Page 1

1

SERVICE MANUAL

PHRIE / PHIE

INVERTER MONOBLOCK

AIR TO WATER HEAT PUMP

MEDIUM TEMPERATURE

Refrigerant R410A

For applications with electrical support heater or boiler back-up

Jun. 2015 10 12 211 – GB – 06

Page 2

2

Page 3

3

WARNING:

Before carrying out any work on the machine, make sure that its power supply is switched off and the access to it

is prevented. Any work must be carried out by personnel qualified and authorized to work on this type of machine.

Page 4

4

▬ CONTENTS ▬

1 SPECIFICATIONS

1.1 Application - Use

1.2 Presentation & Components

1.3 Technical characteristics

1.4 Physical characteristics

1.5 Description

1.6 Heat pumps capacities

1.7 Available pressures on water circuit

1.8 Sound levels

1.9 System control solutions

2 FRIGORIFIC & HYDRAULIC PART - DIAGRAMS / MAIN COMPONENTS

2.1 Frigorific & Hydraulic diagrams

2.2 Frigorific circuit – Main components description

2.3 Hydraulic circuit – Main components description

3 ELECTRICAL PART - DIAGRAMS / MAIN COMPONENTS

3.1 Diagrams

3.2 Main components

4 SPECIFIC FUNCTIONS ON INVERTER CONTROL

4.1 Water temperature control

4.2 Compressor frequency control

4.3 Max & Min frequency control

4.4 Current release control

4.5 Cooling high-load prevention control

4.6 Heating high-load prevention control

4.7 Freeze prevention control in cooling mode

4.8 Discharge temperature control

4.9 Air heat exchanger defrost control

4.10 Fan control

4.11 Electronic expansion valve control

4.12 Water circulating pump control

4.13 Water flow monitoring

4.14 Heat pump base de-ice heater control

4.15 Heat pump outgoing water temperature alarm

4.16 Heat pump stand alone operation

4.17 Heat pump alarm signal for system control

Page 5

5

5 SERVICE PROCEDURES

5.1 Frigorific circuit alarms

5.2 Hydraulic circuit alarms

5.3 System control alarms

5.4 Boards replacement

5.5 Sensors characteristics

5.6 Electric heater replacement for units 095 & 125

6 MAINTENANCE CONTROLLER FUNCTIONS - PARAMETERS

6.1 Presentation

6.2 Standard display and settings - Connection to A2 control board

6.3 Advanced display and setting - Connection to A3 power board

Page 6

6

PART 1 – TECHNICAL SPECIFICATION

1.1 Application - Use

1.2 Presentation & Components

1.3 Technical characteristics

1.4 Physical characteristics

1.5 Description

1.6 Heat pumps capacities

1.7 Available pressures on water circuit

1.8 Sound levels

1.9 System control solutions

Page 7

7

1.1 – APPLICATION - USE

• Hot water generator for residential heating exclusively in the scope of TECHNIBEL systems

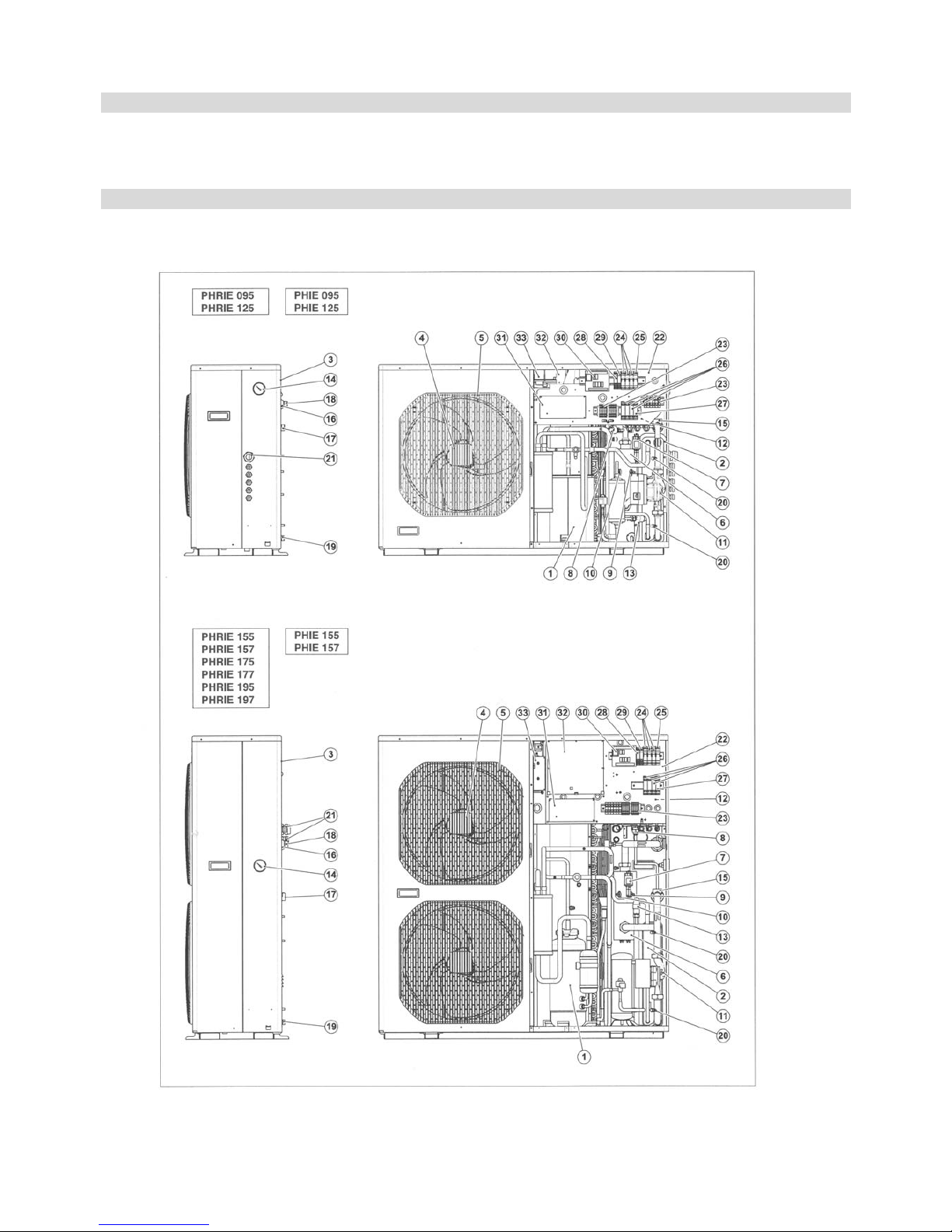

1.2 – PRESENTATION & COMPONENTS

1.2.1 DESCRIPTION

Page 8

8

1.2.2 ELECTRICAL EQUIPEMENT

• According EN 60 335-2-40.

• INVERTER technology control

• Staged electric support heater (with thermal overload protection and water pressure switch).

• Water flow detector.

• System control board.

Page 9

9

1.3 – TECHNICAL CHARACTERISTICS

The specifications are valid for a device in working order with clean heat exchanger.

Note:

• Water circuit pressure: Minimum = 1.5bar,

Maximum = 2.5Bar.

• Maximum allowable water temperature at the inlet of the heat pump when off is 75°C.

• System water volume: see §. 1.5.

• Available water pressure: see §. 1.7.

• Sound level: see §. 1.8.

1.3.1 SINGLE PHASE MODELS

Page 10

10

Page 11

11

Page 12

12

1.3.2 THREE PHASES MODELS

Page 13

13

Page 14

14

Page 15

15

Page 16

16

1.3.3 OPERATING LIMITS

• Automatic devices of the control reduce or prohibit operation of the appliance outside the following limits.

HEATING MODE OPERATING LIMITS:

Page 17

17

1.4 – PHYSICAL CHARACTERISTICS

Page 18

18

Page 19

19

1.5 – DESCRIPTION

1.5.1 SINGLE PHASE MODELS

Page 20

20

1.5.2 THREE PHASES MODELS

Page 21

21

1.6 – HEAT PUMP CAPACITIES

1.6.1 HEATING / COOLING CAPACITIES

See technical manual 10 12 202

1.6.2 CAPACITY CORRECTION ACCORDING GLYCOL RATIO

IMPORTANT: Use monopropylen glycol. A minimum rate of 15 to 20% is needed to avoid any risk of corrosion.

Curves use principle:

Choose the percentage of glycol according to the minimum temperature in order to protect the hydraulic circuit against frost and

then determine the coefficients to be applied to the capacity of the unit, the water flow rate and the pressure drop.

Cooling Mode:

Heating mode:

For current applications, the impact of glycol ratio can be ignored.

1.7 – AVAILABLE PRESSURES ON WATER CIRCUIT

These available pressures are indicated for the water flow to be set at the installation, according to the maximum water outlet

temperature (which is determined according to the application).

Please refer to part 3 for water flow setting.

Example:

-Protection at a outdoor temperature of -15°C gives 30%

glycol (“freezing point curve”).

-This percentage of glycol induces:

• A reduction coefficient of cooling capacity of 0.94.

• A water flow rate coefficient of 1.113 (flow must be

increased).

• A water pressure drop coefficient of 1.19 to be

applied for pressure drop calculation.

Page 22

22

Page 23

23

Page 24

24

Model

Power

level

Lw (dBA

)

Sound-pressure

level (dBA)

Max.

capacity

Puissance

maximum

Nominal

capacity

Max.

capacity

PHRIE 095

PHIE 095

65 67

37 39

PHRIE 125

PHIE 125

65 67

37 39

PHRIE 155

PHIE 155

66 70

38 42

PHRIE 157

PHIE 157

66 70

38 42

PHRIE 175

PHRIE 177

68 72

40 44

PHRIE 195

PHRIE 197

70 74

41 45

PHRIE 257

PHRIE 307

68 72

40 44

1.8 – SOUND LEVELS

Reference standard:

Measurements as per standard EN 12 102.

Measuring method: reverberating chamber

Sound-pressure level:

Unit installed outdoors (free field) on a reflective

surface.

Measurement carried out at a distance of 10m.

Silent mode:

It is possible to activate a silent-mode on the unit.

In this case, the compressor speed is limited for

the nominal capacity of the unit.

For details, see part 4.

Page 25

25

Sound power level spectrum:

Tests conditions:

-Unit at nominal capacity

-Air temperature: 7°C (DB)

-Water inlet temperature: 47°C

-Water outlet temperature:55°C

PHRIE 95

frequency (Hz) Lw dB(A)

100 38,3

125 35,6

160 48,4

200 51,4

250 46,3

315 59,2

400 53,2

500 48,6

630 51,1

800 55,6

1000 55,8

1250 55,3

1600 51,2

2000 45,7

2500 52,8

3150 48,2

4000 48,7

5000 46,6

6300 42,2

8000 37,5

10000 36,7

Sound power level 65,0

PHRIE 125

frequency (Hz) Lw dB(A)

100 44,4

125 41,5

160 42

200 50,5

250 51,3

315 47,7

400 62,3

500 54,2

630 51,5

800 54,5

1000 50,4

1250 47,8

1600 46,4

2000 44,5

2500 46,6

3150 49,8

4000 42,3

5000 38,6

6300 37,3

8000 33,9

10000 28,3

Sound power level 65,0

Page 26

26

PHRIE 155

frequency (Hz) Lw dB(A)

100 52,4

125 49,7

160 53,3

200 55,8

250 46,7

315 46,8

400 49,2

500 54,9

630 60,7

800 59,3

1000 53

1250 48,2

1600 43,2

2000 46,9

2500 46,5

3150 48,1

4000 46,8

5000 47,2

6300 44,5

8000 39

10000 37,7

Sound power level 66,0

PHRIE 175

frequency (Hz) Lw dB(A)

100 57,6

125 52,6

160 53,5

200 54,4

250 51,2

315 50,5

400 52,9

500 56,1

630 62,2

800 61,6

1000 55,2

1250 51,6

1600 48,3

2000 50,0

2500 49,4

3150 51,0

4000 49,8

5000 48,5

6300 45,6

8000 39,5

10000 38,1

Sound power level 68,0

PHRIE 195

frequency (Hz) Lw dB(A)

100 62,4

125 55

160 53,3

200 52,6

250 55,2

315 53,7

400 56,1

500 56,9

630 63,3

800 63,4

1000 56,9

1250 54,5

1600 53

2000 52,7

2500 51,9

3150 53,5

4000 52,4

5000 49,3

6300 46,3

8000 39,5

10000 38

Sound power level 70,0

Page 27

27

PHRIE 257

frequency (Hz) Lw dB(A)

100 52,7

125 44,3

160 50,1

200 48,5

250 50,2

315 57,8

400 55,8

500 56,3

630 62,4

800 61,9

1000 54,2

1250 53,5

1600 53,7

2000 51,3

2500 49,3

3150 50,8

4000 49,7

5000 44,2

6300 43,1

8000 38,4

10000 37,4

Sound power level 68,0

PHRIE 307

frequency (Hz) Lw dB(A)

100 51,1

125 50,8

160 52,9

200 53,7

250 52,4

315 54,4

400 56,3

500 57,5

630 61,1

800 60,3

1000 57,7

1250 55,9

1600 54

2000 53,1

2500 51,5

3150 50,9

4000 49,4

5000 47,9

6300 44,7

8000 39,9

10000 37,5

Sound power level 68,0

Page 28

28

1.9 – SYSTEM CONTROL SOLUTIONS

It features 2 parts:

- Monitoring / control assembly with INVERTER technology, for the

thermodynamic

device. Built into the heat pump, it

controls:

- The variable-speed compressor.

- The variable-speed fan.

- The electronic expansion valve and the cycle inversion valve.

- The water circulating pump (with frost protection and anti-sticking functions).

- System monitoring and control assembly. It ensures:

- Thermodynamic heating control with permanent control of the required capacity based on the needs of the

installation.

- Control of the supplementary support heating.

- Control of the circulators.

- Management of the installation safeties and alarms.

A system control kit must be ordered separately - 2 possibilities:

• For standard applications with integrated electric support heater : system control kit K60D070Z

• For applications with boiler back-up: system control kit K60D071Z

9 System control kit K60D070Z

For standard applications using heat pump with

integrated electric heater

:

A

PPLICATIONS

K60D070ZA. K60D070ZB.

- 1 Floor Zone

- 2 floor Zones

- 1 Terminal Units Zone

- 1 Radiators Zone

- 2 Mixed Zones; Floor + Terminal Units

- 2 Mixed Zones; Floor + Radiators

- 1 Radiators zone + Domestic Hot Water tank

Until mid 2012

- 1 Floor Zone + Domestic Hot Water tank

- 1 Radiators Zone + Domestic Hot Water tank

Since mid 2012, extension B has been dedicated to

applications with Domestic Hot Water

For all details concerning system control operation, please refer to the corresponding technical manuals:

Technical manual 10 12 200 Technical manual 10 12 204

9 System control kit K60D071Z

For applications with boiler back-up:

- 1 Floor Zone

System control kit includes:

- system remote control box,

- outdoor temperature sensor,

- system control manuals.

Page 29

29

- 1 Radiators Zone

For all details concerning system control operation, please refer to the corresponding technical manual 10 12 201

Note: With both system controls, for 1 Zone applications, possibility to activate a 2nd zone with electric convectors. These

appliances must be equipped with an electronic thermostat (out of supply) able to receive controls signals

by means of a

230Vac pilot wire (according standard GIFAM 4).

System control kit includes:

- system remote control box,

- outdoor temperature sensor,

- system control cabinet,

(to be installed in a sheltered technical room)

- system water temperature sensors,

- system control manuals.

Page 30

30

PART 2 – FRIGORIFIC & HYDRAULIC

2.1 Frigorific / Hydraulic diagrams

2.2 Frigorific circuit – Main components description

2.2.1 Compressor

2.2.2 Electronic expansion valve

2.2.3 Four way valve

2.2.4 Fan motor

2.2.5 Pressure sensor

2.3 Hydraulic circuit – Main components description

2.3.1 Water circulating pump

2.3.2 Water flow switch

2.3.3 Pressurized expansion vessel

2.3.4 Safety relief valve

Page 31

31

2.1 – FRIGORIFIC / HYDRAULIC DIAGRAMS

2.1.1 DIAGRAMS FOR MODELS 095/125/155/157/175/177/195/197

Page 32

32

2.1.2 DIAGRAMS FOR MODELS 257/307

Page 33

33

2.2 – FRIGORIFIC CIRCUIT – MAIN COMPONENTS DESCRIPTION

2.2.1 COMPRESSOR

CONTENT

Unit

095 125 155 157 175 177 195 197 257 307

Type

SANYO Hermetic rotary compressor

Reference

C-6RVN93

H0R

C-6RVN103

H0S

C-9RVN273

H0M

C-9RVN273

H0K

C-9RVN273

H0M

C-9RVN273

H0K

C-9RVN273

H0M

C-9RVN273

H0K

C-9RVN273

H0K

C-9RVN393

H0U

Rated output W 900 1000 2700 2700 2700 2700 2700 2700 2700 3900

Comp. Cooling natural

Power source DC inverter

Voltage V 132V 124V 150V 246V 150V 246V 150V 246V 246V 282V

Refrigerant R410A

Oil type DAPHNE FV68S or equivalent

Oil volume L 0.35 0.6 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.9

Motor type DC Brushless motor

Number of poles 4

Insulation class E

Coil resistance T-R (*) Ω 0.482 0.452 0.169 0.552 0.169 0.552 0.169 0.552 0.552 0.608

Coil resistance T-S (*) Ω 0.482 0.452 0.169 0.552 0.169 0.552 0.169 0.552 0.552 0.608

Coil resistance T-S (*) Ω 0.482 0.452 0.169 0.552 0.169 0.552 0.169 0.552 0.552 0.608

Thermistor sensor Discharge temperature sensor

Cranckase heater _ _ _ _ _ _ _ _ 28W

240V

28W

240V

(*) at 25°C

Refrigerant charge

In the heat pump

Kg 1.8 1.9 3.5 3.5 3.8 3.8 4.2 4.2 5.8 6.5

Connection diagram for 095 :

Connection diagram for 125 :

Page 34

34

Connection diagram for 155/175/195 :

Connection diagram for 157/177/197/257/307 :

(257/307)

Page 35

35

2.2.2 ELECTRONIC EXPANSION VALVE

CONTENT UNIT 095 125 155 157 175 177 195 197 257 307

Type SAGINOMIYA type KV Electronic Expansion Valve – bi-flow

Reference UKV 18D UKV 25D

Motor Permanent magnet type direct operating stepper motor – 480 steps

Coil supply V dc 12 Vdc

Insulation class E

Enclosure IP 66

Motor reference UKV

A053

UKV

U030

UKV

A053

UKV

U030

UKV

A053

UKV

U030

UKV

A053

UKV

A053

Motor checking – to be done with ohmmeter on motor disconnected

Between wires Resistance

Between wires Resistance

Grey (common) Orange (A) 46 +/-3 Ω Grey (common A) Orange (A) 46 +/-3 Ω

Grey (common) Yellow (non A) 46 +/-3 Ω Grey (common A) Yellow (non A) 46 +/-3 Ω

Grey (common) Red (B) 46 +/-3 Ω White (common B) Red (B) 46 +/-3 Ω

Grey (common) Black (non B) 46 +/-3 Ω White (common B) Black (non B) 46 +/-3 Ω

Motor UKV-A053

5 wires connection

Motor UKV-U030

6 wires connection

Page 36

36

2.2.3 FOUR WAY VALVE

CONTENT UNIT 095 125 155 157 175 177 195 197 257 307

Type

SAGINOMIYA 4 – Way valve STF

Reference

STF-0306G STF-0401G STF-0712G

Coil type

STF

Coil supply

V ac 220 – 240V 50Hz 6W

Insulation class

Class B

Coil presentation:

1.34 kΩ

ActuatedinHeatingmode

Page 37

37

2.2.4 FAN MOTOR

CONTENT UNIT 095 125 155 157 175 177 195 197 257 307

Type

SANYO DC brushless fan motor

Reference

SIC-71FW-D890-3 SIC-71FW-D890 - 1A (lower) / 2A (upper) SIC-71FW-D8120-

5 (lower)/ 6 (upper)

Rated output W

90 142

Voltage (nominal) V dc

Vm = 280 Vdc

Current limit

(nominal)

A

Im (lim) = 2.1A

Speed (nominal) Rpm

800 860

Pole number

8P

Electronic control &

supply

Built in electronic driver

Control power

supply

Vcc = 15 Vdc

Speed control input

voltage

V dc

Vsp = 0 to 6.5 V dc max – see diagram

Revolution pulse

output

PG = 12 pulses per round – see diagram

Motor protection

Integrated over current and over heating protection

Elec insulation

E

Schematic diagram:

Page 38

38

Speed control input voltage Vsp :

Revolution pulse output :

Control :

1 = Vcc

2 = PG

3 = Vsp

Power :

1 = Vm

2 = not used

3 = GND

Page 39

39

2.2.5 PRESSURE SENSOR

Note:

Used to measure refrigerant circuit pressure on water heat exchanger (sensor “E2P”).

The pressure signal is converted by A2 board in equivalent temperature.

Page 40

40

2.3 – HYDRAULIC CIRCUIT – MAIN COMPONENTS DESCRIPTION

2.3.1 WATER CIRCULATING PUMP

CONTENT Unit 095 125 155 157 175 177 195 197 257 307

Type

WILO – STRATOS PARA

Reference

25/1-7 25/1-8 25/1-12

Control

High Efficiency electronically commutated brushless motor – Control module integrated

Power supply

Vac 230 V / 1 / 50Hz

Protection class

IP 44

Insulation class

H

Protection

Full integrated motor protection

Power consumption W

4-38 8-140 16-310

Max head pressure

(*)

m

Max flow rate (*)

Pipe connection

Threaded – 1’’1/4 G

(*) See curves

Flow rate adjustment:

The heat pump is fitted with an high efficiency electronically controlled water circulating pump ensuring optimum efficiency

according to the different installations.

The adjustment is made using the red knob on the front

panel of the circulating pump.

It is advised to perform this adjustment according to

the “constant pressure control” model :

symbol

In this mode, the circulating pump electronic control

maintains the differential pressure produced by the

circulating pump at a constant level equal to the

setpoint pressure ∆P adusted with the red knob

(see characteristic curves below)

Note:

• For our applications, the adjustment according the “variable pressure control” (symbol )

is not recommended.

• Selection of the position “ext in” corresponds to an external control

which is not used on the heat pump. In this

condition, water pump operates at a minimum speed.

Setpoint adjustment ∆P

(manometric head pressure in m W)

Electronic

Page 41

41

Water flow rate adjustment:

• Connect a hydraulic pressure gauge to the ¼’’ SAE pressure

taps at the inlet and the outlet of the circulating pump in order to

measure the differential pressure.

• Adjust the red knob to the maximum pressure

• Take the differential pressure measurement ∆Pm and record

The corresponding flow rate value Qm on the envelope curve

of the circulating pump

Units :

095

125

155

157

Units :

175

177

195

197

257

Page 42

42

• Then adjust the red knob to the value ∆P for the requested water flow rate Q as per the following formula:

∆P = (Q / Qm)² x ∆Pm

For example:

With unit type 155 – fitted with Stratos Para 25/1-7, the requested water flow Q is 1.75 m3/h (see tables below).

For an adjustment in the maximum position (7 m w),if the measured water pressure is ∆Pm = 4.7 m, according circulating pump

curve, it relates to a flow rate of Qm = 2.3 m3/h.

Then, for a requested water flow of 1.75 m3/h, the adjustment will be :

∆P = (1.75 / 2.3)² x 4.7 = 2.1m w

Requested water flow (nominal): in m3/h

CONTENT 095 125 155 157 175 177 195 197 257 307

Pump reference

25/1-7 25/1-8 25/1-12

Water temp. 35°C

0.92 1.40 1.84 2.32 2.60 3.50 4.09

Water temp. 45°C

0.80 1.36 1.75 2.23 2.55 3.30 3.91

Water temp. 55°C

0.65 0.82 1.03 1.30 1.32 2.05 2.46

Wilo-Stratos Para 25/1-12

0 1 2 3 4 5 6 7 8 9 10 11 12

Water flow – m3/h

Differential pressure ∆P (mW)

Unit :

307

Page 43

43

Failure matrix:

Page 44

44

Failure handling:

Page 45

45

2.3.2 WATER FLOW SWITCH

Factory mounted:

CONTENT Unit 095 125 155 157 175 177 195 197 257 307

Type

IMIT / ALCO – AFS

Reference

AFS 72 AFS 72 AFS 81

Setting – ON point l/mn

9 9 30

Setting – OFF point

l/mn 7 7 27

Body

Plastic – Nylon 66 GF30% Brass

Pipe connection

1’’ G nut PF 1’’1/4 G

Contact rating

250Vac – 0.2A max.

Protection

IP 56

AFS 72 – 9l/mn

AFS 81 – 30l/mn

Page 46

46

After sales kit 9901280 for models 095 & 125:

CONTENT Unit 095 125

Type

SIKA / VKX

Reference

VKX 20M

Setting – ON point l/mn

4.5

Setting – OFF point

l/mn 4

Body

PPO Noryl GFN3

Connection

¾’’G

Pipe connection

Contact rating

230Vac - 26 VA max.

Protection

IP 65

Installation of the kit on heat pumps 095 and 125:

• Remove the original water flow switch (9 l/mn IMIT model).

• Put in place the new water flow switch (4,5 l/mn SIKA model).

¾ Respect the water direction (see the arrow on the top of the flow switch).

¾ Use the two supplied gaskets.

• Connect the two wires on the terminals 24 and 25 of the terminal block XA in the electrical box.

Flow switch SIKA VKX 4.5 l/mn

Pipe connection

1’’ Nut

Flow switch connector ¾’’

Original flow switch

SIKA flow switch

Arrow indicating

water flow

Page 47

47

2.3.3 PRESSURIZED EXPANSION VESSEL

CONTENT Unit 095 125 155 157 175 177 195 197 257 307

Volume L

4 6 8

Max. operating

pressure (water)

Bar

5 4 4

Pre-charge

pressure (air)

Bar

0.5 0.75 0.75

Maintenance:

• Before maintenance or control, make sure that:

-the system is off, cooled and not pressurized,

-power supply is off,

-vessel is empty.

• Every 6 months, expansion vessel is verified by checking

pre-charge pressure.

• Expansion vessel must be changed by a new one in case

of excessive deterioration and, anyway, at the latest

5 years later from the installation date.

2.3.4 SAFETY RELIEF VALVE

Setting: 3 Bar

Maintenance:

• Checking:

Every year, safety valve must be checked by turning

the red knob, so that the medium is discharged, thus cleaning

the seal seat.

• Leaks:

If the valve leaks, with the medium flowing out constantly

or dripping, it should be checked by a qualified technician and

replaced if necessary.

Pre-charge valve

Page 48

48

PART 3 – ELECTRIC

3.1 Electrical diagrams

3.2 Main components description

3.2.1 Control synoptic – heat pump with electrical support heater

3.2.2 Control synoptic – heat pump in boiler back up

3.2.3 System control board - A1

3.2.4 Communication & control board CWC2 – A2

3.2.5 Refrigerant circuit power board for units 095 / 125 – A3

3.2.6 Refrigerant circuit power boards for units 155 / 175 / 195 – A3 + HIC

3.2.7 Refrigerant circuit power boards for units 157 / 177 / 197 – A3 + HIC

3.2.8 Refrigerant circuit power boards for units 257 / 307 – A3 + HIC + A4

3.2.9 Electric support heater

Page 49

49

3.1 – ELECTRICAL DIAGRAMS

3.1.1 MODEL 095 (2 HP) – 230V Single phase

Page 50

50

3.1.2 MODEL 125 (3 HP) – 230V Single phase

Page 51

51

3.1.3 MODELS 155/175 (4/5 HP) – 230V Single phase

Page 52

52

3.1.3 MODEL 195 (6 HP) – 230V Single phase

Page 53

53

3.1.3 MODELS 157/177/197 (4/5/6 HP) – 400V Three phases

Page 54

54

3.1.3 MODELS 257/307 (8/10 HP) – 400V Three phases

Page 55

55

3.1.4 SYMBOLS

Page 56

56

3.2 – MAIN COMPONENTS DESCRIPTION

3.2.1 CONTROL SYNOPTIC FOR HEAT PUMP + ELECTRICAL SUPPORT HEATER APPLICATIONS

Page 57

57

3.2.2 CONTROL SYNOPTIC FOR HEAT PUMP IN BOILER BACK UP APPLICATIONS

Page 58

58

Important:

For “Boiler back up” applications, 2 modifications have to be performed on the heat pump:

1) The system control board A1 (and the electric support heater) included in the heat pump must be de-activated. To do

this (with power supply switched off), remove the connectors CX2 and CX3 at the bottom of the electrical plate.

2) The heat pump water temperature control sensor is connected to the input “TW1”of A2 (CCWC2) control board.

Considering that water temperature of the system is controlled according outgoing water temperature

, this sensor

connected to “TW1” must be placed on the heat pump water outlet.

To do this, remove this sensor from its housing on the heat pump water inlet (factory mounted) and put it into the

housing provided for this purpose on the water outlet pipe of the heat pump.

Use thermal paste and place correctly the insulating material in order to have a good thermal contact between the

sensor and the pipe.

Page 59

59

3.2.3 SYSTEM CONTROL BOARD A1

• Mounted in the heat pump, it controls the heat pump and its electric heater.

• It is connected to the system remote control by the communication line (BUS).

Note: please refer to specific system control service manual for system operation details.

Software versions for units in “FA” version:

Version A1 Board

code

Date Modification System remote control box – Elec support heater solution

Version Code Date

V3.01 2220126 Dec. 2010

V3.01 2220125 Dec. 2010

V3.02 2220125-02 Mar. 2013

Software versions for units in “FB” version:

Version A1 Board

code

Date Modification System remote control box – Elec support heater solution

Version Code Date

V4.01 2220171 Jul. 2012 First issue

V4.01 2220170 Jul. 2012

V4.02 2220170 Nov.2012

V4.03 2220170-02 Mar.2013

Page 60

60

3.2.4 COMMUNICATION & CONTROL BOARD FOR HEAT PUMP A2 (CWC2)

• It ensures 3 functions:

- Communication interface between system control and heat pump control.

- Management of the heat pump heat exchanger and water circulating pump.

- Possible base de-ice electric heater control.

IU EEPROM

Page 61

61

PCB switches / configuration & alarms:

• This board is fitted out with 2 “SW1” and “SW2” microswitches as well as “JTP” and “JPC” jumpers for the configuration:

- SW1 - 1 Micro-switch:

In “ON” position (factory setting), the circulating pump starts automatically if the outdoor temperature is below 0°C to

prevent the hydraulic circuit from freezing.

Caution: In the “oFF” position, this function is deactivated.

- SW1 - 2 Micro-switch:

The “ON” position (factory setting) activates the “FL” alarm (heat pump water flow rate) at the system.

Caution: For heat pump with electric support heater applications, this micro-switch must be in the “ON”

position.

For heat pump in boiler back-up applications, the micro-switch must be placed in the “OFF” position.

- SW2 - 1 micro-switch:

The “ON” position activates the “Circulating pump speed variation” function.

The function is not available on this version.

The SW2-1 micro-switch is left in “OFF” position (factory setting).

- SW2 - 2 micro-switch:

To select the circulating pump speed variation control algorithm.

SW2-2 in “OFF” position (factory setting) = “PWM” control.

SW2-2 in “ON” position = “0/10V” control.

The function is not available on this version.

- JTP jumper:

E2P input selection.

Must be positioned on “2-3” (factory setting).

- JPC jumper:

Selection of type of circulating pump speed variation signal.

JPC on “1-2” = “PWM” (factory setting).

JPC on “2-3” = “0/10V”.

-Other plugs:

CHK: not to be used

DISP: short circuiting this plug allows operation of CWC2 board by a service remote control even if the power board A3 is not

connected. In this case, alarm E04 (see part 5), which indicates trouble in the communication between A2 and A3 board, does

not occur. This is signaled by power LED flashing.

• Alarms:

- "AL" LED:

- Flashing = Automatic reset heat pump alarm.

- Stays on = Manual reset heat pump alarm.

- "W" LED:

- Off = No water flow.

- Stays on = Water flow.

- Slow flashing = Water flow rate alarm.

(once a second)

- Quick flashing = Water outlet temperature too low alarm.

(twice a second)

- Flickers = TW2 water outlet temperature sensor fault.

-“Power” LED: illuminates when the power is on. Flashes if there is trouble with the EEPROM of the board (and also if short

circuiting “DISP” plug – see before).

Page 62

62

Forced circulating water pump operation:

- Make sure that the hydraulic circuit is ready (no leakage, pressure, valves open…)

- Press during 5 seconds the “RESET” button of the CWC2 control board.

The circulating pump starts (if it was stopped). This action has the priority to any control signal from the system.

The circulating pump indicator light “PP” flashes.

- Check that the “W” water flow rate indicator light is on.

EEPROM:

Non volatile memory. Used to store model information (and other data) – see Part 6 parameters.

When replacing A2 board, remove the EEPROM from the old PCB and install it onto the new PCB. If there is trouble with the

EEPROM, replace it with the new one provided with the servicing PCB) and set the necessary parameters with the service

remote controller (for setting procedure, refer to the servicing document or see Part 5).

Software versions:

Version A2 Board

code

Date Modification

V

1.00

2220127 Dec. 2010 First issue

V

3.01

2220127-01 Jul. 2012 Activation of forcing input in system ctrl (for heat only version - PHIE)

V

3.03

2220127-02 Mar. 2013 Safety on outlet temperature TW2 added

V

3.04

2220127-02 May 2013 Filter on temperature signal E1 added (used for defrost information with DHW)

Page 63

63

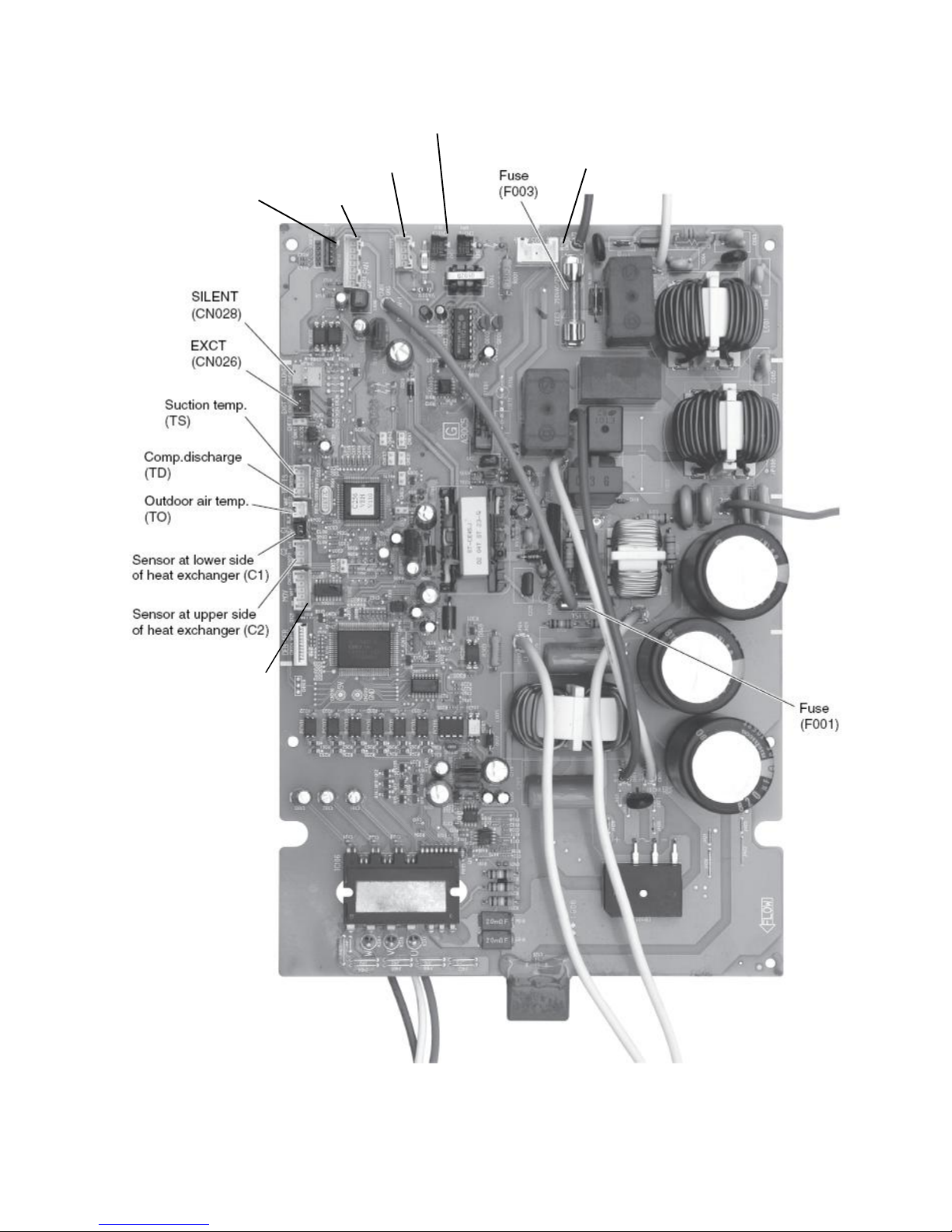

3.2.5 REFRIGERANT CIRCUIT POWER BOARD FOR UNITS 095 / 125

A3 board A056VH (up side) FOR UNIT 095

HIC temperature sensor plug

« Power » LED

EEPROM LED

Page 64

64

A3 board A056VH (bottom side) FOR UNIT 095

Expansion valve

(MOV)

Service Remocon

(RC-P)

Board ctrl signal (OC)

Board programming

PAC checker (ROM)

Fan

4 way valve (20S)

CHECK

Page 65

65

A3 board A086VH (up side) FOR UNIT 125

HIC temperature sensor plug

« Power » LED

EEPROM LED

Page 66

66

A3 board A086VH (bottom side) FOR UNIT 125

Expansion valve

(MOV)

4 way valve (20S)

Board ctrl signal (OC)

Board programming

PAC checker (CN012 ROM)

Fan

Service Remocon

(

RC-P)

Page 67

67

UNITS 095 / 125 – COMMENTS

• S002 rotary switch (10 positions, black) / S003 DIP switches (2P, blue):

Address for split air to air units – not used for the application.

The factory setting below must not be changed :

• CN041 Auto address plug (2P, white):

Normally, the addressing sequence between refrigerant circuit power board A3 and control board A2 takes place when power is

initially turned on at the factory.

In case of board replacement or problem of communication on the field, it can be necessary to launch again an addressing

sequence. For that, short circuit the pins of the plug.

During automatic address setting, LEDs 1 & 2 are blinking alternatively (open circuit these pins stops automatic address

setting).

After the power is turned ON, automatic address setting will not be functioned for over 1 minute and 30 seconds.

• CN042 Pump down plug (2P, white):

Used for split air to air units for refrigerant recovery sequence – not used for the application.

• CN032 RC-P Service remocon connection plug (5P, red): See PART 6

• JP007 jumper: Not used.

• S010 TERMINAL switch (black): Not used – Switch position “ON”.

• CN036 Test plug (2P): Used for PCB inspection in factory.

• CN031 MODE plug (2P): Not used.

• CN012 ROM plug (4P, white):

Used for PCB software loading in factory with “PAC checker” interface.

• CN026 EXCT plug (3P, red): Designed for capacity control – not used.

• CN028 SILENT (or QUIET) MODE plug :

Software version:

Unit Version Date

095 (2HP)

V110 Dec. 2011

125 (3HP)

V100 Jul. 2011

Page 68

68

3.2.6 REFRIGERANT CIRCUIT POWER BOARDS FOR UNITS 155 / 175 / 195

A3 board A116VH for units 155 / 175

A3 board A166VH for unit 195

Expansion valve

(MOV)

Service

Remocon

(RC-P CN032)

Board programming

PAC checker

(CN012 ROM)

4 way valve (20S) Fans ctrl

Fans supply

Board ctrl signal (OC)

« Power » LED

EEPROM LED

Page 69

69

UNITS 155 / 175 / 195 – COMMENTS

• S002 rotary switch (10 positions, black) / S003 DIP switches (2P, blue):

Address for split air to air units – not used for the application.

The factory setting below must not be changed :

• S001 AUTo ADDress push button switch (black):

Normally, the addressing sequence between refrigerant circuit power board A3 and control board A2 takes place when power is

initially turned on at the factory.

In case of board replacement or problem of communication on the field, it can be necessary to launch again an addressing

sequence. For that, press once the switch.

During automatic address setting, LEDs 1 & 2 are blinking alternatively (pressing again this switch stops automatic address

setting).

• S005 Pump down push button switch (red):

Used for split air to air units for refrigerant recovery sequence – not used for the application.

• CN032 RC-P Service remocon connection plug (5P, red): See PART 6

• JP007 jumper: Not used.

• CN036 Test plug (2P, red): Used for PCB inspection in factory.

• CN031 MODE plug (2P, white): Not used.

• CN012 ROM plug (4P, white):

Used for PCB software loading in factory with “PAC checker” interface.

• CN026 EXCT plug (3P, red): Designed for capacity control – not used.

• CN028 SILENT (or QUIET) MODE plug:

Software version:

Unit Version Date

155 (4HP)

V150 Sep. 2011

175 (5HP)

195 (6HP)

Page 70

70

HIC board for units 155 / 175 /195

Hybrid Integrated Circuit for inverter compressor

Diode bridge

HIC board

HIC temperature sensor plug

Page 71

71

3.2.7 A3 REFRIGERANT CIRCUIT POWER BOARD FOR UNITS 157 / 177 / 197

A3 board A166VH8

4 way valve (20S)

Power relay

Ctrl (MG-SW)

Fans ctrl

Expansion valve(MOV)

Fans

supply

Board programming

PAC checker (ROM)

Service Remocon

(RC-P CN032)

Board ctrl signal (OC)

« Power » LED

«Charge LED »

EEPROM LED

Page 72

72

UNITS 157 / 177 / 197 – COMMENTS

• S002 rotary switch (10 positions, black) / S003 DIP switches (2P, blue):

Address for split air to air units – not used for the application.

The factory setting below must not be changed :

• S001 AUTo ADDress push button switch (black):

Normally, the addressing sequence between refrigerant circuit power board A3 and control board A2 takes place when power is

initially turned on at the factory.

In case of board replacement or problem of communication on the field, it can be necessary to launch again an addressing

sequence. For that, press once the switch.

During automatic address setting, LEDs 1 & 2 are blinking alternatively (pressing again this switch stops automatic address

setting).

• S005 Pump down push button switch (red):

Used for split air to air units for refrigerant recovery sequence – not used for the application.

• CN032 RC-P Service remocon connection plug (5P, red): See PART 6

• JP007 jumper: Not used.

• CN036 Test plug (2P, red): Used for PCB inspection in factory.

• CN031 MODE plug (2P, white): Not used.

• CN012 ROM plug (4P, white):

Used for PCB software loading in factory with “PAC checker” interface.

• CN026 EXCT plug (3P, red): Designed for capacity control – not used.

• CN028 SILENT (or QUIET) MODE plug:

Software version:

Unit Version Date

157 (4HP)

V150

Nov. 2011

177 (5HP)

197 (6HP)

Page 73

73

HIC board for units 157 / 177 /197

Hybrid Integrated Circuit for inverter compressor

Diode bridge

HIC board

HIC temperature sensor plug

Page 74

74

3.2.8 REFRIGERANT CIRCUIT POWER BOARD FOR UNITS 257 / 307

A3 control board A246VH8

Service Remocon

(RC-P CN039)

Board programming

PAC checker

(

ROM

)

Board ctrl

signal (OC)

4 way valve (20S)

Expansion

valves

(MOV1-2)

Cranckcase heater

(20S)

Fan supply

Fan supply

Fan control

Fan control

Power relay

Ctrl (MG-SW)

« Power » LED

EEPROM LED

Page 75

75

UNITS 257 / 307 – COMMENTS

• S002 rotary switch (10 positions, black) / S003 DIP switches (2P, blue):

Address for split air to air units – not used for the application.

The factory setting below must not be changed :

• CN047 Auto address plug (2P, white):

Normally, the addressing sequence between refrigerant circuit power board A3 and control board A2 takes place when power is

initially turned on at the factory.

In case of board replacement or problem of communication on the field, it can be necessary to launch again an addressing

sequence. For that, short circuit the pins of the plug.

During automatic address setting, LEDs 1 & 2 are blinking alternatively (open circuit these pins stops automatic address

setting).

After the power is turned ON, automatic address setting will not be functioned for over 1 minute and 30 seconds.

• CN048 Pump down plug (2P, white):

Used for split air to air units for refrigerant recovery sequence – not used for the application.

• CN039 RC-P Service remocon connection plug (5P, red): See PART 6

• CN033 Test plug (2P, red): Used for PCB inspection in factory.

• CN038 MODE plug (2P, white): Not used.

• CN501 ROM plug (4P, white):

Used for PCB software loading in factory with “PAC checker” interface.

• CN030 EXCT plug (3P, red): Designed for capacity control – not used.

• CN037 SILENT (or QUIET) MODE plug:

Software version:

Unit Version Date

257 (8HP)

V110

Jan. 2012

307 (10HP)

Page 76

76

HIC board for units 257 / 307

Hybrid Integrated Circuit for inverter compressor

Diode bridge

HIC board

Page 77

77

A4 Supply and filter board for units 257 / 307

Page 78

78

3.2.9 ELECTRIC SUPPORT HEATER

Content Unit 095 125 155 157 175 177 195 197 257 307

Number of

elements

3 in parallel 3 – star coupling

Nominal voltage V 230V - on each heater element

Capacity kW 3 x 1.5 3 x 2 3 x 3

Body material Stainless steel 304L

Heating element

material

Stainless steel Incoloy 800

Heater

connected on

outlet of heat

exchanger

Safety thermostat

Manual

reset

Open if T > 115°C

Safety thermostat

Automatic

reset

Open if T > 80°C

Heat exchanger

Water pressure switch

Open if P< 0.6 bar

Page 79

79

PART 4 – INVERTER CONTROL

SPECIFIC FUNCTIONS

4.1 Heat pump water temperature control

4.2 Compressor frequency control

4.3 Max & Min frequency control

4.4 Current release control

4.5 Cooling high-load prevention control

4.6 Heat

ing high-load prevention control

4.7 Freeze prevention control in cooling mode

4.8 Discharge temperature control

4.9 Air heat exchanger defrost control

4.9.1 Flow chart of defrost control

4.9.2 Frost adherence detection

4.9.3 Heating mask time

4.9.4 Defrost cycle end

4.10 Fan control

4.11 Electronic expansion valve control

4.12 Water circulating pump control

4.13 Water flow monitoring

4.14 Heat pump base de-ice heater control

4.15 Heat pump outgoing water temperature alarm

4.16 Heat pump stand alone operation

4.17 Heat pump alarm signal for system control

Page 80

80

4.1 HEAT PUMP WATER TEMPERATURE CONTROL

Performed by A3 board

• The Inverter gestion is working or waiting in accordance with the ᇞT shown below.

ᇞT= TA – TY

T

A

: Water temperature from the installation – read by sensor TW1.

T

Y

: Resulting water temperature Setpoint Y

Note 1

: 10-minute mask time of the Inverter Gestion from WORKING to WAITING to avoid cycling.

Note 2

: 3-minute mask time of the Inverter Gestion from WAITING to WORKING to avoid cycling.

• By the control method the frequency of the compressor’s inverter is controlled in accordance with

the

ᇞT and the return water temperature from the installation.

Inverter frequency is controlled as follows

:

When

ᇞT is high (not yet reached the Controlled so that the inverter frequency is increased.

water temperature setpoint).

When

ᇞT is low Controlled so that the inverter frequency is decreased or kept.

(approximately +1.0 or less in the cooling mode or

approximately -1.0 or more in the heating mode).

When the return water temperature is Controlled so that the inverter frequency is increased.

rising in the cooling mode and

dropping in the heating mode.

When the return water temperature is Controlled so that the inverter frequency is decreased.

dropping in the cooling mode and

rising in the heating mode.

Note: The fluctuations of the compressor inverter frequency adjustments are calculated taking into account not only ᇞT, but

also-fluctuations in TA.

Page 81

81

4.2 COMPRESSOR FREQUENCY CONTROL

Performed by A3 board

The frequency of the compressor's inverter is limited by either of the following controls

depending on whether the cooling or heating mode is in operation.

• Cooling Mode : · Water Inlet temperature control

· Maximum and minimum frequency control

· Current release control

· Cooling high-load prevention control

· Cooling freeze prevention control

· Discharge temperature control

• Heating Mode : · Water Inlet temperature control

· Maximum and minimum frequency control

· Current release control

· Heating high-load prevention control

· Discharge temperature control

4.3 MIN. & MAX. FREQUENCY CONTROL

Performed by A3 board

The compressor's inverter frequency is controlled in accordance with the model and operation mode.

The maximum and minimum frequencies for each model are shown in the table below.

Note: There are cases in which frequency is limited with other control functions depending on operational conditions,

so operations are not always carried out in accordance with the maximum frequencies listed below.

Cooling Mode Heating Mode

Minimum Hz * Maximum Hz Minimum Hz * Maximum Hz

PHRIE 095

15~24 Hz 87 Hz 15~24 Hz 108 Hz

PHRIE 125

24 Hz 111 Hz 24 Hz 114 Hz

PHRIE 155

15~24 Hz 54 Hz 18~24 Hz 72 Hz

PHRIE 157

15~24 Hz 54 Hz 18~24 Hz 72 Hz

PHRIE 175

15~24 Hz 69.6 Hz 18~24 Hz 85 Hz

PHRIE 177

15~24 Hz 68.4 Hz 18~24 Hz 78 Hz

PHRIE 195

15~24 Hz 75 Hz 18~24 Hz 88 Hz

PHRIE 197

15~24 Hz 80.4 Hz 18~24 Hz 85 Hz

PHRIE 257

25~33 Hz 91.2 Hz 25~33 Hz 96 Hz

PHRIE 307

25~33 Hz 80 Hz 25~33 Hz 85 Hz

*There are cases in which the minimum frequency can vary to protect the compressor in accordance with outdoor air

temperature and thermal loads.

Page 82

82

4.4 CURRENT RELEASE CONTROL

Performed by A3 board

The inverter frequency is controlled so that the current value for the inverter compressor is less than the value listed

in the table below.

This current release control is required in order to prevent abnormal temperature increases in the inverter circuit

located within the electrical box and avoid HIC board damages.

The limited values of the primary current are modified in accordance with outdoor air temperature (T

O

).

Is (A)

Cooling Mode Heating Mode

PHRIE 095

10.2 A 12 A

PHRIE 125

16.5 A 18 A

PHRIE 155

20 A 21 A

PHRIE 157

7 A 8 A

PHRIE 175

23 A 23.5 A

PHRIE 177

10 A 11 A

PHRIE 195

27 A 27.5 A

PHRIE 197

13 A 14 A

PHRIE 257

13 A 13 A

PHRIE 307

15 A 15 A

Note

: The limited values are lowered when the outdoor air temperature is higher than 40°C in the cooling mode and

higher than 14°C in the heating mode.

4.5 COOLING HIGH-LOAD CONTROL

Performed by A3 board

This control is performed to limit the inverter frequency in order to restrict abnormal increases in pressure and highload operations in the cooling mode.

In accordance with the temperature of the outdoor heat exchanger temperature sensors (C1, C2), such controls are

performed as decreasing the inverter frequency and restricting its increase, etc.

If the temperature max (C1, C2) exceeds 64°C, operations are halted and then restarted 3 minutes later. If this

start/stop activity is repeated 10 times consecutively, alarm "P20" (cooling high-load error) occurs.

Type 95 125 155 157 175 177 195 197 257 307

a 64 64 61 61 61 61 61 61 64 64

b 61 59 55 57 55 57 55 57 55 53

c 59 57 53 55 53 55 53 55 54 52

d 58 56 51 53 51 53 51 53 52 50

e 53 53 49 51 49 51 49 51 48 47

Page 83

83

4.6 HEATING HIGH-LOAD CONTROL

Performed by A3 board

This system controls the inverter frequency when the high pressure's abnormal increase and high-load operating

prevention occur in the heating mode.

In accordance with the temperature of the water heat exchanger temperatures sensor (E1, E2), such controls are

performed as to limiting the increase of inverter frequency, decreasing it or halting operation of the compressor.

When the maximum temperatures (E1, E2) exceeds 64°C, the operation is halted and restarted after 3 minutes.

type 95 125 155 157 175 177 195 197 257 307

a

64 64 63 63 63 63 63 63 63 63

b

58 58 58 58 58 58 58 58 58 58

c

54 54 55 55 55 55 55 55 55 55

4.7 FREEZE PREVENTION CONTROL IN COOLING MODE

Performed by A3 board

The following control is performed during cooling operations, in accordance with the lowest water heat exchanger

temperatures (E1 or E2). (See the chart below.)

(1) If the temperature remains in the "J" zone (decreasing operation frequency) for 6 minutes, the operating

frequency of the compressor is decreased.

The operation frequency is amended every 30 seconds as long as the temperature is in this zone.

(2) If the temperature is in the "K" zone (operating frequency increase prevention zone), the operating frequency

of the compressor is maintained.

(3) If the temperature is in the "H" zone (operating frequency restriction zone) and the outdoor air temperature is

less than 32°C, the maximum operating frequency of the compressor is limited.

(4) If the temperature is in the "I" zone (normal operation zone), normal operations are performed.

(5) If the temperature is continuously in the "J" zone with the compressor's operating frequency reaches "0",

then temperature A, which is temperature for changing from the "J" zone to the "H" zone, is raised from 5°C

to 8°C, and operation continues until the temperature enters the "H" zone.

Page 84

84

4.8 DISCHARGE TEMPERATURE CONTROL

Performed by A3 board

The following control is performed to prevent the discharge temperature from rising abnormally in order to protect

the inverter compressor. In accordance with the temperature of the discharge sensor TD, such controls are

performed as to limiting the increase of inverter frequency, decreasing it or halting operation of the compressor.

* If the discharge temperature exceeds 111°C (or 115°C for 257 & 307 units), operations of the compressor are

halted and then restarted 3 minutes later.

If this start/stop activity is repeated 4 times consecutively, the alarm "P03" (abnormal discharge temperature)

occurs.

Page 85

85

4.9 AIR HEAT EXCHANGER DEFROST CONTROL

Performed by A3 board

4.9.1 FLOWCHART OF DEFROST CONTROL (1) (2) (3)

Page 86

86

4.9.2 FROST ADHERENCE DETECTION (1)

If the following conditions are satisfied during heating operations, it is regarded as "frost adherence is detected".

• Frost adherence detection is performed in accordance with the outdoor air temperature (TO) and the outdoor

heat exchanger temperature sensor (C1).

Note

: Frost adherence detection is not performed for the first 15-minute of compressor operations in the normal

heating mode.

• Frost adherence detection conditions

(a) With the outdoor air temperature (TO) being -13°C or above, the frost adherence condition shown

below are satisfied for whether 3 consecutive minutes or a total of 60 intermittent minutes, or the

outdoor heat exchanger temperature sensor (C1) remains -18°C or below for 20 consecutive

seconds.

(b) With the outdoor air temperature (TO) being less than -13°C, the outdoor heat exchanger

temperature sensor:

(C1) ≤ [(TO) – 5°C] for 20 consecutive seconds → Defrosting condition

(c) With the outdoor heat exchanger temperature sensor (C1) being less than -3°C, a total of 90 minutes

has elapsed (defrosting carried out periodically in accordance with the time).

4.9.3 HEATING MASK TIME (2)

This refers to the shortest time that heating operations must be performed without defrosting operations being

executed.

The mask time for this model is 25 minutes.

Note

: Defrosting operations will not be commenced until the defrosting mask time has elapsed, even if frost

adherence has been detected.

4.9.4 DEFROST CYCLE END (3)

Defrosting operations are ended when the following conditions are aligned:

(a) When the temperature of the outdoor heat exchanger temperature sensor (C1) is 12 or higher.

(b) When the temperature of the outdoor heat exchanger temperature sensor (C1) is 7 or higher for

60 consecutive seconds.

(c) When defrosting has been initiated for 10 minutes.

Page 87

87

4.10 FAN CONTROL

Performed by A3 board

• Cooling Mode:

The appropriate rotations per minute for the fan are determined in accordance with the outdoor air

temperature and the frequency of the compressor inverter.

The fan step is controlled between a range of W1 (Step 1) and WF (Step 16).

• Heating Mode:

The appropriate rotations per minute for the fan are determined in accordance with the outdoor air

temperature and the frequency of the compressor inverter.

The fan step is controlled between a range of W1 (Step 1) and WF (Step 16).

Note

: However, the fan is halted (Step 0) when defrosting is being carried out.

4.11 ELECTRONIC EXPANSION VALVE CONTROL

Performed by A3 board

The electrical expansion valve controls the amount of refrigerant that is allowed to flow in accordance with the

operation status.

The valve is adjusted in accordance with the discharge temperature (TD), the outdoor heat exchanger

temperature sensor (C1), the suction temperature sensor (TS), and the heat exchanger temperature sensors (E1

and E2).

• Cooling Mode:

Controlled so that the suction temperature (TS) - water heat exchange temperature minimum (E1 and E2)

is between 1°C and 5°C under normal conditions.

There are cases where the aperture opens wider than usual if the discharge temperature increases.

• Heating Mode:

Controlled so that the Suction Temperature (TS) - Outdoor heat exchange temperature (C1) is between

1°C and 5°C under normal conditions.

There are

4.12 WATER CIRCULATING PUMP CONTROL

Performed by A2 board -

see presentation § 3.2.4

In normal operation, water pump is actuated automatically by system control

(see details in the corresponding technical manual) :

-in heating mode when outdoor temperature is lower than the “non heating threshold”,

-during “Domestic Hot Water” cycle,

-in cooling mode (as soon as it is selected).

Anyway, it is possible to operate the circulating pump in a forced way; then water pump runs permanently. This

kind of operation can be needed for commissioning or maintenance (or operation without system control).

Forced circulating water pump operation:

- Make sure that the hydraulic circuit is ready (no leakage, pressure, valves open…).

- Press during 5 seconds the “RESET” button of the CWC2 control board.

The circulating pump starts (if it was stopped). This action has the priority to any control signal from the system.

The circulating pump indicator light “PP” flashes.

Page 88

88

- Check that the “W” water flow rate indicator light is on.

Other functions:

• Time delay: Water pump stop is time delayed (3 mn), but immediate in the case forcing is stopped.

• Anti-sticking: automatic operation for 5 seconds every 24 hours.

• Anti-freeze": function activated by setting micro-switch sW1-1 to "on" (delivery default setting). The pump

is started if outside temperature is below 0°C.

4.13 WATER FLOW MONITORING

Performed by A2 board -

see presentation § 3.2.4

When the circulating pump is in operation, a lack of water flow longer than 10 seconds will cause the heat pump to

stop.

The alarm light "AL" flashes.

If the lack of water flow continues for more than one minute (or if it happens more than 3 in the last hour), the water

flow fault is stored in A2 memory:

- The alarm light "AL" then remains on steady; the "W" water flow light flashes (once a second).

- The flow alarm has to be sent to the system, for that, the micro-switch sW1-2 must be set to "on".

- On A2 boards version 00 the circulating pump stops. On A2 boards versions 01 & 02, the water circulating

pump remains operating.

The alarm is reset by pressing the "reset" button, or turning the system "OFF", or by disconnecting the power.

4.14 HEAT PUMP BASE DE-ICE HEATER CONTROL

Performed by A2 board - see presentation § 3.2.4

The heater is actuated for a period of 30 mn if heat pump is in defrost and outdoor temperature

(measured by heat pump sensor “OT”) is lower than 0°C.

4.15 HEAT PUMP OUTGOING WATER TEMPERATURE ALARM

Performed by A2 board -

see presentation § 3.2.4

Note: this function is available only on A2 board in version 02.

See installation manual 1011597 concerning additional water outlet temperature sensor kit.

This alarm is detected by the TW2 sensor at the heat pump exchanger water outlet.

It is generated and stops the heat pump if the heat pump exchanger outgoing water temperature goes below a

threshold in the following cases:

- In heat mode, during defrost exclusively, if the temperature is below 16°C.

- In cool mode if the temperature is below 4°C.

This alarm is reset automatically (with a re-set differential on the threshold of + 4 K) for the first 3 events occurred the

previous hour. The "W" light of the CWC2 board flashes according to a specific rate (twice a second) to signal this

alarm. The "AL" light of the CWC2 board also flashes to signal this heat pump alarm in "automatic" phase.

If a 4th event occurs within the hour, the alarm is saved and goes to manual reset. The "AL" light of the CWC2

board remains steady to signal this heat pump alarm in "manual" phase. The alarm saved is transmitted to the

system for "GR" display. To help in troubleshooting this alarm, the "W" light continues to flash according to the

specific rate until the alarm is reset. The alarm report contact of the CWC2 board is activated.

On alarm reset, the "W" light resumes the state of the water flow input.

TW2 sensor fault:

This fault is managed like another fault on the heat pump giving rise to a "GR" system alarm.

When a sensor fault is detected, the heat pump stops and the "AL" light of the CWC2 board flashes during the

automatic reset phase. The "W" light of the CWC2 board flashes very quickly (flickers) to signal this alarm.

If the sensor fault persists, the alarm is saved after 30 minutes and goes into manual reset. The "AL" light of the

CWC2 board remains steady to signal this heat pump alarm in "manual" phase. The alarm saved is transmitted to

the system for "GR" display. To help in troubleshooting this alarm, the "W" light continues to flicker until the

alarm is reset.

On alarm reset, the "W" light resumes the state of the water flow input.

Page 89

89

4.16 HEAT PUMP STAND ALONE OPERATION

Performed by A2 board -

see presentation § 3.2.4

For the maintenance and commissioning operations, the heat pump can be operated in a “stand-alone”

configuration, without system control, using the specific maintenance remocon (see PART 6) and/or external

voltage free contacts.

The system can be disconnected in two ways:

- Either, with power off, disconnect the system communication line "BUS" from A2 board (connector “SC”).

- Or, by the system control unit, deactivate heat pump control by setting parameter 76 to "0" – see System

control manual.

To operate the heat pump, force the circulating pump (see § 4.12) before initiate an order via the specific

maintenance remote control or the external contacts.

Heat pump control with voltage free external contacts:

Inputs for external contacts are available on A2 (CWC2) board in order to force heat pump operation

(ON / OFF - Heat / cool). These inputs have priority

to the control signals initiated by means of the possible

maintenance remote control.

The state of these inputs is indicated by the lights placed on the board. Set points (heat and cool) must be adjusted

by

the maintenance remote control but for operation and control by contacts, maintenance remote control is not

mandatory.

ON/OFF:

-Closing a contact between “C” and “1” on the terminals block “ON/OFF” makes the unit starts.

Corresponding LED is lighted in green.

-Closing a contact between “C” and “0” on the terminals block “ON/OFF” makes the unit stops.

Corresponding LED is lighted in red.

In case of closing both contacts at the same time, priority is given to “OFF”.

Note: on A2 board in versions 01 & 02, “OFF” input is also active with system control connected.

HEAT / COOL:

-Closing a contact between “C” and “1” on the terminals block “HEAT/COOL” selects “HEAT” mode.

Corresponding LED is lighted in red.

-Closing a contact between “C” and “0” on the terminals block “HEAT/COOL” selects “COOL” mode. Corresponding

LED is lighted in green.

In case of closing both contacts at the same time, priority is given to “HEAT”.

Note: on A2 board in versions 01 & 02, “HEAT” input is also active with system control connected.

A voltage free change-over contact (use in 24 V max.) is available on A2 (CWC2) board for remote heat pump alarm

signaling.

4.17 HEAT PUMP ALARM SIGNAL FOR SYSTEM CONTROL

Performed by A2 board - see presentation § 3.2.4

Heat pump faults coming from the frigorific circuit are classified in 2 categories:

- Manual reset faults:

Memorized by board A2 as soon as they appear and transmitted to the system control. The A2 board alarm light

“AL” comes on steady.

- automatic reset faults:

The A2 board alarm light “AL” flashes as soon as a fault appear. If it lasts longer than 30 minutes, fault is memorized in

board A2 and transmitted to the system control. The alarm light “AL” then remains steady.

The detailed list of faults is indicated in part 5.

To determine the exact nature of the fault, refer to LED1 & LED2 on the power board A3 or connect the specific

maintenance remocon to the heat pump (see Part 6).

Page 90

90

PART 5 – SERVICE PROCEDURES

5.1 Frigorific circuit alarms

5.1.1 List of alarms

5.1.2 Alarm messages display

5.1.3 Alarms reset

5.1.4 Symptoms & parts to inspect

5.1.5 Alarms diagnosis

5.1.6 HIC board checking

5.1.7 Diode bridge checking

5.2 Hydraulic circuit alarms

5.2.1 List of alarms

5.2.2 Alarms reset

5.2.3 Symptoms & parts to inspect

5.2.4 A2 board checking

5.3 System control alarms

5.3.1 List of alarms

5.3.2 Alarms reset

5.3.3 A1 board checking

5.4 Boards replacement

5.4.1 A2 board

5.4.2 A3 board

5.4.3 A4 board

5.4.4 HIC board

5.5 Sensors characteristics

5.5.1 Heat pump control sensors

5.5.2 System control sensors

WARNING:

Before carrying out any work on the machine, make sure that its power supply is switched off and the access to it

is prevented. Any work must be carried out by personnel qualified and authorized to work on this type of machine.

Page 91

91

5-1 FRIGORIFIC CIRCUIT ALARMS

Managed by A3 board and partially by A2 board.

5.1.1 LIST OF ALARMS

Type Designation Code Action Reset(*)

Serial

communication

errors

&

Mis-setting

Maintenance

remocon detects

error signal from

A2 board

-Poor reception of the signal on the maintenance remocon

-Auto address not completed

E01 stop

Automatic

(then manual)

-Poor transmission of the signal on the maintenance

remocon

E02 stop

Automatic

(then manual)

A2 board detects

error signal from

remocon

-Poor reception of the signal on A2 board from the

maintenance remocon

E03 stop

Automatic

(then manual)

A2 board detects

error from A3

board

-Poor reception of the signal on A2 board from the A3

board

E04 stop

Automatic

(then manual)

-Poor transmission of the signal from A2 board to the A3

board

E05 stop

Automatic

(then manual)

A3 board detects

error from A2

board

-Poor reception of the signal on A3 board from the A2

board

E06 stop

Automatic

(then manual)

-Poor transmission of the signal from A3 board to A2 board E07 stop

Automatic

(then manual)

Automatic address

setting failed

-Incorrect capacity set in A2 board detected. Too low. E15 stop manual

-Incorrect capacity set in A2 board detected. Too high. E16 stop manual

-A2 board not detected during automatic address

sequence

E20 stop manual

Mis-wiring

-Mis-wiring between boards

-Missing phase on power supply

E22 stop manual

Communication

trouble

-Communication abnormal (A3 board). E31 stop

Automatic

(then manual)

Sensor failure

Sensor circuit

open or short

circuit /

Sensor failure

-Abnormal sensor for the inlet temp. on the H/E – “liquid

line” in cooling - (E1/S7)

F01 stop

Automatic

(then manual)

-Abnormal pressure sensor (E2P/B1) on the H/E

-Loss of refrigerant charge

F02 stop

Automatic

(then manual)

-Abnormal sensor for the compressor discharge

temperature (TD/S5)

F04 stop

Automatic

(then manual)

-Abnormal sensor for the air heat exchanger temp. (C1/S2) F06 stop

Automatic

(then manual)

-Abnormal sensor for the air heat exchanger temp. (C2/S1) F07 stop

Automatic

(then manual)

-Abnormal sensor for outdoor temp. (TO/S4) F08 stop

Automatic

(then manual)

-Abnormal sensor for water inlet temp. (TW1/S8) F10 stop

Automatic

(then manual)

-Abnormal sensor for compressor suction temp. (TS/S3) F12 stop

Automatic

(then manual)

Component

failure

EEPROM

-Abnormal non-volatile memory (EEPROM) on A2 board. F29 stop manual

-Abnormal non-volatile memory (EEPROM) on A3 board F31 stop manual

Mis-setting Setting error

-Unit type mismatch between A3 and A2 (parameter) L02 stop manual

-No address setting on A2 board L08 stop manual

-No unit capacity setting on A2 board L09 stop manual

-Incorrect capacity setting on A3 board L10 stop manual

-incorrect unit type setting on A2 board L13 stop manual

Activation of

protective

device

A3 board

-High discharge temperature of compressor P03 stop manual

-High refrigerant pressure switch activated

(for 257 & 307 units only)

P04 stop manual

-Low current on power supply

(missing phase or incorrect phases order)

P05 stop manual

-No refrigerant P15 stop manual

-Four way valve locked P19 stop manual

-High refrigerant pressure P20 stop manual

-Fan(s) trouble P22 stop manual

-Incorrect current value for compressor (over current on

HIC PCB)

P26 stop manual

-Incorrect current value for compressor (trouble on motor

detection circuit - MDC)

P29 stop manual

-Incorrect current value for compressor (overload) H01 stop manual

(*) see § 5.1.3

Page 92

92

5.1.2 ALARM MESSAGES DISPLAY

2 ways for reading alarm messages:

-with maintenance remocon connected to A2 board (connector RC). Alarm code is directly displayed.

See details PART 6.

-with LED 1 & LED 2 on A3 board.

LED 1 & LED 2 display:

Page 93

93

Alarm Code is composed of two parts. First part is a letter, second part is a number:

The blinking of LED 1 indicates the code letter The blinking of LED 2 indicates the number

LED 1 LED 2

Number of Blinks Alarm Code Letter Number of Blinks Alarm Code Number

0 No alarm 0 No alarm

2 P 1 1

3 H 2 2

4 E …. ….

5 F 16 16

6 L

17 17

Examples: (other than E15, E16 and E20)

Alarm code LED 1 alternately LED 2

P04 Blinks twice = P Blinks four times = 04

-

H01 Blinks three times = H Blinks once = 01

-

E03 Blinks four times = E Blinks three times = 03

-

F07 Blinks five times = F Blinks seven times = 07

-

L09 Blinks six times = L Blinks nine times = 09

-

LED 1 & 2 – Other indications:

LED 1 LED 2 Remarks

Power ON sequence

Step 1 : no communication A3 / A2

Step 2 : communication received from A2

Step 3 : normal communication

On

Off

Off

On

On

Off

In normal operation

A3 EEPROM error (F31)

Pre trip (insufficient gas)

Pre-trip (P20 - HP)

Pre-trip (other)

On

Blinks (0.25/0.75)

Blinks (0.75/0.25)

Blinks (0.5/0.5)

Blinks (0.5/0.5)

Off

Off

Off

During auto address & initial

communication ; then F31 displayed.

P03

Alarms Blinks Blinks See details in table before

Insufficient refrigerant indicator Blinks (0.5/0.5) Off

Refrigerant recovery mode Blinks (0.5/0.5) On Not used – only for split heat pumps

Automatic address setting (A3 – A2)

Automatic address setting in progress

Automatic address setting alarm (E15)

Automatic address setting alarm (E20)

Automatic address setting (other than E15/E20)

Blinks (0.5/0.5)

Blinks (0.25/0.75)

Blinks (0.75/0.25)

Blinks (0.5/0.5)

Blinks (0.5/0.5)

Blinks (0.25/0.75)

Blinks (0.75/0.25)

Blinks (0.5/0.5)

Blinking alternately

Blinking simultaneously

Blinking simultaneously

Blinking simultaneously

Note: blinking (0.25/0.75) means that LED illuminates for 0.25 seconds and then is Off for 0.75 seconds.

Page 94

94

5.1.3 ALARMS RESET

Performed by A2 board

Heat pump faults coming from the frigorific circuit are classified in 2 categories:

- “Manual” reset faults:

Memorized by board A2 as soon as they appear and transmitted to the system control.

The A2 board alarm light “AL” comes on steady.

Heat pump is stopped until alarm is reset.

- “Automatic” reset faults:

The A2 board alarm light “AL” flashes as soon as a fault appear. Heat pump is stopped.

If the default lasts less than 30 minutes, alarm is automatically cleared and heat pump starts again.

If it lasts longer than 30 minutes, default is memorized by board A2 and transmitted to the system control.

The alarm light “AL” then comes on steady.

Heat pump is stopped until alarm is reset.

How to reset the alarm:

Note : problem must be solved before final reset action.

Alarm reset by pressing push button « RESET » on A2

board for 5 seconds

Alarm reset by setting the system control in OFF position

See detail in corresponding technical manual

Alarm reset by switching off power supply

This action is recommended in case of problem of

setting error (E15, E16, E20, L02, L08, L09, L10, L13)

and memory (F29, F31).

Page 95

95

5.1.4 SYMPTOMS & PARTS TO INSPECT

Serial communication errors & mis-setting

Maintenance

remocon

alarm

display

Alarm

contents

Judgement conditions

clearing

condition

Judgement and correction

E01

Maintenance

Remocon detected

error signal from

A2 board

Serial signal receiving failure

Automatic

recovery

1. Check remocon connection

2. Check address on A2 board

3. Check A2 board

E02

Serial signal sending failure

E03

A2 board detected

error signal from

remocon

Serial signal failure

Automatic

recovery

1. Check remocon connection

2. Check remocon configuration (see part 6)

3. Check address on A2 board

4. Check A2 board

E04

A2 board detected

error signal from

A3 board

Serial signal receiving failure

Automatic

recovery

1.Check connection between boards

(OC connector)

2. Check addresses – if necessary, launch

auto address sequence

3. Check boards

E05

Serial signal sending failure

E06

A3 board detected

error signal from

A2 board

Serial signal receiving failure

Automatic

recovery

Automatic

recovery

1. Check connection between boards

(OC connector)

2. Check A2 and A3 boards.

E07

Serial signal sending failure

E15

Automatic address

setting failure.

A2 capacity/number

parameters (too low)

Power supply

reset

recovery

1. Check A2 parameters (see Part 6) - if

necessary, launch auto address sequence

2. Check connection between boards (OC

connector)

3. Check A2 board

4. Check A3 board

E16

A2 capacity/number

parameters (too low)

E20

A3 board cannot receive any

serial signals from A2 board.

E22

Mis-wiring error

Mis-wiring between boards

or

Missing phase on power

supply

Power supply

reset

recovery

1. Check wiring.

2. Check power supply connections

E31

(*)

Communications

trouble within

boards

No communication possible

with MDC for 3 minutes or

longer

Automatic

recovery

Check A3 board

Refer to diagnosis method (section 5.1.5)

(*) see detail § 5.1.5

Page 96

96

Sensors failure

Maintenance

remocon

alarm

display

Alarm

contents

Judgement conditions

clearing

condition

Judgement and correction

F01

Disconnection, open

circuit or short

circuit

in H/E temp. sensor

“liquid line”

E1/S7

Open circuit or short circuit

Automatic

recovery

1. Check “liquid line” temp. sensor E1/S7

2. Check connection

3. Check A2 board

F02

Abnormal pressure

detected in the plate

exchanger

with

E2P/B1 pressure

sensor

Value delivered by

pressure sensor is out off

range

Automatic

recovery

1. Check pressure in the frigorific circuit

2. Check connection between E2P and A2

board

3. Check JTP bridge on A2 board, (set between

pins 2 & 3” = factory setting)

3. Check U voltage on E2P connector on A2

board, pins 1/3 (24V DC):

20V < U < 26V

Right voltage: E2P sensor damaged

Wrong voltage: A2 board damaged

F04

(*)

Disconnection, open

circuit or short

circuit

in discharge

temperature sensor

TD/S5

Sensor detection error

(90°C or more after

60 minutes has

elapsed since the

compressor was halted

- open circuit)

Automatic

recovery

1. Check discharge temp. sensor TD/S5

2. Check (A3) board

Refer to diagnosis method (section 5.1.5)

F06

(*)

Disconnection, open

circuit or short

circuit

in sensor C1/S2

Open circuit or short circuit

Automatic

recovery

1. Check Air heat exchanger temperature

sensor C1/S2

2. Check A3 board

Refer to diagnosis method (section 5.1.5)

F07

(*)

Disconnection, open

circuit or short

circuit

in outdoor unit heat

exchanger temp.

sensor C2/S1

Open circuit or short circuit

Automatic

recovery

1. Check Air heat exchanger temperature

sensor C2/S1

2. Check A3 board

Refer to diagnosis method (section 5.1.5)

F08

(*)

Disconnection, open

circuit or short

circuit

in sensor TO/S4

Open circuit or short circuit

Automatic

recovery

1. Check outdoor air temp. sensor TO/S4

2. Check (A3) board

Refer to diagnosis method (section 5.1.5)

F10

Disconnection, open

circuit or short

circuit

in water inlet temp.

sensor TW1/S8

Open circuit or short circuit

Automatic

recovery

1. Check water inlet temp. sensor TW1/S8

2. Check (A2/CWC2) board

F12

(*)

Disconnection, open

circuit or short

circuit

in suction temp.

sensor TS/S3

Open circuit or short circuit

Automatic

recovery

1. Check suction temp. sensor TS/S3

2. Check A3 board

Refer to diagnosis method (section 5.1.5)

F29

EEPROM trouble

on A2 board

Reading/writing failure

Power supply

reset recovery

1. Check EEPROM of A2 board

2. Check A2 board

F31