Page 1

Instructions for Use for

Infinite 200 PRO

Document Part No.: 30052730

2016-04

Document Revision No.: 1.6

Page 2

WARNING

CAREFULLY READ AND FOLLOW THE INSTRUCTIONS PROVIDED

IN THIS DOCUMENT BEFORE OPERATING THE INSTRUMENT.

Notice

Every effort has been made to avoid errors in text and diagrams; however, Tecan

Austria GmbH assumes no responsibility for any errors, which may appear in this

publication.

It is the policy of Tecan Austria GmbH to improve products as new techniques

and components become available. Tecan Austria GmbH therefore reserves the

right to change specifications at any time with appropriate valid ation, ver if icatio n,

and approvals.

We would appreciate any comments on this publication.

Manufacturer

Tecan Austria GmbH

Untersbergstr. 1A

A-5082 Grödig, Austria

T +43 62 46 89 33

F +43 62 46 72 770

E-mail: office.austria@tecan.com

www.tecan.com

Copyright Information

The contents of this document are the property of Tecan Austria GmbH and are

not to be copied, reproduced or transferred to another person or persons without

prior written permission.

Copyright Tecan Austria GmbH

All rights reserved.

Printed in Austria

Declaration for EU Certificate

See the last page of these Instructions for Use.

About the Instructions for Use

Original Instructions. This document describes the Infin ite 200 PRO

multifunctional microplate reader. It is intended as reference and instructions for

use. This document instructs how to:

• Install the instrument

• Operate the instrument

• Clean and maintain the instrument

2 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 3

Remarks on Screenshots

The version number displayed in screenshots may not always be the one of the

currently released version. Screenshots are replaced only if content related to

application has changed.

Trademarks

The following product names and an y registered and unr eg ister ed tr ademarks

mentioned in this document are used for identification purposes only and remain

the exclusive property of their respective owners:

®,

• Infinite

and the Tecan Logo are registered trademarks of

Tecan Group Ltd., Männedorf, Switzerland

• Windows

Redmond, WA, USA

• ChromaGlo

Promega Corporation Madison, WI, USA

• Starna

Road, Hainault, Essex IG6 3UT England, United Kingdom

• BRET2

registered trademarks of PerkinElmer, Inc., Waltham, Massachusetts, USA

i-controlTM, GCMTM, magellanTM, NanoQuant PlateTM,Tecan®

®

and Excel® are registered trademarks of Microsoft Corporation,

TM

Dual-Luciferase® and Enliten® are registered trademarks of

®

is a registered trademark of Starna Scientific Limited, 52-54 Fowler

TM

, DeepBlueC®, PerkinElmer®, AlphaScreen® and AlphaLISA® are

Warnings, Cautions, and Notes

The following types of notices are used in this publication to highlight important

information or to warn the user of a potentially dangerous situation:

Gives helpful information.

CAUTION

INDICATES A POSSI B ILITY OF INSTRUMENT DAMAGE OR DATA LOSS

INDICATES T HE POSSIBILITY OF SEVERE PERSONAL INJURY,

LOSS OF LIFE OR EQUIPMENT DAMAGE IF THE INSTRUCTIONS

THIS SYMBOL INDICATES THE POSSIBLE PR ESENCE OF

BIOLOGICALLY HAZARDOUS MATERIAL. PROPER LABORATORY

IF INSTRUCTIONS ARE NOT FOLLOWED.

WARNING

ARE NOT FOLLO WED.

WARNING

SAFETY PRECAUTIONS MUST BE OBSERVED.

Note

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 3

Page 4

WARNING

THIS SYMBOL INDICATES THE POSSIBLE PR ESENCE OF

FLAMMABLE MA TERIALS AND A RISK OF FIRE. PROPER

LABORATORY SAFETY PRECAUTIONS MUST BE OBSERVED.

ATTENTION

NEGATIVE E NVIRONMENTAL IMPACTS ASSOCIA TE D WITH THE

TREATMENT O F W ASTE.

DO NOT TREAT ELECTRICAL AND ELECTRONIC EQUIPMENT

AS UNSORTED MUNICIPAL WASTE.

COLLECT WASTE ELECTRIC AL AND ELECTRONIC

EQUIPMENT SEPARATELY.

Symbols

Manufactured by

Date of manufacture

Conformité Européenne

Read the Instructions for Use

before operating the instrument

Order number

Serial Number

USB label

WEEE symbol

RoHS Orange Logo

TÜV NRTL

4 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 5

Table of Contents

1. Safety ................................................................................................................. 9

1.1 Instrument Safety ................................................................................. 9

2. General Description ........................................................................................ 11

2.1 Instrument ........................................................................................... 11

2.1.1 Intended Use ........................................................................................ 11

2.1.2 Multifunctionality ................................................................................... 12

2.1.3 Performance ......................................................................................... 13

2.1.4 User Friendliness ................................................................................. 13

2.1.5 Onboard Control Button ....................................................................... 13

2.1.6 Rear View ............................................................................................. 14

2.2 Software .............................................................................................. 15

2.3 Injectors (Optional) ............................................................................ 15

2.3.1 Injector Measurem ent M odes ............................................................... 15

2.3.2 Injector Module Diagram ...................................................................... 16

2.3.3 Injector Pump Options .......................................................................... 16

2.3.4 Storage Bottles and Bottle Holders ...................................................... 17

2.3.5 Injector Carrier ..................................................................................... 18

2.4 Measurement Techniques ................................................................. 20

2.4.1 Fluorescence ........................................................................................ 20

2.4.2 Absorbance .......................................................................................... 22

2.4.3 Luminescence ...................................................................................... 23

2.4.4 AlphaScreen/AlphaLISA ....................................................................... 23

2.5 Optical System ................................................................................... 24

2.5.1 Fluorescence Intensity System (Infinite M200 PRO) ............................ 24

2.5.2 Fluorescence Intensity System (Infinite F200 PRO) ............................. 30

2.5.3 Fluorescence Polarization System (Infinite F200 PRO) ....................... 34

2.5.4 Absorbance System (Infinite F200 PRO) ............................................. 35

2.5.5 Absorbance System (Infi ni te M2 00 PR O) ............................................. 37

2.5.6 Luminescence System ......................................................................... 39

2.5.7 Cuvette Port (Infinite M200 PRO) ......................................................... 42

2.5.8 AlphaScreen/AlphaLISA System (Infinite F200 PRO only) ................... 45

3. Installation ....................................................................................................... 47

3.1 Unpacking and Inspection ................................................................. 47

3.1.1 Unpacking Procedure ........................................................................... 48

3.2 Removal of the Transport Locks....................................................... 49

3.3 Transport and Storage ....................................................................... 50

3.3.1 Transport .............................................................................................. 50

3.3.2 Storage ................................................................................................. 50

3.4 Power Requirements .......................................................................... 51

3.5 Switching the Instrument On ............................................................ 52

4. Gas Control Module (Enhanced) ................................................................... 53

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 5

Page 6

4.1 Safety ................................................................................................... 53

4.2 Gas Control Module Features............................................................ 54

4.2.1 Gas Control Module Configurations ...................................................... 54

4.2.2 Top and Rear Views of the Gas Control Module .................................. 55

4.3 Main Menu of Modes .......................................................................... 57

4.3.1 CO2 Mode ............................................................................................ 57

4.3.2 O2 Mode ............................................................................................... 58

4.3.3 DUAL Mode .......................................................................................... 59

4.3.4 Manual Mode ........................................................................................ 60

4.4 Settings Menu ..................................................................................... 61

4.5 Installing the Gas Control Module .................................................... 62

4.5.1 Requirements ....................................................................................... 62

4.5.2 Installation Procedure ........................................................................... 63

4.6 Operating the Gas Control Module ................................................... 67

4.7 CO2 and N2 Gas Cylinders (Not Supplied Accessory) ..................... 71

4.8 Troubleshooting the Gas Control Module ........................................ 72

5. Operating the Instrument ............................................................................... 75

5.1 Introduction......................................................................................... 75

5.2 General Operating Features .............................................................. 76

5.2.1 Instrument Start Up .............................................................................. 76

5.3 General Options .................................................................................. 76

5.4 Defining Filter Slides (Infinite F200 PRO only) ................................. 78

5.4.1 About Filters ......................................................................................... 78

5.4.2 Filter Slide and Filter Orientation .......................................................... 78

5.4.3 Installing a Custom Filter ...................................................................... 80

5.4.4 Defining the Filters ................................................................................ 83

5.5 Optimizing Fluorescence Measurements ......................................... 87

5.5.1 Instrument Parameters ......................................................................... 87

5.5.2 Z-Optimization (FI Top measurements with the Infinite M200 PRO only)88

5.5.3 FI Ratio Mode ....................................................................................... 93

5.5.4 Optimal Read........................................................................................ 94

5.6 FP Measurements ............................................................................... 96

5.6.1 Fluorescence Polarization .................................................................... 96

5.6.2 Measurement Blank Range .................................................................. 96

5.6.3 G-Factor Settings ................................................................................. 97

5.6.4 Measurement with an Uncali br ate d G-Factor ....................................... 97

5.6.5 Measurement with a Simultaneous G-Factor Cali br ati on ..................... 98

5.6.6 Measurement with a Cali br ated G-Factor ............................................. 99

5.6.7 Measurement with a Manual G-Factor ............................................... 100

5.6.8 Calculation of Fluorescence Polarizat ion Para meters ........................ 101

5.7 Optimizing Absorbance Measurements ......................................... 102

5.7.1 Measurement Parameters .................................................................. 102

6 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 7

5.7.2 Absorbance Ratio Mode ..................................................................... 102

5.8 Multiple Reads per Well ................................................................... 103

5.8.1 MRW Type ......................................................................................... 103

5.8.2 MRW Size .......................................................................................... 104

5.8.3 MRW Border ...................................................................................... 104

5.8.4 Result Display in MS Excel ................................................................ 106

5.8.5 Miscellaneous Software Features of MRW ........................................ 106

5.9 Optimizing Luminescence Measurements ..................................... 107

5.9.1 Integration Time ................................................................................. 107

5.9.2 Light Level Attenuation ....................................................................... 107

5.10 Optim i z i ng AlphaScreen/AlphaLISA Measurements ..................... 108

5.10.1 Instrument Parameters ....................................................................... 108

5.11 Measurements with Injectors .......................................................... 110

5.11.1 Priming and Washing of the Infinite 200 PRO .................................... 110

5.11.2 Washing ............................................................................................. 114

5.11.3 Before Starting a Measurement with Injectors .................................... 118

5.11.4 Injector Modes (i-control) .................................................................... 118

5.12 Bla nking Measurements .................................................................. 123

5.13 Cuvette Measurements .................................................................... 124

5.13.1 Cuvette Strip ...................................................................................... 124

5.13.2 Cuvette Movements ........................................................................... 124

5.13.3 i-control Cuvette Examples ................................................................ 125

5.14 i-control Examples ........................................................................... 129

5.15 Fini shing a Measurement Session .................................................. 133

5.15.1 Disconnecting the Instrument ............................................................. 133

5.15.2 Instrument Shut Down ........................................................................ 133

6. Instrument Features ..................................................................................... 135

6.1 Introduction ...................................................................................... 135

6.2 Instrument Specifications ............................................................... 136

6.3 Fluorescence Intensity and Time Resolved Fluorescence (TRF). 138

6.3.1 Definition of the Detection Limit .......................................................... 139

6.3.2 Fluorescein (Fluorescence Intensity) Top .......................................... 139

6.3.3 Fluorescein (Fluorescence Intensity) Bottom ..................................... 139

6.3.4 Europium (Time Resolved Fluorescence) .......................................... 139

6.4 Fluorescence Polarization (FP) ....................................................... 140

6.5 Absorbance ...................................................................................... 141

6.6 Glow Type Luminescence ............................................................... 142

6.6.1 ATP Glow Luminescence ................................................................... 142

6.7 Flash Type Luminescence ............................................................... 143

6.8 Dual Color Luminescence (e.g. BRET) ........................................... 144

6.9 AlphaScreen/AlphaLISA .................................................................. 144

6.10 “On the Fly” Measurements ............................................................ 145

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 7

Page 8

6.11 Cuvette Features (Infinite M200 PRO only) ..................................... 146

6.11.1 Cuvette Specifications ........................................................................ 146

6.12 Injector Specifications ..................................................................... 147

6.12.1 Injector Reagent Compatibility ............................................................ 147

6.13 Measurement Accessories .............................................................. 148

6.13.1 Recommended Filters (Infinite F200 PRO only) ................................. 148

6.13.2 Recommended Types of Microplates ................................................. 149

6.13.3 Luminescence Detection .................................................................... 153

7. Quality Control .............................................................................................. 155

7.1 Periodic Quality Control Tests ........................................................ 155

7.2 Specifications - Passed/Failed Criteria ........................................... 156

7.3 Specifications - Test Instructions ................................................... 157

7.3.1 Fluorescence Top ............................................................................... 157

7.3.2 Fluorescence Bottom .......................................................................... 161

7.3.3 Time Resolved Fluorescence ............................................................. 165

7.3.4 Fluorescence Polarization (Infinite F200 PRO only) ........................... 167

7.3.5 Glow Luminescence ........................................................................... 169

7.3.6 Absorbance Accuracy ......................................................................... 170

7.3.7 Absorbance Wavelength Accuracy ..................................................... 170

7.3.8 Absorbance Baseline Flatness (Infinite M200 PRO)........................... 171

7.3.9 Absorbance Baseline F l atness (I nfi ni te F20 0 PR O) ........................... 172

7.3.10 Absorbance Cuvette (Infinite M200 PRO only) ................................... 173

7.3.11 AlphaScreen/AlphaLISA (Infinite F200 PRO only) .............................. 174

8. Cleaning and Maintenance ........................................................................... 177

8.1 Introduction....................................................................................... 177

8.2 Liquid Spills ...................................................................................... 178

8.3 Injector Cleaning and Maintenance ................................................ 178

8.3.1 Daily Maintenance: ............................................................................. 179

8.3.2 Weekly/Periodical Maintenance:......................................................... 179

8.4 Instrument Disinfection ................................................................... 180

8.4.1 Disinfection Solutio ns ......................................................................... 180

8.4.2 Disinfection Proced ur e ....................................................................... 181

8.4.3 Safety Certificate ................................................................................ 181

8.4.4 Disposal .............................................................................................. 182

8.4.5 Disposal of Packing Material .............................................................. 182

8.4.6 Disposal of Operating M at eri al ........................................................... 182

8.4.7 Disposal of the Instrument .................................................................. 183

9. Troubleshooting ............................................................................................ 185

Index ....................................................................................................................... 189

8 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 9

1. Safety

1. Safety

1.1 Instrument Safety

1. Always follow basic safety precautions when using this product to reduce

the risk of injury, fire, or electrical shock.

2. Read and understand all information in the Instructions for Use. Failure to

read, understand, and follow the instructions in this document may result

in damage to the product, injury to operating personnel or poor

instrument performance.

3. Observe all WARNING and CAUTION statements in this document.

4. Never open the housing of the Infinite 200 PRO while the instrument is

plugged into a power source.

5. Never force a microplate into the instrument.

6. The Infinite 200 PRO is intended as a general purpose laboratory

instrument for professional use. Observe proper laboratory safety

precautions, such as wearing protective clothing and using approved

laboratory safety procedures.

STOP

CAUTION

TECAN AUSTRIA GMBH HAS TAKEN GREAT CARE IN CREATING THE

STORED PLATE DEFINITION FILES THAT ARE RECEIVED WITH THE

INSTRUMENT SOFTWARE.

WE HAVE TAKEN EVERY PRECAUTION TO ENSURE THAT THE PLATE

HEIGHTS AND WELL DEPTHS ARE CORRECT ACCORDING TO THE DEFINED

PLATE TYPE. THIS PARAMETER IS USED TO DETERMINE THE MINIMUM

DISTANCE BETWEEN THE TOP OF THE PLATE AND THE CEILING OF THE

MEASUREMENT CHAMBER. ADDITIONALLY, TECAN AUSTR IA HAS ADD E D A

VERY SMALL SAFETY GAP TO PREVENT ANY DAMAGE OCCURRING TO THE

MEASUREMENT CHAMBER AS A RESULT OF SMALL CHANGES IN PLATE

HEIGHT. THIS DOES NOT AFFECT THE PERFORMANCE OF THE

INSTRUMENT.

USERS MUST ENSURE THAT THE PLATE DEFINITION FILE SELECTED

CORRESPONDS TO THE ACTUAL PLATE BEING USED.

USERS SHOULD ALSO TAKE CARE THAT NO POTENTIAL FLUORESCENT

OR LUMINESCENT CONTAMINATION LIES ON TOP OF THE PLATE. BE

AWARE THAT SOME PLATE SEALERS LEAVE BEHIND A STICKY RESIDUE

THAT MUST BE COMPLETELY REMOVED BEFORE STARTING

MEASUREMENTS.

CAUTION

STOP

BEFORE STARTING MEASUREMENTS, MAKE SURE THAT THE MICROPLATE

POSITION A1 IS INSERTED CORRECTLY. THE POSITION OF WELL A1 HAS

TO BE ON THE UPPER LEFT SIDE.

CAUTION

STOP

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 9

TO INSURE THE OPTIMAL WORKING OF TECAN INSTRUMENTS

WE RECOMMEND A SER VICE INTERVAL OF 6 MONTHS.

Page 10

1. Safety

It is assumed that the instrument operators, because of their vocational

experience, are familiar with the necessary safety precautions for handling

chemicals and biohazardous substances.

Adhere to the following laws and guidelines:

1. National industrial protection law

2. Accident prevention regulations

3. Safety data sheets of the reagent manufacturers

WARNING

DEPENDING ON THE AP PLICA TIONS, PARTS OF THE INFINITE 200

PRO MAY COME IN CONTACT WITH BIOHAZARDOUS/INFECTIOUS

MATERIAL. MAKE SURE THAT ONLY QUALIFIED PERSONNEL

OPERATE THE INSTRUMENT. IN CASE OF SERVICE OR WHEN

RELOCATING OR DISPOSING OF THE INSTRUMENT, ALWAYS

DISINFECT THE INSTRUMENT ACCORDING TO THE

INSTRUCTIONS GIVEN IN THIS MANUAL.

10 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 11

2. General Description

2. General Description

2.1 Instrument

The Tecan Infinite 200 PRO is a multifunctional microplate reader with injec tor

option. The Infinite 200 PRO provides high performance for the vast majority of

today’s microplate applications and research and is robotic compatible.

2.1.1 Intended Use

The Infinite 200 PRO has been designed as a general purpose laboratory

instrument for professional use, supporting common 6 to 384-well microplates

conforming to the ANSI/SBS standards (see 6.13.2 Recommended Types of

Microplates for further details).

Note

System Validation by Operating Au th o rity is required. The Infinite 200

PRO has been validated on a selected set of assays only. It is the

responsibility of any operating authority to ensure that the Infinite 200

PRO has been validated for every specific assay used on the

instrument.

WARNING

LIMITATION:

WHEN USING THE GAS MODULE OPTION TO MEASURE AND

CONTROL OXYGEN LEVELS, THE INSTRUMENT IS INTENDED FOR

RESEARCH USE ONLY - NOT FOR USE IN DIAGNOSTIC

WHEN OXYGEN LEVELS ARE NOT MEASURED OR CONTROLLED, THE

INSTRUMENT IS INTENDED FOR USE AS A GENERAL PURPOSE

LABORATORY INSTRUMENT FOR PROFESSIONAL USE.

PROCEDURES.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 11

Page 12

2. General Description

2.1.2 Multifunctionality

Depending on the mode of wavelength selection, the Infinite 200 PRO is

available in two different versions:

Infinite M200 PRO

Infinite F200 PRO

The following measurement techniques are supported by the Infinite M200 PRO:

Fluorescence Intensity (FI) Top

Fluorescence Intensity (FI) Bottom

Time-Resolved Fluorescence (TRF)

Fluorescence Resonance Energy Transfer (FRET)

Flash Fluorescence (with injectors)

Absorbance

Absorbance (with injectors)

Absorbance in cuvettes

Glow Luminescence

Flash Luminescence

Bioluminescence Resonance Energy Transfer (BRET)

A fully-equipped Infinite F200 PRO supports the following measurement

techniques:

Fluorescence Intensity (FI) Top

Fluorescence Intensity (FI) Bottom

Time-Resolved Fluorescence (TRF)

Fluorescence Resonance Energy Transfer (FRET)

Time-Resolved Fluorescence Resonance Energy Transfer (TR-FRET)

Flash Fluorescence (with injectors)

Fluorescence Polarization (FP)

Absorbance

Absorbance (with injectors)

Glow Luminescence

Flash Luminescence

Bioluminescence Resonance Energy Transfer (BRET)

AlphaScreen/AlphaLISA

Any common microplate ranging from 6 to 384 well formats conforming to the

ANSI/SBS standards (ANSI/SBS 1-2004; ANSI/SBS 2-2004, ANSI/SBS 3-2004

and ANSI/SBS 4-2004) may be measured with any of the above measurement

techniques. Switching between measurement techniques or plate formats is fully

automated via software. It is not necessary to manually reconfigure the optics in

order to switch between the reading modes supported by the Infinite 200 PRO.

Both instrument versions, the filter-based Infinite F200 PRO and the

monochromator-based Infinite M200 PRO, may be equipped with up to two

injectors.

12 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 13

2. General Description

2.1.3 Performance

The Infinite 200 PRO has been designed to meet the requirements of a generalpurpose laboratory instrum ent.

The Infinite 200 PRO provides a range of parameters for optimizing the

measurement results according to: the assay type (cell-based or homogeneous),

the microplate type, and the dispensed volumes per well and dispensing speeds.

2.1.4 User Friendliness

The Infinite M200 PRO offers unparalleled flexibility in wavelength selection for

fluorescence intensity and absorbance measurements. Via software any

wavelength can be easily adjus ted within the specified wavelength range. In

addition to single wavelength measurements, absorbance and fluorescence

spectra can be recorded. When running a spectrum there is no restriction due to

cut-off filters .

The Infinite F200 PRO offers high flexibility for the customization of fluorescence

and absorbance measurements; slides containing fluorescence and absorbance

interference filters are easily accessible to the user.

If the instructions given in this do cument are not correctly performed,

the instrument will either be dam aged or the procedures will not be

performed correctly and the safety of the instrument is not guaranteed.

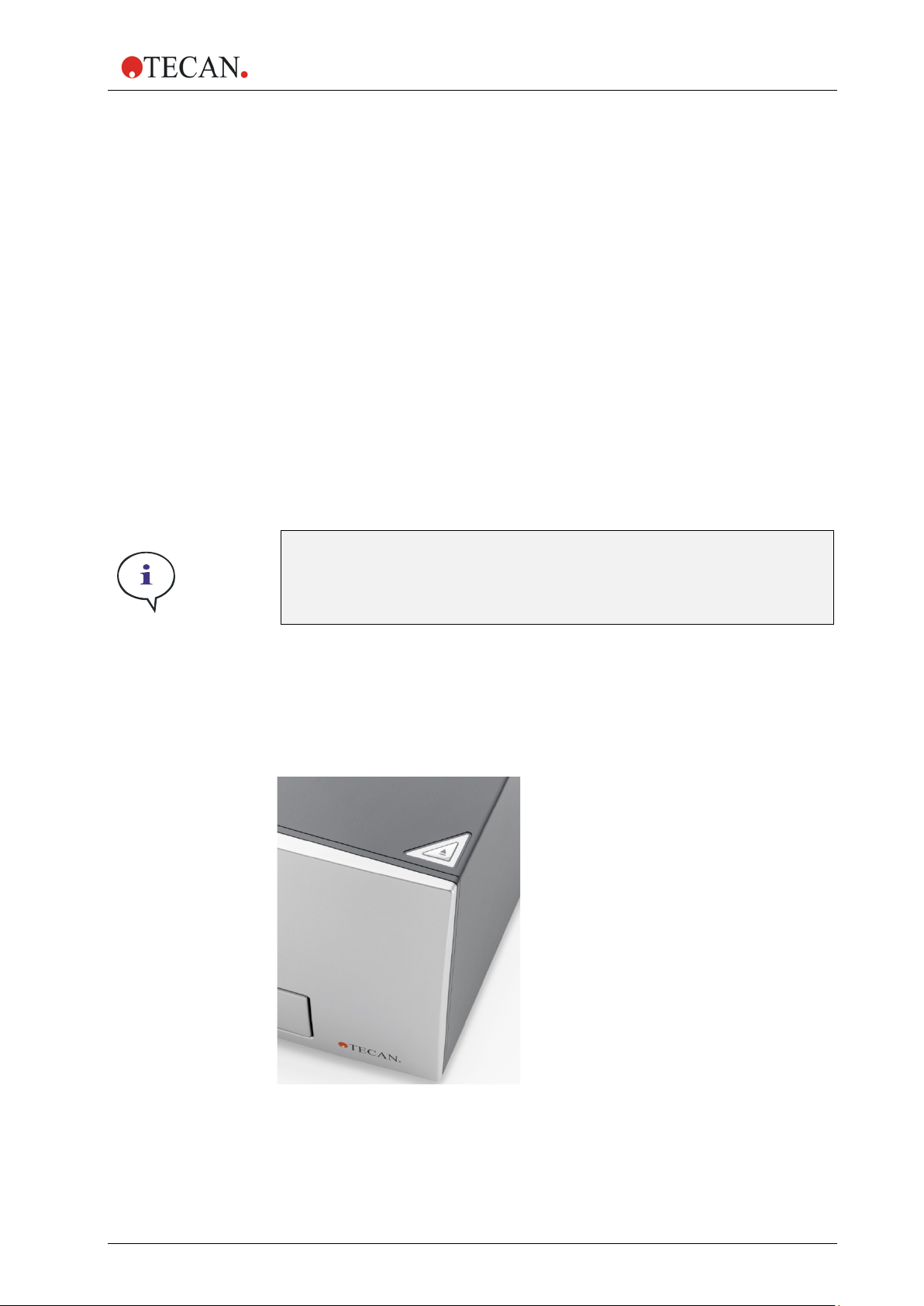

2.1.5 Onboard Control Button

The Infinite 200 PRO possesses an onboard control button to control plate

movements without the need to be connected to the software. Upon pressing the

‘Plate In/Out’ button, the current position of the plate carrier is automatically

recognized and the plate is moved into or out of the instrument.

Note

Figure 1: Onboard of the Infinite 200 PRO. The ‘Plate In/Out’ button is located in the front

right corner of the top cover.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 13

Page 14

2. General Description

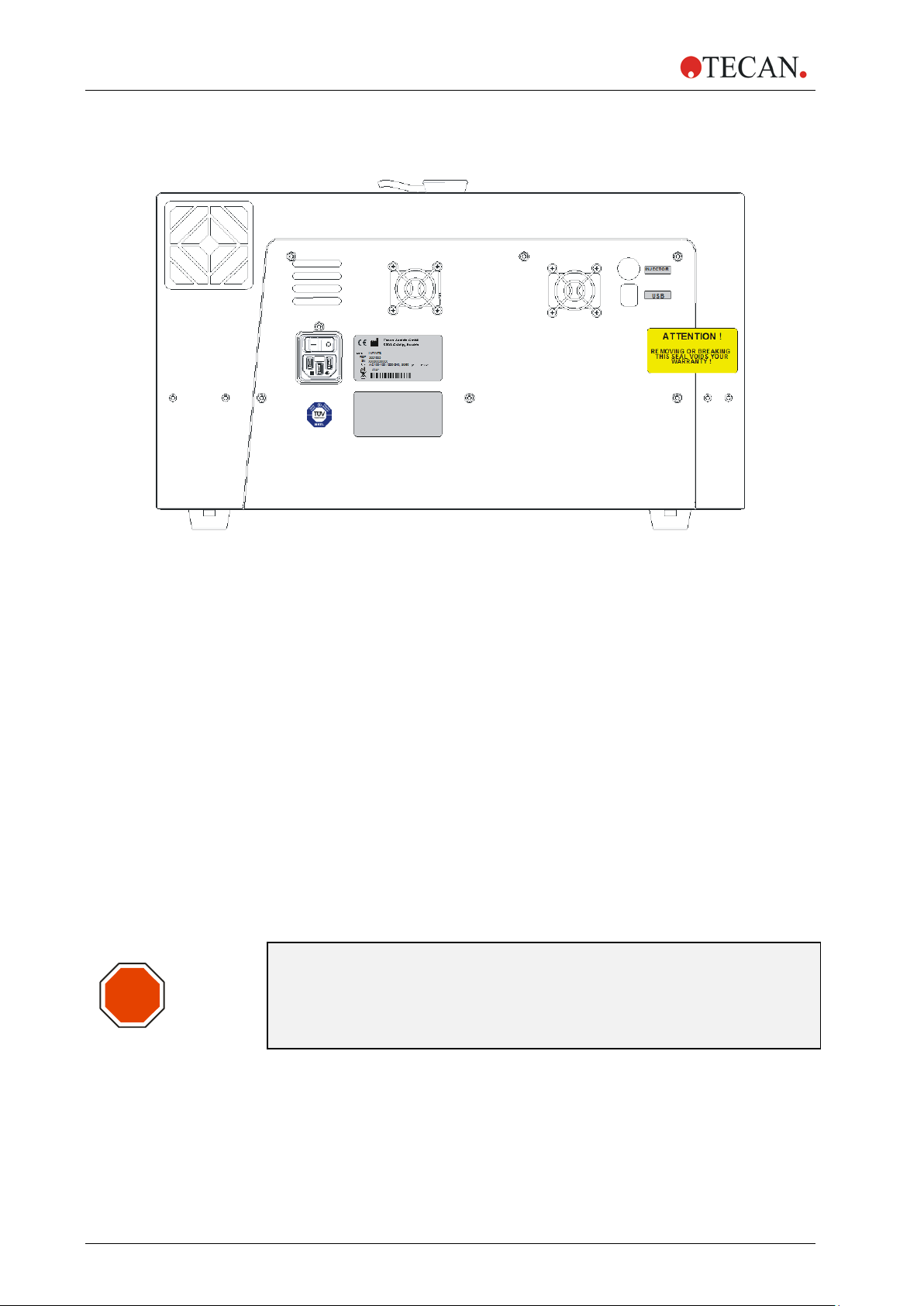

2.1.6 Rear View

Figure 2: Rear panel

STOP

1 Instrument Fan

2 Main Power Switch

3 Main Power Socket

4 Label – RoHS Orange Logo

5 Label – Technical Inspection Agency (TÜV)

6 Power Supply Fan

7 Name Plate

8 Label – Options/Configuration

9 Injector Connection

10 USB Connection

“ATTENTION

11 Warranty Label:

REMOVING OR BREAKING

THIS SEAL VOIDS

WARRANTY!”

CAUTION

ONLY TECAN AUTHORIZED SERVICE TECHNICIANS ARE ALLOWED

TO OPEN THE INSTRUMENT. REMOVING OR BREAKING THE

WARRANTY SEAL VOIDS THE WARRANTY.

14 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 15

2. General Description

2.2 Software

The Infinite 200 PRO is delivered with the i-control software, for operating the

instrument and includes an online-help file and a printed Instructions for Use. The

software is formatted as a self-extracting archive on CD-ROM. (For information

about the system requirements, refer to the Instructions for Use for the i-control

software. The Instructions for Use for the i-control can be found on the software

CD.)

For advanced data reduction, the Magellan software can be used to control the

Infinite 200 PRO. Magellan offers all functionality for compliance with the FDA

regulation 21 CFR part 11 for electronic records and signatures (for more

information, contact your local Tecan representative).

2.3 Injectors (Optional)

The Infinite 200 PRO can be optionally equipped with an injector module

consisting of one or two syringe pumps (XE-1000, Tecan Systems) located in a

separate box, which feed one or two injector needles.

The injector needles are designed to inject liquid in any SBS-conform microplate

well types, in which the well-size is equal to or larger than an SBS standard 384well plate.

Figure 3: Injector-box with bottle holders

2.3.1 Injector Measurement Modes

The injectors of the Inf in ite 200 PRO can be used with the following measurement

modes:

• Fluorescence Intensit y top and bottom

• Time Resolved Fluorescence

• Absorbance

• Flash Luminescence

• Glow Luminescence

• Dual Color Luminescence

As the measurement position is not the same as the injector position, a short time

delay (approx. < 0.5 s) between injection and reading occurs.

For details on how to set up a measurement with injectors, please refer to chapter

5.10.5 Injector.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 15

Page 16

2. General Description

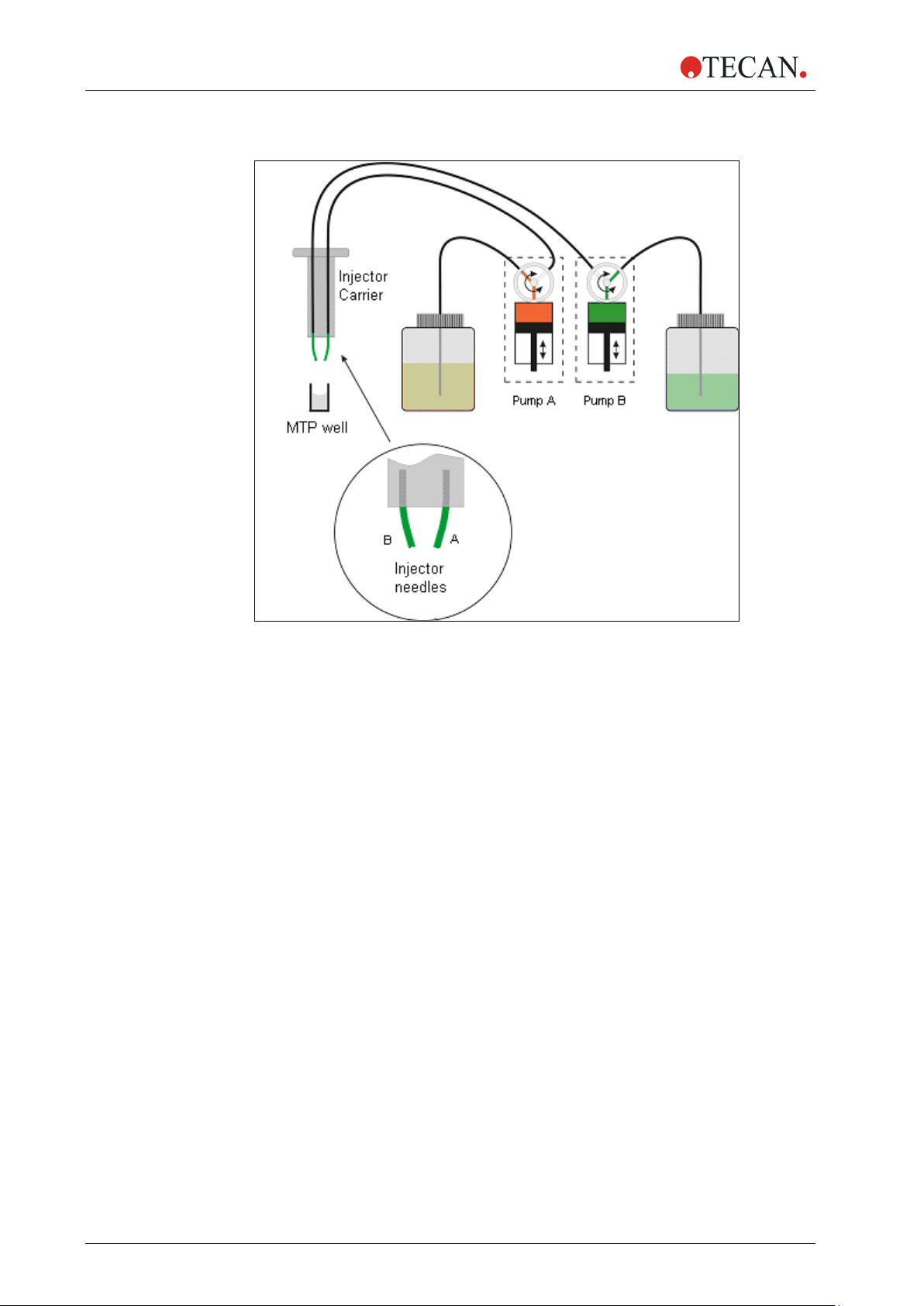

2.3.2 Injector Module Diagram

Figure 4: Schematic view of the injector module

2.3.3 Injector Pump Options

There are up to two pumps available for the Infinite 200 PRO (see Figure 4

above):

• Pump A feeds injector needle A

• Pump B feeds injector needle B

The Infinite 200 PRO can be equipped with one pump (pump A) or two pumps

(pumps A and B):

• One Injector Option (one pump): An Infinite 200 PRO equipped with one

pump allows injections in any SBS-conform microplate well types, in which

the well-size is equal to or larger than an SBS standard 384-well plate.

• Two Injector Option (two pumps): Some applications, such as flash

luminescence reactions or dual reporter gene assays require the injection of

two independent liquids into the same well; therefore, Tecan Austria offers a

two-injector option.

16 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 17

2. General Description

2.3.4 Storage Bottles and Bottle Holders

The injector box can accommodate up to two 125 ml bottles.

The standard bottle set supplied with the Injector option consists of:

• One 125 ml bottle and one 15 ml bottle for the “One Injector option”

(one pump) or

• One 125 ml bottles and two 15 ml bottles for the “Two Injectors option”

(two pumps).

The injector option includes up to two bottle holders that are designed for tubes of

different sizes and volumes. The bottles and tubes containing the fluids that are

to be injected can be attached securely to the holder using flexible PVC clasps.

The tubes from the injector syringe can be inserted into a carbon needle reaching

down to the bottom of the flask to ensure the optimal aspiration of even small

volumes of fluid.

Figure 5: Bottle holders

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 17

Page 18

2. General Description

2.3.5 Injector Carrier

The injector carrier, whic h i nclud es the injector needles, can be easily removed

from the instrument for priming or washing the system and for optimizing the

injection speed.

Figure 6: Injector carrier

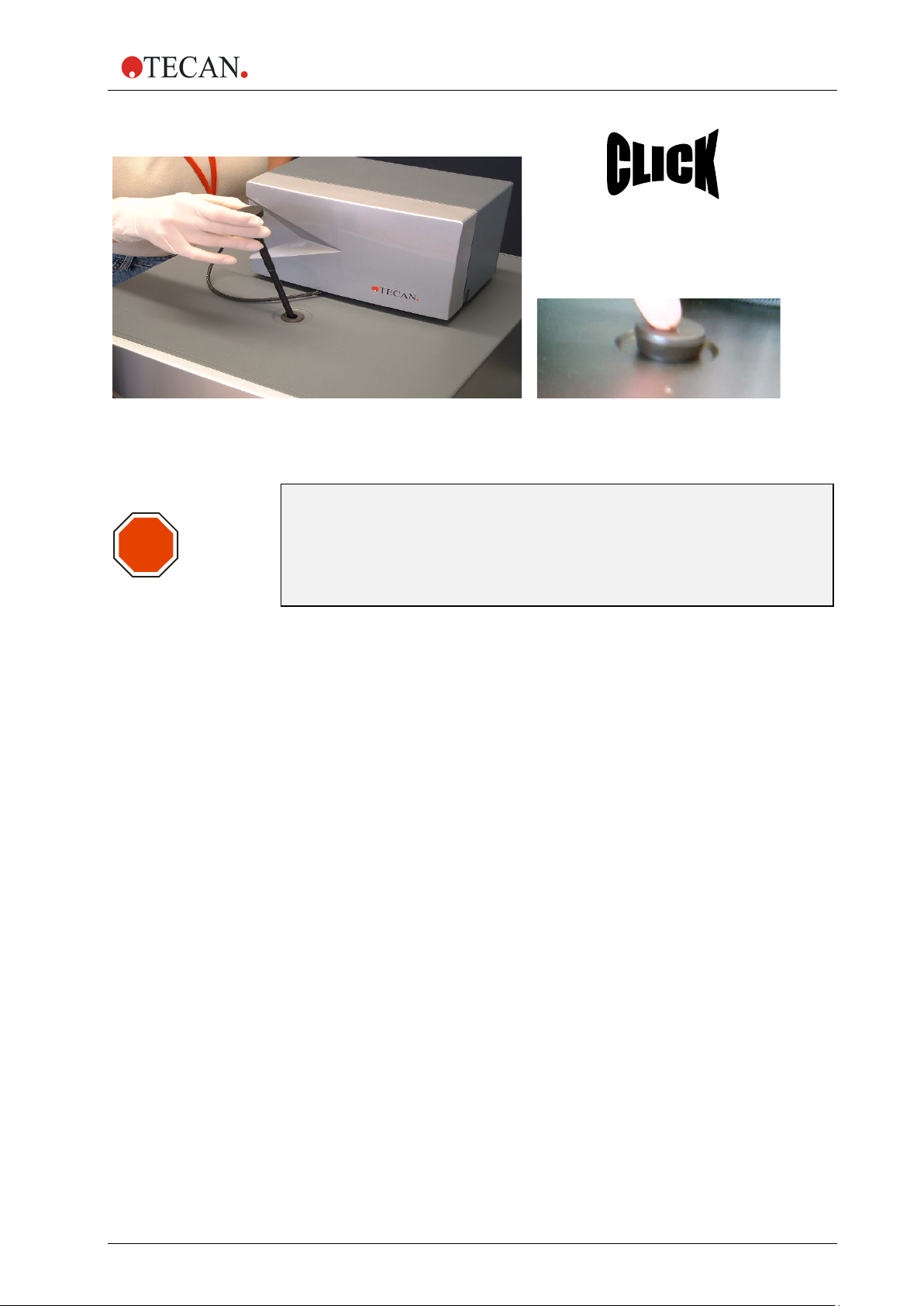

STOP

When using the injector during a measurement or for just dispensing a plate the

injector carrier must be inserted correctly into the instrument. Remove the injector

dummy and insert the carrier into the injector port. Press the carrier softly into the

injector port until you hear a clicking noise.

The instrument contains an injector sensor that checks that the position of the

injector carrier for the actions ‘inject’ and ‘dispense’ is correct.

If the injector carrier is not inserted correctly, the injector sensor does not

recognize the inserted carrier and neither dispensing nor injection is possible.

On the other hand, actions like washing and priming are enabled although the

injector carrier is inserted; therefore, always make sure that the injector carrier is

in the service position for washing and priming.

CAUTION

THE INJECTOR CARRIER MUST BE IN THE SERVICE POSITION

FOR WASHING UND PRIMING.

PRIME AND WASH MUST NOT BE PERFORMED

WHEN THE INJECTOR IS IN THE INSTRUMENT!

18 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 19

2. General Description

STOP

Figure 7: Inserting the injector carrier into the injector port

CAUTION

IF THE INJECTOR CARRIER IS NOT INSERTED CORRECTLY IN THE

INJECTOR PORT, THE INJECTOR SENSOR WILL NOT DETECT THE

INSERTED INJECTOR AND THEREFORE WASHING AND PRIMING

WILL BE ENABLED, WHICH CAN DAMAGE THE INSTRUMENT.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 19

Page 20

2. General Description

2.4 Measurement Techniques

The following sections provide an introduction to the Inf inite 200 PRO

measurement techniques when fully equipped. To keep this compact, a few

simplifications have been made. For details see the references.

2.4.1 Fluorescence

The Infinite 200 PRO offers the basic fluorescence measurement technique and

some even more sophisticated variants:

• Fluorescence Intensit y (FI) (or simply Fluorescence)

• Fluorescence Resonance Energy Transfer (FRET)

• Fluorescence Time Resolved (TRF)

• Fluorescence Polarization (FP)

FI may also be used to measure Fluorescence Resonance Energy Transfer

(FRET). For some microplate applications, FRET offers advantages over FI and

TRF, because they simplify assay preparation. These preferably apply for mix

and measure binding studies. Compared to FP, FRET requires both binding

partners to be label ed in a suitab le way. On the other hand, FRET may utilize

TRF labels for increased sensitivity, then being referenced as HTRF

(Homogeneous TRF).

TRF should not be confused with Fluorescence Lifetime measurements.

Fluorescent molecules emit light of specific wavelength when struck by light of

shorter wavelength (Stokes Shift). In particular, a single fluorescent molecule can

contribute one fluorescence photon (quantum of light). This is a part of the

energy, which has been absorbed before (electronic excitation), but could not be

released quickly enough into thermal energy.

The average time it takes between excitation and emission is called the

fluorescence lifetime. For many fluorescent molecular species, fluorescence

lifetime is on the order of nanoseconds (prompt fluorescence). After excitation,

fluorescence emission occurs with a certain probability (quantum yield), which

depends on the fluorescent species and its environmental conditions.

For a detailed treatise on fluorescence techniques and applications see:

Principles of Fluorescence Spectroscopy by Joseph R. Lakowicz, Plenum

Press.

A) Fluorescence Intensity (FI)

In many microplate applications, the intensity of fluorescence emission is

measured to determine the abundance of fluorescent labeled compounds. In

these assays, other factors having an influence on fluorescence emission need to

be controlled experimentally. Temperature, pH-value, dissolved oxygen, kind of

solvent etc. may significantly affect the fluorescence quantum yield and therefore

the measurement results.

20 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 21

2. General Description

B) Fluorescence Resonance Energy Transfer (FRET)

Some microplate applications utilize a sophisticated dual labeling strategy. The

FRET effect enables you to measure how many of two differently labeled

compounds are in close proximity. This makes it suitable for binding studies.

Basically, FRET is a fluorescence intensity measurement of one of the two

fluorescent labels (acceptor). However, the acceptor is not susceptible to the

excitation wavelength of the light source being used. Instead, the acceptor may

receive excitation energy from the other fluorescent label (donor), if both are

spatially close together. As a prerequisite, the excitation wavelength has to apply

to the donor. Secondly, the emission spectrum of the donor has to overlap the

excitation spectrum of the acceptor (resonance condition). Nevertheless, the

transfer of excitation energy from donor to the acceptor is radiation free.

Some FRET-based applications utilize suitable pairs from the fluorescent protein

family, like GFP/YFP (Green/Yellow Fluorescent Protein, (ref. Using GFP in

FRET-based applications by Brian A. Pollok and Roger Heim – trends in Cell

Biology [Vol.9] February 1999). Overview is given in the Review Article –

Application of Fluorescence R eso n ance Energy Transfer in the Clinical

Laboratory: Routine and Research by J. Szöllösi, et al. in Cytometry 34, page

159-179 (1998).

Other FRET-based applications take advantage from using TRF labels as the

donor. For example see, High Throughput Screening – Marcel Dekker Inc.

1997, New York, Basel, Hong Kong, section 19 Homogeneous, Time-Resolved

Fluorescence Method for Drug Discovery by Alfred J. Kolb, et al.

C) Time Resolved Fluorescence (TRF)

TRF applies to a class of fluorescent labels (chelates of lanthanides like

Europium, [ref. Europium and Samarium in Time-Resolved

Fluoroimmunoassays by T. Stâhlberg, et. al. - American Laboratory, December

1993 page 15]), some of them having fluorescence lifetimes in excess of 100

microseconds. The I nf inite 200 PRO uses a Flash lamp light source with flash

duration much shorter than fluorescence lifetime of these species. This offers the

opportunity to measure fluorescence emission at some time, when stray light and

prompt fluorescence have already vanished (Lag Time). Thus, background can

be significantly lowered while sensitivity is improved.

The benefits of TRF consequently apply to assays using multiple labels w ith

different fluorescence lifetimes.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 21

Page 22

2. General Description

D) Fluorescence Polarization (FP)

Fluorescence Polarization (FP) measures rotational mobility of a fluorescent

labeled compound. FP is therefore particular suitable for binding studies, because

the tumbling motion of small molecules may be dramatically slowed down after

binding to a larger molecule.

Fluorescence polarization measurements are based on the detection of the

depolarization of fluorescence emission after excitation of a fluorescent molecule

by polarized light. A fluorescent molecule can be visualized as an antenna. Such

a molecule can absorb energy if and only if the polarization of the excitation light

matches the orientation of the antenna. During the fluorescence lifetime, i.e. the

time a molecule remains in the excited state, small molecules diffuse rotationally

relatively rapidly. Hence they re-orient before they emit their photon. As a result

and due to the random character of diffusion, a linearly polarized excitation light

will be translated into a less polarized emission light. Thus, a high resultant mP

value denotes the slow rotation of the labeled molecule, indicating that binding

probably did occur. A resultant low mP value denotes a fast rotation of a

molecule, indicating that binding probably did not occur.

The FP measurement result is calculated from two successive fluorescence

intensity measurements. They differ in the mutual orientation of polarizing filters,

one being placed behind the excitation filter, another ahead of the emission filter.

By processing both data sets, it is possible to measure the extent of how much

the fluorescent label has changed orientation in the time span between excitation

and emission.

2.4.2 Absorbance

Absorbance is a measure for the attenuation of monochromatic light when

transmitted through a sample. Absorbance is defined as:

A = LOG

Where I

not attenuated by sample. The unit is assigned with Optical Density (OD)

Thus, 2.0 OD means 10

1.0 OD means 10

0.1 OD means 10

If the sample contains only one species absorbing in that narrow band of

wavelengths, the background corrected absorbance (A) is proportional to the

corresponding concentration of that species (Lambert-Beer's Law).

(I0 / I

10

is the intensity of the light being transmitted, I 0 the light intensity

SAMPLE

),

SAMPLE

2.0

or 100-fold attenuation (1% transmission),

1.0

or 10-fold attenuation (10% transmission), and

0.1

or 1.26-fold attenuation (79.4% transmission).

22 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 23

2. General Description

2.4.3 Luminescence

Glow Type Chemi- or Bioluminescence

The Infinite 200 PRO provides measurement of glow type chemi- or

bioluminescence. Glow type means that the luminescence assay glows much

longer than a minute. Luminescence substrates are available, which provide

stable enough light output over hours.

As an example, luminescence can be measured to determine the activity of an

enzyme labeled compound (-peroxidase, -phosphatase). Light emission results

from a luminescence substrate being decomposed by the enzyme. Under excess

of substrate the luminescence signal can be assumed to be proportional to the

abundance of the enzyme labeled com poun d. As with en z yme-based assays,

control of environmental conditions is rather critical (temperature, pH-value).

For practical aspects of luminescence assays see the follo wing ex ample:

Bioluminescence Methods and Protocols, ed. R.A. LaRossa, Methods in

Molecular Biology 102, Humana Press, 1998.

Bioluminescence Resonance Energy Transfer (BRET)

BRET is an advanced, non-destructive, cell-based assay technology that is

perfectly suited for proteomics applications, including receptor research and the

mapping of signal transduction pathways. BRET is based on energy transfer

between fusion proteins containing Renilla luciferase (Rluc) and a mutant of the

Green Fluorescent Protein (GFP). The BRET

of p.a. DeepBlueC, a coelenterazine derivative that maximizes spectral resolution

for superior sensitivity. This homogeneous assay technology provides a simple,

robust and versatile platform with applications in basic academic as well as

applied research.

signal is generated by the oxidation

Flash Luminescence

In flash type luminescence assays, the measurement is only done during the

dispensing of the activating reagent or after a short delay time (for Flash

luminescence measurements with the Infinite 200 PRO, see also 2.3.1 Injector

Measurement).

Over the past years luminescence substrates have been improved towards

providing more stable signals. In so-cal led glo w t ype luminescence assays the

luminescence signal is spread over a wide time scale (e.g. a half-life of 30 min.).

2.4.4 AlphaScreen/AlphaLISA

The Infinite F200 PRO is able to measure Amplified Luminescent Proximity

Homogeneous Assays (AlphaScreen and AlphaLISA). Due to their

nonradioactive, homogenous and sensitive nature, these bead-based

technologies are perfectly suited for the study of biomolecular interactions.

Upon illumination at 680 nm, the photosensitive molecules contained in the donor

beads produce high levels of oxyradicals. These oxyradicals are able to travel to

the acceptor beads and trigger a cascade of reactions that ultimately lead to the

generation of a strong chemiluminescent signal.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 23

Page 24

2. General Description

2.5 Optical System

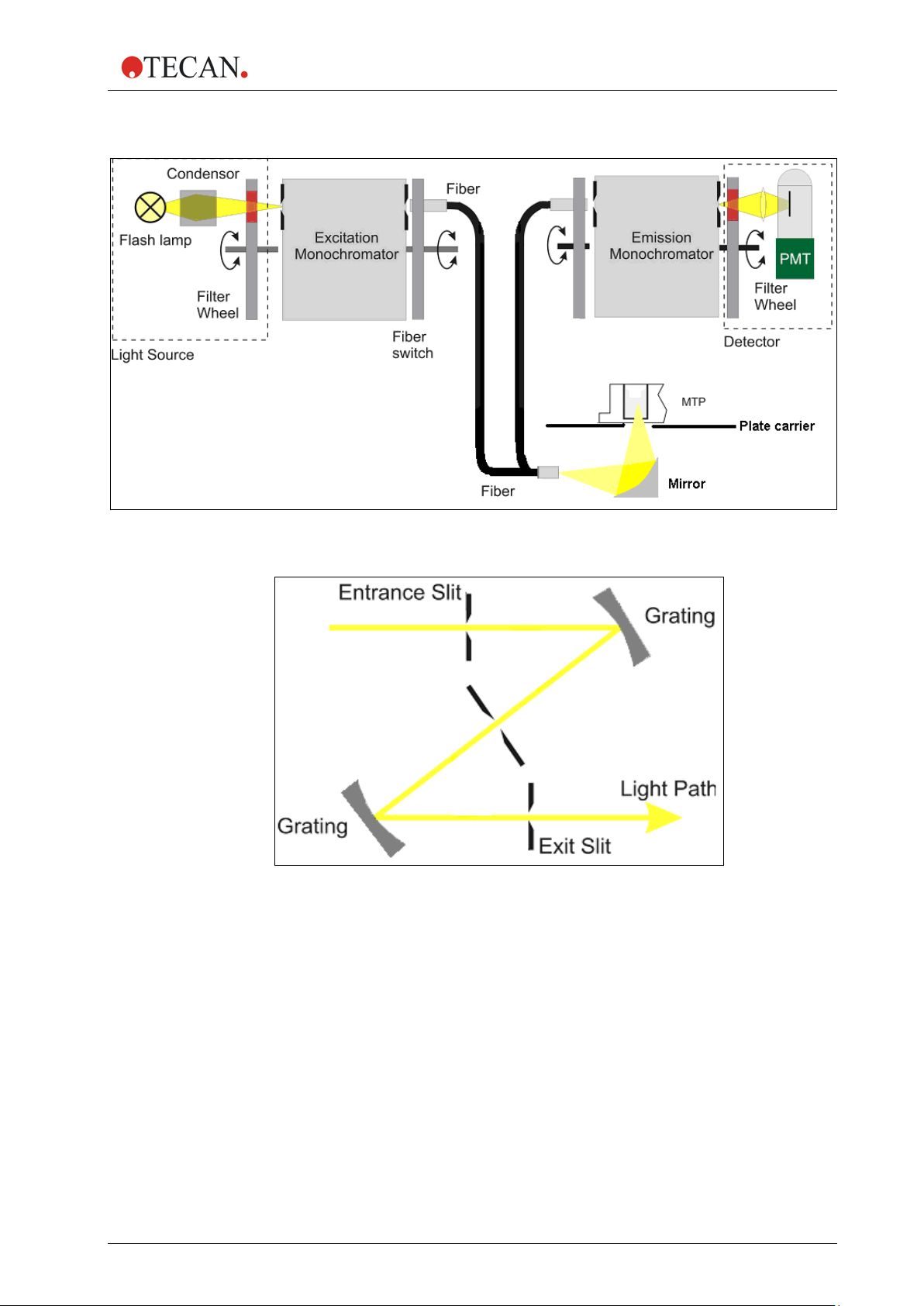

2.5.1 Fluorescence Intensity System (Infinite M200 PRO)

The optical system of the fluorescence top and bottom system of the Infinite

M200 PRO is sketched below.

The system consists of:

1. Light source system

2. Excitation double monochromator

3. Fluorescence top optics

4. Emission double monochromator

5. and fluorescence detection

The solid arrows indicate the light path of the excitation light; the dashed arrows

indicate the emission light path.

To simplify the system, the ‘Flash Monitor’ (see section F lash Mon itor , pag e 27) is

not shown. Each monochromator unit, (2) and (4), is built of two gratings and a

schematic view is displayed in more detail in the figures below.

Fluorescence Intensity Top Diagram

Figure 8: Optical System Fluorescence Top

24 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 25

2. General Description

Fluorescence Intensity Bottom Diagram

Figure 9: Optical System Fluorescence Bottom

Figure 10: Detailed view of excitation and emission double monochromator unit

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 25

Page 26

2. General Description

Fluorescence Intensity Light Source System

Fluorescence applications usually require a specific range of excitation

wavelengths. Additionally, pulsed excitation light may be required (Time Resolved

Fluorescence [TRF]).

The Infinite M200 PRO light source system is built from the following

components:

• Flash Lamp

• Condensing Optics

• Filter Wheel

• Excitation Double Monochromator

• Fiber Optic Bundle

• Flash lamp Monitor

Flash Lamp

The Infinite M200 PRO utilizes a high energy Xenon arc discharge lamp (flash

lamp). The flash sparks across a small gap between two electrodes. The lamp

bulb contains a high pressure Xenon atmosphere. The flash decays within a few

microseconds. The flash frequency is 40 Hz.

The Infinite M200 PRO uses the flash lamp for fluorescence and for absorbance

measurements, although pulsed illumination is a must only for TRF. The main

benefits of this singular kind of lamp are:

1. High intensity from the deep UV to the near IR

2. Very long lifetime

3. Many applications - only one kind of lamp

4. No warm up time required

Condenser

Condenser type optics from fused silica focus the flash light onto the entrance slit

of the excitation monochromator.

Filter Wheel

A filter wheel is located between the condenser and the excitation

monochromator. The filter wheel contains wavelength specific optical filters,

which are necessary to block undesired diffraction orders produced by the optical

gratings. The filters are set automatically.

Excitation Double Monochromator

In both fluorescence and absorbance applications, the Excitation Double

Monochromator is used to select any desired wavelengths from the flash lamp

spectrum in the range from 230 nm to 600 nm (standard version) or

230 to 850 nm (spectrally enhanced version) for fluorescence intensity and from

230 nm to 1000 nm for absorbance app lica tio ns .

Fluorescence emission spectra in many cases do not depend on the exact

excitation wavelength. For a maximum total fluorescence signal; therefore, rather

broad excitation bandwidth may be used. The bandwidth of the Infinite M200

PRO monochromator system is < 9 nm for wavelengths > 315 nm and < 5 nm for

wavelengths ≤ 315 nm.

For a more detailed description of how a monochromator works, see below.

26 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 27

2. General Description

Description of how a Monochromator Works

A monochromator is an optical instrument that enables any wavelength to be

selected from a defined optical spectrum. Its method of operation can be

compared to a tunable optical filter, whic h allo ws bot h the wav ele ngt h and

bandwidth to be adjusted.

A monochromator consists of an entrance slit, a dispersive element and an exit

slit. The dispersive element diffracts the light into the optical spectrum and

projects it onto the exit slit. A dispersive element can be realized by using a glass

prism or an optical grating. Modern monochromators such as those used in the

Infinite M200 PRO are designed with optical gratings.

Rotating the optical grating around its vertical axis moves the spectrum across

the exit slit and only a small part of the spectrum (band pass) passes through the

exit slit. This means that when the monochromator entrance slit is illuminated with

white light, only light with a specific wavelength (monochromatic light) passes

through the exit slit. The wavelength of this light is set by the rotation angle of the

optical grating. The bandwidth is set by the width of the exit slit. The bandwidth is

defined as full width at half maximum (FWHM).

Monochromators block undesired wavelengths, typically amounting to 10

means when the monochromator is set for light with a wavelength of 500 nm and

the detector detects a signal of 10,000 counts, light with different wavelengths

creates a signal of only 10 counts. For applications in the fluorescence range, this

blocking is often not sufficient, since the fluorescence light to be detected is

usually much weaker than the excitation light. To achieve a higher level of

blocking, two monochromators are connected in series, i.e. the exit slit of the first

monochromator acts as the entrance slit of the second monochromator

simultaneously. This is known as a double monochromator. In this case, the

blocking count reaches a factor of 10

filters.

In the Infinite M200 PRO, a double monochromator is installed on both the

excitation and detection side. This opens the opportunity for easy selection of

excitation and fluorescence wavelengths with no limitations by cut off filters.

3

. This

6

, a value typically achieved by Interference

Fiber Optic Bundle

Light from the exit slit of the Excitation Monochromator is coupled into a fiber

optic bundle, which guides the light either to the top measuring optics or the

bottom measuring optics. The lower end of each fiber bundle acts as a color

specific light source. In both cases, a small portion of the light is always guided to

the flash lamp monitor diode.

Flash Monitor

The light energy of single flashes may fluctuate slightly. To take these variations

into account, a silicon photodiode monitors the energy of every single flash.

Fluorescence and Absorbance measurement results are compensated

correspondingly.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 27

Page 28

2. General Description

Fluorescence Top/Bottom Optics

Flash light enters the optical system and is focused by the condenser ont o the

entrance slit of the Excitation Monochromator. The wavelength of the excitation

light is selected within the monochromator. After passing the monochromator, the

excitation light is coupled into a fiber bundle, which guides the light to the top or

bottom measuring head. The light is then focused into the sample by the

top/bottom lens system.

The fluorescence light is collected by the top/bottom lens system again, coupled

into the fluorescence fiber bundles and guided to the detection system.

The Fluorescence Measuring Optics Top is built from the following components:

• Fluorescence Intensity Lens System Top

• Fluorescence Fiber Bundle

• The bottom optics consists of the following components:

• Fluorescence Bottom Mirror

• Fluorescence Fiber Bundle

Fluorescence Intensity Lens System Top

The exit side of the bundle acts as a color specific light source. The lens system

at the end of the excitation top fiber is designed to focus the excitation light into

the sample, and also collect the fluorescence light and focus it back onto the

fluorescence fiber bundle.

The objective lenses are made from fused silica. This material provides high UV

transmission and is virtually void of auto-fluorescence.

Excitation Spot Size

The size of the fiber bundle cross section determines the diameter of the beam

waist (spot size) in the microplate well. The spot diameter for the M-series is

about 3 mm for the top optics and 2 mm (standard) or 4 mm (enhanced) for the

bottom optics.

Fluorescence Fiber Bundle Top and Bottom

The fiber bundle plugged into the top/bottom measuring head contains a

homogeneous mixture of both excitation and emission fibers. The emission fibers

guide the fluorescence light emission monochromator head where a lens system

focus the light onto the entrance slit of the Emission Monochromator.

Fluorescence Bottom Mirror

The exit side of the bundle acts as a color specific light source. The mirror at the

end of the excitation bottom fiber is designed to focus the excitation light into the

sample and also collects the fluorescence light and focuses it back onto the

fluorescence fiber bundle.

Z-Positioning (Fluorescence Top on Infinite M200 PRO only)

The height of the objective above the sample can be adjusted using the Zposition function. As excitation light is reflected by the sample fluid, z-adjustment

helps to maximize the signal-to-noise ratio. For further details about z-positioning

see chapter 5.5.2 Z-Optimization (FI Top measurements with the Infinite M200

PRO only).

28 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 29

2. General Description

Fluorescence Intensity Detection

The fluorescence detection system is used for both measuring modes:

fluorescence from above (top) and below the microplate wells (bottom).

The fluorescence light is focused onto the entrance slit of the Emission

Monochromator. After passing the monochromator the light is focused onto the

detector (PMT). A filter wheel is located between the monochromator and the

PMT.

The Fluorescence Detection system is built from the following components:

• Emission Double Monochromator

• Filter Wheel PMT

• PMT Detector

Emission Double Monochromator

Similar to the Excitation Double Monochromator, the Emission Double

Monochromator is used to select any wavelength of the fluorescence signal.

It acts like an adjustable filter to discriminate scatter of excitation light and

nonspecific fluorescence. The wavelength range is selectable from 330 – 600 nm

in the standard instrument and from 280 – 850 nm in the spectrally enhanced

instrument. The bandwidth is 20 nm.

Filter Wheel PMT

The filter wheel contains wavelength specific optical filters, which are necessary

to block undesired diffraction orders produced by the optical gratings. The filters

are set automatically.

PMT Detector

A photo-multiplier tube (PMT) is used for the detection of such low light levels

associated with fluorescence. The Infini te M20 0 PRO is available in two versions:

The PMT of the standard version is sensitive up to 600 nm. The PMT of the

spectrally enhanced version of the Infinite M200 PRO is sensitive up to the near

infrared (NIR) while still having low dark current. Electronic circuitry uses analog

to digital conversion of PMT output current. Adjusting the PMT gain enables

measurement of a wide range of concentrations in lower or higher concentration

domains. For details, see Section 5.5.1 Instrument Parameters.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 29

Page 30

2. General Description

2.5.2 Fluorescence Intensity System (Infinite F200 PRO)

The following parts constitute the fluorescence intensity system of the Infinite

F200 PRO instrument:

1. Light Source

2. Fluorescence Optics

3. Fluorescence Detection System

The fluorescence top system is shown in Figure 11, the bottom system in Figure

12. The solid arrows indicate the excitation light path; the dashed arrows

determine the emission light path.

Fluorescence Intensity Top Diagram

Figure 11: Fluorescence intensity top system of the Infinite F200 PRO

30 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 31

2. General Description

Fluorescence Intensity Bottom Diagram

Figure 12: Fluorescence intensity bottom system of the Infinite F200 PRO

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 31

Page 32

2. General Description

Light Source System

Flash light enters the optical system by being focused through a slit containing

the filter. This opening acts as a color specific light source.

The Infinite F200 PRO light source system is built from the following components:

• Flash lamp

• Condensing Optics

• Excitation Filters

• Flash lamp Monitor

Flash lamp

The Infinite F200 PRO utilizes a high energy Xenon arc discharge lamp (Flash

lamp). The flash sparks across a small gap between two electrodes. The lamp

bulb contains a high pressure Xenon atmosphere. The flash decays within some

microseconds.

The flash frequency is 40 Hz.

The Infinite F200 PRO uses the Flash lamp for fluorescence and for absorbance

measurements, although pulsed illumination is a must only for TRF. The main

benefits of this singular kind of lamp are:

1. High intensity from the deep UV to the near IR

2. Very long lifetime

3. Many applications - only one kind of lamp

4. No warm up time required

Condenser

Condenser type optics focus the light through the entrance slit to the fluorescence

optical system.

Excitation Filter

Wavelength-specific bandpass filters serve to select the wavelength range of

interest from the whole spectrum of excitation light coming from the flash lamp.

Filters are installed in removable slides and are user-exchangeable.

Flash Monitor

The light energy of single flashes may fluctuate slightly. To take these variations

into account, a reference silicon photodiode monitors the energy of every single

flash. Fluorescence measurement results are compensated correspondingly.

Fluorescence Optics Top

Flash light enters the optical system by being focused through a slit and then

through the excitation filter. Depending on the measured wavelength either a

semi-transparent (50%) or a special dichroic mirror reflects the light towards the

microplate. The objective lens system focuses the light into the sample.

Fluorescence Emission is measured from above the well. Fluorescence light is

collected by the objective, directed through the appropriate mirror, and focused

through the exit slit for detection.

Objective Lens System

The objective is designed to collect the fluorescent light emitted from a well and

focus it through the exit slit to the detection system.

The objective lenses are made from fused silica. This material provides high UV

transmission and is virtually void of auto-fluorescence.

32 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 33

2. General Description

Mirror Selection - Fluorescence Top (Infinite F200 PRO only)

The Infinite F200 PRO is equipped with a mirror carrier, which houses a 50%

mirror as well as a 510 dichroic mirror or, alternatively, a specific dichroic for

AlphaScreen/AlphaLISA measurements (see 2.5.8 AlphaScreen/AlphaLISA

System (Infinite F200 PRO only)).

The advantage of the 50% mirror is that is works with any pair of excitation and

emission wavelengths. However, 50% of excitation light that is directed into the

sample and, subsequently, 50% of the emission light coming out of the sample

are lost.

Dichroic mirrors are wavelength dependent and are designed to reflect a certain

range of wavelengths almost entirely. Dichroic mirrors exhibit a high reflection of

excitation light and a high transmission of emission light and usually give a better

signal-to-noise ratio compared to 50% mirrors.

Available for plate formats up to 384 wells.

Note:

A dichroic mirror needs to match the selected fluorescence excitation

and emission wavelengths.

Mirror Type Reflection (Excitation) Transmission (Emission)

50% mirror

510 dichroic (e.g. fluorescein)

650 dichroic (AlphaScreen/Al p haLI SA)

The dichroic mirror used for AlphaScreen/AlphaLISA cannot be used

for standard fluorescence measurements. It is selected automatically

According to the wavelengths defined in the measurement script, the dichroic

mirror is selected automatically if both excitation and emission wavelength match

the specified range of that mirror. If either the excitation or the emission

wavelength does not match the ranges of the dichroic mirror, the 50% mirror is

chosen automatically for the measurement.

230 – 900 nm 230 – 900 nm

320 – 500 nm 520 – 780 nm

665 – 700 nm 540 – 635 nm

Note:

for Alpha measurements.

Fluorescence Optics Bottom

Flash light enters the optical system by being focused through a slit and then

through the excitation filter. The excitation bottom fiber guides the light to the

bottom optics probe, which consists of an elliptical mirror which focuses the light

through the bottom of the microplate into the well. The emitted light is focused

onto the excitation bottom fiber, which guides the light over a mirror through the

emission filter to the fluorescence detection system.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 33

Page 34

2. General Description

Fluorescence Detection

Emission Filter

Wavelength-specific bandpass filters serve to discriminate unspecific

fluorescence signals from the sample-specific emission light of interest. Filters

are installed in removable slides and are user-exchangeable.

Fluorescence filters may be used interchangeably as excitation or emission

filters, depending on the measurement requirements.

The spot diameter for the Infinite F200 is about 2 mm (Standard Bottom Reading)

or 4 mm (Enhanced Bottom Reading), respectively.

PMT Detector

A photomultiplier tube (PMT) is used for the detection of such low light levels as

involved with fluorescence. For details, see section Fluorescence Intensity

Detection, page 29.

2.5.3 Fluorescence Polarization System (Infinite F200 PRO)

For technical details please refer to chapter 2.5.2 Fluorescence Intensity System

(Infinite F200 PRO).

An Infinite F200 PRO configured for Fluorescence Polarization (FP)

measurements is delivered with a standard FP filter slide. The filter slide is

equipped with filters and polarizers for excitation and emission, at 485 and

535 nm respectively, and can be applied for measuring, for example, fluoresceinbased FP applications.

For details on how to mount polarizers and FP filters please refer to

chapter 5.4 Defining Filter Slides (Infinite F200 PRO only).

34 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 35

2. General Description

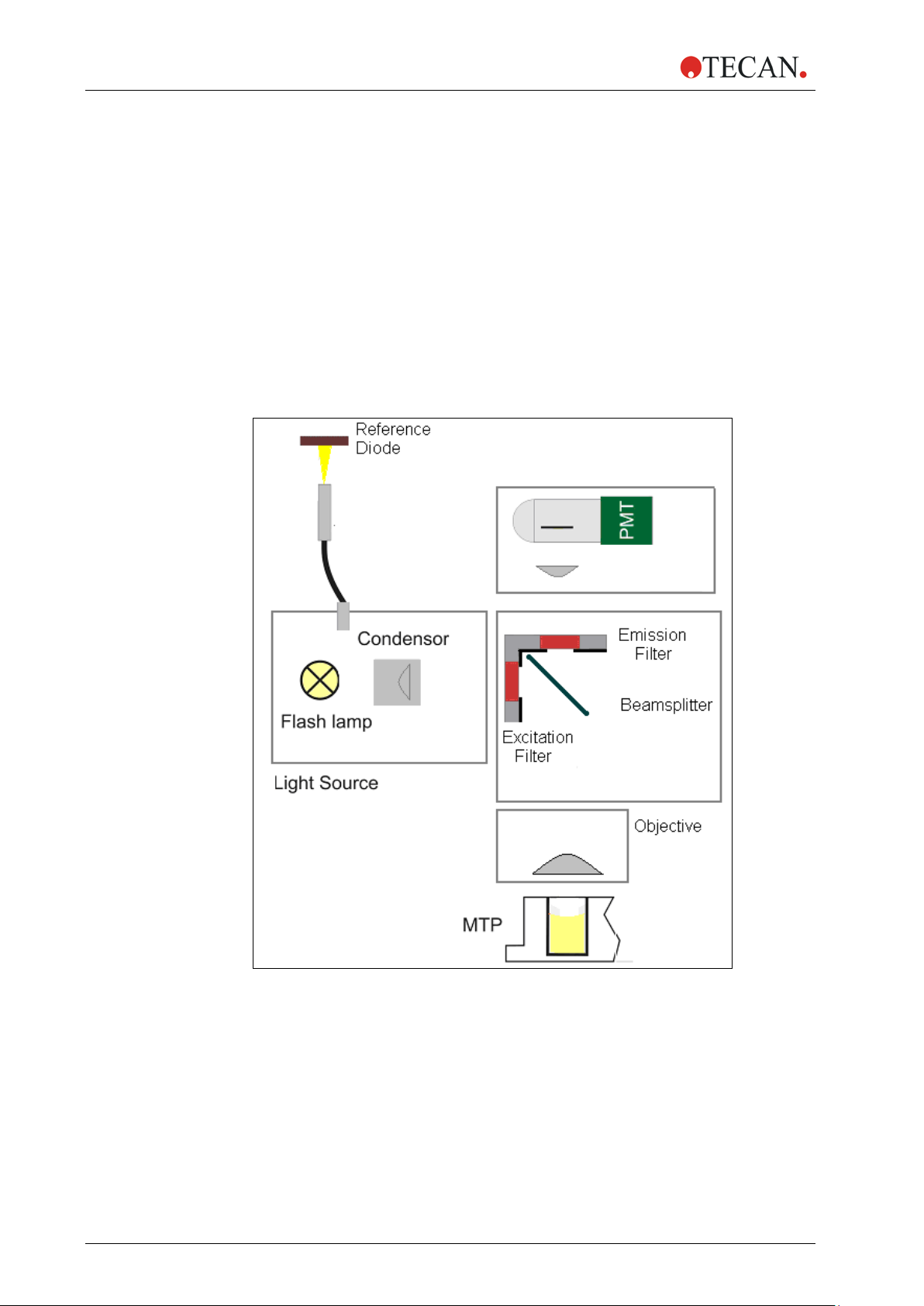

2.5.4 Absorbance Syste m (Infinite F200 PRO)

For absorbance measurements a similar optical path is used as for fluorescence

excitation. The absorbance measurement module is located underneath the plate

carrier. It measures the light being transmitted through the sample. Before

measurement of the microplate, a reference measurement is performed with the

plate carrier moved out of the light beam (see also 2.4.2 Absorbance).

The absorbance system is shown in Figure 13 and consists of the following

components:

• Light Source

• Absorbance Optics

• Absorbance Detection Unit

Figure 13: Absorbance System of the Infinite F200 PRO

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 35

Page 36

2. General Description

Light Source System

The absorbance light source system is similar to the fluorescence top system.

Band Pass Filter

In absorbance applications, optical filters of band pass type are necessary to

select the useful wavelengths from the flash lamp spectrum. Filters are mounted

in removable slides.

Absorbance Filter

Absorbance measurements require relatively narrow band pass filters (2 – 10 nm)

with steep slopes.

Absorbance Optics

The mirror carriage has an absorbance position. A pair of small slits forms a

narrow and more collimated light beam when compared with fluorescence

excitation.

Light focused through the dispensed liquid is slightly refracted at the interfaces

between air, liquid, and plate bottom. To accomplish a reliable measurement in

the presence of the meniscus, a focusing lens recollects the rays of light, which

might have been refracted too far away from the optical axis.

The spot size of the absorbance light beam is 0.5 mm (diameter).

Absorbance Detection

A silicon photodiode is used for the measurement of the light beam. It is sensitive

to a wide range of wavelengths. The photodiode is well suited for the light levels

being encountered with absorbance measurements up to 4 OD.

Note

For absorbance measurement of nucleic acids

in small volumes (2 µl) use Tecan’s NanoQuant PlateTM.

With this device it is possible to measure

16 different samples in one measurement.

For further information please contact

your local Tecan distributor or visit: www.tecan.com.

36 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 37

2. General Description

2.5.5 Absorbance System (Infinite M200 PRO)

For absorbance measurements, a similar optical path is used as for fluorescence

excitation.

The absorbance system consists of:

1. light source

2. excitation monochromator

3. absorbance MTP optics

4. absorbance MTP measurement module

Condenser type optics focus the light through the excitation filter and then

through the entrance slit to the excitation monochromator. A fiber bundle then

guides the light from the excitation monochromator to the absorbance MTP

optics, which focuses the light into the wells. The absorbance MTP measurement

module is located underneath the plate carrier. These modules measure the light

being transmitted through the sample.

Before measurement of the microplate (MTP), a reference measurement is

performed with the plate carrier moved out of the light beam.

Figure 14: Optical System Absorbance Infinite M200 PRO

For details about the light source (1) and the excitation monochromator (2),

please refer to Fluorescence Intensity Light Source System, page 26.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 37

Page 38

2. General Description

Absorbance Optics MT P

A fiber bundle guides the light from the excitation monochromator system to the

absorbance MTP optics.

The absorbance optics consists of a pair of lenses focusing the light beam into

the well of the microplate.

The spot size of the absorbance light beam is 0.7 mm in diameter.

Absorbance Detection MTP

A silicon photodiode is used for the measurement of the transmitted light. It is

sensitive to a wide range of wavelengths. The photodiode is well suited for the

light levels being encountered w ith absor ba nc e m easur ements up to 4 OD.

Note

For absorbance measurement of nucleic acids

in small volumes (2 µl) use Tecan’s NanoQuant PlateTM.

With this device it is possible to measure

16 different samples within one measur ement.

For further information please contact

your local Tecan distributor or visit:

www.tecan.com

38 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Page 39

2. General Description

2.5.6 Luminescence System

The Infinite 200 PRO Luminescence System consists of the following parts:

• Luminescence Optics

• Detection Unit (Basic or Standard PMT)

Figure 15: Optical System Luminescence

The luminescence fiber bundle guides the light from the sample to the detection

unit (PMT) passing through a filter wheel. The photon counting PMT

(photomultiplier tube) is designed for applications in chemo- and bioluminescence

providing a high dynamic range. The exceptionally low noise and high sensitivity

allows the detection of very low light levels.

The z-position of the luminescence fiber bundle fixed onto the optics carrier is

adjusted automatically by the software and depends on the selected plate

definition file. As light is refracted at the sample liquid surface, z-adjustment helps

to maximize signal to noise and minimize cross-talk.

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 39

Page 40

2. General Description

0

10

20

30

40

50

60

70

80

90

100

400 450 500 550 600 650

Wa ve l ength [nm]

Transm issi o n [%]

Luminescence Optics

In luminescence measurement mode, the Inf in ite 20 0 PRO uses fixed microplate

position and a moveable luminescence measurement head (see Figure 15:

Optical System Luminescence). The plate thickness is defined by selecting the

corresponding plate type in the software (see i-control Instructions for Use).

Fiber

A glass fiber guides the light from the sample to the detection unit. The fiber is

designed to measure from 6-well up to 384-well plates.

Filter Wheel

A filter wheel with 6 filter positions in front of the PMT window is switched to the

required luminescence channel. The sensitivity of the detection system makes it

necessary to attenuate high luminescence light levels; therefore, the filter wheel

can also switch a neutral density filter across the selected fiber exit.

Filter Wheel Position Filter

Position 1 Lumi Green*

Position 2 Lumi Magenta*

Position 3 OD2 neutral density filter

Position 4 No attenuation

Position 5 Blue 1**

Position 6 Green 1**

* recommended for the BRET

** recommended for the BRET assay

The OD2 neutral density filter serves to attenuate high light levels by a factor of

100 (corresponding to 2 OD absorbance). The resulting values are automatically

scaled to counts per second and displayed accordingly in the software results

output.

See Figure 16 to Figure 19 for transmission spectra of luminescence filters.

2

assay and the ChromaGlo - Luciferase Assay

40 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

Figure 16: Transmission spectrum of filter ‘Lumi Magenta’

Page 41

2. General Description

0

10

20

30

40

50

60

70

80

90

100

400 450 500 550 600 650 700 750

Wavelength [nm ]

Transmissi on [% ]

0

10

20

30

40

50

60

70

80

90

100

400 450 500 550 600 650 700 750

Wavelength [nm ]

Transmissi on [% ]

Figure 17: Transmission spectrum of filter ‘Lumi Green’

Figure 18: Transmission spectrum of filter ‘Blue 1’

2016-04 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 41

Figure 19: Transmission spectrum of filter ‘Green 1’

Page 42

2. General Description

2.5.7 Cuvette Port (Infinite M200 PRO)

The Infinite M200 PRO may be optionally equipped with a cuvette port for

absorbance measurements.

For absorbance measurements with the cuvette port of Infinite M200 PRO a

similar optical path is used as for fluorescence excitation.

The absorbance system consists of:

1. light source

2. excitation monochromator

3. absorbance cuvette measurement module

4. absorbance microplate module

Condenser type optics focus the light through the excitation filter and then

through the entrance slit to the excitation monochromator. A fiber bundle then

guides the light from the excitation monochromator to the absorbance cuvette

optics, which focuses the light through the cuvette. The absorbance cuvette

measurement module is located right after the cuvette port. A silicon photo diode

measures the light being transmitted through the sample. Before measurement of

the cuvette, a reference measurement against air is performed with the cuvette

port moved out of the light beam.

Figure 20: Optical System of the absorbance module of Infinite M200 PRO including the

cuvette port The figure also shows the light path of the absorbance microplate module (5).

For details of the light source (1) and the excitation monochromator (2), please

42 IFU for Infinite 200 PRO No. 30052730 Rev. No. 1.6 2016-04

refer to chapter 2.4.1 Fluorescence/A) Fluorescence Intensity (FI).