Page 1

ORDER NO. MD9707082C2

Receiver

AV Control Stereo Receiver

Colour

(K) . . . . . . . . Black Type

SA-EX310

© 1997 Matsushita Electronics (S) Pte. Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

Area

®

Manufactured under license from Dolby Laboratories Licensing Corporation. Additionally licensed

under one or more of the following patents: U.S. numbers 3,632,886,3,746,792 and 3,959,590;

Canadian numbers 1,004,603 and 1,037,877.

"Dolby" and the double-D symbol are trade marks of Dolby Laboratories Licensing Corporation.

*

Colour

Area

Suffix for

Model No.

(E) Europe

(EB) Great Britain

(EG) Germany and Italy

(K)

SPECIFICATIONS\ ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

PROTECTION CIRCUITRY\ СИСТЕМА ЗАЩИТЫ

CAUTION FOR AC MAIN LEADS\ МЕРЫ БЕЗОПАСНОСТИ ПРИ РАБОТЕ СО ШНУРОМ

ПИТАНИЯ ПЕРЕМЕННОГО ТОКА

OPERATION CHECKS AND MAIN COMPONENT REPLACEMENT

PROCEDURES\ПРОВЕРКА РАБОТОСПОСОБНОСТИ И ЗАМЕНА ОСНОВНЫХ

КОМПОНЕНТОВ

FAN MOTOR TROUBLESHOOTING\ НЕИСПРАВНОСТИ ДВИГАТЕЛЯ ОХЛАЖДЕНИЯ

TROUBLESHOOTING\ НЕИСПРАВНОСТИ И МЕТОДЫ ИХ УСТРАНЕНИЯ

BLOCK DIAGRAM\ БЛОК-СХЕМА

TERMINAL FUNCTIONS OF IC's\ ФУНКЦИОНАЛЬНОЕ НАЗНАЧЕНИЕ ВЫВОДОВ

ИНТЕГРАЛЬНЫХ МИКРОСХЕМ

TERMINAL GUIDE OF IC's, TRANSISTORS & DIODES\ ЦОКОЛЕВКА ВЫВОДОВ

ИНТЕГРАЛЬНЫХ МИКРОСХЕМ, ТРАНЗИСТОРОВ И ДИОДОВ

SCHEMATIC DIAGRAMS\ ПРИНЦИПИАЛЬНЫЕ СХЕМЫ

PRINTED CIRCUIT BOARDS\ ПЕЧАТНЫЕ ПЛАТЫ

WIRING CONNECTION DIAGRAM\ СХЕМА СОЕДИНЕНИЯ

CABINET PARTS LOCATION\ РАСПОЛОЖЕНИЕ ЧАСТЕЙ КОРПУСА

REPLACEMENT PARTS LIST\ СПИСОК ЗАПАСНЫХ ЧАСТЕЙ

RESISTORS & CAPACITORS\ РЕЗИСТОРЫ И КОНДЕНСАТОРЫ

PACKAGING\УПАКОВКА

Page 2

SA-EX310

Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

No sound is heard when the power is turned on.

Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for

example, the positive and negative speaker connection wires

are "shorted", or if speaker systems with an impedance less than

the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate

unless the power is first turned off and then on again.

IF rejection ( at 999 kHz ) 55 dB

Amplifier Section

Power output (at 240 V)

DIN 1 kHz (T.H.D. 1%) 2 X 60 W(4Ω)

40 Hz20 kHz continuous power output

both channels driven 2 X 40 W(8Ω)

Total harmonic distortion

Rated power at 40 Hz 20kHz 0.8 % (8Ω)

Half power at 1 kHz 0.07 % (8Ω)

Power output at the Dolby Pro Logic operation

DIN 1 kHz ( T.H.D. 1 % )

Front 2 X 50 W (4Ω)

Center 50 W (8Ω)

Surround 50 W (8Ω)

Damping factor 30 (8Ω)

Load impedance

Front 4 - 16 Ω

Center 8 - 16 Ω

Surround 4 - 16 Ω

Power bandwidth both channels driven, -3 dB 10 Hz - 40 kHz (8Ω)

Intermodulation distortion rated

power at 60 Hz : 7 kHz = 4:1, SMPTE 0.5 % (8Ω)

Frequency response

PHONO RIAA standard curve(30Hz-15kHz)

+0.8 dB

CD, TAPE, VCR, TV/DVD 10Hz 40kHz,

+3 dB

Input sensitivity and impedance

PHONO 3 mV / 47 kΩ

CD, TAPE, VCR, TV/DVD 200 mV / 22 kΩ

S/N at rated power ( 8Ω )

PHONO 70 dB (IHF, A: 80 dB)

CD, TAPE, VCR, TV/DVD 75 dB (IHF, A: 85 dB)

Tone controls

BASS 50 Hz , +10 to -10 dB

TREBLE 20 kHz, +10 to -10 dB

Output voltage

TAPE REC (OUT), VCR OUT 200 mV

Channel balance (250 Hz - 6.3 kHz)

+ 1 dB

Channel separation 55 dB

Headphones output level and impedance 430 mV / 330 Ω

Subwoofer frequency responce 7 100 Hz,

+ 3 dB

General

Power consumption 160 W

Power supply

E , EG AC 230 V, 50 Hz

EB AC 230 - 240 V, 50 Hz

Dimensions (W x H x D) 430 x 136 x 309 mm

Weight 7.3 kg

Notes :

1. Specifications are subject to change without notice.

Weight and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

Specifications

FM Tuner Section

Frequency range 87.50 108.00 MHz

Sensitivity

S/N 30 dB 1.5 µV / 75Ω

S/N 26 dB 1.3 µV / 75Ω

S/N 20 dB 1.2 µV / 75Ω

IHF usable sensitivity 1.5 µV / 75Ω (IHF '58)

IHF 46 dB stereo quieting sensitivity 22 µV /

75Ω

Total harmonic distortion

MONO 0.2%

STEREO 0.3%

S/N

MONO 60 dB (75 dB, IHF)

STEREO 58 dB (71 dB, IHF)

Frequency response 20Hz 15 kHz (+1dB, 2dB)

Alternate channel selectivity

+ 400 kHz 65 dB

Capture ratio 1 dB

Image rejection at 98MHz 40 dB

IF rejection at 98MHz 70 dB

Spurious response rejection at 98MHz 70 dB

AM suppression 50 dB

Stereo separation 1kHz 40 dB

Carrier leak

19kHz -30 dB (-35 dB, IHF)

38kHz -50 dB (-55 dB, IHF)

Channel balance (250 Hz - 6.3 kHz )

+1.5 dB

Limitting point 1.2 µV

Bandwidth

IF amplifier 180 kHz

FM demodulator 1000 kHz

Antenna terminal(s) 75Ω (unbalanced)

Video Section

Output voltage at 1V input (unbalanced) 1±0.1 Vp-p

Maximum input voltage 1.5 Vp-p

Input/output impedance 75 Ω (unbalanced)

AM Tuner Section

Frequency range AM

( 9 kHz steps ) 522 1611 kHz

( 10 kHz steps ) 530 1620 kHz

Sensitivty 20 µV, 330 µV / m

Selectivity ( at 999 kHz ) 55 dB

Image rejection ( at 999 kHz ) 40 dB

Page 3

SA-EX310

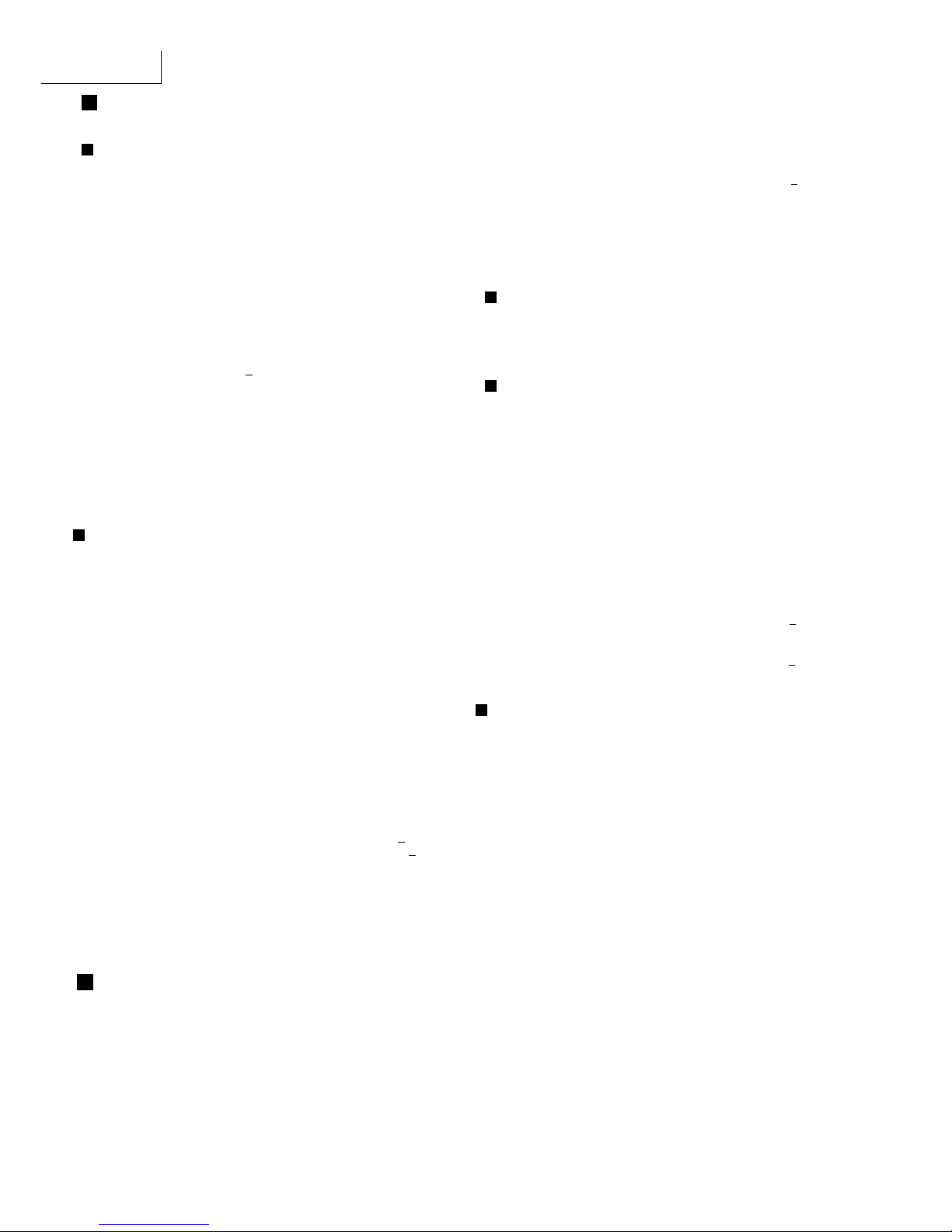

(For EB area code model only.)

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5-ampere and that it is approved

by ASTA or BSI to BS1362.

Check for the ASTA mark

A S

A

or the BSI mark on the body

of the fuse.

If the plug contains a removable fuse cover you must ensure that

it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

dealer.

If a new plug is to be fitted, please observe the wiring code as

shown below.

If in any doubt please consult a qualified electrician.

IMPORTANT

The wires in this mains lead are coloured in accordance with the

following code:

Blue: Neutral

Brown: Live

As these colours may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows:

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Black or Blue.

The wire which is coloured Brown must be connected to the

terminal which is marked with the letter L or coloured Brown or

Red.

WARNING: DO NOT CONNECT EITHER WIRE TO

THE EARTH TERMINAL WHICH IS MARKED WITH

THE LETTER E, BY THE EARTH SYMBOL OR

COLOURED GREEN OR GREEN/YELLOW.

THIS PLUG IS NOT WATERPROOFKEEP DRY.

Before use

Remove the connector cover.

How to replace the fuse

The location of the fuse differ according to the type of AC mains

plug (figures A and B). Confirm the AC mains plug fitted and follow

the instructions below.

Illustrations may differ from actual AC mains plug.

1. Open the fuse cover with a screwdriver.

Figure A

Figure B

2. Replace the fuse and close or attach the fuse

cover.

Figure A

Figure B

CAUTION !

IF THE FITTED MOULDED PLUG IS

UNSUITABLE FOR THE SOCKET OUTLET IN

YOUR HOME THEN THE FUSE SHOULD BE

REMOVED AND THE PLUG CUT OFF AND

DISPOSED OFF SAFELY.

THERE IS A DANGER OF SEVERE

ELECTRICAL SHOCK IF THE CUT OFF PLUG

IS INSERTED INTO ANY 13-AMPERE

SOCKET.

Caution for AC Main Leads

Fuse cover

Fuse

(5 ampere)

Fuse

(5 ampere)

Page 4

SA-EX310

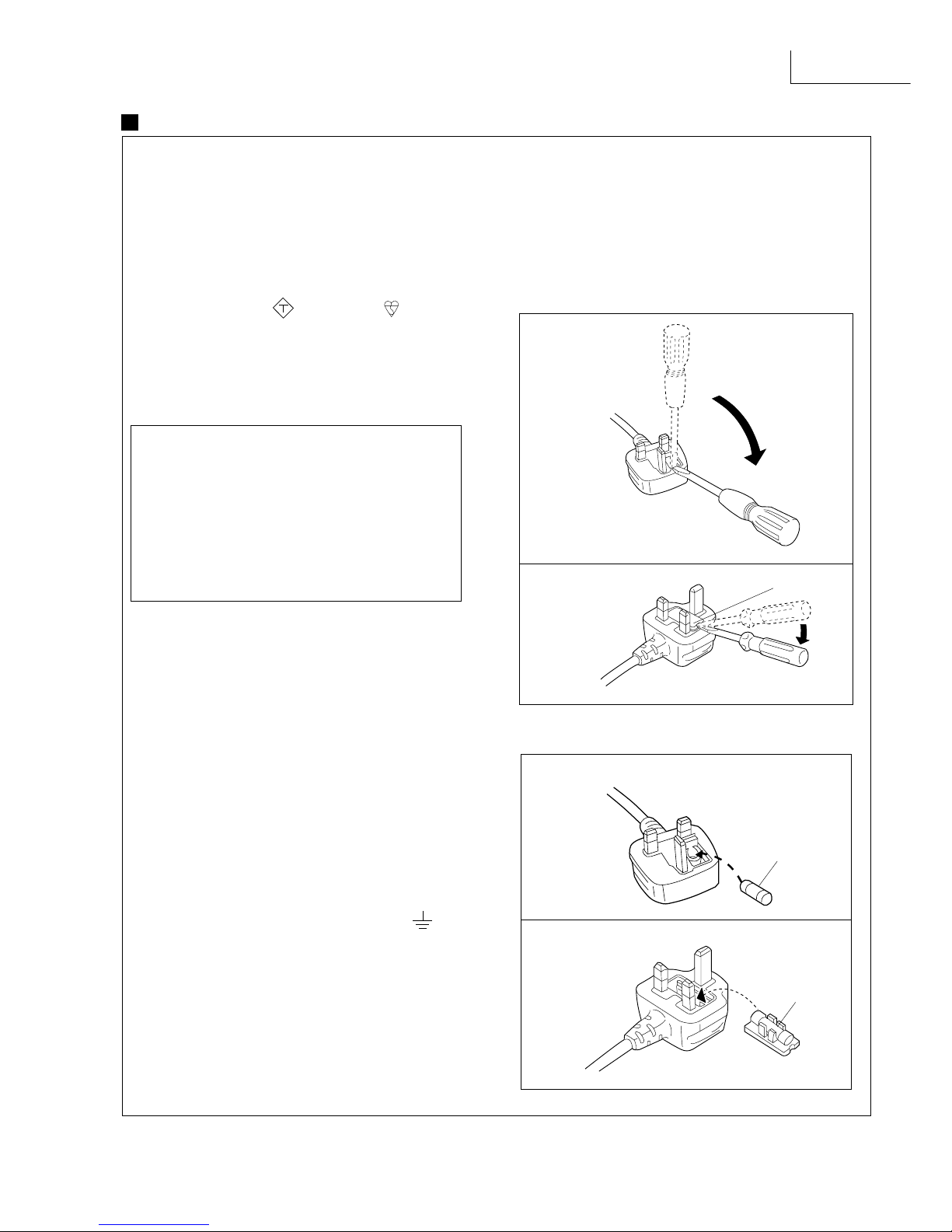

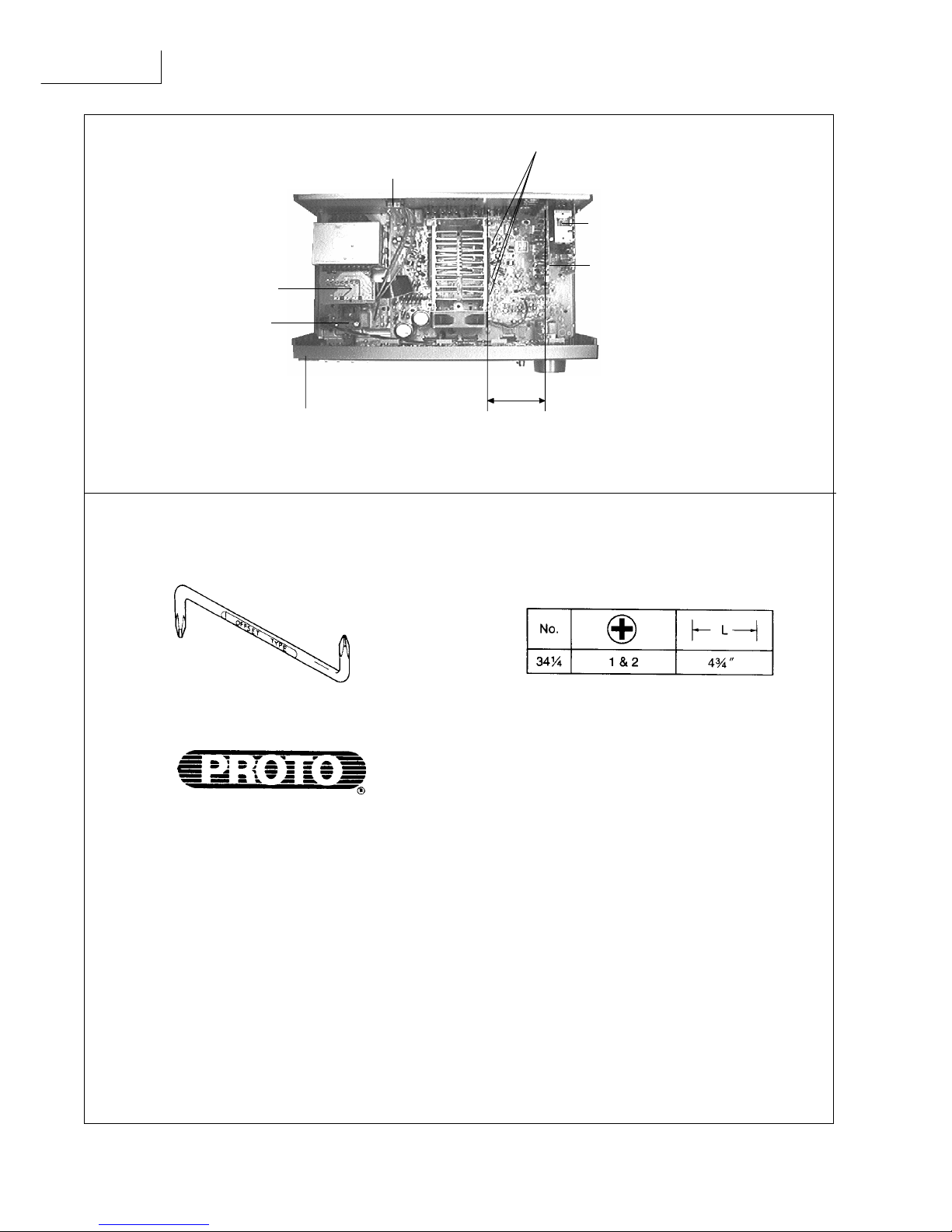

Operation Checks and Main Component Replacement Procedures

"ATTENTION SERVICER" Some chassis components may have sharp edges. Be careful when disassembling and servic-

ing. Please take note that the diagrams shown are for model SA-EX510 which is similar to SAEX310.

1. This section describes procedures for checking the operation of the major printed circuit boards and

replacing the main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Checking Procedure For Each Major P.C.B ........................................................................................ 4 ~ 6

Main Component Replacement Procedures ........................................................................................ 6 ~ 8

Contents

Checking Procedure For Each Major P.C.B.

1. Checking of the Panel P.C.B., and Tuner P.C.B.

a

X

4

a

a

a

b

b

Step 2

X

2

PANEL P.C.B.

(Solder Side)

IN/OUT TERMINAL P.C.B.

(Solder Side)

Step 1

Remove the top cabinet.

TUNER P.C.B.

(Solder Side)

[XTBS3+8JFZ1] (Black)

b

[SNE2129-1] (Black)

a

2. Checking of the In/Out Terminal P.C.B.

b

Step 2

X 14

Step 3

Release the catch, pull

the rear panel in the

direction of arrow 1 and

simultaniously remove the

In/Out Terminal P.C.B. in

the direction of arrow 2

.

1

2

Step 1

Catch

Catch

IN/OUT TERMINAL

P.C.B.

Page 5

SA-EX310

Step 1

Remove the top cabinet.

c

c

c

c

c

c

c

c

c

c

d

Step 4

Remove the Volume Knob

and Nut.

Step 6

X

18

X 1

Step 7

Step 5

Pull out 3 knobs.

d

[XTBS26+10J]

c

b

b

b

X 3

Step 2

Step 3

Remove the front panel in

the direction of arrow.

Power Switch P.C.B.

Panel P.C.B.

Step 8

Pull out the Headphone

Jack P.C.B.

Headphone Jack P.C.B.

3. Checking of the MAIN P.C.B.

[RHD26016]

f

catch

catch

Step 1

Remove the top cabinet.

Step 2

Remove the front panel.

f

X

13

e

Step 3

b

b

b

b

Step 5

X 4

Step 6

Release 2 catches and pull the rear panel in

the direction of arrow 1 for about 10mm.

(Note : Main, Tuner and In/Out Terminal

P.C.B. are attach to the rear panel)

1

2

Step 7

Lift the rear panel in the direction of arrow

2 .

To Remove Front Panel, Panel P.C.B., Power Switch

P.C.B. and Headphone Jac k P.C.B.

f

b

Step 4

X 4

f

Page 6

SA-EX310

Step 8

Connect the front panel to

the main P.C.B. as shown.

[XTB3+20JFZ] (Black)

f

[XTB3+8FFZ] (Black)

e

MAIN P.C.B. (Solder Side)

Check the Main P.C.B. as shown

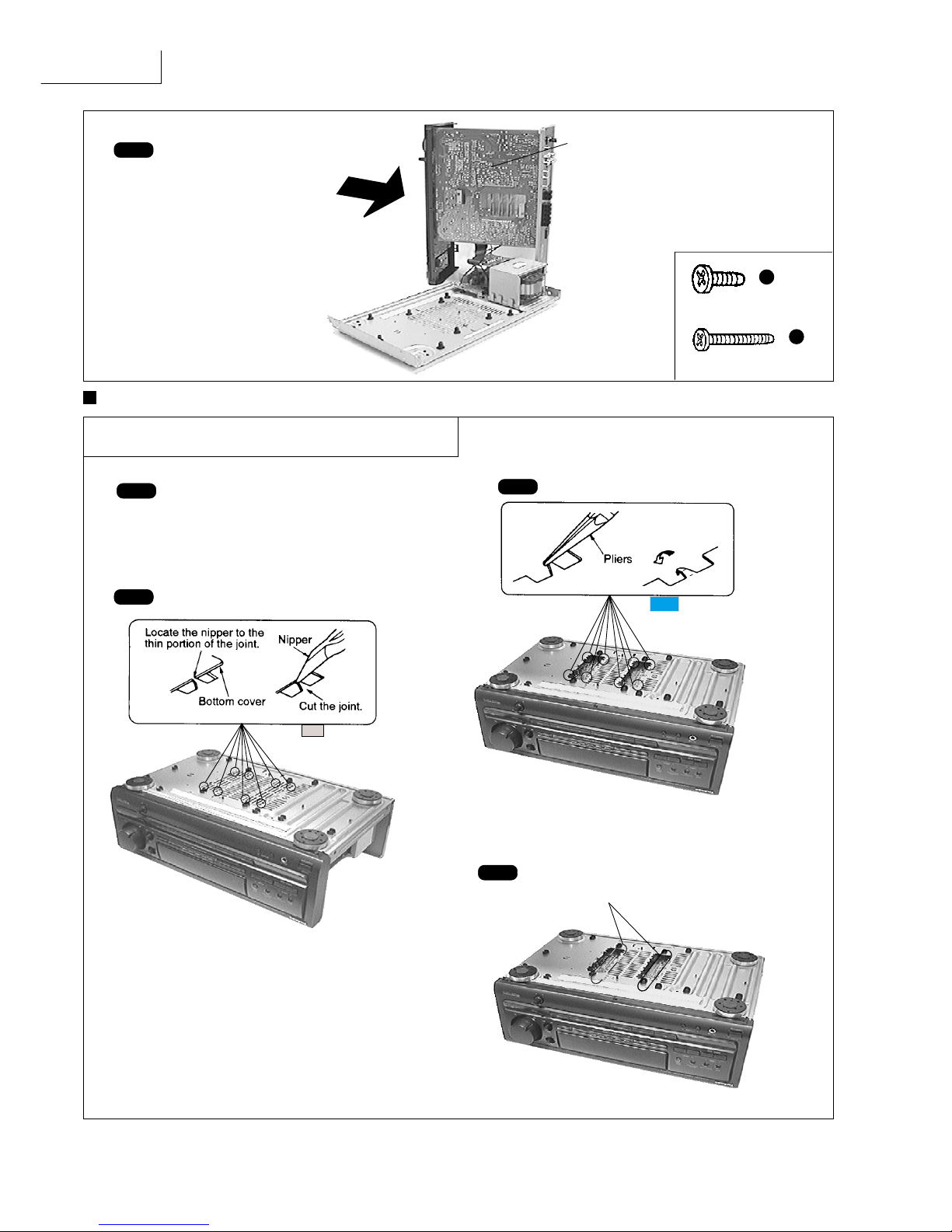

Main Component Replacement Procedures

Step 1

Remove the top cabinet.

Step 2 Cut the joints as shown below. (6 joints)

Step 4

Desolder the terminals of Power IC and

Regulator Transistor.

Step 3 Fold the joints. (6 joints)

1. Replacement of the Power IC and

Regulator Transistor

Page 7

SA-EX310

Installation of the bottom cover after replacement

[XTB3+8J] (Black)

[XTW3+15T]

g

h

Step 1

Step 2

Align the ribs of bottom cover into the lugs.

Step 3

Screw (XTB3+8J)

(Prepare this screw to fix the bottom cover.)

1. After replacing the power IC or regulator transistor, apply a sufficient

quantity of compound grease (RFKX0002/SZZ0L15) between the

heat sink and the power IC or regulator transistor (Radiation

of power IC).

2. Tighten enough the screws ( ) after replacing the power IC and

regulator transistor. Otherwise, the heat radiation works little.

3. When installing or removing the power IC or transistor holder, be sure

to use an offset screwdriver.

A long straight screwdriver cannot be used for removing or mounting

the screws since its long grip interferes with the neighbouring P.C.B.

and transformer.(See Fig.1 & 3)

A short straight screwdriver may be used for removal, but cannot be

used for mounting because the limited space in the unit will not allow

sufficient tightening torque.(See Fig.2 & 3)

A short straight screwdriver

A long straight screwdriver

Fig.2

Fig.1

Insufficient tightening will cause poor heat dissipation from the power

IC and regulator transistor and,in the worst case, may lead to their

thermal breakdown.

g

X 3

Step 5

g

g

Power IC (IC602)

[RSN3305-P]

g

Regulator transistor

(Q701,Q708)

[2SD2374PQAU,2SB1548PQAU]

*

h

Ribs

Lugs

CAUTION

Page 8

SA-EX310

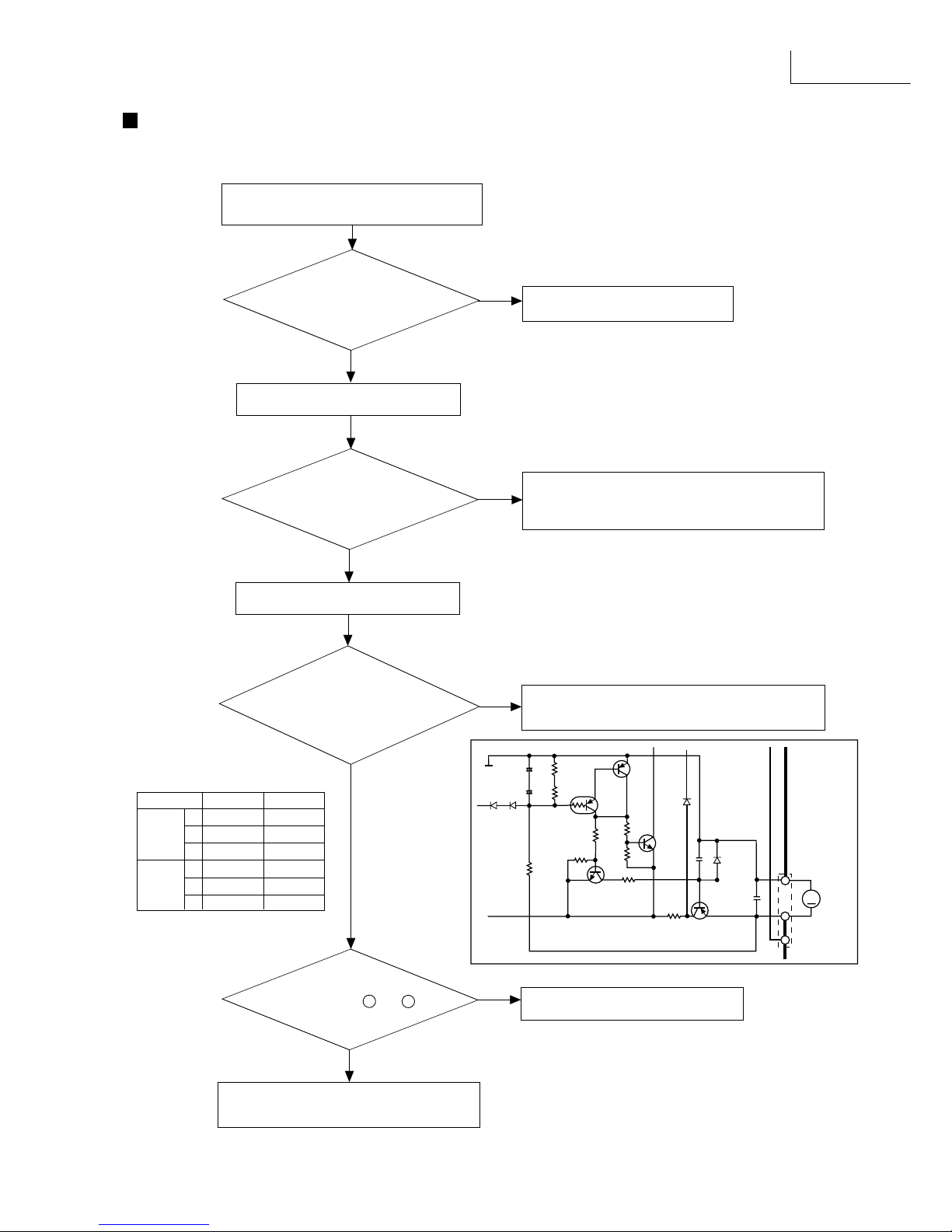

OFFSET SCREWDRIVER

The PROTO offset screwdriver No.34-

1

/4 is recommended for use in the application above.

The address of PROTO International Sales is as follows.

International Sales

International Sales Office

Stanley-Proto Industrial Tools

14117 Industrial Park Blvd.

Covington, GA 30209 U.S.A.

Fax: 706-786-4387

Phone: 706-787-3800

Australia, New Zealand &

South Pacific

Stanley-Proto Industrial Tools

P.O.Box 10

400 Whitehorse Road

Nunrweding 3131

Victoria, Australia

Fax: 61-3-894-1173

Phone: 61-3-878-9244

Singapore, Indonesia,

Philippines, Korea, Hong

Kong, Malaysia, China.

Stanley-Proto Asia Pacific

12 Gul Drive

Singapore 2262

Fax: 65-861-3206

Phone: 65-862-0883

Thailand

Stanley-Proto Thailand Ltd.

1017 Moo 13 Bangkaew

Amphur Bangplee

Samutprakarn, Thailand

Fax: 66-2-316-6071

Phone: 66-2-3168655

Japan

Stanley Works Japan

2-7-16 Hyakunin-Cho

Shinjuku-ku

Tokyo 160 Japan

Fax: 81-3-3360-8456

Phone: 81-3-33608458

Mexico

Herramientas Stanley S.A.

DE C.V.

Apartado Postal 675

72030 Puebla, Pue, Maxico

Fax: 52-22-494-4880

Phone: 52-22-495-300

South & Central America,

Puerto Rico, The Caribbian

Stanley Inter-America

2101 N.W. 84th Ave.

Miami, Florida 33122

Fax: 305-594-4261

Phone: 305-591-3828

Europe

Stanley-Proto Europe

Woodside, Sheffield

539PD

England

Fax: 44-742-739-038

Phone: 44-742-768-888

Canada

Stanley-Proto Canada

1100 Corporate Drive

Burlington, Ontorio

Canada, L7L 5R6

Fax: 416-335-0075

Phone: 416-335-0075

Middel East, Mediterranean

& Africa

Stanley-MEMA

Cory House The Rlng

Bracknell Berkshire

RG 12 1A2

England

Fax: 44-344-485-526

Phone: 44-344-51813

Front Panel

About 9 cm

(A long straight screwdriver

connot be used)

Screws

Tuner & Tuner

Pack P.C.B.

Pro Logic

P.C.B.

Fig.3

Power

P.C.B.

Transformer

P.C.B.

AC In / Out

P.C.B.

Page 9

SA-EX310

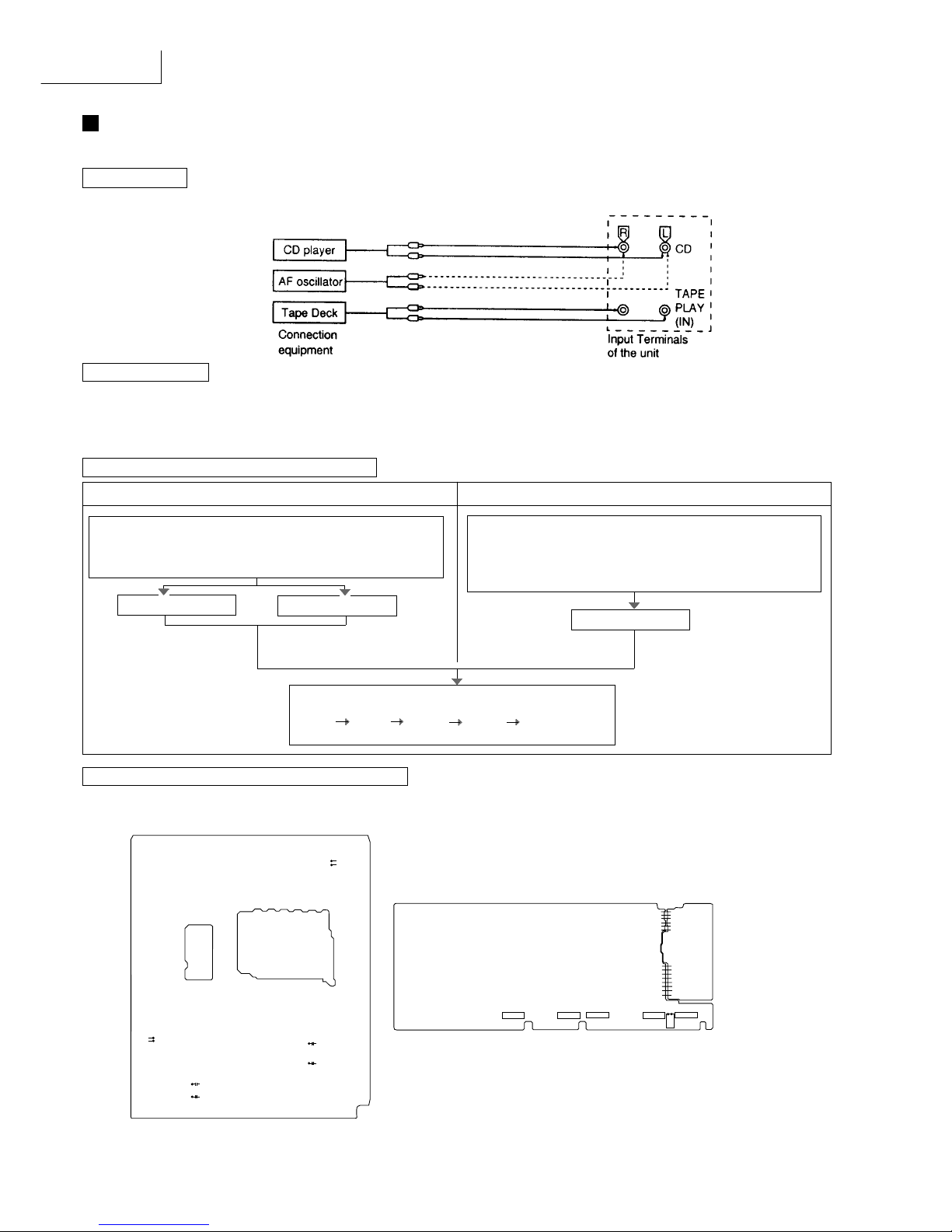

Fan Motor Troubleshooting

Is the air

cooling path blocked

or the fan motorjammed

by any external

obstacle ?

Are the

terminal voltage of

Q772 and Q773 normal in both

and inactive states of the

fan motor ?

(see table1.)

The power IC ( IC601 ) is defective.

The fan motor, power ICs and fan driver

are functioning normally.

YES

Is an audio signal

present at pins 7 and

10

of IC601

NO

YES

NO

Check the integrity of Q772, Q773 and the fan

motor driving circuit. (see Fig.1)

YES

Reinstall the fan on the unit.

Is the fan

motor's DC resistance

20 ~ 30Ω ?

Fan motor failure

Short circuit : DC resistance below 5Ω

Open circuit : DC resistance over 1kΩ

NO

NO

Remove the fan from the unit.

Remove the obstacle.

YES

The Model SA-EX310 employ fan motor error sensing electronics.

If the cooling fan is not operating and "OVER LOAD" is displayed on the FL display, check the fan motor and its driving circuit.

fan. off fan. on

E 14.5V 14.5V

Q772 C 0V 14.5V

B 14.5V 0V

E 0V 8.5V

Q773 C 14.5V 14.5V

B 0V 8.5V

(Table 1)

(Voltage table)

Fig.1

"OVER LOAD" is displayed on the FL display.

M

Q777

Q776

Q773

C775

0.022

2SB621AQSTA

REGULATOR

R778

R772

4.7K

MTZJ9R1CTA

D773

CP771

FAN

MOTOR

C773

0.022

R775

R771

+

+

R776

4.7 1/4W

330

Q772

R779

10K

R777

47K

R773

10K

Q778

47K

47K

C772

C771

35V4.7

50V4.7

R774

3.3M

D771 D772

1SS133

Q772,Q776

2SC1740SSTA

MOTOR DRIVE

Q777

2SA933SSTA

MOTOR DRIVE

Q778

RVTDTA114TST

MOTOR DRIVE

D774

1SS133

Page 10

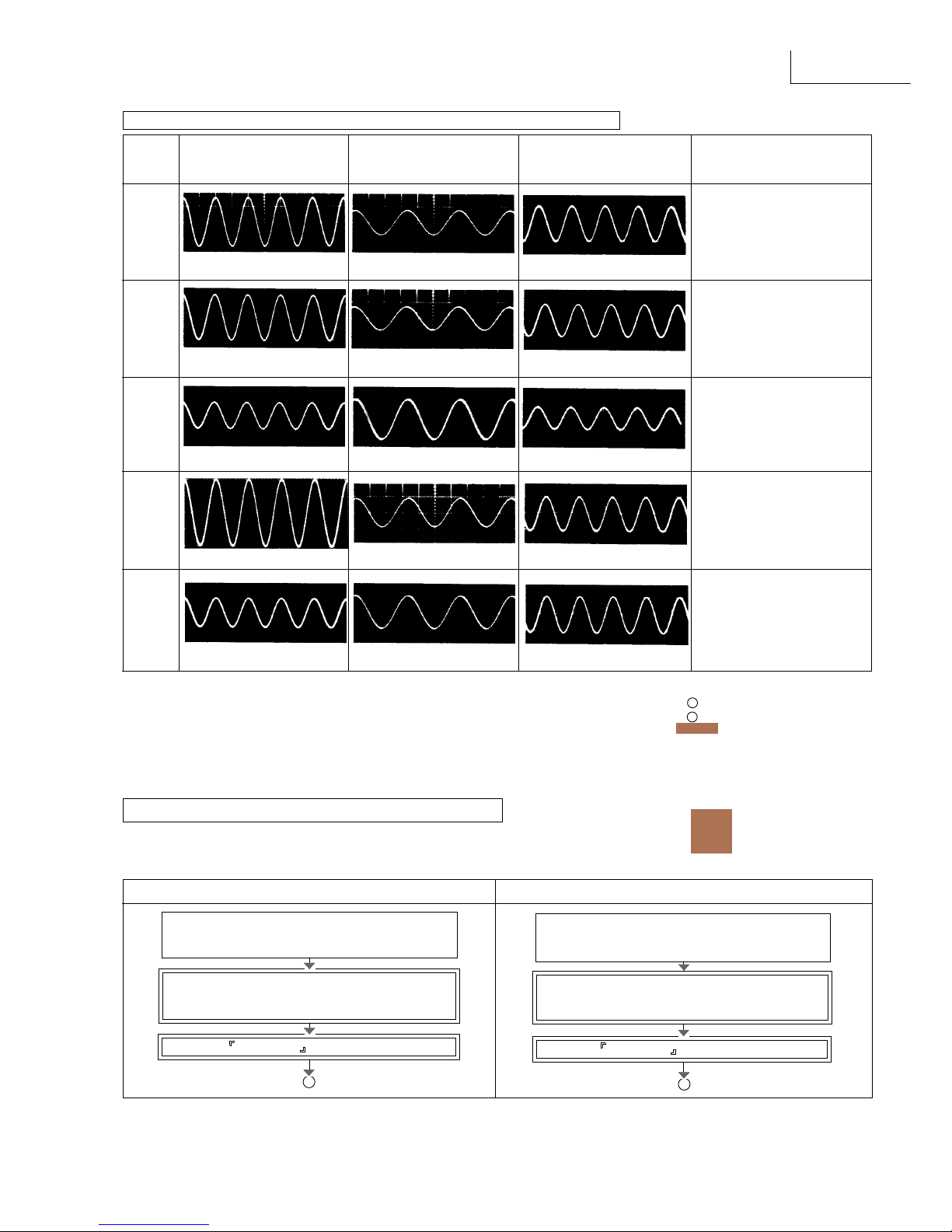

SA-EX310

REQUIRED ITEMS

1. Testing with a CD player Test disc (SZZP1054C / first progarm, 1kHz, 0dB)

2. Testing with a tape deck Test tape (QZZCLA / 315Hz, 0dB)

3. Testing with a AF oscillator Set the output at 500Hz, 200mV

4. Oscilloscope (min. 10MHz) ----------- To measure the output waveform at the test points.

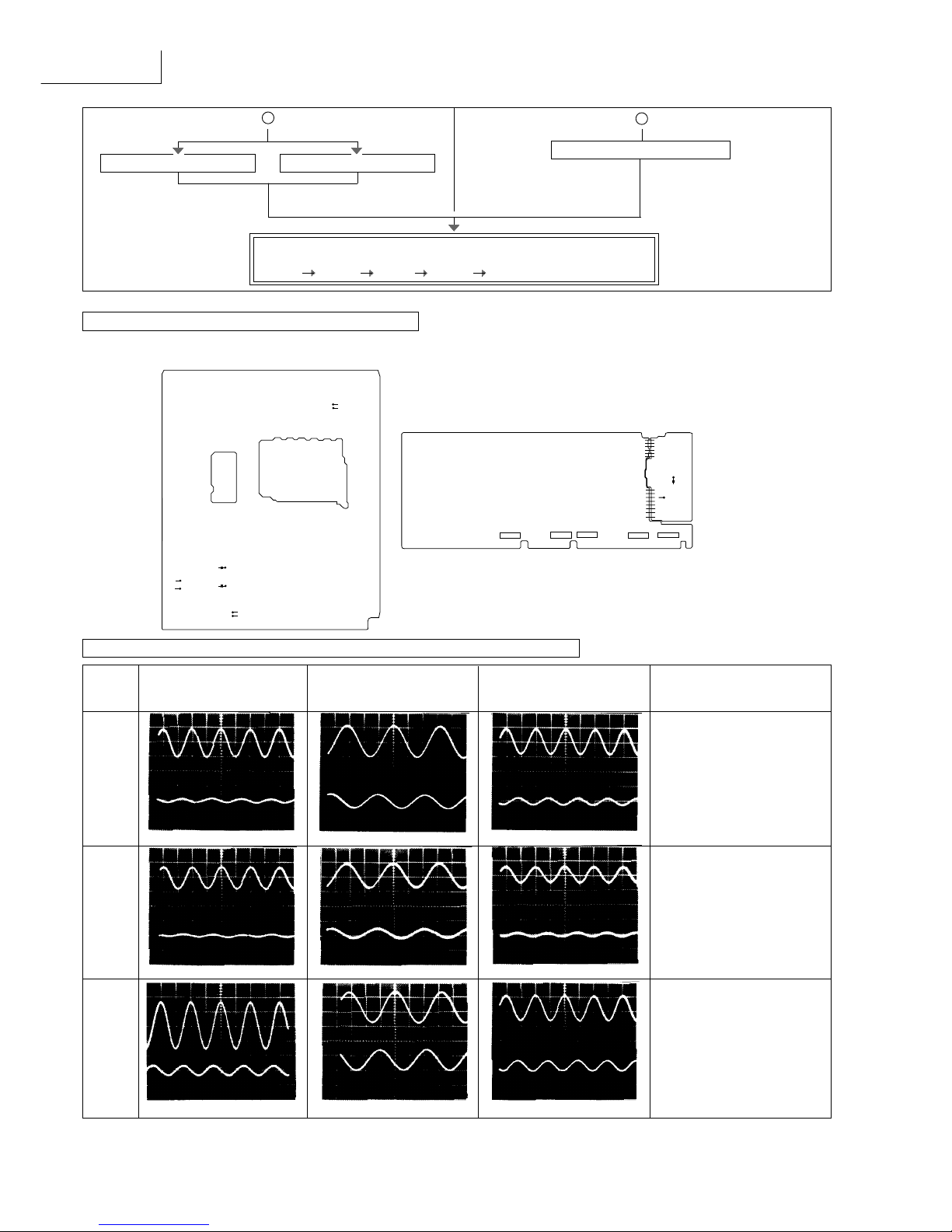

TEST PROCEDURE FOR AMPLIFIER CIRCUIT

When the CD player AF oscillator is connected: When the tape deck is connected:

Troubleshooting

This unit has test points on each circuit board block for use in troubleshooting.

CONNECTION

Connect either a CD player, tape deck or AF oscillator to the input terminals of the unit.

(

(

)

)

Power on the unit.

Set the input selector button of the unit to the "TAPE MONITOR"

postion.

Set the Speaker ON/OFF button of the unit to the SPEAKERS

"ON" position.

Run the tape deck

QZZCLA

315Hz, 0dB

(

)

Using the Oscilloscope, check the output waveforms at the test

points on the circuit boards of the unit in the following order:

(L1,R1) (L2,R2) (L3,R3) (L5,R5) (L6,R6).

Refer to page 10.

TEST POINTS POSITIONS OF AMPLIFIER CIRCUIT

Note: Connect the '+' probe of

the oscilloscope to each

test point and the ''

probe to chassis ground.

Power on the unit.

Set the input selector button of the unit to the "CD" postion.

Set the Speaker select buttons of the unit to the SPEAKERS "

ON" position.

Run the CD player or Run the AF oscillator

SZZP1054C / first program Oscillator output

1kHz, 0dB at 500Hz, 200mV

MAIN P.C.B. ( component side )

PANEL P.C.B. ( component side )

R6

L6

R5

L5

L1

R1

+

+

C1001

C1002

J248

J247

J319

J318

L2

C1004

C1067

R2

+

R3

L3

VR502

Page 11

SA-EX310

Likely faulty block if the normal

TP CD player Tape deck AF oscillator waveform shown at the left is not

present.

L1/R1 Input selector block IC402 &

area

0.5msec 2V 1msec 500mV 1msec 500mV

L2/R2 Dolby pro logic blockIC1001 and

IC1002& area

0.5msec 2V 1msec 500mV 1msec 500mV

L3/R3 Master volume block VR501 &

area

0.5msec 500mV 1msec 50mV 1msec 100mV

L5/R5 Power limiter block Q601 to

Q602 & area

0.5msec 100mV* 1msec 500mV 1msec 500mV

L6/R6 Main amplifier block IC601 &

area

0.5msec 5V* 1msec 10V 1msec 10V

NORMAL WAVEFORMS OF AMPLIFIER CIRCUIT AND LIKELY FAULTY BLOCKS

Measurement conditions. Volume control (VR501), Treble

control (VR512) and Bass control (VR511) positions :

*Volume control position (VR501) for these test :

CHECKING PROCEDURE FOR SURROUND CIRCUIT

Outputting surround signal normally requires that opposite phase signals be applied to both the left and right channels.

However, this unit incorporates a service mode, allowing the surround circuit to be tested using in-phase signals.

The letter SURROUND flash on the FL display.

When the CD player or AF oscillator is connected : When the tape deck is connected :

The letter SURROUND flash on the FL display.

Power on the unit.

Set the input selector button of the unit to the "CD"

position.

Power on the unit.

Set the input selector button of the unit to the "TAPE

MONITOR" position.

A

B

While pressing both "+" and "-" of the surround

level adjustment button "SURROUND, press the

"Power" button.

While pressing both "+" and "-" of the surround

level adjustment button "SURROUND, press the

"Power" button.

Page 12

SA-EX310

Likely faulty block if the normal

TP CD player Tape deck AF oscillator waveform shown at the left is not

present.

C1 Dolby pro logic block

IC1001 and IC1002 & area

S1

0.5msec 1V 1msec 100mV 1msec 200mV

C2 Master volume block VR501 &

area

S2

0.5msec 200mV 1msec 20mV 1msec 50mV

C3 Tone control block IC551 & area

S3

0.5msec 200mV* 1msec 500mV 1msec 1V

( )

( )

B

Run the tape deck

Run the AF oscillatorRun the CD player

QZZCLA

315Hz, 0dB

( )

Oscillator output

at 500Hz, 200mV

SZZP1054C/first program

1kHz, 0dB

A

Using the Oscilloscope, check the output waveforms at the test points on

the circuit boards in the following order :

(C1,S1) (C2,S2) (C3,S3) (C4,S4) (C5,S5).

To exit the service mode, power off the unit.

TEST POINTS POSITIONS OF SOURROUND CIRCUIT

NORMAL WAVEFORMS OF AMPLIFIER CIRCUIT AND LIKELY FAULTY BLOCKS

PANEL P.C.B. ( component side )

Note: Connect the '+' probe of

the oscilloscope to each

test point and the ''

probe to chassis ground.

MAIN P.C.B. ( component side )

C1

S1

S3

C3

C4

+

+

C604

C603

J22

J21

J313

J316

S4

C5

S5

J246

J245

S2

+

C551

R552

C2

Page 13

SA-EX310

NORMAL WAVEFORMS OF AMPLIFIER CIRCUIT AND LIKELY FAULTY BLOCKS

The HIC protection circuit functions if any cord at a speaker terminal is short-circuited or if the unit overheats because of improper

operation. At the same time, OVERLOAD scrolls across the FL display.

In this state, all keys remain in operative; if any key is pressed, SWITCH OFF POWER scrolls across the FL display.

If an overload occurs, immediately power off the unit and check the speaker connection, venting holes and cooling fans. After

fixing any faults, power on the unit again and check for proper operation.

If no defects are found, or if the unit remains overload after it is power on again, check the circuit for faults.

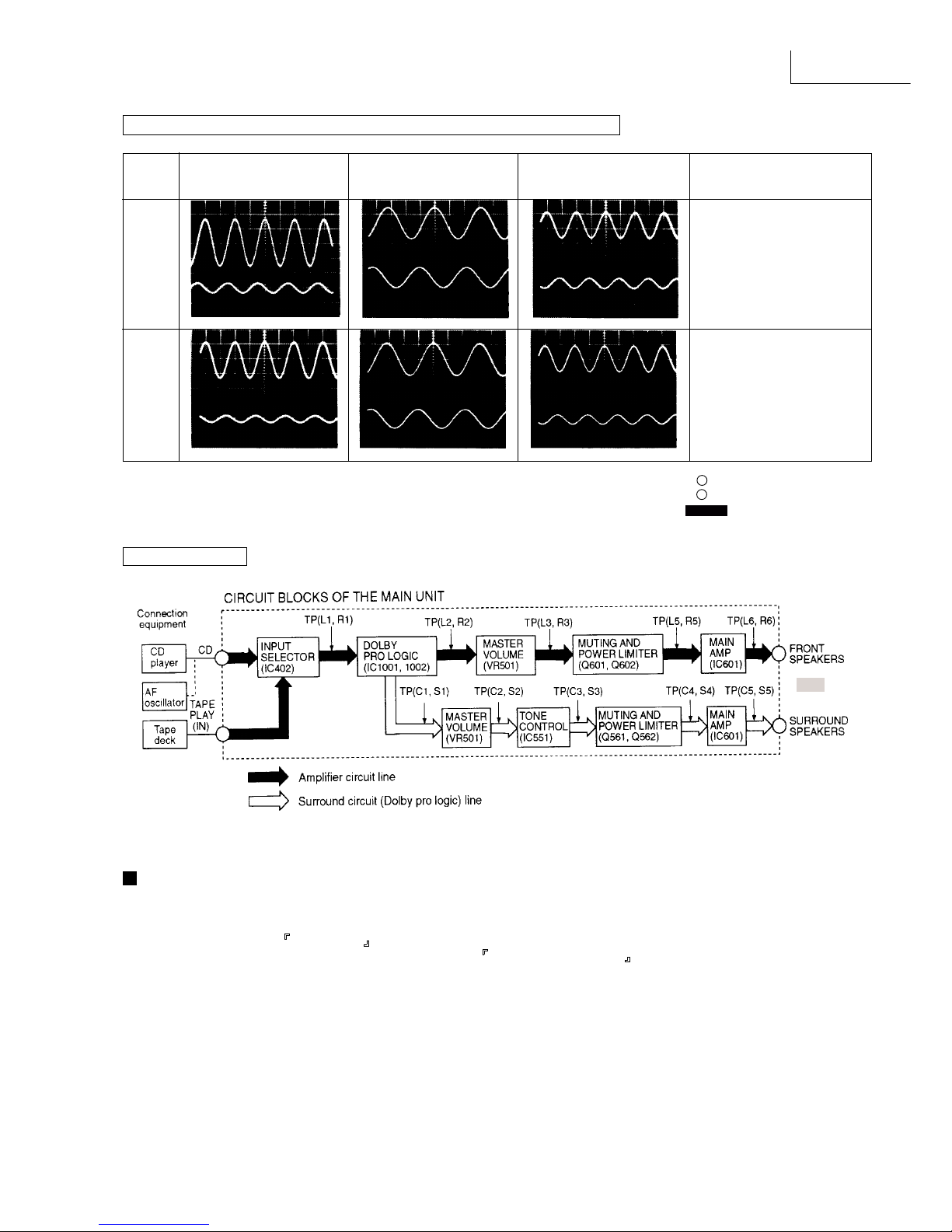

CIRCUIT BLOCKS

OVERLOAD DETECTION FUNCTION

Likely faulty block if the normal

TP CD player Tape deck AF oscillator waveform shown at the left is not

present.

C4 Power limiter block

Q551 to Q552 & area

S4

0.5msec 200mV* 1msec 500mV 1msec 1V

C5 Main amplifier block IC601 &

area IC602 & area

S5

0.5msec 5V* 1msec 10V 1msec 1V*

Measurement conditions. Volume control (VR501), Tremble

control (VR512) and Bass control (VR511) positions :

*Volume control position (VR501) for these test :

Page 14

SA-EX310

Block Diagram

Page 15

SA-EX310

Page 16

SA-EX310

Page 17

SA-EX310

Page 18

SA-EX310

Terminal Functions Of ICs

IC901 (M38B53M4053F) System Microprocessor

Terminal Guide of ICs, Transistors and Diodes

Pin

No.

Mark

I/O

Function

Pin

No.

Mark

I/O

Function

No.1

LA1832A

LC7218

1

12

24

13

NJM2279D

1

7

14

8

TC9163AN 28Pin AN6558F

UPC4570C

1

4

5

8

BA6218

1

9

2SD2137PQTA

2SB1417PQTA

M5218P

LV1016L

1

12

24

13

LA2786L 42Pin

No.1

M38B53M4053F

80 Pin

No. 1

RSN307M44-P

1

18

28

26

2SD592AQSTA

2SA992EFTA

2SB621AQSTA

2SC3940AQSTA

2SA933SSTA

2SC1740SSTA

B

C

E

E

C

B

2SB1548PQAU

2SD2374PQAU

B

C

E

2SC2787LTA

2SC2785FETA

2SC3311ARTA

2SD1915FTA

E

C

B

RVTDTA113ZST

RVTDTA114EST

RVTDTC143XST

RVTDTA143XST

RVTDTC114YST

RVTDTA114YST

RVTDTA114EST

33~48

SEG16~SEG1

O FL segment signal output

49~58

DEG1~DEG10

O FL digit signal output

59 INIT_IN I Diode input

60 VOL_DOWN O

61 VOL_UP O

62 LOUDNESS Not used

63 IF_DATA I Serial data signal

64 REC_MUTE Not used

65 TNR_CE O Chip enable signal

66

SEL/TNR_CK

O Serial clock signal

67

SEL/TNR_DT

O Serial data signal

68 SEL_ST O Level shift control terminal

69 OSD_ST Not used

70

SURR/OSD_CK

O Serial clock signal

71

SURR/OSD_DT

O Serial data signal

72 SURR_CE O Chip enable signal

73 AVSS GND for A-D conveter

74 VREF I Reference voltage for A-D convertion

75 SD I SD signal detect input

76 AC3_LED Not used

77 HELP_LED O LED drive signal (HELP)

78 VIDEO_DET Not used

79 VIDEO_B O Video selector control output B

80 VIDEO_A O Video selector control output A

1~4 KEY4~KEY1 I Key matrix detect terminal

5

THERM/OVLD

I Thermal/Over load detect terminal

6 FM_ST I Stereo signal detect terminal

7 6CH_ST Not used

8 RDS_ST Not used

9 REMOTE I Remote control terminal

10 RESET I Reset detect terminal

11 RDS_CK Not used

12 RDS_DT Not used

13 GND GND terminal

14 XIN I Crystal oscillator terminal

15 XOUT O (4 MHz)

16 VDD I Power supply terminal

17~21 SFC5~SFC1 O SFC LED indicator output

22 HOLD I Power trip detection input

23

STANDBY_LED

Not used

24 FAN_STOP Not used

25 RLY O Power relay control output

26 TV/DVD I TV/DVD select control input

27 LIMITTER O Power limitter control output

28 VEE I FL driver pull down voltage

29 S/C_SP O Surround/center speaker control output

30 SP_B O Speaker B control output

31 SP_A O Speaker A control output

32 AF_MUTE O Muting control output

Rotate control terminal of volume motor

B

C

E

1

4

5

8

STK311-010

BLUE

Page 19

SA-EX310

MTZJ5R1BTA

MTZJ5R6BTA

MTZJ7R5CTA

MTZJ9R1CTA

MTZJ6R2BTA

MTZJ15CTA

MTZJ6R8BTA

MTZJ4R7BTA

MTZJ3R9ATA

MTZJ10CTA

MTZJ27DTA

MTZJ24DTA

RVD1SS133TA

1SR35200TB

1SS291TA

MA165TA

Ca

A

Cathode

Anode

Ca

Cathode

Anode

A

: +B line

: Main signal line

: B line

: AM signal line

: AM OSC signal line

: FM/AM signal line

: FM signal line

: FM OSC signal line

Signal line

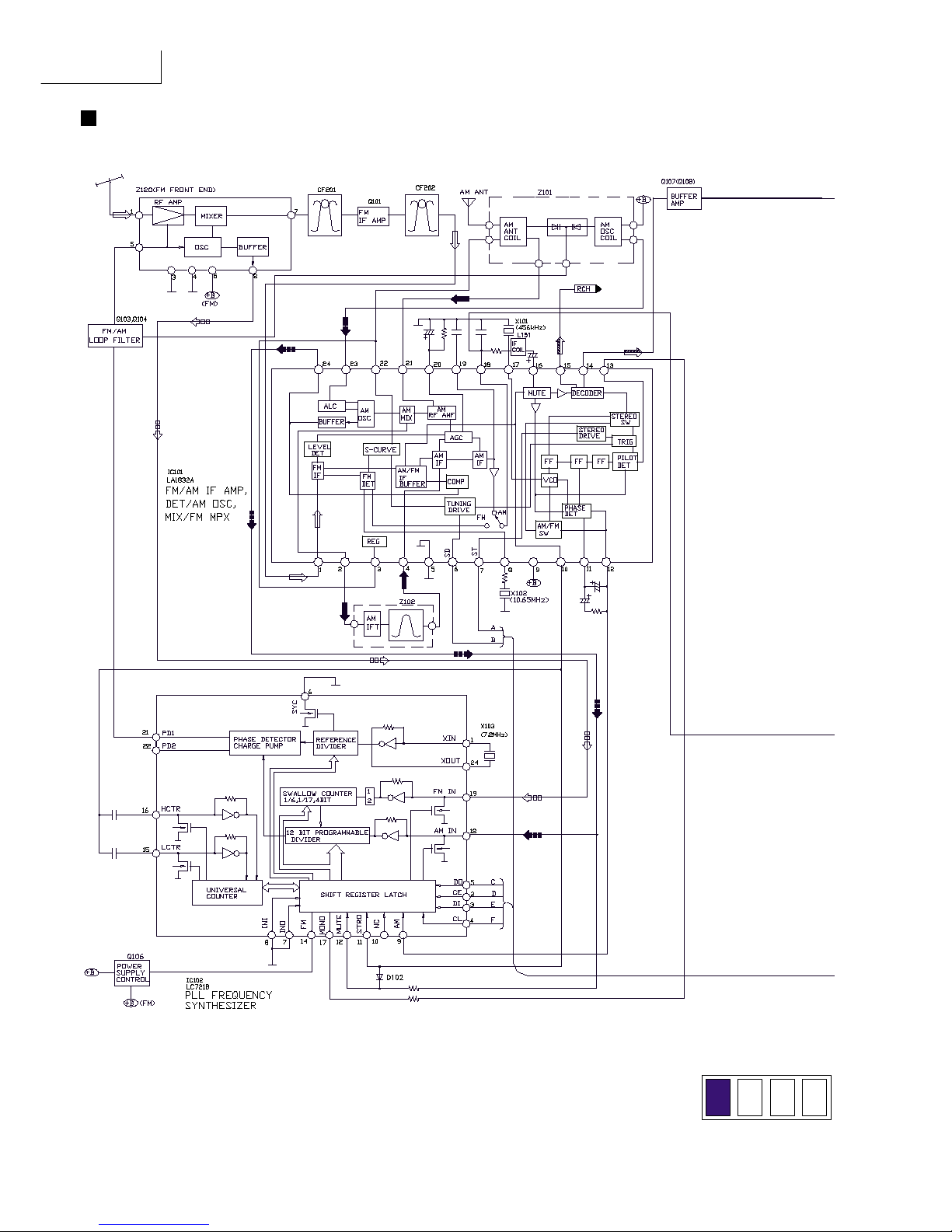

Schematic Diagram

(All schematic diagrams may be modified at any time with the development of new technology)

Note :

S946 : Power switch

S947 : Phono select switch

S948 : Muting switch

S950 : FM Auto/ Mono switch

S951 : Band select switch

S952 : Tuning decrease switch

S953 : Tuning increase switch

S955 : Memory manual/auto switch

S956 : Preset decrease switch

S957 : Preset increase switch

S960 : Tuner select switch

S961 : CD select switch

S962 : Tape select switch

S963 : TV/DVD select switch

S964 : VCR select switch

S970 : Search switch

S971 : EON switch

S972 : PTY up switch

S973 : PTY down switch

S974 : Display mode switch

S980 : Speaker switch

S983 : Dolby Pro Logic/SFC off on switch

S984 : Dolby Pro Logic mode select switch

S985 : Center mode select switch

VR501-1 ~ VR501-4 : Volume control

VR502 : Balance control

VR511-1 ~ VR511-2 : Bass control

VR512-1 ~ VR512-2 : Treble control

Importance safety notice:

Components identified by

mark have special characteristics important for safety. Furthermore, special parts which have purposes of

fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors), etc. are used. When replacing any of components, be sure

to use only manufacturer's specified parts shown in the parts list.

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

Cover the parts boxes made of plastics with aluminium foil.

Ground the soldering iron.

Do not touch the pins of IC, LSI or VLSI with fingers directly.

Put a conductive mat on the work table.

The voltage value and waveforms are the reference voltage of this unit measured by DC electronic voltmeter (high impedance) and oscillo-

scope on the basis of chassis.

Accordingly, there may arise some error in voltage values and waveforms depending upon the internal impedance of the tester or the

measuring unit.

( ) ..... AM < > ..... FM

1N5402BM21

SB360L6508

Ca

A

Cathode

Anode

Anode

Cathode

Ca

A

LN846RPH

Page 20

SA-EX310

Schematic Diagram

Page 21

SA-EX310

Page 22

SA-EX310

Page 23

SA-EX310

Page 24

SA-EX310

Page 25

SA-EX310

Page 26

SA-EX310

Page 27

SA-EX310

Page 28

SA-EX310

Page 29

SA-EX310

Page 30

SA-EX310

Printed Circuit Board

C MOTOR P.C.B. (REP2445D-S)

B PANEL P.C.B. (REP2445D-S)

E HEADPHONE JACK P.C.B. (REP2445D-S)

Page 31

SA-EX310

D POWER SWITCH P.C.B. (REP2445D-S)

Page 32

SA-EX310

A MAIN P.C.B. (REP2444C-M)

Page 33

SA-EX310

Page 34

SA-EX310

F TUNER P.C.B. (REP2158A-T).....EG

(REP2158D-T).....E/EB

Page 35

SA-EX310

J POWER P.C.B.

(REP2446D-P).....E/EG

(REP2446E-P).....EB

H TRANSFORMER P.C.B.

(REP2444C-M)

Page 36

SA-EX310

I IN / OUT TERMINAL P.C.B.

(REP2446D-P).....E/EG

(REP2446E-P).....EB

K AC IN/OUT P.C.B.

(REP2446D-P).....E/EG

(REP2446E-P).....EB

Page 37

SA-EX310

Wiring Connection Diagram

7 ..... 17 ..... 1

CN102

CN101

SOLDER

SIDE

JK101

FM ANT

AM ANT

1..........12

W701

4

.

1

.

CP502

CP905

CP903

CP902

CP901

7

.

.

.

.

.

1

CP501

CN905

7 ..... 1

7 ..... 1

7 ..... 1

7 ..... 1

CP101

CP102

CP401

CP402

CN903

CN902

CN901

1

2

3

CP771

CN502

CN501

7

.

.

.

.

.

1

4

.

1

.

SOLDER

SIDE

PHONO

JK401

VIDEO

JK351

SUB-WOOFER

JK405

SURROUND

R

L

CENTER

SPEAKERS

JK602

JK601

PHONE

HP601

COMPONENT

SIDE

COMPONENT

SIDE

SOLDER

SIDE

7 ..... 1

7 ..... 1

CN401

CN402

CD

REC (OUT)

PLAY (IN)

TAPE

JK402

JK403

JK404

VCR

OUT

IN

SOLDER

SIDE

TV/ DVD

W752

T751

CN751

COMPONENT

SIDE

T701

(POWER

TRANSFORMER)

3 2 1

COMPONENT

SIDE

W1

W2

JK794

W1

W2

BLACK

WHITE

JUMPER

FAN MOTOR

TUNER P.C.B

F

MAIN P .C.B

A

PANEL P.C.B

B

POWER SWITCH

P.C.B

D

HEADPHONE

JACK P.C.B

E

MOTOR P.C.B

C

TRANSFORMER

P.C.B

H

POWER P.C.B

J

IN / OUT

TERMINAL

P.C.B

G

FRONT

AC / IN OUT

P.C.B

K

GND

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

CP904

CN904

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

8

.

.

.

.

.

.

.

1

1 . . 4

CN701B

CN701C

1 . . 41 . . 4

CN701A

1 2 3

CN752

NOTE :

Dotted lines means direct

contact connectors ( no wires ).

R

L

Page 38

SA-EX310

Cabinet Parts Location

30

30

3

24

30

30

30

JK402

JK403

JK404

CN401

CN402

JK101

(TUNER PACK

P.C . B )

CN101

CN102

CP101

JK401

CP401

CP402

E401

JK351

CP102

E601

JK601

JK405

JK602

26

CN752

CN901

CN902

CN903

CN904

CN905

29

29

(OPERATION

P.C . B )

4

CP502

CN502

CN501

5

6

29

29

29

29

29

CP501

CP901

CP902

CP903

19

(VOLUME P.C.B)

29

CP904

CP905

(PANEL P.C.B)

29

9

8

8

10

8

7

30

30

2

(HEADPHONE

P.C . B )

(TUNER P.C.B)

(MAIN P.C.B)

25

25

30

30

13

25

25

30

HP601

F1

CN751

(POWER P.C.B)

T751

W2

W1

W1

JK794

F4

F3

W701

W752

CN701A

CN701B

CN701C

20

(IN/OUT TERMINAL P.C.B)

(AC IN/OUT P.C.B)

23

26

28

28

26

22

31

16

26

26

26

31

31

14

14

14

14

14

18

15

28

26

28

1

27

W2

CP771

21

12

17

12

17

17

12

17

12

Page 39

SA-EX310

Ref No. Part No. Part Name & Description Remarks Ref No. Part No. Part Name & Description Remarks Ref No. Part No. Part Name & Description Remarks

Replacement Parts List

Notes:* Important safety notice :

Components identified by

mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors), etc. are used.

When replacing any of components, be sure to use only manufacturer's specified parts shown in the parts list.

* The parenthesized in the Remarks columns specify the areas. (Refer to the cover page for area.)

Parts without these indication can be used for all areas.

* [M] in Remarks column indicates parts that are supplied by MESA.

* Remote Control Unit : Supply period for three years from terminal of production.

* The "(SF)" mark denotes the standard part.

CABINET AND CHASSIS

1 REM0069 FAN UNIT [M]

2 RFKGEX310EK FRONT PANEL ASSY [M]

3 RGR0251B-A REAR PANEL [M]EG E

3 RGR0251B-B REAR PANEL [M] EB

4 RGU1350-K MODE BUTTON [M]

5 RGU1352M-K DOLBY BUTTON [M]

6 RGU1493-K SELECTOR BUTTON [M]

7 RGW0243A-K VOLUME KNOB [M]

8 RGW0244-K1 BASS TREBLE KNOB [M]

9 RHD26016 SCREW [M]

10 RHN90001 M9 NUT [M]

12 RKA0079-A LEG [M]

13 RKM0260D-K TOP CABINET [M]EG E

14 RKQ0089-J PCB HOLDER [M]

15 RKW0436E-Q FL WINDOW [M]

16 RMC0158-S TRANSISTOR HOLDER [M]

17 RMG0270-K LEG CUSHION [M]

18 RMK0350 B OTTOM CHASSIS [M]

19 RMN0372 FL HOLDER [M]

20 RMQ0709 TUNER PCB BRACKET [M]

21 RMZ0339 ZNR COVER [M]

22 RXX0186 HEAT SINK UNIT [M]

23 SJS9231A A/C INLET COVER [M]

24 SNE2123 EARTH TERMINAL [M]

25 SNE2129-1 SCREW (CABINET) [M]

26 XTB3+20JFZ SCREW [ M]

27 XTB3+30J SCREW (FAN) [M]

28 XTB3+8FFZ SCREW [M]

29 XTBS26+10J SCREW (FRONT) [M]

30 XTBS3+8JFZ1 SCREW [M]

31 X TW3 +15 T SCREW [M]

INTEGRATED CIRCUITS

IC101 LA1832A IC, IF/MPX [M]

IC102 LC7218 IC, PLL [M]

IC351 NJM2279D IC, VIDEO SELECTOR [M]

IC401 TC9163AN IC, SELECTOR [M]

IC402 M5218AP IC, BUFFER AMP [M]

IC451 AN6558F IC, OP AMP [M]

IC501 BA6218 IC, MOTOR DRIVER [M]

IC511 UPC4570C IC, TONE CONTROL [M]

IC551 UPC4570C IC, TONE CONTROL [M]

IC601 RSN307M44-P IC, HIC [M]

IC901 M38B53M4053F IC, MICOM [M]

IC902 STK311-010 IC, RDS DECODER [M]

IC1001 LA2786L IC, DPL [M]

IC1002 LV1016L IC, SURR DECODER [M]

TRANSISTORS

Q101 2SC2787LTA TRANSISTOR [M ]

Q103 2SC2785FETA TRANSISTOR [M ]

Q104 2SC2785FETA TRANSISTOR [M ]

Q106 RVTDTA143XST TRANSISTOR [M ]

Q107 2SC3311ARTA TRANSISTOR [M ]

Q108 2SC3311ARTA TRANSISTOR [M ]

Q351 2SD592AQRSTA TRANSISTOR [M ]

Q352 2SB621AQSTA TRANSISTOR [M ]

Q505 2SD1915FTA TRANSISTOR [ M ]

Q506 2SD1915FTA TRANSISTOR [ M ]

Q561 2SD1915FTA TRANSISTOR [ M ]

Q562 2SD1915FTA TRANSISTOR [ M ]

Q601 2SC1740SSTA TRANSISTOR [M ]

Q602 2SC1740SSTA TRANSISTOR [M ]

Q603 2SC1740SSTA TRANSISTOR [M ]

Q604 2SC1740SSTA TRANSISTOR [M ]

Q605 RVTDTA113ZST TRANSISTOR [ M ]

Q606 RVTDTA113ZST TRANSISTOR [ M ]

Q608 2SD1915FTA TRANSISTOR [ M ]

Q681 2SD1915FTA TRANSISTOR [ M ]

Q682 2SD1915FTA TRANSISTOR [ M ]

Q701 2SD2374PQAU TRANSISTOR [M ]

Q703 2SC1740SSTA TRANSISTOR [M ]

Q704 2SC1740SSTA TRANSISTOR [M ]

Q706 2SC3940AQSTA TRANSISTOR [ M ]

Q707 2SB621AQSTA TRANSISTOR [M ]

Q708 2SB1548PQAU TRANSISTOR [M ]

Q731 2SB1417PQTA TRANSISTOR [M ]

Q732 2SC1740SSTA TRANSISTOR [M ]

Q733 2SC1740SSTA TRANSISTOR [M ]

Q734 2SD2137PQTA TRANSISTOR [M ]

Q735 2SA992EFTA TRANSISTOR [M ]

Q737 2SA992EFTA TRANSISTOR [M ]

Q751 RVTDTC143XST TRANSISTOR [ M ]

Q752 2SC3940AQSTA TRANSISTOR [ M ]

Q771 2SA933SSTA TRANSISTOR [ M ]

Q772 2SC1740SSTA TRANSISTOR [M ]

Q773 2SB621AQSTA TRANSISTOR [M ]

Q774 RVTDTA114EST TRANSISTOR [ M ]

Q775 2SA933SSTA TRANSISTOR [ M ]

Q776 2SC1740SSTA TRANSISTOR [M ]

Q777 2SA933SSTA TRANSISTOR [ M ]

Q778 RVTDTA114TST TRANSISTOR [ M ]

Q779 RVTDTA114TST TRANSISTOR [ M ]

Q901 RVTDTC114YST TRANSISTOR [ M ]

Q902 2SA933SSTA TRANSISTOR [ M ]

Q907 RVTDTC114YST TRANSISTOR [ M ]

Q909 2SC1740SSTA TRANSISTOR [M ]

Q937 RVTDTA114YST TRANSISTOR [ M ]

Q1001 2SC3940AQSTA TRANSISTOR [M ]

DIODES

D101 MTZJ5R1BTA DIODE [M]

D102 MA165TA DIODE [ M ]

D351 MTZJ5R6BTA DIODE [M]

D352 MTZJ5R6BTA DIODE [M]

D401 MTZJ7R5CTA DIODE [M ]

D601 SB360L6508 DIODE [M ]

D602 SB360L6508 DIODE [M ]

D605 RVD1SS133TA DIODE [ M ]

D606 RVD1SS133TA DIODE [ M ]

D608 MTZJ6R2BTA DIODE [ M]

D701 1N5402BM21 DIODE [ M ]

D702 1N5402BM21 DIODE [ M ]

D703 1N5402BM21 DIODE [ M ]

D704 1N5402BM21 DIODE [ M ]

Page 40

SA-EX310

Ref No. Part No. Part Name & Description Remarks

Ref No. Part No. Part Name & Description Remarks Ref No. Part No. Part Name & Description Remarks

D705 MTZJ6R2BTA DIODE [ M]

D707 MTZJ27DTA DIODE [ M ]

D708 MTZJ15CTA DIODE [ M ]

D721 1N5402BM21 DIODE [ M]

D722 1N5402BM21 DIODE [ M]

D723 1N5402BM21 DIODE [ M]

D724 1N5402BM21 DIODE [ M]

D731 MTZJ24DTA DIODE [ M ]

D732 RVD1SS133TA DIODE [ M ]

D733 RVD1SS133TA DIODE [ M ]

D751 1SR35200TB DIODE [ M ]

D752 1SR35200TB DIODE [ M ]

D753 1SR35200TB DIODE [ M ]

D754 1SR35200TB DIODE [ M ]

D755 RVD1SS133TA DIODE [ M ]

D756 MTZJ6R8BTA DIODE [ M]

D771 RVD1SS133TA DIODE [ M ]

D772 RVD1SS133TA DIODE [ M ]

D773 MTZJ9R1CTA DIODE [M ]

D775 RVD1SS133TA DIODE [ M ]

D781 RVD1SS133TA DIODE [ M ]

D782 RVD1SS133TA DIODE [ M ]

D901 1SS291TA DIODE [M ]

D903 MTZJ4R7BTA DIODE [ M]

D921 RVD1SS133TA DIODE [ M ]

D923 RVD1SS133TA DIODE [ M ]

D924 MTZJ3R9ATA DIODE [ M]

D925 RVD1SS133TA DIODE [ M ]

D929 LN846RPH DIODE [ M ]

D1001 MTZJ10CTA DIODE [ M ]

VARIABLE RESISTORS

VR501 EUWMRH026B15 VR, MOTOR [ M]

VR502 EVJ02QF01G15 VR, BALANCE CONTROL [M]

VR511 EVJYA1F01C15 VR, TONE CONTROL [M ]

VR512 EVJYA1F01C15 VR, TONE CONTROL [M ]

SWITCHES

S946 EVQ21405R SW, POWER [ M ]

S947 EVQ21405R SW, PHONO [M ]

S948 EVQ21405R SW , MUTING [M]

S950 EVQ21405R SW , FM MODE [M]

S951 EVQ21405R SW , BAND [M]

S952 EVQ21405R SW , TUNING DOWN [M ]

S953 EVQ21405R SW , TUNING UP [M]

S955 EVQ21405R SW , MEMORY [M]

S956 EVQ21405R SW , PRESET DOWN [ M]

S957 EVQ21405R S W, PRESET UP [ M]

S960 EVQ21405R SW , TUNER [ M]

S961 EVQ21405R S W, CD [M]

S962 EVQ21405R S W, TAPE [M]

S963 EVQ21405R S W, TV/DVD [ M]

S964 EVQ21405R S W, VCR [M]

S970 EVQ21405R S W, SEARCH [M]

S971 EVQ21405R S W, EON [M ]

S972 EVQ21405R S W , PTY UP [M]

S973 EVQ21405R S W, PTY DOWN [M]

S974 EVQ21405R S W , DI S PL A Y MO D E [M]

S980 EVQ21405R S W, SPEAKERS [M]

S983 EVQ21405R SW , OFF/ON [M ]

S984 EVQ21405R S W, PRO-LOGIC [M ]

S985 EVQ21405R S W, CENTER MODE [M ]

CONNECTORS

CN101 RJU057W007 7P CONNECTOR [M ]

CN102 RJU057W007 7P CONNECTOR [M ]

CN401 RJU100W07 7P CONNECTOR [M ]

CN402 RJU100W07 7P CONNECTOR [M ]

CN501 RJU100W07 7P CONNECTOR [M ]

CN502 RJU100W04 4P CONNECTOR [M ]

CN701A

RJS1A6604T1 4P TAPING CONNECTOR [M ]

CN701B

RJS1A6604T1 4P TAPING CONNECTOR [M ]

CN701C

RJS1A6604T1 4P TAPING CONNECTOR [M ]

CN751 SJS305-1 3P CONNECTOR [ M ]

CN752 RJS1A6603T1 3 PIN TAPING CONNECT [ M]

CN901 RJU003K008M1 BOAD IN CONNECTOR [M ]

CN902 RJU003K008M1 BOAD IN CONNECTOR [M ]

CN903 RJU003K008M1 BOAD IN CONNECTOR [M ]

CN904 RJU003K008M1 BOAD IN CONNECTOR [M ]

CN905 RJU003K008M1 BOAD IN CONNECTOR [M ]

CP101 RJT057W007-1 7P CONNECTOR [ M ]

CP102 RJT057W007-1 7P CONNECTOR [ M ]

CP401 RJT100W07 7 P CONNECTOR [M ]

CP402 RJT100W07 7 P CONNECTOR [M ]

CP501 RJT100W07 7 P CONNECTOR [M ]

CP502 RJT100W04 4 P CONNECTOR [M ]

CP771 RJP3G4YA CONNECTOR [ M ]

CP901 RJT003K008M1 8P CONNECTOR [M ]

CP902 RJT003K008M1 8P CONNECTOR [M ]

CP903 RJT003K008M1 8P CONNECTOR [M ]

CP904 RJT003K008M1 8P CONNECTOR [M ]

CP905 RJT003K008M1 8P CONNECTOR [M ]

COILS & TRANSFORMERS

L101 ELES N 1R 0M A CH O K E COIL [ M]

L103 ELEXTR47MA9 CHOKE COIL [M ]

L105 RLQZ B822KT-D TAPING COIL [ M]

L106 RLQZ B822KT-D TAPING COIL [ M]

L151 SLM 1 B 10 - 1M A . B . F I L T E R [ M ]

L191 ELESNR56MA CH OKE COIL [ M]

L501 RLQZ P1R 0K T- Y A X I A L C O I L [ M ]

L502 RLQZ P1R 0K T- Y A X I A L C O I L [ M ]

L601 RLQYR7 3MW -E CH O K E COIL [M]

L602 RLQYR7 3MW -E CH O K E COIL [M]

L603 RLQYR7 3MW -E CH O K E COIL [M]

L604 RLQYR7 3MW -E CH O K E COIL [M]

L751 ELESN101KA C HOKE COIL [ M]

L791 SLQZ650MH49 A C LI N E CO I L [ M ]

L901 RLQ B101KTA-Y CHO KE COIL [M]

L902 RLQZ P101KT-Y AXIAL COIL [ M]

L1051 ELESN101KA CHOKE COIL [M ]

T701 RTP1N5B025-X

POWER TRANSFORMER

[M]

T751 RTP1I5E006

TRANSFORMER (SMALL)

[M]

COMPONENT COMBINATION

Z101 RLA2Z002M-T AM ANT. COIL [M]

Z102 RLI2Z006M-T AM IFT [M ]

Z120 ENV17290G1R F M TUNER PACK [M]EG

Z120 ENV17290G1Y FM TUNER PACK [M] EB E

Z751 ERZV10V511CS ZNR[M]

Z891 RCDSPS4242N REMOTE SENSOR [M ]

CERAMIC FILTERS

CF201 RLFFETNGD01L CERAMIC FILTER [M ]

CF202 RLFFETMGD01L CERAMIC FILTER [M]

CF901 RVBCST4R00MT CERAMIC OSCILLATOR [M]

CF902 RSXZ456KM07M CERAMIC OSCILLATOR [M ]

CF1051 EF0EC8004T4 CERAMIC OSCILLATOR [M ]

OSCILLATORS

X101 RSXZ456KM07M CERAMIC OSCILLATOR [M ]

X102 RLFDGTD01I FM REZONATOR [M ]

X103 SVQ49U722T-S CERAMIC 7.2MHz [M ]

DISPLAY TUBE

FL901 RSL0233-F FL[M]

EARTH TERMINALS

E401 SNE1004-2 EARTH TERMINAL [M]

E601 SNE1004-2 EARTH TERMINAL [M]

FUSES

F1 XBA2C20TB0 FUSE [ M ]

F3 XBA2C50TB0 FUSE [ M ]

Page 41

SA-EX310

Ref No. Part No. Part Name & Description Remarks

Ref No. Part No. Part Name & Description Remarks Ref No. Part No. Part Name & Description Remarks

Ref N o. P art N o. Values & Remarks

Notes:* Important safety notice:

Components identified by

mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise (resistors),etc. are used.

When replacing any of components, be sure to use only manufacturer's specified parts shown in the parts list.

* Capacitor values are in microfarad (µF) unless specified otherwise, P=Pico-farads (pF) F=Farads (F)

* Resistors values are in ohms, unless specified otherwise, 1k=1,000(OHM), 1M=1,000k(OHM)

Resistors & Capacitors

F4 XBA2C50TB0 FUSE [M ]

FUSE CLIPS

FC701 E YF5 2BC FUSE HOLDER [M ]

FC702 E YF5 2BC FUSE HOLDER [M ]

FC703 E YF5 2BC FUSE HOLDER [M ]

FC704 E YF5 2BC FUSE HOLDER [M ]

FC705 E YF5 2BC FUSE HOLDER [M ]

FC706 E YF5 2BC FUSE HOLDER [M ]

RELAYS

RL601 RSY0013M-0 RELAY [M]

RL602 RSY0013M-0 RELAY [M]

RL751 RSY0019M-0 1 2V TV -5 RE LA Y [ M]

JACKS

JK101 RJH4202 J K , ANT TERMINAL [M]

JK351 SJF3069-3N J K, RCA PIN [M]

JK401 SJF3068-7N J K, RCA TERMINAL [M]

JK402 SJF3069N JK , L I N E I N [ M ]

JK403 SJF3069N JK , L I N E I N [ M ]

JK404 SJF3069N JK , L I N E I N [ M ]

JK405 SJFD7 JK, FM MULTI OUT [M]

JK601 RJH5601 J K , SP TERMINAL [M]

JK602 RJR0054 J K , SP TERMINAL [M]

JK794 SJS9231-1B J K, AC I N [M ]

HEADPHONE

HP601 RJJ63TS01 HEADPHONE JACK [M]

PACKING MATERIALS

P1 RPG3462 PACKING CASE [M] E

P2 RPFX0005 MIR AM AT BAG [M ]

P3 RPN0865 POLYFOAM [ M ]

ACCESSORIES

A1 EUR644377 REMOTE CONTROL [ M ]

A1-1 UR64EC1822-3

REMOTE CONTROL COVER

[M]

A2 RJA0019-2K A C CO R D (SF ) [M]EG E

A2 VJA0733 AC C O RD (SF) [M]EB

A3 RFKSEX310EK I NSTR. MANUAL ASSY [M]E

A3 RFKSEX310EBK I NSTR. MANUAL ASSY [M]EB

A3 RFKSEX310EGK I NSTR. MANUAL ASSY [M]EG

A4 RSA0007 FM ANTENA [M ]

A5 RSA0010 LOO P ANT UNIT [M]

A6 SJP9009 ANT ADAPTER [M ]EB

A7 SPSD152 ACCESSORY BOX [M ]

A8 RPG3592 GI FT BOX [M]EB EG

WIRE

W1 REE0814 WIRE [ M ]

W2 REE0818 WIRE [ M ]

Ref N o. P art N o. Values & RemarksRef N o. P art N o. Values & RemarksRe f No. P art N o. Values & Remarks

RESISTORS

R103 ERDS2TJ101T 100 1/4W [M ]

R104 ERDS2TJ102T 1K1/4W[M]

R105 ERDS2TJ471T 470 1/4W [M ]

R106 ERDS2TJ224T 220K 1/4W [ M ]

R107 ERDS2TJ471T 470 1/4W [M ]

R110 ERDS2TJ102T 1K1/4W[M]

R112 ERDS2TJ104T 100K 1/4W [ M ]

R113 ERDS2TJ103T 10K 1/4W [M ]

R114 ERDS2TJ562T 5. 6K 1/4W [ M]

R115 ERDS2TJ561T 560 1/4W [M ]

R116 ERDS2TJ102T 1K1/4W[M]

R117 ERDS2TJ473T 47K 1/4W [M ]

R118 ERDS2TJ562T 5. 6K 1/4W [ M]

R119 ERDS2TJ183T 18K 1/4W [M ]

R120 ERDS2TJ473T 47K 1/4W [M ]

R121 ERDS2TJ332T 3. 3K 1/4W [ M]

R122 ERDS2TJ272T 2. 7K 1/4W [ M]

R124 ERDS2TJ271T 270 1/4W [M]

R125 ERDS2TJ472T 4.7 K 1/4W [M ]

R126 ERDS2TJ472T 4.7 K 1/4W [M ]

R127 ERDS2TJ103T 10K 1/4W [M]

R128 ERDS2TJ820T 821/4W[M]

R129 ERDS2TJ473T 47K 1/4W [M]

R130 ERDS2TJ102T 1K1/4W[M]

R131 ERDS2TJ102T 1K1/4W[M]

R132 ERDS2TJ103T 10K 1/4W [M]

R133 ERDS2TJ102T 1K1/4W[M]

R134 ERDS2TJ102T 1K1/4W[M]

R135 ERDS2TJ102T 1K1/4W[M]

R136 ERDS2TJ102T 1K1/4W[M]

R137 ERDS2TJ102T 1K1/4W[M]

R139 ERDS2TJ272T 2.7 K 1/4W [M ]

R140 ERDS2TJ272T 2.7 K 1/4W [M ]

R141 ERDS2TJ102T 1K1/4W[M]

R142 ERDS2TJ102T 1K1/4W[M]

R143 ERDS2TJ222T 2.2 K 1/4W [M ]

R144 ERDS2TJ222T 2. 2K 1/4W [ M]

R145 ERDS2TJ102T

(EB,E)

1K1/4W[M]

R145 ERDS2TJ561T

(EG)

560 1 / 4 W [ M ]

R146 ERDS2TJ102T

(EB,E)

1K1/4W[M]

R146 ERDS2TJ561T

(EG)

560 1 / 4 W [ M ]

R147 ERDS2TJ474T 470K 1/4W [ M ]

R148 ERDS2TJ474T 470K 1/4W [ M ]

R149 ERDS2TJ680T 681/4W[M]

R171 ERDS2TJ102T 1K1/4W[M]

R172 ERDS2TJ102T 1K1/4W[M]

R173 ERDS2TJ471T 470 1/4W [M ]

R175 ERDS2TJ102T 1K1/4W[M]

R176 ERDS2TJ391T 390 1/4W [M ]

R181 ERDS2TJ332T 3. 3K 1/4W [ M]

R301 ERDS2TJ750T 751/4W[M]

R302 ERDS2TJ750T 751/4W[M]

R359 ERDS2TJ750T 751/4W[M]

R362 ERDS2TJ750T 751/4W[M]

R367 ERDS2TJ102T 1K1/4W[M]

R368 ERDS2TJ102T 1K1/4W[M]

R369 ERDS2TJ182T 1. 8K 1/4W [ M]

R370 ERDS2TJ182T 1. 8K 1/4W [ M]

R371 ERD2FCVG220T 221/4W[M]

R372 ERD2FCVG220T 221/4W[M]

R373 ERDS2TJ103T 10K 1/4W [M ]

R374 ERDS2TJ103T 10K 1/4W [M ]

R401 ERDS2TJ102T 1K1/4W[M]

R402 ERDS2TJ102T 1K1/4W[M]

R405 ERDS2TJ102T 1K1/4W[M]

R406 ERDS2TJ102T 1K1/4W[M]

R407 ERDS2TJ102T 1K1/4W[M]

R408 ERDS2TJ102T 1K1/4W[M]

R409 ERDS2TJ102T 1K1/4W[M]

R410 ERDS2TJ102T 1K1/4W[M]

R411 ERDS2TJ102T 1K1/4W[M]

R412 ERDS2TJ102T 1K1/4W[M]

R413 ERDS2TJ102T 1K1/4W[M]

R414 ERDS2TJ102T 1K1/4W[M]

Page 42

SA-EX310

Ref N o. P art N o. Values & RemarksRef No . Pa rt No . Values & RemarksRef N o. Pa rt No . Values & Remarks Ref No . Pa rt No . Values & Remarks

R415 ERDS2TJ102T 1K1/4W[M]

R416 ERDS2TJ102T 1K1/4W[M]

R417 ERDS2TJ473T 47K 1/4W [M]

R418 ERDS2TJ473T 47K 1/4W [M]

R419 ERDS2TJ104T 100K 1/4W [M ]

R420 ERDS2TJ104T 100K 1/4W [M ]

R421 ERDS2TJ104T 100K 1/4W [M ]

R422 ERDS2TJ104T 100K 1/4W [M ]

R423 ERDS2TJ102T 1K1/4W[M]

R424 ERDS2TJ102T 1K1/4W[M]

R425 ERDS2TJ103T 10K 1/4W [M]

R426 ERDS2TJ103T 10K 1/4W [M]

R427 ERDS2TJ103T 10K 1/4W [M]

R440 ERDS1FVJ820T 821/2W[M]

R441 ERDS2TJ473T 47K 1/4W [M]

R442 ERDS2TJ473T 47K 1/4W [M]

R443 ERDS2TJ330T 331/4W[M]

R451 ERDS2TJ224T 220K 1/4W [M ]

R452 ERDS2TJ224T 220K 1/4W [ M ]

R453 ERDS2TJ391T 390 1/4W [M]

R454 ERDS2TJ391T 390 1/4W [M]

R455 ERDS2TJ563T 56K 1/4W [M]

R456 ERDS2TJ563T 56K 1/4W [M]

R457 ERDS2TJ271T 270 1/4W [M]

R458 ERDS2TJ271T 270 1/4W [M]

R459 ERDS2TJ680T 681/4W[M]

R460 ERDS2TJ680T 681/4W[M]

R461 ERDS2TJ184T 180K 1/4W [ M ]

R462 ERDS2TJ184T 180K 1/4W [ M ]

R463 ERDS2TJ123T 12K 1/4W [M]

R464 ERDS2TJ123T 12K 1/4W [M]

R465 ERDS2TJ563T 56K 1/4W [M]

R466 ERDS2TJ563T 56K 1/4W [M]

R467 ERDS2TJ102T 1K1/4W[M]

R468 ERDS2TJ102T 1K1/4W[M]

R469 ERDS2TJ102T 1K1/4W[M]

R470 ERDS2TJ102T 1K1/4W[M]

R501 ERDS2TJ222T 2.2 K 1/4W [M ]

R502 ERDS2TJ222T 2.2 K 1/4W [M ]

R503 ERDS2TJ103T 10K 1/4W [M]

R504 ERDS2TJ103T 10K 1/4W [M]

R505 ERDS2TJ103T 10K 1/4W [M]

R506 ERDS2TJ103T 10K 1/4W [M]

R508 ERDS1FVJ2R2T 2 .2 1/2W [M ]

R511 ERDS2TJ471T 470 1/4W [M]

R512 ERDS2TJ471T 470 1/4W [M]

R513 ERDS2TJ474T 470K 1/4W [M ]

R514 ERDS2TJ474T 470K 1/4W [M ]

R515 ERDS2TJ474T 470K 1/4W [ M ]

R516 ERDS2TJ474T 470K 1/4W [ M ]

R517 ERDS2TJ332T 3.3 K 1/4W [M ]

R518 ERDS2TJ332T 3.3 K 1/4W [M ]

R519 ERDS2TJ222T 2.2 K 1/4W [M ]

R520 ERDS2TJ222T 2.2 K 1/4W [M ]

R521 ERDS2TJ223T 22K 1/4W [ M ]

R522 ERDS2TJ223T 22K 1/4W [ M ]

R523 ERDS2TJ392T 3.9 K 1/4W [M ]

R524 ERDS2TJ392T 3.9 K 1/4W [M ]

R525 ERDS2TJ222T 2.2 K 1/4W [M ]

R526 ERDS2TJ222T 2.2 K 1/4W [M ]

R527 ERDS2TJ122T 1.2 K 1/4W [M ]

R528 ERDS2TJ122T 1.2 K 1/4W [M ]

R529 ERDS2TJ273T 27K 1/4W [ M ]

R530 ERDS2TJ273T 27K 1/4W [ M ]

R531 ERDS2TJ332T 3.3 K 1/4W [M ]

R532 ERDS2TJ332T 3.3 K 1/4W [M ]

R533 ERDS2TJ103T 10K 1/4W [ M ]

R534 ERDS2TJ103T 10K 1/4W [ M ]

R543 ERDS2TJ102T 1K1/4W[M]

R544 ERDS2TJ102T 1K1/4W[M]

R545 ERDS2TJ684T 680K 1/4W [ M ]

R546 ERDS2TJ103T 10K 1/4W [ M ]

R551 ERDS2TJ102T 1K1/4W[M]

R552 ERDS2TJ102T 1K1/4W[M]

R553 ERDS2TJ104T 100K 1/4W [ M ]

R554 ERDS2TJ104T 100K 1/4W [ M ]

R555 ERDS2TJ223T 22K 1/4W [ M ]

R556 ERDS2TJ223T 22K 1/4W [ M ]

R557 ERDS2TJ681T 680 1/4W [ M ]

R558 ERDS2TJ102T 1K1/4W[M]

R561 ERDS2TJ332T 3.3 K 1/4W [M ]

R562 ERDS2TJ332T 3.3 K 1/4W [M ]

R563 ERDS2TJ104T 100K 1/4W [ M ]

R564 ERDS2TJ104T 100K 1/4W [ M ]

R565 ERDS2TJ102T 1K1/4W[M]

R566 ERDS2TJ102T 1K1/4W[M]

R567 ERDS2TJ101T 100 1/4W [ M ]

R568 ERDS2TJ101T 100 1/4W [ M ]

R569 ERDS2TJ332T 3.3 K 1/4W [M ]

R601 ERDS2TJ102T 1K1/4W[M]

R602 ERDS2TJ102T 1K1/4W[M]

R603 ERDS2TJ102T 1K1/4W[M]

R604 ERDS2TJ102T 1K1/4W[M]

R605 ERDS2TJ392T 3.9 K 1/4W [M ]

R606 ERDS2TJ392T 3.9 K 1/4W [M ]

R607 ERDS2TJ223T 22K 1/4W [ M ]

R608 ERDS2TJ223T 22K 1/4W [M ]

R609 ERDS2TJ222T 2. 2K 1/4W [ M]

R610 ERDS2TJ222T 2. 2K 1/4W [ M]

R611 ERDS2TJ222T 2. 2K 1/4W [ M]

R612 ERDS2TJ222T 2. 2K 1/4W [ M]

R613 ERDS2TJ182T 1. 8K 1/4W [ M]

R614 ERDS2TJ182T 1. 8K 1/4W [ M]

R615 ERDS2TJ182T 1. 8K 1/4W [ M]

R616 ERDS2TJ182T 1. 8K 1/4W [ M]

R617 ERDS2TJ563T 56K 1/4W [M ]

R618 ERDS2TJ563T 56K 1/4W [M ]

R619 ERDS2TJ563T 56K 1/4W [M ]

R620 ERDS2TJ563T 56K 1/4W [M ]

R621 ERDS2TJ470T 471/4W[M]

R622 ERDS2TJ470T 471/4W[M]

R623 ERDS2TJ470T 471/4W[M]

R624 ERDS2TJ470T 471/4W[M]

R625 ERDS1FVJ100T 101/2W[M]

R626 ERDS1FVJ100T 101/2W[M]

R627 ERDS1FVJ100T 101/2W[M]

R628 ERDS1FVJ100T 101/2W[M]

R629 ERDS2TJ104T 100K 1/4W [ M]

R630 ERDS2TJ124T 120K 1/4W [ M]

R631 ERDS2TJ154T 150K 1/4W [ M ]

R632 ERDS2TJ184T 180K 1/4W [ M]

R633 ERDS2TJ473T 47K 1/4W [M ]

R634 ERDS2TJ684T 680K 1/4W [ M]

R635 ERDS2TJ154T 150K 1/4W [ M]

R636 ERDS2TJ684T 680K 1/4W [ M ]

R637 ERDS2TJ104T 100K 1/4W [ M ]

R638 ERDS2TJ563T 56K 1/4W [M ]

R639 ERDS2TJ273T 27K 1/4W [M ]

R640 ERDS2TJ473T 47K 1/4W [M ]

R641 ERDS2TJ221T 220 1/4W [M ]

R642 ERDS2TJ221T 220 1/4W [M ]

R643 ERDS2TJ221T 220 1/4W [M ]

R644 ERDS2TJ221T 220 1/4W [M ]

R645 ERG1SJ101E 100 1W[M]

R646 ERG1SJ101E 100 1W[M]

R647 ERG1SJ101E 100 1W[M]

R648 ERG1SJ101E 100 1W[M]

R649 ERD2FCVG220T 221/4W[M]

R650 ERD2FCVG220T 221/4W[M]

R652 ERD25FVJ4R7T 4.7 1/4W [ M ]

R653 ERDS2TJ682T 6. 8K 1/4W [ M]

R654 ERDS2TJ682T 6. 8K 1/4W [ M]

R656 ERDS2TJ681T 680 1/4W [M ]

R657 ERDS2TJ333T 33K 1/4W [M ]

R658 ERDS2TJ333T 33K 1/4W [M ]

R659 ERDS2TJ183T 18K 1/4W [M ]

R660 ERDS2TJ224T 220K 1/4W [M ]

R661 ERDS2TJ102T 1K1/4W[M]

R662 ERDS2TJ102T 1K1/4W[M]

R663 ERDS2TJ102T 1K1/4W[M]

R665 ERDS2TJ472T 4. 7K 1/4W [ M]

R666 ERDS2TJ472T 4. 7K 1/4W [ M]

R681 ERDS2TJ270T 271/4W[M]

R682 ERDS2TJ270T 271/4W[M]

R683 ERDS2TJ270T 271/4W[M]

R684 ERDS2TJ270T 271/4W[M]

R685 ERDS2TJ270T 271/4W[M]

R686 ERDS2TJ270T 271/4W[M]

R687 ERDS2TJ270T 271/4W[M]

R688 ERDS2TJ270T 271/4W[M]

R689 ERDS2TJ270T 271/4W[M]

R690 ERDS2TJ270T 271/4W[M]

R691 ERDS2TJ270T 271/4W[M]

R692 ERDS2TJ270T 271/4W[M]

R693 ERDS2TJ270T 271/4W[M]

R694 ERDS2TJ270T 271/4W[M]

R695 ERDS2TJ102T 1K1/4W[M]

R696 ERDS2TJ102T 1K1/4W[M]

R699 ERDS2TJ332T 3. 3K 1/4W [ M]

R703 ERDS1FVJ3R9T 3.9 1/2W [M ]

R704 ERDS1FVJ3R9T 3.9 1/2W [M ]

R705 ERDS2TJ472T 4. 7K 1/4W [ M]

R706 ERDS2TJ102T 1K1/4W[M]

R707 ERD25FVJ221T 220 1/4W [M ]

R708 ERDS2TJ152T 1. 5K 1/4W [ M]

R709 ERDS2TJ1R5T 1.5 1/4W [M ]

R710 ERDS2TJ1R5T 1.5 1/4W [M ]

R711 ERDS2TJ752T 7. 5K 1/4W [ M]

R712 ERDS2TJ682T 6. 8K 1/4W [ M]

R713 ERDS2TJ390T 391/4W[M]

R714 ERDS2TJ390T 391/4W[M]

R721 ERD2FCVG151T 150 1/4W [ M ]

R722 ERDS2TJ392T 3. 9K 1/4W [ M]

R723 ERDS1FVJ3R9T 3.9 1/2W [M ]

R724 ERDS1FVJ3R9T 3.9 1/2W [M ]

R725 ERDS2TJ102T 1K1/4W[M]

R731 ERD2FCVG220T 221/4W[M]

R732 ERDS2TJ153T 15K 1/4W [M ]

R733 ERDS2TJ123T 12K 1/4W [M ]

R734 ERDS2TJ562T 5. 6K 1/4W [ M]

R735 ERDS2TJ103T 10K 1/4W [M ]

R739 ERD2FCVG220T 221/4W[M]

Page 43

SA-EX310

Ref N o. P art N o. Values & RemarksRef No. Part N o. Values & RemarksRef No . Pa rt No . Values & Remarks Ref No . Par t No. Values & Remarks

R740 ERDS2TJ393T 39K 1/4W [M ]

R742 ERDS2TJ393T 39K 1/4W [M ]

R743 ERDS2TJ183T 18K 1/4W [M ]

R754 ERDS2TJ102T 1K1/4W[M]

R771 ERDS2TJ473T 47K 1/4W [M ]

R772 ERDS2TJ473T 47K 1/4W [M ]

R773 ERDS2TJ103T 10K 1/4W [M ]

R774 ERDS2TJ335T 3.3 M 1/4W [ M ]

R775 ERDS2TJ331T 330 1/4W [M ]

R776 ERD25FVJ4R7T 4.7 1/4W [ M ]

R777 ERDS2TJ224T 220K 1/4W [ M ]

R778 ERDS2TJ472T 4. 7K 1/4W [ M]

R779 ERDS2TJ103T 10K 1/4W [M ]

R782 ERDS2TJ470T 471/4W[M]

R783 ERDS2TJ103T 10K 1/4W [M ]

R784 ERDS2TJ154T 150K 1/4W [ M]

R785 ERDS2TJ103T 10K 1/4W [M ]

R786 ERDS2TJ154T 150K 1/4W [ M]

R787 ERDS2TJ223T 22K 1/4W [M ]

R788 ERDS2TJ223T 22K 1/4W [M ]

R789 ERDS2TJ223T 22K 1/4W [M ]

R790 ERDS2TJ223T 22K 1/4W [M ]

R793 ERDS2TJ682T 6. 8K 1/4W [ M]

R794 ERDS2TJ682T 6. 8K 1/4W [ M]

R901 ERDS2TJ102T 1K1/4W[M]

R906 ERDS2TJ182T 1. 8K 1/4W [ M]

R907 ERDS2TJ104T 100K 1/4W [M ]

R908 ERDS2TJ104T 100K 1/4W [M ]

R909 ERDS2TJ104T 100K 1/4W [M ]

R910 ERDS2TJ102T 1K1/4W[M]

R911 ERDS2TJ104T 100K 1/4W [M ]

R917 ERDS2TJ103T 10K 1/4W [M ]

R920 ERDS2TJ271T 270 1/4W [M ]

R921 ERDS2TJ121T 120 1/4W [M ]

R922 ERDS2TJ472T 4. 7K 1/4W [ M]

R924 ERDS2TJ333T 33K 1/4W [M ]

R927 ERDS2TJ181T 180 1/4W [M ]

R929 ERDS2TJ101T 100 1/4W [M ]

R930 ERDS2TJ101T 100 1/4W [M ]

R936 ERDS2TJ104T 100K 1/4W [ M]

R937 ERDS2TJ104T 100K 1/4W [ M]

R941 ERDS2TJ472T 4. 7K 1/4W [ M]

R943 ERDS2TJ102T 1K1/4W[M]

R944 ERDS2TJ104T 100K 1/4W [ M ]

R945 ERDS2TJ104T 100K 1/4W [ M ]

R946 ERDS2TJ103T 10K 1/4W [M ]

R947 ERDS2TJ103T 10K 1/4W [M ]

R948 ERDS2TJ103T 10K 1/4W [M ]

R949 ERDS2TJ103T 10K 1/4W [M]

R950 ERDS2TJ102T 1K1/4W[M]

R951 ERDS2TJ122T 1.2 K 1/4W [M ]

R952 ERDS2TJ152T 1.5 K 1/4W [M ]

R953 ERDS2TJ182T 1.8 K 1/4W [M ]

R954 ERDS2TJ222T 2.2 K 1/4W [M ]

R955 ERDS2TJ332T 3.3 K 1/4W [M ]

R956 ERDS2TJ472T 4.7 K 1/4W [M ]

R957 ERDS2TJ682T 6.8 K 1/4W [M ]

R960 ERDS2TJ102T 1K1/4W[M]

R961 ERDS2TJ122T 1.2 K 1/4W [M ]

R962 ERDS2TJ152T 1.5 K 1/4W [M ]

R963 ERDS2TJ182T 1.8 K 1/4W [M ]

R964 ERDS2TJ222T 2.2 K 1/4W [M ]

R970 ERDS2TJ102T 1K1/4W[M]

R971 ERDS2TJ122T 1.2 K 1/4W [M ]

R972 ERDS2TJ152T 1.5 K 1/4W [M ]

R973 ERDS2TJ182T 1.8 K 1/4W [M ]

R974 ERDS2TJ222T 2.2 K 1/4W [M ]

R980 ERDS2TJ102T 1K1/4W[M]

R981 ERDS2TJ122T 1.2 K 1/4W [M ]

R982 ERDS2TJ152T 1.5 K 1/4W [M ]

R983 ERDS2TJ182T 1.8 K 1/4W [M ]

R985 ERDS2TJ222T 2.2 K 1/4W [M ]

R1001 ERDS2TJ223T 22K 1/4W [M]

R1002 ERDS2TJ223T 22K 1/4W [M]

R1003 ERDS2TJ102T 1K1/4W[M]

R1004 ERDS2TJ102T 1K1/4W[M]

R1005 ERDS2TJ203T 20K 1/4W [M]

R1007 ERDS2TJ473T 47K 1/4W [M]

R1008 ERDS2TJ473T 47K 1/4W [M]

R1009 ERDS2TJ332T 3. 3K 1/4W [M ]

R1010 ERDS2TJ332T 3. 3K 1/4W [M ]

R1011 ERDS2TJ332T 3. 3K 1/4W [M ]

R1012 ERDS2TJ102T 1K1/4W[M]

R1016 ERD2FCVJ6R8T 6.8 1/4W [M ]

R1051 ERDS2TJ393T 39K 1/4W [M]

R1052 ERDS2TJ105T 1M1/4W[M]

R1053 ERDS2TJ102T 1K1/4W[M]

R1055 ERDS2TJ473T 47K 1/4W [M]

R1056 ERDS2TJ473T 47K 1/4W [M]

R1061 ERDS2TJ222T 2. 2K 1/4W [M ]

CAPACITORS

C101 ECBT1C103NS5 0.01 16V [M]

C103 ECBT1C103NS5 0.01 16V [M]

C104 ECBT1H102KB5 1000P 50V [M ]

C105 ECBT1H470J5 47P 50V [M]

C106 ECBT1C103NS5 0.01 16V [M]

C107 ECBT1H473ZF5 0.047 50V [M]

C108 ECBT1H8R2KC5 8.2P 50V [M ]

C109 ECBT1C103NS5 0.01 16V [M]

C110 ECBT1C103NS5 0.01 16V [M]

C111 ECEA1EKA4R7B 4.7 25V [ M]

C112 ECBT1C103NS5 0.01 16V [M]

C113 ECBT1H102KB5 1000P 50V [M ]

C114 ECEA1HKA3R3B 3.3 50V [M]

C115 ECEA1EKA4R7B 4.7 25V [ M]

C116 ECBT1C822MS5 8200P 16V [M ]

C117 ECQB1H471JF3 470P 50V [M ]

C118 ECQB1H103JF3 0.01 50V [M ]

C119 ECQB1H103JF3 0.01 50V [M ]

C120 ECEA1HKA010B 1 50V [ M]

C121 ECEA1HKA010B 1 50V [ M]

C122 ECEA1HKA2R2B 2.2 50V [M]

C123 ECEA1HKA010B 1 50V [ M]

C124 ECBT1H102KB5 1000P 50V [M ]

C125 ECBT1H150JC5 15P 50V [M ]

C126 ECBT1H104ZF5 0.1 50V [M ]

C127 ECEA1CKA220B 22 16V [ M ]

C128 ECBT1C103NS5 0.01 16V [M]

C129 ECEA0JKA101B 100 6.3V [ M]

C130 ECEA0JKA101B 100 6.3V [ M]

C131 ECBT1C103NS5 0.01 16V [M]

C132 ECBT1H102KB5 1000P 50V [M ]

C133 ECBT1H150JC5 15P 50V [M ]

C134 ECBT1H180JC5 18P 50V [M ]

C135 ECBT1C103MS5 0 .01 16V [ M ]

C136 ECBT1C103MS5 0 .01 16V [ M ]

C137 ECBT1H561KB5 560P 50V [ M ]

C138 ECBT1H561KB5 560P 50V [ M ]

C139 ECQB1H682JF3 6800P 50V [M ]

C140 ECQB1H682JF3 6800P 50V [M ]

C141 ECEA1HKA010B 1 50V [ M]

C142 ECEA1HKA010B 1 50V [ M]

C143 ECEA1HKA010B 1 50V [ M]

C144 ECEA1HKA010B 1 50V [ M]

C145 ECBT1H220JC5 22P 50V [M ]

C146 ECBT1H331KB5 330P 50V [M ]

C147 ECBT1H102KB5 1000P 50V [M ]

C148 ECBT1C103NS5 0.01 16V [M]

C149 ECBT1C103NS5 0.01 16V [M]

C150 ECBT1H104ZF5 0.1 50V [M ]

C172 ECBT1H331KB5 330P 50V [ M ]

C173 ECEA1CKA220B 22 16V [ M ]

C174 ECEA1CKA101B 100 16V [ M]

C175 ECBT1C103NS5 0.01 16V [M]

C176 ECBT1C103NS5 0.01 16V [M]

C181 ECBT1H471KB5 470P 50V [ M ]

C196 ECBT1H102KB5 1000P 50V [M ]

C330 ECBT1H470J5 47P 50V [M]

C331 ECBT1H470J5 47P 50V [M]

C332 ECKR1H223ZF5 0.022 50V [ M ]

C333 ECKR1H223ZF5 0.022 50V [ M ]

C351 ECEA1CU101B 100 16V [ M ]

C352 ECEA1CU101B 100 16V [ M ]

C354 ECBT1E103ZF5 0.0 1 25V [M]

C355 ECBT1E103ZF5 0.0 1 25V [M]

C357 ECBT1E103ZF5 0.0 1 25V [M]

C358 ECBT1E103ZF5 0.0 1 25V [M]

C373 ECA1EM470B 47 25V [ M ]

C374 ECA1EM470B 47 25V [ M ]

C401 ECEA1VKA4R7B 4.7 35V [ M]

C402 ECEA1VKA4R7B 4.7 35V [ M]

C403 ECBT1E103ZF5 0.0 1 25V [M]

C404 ECBT1E103ZF5 0.0 1 25V [M]

C405 ECBT1H101KB5 100P 50V [ M ]

C406 ECBT1H101KB5 100P 50V [ M ]

C409 ECEA1CKA100B 10 16V [ M ]

C410 ECEA1CKA100B 10 16V [ M ]

C411 ECBT1H101KB5 100P 50V [ M ]

C412 ECBT1H101KB5 100P 50V [ M ]

C415 ECBT1E103ZF5 0.0 1 25V [M]

C416 ECBT1E103ZF5 0.0 1 25V [M]

C417 ECBT1H101KB5 100P 50V [ M ]

C418 ECBT1H101KB5 100P 50V [ M ]

C419 ECBT1H331KB5 330P 50V [ M ]

C420 ECBT1H331KB5 330P 50V [ M ]

C421 ECBT1H331KB5 330P 50V [ M ]

C422 ECBT1H331KB5 330P 50V [ M ]

C423 ECBT1H101KB5 100P 50V [ M ]

C424 ECBT1H101KB5 100P 50V [ M ]

C425 ECBT1H101KB5 100P 50V [ M ]

C426 ECBT1H101KB5 100P 50V [ M ]

C427 ECBT1H221KB5 220P 50V [ M ]

C428 ECBT1H221KB5 220P 50V [ M ]

C431 ECEA1CKA100B 10 16V [ M ]

C432 ECEA1CKA100B 10 16V [ M ]

Page 44

SA-EX310

Ref N o. P art N o. Values & RemarksRef No . Pa rt No . Values & RemarksRef N o. Pa rt No . Values & Remarks Ref No . Pa rt No . Values & Remarks

C440 ECBT1E103ZF5 0.0 1 25V [ M ]

C451 ECEA1VKA4R7B 4.7 35V [M ]

C452 ECEA1VKA4R7B 4.7 35V [M ]

C453 ECBT1H100JC5 10P 50V [M]

C454 ECBT1H100JC5 10P 50V [M]

C455 ECBT1H102KB5 1000P 50V [ M]

C456 ECBT1H102KB5 1000P 50V [ M]

C457 ECA1CM330B 33 16V [ M ]

C458 ECA1CM330B 33 16V [ M ]

C459 ECFR1E223KR 0.022 25V [ M ]

C460 ECFR1E223KR 0.022 25V [ M ]

C461 ECBT1C682KR5 6800P 16V [M]

C462 ECBT1C682KR5 6800P 16V [M]

C463 ECEA1VKA4R7B 4.7 35V [M ]

C464 ECEA1VKA4R7B 4.7 35V [M ]

C465 ECBT1E103ZF5 0.0 1 25V [ M ]

C466 ECBT1E103ZF5 0.0 1 25V [ M ]

C469 ECBT1H181KB5 180P 50V [ M ]

C470 ECBT1H181KB5 180P 50V [ M ]

C503 ECEA0JKA101B 100 6.3V [ M]

C504 ECEA0JKA101B 100 6.3V [ M]

C505 ECFR1C104MR 0 .1 16V [M ]

C506 ECFR1C104MR 0 .1 16V [M ]

C511 ECEA1HKA3R3B 3.3 50V [ M ]

C512 ECEA1HKA3R3B 3.3 50V [ M ]

C513 ECBT1H150J5 15P 50V [M]

C514 ECBT1H150J5 15P 50V [M]

C515 ECBT1H221KB5 220P 50V [ M ]

C516 ECBT1H221KB5 220P 50V [ M ]

C517 ECBT1H330J5 33P 50V [M]

C518 ECBT1H330J5 33P 50V [M]

C519 ECEA1VKA4R7B 4.7 35V [M ]

C520 ECEA1VKA4R7B 4.7 35V [M ]

C521 ECEA1VKA4R7B 4.7 35V [M ]

C522 ECEA1VKA4R7B 4.7 35V [M ]

C523 ECFR1E123KR 0.012 25V [ M ]

C524 ECFR1E123KR 0.012 25V [ M ]

C525 ECQV1H683JM3 0.068 50V [ M ]

C526 ECQV1H683JM3 0.068 50V [ M ]

C527 ECBT1C562KR5 5600P 16V [M]

C528 ECBT1C562KR5 5600P 16V [M]

C529 ECQB1H273JF3 0 .027 50V [ M ]

C530 ECQB1H273JF3 0 .027 50V [ M ]

C531 ECBT1E103ZF5 0.0 1 25V [ M ]

C532 ECBT1E103ZF5 0.0 1 25V [ M ]

C533 ECEA1CKA220B 22 16V [M ]

C534 ECEA1CKA220B 22 16V [M ]

C536 ECBT1E103ZF5 0.0 1 25V [ M ]

C551 ECEA1HKA3R3B 3.3 50V [ M ]

C552 ECEA1HKA3R3B 3.3 50V [ M ]

C553 ECBT1H101KB5 100P 50V [ M ]

C554 ECBT1H101KB5 100P 50V [ M ]

C555 ECBT1H221KB5 220P 50V [ M ]

C556 ECBT1H221KB5 220P 50V [ M ]

C557 ECBT1E103ZF5 0.0 1 25V [ M ]

C558 ECBT1E103ZF5 0.0 1 25V [ M ]

C559 ECEA1CKA100B 10 16V [M ]

C560 ECEA1CKA100B 10 16V [M ]

C561 ECA1HM3R3B 3. 3 50V [ M ]

C562 ECA1HM3R3B 3. 3 50V [ M ]

C563 ECBT1H104ZF5 0 .1 50V [M ]

C601 ECA1CM330B 33 16V [ M ]

C602 ECA1CM330B 33 16V [ M ]

C603 ECEA1VKA4R7B 4.7 35V [M]

C604 ECEA1VKA4R7B 4.7 35V [M]

C605 ECA1JM330B 336.3V[M]

C606 ECA1JM330B 336.3V[M]

C607 ECA1JM330B 336.3V[M]

C608 ECA1JM330B 336.3V[M]

C609 ECCR1H120KC5 12P 50V [ M ]

C610 ECCR1H120KC5 12P 50V [ M ]

C611 ECCR1H120KC5 12P 50V [ M ]

C612 ECCR1H120KC5 12P 50V [ M ]

C613 ECBT1H821KB5 820P 50V [ M ]

C614 ECBT1H821KB5 820P 50V [ M ]

C615 ECBT1H821KB5 820P 50V [ M ]

C616 ECBT1H821KB5 820P 50V [ M ]

C617 ECQV1H473JZ3 0 .047 50V [ M ]

C618 ECQV1H473JZ3 0 .047 50V [ M ]

C619 ECQV1H473JZ3 0 .047 50V [ M ]

C620 ECQV1H473JZ3 0 .047 50V [ M ]

C621 ECEA2AU100B 10 100V [ M ]

C622 ECEA1HN010SB 1 50V [ M ]

C623 ECA1HM470B 47 50V [ M ]

C624 ECEA2AN2R2SB 2.2 100V [ M ]

C625 ECEA1HN100SB 10 50V [ M ]

C626 ECEA1HN100SB 10 50V [ M ]

C627 ECKR1H223ZF5 0.022 50V [M ]

C628 ECKR1H223ZF5 0.022 50V [M ]

C629 ECKR1H223ZF5 0.022 50V [M ]

C630 ECKR1H223ZF5 0.022 50V [M ]

C631 ECKR1H223ZF5 0.022 50V [M ]

C632 ECKR1H223ZF5 0.022 50V [M ]

C635 ECEA1VKA4R7B 4.7 35V [M]

C636 ECEA1HN010SB 1 50V [ M ]

C637 ECBT1H102KB5 1000P 50V [M ]

C638 ECBT1H101KB5 100P 50V [ M ]

C639 ECBT1H102KB5 1000P 50V [M ]

C640 ECKR1H223ZF5 0.022 50V [ M ]

C641 ECQV1H104JM3 0 .1 50V [ M ]

C642 ECQV1H104JM3 0 .1 50V [ M ]

C643 ECQV1H104JM3 0 .1 50V [ M ]

C644 ECQV1H104JM3 0 .1 50V [ M ]

C683 ECBT1C332KR5 3300P 16V [M ]

C684 ECBT1C332KR5 3300P 16V [M ]

C685 ECBT1E103ZF5 0.0 1 25V [M]

C701 ECBT1E103ZF5 0.0 1 25V [M]

C702 ECQE2104KF3 0 .1 250V [ M ]

C703 EC0S1HP682BB 6800P 50V [M ]

C704 EC0S1HP682BB 6800P 50V [M ]

C705 EC0S1VP562BB 5600P 35V [ M ]

C706 EC0S1VP562BB 5600P 35V [ M ]

C707 ECA1VM101B 100 35V [ M ]

C708 ECKR1H103ZF5 0.01 50V [M ]

C709 ECA1CM330B 33 16V [ M ]

C710 ECBT1E103ZF5 0.0 1 25V [M]

C711 ECKR1H103ZF5 0.01 50V [M ]

C712 ECA1HM100B 10 50V [ M ]

C713 ECKR1H103ZF5 0.01 50V [M ]

C714 ECA1EM470B 47 25V [ M ]

C715 ECEA1CU101B 100 16V [M ]

C721 ECQE2104KF3 0 .1 250V [ M ]

C731 ECKR1H103ZF5 0.01 50V [M ]

C732 ECKR1H103ZF5 0.01 50V [M ]

C751

ECKWRS102MBC

1000P 400V [ M ]

C752 ECKR1H103ZF5 0.01 50V [M ]

C753 ECA1EM102EV 1000 25V [M ]

C754 ECBT1E103ZF5 0.0 1 25V [M]

C755 ECA1CM470B 47 16V [ M ]

C757 ECA1CM100B 10 16V [ M ]

C771 ECEA1VKA4R7B 4.7 35V [ M]

C772 ECEA1VKA4R7B 4.7 35V [ M]

C773 ECBT1E223ZF5 0.02 2 25V [M ]

C774 ECEA0JKA101B 100 6.3V [ M]

C775 ECBT1E223ZF5 0.02 2 25V [M ]

C901 ECA0JM102B 100 0 6.3 V [ M]

C902 ECBT1E223ZF5 0.02 2 25V [M ]

C903 ECBT1E103ZF5 0.0 1 25V [M]

C904 ECA0JM102B 100 0 6.3 V [ M]

C906 ECEA0JKA101B 100 6.3V [ M]

C908 ECBT1E103ZF5 0.0 1 25V [M]

C909 ECEA1HKA220B 22 50V [ M ]

C910 ECEA1HKA220B 22 50V [ M ]

C911 ECEA1HKA220B 22 50V [ M ]

C912 ECEA1HKA220B 22 50V [ M ]

C913 ECEA1VKA100B 10 35V [M ]

C914 ECEA1VKA100B 10 35V [M ]

C916 ECEA1HKA010B 1 50V [ M]

C917 ECEA1HKAR47B 0.47 50V [ M]

C918 ECEA0JKA221B 220 6.3V [ M]

C920 ECEA1HKA010B 1 50V [ M]

C932 ECBT1H101KB5 100P 50V [M ]

C939 ECBT1H101KB5 100P 50V [ M ]

C941 ECBT1E103ZF5 0.0 1 25V [M]

C952 ECBT1H101KB5 100P 50V [M ]

C953 ECBT1H101KB5 100P 50V [ M ]

C956 ECBT1H101KB5 100P 50V [ M ]

C961 ECBT1H101KB5 100P 50V [ M ]

C1001 ECEA1HU010B 1 50V [M]

C1002 ECEA1HU010B 1 50V [M]

C1003 ECA1HM3R3B 3.3 50V [ M ]

C1004 ECA1HM3R3B 3.3 50V [ M ]

C1005 ECEA1HU010B 1 50V [M]

C1007 ECFR1E223KR 0.02 2 25V [M ]

C1008 ECFR1E473KR 0.04 7 25V [M ]

C1009 ECEA0JU221B 220 6.3V [ M]

C1010 ECEA1CKA100B 10 16V [M ]

C1011 ECEA1CKA100B 10 16V [M ]

C1012 ECEA1CKA100B 10 16V [M ]

C1013 ECEA1CKA100B 10 16V [M ]

C1014 ECEA0JU221B 220 6.3V [ M]

C1015 ECQV 1H 104 JM 3 0. 1 50V [ M ]

C1016 ECQV 1H 104 JM 3 0. 1 50V [ M ]

C1017 ECA1HMR47B 0 .47 50V [M]

C1018 ECEA1VKA4R7B 4.7 35V [ M]

C1019 ECA1HMR47B 0 .47 50V [M]

C1020 ECEA1VKA4R7B 4.7 35V [ M]

C1021 ECEA1HKAR15B 0.15 50V [M]

C1022 ECA1HM3R3B 3.3 50V [ M ]

C1023 ECQV 1H154JZ3 0.15 50V [M ]

C1024 ECQV 1H154JZ3 0.15 50V [M ]

C1025 ECA1HM3R3B 3.3 50V [ M ]

C1026 ECEA1HKAR15B 0.15 50V [M]

C1027 ECEA1VKA4R7B 4.7 35V [ M]

C1028 ECA1HMR47B 0 .47 50V [M]

C1029 ECEA1VKA4R7B 4.7 35V [ M]

C1030 ECA1HMR47B 0 .47 50V [M]

C1031 ECQV 1H 104JM3 0.1 50V [ M ]

C1032 ECQV 1H 104JM3 0.1 50V [ M ]

C1033 ECA1EM470B 47 25V [M ]

C1034 ECQV 1H 474 JM 3 0. 47 50V [M ]

C1035 ECBT1H681KB5 680P 50V [M ]

Page 45

SA-EX310

Ref N o. P art N o. Values & Remarks

Packaging (Refer to page 41 for the Parts List.)

Printed in Singapore

G970708000 P/T/O/J/N

MESA

*P3 (C)

P1

(RPG3462)

ACCESSORY

*P3 (B)

P2

(RPFX0005)

*P3 (D)

P3 (RPN0865)

*P3 (A) - Front Left

*P3 (B) - Front Right

*P3 (C) - Rear Left

*P3 (D) - Rear Right

*P3 (A)

A1 (EUR644377) : REMOTE CONTROL UNIT

A2 (RJA0019-2K ...E, EG) : AC CORD

A2 (VJA0733 ...EB) : AC CORD

A3 (RFKSEX310EK ... E) : INSTR. MANUAL ASS'Y

A3 (RFKSEX310EBK ... EB) : INSTR. MANUAL ASS'Y

A3 (RFKSEX310EGK ... EG) : INSTR. MANUAL ASS'Y

A4 (RSA0007) : FM ANTENA

A5 (RSA0010) : LOOP ANT UNIT

A6 (SJP9009 ... EB) : ANT ADAPTER

A7 (SPSD152) : ACCESSORY BOX

ACCESSORY

C1036 ECBT1H101KB5 100P 50V [M ]

C1037 ECBT1H101KB5 100P 50V [M ]

C1038 ECBT1H101KB5 100P 50V [M ]

C1039 ECEA1CU101B 100 16V [M]

C1040 ECEA1CKA100B 10 16V [M ]

C1041 ECBT1E103ZF5 0.0 1 25V [ M ]

C1051 ECA1HM2R2B 2.2 50V [ M ]

C1052 ECA1HMR33B 0 .33 50V [M]

C1053 ECA1HM3R3B 3.3 50V [ M ]

Ref N o. P art N o. Values & RemarksRef N o. Pa rt No . Values & Remarks

C1054 ECEA0JU221B 220 6.3V [ M]

C1055 ECA1HMR47B 0 .47 50V [M]

C1056 ECQV 1H823JZ3 0.082 50V [ M ]

C1057 ECBT1C332KR5 3300P 16V [ M ]

C1058 ECQV 1H823JZ3 0.082 50V [ M ]

C1059 ECEA1CU101B 100 16V [M]

C1060 ECBT1E223ZF5 0.0 22 25V [M ]

C1062 ECBT1E223ZF5 0.0 22 25V [M ]

C1063 ECEA1CU101B 100 16V [M]

C1065 ECBT1H681KB5 680P 50V [M ]

C1067 ECBT1C152KR5 1500P 16V [M]

C1068 ECBT1C152KR5 1500P 16V [M ]

Ref N o. P art N o. Values & Remarks

Loading...

Loading...