Page 1

VOYAGER® 570G

UsER MANUAL

UsER MANUAL

Page 2

Table of Contents

CHAPTER 1 SYSTEM OVERVIEW 1

SYSTEM FEATURES 1

SYSTEM COMPONENTS 2

Matrix Pro 570G Console ..................................................................................................................................................................................2

Matrix Pro 840G Console ..................................................................................................................................................................................3

RealView Camera ................................................................................................................................................................................................ 3

Optional Accessories ......................................................................................................................................................................................... 4

CONFIGURATIONS 6

CHAPTER 2 POWER 11

Power On .............................................................................................................................................................................................................11

Power O .............................................................................................................................................................................................................11

Start Up Sequence ...........................................................................................................................................................................................11

CHAPTER 3 INTRODUCTION 12

JOBS HOME SCREEN 12

Simple Mode ......................................................................................................................................................................................................12

Advanced Mode ................................................................................................................................................................................................12

BASIC SCREEN USE 12

Bottom Tab Keys ........................................................................................................................................................ 12

Warnings and Information Pop-ups ............................................................................................................................. 13

Setup Screens ....................................................................................................................................................................................................13

Side Tab Keys in Unit Setup ....................................................................................................................................... 13

Setup Option Information............................................................................................................................................ 14

Drop Down Menu Selections ...................................................................................................................................... 14

Keyboard Entry Screen .............................................................................................................................................. 15

Unavailable Options When Job is Activate .................................................................................................................. 15

Light or Dark Console Screen ..................................................................................................................................... 15

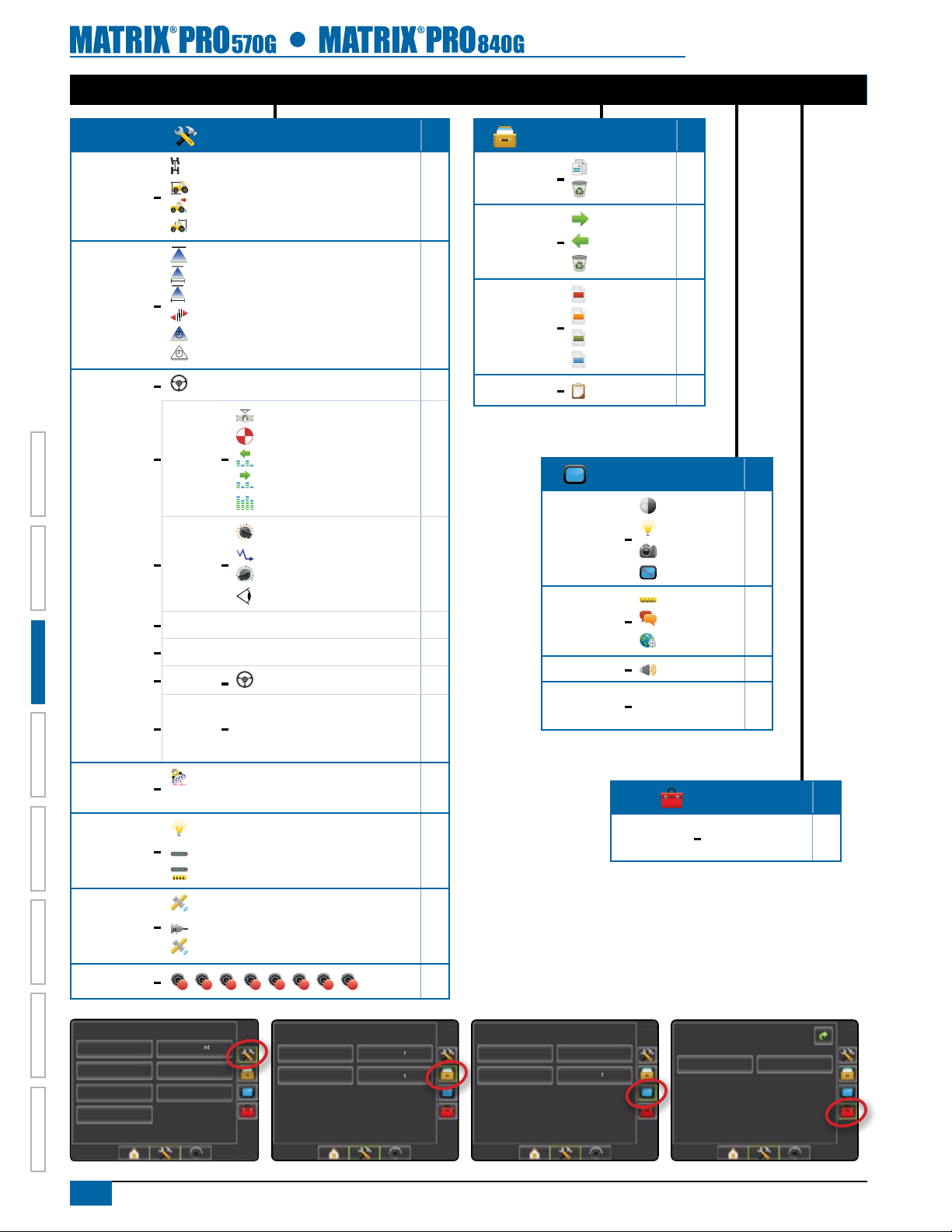

Unit Setup Mode Menu Structure ..............................................................................................................................................................16

Guidance ..............................................................................................................................................................................................................17

Side Tab Keys in Guidance ......................................................................................................................................... 17

Guidance Bar Selectable Information ......................................................................................................................... 18

Status/Information Screens ........................................................................................................................................ 18

Required- Setup Options ...............................................................................................................................................................................19

Cultural Setup ............................................................................................................................................................ 19

GPS ........................................................................................................................................................................... 19

Implement Setup ........................................................................................................................................................ 20

Vehicle Setup ............................................................................................................................................................. 21

AutoSteer Setup ......................................................................................................................................................... 21

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

98-05238 R1 EN-US

i

Page 3

CHAPTER 4 JOBS / HOME SCREEN 22

SIMPLE MODE 23

New Job ...............................................................................................................................................................................................................23

Continue Job ......................................................................................................................................................................................................24

Close Job ..............................................................................................................................................................................................................25

ADVANCED MODE 26

New Job ...............................................................................................................................................................................................................26

Start Job ...............................................................................................................................................................................................................27

Close Job ..............................................................................................................................................................................................................28

CHAPTER 5 FULL SCREEN VIDEO VIEW 29

RealView Full Screen Video View .................................................................................................................................................................29

VSM Not Installed ..............................................................................................................................................................30

Inactive Camera Port .........................................................................................................................................................30

Single Camera Selection .....................................................................................................................................................................30

Split Camera View ..................................................................................................................................................................................31

CHAPTER 6 SYSTEM SETUP 32

OVERVIEW 32

Unit Setup Mode Menu Structure ..............................................................................................................................................................33

Setup Option Information ...................................................................................................................................................34

Drop Down Menu Selections .............................................................................................................................................34

Keyboard Entry Screen ......................................................................................................................................................34

Unavailable Options When Job is Active ...........................................................................................................................34

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

CONFIGURATION 35

Vehicle Setup .....................................................................................................................................................................................................35

Vehicle Type ....................................................................................................................................................... 36

Antenna Height ................................................................................................................................................... 36

Direction to Boom ............................................................................................................................................... 36

Distance to Boom ............................................................................................................................................... 36

Implement - Single Boom Setup .................................................................................................................................................................37

Guidance Width ................................................................................................................................................... 37

Spray Width ......................................................................................................................................................... 37

Implement - SmartCable or SDM ................................................................................................................................................................38

#

Number of Boom Sections .................................................................................................................................. 39

Guidance Width ................................................................................................................................................... 39

Spray Width ......................................................................................................................................................... 39

Overlap ............................................................................................................................................................... 40

Delay On ............................................................................................................................................................. 40

Delay Off ............................................................................................................................................................ 40

AutoSteer .............................................................................................................................................................................................................41

Assisted/Auto Steering Unavailable ...................................................................................................................................41

Enable/Disable Assisted/Auto Steering ............................................................................................................... 42

Valve Setup ................................................................................................................................................................ 42

ii

www.teejet.com

Page 4

Valve Type ..................................................................................................................................................................42

Valve Frequency .........................................................................................................................................................43

Minimum/Maximum Duty Cycle Tests ................................................................................................................................43

Steering Settings ........................................................................................................................................................ 46

Coarse Steering Adjustment ...................................................................................................................................... 46

Fine Steering Adjustment ........................................................................................................................................... 46

Deadband ....................................................................................................................................................................47

Lookahead ..................................................................................................................................................................47

Valve Test .................................................................................................................................................................. 47

Valve Diagnostics ....................................................................................................................................................... 48

Steering Valve – No Master Solenoid ................................................................................................................................49

Steering Valve – With Master Solenoid ..............................................................................................................................49

Options: Steering Wheel Sensor ................................................................................................................................. 50

Angle Sensor ............................................................................................................................................................. 50

Enable/Disable Angle Sensor ...........................................................................................................................................51

Calibrate Sensor ...............................................................................................................................................................51

Offset Adjustment ..............................................................................................................................................................52

Tilt ...........................................................................................................................................................................................................................53

Tilt Correction Unavailable .................................................................................................................................................53

Enable/Disable Tilt .............................................................................................................................................. 53

Field Level ................................................................................................................................................................. 54

LED Brightness................................................................................................................................................... 55

Display Mode ..................................................................................................................................................... 56

LED Spacing ...................................................................................................................................................... 56

GPS .........................................................................................................................................................................................................................57

GPS Type ........................................................................................................................................................... 57

GPS Port ............................................................................................................................................................ 57

External Receiver Minimum Conguration Requirements .................................................................................................58

GPS Status......................................................................................................................................................... 58

GGA Requirements ............................................................................................................................................................58

Video .....................................................................................................................................................................................................................59

Video Setup Unavailable ....................................................................................................................................................59

RealView Camera Full Screen Video View ........................................................................................................................59

Single Camera - Matrix Pro 570G ......................................................................................................................................60

Single Camera - Matrix Pro 840G ......................................................................................................................................60

Four Channel VSM ............................................................................................................................................................60

Eight Channel VSM............................................................................................................................................................60

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

DATA MANAGEMENT 61

Manage Data ......................................................................................................................................................................................................61

Manage Data Unavailable..................................................................................................................................................62

Duplicate Job Data ..................................................................................................................................................... 62

Delete Job Data ......................................................................................................................................................... 63

Transfer .................................................................................................................................................................................................................63

Transfer Unavailable ..........................................................................................................................................................64

USB Storage .............................................................................................................................................................. 64

Internal Storage ......................................................................................................................................................... 65

Delete Job Data ......................................................................................................................................................... 65

98-05238 R1 EN-US

iii

Page 5

Reports .................................................................................................................................................................................................................66

Simple Job Mode Options .......................................................................................................................................... 67

Advanced Job Mode Options ...................................................................................................................................... 67

More Information on File Formats ............................................................................................................................... 68

PDF

PDF Report .................................................................................................................................................................68

KML

KML Data ....................................................................................................................................................................68

SHP

ESRI Data ...................................................................................................................................................................68

Options .................................................................................................................................................................................................................69

CONSOLE 70

Display ..................................................................................................................................................................................................................70

Color Scheme ..................................................................................................................................................... 71

Brightness .......................................................................................................................................................... 71

Screenshot ......................................................................................................................................................... 71

Capture a Screenshot ........................................................................................................................................................72

Touch Screen Calibration .................................................................................................................................... 72

Cultural .................................................................................................................................................................................................................73

Units ................................................................................................................................................................... 73

Language ........................................................................................................................................................... 73

Time Zone ............................................................................................................................................................ 74

Sound ....................................................................................................................................................................................................................74

About ....................................................................................................................................................................................................................74

TOOLS 75

Calculator.............................................................................................................................................................................................................76

Units Converter .................................................................................................................................................................................................76

Set Units ............................................................................................................................................................................77

Select Value .......................................................................................................................................................................77

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

CHAPTER 7 GUIDANCE 78

Navigation Screens Icons ...............................................................................................................................................................................79

GUIDANCE BAR 80

Selectable Job Information ......................................................................................................................................... 80

Navigation Activity & Boom Status .............................................................................................................................. 80

STATUS BAR 81

Status/Information Screens ..........................................................................................................................................................................82

NAVIGATION SCREENS 84

Vehicle View .............................................................................................................................................................................................85

Field View ..................................................................................................................................................................................................86

RealView Guidance................................................................................................................................................................................87

GUIDANCE MODES 88

Straight AB Guidance ..................................................................................................................................................................88

iv

www.teejet.com

Page 6

Curved AB Guidance ...................................................................................................................................................................89

Circle Pivot Guidance ..................................................................................................................................................................90

Last Pass Guidance .......................................................................................................................................................................91

NextRow Guidance ......................................................................................................................................................................92

No Guidance ............................................................................................................................................................................................93

GUIDELINES 94

Curved Lookahead Guideline ............................................................................................................................................................94

Straight AB Guidelines .........................................................................................................................................................................94

Marking A and B Points ...................................................................................................................................................... 94

A+ Nudge Feature .............................................................................................................................................................95

Next Straight AB Guideline Feature ...................................................................................................................................96

A

Azimuth Degree ................................................................................................................................................... 96

Curved AB Guidelines ..........................................................................................................................................................................97

Marking A and B Points ...................................................................................................................................................... 97

A+ Nudge Feature .............................................................................................................................................................98

Next Curved Guideline Feature .........................................................................................................................................99

Circle Pivot Guidelines .........................................................................................................................................................................99

Marking A and B Points .............................................................................................................................................. 99

A+ Nudge Feature ...........................................................................................................................................................100

Next Guideline Feature ....................................................................................................................................................101

Last Pass Guidelines ........................................................................................................................................................................... 101

NextRow Guidelines .......................................................................................................................................................................... 102

APPLICATION BOUNDARY 103

RETURN TO POINT 105

Marking a Return Point ....................................................................................................................................................105

Guidance to a Return Point..............................................................................................................................................105

BOOMPILOT 106

SmartCable or SDM ....................................................................................................................................................................................... 106

Off/Manual & Automatic ............................................................................................................................................ 106

All Sections On Mode ............................................................................................................................................... 106

Single Section ................................................................................................................................................................................................. 107

ZOOM IN/OUT 107

Vehicle View ..................................................................................................................................................................................................... 107

Field View ..........................................................................................................................................................................................................108

PAN MODE 109

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

REALVIEW SPECIFIC OPTIONS 109

98-05238 R1 EN-US

v

Page 7

VSM Not Installed ............................................................................................................................................................ 110

Inactive Camera Port ....................................................................................................................................................... 110

Single Camera Selection .................................................................................................................................................................. 110

Split Camera View ............................................................................................................................................................................... 111

RealView Setup Options ................................................................................................................................................................... 111

Guidance Over Video .........................................................................................................................................112

Guidance Unavailable ...................................................................................................................................................... 11 2

Horizon Line Adjustment .................................................................................................................................. 112

Steering Angle Indicator ..................................................................................................................................... 113

Guidance Unavailable ...................................................................................................................................................... 11 3

APPENDIX A TIME ZONES 114

APPENDIX B FACTORY SETTINGS & RANGES 116

APPENDIX C UNIT SPECIFICATIONS 119

Copyrights

© 2012 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced,

copied, photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without

prior written consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or

organizations.

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY

LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH

DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

Safety Information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety

requirements.

As the operator of the vehicle, you are responsible for its safe operation.

The Matrix Pro in combination with any assisted/auto steering device is not designed to replace the vehicle’s operator.

Do not leave a vehicle while the Matrix Pro is engaged.

Be sure that the area around the vehicle is clear of people and obstacles before and during engagement.

The Matrix Pro is designed to support and improve efciency while working in the eld. The driver has full responsibility for the quality and

work related results.

Disengage or remove any assisted/auto steering device before operating on public roads.

vi

www.teejet.com

Page 8

CHAPTER 1 SYSTEM OVERVIEW

The Matrix Pro allows the management of multiple connected modules plus GPS mapping, Guidance, Assisted/Auto Steering, BoomPilot®,

and data collection in a single console using CAN bus technology. This replaces multiple consoles in the cab with one robust system.

SYSTEM FEATURES

• RealView™ Guidance Over Video Guidance information and video displayed simultaneously with up to eight (8) cameras connections

• Easy-to-use, color 3-D graphical guidance that is precise and accurate in all terrain

• Lightbar guidance for vehicle or swath, plus a graphical display for complete guidance information

• Coverage mapping/data export in PDF, KML or SHP

• Enhanced data organization with Fieldware® Link application – Input job details such as names or images

• Reuse guidelines and/or boundaries

• Bright, daylight readable screen in either 5.7″ / 14.5 cm or 8.4″ / 21.3 cm size

• Product upgrades include:

– FieldPilot® (auto steering) can perform on straight or contour paths

– UniPilot® (assisted steering) can perform on straight or contour paths

– BoomPilot® (automated boom section control) can switch off sprayer or spreader sections automatically reducing overlaps and

eliminating skips

– Tilt Gyro Module

– Video Selection Modules for up to 8 cameras

– External GPS receiver or antenna upgrades

• Handles up to 15 individual boom sections with a separate entry for guidance width

• Guidance in ve modes – Straight AB, Curved AB, Circle Pivot, NextRow and Last Pass

• Additional guidance with Azimuth Degree guidance and Curved Lookahead guidance

• Exterior boundary and up to ve (5) interior boundaries

• Save up to 25 guidelines in a single job

• Create multiple jobs and access them easily with Field Finder

• On screen tools – Calculator and Units Converter

• More than 20 localized languages for international use

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

• Simplied operation of product control and GPS record keeping

• High-quality internal GPS engine with small external antenna

98-05238 R1 EN-US

1

Page 9

SYSTEM COMPONENTS

Matrix Pro 570G Console

The Matrix Pro 570G is designed to provide years of service under typical agricultural operating conditions. A tight tting enclosure, combined

with rubber covers for all connectors mean that typical dusty environments will not cause operational problems. While occasional splashing of

water will not damage the unit, the Matrix Pro 570G is not designed for direct exposure to rain. Take care not to operate the Matrix Pro in wet

conditions.

Figure 1-1: Matrix Pro 570G Console Front and Back

Built In Lightbar

Power Button

USB Port with Rubber Cover

Bright Touch Screen

Standard RAM Bracket

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

Speaker

Power Button

Integrated RAM Mount

USB Port with Rubber Cover

Recessed Connectors

Additional Information

All changes are saved automatically.

The console needs to be cycled off and back on when changing

or attaching equipment to the Matrix Pro system.

Cleaning suggestions – Matrix consoles should be cleaned with

mild cleaners, such as glass cleaner, and a soft cloth. Take care

not to rub dust or other abrasive materials into the touch screen

surface.

• Use a soft lint-free cloth.

• The cloth may be used dry, or lightly dampened with a mild

cleaner or Ethanol.

• Be sure the cloth is only lightly dampened, not wet. Never

apply cleaner directly to touch panel surface; if cleaner

is spilled onto touch panel, soak it up immediately with

absorbent cloth.

GPS Antenna Connection

Rubber Connector Covers

Speed Signal Connection

Camera Connection

Power Connection

• Cleaner must be neither acid nor alkali (neutral pH).

• Wipe the surface gently; if there is a directional surface

texture, wipe in the same direction as the texture.

• Never use acidic or alkaline cleaners, or organic chemicals

such as: paint thinner, acetone, tolulene, xylene, propyl or

isopropyl alchohol, or kerosene.

• Suitable cleaning products are commercially available prepackaged for use; one example of such a product is Klear

Screen™, or commercially available off-the-shelf retail

brands such as Glass Plus® Glass and Surface Cleaner

made by Reckitt-Benckiser.

• Use of incorrect cleaners can result in optical impairment

of touch panel and/or damage to functionality.

2

www.teejet.com

Page 10

Matrix Pro 840G Console

The Matrix Pro 840G is designed to provide years of service under typical agricultural operating conditions. A tight tting enclosure, combined

with rubber covers for all connectors mean that typical dusty environments will not cause operational problems. While occasional splashing of

water will not damage the unit, the Matrix Pro 840G is not designed for direct exposure to rain. Take care not to operate the Matrix Pro in wet

conditions.

Figure 1-2: Matrix Pro 840G Console Front and Back

Built In Lightbar

Power Button

Home Button

USB Port

with Rubber Cover

Bright Touch Screen

Standard RAM Bracket

Zoom In/Out Buttons

Speaker

Integrated RAM Mount

Rubber Connector

Covers

Speed Signal Connection

Camera Connection

Power Connection

GPS Antenna

Connection

RealView Camera

The TeeJet Technologies RealView camera allows video images to be displayed on the Matrix Pro screen. The camera can be pointed

forward to enable RealView guidance over video, or it can be positioned to view other operational aspects of your equipment. The camera

is equipped with a exible RAM mount, integral sun shade and provides infrared illumination, allowing clear video images even in dark

conditions.

Figure 1-3: RealView Camera

Sun Shade

Video Camera

Nighttime Illumination

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

Mounting Bracket

Matrix Pro console connection is compatible with AgCam cameras.

98-05238 R1 EN-US

3

Page 11

Optional Accessories

Fieldware Link

Catalog clients, farms, elds and jobs with Fieldware Link to take

full advantage of the Matrix Pro console. Duplicate and edit jobs

for reuse of boundaries and guidelines. Download this Matrix Pro

software for free at www.teejet.com.

Video Selector Modules

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

A Video Selector Module (VSM) allows connection of up to 8 video

cameras to your Matrix console. The module is compact and robust,

and can be mounted in any convenient location. No interaction is

required after installation.

Steering Control Module

The Steering Control Module

performs assisted/auto steering

on straight and contour paths.

The Matrix Pro system can link

with the FieldPilot or UniPilot

system to take precise control of

the vehicle position. The operator

manages the assisted/automatic steering

system with the Matrix Pro – a benet of a

single, in-cab console.

FieldPilot

FieldPilot automatic steering drives a vehicle with tremendous,

repeatable accuracy in both straight and curved patterns by tapping

directly into the vehicles hydraulic steering system. The ability to

operate in fog or dust, day or night with high levels of accuracy

means a better return on capital investment for equipment, a more

effective application and more attentive, alert operation.

UniPilot

UniPilot assisted steering drives a vehicle

with tremendous, repeatable accuracy

in both straight and curved patterns by

controlling the steering wheel. The ability

to operate in fog or dust, day or night with

high levels of accuracy means a better

return on capital investment for equipment,

a more effective application and more

attentive, alert operation.

Articulated Gyro Module

Combined with the Steering Control Module,

the Articulated Gyro Module makes

assiste/auto steering on an articulated

tractor even better.

Foot Switch

TeeJet Foot Switch is a convenient

method of engaging assisted/auto

steering. It is connected to the system

via the SCM Harness.

4

www.teejet.com

Page 12

Section Driver Module

Combined with software

built into the Matrix Pro

console, the Section Driver

Module (SDM) makes

BoomPilot (automatic boom

section control) possible. The SDM

should be combined with the appropriate cable

to interface with your BoomPilot system, spray controller

and/or spraying machine for quick and easy installation. Section

Driver Modules and their related cables are designed to control

as many boom sections as the spray controller to which they are

connected, up to a maximum of 15 boom sections.

GPS Antennas

TeeJet offers a full range of high-quality GPS receivers to t your

precision farming needs.

RXA-30 GPS antenna provides a higher quality GPS receiver

that can improve GPS performance in areas of sub-optimal GPS

reception.

Tilt Gyro Module

If your GPS antenna is mounted 12 feet /

3.6 meters above the ground, a

10% side slope can cause 2 feet /

0.6 meter of position error. The

TeeJet Tilt Gyro (Compensation)

Module corrects GPS position

errors caused by side slope

conditions. Mounted on a solid

structure on your vehicle, the Tilt

Gyro (Compensation) Module sends tilt corrections to complement

GPS signals from your receiver and provide corrected position data

to your guidance device.

• Diagnostic LEDs indicate status of TGM

• Weatherproof electrical connector for trouble-free operation

• Mounting holes built into housing

• Compatible with Matrix guidance systems

NOTE: If using FieldPilot or UniPilot, a TGM is already built into the

system.

The Patch Antenna provides strong performance in standard

operating conditions. The small size of the patch antenna makes it

easy to mount and unlikely to be damaged.

Figure 1-4: GPS RXA-30 Antenna

Figure 1-5: GPS Patch Antenna II

Harnesses

TeeJet Technologies harnesses are

designed for reliable operation in

harsh environments. Shielding and

weatherproof connections ensure that

the cables and electrical connections

are reliable and trouble free.

Cable Extensions

Cable extensions, or extended length

cables, are available for special applications. Contact your TeeJet

dealer for details if the standard cables provided with your system

are not long enough.

Extended Warranty

TeeJet Technologies offers an extended warranty for many guidance

products. However, this service is not available in all markets. Please

contact your local TeeJet Technologies dealer for details.

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

98-05238 R1 EN-US

5

Page 13

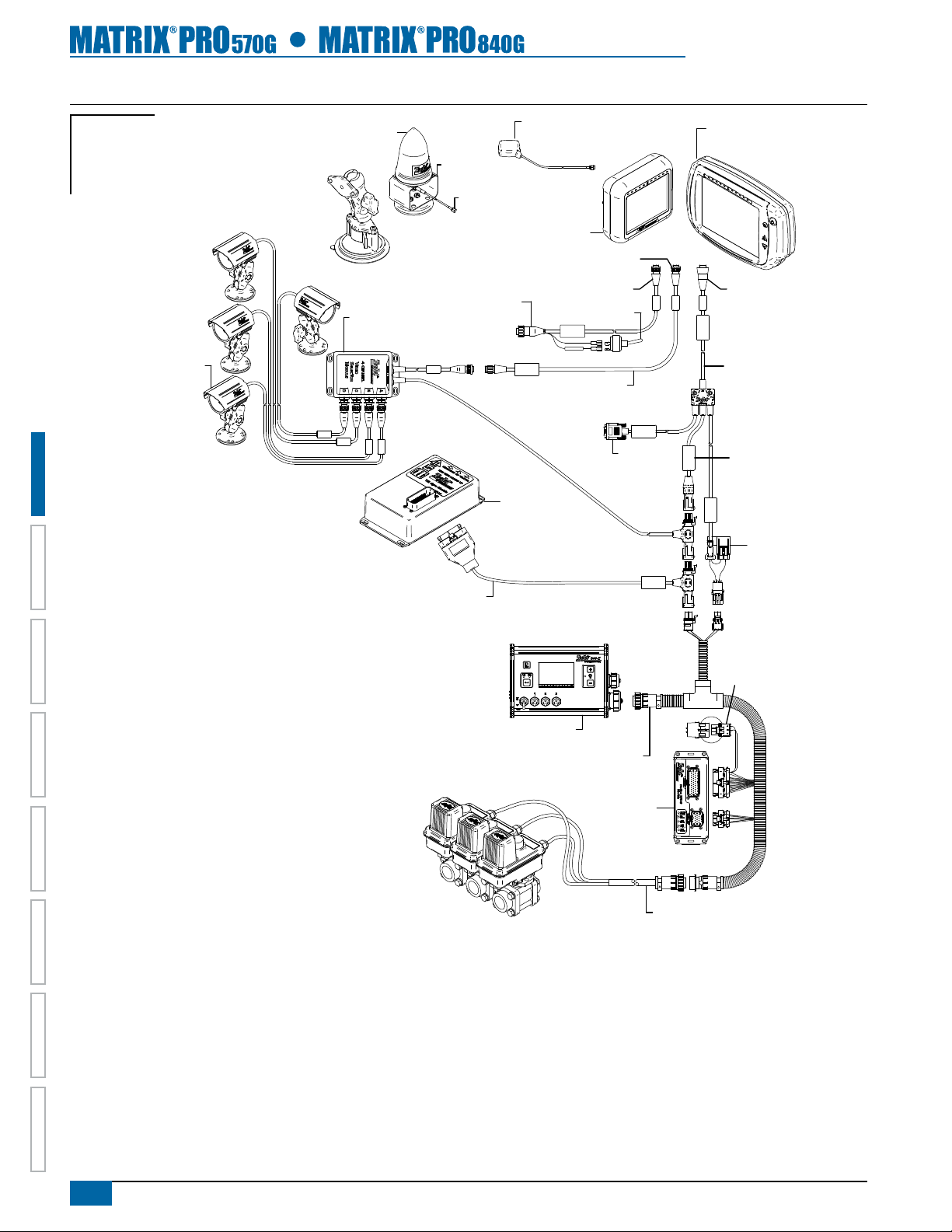

CONFIGURATIONS

Matrix Pro 840G

45-05765

The following diagrams are reective of typical Matrix Pro congurations. Due to the variety of possible congurations, these should be used

for reference purposes only.

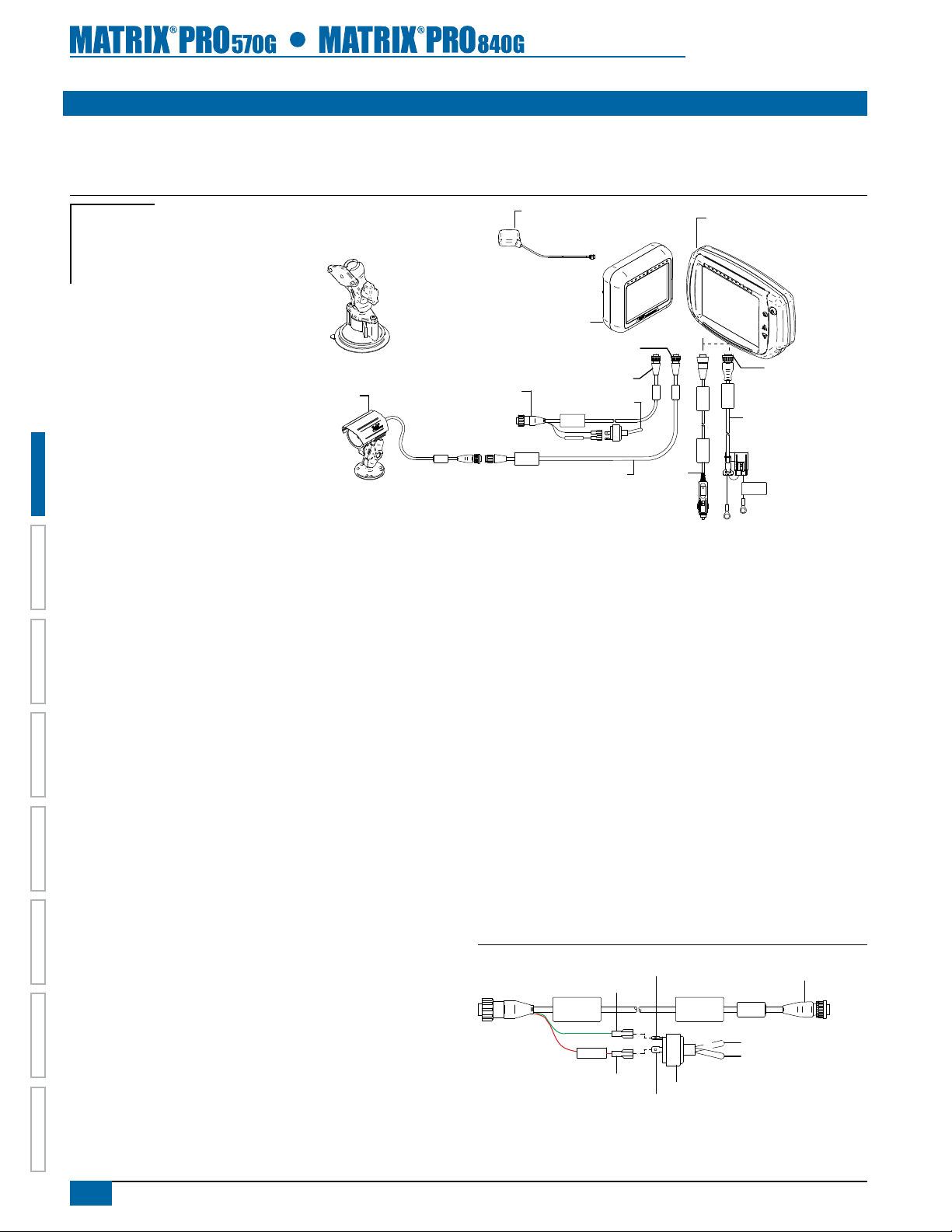

Figure 1-6: Matrix Pro w/RealView Camera

Matrix

FieldPilot

BoomPilot

Optional Accessory

Kit, RAM Mount w/Suction Cup

90-02349 (Matrix 570G)

90-02700 (Matrix 840G)

16-00022: RealView Camera

Speed/Sense Cable

45-05765

GPS Antenna

78-50155

78-50190 w/GLONASS

Matrix Pro 570G

75-30082

75-30083 w/GLONASS

32-50008 Switch

Speed Cable

+12V

Camera

45-05617: 20'/6m

45-05618: 60'/18m

Camera Extension Cable

5 Pos.

8 Pos.

45-05645

Power

Cable, 12V

75-30084

75-30090 w/GLONASS

8 Pos.

POWER CABLE

DC: XXXX

45-05775

Power C able

45-05775

10'/3m Power

Conn e ct to

+12v On ly

Cable, Battery

CAUTION CONN.

TO +12V ONLY

Speed Out / Sense In Cable

The Speed Out / Sense In Cable assists the Matrix Pro with two

additional connections that:

►Send a radar speed signal to an external device

►Allow the user to operate the area applied function of the Matrix

Pro in series with a remote master connection or existing apply

on/off toggle in a single swath manner. However, if the previous

connections are not available, the supplied toggle switch will allow

area applied functionality without the need to connect to a functional

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

application implement.

Connecting to different consoles requires different adapters and

calibrations.

• If connecting to TeeJet consoles, please use speed adapter

45-20042

◄enter calibration # 914 (#1000 in Europe) for 8xx series in

RAD mode

◄enter calibration # 9140 (#10000 in Europe) for below LH 70

Series, LH 85, 500 series, 5000, 6000, IC 18, IC 24 and IC 34

• If connecting to Mid-Tech consoles no adapter is required

◄enter calibration # 1000

• If connecting to Raven consoles use speed adapter 45-05508

(do not connect the 12v red wire from 45-05508)

◄enter calibration # 800

Speed Out / Sense In Cable Is Required To Start

Application Mapping.

The Speed Out / Sense In Cable allows the user to operate the area

applied function of the Matrix Pro in series with a remote master

connection or existing apply on/off toggle in a single swath manner.

However, if the previous connections are not available, the supplied

toggle switch will allow area applied functionality without the need to

connect to a functional application implement.

The cable also sends a radar speed signal to an external device.

To install your cable:

• Connect using included switch (32-50008)

OR

• Connect green wire to master 12 Volts on/off from rate controller,

foot switch or implement status switch

If sensing boom shut-off for applied mapping from an existing

console, attach the green wire to the valve side of the master switch

on the console. The red wire is not used.

Figure 1-7: Speed Out / Sense In cable

Connect Green Wire

Green Wire Sense

Speed/

Status

Radar

Speed

Out

+12v

Red Wire (+12v)

Connect Red Wire

Speed Cable

45-05615

32-50008 Switch, Master

Speed/Sense Cable

ON

OFF

6

www.teejet.com

Page 14

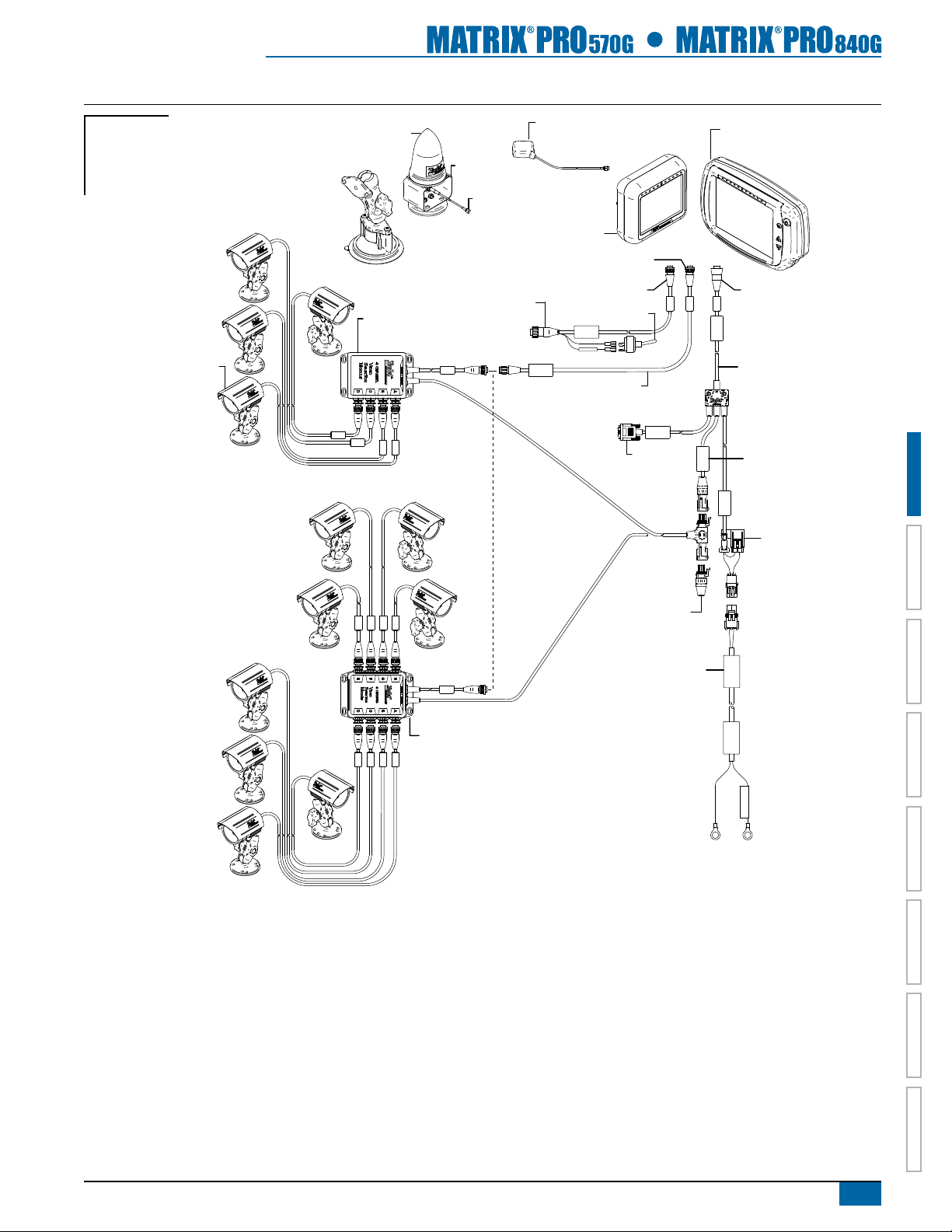

Figure 1-8: Matrix Pro w/8 Channel or 4 Channel VSM & Multiple RealView Cameras

Matrix Pro 840G

Matrix

FieldPilot

BoomPilot

Optional Accessory

Optional RXA-30

Kit, RAM Mount w/Suction Cup

90-02349 (Matrix 570G)

90-02700 (Matrix 840G)

78-50187

GPS Antenna

65-05226

Kit, Bracket

RXA-30 Antenna

45-05786: 20'/6m

45-05787: 30'/9m

Antenna Cable

GPS Antenna

78-50155

78-50190 w/GLONASS

Matrix Pro 570G

75-30083 w/GLONASS

75-30082

75-30084

75-30090 w/GLONASS

5 Pos.

16-00022

RealView Camera

78-08067

Module, 4 Channel

Video CAN

78-08068

Video Selector

Module,

8 Channel Video CAN

Speed/Sense Cable

45-05765

8 Pos.

32-50008 Switch

Speed Cable

+12V

Camera

45-05617: 20'/6m

45-05618: 60'/18m

Camera Extension Cable

CAN Terminator

RS-232

RS-232

45-08101

401-0016

Battery Adapter

Power/DATA

45-05626

CAN

POWER IN

DC: xx/xx

8 Pos.

45-05626

Power/CAN/Data

Cable

(included with

FieldPilot and

BoomPilot kits)

TJ CAN

(Terminated)

10A Fuse

Power Cable

401-0016

WARNING CONNECT

DIRECTLY TO BAT.

CAUTION: CONNECT

TO 12V ONLY

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

98-05238 R1 EN-US

7

Page 15

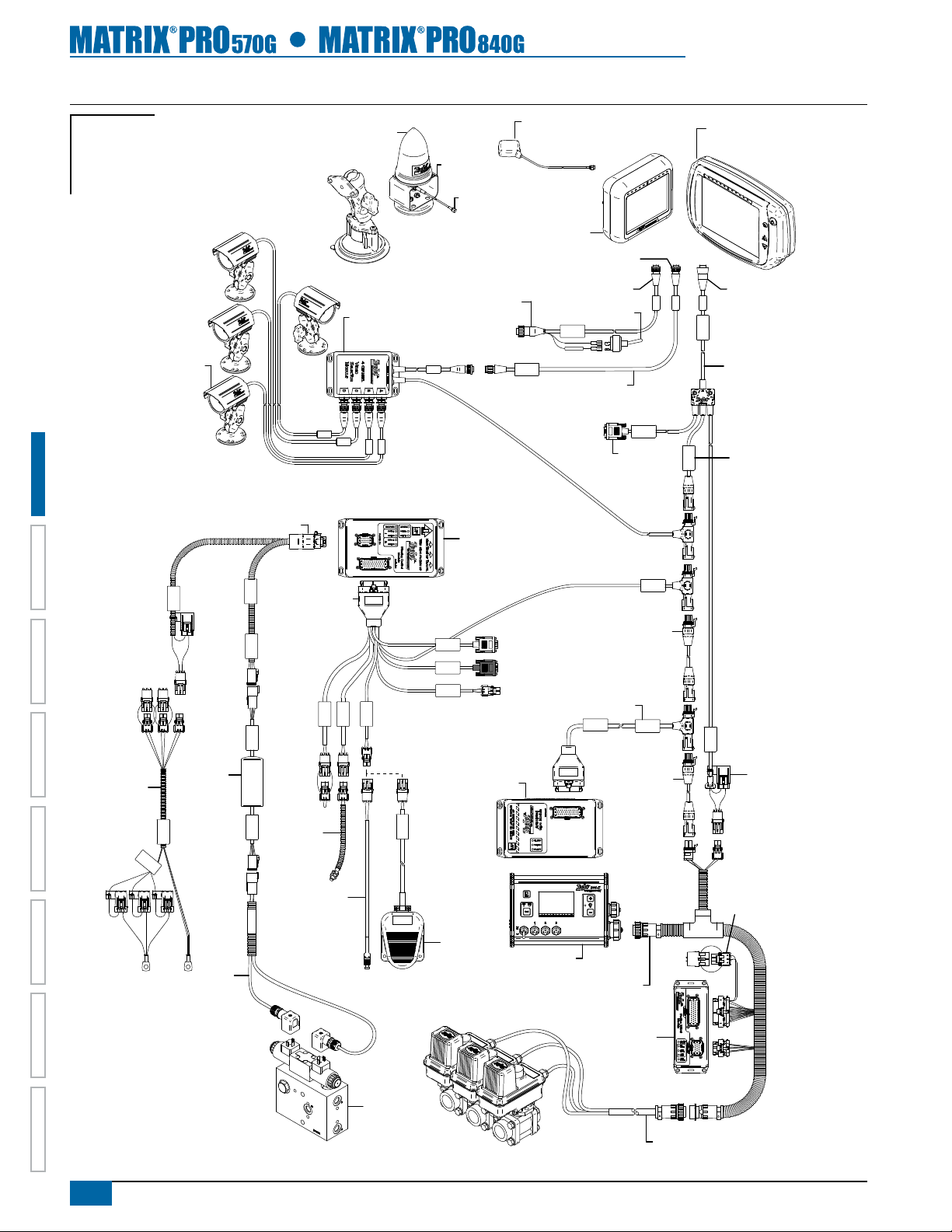

Figure 1-9: Matrix Pro w/VSM & Multiple RealView Cameras, FieldPilot and BoomPilot

Console Harness

Matrix Pro 840G

Matrix

FieldPilot

BoomPilot

Optional Accessory

Optional RXA-30

Kit, RAM Mount w/Suction Cup

90-02349 (Matrix 570G)

90-02700 (Matrix 840G)

78-50187

GPS Antenna

65-05226

Kit, Bracket

RXA-30 Antenna

45-05786: 20'/6m

45-05787: 30'/9m

Antenna Cable

GPS Antenna

78-50155

78-50190 w/GLONASS

Matrix Pro 570G

75-30083 w/GLONASS

75-30082

75-30084

75-30090 w/GLONASS

5 Pos.

RealView Camera

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

45-05381

Battery

12'/3.66m

w/15Amp

Fuses

C

(

Articulated Gyro Module

(AGM) components are

only required for articulated tractors.

16-00022

45-07703 SCM Power In/Out

Power

78-08072

Voltage

Regulator

DC: xx/x x

45-0 5381

o

n

n

e

ct

+

1

o

2

t

v)

o

45-10103

Harness

Steering

(A+B)

SCM Power I/O

45-07703

DC: xx/xx

Valve Output

FieldPilot Interface

78-08072

DC: xx/xx

Steering Valve

45-10103

DC: xx/xx

45-07708

SCM Harness

Seat Sensor

91-07011

Steering

Wheel

Switch

Kit

32-04040

Remote

Engage/

Disengage

Switch

78-08067

Module, 4 Channel

Video CAN

Wheel Sense

Engage/Disengage

Steering

Remote

Steering

Valve

Speed/Sense Cable

SCM COM 2

GPS In

COM 1

GPS Power

32-04020

DC: xx/xx

Engage / Disengage

32-04020

Optional

Footswitch

Valves

45-05765

78-08075

Steering Control

Module (SCM)

78-08076

Articulated

Gyro Module

(AGM)

Rate Controller

dependent on Rate Controller

8 Pos.

32-50008 Switch

Speed Cable

+12V

Camera

45-05617: 20'/6m

45-05618: 60'/18m

Camera Extension Cable

45-08117 CAN

Extension Cable 20'/6m

45-07716

Tilt Gyro Module (TGM)

Harness

Tilt Gyro Module

CAN Harness

45-07716

DC: xx/xx

CAN Extension

Cable 20'/6m

BoomPilot Harness

Part number

78-05077

BoomPilot

Section Driver

(15 sections)

RS-232

RS-232

CAN Tee

45-08117

Module

8 Pos.

Power/DATA

45-05626

45-05626

Power/CAN/Data

Cable

(included with

FieldPilot and

BoomPilot kits)

CAN

TJ CAN

(Terminated)

CAN

POWER IN

10A Fuse

Remote ABSC

Status Switch

Connection

8

www.teejet.com

Page 16

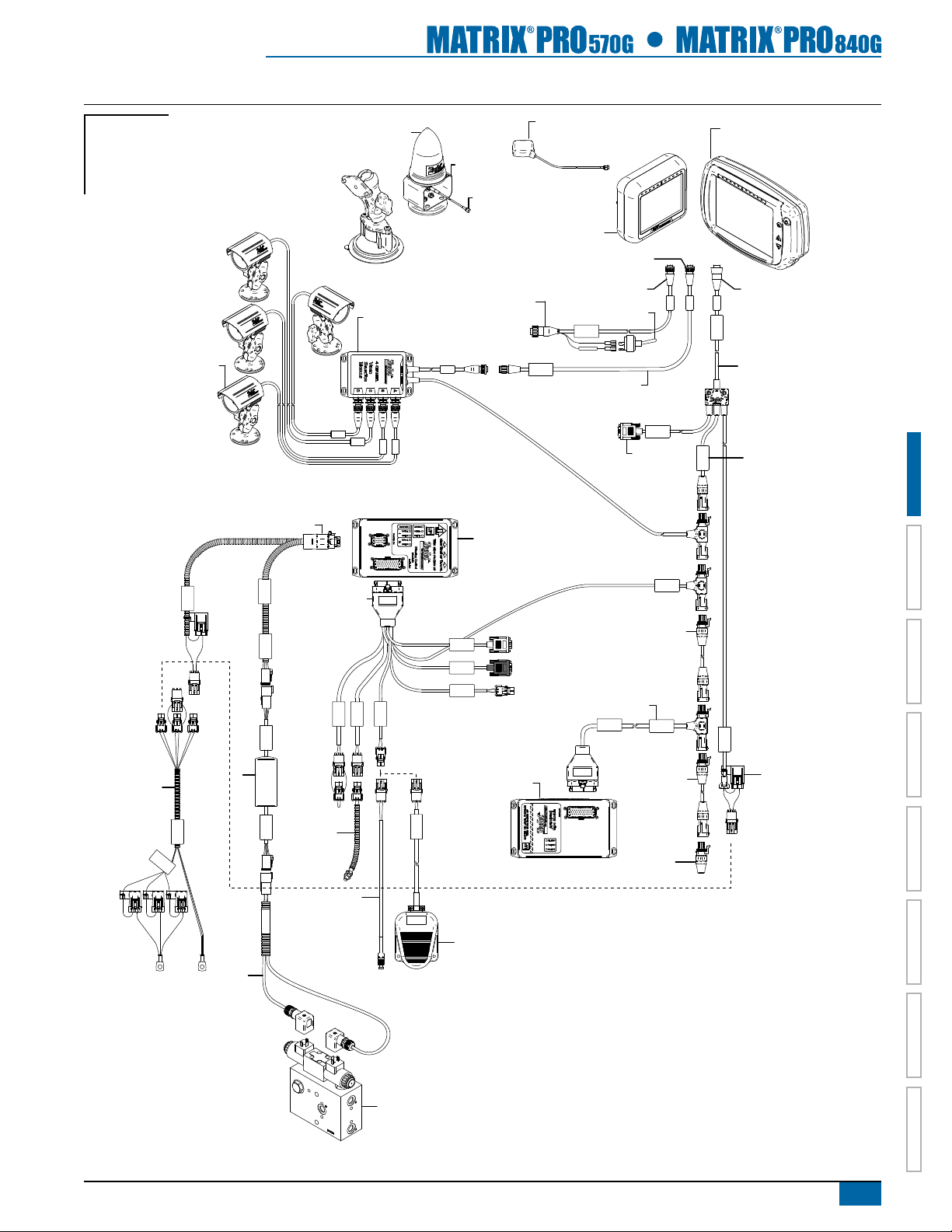

Figure 1-10: Matrix Pro w/VSM & Multiple RealView Cameras and FieldPilot

Matrix Pro 840G

Matrix

FieldPilot

BoomPilot

Optional Accessory

Kit, RAM Mount w/Suction Cup

90-02349 (Matrix 570G)

90-02700 (Matrix 840G)

78-50187

Optional RXA-30

GPS Antenna

65-05226

Kit, Bracket

RXA-30 Antenna

45-05786: 20'/6m

45-05787: 30'/9m

Antenna Cable

75-30083 w/GLONASS

GPS Antenna

78-50155

78-50190 w/GLONASS

Matrix Pro 570G

75-30082

75-30084

75-30090 w/GLONASS

5 Pos.

RealView Camera

45-05381

Battery

12'/3.66m

w/15Amp

Fuses

C

16-00022

45-07703 SCM Power In/Out

Power

78-08072

Voltage

Regulator

DC: xx/x x

45-0 5381

o

n

n

e

(

ct

+

1

o

2

t

v)

o

45-10103

Harness

Steering

(A+B)

SCM Power I/O

45-07703

DC: xx/xx

Valve Output

FieldPilot Interface

78-08072

DC: xx/xx

Steering Valve

45-10103

DC: xx/xx

45-07708

SCM Harness

91-07011

Steering

Wheel

Switch

Kit

32-04040

Remote

Engage/

Disengage

Switch

78-08067

Module, 4 Channel

Video CAN

Wheel Sense

Engage/Disengage

Seat Sensor

Steering

Speed/Sense Cable

45-05765

8 Pos.

32-50008 Switch

Speed Cable

+12V

Camera

45-05617: 20'/6m

45-05618: 60'/18m

Camera Extension Cable

RS-232

RS-232

Power/DATA

45-05626

CAN

8 Pos.

45-05626

Power/CAN/Data

Cable

(included with

FieldPilot and

BoomPilot kits)

TJ CAN

(Terminated)

78-08075

Steering Control

Module (SCM)

CAN

SCM COM 2

GPS In

COM 1

Remote

GPS Power

Tilt Gyro Module (TGM)

45-08117 CAN

Extension Cable 20'/6m

45-07716

Harness

Tilt Gyro Module

CAN Harness

45-07716

DC: xx/xx

CAN Tee

POWER IN

78-08076

Articulated

Gyro Module

(AGM)

45-08117

CAN Extension

10A Fuse

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

Cable 20'/6m

32-04020

DC: xx/xx

Engage / Disengage

45-08101

CAN Terminator

32-04020

Optional

Footswitch

Articulated Gyro Module

(AGM) components are

only required for articulated tractors.

Steering

Valve

98-05238 R1 EN-US

9

Page 17

Figure 1-11: Matrix Pro w/VSM, Tilt Gyro and BoomPilot

Matrix Pro 840G

Matrix

FieldPilot

BoomPilot

78-50187

Optional RXA-30

GPS Antenna

Optional Accessory

Kit, RAM Mount w/Suction Cup

90-02349 (Matrix 570G)

90-02700 (Matrix 840G)

65-05226

Kit, Bracket

RXA-30 Antenna

45-05786: 20'/6m

45-05787: 30'/9m

Antenna Cable

75-30083 w/GLONASS

GPS Antenna

78-50155

78-50190 w/GLONASS

Matrix Pro 570G

75-30082

75-30084

75-30090 w/GLONASS

5 Pos.

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUCTION GUIDANCE

16-00022

RealView Camera

78-08067

Module, 4 Channel

Video CAN

TGM Harness

Speed/Sense Cable

45-05765

78-08057

Tilt Gyro

Module (TGM)

45-07716

Rate Controller

dependent on Rate Controller

8 Pos.

32-50008 Switch

Speed Cable

+12V

Camera

45-05617: 20'/6m

45-05618: 60'/18m

Camera Extension Cable

BoomPilot Harness

Part number

RS-232

RS-232

CAN

Power/DATA

45-05626

CAN

POWER IN

8 Pos.

45-05626

Power/CAN/Data

Cable

(included with

FieldPilot and

BoomPilot kits)

TJ CAN

(Terminated)

10A Fuse

Remote ABSC

Status Switch

Connection

10

www.teejet.com

Valves

78-05077

BoomPilot

Section Driver

Module

(15 sections)

Console Harness

Page 18

CHAPTER 2 POWER

Power On

Press the POWER BUTTON to power on the console.

Upon power up, the Matrix Pro will begin its Start Up Sequence.

Power O

Press and briey hold the POWER BUTTON until a conrmation

screen acknowledges shut down mode.

WARNING! Wait 30 seconds before restarting the console after

powering off.

Figure 2-1: Power Button

Power Button

Start Up Sequence

The console takes approximately 40 seconds to power up. During

this time a series of screen including the TeeJet Technologies logo,

a globe, an hourglass and an information screen will be displayed

(LEDs will power on and off and brightness levels will uctuate.)

Once the power up sequence has completed, the Home screen will

appear.

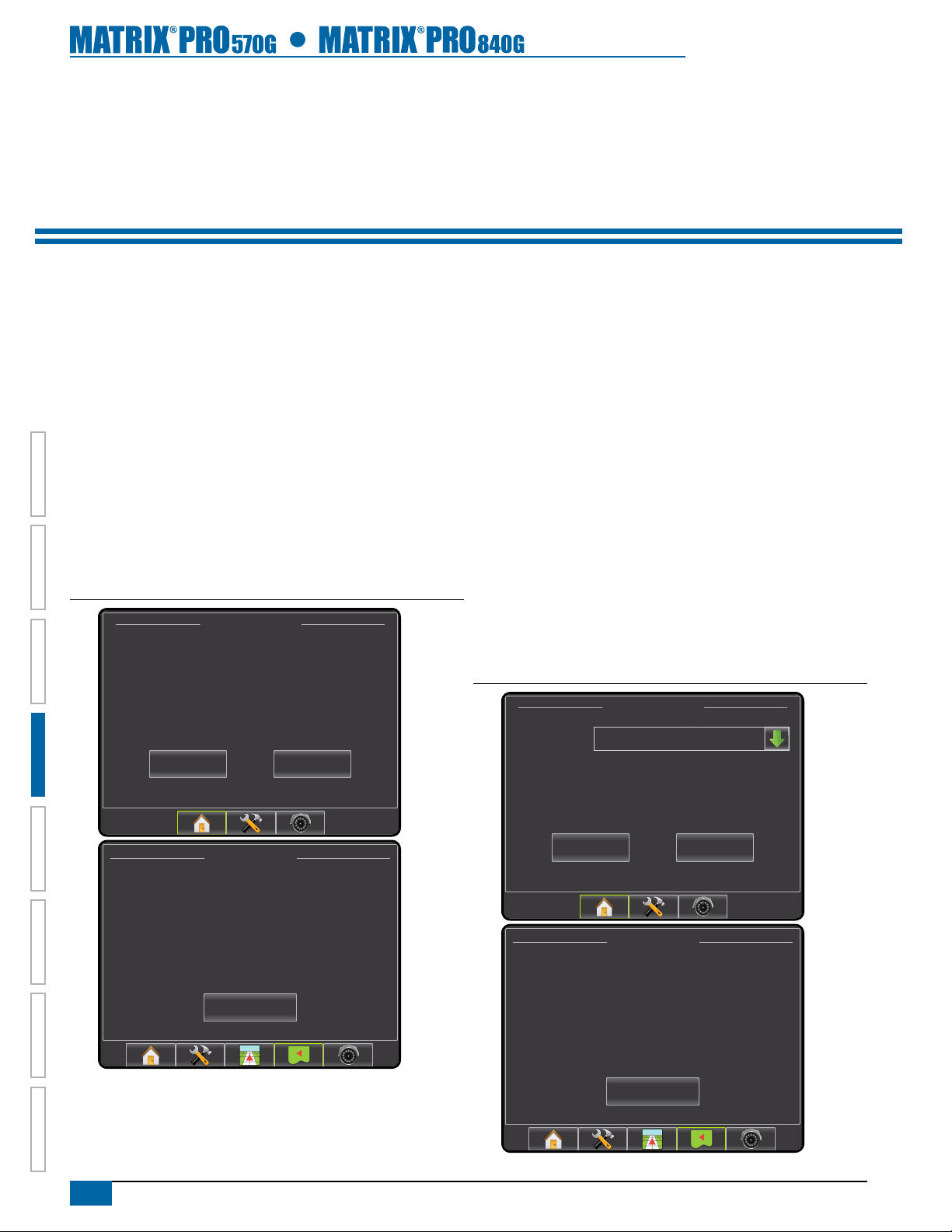

Figure 2-2: Home Screen - Simple Mode

12/14/10 3:52 AM

Do you want to start a new job data or continue last job?

Starting a new job will clear the previous job data.

New Job

Figure 2-3: Home Screen - Advanced Mode

4/4/11 6:38 AM

Continue

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUC TIONGUIDANCE

Fertilize

Power Button

Job

Client: Mr. Nelson

Farm: Townville Station

Field: Nelson Plot #23

New Job

Start Job

98-05238 R1 EN-US

11

Page 19

CHAPTER 3 INTRODUCTION

The Matrix Pro can be used as a simple current job system or advanced multi-job system. Regardless of which mode the console is in, the

basic screen functions are the same.

• Bottom Tab Keys and Side Tab Keys access the various screens and sub-screens

• Warnings and Information Pop-ups inform of console activities and details on setup or guidance functions

• Setup options can easily be set using the drop down menus or keyboard entry screens

To quickly nd a setup feature, see the Unit Setup Mode Menu Structure chart.

For full functionality of the Matrix Pro’s abilities be sure to setup the required setup options.

JOBS HOME SCREEN

Setup for the specic vehicle and its components must be completed before starting a job. Once a job is active, some setup options are not

available to be changed. See the Unit Setup Mode Menu Structure chart in the introduction chapter or setup chapter for details.

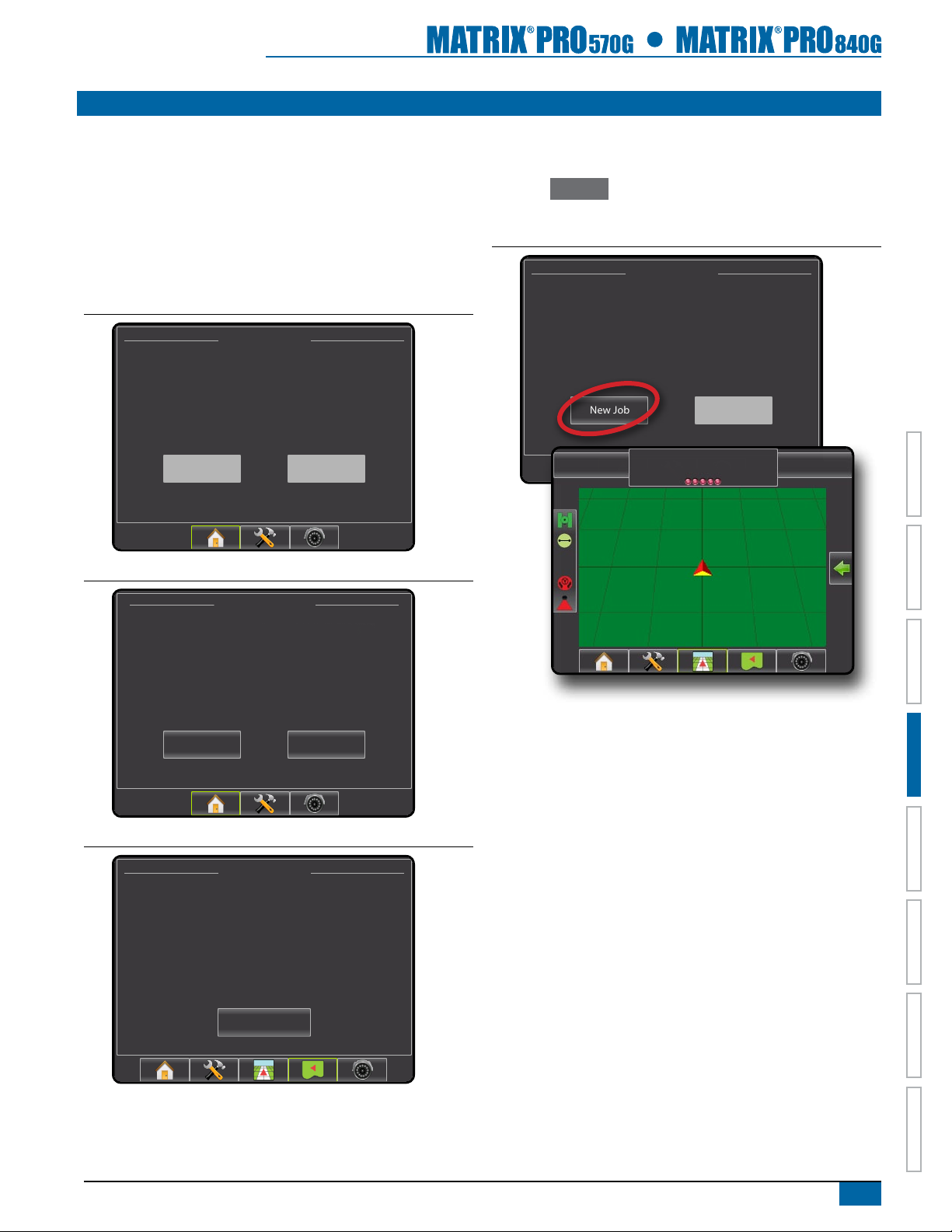

Simple Mode

In simple mode, only one job will be available at a time. Only bounded and applied area are displayed on the home screen. Only the current

job is available for saving in Reports, and use with Fieldware Link is not available.

Advanced Mode

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUC TION GUIDANCE

In advanced mode, more than one job will be available at any time. Client, farm, eld, job, bounded area and applied area are displayed on

the home screen. The Job name is the only information that can be entered using the console. All saved jobs can be saved in Reports. With

Fieldware Link, a user can input client, farm and eld data as well as duplicate/edit jobs for reuse of boundaries and guidelines. Client, Farm

and Field information can only be inputted using Fieldware Link.

BASIC SCREEN USE

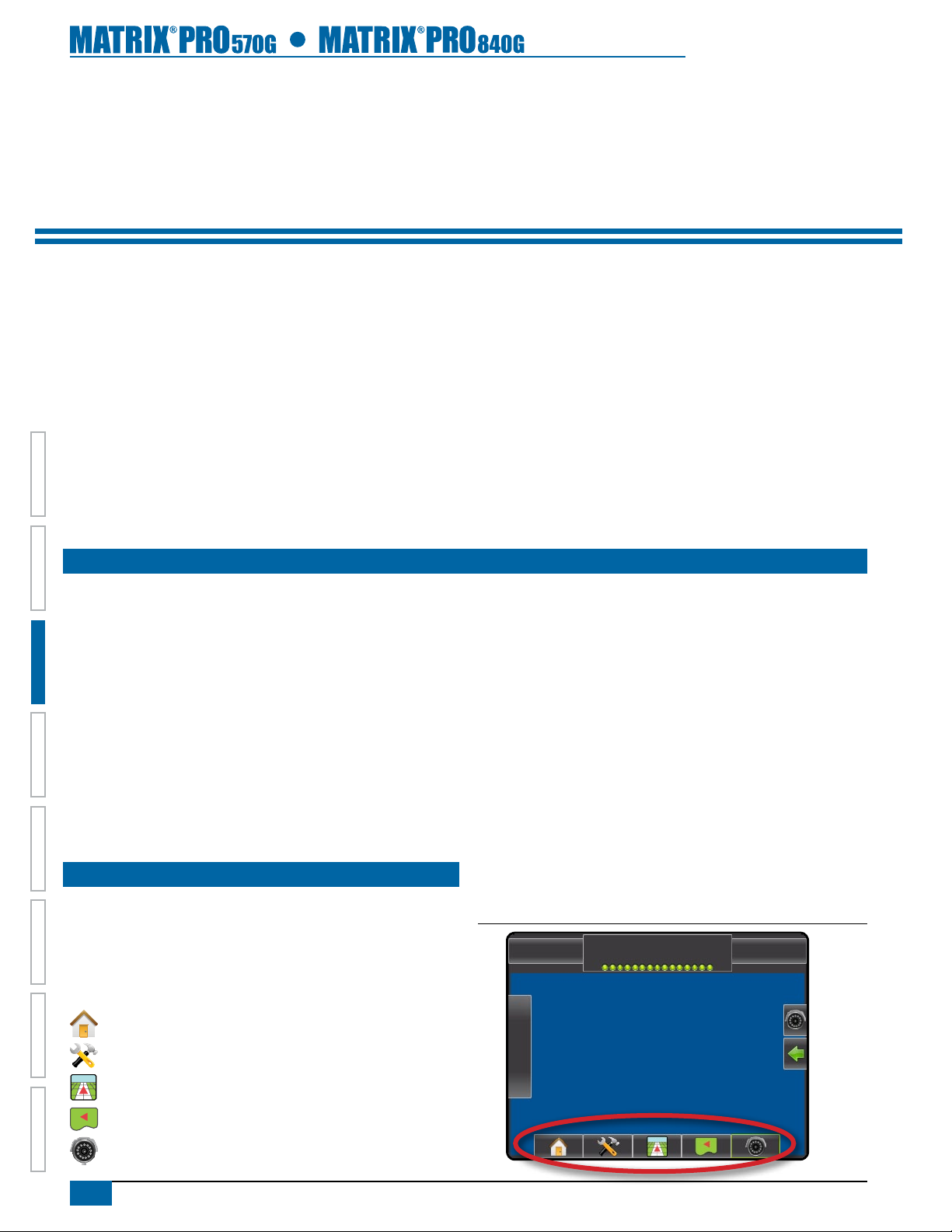

Bottom Tab Keys

The bottom tab keys are always available on screen. These keys

give access to jobs, setup options and navigation.

Five bottom tabs are:

Home/Job Screen

Unit Setup

Vehicle View Guidance

NOTE: RealView Guidance options are only available with a camera

installed on the system.

Figure 3-1: Bottom Tab Keys

-13 7.2 mph

> 0.0 <

Field View Guidance

RealView Guidance or

RealView Camera Full Screen Video View

12

www.teejet.com

Page 20

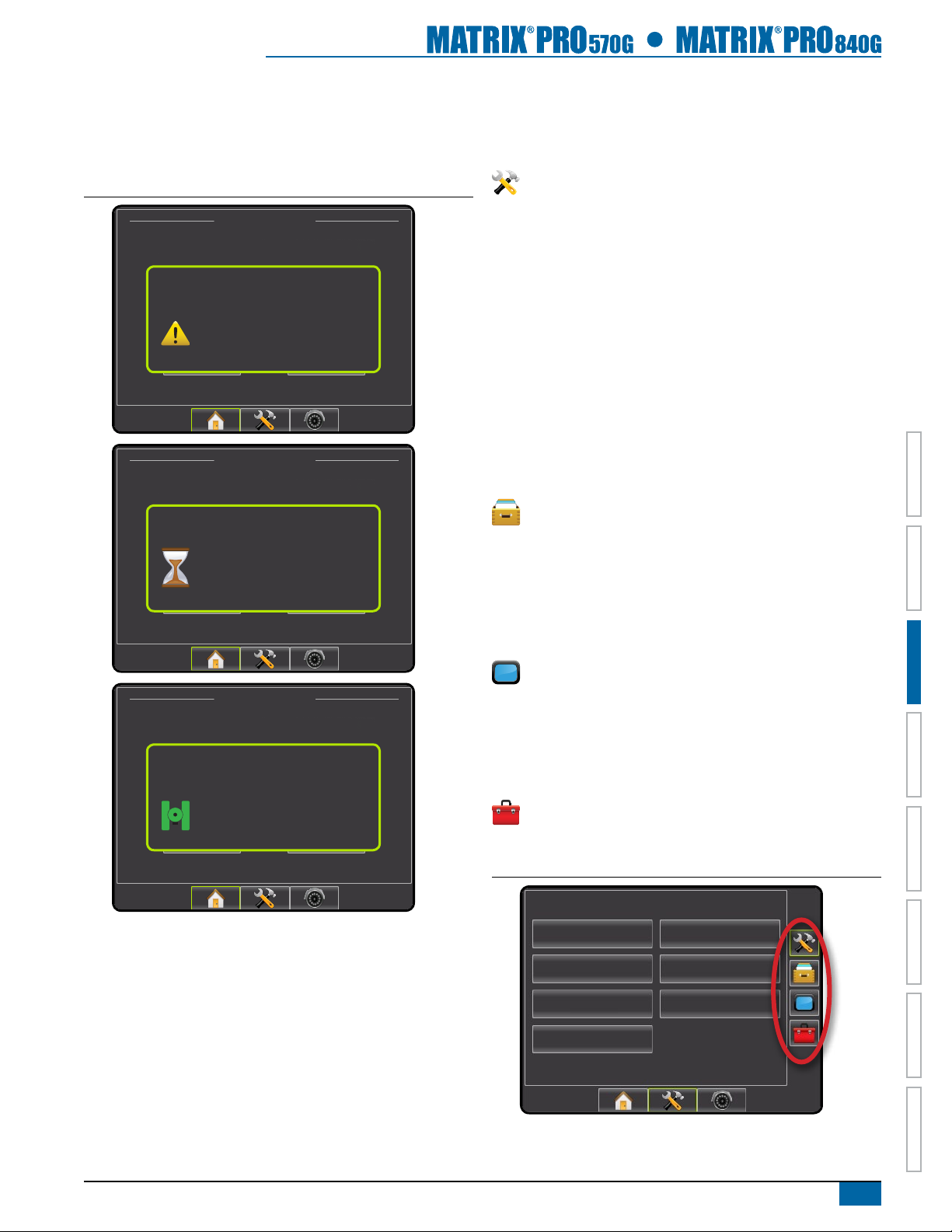

Warnings and Information Pop-ups

A pop-up warning or information box will be displayed for

approximately ve (5) seconds. To remove the information box, tap

anywhere on the screen.

Figure 3-2: Information Screens

12/14/10 3:52 AM

Setup Screens

Side Tab Keys in Unit Setup

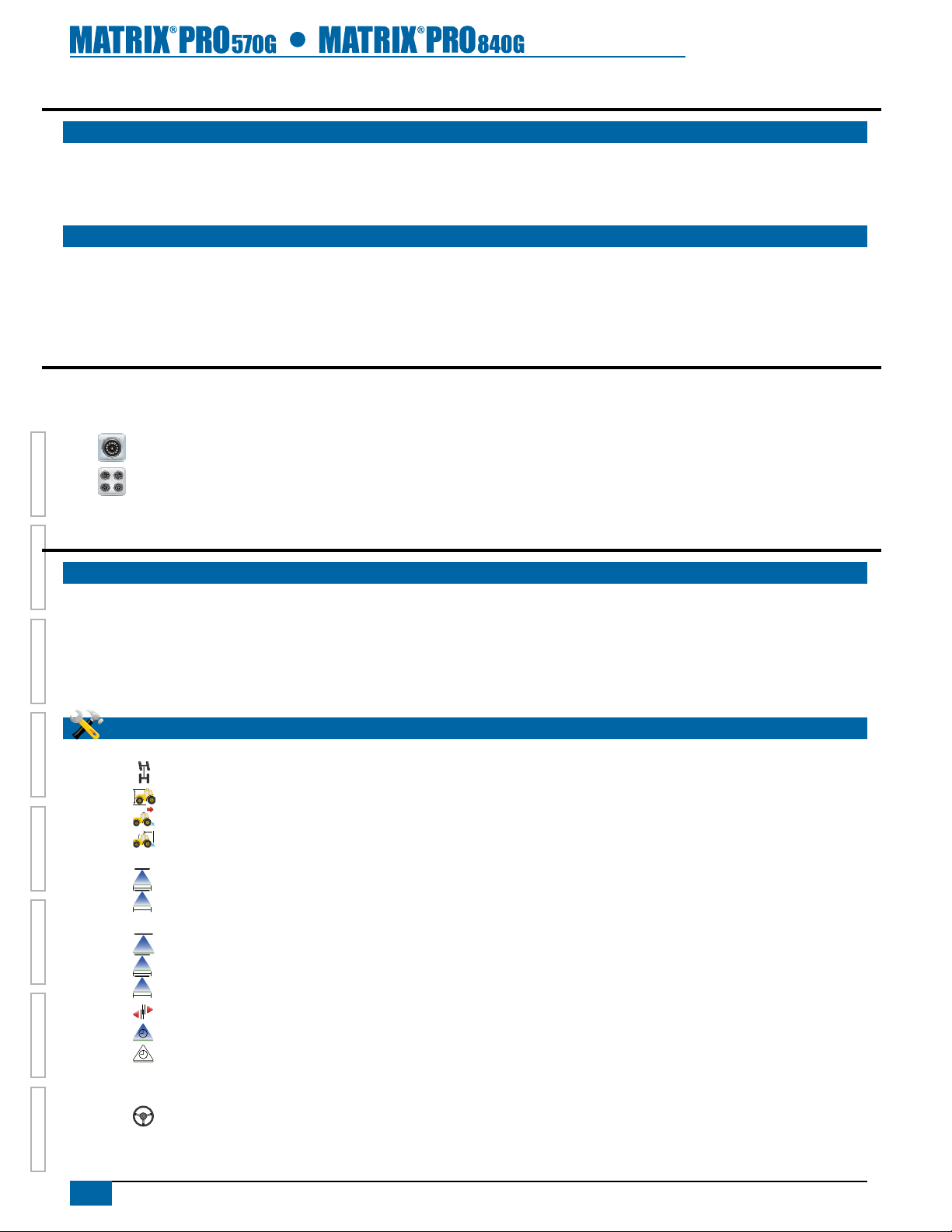

Four side tabs on the Unit Setup screen access setup options for:

Vehicle/Implement Conguration

• Vehicle (Vehicle Type, Antenna Height, Direction to Boom,

Distance to Boom)

Do you want to start a new job data or continue last job?

Starting a new job will clear the previous job data.

Do you want to start a new job data or continue last job?

Starting a new job will clear the previous job data.

Overheat Protection

Dimming backlight brightness to

reduce heat. Previous backlight

brightness will be restored when unit

New Job

New Job

reaches a safe temperature.

12/14/10 3:52 AM

Loading data, please wait.

12/14/10 3:52 AM

Continue

Continue

• Implement (Number of Sections, Guidance Width, Spray Width,

Overlap, Delay On, Delay Off)

• AutoSteer (Valve Type, Frequency, Minimum Duty Cycle Left/

Right, Maximum Duty Cycle, Coarse Adjustment, Deadband,

Fine Adjustment, Lookahead, Valve Test, Valve Diagnostics,

Steering Wheel Sensor, Steering Angle Sensor)

• Tilt Conguration

• Lightbar (Brightness, Mode, LED Spacing)

• GPS (GPS Type, GPS Port, GPS Information)

• Video Conguration

Data Management

• Manage Data (delete a job or duplicate a job’s Guideline Data,

Boundary Data and/or Applied Data)

• Transfer (Delete, Import or Export Job Data)

• Reports (Save PDF, KML and/or SHP le)

• Job Mode

Console Settings

• Display (Color Scheme, Brightness, Screenshot, Calibrate)

Do you want to start a new job data or continue last job?

Starting a new job will clear the previous job data.

GPS quality changed

no GPS to DGPS

New Job

Continue

• Cultural (Units, Language, Time Zone)

• Sound (Volume)

• About System Information

Tools (Calculator, Units Converter)

NOTE: All settings are automatically saved when selected.

Figure 3-3: Side Tab Keys in Unit Setup

Conguration

Vehicle

AutoSteer

Lightbar

Video

Implement

Tilt

GPS

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

98-05238 R1 EN-US

13

Page 21

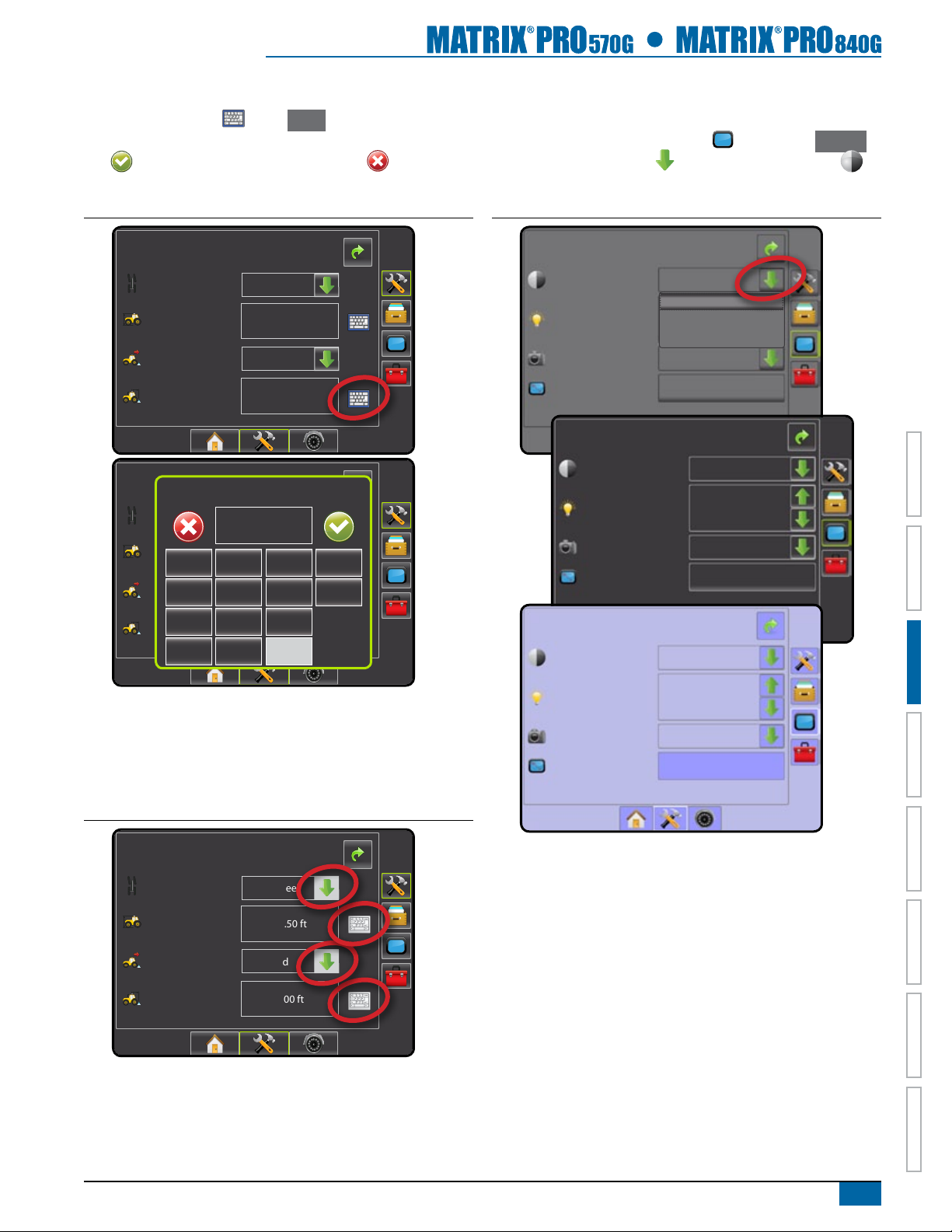

Setup Option Information

Press the option’s icon or option’s name of any menu item to display

a denition and range values of that item. To remove the information

box, press anywhere on the screen.

Figure 3-4: Example of Information Text Box

Cong-> Lightbar

Drop Down Menu Selections

Press DOWN arrow to access the list of options. Use the

UP/DOWN arrows or slide bar if necessary to scroll through

the extended list. Select the appropriate option. To close the list

without selecting an option, tap anywhere on the screen outside the

drop down menu.

Figure 3-5: Example of Drop Down Menu

Brightness

Mode

LED Spacing

Cong-> Lightbar

Brightness

Mode

LED Spacing

50%

Swath

1.50 ft

50%

LED Spacing

The distance illustrated by the

Swath

illuminated LED’s can be customized.

Input the desired spacing as required or

individual preference.

3,50 m

Cong-> Vehicle

Vehicle Type

Ant Height

Dir to Boom

Dist to Boom

Front Wheel

Front Wheel

12.50 ft

Articulated

Tracked

Backward

0.00 ft

Cong->Implement

Num Sections

Guidance Width

Spray Width

15

7

8

9

10

11

12

13

14

15

75.00 ft

75.00 ft

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUC TION GUIDANCE

14

www.teejet.com

Page 22

Keyboard Entry Screen

Press the KEYPAD icon . Press Clear to erase the existing

value. Use the numeric keypad to enter a value. Press the ACCEPT

icon to save the settings or the CANCEL icon to leave the

keypad without saving.

Light or Dark Console Screen

The console is available in three color schemes. From the Unit Setup

Bottom Key, press CONSOLE side tab and enter the Display

options. Press DOWN arrow to access the Color Scheme

options to select color mode.

Figure 3-6: Example of Keyboard

Cong-> Vehicle

Vehicle Type

Ant Height

Dir to Boom

Dist to Boom

Cong-> Vehicle

Front Wheel

Backward

Dist to Boom (ft)

Vehicle Type

Ant Height

1 2 3

Dir to Boom

4 5 6 <--

7 8 9

Dist to Boom

0 .

Front Wheel

0.00

Backward

12.50 ft

0.00 ft

12.50 ft

0.00 ft

+/-

Clear

Figure 3-8: Color Scheme

Console->Display

Color Scheme

Brightness

Screenshot

Calibrate

Console->Display

Style 1

Style 1

Style 2

Style 3

Enabled

Start

Colour Scheme

Brightness

Screenshot

Calibrate

Console->Display

Colour Scheme

Style 2

40%

Enabled

Start

Style 3

Unavailable Options When Job is Activate

When a job is active some setup options are unavailable. See

the Unit Setup Mode Menu Structure Chart for indication of which

options are not accessible.

Figure 3-7: Example of Unavailable Options

Cong-> Vehicle

Vehicle Type

Ant Height

Dir to Boom

Dist to Boom

Front Wheel

12.50 ft

Backward

0.00 ft

Brightness

Screenshot

Calibrate

Enabled

40%

Start

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

98-05238 R1 EN-US

15

Page 23

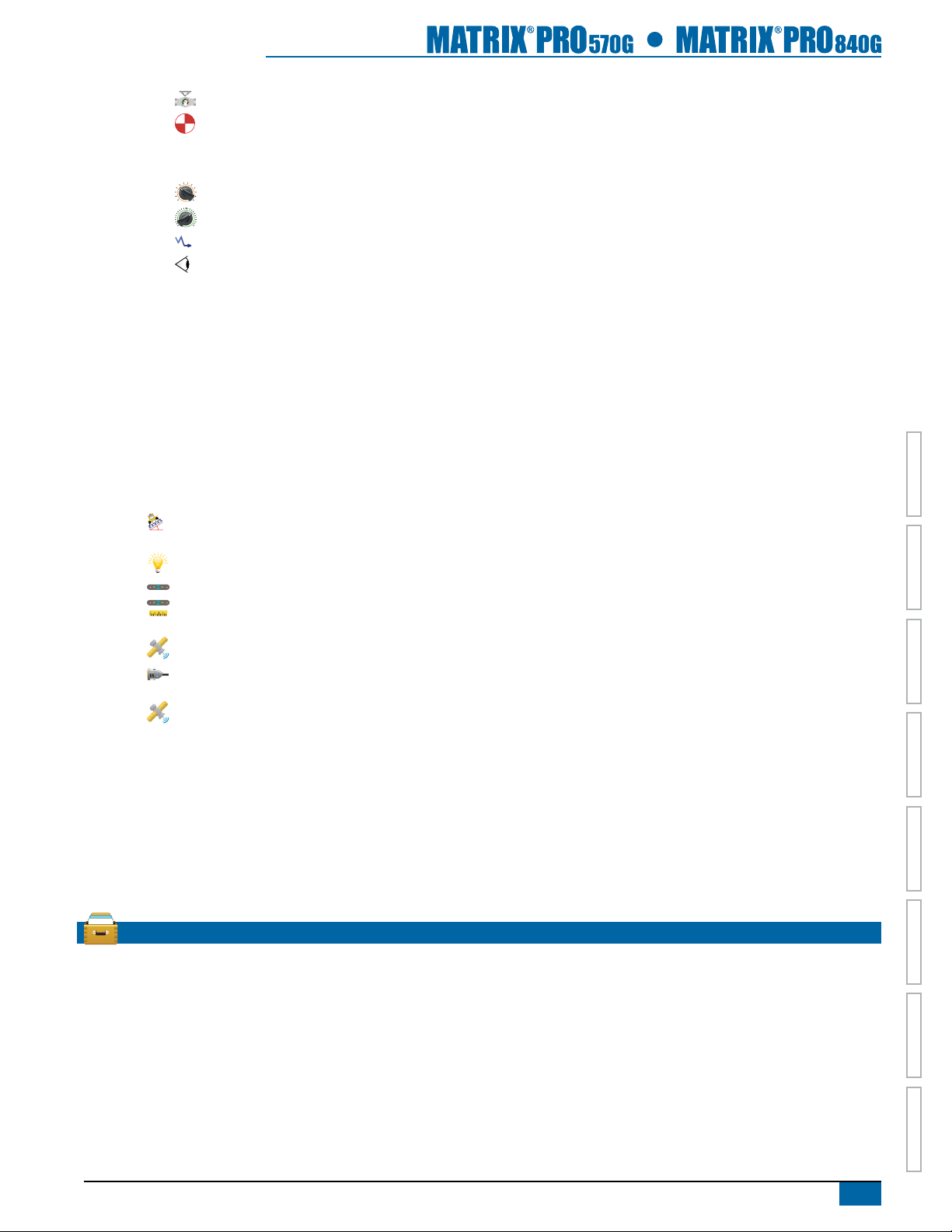

UNIT SETUP MODE MENU STRUCTURE

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUC TION GUIDANCE

Vehicle –

Implement –

AutoSteer

Conguration (page 35)

Vehicle Type

Antenna Height

Direction to Boom

Distance to Boom

#

Number of Sections

Guidance Width

Spray Width

Overlap

Delay On

Delay Off

–

Enable

Valve

–

Setup

Steering

–

Settings

– Valve Test

– Valve Diagnostics

Options

–

Angle

–

Sensor

–

–

–

–

Valve Type

Frequency

Minimum Duty Cycle Left

Minimum Duty Cycle Right

Maximum Duty Cycle

Coarse Adjustment

Deadband

Fine Adjustment

Lookahead

Steering Wheel Sensor

Enable

Calibrate Sensor

Offset Adjustment

Job*

Data Management (page 61)

Manage Data –

Duplicate

Delete Job Data

Job*

Transfer –

Reports –

Options –

Export Job Data

Import Job Data

Delete Job Data

PDF

Save PDF

KML

Save KML

SHP

Save SHP

ALL

Save All Types

Job Mode

Console Settings (page 70)

Display –

Cultural –

Sound –

About –

Color Scheme

Brightness

Screenshot

Calibrate

Units

Language

Time Zone

Volume

• System Information

• Save System Info

Job*

Tilt –

Lightbar –

GPS –

Video –

Conguration

Vehicle

AutoSteer

Lightbar

Video

16

www.teejet.com

Enabled

Field Level

Brightness

Mode

LED Spacing

GPS Type

GPS Port

GPS Status

B C D

A

Implement

Tilt

GPS

E

Data

F G H

Manage Data

Cameras

Transfer

OptionsOptions

Available during an active job

Not Available during an active job

Console Settings

Display

Sound

Extras –

Cultural

About

Tools (page 75)

• Calculator

• Units Converter

Tools->Extras

Calculator

Job*

Units Converter

Page 24

Guidance

6.0 mph 7.6 ac

< 0.0 >

6.0 mph 0 ac

Mark A

6.0 mph 0 ac

< 0.0 >

The Matrix Pro allows product application and vehicle guidance to be

performed simultaneously. Once Unit Setup is complete, guidance can

begin. Five guidance modes allow the operator to optimize the eld

work: Straight AB , Curved AB , Circle Pivot , Last Pass

and NextRow . Additional optimization can be accomplished with

Boundary Application , Curved Lookahead Return to Point

guidance and RealView Guidance Over Video . Three guidance

screens keep the user informed.

Vehicle View Guidance creates a computer-generated image of

the vehicle position displayed in the application area

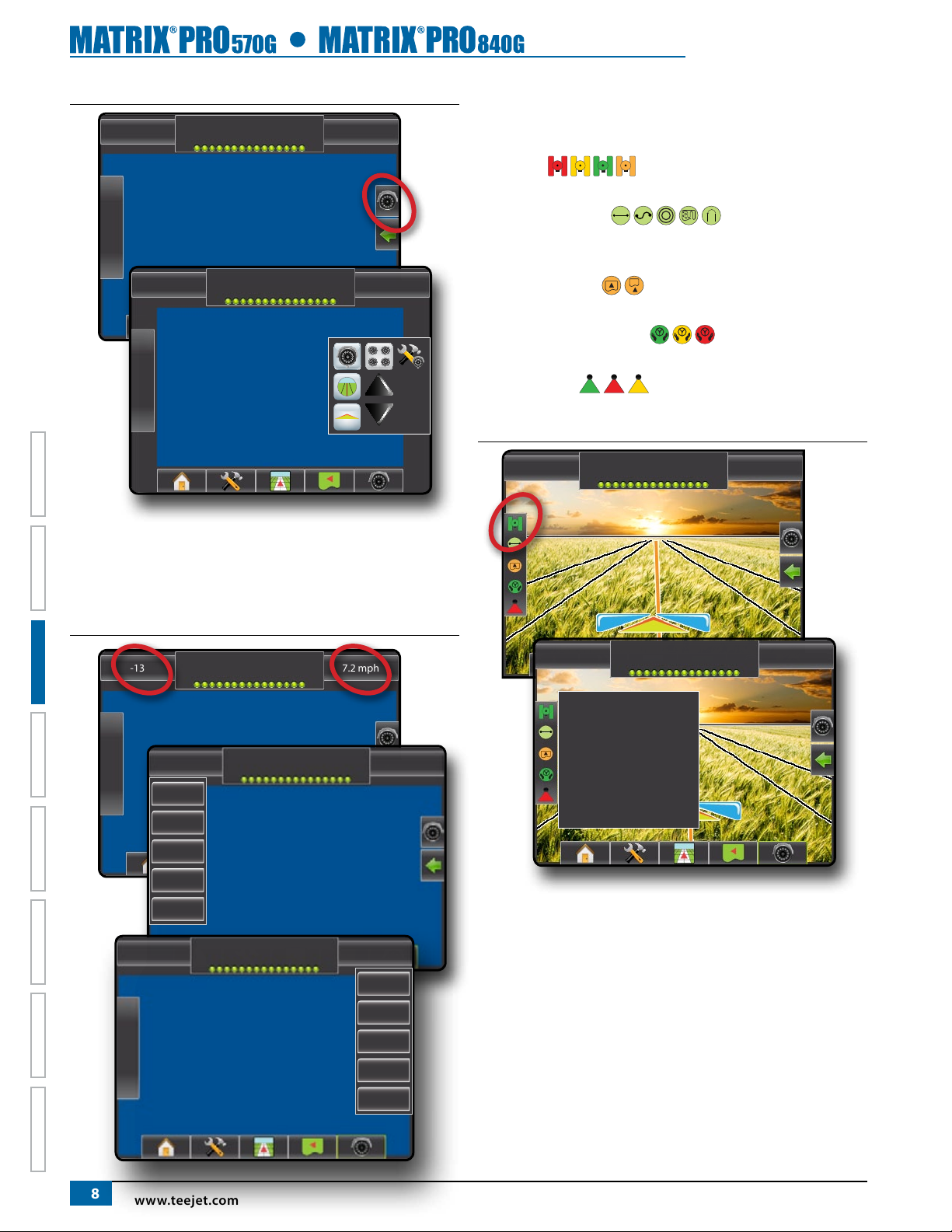

Side Tab Keys in Guidance

Two side tabs on the Guidance screens access setup options for:

Navigation and Guidance Options

• Guidance mode

• Next guideline

• Mark A or mark B

• Azimuth guidance

• Create boundary

• Mark and return to point

• BoomPilot

RealView Guidance

• Single or split camera view

• Guidance over video

• Steering angle indicator

NOTE: All settings are automatically saved when selected.

Figure 3-9: Navigation and Guidance Options*

Field View Guidance creates a computer-generated image of

the vehicle position and application area from an aerial perspective.

RealView Guidance allows live video input to be displayed

instead of a computer-generated image.

-13 7.2 mph

> 0.0 <

A

A

A

B

0.0 mph 0 ac

Mark A

HOME OVERVIEWSETUP POWERAPPENDIX FULL SCREEN INTRODUCTIONGUIDANCE

* Simulated screen example to show all possibilities.

98-05238 R1 EN-US

17

Page 25

Figure 3-10: RealView Options*

-13 7.2 mph

> 0.0 <

Status/Information Screens

Status and information regarding the status bar icons can be

accessed by pressing the icon on the status bar.

GPS Status displays information regarding data

rates, number of satellites in view, and satellite quality and ID.

Guidance Mode Status displays information

regarding the pattern of guidance, name of the current guideline and

how many guidelines are saved in the console.

Bounded Area Status displays information regarding the

areas in the current boundaries.

Assisted/Auto Steering Status displays information

regarding the current status of the auto steering system.

BoomPilot Status displays information regarding the

current status of the BoomPilot system

Figure 3-12: GPS Status

* Simulated screen example to show all possibilities.

Guidance Bar Selectable Information

Press the left or right section of the guidance bar to change the

selectable job information.

Figure 3-11: Selectable Job Information

-13 7.2 mph

HOMEOVERVIEW SETUP POWER APPENDIXFULL SCREENINTRODUC TION GUIDANCE

12:32 PM 1 deg

Speed

Area

Time

Swath #

Heading

> 0.0 <

No GPS

-13 7.2 mph

-13 7.2 mph

GGA Rate: 5 Hz

VTG Rate: 5 Hz

Num Sats: 10

HDOP: 1

PRN: 135

GGA Quality: 2

Receiver: 1

Mark A

Mark A

18

12:32 PM 1 deg

www.teejet.com

No GPS

Speed

Area

Time

Swath #

Heading

Page 26

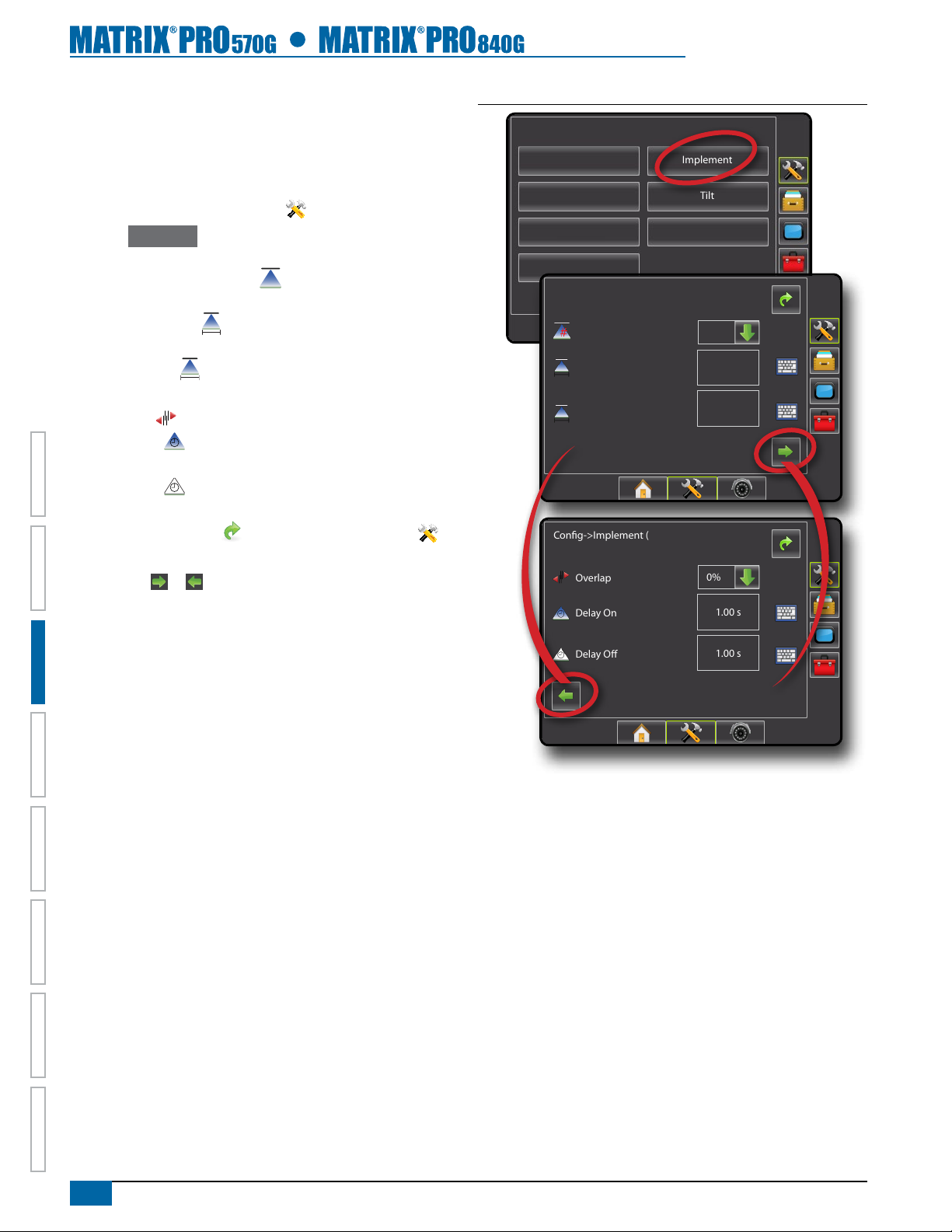

Required- Setup Options

A series of setup options are required for guidance to properly

function. These should be setup before starting a job as they are not

available after a job has been started.

Cultural Setup

1. Press CONSOLE side tab .

2. Press Cultural .

3. Select from:

►Units – denes the system measurements

►Language – denes the system language

►Time Zone – establishes the local time zone.

4. Press RETURN arrow or CONSOLE side tab to return

to the main Console screen.

Figure 3-13: Cultural Options

Console Settings

Display

Sound

Cultural

About

GPS

1. Press CONFIGURATION side tab .

2. Press GPS .

3. Select from:

►GPS Type – select GPS source transmissions

►GPS Port – sets (D)GPS COM port

►GPS Status – displays information for TeeJet Customer

Service use on GGA/VTG (Data Rates), Number of Satellites,

HDOP, PRN, GGA Quality, GPS Receiver and Receiver

Version

4. Press RETURN arrow

return to the main Conguration screen.

Figure 3-14: GPS

Conguration

Vehicle

AutoSteer

Lightbar

Video

or CONFIGURATION side tab to

Implement

Tilt

GPS

Console->Cultural

Units US

Language

Time Zone

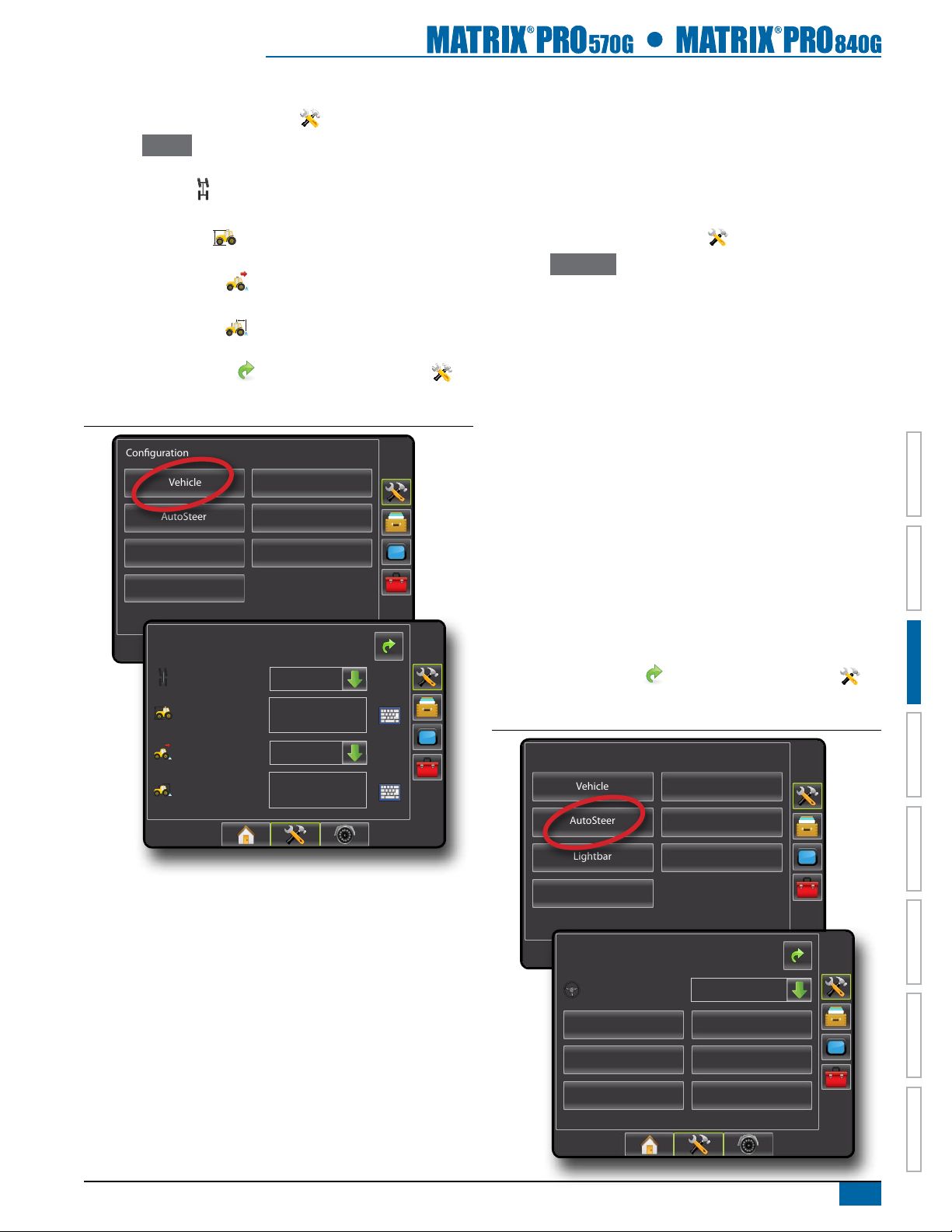

English-US