Page 1

Operating Manual

Cavro

Pump

®

XLP 6000 Modular Syringe

Copyright by Tecan Systems

October 2005

734237-C

Page 2

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 3

Operating Manual

Cavro

®

XLP 6000 Modular Syringe Pump

Tecan Systems, Inc.

2450 Zanker Road

San Jose, CA 95131 USA

T 1 408 953 3100, Toll Free 1 800 231 0711

F 1 408 953 3101

E-mail: tecansystemsinfo@tecan.com

Web Site: www.tecansystems.com

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

October 2005

734237-C

Page 4

Copyright © 2005 Tecan Systems, Inc.

Part Number 734237-C

Copyright and Trademark Information

®

Teflon

Kel-F

CONTRAD

Microsoft Windows

2000

Cavro

is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

®

is a registered trademark of the 3M Company

®

is a registered trademark of Decon Laboratories, Inc.

®

®

are registered trademarks of Microsoft Corporation.

®

is a registered trademark of Tecan Systems, Inc.

, Windows 3.1®, Windows 95®, Windows NT®, and Windows

Product Warranty Information

Tecan Systems warrants that instruments manufactured and sold by Tecan

Systems will be free from defects in materials and workmanship for a period of

twelve (12) months from the date of shipment to customer. Tecan Systems’

liability for the breach of the foregoing warranty is limited to the repair or

replacement of the products found to be other than warranted. Such products will

be accepted for return only if the customer returns them to Tecan Systems’

factory or repair depot within thirty (30) days from the time of discovery of the

alleged defect, and prior to return, fills out a Certificate of Decontamination

(document P/N 730171), obtains a return authorization number from Tecan

Systems, provides Tecan Systems with the serial number of each instrument to

be returned, and prepays freight charges to the factory or a designated Tecan

Systems repair depot. No warranty is expressed or implied for:

Breakage Syringes

Maltreatment Syringe seals

Unauthorized service Tubing and tubing

connections

Units not returned in original or

Cavro valves

adequate packaging

Units which are “life-cycled” Cavro probes

The foregoing warranties and limitations are customer’s exclusive remedies and

are in lieu of all other warranties, express or implied, including without limitation

any warranty of merchantability or fitness for a particular purpose.

Product Documentation Warranty Information

The information contained in this document is subject to change without notice.

Tecan Systems makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and fitness

for a particular purpose.

Tecan Systems shall not be liable for errors contained in this document or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 5

Document Status Sheet

Title: Cavro® XLP 6000 Modular Syringe Pump Operating Manual

ID: 734237-C, en

Version Revision Issue Major changes

1 C New edition

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 6

This page has been left intentionally blank.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 7

Table of Contents

1 Getting Started

1.1 Regulatory Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 XLP 6000 Features at-a-Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Unpacking the XLP 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1 XLP 6000 Features at-a-Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Unpacking the XLP 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Functional Description of the XLP 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6 Tips for Setting Up the XLP 6000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2 Hardware Setup

2.1 Power and Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Settings and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5 Installing Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.6 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

-

3 Software Communication

3.1 XLP 6000 Addressing Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Communication Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Using the XLP 6000 Command Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.4 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.5 Operating Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3.6 Error Codes and Pump Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

4 Setting Up the XLP 6000 for Your Application

4.1 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Optimizing XLP 6000 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Helpful Hints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

5 Maintenance

5.1 Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 On-Site Replacements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 8

-

6 Technical Service

A Ordering Information

A.1 Available Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 XLP 6000 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.3 Other Tecan Systems Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.4 Mating Connector Suppliers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

B Plunger Information

B.1 Typical Plunger Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Plunger Time Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C ASCII Chart of Codes for U.S. Characters

D Chemical Resistance Chart

E XLP 6000 Physical Specifications

F CAN Communication Commands

G Command Quick Reference

G.1 Pump Configuration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

G.2 Initialization Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

G.3 Valve Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-4

G.4 Plunger Movement Commands/Status Bit Reports . . . . . . . . . . . . . . . . . . . G-4

G.5 Set Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

G.6 Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

G.7 Non-Volatile Memory (EEPROM) Commands . . . . . . . . . . . . . . . . . . . . . . . G-6

G.8 Report Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-6

G.9 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

G.10 Error Codes and Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

G.11 DA-15 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 9

List of Figures

Figure 1-1 XLP 6000 Modular Syringe Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2 Syringe Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

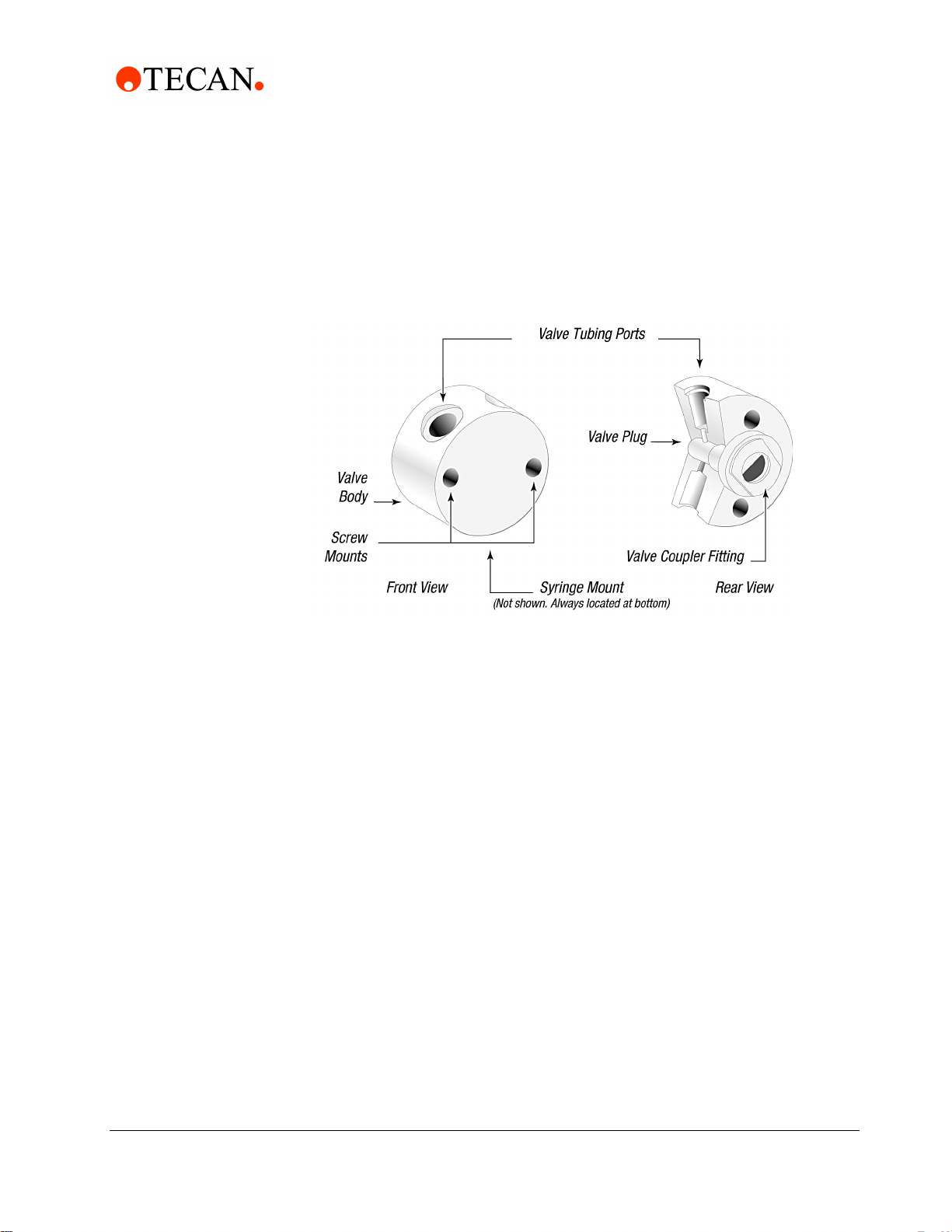

Figure 1-3 3-Port Valve Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

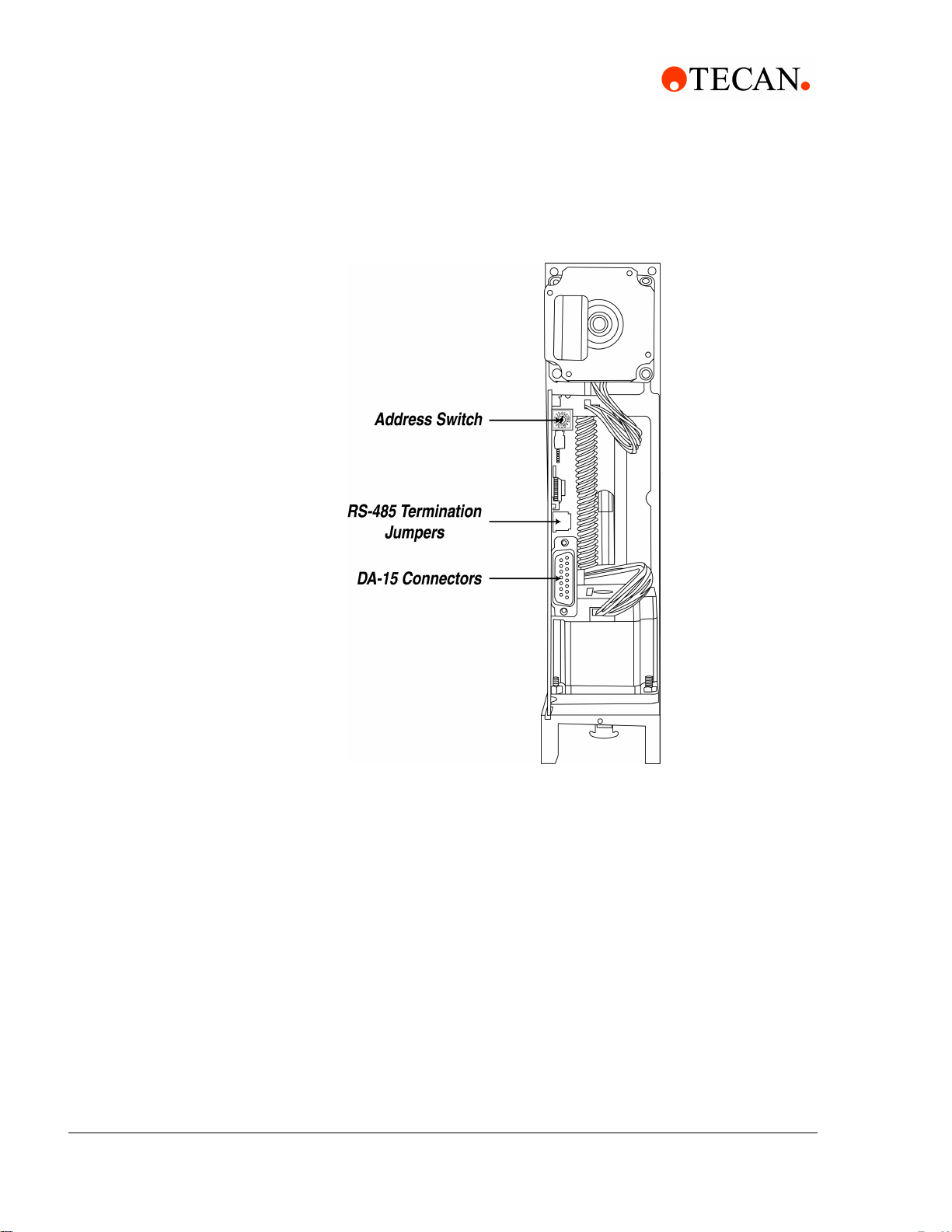

Figure 1-4 XLP 6000 Printed Circuit Assembly External Connectors . . . . . . . . . . 1-6

Figure 2-1 DA-15 Connector Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-2 RS-232 Multi-Pump Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-3 RS-485 Multi-Pump Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

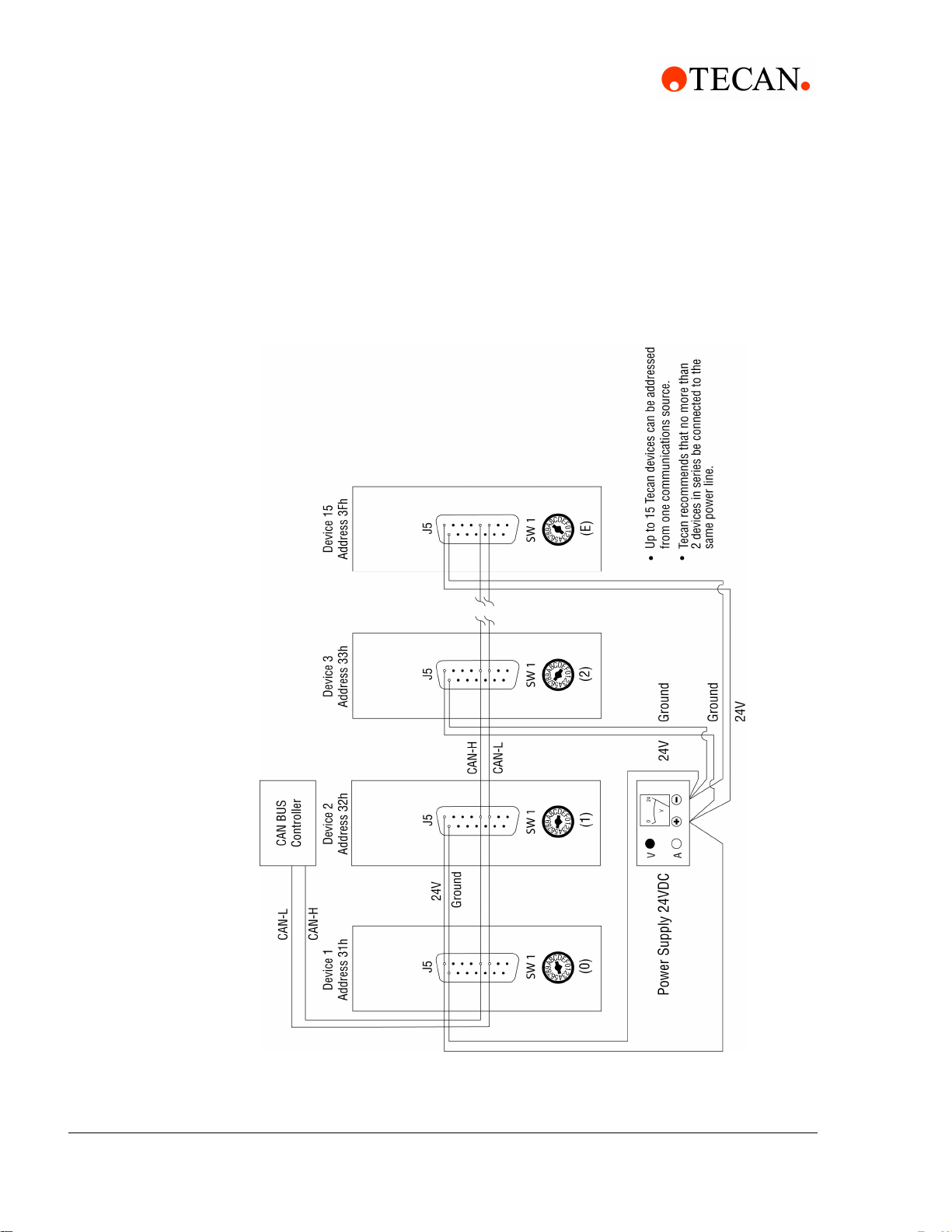

Figure 2-4 CAN Multi-Pump Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

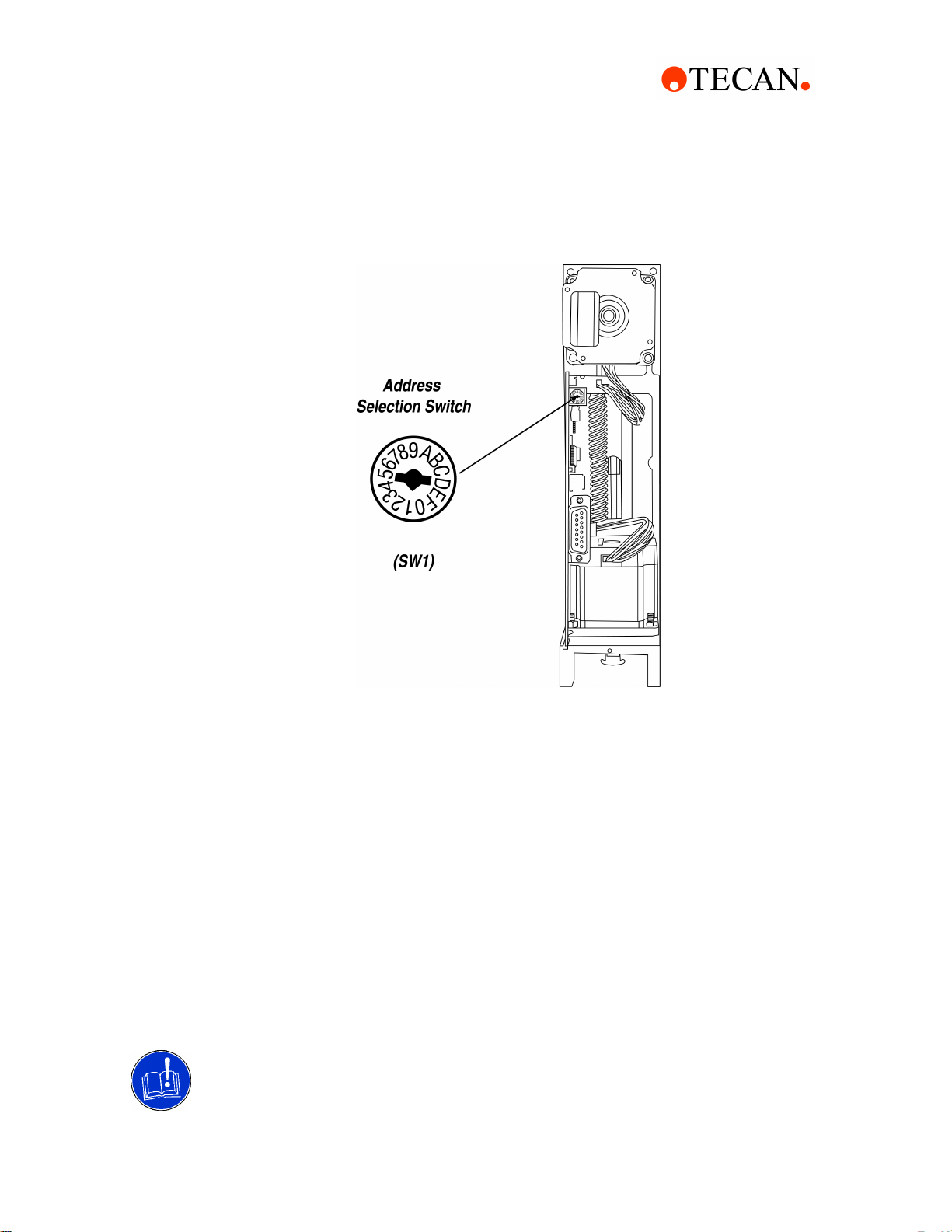

Figure 2-5 Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-6 XLP 6000 Valve Installation (3-Port Valve Shown) . . . . . . . . . . . . . . . 2-12

Figure 2-7 Syringe Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-8 XLP 6000 Outline Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 3-1 CAN Message Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-2 Valve Position Examples for 3-Port Non-Distribution Valves . . . . . . . 3-28

Figure 3-3 Valve Position Examples for 3-Port Distribution Valves. . . . . . . . . . . . 3-29

Figure 3-4 Valve Position Examples for 4-Port Non-Distribution Valves. . . . . . . . 3-30

Figure 3-5 Valve Position Examples for T Valves (Non-Distribution) . . . . . . . . . . 3-31

Figure 3-6 Valve Position Examples for 6-Port Distribution Valves. . . . . . . . . . . . 3-31

Figure 3-7 Valve Position Examples for 9-Port Distribution Valves. . . . . . . . . . . . 3-32

Figure 4-1 Syringe Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 5-1 Syringe Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Figure 5-2 Syringe Seal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Figure 5-3 XLP 6000 Valve Replacement (3-Port Valve Shown) . . . . . . . . . . . . . 5-7

Figure 6-1 XLP 6000 Label Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

-

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 10

-

This page has been intentionally left blank.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 11

1 Getting Started

Congratulations on your purchase of the Cavro® XLP 6000 Modular Syringe

Pump from Tecan Systems.

The XLP 6000 is a fully programmable, open frame, precision liquid handling

pump module, designed for applications in the 5 µL to 25 mL range. It is controlled

by an external computer or microprocessor and automates pipetting, diluting, and

dispensing functions.

This chapter includes these topics:

Regulatory Considerations

XLP 6000 Features at-a-Glance

Unpacking the XLP 6000

Functional Description of the XLP 6000

Safety

Tips for Setting Up the XLP 6000

Regulatory Considerations

1 - Getting Started

1.1 Regulatory Considerations

The XLP 6000 is a general laboratory module. Since it not a medical device, it is

not subject to FDA regulatory approval. The XLP 6000 uses only recognized

components and bears the UL Recognized Component Mark:

The use of UL Recognized components in a product or system allows UL to focus

the evaluation of the complete system on its intended end-use, and thus speeds

up the evaluation of that product or system. For more information regarding UL

certification of Tecan Systems’ syringe pumps, please visit the Underwriters

Laboratories Inc. website at http://www.ul.com/info/st andard.htm. Tecan Systems’

customer file number for the recognized component is E164638.

1.1.1 CE

As a module designed for incorporation into larger systems that require

independent testing and certification, the XLP 6000 does not carry its own CE

mark.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 1 - 1

Page 12

1 - Getting Started

XLP 6000 Features at-a-Glance

1.1.2 Radio Interference

1.0.1 Radio Interference

The XLP 6000 can radiate radio frequency energy , which may cause interference

The XLP 6000 can radiate radio frequency energy , which may cause interference

to radio and television communications. Follow standard good engineering

to radio and television communications. Follow standard good engineering

practices relating to radio frequency interference when integrating the XLP 6000

practices relating to radio frequency interference when integrating the XLP 6000

into electronic laboratory systems.

into electronic laboratory systems.

1.2 XLP 6000 Features at-a-Glance

1.1 XLP 6000 Features at-a-Glance

The XLP 6000 is a syringe pump that is designed for OEM precision liquid

The XLP 6000 is a syringe pump that is designed for OEM precision liquid

handling applications. It has the following standard features and functions:

handling applications. It has the following standard features and functions:

Syringe sizes ranging from 50 L to 25 mL

Syringe sizes ranging from 50 L to 25 mL

Accuracy 1.0% at full stroke

Accuracy 1.0% at full stroke

Precision 0.05% at full stroke

Precision 0.05% at full stroke

Standard dispense/aspirate resolution of 6,000 increments

Standard dispense/aspirate resolution of 6,000 increments

Microstep dispense/aspirate resolution of 48,000 increments

Microstep dispense/aspirate resolution of 48,000 increments

3-Port, 4-Port, Y-Block, T-Valve, 3-Port Distribution, 6-Port Distribution, and 9-

3-Port, 4-Port, Y-Block, T-Valve, 3-Port Distribution, 6-Port Distribution, and 9-

Borosilicate glass, Kel-F and Teflon fluid contact

Borosilicate glass, Kel-F and Teflon fluid contact

RS-232, RS-485 and CAN interface

RS-232, RS-485 and CAN interface

Programmable plunger speeds from 1.2 sec/stroke to 160 min/stroke, with

Programmable plunger speeds from 1.2 sec/stroke to 160 min/stroke, with

Teflon coated lead screw drive with a quadrature encoder for lost-step

Teflon coated lead screw drive with a quadrature encoder for lost-step

Pump diagnostics, self-test, and error reporting

Pump diagnostics, self-test, and error reporting

Auxiliary inputs and outputs

Auxiliary inputs and outputs

Operates using a single 24V DC power supply

Operates using a single 24V DC power supply

Port Distribution valves

Port Distribution valves

ramps and on-the-fly speed changes

ramps and on-the-fly speed changes

detection

detection

1.3 Unpacking the XLP 6000

1.2 Unpacking the XLP 6000

To unpack the module, follow these steps:

To unpack the module, follow these steps:

1 Remove the pump module(s) and accessories from the shipping cartons.

1 Remove the pump module(s) and accessories from the shipping cartons.

2 Check the contents against the packing slip to make sure that all the

2 Check the contents against the packing slip to make sure that all the

components are present.

components are present.

1.3.1 ESD Considerations

1.2.1 ESD Considerations

The XLP 6000 is an electronic device that is sensitive to electrostatic discharge

The XLP 6000 is an electronic device that is sensitive to electrostatic discharge

(ESD). Static discharge from clothing or other fixtures can damage these

(ESD). Static discharge from clothing or other fixtures can damage these

1 - 2 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 13

Functional Description of the XLP 6000

components. To prevent premature failure of pump components, use good ESD

practices when handling the XLP 6000. These include, but are not limited to:

Using wrist or ankle straps

ESD mats or worktables

ESD wax on the floor

Prepare an ESD-free work area before the chassis is grounded.

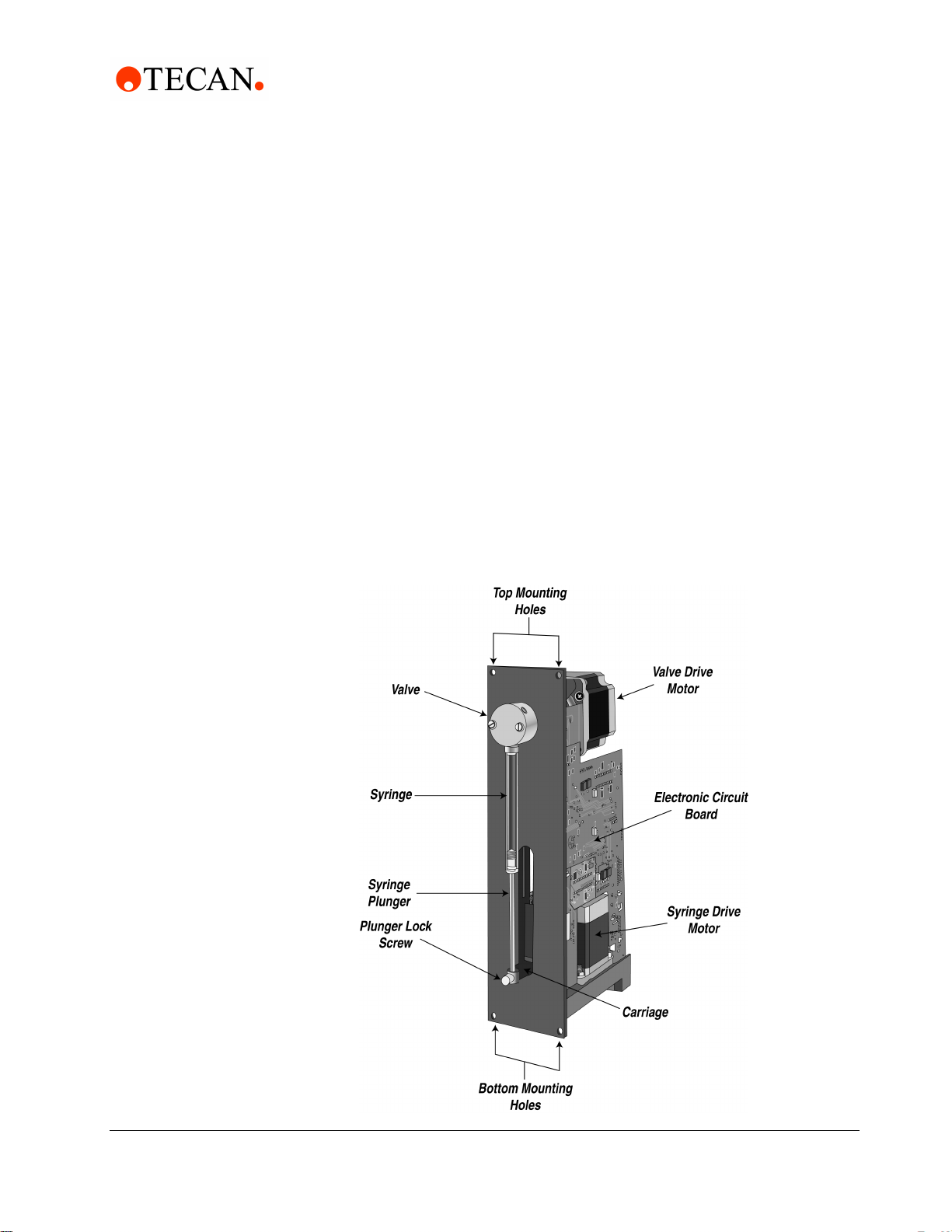

1.4 Functional Description of the XLP 6000

The XLP 6000 uses a stepper-motor driven syringe and valve design to aspirate

and dispense measured quantities of liquid. Both the syringe and the valve are

replaceable. Functional descriptions and illustrations of each major XLP 6000

component are provided in the following sections.

1 - Getting Started

Figure 1-1 XLP 6000 Modular Syringe Pump

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 1 - 3

Page 14

1 - Getting Started

Functional Description of the XLP 6000

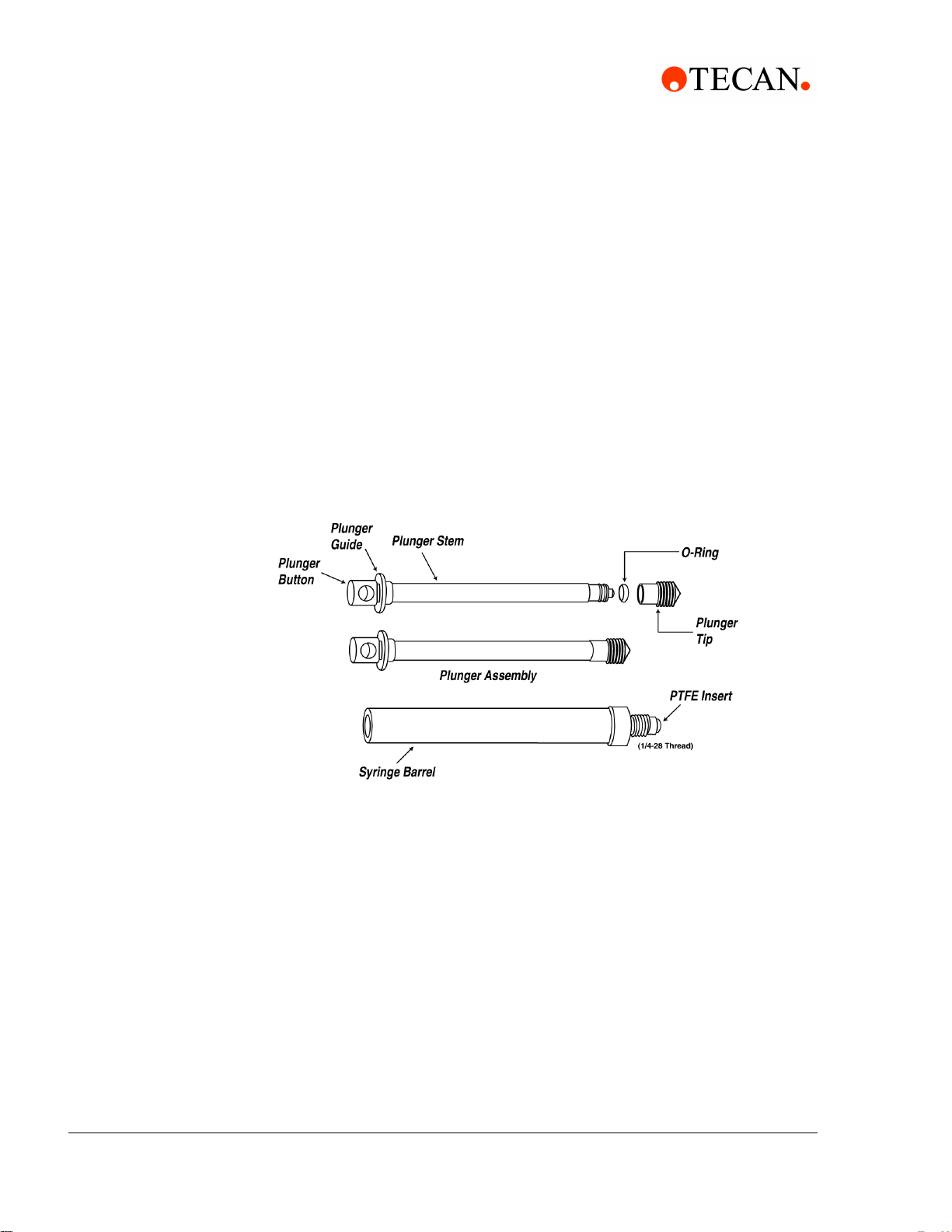

1.4.1 Syringe and Syringe Drive

The syringe plunger is moved within the syringe barrel by a lead screw drive that

incorporates a 1.8 stepper motor and quadrature encoder to detect lost steps.

The syringe drive has a 60 mm travel length and resolution of 6,000 increments

(48,000 increments in fine-positioning and microstep mode). When power is not

applied to the pump, the syringe drive can be removed by releasing the pin

assembly.

The base of the syringe plunger is held to the drive by a knurled screw. The top of

the syringe barrel attaches to the pump valve by a 1/4-28" fitting.

Figure 1-2, ’Syringe Components” shows the components of a typical syringe.

Figure 1-2 Syringe Components

Syringes are available in these sizes: 50 L, 100 L, 250 L, 500 L, 1.0 mL,

2.5 mL, 5.0 mL, 10 mL, and 25 mL.. For ordering information, see Appendix A,

"Ordering Information".

Note: To obtain optimal performance and maximum life from any syringe, please

follow the syringe cleaning and maintenance procedure included with each Cavro

Syringe. Technical Note #1 (PN 730317) contains practical tips for the use and

maintenance of Cavro Syringes.

1.4.2 Valve and Valve Drive

The valve is made of a Kel-F body and Teflon plug. The plug rotates inside the

valve body to connect the syringe port to the various input and output ports. In

addition to input and output ports, non-distribution valves also have a bypass

position. This position “bypasses” the syringe and connects the input and output

ports. The bypass position is often used for flushing fluid lines. The valve is turned

by a 1.8 stepper motor that has an encoder coupled to it for positioning feedback.

1 - 4 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 15

Figure 1-3 shows the components of a 3-port valve.

Figure 1-3 3-Port Valve Components

Functional Description of the XLP 6000

1 - Getting Started

1.4.3 Printed Circuit Assembly

The printed circuit assembly (PCA) holds the microprocessor and circuitry to

control the syringe and valve drive. The PCA provides connectors for electrical

inputs and outputs as well as a communication address switch. For information on

modes of operation, see Chapter 3, "Software Communication".

Figure 1-4 shows the accessible components on the printed circuit board

assembly.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 1 - 5

Page 16

1 - Getting Started

Functional Description of the XLP 6000

Figure 1-4 XLP 6000 Printed Circuit Assembly External Connectors

The XLP 6000 PCA has a DA-15 connector to handle power and communications.

For more information on the printed circuit assembly inputs/outputs and the

address switch, see Chapter 2, "Hardware Setup".

1.4.4 Communication Interfaces

Depending on the pump configuration, the XLP 6000 can communicate singly or

in a multi-pump configuration through an RS-232, RS-485, or CAN (Controller

Area Network) interface. For RS-232 and RS-485, baud rates of 9600 and 38400

are supported. For CAN, baud rates of 100K,125K, 250K, 500K, and 1M are

supported.

For details on the communications interfaces, see Chapter 2, "Hardware Setup".

1 - 6 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 17

1.4.5 Multi-Pump Configurations

Up to fifteen (15) XLP 6000 pumps can be connected together in a multi-pump

configuration (also called “daisy-chaining”). In this configuration each pump is

addressed separately from a single terminal via its unique address, which is set

using the address switch on the back panel of the pump.

Within a multi-pump configuration, the RS-485 communications bus is required,

although the first pump in the chain may receive either RS-232 or RS-485

communications. For CAN communications, neither RS-232 nor RS-485 is

required. For more information on setting addresses, see Chapter 2.

1.5 Safety

1 - Getting Started

Safety

The Cavro® XLP 6000 Modular Syringe Pump is designed for pipetting and

dispensing operations in the 5 µL to 25 mL range. Any other use is considered

improper and may result in damage to the pump and/or unreliable test results.

The XLP 6000 is designed to meet recognized technical regulations and is built

with state-of-the-art components. Nevertheless, risks to users, property and the

environment can arise when the module is used carelessly or improperly.

Appropriate warnings in this Operating Manual serve to make the user aware of

possible hazards.

1.5.1 Notices and Symbols

Warning Notices Used in this Manual

The triangle warning symbol indicates the possibility of personal injury if the

instructions are not followed.

Specific symbols indicate the hazard to which a user is exposed. A few examples

follow.

Toxic Substance

Chemical or biological hazards can be associated with the substances used or the

samples processed with the XLP 6000. Always be aware of possible hazards

associated with these substances.

Explosion and Fire Hazard

Never process explosive or highly flammable liquids with the XLP 6000.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 1 - 7

Page 18

1 - Getting Started

Tips for Setting Up the XLP 6000

Pinch Point, Mechanical Hazards

Automatically moving parts may cause injuries (crushing, piercing)

Attention

The general “Read This” symbol indicates the possibility of equipment damage,

malfunction or incorrect process results, if instructions are not followed.

1.6 Tips for Setting Up the XLP 6000

For complete information on setting up the XLP 6000, see Chapter 2, "Hardware

Setup" and “Chapter 3, "Software Communication".

Note: Before performing any work with the XLP 6000, first read this Operating

Manual carefully.

To ensure proper operation, follow these tips:

Always set up and mount the pump in an upright position. Failure to do so can

cause problems priming the system.

Always run liquid through the syringe and valve when they are moving. Failure

to do so can damage the sealing surfaces.

Before running any organic solvents through the pump, see Appendix D,

"Chemical Resistance Chart" for more information on chemical compatibility.

Always power down the instrument when connecting or disconnecting pumps.

Caution! Keep fingers out of the syringe slot while the pump is running. Failure to

do so can cause injury.

1 - 8 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 19

2 Hardware Setup

This chapter includes these sections describing the various parts of hardware

setup:

Power and Electrical Considerations

Cabling

Communication Interfaces

Settings and Options

Installing Components

Mounting

2.1 Power and Electrical Considerations

Power and Electrical Considerations

2 - Hardware Setup

The XLP 6000 requires a 24V DC power supply with a current rating of at least

1.5A, provided through a DA-15 connector. Tecan Systems recommends using

one power cable for every two pumps to provide noise immunity, i.e., power

should not be daisy-chained to more than two pumps.

2.1.1 Choosing a Power Supply

The 24V DC supply for a single XLP 6000 should meet the following basic

requirements:

Output voltage: 24V nominal

Output voltage tolerance: ±10% maximum, ±5% preferred.

Well-regulated power supplies are recommended, as operating pumps below

24V will affect performance.

Output voltage regulation: ±1% with varying line (input voltage) and load

Output current (not including loads other than a single pump):

– 1.5A for power supplies with minimal capacitance.

– 850mA for power supplies with internal filter capacitance of at least 1000

F per amp of output current

– 850mA for power supplies with external capacitance of at least 1000 F

per amp of output current (aluminum electrolytic capacitor preferred)

Output voltage ripple: 50mV rms maximum at full load

Conformance to required safety and EMI/RFI specifications

Voltage turn-on and turn-off overshoot: < 2 volts

Minimum current load (for switchers): see “Switching Power Supplies” in this

chapter.

To meet the above basic requirements, the supply must incorporate either linear

or switching regulation and must have adequate output filter capacitance.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 1

Page 20

2 - Hardware Setup

Power and Electrical Considerations

A current-limiting power supply is recommended. Current limiting above 1.0A is

acceptable, assuming that no additional equipment is operated from the supply.

If the power supply uses current feedback, the time-current foldback point must be

sufficient to allow charging of a 470 F capacitor without folding back. If an

external capacitor is used, exercise care to ensure that the supply always starts

after foldback, particularly at low AC line voltage.

2.1.2 Integrating a Power Supply

When a power supply is used to operate more than one XLP 6000 or other device,

it must provide the total average current for all devices. The power supply and

filter capacitance together must satisfy the total peak input current for all devices.

For example, if a system incorporates six XLP 6000 pumps with other equipment

that together require 4 amps, a 10A power supply is satisfactory, provided the

output filter capacitance in the supply is at least 10,000 F:

6 x 0.85 = 5.1A; +4A = 9.1A (choose a 10A power supply)

If the power supply filter capacitance is less than 10,000 F, use either additional

external capacitance or a 15A power supply:

6 x 1.5 = 9.0A; +4A = 13A (choose a 15A power supply)

In this example, it is assumed that all the pumps and other equipment will

sometimes operate simultaneously.

External equipment with inadequate bypass capacitance or that is inadequately

sourced for current can cause overvoltage transients and sags, and can create

unnecessary ripple current in the XLP 6000. This can result in decreased

component life. Additionally , it is possible for a regulated power supply to become

unstable with certain loads and oscillate if adequate filter capacitance is not

present. Some forms of oscillation can cause failures in the XLP 6000. These

issues can be avoided by using a properly designed commercial power supply.

Consideration should also be given to the wiring of the XLP 6000 and any

additional devices. Wiring should be of sufficient gauge for the current, and as

short as possible. Unless otherwise required by safety requirements, the power

supply lines to the XLP 6000 should be 20AWG or heavier. Multiple XLP 6000s

can be daisy-chained, provided that the wire size and the power supply are

adequate for the total current. In the example of the six XLP 6000 pumps above,

use 18AWG wire if the units are daisy-chained. It is best if each pair is twisted or

dressed together from the device to the supply. For more information on multipump cabling, see Section 2.2, Cabling.

To control power to the XLP 6000, switch power to the power supply. Do not use a

relay or switch contacts between the 24V supply and the XLP 6000 (i.e., do not

switch DC input to the pump).

2 - 2 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 21

2.1.3 Switching Power Supplies

Be sure to check carefully the minimum load requirement of the power supply.

Typically, switching supplies have a minimum load requirement of up to 10% of

the rated output current.

Note: The XLP 6000 idle current is less than 10% of the full running current.

For example, in a system with multiple XLP 6000 pumps, a 24V 5-amp switcher

with a minimum load less that 500mA may not provide sufficient current when the

XLP 6000 motors are idle and all other devices are in a low current state. If the

XLP 6000 is the only load on the 24V supply, a switcher should have a minimum

load specification of 50mA or less. An appropriate external power resistor can be

used to ensure that the minimum load is met.

2 - Hardware Setup

Cabling

2.2 Cabling

A single cable supplies both power and communications to each XLP 6000. A

unique address identifies each pump module. For more information, see “Address

Switch Settings” later in this chapter. See also Chapter 3, "Software

Communication".”

Power requirements are described in Section 2.1, Power and Electrical

Considerations.

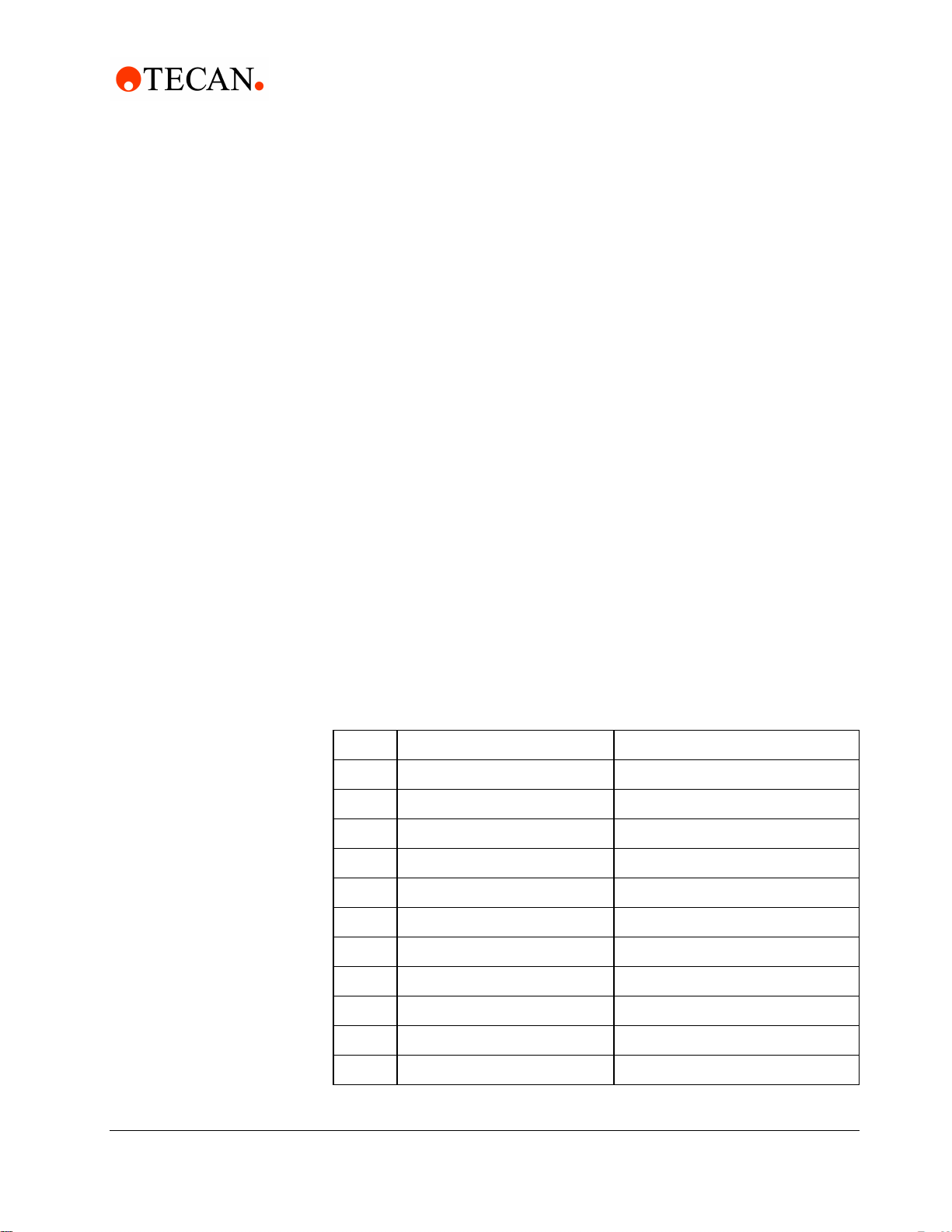

Table 2-1 DA-15 Connector Pin Assignments

Pin Function Remarks

124V DC

2 RS-232 TxD line Output data

3 RS-232 RxD line Input data

4Reserved

5 CAN high signal line

6 CAN low signal line

7 Auxiliary input #1 TTL level

8 Auxiliary input #2 TTL level

9 Ground Power and logic

10 Ground Power and logic

11 RS-485 A line Data +

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 3

Page 22

2 - Hardware Setup

Communication Interfaces

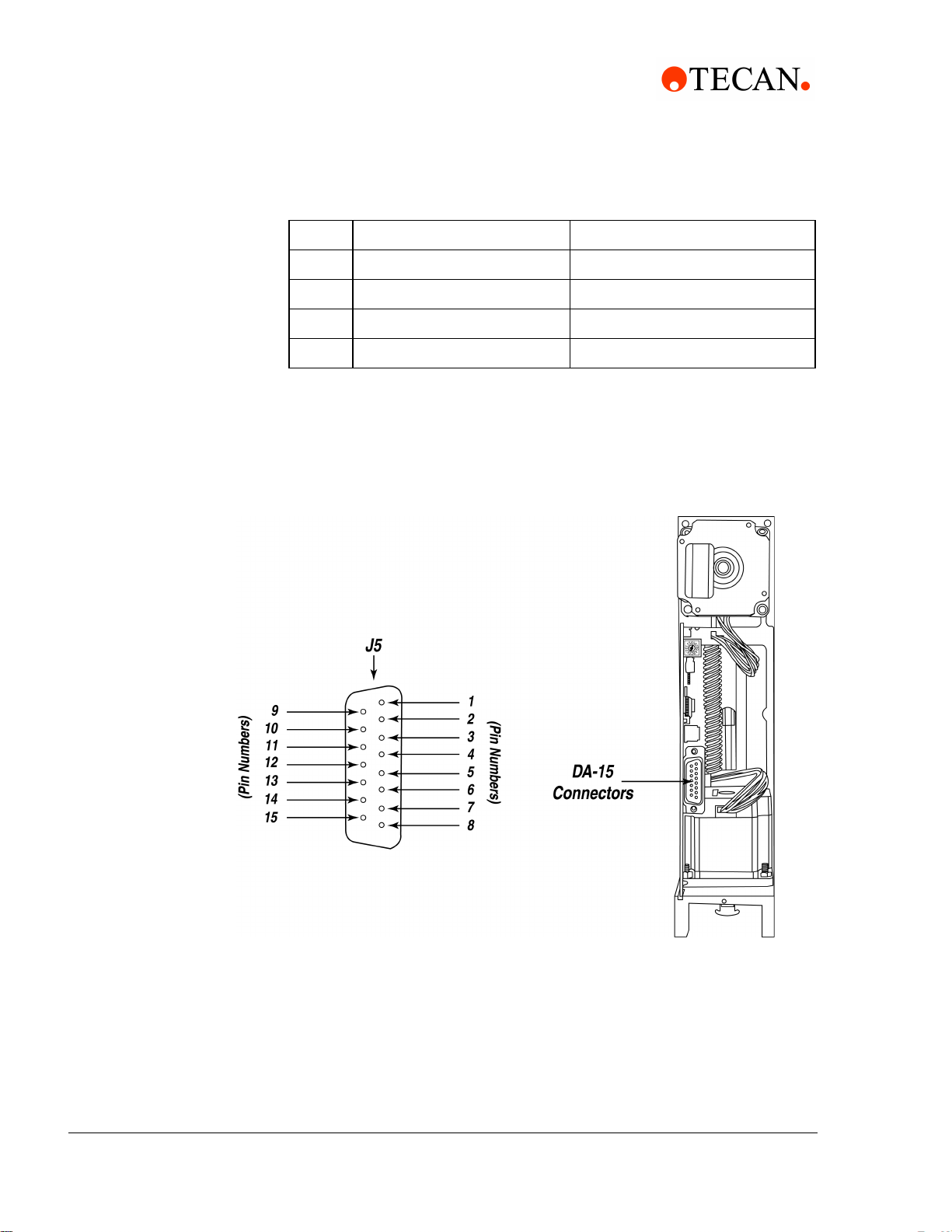

Figure 2-1 DA-15 Connector Pins

Pin Function Remarks

12 RS-485 B line Data 13 Auxiliary output #1 TTL level

14 Auxiliary output #2 TTL level

15 Auxiliary output #3 TTL level

Figure 2-1 shows the pin positions of the DA-15 connector on the printed circuit

assembly. This is a male connector that requires a female connector on the

mating cable.

2.3 Communication Interfaces

The computer or controller communicates with the XLP 6000 through an RS-232

interface, RS-485 interface, or CAN (Controller Area Network) interface.The XLP

6000 automatically detects the communication interface.

2 - 4 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 23

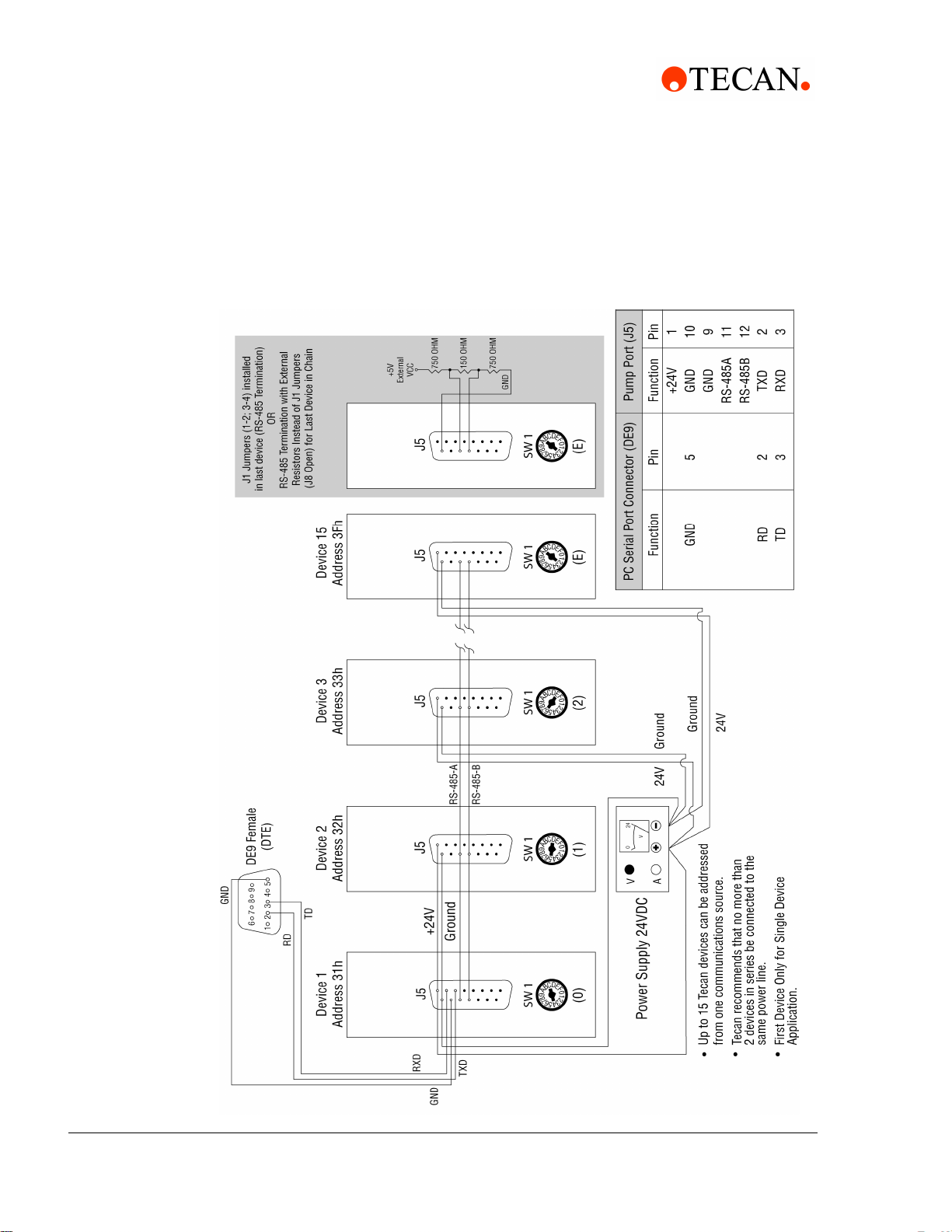

Examples of cabling connections are shown in Figure 2-2, Figure 2-3, and

Figure 2-4 on the following pages.

2.3.1 RS-232/RS-485 Interface

The RS-232 interface automatically converts the protocol to RS-485 for the

benefit of any other devices which may be connected to the XLP 6000’s RS-485

communication bus (this constitutes the so-called “multi-drop” device

configuration).

Note: The RS-232 interface does not support hardware handshaking and

requires only three lines: RXD, TXD, and Signal Ground.

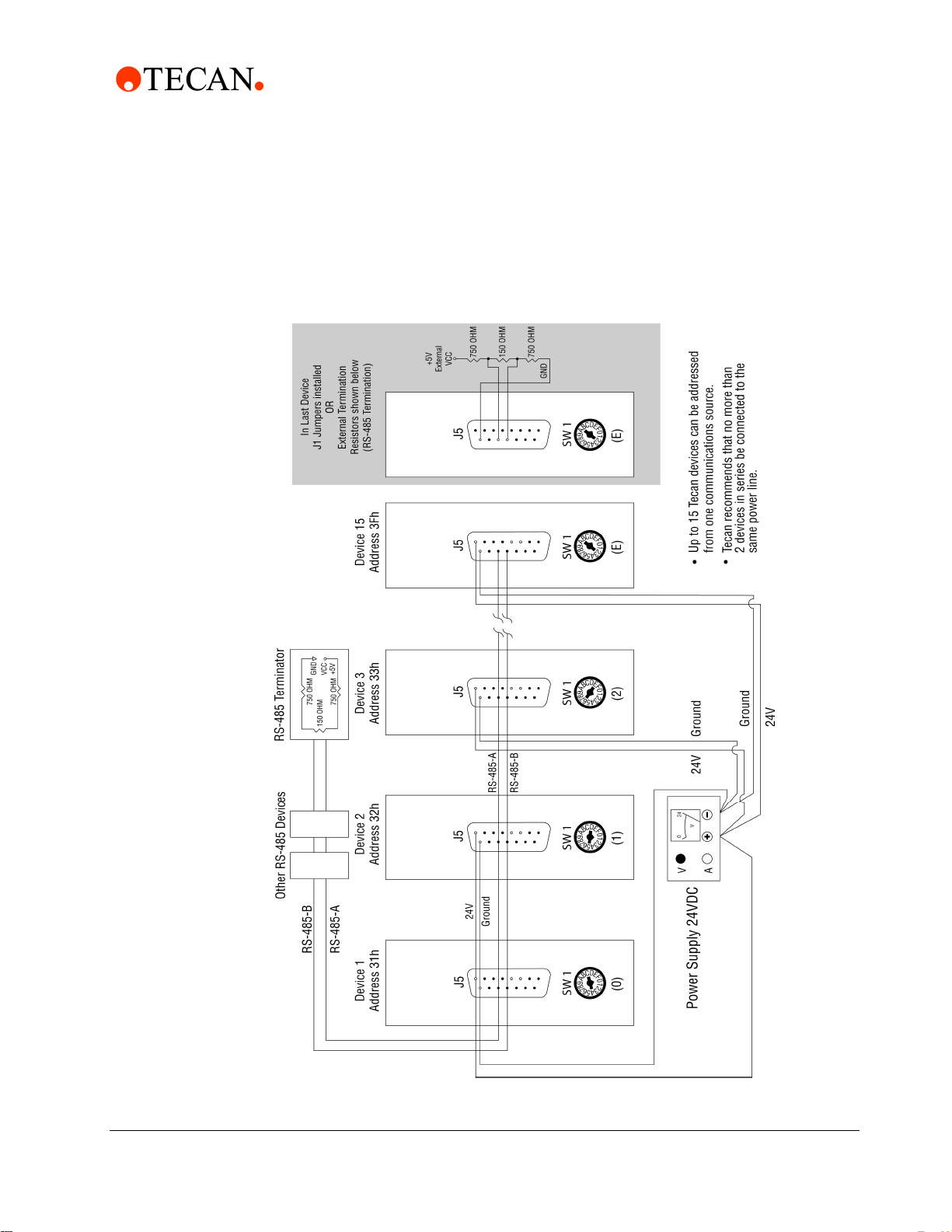

When using a multi-drop arrangement, up to 15 pumps can be addressed by the

controller on the same communications bus. Take special care to ensure that the

RS-485 A and B lines are not reversed. Refer to the cabling illustrations on the

following pages. These illustrations show the multi-pump cabling for RS-232, RS485, and CAN connections, respectively. Also shown is the external termination

scheme for the RS-485 chain.

2 - Hardware Setup

Communication Interfaces

2.3.2 CAN Interface

The CAN interface is a two-wire serial system. The bus is driven differentially in a

manner similar to RS-485. The major difference is in the protocol. The CAN

protocol is designed to allow any device on the bus to send a message at any

time. This is unlike other two-wire interfaces in which the slave devices can only

transmit in response to a query. Using the CAN interface, the pump can send a

message to inform the master that it has completed its task. Anti-collision

detection (which reconciles problems that occur when two devices talk at once) is

carried out by the CAN controller hardware.

Caution! Always power off pumps before connecting to or disconnecting from the

bus.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 5

Page 24

2 - Hardware Setup

Communication Interfaces

RS-232 Cabling

Figure 2-2 RS-232 Multi-Pump Cabling

2 - 6 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 25

RS-485 Cabling

2 - Hardware Setup

Communication Interfaces

Figure 2-3 RS-485 Multi-Pump Cabling

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 7

Page 26

2 - Hardware Setup

Communication Interfaces

CAN Cabling

Figure 2-4 CAN Multi-Pump Cabling

2 - 8 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 27

2.4 Settings and Options

2.4.1 Configuration Commands

The XLP 6000 firmware allows the user to configure the pump for different modes

of operation. The U commands (see Chapter 3, "Software Communication") are

used to write the configuration information to the non-volatile memory and control

the following options:

Valve type: The pump can be configured to operate with different valve

options (3-port, 4-port, T-valve, Y Block, 3-port distribution, 6-port distribution,

and 9-port distribution).

Baud rate: RS-232/RS-485 communication is possible at 9600 baud (default)

and 38400 baud. CAN communication is possible at 100K baud (default),

125K baud, 250K baud, 500K baud, and 1M baud rates.

Non-Volatile Memory Auto Mode: Allows the pump to run command strings

out of the non-volatile memory.

2 - Hardware Setup

Settings and Options

2.4.2 Address Switch Settings

The address switch (see Figure 2-5, "Address Switch") is located near the top of

the XLP 6000 electronic circuit board. It is used to give each XLP 6000 in a multipump configuration a unique or specific address, allowing the user to direct

commands to specific pumps. The address switch has sixteen positions

(numbered 0 through F). Fifteen positions (addresses 0 through E) are valid pump

addresses.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 9

Page 28

2 - Hardware Setup

Settings and Options

Figure 2-5 Address Switch

To set the address switch:

To set the address switch, use a jeweler’s screwdriver or small flat head

screwdriver and turn the switch in either direction to the desired position.

Note: Power cycle (or power up) the pump after setting the address switch.

For information on the addressing schemes for different pump configurations, see

Chapter 3, "Software Communication".

2.4.3 Self-Test

The “F” address switch position is used to activate the XLP 6000 self-test. Selftest causes the XLP 6000 to initialize, then cycle repeatedly through a series of

plunger movements. The self-test cycles through speed codes 0 to 14. If an error

condition occurs, the pump stops moving.

To run the self-test, set the address switch to position “F.” Then supply power to

the pump.

Caution! Always run liquid through the syringe and valve. Failure to do so can

damage the valve and syringe seal.

2 - 10 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 29

2.4.4 J5 Inputs/Outputs

The XLP 6000 provides two auxiliary inputs and three auxiliary outputs that can be

accessed through the DA-15 connector, J5. They provide TTL level signals. The

outputs are controlled by the [J] command.

The auxiliary inputs are located on J5, pins 7 and 8. They can be read back using

report commands ?13 and ?14. Additionally, the inputs can be used to externally

trigger a command sequence using the [H] command. The commands are

described in Chapter 3, "Software Communication".

The auxiliary outputs are located on J5, pins 13, 14, and 15.

2.5 Installing Components

2 - Hardware Setup

Installing Components

2.5.1 Installing the XLP 6000 Valve

To install the XLP 6000 valve, follow these steps:

1 Remove as much fluid as possible from the system by cycling the pump and

using air as the system fluid.

2 Initialize the pump using the [ZR] command so that the valve motor shaft is in

the correct position.

3 Issue an [A6000R] command to move the plunger to the bottom of travel.

4 Remove the syringe and tubing.

5 Remove the two socket head screws on the front of the valve, then remove

the valve from the pump. Do not remove the spacer.

6 Install the new valve by placing it on the front panel so that the screw holes

line up. The valve coupler fitting mates to the valve motor shaft. The shaft

should be in the correct position. If it is not, re-initialize the pump using the

command [ZR].

7 Replace the valve screws but do not tighten completely.

8 Install the syringe and pull the syringe plunger until it is aligned with the

carriage. Align the valve using the plunger as a guide, and tighten from 1/4 to

1/2 turn after the screws contact the valve body.

9 Pull the syringe plunger all the way into the carriage and secure by tightening

the plunger lock screw.

Caution! Be sure to reconfigure the pump firmware when changing valve types.

Failure to do so may damage the valve. See Section 3.3.2, Pump Configuration

Commands, for instructions on reconfiguring the pump.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 11

Page 30

2 - Hardware Setup

Installing Components

Figure 2-6 XLP 6000 Valve Installation (3-Port Valve Shown)

2.5.2 Installing a Syringe

To install a syringe, follow these steps:

1 Remove the plunger lock screw.

2 Install the syringe as shown in Figure 2-7, following these steps:

a. Screw the syringe into the valve.

b. Pull the syringe plunger down to the plunger holder assembly.

c. Align the plunger button through hole to the carriage mounting hole.

d. Slide the plunger lock screw through the plunger button and fasten to the

carriage.

Note: Make sure the plunger lock screw is securely tightened and the plunger

button is free to move on the plunger lock screw.

2 - 12 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 31

Figure 2-7 Syringe Installation

2 - Hardware Setup

Mounting

Note: To obtain optimal performance and maximum syringe life, follow the syringe

cleaning and maintenance procedures described in Chapter 5, "Maintenance".

Technical Note #001 (PN730317) contains practical tips for the tuse and care of

Tecan precision syringes.

2.6 Mounting

The XLP 6000 contains four mounting holes on the front plate of the frame.

Note: Always mount the pump in an upright position. Failure to do so can cause

problems in priming the system.

To facilitate mounting, see Figure 2-8, "XLP 6000 Outline Drawing" for critical

dimensions and location of the mounting holes.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 2 - 13

Page 32

2 - Hardware Setup

Mounting

Figure 2-8 XLP 6000 Outline Drawing

\

2 - 14 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 33

3 Software Communication

This chapter describes how to communicate with the XLP 6000: through an

RS-232, RS-485, or CAN (Controller Area Network) interface.

This chapter includes these topics:

XLP 6000 Addressing Scheme

Communication Protocols

Using the XLP 6000 Command Set

Initialization

Operating Commands

Error Codes and Pump Status

3 - Software Communication

XLP 6000 Addressing Scheme

3.1 XLP 6000 Addressing Scheme

As part of the communication protocol, an address for each pump must be

specified. The user has the option of addressing a single pump, two pumps (dual

device), four pumps (quad device), or all 15 pumps (all devices), depending on the

address byte used. Each physical address in the address switch corresponds to a

hexadecimal value, as shown in Table 3-1, Hexadecimal Addressing Scheme.

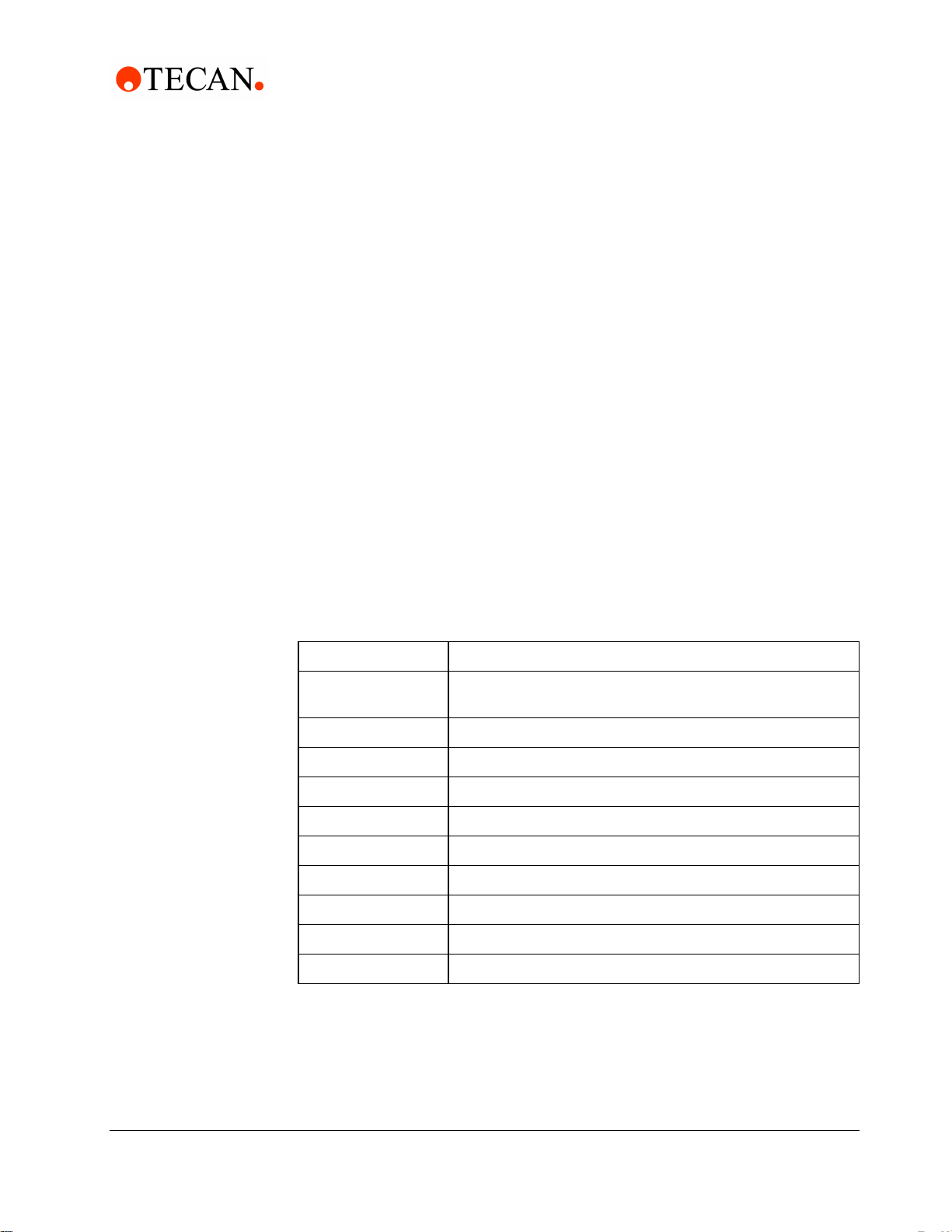

Table 3-1 Hexadecimal Addressing Scheme

Address (hex)

30 0 Master Address (master controller, personal com-

puter, etc.)

31..3F 1..F Addresses single device

41..4F N/A Addresses two devices at a time (dual device)

51..5D N/A Addresses four devices at a time (quad device)

5F N/A Addresses all devices on the bus

For example, an XLP 6000 with address switch set to 0 is addressed as device

“31h” in the RS-232 or RS-485 communication protocol, hardware address 1 is

addressed as device “32h,” and so on.

DeviceRS-232/RS-485 CAN

Table 3-2, Address Switch Settings in Hex (ASCII), shows the different address

switch settings for each of these configurations.

Note: When using the Pump:Link software to send commands to a device, use

the ASCII address values in Table 3-2.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 1

Page 34

3 - Software Communication

XLP 6000 Addressing Scheme

Table 3-2 Address Switch Settings in Hex (ASCII)

Single Device Dual Device Quad Device All Devices

Switch

Setting

0 31 1 41 A 51 Q 5F –

1322

233343C

3344

435545E55 U

5366

637747G

7388

839949I59 Y

93A:

A3B;4BK

B3C<

C3D=4DM5D ]

D3E>

Hex

Address

ASCII

Address

Hex

Address

ASCII

Address

Hex

Address

ASCII

Address Address

Value to

Send

E3F?4FO

FSelf Test

The user can communicate with all pumps in the chain by using address “5Fh,” for

example to initialize all pumps at once. Then each pump can be controlled

independently by using addresses “31h” to “3Fh.”

Note: Multiple address commands cannot be used to determine device status or

to request reports. Each device must be queried separately to gather status or

generate a report.

3 - 2 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 35

3.2 Communication Protocols

Three communication protocols are available:

OEM communications protocol

Data Terminal (DT) protocol

CAN protocol

The XLP 6000 firmware automatically detects the communication protocol.

The DT protocol can be run via an ASCII data terminal because no sequence

numbers or checksums are used. For instructions on using a Microsoft Windows

Terminal Emulator, see “Using DT Protocol with Microsoft Windows” in this

chapter.

Note: Tecan Systems recommends using the OEM protocol for RS-232 and

RS-485 interfaces. It provides increased error checking through the use of

checksums and sequence numbers.

3 - Software Communication

Communication Protocols

Once the XLP 6000 detects either the OEM or DT protocol, it will ignore the other

protocol until the next power cycle.

3.2.1 OEM Communication Protocol

OEM communication is a robust protocol that includes automatic recovery from

transmission errors. Table 3-3, OEM Protocol describes each setting within the

OEM communication protocol.

Table 3-3 OEM Protocol

Parameter Setting

Character Format

Baud rate 9600 or 38400

Data bits 8

Parity None

Stop bit 1

Command Block

(see “OEM Protocol Command Block Characters” for details)

1 STX (^B or 02h)

2 Pump address

3 Sequence number

3+n Data block (length n)

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 3

Page 36

3 - Software Communication

Communication Protocols

4+n ETX (^C or 03h)

5+n Checksum

1 STX (^B or 02h)

2 Master address (0 or 30h)

3 Status code

3+n Data block (length n)

4+n ETX (^C or 03h)

5+n Checksum

Answer Block

(see “OEM Protocol Answer Block Characters” for details)

OEM Protocol Command Block Characters

The command block characters in the OEM communication protocol are

described below. All characters outside the command block are ignored.

When developing a parsing algorithm, the programmer should key on the STX as

the beginning of the answer block and the checksum (character after the ETX) as

the end of the answer block.

STX (^B or 02h)

The STX character indicates the beginning of a command

Pump Address

The pump address is a hexadecimal number specific for each pump.

Sequence Number/Repeat Flag

The sequence number is a single byte that conveys both a sequence number

(legal values: 0 to 7) and a bit-flag indicating that the command block is being

repeated due to a communications breakdown. The sequence number is used

as an identity stamp for each command block. Since it is only necessary that

every message carry a different sequence number from the previous

message (except when repeated), the sequence number may be toggled

between two different values (e.g., “1” and “2”) as each command block is

constructed. During normal communication exchanges, the sequence number

is ignored. If, however, the repeat flag is set, the pump compares the

sequence number with that of the previously received command block to

determine if the command should be executed or merely acknowledged

without executing.

Note: If the operator chooses not to use this option, the sequence number can be

set to a fixed value of 1 (31h).

3 - 4 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 37

3 - Software Communication

Communication Protocols

The following two scenarios clarify this error detection mechanism.

Scenario 1.

1 The computer sends a command block stamped with sequence #1 to the

pump.

2 The pump receives the command, sends an acknowledgement to the PC, and

executes it.

3 Transmission of the acknowledgement message is imperfect; the PC does not

receive it.

4 The PC waits 100 ms for the acknowledgement, then retransmits the

command block with the sequence number left at 1 and the repeat bit set to

indicate a retransmission.

5 The pump receives the transmission, identified as such by the repeat bit.

6 The pump checks the sequence number against that of the previously

received command block. Noting a match, the pump sends an

acknowledgement to the PC, but it does not execute the command (since it

has already been executed).

7 The PC receives the acknowledgement and continues with normal

communications.

8 The next command block is stamped with sequence #2 to indicate a new

command.

Scenario 2.

1 The computer sends a command block stamped with sequence #1 to the

pump.

2 The pump never receives the command due to a communication error and

thus does not send an acknowledgement to the PC.

3 The PC waits 100 ms for the acknowledgement, then retransmits the

command block with the sequence number left at 1 and the repeat bit set to

indicate a retransmission.

4 The pump receives the retransmission, identified as such by the repeat bit.

5 The pump checks the sequence number against that of the previously

received command block. Noting a mismatch, the pump recognizes this as a

new command block and sends an acknowledgement to the PC. It then

executes the command.

6 The PC receives the acknowledgement and continues with normal

communications.

7 The next command block is stamped with sequence #2 to indicate a new

command.

The sequence number/repeat byte is constructed as follows:

Bit # 76543210

Value 0011REPSQ2SQ1SQ0

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 5

Page 38

3 - Software Communication

Communication Protocols

REP

SQ0 – SQ2

0 for non-repeated / 1 for repeated

Sequence value, as follows:

Sequence Value SQ2 SQ1 SQ0

1001

2010

3011

4100

5101

6110

7111

Note: Bits 4 through 7 are always fixed to the values shown.

Data Block (length n)

The data block consists of the data or commands sent to the pump or host

(this is an ASCII string). When the pump is responding to a move or [Q]

command, the data block length is 0 (i.e., no data string exists).

ETX

The ETX character indicates the end of a command string.

Checksum

The checksum is the last byte of the message string. All bytes (excluding line

synchronization and checksums) are XORed to form an 8-bit checksum. This

is appended as the last character of the block. The receiver compares the

transmitted value to the computed value. If the two values match, an error free

transmission is assumed; otherwise, a transmission error is assumed.

OEM Protocol Answer Block Characters

The answer block characters in the OEM communication protocol are described

below.

Only the unique answer block entries are listed in this section. For common

commands and answer block commands (characters), see the previous section,

“OEM Protocol Command Block Characters.”

3 - 6 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 39

Master Address

The master address is the address of the host system. This should always be

30h (ASCII value “0”).

Status and Error Codes

The status and error codes define pump status and signal error conditions.

For a description of status and error codes, see “Error Codes and Pump

Status” in this chapter.

3.2.2 Data Terminal (DT) Protocol

The DT protocol can be used easily from any terminal or terminal emulator

capable of generating ASCII characters at 9600 baud, 8 bits, and no parity.

Table 3-4 DT Protocol

3 - Software Communication

Communication Protocols

Character Format

Parameter Setting

Baud rate 9600 or 38400

Data bits 8

Parity None

Stop bit 1

Command Block

(see “DT Protocol Command Block Characters” for details)

1 Start command (ASCII “/” or 2Fh)

2 Pump address

2+n Data block (length n)

3+n Carriage Return ([CR] or 0Dh)

Answer Block

(see “DT Protocol Answer Block Characters” for details)

1 Start answer (ASCII “/” or 2Fh)

2 Master address (ASCII “0” or 30h)

3 Status character

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 7

Page 40

3 - Software Communication

Communication Protocols

3+n Data block (if applicable)

4+n ETX (03h)

5+n Carriage return (0Dh)

6+n Line feed (0Ah)

DT Protocol Command Block Characters

The command block characters in the DT communication protocol are described

below.

Start Block

The start character indicates the beginning of a message block.

Pump Address

The pump address is an ASCII character specific to each pump.

Data Block (length n)

The data block consists of the ASCII data or commands sent to the pump or

host.

End Block

The end character indicates the end of a message block.

DT Protocol Answer Block Characters

The answer block characters comprising the DT communication protocol are

described below.

Only unique answer block entries are listed in this section. For information on

command and answer block commands (characters), see the previous section,

“OEM Protocol Command Block Characters.”

Master Address

The master address is the address of the host system. This should always be

30h (ASCII “0”).

Status Character

The status and error codes define pump status and signal error conditions.

See the description of the [Q] command in “Error Codes and Pump Status.”

Data Block

This is the response from all Report commands with the exception of the [Q]

command.

3 - 8 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 41

Carriage Return (0Dh)/Line Feed (0Ah)

This character terminates the reply block.

3.2.3 Using DT Protocol with Microsoft Windows

The XLP 6000 can be controlled in DT protocol mode directly from the Microsoft

Windows terminal accessory.

To communicate with the XLP 6000 using Windows 3.x, follow these steps:

1 Connect the XLP 6000 to a communications port of the PC (for example,

COM1).

2 From the Microsoft Program Manager window, select Terminal from the

Accessories group window.

3 Select the Settings menu, and choose Communications.

4 Select a baud rate of 9600, 8 data bits, 1 stop bit, no parity, communications

port connector, and no flow control.

5 Click OK.

6 Set the pump address switch to 0.

7 Power on the pump.

8 Type /1ZR<CR> to initialize the pump.

9 To run the pump, see the commands listed in “Using the XLP 6000 Command

Set” in this chapter.

3 - Software Communication

Communication Protocols

To communicate with the XLP 6000 using Windows 95/98/NT/2000/XP, follow

these steps:

1 To connect the XLP 6000 to a communications port on the PC, first select the

Start Programs/Accessories/Communications Hyperterminal menu and

choose Run.

2 In the Run dialog box, type Hyperterm.exe. The Connection Description

dialog box appears.

3 Enter a name for the connection and select an icon, then click OK. The Phone

Number dialog box appears.

4 Select the following in the fields provided:

Connect using: Direct to <communication port> (usually COM1 or COM2,

depending on how the hardware is set up)

Click OK. The COM Properties dialog box appears.

5 Select the following in the fields provided:

– Bits per second: 9600

– Data bits: 8

–Parity: None

– Stop bits: 1

– Flow control: None

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 9

Page 42

3 - Software Communication

Communication Protocols

6 Click OK.

7 Select the File menu, and choose Properties. The Properties dialog box

8 Select the Settings tab, and enter or select these options:

9 Enter or select these options:

10 Click OK to close the ASCII Setup dialog box, then click OK to close the

11 Set the pump address to 0 or the appropriate address.

12 The communication protocol is detected automatically.

13 Power on the pump and initialize it by typing /1ZR and pressing Enter.

appears.

– Function, arrow, and Control keys act as:

• Select “Terminal keys”

– Emulation:

• Select “Autodetect”

• Enter “500” in Backscroll buffer lines

– Click the ASCII Setup button. The ASCII Setup dialog box appears.

– Select “Send line ends with line feed”

– Select “Echo typed characters locally”

– Enter a Line delay of “0”

– Enter a Character delay of “0”

– Select “Wrap lines that exceed terminal width”

Properties dialog box.

To run the pump, see the commands listed in “Using the XLP 6000 Command

Set” in this chapter.

3.2.4 CAN Interface Communications

CAN (Controller Area Network) is a two-wire, serial communication bus. It

eliminates polling sequences that verify task completion. Using CAN, the pumps

asynchronously report to the master or host when they have finished the current

task.

Note: All Tecan XLP 6000 systems use CAN controller chips compatible with

Phillips Semiconductor CAN bus specification, version 2.0.

When using the CAN interface, termination resistors (120 ohm) are necessary at

both ends of the bus. The pump does not provide CAN termination resistors.

CAN Messages

CAN messages consist of frames. Each frame has an 11-bit Message Identifier

(MID) and a 4-bit length identifier. The bits:

Indicate to which device on the bus the message is directed

Identify the message type

Show the direction of the message (to or from the master device)

3 - 10 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 43

Represent the length of the data block. Data blocks can be from zero to eight

bytes in length. Any message that requires more than eight bytes must be

sent in a series of multi-frame messages. The receiving unit then assembles

the separate frames into one long string.

CAN Message Construction

Each message frame begins with the Message ID (MID). The data block (up to 8

bytes in length) follows the MID and length information. The MID makes up three

nibbles that are transmitted first in a message frame. The bits are grouped as

shown in Figure 3-1, ’CAN Message Structure”.

Figure 3-1 CAN Message Structure

3 - Software Communication

Communication Protocols

Direction

This is the direction bit. It lets the devices on the bus know whether the current

message is to or from the master. “0” means that the message is from master

to slave; “1” means the message is from the slave to the master.

Note: Peer-to-peer messaging is not supported.

Group

This is the group number (0 - 7). Each type device on the CAN bus has a

group assignment. The XLP 6000 is assigned to group 2. The group number

“1” is reserved for the boot request procedure.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 11

Page 44

3 - Software Communication

Communication Protocols

Device

Frame

RTR

IDE

This is the address of the module in the particular group. Each group can have

up to 16 devices. The address value is 0 - 15.

This lets the device know what type of message is coming. See “CAN Frame

Types” in this chapter.

This bit is not used in T ecan Systems’ CAN implementation and should always

be set to 0.

This will always be set to 0 for standard format frames.

r0

Reserved bit, set to 0.

Length

This is the length of the data block in the message. Data blocks can be from

zero to eight bytes in length.

CAN Frame Types

The frame types allow each device to know what type of command is coming in

and enables faster processing of commands. Pumps respond to the frame types

described below.

“On-the-Fly” Commands (V and T), Type 0

Normal commands use a frame type 1 (i.e., “Action Commands”). Since

commands sent over the CAN bus with a particular frame type must complete

before a subsequent command using the same frame type can be issued, a

different ID must be used when issuing an “on-the-fly” command. For this

reason, “on-the-fly” commands must be issued over the CAN bus with a frame

type of 0 (zero).

When issuing “on-the-fly” commands, the frame type 0 commands will not

generate completion messages and thus no pairing code is needed (these

commands are simply acknowledged immediately).

Action Frames, Type 1

This frame type is used for action commands, such as Initialization

commands, Movement commands, Valve commands, or to set pump

operating parameters. All “task-type” commands are sent in this type

message frame. When multi-frame messages are used to send an action

command, this frame is the end message sent to the pump.

3 - 12 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 45

3 - Software Communication

Communication Protocols

Common Commands, Type 2

This frame type is used for commands that are common to every device on

the bus. The frame type is set to 2 and the command is a single ASCII

character in the data block. The single ASCII character is described below.

Command Description

0 Reset mode. This resets the pump and begins the boot request

procedure.

1 Start loaded command. Just like sending an [R] command after a string

has been loaded.

2 Clear loaded command. This clears out the command buffer.

3 Repeat last command. This command does the same thing as the [X]

command.

4 Stop action immediately. This acts like a [T] command.

Multi-Frame Start Message, Type 3

This frame type lets the pump know that the next message will be longer than

the 8-byte maximum for each frame. Subsequent frames will follow to

complete the message.

Multi-Frame Data, Type 4

This frame type is used to identify a frame in the middle of a multi-frame

message. The last frame of a multi-frame message for action commands must

be type 1. The last frame of a multi-frame message response from the pump

for report commands will be type 6.

Note: There is no type 5 frame.

Report/Answer Commands, Type 6

This frame type is used to get information back from the pump. It is similar in

operation to the query commands (i.e., [?]) used in the OEM and DT

protocols. The report command is one byte long and consists of one or more

ASCII characters in the data block. Report commands in ASCII format are:

Command Description

0 Report calculated plunger position in increments (standard/fine position-

ing)

1 Report start speed in increments per second

2 Report top speed in increments per second

3 Report cutoff speed in increments per second

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 13

Page 46

3 - Software Communication

Communication Protocols

6 Report current valve position

10 Report buffer status

13 Report status of input #1

14 Report status of input #2

15 Report the number of pump initializations

16 Report the number of plunger movements

17 Report the number of valve movements

18 Report the number of valve movements since last report

20 Report checksum

23 Report firmware version

24 Report zero gap increments

29 Report current status

When the pump responds to a query, the first two bytes of the data block are the

status bytes. The first byte contains an error code (same error codes used with

the RS-232 and RS-485 protocols) added to Ox20h. The second byte contains the

value Ox60h and is not used. The remaining six bytes are for the response in

ASCII. If the pump is only reporting current status, the message is only two bytes

long. If the reply consists of more than six bytes, multi-frame messages are used.

CAN Data Block

The data block tells the pump what to do. Pump commands are sent in ASCII just

like in RS-232 or RS-485. For command strings that are more than eight bytes in

length, multi-frame messages are used. This permits long program strings to be

sent as with the other communications interfaces (remember that the XLP 6000

buffer size is 255 characters).

Handling of Pump Boot Requests

When the pump is first powered up or receives a system reset command (frame

type 2, command 0), the pump notifies the host of this condition by sending a boot

request message at 100 millisecond intervals until it receives a proper response.

The group number is 1 for the boot request message. The frame type is 2 when

the pump sends messages to the host, and the frame type must be 0 when the

host replies to the boot request.

3 - 14 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 47

3 - Software Communication

Communication Protocols

Example 1. The pump is set to address 0

Pump sends:

Dir Group Device Frame RTR Length

1 001 0000 010 0 0000

Host acknowledges:

Dir Group Device Frame RTR Length Node ID Slave ID

0 001 0000 000 0 0010 0010 0000 0010 0000

Host acknowledges the boot request with:

Dir = 0 Host to slave Note:

Group = 1 Boot request response group

Device = 0 Always 0 in boot response

Boot MID is the same for

all nodes

Frame = 0 Boot request response frame

RTR = 0 Always 0

Length = 2 Two data bytes in return message

Node ID Group ID (2) +

Pump Address (0)

Slave ID Same as Node ID

(hex 20)

“ ” 00h Must respond with

“ ” 00h

Group & Address

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 15

Page 48

3 - Software Communication

Communication Protocols

Example 2. The pump is set to address 6

Pump sends:

Dir Group Device Frame RTR Length

1 001 0110 010 0 0000

Host acknowledges:

Dir Group Device Frame RTR Length Node ID Slave ID

0 001 0000 000 0 0010 0010 0110 0010 0110

Host acknowledges the boot request with:

Dir = 0 Host to slave Note:

Group = 1 Boot request response group

Device = 0 Always 0 in boot response

Boot MID is the same for

all nodes

Frame = 0 Boot request response frame

RTR = 0 Always 0

Length = 2 Two data bytes in return message

Node ID Group ID (2) +

Pump Address (6)

Slave ID Same as Node ID

(hex 26)

“&” Hex 26

Hex 26

The pump will save the Node ID to use for message filter Group ID.

Note: The slave ID does not have to be the same as the node ID. The pump can

be assigned any number between 0 and 0x7F (127) for the slave ID.

CAN Host and Pump Exchanges

When a slave pump receives a command, finishes a command, encounters an

error condition, or responds to a query , it sends an answer frame to the host using

the same frame type as the command it belongs to. The answer frame format is

device dependent. Generally, it will have the following format:

<MID><DLC><Answer>

<MID>

11-bit message identifier. The direction bit is 1. The group number and the

frame type are the same as received. Device ID is the slave message ID

assigned by the host.

3 - 16 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 49

3 - Software Communication

Communication Protocols

<DLC>

4-bit data length code

<Answer>

Data bytes block. The first byte of the data block is always the status byte,

which is an error code (same error codes used with the RS232 and RS485

protocols) added to Ox20h. The second byte is always Ox60h. The remaining

bytes contain the response in ASCII format. If the reply consists of more than

six bytes, the multi-frame messages are used.

Note: Only one command of a given frame type can be in progress at any one

time; e.g., after issuing a command to a slave pump with frame type = 1, the

master must wait for the answer with frame type = 1 before issuing the next

command with frame type = 1. If the user insists on sending the command, a

command overload status results.

Several commands with different frame types can be in progress at the same

time; e.g., an action command and a query command.

Following are typical exchanges between the host and slave for action

commands, multi-frame commands, common commands, and query commands.

Action Command

The host commands [ZR] to a pump, and the pump is set to address 0.

Host sends:

0 XXXXXXX 001 0 0010 ZR

Dir Slave ID Frame Type RTR DLC Data bytes

Pump acknowledges:

1 XXXXXXX 001 0 0000

Dir Slave ID Frame Type RTR DLC

After executing the command, pump reports status:

1 XXXXXXX 001 0 0010 <20h><60h>

Dir Slave ID Frame Type RTR DLC Data bytes

Note: The mixed formats ASCII and hexadecimal are used in the data bytes

block. The hexadecimal number is bracketed (< >). The rest of the fields are

displayed in binary format.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 17

Page 50

3 - Software Communication

Communication Protocols

Multi-Frame Command

The host commands [Z2S5gIA3000OgHD300G10G5R] to a pump, and the pump

is set to address 0.

Host sends:

0 XXXXXXX 011 0 1000 Z2S5gA3

Dir Slave ID Frame type RTR DLC Data bytes

0 XXXXXXX 100 0 1000 000OgHD30

Dir Slave ID Frame type RTR DLC Data bytes

0 XXXXXXX 001 0 1000 00G10G5R

Dir Slave ID Frame type RTR DLC Data bytes

Pump acknowledges:

1 XXXXXXX 001 0 0000

Dir Slave ID Frame type RTR DLC

After executing the command, pump reports status:

1 XXXXXXX 001 0 0010 <20h><60h>

Dir Slave ID Frame type RTR DLC Data bytes

Note: For multi-frame commands, the pump only acknowledges the last frame.

Common Command

After the host has sent command [A1000A0] to the pump, it sends command 0 of

frame type 2 to a pump and makes the pump move. The pump is set to address 0.

Host sends:

0 010 0000 010 0 0001 1

Dir Group Device Frame type RTR DLC Data bytes

Pump does not acknowledge common commands.

Pump does not report status after common commands.

Query Command

The host commands 29 of frame type 6 to a pump, and the pump is set to address

1.

3 - 18 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 51

3 - Software Communication

Communication Protocols

Host sends:

0 XXXXXXX 110 0 0010 29

Dir Slave ID Frame Type RTR DLC Data bytes

Pump reports:

1 XXXXXXX 110 0 0010 <20h><60h>

Dir Slave ID Frame Type RTR DLC

Note: For query commands, no acknowledge frame is needed.

Report Command

The host sends command report 23 of frame type 6 to a pump, and the pump is

set to address 1.

Host sends:

0 XXXXXXX 110 0 0010 23

Dir Slave ID Frame

Type

Pump reports:

1 XXXXXXX 011 0 1000 <20h><60h><XLP60>

Dir Slave ID Frame

Type

1 XXXXXXX

Dir Slave ID

100 0 0111 00 - Vx.x.

Frame

Type

RTR DLC Data bytes

RTR DLC

x<20h>x/200x (frame type 4)

<20h>734604<20h>

(frame type 4)

Rev <20h>X (frame type 6)

RTR DLC Data bytes

Note: For a multi-frame reply, the start frame is type 3, the middle frame is type 4,

and the last frame is type 6.

Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en 3 - 19

Page 52

3 - Software Communication

Using the XLP 6000 Command Set

3.3 Using the XLP 6000 Command Set

The XLP 6000 features a robust command set which allows a wide range of

parameters to be defined by the user. Many of the commands have default

values; however, the default values may not provide the optimal settings for your

application. Take a moment to familiarize yourself with each command in order to

obtain the best performance for your application.

For a quick summary of all commands, see Appendix G, "Command Quick

Reference".

When problems are detected, the XLP 6000 sends an error code. The error codes

are described in “Error Codes” at the end of this chapter.

Note: Some commands are invalid in the CAN interface. For a list of these

commands, see Appendix F, "CAN Communication Commands".

3.3.1 Command Execution Guidelines

To use the commands properly, keep the following in mind:

All commands, except Report commands and most Control commands, must

be followed by an [R] (Execute) command.

Single or multiple command strings can be sent to the pump.

For example:

– A single command such as [A6000R] moves the plunger to position 6000.

–A multi-command string such as [IA6000OA0R] moves the valve to the

input position, moves the plunger to position 6000, turns the valve to the

output position, and finally returns the plunger to position 0.

The pump’s command buffer holds a maximum of 255 characters. If a

command is sent without the [R] (Execution) command, it is placed into the

buffer without being executed. If a second command is sent before the first

command is executed, the second command overwrites the first command

(i.e., the first command string is erased).

Once a command is executed, new commands are not accepted until the

sequence is completed. Exceptions to this rule include interruptible (see “T

Terminate Command” in this chapter) and Report commands.

When a command is sent, the pump answers immediately. If an invalid

command has been sent in a command string, the pump reports an error

immediately. If there was an invalid parameter in the command, the pump will

execute up to the invalid parameter, then stop. In the case of a [Q] (Query)

command, the error is read back to the host computer.

Always run liquid through the syringe and valve when issuing a Move

command. Failure to do so may damage the valve and syringe seal.

Keep fingers out of the syringe slot while the pump is running. Failure to do so

can result in injury.

3 - 20 Cavro® XLP 6000 Modular Syringe Pump Operating Manual, 734237-C, en

Page 53

3 - Software Communication

Using the XLP 6000 Command Set

Command Syntax and Notes

The syntax for each command in the command set is:

<n> Numerical value within a given range

0..6000 Range of numerical values allowed

(n) Default value

Note:

• Multiple values of <n> in a single command must be separated by commas

• Square brackets, [ ], are used to distinguish commands and should not be

sent as part of the command strings.

• Commands are case-sensitive.

• Response time from the transmission of the checksum byte to transmission

of the start character is less than 5 msec.

3.3.2 Pump Configuration Commands

XLP 6000 pumps are preconfigured at the factory to the default settings. The

firmware, however, allows the user to configure the pump to meet his or her

specific requirements. Configuration options available to the user include

resolution, backlash, valve type, and baud rate.

N <n> Set Microstep Mode Off/On

The [N] command enables or disables microstepping (fine positioning). The

syntax for this command is:

[N<n>]

where <n> = 0 or 1 (0 is the default)

Value of <n> Description

0 Normal mode: All positions set and reported in half-steps; all speed

settings in half-steps/sec and all slopes in half-steps/sec

1 Fine positioning mode: All positions set and reported in micro-steps;

all speed settings in half-steps/sec and all slopes in half-steps/sec

Maximum cutoff frequency limited to 750 half-steps/sec; maximum on-

the-fly set velocity limited to 750 half-steps/sec.

2 Micro-step mode: All positions set and reported in micro-steps; all

speed settings in micro-steps/sec and all slopes in micro-steps/sec

2

.

2

.

2

.