Page 1

TECAN

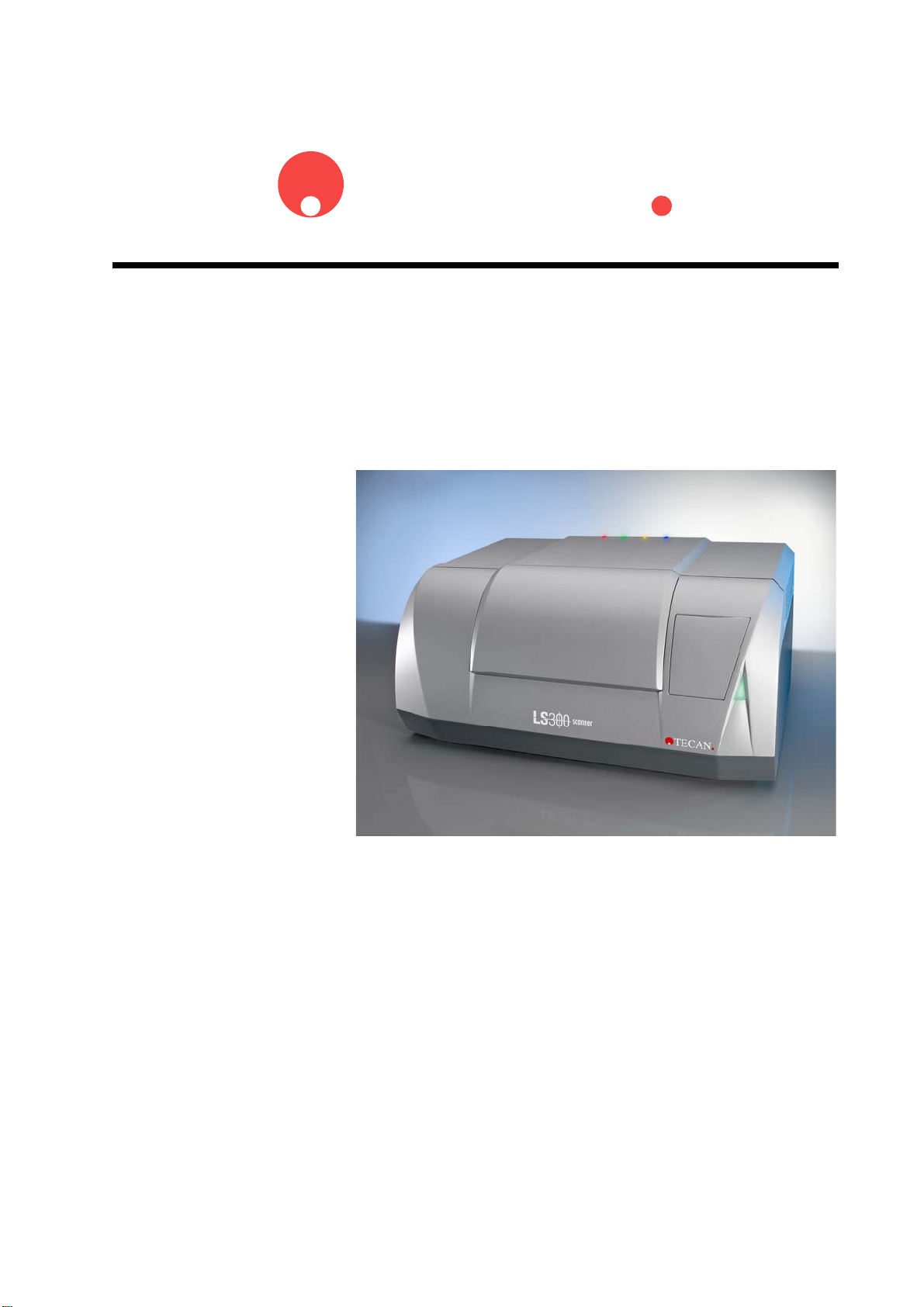

Operating Manual for the

LS Series Scanner

Document Part No.: 30001798

2004-11

Document Revision No.: 1.5

Page 2

Tecan Affiliates and Service Centers

Austria

Tecan Austria GmbH

Untersbergstrasse 1a

A-5082 Grödig / Salzburg

Austria

Tel.: +43 62 46 89 33

Fax: +43 62 46 72 770

Belgium

Tecan Benelux B.V.B.A.

Vaartdijk 55

B-2800 Mechelen

Belgium

Tel.: +32 15 42 13 19

Fax. +32 15 42 16 12

Italy

Tecan Italia S.r.l.

Via F.lli Cervi

Palazzo Bernini

Centro Direzionale Milano2

20090 Segrate (Mi)

Italy

Tel.: +39 02 215 21 28

Fax: +39 02 215 97 441

Spain

Tecan Spain

Sabino de Arana, 32

E-08028 Barcelona

Spain

Tel.: +34 93 490 01 74

Fax: +34 94 411 24 07

United Kingdom

Tecan UK

Theale Court

11-13 High Street

Theale

UK-Reading RG7 5AH

United Kingdom

Tel.: +44 11 89 300 300

Fax: +44 11 89 305 671

Austria

Tecan Sales International GmbH

Untersbergstrasse 1a

A-5082 Grödig / Salzburg

Austria

Tel.: +43 62 46 89 33

Fax: +43 62 46 72 770

France

Tecan France26 Avenue Tony

Garnier

69007 LYON

France

Tel.: +33 47 27 60 480

Fax: + 33 47 27 60 499

Japan

Tecan Japan Co. Ltd

Meiji Seimei Fuchu Building 10F

1-40 Miyamachi

Fuchu City, Tokyo

Japan

Tel.: +81 42 334 88 55

Fax: +81 42 334 04 01

Sweden

Tecan Nordic AB

Box 208, SE-431 23

Mölndal

Sweden

Tel: +46 31 75 44 000

Fax: +46 31 75 44 010

USA

Tecan US

P.O. Box 13953

Research Triangle Park,

NC 27709

USA

Tel.: +1 919 361 5200

Fax: +1 919 361 5201

Asia

Tecan Asia (Pte) Ltd.

80, Marine Parade #13-04

Singapore 449269

Singapore

Tel.: +65 44 41 886

Fax: +65 44 41 836

Germany

Tecan Deutschland GmbH

Theodor-Strom-Straße 17

D-74564 Crailsheim

Germany

Tel.: +49 79 51 94 170

Fax: +49 79 51 50 38

Netherlands

Tecan Benelux B.V.B.A.

Industrieweg 30

NL-4283 Giessen

Netherlands

Tel.: +31 018 34 48 17 4

Fax: +31 018 34 48 06 7

Switzerland

Tecan Sales Switzerland AG

Seestrasse 103

CH-8708 Männedorf

Switzerland

Tel: +41 922 8 922

Fax: +41 922 8 923

2 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 3

WARNING

CAREFULLY READ AND FOLLOW THE INSTRUCTIONS PROVIDED IN

Notice

Every effort has been made to avoid errors in text and diagrams, however, Tecan

Austria GmbH assumes no responsibility for any errors which may appear in this

publication.

It is the policy of Tecan Austria GmbH to improve products as new techniques

and components become available. Tecan Austria GmbH therefore reserves

the right to change specifications at any time.

We would appreciate any comments on this publication.

Tecan Austria GmbH

Untersbergstraße 1A

A-5082 Grödig/Salzburg

AUSTRIA / EUROPE

Telephone: 0043 (0) 6246 8933

FAX: 0043 (0) 6246 72770

E-mail: office.austria@tecan.com

THIS DOCUMENT BEFORE OPERATING THE INSTRUMENT.

Copyright Information

The contents of this document are the property of Tecan Austria GmbH and are

not to be copied, reproduced, or transferred to another person or persons without

prior written permission.

Copyright © Tecan Austria GmbH,

All rights reserved.

Printed in Austria

Declaration for EU Certificate

See the back of this document.

About the Instructions for Use

This publication is intended as Instructions for Use for the LS Series Scanner

instruments, which are designed to detect highly quantitative fluorescence

images that have been read from microarray slides or other compatible sample

formats.

This document provides information about:

• Installing the instrument

• Operating the instrument

• Cleaning and maintenance routines

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 3

Page 4

Warnings, Cautions and Notes

There are four types of notices used in this publication. These notices highlight

important information or warn the user of a potentially dangerous situation.

The notices appear below:

Note

Gives helpful information.

Caution

Indicates a possibility of instrument damage or data loss if instructions

are not followed.

WARNING

INDICATES THE POSSIBILITY OF SEVERE PERSONAL INJURY, LOSS

OF LIFE OR EQUIPMENT DAMAGE IF THE INSTRUCTIONS ARE NOT

FOLLOWED.

WARNING

INDICATES LASER. DO NOT STARE INTO THE BEAM!

WARNING

INDICATES THE POSSIBLE PRESENCE OF BIOLOGICALLY

HAZARDOUS MATERIAL. PROPER LABORATORY SAFETY

PRECAUTIONS MUST BE OBSERVED.

4 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 5

Table of Contents

1 Safety

1.1 Instrument Safety .......................................................................... 1-1

2 General

2.1 Instrument Features ...................................................................... 2-1

2.1.1 Samples........................................................................................... 2-2

2.1.2 Modes of operation.......................................................................... 2-3

2.1.3 Automation friendliness................................................................... 2-4

2.1.4 Integrated Image Analysis Software Array Pro................................ 2-4

3 Installation

3.1 Unpacking & Inspection................................................................ 3-1

3.2 Remove Transport Lock ............................................................... 3-7

3.3 Filter Installation............................................................................ 3-8

3.4 Power Requirements..................................................................... 3-9

4 Technical Description

4.1 Optical System............................................................................... 4-1

4.2 Autofocus....................................................................................... 4-3

4.3 Data Processing ............................................................................ 4-3

5 Operation

5.1 General Operating Features ......................................................... 5-2

5.1.1 Instrument Start Up ......................................................................... 5-2

5.1.2 Instrument Power On....................................................................... 5-2

5.1.3 Connect to Instrument..................................................................... 5-3

5.1.4 Finish a Measurement Session....................................................... 5-3

5.2 Insert Slide(s) into Slide Adapter ................................................. 5-4

6 LSServer, Scanner Shell and Download

6.1 Introduction.................................................................................... 6-1

6.1.1 Overview.......................................................................................... 6-1

6.1.2 Hardware Requirements.................................................................. 6-1

6.1.3 Software Requirements...................................................................6-2

6.1.4 Software Installation Procedure....................................................... 6-2

6.2 Tecan LS Scanner Interface ......................................................... 6-4

6.2.1 Overview.......................................................................................... 6-4

6.2.2 Starting LS Scanner Interface ......................................................... 6-4

6.3 LSServer......................................................................................... 6-6

6.3.1 Starting the First Time..................................................................... 6-6

6.3.2 Measurement Control......................................................................6-6

6.3.3 File Types used in LSServer ........................................................... 6-9

6.3.4 Measurement................................................................................. 6-11

6.3.5 Instrument...................................................................................... 6-26

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 5

Page 6

6.3.6 Measurement Parameter................................................................ 6-28

6.3.7 Excitation Angle Tab ......................................................................6-49

6.3.8 Settings .......................................................................................... 6-54

6.3.9 Slide Adapter Format .....................................................................6-62

6.3.10 Slides to Process............................................................................6-62

6.4 LS Scanner Shell..........................................................................6-64

6.4.1 General ..........................................................................................6-64

6.4.2 Starting Scanner Shell....................................................................6-64

6.4.3 Window Elements...........................................................................6-64

6.4.4 File types used in Scanner Shell....................................................6-66

6.4.5 Scanner Shell Menus.....................................................................6-68

6.4.6 Service Menu .................................................................................6-75

6.4.7 Stacker Setup - Twister..................................................................6-89

6.4.8 Scanner Shell Wizards...................................................................6-91

6.4.9 The Transport Lock Wizard............................................................6-92

6.4.10 The Transport Unlock Wizard.........................................................6-95

6.5 LSDownload................................................................................6-101

6.5.1 Starting LSDownload....................................................................6-101

6.5.2 LSDownload Menus.....................................................................6-102

7 Instrument Features

7.1 Specifications.................................................................................7-1

7.1.1 Lasers ..............................................................................................7-4

7.1.2 Optional Barcode Scanner...............................................................7-4

7.1.3 Reproduction of labels placed on the instrument.............................7-5

8 Cleaning & Maintenance

8.1 Introduction ....................................................................................8-1

8.2 Liquid Spills....................................................................................8-1

8.3 Replacing the Fuse ........................................................................8-2

8.4 Remote Control and Data Exchange ............................................8-3

8.4.1 FTP up / download...........................................................................8-3

8.4.2 Working with pcAnywhere:...............................................................8-3

8.4.3 Working with CITRIX web conferencing manager:...........................8-5

8.5 Instrument Disinfection .................................................................8-6

8.5.1 Disinfection Solutions.......................................................................8-6

8.6 Disinfection Procedure..................................................................8-7

8.7 Disinfection Certificate ..................................................................8-7

8.8 Disposal of Instrument ..................................................................8-8

8.8.1 Disposal of Packing Material............................................................8-8

8.8.2 Disposal of Operating Material.........................................................8-8

Index

6 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 7

1. Safety

1. Safety

1.1 Instrument Safety

1. Always follow basic safety precautions when using this product to reduce the risk of

injury, fire, or electrical shock.

2. Read and understand all information in the Operating manual. Failure to read,

understand, and follow the instructions in the manual may result in damage to the

product, injury to operating personnel or poor instrument performance.

3. Observe all WARNING and CAUTION statements in the manual.

4. Never open the LS SERIES SCANNER while the instrument is plugged into a power

source. The instrument contains class 2, 3a and 3b lasers inside.

5. Never force a slide or another sample into the instrument.

6. LS SERIES SCANNERS are intended for laboratory research use only. Observe

proper laboratory safety precautions, such as wearing protective clothing and using

approved laboratory safety procedures.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 1-1

Page 8

Page 9

2. General

2. General

2.1 Instrument Features

The LS SERIES SCANNERS are laser-scanning instruments designed to detect

highly quantitative fluorescence images. The scanners are designed to read

microarray slides as well as other customer specific sample formats. They have

exceptional flexibility with respect to sample formats and measurement modes.

They can read samples up to the size of microplates as well as thick samples like

gels or, for instance, liquid cells. They can read both in confocal and in nonconfocal mode and a selection of up to 4 excitation wavelengths (lasers) and an

almost unlimited number (28) of emission wavelengths or emission filters.

Automation friendliness is another key feature of the LS SERIES SCANNERS.

The design allows the use of standard microplate equipment to load very high

numbers of slides automatically. For instance, with a Connect, up to 200 slides or

50 microplates can be loaded and processed automatically within one run.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2-1

Page 10

2. General

2.1.1 Samples

Slide adapters

Its special microplate/slide adapters accommodate 4 slides at once and loading is

easily automated with standard microplate equipment.

Other formats

Due to its flexible design, other sample formats can be measured as well.

The software allows special formats to be defined and special scanning areas to

be processed. Due to an exceptionally high working distance of 6.5 mm,

‘thick’ samples, well structures, samples within a liquid cell or even gels can be

measured. An automatic autofocus system is able to bring all of these samples

into the proper focal plane. If you are in doubt whether a special sample format

can be measured with the LS SERIES SCANNERS, please contact a Tecan

representative.

2-2 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 11

2. General

2.1.2 Modes of operation

Confocal or non-confocal

The LS SERIES SCANNERS are equipped with 3 different user selectable

pinholes for selection of the appropriate depth of focus. The smaller the pinhole

the higher is the confocality of the optical system and the shorter the depth of

field. A small pinhole typically gives a better signal to background ratio, because

all background contributions from outside the focal plane, e.g. the glass material

or the backside of the slide are rejected. However for bulkier samples or samples

with an uneven or a slightly bent surface confocality can result in lower signals or

in a poor reproducibility. Here a larger pinhole is more appropriate. That’s why the

LS SERIES SCANNERS offer the choice. Just choose the degree of confocality

that is best suited for the samples.

Excitation wavelengths

• The LS Scanner can be equipped with up to 4lasers.

• Every Scanner has a HeNe laser with 633nm.

• Lasers with the wavelengths 488nm, 532nm and 694 nm are optional.

Emission wavelengths

Filters are located in special filter slides. The standard configuration comes with

one filter for each excitation wavelength or laser respectively.

Additional filters can be added into the filter slides. The filter slides can be

exchanged by the user. The ‘identity’ of each filter slide is automatically detected

by the instrument when it is inserted into the slot.

Dual scanning

In order to increase the overall scan speed, two colors can be measured

simultaneously with a dual channel instrument. A calibration algorithm takes care

of the crosstalk between the two colors and corrects for it online. If you have

purchased a single channel instrument, or if the wavelengths are too close to

each other, the instrument can measure the two colors sequentially as well.

Resolution

The standard resolution is 10 µm.

For larger sample features there is the option to scan with 20 µm or 40 µm thus

both increasing scan speed and decreasing the amount of data.

Smaller structures can be better resolved with 6 µm or 4 µm pixel resolution.

Scan widths for a single path scan are 22 mm for 10 µm, 20 µm and 40 µm, 6 µm

pixels and 15 mm for 4 µm pixels.

Optimize sensitivity

For smaller scanning areas, there is a user selectable option to increase

sensitivity without changing the scan time.

Another way to increase sensitivity is to scan transparent slides upside down.

The reason is because surface bound molecules emit the greater part of their

fluorescence into the medium with higher refractive index (e.g. glass).

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2-3

Page 12

2. General

2.1.3 Automation friendliness

Because the LS SERIES SCANNERS are designed to interface with microplate

technology, they are very well prepared for automation using existing microplate

equipment. Four slides can be loaded in an adapter with the outer dimensions of

a microplate. The number of slides is limited only by the stacking capacity of the

external microplate device.

2.1.4 Integrated Image Analysis Software Array Pro

The LS SERIES SCANNERS come with an integrated array analysis software

package.

Caution

If the instructions given in this manual are not correctly carried out, the

instrument May either become damaged or May no Longer be Able to

perform Its Procedures correctly and the Accuracy of the instrument

can no longer be guaranteed.

Note

In order to obtain reliable results it is strongly recommended to place

reference spots onto your sample for quality control. These spots should

represent every dye of your experiment and it is recommended that they

are distributed in a non symmetric pattern across your sample. It is also

recommended to place ‘blank’ spots onto your arrays in order to check

for the variation of the background in your experiment.

2-4 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 13

3. Installation

3. Installation

3.1 Unpacking & Inspection

The delivered container includes the following:

• Instrument

• PC

• PC Monitor

• Manual

• Software: Driver LS Series Scanner (1 CD-ROM)

• Cables (RS232 cable and 1 interface cable)

• Slide Adapters

• Filter Slide

• Reference slides (histological section of mouse; spots)

• Array Pro Software

• Hardware Key Array Pro SW

• Installation CD Array Pro SW

• Array Pro User Manual

• Scattered light glass slide

• Filter Slide for Calibration

• 2 Filter Slides

Caution

Before the instrument is installed and switched on, it should be left to

stand for at least three hours, so there is no possibility of condensation

causing a short circuit.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 3-1

Page 14

3. Installation

Visually inspect the container for damage before it is opened.

Report any damage immediately.

Select a location to place the instrument that is flat, level, vibration free, away

from direct sunlight, and free from dust, solvents and acid vapors. Allow at least

10 cm between the instrument and the wall or any other equipment.

Remove transportation locks.

Caution

The LS Series Scanners are precision instruments

and are very heavy. At least two people

3-2 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

must carefully lift the instrument from the box.

Page 15

3. Installation

Visually inspect the instrument for loose, bent or broken parts.

Report any damage immediately.

Compare the serial number on the rear panel of the instrument with the serial

number on the packing slip.

Report any discrepancy immediately.

Check the instrument accessories against the packing list.

Save packing materials and transport locks (see next section) for further

transportation purposes.

Caution

Do not try to open or close

the instrument flap manually.

Ensure that the flap cannot be accidentally hit when it is opened automatically.

Ensure that the main switch and the main cable can be reached at all times

and are in no way obstructed.

Caution

The maximum load for the top of the housing

of an LS Series Scanner is 3 kg.

Caution

Keep fingers away from the flap when it is closing

or when a scan has been started.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 3-3

Page 16

3. Installation

Place the PC with monitor, keyboard and mouse next to the instrument.

Ensure the computer is switched OFF and the instrument's main power switch on

the back panel of the instrument is in the OFF position.

Check the voltage specifications on the computer and ensure that the voltage

supplied to the computer is correct according to the specification input range

selector (red button) at the power supply.

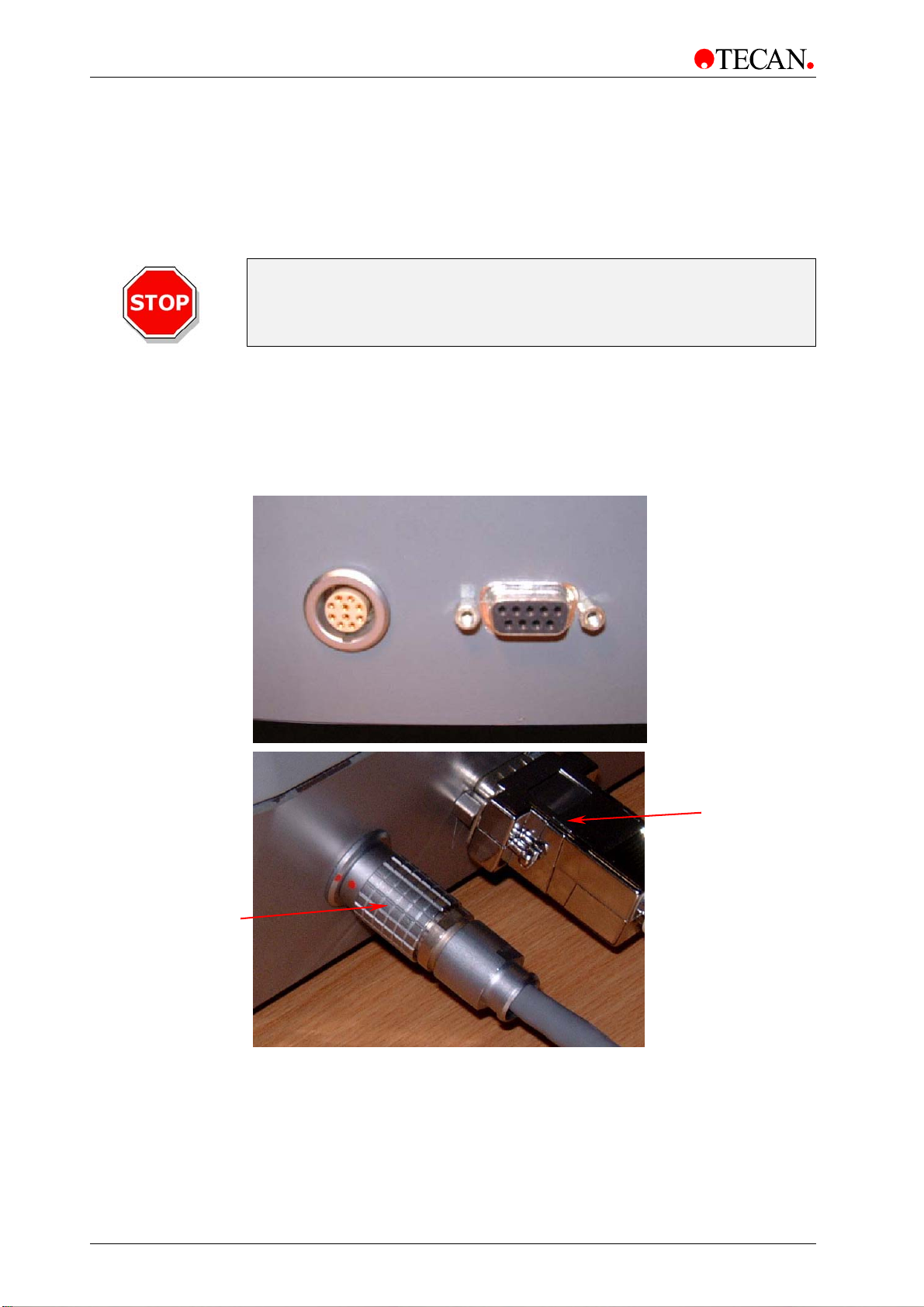

Caution

Check voltage specification on the computer BEFORE switching ON. If

computer is switched ON with the incorrect voltage supply it will be

Connect the computer to the instrument with the delivered RS 232 interface

cable.

Connect the computer to the instrument with the delivered special interface cable.

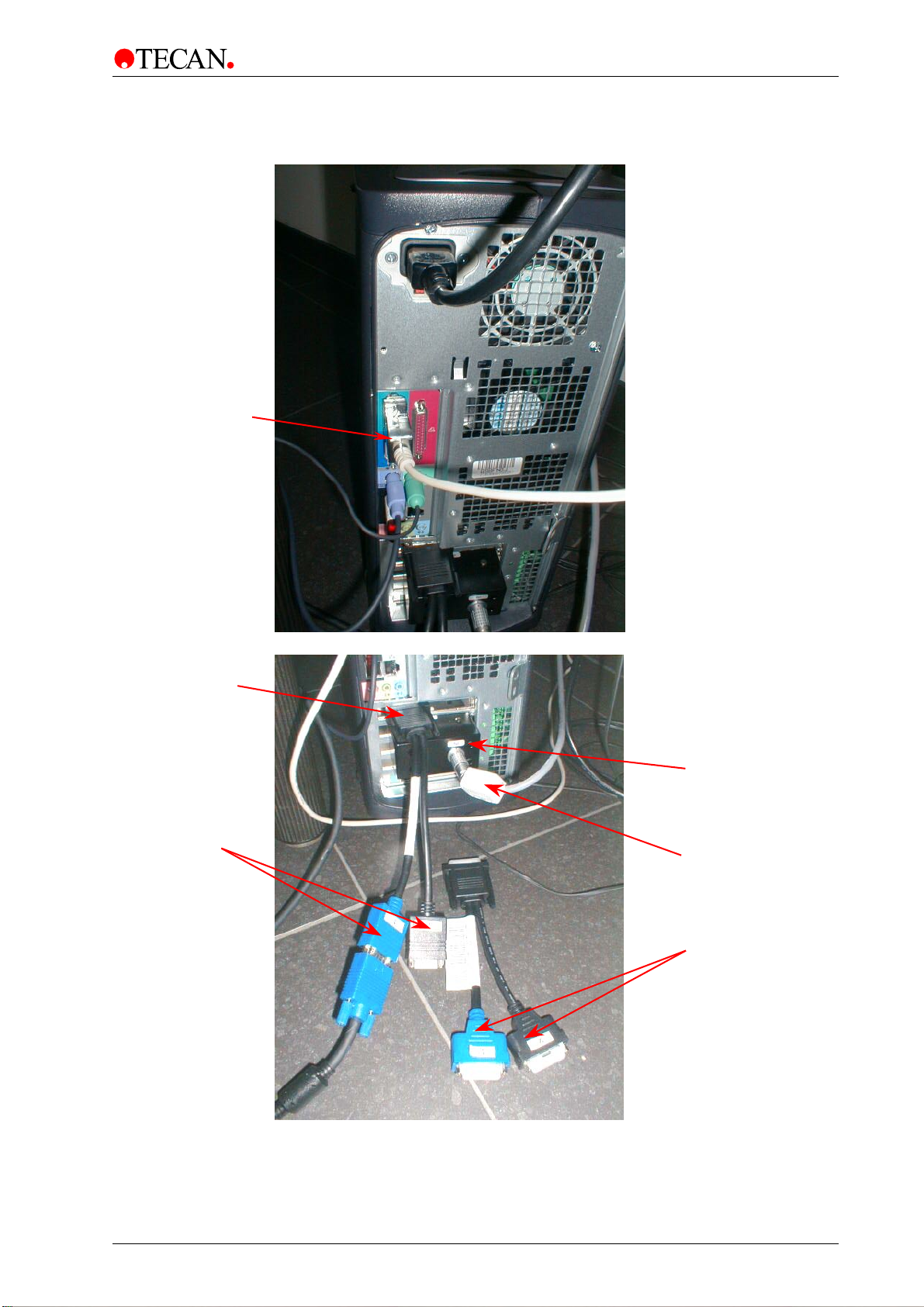

The pictures below show the connection of the interface cables

to the rear of the instrument:

damaged.

Data cable to

connector box

RS232 to

computer

3-4 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 17

RS232 to

instrument

3. Installation

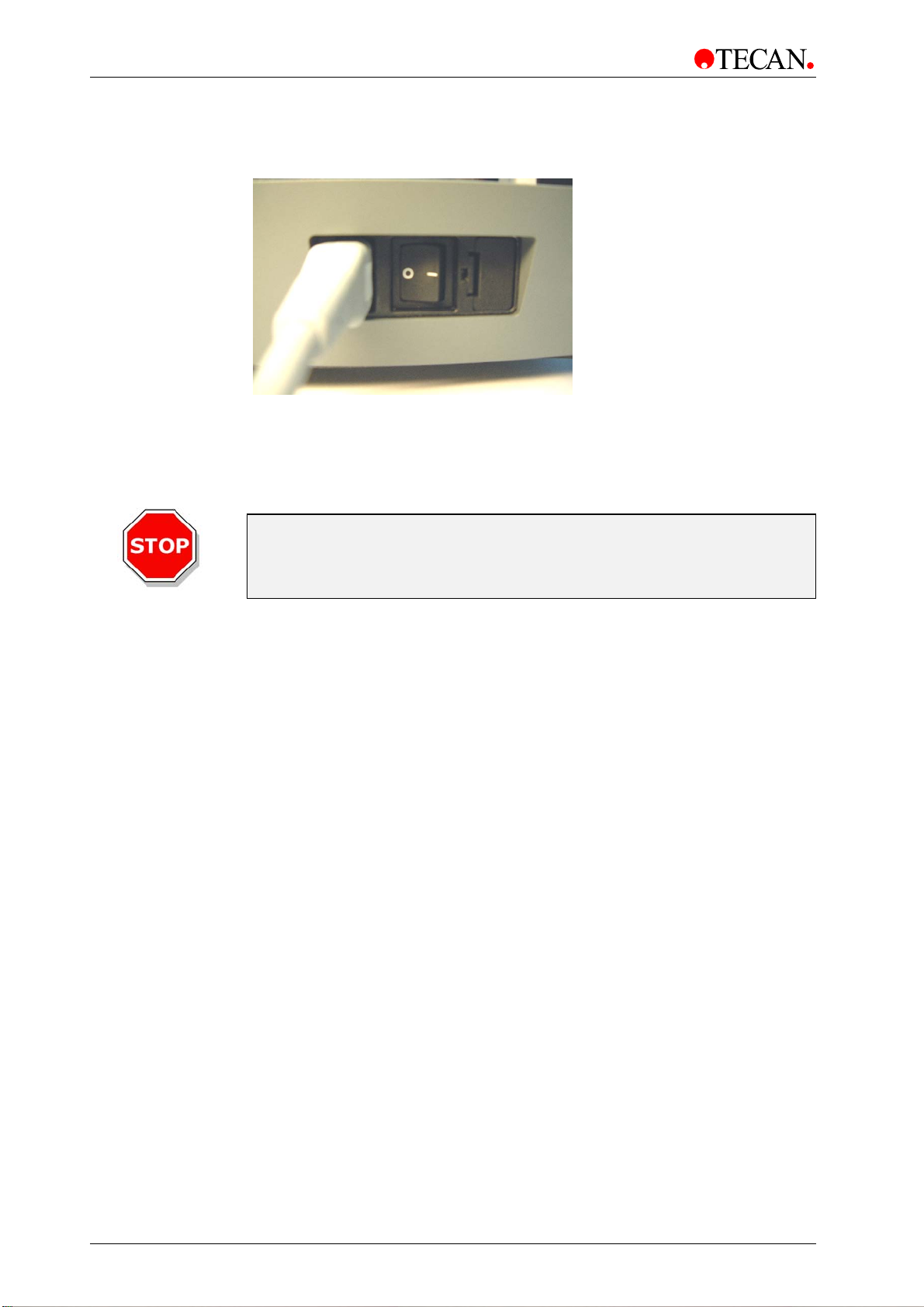

The pictures below show the connection of the interface cables

to the back of the computer:

Connection

for monitor

cables

Digital

monitor

cables

Connector

box

Data cable to

instrument

Analog

monitor

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 3-5

Page 18

3. Installation

Insert the power cable (with protective ground connection) into the main power

socket in the back panel of the instrument.

All connected devices must be approved and listed with regulations EN 60950,

UL 1950 or CSA C22.2 No. 950 for Data Processing Devices.

Switch the computer ON.

Switch the instrument ON using the switch on the back panel of the instrument.

Caution

Keep fingers away from the flap when it is closing

or when a scan has been started.

3-6 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 19

3. Installation

3.2 Remove Transport Lock

Start LS Scanner Shell.

Select Instrument and click Connect.

A message appears that instrument is locked.

For more information on removing the transport lock see chapter 6.4.10 The

Transport Unlock Wizard.

Do not try to open or close

Save packing materials and transport locks

for further transportation purposes. The LS series scanners must be

and the transport locks must be installed.

the instrument flap manually.

shipped with the original packing

Caution

Caution

Caution

Before Transportation

Place the instrument carefully in the indicated orientation before fixing the

transportation locks, otherwise the instrument will become damaged.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 3-7

Page 20

3. Installation

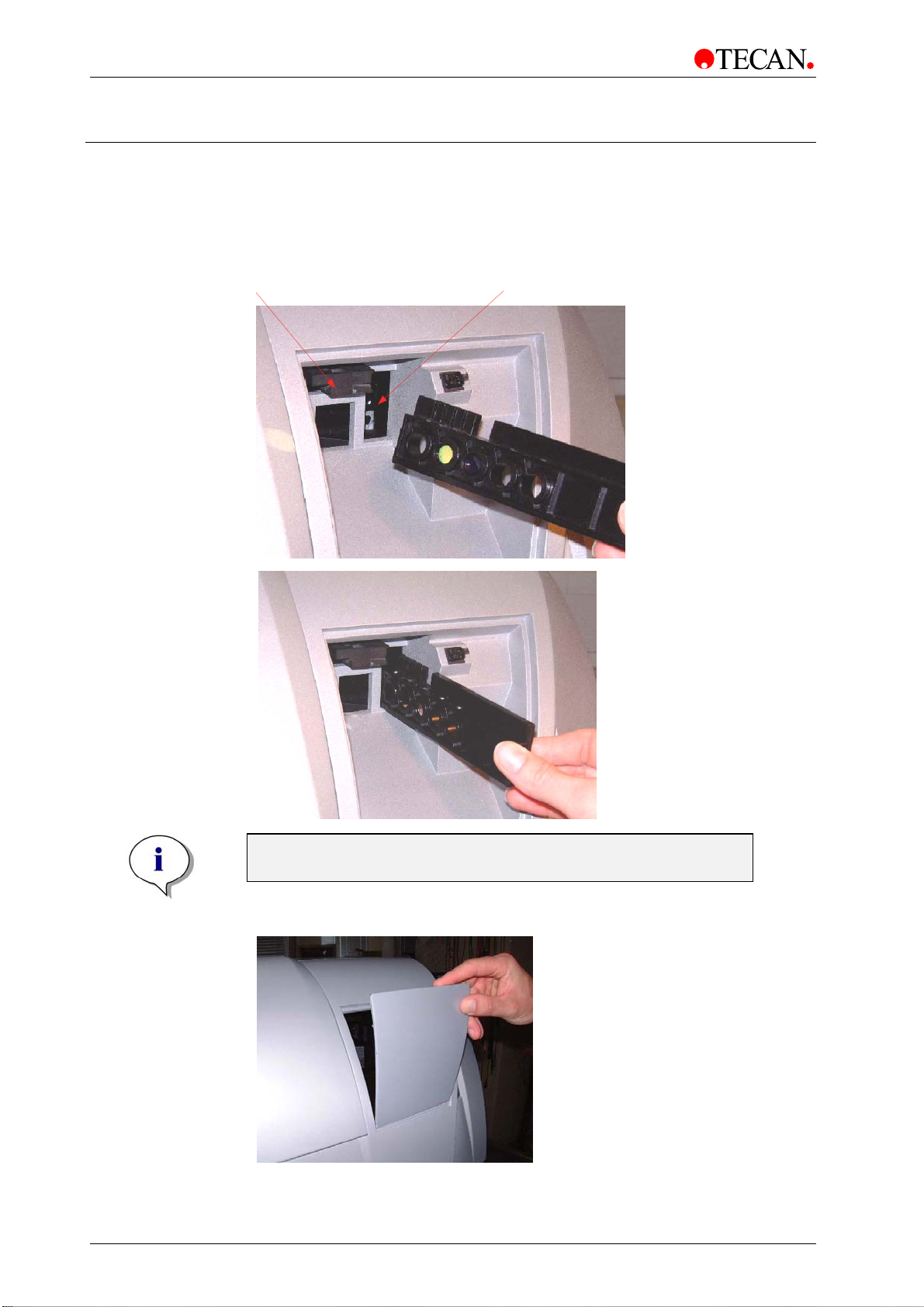

3.3 Filter Installation

Insert the Filter Slides into Filter Channel 1(vertical orientation) and Filter Channel

2 (horizontal orientation) and make sure that the filters are oriented properly, (see

pictures below).

Filter Channel 1 Filter Channel 2

Note

Both filter slides are only necessary in dual channel instruments.

• Close the filter compartment

3-8 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 21

3. Installation

3.4 Power Requirements

The instrument is auto sensing and it is, therefore, unnecessary to make any

changes to the voltage range.

Check the voltage specifications on the rear panel of the instrument to ensure

that the voltage supplied to the instrument is correct according to the

specification.

The voltage range is 100-120 / 220-240 V.

If the voltage is not correct, please contact your distributor.

Ensure that a fuse of the correct type and rating is fitted.

Fuse = T 2.0 A / 250 V (slow blow) UL recognized

WARNING

RISK OF FIRE!

REPLACE ONLY WITH FUSES

OF THE SAME TYPE AND RATING.

Caution

When installing or uninstalling the instrument ensure that the instrument

and the computer are both switched off and disconnected from the main

power supply before the RS 232 interface cable or the special connector

cable is connected or removed.

Caution

If the instructions given in this manual are not correctly carried out, the

instrument May either become damaged or May no Longer be Able to

perform Its Procedures correctly and the Accuracy of the instrument

can no longer be guaranteed.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 3-9

Page 22

Page 23

4. Technical Description

4. Technical Description

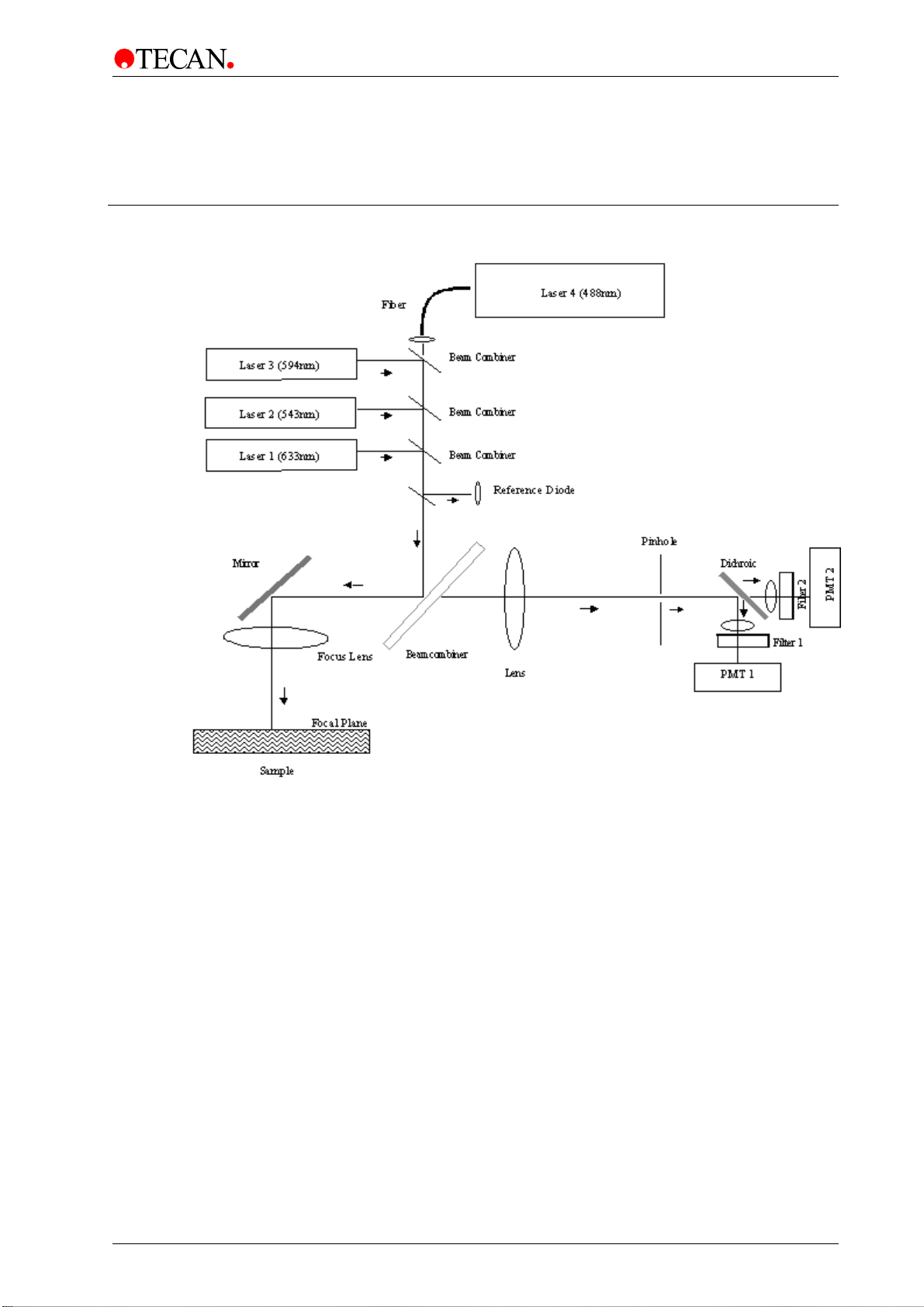

4.1 Optical System

Figure 4.1

For excitation of fluorescence signals up to 4 lasers are installed. The lasers for

633 nm, and 594 nm are Helium Neon lasers; the lasers for 488 nm and 532nm

are solid state lasers. Both of these laser types have excellent beam quality and

stability.

Laser beams are combined with dichroic elements to enter the scanner in a

collinear alignment.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 4-1

Page 24

4. Technical Description

Scanning is done in a first direction with the excitation beam. This very fast

scanning mechanism scans 40 lines per second. The overall scanning speed and

scanning time in this direction is independent from both pixel resolution and scan

width. The second scanning dimension is achieved by moving the sample in a

perpendicular direction. This movement is exactly synchronized with the first scan

axis to create a 2-dimensional fluorescence image. For example at 10 µm

resolution 4 mm are scanned within 10 s ((4 mm / 40 lines / s) * (100 lines / mm

10 µm pixel size)

) = 10 s). For this second direction the scanning speed is reciprocal

to the resolution and the overall scanning time depends linearly on the scan

length.

Fluorescence light is collected with a high aperture lens with exceptional working

distance (up to 6.5 mm). This long working distance is the key for the ability to

measure flexible sample formats other than slides.

A second lens refocuses the collected light onto a pinhole, thus creating a

confocal detection scheme.

Three pinholes of different sizes are mounted on an automatic slide carrier. The

smaller the pinhole, the lower the focal depth of the detected volume. The larger

pinholes typically create images with a slightly lower signal to background ratio

but offer the choice to measure bulky samples or uneven surfaces as well.

Behind the pinhole the fluorescence light passes through a bandpass filter that

rejects light of the excitation wavelength and all other spectral contributions that

are not within the detection bandwidth of the selected filter. Filters are arranged in

filter slides that can hold up to four different filters. Each filter slide has five

positions, but one of them has to stay open for autofocus purposes.

Filter slides can easily be removed or exchanged; up to 8 different slides can be

automatically identified by the instrument firmware when they are inserted in the

filter slots.

In the dual channel instrument a dichroic beamsplitter separates the two emission

wavelengths of the first and the second dye (e.g. Cy3 and Cy5) and lets them

pass trough two different emission filters and to two different photomultiplier tubes

(PMT’s). The two different filters are located on two different filter slides in that

case.

A reference diode monitors laser power before each measurement.

(=

Figure 4.2

4-2 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 25

4. Technical Description

4.2 Autofocus

A key element for the flexibility of the instrument is the autofocus system. It allows

every sample individually to be adjusted - exactly in the focal plane of the optics.

Because this is done immediately before each scan, out of focus images due to

long term drifts of the optical alignment are not an issue with the LS SERIES

SCANNERS.

Before each scan two z-scans are done across user defined lines in the sample.

This way two short ‘vertical’ images are recorded typically close to both ends of

the slide or the sample. (z-axis is moved instead of x-axis). These z-scan images

are taken to calculate the exact position and the orientation of the sample.

Orientation of the sample is also calculated because slight amounts of tilt could

give poor results with a confocal measurement scheme.

The sample is then brought into the exact focal plane both with regard to z as well

as the two angles of tilt. This process is fully automated. Signals are recorded in

reflection mode and with a dimmed beam (4 orders) to prevent bleaching.

To realize this functionality a high precision 5-axis transport system is

implemented in the LS SERIES SCANNERS. The five axis are: X (scan axis), Y

(moves sample tray between different slides or different areas on larger

samples), Z (brings sample into focal position), ϑ and Φ (correct for angles of tilt

of the sample or tolerances of the adapters). Precisions for the axis’ are in the

range of 1-2µm.

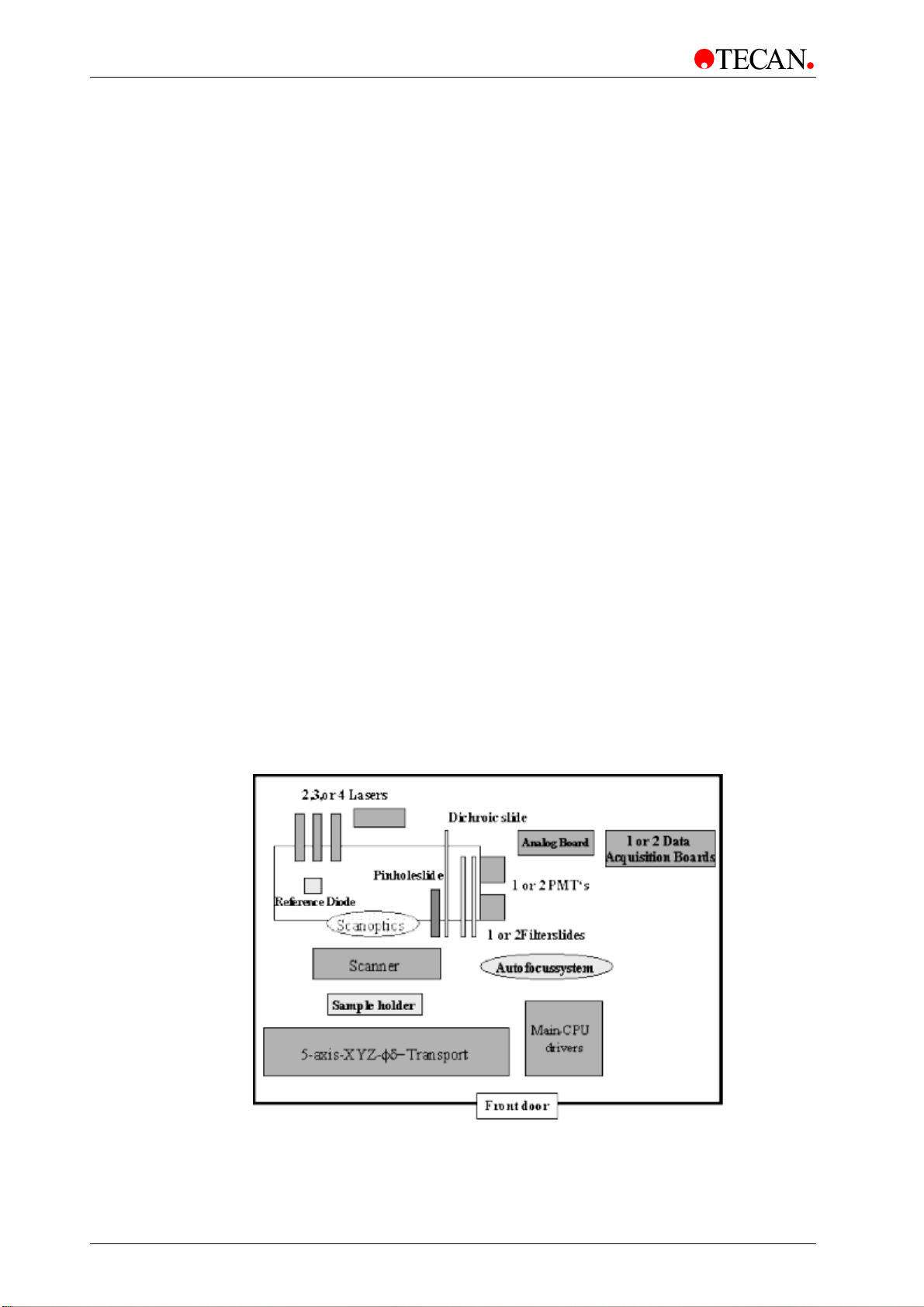

4.3 Data Processing

Further data processing is done by an analog amplifier PCB and fast 16 bit data

acquisition boards. The latter ones are plugged into the PC and connected to the

instrument with a special interface cable.

An internal Main-CPU takes control of all the actuators and data acquisition steps

during scan. It is interfaced with a RS232 cable with the PC.

On the PC the Array Pro software is an integrated package both for instrument

control and for array processing.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 4-3

Page 26

Page 27

5. Operation

5. Operation

The LS SERIES SCANNER is operated using personal computer based software

control. The Array Pro Software is used both for instrument control and data

analysis.

This chapter describes the instrument and the instrument control software. It is

intended for a general understanding of instrument parameters and operation.

For details of the data analysis see the corresponding Array Pro software manual.

Suggestions are made on how to optimize the instrument parameters for your

applications.

Every effort has been made to ensure that the instrument will work correctly even

if the default parameters are not appropriate for a particular application

- with an important exception:

When placing a sample into the sample carrier,

always make sure that the correct slide and slide carrier definitions are

Wrong definitions, especially with special samples can lead to damage of

the instrument or the sample.

Caution

selected in the software.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 5-1

Page 28

5. Operation

5.1 General Operating Features

The LS Series Scanner has some general behavior and options, which are

independent from particularly selected measurement techniques.

5.1.1 Instrument Start Up

Before the instrument is powered ON, ensure that both of the interface cables are

connected.

Caution

When the serial interface cable

or the special interface cable

is being plugged in or unplugged,

the instrument and the PC should be powered off.

5.1.2 Instrument Power On

When switching the instrument ON, the following actions are induced:

• The filter slides move into the reference position

• The dichroic filter carrier moves into the reference position

• The pinhole carrier moves into the reference position

• The microplate transport moves into the reference position

• The cooling fans start to ventilate

At the beginning of each session the user is requested to choose the lasers to be

used in this session. Only the selected lasers will be switched on. This is done to

increase the lifetime of the lasers.

The lasers need a warm up time of 20 minutes. The instrument is already

functional before that time, but performance according to the

specifications is guaranteed only after the warm up time has elapsed.

Scans can be done before that time.

Note

5-2 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 29

5. Operation

5.1.3 Connect to Instrument

When the software connects to the instrument, communication is established

between the instrument and the user interface. The instrument is ready for

operation.

5.1.4 Finish a Measurement Session

Disconnect from Instrument

When disconnecting, communication between the instrument and the PC is

terminated.

Please remove the recently measured sample before disconnect.

Instrument Shut Down

Note

Upon shut down, the instrument activity is stopped immediately. Normally, you

should disconnect before shut down. In the rare case of an unexpected hardware

error, immediate instrument shut down will reduce the risk of possible damage.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 5-3

Page 30

5. Operation

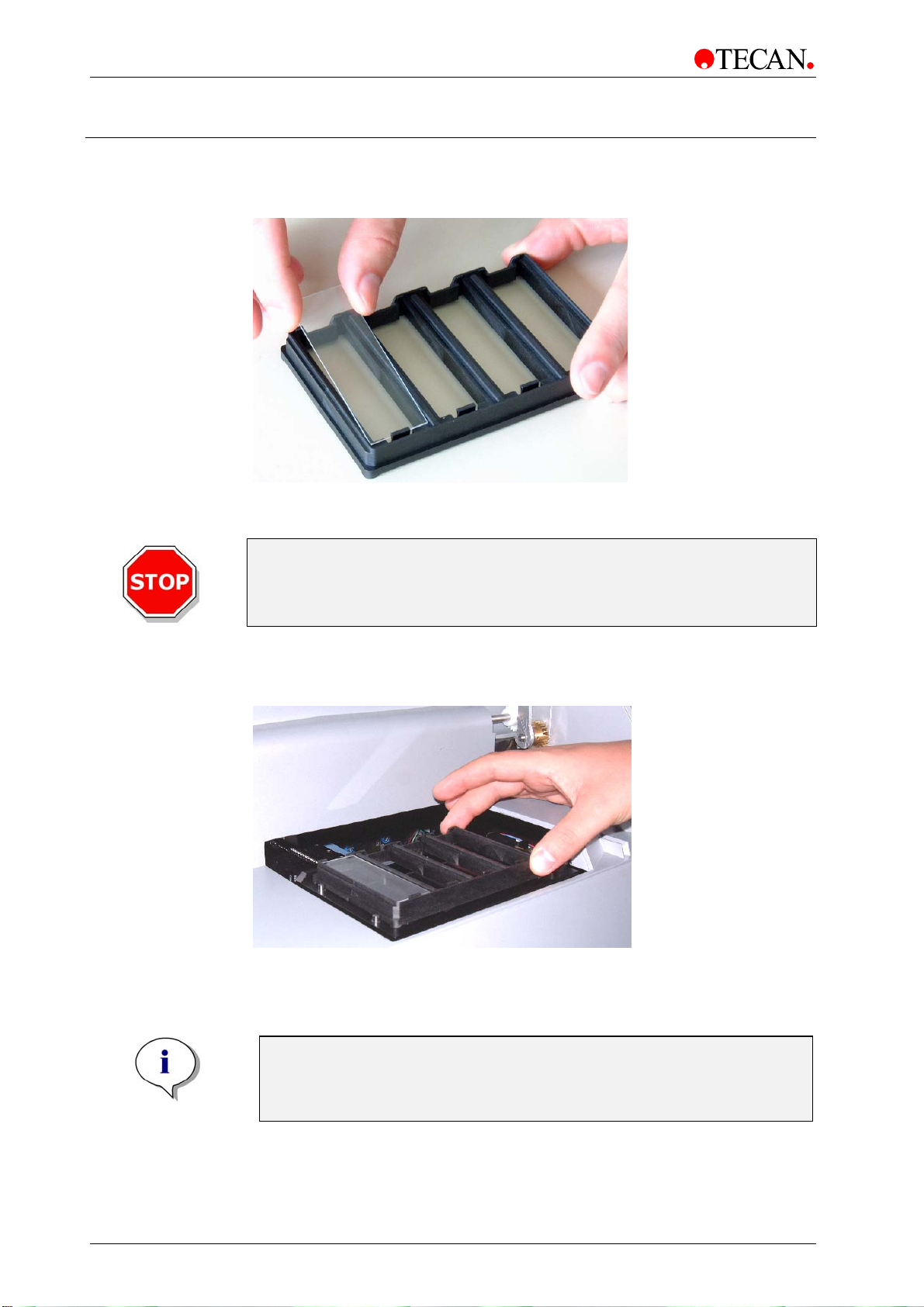

5.2 Insert Slide(s) into Slide Adapter

Insert slide(s) into slide adapter as shown below:

Figure 5.5 a

Caution

Ensure that the slide is placed tightly on its support And in the right

orientation in the adapter. If it is not placed correctly in the adapter the

Place slide adapter on the plate transport in the same orientation as shown below

(Fig. 5.5 b): - moveable spring should be located in the front

autofocus algorithm might fail to find a focal plane.

Figure 5.5 b

Note

The adapter is semi-disposable. The clamps that secure the slide might

5-4 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

wear and the slides might become too loose in the adapter. Please call

your Tecan sales representative to order new adapters.

Page 31

6. LSServer, Scanner Shell and Download

6. LSServer, Scanner Shell and Download

6.1 Introduction

6.1.1 Overview

LSServer and Scanner Shell are software applications designed to give the user

an easy and flexible way to operate Tecan LS SERIES SCANNER instruments.

LSServer is called up in Array Pro 4.5, a special tool for analyzing microarrays,

and Scanner Shell.

LSServer Functions:

• Connecting to LS Series Scanner

• Preparing measurement parameters in order to get the best results in

scanning

• Scanning in different modes

Scanner Shell Functions:

• Connecting to Tecan LS Series Scanner

• Preparing measurement parameters in order to get the best results in

scanning

• Calibrating LS Series Scanner instruments

• Creating special formats for scanning different plates and slides

• Filter Definition

• Stacker Setup

LSDownload is a software tool needed for downloading new firmware versions to

LS SERIES SCANNER instruments.

For details on

• data analysis, see the corresponding Array Pro 4.5 operating manual.

• instrument features and technical description refer to the Tecan LS Series

Scanner operating manual.

6.1.2 Hardware Requirements

The following hardware requirements are needed for LSServer and Scanner

Shell:

Hardware Minimum Recommend

Memory 512 Mbytes 1 Gbyte

CPU Pentium III 1 GHz Pentium IV 1.7 GHz

Resolution 1024 x768 1280 x 1024

Serial Ports 2 2

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-1

Page 32

6. LSServer, Scanner Shell and Download

6.1.3 Software Requirements

The following software requirements are needed for LSServer and Scanner

Shell:

Operating system Minimum Recommend

Microsoft Windows Windows 2000 Windows 2000

Additional supported software:

Array Pro 4.5 for microarray image analysis.

Note

Microsoft®Excel and Microsoft®Word must be registered by the user !

6.1.4 Software Installation Procedure

Automatic Software Setup

LSServer / Scanner Shell and LSDownload are installed by an automatic

software setup program:

Note

Before installing LSServer components be sure that Array Pro 4.5

Software for Microarray Image Analysis is installed on your system.

Note

It is necessary that the person who installs the software has administrator

rights on a PC with a Win 2000 operating system.

Step Procedure

1. Place the LS Driver for Tecan LS V2.2 Setup CD in the CD-ROM

drive.

2. Open the CD drive folder and start LSServer.exe. The installation

procedure begins.

3. A Welcome window informs the user about the beginning of the

installation process. Click Next to continue.

4. A Read Me File window informs the user about the new features of

the setup.

5. The installation of the required files is carried out and files are copied

to the computer. At the end of a successful installation the user can

quit the installation wizard by clicking the Finish button.

After successful installation, installed software components for LSServer can be

started via the Window Start menu by selecting Start - Programs - Array-Pro

Analyzer 4.5 - Array-Pro Analyzer and installed software components for

Scanner Shell and LSDownload can be started via the Window Start menu by

selecting Start - Programs - Tecan - ScannerShell or LSDownload.

6-2 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 33

6. LSServer, Scanner Shell and Download

Automatic Software Removal

Scanner Shell / LSDownload can be removed using the Windows standard

uninstall routine:

Step Procedure

1. Make sure the ScannerShell / LSDownload application is closed.

2. Select Add / Remove software from Settings - Control Panel in the

3. Select the ScannerShell / LSDownload icon and click Remove.

4. The Uninstall wizard is started. Select the preferred uninstall method

5. In the next window press Finish to uninstall ScannerShell /

6. A message box pops up asking if shared components should be

Start menu.

(Automatic or Custom) and click Next to continue.

LSDownload.

removed. Select Yes to completely uninstall application. Leaving the

components will not harm your system. If you are not sure what to do, it

is suggested that the shared components not be removed.

The ScannerShell / LSDownload is now uninstalled.

Note

This chapter does not apply to LSServer application.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-3

Page 34

6. LSServer, Scanner Shell and Download

6.2 Tecan LS Scanner Interface

6.2.1 Overview

The Tecan LS Scanner Interface is a dialog box in which the options for

connecting to instruments such as the Tecan LS Series Scanner can be set.

The next chapters describe how to:

• Set Communication port

• Choose Instrument type

• Work in Demo mode

6.2.2 Starting LS Scanner Interface

Port Setup

The Port Setup dialog box serves to set up options for connecting instruments:

The desired instrument and the communication port are chosen. The demo

mode provides the possibility to simulate any Tecan instrument.

To open the Port Setup dialog box:

• In Tecan LSA Software, Acquire menu select Tecan Scanner... or

• In Scanner Shell Software, Setup menu select Setup Port… or

• In LSDownload, Instrument menu select Connect…

The Port Setup dialog box:

In the Port Setup dialog box the instrument type and the communication port

are selected.

Alternatively, select Find any and the LSServer can automatically search for a

connected instrument.

Click OK to save changes and close the dialog box.

6-4 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 35

6. LSServer, Scanner Shell and Download

The Port Setup dialog box contains the following elements:

Instrument group box The Instrument group box contains the following

elements:

• Select option button:

A specific instrument can be selected (choose in

instrument type combo box).

• Find any option button:

The LSServer searches for available instruments

automatically.

Port group box The Port group box contains the following elements:

• Select option button:

A list in which the appropriate communication port

can be selected is shown.

• Find any option button:

The LSServer searches for any available port.

• Demo mode option button:

Allows the simulation of any instrument, e.g. for

test purposes. Refer to chapter 6.4.6 Service

Menu - Demo Mode Allowed for enabling the

demo mode.

Stacker Port group box The Stacker Port group box contains the following

elements:

• Select option button:

A list in which the appropriate communication port

can be selected is shown.

• Find any option button:

The LSServer searches for any available port.

• Demo mode option button:

Allows the simulation of an instrument. Refer to

chapter 6.4.6 Service Menu - Demo Mode Allowed

for enabling the demo mode.

• None: option button

No Stacker available for the instrument.

OK button Click OK to save data and close the dialog box.

Cancel button Click Cancel to close the dialog box. The selected

options are not saved.

Help button Click Help to display the online help for the dialog box.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-5

Page 36

6. LSServer, Scanner Shell and Download

6.3 LSServer

The LSServer is an instrument control and data scanning software specially designed for connecting to Tecan instruments such as the Tecan LS SERIES SCANNER. This chapter describes the parameters and operations; giving a general understanding in preparing and scanning data and in getting the best results for attached data analysis.

For details of data analysis see the corresponding Tecan LSA Software manual.

6.3.1 Starting the First Time

When starting LSServer for the first time, the Tecan LS Scanner Interface dialog

box is opened. After selecting instrument type and communication port and

confirming with OK the Measurement Control dialog box is displayed.

For all future starts of the LSServer:

In Tecan LSA Software, Acquire Menu select Tecan Scanner... and the

Measurement Control dialog box is displayed.

6.3.2 Measurement Control

In the Measurement control dialog box, several groups, each containing

individual buttons, are shown that offer special operations for preparing and

scanning data. Measurement parameters and measurement options are defined

and finally measurements are started here.

The Measurement Control dialog box is divided into individual groups:

• Measurement group

• Instrument group

• Measurement Parameter group

• Settings group

• Slides to Process group

6-6 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 37

Measurement

6. LSServer, Scanner Shell and Download

The Measurement Control dialog box consists of the following elements:

• The Measurement group element with the Start and Prescan button

• The Instrument group element to move plate and filters and to switch on

lasers

• The Measurement Parameter group element to Edit parameters or to

Save and Load certain predefined parameter files

• The Settings group element with the Settings button to enter the

filename and to select the scan areas

• The Slide Adapter Format group element to load existing Slide Adapter

Format (.saf) files

• The Slides to Process group element to display arrangement of the scan

areas

• File size of chosen slides

The Measurement group contains the following elements:

Start button Click the Start button to start a measurement with the

Prescan button Click the Prescan button to select three different

Instrument

The Instrument group contains the following elements:

Plate / Filter button Click the Plate / Filter button to open the Movements

Laser Control button Click the Laser Control button to open the Laser

Measurement Parameter

The Measurement parameter group contains the following elements:

current measurement parameter. The Status dialog

box is displayed.

prescan modes:

o Image prescan

o Adapter prescan

o Focus prescan

dialog box: Plate and filter can be moved.

Control dialog box: Laser type can be selected and

power control can be set / changed.

Edit button Click the Edit button to open the Measurement

Parameter dialog box: Measurement parameters can

be edited.

Load button Click the Load button to open the Open dialog box:

Measurement parameters can be loaded from a file.

Save button Click the Save button to open the Save As dialog box:

Measurement parameters can be saved to a file.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-7

Page 38

6. LSServer, Scanner Shell and Download

Settings

The Settings group contains the following elements:

Settings button Click the Settings button to open the Slide Settings

dialog box: Filename can be entered and scan areas

can be selected.

Slide Adapter Format

The Slide Adapter Format group contains the following elements:

Load button Click the Load button to open the Open Slide Adapter

Format dialog box: SAF can be selected.

Slides to Process

The Slides to process group gives a general view of the slide / plate format

used and the arrangement of available scan areas. Scan areas that will be

scanned after pressing Start / Prescan button are green, those that will not be

scanned are dark gray. Select / unselect slides with left mouse click. Also the

calculated file size will be displayed right under the scan area window.

6-8 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 39

6. LSServer, Scanner Shell and Download

f

6.3.3 File Types used in LSServer

The following file types are used with LSServer:

File Type File

Extension

Image

Measurement

Parameter

Slide adapter

ormat

Gain

calibration

Crosstalk

calibration

Focus

.tif Scanned image files are saved in a 16bit TIF

.lsp Measurement data is saved as .lsp files.

.saf Slide adapter format data is saved as .saf files.

.dat

.cvs

.dat Crosstalk data is saved as CrosstalkCor.dat

.tif Focus image files are saved as

Description

format (Tagged Image File)

Gain calibration data is saved as

GainCalibration.dat files.

Gain calibration data is stored as a comma

separated list (.cvs files). For analysis these

files can be loaded in Excel or another

calculation program.

files.

• Focus1.tif for first autofocus scan

• Focus2.tif for second autofocus scan

• Focus3.tif for third autofocus scan (only

created during MTP-autofocus)

Log

Each time the LSServer is started, the LSServer.log file is overwritten;

.log

.log1 -.log5

old data is saved in LSServer.logn file.

Log file data is saved in the following file

format:

• LSServer.log:

A record of current measurement data.

• LSServer.log1 - LSServer.log5:

A record of earlier measurement data.

Note

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-9

Page 40

6. LSServer, Scanner Shell and Download

Locating Files

LSServer Files

By default the files associated with LSServer are stored as subdirectories in the

directory where LSServer.dll is found:

C:\Program Files\Common Files\Tecan\Reader\….

The subdirectories are displayed in the table below:

Temporary Files

Type of File File

Extension

Measurement

parameter

Slide adapter format

Gain calibration

Crosstalk

Temporary files needed for diagnostic and controlling purposes are stored in the

directory:

C :\Documents and Settings\user_logged_in\Local Settings\

The file types are displayed below:

Type of File File Extension Directory

Focus

Log

.lsp Parameter

.saf SAF

.dat

.csv

.dat CalData

.tif Temp

.log

.log1 to .logn

Directory

CalData

Temp

File Management

The default paths for saving files can be changed in the Slide Settings dialog

box on the Folder Options tab. See Folder Options for more information.

6-10 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 41

6. LSServer, Scanner Shell and Download

6.3.4 Measurement

Start

In the Measurement Control dialog box, Click Start…to start a measurement

using the current measurement parameters. The Status dialog box appears and

displays the current process of the scanner as static text.

In the Time group box, the Elapsed time of the measurement and the Estimated

run time are shown.

In the Gain control group box, the gain of the PMT can be adjusted online during

the measurement.

The display of the Status dialog box can be changed using the Shrink or the

Default view button.

Click Break to interrupt the measurement.

The Status dialog box contains the following elements:

Instrument is…

This static text gives information about the current

process, e.g.:

Instrument is performing autofocus

Instrument is measuring dark

Instrument is measuring image

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-11

Page 42

6. LSServer, Scanner Shell and Download

Prescan

Image Prescan

Time

group box

Gain control

group box

Please wait…

progress bar

Shrink button Click Shrink to minimize the display of the Status

Default button Click Default to maximize the display of the Status

Break button Click Break to abort the current measurement.

• Elapsed time static text box

• Estimated run time static text box

• Gain 1 slider / spin control:

Use the slider or spin control to online adjust the

gain in Channel 1.

• Gain 2 slider / spin control

Use the slider or spin control to online adjust the

gain in Channel 2. (only active during dual

parallel measurements).

Please wait… under the static text a progress bar

indicates the progress of the ongoing process.

dialog box.

dialog box.

In the Measurement Control dialog box, click Prescan and select Image

Prescan to start an overview measurement for the first selected scan area.

The Image Prescan serves to position the autofocus scan lines and to select the

scan area for the final measurement. The image prescan procedure scans the

complete Slide Area as defined in the selected .saf file. It is performed using the

following default measurement parameters:

• Single Scan mode

• 40 µm scan resolution

• Large pinhole

• Optimize integration time selected

• No autofocus

• Scan Settings from Channel 1 only

6-12 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 43

6. LSServer, Scanner Shell and Download

On clicking the Image Prescan option the Status dialog box appears and an

overview measurement is started.

The Status dialog box contains the following elements:

Instrument is…

static text

The static text gives information about the actual process,

e.g.:

Instrument is performing prescan

Instrument is measuring dark

Time

group box

Gain control

group box

• Elapsed time static text box

• Estimated run time static text box

• Gain 1 slider / spin control

Use the slider or spin control to online adjust the gain in

Channel 1

• Gain 2 slider / spin control

Channel 2 is disabled in Prescan mode.

Please wait…

progress bar

Shrink

button

Default

button

Break

Please wait… under the static text a progress bar indicates

the progress of the ongoing process.

Click the Shrink button to minimize the display of the

Status dialog box.

Click the Default button to maximize the display of the

Status dialog box.

Click the Break button to abort the current measurement.

button

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-13

Page 44

6. LSServer, Scanner Shell and Download

Image Prescan Dialog Box

When the image prescan of the first selected area is complete, the Image

Prescan dialog box appears with the Area Selection group box and the image

appears with an AOI (Area of Interest). The user is asked to set the Scan Area,

the Autofocus Area and the AGC Scan Area. In Tecan LS with integrated barcode

reader, it is also possible to set the Barcode Area. Click Apply to confirm the

newly defined areas. Click OK to save the settings and close the dialog box.

The Image Prescan dialog box contains the following elements:

Area Selection group box

Scan Area option button

Select the Scan Area option button to adjust the boundaries of the rectangular

AOI. To adjust a boundary, place the cursor along the edge or corner of the AOI

and drag it when the 2-way cursor appears. To move the AOI, place the cursor in

the middle of the rectangle and drag it when the 4-way cursor appears. Confirm

the AOI position by clicking the Apply button.

figure 6-1

Minimum scan area: 1mm x1mm.

AOI

6-14 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 45

6. LSServer, Scanner Shell and Download

Autofocus Area option button

Select the Autofocus Area option button to enable the

Autofocus Settings group box.

Set the Autofocus lines by adjusting the boundaries of the rectangular AOI. To

adjust a boundary, place the cursor along the edge or corner of the AOI and drag

it when the 2-way cursor appears. To move the AOI, place the cursor in the

middle of the rectangle and drag it when the 4-way cursor appears. Click Apply

to confirm the newly defined areas. If HS or Wellmode Autofocus has been

chosen, a green check mark appears and the Autofocus area is centered

automatically to the scan area.

Legend:

barcode line

autofocus lines

scan area

AGC area

figure 6-2

Minimum distance between Autofocus lines: 3mm x 3mm.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-15

Page 46

6. LSServer, Scanner Shell and Download

Barcode Area option button

Select the Barcode Area option button to enable barcode area selection.

The barcode is always read centered to the slide width and must be set within the

useable barcode area.

The Barcode Area button is enabled only if a barcode top reader is available to

the Tecan LS Series Scanner and Read barcode has been selected from the

Measurement Parameter dialog box.

Figure 6-3

The total slide area must be at least 37.5 x 15.0 mm, otherwise there is no

room for a barcode. The barcode area is from 37.5 mm to the total slide length.

If your instrument is equipped with a barcode bottom reader, the barcode

area is fixed. The barcode label has to be placed at the upper end of the

slide. The barcode must cover at least the area about 5mm away from the

upper end.

AGC Scan Area option button

Select the AGC Scan Area option button to enable the AGC area selection. If the

AGC feature is activated the selected area will be scanned and that image will be

consulted for the automatic gain calculation.

Set the AGC Scan Area lines by adjusting the boundaries of the rectangular AOI.

To adjust a boundary, place the cursor along the edge or corner of the AOI and

drag it when the 2-way cursor appears. To move the AOI, place the cursor in the

middle of the rectangle and drag it when the 4-way cursor appears. Click Apply

6-16 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 47

6. LSServer, Scanner Shell and Download

to confirm the newly defined areas, (see figure 6-2, on page 6-15 for a picture of

the AGC area). AGC is only available in:

• Single Scan Mode

• Dual Sequential Scan Mode

It is not possible in Dual Parallel Scan Mode because the Cross Talk

phenomenon with special dye combinations (e.g. Cy3 and Cy5), where signal

from one channel will be detected in the other channel and can therefore lead to

incorrectly calculated gain values. To start a scan with the AGC feature first of all

a special area for AGC must be selected. This can be done from either the

Geometry Parameters tab of the Measurement Parameter dialog box or during a

prescan from the Prescan dialog box:

Figure 6-4 Geometry Parameters tab Figure 6-5 Prescan dialog box

(For more information, see AGC (Automatic Gain Control) on page 6-37).

When a scan with AGC is started, the instrument performs a scan of the selected

AGC-area. After this scan, all pixels of that image will be calculated and will be

virtually drawn in a histogram, where the amount of pixels against the signal

values will be plotted.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-17

Page 48

6. LSServer, Scanner Shell and Download

On the Scan Settings tab of the Measurement Parameter dialog box, the values

for calculating the AGC can be set: Noise level and Signal level.

Figure 6-6 Noise level and signal level

For more information, see Scan Settings Tab on page 6-38.

Noise level: = amount of pixels in the percentage, which will be discarded

Range: 0,01% - 1%

Signal level: = mean value of all pixels in the selected signal level range

will be set to

50.000 Range: 0,01% - 1%

50.000

%Noise level %Signal level

Amount of pixels

Signal intensity

65.535

Figure 6-7 Histogram of AGC image

Noise level are pixels, which have a very high signal value and derive from dust

or other particles, which gave a high fluorescent signal. These pixels will be

excluded for the calculation. For the right gain settings only all pixels in the signal

level area will be consulted. Please keep in mind that only percentage of all pixels

can be selected and not different signal values.

6-18 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 49

6. LSServer, Scanner Shell and Download

y

A good starting point to find the right settings for the AGC will be 0,1% Noise level

and 0,1% Signal level. To increase the overall signal, the noise level and/or signal

level must be extended.

65.535

50.000

50.000

65.535

¨

Amount of pixels

Signal intensit

Amount of pixels

Signal intensity

Before AGC scan

Figure 6-8 AGC Scan Functionality; Gain setting will be adjusted to the

appropriate value. The result is an automatic increase of the gain value!

Autofocus Settings group box

Autofocus Amplitude [mm]

Enter the amplitude in mm into the Autofocus Amplitude

text box.

Select the appropriate autofocus from the Autofocus Selection group box:

• No Autofocus

• HS Autofocus

• Wellmode

• MTP mode

Select MTP in the Measurement Parameter dialog box to enable the MTP

option button.

(For further information see chapter Advanced Autofocus).

Image Prescan Buttons

After AGC scan

Apply

button

OK

button

Cancel

button

Help

button

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-19

Click Apply to confirm the defined areas of the AOI.

Click OK to save data and close the dialog box.

Click Cancel to close the dialog box.

The selected options are not saved.

Click Help to display the online help for the dialog box.

Page 50

6. LSServer, Scanner Shell and Download

Adapter Prescan

In the Measurement Control dialog box, click Prescan and select Adapter

Prescan to scan the currently used MTP adapter.

The Adapter Prescan serves to define the current slide adapter format (.saf) file.

The adapter prescan procedure scans the complete traverse path of the Tecan

LS. It is performed using the following default measurement parameters:

• Single Scan mode

• 40 µm scan resolution

• Large pinhole

• Optimize integration time selected

• No autofocus

• Scan Settings from Channel 1 only

On the displayed traverse path it is possible to define the slide areas.

Enter the correct adapter height and sample height.

The chosen sample height of this dialog is taken as default height for the

following adapter scan. The total height is only taken into account to avoid

damaging the optics.

Maximum Values for total height = 16.0 mm

Maximum Value for sample height = 16.0 mm

Minimum Value for sample height = total height – 5.00 mm

Differences greater than 5.00 mm must be aborted, because of possible damage

to the optics. The software produces a warning message for differences in the

interval of 5.0 mm.

Caution

If the heights inserted in this dialog are not correctly entered, the

instrument may either become damaged or may no longer be able to

perform Its procedures correctly and the accuracy of the instrument

can no longer be guaranteed.

6-20 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 51

6. LSServer, Scanner Shell and Download

,

,

After clicking OK on the Insert Plate Heights dialog box the instrument starts the

prescan:

After the adapter prescan has finished, the scanned image is displayed. The

currently active .saf file is displayed as an overlay on the adapter prescan image.

The red rectangles represents the available scan areas. The big green rectangle

represents the outer dimension of the active area of the adapter.

After the instrument has performed the prescan, the first page of the adapter

format wizard appears.

5 mm

14 mm

5 mm

11

12

Table MTP adapter

Adapter Prescan = Non confocal scan of the complete transport-table-area.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-21

Page 52

6. LSServer, Scanner Shell and Download

The first page of the Adapter Format Wizard has the following buttons:

Reset

Click Reset to return all the values to the default settings.

button

Next

button

Cancel

button

Help

Click Next to save data temporarily and perform the second part

of the wizard.

Click Cancel to close the dialog box.

The selected options are not saved.

Click Help to display the online help for the dialog box.

button

After all the settings have been correctly entered click Next to continue to the

second page of the wizard.

Example of current SAF parameters

Slide Thickness

Total Height

Sample

Table

Shuttle

Height

Clamp

Height

Carrier

Height

MTP Adapter

6-22 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 53

6. LSServer, Scanner Shell and Download

The second page of the Adapter Format Wizard has the following buttons:

Reset

Click Reset to return all the values to the default settings.

button

Back

button

Finish

Click Back to save data temporally and perform the first part of

the wizard.

Click Finish to save data and close the wizard.

button

Cancel

button

Help

Click Cancel to close the dialog box.

The selected options are not saved.

Click Help to display the online help for the dialog box.

button

After all the settings have been correctly entered click Finish to save the settings.

The Save dialog box will then appear.

To save the Slide Adapter Format file, type in the desired filename of the newly

created .saf file and click Save.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-23

Page 54

6. LSServer, Scanner Shell and Download

Focus Prescan

In the Measurement Control dialog box, click Prescan and select Focus

Prescan to perform a focus scan of the first selected scan area of the currently

used MTP adapter.

The focus prescan enables the user to define the desired focal plane and the

focus offset on a z-scan image. This can also be used for probes, where the auto

focus fails. The focus offset can be adjusted directly on the image, so refraction

considerations are not necessary.

If no focus was previously selected, the focus prescan will be aborted with

following error message: ‘No focus mode selected. Please select focus mode in

Advanced Autofocus dialog!’

Fluorescence focus scans will be performed with the laser / filter setting of

channel 1. This focus scan mode can be relevant for gel applications. The default

settings are reflection modus with the red ( 633nm ) laser.

Click OK, and Focus Prescan dialog box appears:

Example of HS and well mode auto focus.

The Focus Prescan dialog box has the following buttons:

Reset

button

OK button Click OK to save the settings. The focus values are stored for the

Cancel

button

Help

button

6-24 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Click Reset to return all values to the default settings.

currently scanned slide. A message appears, which asks if the focus

offset should only be stored for this slide or for all slides of the

adapter.

Click Cancel to close the dialog box.

The selected options are not saved.

Click Help to display the online help for the dialog box.

Page 55

6. LSServer, Scanner Shell and Download

Depending on the selected focus mode, two (HS and well mode) or three (MTP

mode) focus scans will be performed.

The focus images will be displayed together with an overlay of lines, representing

the Baseline (blue), Identified/scanning plane (red) and Focus Offset (green).

Manual Focus radio button: Changes in the three combo boxes changes the

plane that will be scanned for the next image scan. This plane will be displayed

as red line in the focus images.

Focus Offset radio button: The green line represents the focus offset.

Example of focus prescan for MTP autofocus

After clicking OK, the following dialog box appears:

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-25

Page 56

6. LSServer, Scanner Shell and Download

6.3.5 Instrument

Plate/ Filter

In the Measurement Control dialog box, click Plate/ Filter…to move the plate

carrier and the filter slides of certain instrument. The Movements dialog box will

appear.

In the Movements dialog box, the respective In and Out buttons can be used to

move the plate carrier into or out of the LS Series Scanner. The respective Out

buttons for the filter slides can be used to move the filter slides out of the LS

Series Scanner.

Click OK to close the dialog box.

The Movements dialog box contains the following elements:

Plate

group box

Filter Slide 1

group box

Filter Slide 2

group box

OK button Click OK to close the dialog box.

The Plate group box consists of the following elements:

• Plate In button:

Click the Plate In button to close the door and to move in the plate

transport.

• Plate Out button

Click the Plate Out button to open the door and to move out the

plate transport.

The Filter Slide 1 group box consists of the following elements:

• In button

The In button is disabled. Insert the filter slide (making sure that it

is properly oriented), until a slight resistance is felt, the LS Scanner

will automatically move the filter slide in from this point.

• Out button:

Click the Out button to move out Filter Slide 1.

The Filter Slide 2 group box consists of the following elements:

• In button

The In button is disabled. See the description for Filter slide 1.

• Out button

Click the Out button to move out Filter Slide 2.

Help button Click the Help button to display the online help for the dialog box.

6-26 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Page 57

Laser Control

6. LSServer, Scanner Shell and Download

In the Measurement Control dialog box, select Laser Control… and the Lamp /

Laser Control dialog box appears.

All lasers installed in your instrument are shown in the dialog box:

Click OK to save the changes and close the dialog box.

In the Laser Control dialog box specific lasers (1-4) can be activated /

deactivated and laser power can be set (Laser 4).

The Laser Control dialog box contains the following elements:

Laser 1 (633 nm)

check box

Laser 2 (532 nm)

check box

Laser 3

check box

Laser 4

check box

OK button Click OK to save the selected options and close the dialog

Cancel button Click the Cancel button to close the dialog box.

Help button Click the Help button to display the online help for the dialog

Select Laser 1 check box to activate the 633 nm laser.

Red LED is switched on at the rear of the instrument.

Select Laser 2 check box to activate the 532 nm laser.

Green LED is switched on at the rear of the instrument.

Select Laser 3 check box to activate the 594 nm laser and

the orange LED is switched on at the rear of the

instrument.

Select Laser 4 check box to activate the 488 nm laser and

the blue LED is switched on at the rear of the instrument.

(The blue laser can be power controlled).

box.

The selected options are not saved.

box.

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-27

Page 58

6. LSServer, Scanner Shell and Download

6.3.6 Measurement Parameter

Edit…

In the Measurement Control dialog box, click Edit… to edit general options like

Scan Mode, Stacker and/or Barcode as well as define Geometry Parameters,

Scan Settings and Autofocus Settings. The Measurement Parameter dialog box

appears:

The Measurement Parameter dialog box contains the following elements:

• General Tab

• Geometry Parameter Tab

• Scan Settings Tab

Depending on the installed hardware features, a fourth element can also appear:

• Excitation Angle

(See 6.3.7 Excitation Angle).

OK

Cancel

Help

6-28 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 2004-11

Click OK to save the selected options and close the dialog box.

Click Cancel to close the dialog box without saving the options.

Click Help to display the online help associated with the dialog box.

Page 59

General Tab

6. LSServer, Scanner Shell and Download

In the General tab the type of Scan mode can be selected, as well as the

Barcode reader and the Stacker options for automation purposes. The user can

also select the option of having the plate move out of the instrument after

scanning.

The General tab:

The General tab contains the following elements:

• Scan Mode group box

• Stacker group box

• Plate group box

• Barcode group box

2004-11 Operating Manual for the LS Series Scanner No. 30001798 Rev. No. 1.5 6-29

Page 60

6. LSServer, Scanner Shell and Download

Scan Mode

Scan Mode

group box

In the Scan Mode group box, several scan modes can be selected.

• Single option button:

Selects the Single Scan Mode. One excitation (= laser) and one

emission (= filter) wavelength can be selected. The detection will be

performed in channel 1. This is appropriate for single label

experiments.

• Dual Sequential option button:

Selects the Dual Sequential Scan Mode. Two excitation and emission

wavelengths can be selected. This is appropriate for dual label

experiments in single channel instruments. The second label is

measured immediately after the first and the two emissions are

detected sequentially in channel 1.

• Dual Parallel option button:

Selects Dual Parallel Scan Mode. Two excitation and emission

wavelengths can be selected and are measured simultaneously. This

requires dual channel instruments as detection is performed in both

channels at once and scanning is done in half the time. The Dual

Parallel Scan Mode needs a Crosstalk correction (see Scan Settings

tab) and a valid set of K-factors in order to compensate for spectral

crosstalk.

For further information, refer to the chapter 6.4.6 Service Menu Crosstalk… description in this manual.

Stacker