Technip A0403-03 User Manual

:

:

:

:

:

SUPPLIER'S

REVISION

0

:

:

PACKAGE

DESCRIPTION

:

1,

EQUIPMENT

TAG

:

2,

RD CODE :

3,

4,

TO BE ISSUED AS FINAL PROVIDED COMMENTS ARE

INCORPORATED.

A0403

NO COMMENT – FINAL ISSUE.

FOR INFORMATION ONLY

NAME:

SIGNATURE:

DATE :

REV

REVISE AND RESUBMIT.

3800-210

SUPPLIER DOCUMENT REVIEW

PROJECT TITLE

MIDOR REFINARY EXPANSION

PERMISSION TO PROCEED DOES NOT CONSTITUTE

ACCEPTANCE OR APPROVAL OF DESIGN DETAILS,

CALCULATIONS, ANALYSIS, TEST METHODS OR

MATERIALS DEVELOPED OR SELECTED BY SUPPLIER FROM

FULL COMPLIANCE WITH CONTRACTUAL

OBLIGATIONS.

ENPPI PROJECT

NUMBER

SUPPLIER'S OWN DOCUMENT No

DATE

SUPPLIER APPROVAL

SIGNATURE

DOCUMENT TITLE

index for vendor data book

TOTAL No OF PAGES

4

SUPPLIER'S ORDER No

NA

SUPPLIER'S NAME

ASCO FILTRI S.P.A.

PURCHASE ORDER No

3800-210-0841-201-22

BINASCO

(MI) ITALY

02/07/2020

VDB-19-3090-006

1

2

20/07/2020

04/11/2020

LVGO FILTER

17-FL-53 A/B

A0403-03

2

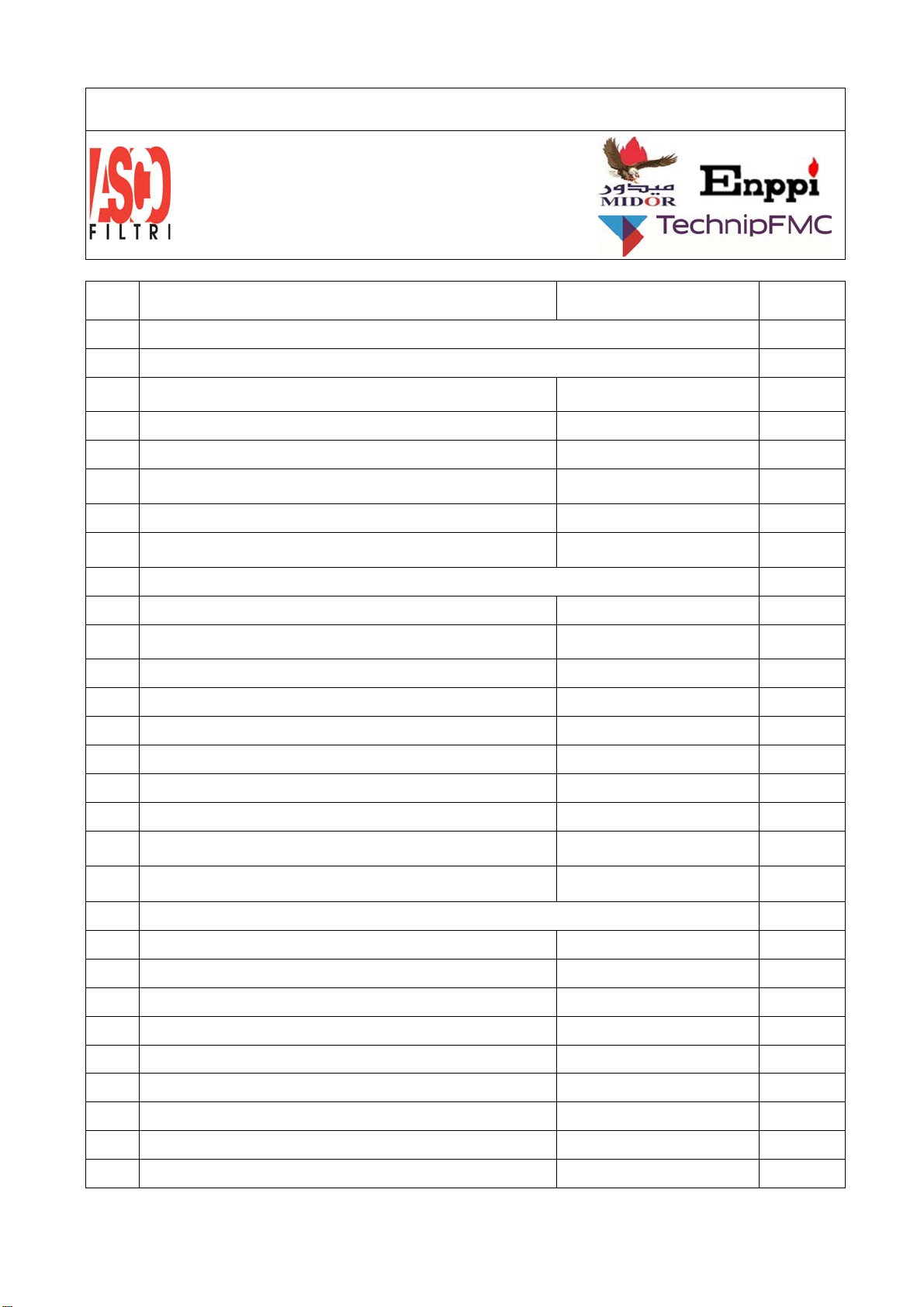

VENDOR DATA-BOOK (VDB) - INDEX

A

CLIENT: ENPPI

PROJECT NAME: MIDOR REFINARY EXPANSION

EQUIPMENT: 17-FL-53 A/B

Part DESCRIPTION DOC. REF. PAGE No.

1. ERECTION, OPERATING AND MAINTENANCE INSTRUCTION MANUAL

1.1 General

1.1.1 VDB Index

1.1.2 Process Theory See Attached

1.1.3 Process Description See Attached

1.1.4 Data Sheets

1.1.5 Chemicals, Catalyst Utilities Consumption N/A

RECCOMENDATION FOR TRANSPORTATION, HANDLING AND

1.2

STORAGE

1.3 Erection

1.3.1 List of components to be erected/installed on site N/A

Detailed schedule of the erection including hypothesis taken into

1.3.2

account

1.3.3 Procedures for erection and installation of the equipment See 1.10.1

Filtering Element / Basket Data

A0403

VDB-19-3090-006

Sheet Attached

N/A

N/A

1.3.4 List of connection points detailing location and dimensions N/A

1.3.5 Details of site assembly and field welds N/A

1.3.6 List of special tools for site erection and assembly N/A

1.3.7 Procedures for site assembly, leveling and welding N/A

1.3.8 Welding specifications for field welds N/A

List of checks and tests to be performed on site with SAT (Site

1.3.9

1.4 Pre-commissioning, Commissioning and Start-Up Procedure See 1.10.1

1.5 Normal Operation

1.5.1 Normal Operating Procedure See 1.10.1

1.5.2 Sequence Flow Chart (valve positioning, controls, etc.) N/A

1.5.3 Description of Control System (Functional design Specification) N/A

1.5.4 List of Alarms and Set Points N/A

1.5.5 Program List (logic and ladder diagram, AND/OR, etc.) N/A

1.6 Normal Shutdown Procedure N/A

1.7 Emergency Shutdown Procedure N/A

1.8 Special operation (chemical cleanings, catalyst regeneration, etc…) N/A

cceptance Test) & Site Quality Control Plan

N/A

1.9 Trouble Shooting N/A

Loading...

Loading...