DOSSIER TECHNIQUE

F

TECHNICAL INSTRUCTIONS

DOSSIER TECNICO

MANUAL TÉCNICO

TECHNISCHE DOKUMENTATION

MW

UNITES TERMINALES MURALES

WALL TYPE TERMINAL UNITS

UNITÀ TERMINALI MURALI

UNIDADES TERMINALES TIPO MURAL

WANDGERÄTE-WASSERGEKÜHLT

GB

I

E

D

Froid Chaud

Cooling Heating

Freddo Caldo

Frio Calefaccion

Kalt Warm

MW 2 - 2 100 W - 2 700 W

MW 3 - 2 800 W - 3 500 W

MW 4 - 4 000 W - 5 100 W

MW 5 - 5 200 W - 6 500 W

Janvier 1996 10 12 088 - F.GB.I.E.D - 01

MARKING

GB

This product marked conforms to the essential requirements of the European Directives:

- Low voltage no. 73/23 EEC, modified 93/68 EEC,

- Electromagnetic Compatibility no. 89/336 EEC, modified 92/31 and 93/68 EEC.

CONTENTS

TECHNICAL INSTRUCTIONS

1 - Application - Use........................................................................................................2

2 - Description.................................................................................................................3

3 - Physical characteristics .............................................................................................4

4 - Performances.............................................................................................................4

5 - Control ....................................................................................................................... 6

6 - Accessories................................................................................................................6

INSTALLATION INSTRUCTIONS

1 - General ......................................................................................................................7

2 - Introduction ................................................................................................................7

3 - Installation..................................................................................................................7

4 - Connections.............................................................................................................10

5 - Starting.....................................................................................................................14

6 - Maintenance ............................................................................................................15

7 - Wiring diagram.........................................................................................................15

TECHNICAL INSTRUCTIONS

1 - APPLICATION - USE

• This equipment is intended for the air-conditioning of premises and to provide comfort for the personnel.

FUNCTIONS

• Cooling or heating by means of a 2-pipe water coil.

• Ventilation with filtration (built-in filter).

RANGE

• There are 4 models with different capacities in the MW range.

• The air handler is supplied with its room thermostat.

• A condensate drain pump system is a factory-fitted accessory.

APPLICATIONS

• This range of air handlers, stemming directly from the direct expansion range, is characterised, thanks to its wall-mounting

configuration, by:

- attractiveness,

- compactness (using unused spaces),

- a low sound level.

2

2 - DESCRIPTION

GB

MW 2

MW 3

1

6

1 - Air inlet (suction)

2 - Air outlet (blowing)

3 - Vertical deflection louvre control switch

4 - Motorised vertical deflection louvre

5 - Manual horizontal deflection louvre

6 - Air filters

1

6

MW 4

MW 5

2

2 45 3

4

35

Model

Tangential fan

Electric motor

with internal thermal protection

Power supply 230 V / 1 + T / 50 Hz

Number of speeds

Copper / Aluminium exchanger

Number of rows

Hydraulic connection Copper

Water capacity litres

Condensate drain pump (accessory)

Air filter (washable)

• Plastic body.

• P.E.R. piping.

PER

MW 2

●

●

●

3

●

2

10/12

10/12

0.9

●

●

MW 3

●

●

●

3

●

2

10/12

10/12

0.9

●

●

MW 4

●

●

●

3

●

2

14/16

13/16

1.2

●

●

MW 5

●

●

●

3

●

2

14/16

13/16

1.2

●

●

3

3 - PHYSICAL CHARACTERISTICS

GB

3.1 WEIGHT

Air handler

Net weight (kg)

MW 2

MW 3

MW 4

MW 5

3.2 DIMENSIONS

H

312

°C

20

71

15

25

30

117

Thickness : 27.5 mm

4 - PERFORMANCES

4.1 NOMINAL CONDITIONS

Model

Total cooling capacity LS kW

(1) MS kW

Sensible cooling capacity LS kW

(1) MS kW

10

10

13.5

13.5

HS kW

HS kW

Packed weight (kg)

13

13

17.7

17.7

LP

MW 2

MW 3

MW 4

MW 5

MW 2

1.4

1.5

2.1

1.3

1.5

1.5

MW 3

2.4

2.6

2.8

1.7

1.9

2.1

MW 4

3.3

3.7

4

2.3

2.7

2.9

L

810

810

1000

1000

MW 5

4.6

4.9

5.2

3.2

3.5

3.8

H

360

360

360

360

P

180

180

205

205

Pressure drop on water in cooling mode kPa

(1) (10 kPa = 1 m W.G.)

Heating capacity LS kW

(2) MS kW

HS kW

Pressure drop on water in heating mode kPa

(2) (10 kPa = 1 m W.G.)

Air flow rate LS m

MS m

HS m

3

3

3

/h

/h

/h

3

2.2

2.4

2.7

2.4

325

370

430

5

2.9

3.2

3.5

4.1

325

370

430

Characteristics of fan motor

230 V / 1/ 50 Hz (3) W

(4) A

Maximum power input W

28

0.13

54

28

0.13

54

(with condensate pump)

Maximum current A

Sound power level LS dB(A)

(5) MS dB(A)

HS dB(A)

Sound pressure level (at 2.5 m indoors) LS dB(A)

(5) MS dB(A)

HS dB(A)

0.25

40

45

49

22

27

31

0.25

40

45

49

22

27

31

(1) Air inlet: 27°C (DB) / 19°C (WB) ; water: inlet at 7°C at high speed, outlet at 12°C

(2) Air inlet: 20°C; water inlet: 50°C (same flow-rate as under other conditions(1)).

(3) Max. power consumption (at high speed).

(4) Max. current consumption (at high speed).

(5) Without condensate pump accessory.

11

3.8

4.5

5.1

9

495

630

760

13.8

665

760

855

72

0.30

98

0.39

112

0.45

46

51

54

28

33

36

Note :

Maximum water inlet

temperature: 60°C

17

5.5

6

6.5

86

0.5

54

57

58

36

39

40

4

4.2 COOLING PERFORMANCES

AIR INLET 24°C, 50% RH

Model

MW 2

MW 3

MW 4

MW 5

Fan speed

LS

MS

HS

LS

MS

HS

LS

MS

HS

LS

MS

HS

P tot

0.9

0.9

1

1.2

1.2

1.3

1.9

2

2.2

2.6

2.7

2.9

AIR INLET 27°C, 47% RH

Model

MW 2

MW 3

MW 4

MW 5

Fan speed

LS

MS

HS

LS

MS

HS

LS

MS

HS

LS

MS

HS

P tot P sens Dve Pdc

1.1

1.2

1.3

2

2.1

2.2

2.7

3

3.2

3.8

3.9

4.1

7/14°C 7/12°C

P sens Dve Pdc

0.9

0.9

1

1.2

1.2

1.3

1.7

2

2.2

2.3

2.5

2.9

7/14°C 7/12°C

1.1

1.2

1.3

1.5

1.7

1.8

2.1

2.4

2.7

2.9

3.1

3.3

Water temperatures (*)

P tot P sens Dve Pdc

1

125

162

274

351

155

275

392

502

0.5

1

2

3

Water temperatures (*)

1

2

4

6

1.1

1.1

1.5

1.9

2

2.4

2.7

2.9

3.3

3.5

3.7

P tot

1.4

1.5

2.1

2.4

2.6

2.8

3.3

3.7

4

4.6

4.9

5.2

1

1.1

1.1

1.5

1.9

2.4

2.7

2.9

3.3

3.5

3.7

P sens Dve Pdc

1.3

1.5

1.5

1.7

1.9

2.1

2.3

2.7

2.9

3.2

3.5

3.8

196

345

2

496

634

356

486

695

887

1

3

6

10

3

5

11

17

GB

P tot : Total cooling capacity in kW

P sens : Sensible cooling capacity in kW

(*) Calculated with the high fan speed, water flow constant for the 3 speeds.

Dve : Water flow rate in litres/hour

Pdc : Pressure drop on water in kPa (1 m W.G. = 10 kPa)

4.3 HEATING PERFORMANCES

Water inlet

Model

MW 2

MW 3

MW 4

MW 5

P tot : Total cooling capacity in kW.

Dve : Water flow rate in litres/hour (corresponding to nominal conditions - § 4.1).

Pdc : Pressure drop on water in kPa (1 m W.G. = 10 kPa).

Fan speed

P tot Dve Pdc

LS

MS

HS

LS

MS

HS

LS

MS

HS

LS

MS

HS

50°C 35°C

2.2

2.4

2.7

2.9

3.2

3.5

3.8

4.5

5.1

5.5

6

6.5

356

486

695

887

2.4

4.1

9

13.8

P tot

1.1

1.2

1.3

1.4

1.6

1.8

1.9

2.2

2.5

2.7

3

3.2

Dve Pdc

356

486

695

887

2.6

4.4

9.7

14.8

5

5 - CONTROL

GB

• Control by "On/Off" action on ventilation. (Operation of the on-off valve, not supplied, is possible).

• Provided by an electronic room thermostat supplied with each air handler (connection not included).

CHARACTERISTICS OF THE ROOM THERMOSTAT

Supply voltage : 230 VAC

Control differential : 0.4 K ± 0.1 K

Operating temperature : 0 / 40°C

Protection class : Cl. II

Interference immunity : Level 4 CEI 801-2 and 801-4

• It is possible to invert the direction of action of the room

thermostat (cooling or heating) by connecting an external

contact (not included), for example, from the hydraulic

module (MH).

The same contact can control several room thermostats

provided the length of the control wire to each room thermostat does not exceed 150 m.

• Available as an accessory: Remote temperature probe.

3-position

speed selector

switch

On/Off

switch

3

2

1

°C

20

15

25

30

Indicator light Temperature setting

knob

(15 to 30°C)

6 - ACCESSORIES

6-1 CONDENSATE DRAINAGE SYSTEM

• Factory-fitted accessory.

• Oscillating piston electromagnetic type pump with float

detection unit controlling the 3 levels of operation (On/Off/

Safety).

• If the water is not discharged correctly, a safety device

prevents the fan from operating.

CAUTION: This device requires regular specific maintenance.

6.2 REMOTE TEMPERATURE PROBE

for room thermostat

• Enables the control thermostat to be put outside the premises to be air-conditioned.

• This temperature probe (CTN type - 33 ký) comes in an attractive, unobtrusive, wallmounted plastic case (protection class IP30).

Discharge

height in m

(W G) *

*Under nominal operating conditions (at high speed).

MW 2 MW 3 MW 4 MW 5

5543

6

INSTALLATION INSTRUCTIONS

°C

20

15

25

30

1

2

3

1 - GENERAL

• The equipment must be installed, started-up and maintained by authorised and qualified personnel, in accordance with local

rules and professional standards.

1.1 GENERAL SUPPLY CONDITIONS

• Generally speaking, the material is transported at the consignee's risk.

• The consignee must immediately provide the carrier with written reserves if he finds any damage caused during transport.

1.2 VOLTAGE

• Before any operation, check that the voltage and the frequency indicated on the device corresponds with that of the mains.

2 - DESCRIPTION

• See § 2 above of the Technical Manual.

ACCESSORIES SUPPLIED WITH THE UNIT

Accessory Q

1 - Support plate

ty

Wall support for the internal

1

Use

unit.

Accessory Q

5 - Large screws 12

ty

Use

For fixing the support plate

with the plugs and the remote

control.

GB

2 - Instructions 2 • Installation instructions.

• Operating instructions.

3 - Plugs 10

For fixing the support plate

and remote control.

4 - Hydraulic

adaptors

Adaptors for connection with

2 + 2

copper or PER pipes

3 - INSTALLATION

3.1 CHOOSING THE LOCATION

Select the location for the unit on the basis of the following

criteria:

• The device is intended for installation in sheltered premises.

Do not install in very damp places or exposed to projections of water (e.g., laundry rooms).

• Do not install next to electric connections.

• The air intake and blowing grilles must be free from any

obstacle so that blowing can occur correctly in the whole

room.

• The wall on which the air handler will be fixed must be

sufficiently thick for there not to be any resonance and so

as not to produce any noise.

• Provide for the pipes and electric cables.

• It is essential to leave the clear space around the unit (see

drawing opposite).

16 - Room

Regulation and control

thermostat

7- Trim 1 Finger plate for the hole in

the wall.

8 - Filters

Spare parts

5

(only with units fitted with a

pump)

9 - Insulation 1 Insulation connections

150

B

150

MW 2

MW 3

MW 4

MW 5

Equipment

A (mm)

1 150

1 150

1 310

1 310

250

A

B (mm)

760

760

760

760

150

7

GB

3.2 INSTALLATION OF THE SUPPORT PLATE

A- After deciding on the position of the internal unit, position the support plate according

to the overall dimensions of the unit and referring to the measurements on the drawing

opposite.

B- Mark and dot punch the six 5 mm dia. fixing holes.

C- Make the hole for the pipes (see § 4.2):

- either by removing the cover (see sketch) for pipes entering through the side,

- or by positioning the 80 dia. hole (lining up on the arrow) and by making it (see

3.3) for pipes entering through the rear of the handler.

D- Drill the six 32 mm deep, 5 mm dia. fixing holes.

E- Put the 6 plugs in the 5 mm dia. holes.

F- Fix the support plate on the wall using the six 4 x 16 screws.

Support plate

cover

MW 2

MW 3

80 mm dia. hole

MW 4

MW 5

Guide arrows

800

20 105 75 20

50 30

30

360

60

35

155 380

760

Guide arrows

38

60

D F

Ø 5

32

E

360

1 000

Hole Ø 80 mm

8

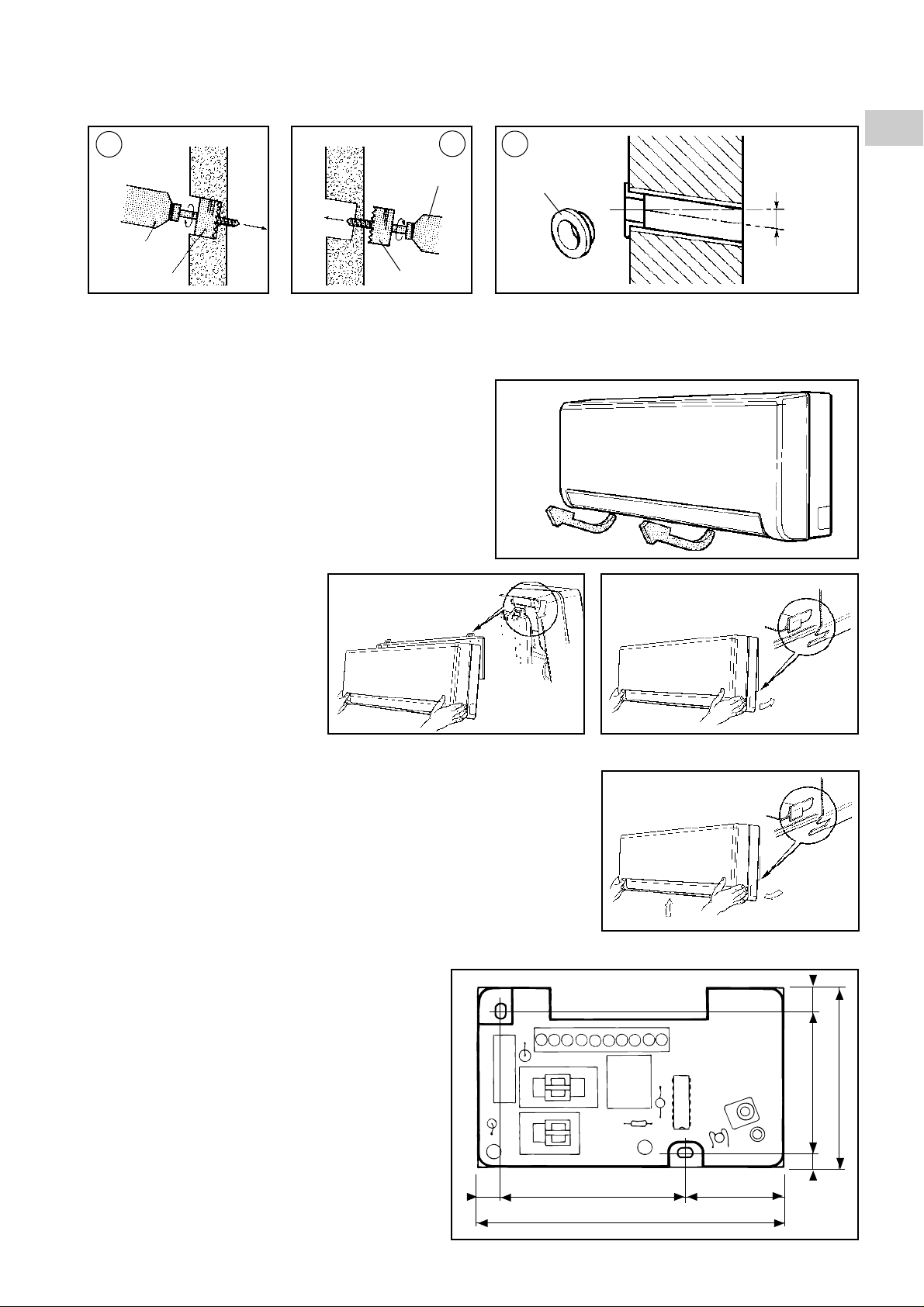

3.3 DRILLING THE HOLES FOR THE PIPES

(for pipes entering through the rear of the air handler)

• Using an 80 mm dia. bell saw attachment, drill a hole in the wall for the pipes.

A

Wall Wall

B

C

GB

Inside

Drill

80 mm dia.

bell saw

attachment

A - Start drilling (at a slight

angle) from the inside.

Outside

Inside

B -

Complete the drilling from

the outside, keeping to

the same angle.

Outside

3.4 HOOKING OF THE INTERNAL UNIT

• Remove the foam packing-pieces in the baffle.

• Hook the air handler on the support

plate according to the sketch

opposite.

• Connect the water pipes (see § 4).

• Run in any electric cables (see § 4).

• Then, press on the bottom of the unit

in order to engage the bottom hooks

in the holes in the support plate.

Hooking

Drill

80 mm dia.

bell saw

attachment

Trim

5 - 10 mm

C - Put in a plastic tube and adapt it to suit. Fix the trim

which is part of the equipment.

3.5 UNHOOKING THE INTERNAL UNIT

• In order to unhook the unit from the support plate, push the unit upwards and pull

it towards you. The hooks are then released from the support plate.

3.6 FIXING THE ROOM THERMOSTAT

• Remove the setting wheel in order to reveal the thermostat cover fixing screw.

• Remove the cover.

• Fix the thermostat using 2 screws (dimensions in

accordance with sketch opposite).

POSITIONING THE THERMOSTAT

• Fixing height: approx. 1.50 m above the floor.

• Avoid draughts from doors and windows.

• Also make sure that the thermostat is in the premises'

normal convection currents, and that it is not fitted inside

shelving or covered by curtains.

• All unwanted heat sources adversely aff ect control; a void

therefore sunlight, the proximity of supplementary

heaters, lights, chimneys, television sets, etc...

869 36

113

8,5

53,55

67

9

4 - CONNECTIONS

GB

4.1 CONNECTING THE CONDENSATE DISCHARGE PIPE

(For air handlers which can operate in cooling mode)

• Connect the condensate pipe to a discharge pipe.

• Fix the two pipes using adhesive tape:

- MW 2, MW 3: Ø 18 mm.

- MW 4, MW 5: Ø 26 mm.

• For air handlers equipped with a condensate lift system, the pump discharge is

connected to a flexible PVC pipe of internal diameter 6 mm, equipped with a splined

connector.

See the "Technical Manual" for the pressures available at the discharge.

IMPORTANT NOTE

• If the end of the condensate discharge pipe goes into the

water and forms a trap, the flow will not be correct and the

condensate will flow in the internal unit (see drawing

opposite).

• Check that the condensate is discharged smoothly.

• Seal the hole in the wall through which the pipes pass in

order to prevent water entering.

Slope

Condensate discharge

pipe

Trap

Adhesive

tape

Condensate

discharge

Sealing

compound

Immersion

• Using a bottle, pour water into the condensate tray in order

to ensure that the water is correctly discharged.

4.2 HYDRAULIC CONNECTION

• MW can be connected either with metric copper pipe or with PER

(interlaced polyethylene).

• Diameter of the pipes to be used:

- MW 2 and MW 3:

- copper pipe 10/12 or

- PER pipe 10/12

- MW 4 and MW 5:

- copper pipe 14/16 or

- PER pipe 13/16

• Adaptors for copper pipe or PER pipe are supplied with the air handler.

Copper pipe

P.E.R. pipe

4.2.1 ORIENTATION OF THE PIPES

• For orientations 1 cut the plate (in

order to put the pipes through leaving

the contour free from any roughness).

• Keep the piece of plate cut for possible later use.

10

1

2

Cover

4.2.2 INSTALLATION WITH HORIZONTAL

CONNECTIONS

• Before fitting the unit on the support plate, connect the

condensate discharge pipe and the connecting pipes and

connect them using adhesive tape.

• Install them in the custom-made housing. Leave the ins-

Insulation

tallation clear along the front.

Pipes

4.2.3 INSULATION OF PIPES

• The insulation concerns the water return and inlet pipes.

• Use polyethylene sheathing at least 6 mm thick.

• After connecting the pipes and checking for leaks, put the insulating sleeves on the

fittings and force them against the cassette in order to prevent condensation.

Note : This operation must be done carefully to avoid any risk of condensation.

4.2.4 PURGING THE AIR HANDLER'S WATER CIRCUIT

• Done by means of a purge screw located on the water coil's header.

• To have access to the screw, remove the air handler's cover.

GB

Electrical cables

(if applicable)

Condensate

pipe

Insulation

MW 2

MW 3

• Then act on the purge screw.

4.3 ELECTRICAL CONNECTIONS

4.3.1. PRINCIPLE

• Control by action on ventilation.

MW 4

MW 5

Purge screw

1

7

2

5

6

312

3

°C

20

15

25

30

4

(*) To be fitted only for a unit operating in cooling and in heating.

1 - Power supply and protection device

(not supplied)

2 - Power cable

(not supplied)

3 - Thermostat

4 - Control cable

(not supplied)

(*)

5 - Cooling/heating change-over contact

(not supplied - integrated in MH)

6 - Cooling/heating change-over control

cable

(not supplied)

7 - Air handler

11

GB

4.3.2. POWER SUPPLY

• 230V / 1+Earth / 50Hz power supply from a power supply

and protection device (not included) in accordance with

with the rules in force especially NFC 15-100 CEI 364.

• The voltage variation tolerance is + or - 10 % during

operation.

• The power cable must be fixed.

• Section of an air handler's power cable: 3G 1.5 mm

• Current consumption of an air handler (with condensate

pump):

Max. current A

MW 2

0.25

MW 3

0.25

MW 4

0.45

2.

MW 5

0.5

• Preparation of the cable (see sketch below).

• Connection to the air handler according to the indications

and diagrams below.

Air handler side

655

4.3.3. CONTROL

• Connection of the thermostat to the

air handler by cable 6 x 0.75 mm

2

.

655

• The power cable must be fixed.

• Preparation of the cable (see sketches opposite).

• Connections according to the indications and diagrams in § 4.3.5.

Air handler side Thermostat side

4.3.4. DETAIL OF THE ELECTRICAL CONNECTION OF THE AIR HANDLER

To have access to the terminal board:

• Remove the air handler's cover (see sketches below).

MW 2

MW 3

• Remove the terminal board access

door (see sketches below).

MW 2

MW 3

MW 4

MW 5

• Then prepare the wires and connect them to the

terminal board.

• Note : on certain devices, the terminals are of the

"cage with spring" type.

Follow the indications below to connect them.

- These terminals take the following wires:

- rigid

- flexible (avoid splicing the strands!)

- with ends

- A single conductor per securing point

- Make sure that the wires are correctly

connected to the terminal board. Incorrect

connection can cause operating problems as

well as overheating which can cause fires.

MW 4

MW 5

40 7

4.3.5 CONNECTION DIAGRAMS

• The wiring of the thermostat shown opposite corresponds

to control in cooling mode with action on the ventila-

tion (standard assembly).

12

COOLING MODE

ONLY

Action on ventilation

Control cable

19

1

3

Thermostat

4

20

21

22

Protected supply

230 V / 1 + T / 50

NPh

Hz

Power supply

cable

U

N

1

3

4

20

21

22

Air handler

MW

• Note :

It is possible to obtain temperature control by actuating a

temperature control valve (not supplied) operating in onoff mode and feeding the terminal unit.

In this case, ventilation is permanent.

Valve power supply: 230 VAC (Max. intensity = 0.5 A inductive).

COOLING MODE

ONLY

Action on valve

19

1

Thermostat

3 6

4

20

21

22

Protected supply

230 V / 1 + T / 50

NPh

Hz

Power supply cable

U

N

N

1

3

4

20

21

22

GB

Air handler

MW

Valve

Control cable

• It is possible to invert the direction of action of control and

thus to change to heating mode by connecting thermostat

terminal 19 to the installation's neutral which can be found

on thermostat terminal 4.

19

Thermostat

1

3

4

20

21

22

HEATING MODE

• For installations which can operate in cooling mode or in

heating mode, it is possible to connect a contact which:

- if it is closed, connects terminal 19 to the installation's

neutral and causes the installation's thermostat to

Air conditioning/

heating change-over

contact

operate in heating.

- if it is open, isolates terminal 19 and causes the control

thermostat to operate in cooling mode.

• This contact (not supplied) can come, for example, from

the hydraulic module MH.

Note : The same contact can control the mode changeover of several room thermostats provided:

- That the length of the wire connecting to the change-

19

1

3

4

20

21

22

19

1

3

4

20

21

22

AIR CONDITIONING/HEATING MODE

over contact does not exceed 150 m (wire of section 1.5 mm2).

- That the neutral on which the change-over contact is connected is the same as the one for the various air handlers.

- Do not run this control cable near power cables in order to avoid interference.

19

1

3

4

20

21

22

4.3.6 REMOTE TEMPERATURE PROBE ACCESSORY

• Enables the control thermostat to be put outside the premises to be air-conditioned.

The probe connects to the thermostat.

• Fixing:

- Make sure that the installation is switched off.

- Open the probe case cover.

- Fix the probe case in the required place, following these rules:

- Avoid draughts

- Avoid any unwanted heat source which could affect the probe (sunlight, pro ximity

of supplementary heaters, lights, chimneys, television sets, etc.)

- Make sure that the probe is in the normal convection currents.

• Remove the cover of the control thermostat case.

• Remove the probe inside the thermostat shown opposite

(by cutting this component's fixing lugs using pliers).

27

71

71

Probe

13

• Connect as indicated:

- Max. length of cable: 50 m on 1.5 mm

2

2

4

GB

• Use shielded cable if the latter runs next to power cables.

• Refit the protective covers.

5 - STARTING

IMPORTANT

Before doing any work on the installation, make sure it is switched off and put out of bounds.

5.1 PRELIMINARY CHECKS

Make sure:

• That the water circulates correctly in the air handler.

• That the heat exchanger has been purged.

• That the fittings are correctly tightened.

• That there are no leaks.

• That the air handler is well fixed.

• That the power cables are well fixed to their connection

terminals.

• That the electric cables are properly insulated from any

pieces of sheet or metal parts which could damage them.

• That the unit is connected to earth.

• That no tools or any other objects have been left in the

units (specially form packing-pieces in the discharge

louvers).

• That the filter is correctly fitted.

• That the condensate discharge outlet is correctly

connected.

• That the condensate collection tank is clean. Particles can

damage the condensate lift pump (if fitted).

5.2 SWITCH ON THE UNIT

• Using the isolation and protection device.

5.3 STARTING

• Through the On/Off switch located on the room thermostat.

• Select one of the three ventilation speeds using the switch

provided for this purpose on the room thermostat.

• Move the temperature setting wheel in order to check the

operation and direction of action of control (*):

- In cooling mode, the fan is operated if the ambient

temperature is above the setpoint.

- In heating mode, the fan is operated if the ambient

temperature is below the setpoint.

• Adjust the temperature setpoint value to the required value.

• If necessary, adjust the position of the vertical deflection

louvre using the "SWEEP" switch on the front of the air

handler (take care of flap movements).

Do not move the flap by hand, as it is motorised.

(*) In the case of adjustment on the valve, ventilation is perma-

nent

4

Probe

Connecting cable

(not included)

11

Thermostat

Note:

A fuse on the printed circuit board next to the air handler's

terminal board protects the circuits (see diagram)

Fuse rating : 2A GI 250 V

Fuse size : 5 x 20

5.4 CONDENSATE LIFT PUMP SYSTEM

Factory-fitted accessory.

• It consists of a float type water detection unit which receives

the water collected by the collection tank placed under the

heat exchanger and of a pump unit which sucks the water

from the detection unit.

• The pump's discharge is to be connected as indicated in §

4.1.

• It is necessary to clean and/or change the filter in the

detection unit (frequency according to handler's operating

conditions). See § 6 - maintenance.

• 5 spare filters are supplied with the air handler.

• When reassembling, make sure that:

- the unit is perfectly level

- the float is not stuck (and its locating stud is facing

upwards)

- the pipes are correctly connected (no leaks).

CAUTION :

Stop the air-conditioning system 30 minutes before any

switching off of terminal units, in order to discharge residual

condensates (and avoid inadvertent overflows).

Vent pipe

Suction of

condensates

Inlet for

condensates

Locating stud

Filter

Float

Cable

14

6 - MAINTENANCE

IMPORTANT

Before doing any work on the installation, check that the power supply is switched off and secured

• Air filter: Clean every two weeks. See “Operating

Manual”.

. External unit air exchanger: Cleaning recommended

once a year.

. Electric connections: Once a year, check that the

electric wires are well fastened to their terminals.

condensates

. Electric box : Dusting is recommended once a year.

• Condensate pumping system: This requires regular

specific maintenance.

- The level detection unit must be cleaned and its filter

Inlet for

condensates

replaced regularly (the frequency depends on the operating

conditions) (see fig. below).

- Clean with water containing 5% bleach.

- The device is delivered with 5 replacement filters.

• When reassembling, make sure:

Locating stud

- that the detection unit is horizontal,

- that the float is clean and not jammed (and that its polarising slot is directed upwards),

- that the pipes are clean and correctly connected (no leaking),

- that the assembly operates correctly by testing it.

Vent pipe

Suction of

Filter

GB

Float

Cable

7 - WIRING DIAGRAM

MW 2 - MW 3 - MW 4 - MW 5

Power supply 230/1/50

Remote sensor

(option)

4 11

19

4

1

T

REMOTE CONTROL

ON/OFF

LS

MS

HS

2

3

20

21

22

20

21

22

10 05 357 - 00

F1

U

2A

N

C2/1

C1/1

C1/2

C2/4

4

1

S1

2

1

N

P

C2/2

P1

C

NC

3

4

C2/3

M1

3

C3/6

C2

C3/5

C3/4

P

M

M2

J

L

G

C3/3

C3/2

W

C3/1

M1 Louvre motor

M2 Fan

P1 Condensate pump (as accessory)

C2 Capacitor of M2

NOTE :

Terminal 19 not connected: control operates in COOLING mode.

Terminal 19 connected to the installation's neutral (terminal 4): control oper ates

in HEATING mode.

F1 Control circuit fuse

S1 Louvre switch

Standard assembly with control by actuating the ventilation.

15

F

GB

I

E

D

En el interés de mejoras constantes, nuestros productos pueden modificarse sin aviso prévio.

R.D. 28 Reyrieux BP 131 01601 Trévoux CEDEX France

Tél. 33 4 74 00 92 92 - Fax. 33 4 74 00 42 00

R.C.S. Bourg-en-Bresse B 759 200 728

Loading...

Loading...