TEC b-472 User Manual

TEC Thermal Printer

B-470 SERIES

Maintenance Manual

Document No. EM18-33011

Original Feb., 1994

(Revised )

PRINTED IN JAPAN

EM18-33011

(Revision Date: Feb. 01 '96)

TABLE OF CONTENTS

|

|

|

Page |

|

1. |

UNPACKING ........................................................................................... |

1- 1 |

||

|

1.1 |

Procedures ...................................................................................... |

1- |

1 |

|

1.2 |

Checks ............................................................................................. |

1- 1 |

|

2. |

MAJOR UNIT REPLACEMENT .............................................................. |

2- 1 |

||

|

2.1 |

Replacing the PS Unit, I/F PC Board and CPU PC Board .............. |

2- 2 |

|

|

2.2 |

Replaceing the Stepping Motor ....................................................... |

2- |

4 |

|

2.3 |

Replacing the Ribbon Motors .......................................................... |

2- |

5 |

|

2.4 |

Replacing the Take-up Motor .......................................................... |

2- |

5 |

|

2.5 |

Replacing the Solenoid .................................................................... |

2- |

7 |

|

2.6 |

Replacing the Print Head ................................................................. |

2- |

8 |

|

2.7 |

Replacing the Platen and Feed Roller ............................................ |

2- 11 |

|

|

2.8 |

Replacing the Paper Sensor ........................................................... |

2- 13 |

|

|

2.9 |

Replacing the Ribbon Back Tension Block ..................................... |

2- 13 |

|

|

2.10 |

Replacing the Pinch Roller Shaft Ass'y .......................................... |

2- 14 |

|

|

2.11 |

Correcting Skew Priting .................................................................. |

2- 16 |

|

3. |

INSTALLATION PROCEDURE FOR |

|

|

|

|

|

THE OPTIONAL EQUIPMENTS .......................................... |

3- 1 |

|

|

3.1 |

High Speed PC Interface Board (B-4800-PC-QM) .......................... |

3- 1 |

|

|

3.2 |

Cutter Module (B-4205-QM) ............................................................ |

3- |

3 |

|

3.3 |

Memory Module ............................................................................... |

3- 5 |

|

|

3.4 |

Ribbon Saving Module (B-4905-R-QM) ........................................... |

3- 6 |

|

|

3.5 |

Strip Module (B-4905-H-QM) ........................................................... |

3- |

8 |

|

3.6 |

I/F PC Board (B-4700-IO-QM) ........................................................ |

3- 11 |

|

|

3.7 |

Fanfold Paper Guide Module (B-4905-FF-QM) .............................. |

3- 12 |

|

4. |

MECHANISM DESCRIPTIONS ............................................................... |

4- 1 |

||

|

4.1 |

Cutter Drive (Cut mode) .................................................................. |

4- |

1 |

|

4.2 |

Harness Wiring ................................................................................ |

4- |

2 |

5. |

TROUBLESHOOTING ............................................................................. |

5- 1 |

||

6. |

DIAG. TEST OPERATION ....................................................................... |

6- 1 |

||

CAUTION:

1.This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2.The contents of this manual may be changed without notification.

3.Please refer to your local Authorized Service representative with regard to any queries you may have in this manual.

Copyright © 1999

by TOSHIBA TEC CORPORATION All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

1. UNPACKING

EM18-33011

(Revision Date: Sep. 14 '95)

1.1 Procedure

1. UNPACKING

1.1 Procedure

1)Open the carton.

2)Unpack the accessories from the carton.

3)Unpack the side pad (L)/(R) and the printer from the carton.

4)Place the printer on the level surface.

|

Owner's Manual |

Unpacking Procedure |

|

|

|

Side Pad (L) |

|

Thermal Printer |

|

|

Rear Pad |

Power Cord |

|

|

Side Pad (R)

Supply Holder

Carton

Fig. 1-1

1.2 Checks

1)Check for damages or scratches on the machine.

2)Confirm that none of the accessories are missing.

NOTE: Keep the carton and side pads for later transport.

1-1

2. MAJOR UNIT REPLACEMENT

EM18-33011 (Revision Date: Dec. 09 '94)

2. MAJOR UNIT REPLACEMENT

2. MAJOR UNIT REPLACEMENT

WARNING!

Disconnect the power cord before replacing the main parts.

CAUTION:

1.NEVER separate the ribbon motors from the attaching plate, (bracket) because doing so will change their adjustment. (See Fig. 2-8)

2.NEVER remove the two screws painted red on the side of the print block. (See Fig. 2-13)

3.NEVER remove the four screws on the side of the print block. (See Fig. 2-13)

4.NEVER remove the four screws painted red fixing the right plate and reinforcing plate. (See Fig. 2-16) However, the machine with a serial number of 4Txxxxxx or later is not equipped with the red screws because of the change in the right plate shape.

5.NEVER remove unmentioned screws because doing so will change their adjustment.

1)Turn the power off.

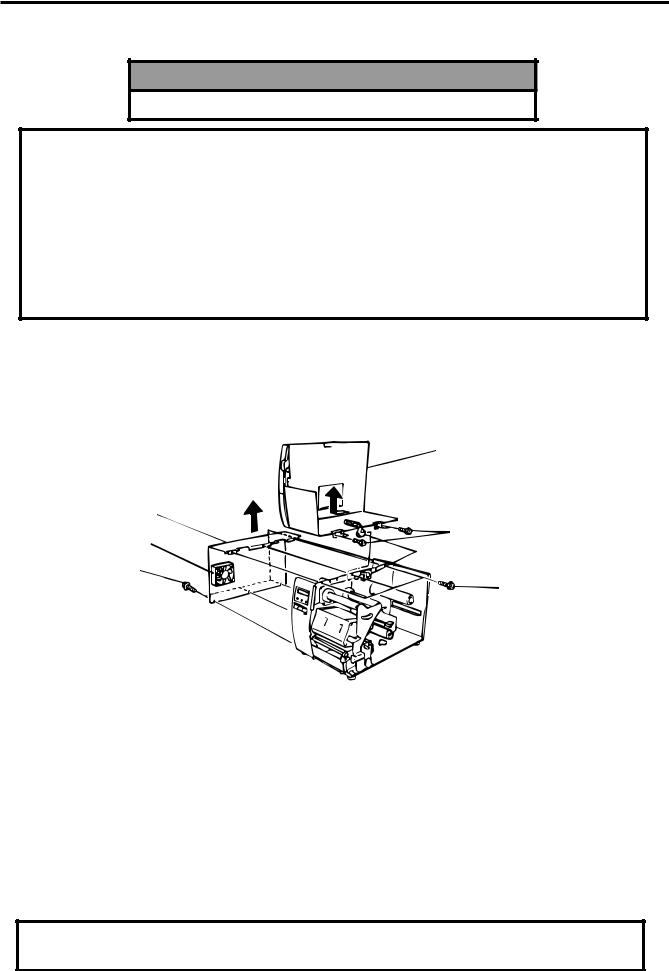

2)Open the top cover to remove the four FL-3x5 screws. Slide the top cover to the left to release the damper and remove the top cover.

3)Remove the seven screws (FL-4x5 and B-4x5) to remove the left side cover.

4)Disconnect the FAN motor connector from the PS unit.

Top Cover

Left Side Cover

Screw (FL-3x5)

FAN Motor

Damper

Screw (B-4x5)

Screw (FL-4x5)

Fig. 2-1

NOTE: Instructions to remove the top cover and left side cover are omitted from each removal/ installation procedure provided below.

■ Lubrication

CAUTION: 1. Lubrication: |

During parts replacement |

2. Kinds of oil: |

FLOIL G-488: 1kg kan (Part No. 19454906001) |

|

|

Any machine is generally in its best condition when delivered; therefore, it is necessary to try to keep this condition. Unexpected failure occurs due to lack of oil, debris or dust. To keep its best condition, periodically clean the machine and apply proper kinds of oil to each part in which lubrication is needed. Although the frequency of lubrication varies according to how much the machine is used, at least it is necessary to lubricate before the machine becomes dry. It is also necessary to wipe off excessive oil as it collects dirt.

CAUTION: Do not spray the inside of the printer with lubricants unsuitable oil can damage the mechanism.

2-1

2. MAJOR UNIT REPLACEMENT

EM18-33011 (Revision Date: Oct. 14 '94)

2.1 Replacing the PS Unit, I/F PC Board and CPU PC Board

2.1 Replacing the PS Unit, I/F PC Board and CPU PC Board

CAUTION: Replace only with same type and ratings of fuse for continued protection against risk of fire.

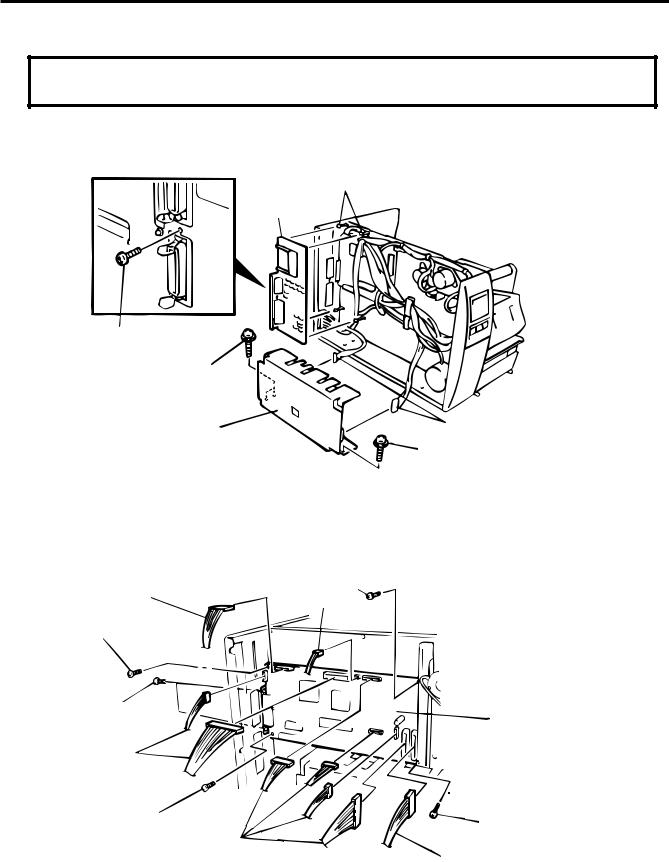

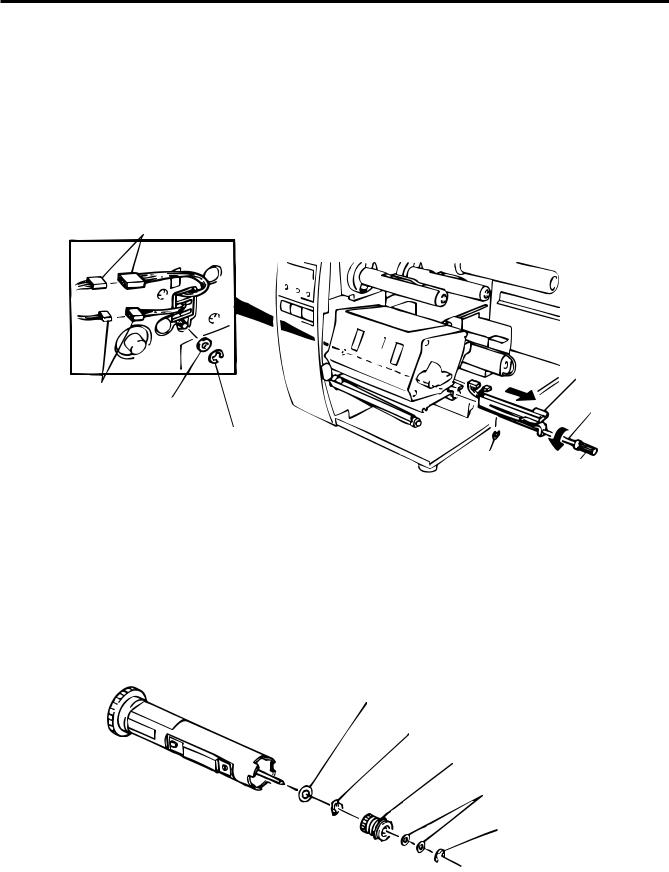

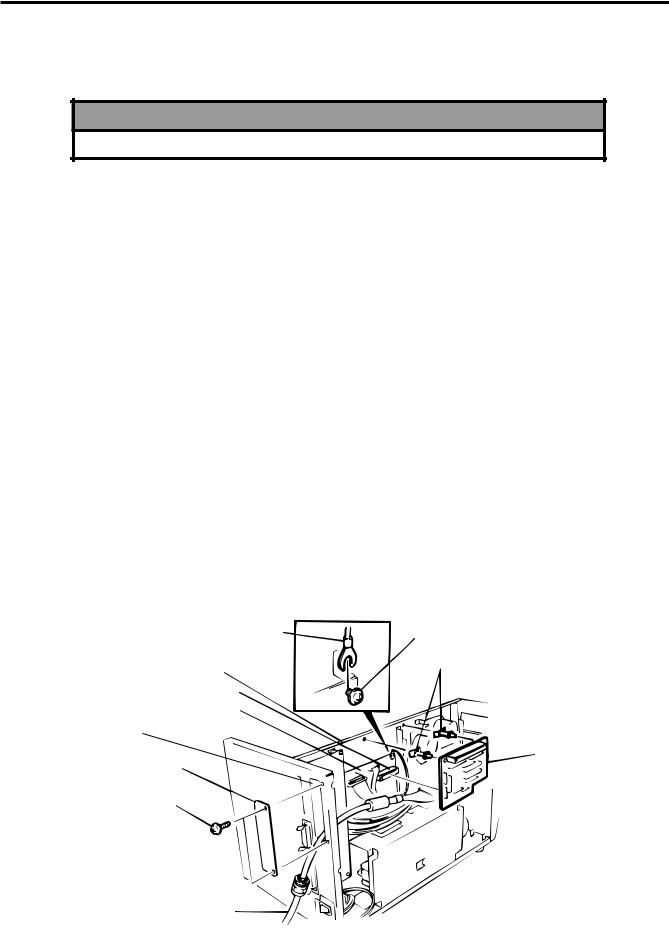

1)Remove the three FL-4x6 screws and disconnect the two connectors to detach the PS unit.

2)Remove the FL-3x5 screw and the four locking supports to remove the I/F PC board.

Locking Support

I/F PC Board

Screw (FL-3x5)

Screw (FL-4x6)

PS Unit |

Connector |

|

Screw (FL-4x6)

Fig. 2-2

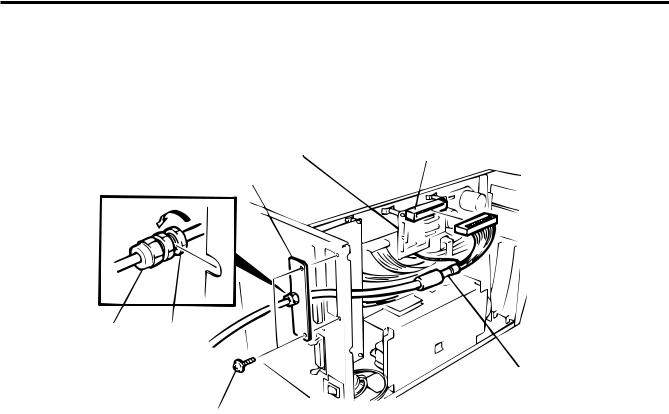

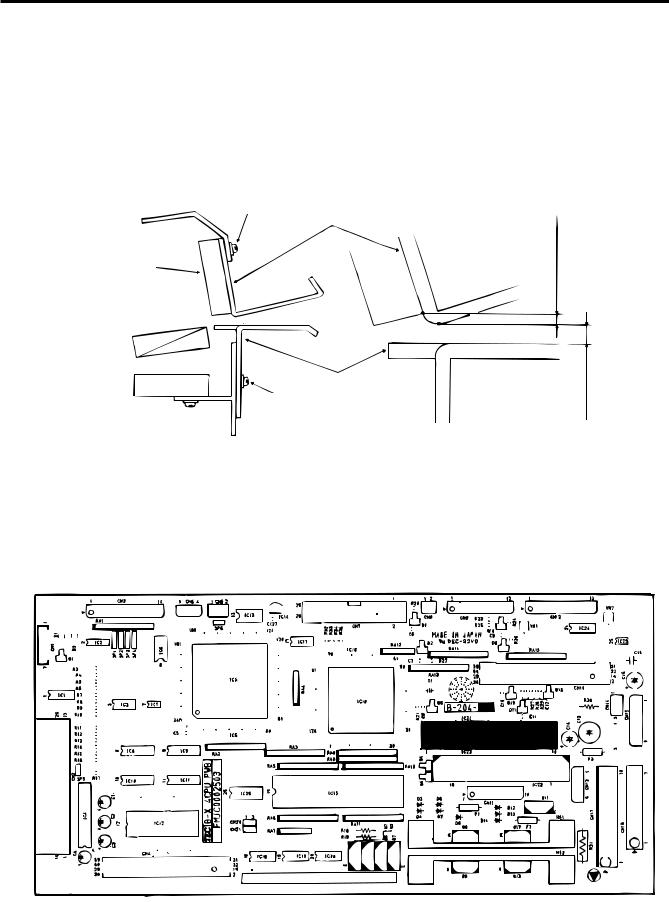

3)Disconnect the 9 connectors from the CPU PC board.

4)Remove the six screws (SM-3x6B, SM-3x6C) to detach the CPU PC board from the printer.

Screw (SM-3x6B)

Connector |

Connector |

|

|

Screw (SM-3x6B) |

|

Screw (SM-3x6C)

CPU PC Board

Connector

Screw (SM-3x6B) |

Screw (SM-3x6B) |

Connector

Connector

Fig. 2-3

5)Replace the PS unit, I/F PC board and CPU PC board. Insert the connectors correctly and install in the reverse order of removal above. Do not mount the left side cover and top cover.

6)Make sure to adjust the various voltages after replacing the CPU PC board.

2-2

2. MAJOR UNIT REPLACEMENT

EM18-33011

2.1 Replacing the PS Unit, I/F PC Board and CPU PC Board

7) Adjust the ribbon end sensor.

Use the following Ribbons; TTM-78 (Maker: Fujicopian)

1 Set the ribbon so that the ribbon end sensor can detect the ribbon. Turn the power on.

2 Turn the VR1 so that the voltage between Pin 1 (GND) and Pin 7 of CN12 is 3.0 ± 0.2 V with an oscilloscope.

3 Turn the power off and mount the left side cover and top cover.

Fig. 2-4

Range: 1 V / 0.2 m sec.

Voltage

3.0 ± 0.2 V

VR1

GND

Fig. 2-5

8)Adjust the black mark sensor.

As the black mark sensor is adjusted by key entries in system mode, refer to page 6-38 for the adjustment procedure.

9)Adjust the feed gap sensor.

As the feed gap sensor is adjusted by key entries in system mode, refer to page 6-39 for the adjustment procedure.

CAUTION: Be careful when replacing the CPU PC board, since a non-resettable counter (IC13) is installed on this board. (Refer to Section 6.2.1 Maintenance Counter Printing.)

If this counter should be reset, replace IC13.

2-3

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Apr. 05 '94)

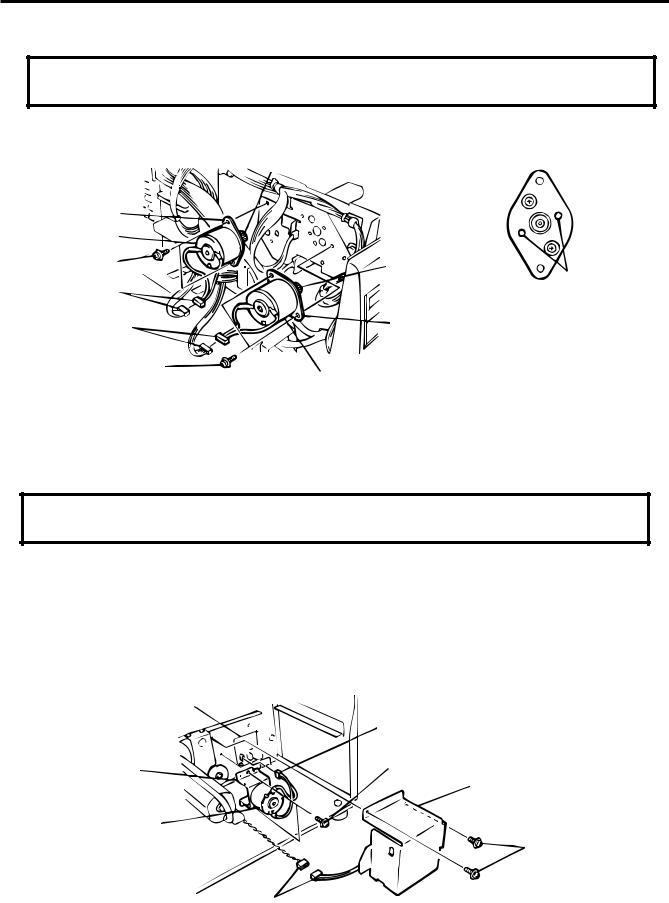

2.1 Replacing the Stepping Motor

2.2 Replacing the Stepping Motor

1)Remove the two black screws to detach the front plate, remove the two FL-4x6 screws to detach the belt cover.

Front Plate

Belt Cover

Black Screw |

Screw (FL-4x6) |

Fig. 2-6 |

|

2)Unclamp and disconnect the connector from CN13 on the CPU PC board.

3)Remove the two SM-4x10C screws, loosen the two belts from the pinion gear, and remove the stepping motor.

Partition

Platen Belt

CPU PC Board |

Clamp |

Screw (SM-4x10C)

CN13

Pinion Gear

Feed Roller Belt

PS Unit

Stepping Motor

Fig. 2-7

4)When replacing the stepping motor, place the platen belt first then the feed roller belt around the pinion gear so that the partition is positioned between two belts. Hold down the stepping motor at 3.5 kg ± 300 g force and secure it so that the belts have no slack or disengagement.

5)Reassemble in the reverse order of removal.

2-4

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Apr. 05 '94)

2.3 Replacing the Ribbon Motors

2.3 Replacing the Ribbon Motors

CAUTION: NEVER separate the ribbon motors from the attaching plate because doing so will change their adjustment.

1) Disconnect the connector and remove the two SM-3x5B screws to detach the ribbon motors.

FLOIL G-488

Attaching Plate |

|

|

Ribbon Motor |

|

|

Screw (SM-3x5B) |

FLOIL G-488 |

|

|

Dowels |

|

Connector (Red) |

|

|

|

|

|

Connector (Black) |

Attaching Plate |

|

Screw (SM-3x5B) |

Ribbon Motor |

Fig. 2-8 |

|

|

2)Replace the ribbon motors, then align the dowels to attach the ribbon motors. Reassemble in the reverse order of removal.

2.4 Replacing the Take-up Motor

CAUTION: NEVER separate the take-up motor from the bracket because doing so will change the adjustment.

NOTE: The following procedure can be employed without removing the top cover and left side cover.

1)Remove the four FL-3x5 screws to detach the motor cover.

2)Remove the connector for the rewind full sensor (LED).

3)Disconnect the connector from the CN1 on the PWM PC board and remove the two FL-3x5 screws to detach the take-up motor.

PWM PC Board

Connector (CN1)

Bracket |

Screw (FL-3x5) |

Motor Cover

Take-up Motor

Screw (FL-3x5)

Fig. 2-9

Connector

4)Replace the take-up motor, then align the dowels to attach the motor cover and rewind full sensor (Tr).

2-5

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Apr. 05 '94)

2.5 Replacing the Solenoid

2.5 Replacing the Solenoid

NOTE: The following procedure can be employed without removing the top cover and left side cover.

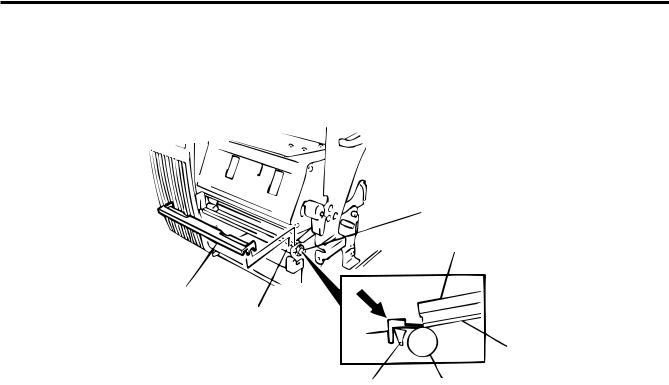

1)Before removing the ribbon stopper, check its attaching direction for later installation. Remove the ribbon stopper from the ribbon shaft on which the ribbon is wound.

2)Remove the two SM-4x8B screws, disconnect the connector CN1 on the RSV PC board to detach the solenoid unit.

Connector CN1 (3 pin) |

Screw (SM-4x8B) |

|

Solenoid Attaching Plate |

Ribbon Shaft

CN2 (2 pin)

Ribbon Stopper

RSV PC Board

Print Block

Fig. 2-10

3)Remove the two SM-3x5B screws and disconnect the connector CN2 on the RSV PC board to detach the solenoid.

Solenoid

Connector CN2 (2 pin)

Solenoid Attaching Plate

RSV PC Board

Screw (SM-3x5B)

Fig. 2-11

2-6

2. MAJOR UNIT REPLACEMENT

EM18-33011

2.5 Replacing the Solenoid

NOTE: Make sure to remove any dust that appears during removal or installation because it may affect the print quality.

4)Replace the solenoid and attach it to the solenoid attaching plate.

5)Assemble the solenoid unit so that the head up link engages the spring pin.

Solenoid

Spring Pin

Head Up Link

Fig. 2-12

CAUTION: Take care to orient the screw so that they are vertically aligned with the solenoid attaching plate.

6) Reasemble in the reverse order of removal.

2-7

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Feb. 01 '96)

2.6 Replacing the Print Head

2.6 Replacing the Print Head

CAUTION:

1.NEVER touch the element when handling the print head.

2.NEVER touch the connector pins to avoid a breakdown of the print head by static electricity.

3.NEVER remove the two screws painted red on the side of the print block.

4.NEVER remove the four screws on the side of the printer block.

5.NEVER remove the print block, otherwise it requires the adjustment of the position when reassembling.

NOTE: The following procedure can be employed without removing the top cover and the left side cover.

2.6.1 Old type print head

1)Turn the head lever clockwise to lower the print head. Remove the two SM-4x8B screws.

2)Turn the head lever counter clockwise and disconnect the two connectors to detach the print head from the print block.

Screws

(NEVER remove these screws.)

Screw (SM-4x8B)

Print Block

Connector

Screws painted red

(NEVER remove these screws.)

Head Lever

Print Head |

Connector |

|

Fig. 2-13

3)Replace the print head, connect the connectors and install it in the print block.

4)Turn the head lever clockwise. Push the print head and secure it temporarily. Follow the procedure on the next page.

2-8

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Feb. 01 '96)

2.6 Replacing the Print Head

■ Adjusting the print head position

1 Fit the jig in the platen and strip shaft.

2 Press the jig at an angle of 45 until it is sung against the print head. Then secure the print head.

Platen

Print Head

Jig

Strip Shaft

Jig |

Ceramic |

Strip Shaft |

Platen |

Fig. 2-14

3 Remove the jig.

4 Refer to page 6-42 and clear the maintenance counter.

5 Refer to page 6-30 and perform test print.

NOTE: Use caution to prevent damage to the element during adjustment of the print head.

2-9

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Feb. 01 '96)

2.6 Replacing the Print Head

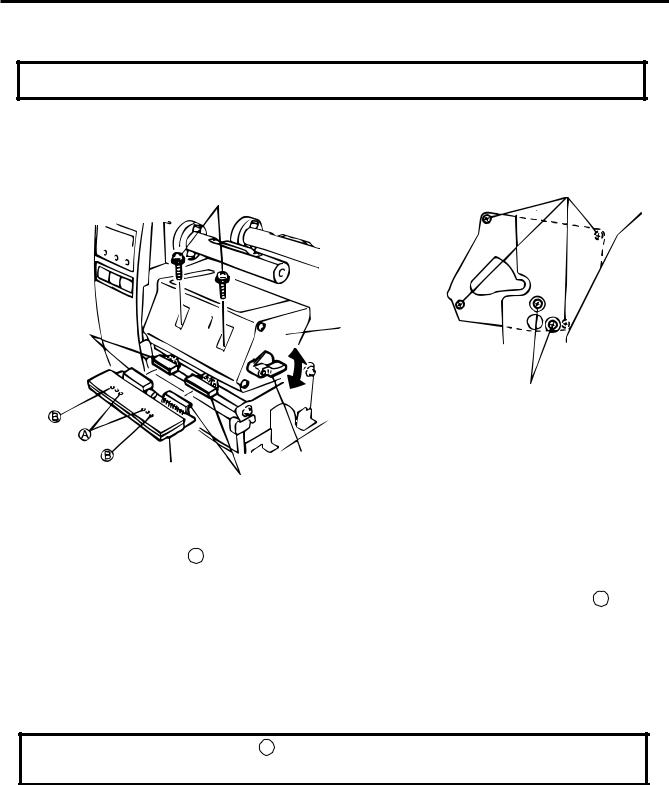

2.6.2 New type print head

NOTE: Never loosen screws other than two SM-4x8B.

1)Turn the head lever clockwise to lower the print head. Remove the two SM-4x8B screws.

2)Turn the head lever counterclockwise and disconnect the two connectors to detach the print head from the print block.

Screws

(NEVER remove these screws.)

Screw (SM-4x8B)

Connector |

Print Block |

|

Screws painted red

(NEVER remove these screws.)

Head Lever

Print Head

Connector

Fig. 2-15

3)Replace the print head and connect the connectors.

4)Align the two holes A in the middle of the print head with the print head position adjusting pins provided in the print block and fit the print head into the print block.

5)Turn the head lever clockwise and secure the print head with screws in the holes B .

NOTE: Use caution to prevent damage to the element during print head adjustment.

■Adjusting the print head position

When print tone becomes light from using special paper with improper print head position, please follow the procedure below and adjust the print head position.

NOTE: Never loosen screws C unless print position fine adjustment is required because they have been adjusted properly. Doing so will change the adjustment.

2-10

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Feb. 01 '96)

2.6 Replacing the Print Head

Print Head Bracket

Print Head

(securing the print head)

(securing the print head)

(securing the adjusting pin) (Print Head Position

Adjusting Pin)

Fig. 2-16

(1)Loosen the screws c securing the print head position adjusting pin.

(2)Loosen the screws b one by one, slightly move the print head backward or forward, and then tighten the screws b and c . Ensure that the print head is parallel to the platen. If not, print tone will be uneven.

(3)Make a test print and if necessary, repeat Step 2) until the printer prints properly.

2.7Replacing the Platen and Feed Roller

CAUTION:

1.NEVER remove the four screws painted red fixing the right plate and reinforcing plate. (See Fig. 2-16)

2.The pinch roller belt assembled inside the printer does not need to be replaced because it receives less load.

1)Remove the front plate and belt cover. (See Fig. 2-6.)

2)Turn the head lever counterclockwise, then release the ribbon shaft holder plate.

E-ring (M3)

Head Lever

Hold Shaft

Ribbon Shaft Holder Plate

Fig. 2-17

2-11

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Sep. 29 '95)

2.7 Replacing the Platen and Feed Roller

3)Disconnect the connector for the strip sensor (LED).

4)Remove the six screws (FL-4x6, B-4x12 and P-3x12) to detach the right plate Ass’y.

|

Right Plate |

|

|

Screw (B-4x12) |

|

|

Screw (FL-4x6) |

|

Connector |

Screws painted red |

|

Strip Sensor (LED) |

(NEVER remove these screws.) |

|

Screw (P-3x12) |

Screw (B-4x12) |

|

Fig. 2-18 |

||

|

NOTE: The machine with a serial number of 4Txxxxxx or later is not equipped with the red screws because of the change in the right plate shape.

5)Loosen the two screws (SM-4x8B) fixing the stepping motor to loosen the platen belt and feed roller belt.

6)Remove the platen belt to detach the platen. Remove the feed roller belt to detach the feed roller.

7)Remove both bearings from the platen or feed roller.

Feed Roller Belt

Holder

Feed Roller (Gray)

Platen Belt

Holder

Holder

Platen (Black)

Fig. 2-19

8)Replace the platen and feed roller, put on the belt and assemble it with the printer. The longer belt is the platen belt.

9)Attach the right plate.

10)Hold down the stepping motor and secure it so that the belts have no slack or disengagement.

11)Reassemble in the reverse order of removal.

2-12

2. MAJOR UNIT REPLACEMENT

EM18-33011

2.8 Replacing the Paper Sensor

2.8 Replacing the Paper Sensor

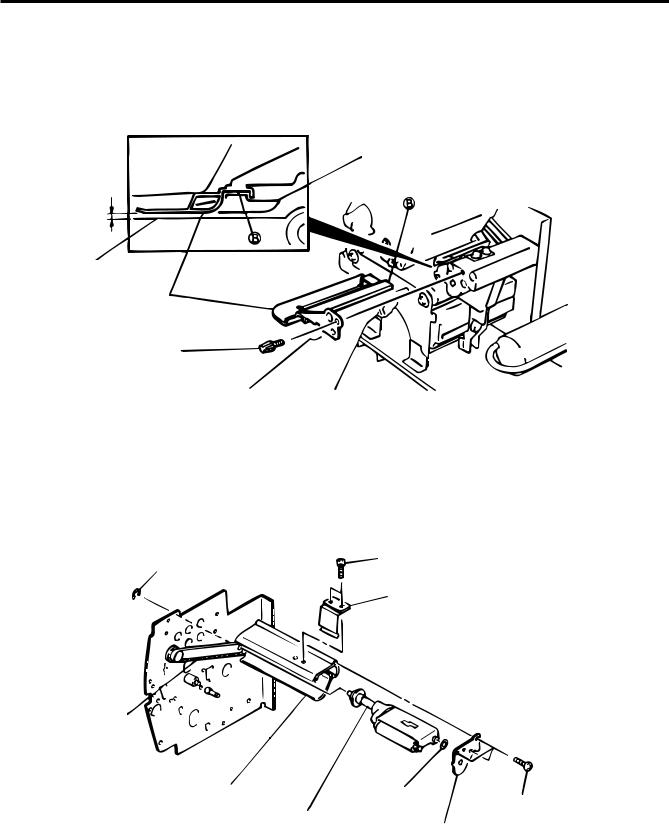

NOTE: Turn the knob until the paper sensor reaches full forward.

1)Disconnect the connector for the strip sensor (LED) to remove right plate ass’y. (See Figs. 2-17 and 2-18.)

2)Disconnect the connectors for the paper sensor.

3)Remove M1.5 E-ring, M3 washer and paper sensor unit.

4)Remove M1.5 E-ring, turn the knob counter clockwise, then remove the paper sensor.

Connector (4 pin)

|

|

Paper Sensor |

Connector (2 pin) |

|

|

Washer (M3) |

|

Sensor Shaft |

(24A62101030) |

|

|

|

|

|

E-ring (M1.5) |

|

|

(24A64250F50) |

E-ring (M1.5) |

|

|

Knob |

|

|

(24A64250F50) |

|

|

|

Fig. 2-20

5)Replace the paper sensor and reassemble in the reverse order of removal.

6)After replacing the paper sensor, refer to page 6-32/6-33 and adjust the voltage.

2.9 Replacing the Ribbon Back Tension Block

1)Turn the head lever counterclockwise, then release the ribbon shaft holder plate.

2)Remove the M3 E-ring and the two M3 washers to remove the ribbon back tension block. At this time, remove the back tension stopper and ribbon back tension washer from the ribbon back tension block.

Ribbon Back Tension Washer

Back Tension Stopper

Ribbon Back Tension Block

Washer (M3) (24A62101030)

E-ring (M3) (24A64050030)

Fig. 2-21

3) Replace the ribbon back tension block and reassemble in the reverse order of removal.

2-13

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Sep. 29, '95)

2.10 Replacing the Pinch Roller Shaft Ass'y

2.10Replacing the Pinch Roller Shaft Ass’y

1)Turn the head lever to position 3, and release the ribbon shaft holder plate.

2)Remove the black screw to detach the media guide plate.

Media Sensor

1.5 ~ 2.5 mm

Printer Block Base

Media Guide Plate

Black Screw (HAA-0004001)

Fig. 2-22

3)Remove the SM-4x8B screw to detach the spring plate.

4)Remove the six B-4x12 screws to detach the pinch roller cover.

5)Remove the E-5 E-ring to loosen the pinch roller belt, and remove the pinch roller shaft ass’y.

SM-4x8B

E-5

Spring Plate

Pinch Roller Belt

Pinch Roller Cover |

W-8 |

B-4x12

Pinch Roller Shaft Ass'y

Pinch Roller Cover

Fig. 2-23

6)After replacing the pinch roller shaft ass’y, make the following adjustment while you reassemble the pinch roller shaft ass’y in the reverse order of removal.

2-14

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Sep. 29, '95)

2.10 Replacing the Pinch Roller Shaft Ass'y

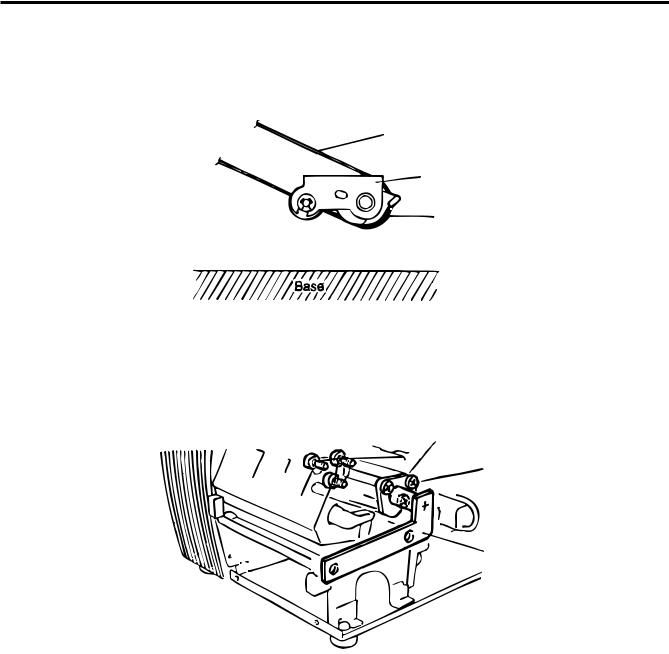

■Adjustment

1.Install the pinch roller unit so it parallels the base. If it does not, change the engaging position of the pinch roller belt and the pulley.

Pinch Roller Belt

Pinch Roller Unit

Pulley

Fig. 2-24

2.Attach the jig to the platen, feed roller and pinch roller shaft as shown in the figure below. Then attach the pinch roller cover to the pinch roller frame with the three B-4x12 screws. Then secure the pinch roller frame with the three B-4x12 screws.

Pinch Roller Cover

B-4x12 (6 screws)

Jig

Fig. 2-25

NOTES: 1. Replace the platen and the feed roller prior to attaching the jig.

2.Attach the jig while the pinch roller frame is tentatively attached to the main frame with the B-4x12 screws. Secure the pinch roller cover to the pinch roller frame with the three B-4x12 screws, then tighten the other side of the screws.

3.The flat top of the pinch roller frame must be installed in parallel to bosses on the printer frame.

Check

1 Check if excessive load is applied to the jig after the above NOTE 2.

(For example, check if the pinch roller frame moves when the jig is removed.)

2Check that there is no gap caused by a slant shaft between the pinch roller and the feed roller when the pinch roller is lowered.

2-15

2. MAJOR UNIT REPLACEMENT

EM18-33011

(Revision Date: Sep. 29, '95)

2.10 Replacing the Pinch Roller Shaft Ass'y

3.Turn the head lever clockwise to lock the pinch roller shaft ass’y. Attach the spring plate to the pinch roller frame with the two SM-4x8B screws, pushing the spring plate toward the rear of the printer.

SM-4x8B

Pinch Roller Frame

Spring Plate

Pinch Roller Shaft Ass'y |

Fig. 2-26 |

NOTE: Check that the pinch roller shaft ass’y moves up and down smoothly when turning the head lever clockwise/counterclockwise.

4.Install the media guide plate to the printer so there is a 1.5 to 2.5 mm gap between the media guide plate and the printer block base.

2.11 Correcting Skew Printing

•If media still skews after adjusting the pinch roller shaft ass’y with the jig, follow the procedure below to correct the skew problem.

1.Check if the media skews right or left.

2.Loosen the B-4x12 screw to move the pinch roller cover to the front or rear of the printer depending on the skew direction.

Fig. 2-27

When the media skews right, move the pinch roller cover to the front.

When the media skews left, move the pinch roller cover to the rear.

•If a paper skew problem should occur when using rolls wound with labels facing outside after completing the modification, adjust the paper guide as follows.

*In case the label skews to the right side of the print head, move the guide downward.

*In case the label skews to the left side of the print head, move the guide upward.

Guide Plate

Fig. 2-28

2-16

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT |

EM18-33011 |

(Revision Date: Apr. 05 '94)

3.1 High Speed PC Interface Board (B-4800-PC-QM)

3.INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

WARNING!

Make sure to unplug the power cord before installing the optional equipment.

3.1 High Speed PC Interface Board (B-4800-PC-QM)

The high speed PC interface board can be used together with the IBM PC-AT or its compatible machine only.

Description |

Q'ty/Unit |

|

Description |

Q'ty/Unit |

|

|

|

|

|

BPE PC board |

1 |

|

Locking support |

2 |

|

|

|

|

|

BPC PC board |

1 |

|

Program diskette |

1 |

|

|

|

|

|

Printer cable |

1 |

|

Manual |

1 |

|

|

|

|

|

Cable support |

1 |

|

|

|

|

|

|

|

|

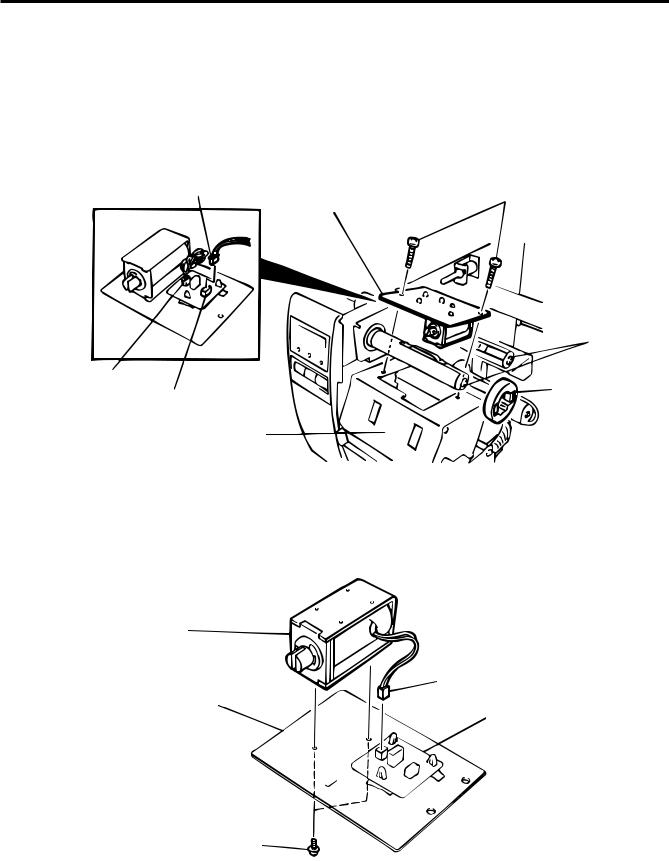

1.Remove the top cover and left side cover. (See Fig. 2-1.)

2.Remove the two FL-3 x 5 screws to detach the blind plate.

3.Pass the printer cable through the opening.

4.Fasten the ground wire of the printer cable to the CPU PC board at the upper right with the SM-3 x 6B screw securing the CPU PC board.

5.Attach the two locking supports to the main frame plate. Install the BPE PC board aligning with the connector (CN10) and locking supports.

Ground Wire |

Screw (SM-3x6B) |

|

Locking Supports

Main Frame Plate

Connector (CN10)

CPU PC Board

Opening

BPE PC Board

Blind Plate

Screw (FL-3x5)

Printer Cable

Fig. 3-1

3-1

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT |

EM18-33011 |

(Revision Date: Apr. 05 '94)

3.1 High Speed PC Interface Board (B-4800-PC-QM)

6.Connect the printer cable to the connector (CN1) on the BPE PC board.

7.Put the cable strain relief of the printer cable in the notch of the cable support plate. Secure the cable strain relief to the cable support plate by turning the nut.

8.Attach the cable support plate to the printer with the FL-3X5 screws removed in step 2.

BPE PC Board |

Connector (CN1) |

Cable Support

Cable Strain Relief |

Nut |

Printer Cable

Screw (FL-3x5)

Fig. 3-2

9.Reassemble in the reverse order of removal.

10.Following procedure should be employed with your PC after this.

11.Set the DIP SW. on the BPC PC board for the I/O address according to your PC.

12.Install the BPC PC board on the expansion port bus line of your PC.

13.Connect the printer cable mentioned in step 5 to the BPC PC board.

14.Insert the attached FDK into the FDD and install the data in the hard disk. Since the installation procedure is different between MS-DOS and Windows, refer to the attached manual.

15.Perform a motion check.

3-2

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

(Revision Date: Nov. 21 '97)

3.2 Cutter Module (B-4205-QM)

3.2 Cutter Module (B-4205-QM)

Description |

Q'ty/Unit |

|

Description |

Q'ty/Unit |

|

|

|

|

|

Cutter Unit |

1 |

|

Cutter Attaching Screw |

2 |

|

|

|

|

|

Cutter Cover |

1 |

|

Screw (FL-4x6) |

1 |

|

|

|

|

|

Take-up/Cutter Harness |

1 |

|

Cleaner |

1 |

|

|

|

|

|

1.Remove the top cover and left side cover. (See Fig. 2-1.)

2.Remove the front plate. (See Fig. 2-6.)

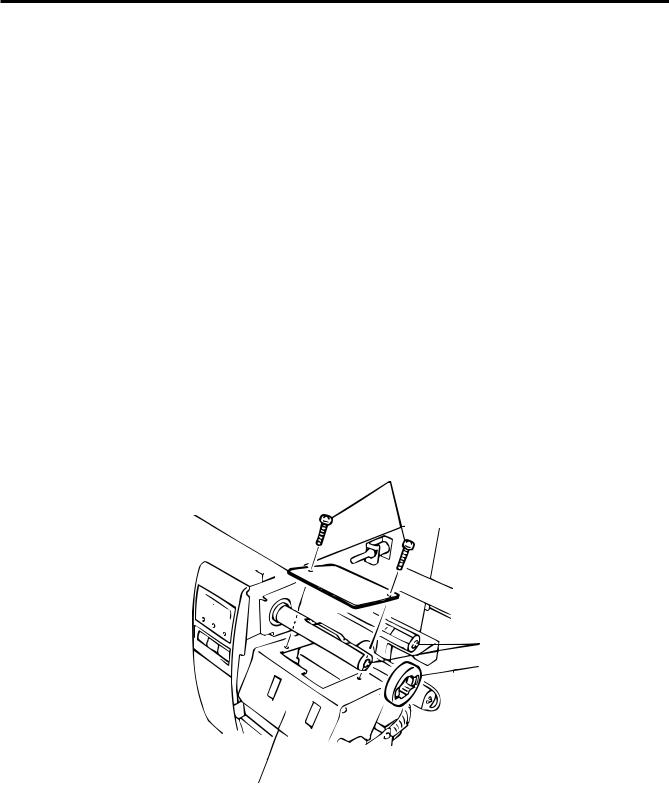

3.Remove the screw (SM-4 x 8B) and two connectors to detach the operation panel.

Screw (SM-4x8B)

Screw (SM-4x8B)

Connector

Operation Panel

Fig. 3-3

4.Install the cutter unit with the attached screws (cutter attaching screw, FL-4 x 6).When installing the cutter, make sure that the guide is not in contact with the platen. If it is, print failure or noise may be caused.

Cutter Unit

Platen

Cutter Attaching Screw |

Screw (FL-4x6) |

Cutter Guide

Fig. 3-4

3-3

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

(Revision Date: Sep. 27 '94)

3.2 Cutter Module (B-4205-QM)

5.Connect the take-up/cutter harness to CN1 on the Cutter I/F PC board and CN15 on the CPU PC Board, then fix it with the clamp.

Clamp

CPU PC Board

Cutter Unit

Cut I/F PC Board

Connector (CN1)

Take-up/Cutter Harness

Fig. 3-5

6. Mount the cutter cover with the two white screws.

Screw

Cutter Attaching Screw

Cutter Cover

Fig. 3-6

7.Reassemble the left side cover and the top cover in the reverse order of removal.

8.After reassembly is complete, perform a test print to confirm that the cutter works properly.

After printing a print sample at a speed of 6"/sec., feed the media about 33 mm and check that the swing cutter works without error. After cutting the media, feed the media about 33 mm in the reverse direction and check that it correctly stops at the print start position.

NOTES: 1. If the top edge of label winds onto the platen in cut issue, set DIP SW. 1-5 to ON.

(Refer to the Owner’s Manual)

2.Retain the parts that are removed during installation of the cutter unit. They will be required when the printer is modified to a standard type.

Removed Parts |

Q'ty/Unit |

|

Removed Parts |

Q'ty/Unit |

Front plate |

1 |

|

Black screws |

2 |

|

|

|

|

|

3-4

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

(Revision Date: Aug. 11 '95)

3.3 Memory Module

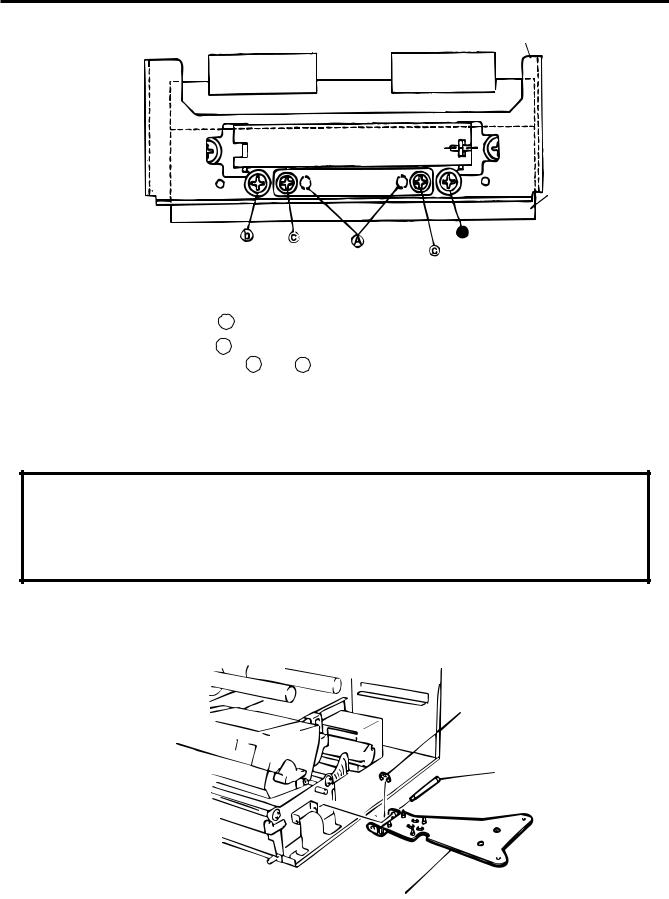

■ Adjusting the Cutter Guide Plates

After replacing the cutter unit the following adjusting procedure should be employed to prevent paper jams.

1.Attach the cutter guide plate A with two SM-4 x 6C screws so that the fixed cutter is positioned 0.1 mm to 0.4 mm above the bottom of the cutter guide plate A.

2.Attach the cutter guide plate B with two FL-4 x 8 screws so that there is a clearance of 0.5 mm between the cutter guide plate A and cutter guide plate B using a clearance gauge.

Screw (SM-4x6C)

Cutter Guide Plate A

Fixed Cutter

Cutter Guide Plate B

Screw (FL-4x8)

0.1-0.4 mm

0.5 mm

Fig. 3-7

3.3 Memory Module

1.Remove the top cover and left side cover. (See Fig. 2-1.)

2.Hold the memory module so that the Pin 1 is on the upper right, then solder the memory module to the CPU PC board. Expanding the memory must be performed in sequence, IC21 and IC22.

Fig. 3-8

3. Reassemble the left side cover in the reverse order of removal.

3-5

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

(Revision Date: Apr. 05 '94)

3.4 Ribbon Saving Module (B-4905-R-QM)

■ Expansion memory and drawing size

RAM |

|

Max. drawing size (normal) |

Max. drawing size (on-the-fly) |

|

||||

IC No. |

|

(W) x (H) (mm) |

|

(W) x (H) (mm) |

Remarks |

|||

Capacity |

|

|

|

|

|

|

|

|

|

Batch |

Strip |

Auto-cut |

Batch |

Strip |

Auto-cut |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

512KB |

IC21 |

104.0 x 384.0 |

104.0 x 192.0 |

Standard |

||||

|

|

|

|

|

|

|

|

|

1MB |

IC21, 22 |

104.0 x 896.0 |

104.0 x 448.0 |

Option |

||||

|

|

|

|

|

|

|

|

|

3.4 Ribbon Saving Module (B-4905-R-QM)

|

|

Description |

Q'ty/Unit |

|

|

|

|

|

|

|

Ribbon Saving Module |

1 |

|

|

|

|

|

|

|

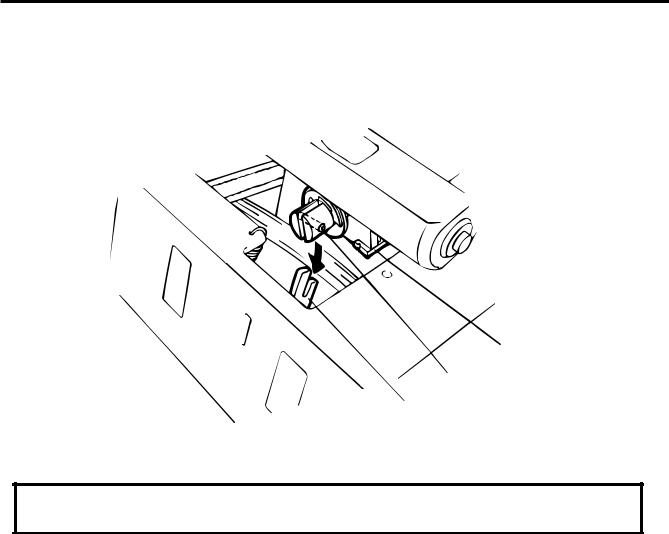

1. |

Turn the head lever counterclockwise to release the ribbon shaft holder plate. |

|||

2. |

Remove the ribbon stopper from the ribbon shaft on which the ribbon is wound. Before removing the |

|||

|

|

ribbon stopper, check its attaching direction for later installation. Remove the ribbon stopper from the |

||

|

|

ribbon shaft on which the ribbon is wound. |

||

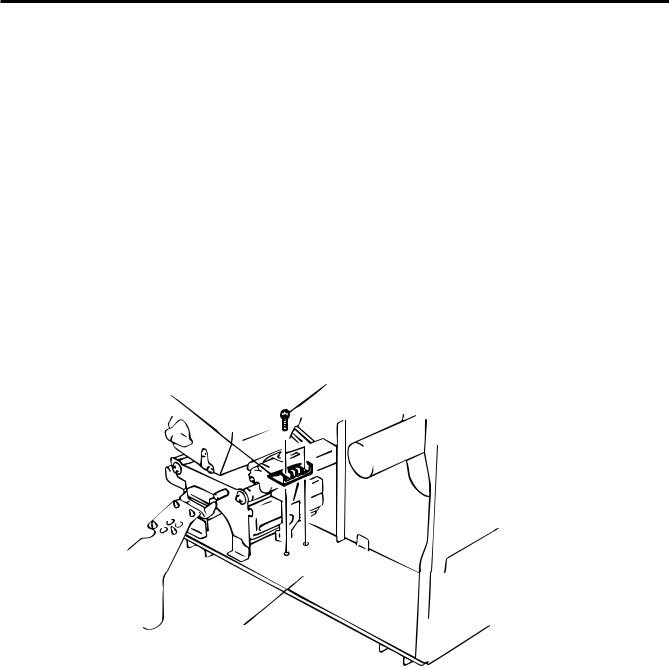

3. |

Remove the two SM-4 x 8 screws to detach the solenoid attaching plate. |

|||

Screw (SM-4x8B)

Solenoid Attaching Plate

Ribbon Shaft

Ribbon Stopper

Print Block

Fig. 3-9

3-6

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

(Revision Date: Apr. 05 '94)

3.4 Ribbon Saving Module (B-4905-R-QM)

4.Pass the solenoid harness of the ribbon saving module through the opening from the print block side and connect to CN14 on the CPU PC board. Fix the harness with the clamp.

5.Install the ribbon saving module on the print block.

6.Assemble the solenoid unit so that the head up link engages the spring pin.

7.Secure the ribbon saving module with the SM-4x8B screws removed in Step 3.

Ribbon Saving Module

CN14

Screw (SM-4x8B)

CPU PC Board

Opening

Clamp

Solenoid Harness

Print Block

Solenoid

Ribbon Shaft

Spring Pin

Head Up Link

Fig. 3-10

8. Set the DIP SW 1-1 to ON.

NOTE: Make sure to remove any dust that appears during removal or installation because it may affect the print quality.

CAUTION: Take care to orient the screws so that they are vertically aligned with the ribbon saving module.

3-7

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

(Revision Date: Sep. 29 '95)

3.5 Strip Module (B-4905-H-QM)

3.5 Strip Module (B-4905-H-QM)

Description |

Q'ty/Unit |

|

Description |

Q'ty/Unit |

|

|

|

|

|

Rewinder Ass'y |

1 |

|

Rewinder Guide Plate |

1 |

|

|

|

|

|

Rewind Full Sensor (LED) |

1 |

|

Screw (FL-4x6) |

4 |

|

|

|

|

|

Strip Sensor (Tr) |

1 |

|

Screw (SM-3x6B) |

1 |

|

|

|

|

|

Strip Sensor (LED) |

1 |

|

Screw (SM-4x6B) |

2 |

|

|

|

|

|

Rewind Paper Guide |

1 |

|

|

|

|

|

|

|

|

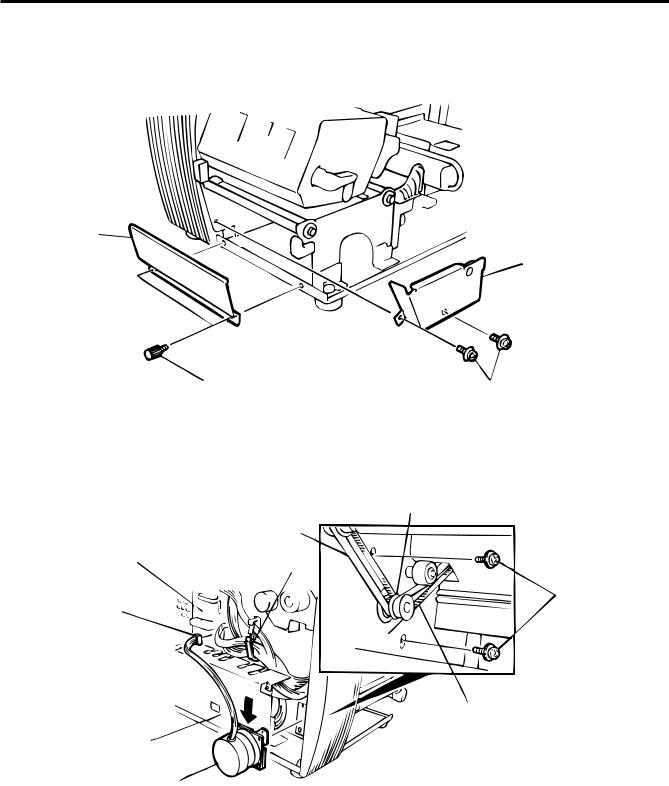

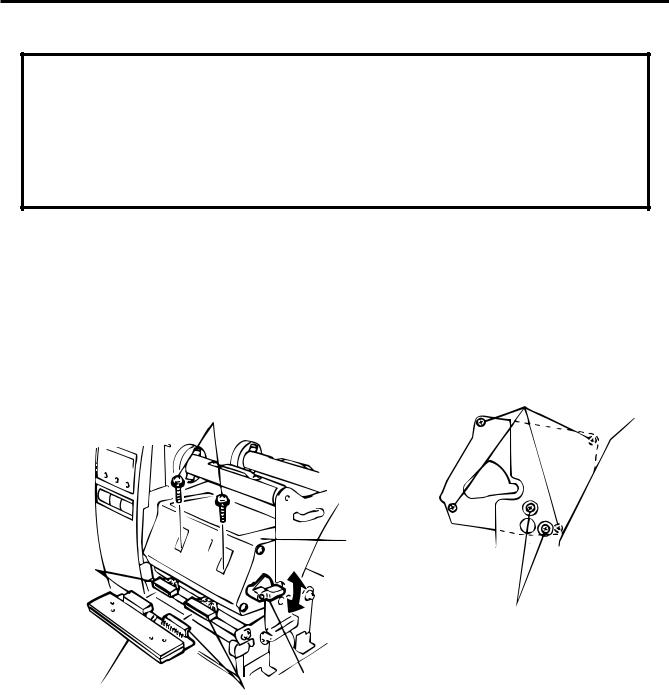

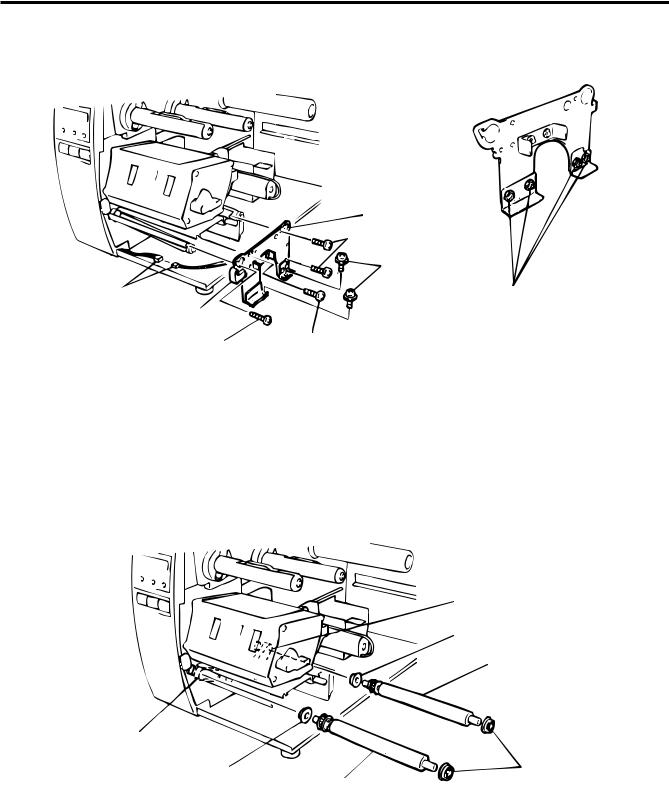

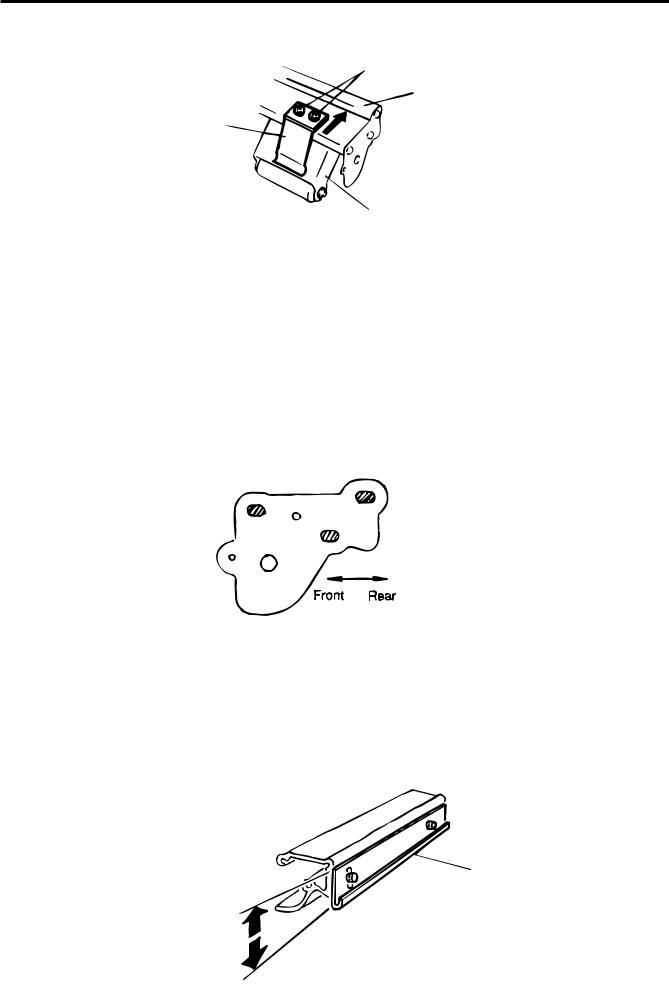

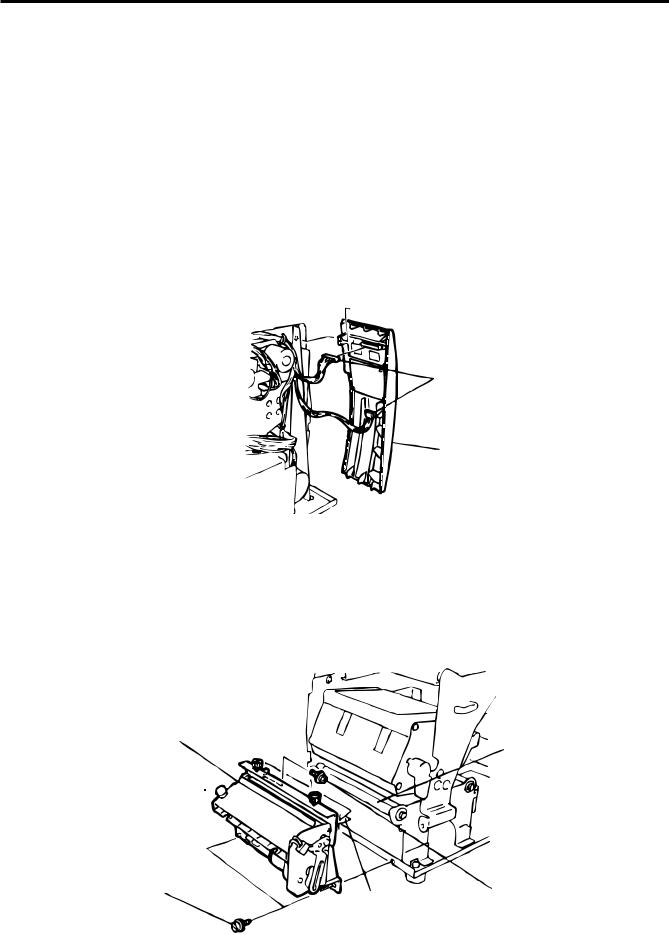

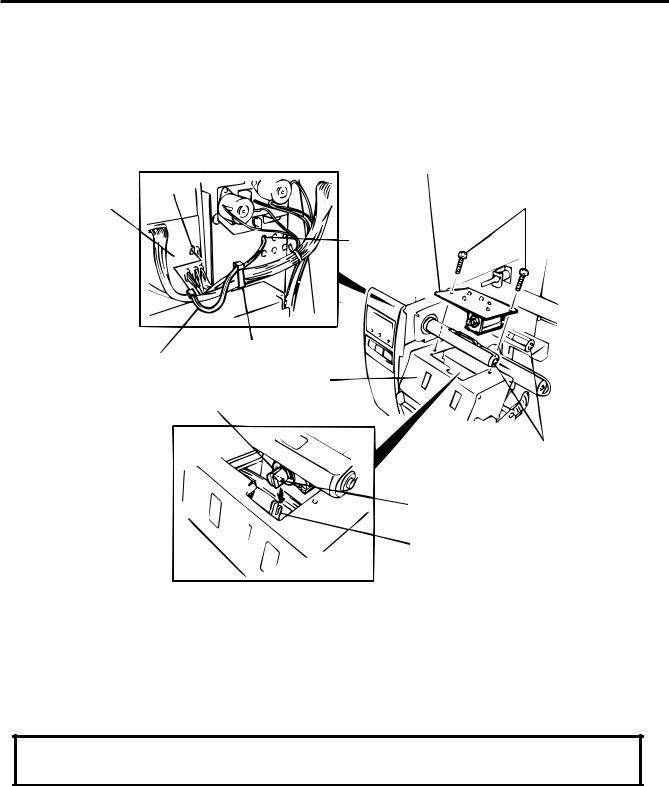

1.Remove the top cover and left side cover (See Fig. 2-1.)

2.Remove the operation panel. (See Fig. 3-3.)

3.Fasten the rewind paper guide to the base with the two SM-4 x 6B screws.

Rewind Paper Guide |

SM-4x6B |

Base

Fig. 3-11

3-8

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT

EM18-33011

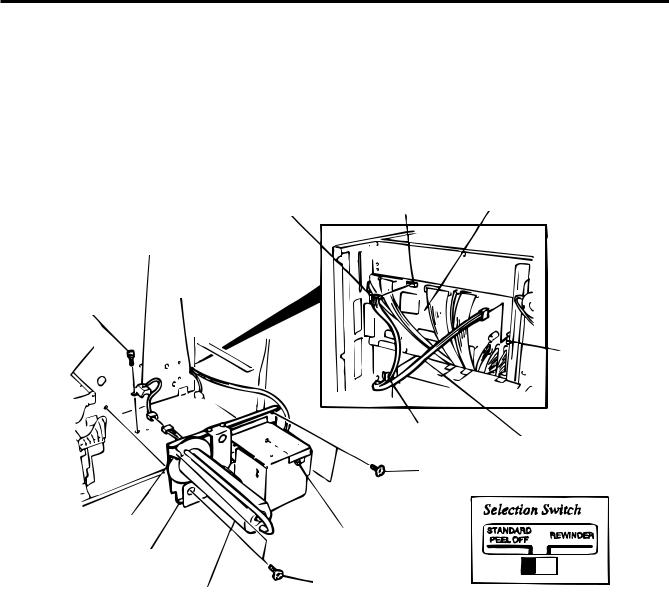

3.5 Strip Module (B-4905-H-QM)

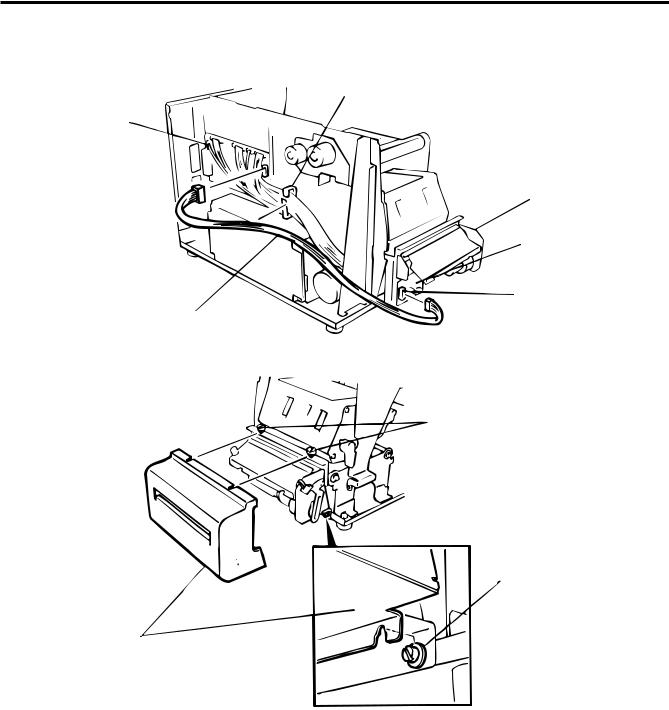

4.Pass the take-up harness of the rewinder ass’y and the longer harness of the rewind full sensor through the hole of the main frame. Connect the take-up harness and rewind full sensor harness to CN15 and CN5 on the CPU PC board respectively. Fix the harness at two points with the clamps.

5.Connect the connector of the rewind full sensor (LED) with the other harness of the rewind ass’y.

6.Align the notch of the take-up holder with the screw hole of the rewinder ass’y and attach it to the printer with four FL-4 x 6 screws.

7.Attach the rewind full sensor (LED) to the base with SM-3 x 6B screw.

Rewind Sensor Harness |

CN5 |

CPU PC Board |

|

|

|

Rewind Full Sensor (LED) |

|

|

Opening |

|

|

Screw (SM-3x6B)

CN15

Clamp

Take-up Harness

FL-4x6

Notch |

Selection switch |

|

Rewinder Ass'y

FL-4x6

Take-up Holder

Fig. 3-12

NOTE: You should change the selection switch position depending on the usage of the take-up holder. Improper setting can affect the print quality.

STANDARD/PEEL OFF (STRIP): Batch and strip types

REWINDER: |

Built-in rewinder type |

For the cutter type, the selection switch can be set to either position.

3-9

Loading...

Loading...