninety (90) days shall begin on the date serviced by Midwest Technologies.

Warranty periods for Midwest Technologies products shall be:

TeeJet and Mid-Tech Control Consoles – 2 ½ years

Mid-Tech Switch Boxes – 2 ½ years (3, 5, 9 booms)

All other products – 12 months (unless otherwise noted)

WARRANTY LIMITATIONS AND EXCLUSIONS

Midwest Technologies will have no warranty obligation hereunder if the product is subjected to abuse,

misuse, improper or abnormal usage, acts of God, faulty installation, or improper maintenance as outlined

in Midwest Technologies’ product operator manual or service bulletins. Consumable items (items that are

used during normal operation) such as light bulbs, batteries, etc., and expendable items (items which wear

out in normal use) such as injection pump tubes, flow meter bearings, etc., will not be covered by warranty.

For products that come in direct contact with chemical, the specific recommendations contained in Midwest

Technologies product bulletins must be adhered to, or this warranty is void. Any repairs or alterations,

other than those provided by Midwest Technologies and/or its authorized representatives, will void the

warranty. Midwest Technologies neither assumes nor authorizes anyone to assume for it any other obligation

or liability in connection with said product.

DISCLAIMER OF UNSTATED WARRANTY

98-05086

R1

Midwest Technologies

MT 600 PISTON INJECTION PUMP

INSTALLATION & SETUP

INSTALLATION

MOUNTING

The MT 600 injection pumps must be located as close as possible to the

point where the chemicals are injected into the main boom supply line. As

close to the delivery point as possible is the preferred injection point. A

consideration should be made to use check valves between the pump and

injection point as well as ahead of the injection point in the main flow

line (See the pluming diagram on page 6). Another consideration is the

location for the chemical containers must also be given, keeping the

distance between the MT 600 pump and the chemical container to a

minimum.

Once the location for the Legacy injection pump is selected, orient the

assembly so that the pump cover is easily opened, allowing access for

service. All sides of the pump may need to be accessible for service. The

pump must be mounted upright.

5oz of SAE 10w 30 oil must be added to each pump head via the red cap

port prior to operation. Oil should be visible and never overfilled

above 1/2 of the viewing window.

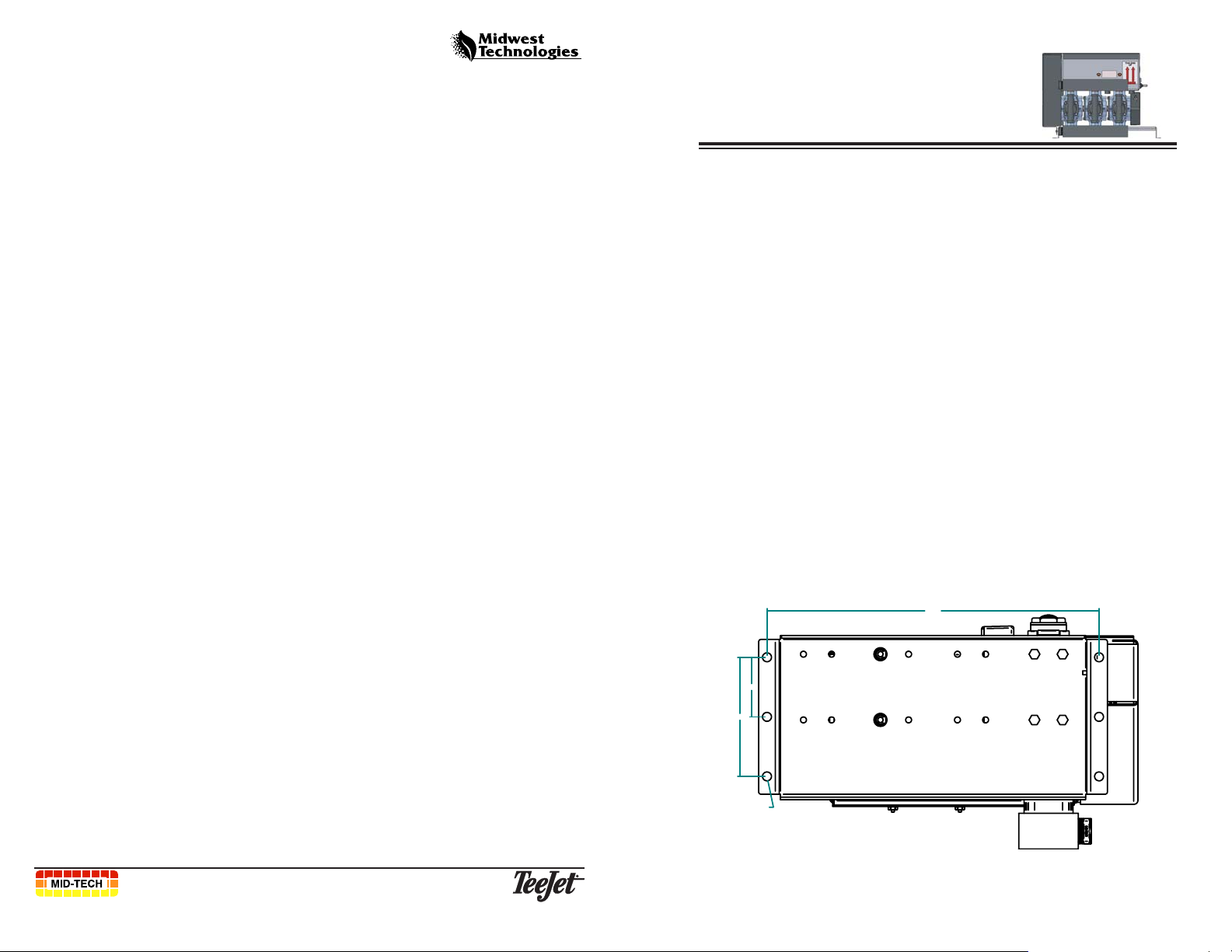

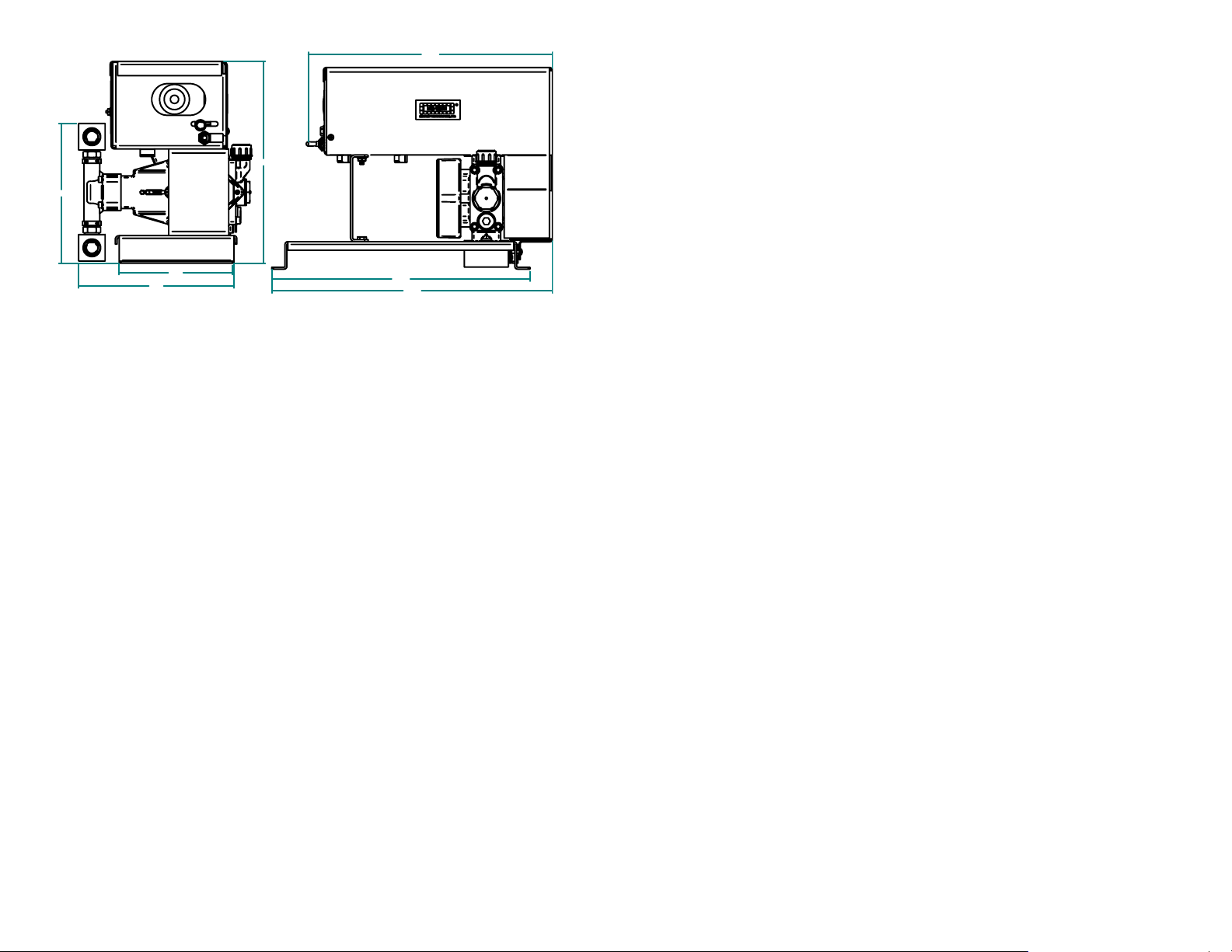

Figures 1 and 2 provide measurements to help you place the mounting

holes for the pumps.

The warranty printed above is the only warranty applicable to this purchase. Midwest Technologies’

warranty cannot be modified by any person or entity, including without limitation, any distributor or retailer

of Midwest Technologies. All other warranties, express or implied, including but not limited to, the implied

warranties of merchantability and fitness for a particular purpose, are disclaimed.

LIMITATION OF LIABILITY

It is understood and agreed that Midwest Technologies’ liability, whether in contract, in tort, under any

warranty, in negligence or otherwise, shall not exceed the return of the amount of the purchase price paid

by purchaser and under no circumstances shall Midwest Technologies be liable for special, indirect or

consequential damages. In particular, Midwest Technologies shall not be liable for damage to crops as the

result of misuse or negligence in the application of chemicals or operation of Midwest Technologies products.

The price stated for the equipment is a consideration in limiting Midwest Technologies’ liability. No

action, regardless of form, arising out of the transactions under this agreement may be brought by purchaser

more than one year after the cause of action has occurred.

Midwest Technologies Illinois, LLC

2864 Old Rochester Rd. - Springfield, IL 62703

®

Phone - (217) 753-8424 * Fax - (217) 753-8426

12

14.00

2.50

5.00

O

.38

(6 Plcs.)

Fig. 1: Bottom Template

1

Page 2

98-05086

R1

7.91

11.43

14.00

98-05086

R1

NOTES

6.40

8.80

14.63

15.91

Fig. 2: Side Template

NOTE: Secure each pump firmly to eliminate vibration and possible

damage to the connecting hoses and cables.

PLUMBING

See the sample plumbing diagram on page 6 for suggestions on how to

plumb the system.

CABLING

Each MT600 injection pump comes with two cables, a pump control cable

and a pump power cable. See the sample system diagrams on pages 7 and 8

for suggestions on how the system should be connected.

Route all cables carefully, avoiding moving parts, excessive heat and

exposure to tree limbs, stubble, or other debris. Allow enough slack at

all pivot points to prevent pinching or stretching the cables.

Secure the cables in place with cable fasteners and/or cable clamps.

Pump Control Cables: When the injection pumps have been designated

#1 , #2, etc., Midwest Technologies suggests the cable tags be marked

accordingly (use a permanent ink - water proof marker). Carefully route the

cable to the console (TASC system) or Product Control Module (Legacy

system).

Pump Power Cable: Route each power cable to the vehicle battery (12

VDC only). Attach the red lead (fused) to the positive post and the black

lead to the negative post of the battery.

2

11

Page 3

98-05086

R1

CALIBRATION NUMBERS

SETUP

98-05086

R1

Pumps:

1. _____ 2. _____ 3. _____ 4. _____ 5. _____ 6. _____

Swath 1 - Booms:

1. _____ 3. _____ 5. _____ 7. _____ 9. _____

2. _____ 4. _____ 6. _____ 8. _____

Swath 2 - Booms:

1. _____ 3. _____ 5. _____ 7. _____ 9. _____

2. _____ 4. _____ 6. _____ 8. _____

Swath 3 - Booms:

1. _____ 3. _____ 5. _____ 7. _____ 9. _____

2. _____ 4. _____ 6. _____ 8. _____

Swath 4 - Booms:

1. _____ 3. _____ 5. _____ 7. _____ 9. _____

SELECTING PROPER P UMP SIZE

Use the following formula to determine the flow capacity requirements of

the pump; then check the Pump Size Selection Chart (Fig. 3) for the proper

pump size.

Pump Cap.= Max. Boom Width x Max. Speed x Chemical Rate x (.00202)

(Oz./Min.) = (Ft.) x (MPH) x (Oz./Acre) x (.00202)

Example: A sprayer with 35 ft. booms, traveling at a maximum speed of

14 mph and applying 1 quart of chemical per acre would require a maximum pump capacity of 31.67 Oz./Min. (i.e. 35 ft. x 14 mph x 32 oz./ac. x

.00202 = 15.8 oz./min.). Referring to the Pump Size Selection Chart we

find that a 1Pump Head pump would be sufficient for this rate. However, if

you needed to apply 100 oz./ac. of chemical, you should use the 2 Head

pump; (35 ft. x 14mph x 100 oz./ac. x .00202 = 98.98 oz./min. exceeds the

recommended range of the smaller 1 Head Pump).

PUMP SIZE SELECTION CHART for MT 600 PUMP

270

2 Head Pump

2 4 6 8

4 Head Pump

3 Head Pump

1.2

.9

.6

1 Head Pump

PUMP SIZE (# of Pump Heads)

.3

.2 .4 .6 .8

1 10 20 30 40 50 100 150 200 250 3000

200

135

65

MAX. FLOW RATE (Oz. / Min.)

Fig. 3: Pump Size Chart

TYPICAL CALIBRATION NUMBERS

2. _____ 4. _____ 6. _____ 8. _____

Swath 5 - Booms:

1. _____ 3. _____ 5. _____ 7. _____ 9. _____

2. _____ 4. _____ 6. _____ 8. _____

DISTANCE: _______ FLOW METER: _______

10

Typical calibration numbers for the various pump heads listed above are:

TASC Legacy

• 1 Pump Head 10.8 340

• 2 Pump Head 4.4 170

• 3 Pump Head 3.1 115

• 4 Pump Head 2.4 85

NOTE: When adding a pump head to and existing pump there two types of

heads. Contact your MID-TECH dealer to determine which head is needed.

3

Page 4

98-05086

C

R1

CALIBRATION

Refer to your TASC 6300/6600, TASC 6500, or Legacy 6000 console user

guide for specific calibration instructions related to your specific console.

When you see a reference to placing a magnet on the motor control

module or PCM (Product Control Module), press and hold the Calibrate

switch on the MT 600 pump instead. You can record your system calibration numbers on page 10.

alibration

Switch

98-05086

R1

MT600 PISTON PUMP GENERAL SPECIFICATIONS

Product Description :

Pump T ype : Positive Displacement Piston Pump

V ersatility : Modular, serviceable, and compatible with

various controllers

Performance Characteristics :

Response : Chemical moves immediately when

motor is driven

Motor Speed : 0 to 225 rpm at 12.5 Vdc

Pumped Media :

Fluids : Liquid chemicals only

Electrical :

Power : 30 to 120 watts typical (30amp Fused)

Voltage : 12 volt DC vehicle

Connection : 2 pin MetriPak 480 T ower-Sealed

Fig. 4: Pump Calibration Switch

Physical Properties :

Dimensions : 11.5”H, 10”D, 116”W

Plumbing : 3/4” FPT Manifold 1/2" NPT

W eight : 1 Head 26lbs @ 650 ft above sea level

Key - feather

4 x 4mm

60-10073

Piston

O-Rings - Viton 64-90027

Bushing - Delrin

Seal, Teflon 64-05100

Seal, Niltrile

Fitting 1/2" male NPT

67-00018

O-Ring

64-90028

KIT, Piston Pump Valves

54-02031

includes : 1 seat, 10 balls,

1 spring, & 1 slive

Environmental :

T emperature : 34 degrees F. to 140 degrees F.

Humidity : W eatherproof (high humidity)

V ibration : N/A

4 Head 46lbs @ 650 ft above sea level

Dust : N/A

KIT, Piston Pump Seals, Viton

54-02030

Oil Plug & Seal

54-02033

Piston

ceramic &

316 series SST

O-Ring

64-90028

Pump Head

Clip

KIT, Piston Pump Valves

54-02031

includes : 1 seat, 10 balls,

1 spring, & 1 slive

Fitting 1/2" male NPT

67-00018

Fig. 5: Pump Diagram

4

9

Page 5

98-05086

R1

TYPICAL LEGACY SYSTEM WIRING

Legacy 6000 Controller

98-05086

R1

MAINTENANCE

Midwest Technologies recommends the following maintenance to keep

your system operating at peak efficiency.

Legacy 6000 Injection

Wiring Diagram

Power

Speed

Module

A

B

A

B

Flowmeter

RS-232 Port

CAN Gateway

Ignition

Speed Sensor

P

roduct

C

ontrol

M

odule

PRG CAN

Flow Control Valve

PSM

PRG CAN

PCM

Product Switchbox

1 2 3 4 5 6 7 8

RATE

B

A

OFF

PRODUCT CONTROL

% RATE

HANDGUN

+

-

SSM

S

witch

S

ense

M

odule

PRG CAN

Terminator

SLOPE

OFF

FLUSHING AND CLEANING

Always refer to the chemical manufacturer's directions regarding cleaning

SW TXDMAG

Boom Sense 1 - 10 (or 1 - 20)

GSO

Imp. Stat.

and flushing

DAILY PUMP M AINTENANCE

Check pump head oil level. Oil level should be visible and never overfilled above 1/2 of the viewing window

Do not leave chemical in the pump or application lines overnight. The

system should be flushed and cleaned at the end of each day’s operation.

WEEKLY PUMP M AINTENANCE

Check the pump carefully for wear each week during frequent operations.

Check for cracking, belt wear, or other signs of material fatigue. If any

+

-

signs of deterioration are seen, that may need replaced immediately

(contact your Mid-Tech dealer).

The pump calibration must be checked anytime the pump head is added or

PCM

P

roduct

C

ontrol

M

odule

PRG CAN

subtracted.

SEASONAL PUMP M AINTENANCE

A

B

A

B

Black

White

+

Vehicle Battery

(12 Volts)

Terminator

Install ball and seat repair kit (Part# 54-02031) See Figure 5 above

A

A

B

B

MT600 Injection Pump

8

The pump calibration must be checked at the begin of each season of

operation and periodically throughout the year.

5

Page 6

98-05086

R1

TYPICAL INJECTION SYSTEM PLUMBING

To

Spray

Booms

Boom Valves

98-05086

R1

TYPICAL TASC SYSTEM WIRING

MT 600 Plumbing Diagram

INJECTION PUMP

INJECTION PUMP

Mixing

Chamber

Status

Implement

GSO

Boom

Status

MT600 Inj. Pump

90-06019 - 1 Head

90-06020 - 2 Head

90-06021 - 3 Head

90-06022 - 4 Head

MT600 Inj. Pump

90-06019 - 1 Head

90-06020 - 2 Head

90-06021 - 3 Head

90-06022 - 4 Head

MT600 Inj. Pump

90-06019 - 1 Head

90-06020 - 2 Head

90-06021 - 3 Head

90-06022 - 4 Head

FLOW METER

Check

Valves

M

Bypass line

FLOW CONTROL VALVE

"AUTO RANGE"

Carrier Pump

ON OPERATE INC.

®

Flow

DEC.

SET- UP

OFF

MID-TECH

MIDWEST TECHNOLOGIES, INC.

-Ac

RATE

405-0036

Width

Distance

Total Applied

Appl. Rate

Prime

Test

Speed

%Rate

DISPLAY SELECTOR

Scan

Area

Speed

Chem. Rate

BOOMS

CHEMICALS CARRIER

Chem. Applied

1234567 8 9

TASC-6300

SPRAYER CONTROL

TOTAL APPLICATION

.

Gal./

ON

OFF

Alt.-

Rate

3

12

CHEMICAL APPLICATORS

Boom Interface Cable

Signal Extension Cable

45-05301

Power Extension Cable

45-05302

Signal Extension Cable

To Battery

45-05301

45-05302

Power Extension Cable

404-0022

45-05302

45-05301

Power Extension Cable

Signal Extension Cable

To Battery

To Battery

Flow Control Cable

In-Line Filter

114-0002

TASC 6300 Console

45-05322

Ground Cable Assy

Fuse,(5 amp)

Fuse,(10 amp)

405-0143

Valve Driver

Flowmeter

Interface Cable

405-0044

CHEMICAL TANK ASSEMBLIES

CLEAN WATER

Ground Speed

r

a

d

a

8

6

1

2

t II R

c

-0

a

0

p

9

m

o

C

FLUSH PORTS

Carrier Tank

Main Shut Off Valve

Quick Fill Port

Wiring Diagram

TASC 6300 Injection

6

White

Black

7

45-05037

Battery cable

+

(12 Volts)

Vehicle Battery

1" Flow Control Valve

879-XXXX

120-XXXX

1" Flowmeter

Loading...

Loading...