Page 1

m1000™ Operating Manual Addendum

for the Advanced Operator

m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 2

Manufacturer Address

Tecan Schweiz AG

Seestrasse 103

CH-8708 Männedorf

Switzerland

Distributor Address

Abbott Laboratories

Abbott Park, IL 60064

USA

Document Status Sheet

Title: m1000™ Operating Manual Addendum for the Advanced Operator

ID: 392813

Version Revision Issue Major changes

1 0 may 2003 First issue

1 1 LiHa/RoMa Calibration Procedure updates

New Procedure: Move Plate Test.

© 2003, Tecan Schweiz AG, Switzerland, all rights reserved

Information contained in this document is subject to change without notice.

Pictorial Disclaimer

The screens and figures contained in this manual are for information and illustration purposes only. Abbott Laboratories makes no representations or warranties about the accuracy and reliability of the information on the screens and figures in this manual; their information is

not to be used for clinical or maintenance evaluation.

Page 3

Table of Contents

m1000™ Operating Manual Addendum ....................................................... 1

Notices and Symbols .....................................................................................2

NAT Admin Software ...................................................................................... 4

Start NAT Admin ............................................................................................. 5

NAT Worktable ................................................................................................ 6

NAT Options ...................................................................................................7

Table of Contents

Database Maintenance ................................................................................... 7

Restore Database ........................................................................................... 8

Temperature Check ........................................................................................ 9

NAT Teach Worktable Racks and Locations ............................................. 10

Calibrate the LiHa .........................................................................................11

Calibrating the DiTi rack carriers for the LiHa ...........................................15

Removing the DiTi Reference Tip ...............................................................17

Calibrate the RoMa .......................................................................................18

Calibrating the DiTi rack carriers for the RoMa ......................................... 20

Calibrating the DiTi rack shelves for the RoMa .........................................22

Fine-tuning the DiTi rack carriers for the LiHa .......................................... 23

Move Plate Test ............................................................................................25

Disconnect from the Instrument .................................................................25

GENESIS Setup & Service Procedures ...................................................... 26

NAT MBS Worktable ..................................................................................... 27

m1000™ Operating Manual Addendum, 392813, en, V1.1 iii

Page 4

Table of Contents

Initialise Instrument ......................................................................................29

Dilutor Tool ....................................................................................................30

Door Lock Check ..........................................................................................32

FaWa Test ......................................................................................................36

Liquid Detection Test ...................................................................................40

Lower DiTi Eject Test ...................................................................................43

PosID Test .....................................................................................................46

iv m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 5

m1000™ Operating Manual Addendum

Read this information prior to using the NAT Admin or the GENESIS Setup &

Service software features. This information should be used in conjunction with

the m1000™ Operating Manual.

This information is issued by Abbott Diagnostics Division to provide you with

advanced m1000™ information.

Intended Use of Operating Manual Addendum:

This manual supports the operator of the m1000™ with instrument calibration

and troubleshooting procedures.

This manual does not enable the operator to generate user-defined protocols.

It is strongly recommended that operators contact Abbott Laboratories for

assistance with any protocol or process step change.

Categories include:

NAT Admin

NAT Worktable

NAT Options

Database Maintenance

Temperature Check

NAT Teach Worktable

GENESIS Setup & Service procedures

NAT MBS Worktable

Initialise Instrument

Dilutor Tool

Door Lock Check

FaWa Test

Liquid Detection Test

Lower DiTi Eject Test

PosID Test

User Qualification

The laboratory personnel must be qualified and trained to operate the m1000™.

The operators must fulfill the following qualifications to perform the procedures

described in this Addendum:

They must have a thorough knowledge of the applications run on the system.

They must be familiar with the Good Laboratory Practice guidelines or

equivalent guidelines.

They must have read and understood the instructions in the m1000™

Operating Manual and this Addendum.

m1000™ Operating Manual Addendum, 392813, en, V1.1 1

Note: Abbott offers onsite training for the primary operator. Abbott recommends

that the primary operator attend this primary operator training course.

Page 6

Notices and

Symbols

Warning Notices Used in this Manual

The symbols used for safety-related notices have the following significance:

Warning Symbols

WARNINGS appear as follows:

WARNING

Generally, the triangular warning symbol indicates the possibility of personal injury

or even loss of life if the instructions are not followed.

Whenever possible, the symbol indicates the hazard a person is exposed to more

specifically. The symbols used in this Operating Manual Addendum have the

following significance:

WARNING

Potentially infectious material

Indicates an area where the operator may be exposed to infectious material.

WARNING

Automatically moving parts.

Injuries (crushing, piercing) possible, if the safety panels are not in place.

Before starting the m1000™, make sure that the safety door is closed.

Never operate the instrument without panels on and door closed.

WARNING

Laser Hazard

Identifies a Class II laser product that contains an embedded low power

visible Class II laser diode barcode scanner. Warns against direct viewing into

barcode laser beam or reflections from the beam.

WARNING

Hot Surface Hazard: Identifies an area where the operator may be exposed to hot

surfaces, such as heater zone 1 and heater zone 2.

2 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 7

ATTENTION Symbols

ATTENTIONS appear as follows:

ATTENTIO N

With the general “Read This!” symbol, ATTENTION indicates the possibility of

equipment damage, malfunctions, or incorrect process results if instructions are

not followed.

m1000™ Operating Manual Addendum, 392813, en, V1.1 3

Page 8

NAT Admin Software

NAT Admin

Software

The NAT Admin software allows you to configure the m1000™ with information to

meet your site’s specific requirements.

WARNING

The Abbott 1 ml Protocol v1.0 cannot be edited.

The use of the Abbott sample preparation kit and the provided Generic 1 ml

Protocol will allow an operator successful RNA separation. The Generic 1 ml

Protocol processes all specimens and controls as samples. Because the NAT

software does not check dependencies of process steps, instrument damage

and/or poor specimen yield and purity may result from any protocol or process

step change. It is strongly recommended that users contact Abbott Laboratories

for assistance with any protocol or process step change. Technical Support may

be limited for any changes to the Generic 1 ml Protocol not recommended by

Abbott Laboratories. The user has sole responsibility to verify and/or validate any

user-defined protocols.

WARNING

Automatically moving parts.

Injuries (crushing, piercing) possible, if the safety panels are not in place.

Before starting the m1000™, make sure that the safety door is closed.

Never operate the instrument without panels on and door closed.

WARNING

Potentially infectious

Instrument parts may be contaminated with potentially infectious materials.

Follow basic biohazard precautions

Wear appropriate personal protective equipment, such as gloves, lab coats

and protective eye wear

WARNING

The operator may be exposed to hazardous chemicals when handling sample

preparation reagents. The exposure to hazardous chemicals is minimized by

following instructions provided in produce-specific labels and product-specific

Material Safety Data Sheets (MSDS). Wear appropriate personal protective

equipment, such as gloves, lab coats, and protective eye wear.

4 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 9

Start NAT

Admin

The NAT Wizard must be closed to start the NAT Admin.

Select the NAT Admin icon.

The NAT Admin Login screen is displayed.

Enter User Name and Password (case sensitive) and select <OK>.

The NAT Admin main screen is displayed.

m1000™ Operating Manual Addendum, 392813, en, V1.1 5

Page 10

A

X

NAT Worktable The following figure shows the m1000™ worktable locations used in NAT Admin

software:

X

W

V

U

T

S

R

Q

7

N

K

1

H

G

A

J

I

B

L

2

M

3

8

O

P

C

9

E

D

F

Note: Worktable locations are fixed and cannot be changed.

Fig. 1 NAT Admin Worktable

Control Loc

B Input Loc

C Output Loc

D System Fluid

E DiTi Waste

F Liquid Waste

G 1 ml Subsystem Loc Heater Zone 1

H 1 ml Subsystem Loc Heater Zone 2

Q Shelf Loc 1

R Shelf Loc 2

S Shelf Loc 3

T Shelf Loc 4

U Shelf Loc 5

V Shelf Loc 6

W Shelf Loc 7

Shelf Loc 8

I 1 ml Subsystem Loc RT

J 1 ml Subsystem Loc Mag Low

K Plate Carrier 1, Loc 1

L Plate Carrier 1, Loc 2

M Plate Carrier 1, Loc 3

N Plate Carrier 2, Loc 1

O Plate Carrier 2, Loc 2

P Plate Carrier 2, Loc 3

1 Trough Loc 1

2 Trough Loc 2

3 Trough Loc 3

7 Trough Loc 7

8 Trough Loc 8

9 Trough Loc 9

6 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 11

NAT Options The Options screen allows the operator to configure printers, directories, log

durations, and barcode settings.

Accessing the Options Page:

1 Select the NAT Admin icon.

2 Enter User Name and Password. Select <OK>.

3 The NAT Admin main screen is displayed.

4 Select Options from the NAT Admin main screen.

5 Select Set NAT Options.

Database

Maintenance

Field Description

Default Printer Select the default printer for report printing.

Import Directory Select default directory from which to import files

Export Directory Select default directory to export files.

Days to save log entries Default is 100

Barcode Settings

Code 2/5 Interleaved*

Codabar

Note: Barcode length for Code 2/5 must be an even number of characters. The

*

Configure the appropriate barcode length

Select 2 to 30

Select 1 to 31

barcode length configured should include the check digit and extra character, if

necessary, for an even number of characters.

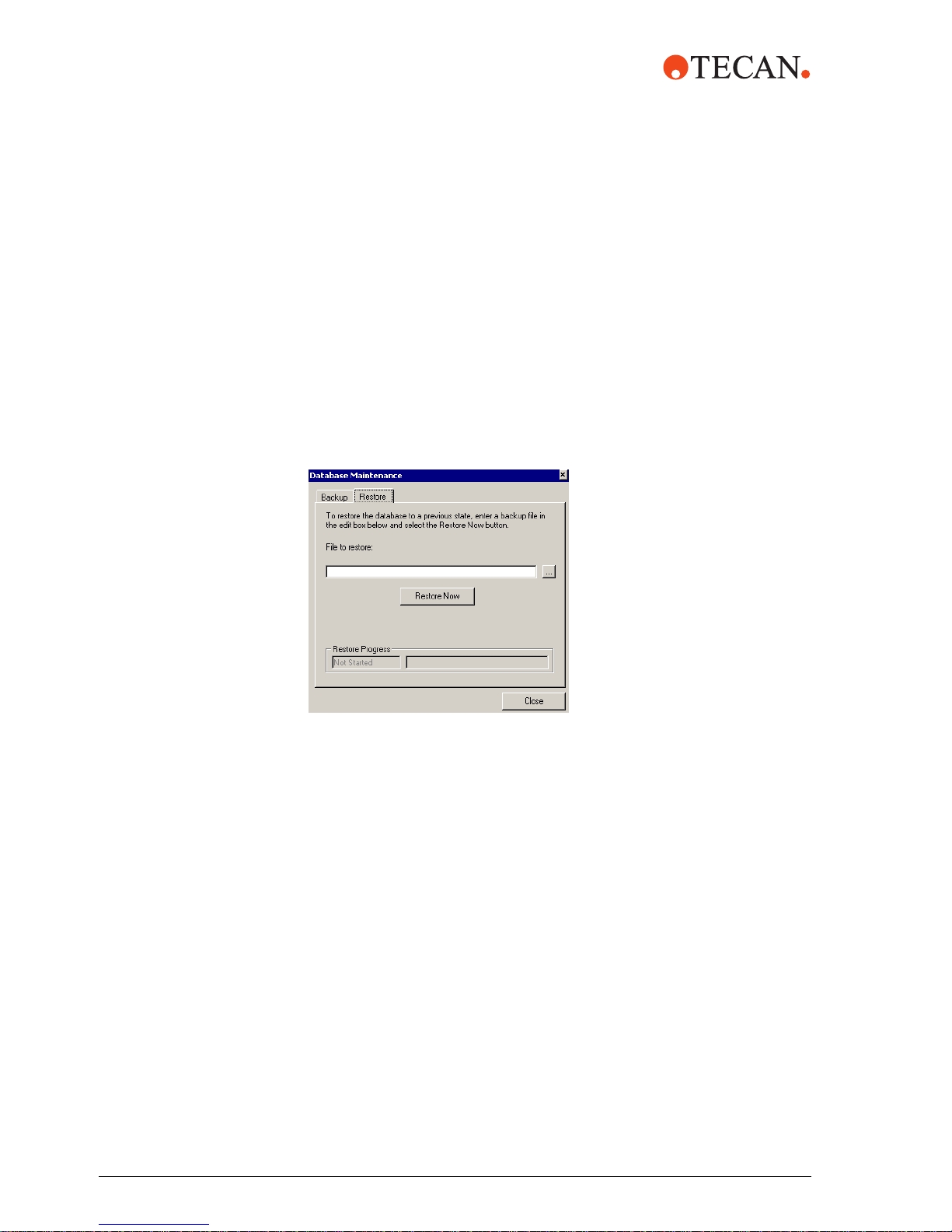

Database Maintenance is performed daily at 01:00 a.m. in the form of a daily

backup. In the case of a database corruption, a previous database can be

restored.

m1000™ Operating Manual Addendum, 392813, en, V1.1 7

Page 12

The backup files will be assigned a name based on the date of backup.

For example,

NATMBS_db_200304010100.BAK

NATMBS will always precede the name

20030401 is the backup date: Year/Month/Date

0100 is the backup time

BAK is the file extension

Restore

Database

1 Select the NAT Admin icon.

2 Enter User Name and Password (case sensitive) and select <OK>.

3 The NAT Admin main screen is displayed.

4 Select Tools from the NAT Admin main menu.

5 Select Database Maintenance.

6 Select the file to restore.

7 Select Restore Now.

8 Select Close to exit to the NAT Admin main menu.

8 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 13

Temperature

Check

The temperature check for the 1 ml subsystem should be performed according to

your laboratory procedures or as directed for troubleshooting. Refer to the

m1000™ Operating Manual, Chapter 8, Troubleshooting, for additional

assistance.

WAR NING

Potentially infectious

Instrument parts may be contaminated with potentially infectious materials.

Follow basic biohazard precautions

Wear appropriate personal protective equipment, such as gloves, lab coats

and protective eye wear

WAR NING

Hot Surface Hazard: Identifies an area where the operator may be exposed to hot

surfaces, such as Heater Zone 1 and Heater Zone 2.

Perform the following steps:

1 Power on the m1000™, if necessary.

2 Select the NAT Wizard icon from the desktop screen. The Main menu is

displayed.

3 From the Main Menu, select Select Protocol.

4 The Authorization dialog window is displayed. Enter your User Name and

password and select > to proceed to the next screen.

5 Select the Abbott 1 ml Protocol v1.0 or the Generic 1 ml Protocol v1.0 to be

run.

6 Place one reaction vessel in the 1 ml subsystem carrier (any location). Add

approximately 1 ml of water, or enough to cover the base of the thermometer.

Place the 1 ml subsystem carrier into heater zone 1.

7 Select > to proceed.

8 The operator is prompted to initiate the Pre-heat protocol to allow heater

zone 1 to reach correct temperature. Select <OK>.

9 Once heater zone 1 reaches the correct operating temperature, the operator

is prompted Heater Zone 1 Achieved Operating Temperature. Select

<OK>.

10 Insert a thermometer into the reaction vessel in heater zone 1. Allow to

equilibrate to 50°C (± 2.5°C). Verify this temperature is 50°C (± 2.5°C).

m1000™ Operating Manual Addendum, 392813, en, V1.1 9

Note: DO NOT place the thermometer into the reaction vessel until the Scan

Rack screen displays.

11 Move the 1 ml subsystem carrier to heater zone 2. Allow the thermometer to

equilibrate to 75°C (± 2.5°C). Verify this temperature is 75°C (± 2.5°C).

12 If the temperature for heater zone 1 and heater zone 2 are not within the

specified range, repeat this procedure. Do not run a sample preparation

protocol until the temperature for both heater zones are correct. Refer to the

m1000™ Operating Manual, Chapter 8, Troubleshooting, for additional

assistance.

13 Remove the thermometer.

14 Select < twice to return to the Main Menu.

Page 14

NAT Teach

Worktable

Racks and

Locations

The liquid handling arm (LiHa) and robotic manipulator arm (RoMa) must be

calibrated with the GENESIS Setup & Service software by an Abbott Field

Service Engineer. In addition, once the GENESIS Setup & Service Worktable

calibrations are performed, the NAT software requires calibration. This can be

performed using the Teach Worktable Racks and Locations screen.

In addition, the vertical and horizontal position for the LiHa and RoMa for carriers

and racks on the m1000™ worktable must be determined by using the NAT

Admin Teach Worktable Racks and Locations procedures.

General Information

WARNING

Automatically moving parts.

Injuries (crushing, piercing) possible, if the safety panels are not in place.

Before starting the m1000™, make sure that the safety door is closed.

Never operate the instrument without panels on and door closed.

WARNING

Potentially infectious

Instrument parts may be contaminated with potentially infectious materials.

Follow basic biohazard precautions

Wear appropriate personal protective equipment, such as gloves, lab coats

and protective eye wear

WARNING

All carriers and racks must be removed from the m1000™ worktable, including the

sample and control racks, reagent trough carriers, 1 ml subsystem carrier, DiTi

racks, waste station chute, and 1.5 ml output tube carriers. Failure to remove

these instrument accessories could result in crashing and damage to the LiHa,

calibration reference tip, and/or the RoMa.

To access the Teach Worktable Racks and Locations screen:

1 Select the NAT Admin icon.

2 Enter User Name and Password and select <OK> to continue. The NAT

Admin screen is displayed.

3 Select File from the NAT Admin main screen.

4 Select Teach Worktable Locations.

5 The Teach Worktable Racks and Locations screen is displayed.

10 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 15

Fig. 2 Teach worktable locations

6 Select Connect to the Instrument.

Connect

to the

Instrument

7 The operator is prompted to remove the sample and control racks, reagent

trough carriers, 1 ml subsystem carrier, DiTi racks, waste station chute, and

1.5 ml output tube carriers. Select <OK>.

8 Once the instrument is connected, the Connect to the Instrument button will

display Disconnect from the instrument.

9 Close the Safety door.

10 Select Initialise all Devices. The LiHa, RoMa, and PosID will move to the

Home position and the Instrument status button will change to Instrument

Status In Init during initialisation.

11 Once Initialization is complete, the Instrument status button will change to

Instrument Status Connected.

Calibrate the

LiHa

m1000™ Operating Manual Addendum, 392813, en, V1.1 11

Calibrating the 1 ml subsystem for the LiHa

During this step, the LiHa is calibrated to correctly aspirate and dispense

specimens, controls, and reagents into the reaction vessels. This calibration will

include X, Y, and Z direction.

Page 16

The LiHa can move in three different

directions:

X: arm movement left and right

Y: tip movement and spacing front and rear

Z: range for tip movement up and down.

The target for the 1 ml subsystem is the small indention in the center of each

zone. The reference tip should just touch the target in the X and Y direction and

the tip of the reference tip must touch or just be level with the surface of each

zone.

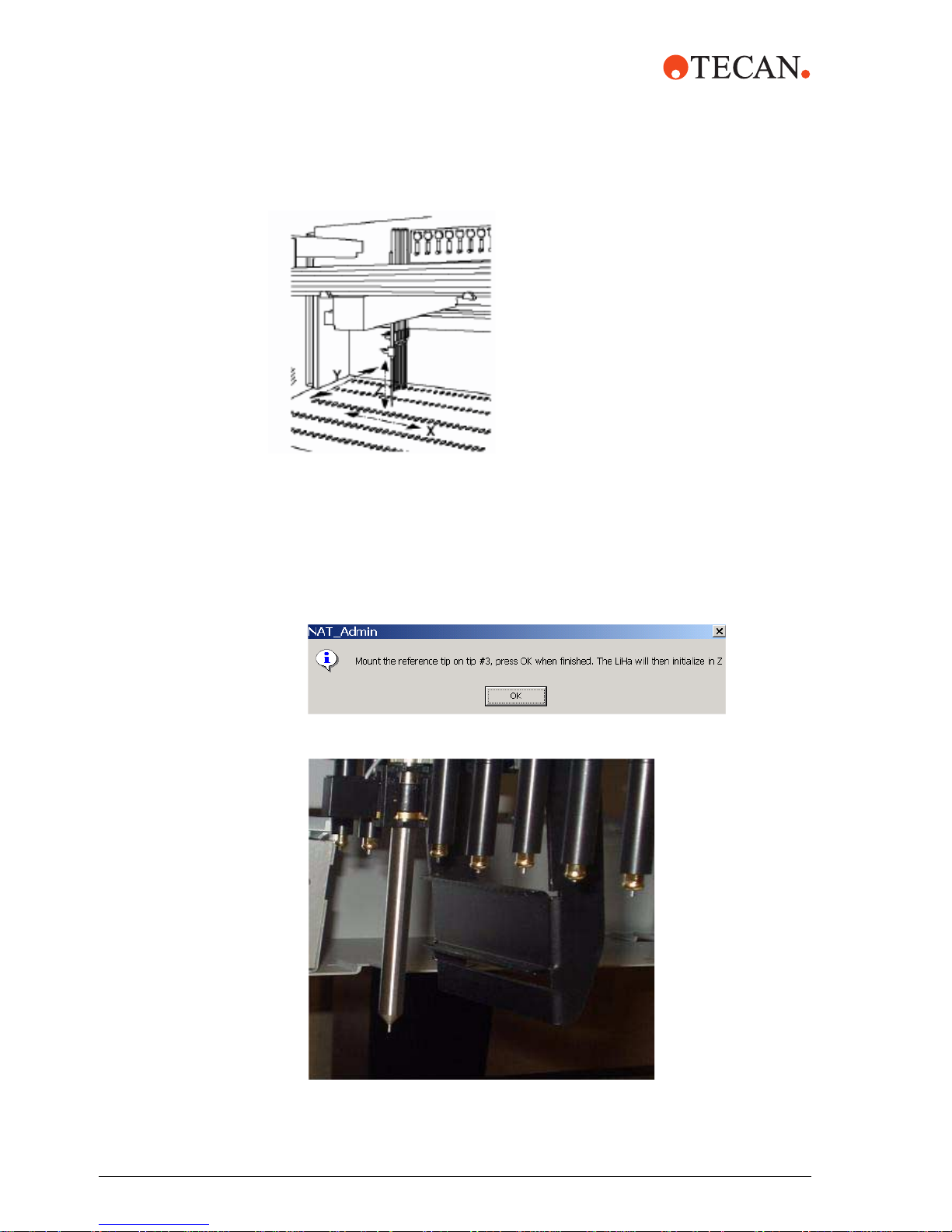

1 Under Calibrate LiHa, select Mount Reference Tip. The DiTi channels will

separate, allowing easy access to install the reference tip to the third DiTi

channel.

2 The operator is prompted to mount the reference tip to DiTi #3.

Fig. 3 Mounting the Reference Tip

12 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 17

3 Touch the workstation before touching DiTi cones to discharge static electricity

from your body.

4 Add the reference tip to DiTi #3.

A. Tip ejector tube (black, grooved end up)

B. Tubing extension

C. DiTi cone

– Using the DiTi cone wrench, turn the DiTi cone #3 clockwise to loosen and

remove.

– Remove the black tip ejector tube.

– Disconnect the tubing extension from the tubing.

– Unscrew the stainless steel adapter cylinder.

– Screw the reference tip on the tip adapter and tighten.

– Set aside the DiTi cone, tubing extension, and adapter cylinder.

5 Select <OK> once the reference tip is mounted.

6 Close Safety door.

7 The operator is prompted that the LiHa will move to its Home position. Select

<OK>.

8 Select a calibration point from the list box icon located under the Current

Rack field. The following 1 ml subsystem positions need to be calibrated with

the LiHa using the NAT software:

– 1 ml Heater Zone 1 Calibration Point

– 1 ml Heater Zone 2 Calibration Point

– 1 ml Mag Calibration Point

– 1 ml RT Calibration Point

– 1 ml Mag Rest Calibration Point

m1000™ Operating Manual Addendum, 392813, en, V1.1 13

Page 18

Fig. 4 Calibrate LiHa

9 Select Travel Home to home the LiHa.

10 Select Travel With the LiHa to Location on Carrier. The LiHa will move to

the selected position.

11 Select a Travel increment of 1, 10, or 100, with 1 being the smallest travel

increment and 100 being the largest travel increment.

Fig. 5 1 ml RT Calibration point

– The target for the 1 ml subsystem is the small indention in the center of

– Adjust the reference tip to the X and Y positions first, and then adjust for

– Use the "<" or ">" buttons beside X/Y to move the LiHa in the X direction.

– Use the "^" or "v" buttons beside X/Y to move the LiHa in the Y direction.

– Use the "^" or "v" buttons under Z to move the LiHa in the Z direction.

– Once the reference tip is close to the target, select a target increment of 1

– Once the reference tip is touching the surface of the zone, select Save

12 The position should be verified. Select Travel Home to home the LiHa. Next,

select Travel with the LiHa to Location on Carrier. The LiHa returns to the

new position. If the position is incorrect, repeat steps 8 through 11. If the

position is correct, select Travel Home.

14 m1000™ Operating Manual Addendum, 392813, en, V1.1

each zone. The reference tip should just touch the target in the X and Y

direction and the tip of the reference tip must touch or be level with the

surface of each zone. A piece of paper may be used to ensure a flat

surface.

the Z direction.

to adjust the reference tip as close to the target as possible.

LiHa calibration.

Page 19

13 Once the X, Y, and Z direction are calibrated and saved for one location, then

repeat steps 8 through 12 for each remaining location to be calibrated.

14 The 1 ml Mag Rest Calibration Point is calibrated as described below:

Place the 1 ml subsystem carrier (without cover) in the Mag Rest position,

allowing the carrier to be in the raised position. Close the Safety door.

Select 1 ml Mag Rest Calibration Point.

The operator is prompted to only set the Z direction for the 1 ml Mag Rest

Calibration Point. Select <OK>.

Select Travel with the LiHa to Location on Carrier. To avoid setting the

reference tip in the groove, move the LiHa to the right (X adjustment) by

20 steps. Adjust the reference tip such that the tip is level with or slightly

above the 1 ml subsystem. A piece of paper may be used to adjust the

Z-height. When the Z direction has been calibrated, move the LiHa back to the

left (X adjustment) by 20 steps.

Reference tip

level with main

surface.

Once the reference tip is even with the main surface of the carrier, select Save

LiHa calibration.

The position should be verified. Select Travel Home to home the LiHa. Next,

select Travel with the LiHa to Location on Carrier. The LiHa returns to the

new position.

If the position is incorrect, repeat the above steps.

If the position is correct, select Travel Home.

Remove the 1 ml subsystem carrier from the worktable.

Calibrating the

DiTi rack

carriers for the

During this step, the LiHa is calibrated to correctly pick up disposable tips (DiTis)

used for aspiration and dispense and delivery of DiTis to the DiTi Reuse rack. This

calibration will include X, Y, and Z direction.

LiHa

m1000™ Operating Manual Addendum, 392813, en, V1.1 15

Page 20

The target for the DiTi carrier racks is the left, rear inside corner. The reference tip

should just touch the inside corner in the X and Y direction, without the reference

tip deflecting in either direction. The tip of the reference tip must touch or just be

level with the surface of the DiTi rack carrier.

1 Select a carrier from the list box icon located under the Current Rack field.

The following positions on the worktable need to be calibrated with the LiHa

using the NAT software:

A

B

C

A Plate Carrier 1 Loc 1

B Plate Carrier 1 Loc 2

C Plate Carrier 1 Loc 3

D

E

F

D Plate Carrier 2 Loc 1

E Plate Carrier 2 Loc 2

F Plate Carrier 2 Loc 3

2 Remove the DiTi racks and DiTi reuse racks.

Note: Before calibrating the LiHa, make certain the DiTi rack carrier (plate carrier)

is properly seated on the worktable.

Fig. 6 Calibrate LiHa

3 Close the Safety door.

4 Select Travel With the LiHa to Location on Carrier. The LiHa will move to

the selected position.

5 Select a Travel increment of 1, 10, or 100, with 1 being the smallest travel

increment and 100 being the largest travel increment.

16 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 21

Reference

tip should

touch the

left rear

inside

corner.

Fig. 7 Plate Carrier 2 Loc 3—LiHa calibration.

The reference tip should be touching the left rear inside corner of the DiTi rack

position carrier.

– Adjust the reference tip to the X and Y positions first, then adjust for the Z

direction.

– Use the "<" or ">" buttons beside X/Y to move the LiHa in the X direction.

– Use the "^" or "v" buttons beside X/Y to move the LiHa in the Y direction.

– Use the "^" or "v" buttons under Z to move the LiHa in the Z direction.

– Once the reference tip is close to the target, select a target increment of 1

to adjust the reference tip as close to the target as possible.

– Once the reference tip is touching the left rear inside corner of the DiTi

rack carrier, select Save LiHa Calibration.

6 The position should be verified. Select Travel Home to home the LiHa. Next,

select Travel with the LiHa to Location on Carrier. The LiHa returns to the

new position. If the position is incorrect, repeat steps 3 through 5. If the

position is correct, select Travel Home.

7 Once the X, Y, and Z direction are saved for one DiTi rack carrier position,

then repeat the steps 1 through 6 for each remaining DiTi rack carrier position

to be set.

8 Once all positions have been calibrated, select Dismount Reference Tip.

The operator is prompted to Remove the Reference Tip. Select <OK>.

Removing the

DiTi Reference

Tip

m1000™ Operating Manual Addendum, 392813, en, V1.1 17

A. Tubing extension

B. Separator ring (white)

C. O-ring (black)

Page 22

Unscrew the reference tip from the tip adapter.

Replace the stainless steel adapter cylinder.

Connect the tubing extension to the tubing. Ensure the separator ring and

o-ring are on the tubing extension.

Add the black tip ejector tube with the grooved end up. Secure in place with

the DiTi cone.

Tighten with the DiTi cone wrench.

The operator is prompted that the LiHa will move to the Home position. Select

<OK>.

Calibrate the

RoMa

Calibrating the 1 ml subsystem for the RoMa.

1 During this step, the RoMa is calibrated to correctly pickup the 1 ml subsystem

carrier and move to different positions on the worktable. This calibration will

include X, Y, and Z direction.

2 Select a rack from the list box icon located under the Current Location field.

The following 1 ml subsystem positions need to be calibrated with the RoMa

using the NAT software:

– 1 ml Subsystem Loc Heater Zone 1

– 1 ml Subsystem Loc Heater Zone 2

– 1 ml Subsystem Loc Mag Low

– 1 ml Subsystem Loc RT

– 1 ml Subsystem Loc Rest

Note: 1 ml Subsystem Loc Mag Med and 1 ml Subsystem Loc Mag High will be

automatically calibrated. No calibration is necessary.

18 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 23

Fig. 8 1 ml subassembly

c

1 ml Subsystem

Loc Heater Zone 1

1 ml Subsystem Lo

Heater Zone 2

1 ml Subsystem

Loc RT

1 ml Subsystem

Loc Mag Low

Fig. 9 Calibrate RoMa

3 Move the 1 ml subsystem carrier with cover on to the position being

calibrated.

4 Close the Safety door.

5 Select Travel With the RoMa to the Location.

6 Select a Travel increment of 1, 10, or 100, with 1 being the smallest travel

increment and 100 being the largest travel increment.

– The RoMa gripper arms should be just below the lip on the sides of the

carrier and centered on both sides of the carrier. The gripper pins on the

RoMa should fit in the indentations on the side of the carrier.

– Use the "<" or ">" buttons beside X/Y to move the RoMa in the X direction.

– Use the "^" or "v" buttons beside X/Y to move the RoMa in the Y direction.

– Use the "^" or "v" buttons under Z to move the RoMa in the Z direction.

– Once the RoMa gripper arms are close to the surface, select a target

increment of 1 to adjust the gripper arms as close to the target as

possible.

– Once the RoMa is positioned, select Save RoMa Calibration.

7 The position should be verified. Select Travel Home to home the RoMa. Next,

select Travel with the RoMa to the Location. The RoMa returns to the new

position. If the position is incorrect, repeat steps 5 through 6. If the position is

correct, select Travel Home.

m1000™ Operating Manual Addendum, 392813, en, V1.1 19

Page 24

The RoMa

gripper pin

should be equal

distance when

viewed from the

interior of the

RoMa.

Fig. 10 1 ml subsystem heater zone 1

8 Once the X, Y, and Z direction are saved for one subsystem position, then

repeat the steps 2 through 7 for each remaining 1 ml subsystem position to be

calibrated.

Calibrating the

DiTi rack

carriers for the

RoMa

During this step, the RoMa is calibrated to correctly pickup DiTi racks to move to

the DiTi rack carrier and the DiTi rack shelves. This calibration will include X, Y,

and Z direction.

1 Select a carrier from the list box icon located under the Current Location

field. The following positions on the worktable need to be calibrated with the

RoMa using the NAT software:

– Plate Carrier 2, Loc 1

– Plate Carrier 2, Loc 2

– Plate Carrier 2, Loc 3

2 Position the DiTi rack being calibrated.

3 Close the Safety door.

4 Select Travel with the RoMa to the Location.

5 Select a Travel increment of 1, 10, 100, with 1 being the smallest travel

increment and 100 being the largest travel increment.

The RoMa gripper arms should be centered on both sides of the DiTi rack and

approximately 1 mm above the surface of the DiTi Rack carrier.

20 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 25

RoMa gripper pins

should be just

touching the

DiTi rack.

– Use the "<" or ">" buttons beside X/Y to move the RoMa in the X direction.

– Use the "<" or ">" buttons beside X/Y to move the RoMa in the Y direction.

– Use the "^" or "v" buttons under Z to move the RoMa in the Z direction.

– Once the RoMa gripper arms are close to the surface, select a target

increment of 1 to adjust the gripper arms as close to the target as

possible. Once the gripper arms are just touching the surface, raise the

gripper arms approximately 1 mm (10 steps) (Z adjustment).

– Move the RoMa in the X direction so the gripper pins just touch the DiTi

rack.

– Select Save RoMa Calibration.

– The gripper pins should be positioned in the X direction so there is not a

collision with the DiTi rack and the DiTi tray when Travel with the RoMa

to the Location is selected.

6 The position should be verified. Select Travel Home to home the RoMa. Next

select Travel with the RoMa to the Location. The RoMa returns to the new

position. If the position is incorrect, repeat steps 4 through 5. If the position is

correct, select Travel Home.

7 Once the X, Y, and Z direction are saved for one DiTi rack carrier position,

then repeat the steps 1 through 6 for each remaining DiTi rack carrier position

to be calibrated.

m1000™ Operating Manual Addendum, 392813, en, V1.1 21

Fig. 11 Calibrate RoMa

Page 26

Calibrating the

DiTi rack

shelves for the

RoMa

1 Select a carrier from the list box icon located under the Current Location

field. Shelf Loc 1 through Shelf Loc 8 should be calibrated for the RoMa using

the NAT software.

2 Center the DiTi rack in the Shelf location being calibrated.

3 Close the Safety door.

4 Select Travel with the RoMa to the Location.

5 Select a Travel increment of 1, 10, 100, with 1 being the smallest travel

increment and 100 being the largest travel increment.

The RoMa gripper arms should be just touching on the surface of the DiTi rack

shelf (Z adjustment) and centered (X adjustment) on both sides of the rack.

RoMa gripper arms

should be just

touching the surface

of the DiTi shelf and

gripper pins 10

steps from the DiTi

rack.

– Use the "<" or ">" buttons beside X/Y to move the RoMa in the X direction.

– Use the "^" or "v" buttons beside X/Y to move the RoMa in the Y direction.

– Use the "^" or "v" buttons under Z to move the RoMa in the Z direction.

– Once the RoMa gripper arms are close to the surface, select a target

increment of 1 to adjust the gripper arms as close to the target as

possible.

– Once the RoMa gripper pins are touching the DiTi rack, move the gripper

arms 10 steps (Y adjustment) toward the front of the instrument.

– Once the RoMa is positioned, select Save RoMa Calibration.

– For Shelf location 1 only: Once the RoMa gripper pins have been centered

on both sides of the DiTi rack, move to the left 20 steps (X adjustment).

Select Save RoMa Calibration.

6 The position should be verified. Select Travel Home to home the RoMa. Next,

select Travel with the RoMa to the Location. The RoMa returns to the new

position. If the position is incorrect, repeat steps 2 through 5. If the position is

correct, select Travel Home.

7 Once the X, Y, and Z direction are saved for one Shelf location, then repeat

the steps 1 through 6 for each remaining Shelf location to be calibrated.

22 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 27

Fine-tuning the

DiTi rack

carriers for the

LiHa

During this step, the LiHa is fine-tuned to correctly pick up disposable tips (DiTi)

used for aspiration and dispense and delivery of DiTi to the DiTi Reuse rack.

A

B

C

Fig. 12 Plate Carrier Positions

D

E

F

A Plate Carrier 1, Loc 1

B Plate Carrier 1, Loc 2

C Plate Carrier 1, Loc 3

D Plate Carrier 2, Loc 1

E Plate Carrier 2, Loc 2

F Plate Carrier 2, Loc 3

Check DiTi Locations:

1 Select Disconnect from the Instrument.

2 Select Close to exit to the NAT Admin main menu.

3 Exit NAT Admin.

4 Select the NAT Wizard icon from the desktop screen. The main screen is

displayed.

5 From the Main Menu, select Select Protocol.

6 Enter your User Name and Password and select > to proceed to the next

screen.

7 From the Select Protocol screen, select the Check DiTi Locations protocol

and select > to continue.

8 At the Pre-heat Protocol prompt, select <OK>. Allow up to 20 minutes for

Heater Zone 1 to reach the correct operating temperature.

9 Once Heater Zone 1 reaches temperature, select <OK>.

10 At the Sample screen, add a sample rack with eight barcode labeled tubes to

grid 4, 5, or 6.

11 Select <Scan Rack> and > to continue.

12 At the Reagent Report screen, select > to continue.

m1000™ Operating Manual Addendum, 392813, en, V1.1 23

Page 28

13 At the Load DiTis prompt, select Using Full DiTi Racks. Add full 1000 uL DiTi

racks to Plate Carrier 1, Loc 1 and 2, and Plate Carrier 2, Loc 1 and 2. Add a

full 200 uL DiTi rack to Plate Carrier 2, Loc 3. Add a full 1000 uL DiTi rack to

Plate Carrier 1, Loc 3, the DiTi Reuse Rack.

14 At the checklists, select > to continue.

15 Select <Scan Reagents>.

16 Enter a value for the Reagent Lot ID field and select > to continue.

17 Select <Flush System>. Select > to continue.

18 At the Acknowledge screen, select > to continue.

19 The operator is prompted "Use Full DiTi Boxes only". Select <OK>.

20 The operator is prompted "Plate Carrier 1 Loc 1, 1000 DiTi". Select <OK>.

21 Observe the LiHa as it picks up the disposable tips. Determine if any

adjustment is needed for the DiTi cone to be centered over the DiTis and note

the required adjustment.

Note: The adjustment will be made in Step 33.

22 The Check DiTi Locations protocol will access each of the 6 locations,

prompting the user prior to moving to the next Plate Carrier location. To

proceed with the next location, select <OK>.

23 When the Check DiTi Locations protocol completes, select <Finish>. Enter

your User Name and password and select > to proceed to the next screen.

24 Exit NAT Wizard and select <Exit>.

25 Select <Yes>.

26 Open NAT Admin.

27 Enter your User Name and Password and <OK> to proceed.

28 Select File from the NAT Admin main screen.

29 Select Teach Worktable Locations.

30 Select Connect to the Instrument.

31 Select Initialise all Devices.

Note: This step is only needed if the instrument has NOT been initialized. It is not

necessary to initialize all devices each time you enter NAT Admin unless there

has been an error with a device.

32 Remove the DiTi rack carriers.

33 Select Calibrate LiHa. Select a carrier from the list box icon located under the

Current Rack field. The following positions on the worktable need to be

adjusted for X and Y direction based upon the observations from the Check

DiTi Locations protocol:

– Plate Carrier 1, Loc 1

– Plate Carrier 1, Loc 2

– Plate Carrier 1, Loc 3

– Plate Carrier 2, Loc 1

– Plate Carrier 2, Loc 2

– Plate Carrier 2, Loc 3

Note: Only adjust by 5, 10, 15, or 20 steps. DO NOT adjust the Z direction. Once

each location is adjusted, select Save LiHa Calibration.

34 Raise the Z direction for only Plate Carrier 1, Loc 3 (DiTi Reuse Rack)

28 steps. Select Save LiHa Calibration.

24 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 29

35 Repeat steps 1 through 33 until all DiTi cones are centered in all DiTi Rack

carrier positions by performing the Check DiTi Locations protocol.

Once the Calibration Procedure has been completed, perform Move Plate Test

and visually observe the LiHa and RoMa for proper positioning.

36 Select Disconnect from the Instrument.

37 Exit NAT Admin.

Move Plate Test The Move Plate Test should be performed after fine-tuning the NAT worktable

using the NAT Teach Worktable Racks and Locations.

1 Access NAT Wizard.

2 Access Main menu.

3 From Main menu, select <Select Protocol>.

4 Enter User Name and Password.

5 Select > to proceed to the next screen.

6 From the Select Protocol screen, select Move Plate Test and > to continue.

7 At the Pre-heat Protocol prompt, select <OK>.

8 Once Heater Zone 1 reaches the correct operating temperature, select <OK>.

9 At the Sample screen, add a sample rack with eight barcode labeled tubes to

grid 4, 5, or 6. Place the 1 ml subsystem carrier in Heater Zone 1 of the 1 ml

Subsystem.

10 Select <Scan Rack> and > to continue.

11 At the Reagent Report screen, select > to continue.

12 At the checklists, select > to continue. Select Using Full DiTi Racks.

13 Select <Scan Reagents>.

14 Enter a value for the Reagent Lot ID field and select > to continue.

15 Select <Flush System>. Select > to continue.

16 At the Acknowledge screen, select > to continue.

17 The RoMa will move the 1 ml subsystem carrier to different locations in the

1 ml subsystem.

18 The operator is prompted “You must have selected <Using Full DiTi Racks>”.

Ensure the DiTi racks are full. Select <OK>.

19 The operator is prompted “Plate Carrier 2, Loc 1 should have a 1000 DiTi

Box”. Ensure a 1000 DiTi rack is in this position. Select <OK>.

20 The operator is prompted “Plate Carrier 2, Loc 3 should have a 200 DiTi Box”.

Ensure a 200 DiTi rack is in this position. Select <OK>.

21 The operator is prompted “The Shelf should be empty”. Remove any DiTi

racks. Select <OK>.

22 If any of the positions of the 1 ml subsystem carrier are not correct, repeat

Calibrating the 1 ml subsystem for the RoMa.

23 If any of the positions of the DiTi rack are not correct or DiTi racks are tilted,

repeat Calibrating DiTi rack shelves for the RoMa.

Disconnect

from the

Instrument

m1000™ Operating Manual Addendum, 392813, en, V1.1 25

Once the LiHa and RoMa have been calibrated for the m1000™ worktable, return

the carriers and racks, including the Waste Station Chute to the m1000™

worktable. Close the safety door and select Disconnect from the Instrument.

Page 30

GENESIS Setup

& Service

Procedures

The following procedures listed in this section use the GENSESIS Setup &

Service software. These procedures are to be used to assist with troubleshooting

the m1000™ instrument.

Initialise Instrument

Dilutor Tool

Door Lock Check

FaWa Test

Liquid Detection Test

Lower DiTi Eject Test

PosID Test

Starting Setup & Service procedures

The NAT Software must be closed to start the Genesis Setup & Service

software.

Start the GENESIS Setup & Service software by selecting the TECAN

icon from the desktop screen. The GENESIS Setup & Service main screen is

displayed.

Tool bar Can be switched

on/off with View → To o l Bar

Menu bar

Status bar Can be switched

on/off with View → Status Bar

The GENESIS Setup & Service main screen is divided into four sections:

Menu bar

Tool bar

Worktable

Status bar

26 m1000™ Operating Manual Addendum, 392813, en, V1.1

Worktable (empty)

Page 31

NAT MBS

Worktable

To perform tests, the GENESIS Setup & Service software needs information

about the location of carriers and racks on the worktable.

To load the NAT MBS (Magnetic Bead Separation) Worktable:

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

.

2 From the GENESIS Setup & Service screen, select System from the menu

bar.

3 Select Load Worktable from the System menu.

4 The Select Worktable screen is displayed. Select NAT MBS Worktable and

then <OK>.

NAT MBS

Worktable

m1000™ Operating Manual Addendum, 392813, en, V1.1 27

Page 32

5 The NAT MBS Worktable is displayed.

Note: Once the NAT MBS Worktable has been opened, it is not necessary to

open the worktable for each procedure.

Fig. 13 NAT MBS Worktable

Description Worktable grid NAT MBS Worktable

C4, C1, C2, C3 1 - 4 Sample and control racks

Heater

R1

R2

R3

R4

W1

Waste, R R

Waste, R M

DiTi Waste

T1

RR

RM

RF

DiTi

RR

RM

RF

Balance 28-37 Balance (not used)

7-17 1 ml subsystem

Heater zone 1

Room temperature zone

Heater zone 2

Magnet zone

18 Waste Station

20 Reagent Trough Carrier

21-26 DiTi Rack Carriers

28 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 33

Initialise

Instrument

During initialization of the m1000™, all installed subassemblies are moved to their

initial positions.

The PosID and LiHa will move to the left side.

The RoMa will move to the right side.

1 Close the Safety door.

2 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

3 From the GENESIS Setup & Service main screen, select System from the

menu bar.

4 Select Initialise Instrument from the System menu.

m1000™ Operating Manual Addendum, 392813, en, V1.1 29

Instrument initialization begins and the following message appears:

5 Once Initialization is complete, the GENESIS Setup & Service main screen

is displayed.

Page 34

Dilutor Tool The Dilutor tool procedure checks the dilutors and their associated tubings. Each

dilutor can be activated individually.

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

2 From the GENESIS Setup & Service main screen, select System Devices

from the menu bar.

3 Select LiHa from the System Devices menu.

4 Select Dilutor from the LiHa Panel submenu.

30 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 35

5 Complete the following fields:

Field Selection

Grid 18

Position Waste

Use Fast Wash Pump

9

6 Close the Safety door.

7 Select one of the following functions:

Selection Function

Flush Initializes all 8 dilutors at one time.

Flush tips once sequentially

The operator is prompted Do you want to

move LiHa above Washstation?

Initializes the dilutor one by one.

Select Yes.

8 Observe the dilutors for movement and leaks

– If the dilutors are leaking, check the plunger screw and syringe screw for

tightness. Also check the valve connections for tightness. Refer to the

m1000™ Operating Manual, Section 7.3.2.

– Change the syringes and/or 3-way valve. Refer to the m1000™ Operating

Manual, Section 7.5.

– Repeat the Dilutor tool.

– If the leaks continue, notify your local Abbott representative.

9 Select Print to print the report. Select <OK> to exit.

m1000™ Operating Manual Addendum, 392813, en, V1.1 31

Page 36

Door Lock

Check

The Door Lock Test checks whether the door lock is working properly.

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

.

2 From the GENESIS Setup & Service main screen, select Options from the

menu bar.

3 Select Access Status Options from the Options menu.

4 The Access/Status Panel screen is displayed.

.

5 Highlight Access Status under Available Devices.

.

6 Select Device Test option under Test.

7 Select the Configuration & Tools tab.

Access Status

Device Test

32 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 37

8 Select the following options:

Door Lock 1 (left)

Door Lock 2 (right)

9 Select Apply to save the configuration selected.

10 Close the safety door and check the door lock function by selecting Lock and

Unlock for the door lock selected.

11 If the door lock does not respond to the command, repeat the above step. If

the door lock still does not respond, contact your local Abbott representative.

12 Continue to check the door lock function by selecting Start from the

Access/Status Panel.

.

Start

m1000™ Operating Manual Addendum, 392813, en, V1.1 33

Page 38

13 The operator is prompted “Door Lock 1 (left). Please close the main door”.

Select <OK>.

14 The operator is next prompted “Door Lock 1 (left). Check if the left side is

locked now”.

Select <OK> if the left door is locked.

Select Cancel if the left door lock is not locked. Repeat. If the left door is still

not locked, contact your local Abbott representative.

15 The operator is now prompted “Door Lock 1 (left). Check if it is unlocked now”.

Select <OK> if the left door lock is unlocked.

Select Cancel is the left door lock is still locked. Repeat. If the left door lock is

still locked, contact your local Abbott representative.

34 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 39

16 The operator is prompted “Door Lock 2 (right). Please close the main door”.

Select <OK>.

17 The operator is prompted “Door Lock 2 (right). Check if the right side is locked

now”.

Select <OK> if the right door lock is locked.

Select Cancel if the right door lock is not locked. Repeat. If the right door lock

is not locked, contact your local Abbott representative.

18 The operator is prompted “Door Lock 2 (right). Check if it is unlocked now”.

.

Select <OK> if the right door lock is unlocked.

Select Cancel if the right door lock is still locked. Repeat. If the right door lock

is still locked, contact your local Abbott representative.

m1000™ Operating Manual Addendum, 392813, en, V1.1 35

Page 40

19 The operator is now prompted Test Result: Passed or Test Result: Failed.

20 If Cancel was selected due to the door lock not functioning, then the Door

Lock Test fails. Close the door completely and repeat the Door Lock Test. If

the Door Lock Test fails again, contact your local Abbott representative.

21 Select <OK> from the Access Status Options Process prompt.

22 Select <OK> from the Access/Status Panel to return to the Setup & Service

main menu.

FaWa Test The Fast Wash Pump (FaWa) is used to pump a large amount of liquid at high

speed through the system, usually to flush the liquid system and remove any air

bubbles.

Test Sequence

The Fast Wash Pump test performs the following procedure to test the throughput

of the pump through the tips of DiTi adapters.

The tubes are prefilled, using the dilutors.

The level of the prefill is measured, using liquid detection.

The DiTis are removed.

The tubes are filled, using the Fast Wash Pump.

The DiTis are picked up.

The height increase of liquid is measured, using liquid detection.

The height increase is checked and must be within the expected minimum

throughput value.

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

2 From the GENESIS Setup & Service main screen, select Liquid System

from the menu bar.

36 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 41

3 Select FaWa from the Liquid System menu. Select Test from the FaWa

submenu.

4 From the Select Worktable screen, select NAT MBS Worktable and then

<OK>.

NAT MBS

Worktable

5 The prompt Update instrument settings is displayed.

6 The Fast Wash Pump Test Configuration screen is displayed.

m1000™ Operating Manual Addendum, 392813, en, V1.1 37

Page 42

Complete the following fields:

Field Selection

Prefill Volume Enter 600 µL

Destination Rack C3.R1 (Sample rack with eight clean tubes in the first

eight positions.)

Flush Rack W1.WASTE.RM

DiTi Type 1000F E DiTi

DiTi Rack DiTi.RR (full)

DiTi Waste Rack W1.DiTiWaste

First DiTi position Select 1 for the DiTi start position.

7 Select More. The Fast Wash Pump Test-Adv. Configuration screen is

displayed.

8 Complete the following fields:

Field Selection

User defined

Name of user defined test FaWa

Duration 5

Minimal throughput to pass tests 450

38 m1000™ Operating Manual Addendum, 392813, en, V1.1

9

Page 43

9 Select <OK>.

.

10 The prompt Your user-defined configuration is accepted is displayed.

Select <OK>.

11 To avoid an overflow of liquid during the test, use only tubes with a diameter of

16 mm and a tube length of at least 100 mm (maximum is 110 mm). Make

sure the tubes are empty and clean. Place eight tubes in a Sample Rack, and

place the sample rack on the worktable in grid 4. Place a full DiTi rack in the

DiTi.RR position.

12 Check that the System Liquid Container is at least half full with water. Fill the

system liquid container, if required.

13 Close the Safety door.

14 Select Run from Fast Wash Pump Test Configuration screen.

15 The Fast Wash Pump Test Results window is displayed.

m1000™ Operating Manual Addendum, 392813, en, V1.1 39

16 Select Start to begin the test.

17 Once the test is completed, Fast Wash Pump Test passed or Fast Wash

Pump Test failed message is displayed.

18 Select <OK>. The Fast Wash Pump Test Results window displays the test

results.

19 Exit the Fast Wash Test Results by selecting Close.

20 Select Print to print the results from the Fast Wash Pump Test

Configuration window. Select <OK>.

21 Exit the FaWa Test Configuration by selecting Close after test results are

printed.

Pass/Fail Criteria

The FaWa Test will pass when the Throughput value is > the minimal throughput

value displayed under the Tip column. If the Throughput value is < the minimal

throughput value, then the test will fail.

Page 44

Corrective Actions

1 Check that the tips of the DiTi adapters are clean and are free of any

blockage. Refer to the m1000™ Operating Manual, Section 7.3.2.

2 Exit the GENESIS Setup & Service. Start NAT Wizard and perform a Flush

System and look for air bubbles. Refer to the m1000™ Operating Manual,

Section 7.3.6.

3 Repeat the Fast Wash Pump test. If the test fails again, contact your local

Abbott representative.

Liquid

Detection Test

The Liquid Detection Test checks whether the liquid detection feature is working

properly.

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

2 From the GENESIS Setup & Service main screen, select Liquid System

from the menu bar.

3 Select Liquid Detection from the Liquid System menu and next select

Normal Test.

4 From the Select Worktable screen, select NAT MBS Worktable and then

<OK>.

40 m1000™ Operating Manual Addendum, 392813, en, V1.1

NAT MBS

Worktable

Page 45

5 The prompt Update instrument settings is displayed.

6 The Liquid Detector Test Configuration screen is displayed.

Complete the following fields:

Field Selection

Cycles Enter the number of cycles to be performed. Default

is 15.

Submerge Enter the distance the tip dips into the liquid. Default

is 10.

Is the Liquid Source a Rack?

Source Rack Select T1.RF.

Flush Rack Select W1.Waste,RM

Destination Rack Select C4.R1

First Dest Position Enter 1 for the destination start.

DiTi Type Select 1000F EDiTi

DiTi Rack Select DiTi.RR

DiTi Waste Rack Select W1.DiTiWaste

First DiTi Position Enter 1 for the destination start point if the DiTi rack if

9

full or enter where to start picking up DiTis.

m1000™ Operating Manual Addendum, 392813, en, V1.1 41

Page 46

7 Place a sample rack with eight clean and dry tubes in the first eight positions

in grid 1 of the worktable. To avoid an overflow of liquid during the test, use

only tubes with a diameter of 16 mm and a tube length of at least 100 mm

(maximum is 110 mm). Ensure the tubes are empty and clean.

8 Check that the System Liquid Container is at least half full with water. Fill the

system liquid container, if required.

9 Place a reagent trough filled with 20 to 30 ml deionized water in the first

position (RF) of a reagent trough carrier. Place the reagent trough carrier in

grid 20.

10 Start the test with Run. The Liquid Detector Test Results screen is

displayed.

11 Start the test procedure by selecting Start from the Liquid Detector Test

Results screen.

12 The operator is prompted Do flush step? (First cycle with all tips). Select

Yes to perform flush.

13 The operator is then prompted Repeat flush step? If any air bubbles remain

in the lines, select Yes. If the lines do not have air bubbles, then No can be

selected and the Liquid Detection Test will begin.

42 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 47

14 During the test, the results continuously appear on the Liquid Detector Test

Results window.

15 After the test is finished, the Liquid Detector Test passed or Liquid

Detector Test failed message is displayed. Confirm with <OK>.

16 Select Close.

17 Print the result with Print and/or finish the test with Close.

Lower DiTi

Eject Test

Pass/Fail Criteria

The Liquid Detection Test fails:

Check if tips are the same height.

Check DiTi cones are tight and clean. Refer to the m1000™ Operating

Manual, Section 7.3.2.

Check the liquid system for air bubbles. Refer to the m1000™ Operating

Manual, Section 7.3.2.

Repeat the Liquid Detection Test. If the test fails again, contact your local Abbott

representative.

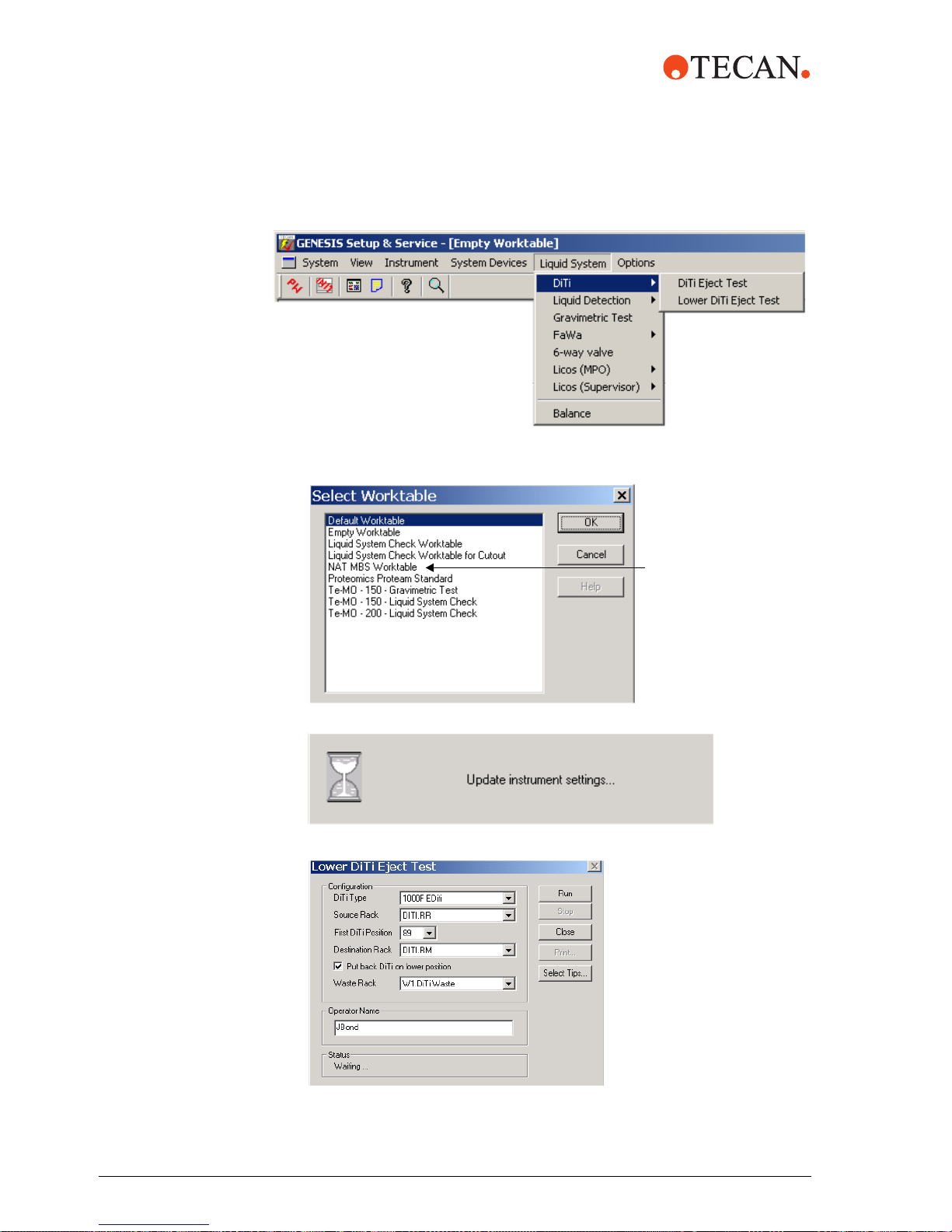

The Lower DiTi Eject Test function tests the disposal of the disposable tips.

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

2 From the GENESIS Setup & Service main screen, select Liquid System

from the menu bar.

m1000™ Operating Manual Addendum, 392813, en, V1.1 43

Page 48

3 Select DiTi from the Liquid System submenu, then select Lower DiTi Eject.

4 From the Select Worktable screen, select NAT MBS Worktable and then

<OK>.

5 The prompt Update instrument settings is displayed.

6 Next, the Lower DiTi Eject Test screen is displayed.

NAT MBS

Worktable

44 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 49

Complete the following fields:

Field Selection

DiTi Type Enter 1000F EDiTi

Source Rack DiTi.RR

First DiTi Position Enter 89 for the first position to find DiTis

Destination Rack Enter DiTi.RM

Put back DiTi on lower position

Waste Rack Select W1.DiTiWaste

Operator Name Enter operator name

9

7 Place a DiTi rack with an empty DiTi tray in the 1000 µL DiTi.RM position and

a DiTi rack with a full DiTi tray in the 1000 µL DiTi.RR position.

8 Press Run from the Lower DiTi Eject Test screen to start the test.

9 The status changes to Test running.

10 After the test is complete, the status changes to Test passed or Test failed.

Once the test is finished, select Close.

Pass/Fail Criteria

If the Lower DiTi Eject Test fails:

1 Inspect and clean the DiTi cones. Refer to the m1000™ Operation Manual,

Section 7.3.2.

2 Check the DiTi adapter. Refer to the m1000™ Operation Manual, Section

7.3.2.

3 Repeat the Lower DiTi eject. If the test fails again, contact your local Abbott

representative.

m1000™ Operating Manual Addendum, 392813, en, V1.1 45

Page 50

PosID Test This test checks the proper function of the PosID barcode scanner.

During the test a reference read of barcode labels is executed, which is compared

to consecutive reading processes and errors are detected.

ATTENTION

To run the PosID Test, at least two carriers or racks, such as the sample racks and

reagent carriers, must be on the worktable. The carriers must be equipped with

correctly placed barcode labels.

1 Start the GENESIS Setup & Service software by clicking on the

TECAN icon.

2 From the GENESIS Setup & Service main screen, select System Devices

from the menu bar.

3 Select PosID from the System Devices menu. Select Test from the PosID

submenu.

4 The PosID2 Test Configuration screen opens.

46 m1000™ Operating Manual Addendum, 392813, en, V1.1

Page 51

Complete the following fields:

Field Selection

Number of cycles Select 5

Grid Positions Select 1 to 41

Read carrier

Read User ID 9

Operator Enter Operator name

9

5 Place the carriers and racks on the worktable.

Place two sample racks on grids 4 and 5, with multiple barcoded containers

(sample tubes). Face the barcodes to the right side of the sample racks.

Place one reagent carrier trough with barcoded reagent troughs on grid 20.

Place two 1.5 ml output carriers on grids 38 and 39.

6 Select Run to start the test. The PosID2 Test Results window is displayed.

m1000™ Operating Manual Addendum, 392813, en, V1.1 47

7 Select Start to begin the procedure.

8 The PosID2 Test Results window is displayed. During the test, the values in

the PosID2 Test Results window are continuously updated.

Page 52

9 When the test is completed, a PosID2 Test passed or PosID2 Test failed

message is displayed.

10 Confirm with <OK>.

11 Next select Close. The PosID2 Test Configuration screen is now displayed.

12 Select Print to print the test results.

13 Select Close to exit

Pass/Fail Criteria

If the PosID Test fails:

1 Check the positions of the barcode labels.

2 Clean the laser beam output window of the PosID. Refer to the m1000™

Operating Manual, Section 7.4.4.

3 Repeat the PosID test. If the test fails again, contact your local Abbott

representative.

The operator is prompted that the LiHa will move to the Home position. Select

<OK>.

48 m1000™ Operating Manual Addendum, 392813, en, V1.1

Loading...

Loading...