Page 1

Operating Manual

Balance Kit for SAG 285/01

Balance Kit, Operating Manual, 393278, en, V1.0

Page 2

Document Status Sheet

Title: Balance Kit for SAG 285/01, Operating Manual

ID: 393278, en, V1.0

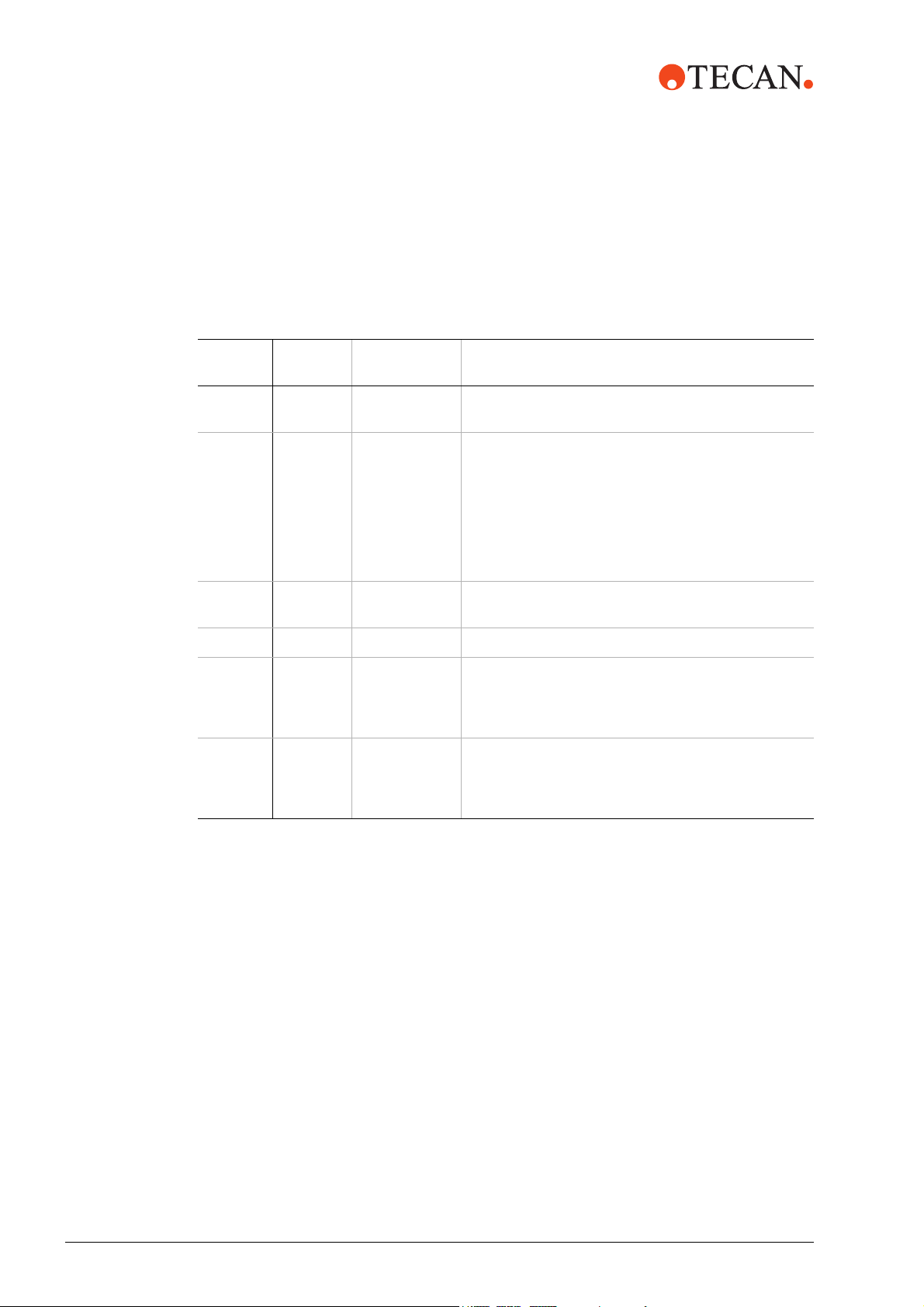

Version Revision Issue Major changes, compatibility

1 0 2004-05-03 First issue

© 2004, Tecan Schweiz AG, Switzerland, all rights reserved

Information contained in this document is subject to change without notice.

Page 3

Table of Contents

1 About This Manual

1.1 Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2Safety

2.1 User Qualification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Notices and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 Warning Notices Used in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Warning Notices Attached to the Product or Its Surroundings. . . . . . . 2-3

2.3 Use of the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 General Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table of Contents

3 Technical Data

3.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Balance Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 SAG 285/01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.1 Balance Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.2 Technical Data of SAG 285/01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.3 Supply, Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.1 Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.2 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.3 Access Rights, Passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.4 Syringes and Liquid for Gravimetric Test. . . . . . . . . . . . . . . . . . . . . . . 3-8

4 Putting into Operation

4.1 Setting up the Balance Kit and the SAG 285/01 . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3 For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.4 Preparing the Weighing Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.5 Connecting the Weighing Cell to the Control Unit . . . . . . . . . . . . . . . . 4-3

4.1.6 Connecting the SAG 285/01 and the Instrument to the Computer . . . 4-3

4.1.7 Set Communication Protocol and Balance Parameters. . . . . . . . . . . . 4-7

4.1.8 Balance Setup with the Instrument Software . . . . . . . . . . . . . . . . . . . . 4-8

4.1.9 Loading the Worktable Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.1.10 Getting Ready for the Gravimetric Test . . . . . . . . . . . . . . . . . . . . . . . . 4-10

5 Operation

5.1 Operating and Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Gravimetric Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.2 Gravimetric Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Balance Kit, Operating Manual, 393278, en, V1.0 i

Page 4

Table of Contents

6 Troubleshooting

6.1 Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

7 Spare Parts and Accessories

7.1 Tecan Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.1 Balance Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.2 Uniport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.3 Instrument Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2 Parts from Other Manufactures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2.1 Weighing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2.2 USB to RS-232 Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

8 Customer Support

9 Glossary

ii Balance Kit , Operating Manual, 393278, en, V1.0

Page 5

1 About This Manual

1 - About This Manual

Purpose of This

Chapter

This chapter points out the purpose of the manual, specifies the product the

manual deals with and who the manual is intended for. Furthermore, it explains

the symbols, conventions and abbreviations used and offers other general

Purpose of This

Manual

information.

This manual describes the Balance Kit SAG 285/01and provides all information

required for the proper installation and setup of the kit as a preparatory step for

the Gravimetric Test. In addition, it provides the necessary references to the

document(s) where the Gravimetric Test is described in detail.

Target Group This manual is addressed to advanced users and authorized field service

engineers (FSEs) who wish to run the Gravimetric Test on instruments that are

equipped with a liquid handling arm (LiHa).

Scope This Operating Manual is limited to the following:

Applicable to the installation and setup of the Balance Kit for the Weighing

Module SAG 285/01 from Mettler Toledo AG.

Software for Gravimetric Test: Instrument Software, version 4.2 or later.

Symbols and

Conventions

Cross-references appear as follows: e.g. “Refer to section 1.1.1, 1-1”

– 1.1.1 refers to the corresponding chapter number.

– The symbol

denotes the “page number”.

– 1-1 refers to the page number, whereas the first number stands for the

chapter number (chapter 1 - page 1).

Command Sequences for functions of the Instrument Software are printed in

bold type, e.g. Select Liquid System > Balance.

Note: The symbols pertaining to safety (WARNINGS and ATTENTIONS) are

explained in Chapter 2 “Safety”,

2-1.

For Your Safety Before performing any work on or with the Balance Kit, first read the

Operating Manual carefully, in particular chapter 2 “Safety”.

Balance Kit V4.7, Operating Manual, 393278, en, V1.0 1 - 1

Page 6

1 - About This Manual

Reference Documents

1.1 Reference Documents

This section provides a list of documents which are needed or may be useful in

connection with the Balance Kit.

System

Manuals

Instrument

Software

Manuals

Operating Manuals of instrument on which Balance Kit is to be installed.

Service Manual of instrument on which Balance Kit is to be installed.

Operating Manual of balance (provided by the manufacturer)

Operating Manual for Balance Kit for Mettler SAG 285/01 (Doc ID 393278)

Software Version V4.2 (Genesis Classic, Doc ID 390 791)

Software Version V4.3 (Genesis Freedom, Doc ID 392 179)

Software Version V4.5 (Freedom EVO, Genesis Freedom & Classic,

Doc ID 390 791)

Software Version V4.6 and later (Freedom EVO, EVOlyzer, Genesis Freedom

& Classic, Doc ID 392 888)

1.2 Trademarks

The following product names and any registered and unregistered trademarks

mentioned in this manual are used for identification purposes only and remain the

exclusive property of their respective owners:

Windows

SAG 285/01, AG 285 and AG 245 are trademarks of Mettler Toledo AG.

UC-232A is a trademark of Aten International Company Ltd.

EX-1331 and EX1334 are trademarks of Exsys Vertriebs GmbH.

TM

is a registered trademark of Microsoft Corporation

1.3 Abbreviations

CAN Controller Area Network

FSE Field Service Engineer

LiHa Liquid Handling Arm

RoMa Robotic Manipulator Arm

USB Universal Serial Bus

1 - 2 Balance Kit V4.7, Operating Manual, 393278, en, V1.0

Page 7

2 Safety

User Qualification

2 - Safety

Purpose of This

Chapter

Significance of

These Safety

Instructions

What Users

Must Know

This chapter specifies the intended use of the Balance Kit and points out the

safety concept. It contains general rules of behavior and warnings from hazards

pertaining to the use of the kit.

Please note that the Balance Kit itself does not contain any hazardous parts.

However, it is installed on instruments where it is necessary to perform the

Gravimetric Test. Such instruments are equipped with parts that can move with

great force and at considerable speed. Moreover, these instruments often handle

toxic or other chemically and biologically hazardous substances which require

adequate safety measures.

As a consequence, the safety of users and personnel can only be ensured if the

safety instructions in this manual and the relevant hardware and software

manuals of the instruments on which the Gravimetric Test is run, are strictly

observed and followed.

Therefore, the relevant manuals must always be available to all persons

performing the tasks described herein.

2.1 User Qualification

All users (laboratory personnel, Tecan authorized field service engineers (FSEs)

etc.), must be qualified and trained to install and use the Balance Kit for the

Gravimetric Test.

In particular, users must fulfill the following qualifications:

They must have a thorough knowledge of the application run on the system.

They must be familiar with the good laboratory practice guidelines.

The must be familiar with the relevant setup and test procedures described in

the “Instrument Software Manual”.

They must know how to set up and operate the Balance that is to be used

together with this kit.

They must have read and understood the instructions in this Operating

Manual.

Only persons who meet the qualifications prescribed here are authorized to

perform the work described in this Operating Manual.

Training

Courses

Balance Kit V4.7, Operating Manual, 393278, en, V1.0 2 - 1

Note: Tecan recommends that users attend an appropriate training course.

• Please ask your nearest Tecan representative about the available courses.

Page 8

2 - Safety

Notices and Symbols

2.2 Notices and Symbols

2.2.1 Warning Notices Used in This Manual

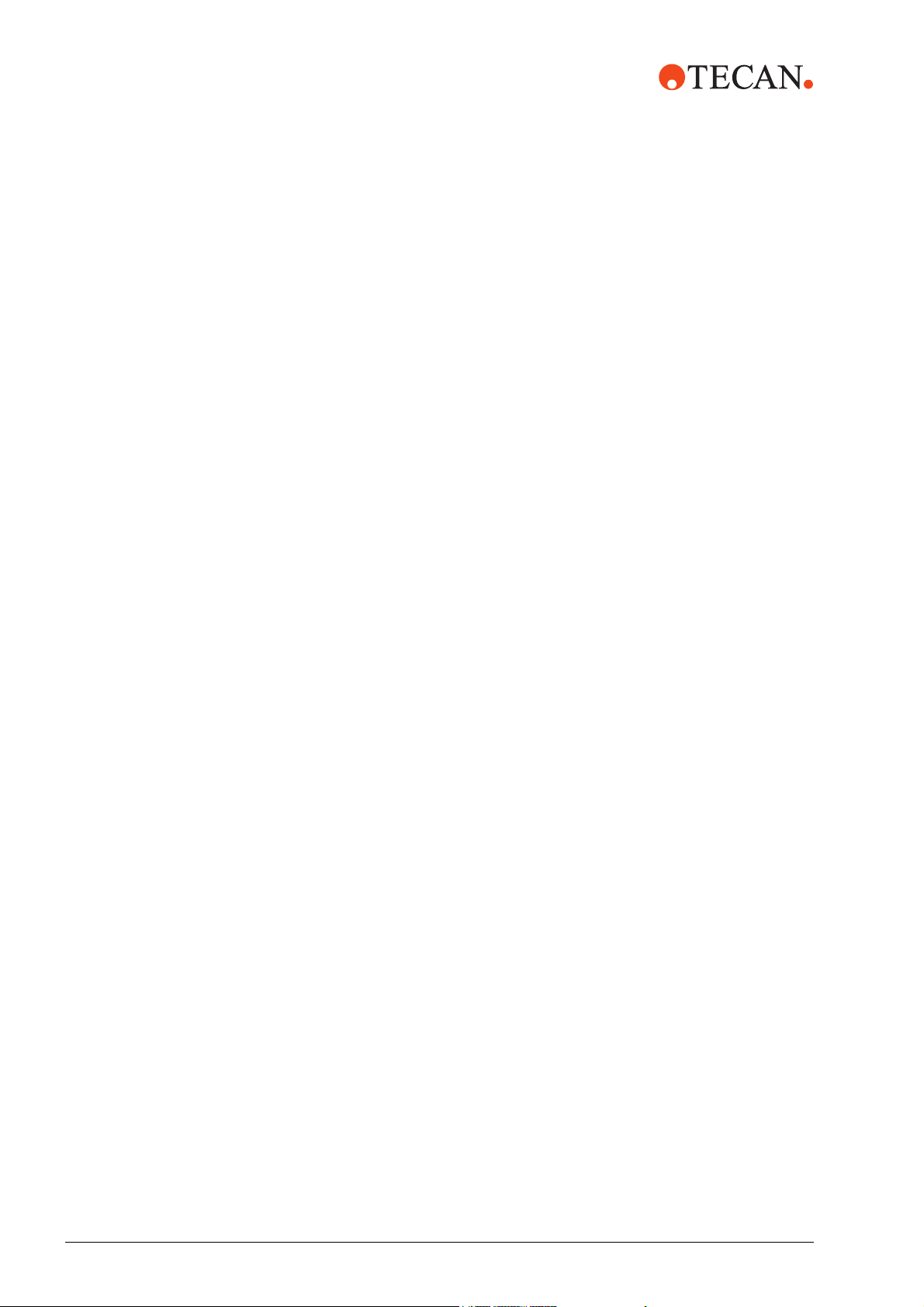

The symbols used for safety-related notices have the following significance:

WARNING

Symbols

WARNINGS appear as follows:

WARNING

Generally, the triangular warning symbol indicates the possibility of personal injury

or even loss of life if the instructions are not followed.

Whenever possible, the symbol indicates the hazard a person is exposed to more

specifically. The symbols used in this Operating Manual have the following

significance:

WARNING

Toxic substances

WARNING

Biological hazard

WARNING

Radioactive radiation

WARNING

Pinch point, mechanical hazards

2 - 2 Balance Kit V4.7, Operating Manual, 393278, en, V1.0

Page 9

Use of the Product

2 - Safety

ATTE NTION

ATTENTIONS appear as follows:

Symbols

ATTENTION

With the general “Read This!” symbol, ATTENTIONs indicate the possibility of

equipment damage, malfunctions or incorrect process results, if instructions are

not followed.

2.2.2 Warning Notices Attached to the Product or Its Surroundings

There are no warning notices attached to the Balance Kit.

2.3 Use of the Product

Intended Use The Balance Kit described in this manual is to be used exclusively together with

the Mettler-Toledo balance model SAG 285/01.

Improper Use The Balance Kit described in this manual is not suitable for other balance models

(e.g. Mettler AG 285 or AG 245).

Legal

Regulations

Duty of

Maintenance

and Care

Observe

Specific Safety

Instructions

2.4 General Safety Rules

Legal regulations, such as local, state and federal laws which prescribe the use or

application as well as the handling of dangerous materials in connection with the

Balance Kit must be strictly followed.

The user is responsible for ensuring that the Balance Kit and the balance itself are

used in proper condition only. Maintenance, service, and repair jobs on the

instrument on which the Balance Kit is to be used must be performed with care

and on schedule, and by authorized personnel only.

When setting up and using the Balance Kit pay due attention to the safety

instructions as laid out in the following manuals:

Operating Manual of the specific instrument

Service Manual of the specific instrument

Instrument Software Manual

Operating Manual of the balance

Balance Kit V4.7, Operating Manual, 393278, en, V1.0 2 - 3

Page 10

2 - Safety

General Safety Rules

2 - 4 Balance Kit V4.7, Operating Manual, 393278, en, V1.0

Page 11

3 Technical Data

A

3 - Technical Data

General Description

Purpose of This

Chapter

What Is a

Balance Kit?

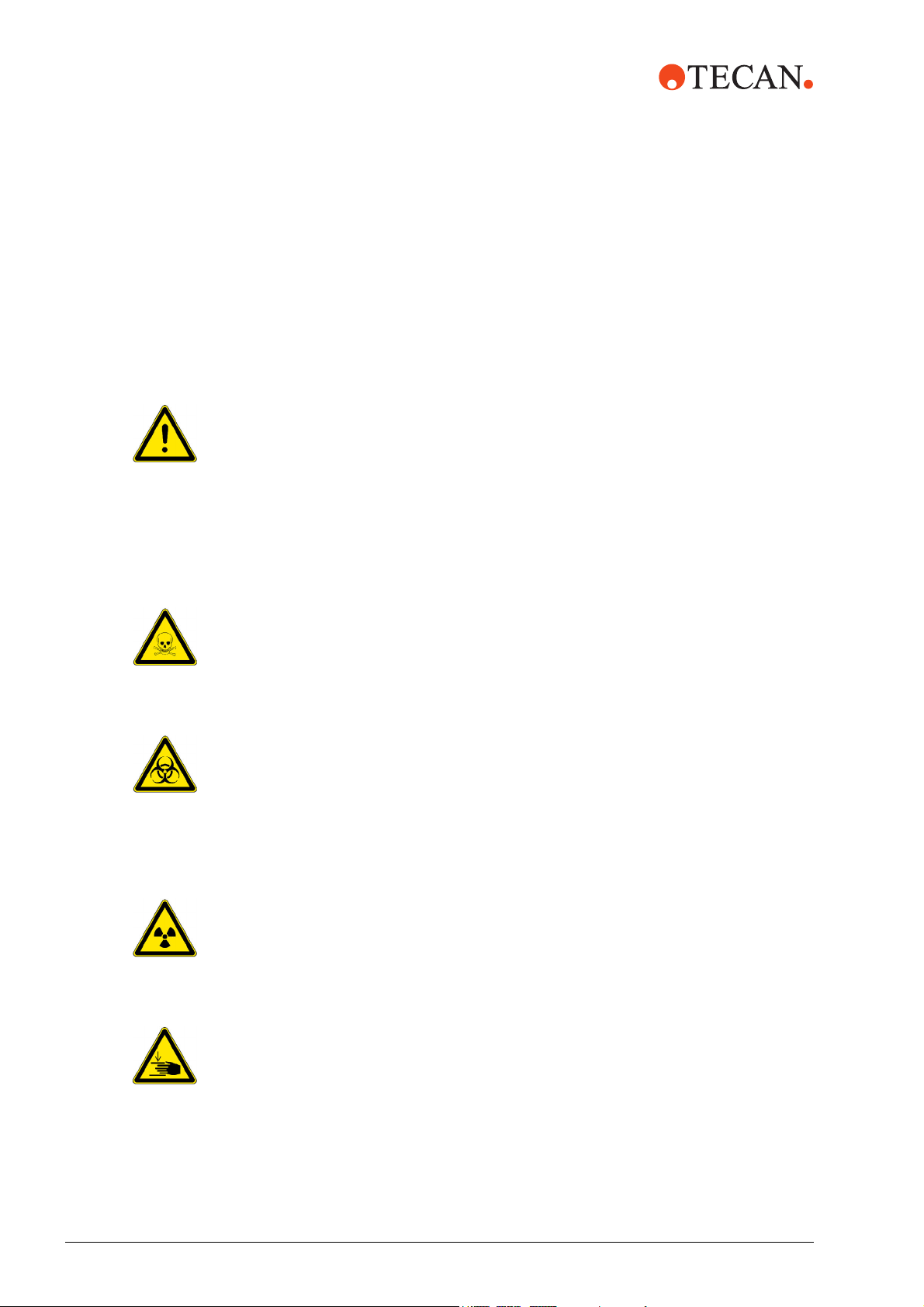

Overview The following figure provides a quick overview of both the Balance Kit and the

This chapter introduces the reader to the Balance Kit and its main components. It

contains technical data, requirements and performance data.

3.1 General Description

The Balance Kit is a set of components that are needed to adapt the Mettler

Toledo Weighing Module SAG 285/01 to the instrument so that it can be used for

the Gravimetric Test.

SAG 285/01 from Mettler Toledo. Brief descriptions are given in the sections after

the figure.

L

K

I

A

B

C

H

J

Fig. 3-1 Parts of Balance Kit + SAG285/01 (Weighing Cell and Control Unit)

Draft shield

B Ring for evaporation compensation

C Vessel

D Centering ring

E Weighing pan (Mettler)

F Foot with counternut

G Adapter plate

H Weighing cell (Mettler)

I Connection cable (Mettler)

J Control unit (Mettler)

K Connection cable LC-RS9 (Mettler)

L Power supply (Mettler)

D

E

F

G

Balance Kit Operating Manual, 393278, en, V1.0 3 - 1

Page 12

3 - Technical Data

General Description

3.1.1 Balance Kit

The following table lists the parts the Balance Kit consists of. Also refer to

Fig. 3-1, 3-1.

Tab. 3-1 Parts of the Balance Kit

Item in

Figure

A 1 Draft shield Protects the vessel (C) with the liquid to be weighed

B 1 Evaporation

C 2 Vessel Contains the liquid to be weighed during the Gravimet-

D 1 Centering ring Holds the evaporation ring (B) in place

F 1 Adapter plate Plate with two handles and positioning slots that can

G 4 Foot + counter-

Quantitiy Designation Explanation

from air drafts.

This ring is placed on the Weighing Cell (H) as shown

ring

nut

in the figure. It contains a groove that can be filled with

distilled or de-ionized water. During operation, part of

this liquid evaporates and thus increases the air

humidity under the draft shield. This, in turn, has the

effect that less liquid evaporates from the vessel during the Gravimetric Test. In this way, the accuracy of

the test results is increased indirectly.

ric Test. The vessel rests on the weighing pan (E).

be placed in the appropriate grid position on the worktable. It also has four positioning holes that allow positioning the Weighing Cell (H) properly on the plate.

The four feet are standard knurled screws with a plastic head. They are screwed to the bottom of the Weighing Cell (H) and can be used to level out the Weighing

Cell. The counternuts serves for securing the feet.

Ordering the

Balance Kit

The Balance Kit (or certain parts of it) can be ordered from Tecan or via a local

Tecan representative. For more details see section

7 “Spare Parts and Accessories”, 7-1.

Note: The Balance Kit does not comprise the Weighing Module (weighing cell +

control unit), nor are the connection cable and other accessories part of the kit.

These items must be ordered directly from Mettler Toledo AG (see next section).

3 - 2 Balance Kit Operating Manual, 393278, en, V1.0

Page 13

3.1.2 SAG 285/01

3 - Technical Data

General Description

Brief

Description

The SAG 285/01 is a product of Mettler Toledo AG and has been available since

January 2004. This SAG 285/01 consists of a Weighing Cell (H) and a separate

Control Unit (J) that are interconnected with a cable. Thanks to this separation a

higher precision and stability can be attained.

The SAG 285/01 is a substitute for the predecessor model AG 285 which

incorporated the weighing cell, the display and the operating and control elements

in one unit. Note, that this model is no longer available.

The following two tables list the parts that must be ordered directly from Mettler

Toledo:

Tab. 3-2, 3-3 lists the parts the SAG 285/01consists of.

Tab. 3-3, 3-3 lists the accessories that must be ordered separately.

See also Fig. 3-1 , 3-1.

Tab. 3-2 Weighing Module SAG 285/01

Item in

figure

H 1 Weighing Cell Is placed on the adapter plate (F) and actually weighs

J 1 Control Unit The control unit is separated from the weighing cell

I 1 Connection

Quantity Designation Explanation

the liquid in the vessel.

(H). It contains a digital display and the necessary controls that allow operating the whole Weighing Module.

Connects the Weighing Cell to the Control Unit. Please

cable 1.5 m

note that a 5 m cable is available as an option (see

below)

Ordering the

SAG 285/01 and

Accessories

L 1 Power supply This power supply unit is connected to the control unit.

Tab. 3-3 Accessories for the SAG 285/01

Item in

Figure

E 1 Weighing pan,

Quantity Designation Explanation

Carries the vessel with the liquid to be weighed.

∅ 50 mm

K 1 Cable LC-RS9 Cable with local CAN bus to RS-232 adapter that con-

nects the Control Unit to the computer.

I 1 Connection

cable 5 m

-- 1 Transport case Optional accessory that allows transporting the

Optional. Can be used instead of the 1.5 m cable to

connect the Weighing Cell to the Control Unit.

SAG 285/01.

See section 7 “Spare Parts and Accessories”, 7-1.

Balance Kit Operating Manual, 393278, en, V1.0 3 - 3

Page 14

3 - Technical Data

Technical Data

3.2 Technical Data

3.2.1 Balance Kit

Overall

Dimensions

The following figure shows the overall dimensions of the adapter plate with

installed Weighing Cell and draft shield.

t

h

a2

a1

h

a

w

l

a

Fig. 3-2 Adapter plate with weighing cell and draft shield

h

Tab. 3-4 Adapter plate (with / without weighing cell and draft shield)

Dimension Measurement [mm / in.]

Overall height with installed Weighing Cell

with draft shield

Height of adapter plate (with handles, without

h

t

h

a2

approx.

130 / 5.1

38 / 1.5

a)

Weighing Cell)

Thickness of adapter plate h

Length of adapter plate l

Width of adapter plate w

Grid positions occupied by adapter plate on

a1

a

a

w

a

6 / 0.23

339.5 / 13.4

149 / 5.9

6 grids

worktable

a) Exact value depends on the adjustment of the feet

3 - 4 Balance Kit Operating Manual, 393278, en, V1.0

Page 15

3 - Technical Data

Technical Data

Other Parts

of Kit

The following table shows the heights and diameters of the other parts of the

Balance Kit. Also see Fig. 3-1 , 3-1.

Tab. 3-5 Dimensions of Parts of Kit

Item in

figure

A Draft shield 55 / 2.2 95 / 3.7

B Evaporation ring 25 / 0.98 87 / 2.2

C Vessel 25 / 0.98 41 / 1.6

D Centering ring 3 / 0.12 62 / 2.4

F Foot 23 / 0.91 16 / 0.63

Designation Height

[mm / in.]

Diameter

[mm / in.]

Weight The Balance Kit (parts A, B, 2 x C, D, F and G) without packaging weighs approx.

1.1 kg (2.42 lb.).

3.2.2 Technical Data of SAG 285/01

For details refer to the SAG 285/01 Operating Manual from Mettler Toledo AG.

3.2.3 Supply, Connections

Balance Kit The Balance Kit contains only mechanical parts; there are no electrical

connections.

SAG285/01 The SAG 285/01 is supplied and connected as follows:

Power supply: Via a separate power supply (included in delivery) that is

connected to the Control Unit.

Interconnection between Control Unit and Weighing Cell: Connection cable

1.5 m (included in delivery) or optional 5 m cable.

Connection to computer: From Control Unit via separate LC-RS9 cable (to be

ordered separately).

Balance Kit Operating Manual, 393278, en, V1.0 3 - 5

Page 16

3 - Technical Data

Requirements

3.3 Requirements

3.3.1 Hardware Requirements

Instrument and Computer

Instrument The Balance Kit together with the SAG 285/01can be used on the following

instruments types: Freedom EVO instruments, Genesis Freedom and Genesis

Classic instruments.

Computer Hardware requirements as specified in the Instrument Software Manual that

corresponds to the installed version of the Instrument Software.

Possible interfaces for connecting the instrument and the SAG 285/01 see below.

Interfaces, Adapters

There is more than one possibility to connect the instrument and the SAG 285/01

to the computer.

Two R S-23 2

Ports

USB Ports To connect the instrument and/or the SAG 285/01 to the computer via USB ports,

If the computer has two free RS-232 ports, both the SAG 285/01 and the

instrument can be connected directly.

Note: Depending on the connectors at the instrument cable and the computer,

adequate 9 to 25-pole RS-232 adapters and / or gender changers may be

needed.

an appropriate USB to Serial converter is needed.

Recommended USB to Serial converters:

Aten UC-232A USB to RS232 Converter. Has one RS-232 connector and

plugs into a USB port on the computer.

Exsys EX-1331 USB to RS232 Converter. One RS-232 and 1 one USB

connector.

Exsys EX-1334 USB to RS-323 Converter. Has four RS-232 connectors and

plugs into a single USB port on the computer.

The above converters feature the following:

Data rate: Up to 230 Kb per second

RS-232 connectors: Male DB9

Compliant with USB Specifications V1.1

Suitable for Windows 2000 and XP

Note: A mixed connection (instrument to RS-232, SAG 285/01 via USB) is also

possible.

3 - 6 Balance Kit Operating Manual, 393278, en, V1.0

Page 17

3 - Technical Data

Requirements

Connection via

Uniport

Instrument

Software

Operating

System

If the computer has only one free RS-232 port and no USB port, the SAG 285/01

may be connected via the Uniport board, provided the following conditions are

fulfilled:

Instrument Software V4.5 or earlier is installed on the computer.

The instrument is equipped with a Uniport board.

Note:

• Apart from Genesis RMP or instruments used in customized solutions, Tecan

instruments are not normally equipped with a Uniport board.

• If possible, a separate Uniport board may be installed for the Gravimetric

Test.

• The connection via the Uniport is not supported by the Instrument Software

version V4.6 or later.

3.3.2 Software

Version V4.2 or later is required.

Note: The connection of the SAG 285/01 via Uniport is no longer supported from

Instrument Software Version 4.6 or later.

According to specifications of installed version of Instrument Software.

Drivers for

USB / RS-232

Converters

The delivery of the recommended USB to RS-232 converters includes drivers that

are suitable for Windows 2000 and Windows XP.

Balance Kit Operating Manual, 393278, en, V1.0 3 - 7

Page 18

3 - Technical Data

Requirements

3.3.3 Access Rights, Passwords

To carry out the Balance Setup function and the Gravimetric Test with the

Instrument Software you need the following access rights:

Version V4.6x or earlier: No password required.

Version V4.7 or later: From version V4.7 onwards, all users need a user

account, together with a user name and a password.

– There are several predefined user groups with different authorization

levels.

– The Balance Setup and the Gravimetric Test can be carried out by users

with SnS_Customer access rights.

Note: For detailed information about user accounts, passwords and access rights

refer to the Instrument Software Manual (for software version V4.7 or later),

section “Tecan User Administration System”.

3.3.4 Syringes and Liquid for Gravimetric Test

Syringes: 250 µl, 500 µl, 1 ml.

System liquid: Demineralized or de-ionized and degassed water. Water

temperature should correspond to ambient temperature.

Pipetting liquid: Tap water. Water temperature should correspond to ambient

temperature.

3 - 8 Balance Kit Operating Manual, 393278, en, V1.0

Page 19

4 Putting into Operation

A

Setting up the Balance Kit and the SAG 285/01

4 - Putting into Operation

Purpose of This

Chapter

This chapter describes how the Balance Kit is installed and gives instructions on

initial operation.

4.1 Setting up the Balance Kit and the SAG 285/01

4.1.1 Overview

The following figure provides an overview of the Balance Kit and the SAG 285/01

Weighing Module. For a description and the detailed specifications see section

3.1, 3-1.

L

K

I

H

A

B

C

D

E

F

J

G

Fig. 4-1 Parts of Balance Kit + SAG285/01 (Weighing Cell and Control Unit)

Draft shield

B Ring for evaporation compensation

C Vessel

D Centering ring

E Weighing pan (Mettler)

F Foot with counternut

Balance Kit Operating Manual, 393278, en, V1.0 4 - 1

G Adapter plate

H Weighing cell (Mettler)

I Connection cable (Mettler)

J Control unit (Mettler)

K Connection cable LC-RS9 (Mettler)

L Power supply (Mettler)

Page 20

4 - Putting into Operation

Setting up the Balance Kit and the SAG 285/01

4.1.2 Unpacking and Inspection

1 Unpack the Balance Kit and the SAG 285/01.

2 Ensure that no parts are missing or damaged.

3 Check whether the voltage range of the SAG 285/01 supply unit corresponds

with the local mains voltage.

4 Contact the supplier of the SAG/01 or your nearest Tecan representative if

any parts are missing or damaged.

4.1.3 For Your Safety

WARNING

Damage to the system and danger of electric shock.

Always switch the instrument and the computer off before making any electric

connections or opening the instrument’s access door.

4.1.4 Preparing the Weighing Cell

Also see Fig. 4-1 , 4-1.

H

4 Carefully place the Weighing Cell onto the adapter plate with the feet inserted

into the corresponding positioning holes.

5 Check whether the Weighing Cell is seated properly on the adapter plate and

does not wobble. If necessary adjust the cell by turning the feet until the cell is

level and stable.

6 Carefully tighten the counternuts to secure the feet when done.

7 Place the centering ring (D) on the cell and insert the cone of the weighing pan

(E) into the corresponding hole as shown in the figure.

D

E

To prepare the Weighing Cell:

1 Screw the counternuts on the

screw bolts of the feet (F)

down until the stop.

2 Screw the feet (F) into the

corresponding mounting

holes at the bottom of the

F

G

Weighing Cell (H).

3 Place the adapter plate (G)

on a the worktable in the grid

position where you want to

perform the Gravimentric test

later.

4 - 2 Balance Kit Operating Manual, 393278, en, V1.0

Page 21

Setting up the Balance Kit and the SAG 285/01

4 - Putting into Operation

4.1.5 Connecting the Weighing Cell to the Control Unit

To connect the SAG 285/01 electrically to the other parts of the system proceed

as follows (also see Fig. 4-1 , 4-1):

Weighing Cell

to Control Unit

1 Place the Control Unit (J) on a table beside the instrument.

2 Lead the connection cable (I) from the Weighing Cell (H) to the Control Unit

(J). A possible way to lay the cable is shown in Fig. 4-1 , 4-1.

3 Plug the connectors at both ends of the cable into the corresponding sockets

on the Weighing Cell and the Control Unit and fix the connectors with their

fixing screws.

Power Supply 4 Connect the power supply unit (L) to the Control Unit (J) as shown in

Fig. 4-1 , 4-1.

4.1.6 Connecting the SAG 285/01 and the Instrument to the Computer

Depending on the computer model and its interfaces there is more than one

possible way to connect the SAG 285/01 and the instrument to the computer.

Note: The Optibo board shown in the following figures is located behind the left

access door of the instrument.

Computer with

2 RS-232 Ports

If two RS-232 ports are available on the computer, both the instrument and the

Control Unit can be connected directly as shown in the following figure. This is the

simplest and least problematic arrangement.

Optibo-Board

L

RS-232

M

I

J

H

Computer

RS-232

RS-232

Fig. 4-2 Direct connection to RS-232 ports

H Weighing Cell

I Cable Weighing Cell to Control Unit

J Control Unit

Balance Kit Operating Manual, 393278, en, V1.0 4 - 3

K LC-RS9 (Control Unit to computer)

L Power supply for SAG 285/01

M Cable instrument to computer

Instrument

K

Page 22

4 - Putting into Operation

Setting up the Balance Kit and the SAG 285/01

Mixed

Connection,

RS-232 / USB

If one RS-232 port and one USB port are available on the computer, the following

configuration is also possible. Recommended connections:

Instrument: Connect the instrument cable directly to the RS-232 port of the

computer.

SAG 285/01: Connect the LC-RS9 cable (K) to the RS-232 port of the USB to

RS-232 converter (Cnv).

L

J

Computer

RS-232

USB

Cnv

RS-232

Optibo-Board

RS-232

M

I

H

Instrument

K

Fig. 4-3 Mixed connection (instrument to RS-232, Control Unit via USB)s

H Weighing Cell

I Cable Weighing Cell to Control Unit

J Control Unit

K LC-RS9 (Control Unit to computer)

L Power supply for SAG 285/01

M Cable instrument to computer

Cnv USB / RS-323 converter

Recommended converters: See sections 3.3.1, 3-6 and 7.2.2, 7-4.

4 - 4 Balance Kit Operating Manual, 393278, en, V1.0

Page 23

Setting up the Balance Kit and the SAG 285/01

4 - Putting into Operation

Computer with

USB Ports (no

RS-232)

Modern computers, particularly notebooks, often have no RS-232 ports at all, but

are equipped with two or more USB-ports. In such a case the instrument and the

Control Unit must be connected via appropriate USB to Serial converters

according to the following figure.

Note: The connection of the computer to the instrument via an USB to Serial

converter will reduce the communication speed between the instrument and the

computer. As a consequence, the execution time for the Gravimetric Test may

increase by 10 to 20 %, compared to the time it takes when the instrument is

connected to the computer directly.

Optibo-Board

L

J

K

RS-232

M

I

H

Instrument

RS-232

RS-232

Cnv

Notebook

Fig. 4-4 Connection via USB to Serial converter

H Weighing Cell

I Cable Weighing Cell to Control Unit

J Control Unit

K LC-RS9 (Control Unit to computer)

Recommended converters: See sections 3.3.1, 3-6 and 7.2.2, 7-4.

USB

L Power supply for SAG 285/01

M Cable instrument to computer

Cnv USB to serial converter

Balance Kit Operating Manual, 393278, en, V1.0 4 - 5

Page 24

4 - Putting into Operation

Setting up the Balance Kit and the SAG 285/01

Connection

via Uniport

As has been mentioned earlier (see section 3.3.1, 3-6) the SAG 285/01 may be

connected via the Uniport board under the following conditions:

Uniport board must be installed and connected to the Optibo board as shown

in the following figure.

The connection via the Uniport is only supported by Instrument Software

versions V4.5 or earlier.

Note: This configuration requires a gender changer between the LC-RS9 cable

(K) and the Uniport board. A special intermediate cable (N) that serves as a

gender changer is available from Tecan (see section 7.1.2,

Uniport

L

K

J

RS-232

7-2).

Optibo-Board

RS-232

N

M

I

H

Computer

RS-232

Fig. 4-5 Connection via the Uniport

H Weighing Cell

I Cable Weighing Cell to Control Unit

J Control Unit

K LC-RS9 (Control Unit to Uniport)

L Power supply for SAG 285/01

M Cable instrument to computer

N Intermediate cable between LC-RS9

Instrument

and Uniport (gender changer)

Procedure To connect the SAG 285/01 and the instrument to the computer:

1 Decide which of the following connection methods is suitable in your case:

– Direct connection to two RS-232 ports (see Fig. 4-2 , 4-3).

– Mixed connection, instrument to RS-232 and SAG 285/01 via a USB to

Serial converter (see Fig. 4-3 , 4-4).

– Connection via USB to Serial converter (see Fig. 4-4 , 4-5)

– Connection of SAG 285/01 via Uniport (see Fig. 4-5 , 4-6).

2 Connect the units together.

3 If you use a USB to Serial converter you must also install the appropriate

driver software on the computer. Follow the instructions provided by the

supplier of the converter.

4 Check your installation.

4 - 6 Balance Kit Operating Manual, 393278, en, V1.0

Page 25

Setting up the Balance Kit and the SAG 285/01

A

4 - Putting into Operation

4.1.7 Set Communication Protocol and Balance Parameters

Next you must set up the following:

Communications protocol

Balance parameters

Communication

Protocol

The communication protocol can be adapted by means of the three rotary

switches located inside the protocol converter of the LC-RS9 cable (over which

the Control Unit is connected to the computer).

ABC

Fig. 4-6 Protocol converter in LC/RS 9

cable

D

Peripheral selection

B Baudrate selection

C Bit/Par/HS selection

D Cover (opened)

1 Open the cover of the protocol converter.

2 Set the rotary switches (A), (B) and (C) according to the following table.

3 Close the cover.

Tab. 4-1 Setting of Communication Protocol

Switch Set to position Comment

A 0 Peripheral = Host

B 3 Baudrate = 2400 Baud

C 0 7 bits, even parity

Balance

Parameters

Next, the balance parameters must be set. For detailed information consult the

Operating Manual of the SAG 285/01.

To set the balance parameters:

1 If not done yet, connect the SAG 285/01 to the mains via the power supply

unit and switch the balance on.

2 Set the balance parameters according to the following table and store them

(except the “Reset” parameter !).

1/10 d

Cal

3 Use the 1/10 d key of the Control unit to set the

display to 2 decimal places (1/100 g).

4 Check your settings.

Balance Kit Operating Manual, 393278, en, V1.0 4 - 7

Page 26

4 - Putting into Operation

Setting up the Balance Kit and the SAG 285/01

Tab. 4-2 Required settings of balance parameters

Property Set to Comment

Vibration adapter 2 Medium weighing speed

Weighing process adapter 1 Suitable for small quantities

Reproducibility Std Standard reproducibility

Weighing unit 1 unit 1 mg Both weighing units must be mg

Weighing unit 2 unit 2 mg

Automatic zero correction az. off No automatic zero correction

Automatic off aoff - No automatic switch off

Start mode qu start Quick start. No display check at

startup.

ATTENTION

Do not reset the parameters unnecessarily, otherwise you will have to set them

again!

4.1.8 Balance Setup with the Instrument Software

Purpose The purpose of this setup is to establish the proper communication with the

SAG 285/01.

Nomenclature The Instrument Software uses the term “Balance” for the Weighing Module,

regardless of whether the Weighing Cell and the Control Unit are separated or

incorporated in the same device.

Required for

the Setup

To run the setup procedure you need the following:

Instrument Software Manual that corresponds to the installed version.

– A PDF-file of the manual is stored on the installation CD of the Instrument

Software.

– Operating Manual of the SAG 285/01 Weighing Module.

If version V4.7 or later is installed on the computer you need a user account

with a user name and a password.

– Required access rights: SnS_Customer access level or higher.

– If necessary turn to the system administrator for an appropriate user

account and the necessary access rights.

Procedure The procedure varies slightly, depending on the version of the installed Instrument

Software: Always follow the instructions provided in the Instrument Software

Manual and/or the SAG 285 Operating Manual.

To perform the Balance Setup:

1 Switch on the computer and the SAG 285/01.

2 Tare the Weighing Cell (see SAG 285 Operating Manual).

4 - 8 Balance Kit Operating Manual, 393278, en, V1.0

Page 27

3 Switch the instrument on.

4 From the Windows task bar start the Setup & Service software (which is part

of the Instrument Software package) with

Start > Programs > Instrument Software > Setup & Service

5 If the Instrument Software V4.7 or later is installed:

– You will be prompted to log in with your user name and password.

– If you log in for the first time you must change the password.

6 Call up the function Liquid System > Balance. Follow the instructions in the

Instrument Software Manual to set up and test the communication with the

balance.

4.1.9 Loading the Worktable Map

Setting up the Balance Kit and the SAG 285/01

4 - Putting into Operation

General

Procedure

In order to perform the Gravimetric Test you must load a suitable worktable map.

Refer to the Instrument Software Manual for details.

1 Call up the Setup & Service software function System > Load Worktable.

2 Choose the appropriate worktable map for the Gravimetric Test (see

remarks below).

3 If necessary, store the worktable map under a new name and use the

Worktable Complete Editor to adapt it to your needs.

Remarks

Instrument

Software V4.7

or later

Earlier Versions

of Instrument

Software

The Instrument Software V4.7 or later includes a worktable map that corresponds

to the adapter plate for the SAG 285/01 Weighing Cell. If necessary, you can

modify this map according to your needs with the Worktable Complete Editor.

If version V4.6 or earlier is used, you will probably not find a worktable map that

corresponds to the adapter plate for the SAG 285/01, but one that was suitable for

the predecessor model (for AG 285/245 and other models).

This previous adapter plate was 10 grid positions wide, whereas the SAG 285/01

plate occupies 6 grid positions. Moreover, the SAG 285/01 adapter plate (with

Weighing Cell and draft shield) is approx. 5 mm higher than the previous model.

Workaround: However, you can still use the old worktable map if you place the SAG 285/01

adapter plate into a grid position that corresponds to the middle of the old map.

Example: If the left grid position for the old adapter plate is 2, then place the

SAG 285/01 adapter plate in grid position 4.

Generally speaking: Left grid position of SAG 285/01 adapter plate = Left grid

position of AG 285/245 plate + 2.

Professional

Solution

A better solution is to store the existing worktable map under a new name and to

use the Worktable Complete Editor to adapt the following parameters:

Width of adapter plate: 6 grid positions

Overall height: 130 mm (corresponds to height of adapter plate with installed

Weighing Cell and draft shield, also see section 3.2.2, 3-5).

Balance Kit Operating Manual, 393278, en, V1.0 4 - 9

Page 28

4 - Putting into Operation

Setting up the Balance Kit and the SAG 285/01

4.1.10 Getting Ready for the Gravimetric Test

Now the last steps before the Gravimetric Test can be carried out.

A

t

i

l

l

e

d

W

a

D

i

s

t

e

r

C

E

B

H

Fig. 4-7 Getting ready for the Gravimentric Test

Procedure To make the installation ready for the Gravimetric Test:

1 If not done yet, place the adapter plate (G) with the installed Weighing Cell (H)

on the worktable in the grid position that corresponds to the worktable map.

2 Place the evaporation ring (B) on the Weighing Cell.

3 Place the vessel (C) on the weighing pan (E).

4 Carefully fill the evaporation ring with distilled or de-ionized water until the ring

is about half-full.

B

G

ATTENTION

Damage to Weighing Cell possible if liquid is spilled over the cell.

Be careful not to fill up the ring too much, so that you can safely remove it

from or place it on the Weighing Cell without spilling any liquid.

Wipe up any spilled liquid with a soft lint-free cloth.

5 Cover the evaporation ring and the parts inside it with the draft shield (A).

The Gravimetric Test can now be carried out.

4 - 10 Balance Kit Operating Manual, 393278, en, V1.0

Page 29

5 Operation

A

Operating and Display Elements

5 - Operation

Purpose of This

Chapter

This chapter briefly explains the operating elements and gives instructions on how

to carry out the Gravimetric Test.

5.1 Operating and Display Elements

A

B

E

Operating

Elements

C

Fig. 5-1 Operating elements for Gravimetric Test

Computer display

B SAG 285 Control Unit

C Keyboard (not directly visible)

The Balance Kit itself has no operating and display elements of its own. Most of

the operating and display elements needed for the Gravimetric Test are shown in

D

D Mouse

E Power switch of instrument (not

directly visible)

the above figure.

Power Switches The location of the power switches of the computer and the instrument depend on

the models used to run the Gravimetric Test.

Balance Kit Operating Manual, 393278, en, V1.0 5 - 1

Page 30

5 - Operation

Gravimetric Test

5.2 Gravimetric Test

5.2.1 Safety Instructions

WARNING

Automatically moving parts.

Injuries (crushing, piercing) possible, if the safety covers are not in place.

Before starting the Gravimetric Test, check if the safety panel of the

instrument is closed.

Never run the test without covers.

WARNING

Depending on the application run on the instrument, biohazardous, poisonous or

radioactive materials may have been used.

Make sure you protect your body with adequate protective gear, such as

goggles, gloves and protective clothing before starting the Gravimetric Test.

5.2.2 Gravimetric Test

It is assumed that you have carried out all steps described in chapter “Putting into

Operation” and that the test can now be carried out.

Required

Documentation

Procedure To perform the Gravimetric Test:

Make sure you have the following documents handy:

Instrument Software Manual that corresponds to the installed version of the

Instrument Software.

Operating Manual of SAG 285 Weighing Module.

Operating Manual of the instrument on which you wish to run the test.

1 From the main menu of the Setup & Service software, start the test with

Liquid System > Gravimetric Test.

2 Follow the instructions provided on screen and in the Instrument Software

Manual.

Evaluation of

Results

5 - 2 Balance Kit Operating Manual, 393278, en, V1.0

See Instrument Software Manual.

Page 31

6 Troubleshooting

6 - Troubleshooting

Troubleshooting Table

Purpose of This

Chapter

Trouble-

shooting by

the Operator

This chapter helps to resume operation after a minor problem has occurred with

the Balance Kit or the SAG 285/01 when used for Gravimetric Test and its

preparation. It lists possible problems, their probable cause and suggests how to

remedy the problems.

6.1 Troubleshooting Table

The following table lists problems and errors and gives hints on how to eliminate

them.

Tab. 6-1 Troubleshooting table

Problem / error Possible cause Corrective measures

Weighing Cell wobbles Feet not adjusted

properly

No display on Control

Unit

Control Unit does not

react to changes in

weight on Weighing Cell

Control Unit not connected to mains

Control Unit not connected to Weighing

Cell

Level out the Weighing Cell by adjusting the

feet and secure with counternuts.

Connect the control unit via the power

supply unit.

Check connection between units and connect properly.

Values shown on computer screen do not correspond to those shown on

display of Control Unit.

Control Unit not connected to computer

Control Unit not set up

properly

Wrong communication

protocol

Uniport: Connection

via Uniport not correct

Connection via USB:

RS-232 to USB adapters to slow

USB adapters not

installed properly or

drivers not compatible with operating system

Check connection to computer.

Repeat setup.

Check the settings of the protocol converter

in the LC-RS9 cable.

Check the following connections:

• SAG 285/01 Control Unit to Uniport

• Uniport to Optibo board

Use recommended USB adapters.

Install adapters correctly according to

instructions provided by the supplier. Make

sure the correct drivers are installed.

Balance Kit Operating Manual, 393278, en, V1.0 6 - 1

Page 32

6 - Troubleshooting

Troubleshooting Table

Tab. 6-1 Troubleshooting table (cont.)

Problem / error Possible cause Corrective measures

During Gravimetric Test

the LiHa is not moved to

the correct position above

the Weighing Cell

1 USB, 1 RS-232 port:

Connections mixed

up.

Balance Setup function in Setup & Service SW carried out

incorrectly

Grid position of

adapter plate does not

correspond to worktable map

Wrong worktable map

loaded

Connect instrument to RS-232 port and

Control Unit to USB.

Repeat Balance Setup and test if Control

Unit communicates properly with Instrument

Software.

Place the adapter plate in the correct grid

position.

Load the correct worktable map.

6 - 2 Balance Kit Operating Manual, 393278, en, V1.0

Page 33

7 Spare Parts and Accessories

A

7 - Spare Parts and Accessories

Purpose of This

Chapter

How to Find

Parts

How to

Order Parts

Overview

This chapter lists the parts and accessories used in connection with the Balance

Kit and the Weighing Module SAG 285/01, including the ordering information.

Identify the parts from the following figure and look up the ordering information in

the tables later in this chapter.

Spare parts must be ordered from the corresponding manufacturer or from its

nearest representative:

Balance Kit: From Tecan. Addresses see section 8 “Customer Support”, 8-1

Parts and accessories for the SAG 285/01: Directly from Mettler Toledo.

USB to Serial Converters: From manufacturer or specialized distributor.

Note: This chapter only contains parts that can be replaced by the operator him/

herself. If you want to order Tecan parts that are not listed here, please contact

the Tecan Customer Support.

A

L

K

B

I

C

H

J

Fig. 7-1 Parts of Balance Kit + SAG285/01 (Weighing Cell and Control Unit))

Draft shield

B Ring for evaporation compensation

C Vessel

D Centering ring

E Weighing pan (Mettler)

F Foot with counternut

G Adapter plate

H Weighing cell (Mettler)

I Connection cable (Mettler)

J Control unit (Mettler)

K Connection cable LC-RS9 (Mettler)

L Power supply (Mettler)

D

E

F

G

Balance Kit Operating Manual, 393278, en, V1.0 7 - 1

Page 34

7 - Spare Parts and Accessories

Tecan Spare Parts and Accessories

7.1 Tecan Spare Parts and Accessories

The parts listed in this section must be ordered from Tecan or a Tecan

representative.

7.1.1 Balance Kit

Entire Kit

Tab. 7-1 Balance Kit for SAG 285/01

Designation Tecan Part No.

Balance Kit for SAG 285/01, including:

• 1 Draft shield (A)

• 1 Evaporation ring (B)

• 2 Vessels (C)

• 1 Centering ring (D)

• 4 Feet with counternuts (F)

• 1 Adapter plate (G)

Spare Parts The following parts of the Balance Kit are available as spare parts.

Tab. 7-2 Spare parts of Balance Kit

Designation Tecan Part No.

Draft shield (A) 619 020

T

619 014

7.1.2 Uniport

Note: Remember that the connection via Uniport is not supported by the

Instrument Software V4.6 or later.

Tab. 7-3 Uniport

Designation Tecan Part No.

Uniport board 619 004

Intermediate cable between Uniport and LC-RS9 cable 619 013

7 - 2 Balance Kit Operating Manual, 393278, en, V1.0

Page 35

7.1.3 Instrument Software

The Instrument Software is delivered on a CD-ROM (or a set of diskettes).

Note: The CD-ROM also contains a PDF-file of the associated Instrument

Software Manual.

Tab. 7-4 Instrument Software

Version Used for Tecan Part No.

V4.2 Genesis Classic 615 018

V4.3 Genesis Freedom

V4.5 Genesis Freedom & Classic 615 018

V4.6 Freedom EVO, Genesis Freedom & Classic 615 018

7 - Spare Parts and Accessories

Parts from Other Manufactures

a)

615 093

a)

Weighing

Module

To be Ordered

Separately

V4.7 Freedom EVO, EVOlyzer, Genesis Freedom &

Classic (except RMP)

a) Special version that was validated for Genesis Freedom only

7.2 Parts from Other Manufactures

7.2.1 Weighing Module

The Weighing Module must be ordered from Mettler Toledo.

Tab. 7-5 Balance Kit for SAG 285/01

Designation Mettler Part No.

Weighing Module SAG 285/01, including:

• 1 Weighing Cell (H)

• 1 Control Unit (J)

• 1 Cable Control Unit ↔ Weighing Cell, 1.5 m (I)

• 1 Power supply (L)

The following parts are not included in the SAG 285/01 and must be ordered

separately from Mettler Toledo:

615 018

SAG 285/01

Tab. 7-6 Spare parts of Balance Kit

Designation Mettler Part No.

Weighing pan, diameter 50 mm (E) 238 472

Cable LC-RS 9 (K) 229 065

Cable Control Unit ↔ Weighing Cell, 5 m (I) 210 688

Transport case (optional) 238 852

Balance Kit Operating Manual, 393278, en, V1.0 7 - 3

Page 36

7 - Spare Parts and Accessories

Parts from Other Manufactures

7.2.2 USB to RS-232 Converters

These converters must be ordered from a specialized distributor or directly from

the manufacturer.

Tab. 7-7 USB to Serial Adapters

Manufacturer Designation Part No.

Aten International

Company Ltd.

www.aten.com

Exsys Vertriebs GmbH

www.exsys.ch

www.exsys.de

USB to RS-232 Converter

(1 USB to 1 RS-232 port)

USB to RS-232 Converter

(1 USB to 1 RS-232 port)

USB to RS-232 Converter

(1 USB to 4 RS232 port)

UC-232A

EX-1331

EX-1334

7 - 4 Balance Kit Operating Manual, 393278, en, V1.0

Page 37

8 Customer Support

8 - Customer Support

Purpose of This

Chapter

This chapter informs you how to contact us in case help is needed. It lists

addresses and telephone numbers of the manufacturer’s representatives.

How to get Help Tecan and its representatives maintain a fully trained staff of technical specialists

around the world. For any technical question, contact your system integrator or

nearest Tecan representative.

Addresses Contact your local distributor or one of the addresses below.

Also see our homepage on the web: www.tecan.com

Country/Region Address Telephone/Telefax/E-mail

Switzerland Tecan Sales Switzerland AGSeestrasse 103

CH-8708 Männedorf

Switzerland

Asia Tecan Asia (Pte) Ltd. 80, Marine Parade

#13-04

Singapore 449 269

Austria Tecan Austria GmbH Untersbergstrasse 1a

5082 Grödig / Salzburg

Belgium Tecan Benelux B.V.B.A. Vaartdijk 55

B-2800 Mechelen

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

+41/1 922 82 82

+41/1 922 84 84

helpdesk-ch@tecan.com

+65 644 41 886

+65 644 41 836

tecan@tecan.com.sg

+43 62 46 89 33 444

+43 62 46 89 33 39

helpdesk-at@tecan.com

+32 15 42 13 19

+32 15 42 16 12

tecan-be@tecan.com

France Tecan France S.A. Parc d’Activités de Pissaloup

Bâtiment Hermes II

27, Rue Edouard Branly

F-78190 Trappes

Germany Tecan Deutschland GmbH Theodor-Storm-Strasse 17

D-74564 Crailsheim

Great Britain Tecan UK Theale Court

11-13 High Street

Theale, UK-Reading

Berkshire RG7 5AH

Italy Tecan Italia, S.r.l. Via Fratelli Cerci

Palazzo Bernini

Centro Direzionale Milano 2

I-20090 Sergate (Mi)

Japan Tecan (Japan) Co. Ltd. Meiji Seimei Fuchu Building

10F

1-40, Miyamachi

Fuchu City

Tokyo

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

+33 1 30 68 81 50

+33 1 30 68 98 13

helpdesk-fr@tecan.com

+49 7951 94 170

+49 7951 50 38

helpdesk-de@tecan.com

+44 118 930 0300

+44 118 930 5671

helpdesk-uk@tecan.com

+39 02 215 21 28

+39 02 215 97 441

helpdesk-it@tecan.com

+81 66 30 58 511

+81 42 33 40 401

helpdesk-jp@tecan.com

Balance Kit, Operating Manual, 393278, en, V1.0 8 - 1

Page 38

8 - Customer Support

Country/Region Address Telephone/Telefax/E-mail

Netherlands Tecan Benelux B.V.B.A. Industrieweg 30

NL-4283 Giessen

Scandinavia Tecan Nordic AB Box 208

SE-43123 Mölndal

Sweden

Spain Tecan Ibérica

Instrumentación S.L.

Sabino de Arana

32

E-08028 Barcelona

USA Tecan U.S. P.O. Box 13953

Research Triangle Park

NC 27709

USA Tecan Systems Inc.

(formerly Cavro)

2450 Zanker Road

San Jose

CA 95131

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

Telephone

Te le f ax

E-mail

+31 018 34 48 174

+31 018 34 48 067

tecan-nl@tecan.com

+46 31 75 44 000

+46 31 75 44 010

tecan.nordic@tecan.com

+34 93 490 01 74

+34 94 411 24 07

tecanbcn@terra.es

+1 919 361 5200

+1 919 361 5201

helpdesk-us@tecan.com

+1 408 953 31 00

+1 408 953 31 07

tecansystemsinfo@tecan.com

8 - 2 Balance Kit, Operating Manual, 393278, en, V1.0

Page 39

9 Glossary

9 - Glossary

Purpose of This

Chapter

Glossary Balance

This chapter contains a glossary to explain terms and expressions used in this

Operating Manual.

– Instrument for determining the weight of something, scales.

– Setup function of the Instrument Software in which the communication of

the balance with the instrument is established so that the balance can be

used for the Gravimetric Test.

Balance Setup

Steps to be performed to adapt the balance parameters to the requirements of

an application (range, units, precision, etc.).

Communication Protocol

A standard set of rules that define how computers communicate with other

computers or devices. In order that connected computers and devices

“understand” each other they must use the same protocol.

Controller Area Network (CAN)

Network used to exchange information between connected devices.

Information is sent/received in the form of “messages” via a high-speed bus,

the CAN-bus. Each “message” consists of a “label” that is unique throughout

the network and a “data part”. From the label, the receiving device knows what

kind of information the data part contains.

Gravimetric Test

Test function implemented in the Instrument Software with which the precision

and the accuracy of the liquid transfer can be checked with the aid of an

external precision balance.

Instrument Software

Software package consisting of several interacting software programs (Setup

& Service, NPS Quick Test, Worktable Editor and Communication driver).

Protocol

See Communication Protocol

SAG 285/01

Precision balance, manufactured by Mettler Toledo, consisting of a Weighing

Cell and a separate Control unit.

Setup & Service Software

Part of the Instrument Software package with which the devices and options

installed on or connected to the instrument can be set up and tested.

Uniport

Interface board (used in Genesis RMP) with 4 RS-232 ports over which up to

4 external devices can be connected to the CAN bus of the instrument. Note

that the connection via Uniport is no longer supported by Instrument Software

V4.6 or later.

Universal Serial Bus (USB)

An external bus standard that supports high data transfer rates. A single USB

port can be used to connect up to 127peripherals of various sorts (e.g. mice,

modems, keyboards etc.). USB also supports Plug and Play installation.

Balance Kit Operating Manual, 393278, en, V1.0 9 - 1

Page 40

9 - Glossary

Worktable

The surface of the instrument on which various objects (carriers, tube racks,

wash stations etc.) are arranged.

Worktable Complete Editor

Graphical editor that allows creating, modifying and deleting worktable maps.

Worktable Map

A graphical representation of the worktable and the objects arranged on it.

The parameters of these objects (e.g. grid position, width, height) are needed

by the software which must know where they are placed. They also serve to

avoid collisions with moving arms, e.g. RoMa or LiHa.

9 - 2 Balance Kit Operating Manual, 393278, en, V1.0

Loading...

Loading...