Page 1

TECAN

Instructions for Use for

infinite® 200

Document Part No.: 30017581

2008-07

Document Revision No.: 1.4

Page 2

WARNING

CAREFULLY READ AND FOLLOW THE INSTRUCTIONS PROVIDED IN

Notice

Every effort has been made to avoid errors in text and diagrams; however, Tecan

Austria GmbH assumes no responsibility for any errors, which may appear in this

publication.

It is the policy of Tecan Austria GmbH to improve products as new techniques

and components become available. Tecan Austria GmbH therefore reserves the

right to change specifications at any time with appropriate validation, verification,

and approvals.

We would appreciate any comments on this publication.

Manufacturer

Tecan Austria GmbH

Untersbergstrasse 1A

A-5082 Grödig/Salzburg

AUSTRIA/EUROPE

T +43 62 46 89 33

F +43 62 46 72 770

E-mail: office.austria@tecan.com

www.tecan.com

THIS DOCUMENT BEFORE OPERATING THE INSTRUMENT.

Copyright Information

The contents of this document are the property of Tecan Austria GmbH and are

not to be copied, reproduced or transferred to another person or persons without

prior written permission.

Copyright © Tecan Austria GmbH

All rights reserved.

Printed in Austria

Declaration for EU Certificate

Available upon request where appropriate.

About the Instructions for Use

This document describes the infinite

It is intended as reference and instructions for use.

This document instructs how to:

• Install the instrument

• Operate the instrument

• Clean and maintain the instrument

®

200 multifunctional microplate reader.

2 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 3

Remarks on Screenshots

The version number displayed in screenshots may not always be the one of the

currently released version. Screenshots are replaced only if content related to

application has changed.

Trademarks

The following product names and any registered and unregistered trademarks

mentioned in this document are used for identification purposes only and remain

the exclusive property of their respective owners:

i-Control

•

registered trademarks of Tecan Group Ltd., Männedorf, Switzerland

• Windows

Redmond, WA, USA

TM

, magellanTM, infinite®, Tecan® and the Tecan Logo are

®

and Excel® are registered trademarks of Microsoft Corporation,

Warnings, Cautions, and Notes

The following types of notices are used in this publication to highlight important

information or to warn the user of a potentially dangerous situation:

STOP

Note

Gives helpful information.

Caution

Indicates a possibility of instrument damage or data loss if instructions

are not followed.

WARNING

INDICATES THE POSSIBILITY OF SEVERE PERSONAL INJURY, LOSS

OF LIFE OR EQUIPMENT DAMAGE IF THE INSTRUCTIONS ARE NOT

FOLLOWED.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 3

Page 4

WARNING

THIS SYMBOL INDICATES THE POSSIBLE PRESENCE OF

BIOLOGICALLY HAZARDOUS MATERIAL. PROPER LABORATORY

SAFETY PRECAUTIONS MUST BE OBSERVED.

WARNING

THIS SYMBOL INDICATES THE POSSIBLE PRESENCE OF FLAMMABLE

MATERIALS AND A RISK OF FIRE. PROPER LABORATORY SAFETY

PRECAUTIONS MUST BE OBSERVED.

ATTENTION

NEGATIVE ENVIRONMENTAL IMPACTS ASSOCIATED WITH THE

TREATMENT OF WASTE.

Symbols

z DO NOT TREAT ELECTRICAL AND ELECTRONIC EQUIPMENT

AS UNSORTED MUNICIPAL WASTE.

z COLLECT WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT

SEPARATELY.

Manufactured by

Indicates the possible presence of biologically hazardous material.

4 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 5

Table of Contents

1. Safety ............................................................................................ 9

1.1 Instrument Safety .................................................................... 9

2. General Description................................................................... 11

2.1 Instrument ..............................................................................11

2.1.1 Intended Use .........................................................................11

2.1.2 Multifunctionality ....................................................................12

2.1.3 Performance ..........................................................................13

2.1.4 User Friendliness...................................................................13

2.1.5 System Requirements ...........................................................14

2.2 Measurement Techniques.....................................................15

2.2.1 Fluorescence

2.2.2 Absorbance

2.2.3 Luminescence........................................................................18

2.3 Injectors..................................................................................20

2.3.1 Measurement with Injectors................................................... 21

2.3.2 Storage Bottles ......................................................................21

2.3.3 Injector/Injector Carrier .......................................................... 22

2.3.4 Priming and Washing of the infinite® 200................................25

.........................................................................15

...........................................................................17

2.3.5 Injector Cleaning and Maintenance .......................................35

2.3.6 Injector Reagent Compatibility............................................... 36

2.4 Software ................................................................................. 38

2.4.1 i-Control and Injectors............................................................38

2.4.2 i-Control Examples ................................................................43

3. Installation .................................................................................. 47

3.1 Unpacking and Inspection ....................................................47

3.1.1 Unpacking Procedure

3.2 Removal of the Transport Locks.......................................... 49

3.3 Transport and Storage ..........................................................51

3.3.1 Transport ............................................................................... 51

3.3.2 Storage ..................................................................................51

3.4 Power Requirements............................................................. 51

3.5 Switching the Instrument On................................................52

............................................................48

4. Defining Filter Slides (infinite® F200 only) ................................ 55

4.1 About Filters ..........................................................................55

4.1.1 Fluorescence Filters ..............................................................55

4.1.2 Absorbance Filters.................................................................55

4.2 Filter Slide and Filter Orientation .........................................55

4.2.1 Filter Slide.............................................................................. 55

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 5

Page 6

4.2.2 Filter Types ............................................................................56

4.2.3 Position of Polarization Filters................................................57

4.3 Installing a Custom Filter ......................................................58

4.3.1 Removing a Filter...................................................................58

4.3.2 Mounting a Custom Filter.......................................................58

4.4 Defining the Filters ................................................................60

5. Optical System ........................................................................... 65

5.1 Fluorescence Intensity System ― infinite® M200.................65

5.1.1 Light Source System Fluorescence Intensity .........................67

5.1.2 Fluorescence Top/Bottom Optics...........................................69

5.1.3 Fluorescence Intensity Detection

5.2 Fluorescence Intensity

System ― infinite® F200..................71

5.2.1 Light Source System..............................................................73

5.2.2 Fluorescence Optics Top .......................................................74

5.2.3 Fluorescence Optics Bottom..................................................74

5.2.4 Fluorescence Detection .........................................................74

5.3 Fluorescence Polarization System ― infinite® F200 ............75

...........................................70

5.4 Absorbance System ― infinite® M200...................................76

5.4.1 Absorbance Optics MTP ........................................................77

5.4.2 Absorbance Detection MTP ...................................................77

5.5 Cuvette Port (infinite® M200) ..................................................78

5.5.1 Absorbance Optics Cuvette ...................................................79

5.5.2 Absorbance Detection Cuvette ..............................................79

5.5.3 Cuvette types .........................................................................80

5.5.4 Inserting the Cuvette

5.5.5 i-Control and the Cuvette Port

..............................................................81

................................................82

5.5.6 i-Control Cuvette Examples ...................................................83

5.6 Absorbance System ― infinite® F200....................................87

5.6.1 Light Source System..............................................................88

5.6.2 Absorbance Optics.................................................................88

5.6.3 Absorbance Detection

5.7 Luminescence Sy

............................................................88

stem ..........................................................89

5.7.1 Luminescence Optics.............................................................90

5.7.2 Luminescence Detection........................................................92

6. Operating the infinite® 200 ......................................................... 93

6.1 Introduction............................................................................93

6.2 General Operating Features

6.2.1 Instrum

ent Start Up................................................................94

6.2.2 Finish a Measurement Session..............................................94

6.2.3 General Options.....................................................................95

6.3 Optimize Fluorescence Measurements................................96

6 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

..................................................94

Page 7

6.3.1 Instrument Parameters ..........................................................96

6.3.2 FI Ratio Mode ........................................................................98

6.3.3 Measurement Accessories ....................................................99

6.4 FP Measurements................................................................ 102

6.4.1 Fluorescence Polarization ...................................................102

6.4.2 Measurement Blank Range ................................................. 102

6.4.3 G-Factor Settings.................................................................103

6.4.4 Measurement with an Uncalibrated G-Factor ...................... 103

6.4.5 Measurement with a Simultaneous G-Factor Calibration..... 104

6.4.6 Measurement with a Calibrated G-Factor ............................105

6.4.7 Measurement with a Manual G-Factor................................. 106

6.4.8 Calculation of Fluorescence Polarization Parameters .........107

6.5 Optimize Absorbance Measurements................................108

6.5.1 Measurement Parameters ................................................... 108

6.5.2 Absorbance Ratio Mode ...................................................... 108

6.6 Multiple Reads Per Well ......................................................109

6.6.1 MRW Type........................................................................... 109

6.6.2 MRW Size............................................................................ 110

6.6.3 MRW Border........................................................................ 110

6.6.4 Result Display in MS Excel®................................................112

6.6.5 Miscellaneous Software Features of MRW.......................... 112

6.7 Optimize Luminescence Measurements............................113

6.7.1 Integration Time...................................................................113

6.7.2 Light Level Attenuation ........................................................ 113

7. Instrument Features ................................................................ 115

7.1 Introduction

7.2 Instrument Specifications...................................................116

7.3 Fluorescence Intensity and

Time Resolved Fluorescence (TRF)................................... 117

7.3.1 Definition of the Detection Lim

7.3.2 Fluorescein (Fluorescence Intensity) Top

7.3.3 Fluorescein (Fluorescence Intensity) Bottom....................... 118

7.3.4 Europium (Time Resolved Fluorescence)............................ 118

7.4 Fluorescence Polarization (FP- infinite® F200 only)........... 119

7.5 Absorbance..........................................................................120

7.6 Glow Type Luminescence...................................................121

7.6.1 ATP Glow Luminescence ....................................................121

7.7 Flash Type Luminescence.................................................. 122

7.8 Dual Color Luminescence (e.g. BRET TM).......................... 123

7.9 “On the Fly” Measurements ...............................................123

7.10 Cuvette Measurements (infinite® M200 only)......................124

7.11 Injector..................................................................................125

..........................................................................115

it ...........................................118

............................118

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 7

Page 8

8. Quality Control ......................................................................... 127

8.1 Periodic Quality Control Tests ...........................................127

8.2 Specifications - Passed/Failed Criteria..............................128

8.3 Specifications - Test Instructions.......................................129

8.3.1 Fluorescence Top ................................................................129

8.3.2 Fluorescence Bottom ...........................................................133

8.3.3 Time Resolved Fluorescence...............................................136

8.3.4 Fluorescence Polarization (infinite® F200 only) .....................138

8.3.5 Glow Luminescence.............................................................140

8.3.6 Absorbance Accuracy ..........................................................141

8.3.7 Absorbance Wavelength Accuracy

8.3.8 Absorbanc

8.3.9 Absorbance Baseline Flatness (infinite® F200) .....................144

8.3.10 Absorbance Cuvette (infinite® M200 only).............................145

e Baseline Flatness (infinite® M200) ....................143

......................................142

9. Cleaning and Maintenance...................................................... 147

9.1 Introduction..........................................................................147

9.2 Liquid Spills .........................................................................148

9.3 Instrument Disinfection.......................................................149

9.3.1 Disinfection Solutions...........................................................149

9.3.2 Disinfection Procedure.........................................................150

9.4 Disinfection Certificate........................................................151

9.5 Disposal................................................................................152

9.5.1 Disposal of Packing Material................................................153

9.5.2 Disposal of Operating Material.............................................153

9.5.3 Disposal of the Instrum

ent ...................................................154

10. Troubleshooting....................................................................... 155

Index................................................................................................ 159

Tecan Customer Support.............................................................. 161

8 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 9

1. Safety

1. Safety

1.1 Instrument Safety

1. Always follow basic safety precautions when using this product to reduce

the risk of injury, fire, or electrical shock.

2. Read and understand all information in the Instructions for Use. Failure to

read, understand, and follow the instructions in this document may result in

damage to the product, injury to operating personnel or poor instrument

performance.

3. Observe all WARNING and CAUTION statements in this document.

4. Never open the housing of the

into a power source.

5. Never force a microplate into the instrument.

infinite® 200 is intended as a general purpose laboratory instrument for

6.

professional use. Observe proper laboratory safety precautions, such as

wearing protective clothing and using approved laboratory safety

procedures.

infinite® 200 while the instrument is plugged

STOP

STOP

Caution

Tecan Austria GmbH have taken great care when creating the stored Plate

Definition Files that are received with the instrument software.

We take every precaution to ensure that the plate heights and well depths are

correct according to the defined plate type. This parameter is used to

determine the minimum distance between the top of the plate and the ceiling of

the measurement chamber. Additionally, Tecan Austria adds a very small

safety gap to prevent any damage occurring to the measurement chamber as a

result of small changes in plate height. This does not affect the performance of

the instrument.

Users MUST ensure that the plate definition file selected corresponds to the

actual plate being used.

Users should also take care that no potential fluorescent or luminescent

contamination lies on top of the plate. Be aware that some plate sealers leave

behind a sticky residue that must be completely removed before starting

measurements.

Caution

Before starting measurements, make sure that the microplate position A1 is

inserted correctly. The position of well A1 has to be on the upper left side.

Caution

STOP

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 9

To insure the optimal working of Tecan instruments

we recommend a service interval of 6 months.

Page 10

1. Safety

It is assumed that the instrument operators, because of their vocational

experience, are familiar with the necessary safety precautions for handling

chemicals and biohazardous substances.

Adhere to the following laws and guidelines:

1. National industrial protection law

2. Accident prevention regulations

3. Safety data sheets of the reagent manufacturers

WARNING

DEPENDING ON THE APPLICATIONS, PARTS OF THE infinite

MAY COME IN CONTACT WITH BIOHAZARDOUS/INFECTIOUS

MATERIAL. MAKE SURE THAT ONLY QUALIFIED PERSONNEL

OPERATE THE INSTRUMENT. IN CASE OF SERVICE OR WHEN

RELOCATING OR DISPOSING OF THE INSTRUMENT, ALWAYS

DISINFECT THE INSTRUMENT ACCORDING TO THE INSTRUCTIONS

GIVEN IN THIS MANUAL.

®

200

10 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 11

2. General Description

2. General Description

2.1 Instrument

The Tecan infinite

The

infinite® 200 provides high performance for the vast majority of today’s

microplate applications and research and is robotic compatible.

2.1.1 Intended Use

The infinite® 200 has been designed as a general purpose laboratory instrument

for professional use, supporting common 6 to 384-well microplates conforming to

the ANSI/SBS standards (see 2.1.2 Multifunctionality for further details).

The infinite® 200 has been validated on a selected set of assays only.

It is the responsibility of any operating authority to ensure that the

infinite® 200 has been validated for every specific assay used on the

®

200 is a multifunctional microplate reader with injector option.

Note

System Validation by Operating Authority is Required

instrument.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 11

Page 12

2. General Description

2.1.2 Multifunctionality

Depending on the type of wavelengths selection, the infinite® 200 is available in

two different versions:

• infinite

• infinite

The following measurement techniques are supported by the infinite

• Fluorescence Intensity (FI) Top

• Fluorescence Intensity (FI) Bottom

• Fluorescence Time Resolved (TRF)

• Flash Fluorescence

• Absorbance

• Absorbance with injectors

• Absorbance with cuvette

• Glow Type Chemi- or Bioluminescence

• Bioluminescence Resonance Energy Transfer (BRET

• Flash Luminescence

The fully equipped infinite

• Fluorescence Intensity (FI) Top

• Fluorescence Intensity (FI) Bottom

• Fluorescence Time Resolved (TRF)

• Flash Fluorescence

• Fluorescence Polarization (FP)

• Absorbance

• Absorbance with injectors

• Glow Type Chemi- or Bioluminescence

• Bioluminescence Resonance Energy Transfer (BRET

• Flash Luminescence

Any common microplate ranging from 6 to 384 well formats conforming to the

ANSI/SBS standards (ANSI/SBS 1-2004; ANSI/SBS 2-2004, ANSI/SBS 3-2004

and ANSI/SBS 4-2004) may be measured with any of the above measurement

techniques. Switching between measurement techniques or plate formats is fully

automated via software. It is not necessary to manually reconfigure the optics in

order to switch between the reading modes supported by the

Both instrument versions, the filter-based (

monochromator-based (

injectors.

®

M200 (monochromator-based instrument)

®

F200 (filter-based instrument)

®

F200 provides the following measurement techniques:

infinite® F200) and the

infinite® M200), may be equipped with up to two

®

M200:

TM

)

TM

)

infinite® 200.

12 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 13

2. General Description

2.1.3 Performance

The infinite

purpose laboratory instrument.

The

results according to: the assay type (cell-based or homogeneous), the microplate

type, and the dispensed volumes per well and dispensing speeds.

®

200 has been designed to meet the requirements of a general-

infinite® 200 provides a range of parameters for optimizing the measurement

2.1.4 User Friendliness

The infinite

fluorescence intensity and absorbance measurements. Via software any

wavelength can be easily adjusted within the specified wavelength range. In

addition to single wavelength measurements, absorbance and fluorescence

spectra can be recorded. When running a spectrum there is no restriction due to

cut-off filters.

The

absorbance measurements; slides containing fluorescence and absorbance

interference filters are easily accessible to the user.

If the instructions given in this document are not correctly performed,

performed correctly and the safety of the instrument is not guaranteed.

®

M200 offers unparalleled flexibility in wavelength selection for

infinite® F200 offers high flexibility for the customization of fluorescence and

the instrument will either be damaged or the procedures will not be

Note

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 13

Page 14

2. General Description

2.1.5 System Requirements

Minimum

• Pentium PIII 1 GHz

• 20 GB HDD

• 256 MB RAM

• 1 x USB 2.0

• CD ROM Drive

• Screen Resolution: 1024 x 768

Recommended

• Pentium P4 2 GHz

• 40 GB HDD

• 512 MB RAM

• 2 x USB 2.0, 1 x RS232

• CD ROM Drive

• Screen Resolution: 1280 x 1024

Operating System Requirements

• Windows XP Professional (English), Minimum Service Pack 1

®

• Microsoft Excel

Infinite 200 and i-control are also compatible with Windows Vista (32 Bit) and Excel

2000 (English) or above (for i-Control)

®

2007

14 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 15

2. General Description

2.2 Measurement Techniques

The following sections provide an introduction to the infinite

techniques when fully equipped. To keep this compact, a few simplifications have

been made. For details see the references.

2.2.1 Fluorescence

The infinite

some even more sophisticated variants:

A. Fluorescence Intensity (FI) (or simply Fluorescence)

B. Fluorescence Resonance Energy Transfer (FRET)

C. Fluorescence Time Resolved (TRF)

D. Fluorescence Polarization (FP)

FI may also be used to measure Fluorescence Resonance Energy Transfer

(FRET). For some microplate applications, FRET offers advantages over FI and

TRF, because they simplify assay preparation. These preferably apply for mix

and measure binding studies. Compared to FP, FRET requires both binding

partners to be labeled in a suitable way. On the other hand, FRET may utilize

TRF labels for increased sensitivity, then being referenced as HTRF

(Homogeneous TRF).

TRF should not be confused with Fluorescence Lifetime Measurements.

Fluorescence (An Abstract)

®

200 measurement

®

200 offers the basic fluorescence measurement technique and

Fluorescent molecules emit light of specific wavelength when struck by light of

shorter wavelength (Stokes Shift). In particular, a single fluorescent molecule can

contribute one fluorescence photon (quantum of light). This is a part of the

energy, which has been absorbed before (electronic excitation), but could not be

released quick enough into thermal energy.

The average time it takes between excitation and emission is called the

fluorescence lifetime. For many fluorescent molecular species, fluorescence

lifetime is on the order of nanoseconds (prompt fluorescence). After excitation,

fluorescence emission occurs with a certain probability (quantum yield), which

depends on the fluorescent species and its environmental conditions.

For a detailed treatise on fluorescence techniques and applications see:

Principles of Fluorescence Spectroscopy by Joseph R. Lakowicz, Plenum

Press.

A) Fluorescence Intensity (FI)

In many microplate applications, the intensity of fluorescence emission is

measured to determine the abundance of fluorescent labeled compounds. In

these assays, other factors having an influence on fluorescence emission need to

be controlled experimentally. Temperature, pH-value, dissolved oxygen, kind of

solvent etc. may significantly affect the fluorescence quantum yield and therefore

the measurement results.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 15

Page 16

2. General Description

B) Fluorescence Resonance Energy Transfer (FRET)

Some microplate applications utilize a sophisticated dual labeling strategy. The

FRET effect enables you to measure how many of two differently labeled

compounds are in close proximity. This makes it suitable for binding studies.

Basically, FRET is a fluorescence intensity measurement of one of the two

fluorescent labels (acceptor). However, the acceptor is not susceptible to the

excitation wavelength of the light source being used. Instead, the acceptor may

receive excitation energy from the other fluorescent label (donor), if both are

spatially close together. As a prerequisite, the excitation wavelength has to apply

to the donor. Secondly, the emission spectrum of the donor has to overlap the

excitation spectrum of the acceptor (resonance condition). Nevertheless, the

transfer of excitation energy from donor to the acceptor is radiation free.

Some FRET-based applications utilize suitable pairs from the fluorescent protein

family, like GFP/YFP (Green/Yellow Fluorescent Protein, (ref. Using GFP in

FRET-based applications by Brian A. Pollok and Roger Heim – trends in Cell

Biology [Vol.9] February 1999). Overview is given in the Review Article –

Application of Fluorescence Resonance Energy Transfer in the Clinical

Laboratory: Routine and Research by J. Szöllösi et al. in Cytometry 34, page

159-179 (1998).

Other FRET-based applications take advantage from using TRF labels as the

donor. For example see, High Throughput Screening – Marcel Dekker Inc.

1997, New York, Basel, Hong Kong, section 19 Homogeneous, Time-Resolved

Fluorescence Method for Drug Discovery by Alfred J. Kolb et al.

C) Fluorescence Time Resolved (TRF)

TRF applies to a class of fluorescent labels (chelates of lanthanides like

Europium, [ref. Europium and Samarium in Time-Resolved

Fluoroimmunoassays by T. Stâhlberg et. al. - American Laboratory, December

1993 page 15]), some of them having fluorescence lifetimes in excess of 100

microseconds. The

duration much shorter than fluorescence lifetime of these species. This offers the

opportunity to measure fluorescence emission at some time, when stray light and

prompt fluorescence have already vanished (Lag Time). Thus, background can

be significantly lowered while sensitivity is improved.

The benefits of TRF consequently apply to assays using multiple labels with

different fluorescence lifetimes.

infinite® 200 uses a Flash lamp light source with flash

16 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 17

2. General Description

D) Fluorescence Polarization (FP)

Fluorescence Polarization (FP) measures rotational mobility of a fluorescent

labeled compound. FP is therefore particular suitable for binding studies, because

the tumbling motion of small molecules may be dramatically slowed down after

binding to a larger molecule.

Fluorescence polarization measurements are based on the detection of the

depolarization of fluorescence emission after excitation of a fluorescent molecule

by polarized light. A fluorescent molecule can be visualized as an antenna. Such

a molecule can absorb energy if and only if the polarization of the excitation light

matches the orientation of the antenna. During the fluorescence lifetime, i.e. the

time a molecule remains in the excited state, small molecules diffuse rotationally

relatively rapidly. Hence they re-orient before they emit their photon. As a result

and due to the random character of diffusion, a linearly polarized excitation light

will be translated into a less polarized emission light. Thus, a high resultant mP

value denotes the slow rotation of the labeled molecule, indicating that binding

probably did occur. A resultant low mP value denotes a fast rotation of a

molecule, indicating that binding probably did not occur.

The FP measurement result is calculated from two successive fluorescence

intensity measurements. They differ in the mutual orientation of polarizing filters,

one being placed behind the excitation filter, another ahead of the emission filter.

By processing both data sets, it is possible to measure the extent of how much

the fluorescent label has changed orientation in the time span between excitation

and emission.

2.2.2 Absorbance

Absorbance is a measure for the attenuation of monochromatic light when

transmitted through a sample. Absorbance is defined as:

A = LOG

Where I

not attenuated by sample. The unit is assigned with Optical Density (O.D.)

Thus, 2.0 O.D. means 10

1.0 O.D. means 10

0.1 O.D. means 10

If the sample contains only one species absorbing in that narrow band of

wavelengths, the background corrected absorbance (A) is proportional to the

corresponding concentration of that species (Lambert-Beer's Law).

(I 0/I

10

SAMPLE

SAMPLE

),

is the intensity of the light being transmitted, I 0 the light intensity

2.0

or 100-fold attenuation (1% transmission),

1.0

or 10-fold attenuation (10% transmission), and

0.1

or 1.26-fold attenuation (79.4% transmission).

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 17

Page 18

2. General Description

2.2.3 Luminescence

Caution

STOP

Switch on the instrument at least 15 minutes before starting a luminescence

measurement. Some components need to warm up to guarantee stable

conditions for the measurement.

Glow Type Chemi- or Bioluminescence

The infinite

Glow type means that the luminescence assay glows much longer than a minute.

Luminescence substrates are available, which provide stable enough light output

over hours.

As an example, luminescence can be measured to determine the activity of an

enzyme labeled compound (-peroxidase, -phosphatase). Light emission results

from a luminescence substrate being decomposed by the enzyme. Under excess

of substrate the luminescence signal can be assumed to be proportional to the

abundance of the enzyme labeled compound. As with enzyme-based assays,

control of environmental conditions is rather critical (temperature, pH-value).

For practical aspects of luminescence assays see the following example:

Bioluminescence Methods and Protocols, ed. R.A. LaRossa, Methods in

Molecular Biology 102, Humana Press, 1998

®

200 provides measurement of glow type chemi- or bioluminescence.

Bioluminescence Resonance Energy Transfer (BRET TM)

BRET TM is an advanced, non-destructive, cell-based assay technology that is

perfectly suited for proteomics applications, including receptor research and the

mapping of signal transduction pathways. BRET

between fusion proteins containing Renilla luciferase (Rluc) and a mutant of the

Green Fluorescent Protein (GFP). The BRET

oxidation of p.a. DeepBlueC™, a coelenterazine derivative that maximizes

spectral resolution for superior sensitivity. This homogeneous assay technology

provides a simple, robust and versatile platform with applications in basic

academic as well as applied research.

TM

TM

is based on energy transfer

signal is generated by the

Flash Luminescence

In flash type luminescence assays the measurement is only done during the

dispensing of the activating reagent or after a short delay time.

Over the past years luminescence substrates have been improved towards

providing more stable signals. In so-called glow type luminescence assays the

luminescence signal is spread over a wide time scale (e.g. a half-life of 30 min.)

*

For Flash reactions with the infinite 200, see also 2.3.1 Measurement with Injectors.

18 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

*

Page 19

2. General Description

Flash Type Luminescence with Injectors

Flash type luminescence is one of the measurement modes that can be

performed with injectors.

The plate detection sensor is only active if one of the injectors is in use

During luminescence measurements it is important to close the lid

covering the syringes and bottles of the reagent system to minimize

(strips “injection” or “dispense”).

Note

Note

background signal.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 19

Page 20

2. General Description

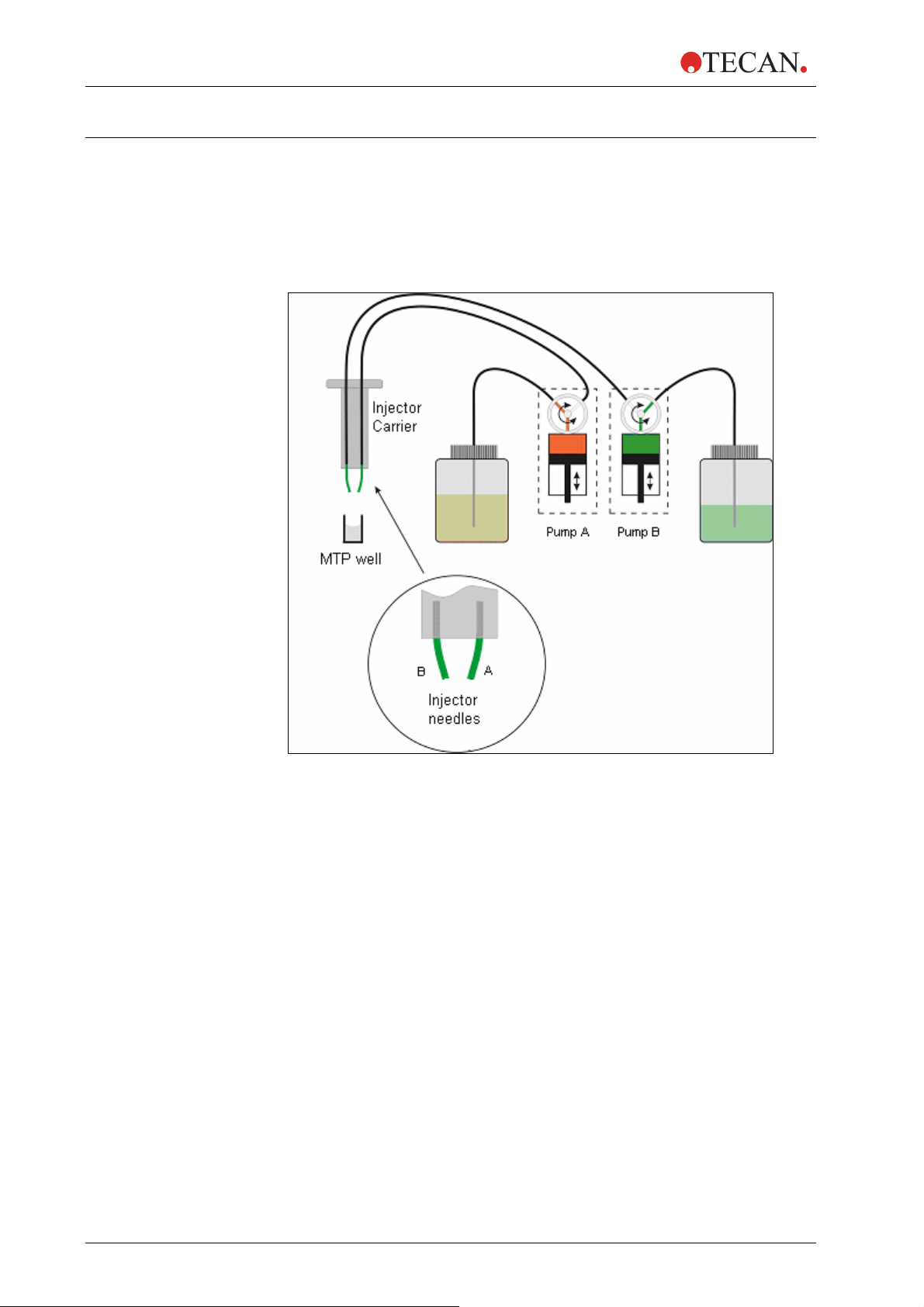

2.3 Injectors

The infinite

one or two syringe pumps (XE-1000, Tecan Systems) located in a separate box,

which feed one or two injector needles. The injector needles are designed to

inject liquid in any SBS-conform microplate well types, in which the well-size is

equal to or larger than an SBS standard 384-well plate.

®

200 can be optionally equipped with an injector module consisting of

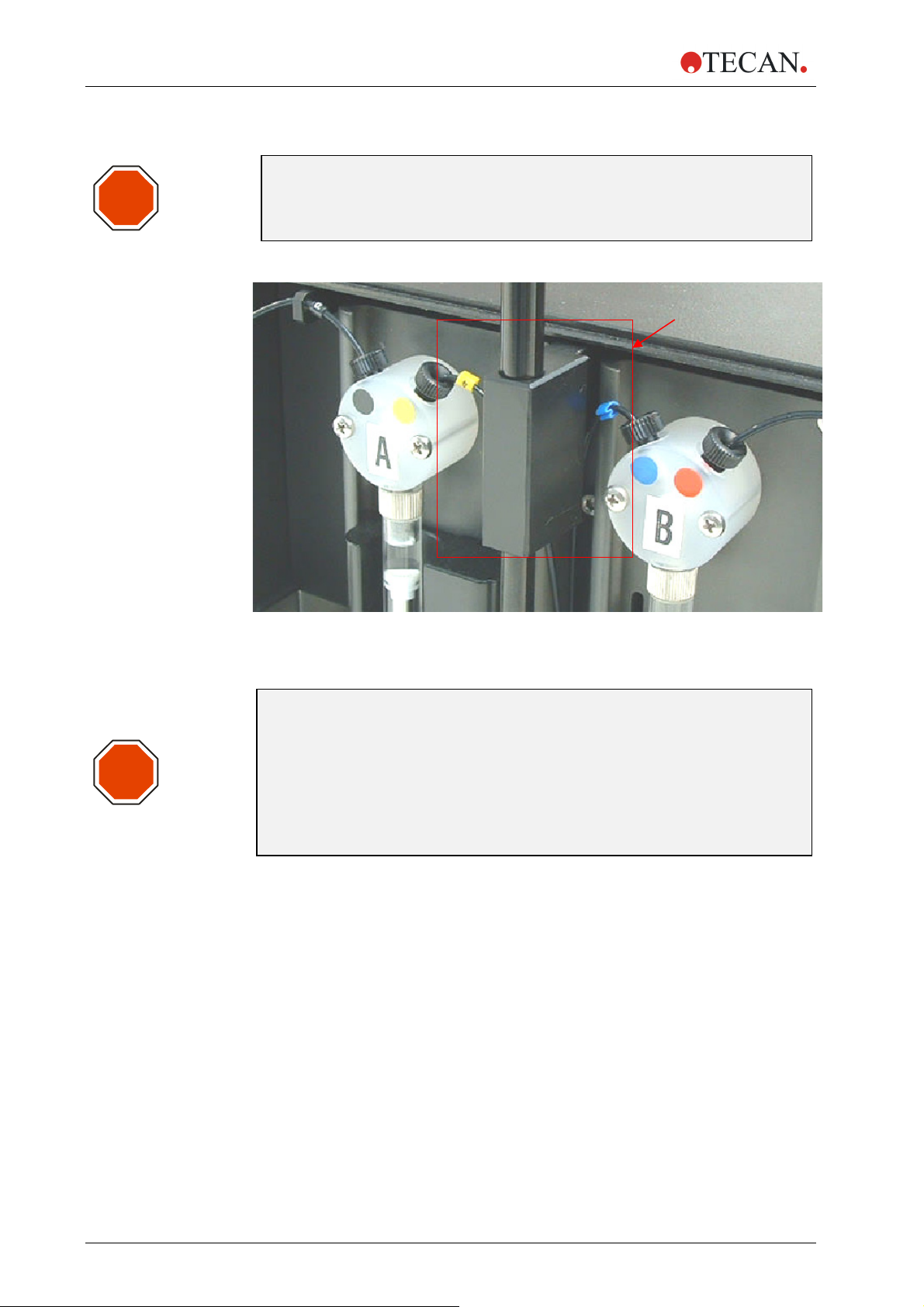

Figure 2-1: Schematic view of the injector module

There are up to two pumps available for the

• Pump A feeds injector needle A

• Pump B feeds injector needle B

The

infinite® 200 can be equipped with one pump (pump A) or two pumps

(pumps A and B).

One Injector Option (one pump): An

allows injections in any SBS-conform microplate well types, in which the well-size

is equal to or larger than an SBS standard 384-well plate.

Two Injector Option (two pumps): Some applications, such as flash

luminescence reactions or dual reporter gene assays require the injection of two

independent liquids into the same well; therefore, Tecan Austria offers a twoinjector option.

infinite® 200 (see Figure 2-1 above):

infinite® 200 equipped with one pump

20 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 21

2. General Description

2.3.1 Measurement with Injectors

The injectors of the infinite

modes: Fluorescence Intensity top and bottom, Time Resolved Fluorescence,

Absorbance, Flash and Glow Type Luminescence and Dual Color Luminescence.

As the measurement position is not the same as the injector position, a short time

delay (approx. < 0.5 s) between injection and reading occurs.

For details on how to set up a measurement with injectors please refer to chapter

2.4.1 i-Control and Injectors.

2.3.2 Storage Bottles

The injector box may hold up to two 125 ml bottles. An adapter for smaller tubes

allows using tubes of different size (1.5 ml, 15 ml, 50 ml tubes etc.)

The standard bottle set supplied with the Injector option consists of:

• One 125 ml bottle and one 15 ml bottle for the “One Injector option” (one

pump) or

• Two 125 ml bottles and two 15 ml bottles for the “Two Injectors option” (two

pumps).

®

200 can be used with the following measurement

Figure 2-2: Storage bottles and adapter for smaller tubes

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 21

Page 22

2. General Description

2.3.3 Injector/Injector Carrier

The carrier, which includes the injector needles, can be easily removed from the

instrument for priming or washing the system and for optimizing the injection

speed.

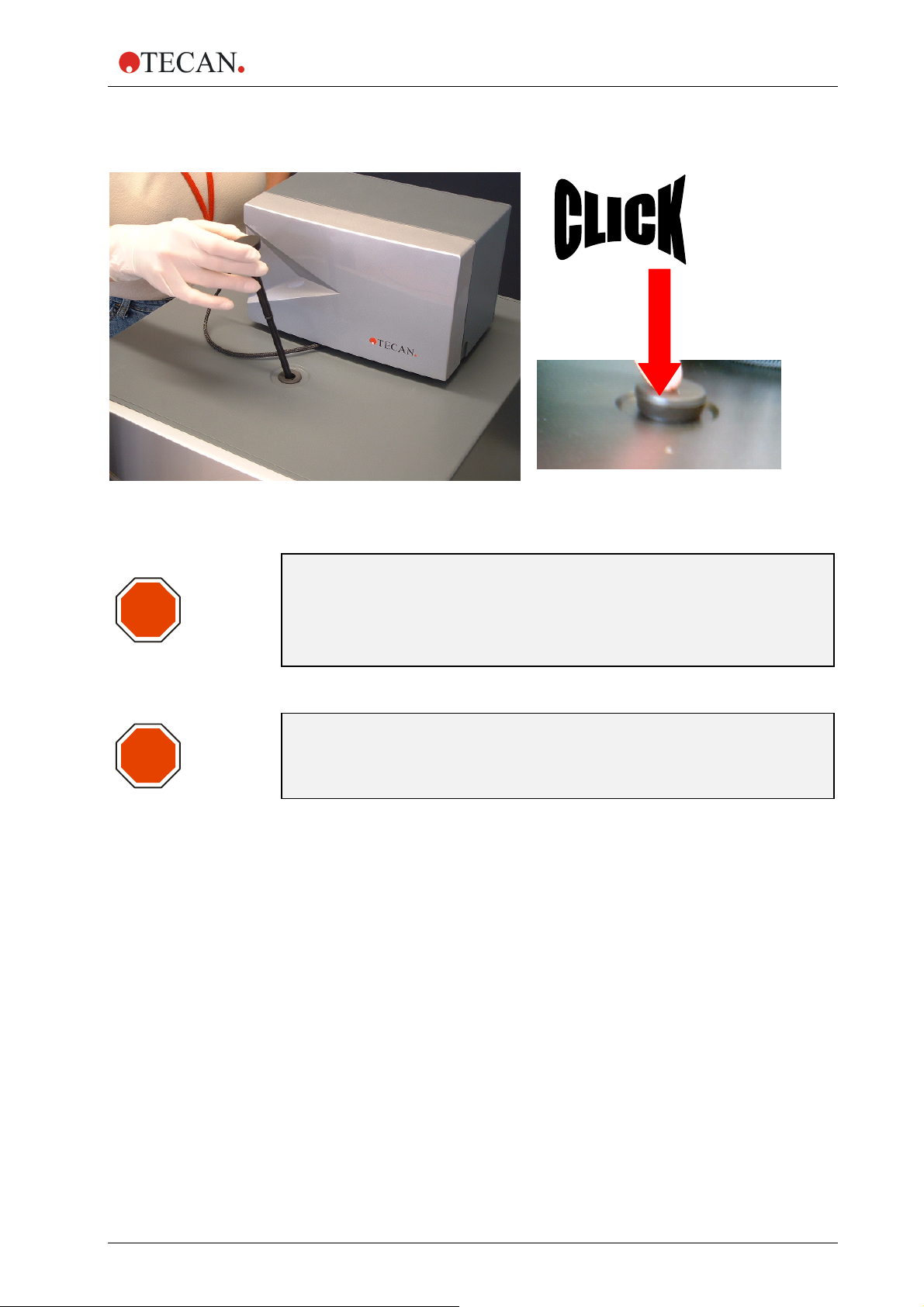

Figure 2-3: Injector carrier

When using the injector during a measurement or for just dispensing a plate the

injector carrier must be inserted correctly into the instrument. Remove the injector

dummy and insert the carrier into the injector port. Press the carrier softly into the

injector port until you hear a clicking noise.

The instrument contains an injector sensor that checks that the position of the

injector carrier for the actions ‘inject’ and ‘dispense’ is correct.

If the injector carrier is not inserted correctly the injector sensor does not

recognize the inserted carrier and neither dispensing nor injection is possible. On

the other hand actions like washing and priming are enabled although the injector

carrier is inserted. Therefore always make sure that the injector carrier is in the

service position for washing and priming.

22 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 23

2. General Description

STOP

Picture 2-1: Inserting the injector carrier into the injector port

Caution

The injector carrier must be in the service position

for washing und priming.

Prime and Wash must not be performed

when the injector is in the instrument!

STOP

Caution

If the injector carrier is not inserted correctly in the injector port, the

injector sensor will not detect the inserted injector and therefore

washing and priming will be enabled, which can damage the instrument.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 23

Page 24

2. General Description

The dead volume of the injection system (injector needles, syringes, valves and

tubing) is approximately 100 µl after ‘backflush’ for each syringe. The function of

backflush is to return any unused reagent to the reservoir bottles. The injection

speed can be adjusted via the software to allow for good mixing of reagents. The

optimum injection speed depends on the assay parameters, such as viscosity of

fluids, the plate format and the measuring behavior of the liquids.

Prime/Wash buttons

for injectors A and B

Figure 2-4: Injector-box with injector in ‘service position’

Before starting a measurement make sure that:

The tubes are clean. If not please refer to chapter 2.3.4 Priming and

Wa

shing of the infinite

®

200 for details how to clean the injector system.

The injector tubes are correctly inserted into the storage bottles and fixed.

The injector system is primed. It is not possible to start a measurement

without priming the system.

When priming the system:

1. Check the tubes for leaks.

2. Check the tubes for kinks.

3. Make sure that the injector needles are not twisted.

If the tubes require replacement for any reason, after the tubes have been

changed do not forget to perform washing and priming before starting a

measurement.

24 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 25

2. General Description

2.3.4 Priming and Washing of the infinite® 200

Caution

The injector carrier must be in the service position

STOP

The initial filling step of the injector system (priming) as well as the cleaning step

of the injector system (washing) must take place outside of the instrument. For

these procedures the injector carrier is removed from instrument and put into the

service position of the injector box. For priming and washing steps of the injector

system, a default setting for injection speed and volume dispensed is provided. If

required the priming parameters can be adjusted in the injector control window of

the i-Control software.

The prime volume depends on the tubing length. Two types of injector tubing are

available: ‘long’: 105 cm, and ‘short’: 80 cm.

For the initial filling step of the injector system (priming) it is recommended to use

at least 2000 µl to remove all air bubbles from the injection system. The minimum

prime volume is therefore 2 ml. To save precious reagents, this initial filling step

can be performed with distilled water. To replace the water with the required

reagent, a second priming step is needed. For this second priming step, the

priming volume can be reduced to approx. 1500 µl.

Prime and Wash must not be performed

when the injector is in the instrument!

for washing und priming.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 25

Page 26

2. General Description

Caution

STOP

A prime volume below 2 ml in an empty system may result in incomplete

filling of the system, and therefore may negatively affect assay

performance.

Service-Position

STOP

Figure 2-5 ‘Service Position’ of the injectors. The injectors are removed from the

carrier slot and inserted into the holder of the injector carrier system.

Caution

Do not touch the injector needles. They can become easily bent or

misaligned, which can cause injection problems or damage the

instrument.

If the injector carrier is not inserted correctly in the injector port, the

injector sensor does not detect the inserted injector and therefore

washing and priming is enabled which can damage the instrument. In

addition to this, the actions ‘dispense’ and ‘inject’ will not be possible.

26 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 27

Priming

2. General Description

Before the injection system can be used, an initial filling step (priming) is needed

to remove all air and to completely fill the system with liquid.

It is recommended to perform a washing step before priming.

Priming can be performed by using the i-Control software or by using the

hardware buttons on the injector box:

Priming procedure (general):

1. Fill the storage bottles with the necessary reagents and insert the feeding

tube(s). Make sure, that the tube(s) reaches the bottom of the bottle.

2. Remove the injector from the carrier slot and insert it into the service

position of the injector box.

3. Put an empty container under the injector.

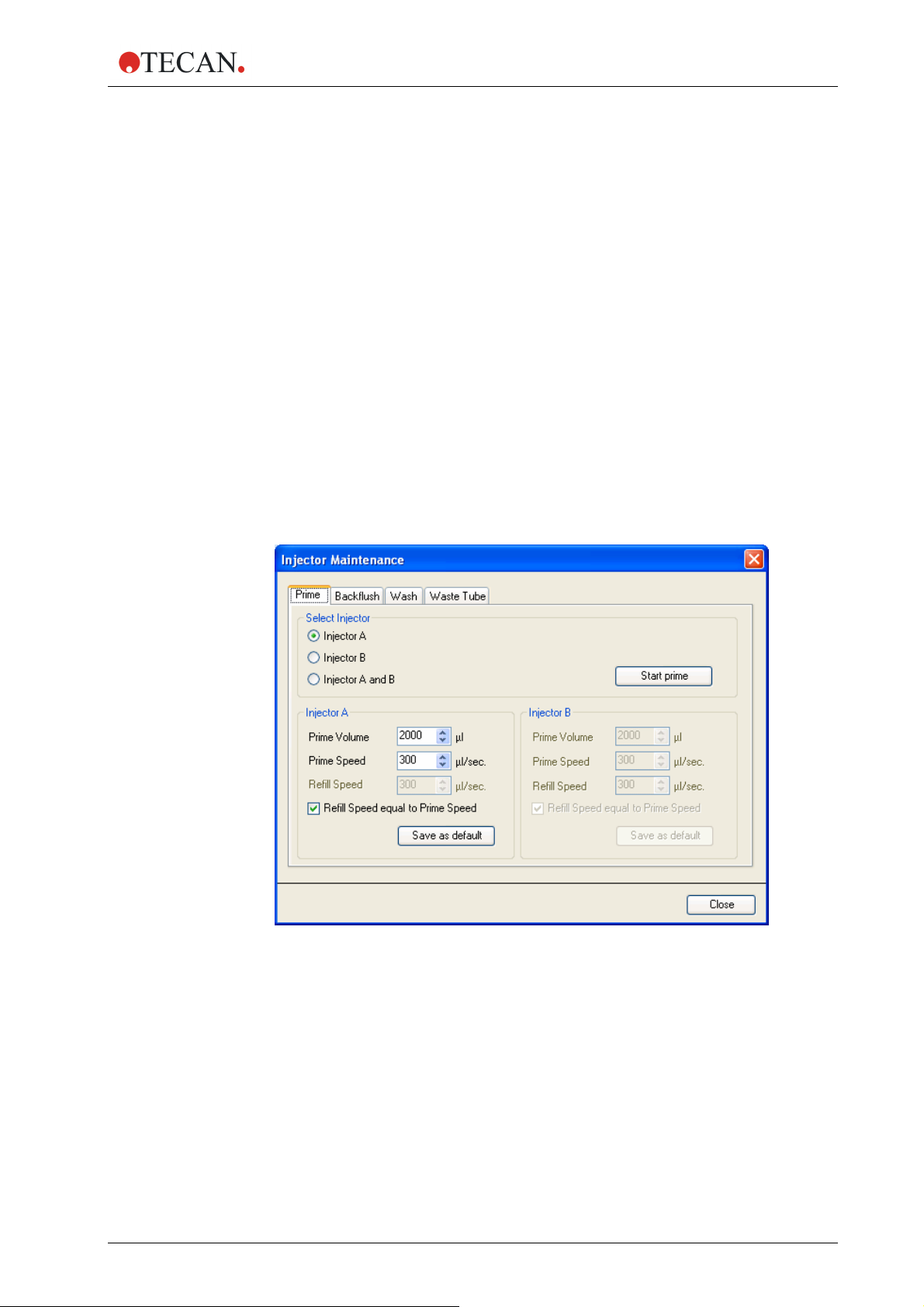

Priming procedure (i-Control):

1. Adjust parameters at the prime tab of the injector maintenance dialog box

in the settings menu

2. Activate the priming procedure by clicking the ‘Start prime’ button in the

injector maintenance dialog box.

3. Visually inspect the syringes for air bubbles. Any bubbles should be

removed after priming to ensure good injection performance.

Prime

Select one of the injectors Injector A or Injector B or Injector A and B.

Select the ‘Prime Volume’ (5 -60000 µl)

Select the ‘Prime Speed’ (100 - 300 µl/sec).

Select the ‘Refill Speed’ (100 – 300 µl/sec.) or select ‘Refill Speed equal to

Prime Speed’.

Start prime by clicking the ‘Start prime’ button.

Click the ‘Save as default’ button to save the selected settings to the

corresponding hardware button (A or B) on the injector box. When using the

hardware buttons for priming, these settings will be applied.

Select ‘Close’ to exit the dialog box

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 27

Page 28

2. General Description

Priming Procedure (hardware button):

Priming can also be performed without using the software. Priming parameters

can be stored on the injector by clicking Save as Default on the Prime tab of the

Injector Maintenance dialog box of the i-Control software (in the Settings menu,

click Injectors... and the Injector Maintenance dialog box appears). Press the

Prime/Wash button on the injector box to start the priming sequence using the

default parameters, (see Figure 2-4: Injector-box with injector in ‘service position’,

page 24). The injector must be connected the inst

be switched on. Start the prime procedure by pressing the Prime/Wash button for

less than 3 seconds.

Visually inspect the syringes for air bubbles. Any bubbles should be removed

after priming to ensure good injection performance.

After a successful priming procedure, reinsert the injector into the instrument.

Close the lid of the pump module completely before starting a measurement. The

injectors are now ready to use.

When starting a measurement with the actions ‘injection’ or ‘dispense’, 5 µl of

liquid are dispensed into a disposable container on the plate carrier before

starting ‘injection’ or ‘dispense’. This initial dispense step makes sure that the

injection/dispense conditions are equal for each well.

rument and the instrument must

Caution

STOP

Close the lid of the pump module (injector box) completely before

starting a measurement.

Priming Example – Operational Sequence of Pump System

The following example describes the operational sequence of the pump system

when performing a prime step with 500 µl.

• The system is already washed (syringe is empty; piston in upper position):

• The first action is always that the syringe has to be filled completely with

liquid. The piston therefore moves down to the lowest position to fill

syringe completely (volume 1 ml).

• Now the system prepares for the priming step. The piston makes space

for the selected prime volume: The selected prime volume is ejected:

500 µl – the piston moves up.

• The piston moves down again to prime the syringe with the selected

volume. The syringe is now completely filled.

• After finishing priming the last action is to eject 5 ml. This step makes

sure that the injection/dispense conditions are equal for each well (for

details please refer to ‘Waste tub’)

Be aware that for selected prime volume of 500 µl, 1500 µl liquid are needed

due to the initial filling step of the syringes.

• The system is not washed (the syringe is partly filled with liquid, the piston is

not in the upper position):

• The first action is always that the syringe is emptied. The piston therefore

moves up to the highest position to empty the syringe.

• The next actions are similar to case 1.

Note

For a selected prime volume of 500 µl, a minimum volume of 1500 µl of

28 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

liquid is required to perform a complete priming step.

Page 29

2. General Description

Reagent Backflush

Reagent backflush allows reagents in the tubing system to be pumped back into

storage bottles. This action can be performed optionally prior to washing the

injector system to minimize the dead volume.

Reagent backflush procedure:

1. Remove the injector carrier from the instrument and insert the injector

carrier into the service position of the injector box.

2. Insert the feeding tubing into the appropriate storage bottle.

3. Adjust parameters on the Backflush tab of the Injector Maintenance

dialog box in the Settings menu

4. Start the reagent backflush procedure by clicking Start backflush.

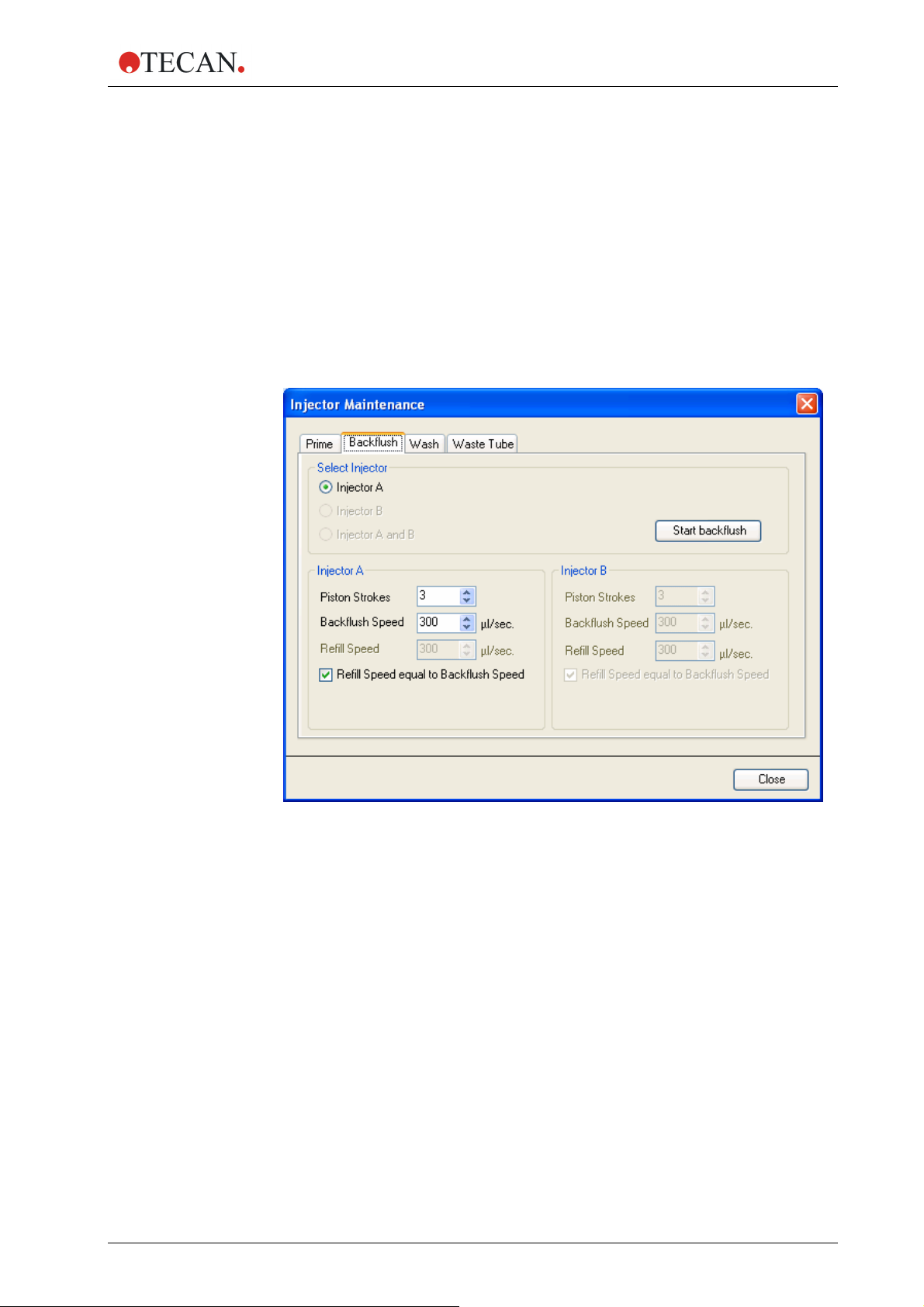

Backflush

Select one of the injectors Injector A or Injector B or Injector A

and B (only ‘primed’ injectors are available for ‘backflush’).

Select the Piston Strokes (1 – 60; 1 stroke equals 1 ml)

Select the Backflush Speed (100 - 300 µl/sec).

Select the ‘Refill Speed’ (100 – 300 µl/sec.) or select the Refill

Speed equal to Backflush Speed check box.

Click Start backflush to start the reagent backflush procedure.

Click Close to exit the dialog box.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 29

Page 30

2. General Description

Caution

STOP

Do not perform backflush when the injector is in the instrument!

The injector carrier must be in the service position

for the action ‘backflush’.

Washing

Before the instrument is switched off, it is recommended to perform a wash

procedure to clean the injector system.

Wash procedure:

Washing can be performed by using the i-Control software or by using the

hardware buttons on the injector box.

Washing (general procedure):

1. Fill the storage bottles with the appropriate wash reagents (distilled water,

70 % ethanol, …) and insert the feeding tube(s). Make sure, that the

tube(s) reaches the bottom of the bottle.

2. Remove the injector from the carrier slot and insert it into the service

position of the injector box.

3. Put an empty container under the injector.

30 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 31

Washing (i-Control):

2. General Description

1. Adjust the parameters on the Wash tab of the Injector Maintenance

dialog box in the Settings menu

2. Start the washing procedure by clicking the Start wash.

Wash

Select one of the injectors Injector A or Injector B or

Injector A and B.

Select the Piston Strokes (1 – 60; 1 stroke equals 1 ml)

Select the Wash Speed (100 - 300 µl/sec).

Select the Refill Speed (100 – 300 µl/sec.) or select Refill

Speed equal to Wash Speed.

Click Start wash to start the wash procedure.

Click Close to exit the dialog box.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 31

Page 32

2. General Description

Washing (hardware buttons):

Washing can also be performed without using the software. Washing parameters

can be stored on the injector by clicking Save as Default on the Wash tab of the

Injector Maintenance dialog box (in the Settings menu, click Injectors... and the

Injector Maintenance dialog box appears) of the i-Control software. Press the

Prime/Wash button on the injector box to start the washing sequence using the

default parameters. (see Figure 2-4: Injector-box with injector in ‘service position’,

page 24). The injector must be connected the inst

be switched on. Start the wash procedure by pressing and holding the

Prime/Wash button for more than 3 seconds.

rument and the instrument must

Caution

STOP

The injector carrier must be in the service position

for the action ‘wash’.

Do not perform washing when the injector is in the instrument!

Important

STOP

Be sure to run a final wash procedure with distilled water and empty the

injector system. For good care and lifetime fill the injector system with

liquid (water) before turning off the instrument.

STOP

STOP

STOP

Important

Please see the corresponding reagent kit for advice on how to remove

the substrate completely from the tubing system.

Important

Take good care of the injectors, because if they are damaged the

accuracy of dispensing may be affected. This can result in damage to

Injector needles can be replaced by exchanging the injector carrier

together with the corresponding tubing.

the instrument.

Note:

Important

The button(s) on the injector box include two functions:

• Press the button for less than 3 seconds to start PRIME.

• Press the button for more than 3 seconds to start WASH.

The parameters have to be set in the i-Control software.

32 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 33

Waste Tub

2. General Description

When starting a measurement with the actions ‘injection’ or ‘dispense’, 5 µl of

liquid are dispensed into a disposable container on the plate carrier before

starting ‘injection’ or ‘dispense’.

This initial dispense step makes sure that the injection/dispense conditions are

equal for each well. This special dispense step depends on the selected refill

mode selected on the injector or dispense strip (see chapter 2.4.1 i-Control and

tors for details).

Injec

When using ‘standard’ refill mode, the dispense step is performed after each refill.

When using ‘refill for every injection’ the dispense step is only performed once

when starting the measurement.

The disposable waste container (waste tub) must therefore be emptied from time

to time. The maximum filling volume is 1.5 ml. An internal counter checks the

dispensed liquid volumes and the software alerts the user when it is time to

empty the waste tub.

Picture 2-2: Waste tub on plate carrier

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 33

Page 34

2. General Description

Waste tub:

Click the ‘Empty Waste tub’ button and the plate carrier will move out

automatically. Remove the waste tub and empty the contents. After the waste tub

has been emptied place it back on the plate carrier. The i-Control software will

alert you when the waste tub needs to be emptied again.

STOP

STOP

Caution

Place the waste tub on the plate transport before starting a

measurement with the actions ‘injection’ and/or ‘dispense’.

Caution

It is recommended to empty the waste tub before starting a

measurement and to empty it at least once a day.

WARNING

BIOLOGICAL HAZARDS CAN BE ASSOCIATED WITH THE WASTE

MATERIAL (MICROPLATE) OF THE PROCESSES

RUN ON THE infinite

TREAT THE USED MICROPLATE, OTHER DISPOSABLES, AND ALL

SUBSTANCES USED, IN ACCORDANCE WITH GOOD LABORATORY

PRACTICE GUIDELINES.

INQUIRE ABOUT APPROPRIATE COLLECTING POINTS AND APPROVED

METHODS OF DISPOSAL IN YOUR COUNTRY, STATE OR REGION.

®

200.

34 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 35

2. General Description

2.3.5 Injector Cleaning and Maintenance

The required maintenance may vary with your application. The following

procedures are recommended for optimal performance and maximum life of the

injector system.

Daily Maintenance:

If not otherwise stated by the manufacturer of the kit to be used, the following

tasks must be performed at least daily:

• Inspect the pump(s) and tubing for leaks.

• Flush the whole system thoroughly with distilled or deionized water after

each use and when the pump is not in use. Failure to do so can result in

crystallization of reagents. These crystals can damage the syringe seal

and valve plug resulting in leakage.

STOP

Do not allow the pump(s) to run dry for more than a few cycles.

Weekly/Periodical Maintenance:

The injector system (tubing, syringes, injector needles) must be cleaned weekly

to remove precipitates and eliminate bacterial growth:

Follow these steps to clean the pump/injector system with 70 % EtOH (ethanol):

1. Depending on the user’s application flush thoroughly the system with

buffer or distilled water before washing with 70 % EtOH.

2. Prime the pump with 70 % EtOH with syringes fully lowered for 30

minutes.

3. After the 30-minute period, cycle all the fluid from the syringe and tubing

into a waste container.

4. Wash the pump/injector system with 70 % EtOH

5. Wash the pump/injector system with distilled or deionized water

6. Prime the pump/injector system with distilled water. Leave the fluid

pathway filled for storage.

7. Clean the end of the injector needles with a cotton swab soaked in 70 %

ethanol or isopropanol.

Caution

WARNING

RISK OF FIRE AND EXPLOSION!

ETHANOL IS FLAMMABLE AND WHEN IMPROPERLY HANDLED CAN

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 35

LEAD TO EXPLOSIONS. PROPER LABORATORY SAFETY

PRECAUTIONS MUST BE OBSERVED.

Page 36

2. General Description

2.3.6 Injector Reagent Compatibility

The injector system of the infinite® F/M200 consist of the following materials:

• Teflon (PTFE): Tubing, valve plug, seal

• KelF: Valve body

• SC05: Injector needles

Please refer to the following list for reagent compatibility. The column ‘Rating’

indicates the compatibility with the reagents listed in the ‘Chemical’ column.

Rating ‘A’ indicates a good compatibility with the injector system. Chemicals with

a rating ‘D’ must not be used with the infinite

damage the injector system.

Chemical Rating

Acetic Acid < 60% A

Acetonytrile A

Butyl Amine D

Carbon Tetrachloride (dry) D

Chloroform A

Diethyl Ether D

Dimethyl Formamide A

Ethanolamine D

Ethanol A

Ethylene Diamine D

Furfural D

Hexane A

Hydrofluoric Acid D

Methanol (Methyl Alcohol) A

Monoethanolamine D

Potassium Hydroxide (Caustic Potash) D

Potassium Hypochlorite D

Sodium Hydroxide D

Sodium Hypochlorite D

Concentrated Sulfuric Acid D

Diluted Sulfuric Acid (Concentration ≤ 1 N) A

Tetrahydrofuran A

Water, Deionized A

Water, Distilled A

Water, Fresh A

®

injectors. They will severely

36 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 37

STOP

STOP

2. General Description

Caution

The information in this table has been supplied to Tecan Austria by

other reputable sources and is to be used ONLY as a guide in selecting

equipment for appropriate chemical compatibility. Before permanent

installation, test the equipment with the chemicals and under the

specific conditions of your application.

Caution

Variations in chemical behaviour during handling due to factors such as

temperature, pressure and temperature, pressure, and concentration

can cause equipment to fail, even though it passed an initial test.

SERIOUS INJURY MAY RESULT. Use suitable guards and/or personal

protection when handling chemicals.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 37

Page 38

2. General Description

2.4 Software

The infinite

instrument and includes an online-help file and a printed Instructions for Use. The

software is formatted as a self-extracting archive on CD-ROM.

For advanced data reduction and full regulatory compliance with CFR 2 part 11

guidelines, The Magellan software can be used to control the

more information, contact your local Tecan representative).

®

200 is delivered with the i-Control software, for operating the

2.4.1 i-Control and Injectors

When using the injector, two modes are available:

• Dispense: The dispense mode allows liquid to be dispensed plate-wise

into the selected wells

• Injection: This mode must be used in combination with a measurement

strip. The injection is performed in a well-wise mode.

Dispense Mode

The dispense settings can be adjusted via the software:

infinite® 200. (For

Dispense

38 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Select Injector: Injector A and/or Injector B can be selected.

Speed: The injection speed is selectable from 100 – 300 µl/sec for each

injector.

Select ‘Refill speed’ from 100 – 300 µl/sec. for each injector or select

‘Refill Speed equal to Dispense Speed’.

Select refill mode ‘Standard’, if refill should be performed when syringe is

empty (multiple dispense steps are performed before refilling, refill occurs

after dispensing approx. 800 µl).

Select ‘Refill for every dispense’ if refill should be performed for every

dispense step.

Page 39

2. General Description

Using the Dispense Strip:

Plate

Part of the plate

Dispense

Dispense volume

Select an appropriate plate type

Optional;

Select the wells to be dispensed

Set up the dispense parameters.

If both injectors are selected, all wells are first dispensed with

injector A and then with injector B.

The dispense strip does not require an additional measurement

strip.

The injection volume depends on the microplate type. The plate

definition files include a so-called working volume. This working

volume defines the maximum volume to be dispensed into the

selected microplate. Therefore, always make sure that the

selected plate definition file contains the correct setting for the

working volume. The maximum dispense volume is

800 µl/dispense strip. If volumes greater than 800 µl are to be

dispensed (e.g. into 6-well plates), more than one dispense strip

has to be used.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 39

Page 40

2. General Description

Injection Mode

The injection settings can be adjusted via the software:

Injection

Select Injector:

Injector A or Injector B can be selected. It is not possible to select

both injectors on one strip. If a measurement with two injectors is to

be performed, two injector strips are necessary.

Speed: The injection speed is selectable from 100 – 300 µl/sec for

each injector.

Select a ‘Refill speed’ from 100 – 300 µl/sec. for each injector or

check the ‘Refill Speed equal to Injection Speed’ box.

Select refill mode ‘Standard’ if refill should be performed when

syringe is empty (multiple injection steps are performed before

refilling, refill occurs after dispensing approx. 800 µl). Select ‘Refill

for every injection’ if refill should be performed for every injection

step.

Injection

volume

The injection volume depends on the microplate type. The plate

definition files include a so-called working volume. This working

volume defines the maximum volume to be injected into the

selected microplate. Therefore, always make sure that the selected

plate definition file contains a correct setting for the working volume.

The maximum injection volume is 800 µl/injection strip. If volumes

greater than 800 µl are to be injected (e.g. into 6-well plates), more

than one injection strip has to be used.

40 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 41

2. General Description

Using the Injection Strip:

Plate

Part of the plate

Well

Injection

Measurement strip

(Example

Absorbance)

Select an appropriate plate type.

Optional;

Select the wells to be dispensed

The well strip is mandatory.

Injection is only possible with a ‘well’ strip. This strip ensures that

the following indented strips are performed well-wise.

Set up the injection parameters.

Only one injector can be selected per strip. If both injectors are

required or one injector will perform two injections, an additional

injection strip has to be inserted.

It is mandatory to use at least one measurement strip in

combination with the injection strip. The position of the

measurement strip(s) (before and/or after the injection strip)

depends on the application and is therefore user-selectable.

Note

Make sure that the corresponding Working Volume value in your plate

definition file is higher than the volume used for injection.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 41

Page 42

2. General Description

Wait Strip

A Wait time (delay or settle time) can be inserted into the procedure.

Wait time

Options

Select a time in hh:mm:ss from 00:00:01 up to 23:59:59

If ‘Wait for injection’ is selected, the wait time includes the injection

time.

If ‘Wait for injection’ is NOT selected, the wait time is added to the

injection time.

42 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 43

2. General Description

2.4.2 i-Control Examples

Example 1: Dual Luciferase Assay™ (Promega Corp.)

For assay details please refer to www.promega.com.

Plate

Part of the plate

Well

Injection (1)

Wait (Timer)

Luminescence (1)

Injection (2)

Wait (Timer)

Luminescence (2)

Move Plate

Select an appropriate plate type. For luminescence measurements, white

microplates are recommended. For this example, a white 96-well plate was

selected.

(Not shown); can be optionally selected if only part of the plate is to be

processed.

Mandatory for measurements with ‘injection’

Injector A injects 100 µl with speed 200 µl/sec., refill mode: standard

2 s wait time

Luminescence measurement with 10 s integration time, attenuation ‘none’

Injector B injects 100 µl with speed 200 µl/sec., refill mode standard

2 s wait time

Luminescence measurement with 10 s integration time, attenuation ‘none’

Plate is moved out after finishing all wells

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 43

Page 44

2. General Description

Example 2: Enliten® ATP Assay System Bioluminescence Detection Kit for ATP (Promega Corp.)

For assay details please refer to www.promega.com.

Plate

Part of the plate

Well

Injection

Wait (Timer)

Luminescence

Move Plate

Select an appropriate plate type. For luminescence

measurements, white microplates are recommended. For

this example, a white 96 well plate was selected.

(Not shown); can be optionally selected if only part of the

plate should be processed

Mandatory for measurements with ‘injection’

Injector A injects 100 µl with speed 100 µl/sec., refill mode:

standard

2 s wait time

Luminescence measurement

with 10 s integration time, attenuation ‘none’

Plate is moved out after finishing all wells

44 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 45

2. General Description

Example 3: Measurement of Ca2+ sensitive probes – Fura-2

Plate

Part of the plate

Well

Kinetic Cycle

Kinetic condition

Injection

Fluorescence Intensity (1)

Fluorescence intensity (2)

Move Plate

Select an appropriate plate type. For fluorescence

measurements, black microplates are recommended.

For this example, a black 96 well plate was selected.

(Not shown), can be optionally selected if only part of the

plate should be processed

Mandatory for measurements with ‘injection’

Select the number of necessary cycles

This strip allows actions to be performed once in a kinetic

run at a certain cycle. The intended injection strip below it

is only processed once at the selected cycle.

Injector A injects 20 µl with speed 200 µl/sec., refill mode:

not selectable; injection is performed at cycle 5 (defined

by kinetic condition strip)

Select the appropriate parameters for the first label:

Excitation wavelength: 380 nm, Emission wavelength:

510 nm; number of flashes: 25; integration time: 40; gain:

manual

Select the appropriate parameters for the second label:

Excitation wavelength: 340 nm, Emission wavelength:

510 nm; number of flashes: 25; integration time: 40; gain:

manual

Plate is moved out after finishing all wells

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 45

Page 46

2. General Description

Example 4: Measurement of Ca2+ sensitive probes – Indo-1

Plate

Part of the plate

Well

Kinetic Cycle

Kinetic condition

Injection

Fluorescence Intensity (1)

Fluorescence intensity (2)

Move Plate

Select an appropriate plate type. For fluorescence

measurements, black microplates are recommended.

For this example, a black 96 well plate was selected.

(Not shown); can be optionally selected if only part of the

plate should be processed

Mandatory for measurements with ‘injection’

Select the number of necessary cycles

This strip allows actions to be performed once in a kinetic

run at a certain cycle. The intended injection strip below it

is only processed once at the selected cycle.

Injector A injects 20 µl with speed 200 µl/sec., refill mode:

not selectable; injection is performed at cycle 5 (defined

by kinetic condition strip)

Select the appropriate parameters for the first label:

Excitation wavelength: 340 nm, Emission wavelength:

410 nm; number of flashes: 25; integration time: 40; gain:

manual

Select the appropriate parameters for the second label:

Excitation wavelength: 340 nm, Emission wavelength:

480 nm; number of flashes: 25; integration time: 40; gain:

manual

Plate is moved out after finishing all wells

46 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 47

3. Installation

3. Installation

3.1 Unpacking and Inspection

The delivered packaging includes the following items:

• CABLE USB 2.0 A/B 1.8 M Black with housing receptacle ferrite

• CDROM

• OOB Quality Report

• Transport lock (mounted)

• Instructions for Use

• Final test protocol

infinite® F200 packaging includes additionally the following items:

The

• Accessory Box

• Filter stop rings (8)

• Filter assembly tool

• Plastic tweezers

• Filter slide

infinite® F200/infinite® M200

STOP

The injector module packaging for 1 injector includes the following items:

• Bottle holder

• Beaker for priming

• 125 ml bottle brown

• Injector dummy (mounted)

• Waste tub

• 15 ml bottle

The second injector comes with the following items:

• Bottle holder

• Beaker for priming

• 125 ml bottle brown

• Waste tub

• 15 ml bottle

Caution

The reader has been tested with the supplied USB cable. If another USB

cable is used, Tecan Austria cannot guarantee the correct performance

of the instrument.

2008-07 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 47

Page 48

3. Installation

3.1.1 Unpacking Procedure

1. Visually inspect the container for damage before it is opened.

Report any damage immediately.

2. Select a location to place the instrument that is flat, level, vibration free,

away from direct sunlight, and free from dust, solvents and acid vapors.

Allow at least 10 cm distance between the back of the instrument and the

wall or any other equipment. Ensure that the plate carrier cannot be

accidentally hit when moved out. Ensure that the main switch and the main

cable can be reached at all times and are in no way obstructed.

3. Place the carton in an upright position and open it.

4. Lift the instrument out of the carton and place it in the selected location.

Take care when lifting the instrument and ensure that it is held on both

sides.

5. Visually inspect the instrument for loose, bent or broken parts.

Report any damage immediately.

6. Compare the serial number on the rear panel of the instrument with the

serial number on the packing slip.

Report any discrepancy immediately.

7. Check the instrument accessories against the packing list.

8. Save packing materials and transport locks (see next section) for further

transportation purposes.

STOP

STOP

STOP

STOP

WARNING

THE infinite

®

200 IS A PRECISION INSTRUMENT AND WEIGHS FULLY

EQUIPPED APPROX. 16 KG.

Caution

The maximum load for the infinite

must be distributed evenly across the entire surface of the cover.

®

200 cover is 16 kg, however the load

Caution

The maximum load for the infinite

®

200 plate transport is 100 g.

Caution

Allow at least 10 cm distance between the back of the instrument and

the wall or any other equipment.

Caution

The instrument must be placed in a location away from direct sunlight.

Illumination > 500 lux can negatively influence luminescence

measurements.

48 Instructions for Use for infinite® 200 No. 30017581 Rev. No. 1.4 2008-07

Page 49

3. Installation

3.2 Removal of the Transport Locks

STOP

Caution

Remove the transport lock before operating the instrument.

The instrument is delivered with the plate carrier and filter carrier/cuvette carrier