Technibel MCW1B5XAB, MPW1B5XAA, MPW2B5XAA, MCW3B5XAB, MPW3B5XAA Technical Data & Service Manual

...Page 1

TECHNICAL DATA

& SERVICE MANUAL

INDOOR UNIT:

MCW1B5XAB MPW1B5XAA

MCW2B5XAB MPW2B5XAA

MCW3B5XAB MPW3B5XAA

MCW4B5XAB MPW4B5XAA

SPLIT SYSTEM AIR CONDITIONER

0.8180.566.1 April 2011

MCW2B5XAB 38.7104.027

MCW3B5XAB 38.7104.028

MCW4B5XAB 38.7104.029

MPW1B5XAA 38.7104.040

MPW2B5XAA

Model No. Product Code No.

MCW1B5XAB 38.7104.026

MPW3B5XAA

MPW4B5XAA

38.7104.043

38.7104.045

38.7104.047

Page 2

Page

1. SPECIFICATIONS 3

1-1 Unit specifications 3

1-2 Major Component specifications 7

1-3 Other Component specifications 11

2. DIMENSIONAL DATA 12

3. ELECTRICAL DATA 13

3-1 Electric Wiring Diagrams 13

3-2 Jumpers Configuration 14

3-3 Contacts for Building Automation 16

3-4 Maintenance 17

4. FUNCTION 18

4-1 Cool Mode Operation 18

4-2 Heat Mode Operation 19

4-3 Auto (cool/heat) Mode Operation 20

4-4 Dry Mode Operation 21

4-5 Fan Mode Operation 21

4-6 Auto Fan Speed 21

4-7 Forced Mode 22

4-8 Protection Operation in Heat Mode 22

4-9 I Feel Function 24

4-10 Night Function 24

4-11 Diagnostic 25

5. CHECKING ELETRICAL COMPONENTS 26

5-1 Measurement of Insulation Resistance 26

5-2 Checking Continuity of Fuse on PCB Ass'y 27

Table of Contents

2

Page 3

1. SPECIFICATIONS

1-1 Unit Specifications

MCW1B5XAB MPW1B5XAA

Power source

Performance

Input kW

Running Amps A

Total cooling capacity (1) High/Med./Low

kW

Sensible cooling capacity (1) High/Med./Low

kW

Heating capacity (2) High/Med./Low

kW

Air circulation High/Med./Low m³/h

Features

Controls/Temperature controls

Control unit

Timer

Fan speed

Airflow direction Horizontal

Vertical

Water FLOW in cooling

High/Med./Low

l/h

Pressure drop on water in cooling (1)

High/Med./Low

kPa

Pressure drop on water in heating (2) High kPa

Air Filter

Power noise level High/Med./Low dB-A

Water tubing connections

Air clean filter

3-Way valve + By-pass (1/2 gas male, KVS 1,6, 230 NC)

Dimensions & Wei

g

ht

Package dimensions Height mm

MCW

Width mm

Depth mm

Shipping volume

m

3

Package dimensions Height mm

MPW

Width mm

Depth mm

Shipping volume

m

3

Weight Net kg

Shipping kg

DATA SUBJECT TO CHANGE WITHOUT NOTICE

(1)

Air inlet 27°C (D.B.) / 19°C (W.B.); Water inlet 7°C; Water outlet 12°C

(2)

Air inlet 20°C; Water inlet 50°C (same water capacity as in conditions (1))

OPERATION LIMITS

Min. water inlet temperature 4°C Min. air recirculation temperature 5°C

Max. water inlet temperature 60°C Max. air recirculation temperature 32°C

Max. operating pressure of hydraulic circuit 16 bar

0,064

11,0

Optional

0,020

0,11

322

855

273

0,075

Manual

1,24/---/0,8

220/---/150

1,72/---/1,11

215/---/135

Microprocessor/ I.C. thermostat

ON/OFF 24 hours

Wireless remote control unit

Optional

1/2" gas female

Washable, polypropylene, class HB (UL94)

41/--/32

230 V - 50 Hz

855

233

8.0

322

16,1/---/5,8

0,94/---/0,58

15,3

3 and Auto

Auto

3

Page 4

MCW2B5XAB MPW2B5XAA

Power source

Performance

Input kW

Running Amps A

Total cooling capacity (1) High/Med./Low

kW

Sensible cooling capacity (1) High/Med./Low

kW

Heating capacity (2) High/Med./Low

kW

Air circulation High/Med./Low m³/h

Features

Controls/Temperature controls

Control unit

Timer

Fan speed

Airflow direction Horizontal

Vertical

Water capacity in cooling

High/Med./Low

l/h

Pressure drop on water in cooling (1)

High/Med./Low

kPa

Pressure drop on water in heating (2) High kPa

Air Filter

Power noise level High/Med./Low dB-A

Water tubing connections

Air clean filter

3-Way valve + By-pass (1/2 gas male, KVS 1,6, 230 NC)

Dimensions & Wei

g

ht

Package dimensions Height mm

MCW

Width mm

Depth mm

Shipping volume

m

3

Package dimensions Height mm

MPW

Width mm

Depth mm

Shipping volume

m

3

Weight Net kg

Shipping kg

DATA SUBJECT TO CHANGE WITHOUT NOTICE

(1)

Air inlet 27°C (D.B.) / 19°C (W.B.); Water inlet 7°C; Water outlet 12°C

(2)

Air inlet 20°C; Water inlet 50°C (same water capacity as in conditions (1))

OPERATION LIMITS

Min. water inlet temperature 4°C Min. air recirculation temperature 5°C

Max. water inlet temperature 60°C Max. air recirculation temperature 32°C

Max. operating pressure of hydraulic circuit 16 bar

0,11

273

0,075

8.0

27,2/---/9,7

26,2

Manual

Auto

290/---/165

855

11,0

233

0,064

322

855

230 V - 50 Hz

Wireless remote control unit

Microprocessor/ I.C. thermostat

1,67/---/0,96

1,30/---/0,74

2,38/---/1,49

270/---/180

0,020

ON/OFF 24 hours

3 and Auto

322

Washable, polypropylene, class HB (UL94)

45/--/35

1/2" gas female

Optional

Optional

4

Page 5

MCW3B5XAB MPW3B5XAA

Power source

Performance

Input kW

Running Amps A

Total cooling capacity (1) High/Med./Low

kW

Sensible cooling capacity (1) High/Med./Low

kW

Heating capacity (2) High/Med./Low

kW

Air circulation High/Med./Low m³/h

Features

Controls/Temperature controls

Control unit

Timer

Fan speed

Airflow direction Horizontal

Vertical

Water capacity in cooling

High/Med./Low

l/h

Pressure drop on water in cooling (1)

High/Med./Low

kPa

Pressure drop on water in heating (2) High kPa

Air Filter

Power noise level High/Med./Low dB-A

Water tubing connections

Air clean filter

3-Way valve + By-pass (1/2 gas male, KVS 1,6, 230 NC)

Dimensions & Wei

g

ht

Package dimensions Height mm

MCW

Width mm

Depth mm

Shipping volume

m

3

Package dimensions Height mm

MPW

Width mm

Depth mm

Shipping volume

m

3

Weight Net kg

Shipping kg

DATA SUBJECT TO CHANGE WITHOUT NOTICE

(1)

Air inlet 27°C (D.B.) / 19°C (W.B.); Water inlet 7°C; Water outlet 12°C

(2)

Air inlet 20°C; Water inlet 50°C (same water capacity as in conditions (1))

OPERATION LIMITS

Min. water inlet temperature 4°C Min. air recirculation temperature 5°C

Max. water inlet temperature 60°C Max. air recirculation temperature 32°C

Max. operating pressure of hydraulic circuit 16 bar

347

Optional

Washable, polypropylene, class HB (UL94)

Optional

20/13/7

19

58/52/46

1/2" gas female

230 V - 50 Hz

3,17/2,53/1,91

2,56/1,89/1,53

4,50/3,50/2,70

510/400/320

0,075

0,35

Microprocessor/ I.C. thermostat

Wireless remote control unit

545/435/330

ON/OFF 24 hours

3 and Auto

Manual

Auto

1065

260

0,096

347

14,0

1065

281

0,104

11,0

5

Page 6

MCW4B5XAB MPW4B5XAA

Power source

Performance

Input kW

Running Amps A

Total cooling capacity (1) High/Med./Low

kW

Sensible cooling capacity (1) High/Med./Low

kW

Heating capacity (2) High/Med./Low

kW

Air circulation High/Med./Low m³/h

Features

Controls/Temperature controls

Control unit

Timer

Fan speed

Airflow direction Horizontal

Vertical

Water capacity in cooling

High/Med./Low

l/h

Pressure drop on water in cooling (1)

High/Med./Low

kPa

Pressure drop on water in heating (2) High kPa

Air Filter

Power noise level High/Med./Low dB-A

Water tubing connections

Air clean filter

3-Way valve + By-pass (1/2 gas male, KVS 1,6, 230 NC)

Dimensions & Wei

g

ht

Package dimensions Height mm

MCW

Width mm

Depth mm

Shipping volume

m

3

Package dimensions Height mm

MPW

Width mm

Depth mm

Shipping volume

m

3

Weight Net kg

Shipping kg

DATA SUBJECT TO CHANGE WITHOUT NOTICE

(1)

Air inlet 27°C (D.B.) / 19°C (W.B.); Water inlet 7°C; Water outlet 12°C

(2)

Air inlet 20°C; Water inlet 50°C (same water capacity as in conditions (1))

OPERATION LIMITS

Min. water inlet temperature 4°C Min. air recirculation temperature 5°C

Max. water inlet temperature 60°C Max. air recirculation temperature 32°C

Max. operating pressure of hydraulic circuit 16 bar

0,40

3,67/3,14/2,62

3,01/2,50/2,12

5,50/4,50/3,70

230 V - 50 Hz

0,080

1/2" gas female

630/540/450

27/20/14

26,0

Optional

Optional

347

1065

710/580/470

Auto

Washable, polypropylene, class HB (UL94)

59/53/48

Wireless remote control unit

ON/OFF 24 hours

3 and Auto

Manual

Microprocessor/ I.C. thermostat

260

0,096

347

1065

281

0,104

11,0

14,0

6

Page 7

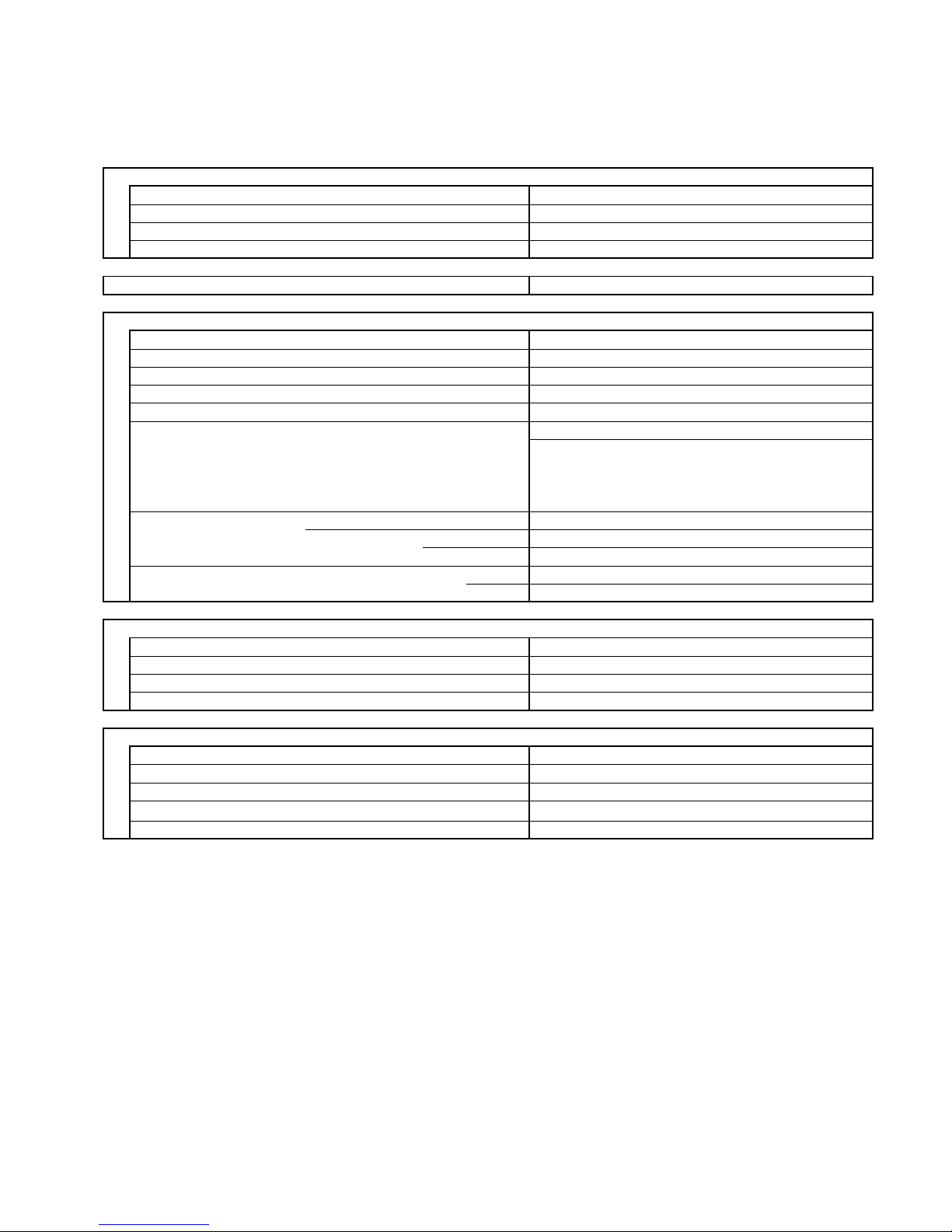

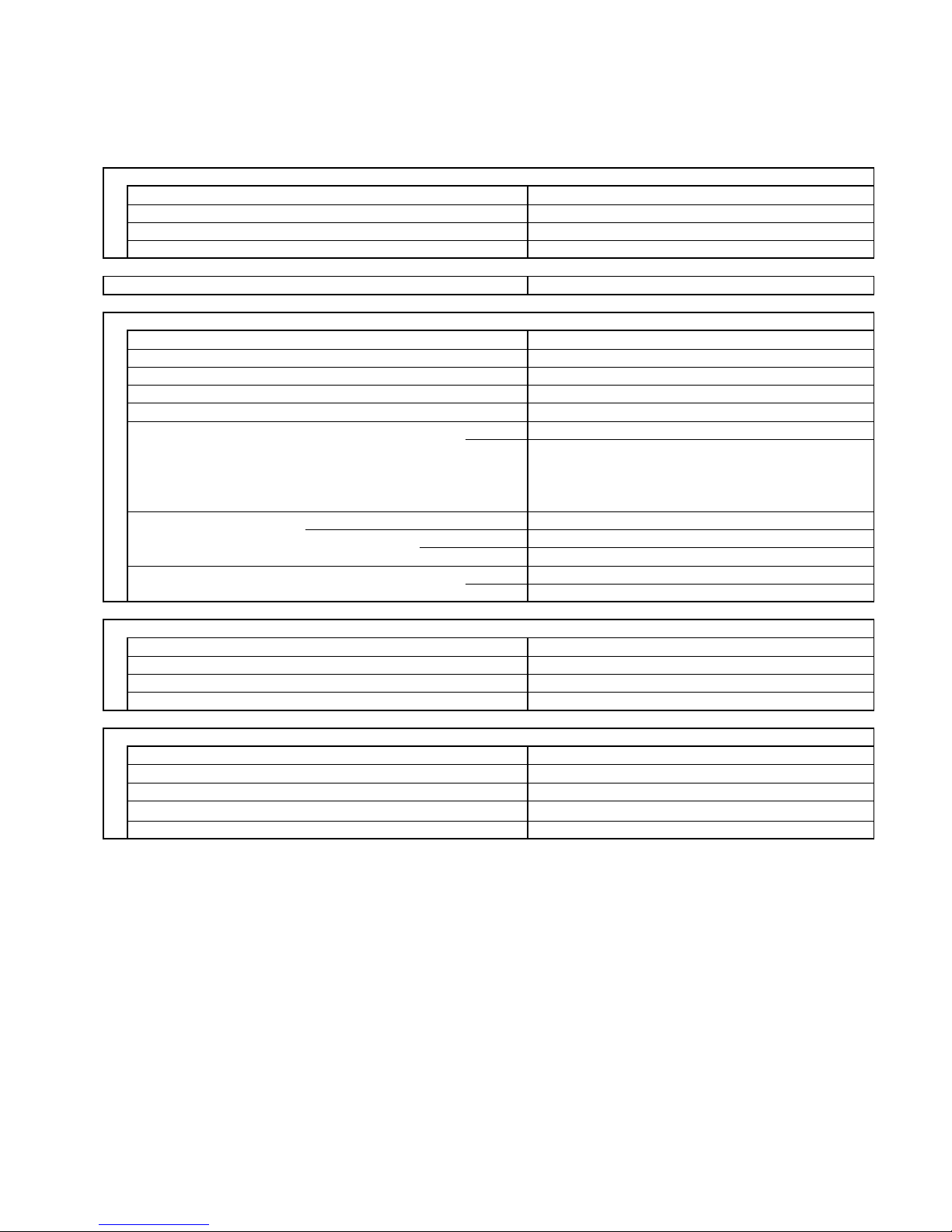

1-2 Major Component Specifications

MCW1B5XAB MPW1B5XAA

Controller PCB

Part No.

Controls

Control circuit fuse

Jumper setting JP1..JP5

Remote Control Unit

Fan & Fan Motor

Type

Q'ty ……. Dia. and lenght mm

Fan motor model…Q'ty

No. Of poles…rpm (230 V - 50 Hz, Hi)

Nominal output W

Coil resistance (Ambient temp. 20 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close

Run capacitor µF

VAC

Flap Motor

Type

Model

Rating

Coil resistance (Ambient temp. 25 °C )

Ω

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

Quantity of water l

DATA SUBJECT TO CHANGE WITHOUT NOTICE

0,095

SAC ON-OFF IDU

SAC W-REM

Cross - flow

KFV4Q-11H5P-S…1

4…1160

Aluminium plate fin / Copper tube

DC 12 V

380 ± 7%

2

1,4

440

MP24Z1

Stepping motor

VLT-WHT: 197,4

10

YEL-ORG: 155,7

Microprocessor

250 V - 3,15 A

1…. Ø 97 / L 617

2,54mm-5pcs

0,30

0,6

-

BRN-WHT: 561,8

VLT-ORG: 63,4

YEL-PNK: 115,9

internal fuse

145 ± 5

7

Page 8

MCW2B5XAB MPW2B5XAA

Controller PCB

Part No.

Controls

Control circuit fuse

Jumper setting JP1..JP5

Remote Control Unit

Fan & Fan Motor

Type

Q'ty ……. Dia. and lenght mm

Fan motor model…Q'ty

No. Of poles…rpm (230 V, Hi)

Nominal output W

Coil resistance (Ambient temp. 20 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close

Run capacitor µF

VAC

Flap Motor

Type

Model

Rating

Coil resistance (Ambient temp. 25 °C )

Ω

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

Quantity of water l

DATA SUBJECT TO CHANGE WITHOUT NOTICE

0,39

YEL-ORG: 155,7

1

430

YEL-PNK: 115,9

internal fuse

145 ± 5

0,115

Stepping motor

MP24Z1

DC 12 V

380 ± 7%

Aluminium plate fin / Copper tube

2

1,4

250 V - 3,15 A

SAC W-REM

1…. Ø 97 / L 617

Cross - flow

2,54mm-5pcs

SAC ON-OFF IDU

Microprocessor

BRN-WHT: 561,8

VLT-ORG: 63,4

VLT-WHT: 197,4

KFV4Q-11H5P-S…1

4…1160

10

8

Page 9

MCW3B5XAB MPW3B5XAA

Controller PCB

Part No.

Controls

Control circuit fuse

Jumper setting JP1..JP5

Remote Control Unit

Fan & Fan Motor

Type

Q'ty ……. Dia. and lenght mm

Fan motor model…Q'ty

No. Of poles…rpm (230 V, Hi/Me/Lo)

Nominal output W

Coil resistance (Ambient temp. 20 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close

Run capacitor µF

VAC

Flap Motor

Type

Model

Rating

Coil resistance (Ambient temp. 25 °C )

Ω

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

Quantity of water l

DATA SUBJECT TO CHANGE WITHOUT NOTICE

0,80

YEL-ORG: 73,55

79 ± 15

0,8

440

YEL-PNK: 43,72

termal protector

130 ± 8

0,156

Stepping motor

MP24Z2

DC 12 V

400 ± 7%

Aluminium plate fin / Copper tube

2

1,4

250 V - 3,15 A

SAC W-REM

1…. Ø 90,5 / L 746

Cross - flow

2,54mm-5pcs

SAC ON-OFF IDU

Microprocessor

BRN-WHT: 163,7

VLT-WHT: 68,84

VLT-ORG: 33,16

UF2Q-21SB5P…1

2… 1550/1250/1025

24,07

9

Page 10

MCW4B5XAB MPW4B5XAA

Controller PCB

Part No.

Controls

Control circuit fuse

Jumper setting JP1..JP5

Remote Control Unit

Fan & Fan Motor

Type

Q'ty ……. Dia. and lenght mm

Fan motor model…Q'ty

No. Of poles…rpm (230 V, Hi/Me/Lo)

Nominal output W

Coil resistance (Ambient temp. 20 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close

Run capacitor µF

VAC

Flap Motor

Type

Model

Rating

Coil resistance (Ambient temp. 25 °C )

Ω

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

Quantity of water l

DATA SUBJECT TO CHANGE WITHOUT NOTICE

0,80

SAC ON-OFF IDU

Microprocessor

250 V - 3,15 A

2,54mm-5pcs

SAC W-REM

Cross - flow

1…. Ø 90,5 / L 746

UF2Q-21SB5P…1

2… 1550/1250/1025

24,07

BRN-WHT: 163,7

VLT-WHT: 68,84

VLT-ORG: 33,16

YEL-ORG: 73,55

YEL-PNK: 43,72

termal protector

130 ± 8

79 ± 15

1,5

440

Stepping motor

MP24Z2

DC 12 V

400 ± 7%

Aluminium plate fin / Copper tube

2

1,4

0,156

10

Page 11

1-3 Other Component Specifications

Trasformer (TR

)

Rating Primary

Secondary

Capacity

Coil resistance

Ω

(

at 25°C

)

Thermal cut-off temp.

Thermistor

(

Coil sensor

)

Resistance

k

Ω

Thermistor ( Room sensor

)

Resistance

k

Ω

A040C5026AA

AC 230 V, 50 Hz

13 V - 5VA

NTC-THERMISTOR

10 at 25 °C

NTC-THERMISTOR

Primary: -

Secondary: -

120°C

10 at 25 °C

11

Page 12

2. DIMENSIONAL DATA

MCW 1 MCW 3 MPW 1 MPW 3

MCW 2 MCW 4 MPW 2 MPW 4

Dimensions

W

mm 805 995 805 995

H mm 270 285 270 285

T mm 181 206 215 240

MCW 1-2 MCW 3-4

MPW 1-2 MPW 3-4

A

mm 99,5 147,5

B mm 58,5 147,5

C mm 41 45

D mm 111 -

E mm 70 -

Water tubing connections:

1/2 gas female

REAR VIEW

H

W

T

Drain hose diam. 18

Centre of tubing

hole (2 places)

E

Diam. 65(1-2)

12

Page 13

3. ELECTRICAL DATA

3-1 Electric Wiring Diagrams

MCW1B5XAB MCW2B5XAB MPW1B5XAA MPW2B5XAA

MCW3B5XAB MCW4B5XAB MPW3B5XAA MPW4B5XAA

13

Page 14

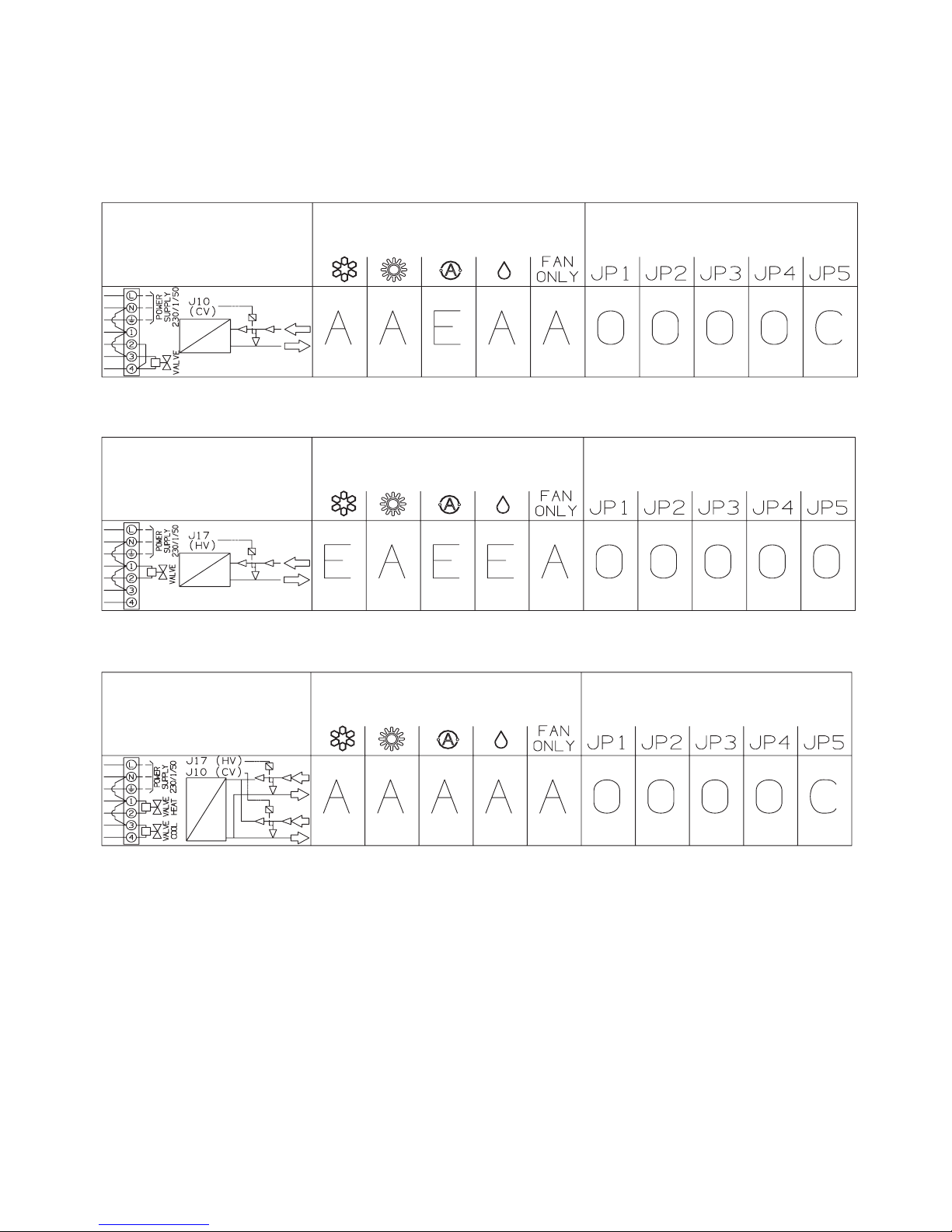

3-2 JUMPERS CONFIGURATION

Jumpers are located on the indoor PCB near the MODE button.

1 - Setting JUMPERS

C = Closed

O = Open

2 - Fonction

A = Available

E = Not available

(when selecting, all leds

blinking)

NOTE: settings different from the factory one must be done by special worker

FACTORY SYSTEM CONFIGURATION:COOLING ONLY WITH VALVE

COOLING ONLY

SYSTEM

FUNCTIONSFUNCTIONS

JUMPERS

14

Page 15

SYSTEM CONFIGURATION:COOLING OR HEATING WITH VALVE

SYSTEM CONFIGURATION:HEATING ONLY WITH VALVE

SYSTEM CONFIGURATION:COOLING WITH VALVE OR HEATING WITH VALVE

COOLING ONLY

SYSTEM

COOLING ONLY

SYSTEM

FUNCTIONS

FUNCTIONS

JUMPERS

JUMPERS

COOLING ONLY

SYSTEM

FUNCTIONS

JUMPERS

15

Page 16

3-3 CONTACTS FOR BUILDING AUTOMATION

3-3.1 INPUT CONTACT (J4 - green)

The status of this input affects system operation according to the following:

Contact OPEN : system does not operate (always OFF) – inputs from wireless remote controller are not processed

Contact CLOSED: system operates in the normal way according to the inputs coming from wireless remote controller

3-3.2 OUTPUT CONTACT (J12)

This connector is directly tied to the contact (normally open) of a power relay which activates every time the following alarm

condition occur:

•

RAT damaged

•

ICT damaged

In this case when alarm happens, on poles 1 and 3 of J12 connector, 220 VAC-50Hz are available.

Max electrical load: 1A- 240VA

C

16

Page 17

3-4 MAINTENANCE

Changing the Address of the Air Conditione

r

In case of more than one air conditioner operating in the same room, it may be necessary to assign an address to each

unit in order to avoid operation conflicts. Address is set acting on the dip-switches located on the indoor PCB and on the

remote controller. The PCB settings must match the corresponding ones on the wireless remote controller.

How to change address of the air conditione

r

Dip switch is located on the indoor PCB near the buzzer.

Set the PCB to the address desidered

As default switches SW1 and SW2 are in off status (PCB factory state).

How to change address on Remote Control Uni

t

Dip switch is located on the battery compartment.

1) Pull out the door and remove the batteries.

2) Set the switch SW1 and SW2 according to the indoor PCB settings

(do not act on SW3 and SW4)

3) Insert the batteries and pull on the door

As default switches SW1 and SW2 are in off status (remote controller factory state).

unit remote control

indoor unit

REMOTE CONTROL

PCB

17

Page 18

4.FUNCTION

4-1 Cool Mode Operation

NOTES

1. In this graph, the FMI is operating with the “Auto Fan Speed” setting. If the user has selected the Low,

Medium or High fan speed, the FMI will run at that speed only.

2. The indoor fan can change speed only after it has operated at the same speed for 30 sec if in AUTO and 1

sec for the other settings (High, Med, Low).

V

ALVE

18

Page 19

4-2 Heat Mode Operation

The Heating mode operation is similar to the Cooling mode operation. The VALVE and FMI are mainly

controlled by the value of (RAT – SPT). In the graph above, the FMI is operating in AUTO speed mode.

Therefore, the FMI speed changes automatically according to the (RT - SPT).

NOTES

1. After VALVE is switched off, the FMI runs for 30s in order to purge heat from the indoor coil.

2. The FMI will not be turned on until the indoor coil temperature is warm enough to prevent the supply of

cool air (see COLD DRAFT PREVENTION mode for details). The indoor fan can change speed only after it

has operated at the same speed for 30 sec if in AUTO and 1 sec for the other settings (High, Med, Low).

V

ALVE

19

Page 20

4-3 Auto (cool/heat) Mode Operation

In Auto Mode, the unit switches automatically between the Auto Cooling and Auto Heating in order to

maintain the room temperature (RAT) at the prescribed set point (SPT).

The switching between the two modes is according to the above graph.

Refer to the sections 5.1 COOLING MODE and 5.2 HEATING MODE for system operation details.

V

ALVE(COOL

)

V

ALVE(HEAT

))

20

Page 21

4-4 Dry Mode Operation

Dry operation remove moisture from indoor air running, in cooling mode, at a low level without reducing the

ambient temperature. This is done cycling ON and OFF indoor and outdoor units according to below.

ROOM DRY LEVEL JP4 OPEN JP4 CLOSED

TEMP

Operation according to Operation according to

≥ SPT+2°C LEVEL 0 COOLING mode COOLING mode

CM off CM off

< SPT+2°C LEVEL 1 FMO on FMO off

≥ SPT-1°C FMI runs at LOW speed FMI runs at LOW speed

RV off RV off

CM off CM off

< SPT-1°C LEVEL 2 FMO switches 3 minutes FMO off

≥ 15°C

on and 9 minutes off

FMI switches LL and L FMI switches LL and L

during FMO operation

(3 MIN. on and 9 OFF)

RV off RV off

CM off CM off

< 15°C DRY OFF ZONE FMO off FMO off

FMI off FMI off

RV off RV off

SPT = Set Point Temperature

4-5 Fan Mode Operation

With this mode, the indoor fan is turned on while cooling and heating valve stay off all the time. The user can

select between 3 speeds: HIGH, MEDIUM and LOW.

4-6 Auto Fan speed

With this option selected, the indoor fan speed changes automatically according to the difference between

the detected air temperature (RAT sensor) and the set point (SPT):

COOLING MODE

2 ≤ (RAT – SPT):

HIGH speed

1 ≤ (RAT – SPT) < 2: MEDIUM speed

(RAT – SPT) < 1: LOW speed

HEATING MODE

2 ≤ (SPT - RAT):

HIGH speed

(SPT - RAT) < 2: MEDIUM speed

NOTE

SPT = Set Point Temperature

21

Page 22

4-7 Forced Mode

In this mode the system operates (COOLING or HEATING mode – fixed settings) or is switched off by

means of the MODE button of the indoor unit control board. The operation modes can be selected

pressing the button in a cyclic way (OFF Ö COOL Ö HEAT Ö OFF…). The settings are:

COOLING mode

SET POINT temperature = 25°C

FAN SPEED = HIGH

HEATING mod

e

SET POINT temperature = 21°C

FAN SPEED = HIGH

4-8 Protection operations in Heat Mode

5-8.1 Cold draft

This feature prevents the supply of cold air forcing the indoor fan to a speed which cannot be changed

by the user. As soon as the protection mode is exited speed can be changed manually through the

remote controller. The protection acts in the following

22

Page 23

4-8.2 Overhea

t

This feature prevents the build up of high pressure in the indoor heat exchanger during heating

operation

A (°C)

65

B (°C)

55

A

B

VALVE (HEAT)VALVE (HEAT)

23

Page 24

4-9 I FEEL Function

As standard configuration the air conditioner operates detecting the room temperature through the sensor

equipped in the wireless remote controller (icon I FEEL shown on the display). This feature provides a

personalised environment since the temperature can be detected where the remote controller is located.

It is possible to de-activate this option pressing the I FEEL button on the remote controller.

In this case the I FEEL icon is no longer displayed and room temperature is detected through the sensor

included in the indoor unit.

4-10 NIGHT Function

When this function is active, room temperature changes automatically to compensate for body temperature

variations while sleeping. After 10 hours of operation system switches automatically to OFF state.

This mode of operation is available both in COOLING and HEATING mode.

24

Page 25

4-11 Diagnostic

With this feature is possible to have a visual signal that a trouble is occurring.

This mode is always active and the signalling is made through the display board LEDS .

In case of no troubles the LEDS status follows its normal function.

NOTES

The troubles are showed according a priority list that is in case of more than one

trouble present, is always showed, at first, the one with the highest priority (1 2 3 etc).

Sensor damaged means a situation where sensor is short-circuited or opened.

In case of damaged sensors, the system (CM, FMO, FMI etc), if in OFF state, does not start.

Priority TROUBLE

LD1(stby) LD2(opr) LD3(timer)

2 RAT damaged F O O

3 ICT damaged F F O

4 WRONG MODE F F F

SELECTED

O = LED off

z = LED on

F = LED blinking

WARNING: Priority 4 only for COOLING

LEDS status Effects

System does not operate

System does not operate

25

Page 26

5 CHECKING ELECTRICAL COMPONENTS

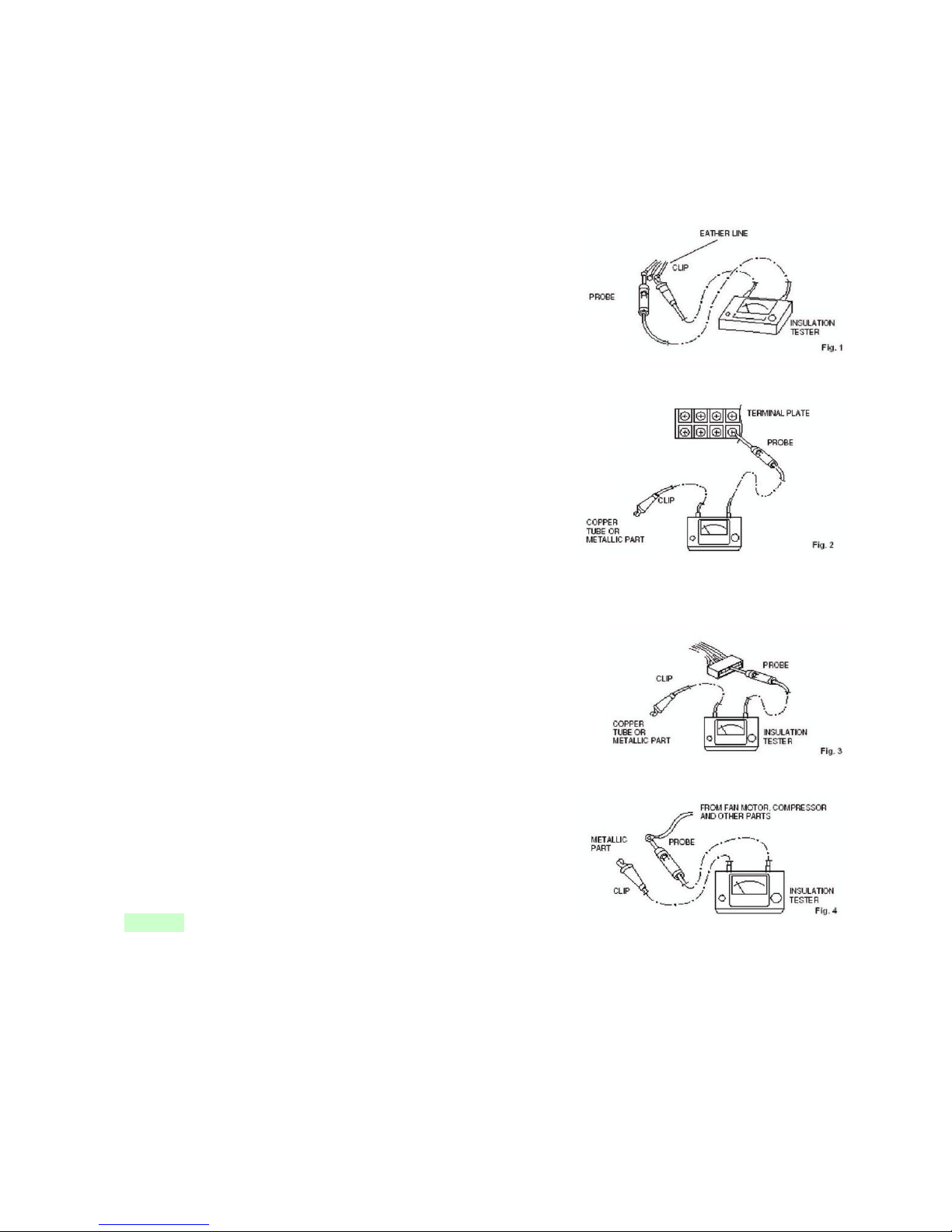

5-1 Measurement of Insulation Resistance

The insulation is in good condition if the resistance exceeds 1 MOhm

a) Power Supply Wires

Clamp the earthed wire of the power supply wires

with the lead clip of the insulation resistance tester

and measure the resistance by placing a probe on

either of the power wires (fig.1).

Then measure the resistance between the earthed

wire and the other power wires (fig.1).

b) Unit

Clamp an alluminium plate fin or copper tube with

the lead clip of the insulation resistance tester and

measure the resistance by placing a probe on N terminal,

and then on Lterminal the terminal plate (fig.2)

c) Measurement of Insulation Resistance

for Electrical Parts

Disconnect the lead wires of the disired electric

part from terminal plate, PCB assy, capacitor, etc.

Similary disconnect the connector. Then measure

the insulation resistance (fig.1 to 4).

Refer to electric wiring diagram.

NOTE

If the probe cannot enter the poles because the hole is too narrow

then use a probe with a thinner pin.

26

Page 27

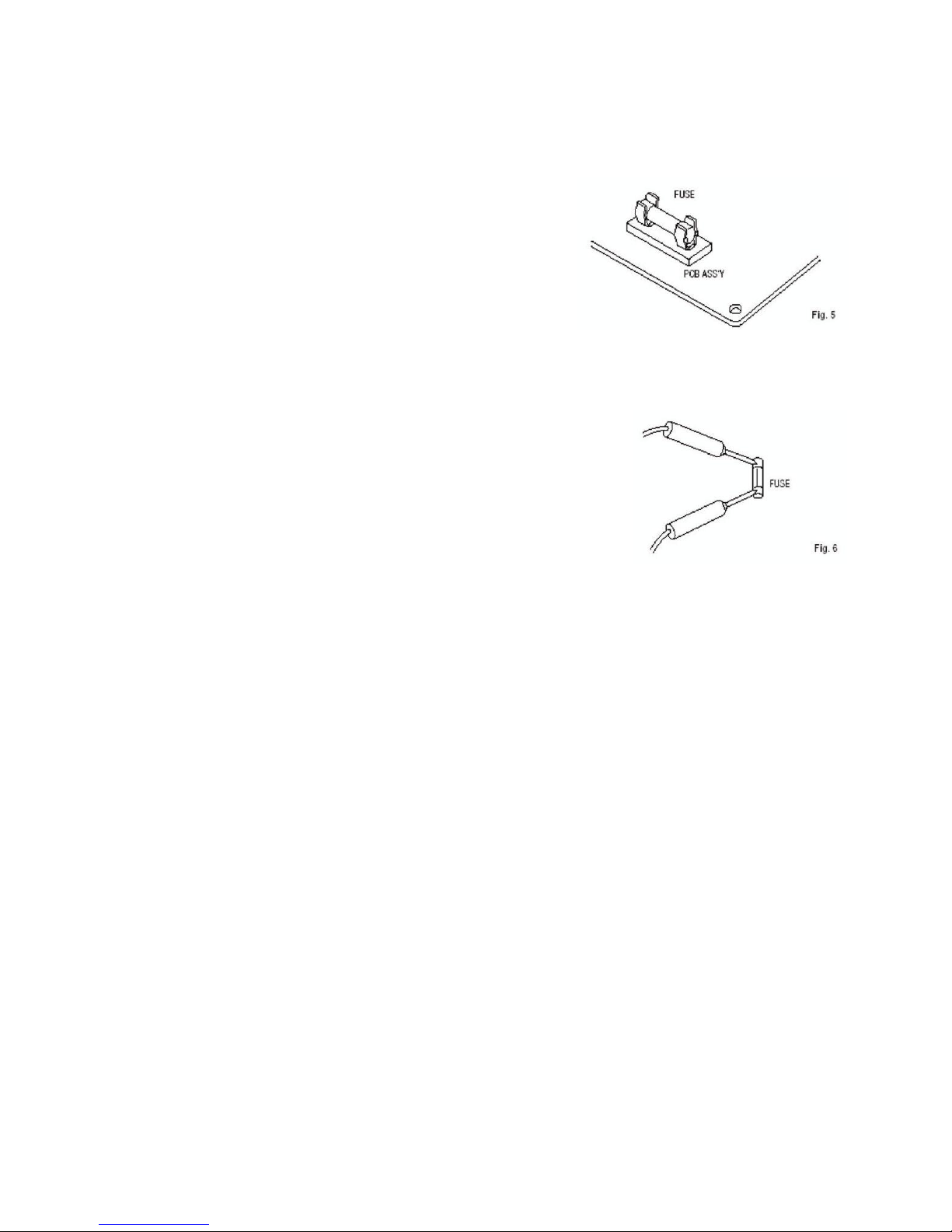

5-2 Checking Continuity of fuse on PCB assy

Remove PCB assy from electrical component box (fig.5)

Then pull out the fuse from PCB assy

Check continuity of fuse by the multimeter (fig.6)

27

Page 28

R.D. 28 Reyrieux BP 131 - 01601 Trévoux CEDEX France

Tél. 04.74.00.92.92 - Fax 04.74.00.42.00

R.C.S. Bourg-en-Bresse B 759 200 728

Loading...

Loading...