Page 1

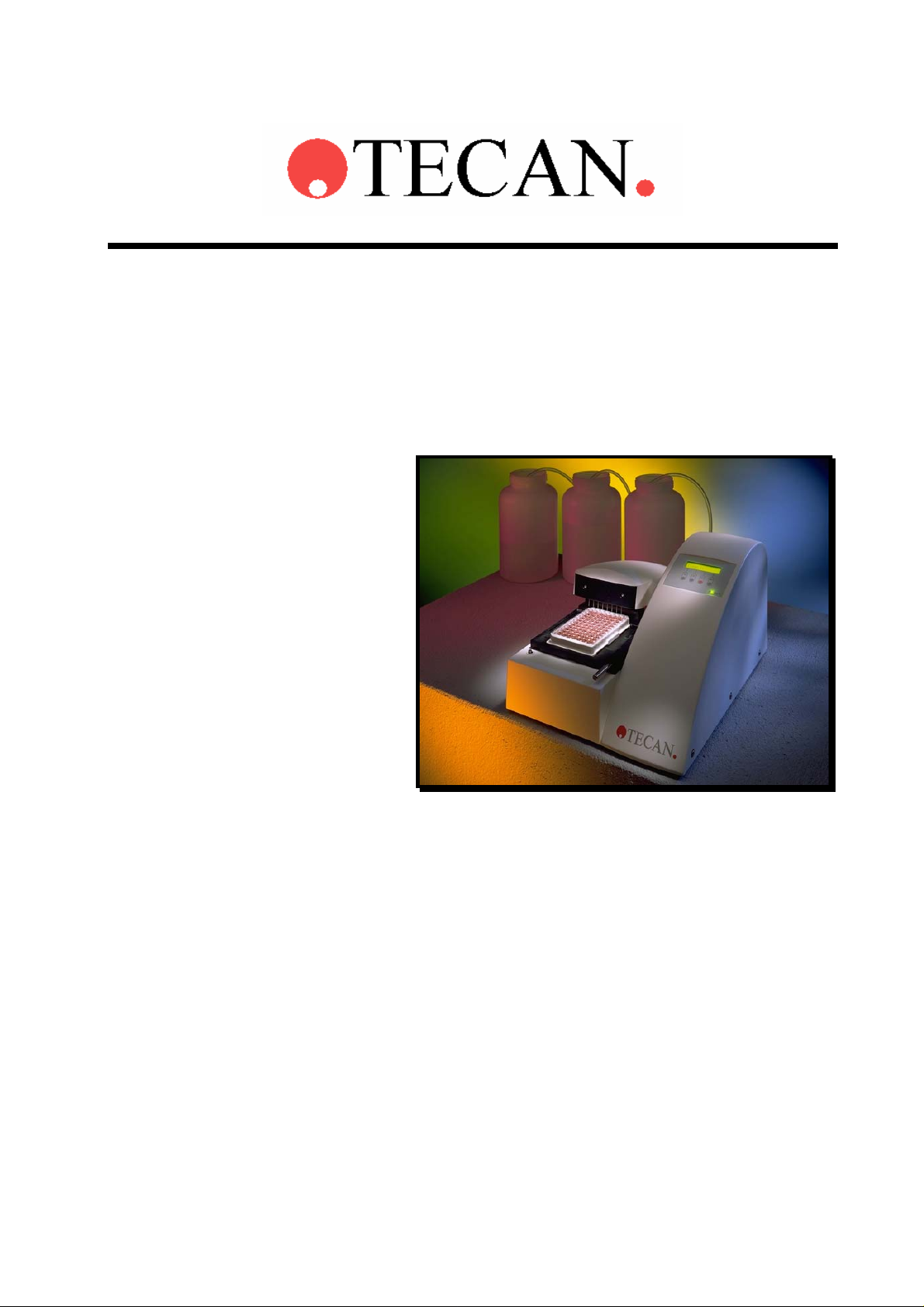

Technical Manual for

Columbus Washer

Document Part No.: 30000294

2006-02

Document Revision No.: 1.7

Firmware Level: 4.xx

Page 2

TECAN Affiliates and Service Centers

Austria

Tecan Austria GmbH

Untersbergstrasse 1a

A-5082 Grödig/Salzburg

Austria

T +43 6246 8933 256

F +43 6246 72 770

helpdesk-at@tecan.com

Belgium

Tecan Benelux bvba

Vaartdijk 55

B-2800 Mechelen

Belgium

T +32 15 42 13 19

F +32 15 42 16 12

tecan-be@tecan.com

Germany

Tecan Deutschland GmbH

Theodor-Storm-Strasse 17

D-74564 Crailsheim

Germany

T +49 1805 8322 633 or

T +49 1805 TECANDE

F +49 7951 9417 92

helpdesk-de@tecan.com

Netherlands

Tecan Benelux bvba

Industrieweg 30

NL-4283 GZ Giessen

Netherlands

T +31 183 44 81 74

F +31 183 44 80 67

tecan-nl@tecan.com

Spain (Madrid)

Tecan Ibérica

Gobelas 17 bjo. Izq. Urb. La Florida

E-28023 Madrid

Spain

T +34 91 151 7107

T +34 93 409 1237 (Helpdesk)

F +34 91 151 7120

helpdesk-sp@tecan.com

United Kingdom

Tecan UK

Theale Court

11-13 High Street

Theale

UK-Reading RG7 5AH

United Kingdom

T +44 118 930 0300

F +44 118 930 5671

helpdesk-uk@tecan.com

Austria

Tecan Sales International GmbH

Untersbergstrasse 1a

A-5082 Grödig/Salzburg

Austria

Tel.: +43 6246 8933

Fax: +43 6246 72 770

China

Tecan Group Ltd, Beijing

Representative Office

Room 2502, Building A

Jianwai SOHO

No. 39 Dongsanhuan Zhong Rd.

100022 Beijing

China

T +86 10 5869 5936

F +86 10 5869 5935

Italy

Tecan Italia S.r.l.

Via F.lli Cervi

Palazzo Bernini

Centro Direzionale Milano 2

I-20090 Segrate (Mi)

Italy

T +39 02 215 21 28

F +39 02 215 97 441

helpdesk-it@tecan.com

Scandinavia

Tecan Nordic AB

Taljegårdsgatan 1

SE-431 53 Mölndal

Sweden

T +46 317 54 40 00

F +46 317 54 40 10

helpdesk@tecan.se

Portugal

Tecan Ibérica

Quinta da Fonte Edificio Pedro I

P-2780-730 Paço D'Arcos

Portugal

T +35 21 000 8216

USA

Tecan US

4022 Stirrup Creek Road

Suite 310

Durham, NC 27703

USA

T +1 919 361 5200

F +1 919 361 5201

Toll Free US:

T +1 800 TECAN US or

T +1 800 832 2687

helpdesk-us@tecan.com

Asia

Tecan Asia Pte Ltd.

80 Marine Parade

#10-09 Parkway Parade

Singapore 449269

Singapore

T +65 6444 1886

F +65 6444 1836

tecan@tecan.com.sg

France

Tecan France SAS

26 avenue Tony Garnier

F-69007 Lyon

France

T +33 820 88 77 36

F +33 472 76 04 99

helpdesk-fr@tecan.com

Japan

Tecan Japan Co., Ltd.

Kawasaki Tech Center

580-16, Horikawa-cho,

Saiwai-ku

Kawasaki, Kanagawa 212-0013

Japan

T +81 44 556 7311 (Kawasaki)

F +81 44 556 7312 (Kawasaki)

T +81 66 305 8511 (Osaka)

helpdesk-jp@tecan.com

Spain (Barcelona)

Tecan Ibérica

Sabino de Arana 32

E-08028 Barcelona

Spain

T +34 93 490 0174

T +34 93 409 1237 (Helpdesk)

F +34 93 411 2407

helpdesk-sp@tecan.com

Switzerland

Tecan Schweiz AG

Seestrasse 103

CH-8708 Männedorf

Switzerland

T +41 44 922 82 82

F +41 44 922 84 84

helpdesk-ch@tecan.com

USA

Tecan Systems Inc.

2450 Zanker Road

San Jose, CA 95131

USA

T +1 408 953 3100

F +1 408 953 3101

Toll Free US/Canada:

T +1 866 798 3226

helpdesk-sy@tecan.com

2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 3

WARNING

CAREFULLY READ AND FOLLOW THE INSTRUCTIONS

PROVIDED IN THIS MANUAL BEFORE OPERATING THE

INSTRUMENT.

Notice

Every effort has been made to avoid errors in text and diagrams, however, Tecan

Austria GmbH assumes no responsibility for any errors whi ch may appe ar in this

publication.

It is the policy of Tecan Austria GmbH to improve products as new techniques

and components become available. Tecan Austria GmbH therefor e reserves

the right to change specifications at any time.

We would appreciate any comments on this publication.

Tecan Austria GmbH

Untersbergstraße 1A

A-5082 Grödig/Salzburg

AUSTRIA / EUROPE

Telephone: 0043 (0)6246/8933

FAX: 0043 (0) 6246/72770

E-mail: office.austria@tecan.com

www.tecan.com

Copyright Information

The contents of this manual are the property of Tecan Austria GmbH and are not

to be copied, reproduced or transferred to another person or persons without our

prior written permission.

Copyright © Tecan Austria GmbH

All rights reserved.

Printed in Austria.

Declaration for EU Certificate

See the back of this manual.

About this Manual

This technical manual describes the servicing of the Columbus Washer, designed

to wash microplates. It is intended only for service personnel.

This manual instructs how to:

• Install the instrument

• Operate the instrument

• Programming the wash procedure

• Definition on the wash parameters

• Cleaning and maintenance procedures

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3

Page 4

Warnings, Cautions and Notes

There are three types of informational notices used in this manual. These notices

highlight important information or warn the user of a potentially dangerous

situation. The following notices are:

Note

Gives helpful information.

Caution

Indicates a possibility of instrument damage or data loss if instructions are

INDICATES THE POSSIBILITY OF SEVERE PERSONAL INJURY, LOSS OF

LIFE OR EQUIPMENT DAMAGE IF THE INSTRUCTIONS ARE NOT

not followed.

WARNING

FOLLOWED.

4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 5

Table of Contents

1. General

1.1 Overview......................................................................................... 1-1

1.2 Instrument Description .................................................................1-2

1.2.1 Rear Panel Connections.................................................................. 1-2

1.2.2 Connection Diagram for Columbus (1 Liquid Channel)*.................. 1-4

1.2.3 Connection Diagram for Columbus (4 Liquid Channels)*................ 1-5

1.2.4 Keyboard and Display Unit..............................................................1-6

1.3 Interconnection Diagram .............................................................. 1-7

2. Installation Procedure

2.1 Unpacking and Inspection............................................................ 2-1

2.2 Unpacking Procedure ................................................................... 2-2

2.3 Power Requirements..................................................................... 2-2

2.4 Installation Procedure................................................................... 2-3

2.4.1 Installing the Instrument .................................................................. 2-3

2.4.2 Connecting the Waste Tubing......................................................... 2-3

2.4.3 Connecting the Solution Tubes ....................................................... 2-4

2.4.4 Fitting and Connecting the Liquid Sensors (Optional).....................2-5

2.4.5 Connecting the Barcode Reader (Optional)..................................... 2-6

2.4.6 Connecting the Printer (Optional)....................................................2-6

2.4.7 Power Connections ......................................................................... 2-6

3. Firmwar e and S oftwar e De s cription

3.1 Instrument Software Features...................................................... 3-1

3.2 Onboard Software Menus............................................................. 3-2

3.2.1 Run..................................................................................................3-2

3.2.2 Prime............................................................................................... 3-2

3.2.3 Rinse ............................................................................................... 3-3

3.2.4 Program........................................................................................... 3-6

3.2.5 Clear................................................................................................3-6

3.2.6 Show................................................................................................ 3-6

3.2.7 Adjust............................................................................................... 3-7

3.2.8 Service Menu................................................................................. 3-24

3.3 External Software ........................................................................ 3-61

3.3.1 Columbus Computer Software ...................................................... 3-61

3.3.2 Firmware Update...........................................................................3-61

3.4 Serial Interface............................................................................. 3-62

3.4.1 Hardware Specifications................................................................ 3-62

3.4.2 Contents........................................................................................ 3-65

3.4.3 A. Protocol.....................................................................................3-67

3.4.4 Sequence Number......................................................................... 3-68

3.4.5 B. Commands - Overview.............................................................. 3-69

3.4.6 Commands - Description............................................................... 3-71

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 5

Page 6

3.4.7 D. Examples for Remote Control - Command Sequences.............3-88

3.5 Description of Error Messages...................................................3-95

4. Removing and Re placing the Instruments Cover

4.1 Removal of Instruments Top Cover..............................................4-1

4.2 Replacing the Instruments Top Cover .........................................4-3

5. Liquid System

5.1 Introduction ....................................................................................5-1

5.1.1 Liquid System Diagram....................................................................5-2

5.1.2 Dispensing System Description........................................................5-3

5.2 Replacement Procedure................................................................5-4

5.2.1 Replacing the Dispensing Pump......................................................5-4

5.2.2 Replacing the Solution Solenoid Valves (Instruments with Pinch

Valves) .............................................................................................

5.2.3 Replacing the Solution Solenoid Valves...........................................5-7

5.2.4 Replacing the Dispense Solenoid Valve ..........................................5-8

5.2.5 Replacing the Aspirating Pump........................................................5-9

5.2.6 Replacing the Aerosol Pump..........................................................5-10

5-6

6. Mechanical System

6.1 Manifold Arm Movement System..................................................6-1

6.1.1 Description of Manifold Arm Movement Parts..................................6-2

6.1.2 Adjusting the Manifold......................................................................6-2

6.2 Plate Transport System.................................................................6-3

6.2.1 Plate Support ...................................................................................6-4

6.2.2 Leveling the Plate Support...............................................................6-5

6.2.3 Microplate Positioning System.........................................................6-7

6.3 Replacement Procedure................................................................6-8

6.3.1 Replacing the Manifold Arm Error Sensor........................................6-8

6.3.2 Replacing the Motor.........................................................................6-9

6.3.3 Replacing the Top Position Optical Switch.....................................6-10

6.3.4 Replacing the Plate Support Home Position Optical Switch ..........6-11

7. Electronic System

7.1 Introduction ....................................................................................7-1

7.2 Interconnection Diagram...............................................................7-2

7.3 Main Board......................................................................................7-3

7.3.1 Replacing the Main Board................................................................7-4

7.3.2 Replacing the Battery.......................................................................7-5

7.4 Power Supply Board......................................................................7-6

7.4.1 Replacing the Power Supply Board..................................................7-7

7.5 Keyboard and Display Unit............................................................7-8

7.5.1 Replacing the Keyboard or Display Unit...........................................7-9

7.6 Manifold Detect Board.................................................................7-11

7.6.1 Replacing the Manifold Detect Board.............................................7-11

6 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 7

7.7 Fill Verification Board ................................................................. 7-13

7.7.1 Replacing the Fill Verification Board.............................................. 7-13

7.8 Optical Switches.......................................................................... 7-15

8. Serial Interface

8.1 Hardware Specifications............................................................... 8-1

8.1.1 Pin Designation ............................................................................... 8-1

8.1.2 RS-232-C Interface Lines................................................................8-2

8.1.3 Synchronization and Data Format...................................................8-3

8.1.4 Daisy Chaining Instruments............................................................. 8-3

9. Description of Options

9.1 Instrument Options ....................................................................... 9-1

9.2 Liquid Detection Option................................................................ 9-3

9.3 Barcode Reader Option ................................................................ 9-4

9.4 Printer Option ................................................................................ 9-5

9.5 Manifold Detection Option............................................................ 9-6

9.6 Fill Verification Option .................................................................. 9-8

9.7 Aerosol Pump Option.................................................................... 9-8

9.8 Activating the Options .................................................................. 9-8

10. Maintenance

10.1 Cleaning Maintenance................................................................. 10-1

10.1.1 Cleaning the Manifold.................................................................... 10-1

10.1.2 Exchanging the Manifold ............................................................... 10-3

10.1.3 Exchanging the Plate Support.......................................................10-5

10.1.4 Instrument Disinfection..................................................................10-6

10.2 Preventive Maintenance Plan..................................................... 10-8

10.2.1 Daily............................................................................................... 10-8

10.2.2 Weekly........................................................................................... 10-8

10.2.3 Every Six Months........................................................................... 10-8

10.2.4 Yearly (Service Technician Required)...........................................10-8

10.3 Service Tools ............................................................................... 10-9

10.3.1 Adjustment Plate (Reference Plate).............................................. 10-9

10.4 Electrostatic Discharge Information........................................ 10-10

10.4.1 Generating Static......................................................................... 10-10

10.4.2 Preventing Electrostatic Damage to Equipment.......................... 10-11

10.4.3 Personal Grounding Methods...................................................... 10-11

11. Trouble Shooting

11.1 Introduction.................................................................................. 11-1

12. Instrument Specifications

12.1 Introduction.................................................................................. 12-1

Index

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 7

Page 8

Page 9

1. General

1. General

1.1 Overview

This is a technical manual for servicing the Columbus Washer.

The instrument is a microprocessor controlled washer, designed to wash

microplates.

The instrument can be fitted with either an 8, 12 or 16 way manifold or a 384 Well

Manifold.

The manifolds are fitted with one aspirating and one dispensing needle per well.

The instrument can store up to nine software user-defined plate types including

dispensing and aspirating positions as well as the shape of the plate.

The dispensing speed can be selected from five set speeds and dropwise.

These features allow the instrument to be used for all washing applications

including Cell Washing applications.

The instrument should only be opened by authorized personnel. Before the

instrument is opened the mains power cable must be disconnected from

Ensure that the instrument has been disinfected before it is serviced.

the mains power socket.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-1

Page 10

1. General

r

r

(

)

A

(

)

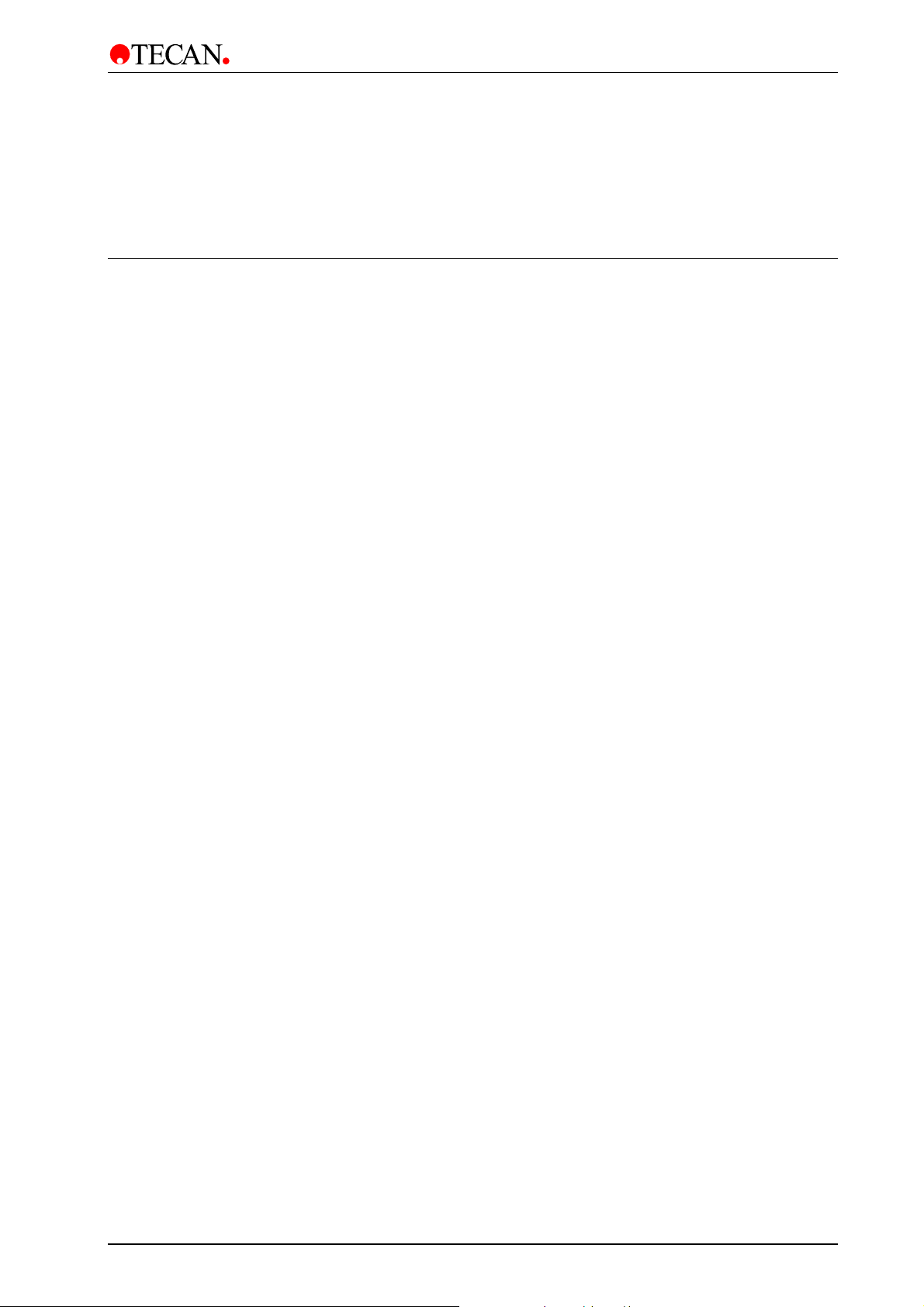

1.2 Instrument Description

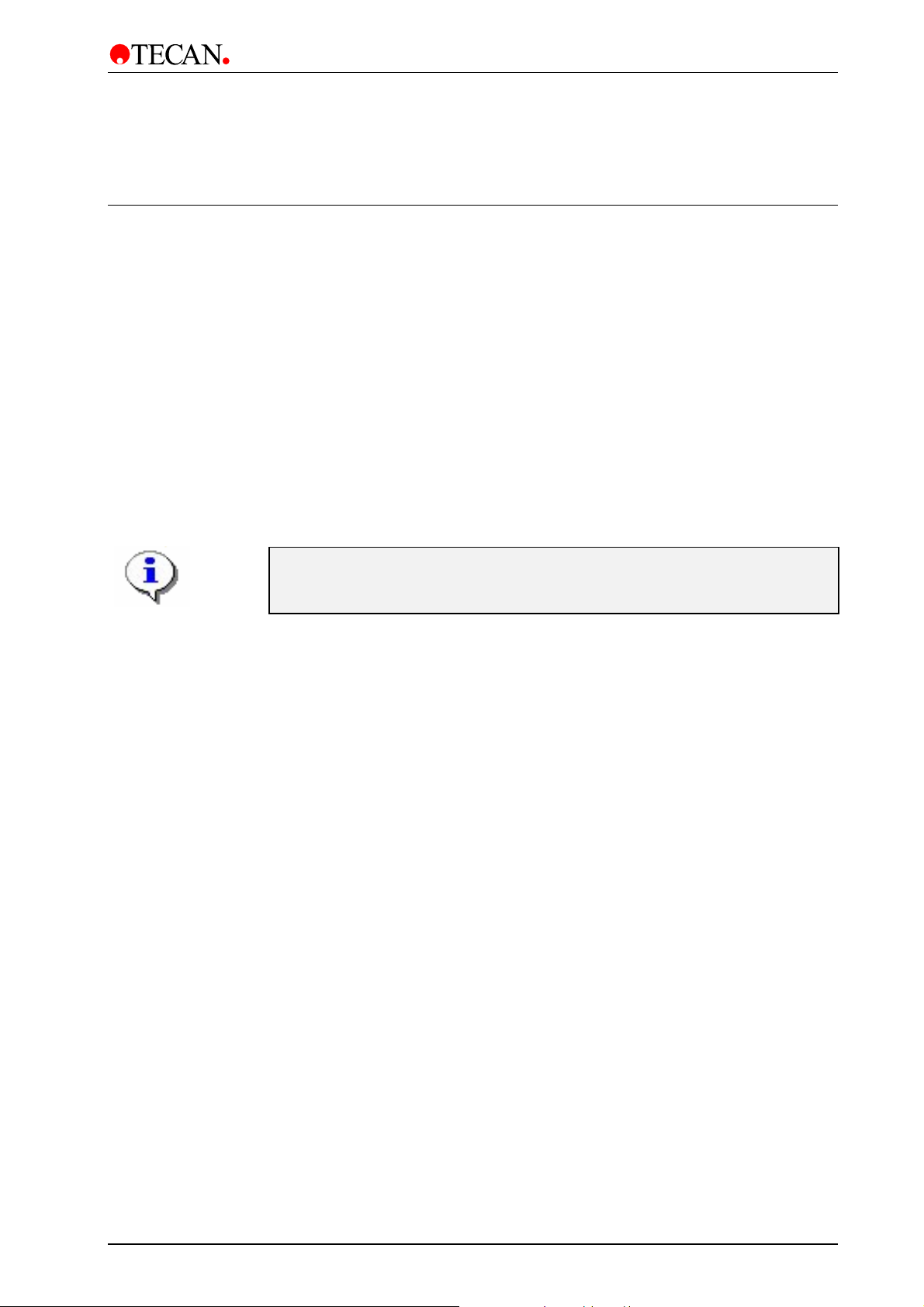

The diagram below shows the main components of the instrument:

Manifold Arm

Manifold

POWER

Power ON LED

Keyboa r d an d

Display Unit

Waste Sink

Plate Support

Guide Bar

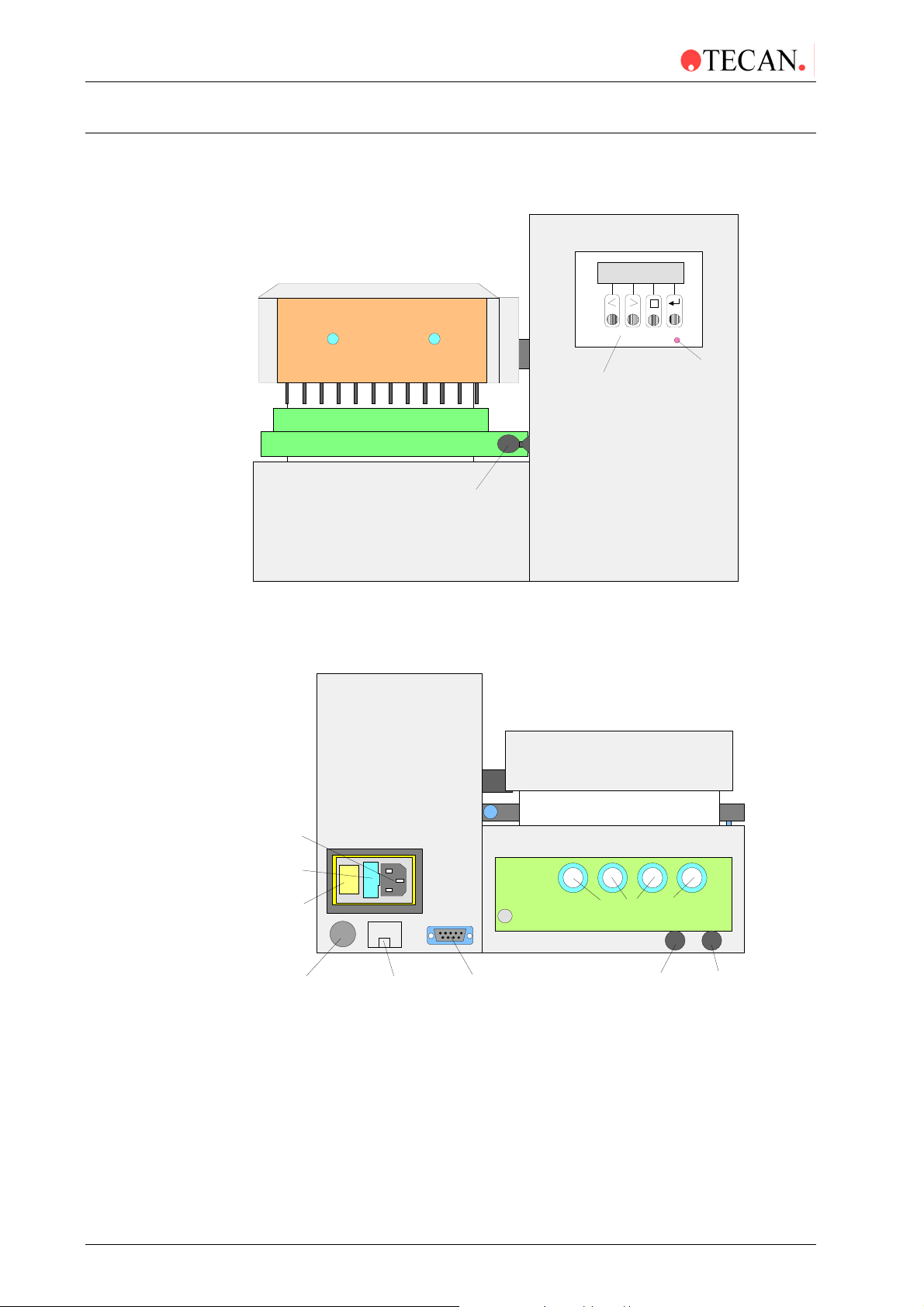

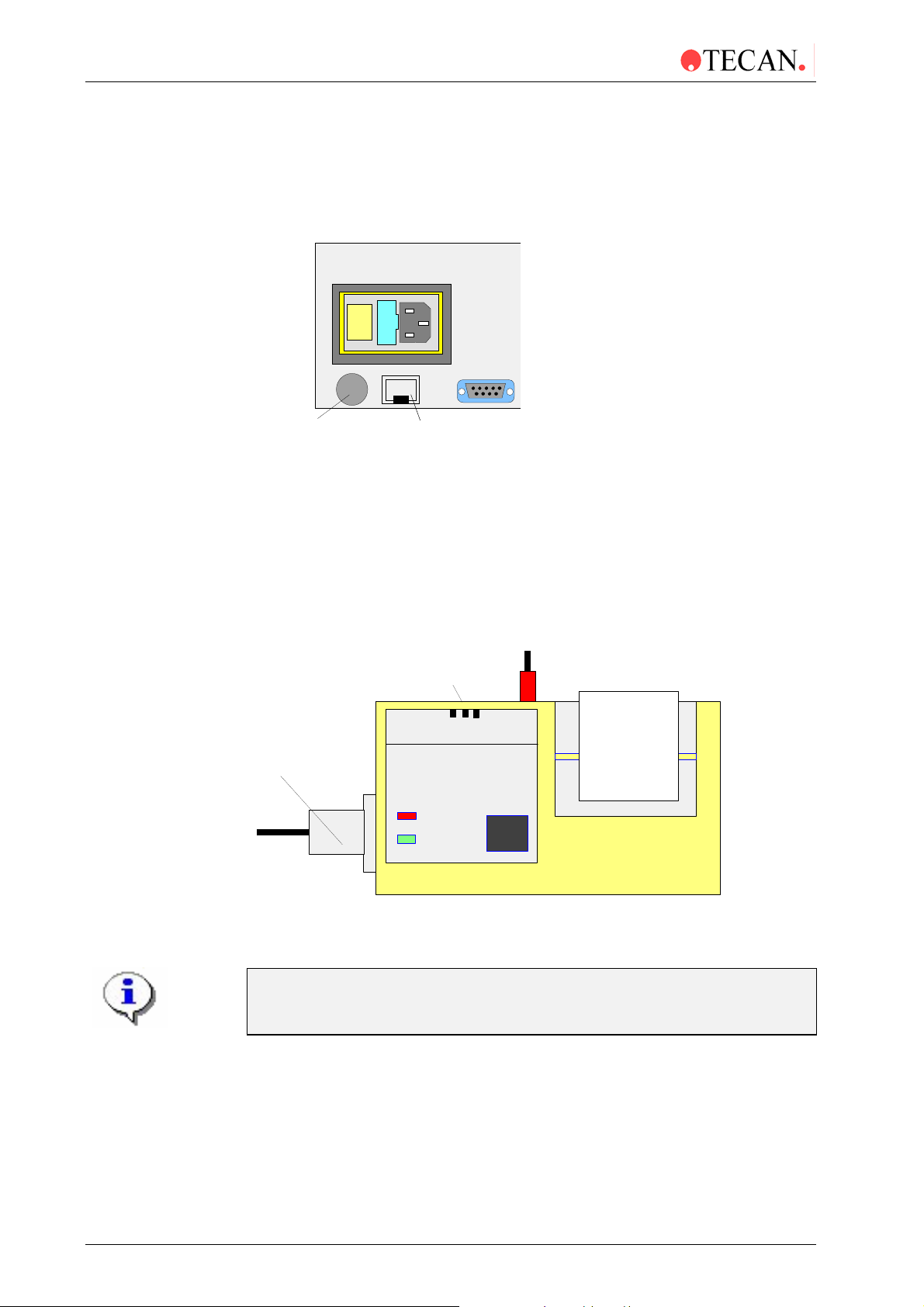

1.2.1 Rear Panel Connections

The instrument has the following connections on the back panel.

Mains Power

Socket

Fuse

Compartment

ON/OFF

Switch

Hand held

Barcode

Reader

Bottle Holder with

Liquid Sensor for

each bottle

Printer Connecto

or

Serial RS 232 fo

Remote Control

Inlets for channels 1 - 4

erosol

Tubing

option

Waste

Tubing

red

1-2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 11

1. General

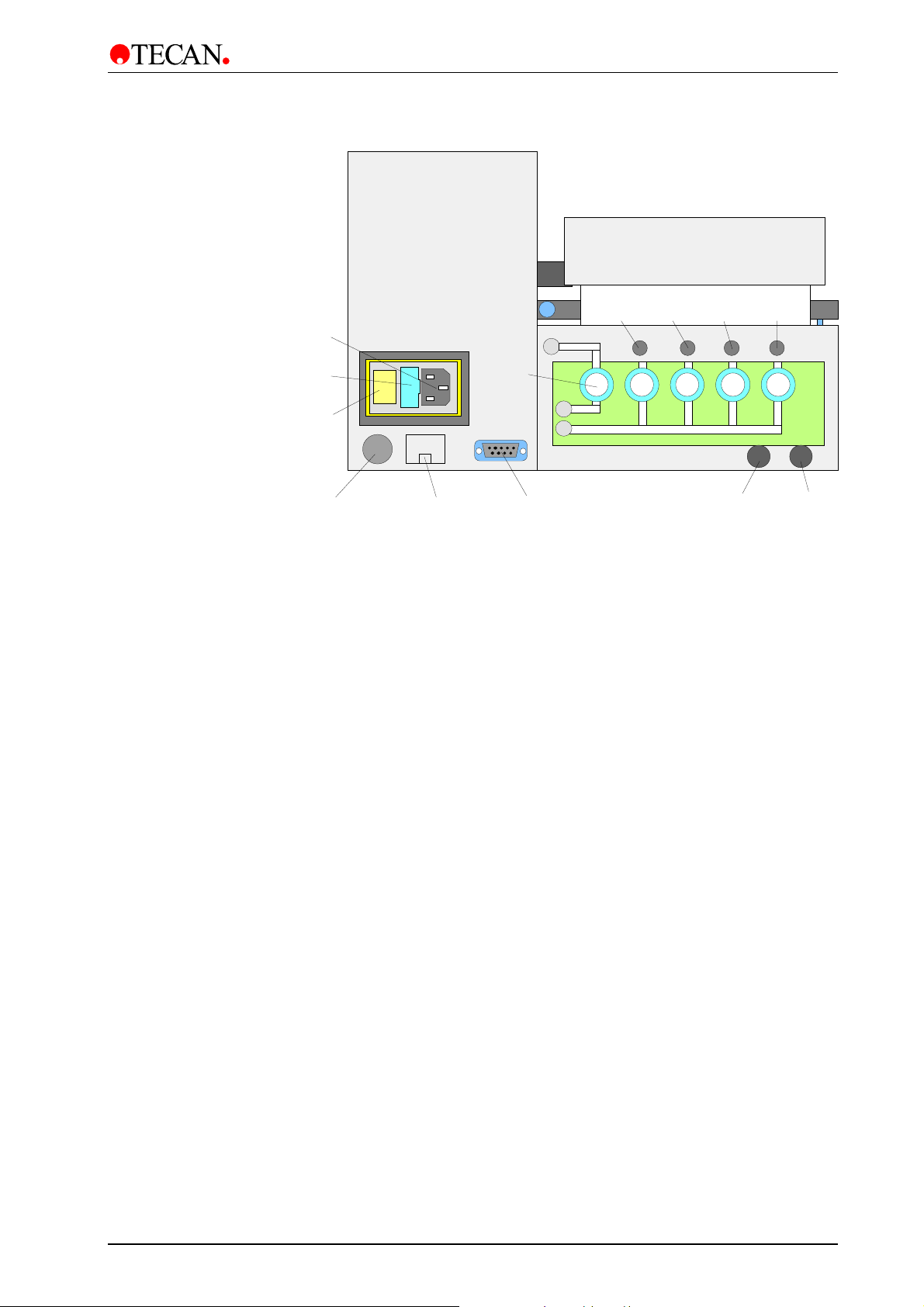

C

A

(Instrument with Pinch Valves)

Mains Power

Socket

Fuse

ompartment

ON/OFF

Switch

Hand held

Barcode

Reader

Bottle Holder with

Liquid Sensor for

each bottle

Prime

valve

Printer Connector

or

Serial RS 232 for

Remote Control

Channel 1

Inlet

Channel 2

Inlet

Channel 3

Inlet

erosol

Tubing

(yellow)

Channel 4

All connected devices must be proved and listed with regulations

EN 60950, UL 1950 or CSA C22.2 No. 950 for Data Processing Devices

Inlet

Waste

Tubing

(red)

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-3

Page 12

1. General

)

p

g

q

g

1.2.2 Connection Diagram for Columbus (1 Liquid Channel)*

Hand held

Barcode

Reader (option)

Prime

valve

Printer (option

or

Com

uter for

Remote Control

Marked

reen

grey

Wash

uid

Li

Bottle Holder with liquid

sensor for each bottle

reen

Rinse

solution

red

Inlet

filter

* Some of the instruments may include the prime valve.

Waste

Bottle

Marked

red

1-4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 13

1. General

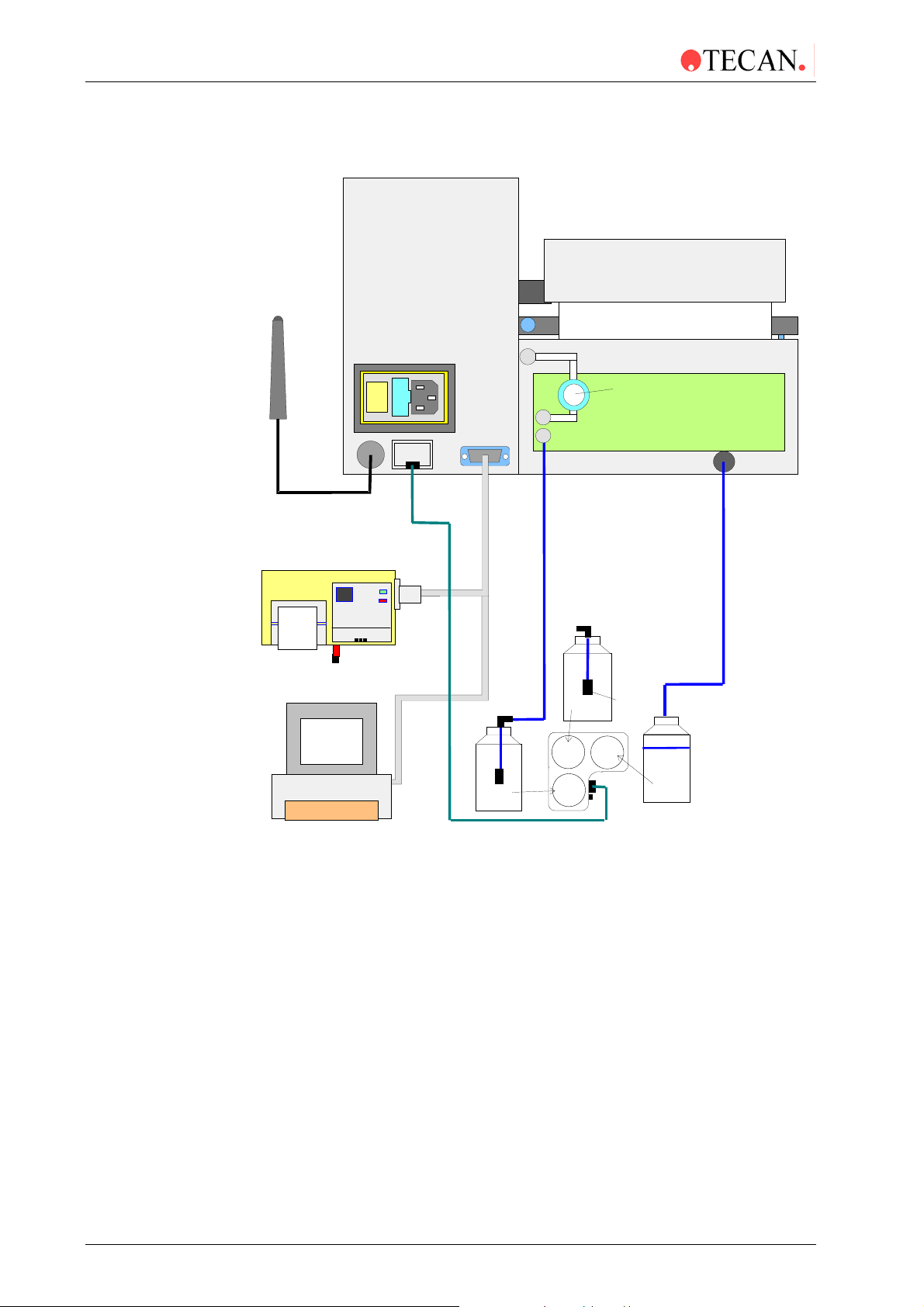

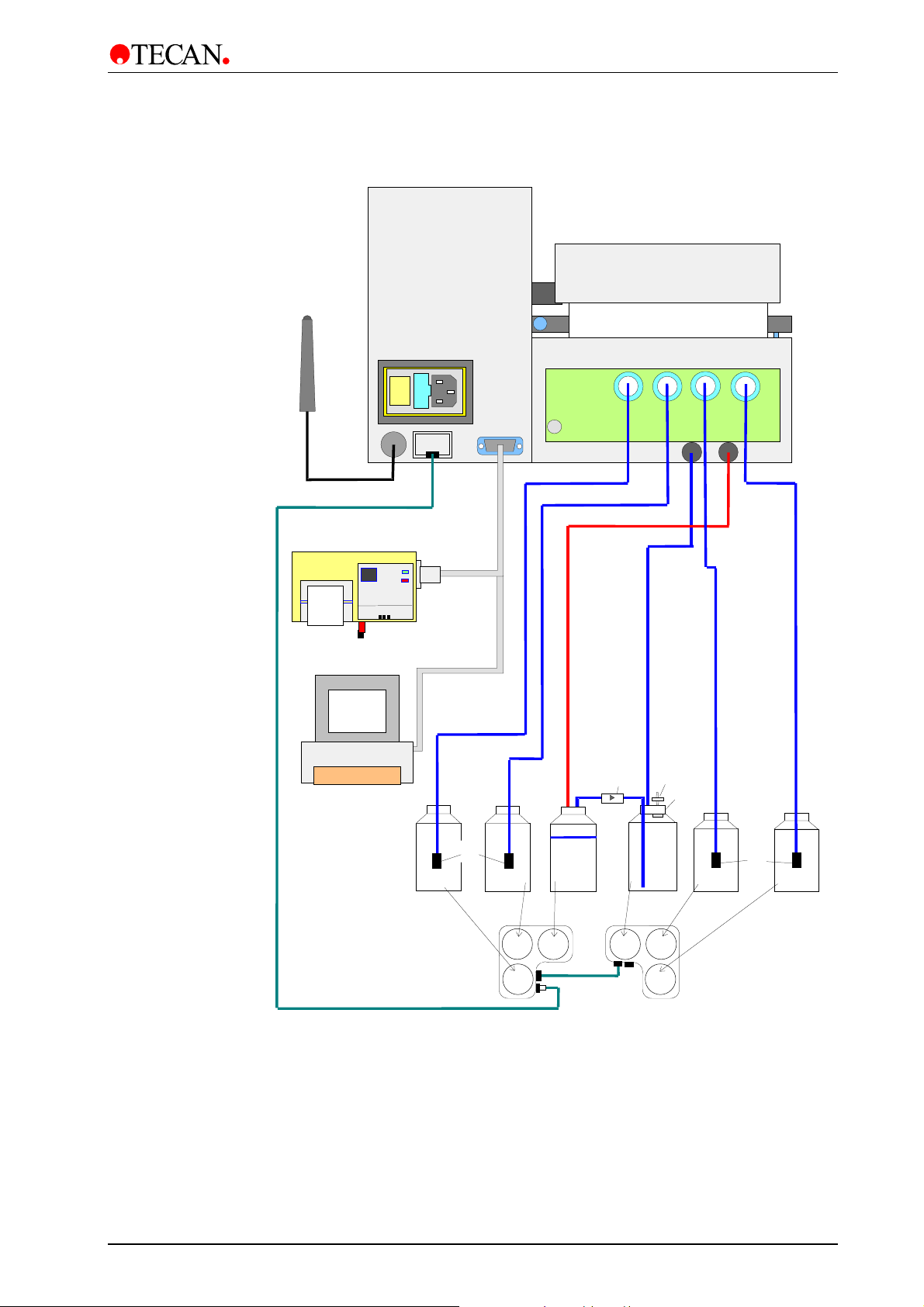

1.2.3 Connection Diagram for Columbus (4 Liquid Channels)*

Hand held Barcode

Reader (option)

Printer (option)

Computer for

Remote Control

Marked green

Inlet

filter

Wash

Liquid 1

Bottle Holders with liquid

sensor for each bottle

or

Marked grey

Rinse

solution

grey red

green

Marked

red

Waste

Bottle

Marked

blue

None Return

Valve

yellow

Marked

yellow

Foam

Bottle

purple

blue

Aerosol

Filter

Seperator

Water

Wash

Liquid 3

Marked

purple

Inlet

filter

Marked

blue

Wash

Liquid 2

* Some of the instruments may include the prime valve.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-5

Page 14

1. General

r

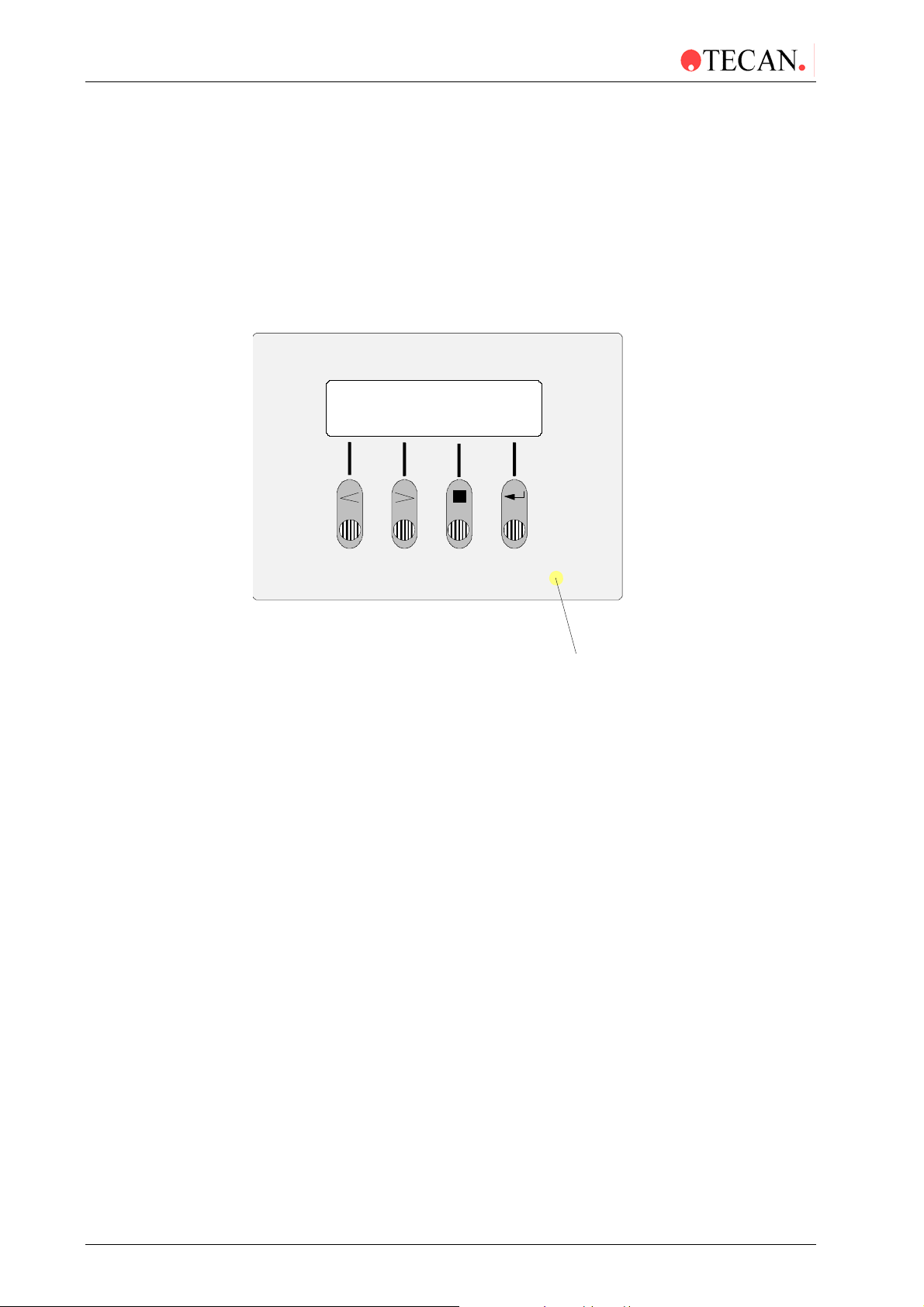

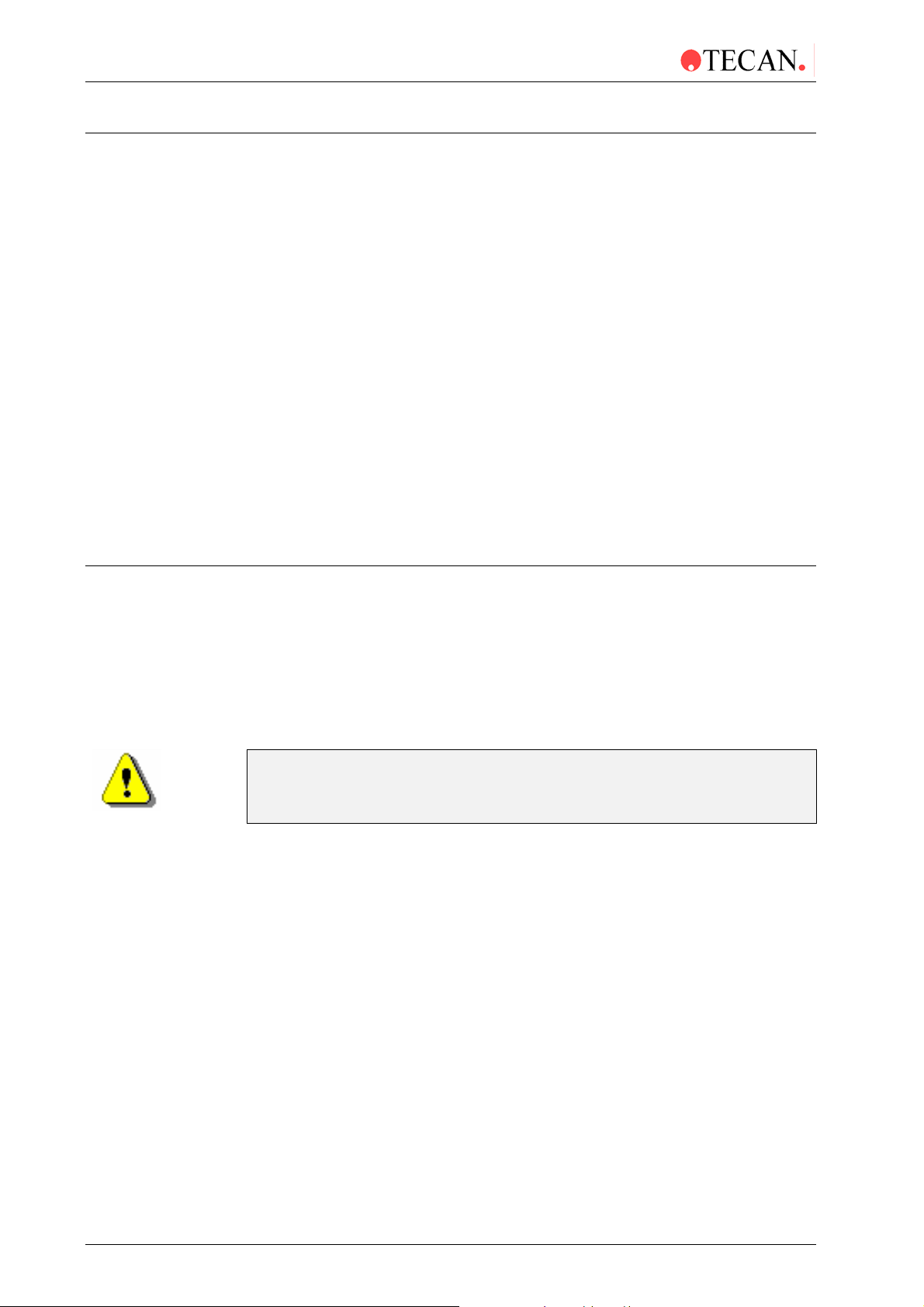

1.2.4 Keyboard and Display Unit

The Washer is operated via a keyboard and a control panel consisting of a two

row, sixteen digit Liquid Crystal Display (LCD) unit.

The top row of the display unit is used for messages and the bottom row for the

key functions or options.

A Light Emitting Diode (LED) in the center of the letter "O" of the word "POWER"

indicates when the Washer is switched ON.

Key 1 Key 2 Key 3

Key 4

POWER

Powe

ON LED

1-6 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 15

1. General

A

A

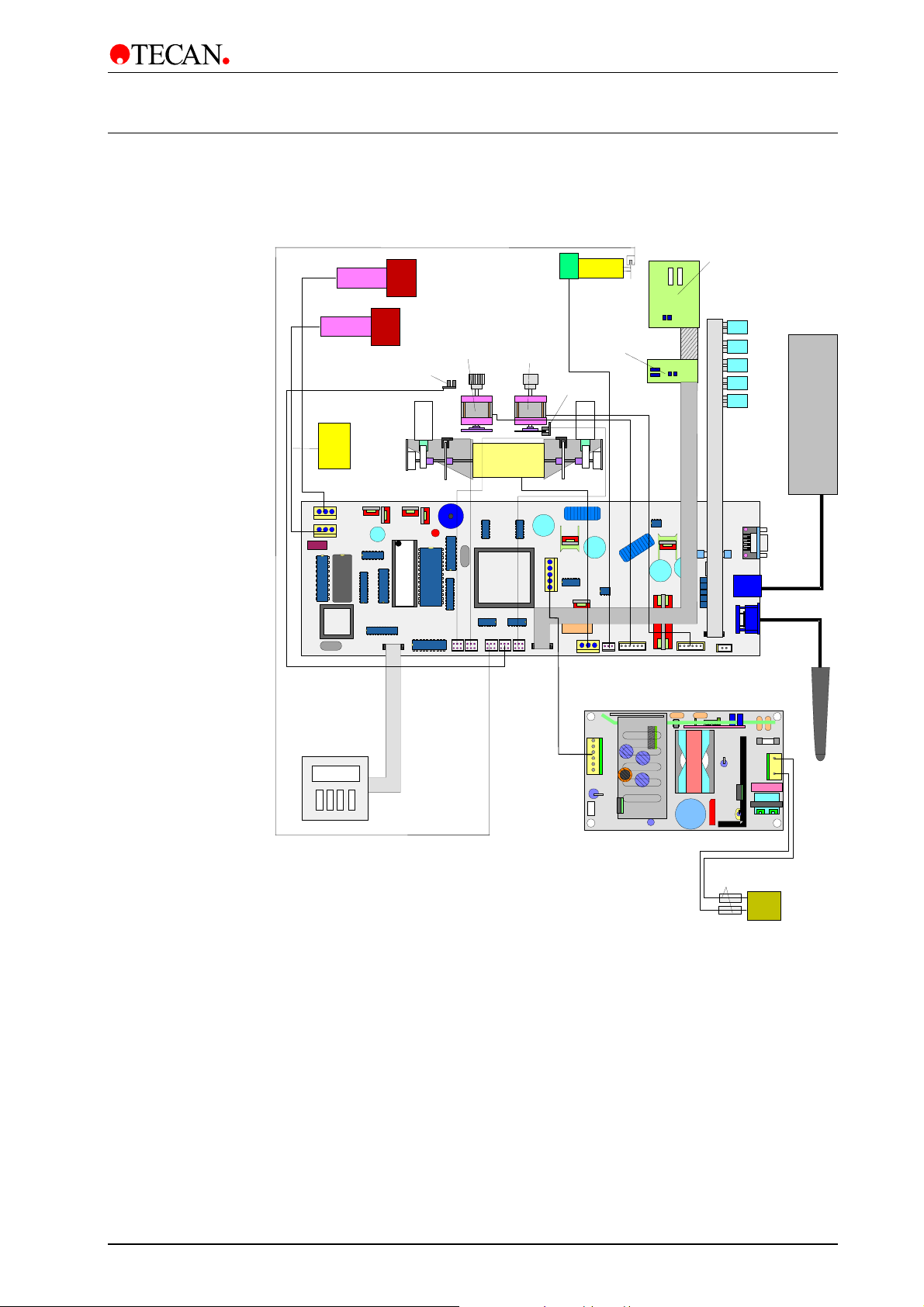

1.3 Interconnection Diagram

The diagram below shows how the various parts of the instrument are

interconnected.

Dispensing Pump

spirating Pump

erosol Pump

Prime Valve

Plate Home Position

Optical Switch

Plate Transport

Motor

Manifold Arm

Orbital Shaking

Motor

*

Motor

Home Position

Optical Switch

Manifold Typeand

Plate MismatchBoard

Fill Verify and

Plate Mismatch

Board

Solenoid 4

Solenoid 3

Solenoid 2

Solenoid 1

Dispense

Solenoid

Liquid

Detection

System

Keyboard /

Display Unit

Printer / Serial

Connector

EEPROM

CPU

Barcode Reader

Power Supply Board

Fuses

Mains Input

ON/OFF Switch

* The Orbital Shaking option is not used.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 1-7

Page 16

Page 17

2. Installation Procedure

(op

)

A

p

2. Installation Procedure

2.1 Unpacking and Inspection

The instrument is shipped in one carton, which contains:

• Instrument

• Accessory package which contains:

Spare manifold cover with two screws and Allen key

Operating manual

Mains power cable

Cleaning needles

2 spare fuses

Solution tube

3 spare 0 – ring seals for manifold

• Bottle set containing:

3 x 2.5 l bottles for the standard instrument

Liquid Sensor System

tional

Bottles

ccessory package

and o

erating manual

Instrument

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2-1

Page 18

2. Installation Procedure

2.2 Unpacking Procedure

1. Visually inspect the container for damage before it is opened.

Report any damage immediately.

2. To place the instrument, select a location that is flat, level, vibration free,

away from direct sunlight, and free from dust, solvents and acid vapors.

Allow 10 cm distance between the back of the instrument and the wall or any

other equipment.

3. Place the carton in an upright position and open it.

4. Lift the instrument out of the carton and place it in the selected location.

5. Visually inspect the instrument for loose, bent or broken parts.

Report any damage immediately.

6. Compare the serial number on the rear panel of the instrument with the

serial number on the packing slip.

Report any discrepancy immediately.

7. Check the instrument accessories against the packing list.

8. Save packing materials for future use.

2.3 Power Requirements

The instrument is designed to operate at either 100 - 120 volt or 220 - 240 volt.

No voltage setting is required as the washer automatically senses the supplied

voltage.

The washer requires 2 x T 1.6 A / 250 V (slow blow) fuses.

WARNING

TO PREVENT THE RISK OF FIRE, THE MAINS FUSES SHOULD ONLY BE

REPLACED WITH THE SAME TYPE AND RATING OF FUSE.

2-2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 19

2. Installation Procedure

A

2.4 Installation Procedure

Before the instrument is installed and switched on, it should be left to stand

for at least three hours, so there is no possibility of condensation causing a

2.4.1 Installing the Instrument

• Unpack the instrument and check the contents.

See 2.2 Unpacking Procedure.

• Connect the solution tubes to the inlet connectors.

See 2.4.3 Connecting the Solution Tubes.

• Setup possible instrument options. See page 2 – 5 and 2 – 6.

• Connect instrument to the power supply. See 2.4.7 Power Connections.

• Define the plate parameters in the Adjust menu. See chapter 3.

short circuit.

• Program the wash procedure. See chapter 3.

2.4.2 Connecting the Waste Tubing

Turn the instrument onto the right hand side.

Slide the waste tube through the hole in the back panel.

erosol Tube Hole

(optional)

Connect the waste tube onto the top connector of the aspirating pump.

Waste Tube Hole

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2-3

Page 20

2. Installation Procedure

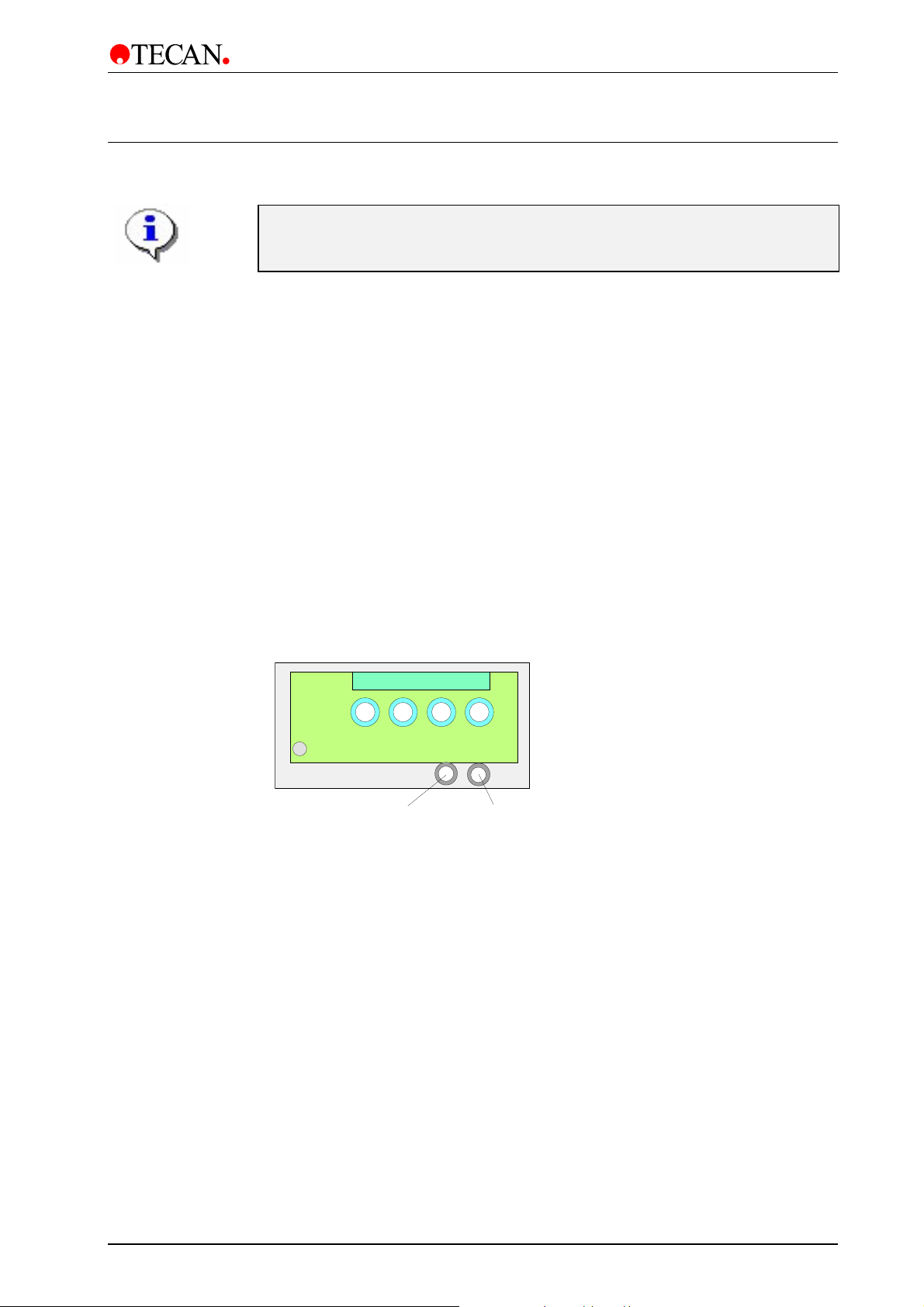

A

A

A

A

A

Standard Instrument

Waste Bottle

Dispensing

Pump

Waste Tube

spirating Tube to

Solution Tubes to Manifold

Aspirating Pump

Turn the instrument back to the normal position.

Place the other end of the waste tubing into the waste bottle.

Connect the aerosol tube onto the aerosol pump if this option is fitted. This is not

necessary for the standard instrument.

Instrument with Aerosol Protection Option

Waste Bottle

Dispensing Pump

erosol Bottle

Aspirating Tube to Manifold

Solution Tubes to Manifold

spirating Pump

erosol

Pump

Turn the instrument back to the normal position.

Place the other end of the aerosol tubing into the aerosol bottle.

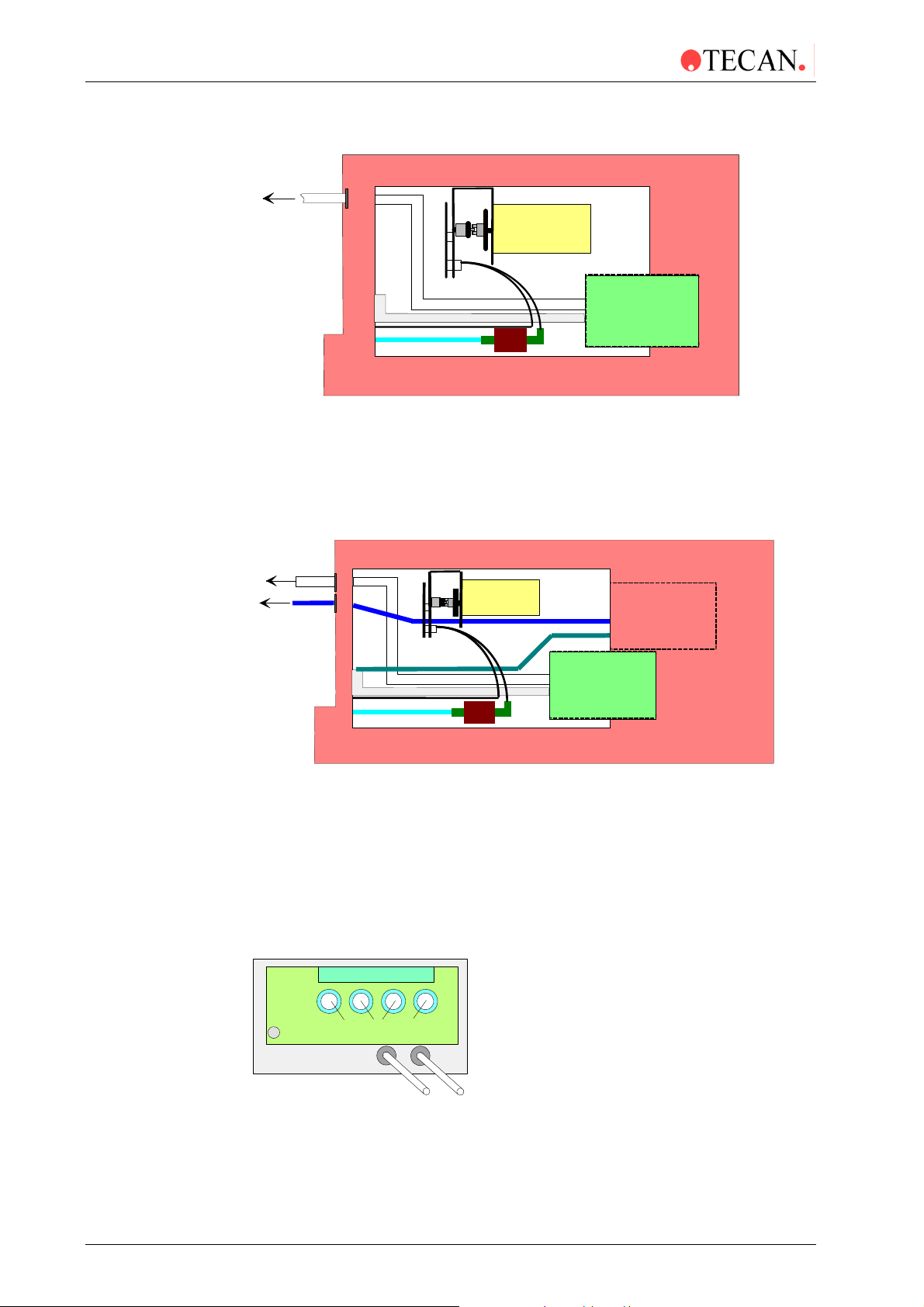

2.4.3 Connecting the Solution Tubes

The solution tubes are connected onto the inlet connectors on the back panel of

the instrument. The instrument is supplied with four meters of tubing that can be

cut to the required length (maximum 1 meter).

Inlets for channe ls 1 - 4

erosol Tube*

(optional)

Waste Tube

red

2-4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 21

2. Installation Procedure

2.4.4 Fitting and Connecting the Liquid Sensors (Optional)

Connect the detector unit cable into the appropriate socket in the back panel of

the instrument. The liquid sensor system can be extended to control up to four

different liquid bottles and one waste bottle.

rinse

grey

liquid 1

green

Liquid Sensor

Fix the tube support in the bottle holder as shown below.

Tube support

waste

red

Insert the tubes and connect the bottle holder to the instrument.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2-5

Page 22

2. Installation Procedure

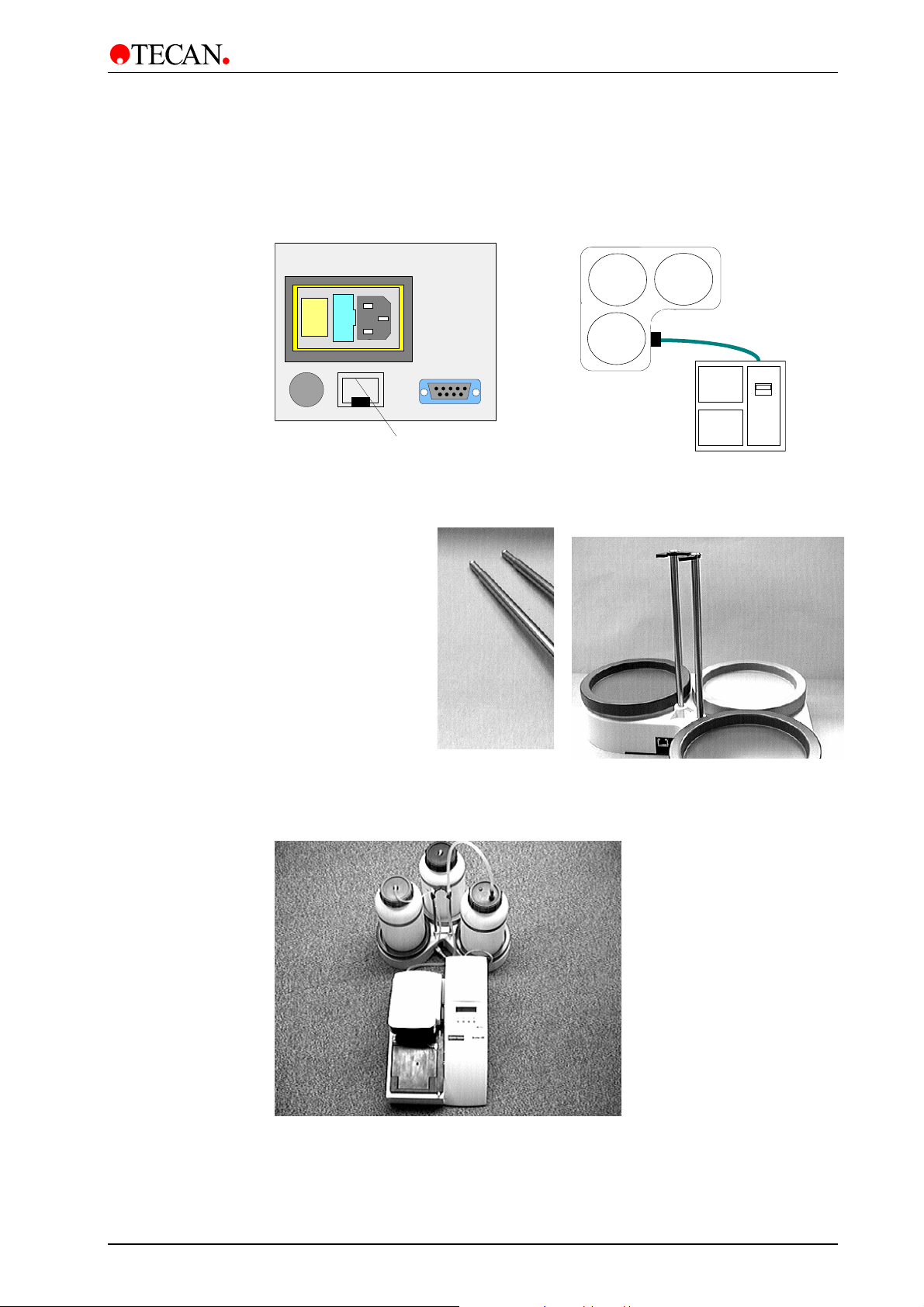

2.4.5 Connecting the Barcode Reader (Optional)

Before the barcode reader can be connected to the instrument, the supplied

barcode chips must be added to the main board. For more details contact your

service technician.

Hand Held Barcode

Reader

Liquid Sensor

2.4.6 Connecting the Printer (Optional)

Before the printer can be connected to the instrument, the supplied chip must be

added to the main board. For more details contact your service technician.

Connect the printer to the instrument using the supplied cable.

Connect the power supply cable to the printer.

ON /OFF

Switch

OFF 1 2

POWER

Connection Cable

BATT. LOW

POWER

ON

PAPER

FEED

Power Cable

2.4.7 Power Connections

Before the instrument is installed and switched on, it should be left to

stand for at least three hours, so there is no possibility of condensation

Ensure that the on / off switch in the back panel of the instrument is in the off

position.

Insert the mains power cable into the mains power socket on the rear of the

instrument.

2-6 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

causing a short circuit.

Page 23

3. Firmware and Software Description

3. Firmware and Software

Description

3.1 Instrument Software Features

The instrument has the following software features:

• 30 user definable washing programs, permanently stored under the

numbers 1 to 30.

• Up to 60 processing steps per program, each processing step can be

identical or different from the previous step.

• 3 washing modes, normal washing, bottom washing and overflow washing.

Set by the Plate Type parameters.

• Soak time. selectable from 1 to 999 seconds.

• Software selectable dispensing speeds

• Software selectable aspirating speeds

• Software selectable bottom position, for aspiration contact to the bottom

of the wells.

• 4 rinse modes, the different rinse modes can be used to select how the

instrument is rinsed before it is left to stand or switched OFF.

• Automatic microplate centering, the microplate is automatically centered

before the start of the washing program.

• Programmable strip selection, the program can be defined so that the

strips to be washed can be selected before starting the washing procedure.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-1

Page 24

3. Firmware and Software Description

3.2 Onboard Software Menus

The instrument can be used in the following onboard software menus.

3.2.1 Run

Selection of the run procedure to perform the selected program.

3.2.2 Prime

Before the instrument can be used, all dispensing channels must be primed

with the required solution.

Ensure that the bottle of priming solution is always full at the beginning of

the priming procedure and check that the inlet filters in the liquid tubes are

clear.

Please ensure that the dispensing and aspiration pumps are not run for

longer than a few minutes without liquid or they will be damaged.

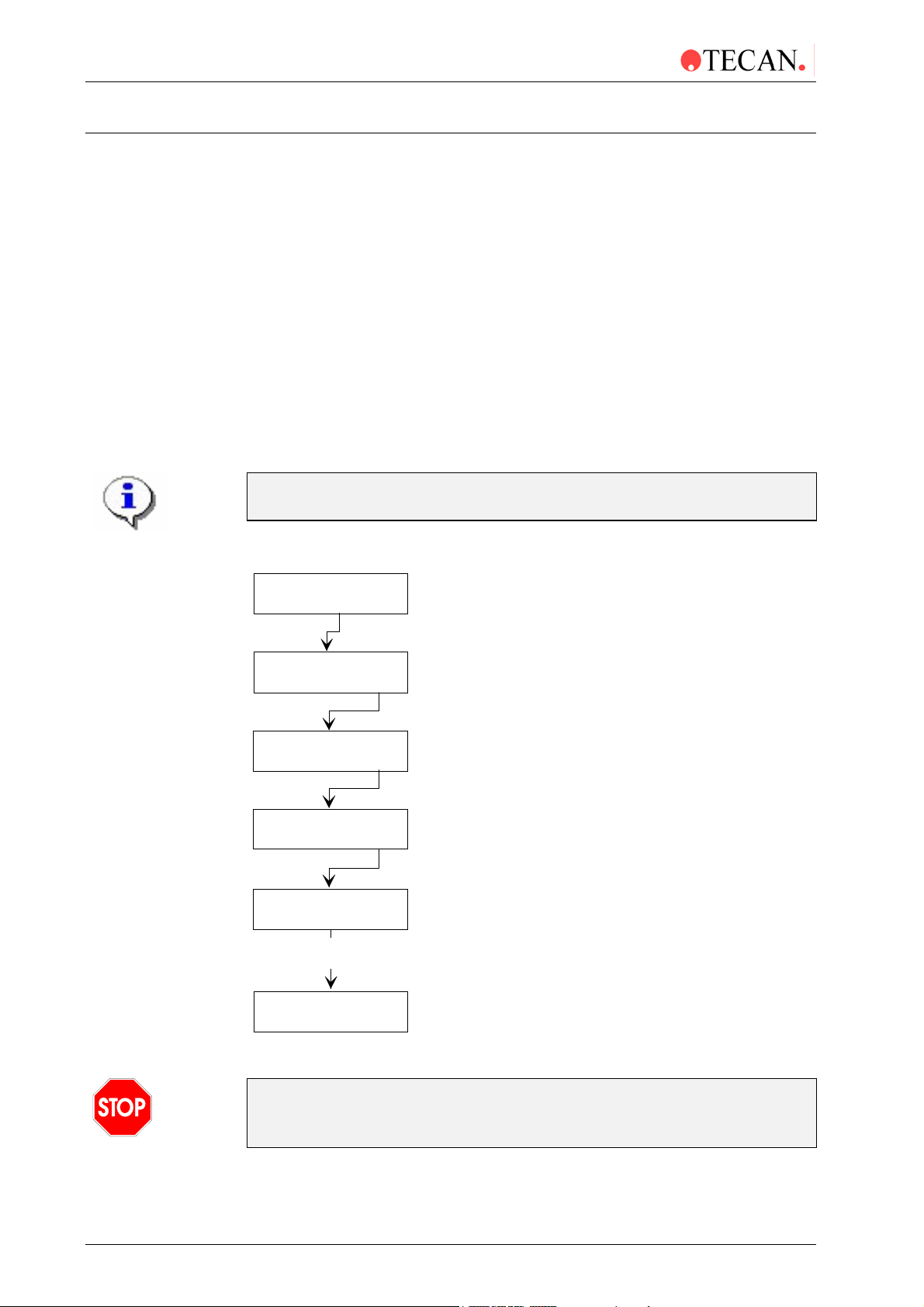

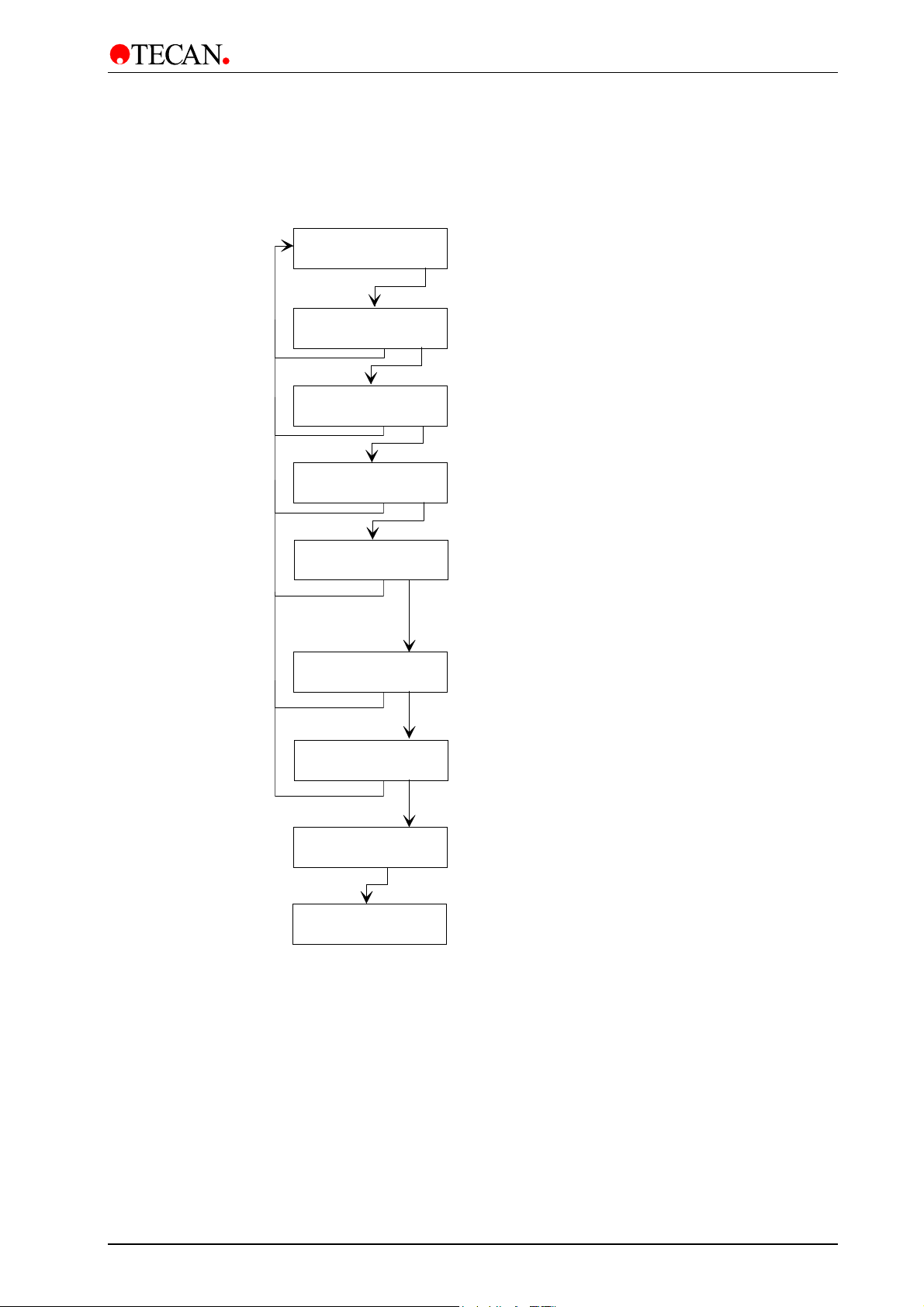

The priming procedure is performed using the following procedure:

Run XX yyyyyyyy

- + other yes

Prime Ch1

- + other yes

Prime Solution ?

exit yes

Waste Bottle OK?

exit yes

Prime ChX Y sec

Stop

Priming Procedure

performed

Run XX yyyyyyyy

- + other yes

Select required channel to be primed

Required solution in bottle and inlet

tube inserted into solution

Waste bottle empty

Priming procedure being performed

Instrument ready to wash microplate

Caution

Do not use the instrument to aspirate or dispense any acidic solutions as

3-2 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

this could damage the instrument.

Page 25

3. Firmware and Software Description

y

y

y

y

g

p

yyyyyyy

3.2.3 Rinse

There are four Rinse modes to flush the liquid system and prevent needle

blockages. They should be carried out when the instrument is left to stand or is

switched off at the end of working.

The Rinse modes are:

Rinse Soak

Rinse Day

Rinse Night

Rinse Auto

Rinse: Soak

This procedure is used if the instrument is to be left to stand for a short time.

(1/2 hr. or less).

With this procedure you can use either distilled water or wash solution.

Rinse: Soak

- + other

Soak: CH1

- + exit

Rinse Solution ?

exit

Waste Bottle OK?

exit

Soakin

Sto

Run XX:

- + other yes

es

es

es

es

Select and confirm Soak Rinse procedure

Select required channel (1 - 4)

Confirm that the rinsing solution

and the tube are in the bottle

Confirm waste bottle is empty

The waste sink is filled with solution

and the manifold is lowered into it

Manifold left in solution until Stop key pressed

Standby mode

Washing procedure can be performed

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-3

Page 26

3. Firmware and Software Description

Rinse: Day

This procedure is used to rinse the wash solution system if the instrument is to be

left standing for a longer time. Alternatively it can be used to rinse the wash

solution system after the instrument has been left for a long time.

With this procedure you can use either distilled water or wash solution.

If the instrument is left to stand for 1 hr to 1/2 day, wash solution can be used, for

longer times use distilled water.

Rinse: Day

- + other yes

Day: CH1

- + exit yes

Rinse Solution ?

exit yes

Waste Bottle OK?

exit yes

Rinse ChX YY sec

Stop

Select and confirm Day Rinse procedure

Select required channel (1 - 4)

Confirm rinsing solution and tube in bottle

Confirm waste bottle is empty

Wash system rinsed for set rinse time

The waste sink is filled with solution and

the manifold is lowered into it

Soaking

Stop

Run XX:yyyyyyy

- + other yes

Manifold left in solution until

key pressed

Stop

Standby mode

Washing Procedure can be performed

3-4 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 27

Rinse: Night

y

g

y

y

y

p

p

g

p

yyyyyyy

p

3. Firmware and Software Description

This procedure is used to thoroughly rinse the wash solution system and leave

the manifold soaking in the waste sink full of solution at the end of working. This

procedure requires distilled water.

Rinse: Night

- + other

ht: CH1

Ni

- + exit

Rinse Solution ?

exit

Waste Bottle OK?

exit

Rinse ChX YY sec

Sto

Soaking xx sec

Sto

es

es

es

es

Select and confirm Night Rinse procedure

Select required channel (1 - 4 or ALL)

Confirm rinsing solution and tube in bottle

Confirm waste bottle is empty

Wash system rinsed for set rinse time

The waste sink is filled with the distilled

water and the manifold is lowered into it

Manifold left in solution for set soak time (1 min)

Rinse: Auto

Rinse ChX YY sec

Sto

Soakin

Sto

Run XX:

- + other yes

Wash system rinsed for set rinse time

The waste sink is filled with the distilled water

and the manifold is lowered into it.

Manifold left in solution until Stop key pressed

Standby mode

Washing procedure can be performed

This procedure is the same as the Rinse: Day procedure, except that the rinsing

procedure is automatically repeated after a set repeat time. The repeat time can

be set in the Adjust menu between 1 and 24 hrs.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-5

Page 28

3. Firmware and Software Description

3.2.4 Program

Selection of the programming procedure, to define the required program.

For more information about the programming procedure, see chapter 4 in

the Columbus Operating Manual.

3.2.5 Clear

This submenu is used to clear a program from the instrument's memory. If the

program is locked it can not be cleared and the following error message is

displayed:

Program locked

yes

The function Clear ALL is available within the Clear Program option. This

function enables you to clear all of the programs (excluding those that are

locked!). The Clear ALL function is found before program 1 and after program

30. Use the cursor keys to skip through the programs and once Clear ALL is

displayed press yes and all of the programs (with the exception of those that are

locked) will be cleared.

This option is not to be confused with the Clear ALL function in the Service

menu.

3.2.6 Show

Procedure to show the parameters for a program.

Clear XX:yyyyyyy

- + other yes

Clear XX:yyyyyyy

no yes

Clear XX:yyyyyyy

- + other yes

Select required program to be

cleared from instrument's memory

Confirm that selected program is

to be cleared

Select next program to be cleared or

required option in Mode Selection menu

For more information about the Show procedure, see Columbus Operating

Manual.

3-6 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 29

3. Firmware and Software Description

3.2.7 Adjust

The Adjust menu has the following options:

Plate Type

Prime Time

Rinse Time

Autorinse

Kit Select

Date

Time

Sel. Manifold

Adj. Liq. Sensor

Exit Adjust

Entering the Adjust Menu

When the instrument is in the standby mode and the following message is

displayed:

Run XX yyyyyyyy

- + other yes

Adjustment procedure for setting the parameters for up

to nine different types of microplates

Adjust the time that the Priming procedure is performed

for.

Adjust the time that the Rinsing procedure is performed

for.

Adjust the time between the Autorinse cycles.

This option is not available in this instrument.

Set the date

Set the time

Set the manifold that is fitted to the instrument

The switch thresholds for the wash, rinse and waste

liquid can be defined.

Exit from the Adjust menu.

To select the Adjust menu, press other u ntil the following message is displayed:

Adjust Menu

other yes

Select yes to enter the Adjust menu and then the various options in the Adjust

menu can now be selected using other.

When the required option is displayed, press yes to enter the parameter setting

procedure.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-7

Page 30

3. Firmware and Software Description

A

A

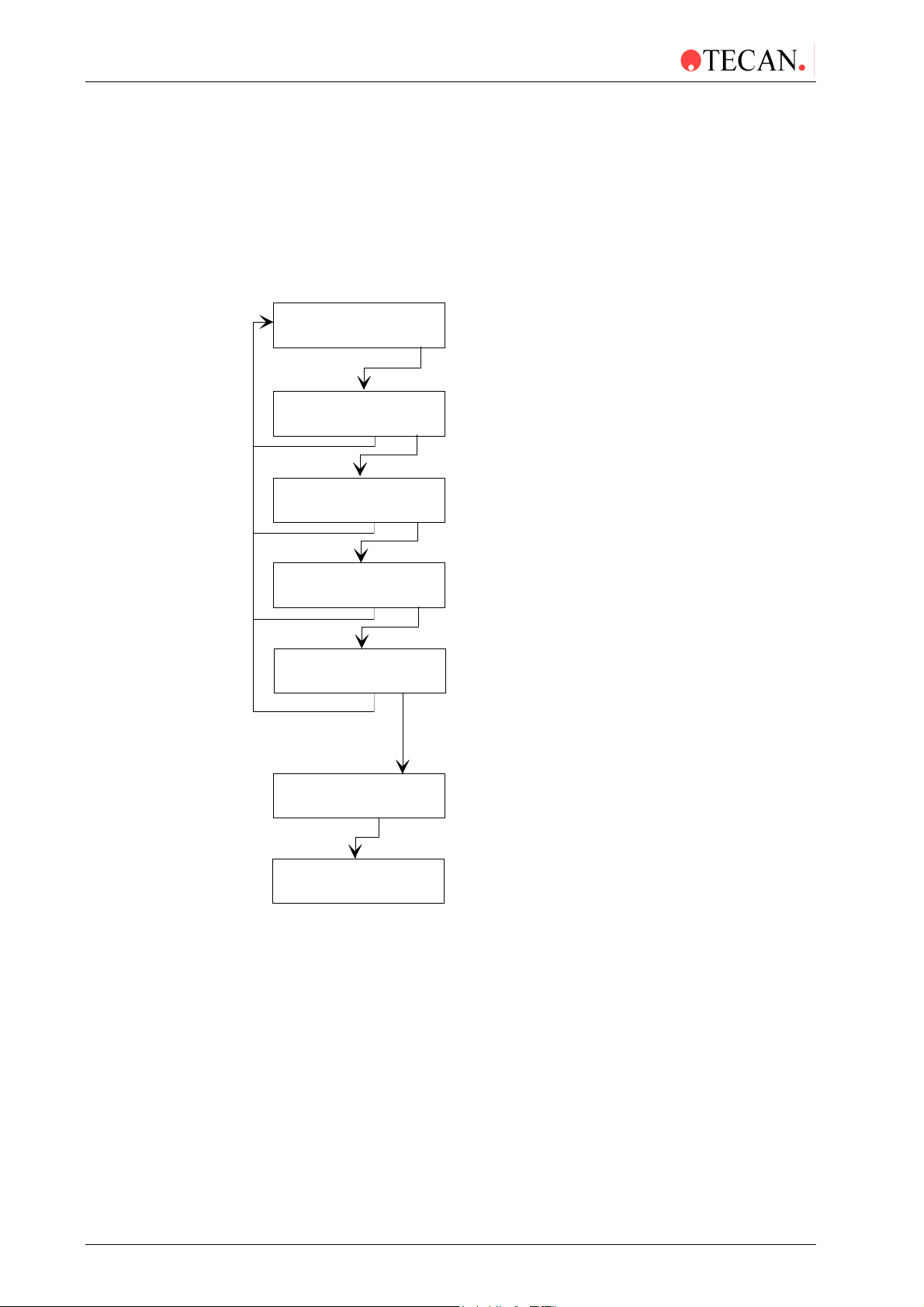

Adjust Menu

other yes

Platetype: 1

- + other yes

Primetime:10 sec

- + other yes

Rinsetime: 10sec

- + other yes

AutoRinse: 1 h

- + other yes

Kit Select: Off

- + other yes

Confirm selection of Adjust Menu

Plate Type definition menu

Use '-' and '+' keys to select required p latet ype

Plate Type definition procedure

Priming Time setting

Use '-' and '+' keys to select required priming time

(5 - 99 sec.)*

Rinse Time setting

Use '-' and '+' key s to select required rinsing time

(5 - 99 sec.)*

utomatic Rinsing Time setting

Use '-' and '+' keys to select required tim e between

utomatic Rinsing procedures (1 - 24 hrs.)

This option is not available in this instrument

Date: ddmmmyyyy

d m other y

Time: hh:mm xx

h m other form

Sel.Manifold: xx

- + other yes

Adj.Liq.Sens.:

other yes

Date Setting

Use 'd' key to change day setting

Use 'm' key to chang month setting

Use 'y' key to change year setting

Time Setting

Use 'h' key to change hour setting

Use 'm' key to chang minute setting

Use 'Form ' key to change from 12 to 24 hrs format

Manifold setting

Use '-' and '+' keys to select fitted manifold . (8, 12, 16)

If Manifold detect option fitted, this setting is used

as the default when programming

Liquid Detection Sensor setting

Exit Adjust

other yes

Exit Adjust Menu

* Instruments that have the prime valve have a priming time of 8 - 99 seconds.

3-8 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 31

3. Firmware and Software Description

Adjust Plate Type

This option is used to set the following parameters for the different types of

microplates. The default is a 96 well Greiner microplate.

The following parameters are set:

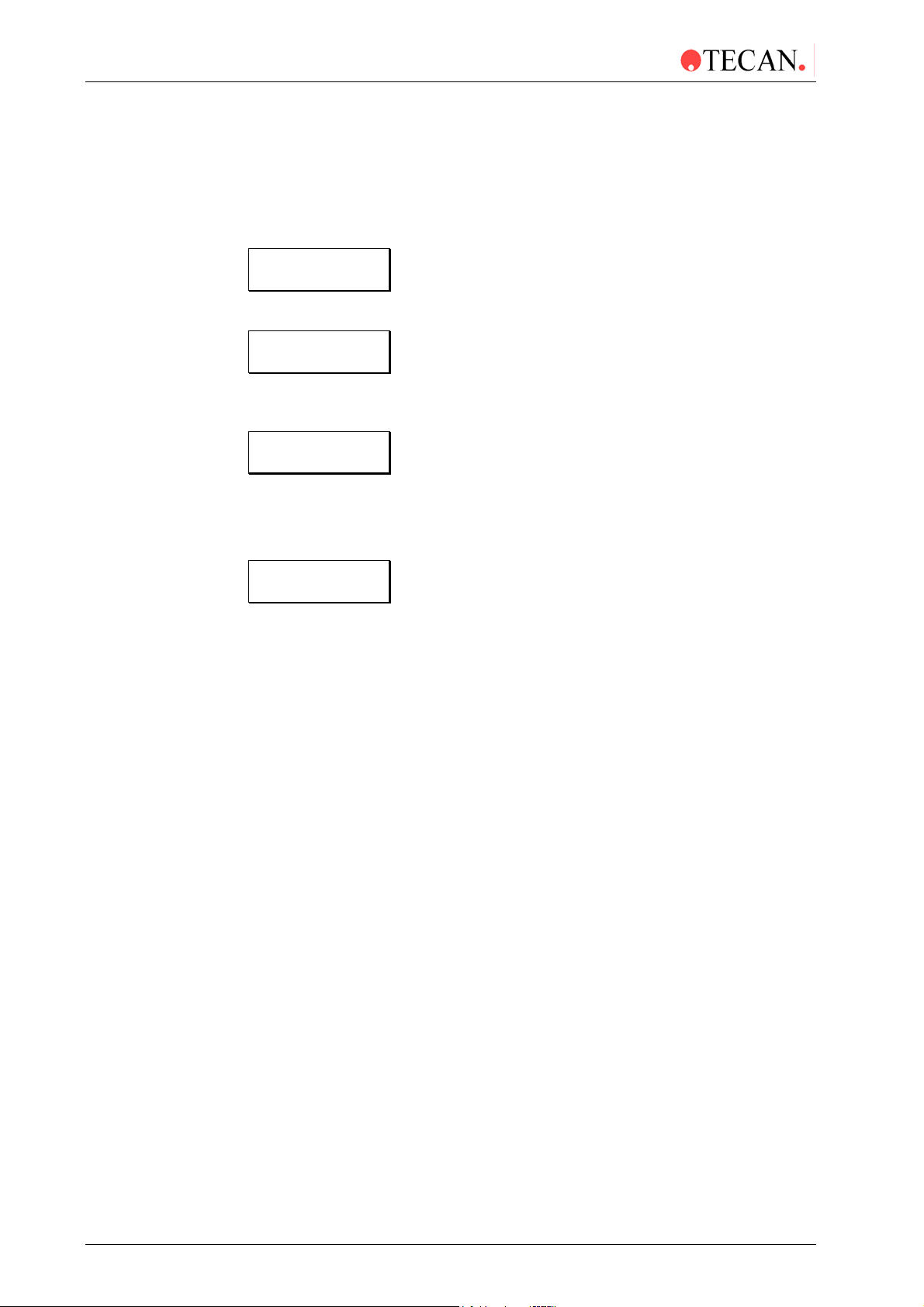

Parameters Options

Plate type number

Bottom Form

Dispensing Position

Aspirate Position

Aspirate Position 2

Bottom Position

Bottom Wash Position

Overflow Wash

Position

Before starting the adjustment procedure, insert the microplate to be

adapted into the plate support.

1 - 9

Set whether the microplate has flat or round

bottom wells.

Set the position in the wells where the solution

will be dispensed.

Set the position in the wells where the solution

will be aspirated.

Set the position in the wells for the crosswise

aspiration procedure. (flat bottom wells only)

Set the position of the aspirating needles for the

bottom of the well.

Set the position of the aspirating needles for the

bottom washing procedure.

Set the position of the aspirating needles for the

overflow washing procedure.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-9

Page 32

3. Firmware and Software Description

Round Bottom Plates

Adjust Menu

other yes

Plate: X

- + other yes

Plate: X

890 , , ABCDE

Bottomform Round

- + exit yes

Disp.Pos XXX

- + exit yes

Asp.Pos XXX

- + exit yes

Confirm selection of Adjust menu

Plate Type definition menu

Use '-' and '+' keys to select required platetype (1 - 9)

Enter the required name for the plate

(up to 8 characters). 1,2,3,4,5,6,7,8,9,0 & A-Z

To enter a name use the ‘<’ and ‘>’ keys to place a character

between the commas. Confirm the selection with the ‘↵’ key.

To delete the last character use the ‘ ’ sign.

When the name is complete, confirm with the ‘↵’ key.

Plate Bottom Form setting

Use '-' and '+' keys to select required bottom form

(flat or round)

Set Dispensing position

Use '-' and '+' keys to move the plate support so

that the dispensing needles are in the correct position

Set Aspirating position

Use '-' and '+' keys to move the plate support so

that the aspirating needles are in the correct position

Asp.Pos Botm XXX

- + exit yes

Washpos Botm XXX

- + exit yes

Washpos Ovfl XXX

- + exit yes

Platetype: X

- + other yes

Use '-' and '+' keys to move the manifold so that the

aspirating needles are in the correct position for

aspirating the bottom of the wells

Set Bottom Washing position

Use '-' and '+' keys to move the manifold so that the

aspirating needles are in the correct position for

the Bottom Washing procedure

Set Overflow Washing position

Use '-' and '+' keys to move the manifold so that the

aspirating needles are in the correct position for

the Overflow Washing procedure

Select plate type to be defined

Set Bottom Aspirating position

3-10 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 33

3. Firmware and Software Description

Flat Bottom Plates

Adjust Menu

other yes

Plate: X

- + other yes

Plate: X

890 , , ABCDE

Bottomform Flat

- + exit yes

Disp.Pos XXX

- + exit yes

Asp.Pos 1 XXX

- + exit yes

Confirm selection of Adjust menu

Plate Type definition menu

Use '-' and '+' keys to select required platetype (1 - 9)

Enter the required name for the plate

(up to 8 characters). 1,2,3,4,5,6,7,8,9,0 & A-Z

To enter a name use the ‘<’ and ‘>’ keys to place a character

between the commas. Confirm the selection with the ‘↵’ key.

To delete the last character use the ‘ ’ sign.

When the name is complete, confirm with the ‘↵ ’ key.

Plate Bottom Form setting

Use '-' and '+' keys to select required bottom form

(flat or round)

Set Dispensing position

Use '-' and '+' keys to move the plate support so

that the dispensing needles are in the correct position

Set Aspirating position 1

Use '-' and '+' keys to move the plate support so

that the aspirating needles are in the correct position

Asp.Pos 2 XXX

- + exit yes

Asp.Pos Botm XXX

- + exit yes

Washpos Botm XXX

- + exit yes

Washpos Ovfl XXX

- + exit yes

Platetype: X

- + other yes

Set Aspirating position 2

Use '-' and '+' keys to move the plate support so

that the aspirating needles are in the correct position

Set Bottom Aspirating position

Use '-' and '+' keys to move the manifold so that the

aspirating needles are in the correct position for

aspirating the bottom of the wells

Set Bottom Washing position

Use '-' and '+' keys to move the manifold so that the

aspirating needles are in the correct position for

the Bottom Washing procedure

Set Overflow Washing position

Use '-' and '+' keys to move the manifold so that the

aspirating needles are in the correct position for

the Overflow Washing procedure

Select Plate type to be defined

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-11

Page 34

3. Firmware and Software Description

To enter the Plate type option, press other until the following message is

displayed:

Plate: XXXXX

- + other yes

Where X is the displayed plate type number and plate name.

Use the - and + keys to select the required plate type number that is to be

defined. (1 - 9).

Pressing - decreases the displayed plate type.

Pressing + increases the displayed plate type.

When the required plate type is displayed press yes and the following message is

displayed:

Bottomform Flat

- + exit yes

Use the - and + keys to select the required bottom form of the wells. (flat or

round).

When the required bottom form is displayed press yes to confirm the selection.

Flat Bottom Wells

The following procedure is used when a microplate with flat bottom wells is to be

defined.

After yes has been pressed to confirm the selection of flat bottom wells, the

instrument initializes the motors and moves the microplate under the manifold.

When the microplate is under the manifold, the following message is displayed:

Disp-Pos: XXX

+ exit yes

Where XXX is the displayed number of steps.

Use the - and + keys to move the microplate until the dispensing needles are in

the correct position.

Pressing the - and + keys moves the microplate forwards and backwards so that

the dispensing needles are positioned further back/forward in the wells.

When the dispensing needles are in the correct position, press yes and the

following message is displayed:

Asp.Pos 1 XXX

- + exit yes

3-12 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 35

3. Firmware and Software Description

Use the - and + keys to move the microplate until the aspirating needles are in

the correct position for aspirating the side of the well.

Pressing the - and + keys moves the microplate forwards and backwards so that

the aspirating needles are positioned further back/forward in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Asp.Pos 2 XXX

- + exit yes

Use the - and + keys to move the microplate until the aspirating needles are in

the correct position for aspirating the side of the well. (crosswise aspiration)

Pressing the - and + keys moves the microplate forwards and backwards so that

the aspirating needles are positioned further back/forward in the wells.

When the aspirating needles are in the correct position press yes and the

following message is displayed:

Pos Botm XXX

Asp.

- + exit yes

Use the - and + keys to move the manifold until the aspirating needles are in the

correct position for aspirating the bottom of the well.

Pressing the - and + keys move the manifold up and down so that the aspirating

needles are positioned higher/lower in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Washpos Botm XXX

- + exit yes

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-13

Page 36

3. Firmware and Software Description

Use the - and + keys to move the manifold until the aspirating needles are in the

correct position for aspirating the solution in the bottom washing position.

Pressing the - and + keys moves the manifold up and down so that the aspirating

needles are positioned higher/lower in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Washpos Ovfl XXX

- + exit yes

Use the - and + keys to move the manifold until the aspirating needles are in the

correct position for aspirating the solution in the overflow washing position.

Pressing the - and + keys move the manifold up and down so that the aspirating

needles are positioned higher/lower in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Platetype: X

- + other yes

The parameters for the next plate type can be defined or press other for the next

option in the Adjust menu.

3-14 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 37

3. Firmware and Software Description

Round Bottom Wells

The following procedure is used when a microplate with round bottom well s is to

be defined.

After yes has been pressed to confirm the selection of round bottom wells, the

instrument initializes the motors and moves the microplate under the manifold.

When the microplate is under the manifold, the following message is displayed:

Disp.Pos XXX

- + exit yes

Where XXX is the displayed number of steps.

Use the - and + keys to move the microplate until the dispensing needles are in

the correct position.

Pressing the - and + keys moves the microplate forwards and backwards so that

the dispensing needles are positioned further back/forward in the wells.

When the dispensing needles are in the correct position, press yes and the

following message is displayed:

Asp.Pos XXX

- + exit yes

Use the - and + keys to move the microplate until the aspirating needles are in

the correct position for aspirating the middle of the well.

Pressing the - and + keys moves the microplate forwards and backwards so that

the aspirating needles are positioned further back/forward in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Asp.Pos Botm XXX

- + exit yes

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-15

Page 38

3. Firmware and Software Description

Use the - and + keys to move the manifold until the aspirating needles are in the

correct position for aspirating the bottom of the well.

Pressing the - and + keys moves the manifold up and down so that the aspirating

needles are positioned higher/lower in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Washpos Botm XXX

- + exit yes

Where XXX is the displayed number of steps.

Use the - and + keys to move the manifold until the aspirating needles are in the

correct position for aspirating the solution in the bottom washing position.

Pressing the - and + keys moves the manifold up and down so that the aspirating

needles are positioned higher/lower in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Washpos Ovfl XXX

- + exit yes

Use the - and + keys to move the manifold until the aspirating needles are in the

correct position for aspirating the solution in the overflow washing position.

Pressing the - and + keys moves the manifold up and down so that the aspirating

needles are positioned higher/lower in the wells.

When the aspirating needles are in the correct position, press yes and the

following message is displayed:

Platetype: X

- + exit yes

The parameters for the next plate type can be defined or press other for the next

option in the Adjust menu.

3-16 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 39

3. Firmware and Software Description

Adjust Prime Time

This option is used to set the time that the Prime procedure is performed for.

Adjust Rinse Time

Primetime:10 sec

+ - other yes

Rinsetime:10 sec

- + other yes

Use '-' and '+' keys to select required priming

time (5- 99 seconds)*

Adjust menu

other yes

To enter the Prime Time option, press other until the following message is

displayed:

Primetime:10 sec

- + other yes

Use the - and + keys select the required priming time in seconds. (5 - 99 sec)*

When the required prime time is displayed, either press other to proceed to the

next option or press yes to exit from the Adjust menu.

This option is used to set the time that the rinse procedure is performed for.

Rinsetime:10 sec

+ - other yes

Autorinse:1 h

- + other yes

Use '-' and '+' keys to select required rinsing

time (5 - 99 seconds)*

Adjust menu

other yes

To enter the Rinse Time option, press other until the following message is

displayed:

Rinsetime:10 sec

- + exit yes

Use the - and + keys select the required rinse time in seconds. (5 - 99 sec)*

When the required rinse time is displayed, either press other to proceed to the

next option or press yes to exit from the Adjust menu.

* Instruments that have the prime valve have a priming time of 8 - 99 seconds.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-17

Page 40

3. Firmware and Software Description

h

Adjust Auto Rinse

This option is used to set the time between the rinse procedures when the

Autorinse mode is selected.

Kit Select

AutoRinse: 1h

+ - other yes

Kit Select: Off

- + other yes

Use '-' and '+' keys to select required Auto

rinsing time (1 - 24 hours)

Adjust menu

other yes

To enter the AutoRinse Time option, press other until the following message is

displayed:

AutoRinse: 1 h

- + exit yes

Use the - and + keys select the required time in hours between each automatic

rinse procedure. (1 - 24 hours)

When the required time is displayed, either press other to proceed to the next

option or press yes to exit from the Adjust menu.

This option is not available in the instrument.

Date

The setting for the date can only be altered if the Printer option is fitted.

Date: dd mmm yyyy

d m other y

Time: hh:mm:ssXX

h m other form

Use the 'd' key (1st key) to set the required Day

Use the 'm' key (2nd key) to set the required Mont

Use the 'y' key (4th key) to set the required Year

To enter the Date option, press other until the following message is displayed:

Date:dd mmm yyyy

d m other y

Where dd mmm yyyy is the displayed date.

3-18 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 41

Time

y

3. Firmware and Software Description

Use the d, m and y to set the required date.

Pressing d increases the displayed day setting

Pressing m increases the displayed month setting

Pressing y increases the displayed year setting

When the required date is displayed, press other to confirm the setting and the

following message is displayed:

Time: hh:mm:ssXX

h m other form

The setting for the time can only be altered if the Printer option is fitted.

Time: hh:mm:ssXX

h m other form

Sel.Manifold: XX

- + other

es

Use the 'h' key (1st key) to set the required Hour

Use the 'm' key (2nd key) to set the required Minute

Use the 'Form' key (4th key) to set the required form

AM/PM or 24 hr.

To enter the Time option, press other until the following message is displayed:

Time: hh:mm:ssXX

h m other form

Where hh:mm:ss is the displayed time and XX is the time form (AM/PM).

Use the h, m and form to set the required time and format.

Pressing h increases the displayed hour setting

Pressing m increases the displayed minute setting

Pressing form changes the time format (a.m./p.m. or 24 hr.)

When the required time and format is displayed, press other to confirm the

setting and the following message is displayed:

Sel.Manifold: XX

- + other yes

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-19

Page 42

3. Firmware and Software Description

Select Manifold

This option is used to set the type of manifold that is fitted.

This setting is used if neither the manifold detect option nor the fill

verification option are fitted.

Sel.Manifold: XX

- + other yes

Exit Adjust

other yes

Use the '-' key (1st key) and '+' (2nd key) to set

the setting for the manifold (8, 12 or 16 way)

Press 'yes' key (4th key) to confirm and save setting

Press 'other' key (3rd key) to move to next option

without saving setting

To enter the Select Manifold option, press other until the following message is

displayed:

Sel.Manifold: XX

- + other yes

Use the - and + keys to set the required manifold. (8, 12 or 16 way)

Press other to proceed to the next option without saving any changes in the

setting.

Press yes to confirm the setting and proceed to the next option.

When other or yes has been pressed, the following message is displayed:

Adjust Liq. Sens.:

other yes

3-20 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 43

3. Firmware and Software Description

y

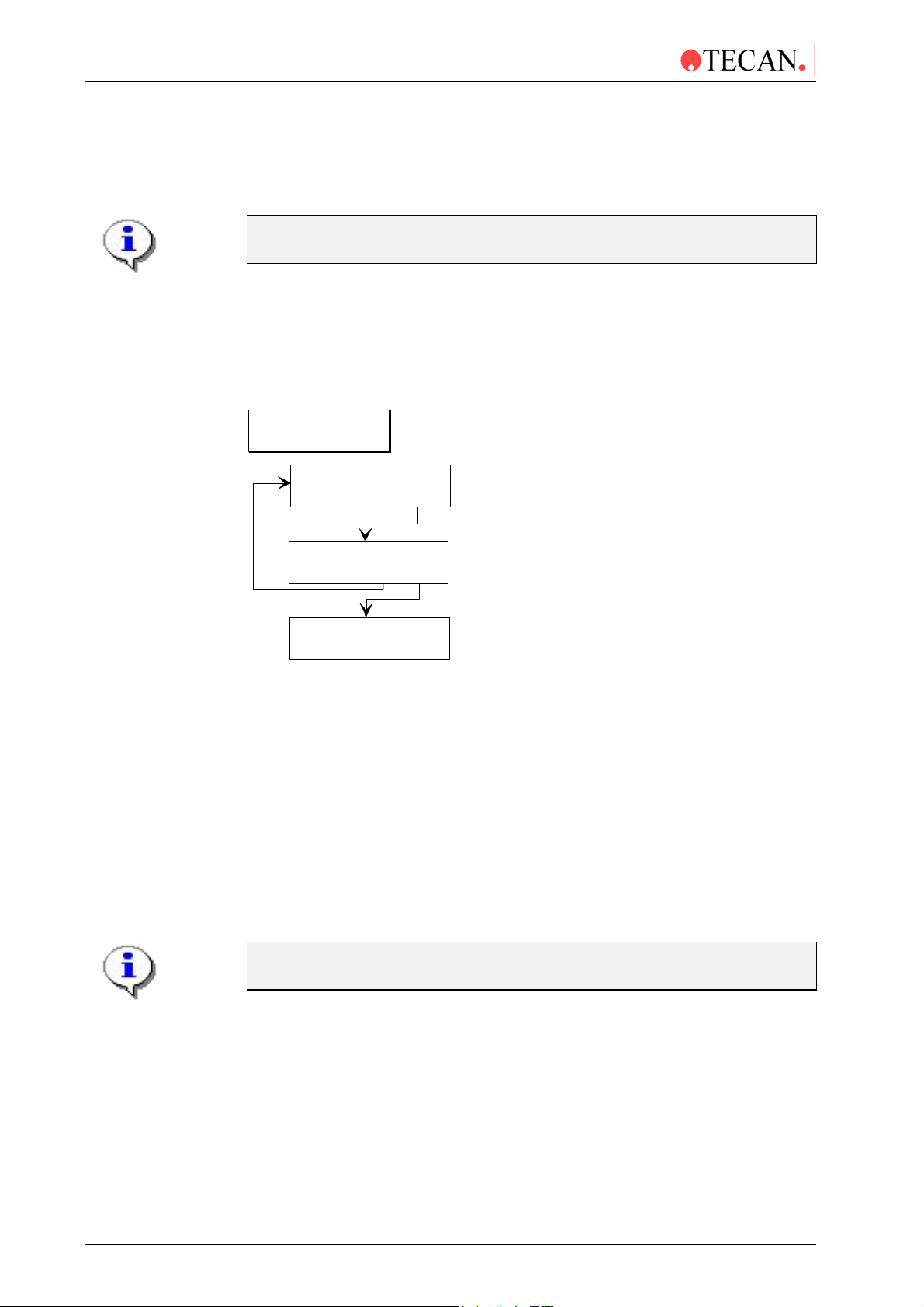

Adjust Liquid Sensors

Please prepare the bottles before performing the procedure below. The bottles

marked green (wash solution) and gray (rinse solution) should be filled with

600ml of water and the bottle marked red (waste) should be filled with 2000 ml of

water. Place all three bottles on the corresponding colored bottle holders. Go to

the Adjust menu and select Adj. Liq. Sens. as described below:

Caution

This procedure must be performed when the instrument is installed.

Adj. Liq. Sens.:

other yes

Liq. Sens. 1

- + exit yes

Empty 1 XX 1

exit yes

Empty 1 XX 0

exit yes

Use the cursor keys to repeat this procedure

for the grey (rinse solution) and red (waste)

bottles. See also below for more details.

Press yes to start the adjustment procedure

Using the - and + keys select the liquid sensor to

be calibrated.

1 = Green (wash solution)

2 = Gray (rinse solution)

W = Red (waste)

Press yes

to continue the adjustment procedure.

Check that the adjustment of the magnet screw has

a blank value of between 5 and 20. See photo1.

XX = displayed sensor value (does not directly

correlate to the volume of liquid in the bottles).

1 = values above limit

Press

to confirm the limit.

es

XX = displayed value 0 = values below limit

Press

to continue the adjustment of other sensors.

exit

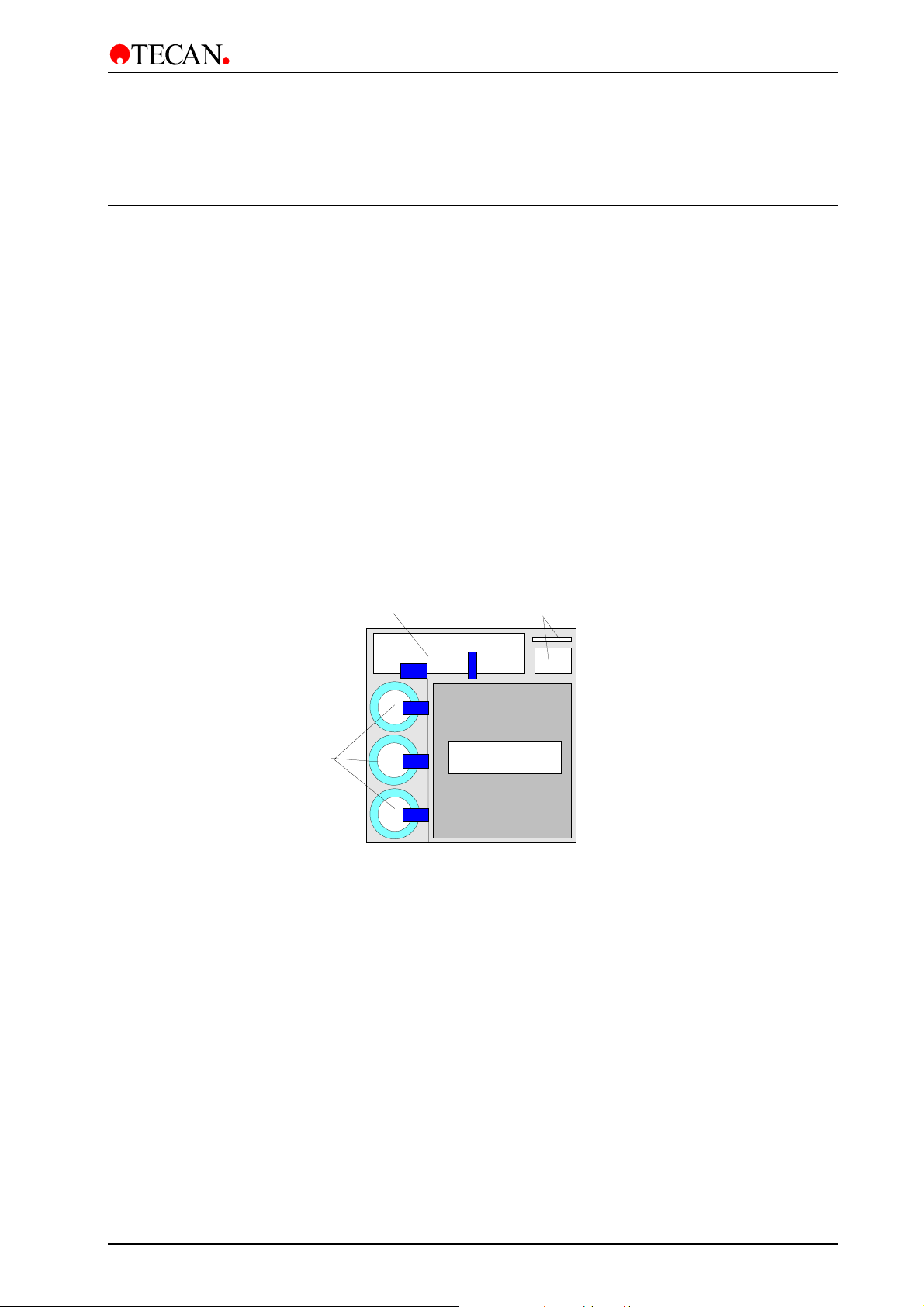

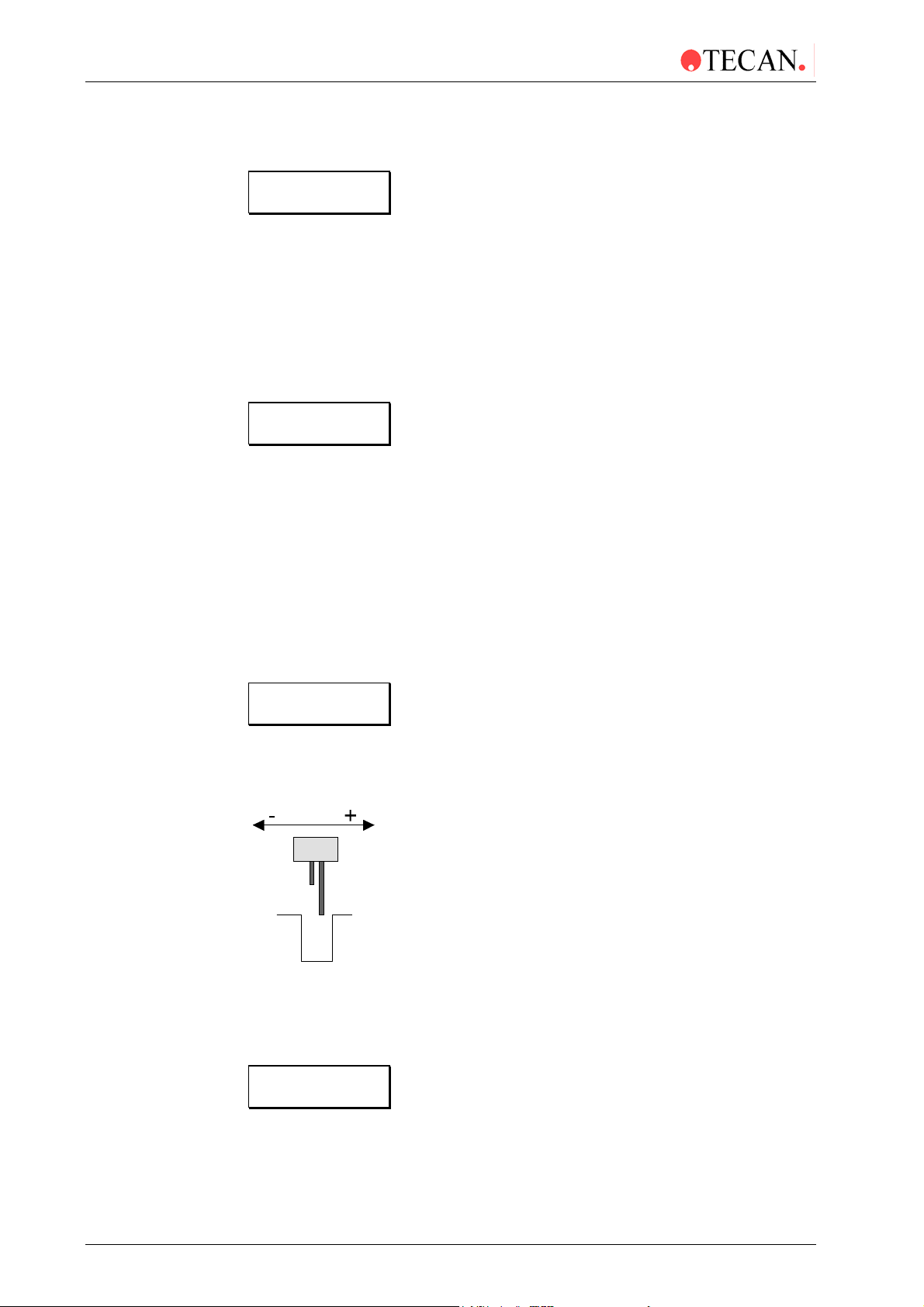

Photo 1

Check that the adjustment of the magnet

screw has a blank value of between

5 and 20

If it was necessary to readjust the

settings, secure the screws with

adhesive.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-21

Page 44

3. Firmware and Software Description

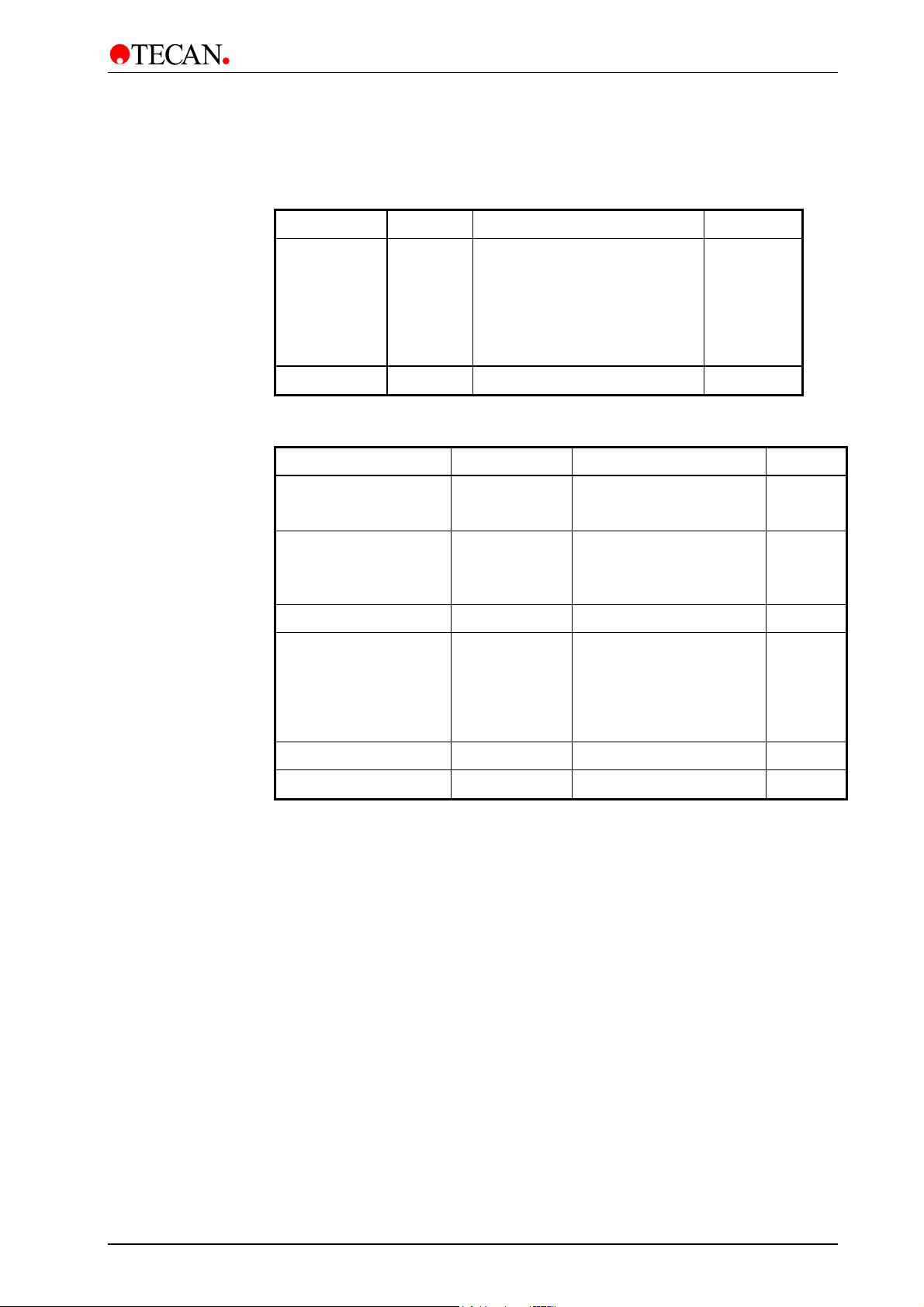

Liquid Sensors 1 – 2 (3 – 4)

When a liquid sensor (1 - 2) has been selected, the following messa ge is

displayed:

Empty S XX Y

exit yes

Where S = the sensor number, XX is the displayed value and Y = limit

(0 = values below limit, 1 = values above limit)

Adjust the volume of solution in the bottle to the lowest volume that can be used

before starting the procedure.

When the minimal volume is in the bottle, press yes to confirm the value

(volume).

Green bottle (wash solution) = 600 ml

Gray bottle (rinse solution) = 600 ml

When the sensor detects a volume less than this entered volum e, it will display

an error message either before starting the test procedure or after the procedure

has been completed.

When the value has been set, press exit and the following message is displayed:

Liquid Sens. 1

- + exit yes

Use the < and > keys to set the next required sensor (1 – 2 or W)

Waste Sensor

When the waste sensor has been selected, the following message is displayed:

Full W XX Y

exit yes

Where W = Waste sensor, XXX is the displayed value and Y = limit

(0 = values below limit, 1 = values above limit)

Adjust the volume of solution in the waste bottle to the highest volume that can be

used before starting the procedure.

When the maximum volume is in the bottle, press yes to confirm the value

(volume).

Red bottle (waste) = 2000 ml

When the sensor detects a volume greater than this entered volume, it will

display an error message either before starting the test procedure or after the

procedure has been completed.

When all the sensors have been set, press exit and the following message is

displayed:

Adj.Liq.Sens.:

other yes

Press other to proceed to the next option.

3-22 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 45

Exit Adjust

3. Firmware and Software Description

This option is used to exit from the Adjust menu.

Exit Adjust

other yes

Platetype: 1

- + other yes

Select if the Adjust Menu is to be exited or not

Run X:yyyyyyy

- + other yes

When the following message is displayed:

Exit Adjust

other yes

Select if the Adjust menu is to be exited or not.

Remain in Adjust Menu

Press other to remain in the Adjust menu and the following message is

displayed:

Platetype: 1

- + other yes

Select the required option in the Adjust menu.

Exit Adjust Menu

Press yes and the following message is displayed:

Run X:yyyyyyy

- + other yes

The instrument is now in the Standby mode and can be used to wash a

microplate.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-23

Page 46

3. Firmware and Software Description

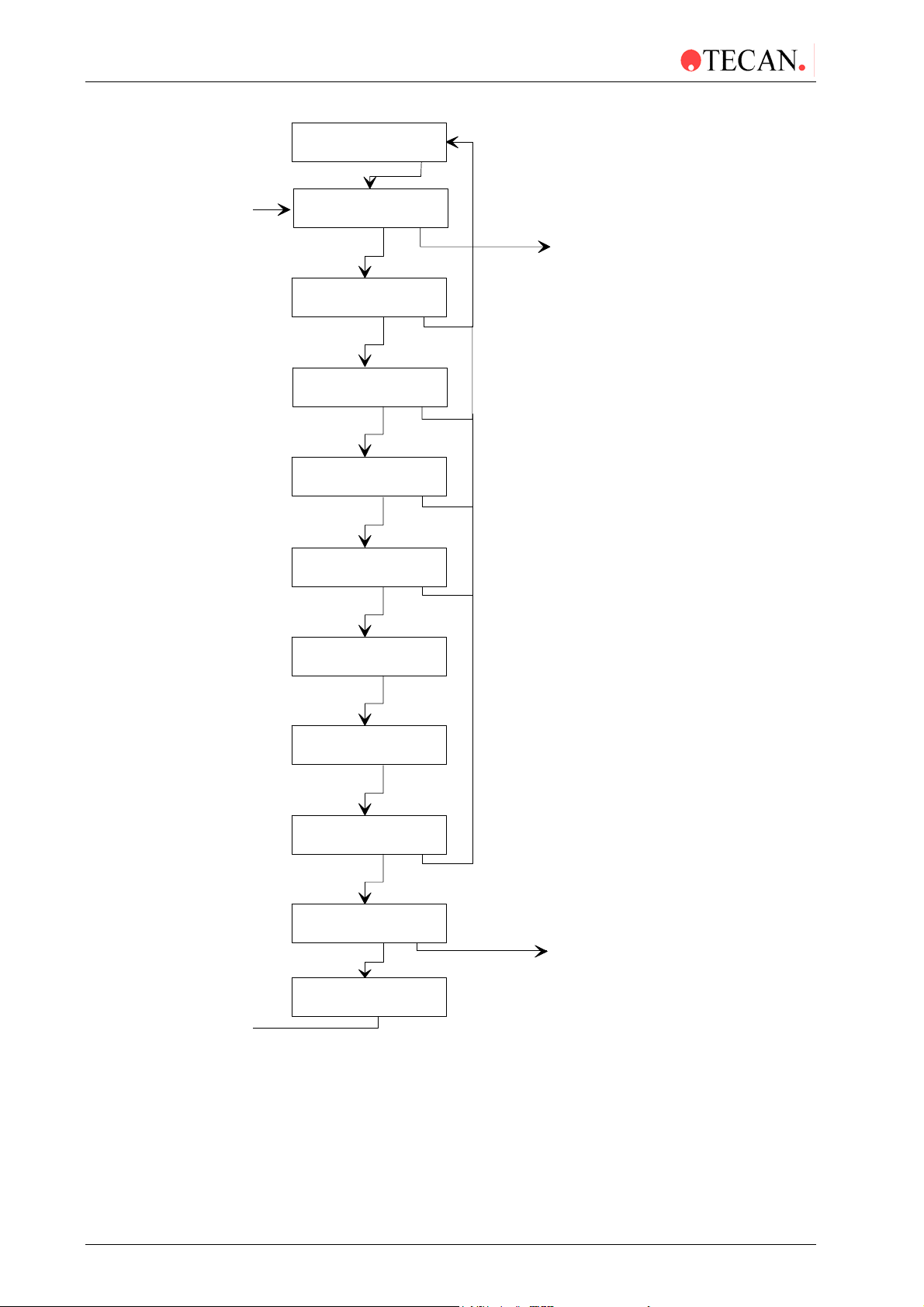

3.2.8 Service Menu

The Service submenu has the following options:

Clear All ?

Prog Access

Adj. Access

Header

Channels

Skip Messages

Duration Test

Function Test

Select Options

Adj. Dispens. Pump

Adj. Prime Pos.

Adj. Plate Ref.

Procedure to clear all the defined programs and

instrument settings from the memory.

Procedure to select if access to the programming

procedure is allowed.

Procedure to select if access to the Adjust menu is

allowed.

Procedure for defining the start-up header for the

instrument.

Procedure for setting the number of dispensing

channels to be used.

Procedure to set if the reminder messages are to be

displayed.

Procedure for life testing the instrument.

Procedure for testing various instrument component.

Procedure for defining fitted instrument options.

Procedure for adjusting the dispensing pump.

Procedure for adjusting the position of the plate support

for the Prime / Rinse procedures. (Important adjustment

with 16 way manifold)

Procedure for adjusting the position of the manifold

needles.

3-24 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 47

3. Firmware and Software Description

V

A

q

Service

other yes

Code:

1 2 1 4 1 8

Clear All ?

yes exit no

Prog Access: On

- + exit yes

Adj. Access: On

- + exit yes

Header:

Set exit yes

Channels: X

- + exit yes

Skip Messages:

yes exit no

Enter required code '121418' (for firmware

4.20 and higher)

(Enter ‘1248’ for firmware V4.01 up to but not

including V4.20)

Clear All programs and settings from memory

ttention: This deletes parameter settings

which re

uire special tools to be redefined.

Select access to programming procedure

If access is off the programme menu is omitted

from the Mode Selection menu.

Select access to Adjust menu

If access is off the Adjust menu is omitted

from the Mode Selection menu.

Set startup header for instrument

Set number of dispensing channels fitted (1 - 4)

Select if warning message are to be skipped

Duration Test

yes exit no

Function Test

yes exit no

Select Options

yes exit no

Adj Dispens Pump

yes exit no

Adj.Prime Pos.

yes exit no

Service End

yes no

Standby Mode

Life testing procedure

Procedure for testing the various

instrument componants

Procedure for defining fitted instrument options

Procedure for adjusting dispensing pump

Procedure for adjusting the position of the

plate support for the Prime / Rinse procedures.

(Important adjustment with 16 way manifold)

Exit Service menu

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-25

Page 48

3. Firmware and Software Description

Entering the Service Menu

The Service menu is entered using the following procedure:

When the instrument has been switched on, it is in the standby mode and

displays the message

Run XX yyyyyyyy

- + other yes

Where XX is the displayed program number and yyyyyyyy the program name.

To select the Service menu, press other until the following message is displayed:

Service

other yes

Press yes to enter the Service menu and the following message is displayed:

Code:

1 2 1 4 1 8

The Service submenu can only be entered by entering the required code.

Enter required code '121418' (for firmware V4.20 and higher)

(Enter ‘1248’ for firmware V4.01 up to but not including V4.20)

When the code has been correctly entered the first option of the Service menu is

displayed:

Clear ALL ?

yes exit no

3-26 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 49

Clear ALL

e

3. Firmware and Software Description

This option is used to clear ALL the defined programs and instrument settings

from the instrument's memory.

This deletes parameter settings, which require special tools to be

redefined.

Service

other yes

Clear All ?

yes exit no

Are you sure ?

exit yes

Initializing

please wait

Run 1:

- + other yes

Prog Access: On

- + exit yes

Clear All defined programs and settings

Confirm that All defined programs and

settings are to be cleared

Instrument re-initialized

Instrument in Standby Mode

Select if access to the programming procedur

is to be allowed or not.

When the following message is displayed:

Clear ALL ?

yes exit no

Select if all the programs and settings are to be cleared or not.

Press no if all the programs are not to be cleared, the instrument then proceeds

to the next option.

Press exit to exit from the Service menu.

Press yes to clear all the programs from the instrument's memory and the

following message is displayed:

Are you sure ?

exit yes

This message is displayed as a control to ensure that the programs and

settings are not accidentally cleared.

Press exit to return to the previous message.

Press yes to confirm that all the programs are to be cleared.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-27

Page 50

3. Firmware and Software Description

A

After yes has been pressed, all the programs and settings are cleared from the

instrument's memory, the instrument is re-initialized and the following message is

displayed:

Run 1:

- + other yes

The instrument is now in the Standby mode.

Re-program the instrument for the required programs and settings.

Instrument options, dispensing pump calibration, priming position.

The following options must be re-calibrated: the dispensing pump calibration, the

liquid sensor and bottle management system and the X and Z offset value using

adjustment plate.

The following data must be reprogrammed using the WinWash software (see

software manual): test parameters, options and plate types.

Programming Access

This option is used to select if access to the programming procedure is permitted.

Service

other yes

Prog Access: On

- + exit yes

Prog Access: Off

- + exit yes

Adj. Access: On

- + exit yes

Use '-' and '+' key to select if access to

programming procedure is permitted.

Use '-' and '+' key to select if access to

djust menu is permitted

When the following message is displayed:

Prog Access: On

- + exit yes

Use the 1st and 2nd keys to select if access is permitted.

On = access permitted, Off = access NOT permitted

When the required setting is displayed, press yes and the following message is

displayed:

Adj. Access: On

- + exit yes

When the access is not permitted, the menu point Programme is omitted from the

Mode Selection menu.

3-28 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 51

3. Firmware and Software Description

A

Adjust Access

This option is used to select if access to the Adjust menu is permitted.

Service

other yes

Adj. Access: On

- + exit yes

Adj. Access: Off

- + exit yes

Header:

Set exit yes

Use '-' and '+' key to select if access to

djust Menu is permitted.

Procedure to define startup header

When the following message is displayed:

Adj. Access: On

- + exit yes

Use the 1stand 2nd keys to select if access is allowed or not.

On = Access allowed, Off = Access NOT allowed

When the required setting is displayed press yes and the following message is

displayed:

Header:

Set exit yes

When the access is not allowed, the Adjust menu is omitted from the Mode

Selection menu.

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-29

Page 52

3. Firmware and Software Description

Header

This option is used to define the start-up header for the instrument.

Service

other yes

Header:

Set exit yes

COLUMBUS

890

Channels: X

- + exit yes

ABCDE

↵

Select if header is to be altered or not

Edit or enter the required header

Select number of dispensing channels fitted

When the following message is displayed:

Header:

Set exit yes

Press Set to enter the header setting procedure.

Press yes to confirm the displayed header and proceed to the next option.

When Set has been pressed, the following message is displayed:

COLUMBUS

890 ABCDE

In the bottom row of the display are shown the characters that can be selected for

the header. A maximum of sixteen characters can be used.

The possible characters for the header are:

1234567890ABCDEFGHIJKLMNOPQRSTUVWXYZ

There are two special characters '

The character '

The character '

' is used to clear the last entered character from the header.

' is used to confirm that the completed header has been entered

' and ' ' .

and is used to exit from the header programming procedure.

st

To enter the required header, use the 1

and 2nd keys to scroll the characters

across the display.

When the required character is displayed between the two highlighters in the

middle of the display, press the 4

th

key. The character is then entered into the top

line of the display.

3-30 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 2006-02

Page 53

3. Firmware and Software Description

After the selected character has been entered, the instrument returns to the start

position with the '

WASHER

890 ABCDE

' character between highlighters. For example:

Channels

When the required header has been entered, the header programming procedure

is exited by pressing the 4

highlighters.

The following message is displayed:

Channels: X

- + exit yes

This option is used to select the number of dispensing channels that are fitted to

the instrument.

th

key when the ' ' character is between the two

Service

other yes

Channels:

- + exit yes

Skip

yes exit no

Use '-' and '+' keys to define the

of dispensing channels fitted (1 - 4)

Select if warning messages are to be

skipped or not.

When the following message is displayed:

Channels: X

- + exit yes

Use the 1st and 2nd keys to select the number of channels that are fitted and that

can be used. (1 - 4)

When the required setting is displayed, press yes and the following message is

displayed:

Skip Messages:

yes exit no

2006-02 Technical Manual for Columbus Washer No. 30000294 Rev. No. 1.7 3-31

Page 54

3. Firmware and Software Description

Skip Messages

This option is used to select if the warning messages are to be displayed or not.

Skip Messages:

yes exit no