TEC B-870 User Manual

TEC Thermal Printer

B-870 SERIES

Maintenance Manual

Document No. EM18-33013

Original Jan., 1995

(Revision )

PRINTED IN JAPAN

(Revision Date: Jul. 26 ’99)

TABLE OF CONTENTS

Page

1. UNPACKING ...................................................................................................... 1- 1

1.1 PROCEDURES...........................................................................................1- 1

1.2 CHECKS ..................................................................................................... 1- 1

2. MAJOR UNIT REPLACEMENT.......................................................................... 2- 1

2.1 REPLACING THE CPU PC BOARD........................................................... 2- 2

2.2 REPLACING THE PS UNIT ........................................................................ 2- 4

2.3 REPLACING THE STEPPING MOTORS AND BELTS .............................. 2- 5

2.4 REPLACING THE RIBBON MOTORS........................................................2- 6

2.5 REPLACING THE SOLENOID....................................................................2- 6

2.6 REPLACING THE PRINT HEAD ................................................................ 2- 8

2.7 REPLACING THE PLATEN ........................................................................ 2- 9

2.8 REPLACING THE ROLLER BELT AND FEED ROLLER .......................... 2-10

2.9 REPLACING THE MEDIA SENSORS ....................................................... 2-12

2.10PERIODIC PARTS REPLACEMENT......................................................... 2-13

EM18-33013

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT ........................ 3- 1

3.1 HIGH SPEED PC INTERFACE BOARD (B-4800-PC-QM)......................... 3- 1

3.2 CUTTER MODULE (B-4208-QM) ............................................................... 3- 3

3.3 MEMORY MODULE.................................................................................... 3- 5

3.4 STRIP MODULE (B-4908-H-QM) ............................................................... 3- 6

3.5 STABILIZER KIT ......................................................................................... 3- 7

4. MECHANISM DESCRIPTION ............................................................................ 4- 1

4.1 CUTTER DRIVE.......................................................................................... 4- 1

5. TROUBLESHOOTING........................................................................................ 5- 1

6. DIAG. TEST OPERATION.................................................................................. 6- 1

7. PROGRAM DOWN LOAD .................................................................................. 7- 1

7.1 FLOPPY DISK............................................................................................. 7- 1

7.2 SETUP ........................................................................................................ 7- 1

7.3 DOWN LOAD PROCEDURE ...................................................................... 7- 2

7.4 ERROR CODE............................................................................................ 7- 3

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission of

TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries

you may have in this manual.

Copyright © 1999

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

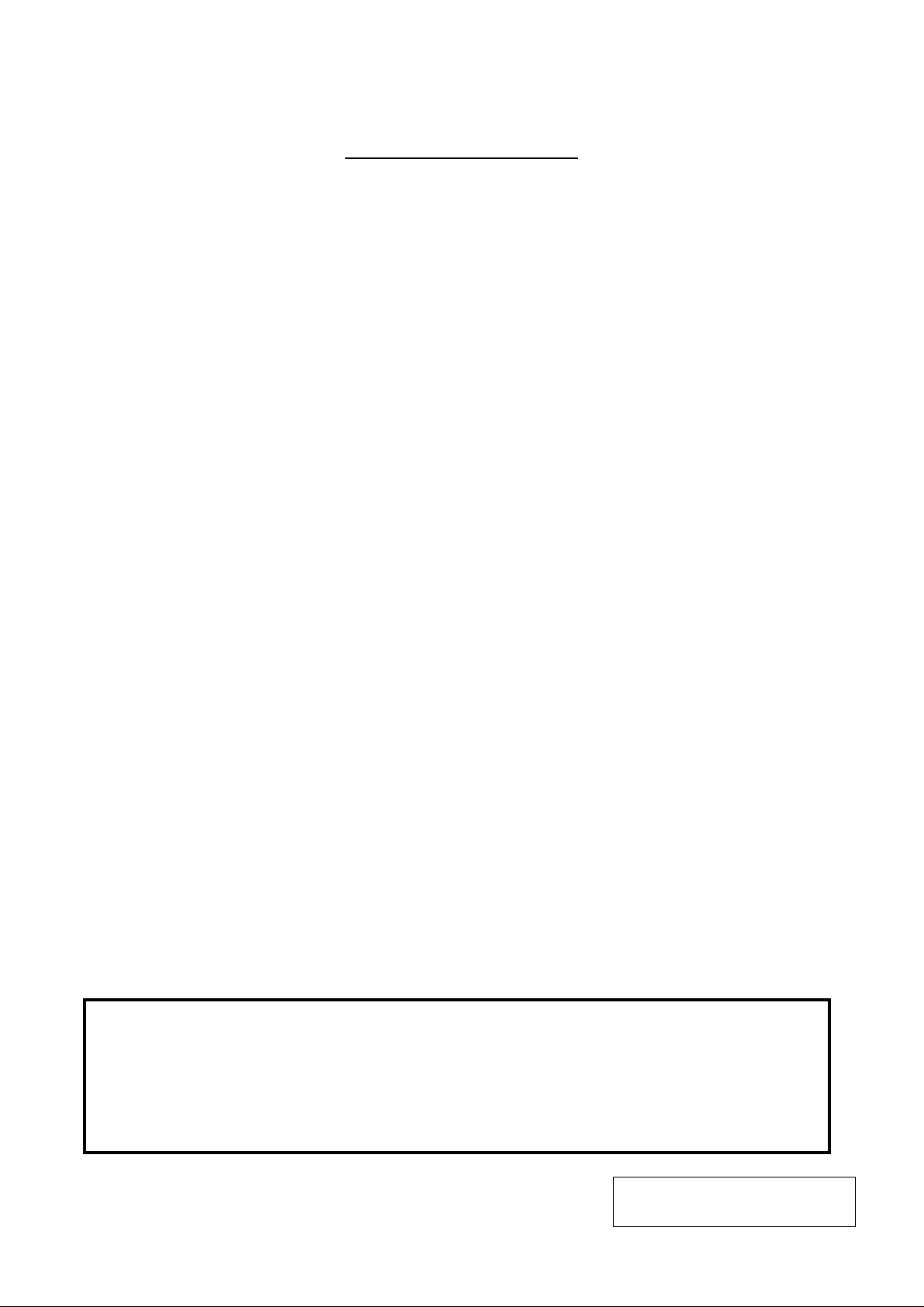

1. UNPACKING

1. UNPACKING

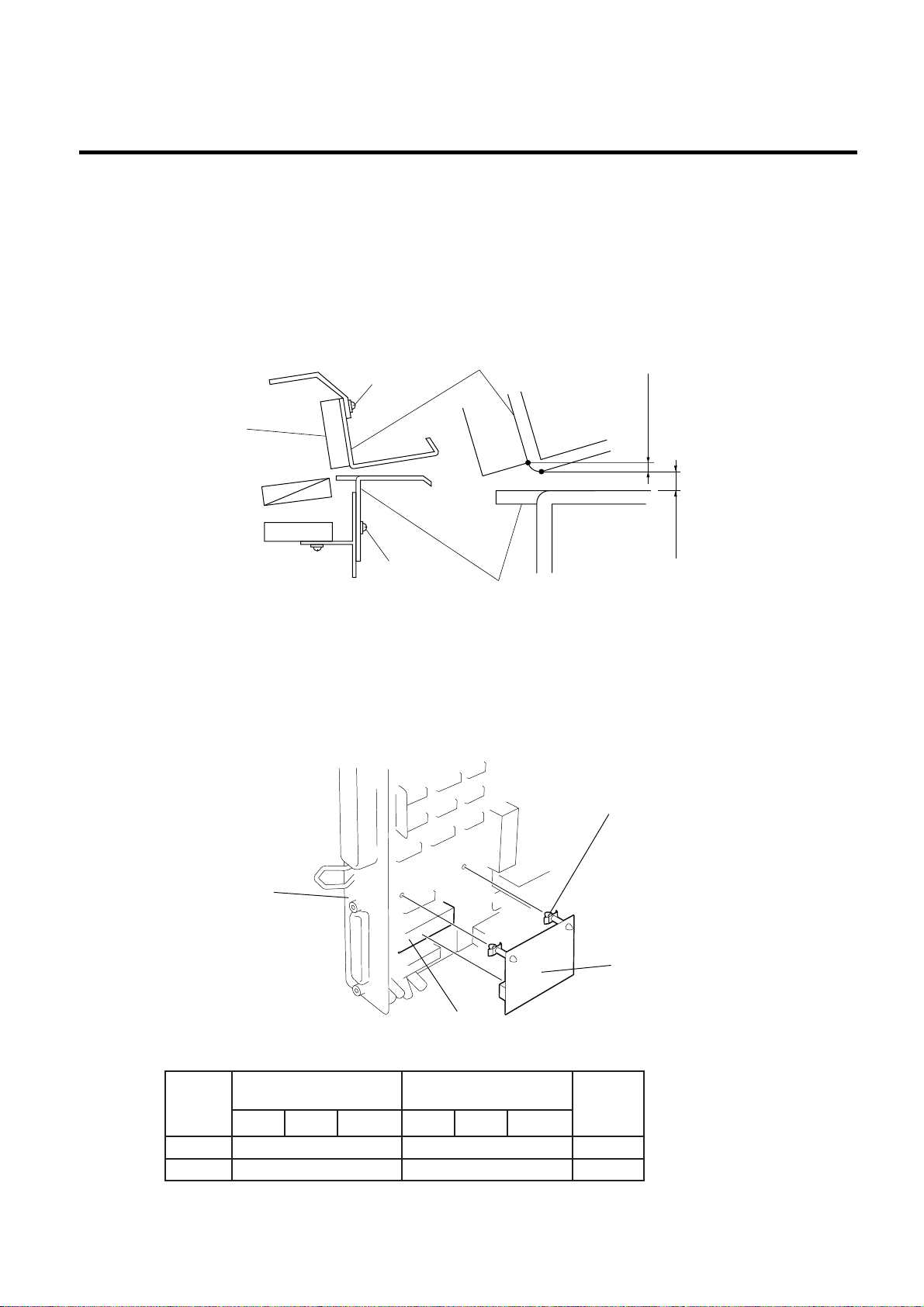

1.1 PROCEDURE

1) Open the carton.

2) Unpack the accesories from the carton

3) Unpack the side pads (L)/(R) and the printer from the carton.

EM18-33013

1.1 PROCEDURE

4) Place the printer on a level surface.

Holder Shaft

Left/Right Side Holders

Accessory Board

Side Pad (L)

Owner’s Manual

Unpacking

Procedure

Holder Base

Media

Holder

Thumbscrew (M-4x6)

Power Cord

Print Head Cleaner

Side Pad (R)

Thermal printer

Carton

1.2 CHECKS

1) Check for damage or scratches on the machine.

2) Confirm that none of the accessories are missing.

NOTE: Keep the carton and side pads for later transport.

1-1

Fig. 1-1

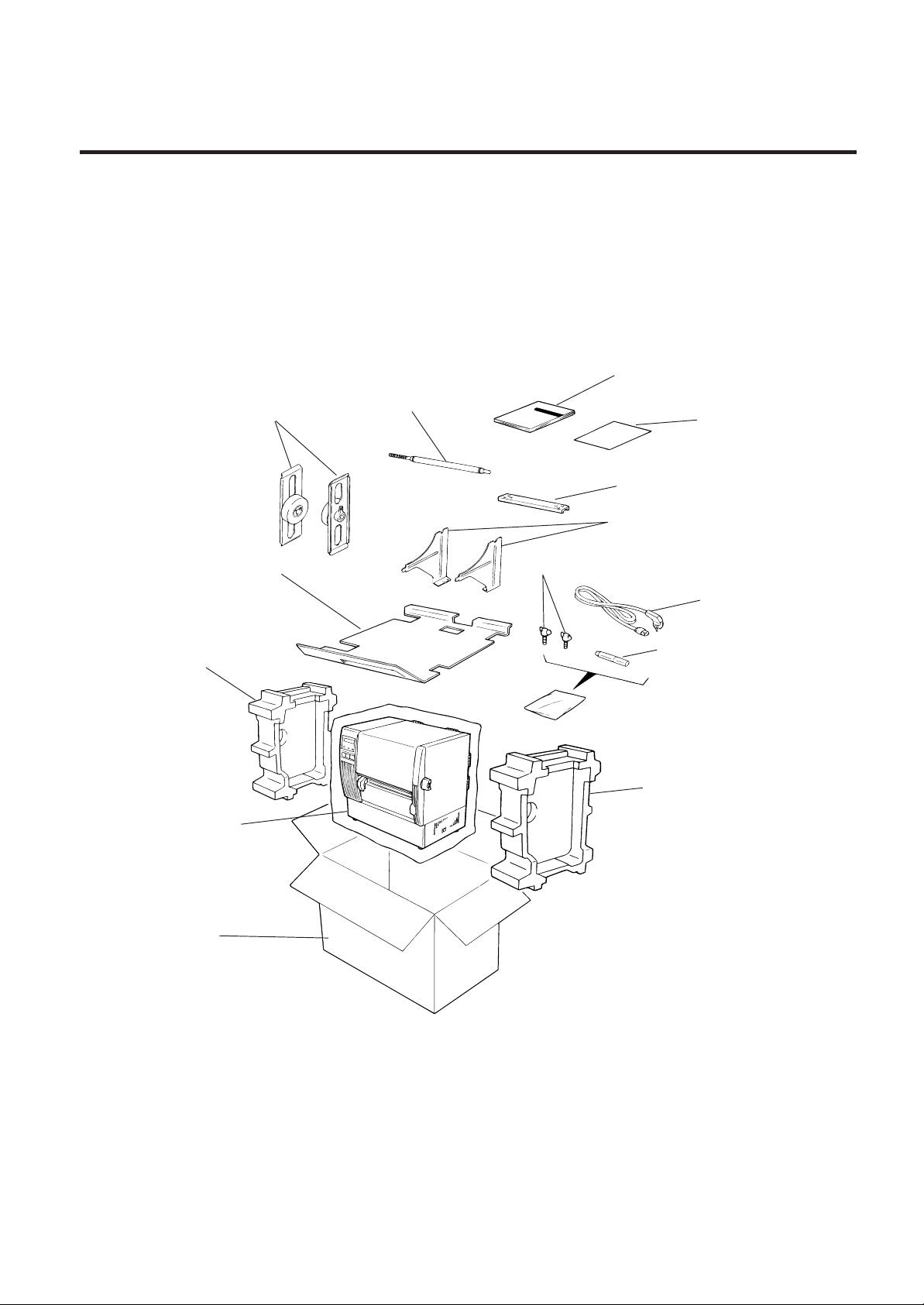

2. MAJOR UNIT REPLACEMENT

2. MAJOR UNIT REPLACEMENT

EM18-33013

2. MAJOR UNIT REPLACEMENT

WARNING!

Disconnect power cord before replacing important parts.

CAUTION:

1. NEVER separate the ribbon motors from the attaching plate (bracket), because doing so will

change their adjustment. (See Fig. 2-8)

2. NEVER remove the two screws painted red on the side of the print block. (See Fig. 2-11)

3. NEVER remove screws unless directed to do so in this manual. Removing screws may change

pre-set adjustments.

1) Turn the power off.

2) Open the right side and top covers.

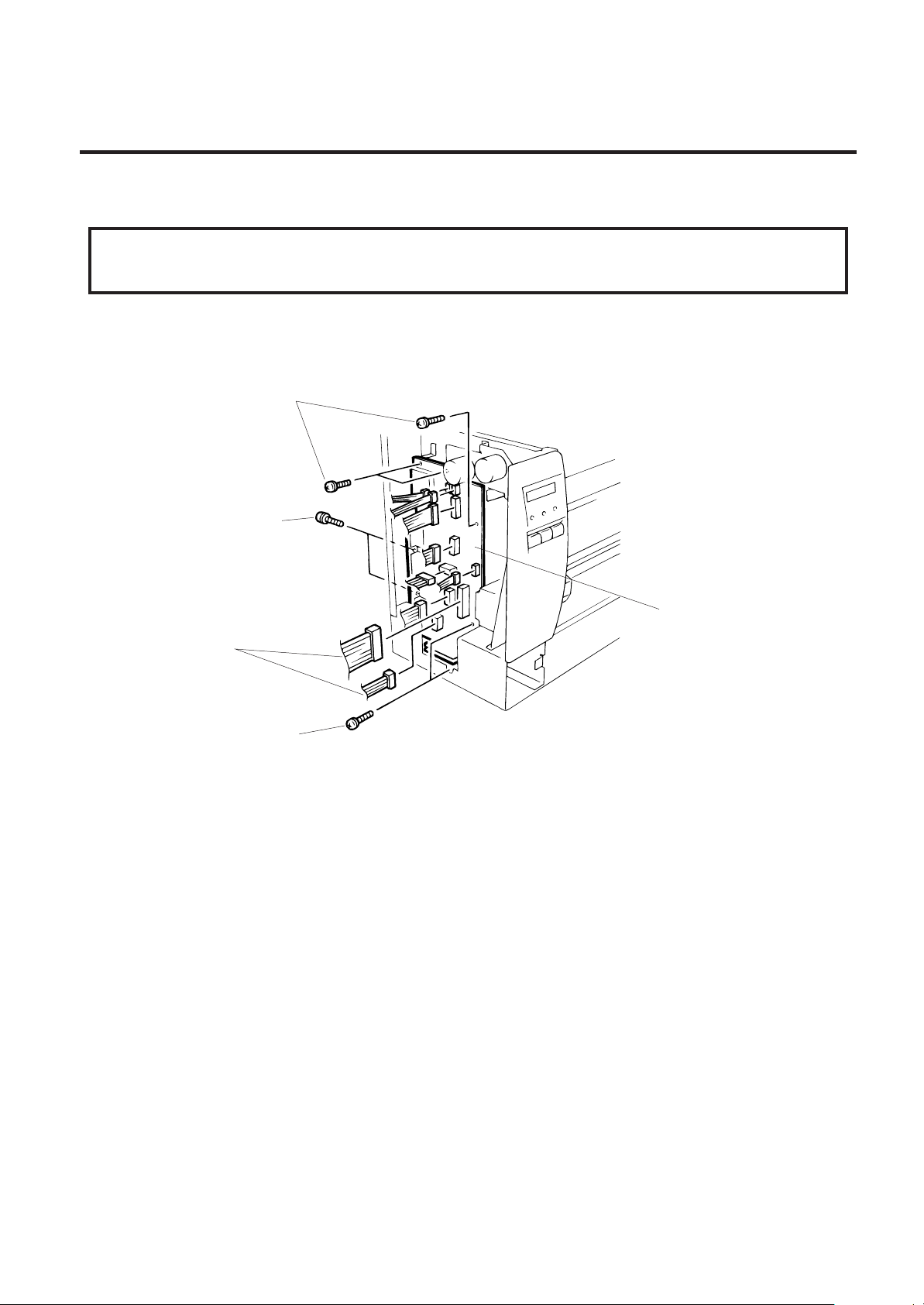

3) Remove the six screws (FL-4x6, B-4x6 and B-3x8) to detach the left side cover.

4) Remove the (B-4x6) screw to remove the bottom plate.

Top Cover

Screw (B-4x6)

Screw (B-3x8)

Left Side Cover

Bottom Plate

Screw (B-3x8)

Screw (FL-4x6)

Right Side Cover

Fig. 2-1

NOTE: Instructions to open the top and right side covers and to remove the left side cover are omitted

from each removal/installation procedure provided below.

■ Lubrication

CAUTION:

1. Lubrication: During parts replacement

2. Kinds of oil: FLOIL G-488: 1 Kg can. (Parts No. 19454906001).

3. Do not spray the inside of the printer with lubricants. Unsuitable oil can damage the

mechanism.

All machines are generally delivered in their best condition. Efforts shoud be made to keep them that

way. Lack of oil, or the presence of debris or dust, may cause an unexpected failure. To maintain

in optimal operating condition, periodically clean the machine and apply the proper kinds of oil to each

part in which librication is needed.

Although the frequency of lubrication varies according to how often the machine is used, as a

minimum it is necessary to lubricate before any part becomes dry. It is also necessary to wipe off

excessive oil or it will collect dirt.

2-1

2. MAJOR UNIT REPLACEMENT

2.1 REPLACING THE CPU PC BOARD

2.1 REPLACING THE CPU PC BOARD

CAUTION:

Replace only with the same type and rated fuse for continued protection against risk of fire.

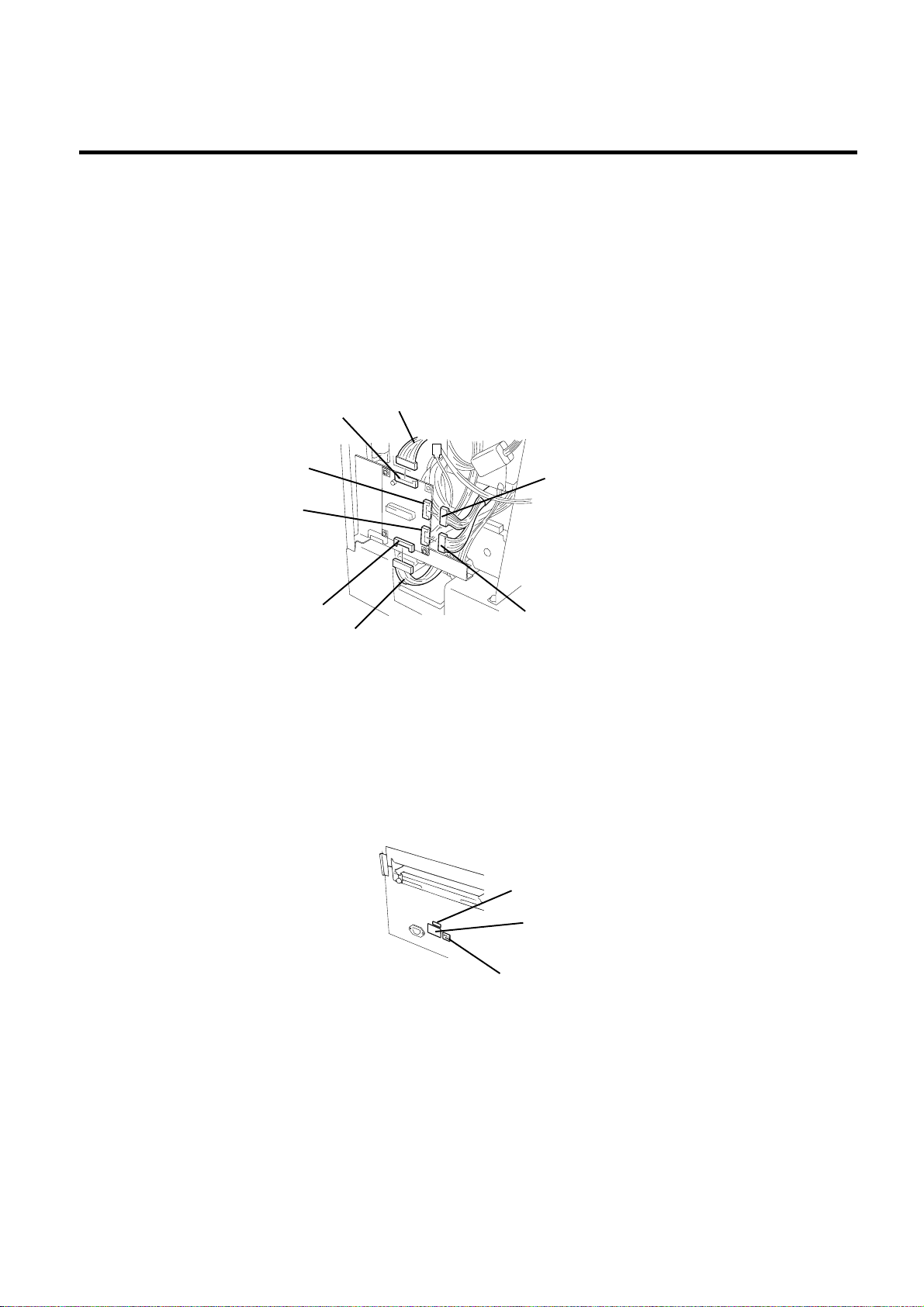

1) Detach the 11 connectors from the CPU PC board.

2) Remove the 7 screws (SM-3x5B and FL-3x5) to detach the CPU PC board.

Screw (SM-3x5B)

Screw (FL-3x5)

EM18-33013

CPU PC Board

Connector

Screw (SM-3x5B)

NOTE: Be sure to support the CPU PC board when detaching the connectors.

3) Replace the CPU PC board and reassemble in the reverse order of removal.

Fig. 2-2

2-2

2. MAJOR UNIT REPLACEMENT

2.1 REPLACING THE CPU PC BOARD

(Revision Date Mar. 15 ’96)

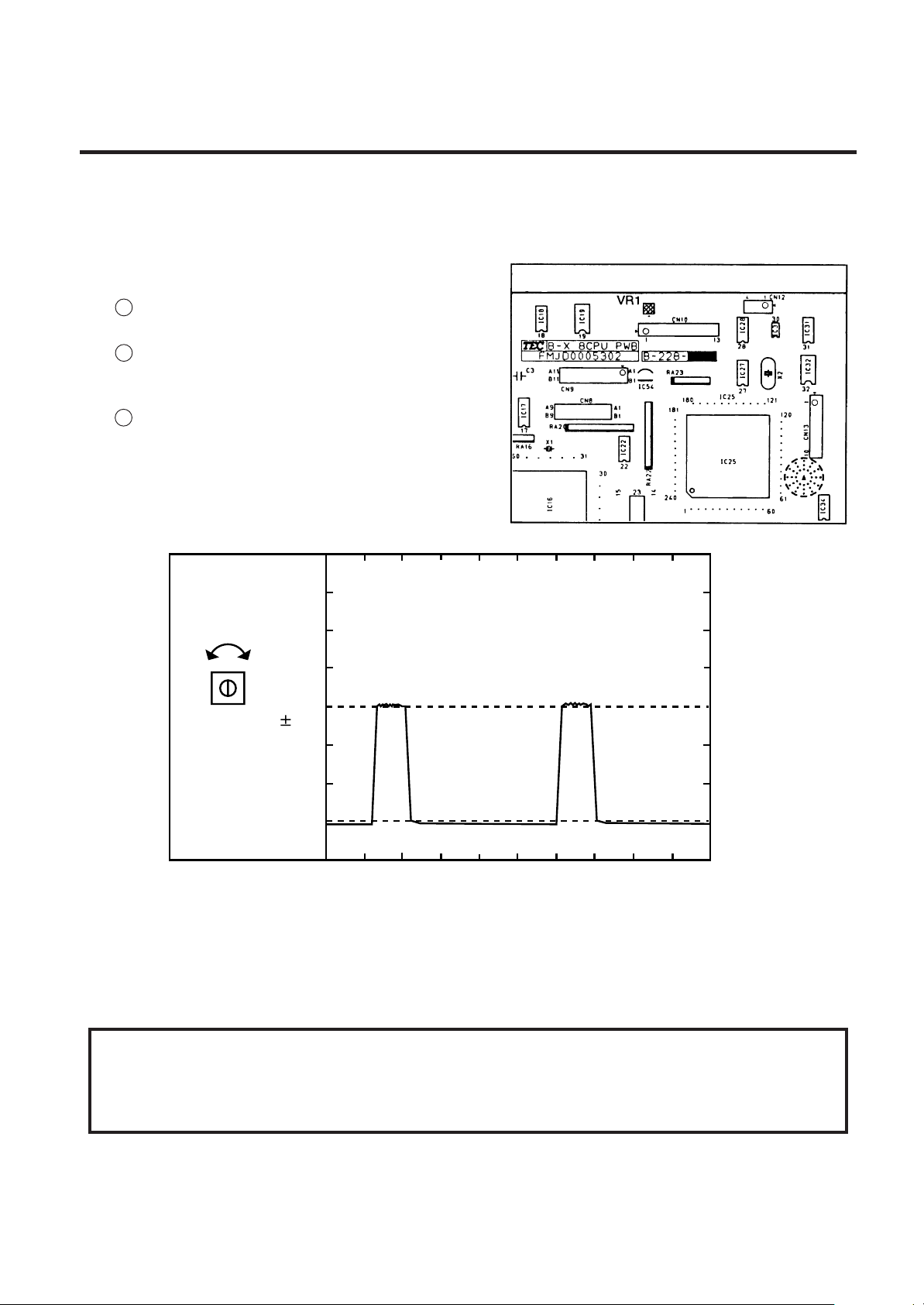

4) Adjust the ribbon end sensor.

After replacing the CPU PC board or changing ribbon type, be sure to adjust the ribbon end

sensor in the following procedure with the ribbon being used.

NOTE: Use TOSHIBA TEC-approved ribbons.

1 Set the ribbon so that the ribbon end sensor

can detect the ribbon, Turn the power on.

2 Turn the VR1 so that the voltage between Pin

1 (GND) and Pin 7 of CN10 is 3.0 ± 0.2 V as

measured with an oscilloscope.

3 Turn the power off and mount the left side

cover and top cover.

Fig. 2-3

EM18-33013

Range : 1V / 0.2 m sec.

Voltage

0.2V

3.0

VR1

GND

Fig. 2-4

5) Adjust the black mark sensor.

Refer to page 6-40 for the adjustment procedure for the black mark sensor which is adjusted by key

entries in system mode.

6) Adjust the feed gap sensor.

Refer to page 6-41 for the adjustment procedure for the feed gap sensor which is adjusted by key

entries in system mode.

CAUTION:

Be careful when replacing the CPU PC board, since a non-resettable counter (IC32) is installed on

thisboard. (Refer to Section 6.2.1 Maintenance Counter Printing.)If this counter should be reset,

replace IC32.

2-3

2. MAJOR UNIT REPLACEMENT

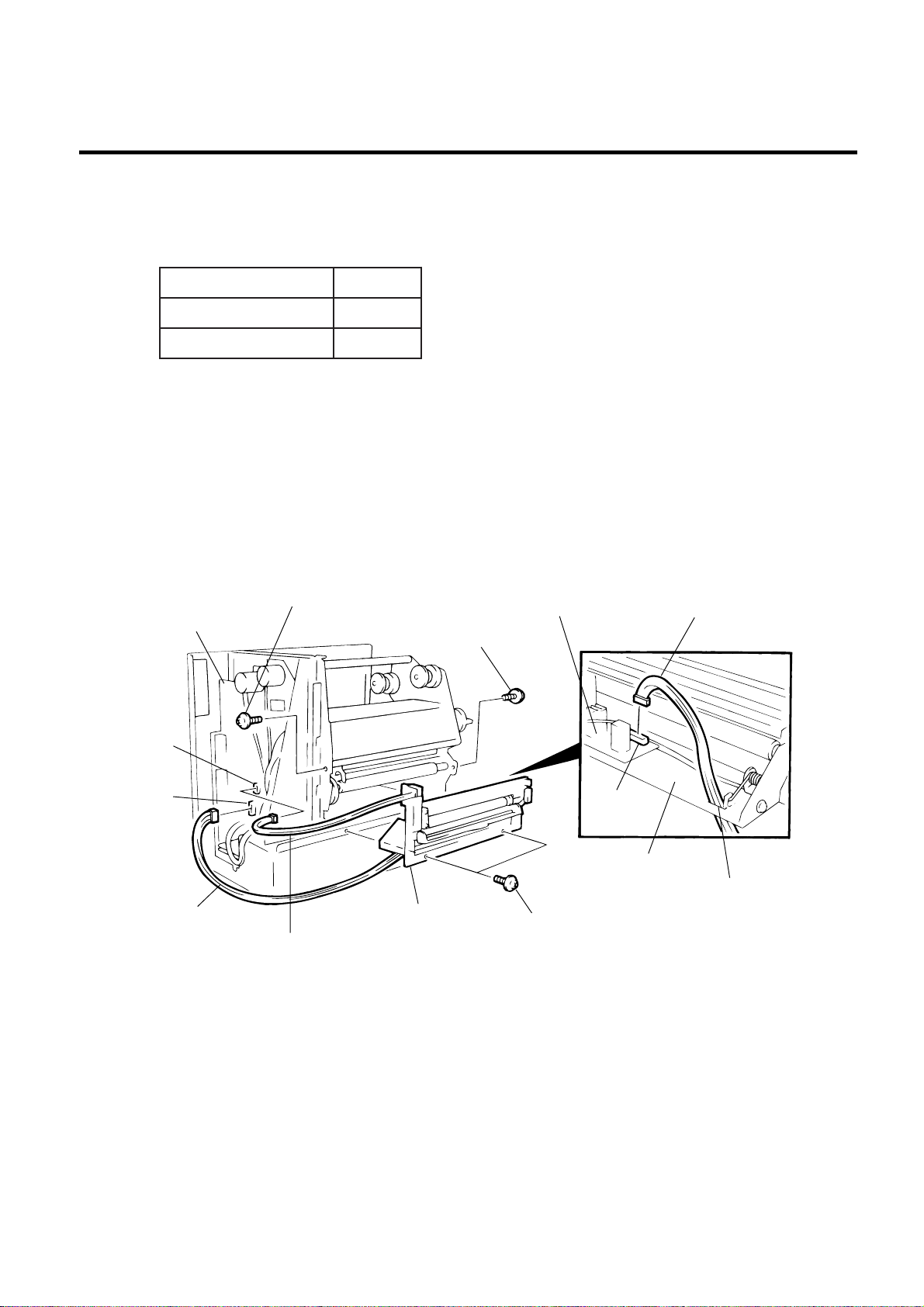

2.2 REPLACING THE PS UNIT

EM18-33013

2.2 REPLACING THE PS UNIT

CAUTION:

Replace only with the same type and rated of fuse for continued protection against risk of fire.

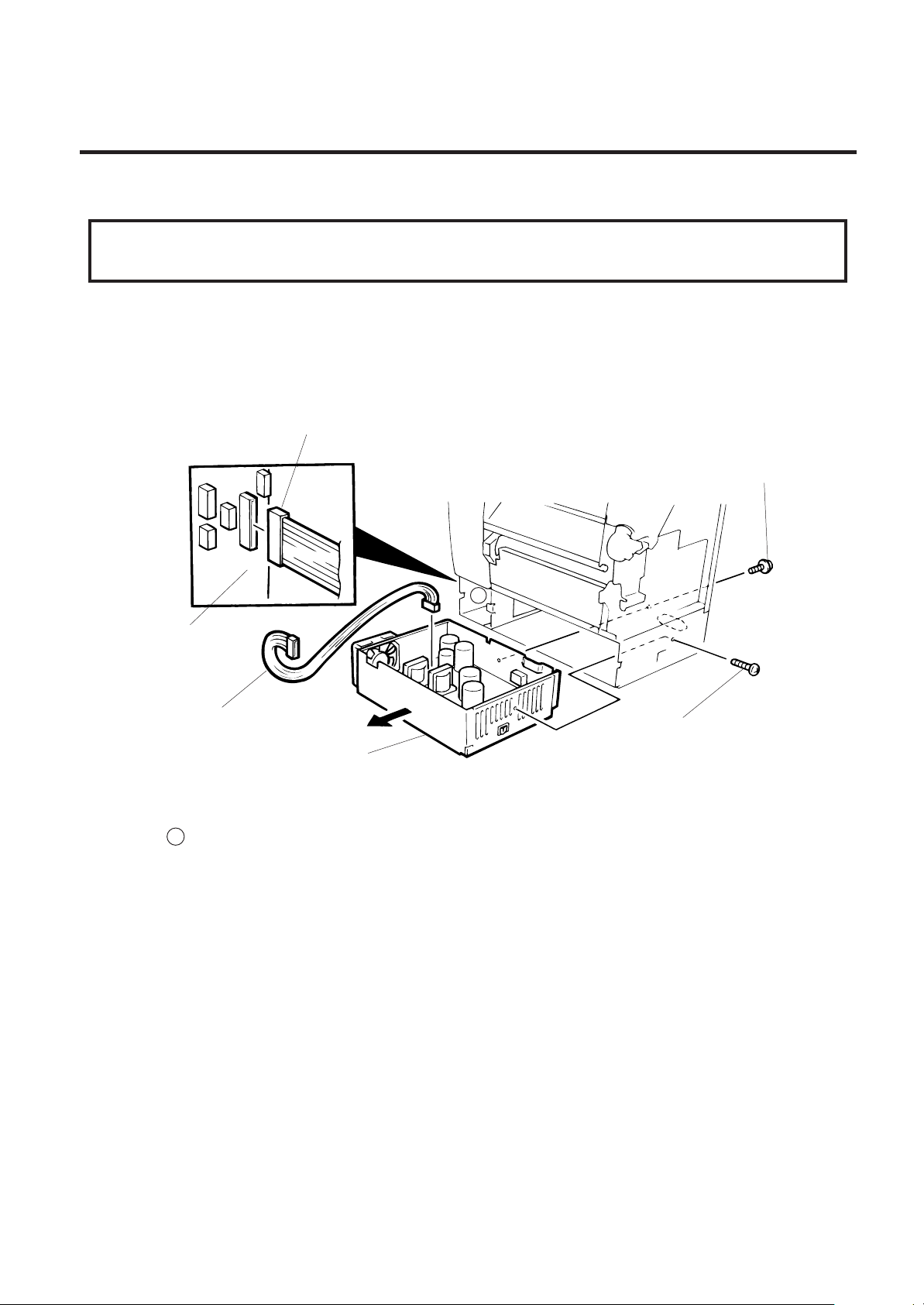

1) Detach all connectors from the CPU PC board.

2) Remove the two screws (FL-4 x 6) to detach the PS unit. Pushing the AC power inlet from behind

will ease the removal of the PS unit.

3) Disconnect the PS cable from the PS unit.

Connecter

Screw (FL- 4x6)

A

CPU PC Board

PS Cable

Screw (FL- 4x6)

PS Unit

Fig. 2-5

4) Replace the PS unit and reassemble in the reverse order of removal. Insert the PS cable into the

notch A .

2-4

2. MAJOR UNIT REPLACEMENT

2.3 REPLACING THE STEPPING MOTOR

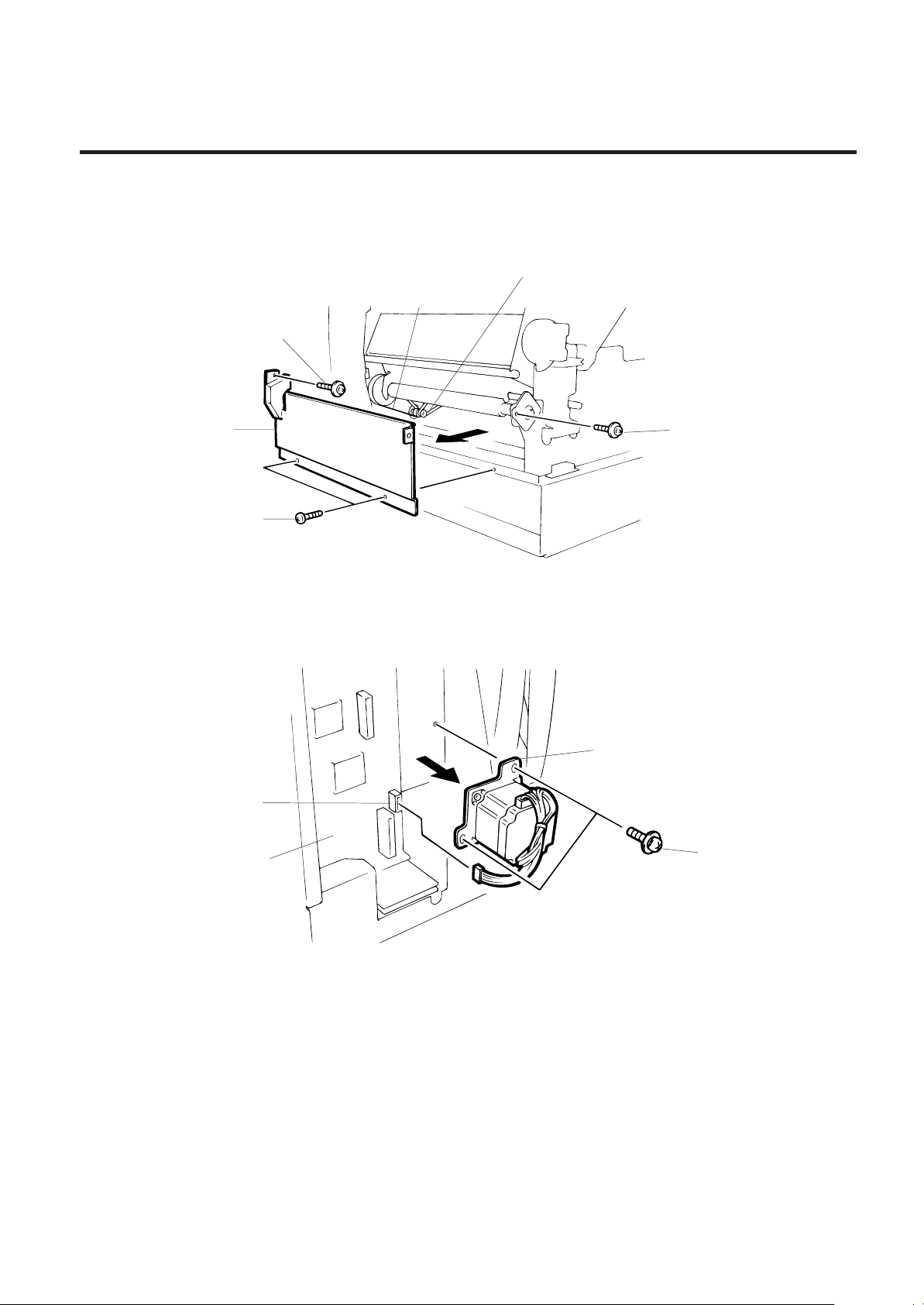

1) Remove the 4 screws (FL-4x6) to detach the front plate.

Platen Belt

Screw (FL-4x6)

EM18-33013

2.3 REPLACING THE STEPPING MOTOR

Feed Roller Belt

Front Plate

Screw (FL-4x6)

Screw (FL-4x6)

Fig. 2-6

2) Disconnect the cable from CN14 on the CPU PC board.

3) Remove the two screws (SM-4x10C), take the two belts off the pinion gear, and remove the stepping

motor.

Stepping Motor

CN14

CPU PC Board

Screw (SM-4x10C)

Fig. 2-7

4) When replacing the stepping motor, place the platen belt around the pinion gear first, then the feed

roller belt, so that the partition is positioned between the two belts. Press down on the stepping motor

with 3.5 Kg ± 300 g force and secure it so the platen belt and feed roller belt have no slack, are

engaged ,and evenly tense.

5) Reassemble in the reverse order of removal.

2-5

2. MAJOR UNIT REPLACEMENT

2.4 REPLACING THE RIBBON MORTOR

EM18-33013

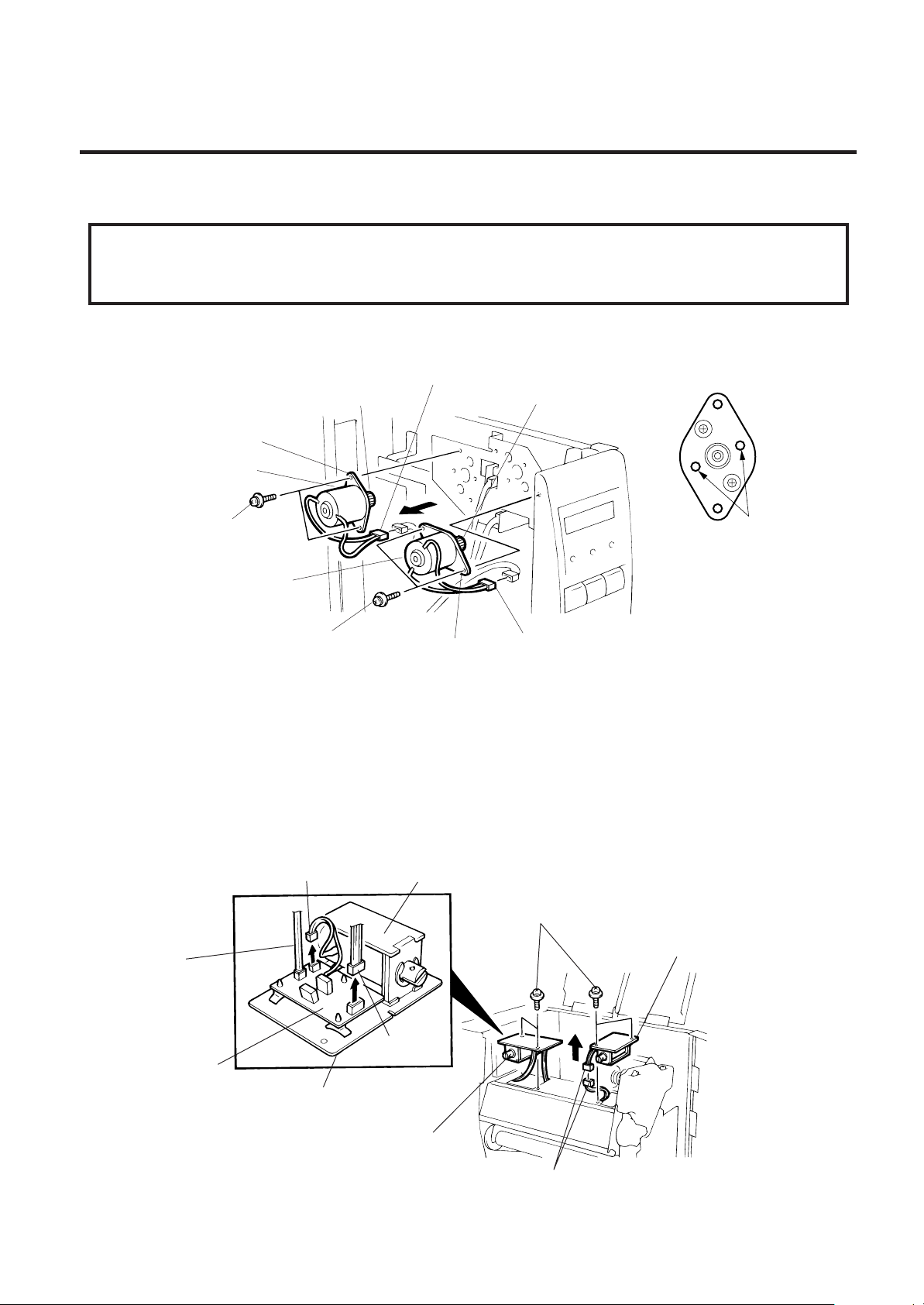

2.4 REPLACING THE RIBBON MOTORS

CAUTION:

NEVER separate the ribbon motor from the attaching plate because doing so will change their

adjustment.

1) Remove the CPU PC board. (Refer to section 2.1.)

2) Detach the connector and remove the two SM-3x5B screws to detach the ribbon motors.

Connector

FLOIL G-488

Attaching Plate

Ribbon Motor

(Red)

FLOIL G-488

Screw (SM-3x5B)

Riboon Motor

Screw (SM-3x5B)

Attaching Plate

Connector

(Black)

Dowels

Fig. 2-8

3) Replace the ribbon motors, then align the dowels to attach the ribbon motors. Reassemble in the

reverse order of removal.

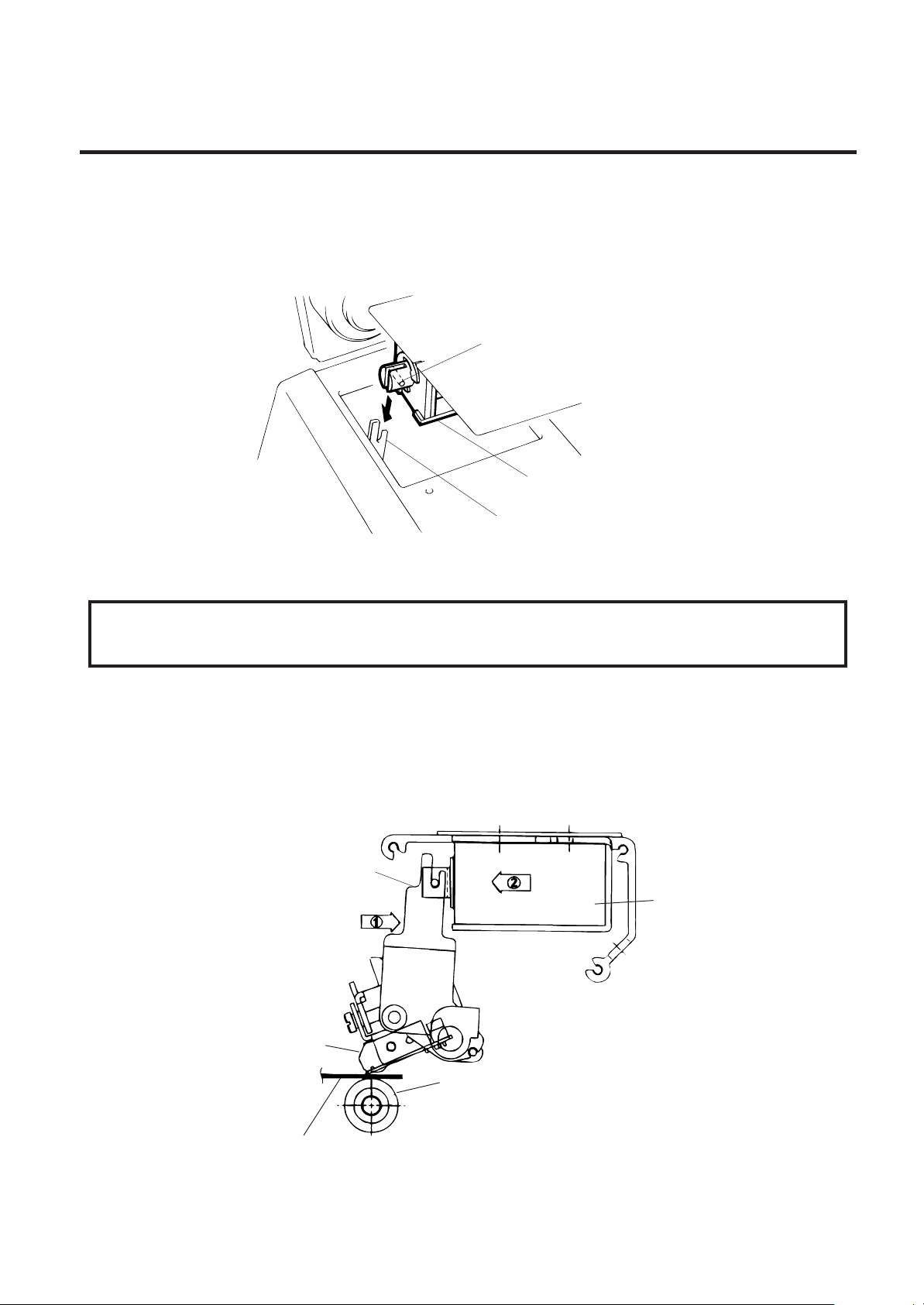

2.5 REPLACING THE SOLENOID

NOTE: This procedure can be done without removing the left side cover.

1) Remove the two SM-4x8B screws, detach the connectors, and remove the solenoid unit (R).

2) Remove the two SM-4x8B screws, disconnect the cables from CN1, CN2 and CN3 on the RSV PC

board and detach the solenoid unit (L).

CN1 (Solenoid L)

CN2

(Solenoid R)

Solenoid

Screw (SM-4x8B)

Solenoid Unit (R)

RSV PC Board

CN3

Solenoid Attaching Plate

Solenoid Unit (L)

Fig. 2-9

Connecter

2-6

2. MAJOR UNIT REPLACEMENT

(Revision Date Aug. 18 ’95)

2.5 REPLACING THE SOLENOID

EM18-33013

3) Remove the two SM-3 x 6B screws each from the solenoid units (L) and (R) to detach the solenoid.

4) Replace the solenoid and attach it to the solenoid attaching plate. Be careful of the differences in

length of the solenoid cables when installing the solenoid.

5) Assemble the solenoid unit so that the head up link engages the spring pin.

Spring Pin

Solenoid

Head Up Link

Fig. 2-10

NOTE: Make sure to remove any dust that appears during removal or installation because it may affect

the print quality.

CAUTION:

Take care to orient the screws so that they are vertically aligned with the solenoid attaching plate.

6) Insert piled 10 pieces of tag paper of 8 inches (203.2 mm) in width, 0.16 mm in thickness (I-BESTS is recommended) between the print head and the platen. Then turn the head lever to the LOCK

position.

7) Press and hold the link against the solenoid, and then press and fit the solenoid unit sungly to the

link. Secure the solenoid unit with the screws.

8) Reassemble in the reverse order of removal.

Link

Press

Press

Solenoid Unit

Print Head

Paper Thickness: 1.6 mm

Platen

Fig. 2-11

2-7

2. MAJOR UNIT REPLACEMENT

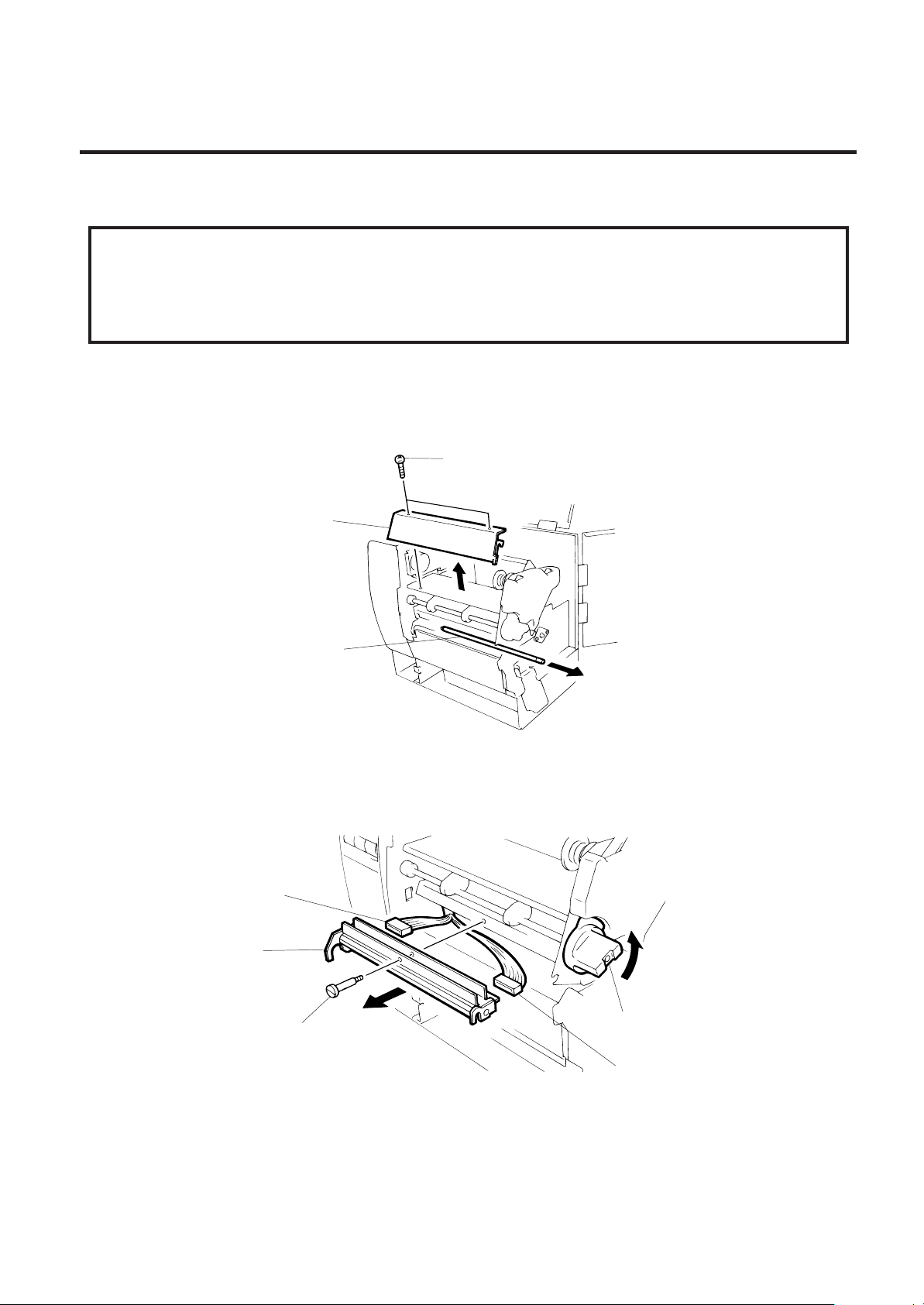

2.6 REPLACING THE PRINT HEAD

2.6 REPLACING THE PRINT HEAD

CAUTION:

1. NEVER touch the element when handling the print head.

2. NEVER touch the connector pins to avoid damage to the print head by static electricity.

3. NEVER remove the two screwws painted red on the side of the print block.

NOTE: This procedure can be done without removing the left side cover.

1) Remove the two (B-4x4) screws to detach the head cover plate.

2) Pull right to remove the front shaft.

Screw (B-4 x 4)

Head Cover Plate

EM18-33013

Front Shaft

3) Turn the head lever counterclockwise to lift the print head.

4) Remove the head fixing screw and pull out the print head.

5) Disconnect the two cables and remove the print head.

Connector

Print Head

Head Fixing Screw

NOTE:Never remove the bracket.

Head Lever

Connecter

Fig. 2-12

Fig. 2-13

6) Replace the print head and reassemble in the reverse order of removal.

7) Refer to page 6-44 and clear the maintenance counter.

8) Refer to page 6-31 and perform a test print.

2-8

2. MAJOR UNIT REPLACEMENT

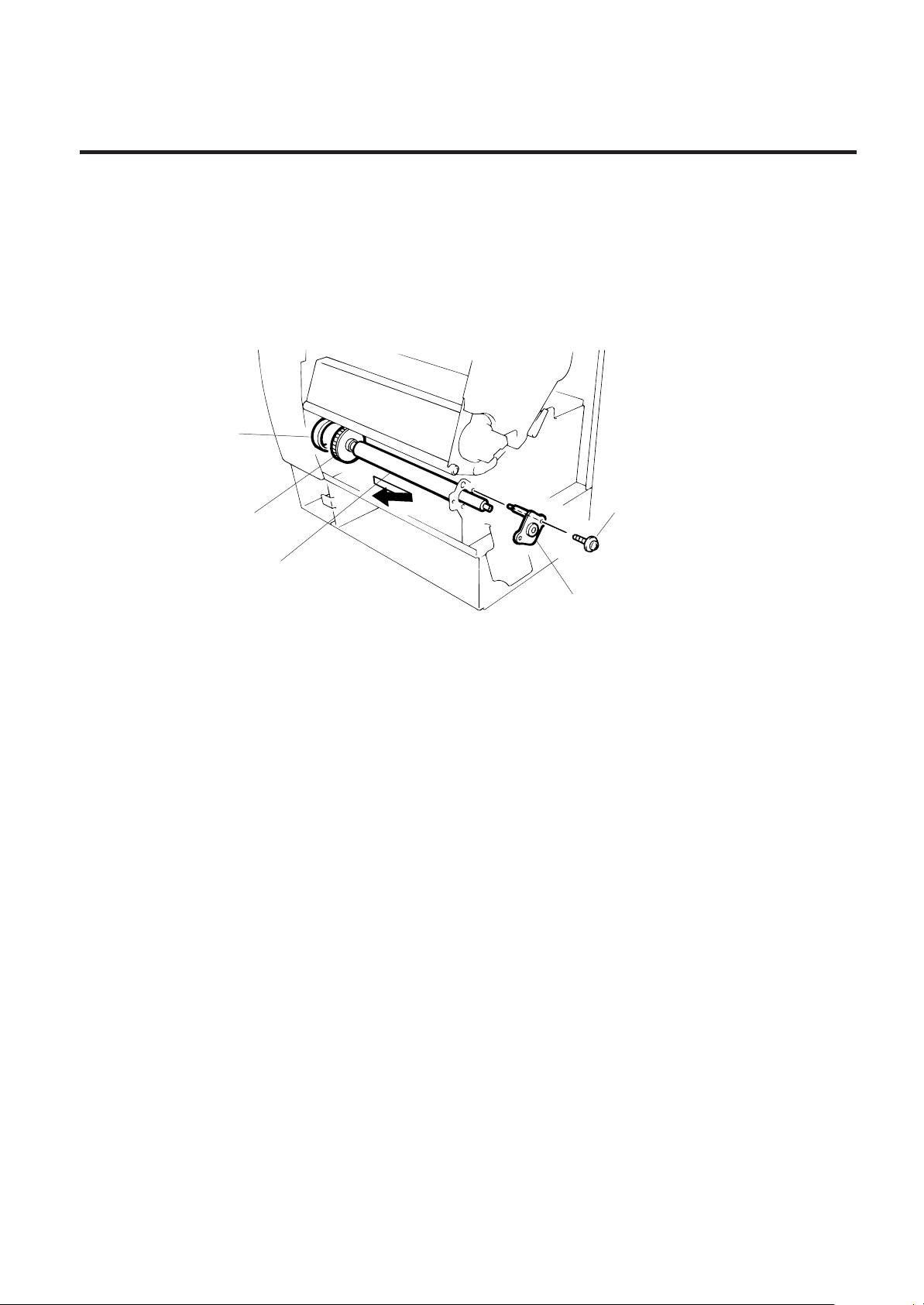

2.7 REPLACING THE PLATEN

EM18-33013

2.7 REPLACING THE PLATEN

1) Remove the front plate. (Refer to Fig. 2-6.)

2) Loosen the two screws (SM-4 x 10C) securing the stepping motor.

3) Remove the (FL-4 x 6) screw to detach the platen positioning plate.

4) Take the platen belt off the platen pulley, move the platen fully to the right and remove the platen from

the left end.

Platen Belt

Platen Pulley

Platen

Platen Positioning Plate

Screw (FL-4 x 6)

Fig. 2-14

5) Replace and install the platen, then place the platen belt around the platen pulley.

6) Install the platen positioning plate.

7) Press down on the stepping motor with 3.5 Kg ± 300 g force and secure it so the platen belt and the

feed roller belt have no slack, are engaged and evenly tense.

8) Reassemble the remaining parts in the reverse order of removal.

2-9

2. MAJOR UNIT REPLACEMENT

2.8 REPLACING THE ROLLER BELT AND FEED ROLLER

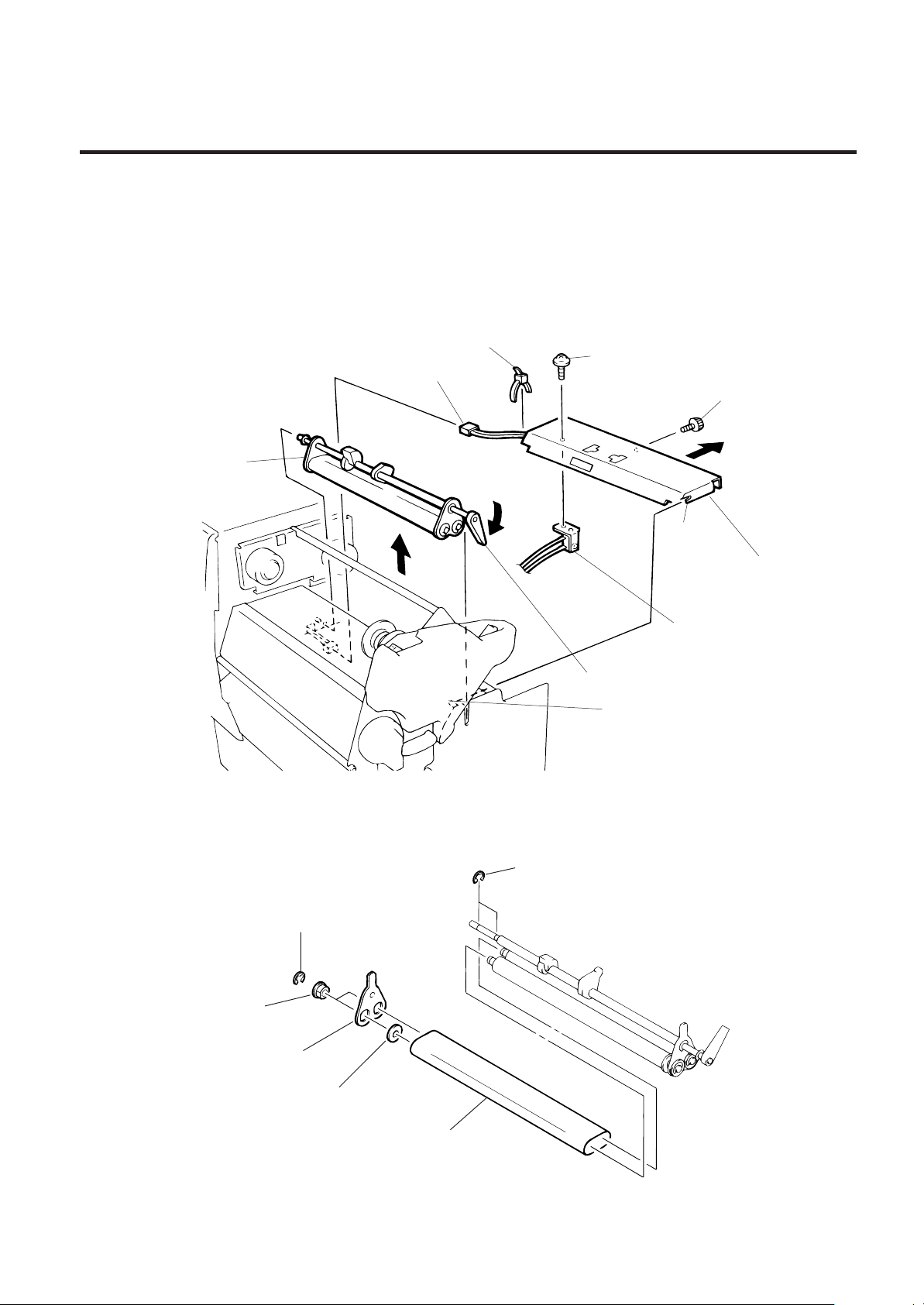

2.8 REPLACING THE ROLLER BELT AND FEED ROLLER

1) Lower the pinch roller lever.

2) Remove the white screw to detach the ribbon end sensor plate.

3) Remove the FL-3 x 5 screw, cut the cable band and remove the head-up switch.

4) Detach the connector of the ribbon end sensor.

EM18-33013

5) Removal the pinch roller block.

Pinch Roller Block

Cable Band

FL-3 x 5

Connector

White Screw

Notch

Ribbon End

Sensor Plate

Head-Up Switch

Pinch Roller Lever

Stud

Fig. 2-15

NOTE: Fit both sides of the studs into the notches when installing the ribbon end sensor plate.

6) Remove the four E-rings (E-5), pinch roller holder, bush, pinch roller washer, and then roller belt.

E-ring (E-5)

E-ring (E-5)

Bush

Pinch Roller Holder

Pinch Roller Washer

Roller Belt

2-10

Fig. 2-16

2. MAJOR UNIT REPLACEMENT

2.8 REPLACING THE ROLLER BELT AND FEED ROLLER

EM18-33013

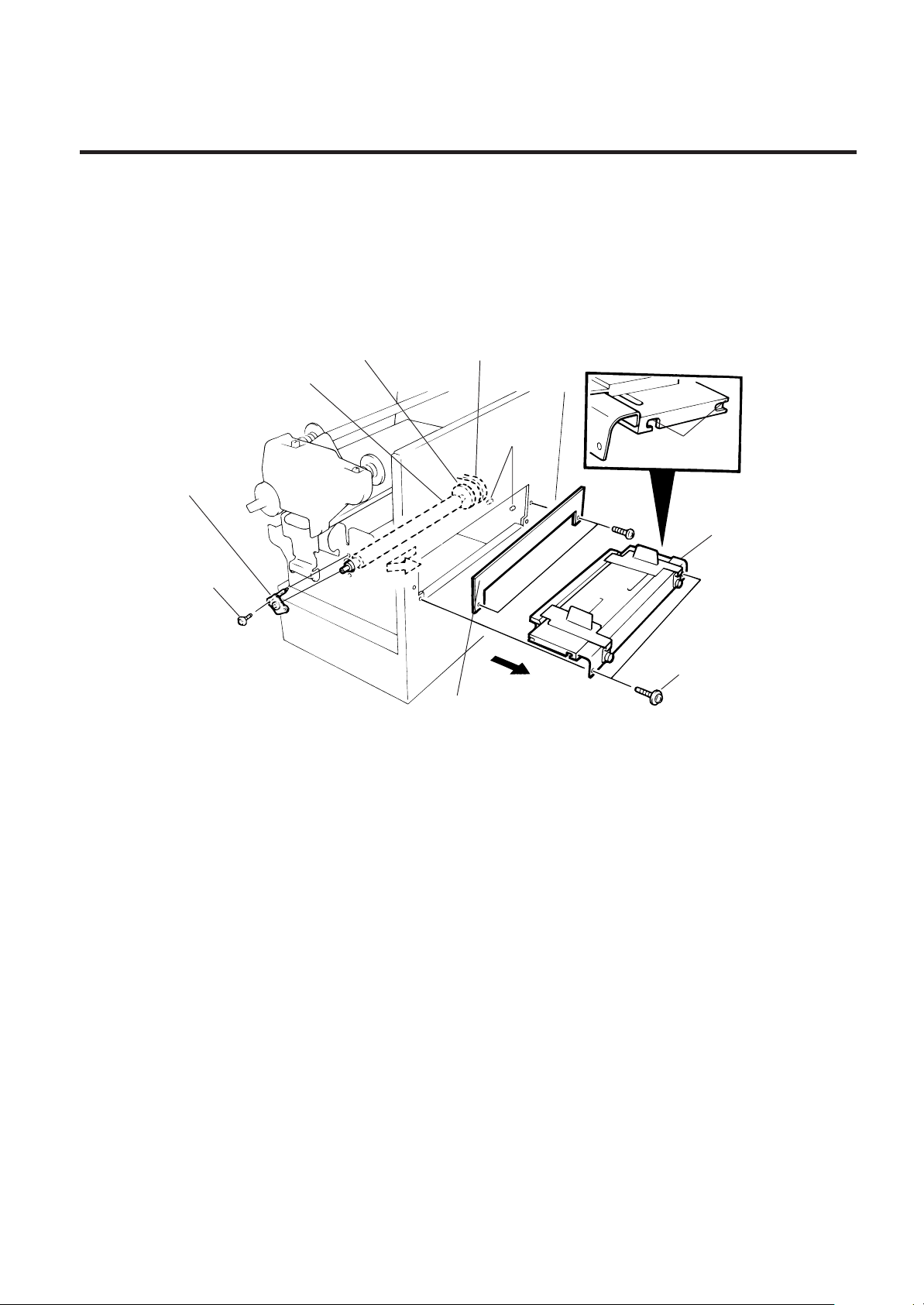

7) Remove the two (FL-4x6) screws and detach the media plate.

8) Remove the two (FL-4x6) screws and detach the media guide unit.

9) Loosen the two (SM-4x10C) screws securing the stepping motor.

10) Remove the two screws to detach the feed roller positioning plate.

11) Take the feed roller belt off the feed roller, move the feed roller fully to the left and remove the feed

roller form the right end.

Roller Pulley

Feed Roller Feed

Feed Roller Belt

Stud

Feed Roller

Positioning Plate

Screw (FL-4x6)

Media Plate

Notch

Media Guide Unit

Screw (FL-4x6)

Fig. 2-17

NOTE: Fit both sides of the studs into the notches when installing the media guide unit.

12) Replace and install the feed roller, place the feed roller belt around the feed roller pulley.

13) Install the feed roller positioning plate.

14) Press down on the stepping motor with 3.5 Kg ± 300 g force and secure it so the platen belt and

the feed roller belt have no slack, are engaged and evenly tense.

15) Reassemble the remaining parts in the reverse order of removal.

2-11

2. MAJOR UNIT REPLACEMENT

2.9 REPLACING THE MEDIA SENSOR

EM18-33013

2.9 REPLACING THE MEDIA SENSOR

CAUTION:

1. When using the fixed sensor, line up the feed gap sensors between the upper and lower sensors.

2.

When shipped from the factory, the black mark sensor is positioned at the center of the effective

print area and the feed gap sensor is located 10 mm left of center as viewed from the front.

1) Detach the 4 connectors from the fixed/movable media sensors.

2) Remove the two screws (FL-3 x 4) and the sensor holder to detach the media sensor unit.

3) Turn the knob of the sensor shaft clockwise and remove the movable media sensor.

4) Remove the E-ring (E-3) from the sensor shaft and detach the lower fixed media sensor.

Media Sensor Unit

Knob

Fixed Media Sensor

E-ring (E-3)

Movable Media Sensor

Media Guide Plate

Screw (FL-3x4)

Connecter

Connecter

Fig. 2-18

5) Remove the white screw to detach the media guide plate.

6) Remove the two SM-3 x 6B screws, then unclamp and detach the upper fixed media sensor.

Upper Fixed Media Sensor

Screw (SM-3 x 6B)

Media Guide Plate

White Screw

B

Clamp

Fig. 2-19

7) Replace the fixed/movable media sensors and reassemble in the reverse order of removal.

2-12

2. MAJOR UNIT REPLACEMENT

2.10 PERIODIC PARTS REPLACEMENT

(Revision Date Sep. 29 ’95)

EM18-33013

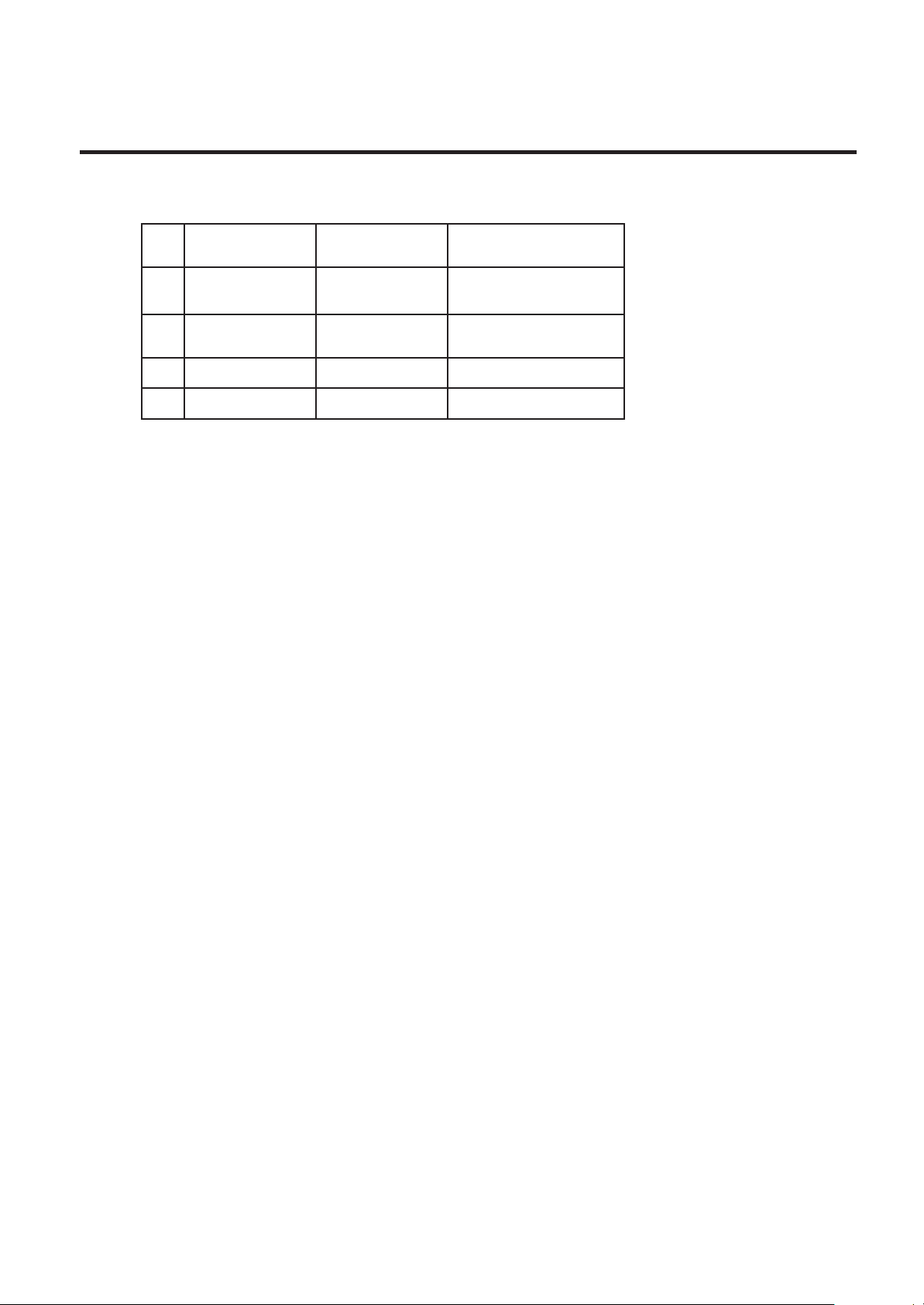

2.10 PERIODICAL PART REPLACEMENT

.oNemaNtraP.oNtraP

1rotoMnobbiR

2dioneloS

3netalP1054400CBMFmK05

4relloRdeeF1064400CBMFmK05

1050300BBMF

2050300BBMF

2012300BBMF

3012300BBMF

mK037

folavretnIdradnatS

tnemecalpeR

semit000,000,1

Since the above intervals are the standard values for a fully maintained machine, they are not

guaranteed, The values vary depending on the operating environment (dust or debris) or use of proper

media and ribbon.

2-13

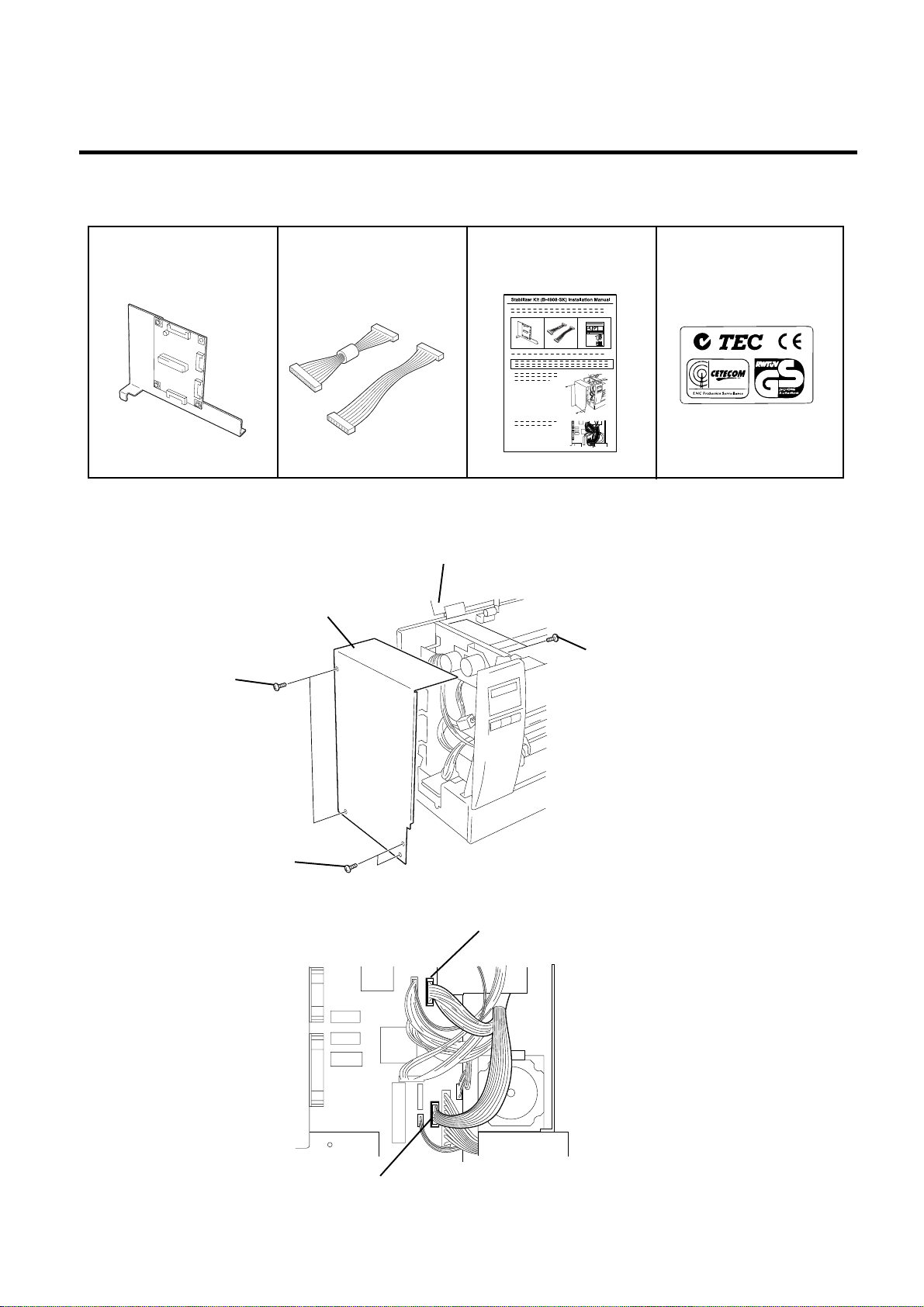

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

3.1 HIGH SPEED PC INTERFACE BOARD (B-4800-PC-QM)

3. INSTALLATION PROCEDURE FOR OPTIONAL

EQUIPMENT

WARNING!

Make sure to unplug the power cord before installing any optional equipment.

3.1 HIGH SPEED PC INTERFACE BOARD (B-4800-PC-QM)

EM18-33013

Description

BPE PC board

BPC PC board

Printer cable

Cable support plate

The high speed PC interface board can be used together with the IBM PC-AT or compatible machine

only.

1) Open the top cover and right side cover. (See Fig. 2-1.)

2) Remove the left side cover. (See Fig. 2-1.)

3) Remove the two FL-3 x 5 screws to detach the blind plate.

4) Pass the printer cable through the opening.

5) Fasten the ground wire of the printer cable to the CPU PC board at the upper right with the

SM-3 x 6B screw which secures the CPU PC board.

6) Remove the two SM-4 x 8C screws from the BPE attachment plate.

7) Install the BPE PC board on the CN5 of the CPU PC board with the screws removed in step 6.

Screw (SM-3 x 5B)

Q'ty/Unit

1

1

1

1

Description

Locking support

Program diskette

Owner's Manual

Ground Wire

Q'ty/Unit

2

1

1

Opening

Blind Plate

Screw (FL-3 x 5)

Printer Cable

CPU PC Board

Screw (SM-4 x 8C)

BPE PC Board

Connector (CN5)

Fig. 3-1

3-1

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

3.1 HIGH SPEED PC INTERFACE BOARD (B-4800-PC-QM)

EM18-33013

8) Connect the printer cable to connecter (CN1) on the BPE PC board.

9) Place the cable strain relief of the printer cable in the notch of the cable support plate. Secure the

cable strain relief to the cable support plate by turning the nut.

10) Attach the cable support plate to the printer with the FL-3 x 5 screws removed in the step 3.

Cable Strain Relief

Screw (FL-3 x 5)

Cable Support Plate

Nut

BPE PC Board

Connector (CN1)

Printer Cable

11) Reassemble in the reverse order of removal.

12) The following procedure should be employed with your PC.

13) Set the DIP SW. on the BPC PC board for the I/O address according to your PC.

Fig. 3-2

14) Install the BPC PC board in the expansion port bus line of your PC.

15) Connect the printer cable mentioned in step 5 to the BPC PC board.

16) Insert the attached FDK into the FDD and install the data in the hard disk. Since the installation

procedure is different between MS-DOS and Windows, refer to the respective owner’s manual.

17) Perform a motion check.

3-2

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

3.2 CUTTER MODULE (B-4208-QM)

SVO7A1003: Nov. 21 ’97

EM18-33013

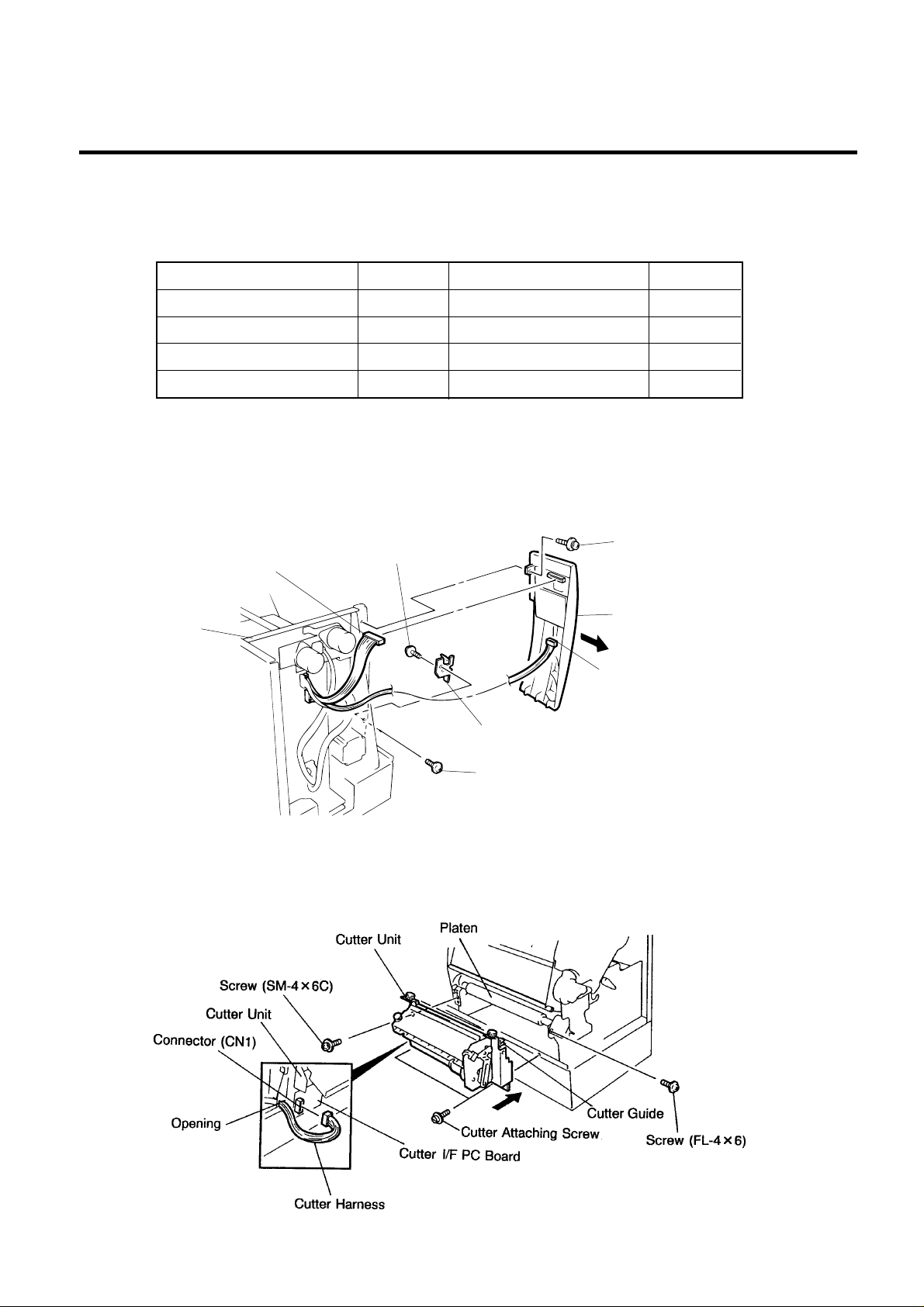

3.2 CUTTER MODULE (B-4208-QM)

NOTE: This module cannot be used together with the B-4908-H-QM strip module. Remove the strip

module if it has been attached to the printer.

Description Q’ty/Unit Description Q’ty/Unit

Cutter Unit 1 Cutter Attaching Screw 2

Cutter 1 Screw (FL-4x6) 2

Cutter Harnes 1 Screw (SM-4x6C) 1

Cutter Support 1 Cleaner 1

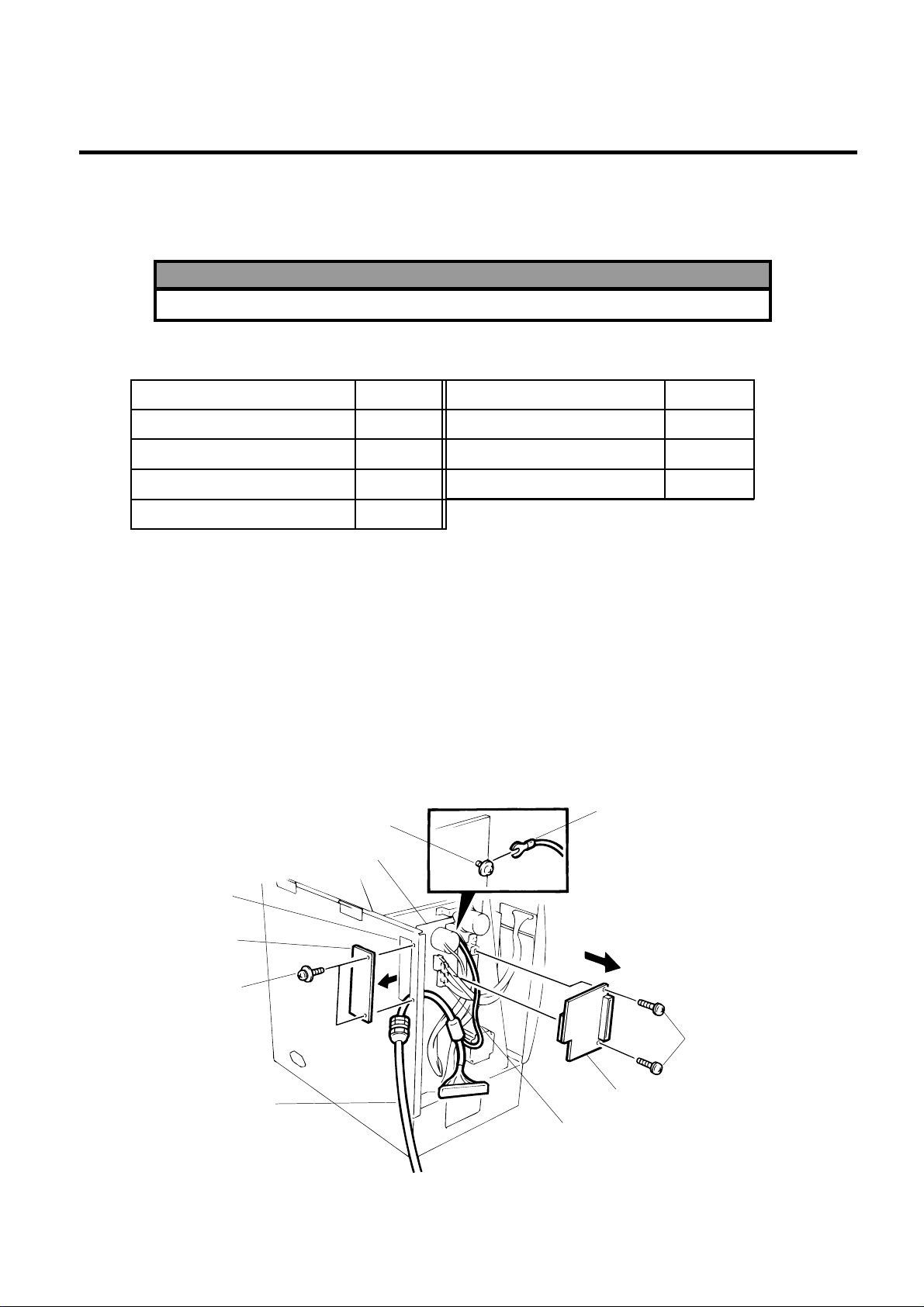

1) Open the right side cover and the top cover. (See Fig. 2-1.)

2) Remove the left side cover. (See Fig. 2-1.)

3) Remove the front plate. (See Fig. 2-6.)

4) Remove the screw (SM-4x8B) and two connectors to detach the operation panel.

5) Attach the cutter support to the main frame with the two screws (FL-4x6).

Screw (FL-4x6)

Connector

Screw (SM-4x8B)

Main Frame

Cutter Support

Screw (FL-4x6)

Operation Panel

Connector

Fig. 3-3

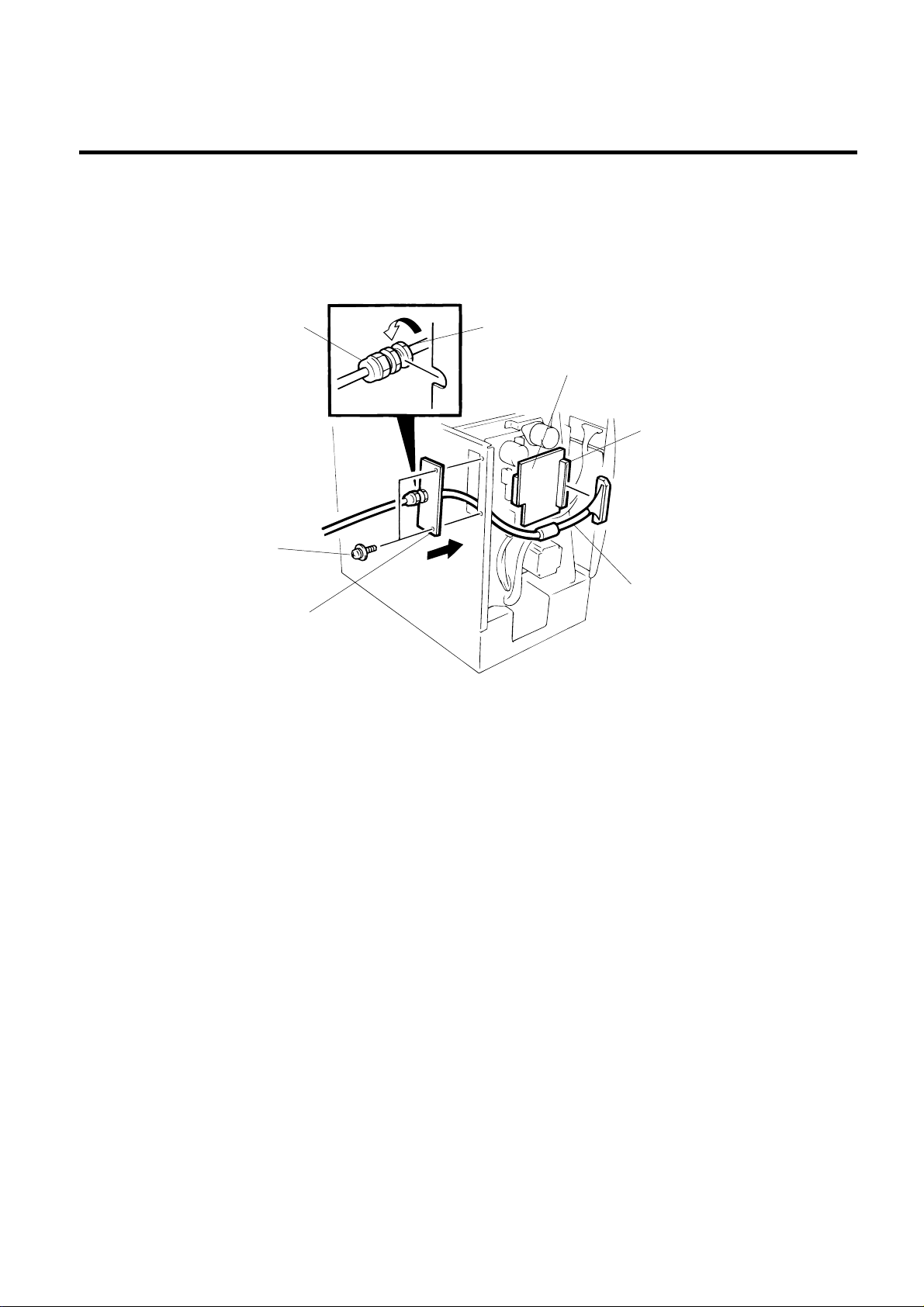

6) Install the cutter unit with the attached four screws (cutter attaching screw, SM-4x6C and

FL-4x6).

7) Connect the cutter harness to CN1 on the cutter I/F PC board through the opening of the cutter unit.

When installing the cutter, make sure that the cutter guide is not in contact with the platen. If it is, print

failure or noise may be caused.

3-3

Fig. 3-4

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

8) Connect the cutter cable to the CN15 on the CPU PC board.

CPU PC Board

(Revision Date Sep. 27 ’95)

EM18-33013

3.2 CUTTER MODULE (B-4208-QM)

Cutter Unit

Cutter Harness

9) Mount the cutter cover with the two screws.

Cutter Cover

Fig. 3-5

Screw

Cutter Attaching Screw

Fig. 3-6

10) Mount the operation panel and the left side cover on the printer.

11) Close the top and right covers.

12) After reassembly is complete, perform a test print to confirm that the cutter works properly. If the print

start position becomes misalign when media is fed in the reverse direction, fine adjust the back feed

value using the Back Feed Fine Adjustment procedure in diag. mode.

NOTES: 1. If the top edge of label winds onto the platen in cut issue, set DIP SW. 1-5 to ON.

(Refer to the Owner’s Manual.)

2. Retain the parts that are removed during installation of the cutter unit. They will be

required when the printer is modified to a standard type.

straPdevomeRtinU/yt'QstraPdevomeRtinU/yt'Q

etalptnorF1 )6x4-LF(wercS3

3-4

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

(Revision Date Apr. 7 '98)

3.3 MEMORY MODULE

EM18-33013

■ Adjusting the Cutter Guide Plates

After replacing the cutter unit the following adjustment procedure should be employed to prevent

paper jams.

1. Attach the cutter guide plate A with two SM-4 x 6C screw so that the fixed cutter is positioned 0.1

mm to 0.4 mm above the bottom of the cutter guide plate A.

2. Attach the cutter guide plate B with two FL-4 x 8 screws so that there is a clearance of 0.5 mm

between the cutter guide plate A and cutter guide plate B using a clearance gauge.

Screw

(SM-4 x 6)

Fixed Cutter

Cutter Guide Plate B

0.1 ~ 0.4 mm

0.5 mm

Fig. 3-7

Screw

(FL-4 x 8)

Cutter Guide Plate A

3.3 MEMORY MODULE

1) Open the right side cover and the top cover. (See Fig. 2-1.)

2) Remove the left side cover. (See Fig. 2-1.)

3) Remove the CPU PC board. (See Fig. 2-2.)

4) Directly connect the D-RAM PC board to CN20 on the CPU PC board, and then secure it with the

two locking support.

Locking Suppoert

CPU PC Board

D-RAM PC

Board Ass’y

IC20

MAR

yticapaC

BM20.023x3.3120.061x3.312dradnatS

BM43.166x3.3126.033x3.312noitpO

hctaBpirtStuc-otuAhctaBpirtStuc-otuA

ezisgniward.xaM

)mm()H(x)W()lamron(

eziagniward.xaM

)mm()H(x)W()ylf-eht-no(

3-5

Fig. 3-8

skrameR

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

3.4 STRIP MODULE (B-4908-H-QM)

(Revision Date Aug. 18 ’95)

EM18-33013

3.4 STRIP MODULE (B-4908-H-QM)

NOTE: This module cannot be used together with the B-4208-QM cutter module. Remove the cutter

module if it has been attached to the printer.

noitpircseDtinU/yt'Q

tinUpirtS1

ssenraHpirtS1

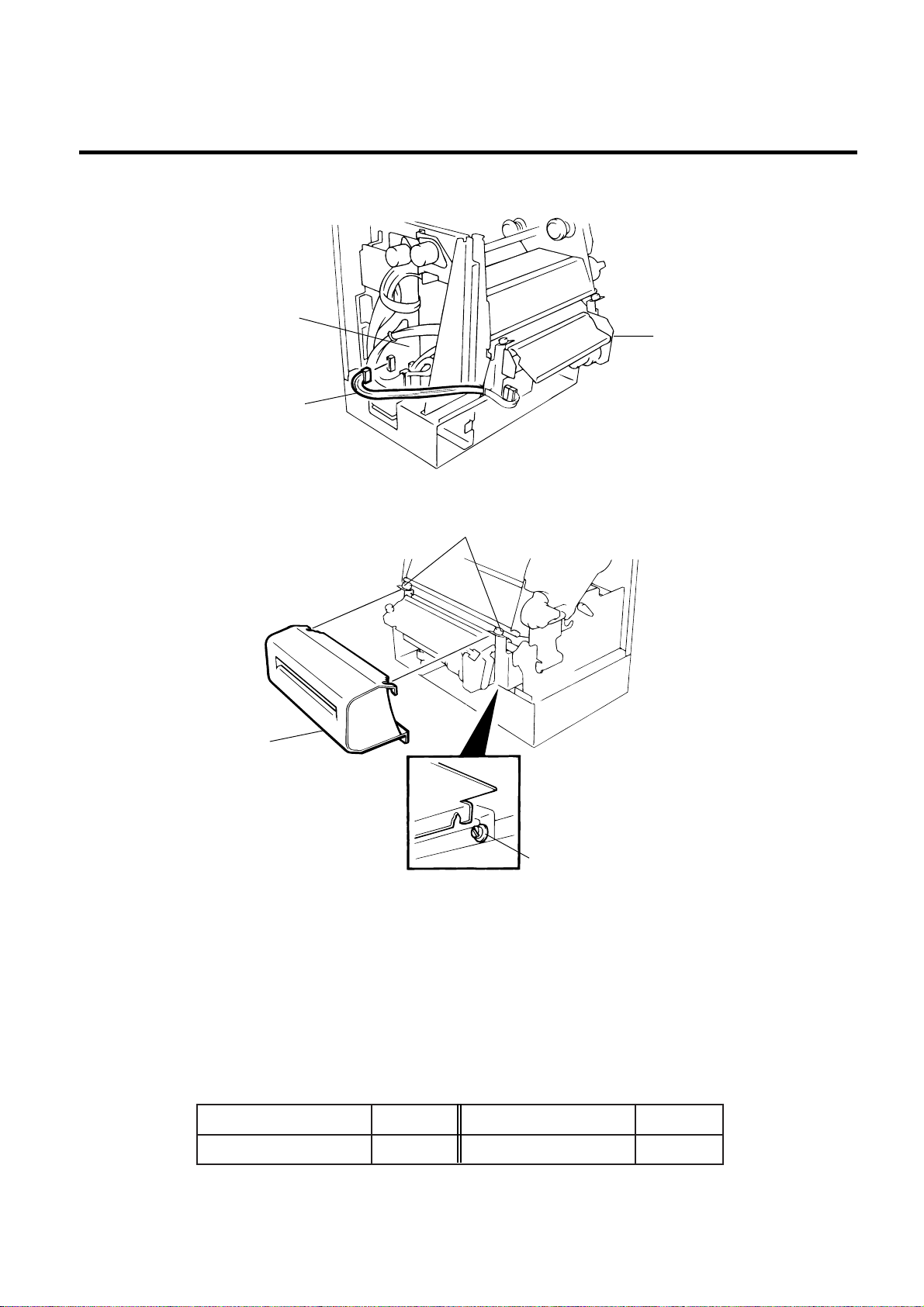

1) Open the right side cover and the top cover. (See Fig. 2-1)

2) Remove the left side cover (See Fig. 2-1)

3) Remove the front plate (See Fig. 2-6)

4) Remove the operation panel (See Fig. 3-3)

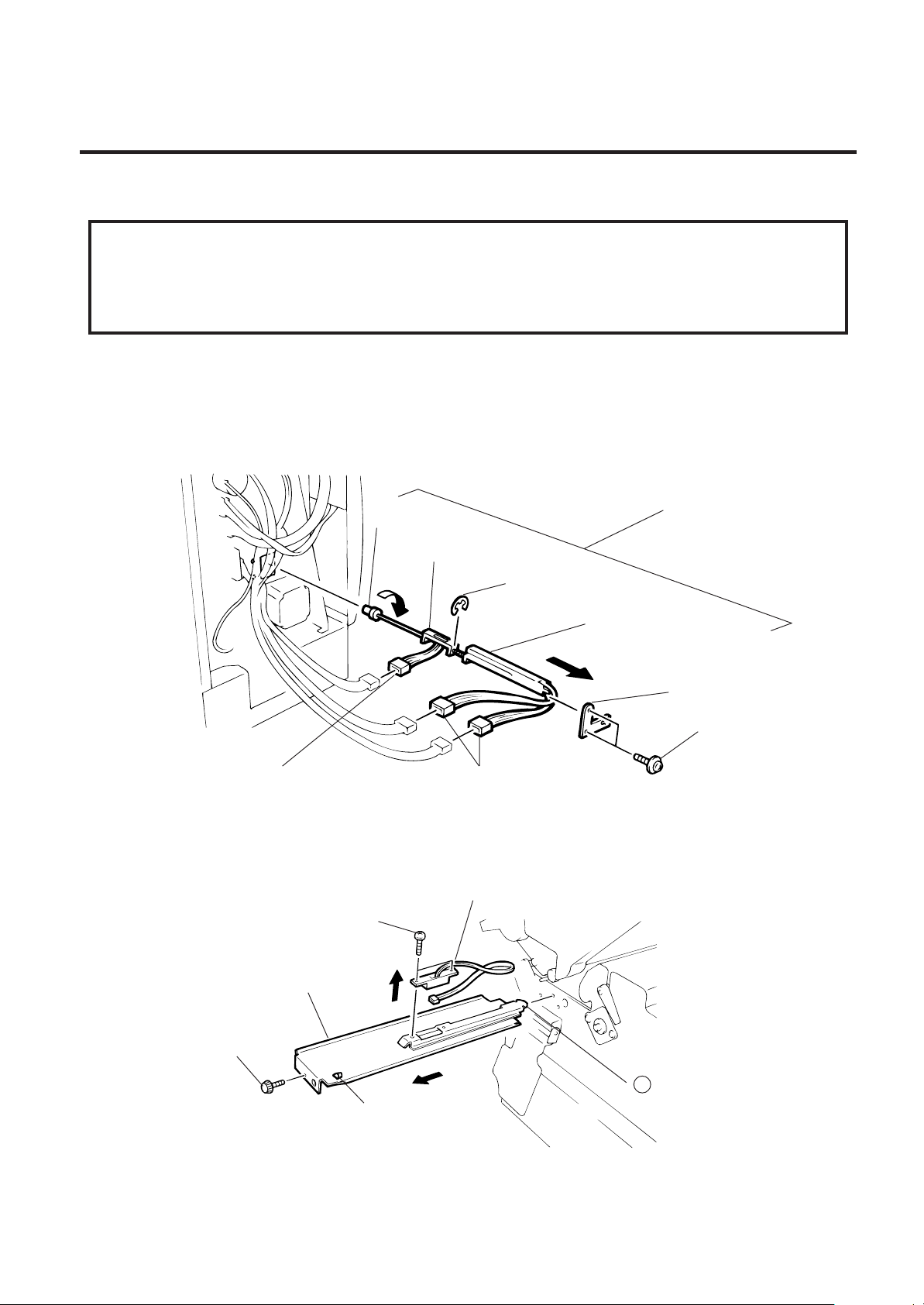

5) Connect the strip harness to the CN2 on the PWM PC board through the opening of the strip base.

6) Install the strip unit to the printer with the four FL-4 x 6 screws removed in STEP 3.

7) Connect the strip harness to the CN15 on the CPU PC board.

8) Connect the strip sensor harness to the CN12 on the CPU PC board.

CPU PC Board

CN12

CN15

Strip Harness

Screw (FL-4 x 6)

Screw (FL-4 x 6)

Strip Unit

Strip Sensor Harness

PWM PC Board

CN2

Strip Base

Screw (FL-4 x 6)

9) Mount the operation panel and the left side cover on the printer.

Strip Harness

Opening

Fig. 3-9

10) Close the top and right covers.

11) Refer to Section 6.4 of the Maintenance Manual to load the label and make a test print to check

forproper strip issue. If not, refer to Section 6.3.2 of the Maintenance Manual to adjust the strip

position.

3-6

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

3.5 STABILIZER KIT

(Revision Date: Jul. 26 ’99)

EM18-33013

3.5 STABILIZER KIT

Stabilizer PC Board Ass’y

(1 pc.)

Harness S (1 pc.) ... Yellow

Harness P (1 pc.) ... Black

Installation Manual (1 pc.)

EU Standard Sticker (1 pc.)

1) Turn the power of the printer off, then open the top cover. Remove the six screws to detach the left side

cover.

Top Cover

Left Side Cover

Screw

Screw

Screw

Fig. 3-10

2) Detach the yellow and the red cables from the CN 9 and the CN 17 on the CPU PC board.

CN9

CN17

3-7

Fig. 3-11

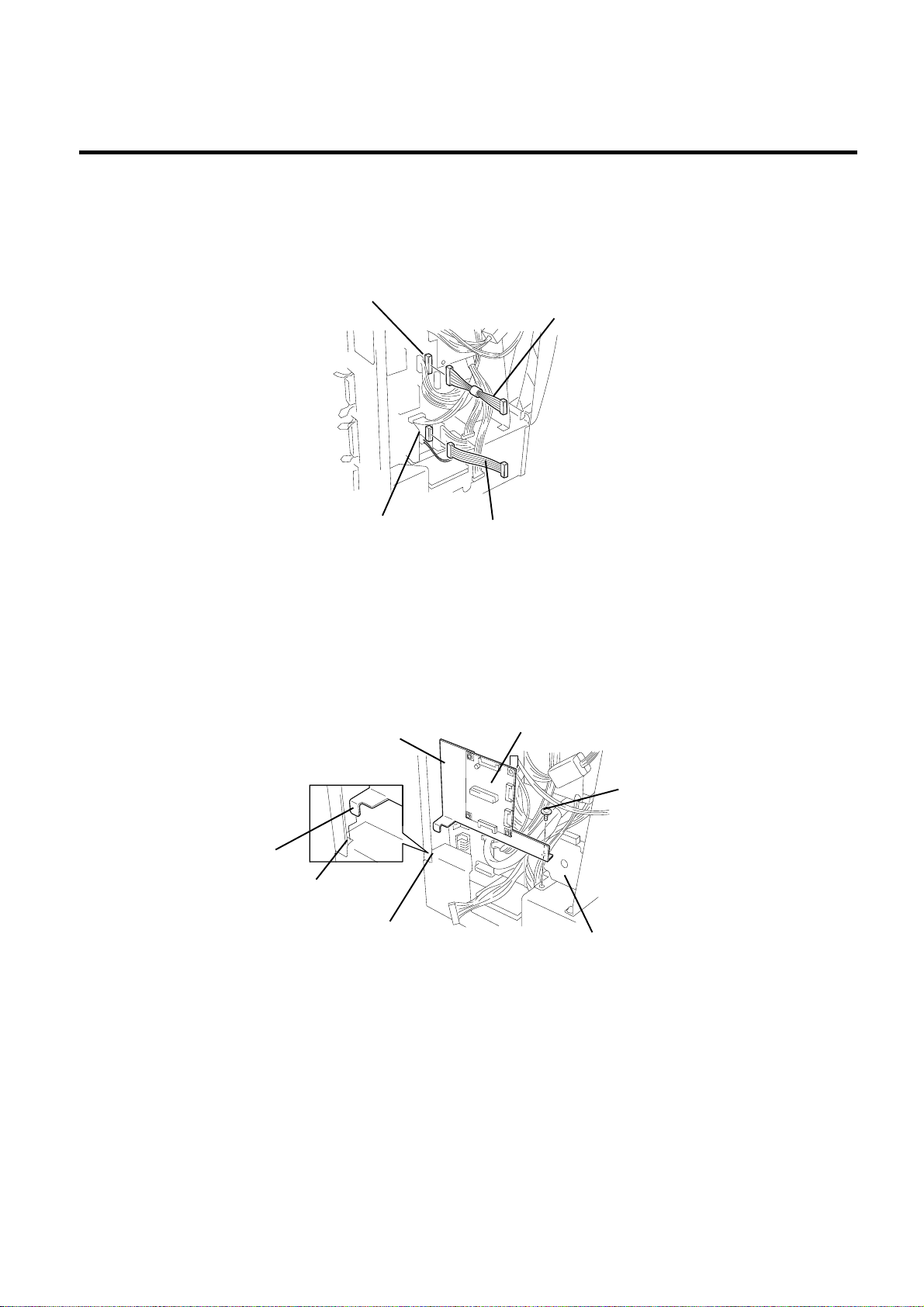

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

(Revision Date: Jul. 26 ’99)

EM18-33013

3.5 STABILIZER KIT

3) Connect the harness S (yellow) to the CN 9 on the CPU PC board and the harness P (black) to the

CN 17, respectively.

NOTE: As for the harness, connect the connector housing which has fewer pins to the connector on

the CPU PC board side.

CN9

CN17

Harness P (Black)

Harness S (Yellow)

Fig. 3-12

4) Remove the screw A, then insert the guide plate provided to the stabilizer PC board ass’y into the

square hole of the part B. Secure the stabilizer PC board ass’y using the screw A.

Guide Plate

Stabilizer PC Board Ass’y

Guide Plate

Square Hole

Part B

Screw A

Stepping Motor

Fig. 3-13

3-8

3. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT

(Revision Date: Jul. 26 ’99)

EM18-33013

3.5 STABILIZER KIT

5) Connect the harness S (yellow) to the CN 2 on the stabilizer PC board ass’y and the harness P (black)

to the CN 3, respectively. Respectively connect the red and the yellow cables detached in the step

2 to the CN 4 and the CN 5 on the stabilizer PC board ass’y.

CN 2:Harness S(Yellow) CN 4:Red cable

CN 3:Harness P (Black) CN 5:Yellow cable

NOTES: 1. The connector design prevents wrong insertion. Therefore, when you connect the

connectors, care must be taken to the connector faces and avoid forcibly pressing the

connectors.

2.After you connect the connectors, check that no looseness exists on them.

CN2

CN5

CN4

CN3

Harness P (Black)

Harness S (Yellow)

Yellow Cable

Red Cable

Fig. 3-14

6) Secure the left side cover using the six screws, then close the top cover. Stick the attached EU

standard sticker on the sticker currently stuck.

NOTE:

Care must be taken to the cables when attaching the left side cover.

3-9

ROM Version Sticker

Model Name Sticker

EU Stundard Sticker

Fig. 3-15

4. MECHANISM DESCRIPTION

4.1CUTTER DRIVE (CUTTER MODE)

EM18-33013

4. MECHANISM DESCRIPTION

4.1 CUTTER DRIVE (CUTTER MODE)

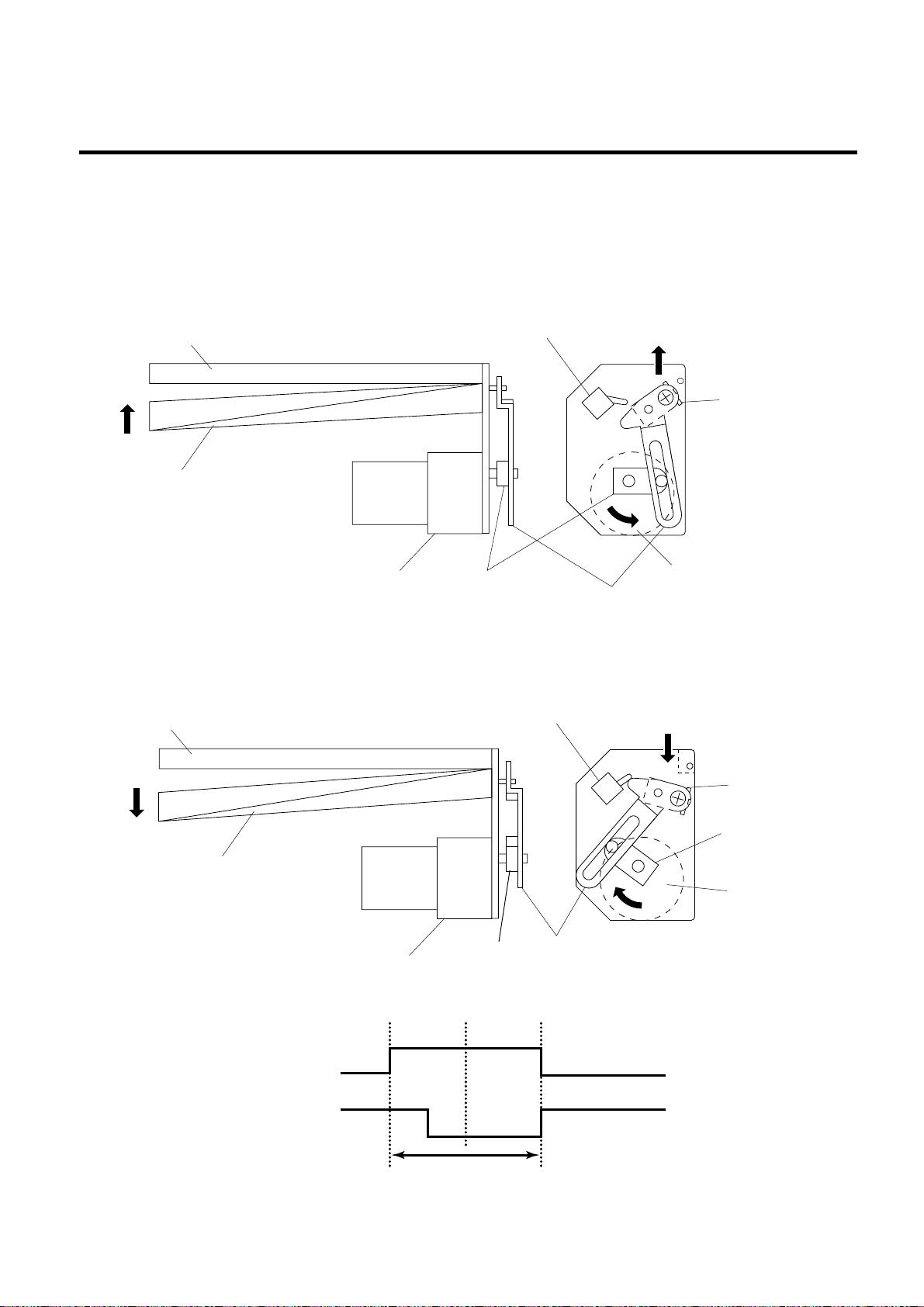

The printer supplies DC + 27 V to the cutter motor to rotate it and the clutch counter clockwise. The arm

swings like a pendulum and moves the fixed slide cutter up and down to make a cut.

Fixed Cutter

Micro Switch

Slide Cutter

Slide Cutter

Cutter Motor

Clutch

Arm

Cutter Motor

Fig. 4-1

After making a cut, the arm turns the micro switch off and the cutter home position is detected.

When the cutter does not return to the home position because of a paper jam, an error occurs and the

next piece of paper will not be cut.

Fixed Cutter

Micro Switch

Slide Cutter

Timing chart

+27

MOTOR

CHOME

Micro Switch

Cutter Motor

Open

Clutch

Close Open

Cutting

(one cycle)

4-1

Slide Cutter

Clutch

Cutter Motor

Arm

Fig. 4-2

5. TROUBLESHOOTING

5. TROUBLESHOOTING

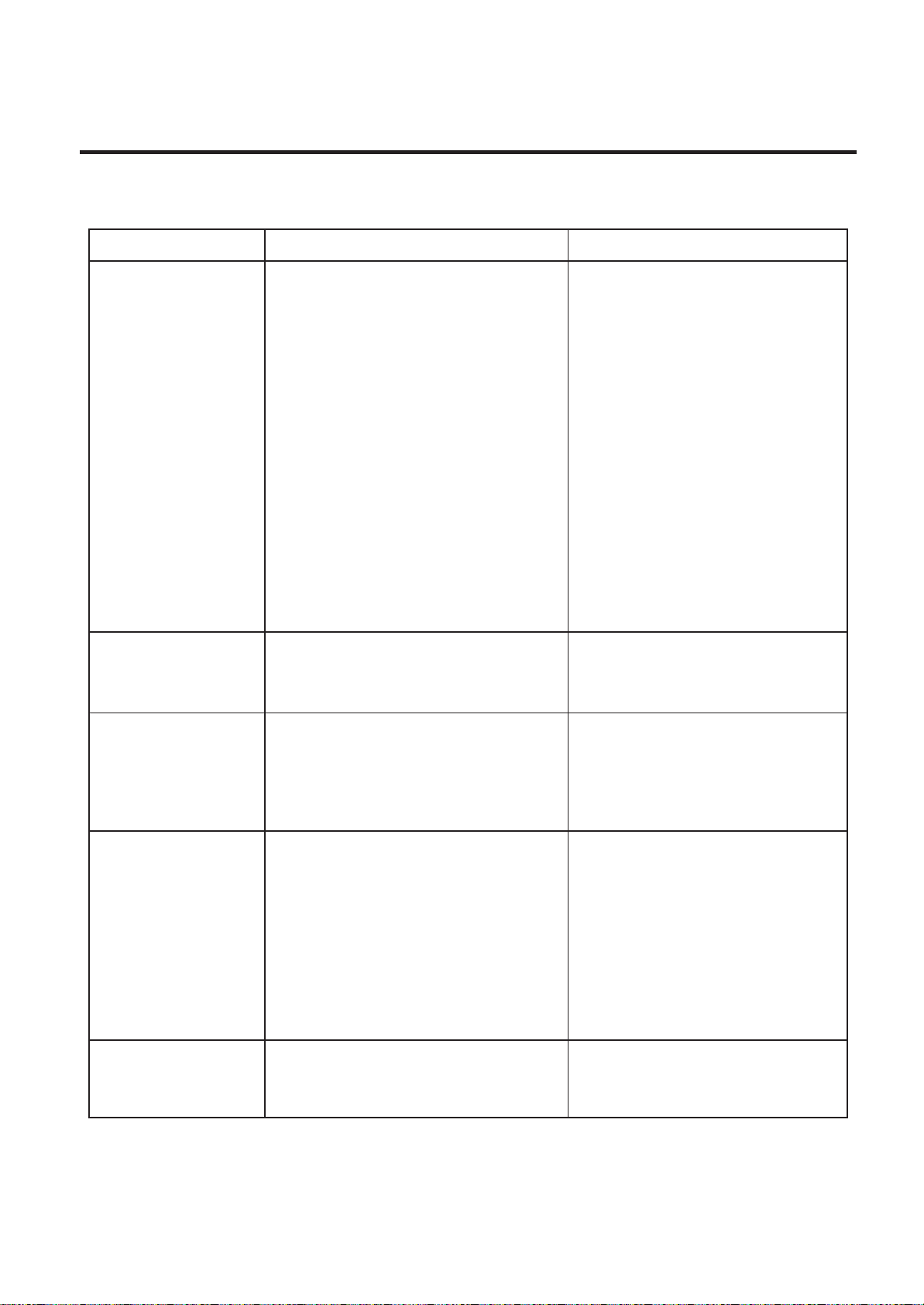

Problems Cause Solution

(Revision Date Sep. 29 ‘95)

EM18-33013

5. TROUBLE SHOOTING

Power does not turn

ON.

LED or LCD does not

light.

1. Input voltage to the printer is not

within the rated voltage.

(Check by CN1 on the PS unit.)

2.Output voltage from the printer is not

within the rated voltage.

(Check that the voltage between Pin

4 and Pin 6 (GND) of CN1 on the PS

unit is 27 V.

And check that the voltage between

Pin 11 and Pin 6 ( GND) is 5 V.)

3.No voltage to the CPU PC board.

(Check that the voltage between Pin

1 and Pin 5 (GND) of CN16 on the

CPU PC board is 27 V.

And check that the voltage between

Pin 11 and Pin 5 (GND) is 5 V.)

4.Failure of CPU PC board.

1.Failure of the LED board/LCD

2.Failure of the LCD/LED harness

3.Failure of the CPU PC board

• Replace the power cable orpower

inlet.

• Replace the PS unit.

• Replace the power harness.

• Replace the CPU PC board.

• Replace the LED board/LCD.

• Replace the LCD/LED harness.

• Replace the CPU PC board.

Poor printing

Printer does not print

Dot missing

1.The print paper is of poor quality.

2.Dirty print head

3.The head lever fastens the print head

incompletely.

1.Print head failure

2.Connection of the print head

connector is incomplete,a bad

contact, or broken wires.

3. Failure in rewinding/feeding of the

ribbon.

4.Failure of the CPU PC board

5.Failure of the software

6.Failure of the printer cable

1.Broken print head element

2.Broken print head cable wires

3.Failure of the CPU PC board

• Use the media approved by

TOSHIBA TEC.

• Clean the print head.

• Fasten the head lever completely.

• Replace the print head.

• Connect the harness completely,

or replace the harness.

• Replace the ribbon rewind motor,

ribbon feed motor or CPU board.

• Replace the CPU PC board.

• Check the program.

• Replace the printer cable.

• Replace the print head.

• Replace the print head harness.

• Replace the CPU PC board.

•

•

•

5-1

Loading...

Loading...