Page 1

V ideo Cassette R eco rder

MV-8080G

Service Manual

NO.289C3090

MV-8080G_1 Cover 97.12.10, 20:35Page 1 Adobe PageMaker 6.0J/PPC

Page 2

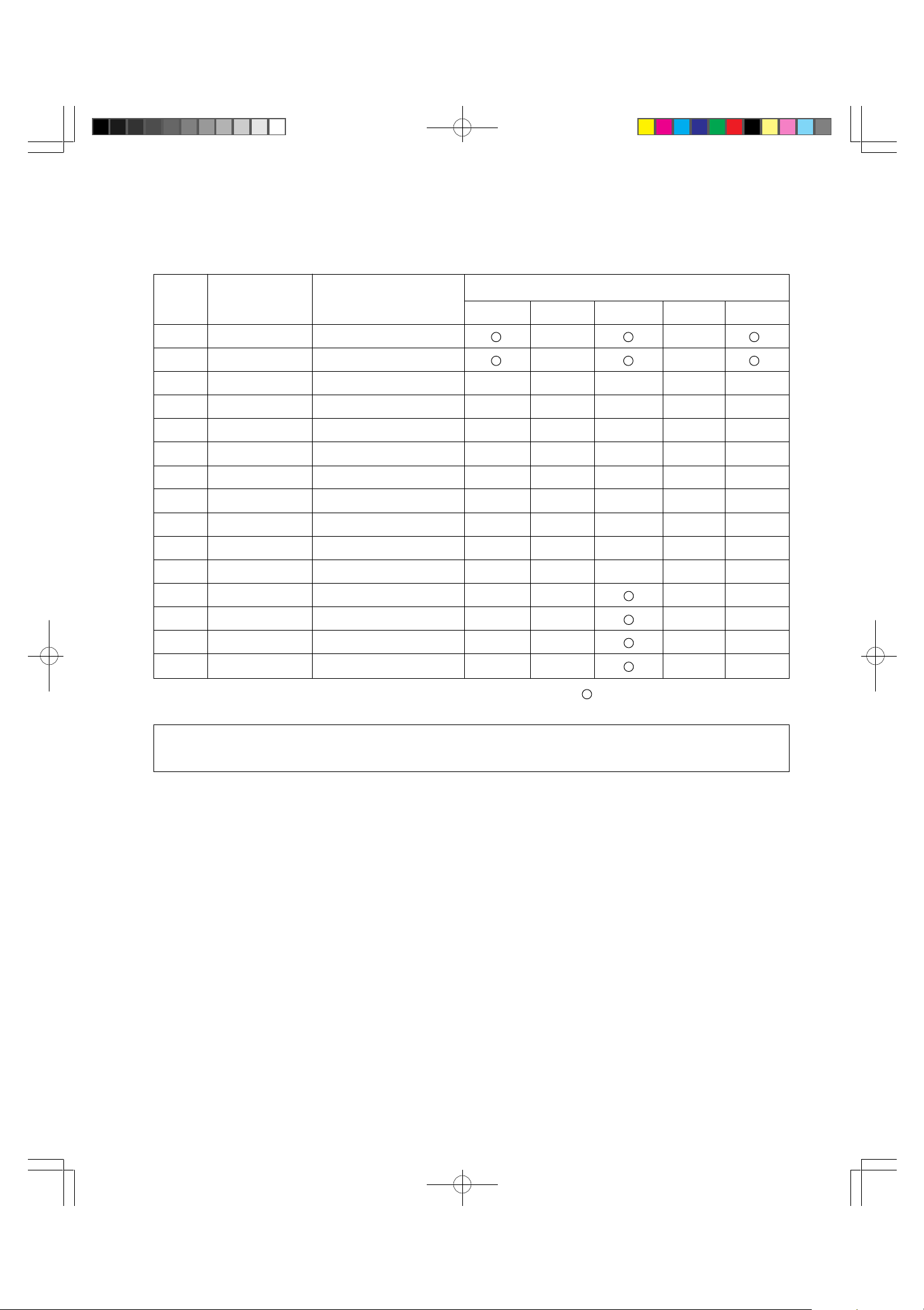

Quick Reference of Specific Parts List

(Latest upgrade list Dec. ’97)

The parts No. of Deck Mechanisms, Face Plate Ass’y and Video Circuit Boards for MV-8080G.

CABINET & CHASSIS

Ref. No. Part No. Description

1 59311

2 59277

21 22329340 FACE PLATE ASS’Y (MV-8080G)

32 26021610 POWER CORD

35R93C0 UPPER VIDEO CIRCUIT BOARD (MV-8080G)

36 MAIN CIRCUIT BOARD (WITH POWER SECTION)

(IC1701) (119412400) (IC,CXP88132-185Q)

37 HEAD CIRCUIT BOARD

38 SCART CIRCUIT BOARD

35R94C0

39 MAIN CIRCUIT BOARD (WITH TUNER)

(ET2A01) (104307420) (ET-TMLG1-103A)

(IC2701) (119413400) (IC,CXP87360-120Q)

(IC2703*) (113112B00) (IC,AT24C02-10PC)

40 HEAD CIRCUIT BOARD

For details, refer to pages 26 to last page.

*The IC ROM settings vary for each model, so please specify the model you are using when ordering replace-

ment IC-ROM 2703 parts.

UPPER DECK MECHANISM (TN6500-116M) FOR P.B. ONLY

LOWER DECK MECHANISM (TN6500-105M) FOR REC/PB

LOWER VIDEO CIRCUIT BOARD (MV-8080G) LOWER DECK

ACCESSORIES

Ref. No. Part No. Description

1 1080738H0 REMOTE CONTROLLER, RC-738

2 28529280 IN-BOX MV-8080G

3 28939060 OWNER'S MANUAL KIT MV-8080G

MV-8080G_1_Cover2 97.12.10, 20:38Page 2 Adobe PageMaker 6.0J/PPC

Page 3

CONTENTS

MAINTENANCE PRECAUTIONS.........................................................................2

ELECTRICAL ADJUSTMENT..............................................................................5

1. PLAYBACK SWITCHING POINT ADJUSTMENT .........................................................................................5

MECHANICAL ADJUSTMENT ............................................................................6

DECK ADJUSTMENT POINTS ...........................................................................................................................6

1. MECHANISM CONTROL ..............................................................................................................................7

2. ADJUSTMENT OF BT TORQUE IN PLAY MODE ........................................................................................8

3. AUDIO/CTL HEAD.........................................................................................................................................9

4. TAPE TRANSPORT SYSTEM CHECKS AND ADJUSTMENT.....................................................................9

5. INTERCHANGEABILITY ADJUSTMENT ....................................................................................................11

6. RG POST HEIGHT ADJUSTMENT ..............................................................................................................14

7. FRONT LOADING ASSEMBLY ATTACHMENT...........................................................................................15

PERIODIC MAINTENANCE ..............................................................................................................................16

SERVICING DIAGRAM AND PARTS LIST ....................................................... 18

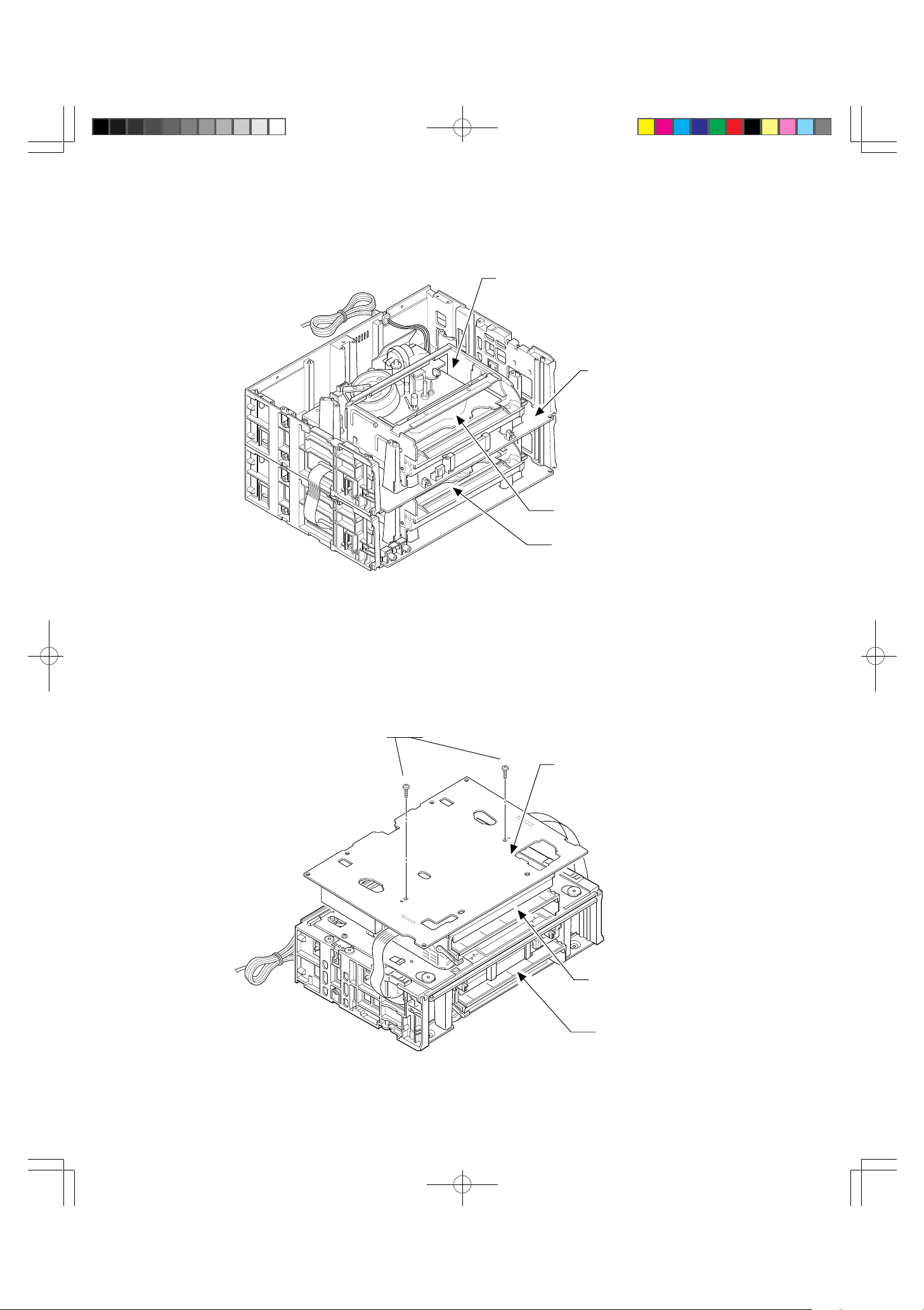

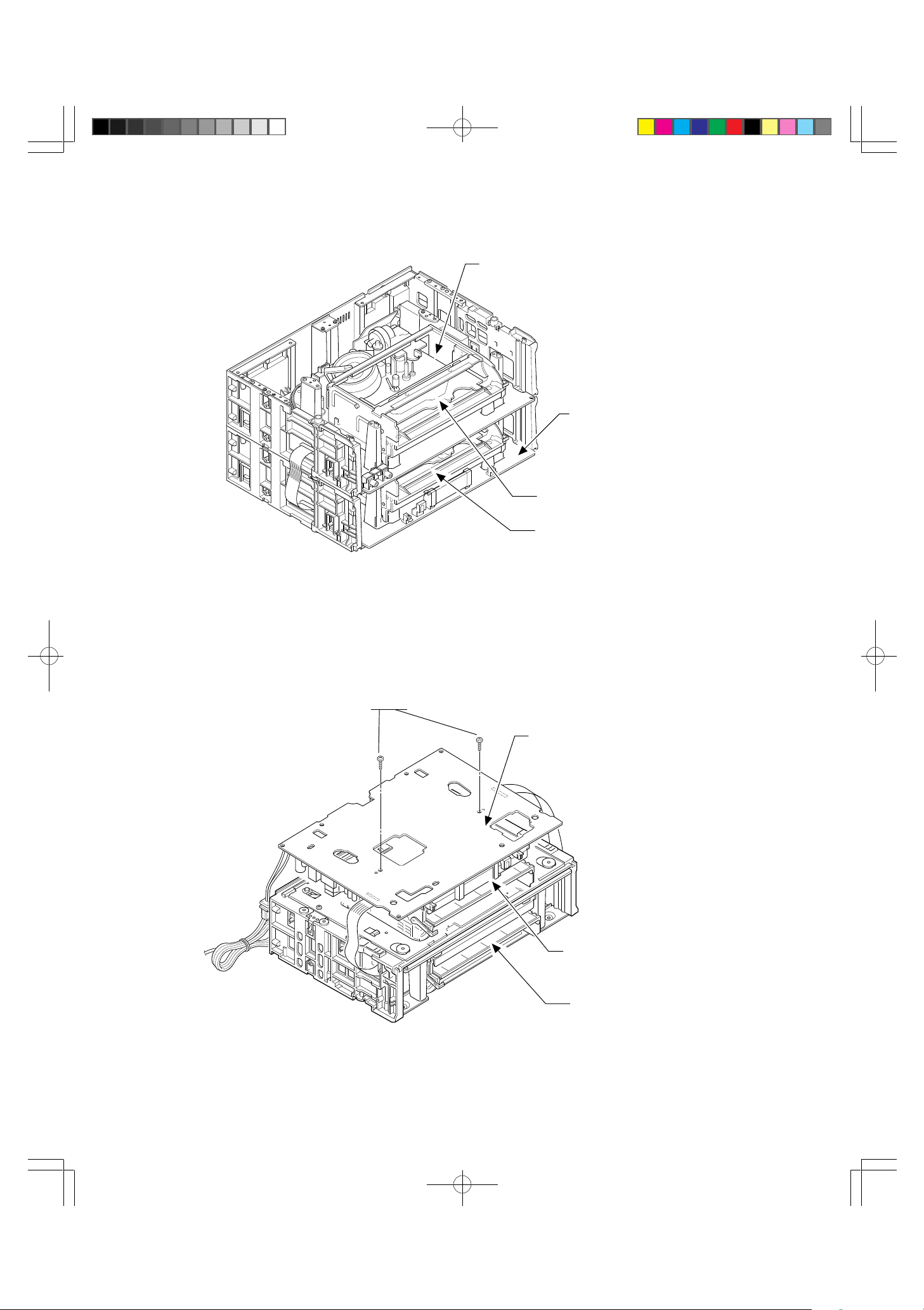

1. EXPLODED VIEW OF THE CASSETTE DECK MECHANISM ...................................................................18

2. BLOCK DIAGRAM .......................................................................................................................................22

3. TERMINOLOGY REFERENCES.................................................................................................................23

4. SCHEMATIC DIAGRAM .........................................................................................................Separate Sheet

5. IC, TRANSISTOR LEAD IDENTIFICATION ................................................................................................25

6. UPPER CABINET EXPLODED VIEW (DECK UNIT 1) ...............................................................................26

LOWER CABINET EXPLODED VIEW (DECK UNIT 2)...............................................................................27

7. PARTS LIST FOR CABINET & CHASSIS ...................................................................................................28

8. PC BOARD ASS'Y (UPPER MAIN) PARTS LOCATION.............................................................................29

PC BOARD ASS'Y (LOWER MAIN) PARTS LOCATION............................................................................31

9. PC BOARD ASS'Y (UPPER MAIN) PARTS LIST .......................................................................................33

10. PC BOARD ASS'Y (HEAD 1, 2) PARTS LIST.............................................................................................41

11. PC BOARD ASS'Y (HEAD 1, 2) PARTS LOCATION..................................................................................41

12. PC BOARD ASS'Y (SCART) PARTS LIST..................................................................................................42

13. PC BOARD ASS'Y (SCART) PARTS LOCATION.......................................................................................42

14. PC BOARD ASS'Y (LOWER MAIN) PARTS LIST.......................................................................................43

TABLE OF IC PIN VOLTAGE ......................................................................................................................52

1

MV-8080G_2 Con(1) 97.12.10, 20:40Page 1 Adobe PageMaker 6.0J/PPC

Page 4

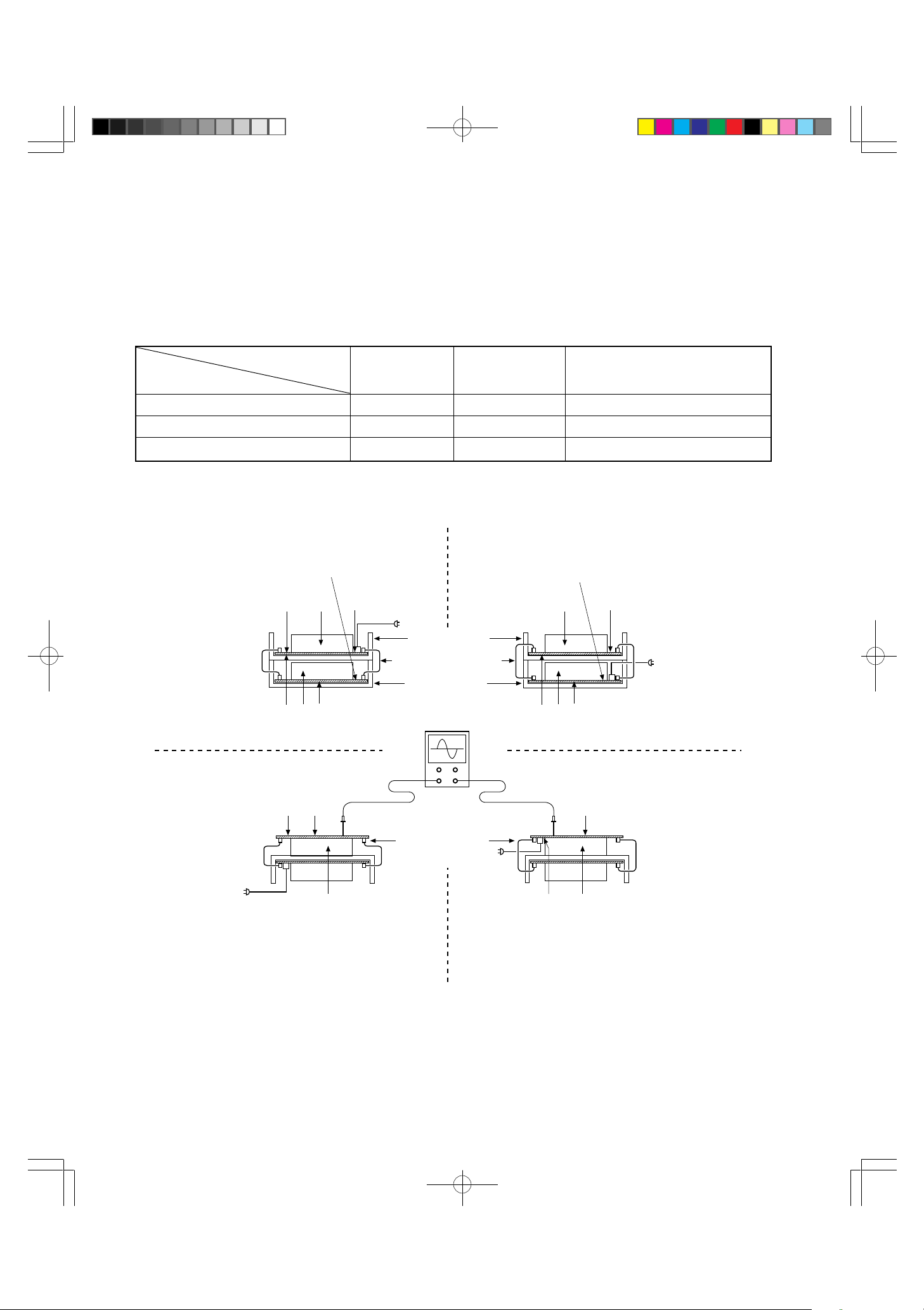

MAINTENANCE PRECAUTIONS

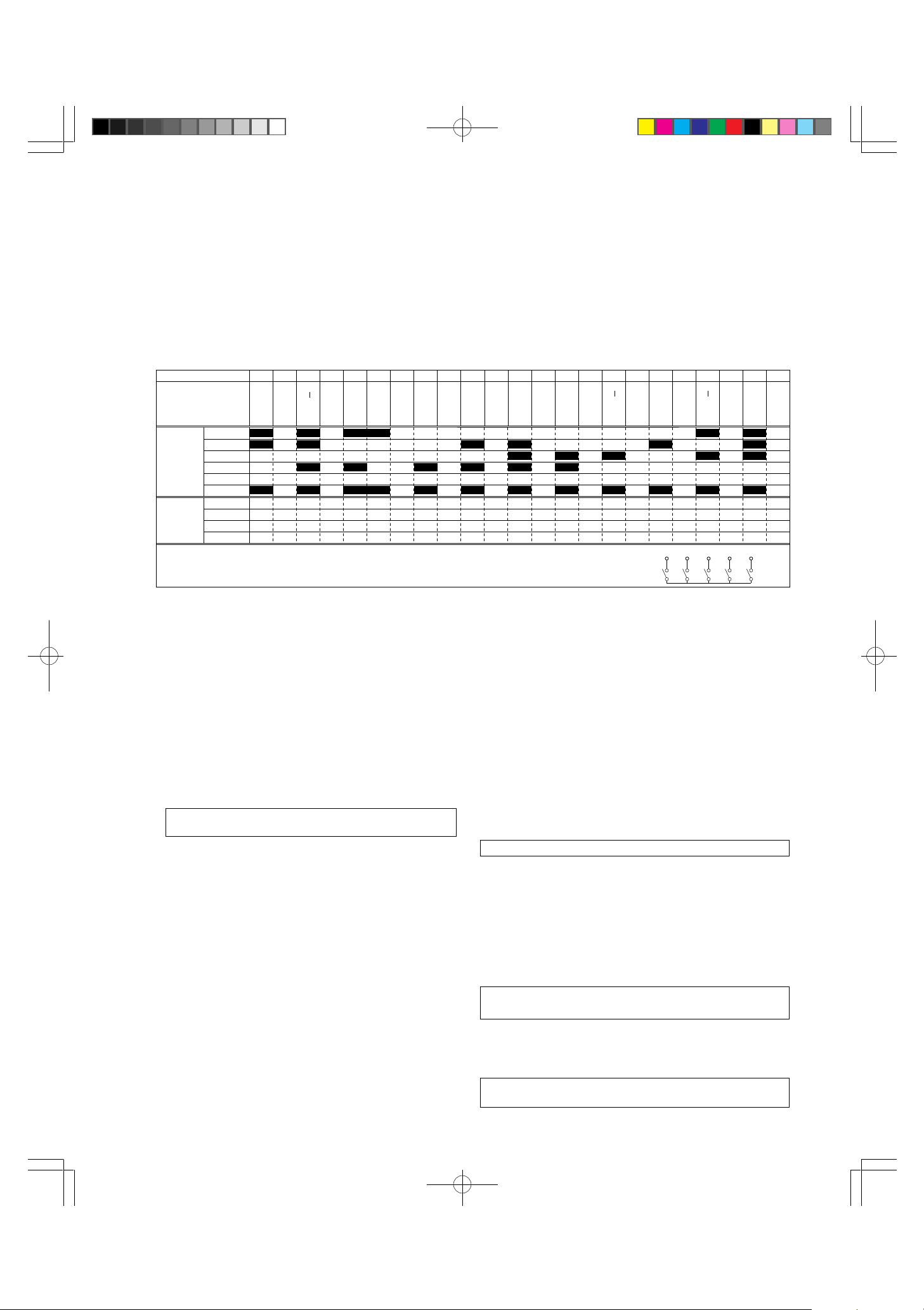

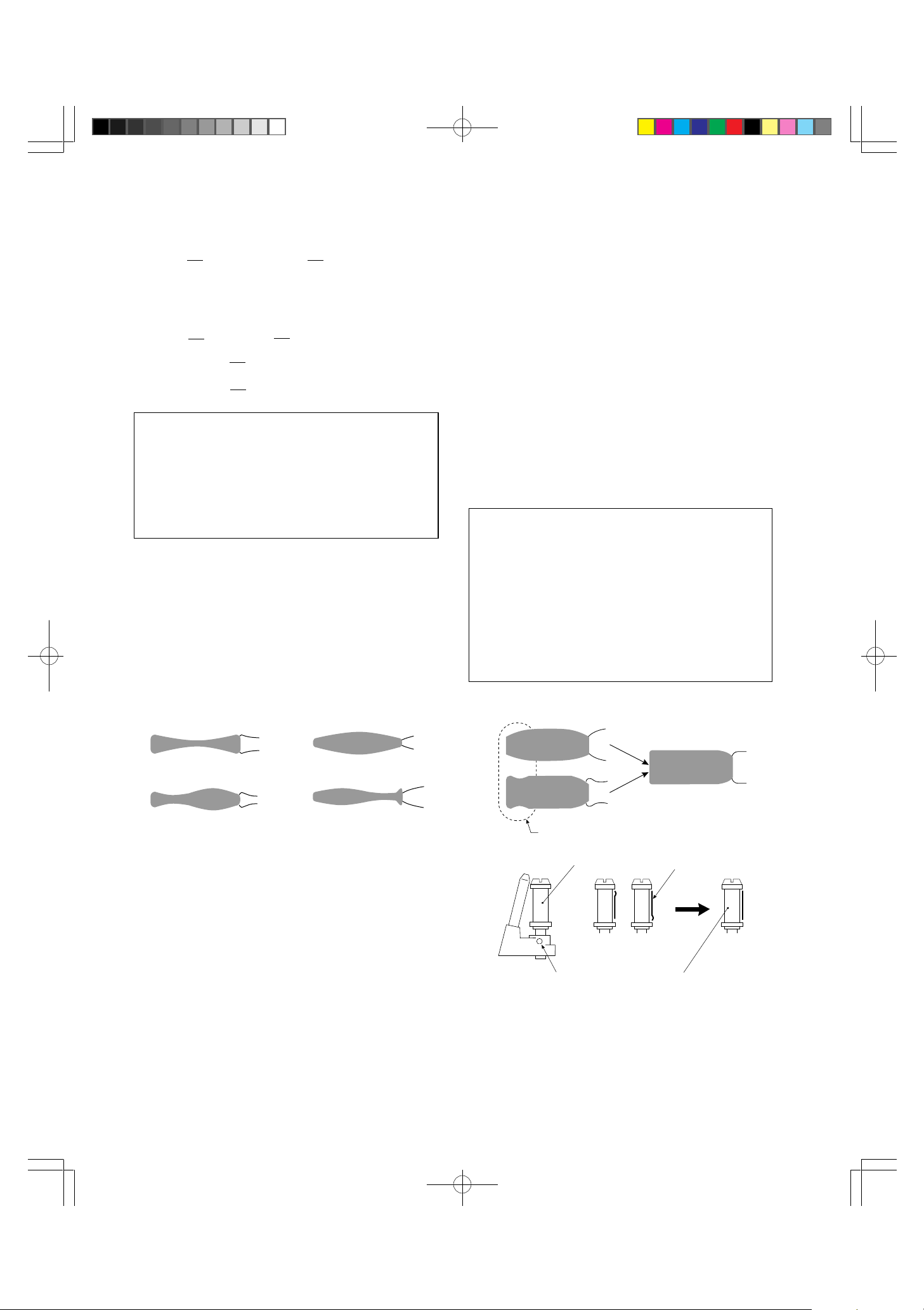

Since this model is a twin-deck system, some of the items to be adjusted during maintenance can be hard to

reach. (These parts are marked with an ¾ in the table below.)

:Serviceable item

○

:Difficult

#

¾ :Cannot be serviced

Position

of the Deck Unit

Items 3, 5, 6, 7 and 8 in the table above cannot be serviced in their current positions. To service these

parts, move the parts marked ¾ to those marked

mechanism and Main PCB). in the table. After testing that the serviced items work, replace the Deck Unit in its

original position.

Maintenance

Upper 1

Lower 4

External 7

Pattern (A) Original Position

4

1

Deck Unit 1

Deck Unit 2

356

()

ELEC. ADJ. MECHA. ADJ. Treatment of the solder side

SWing Point e.t.c.

○

○

or

○

#

on the Deck Unit (a single deck VCR or VCP, including Deck

○

DECK Adj. on the Main PCB

2

○

3 ¾

5 ¾ 6 ¾

8 ¾ 9

Pattern (B) Upper and Lower Deck Unit

Positions Inverted

4

12

AC IN

Upper Position

Flexible Wire Harness

Lower Position

¾

SYNCHROSCOPE

3

()

12

Deck Unit 2

AC IN

Deck Unit 1

Cannot be serviced.56

¾

○

99

7

Deck Unit 2

Deck Unit 1

AC IN

¾ Cannot be

8

serviced.

Pattern (C) External Position (Upside Down)

Operation cannot be tested with the deck mechanism alone.Temporarily assemble the mechanism with the Main PCB

*

to test the mechanism.

To test Pattern (B), remove the Flexible Wire Harness, then exchange the Deck Mechanism Unit 2 with Deck

Mechanism Unit 1 and reconnect the parts.

To test Patterns (C) and (D), remove the Flexible Wire Harness, then the Deck Mechanism and Main PCB (in this

order) from the Chassis. Then temporarily assemble the removed Main PCB and Deck Mechanism and reconnect

the parts. To do this, fix the two spacers of the Deck Mechanism to the back of the Main PCB with screws.

External Position

Pattern (D) External Position (Upside Down)

2

AC IN

#

7

8

¾

Deck Unit 1

Deck Unit 2

MV-8080G_3(2~4) 97.12.10, 20:41Page 2 Adobe PageMaker 6.0J/PPC

Page 5

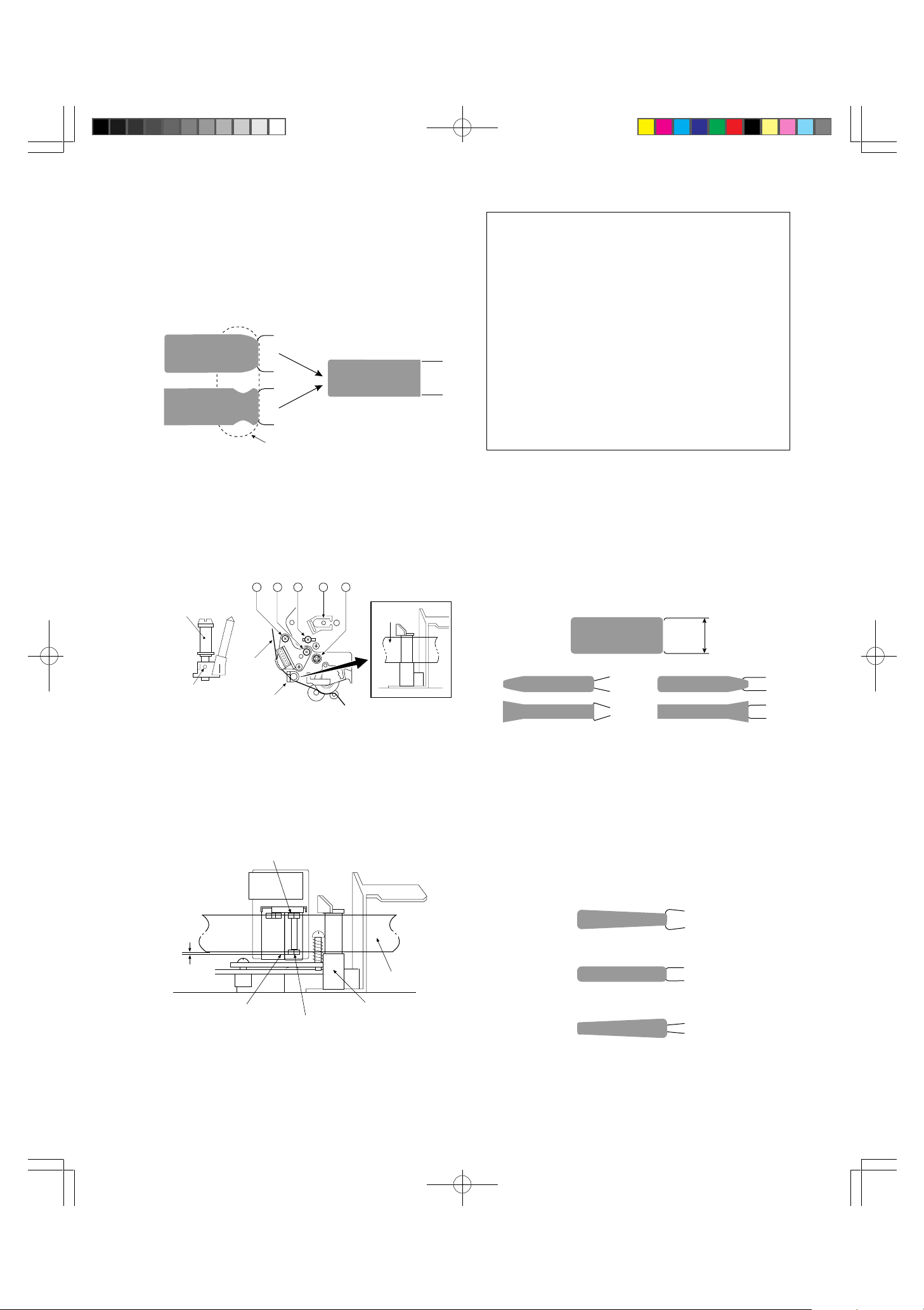

2 Mechanical Adjustment OK

Pattern (A) Original Position

R1713 1 Switching

Point Adjustment OK

Deck Unit 1

Deck Unit 2

*Fix the two spacers of the Deck Mechanism

to the back of the Main PCB with screws.

Pattern (C) External Position (Upside Down)

9 Treatment of the solder side

on the Main PCB

Deck Unit 2

Deck Unit 1

3

MV-8080G_3(2~4) 97.12.10, 20:41Page 3 Adobe PageMaker 6.0J/PPC

Page 6

2 Mechanical Adjustment OK

R1713 1Switching

Deck Unit 2

Deck Unit 1

Pattern (B) Deck Unit 1 and 2 Positions Inverted

Point Adjustment OK

*Fix the two spacers of the Deck Mechanism

to the back of the Main PCB with screws.

9 Treatment of the solder side

on the Main PCB

Deck Unit 1

Deck Unit 2

Pattern (D) External Position (Upside Down)

4

MV-8080G_3(2~4) 97.12.10, 20:41Page 4 Adobe PageMaker 6.0J/PPC

Page 7

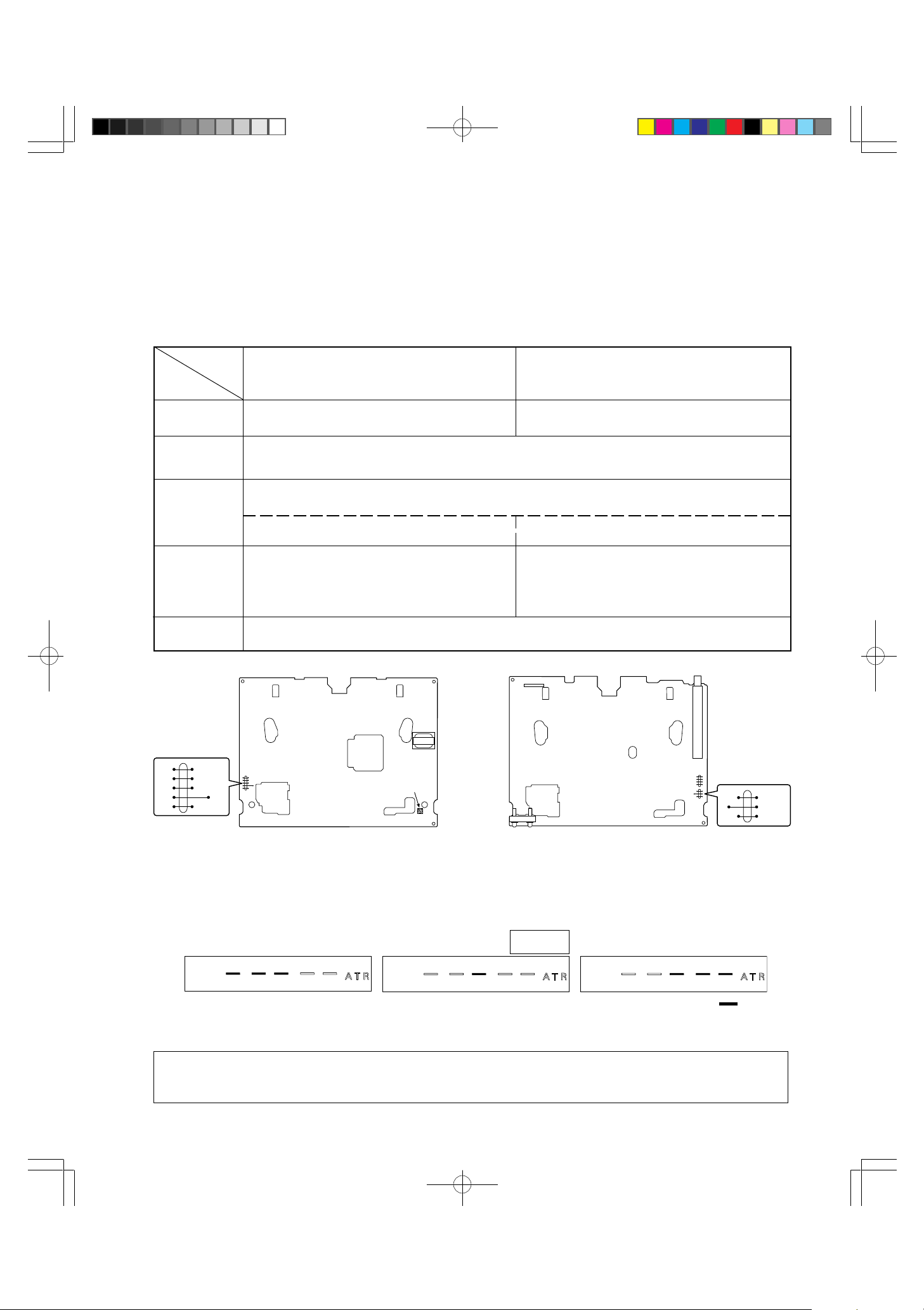

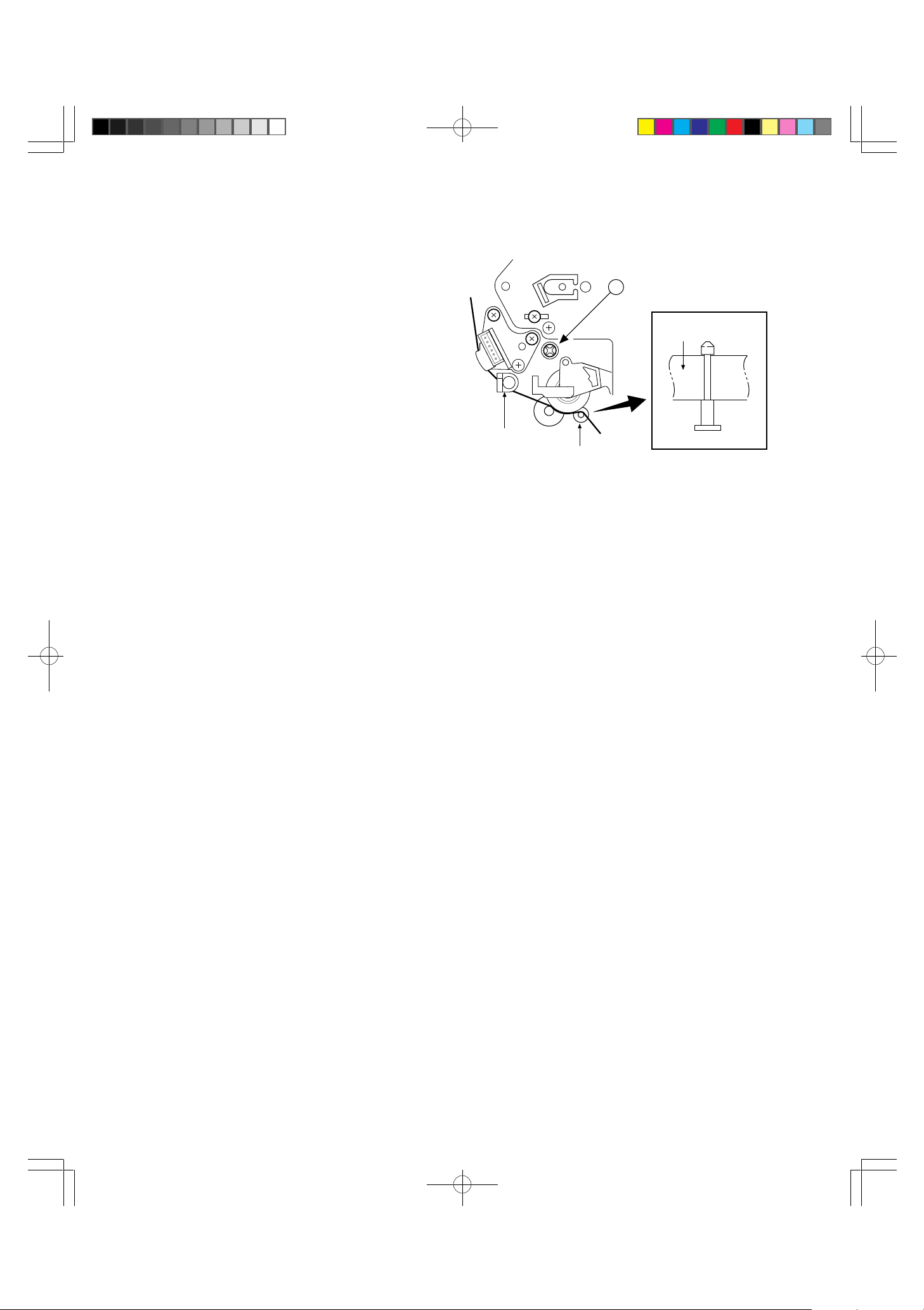

ELECTRICAL ADJUSTMENT

1. PLAYBACK SWITCHING POINT ADJUSTMENT

Mode : PLAY

Test Signal : TPS-13 or 13S

Check Point : FIP

DECK TYPE

Procedure

Adjustment

Point

1)

2)

3)

4)

FOR UPPER DECK UNIT 1 WITH POWER

SECTION

R1713 CH UP/DOWN (

FOR LOWER DECK UNIT 2 WITH TUNER

55

∞∞

5/

∞) KEY

55

∞∞

Plays the adjustment tape and automatically adjusts ATR. The ATR is finished when “ATR” on

the FIP stops blinking.

Short the connection between PG ADJ and GND on the MAIN PCB as indicated in Figure 1.

Then, must of the segments on the FIP, for example, “ATR” goes OFF. See Figure 2 below.

PG ADJ (J257), GND (J259) PG ADJ (J228), GND (J230)

To adjust the display for FIP (H1071) (Display

B below.)

• Turn R1713 to the right (in case of Display A)

• Turn R1713 to the left (in case of Display C)

To adjust the display for FIP (H701), (Display

B below).

• Press the Down ∞ key (in case of Display A)

• Press the Up 5 key (in case of Display C)

Clear the TEST POINT short.

J282

AMP

J258

CTL

J260

RFS

J259

GND

J257

PG ADJ

Figure 1-1

MAIN PCB WITH POWER SECTION FOR

UPPER DECK

Display A Display B Display C

R1713

PG ADJ

Figure 1-2

MAIN PCB WITH TUNER FOR LOWER

DECK

Adjustment

completed.

Figure 2

Due to major changes in the electrical circuits, it is sufficient to perform only this section, “PLAYBACK

SWITCHING POINT ADJUSTMENT,” of the electrical adjustments.

5

J229

J230

J228

: ON

ADJ

GND

PG ADJ

MV-8080G_4(5 97.12.11, 9:45Page 5 Adobe PageMaker 6.0J/PPC

Page 8

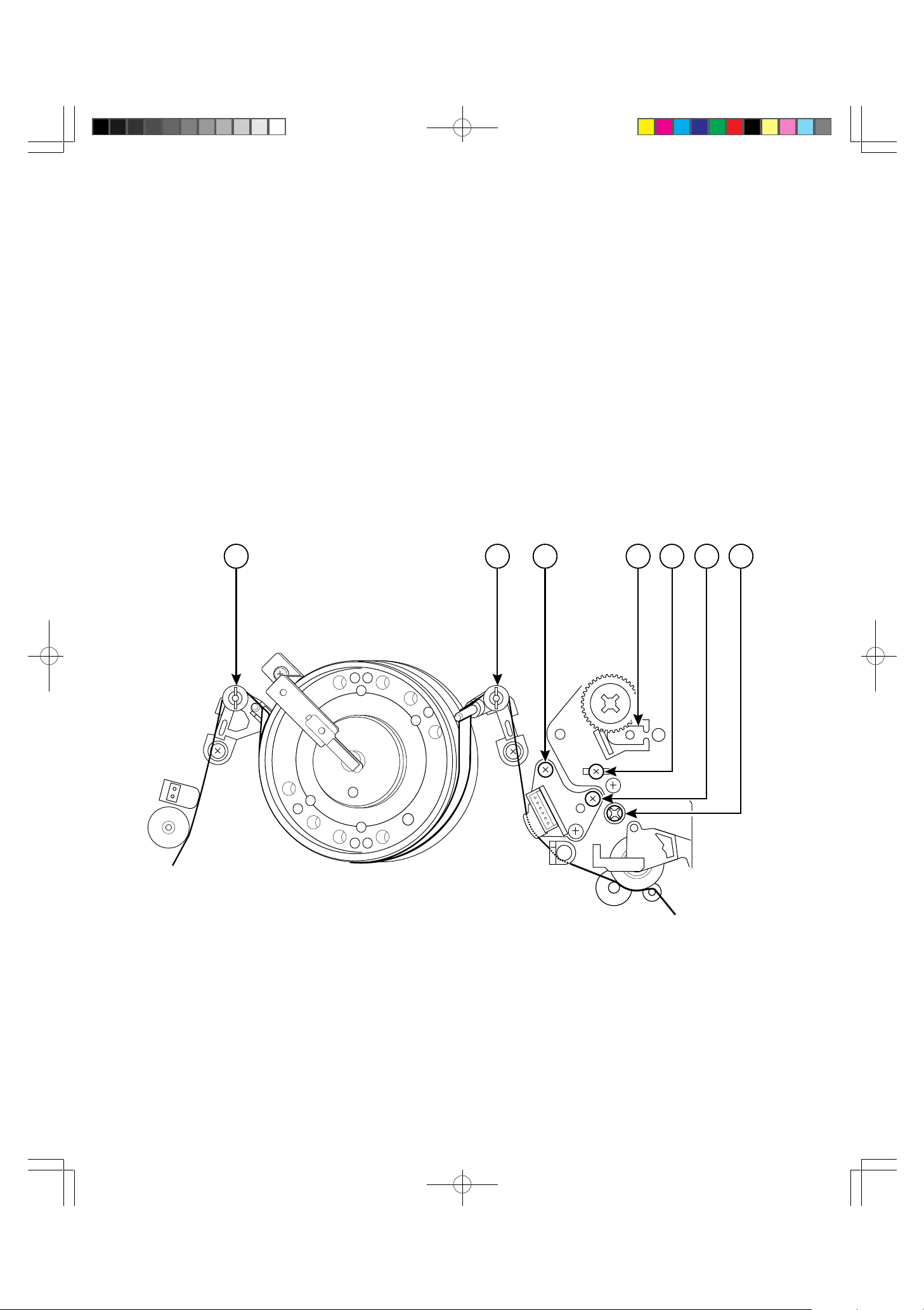

MECHANICAL ADJUSTMENT

DECK ADJUSTMENT POINTS

1 FM Waveform (Envelope) entrance adjustment screw

2 FM Waveform (Envelope) exit adjustment screw

3 Audio Azimuth adjustment screw

4 Control Head phase (X-value) adjustment point

5 Audio/CTL Head height adjustment screw

6 A/C Head tilt adjustment screw

7 RG Post height adjustment screw

1 254367

6

MV-8080G_5(6~16) 97.12.11, 9:36Page 6 Adobe PageMaker 6.0J/PPC

Page 9

1. MECHANISM CONTROL

The mechanism includes its own mode as well as the operation mode of the VCR as shown in the chart below. This mode serves

an important function in working to protect the tape by passing through the VCR when the mode is switched over.

The movement of the mechanism mode is performed by the control signal of the loading motor’s rotary control circuit. With this

control, the operation mode position is detected by the Mode switch (4-bit mode data output), Cassetle ln switch, tape top sensor

and the tape end semsor which detects all modes of the mechanism.

1-1. MODE SW

The composition of the 4 terminals, COM DATA 1, 2, 3, 4, are treated as a 4 bit signal.

POSITION NO

POSITION NAME

SWITCH

ON/OFF

TIMING

WHITE=OFF

BLACK=ON

POSITION

CODE

1=OFF

0=ON

M1 SW

M2 SW

M3 SW

M4 SW

COM SW

COM-M1

COM-M2

COM-M3

COM-M4

1 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23234

E

J

E

C

T

S

R

E

W

ESL

O

A

D

R

E

W

F

F

S

T

O

P

P

L

A

Y

F

S

L

O

W

C

T

R

S

L

O

W

R

E

V

E

R

S

E

0 1 0 1 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 0 1 0 1

0 1 0 1 1 1 1 1 1 0 1 0 1 1 1 1 1 0 1 1 1 0 1

1 1 1 1 1 1 1 1 1 1 1 0 1 0 1 0 1 1 1 0 1 0 1

1 1 0 1 0 1 1 0 1 0 1 0 1 0 1 1 1 1 1 1 1 1 1

M1

M2

M3

MODE SW

Equivalent

Circuit

COM

COM

M1

SW

M2

SW

SW

M4

M3

M4

SW

SW

1-2. CONFIGURATION OF THE

TN6500 VCR MECHANISM

1-2-1. Cassette Drive Mechanism

The cassette is loaded and ejected via the drive from the

capstan motor.

(A) Detection of cassette insertion

When an cassette is inserted, the capstan motor starts and

simultaneously causes the shutter on the main unit to break the light

beam of the Tape Top Sensor. This capstan FG pulse and the Tape

Top Sensor change cause the cassette to be pulled into the VCR.

(B) Detection of completed cassette insertion operation

This is detected by the Cassette Insertion Switch that is linked to

the actuator activated when a cassette is inserted.

Note: The Cassette Insertion Switch is not included

with the deck mechanism.

(C) Detection of completed cassette ejection operation

As above, this is detected by the shutter on the shutter

detecting the change in the Tape Top Sensor. The light

beam that is broken by cassette insertion/ejection is restored

when the cassette has been ejected.

1-2-2. Tape Loading Mechanism

Tape loading mechanism is the mechanism that is loaded

with the tape loading motor linked to the mode switch. The

following actions occur when the 4-bit position code output

from the mode detection switch is used.

(A) The tape is pulled out of the cassette and wound on the

cylinder. (tape loading)

(B) The tape is returned to the cassette. (tape unloading)

(C) Function are switched so that each mechanism can operate.

1-2-3. Tape Transportation Mechanism

The tape is fed through the VCR by the action of the capstan,

pinch roller and reel drive.

1-2-4. Motor

(A) Capstan Motor

The drives the capstan axle directly and also drives the reel

that has been loaded on the belt. This motor is also used to

drive the cassette loading mechanism.

(B) Tape Loading Motor

In addition to cassette loading/unloading, this motor also

switched between the various operating modes(PLAY, FF/

REW etc. )

(C) Cylinder Motor

Connected to the rotating head drum and drives the rotating

head.

1-2-5. Safety Tab Sensor/Actuator

This actuator detects the tab that operates the REC SAFETY

switch.

Note: This mechanism does not include the switch.

1-2-6. Mode Sensor Switch

This detects the 4-bit code before each position and is connected

to the tape loading mechanism.

1-2-7. Take-up/Supply Reel Sensor

Photoelectric Cell

A luminous diode and phototransister at the fixed position for the cell

comprise the reel sensor. (Pulse rate=8pulses/rotation)

Note: This mechanism does not include the luminous diode

or the phototransister.

1-2-8. Tape Start/End Sensor Photoelectric Cell

A luminous diode and phototransister at the fixed position for the cell

comprise the start/end sensor. (Pulse rate=8pulses/rotation)

Note: This mechanism does not include the luminous diode

or the phototransister.

7

MV-8080G_5(6~16) 97.12.11, 9:36Page 7 Adobe PageMaker 6.0J/PPC

Page 10

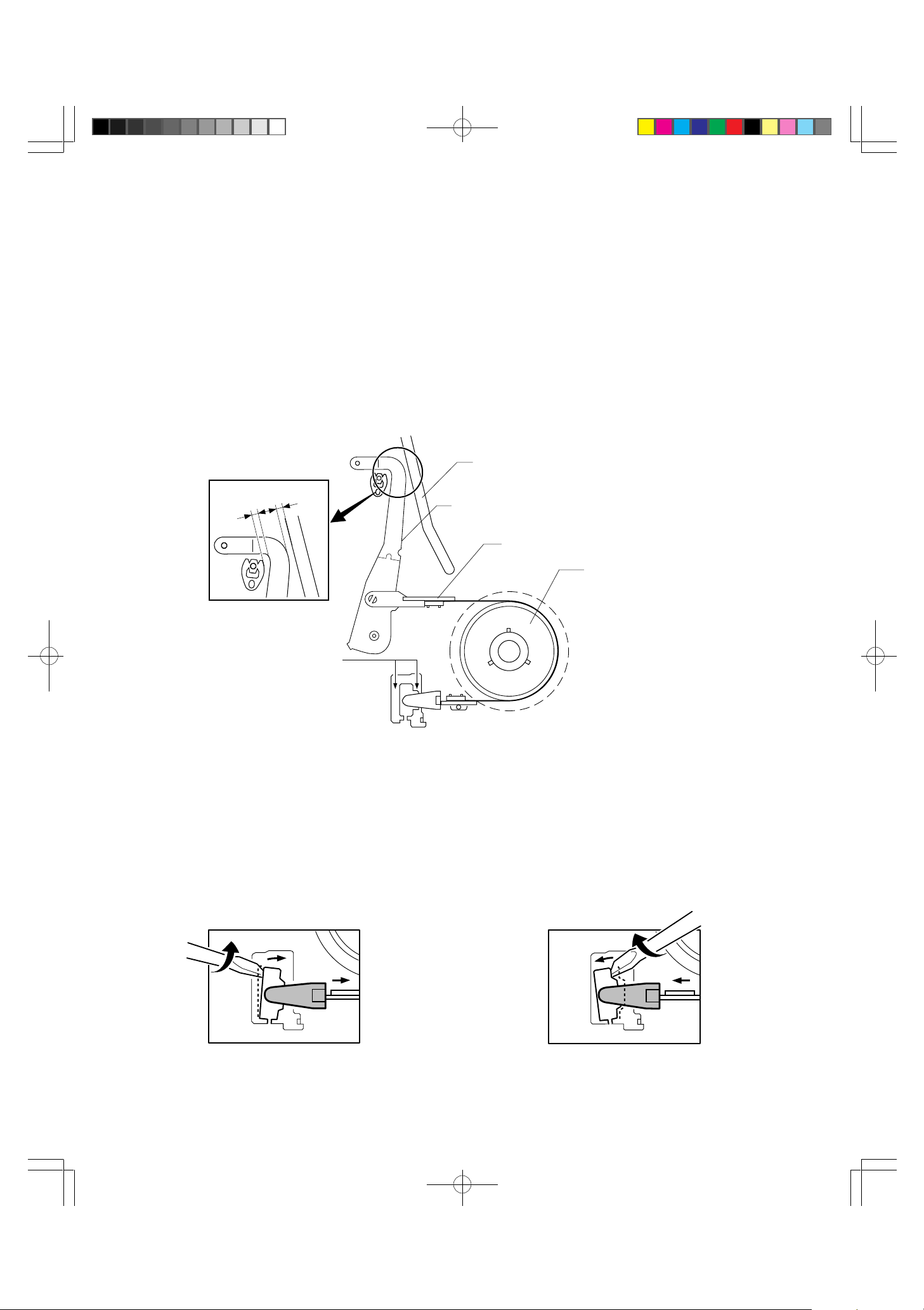

2. ADJUSTMENT OF BT TORQUE IN PLAY MODE

u

(ADJUSTMENT OF THE TENSION ARM POSITON)

1. Remove the FL Ass’y.

2. Rotate the loading pulley with your finger until PLAY mode is reached.

3. Insert a standard screwdriver into the BT adjustment groove (a or b) of the main chassis.

Twist the screwdriver left and right to adjust gap (A) and gap (B) so that they are the same.

[fBOubN

Loading Block Rail Groove

[a

A=B

B

A

Tension Arm

eVA[

BT Band Ass'y

BTohAZu

Reel Ass'y

[AZ

BT adj. Groove

BT†fipa

a b

• To reduce the gap (BT torque reduction), insert into

adjustment groove “a” and twist counter-clockwise as

shown in the figure below.

• To increase the gap (BT torque increase), insert into

adjustment groove “b” and twist clockwise as shown

in the figure below.

CAUTION: Do not twist at too much of an angle. Doing so will have adverse effects on other areas as well.

8

MV-8080G_5(6~16) 97.12.11, 9:36Page 8 Adobe PageMaker 6.0J/PPC

Page 11

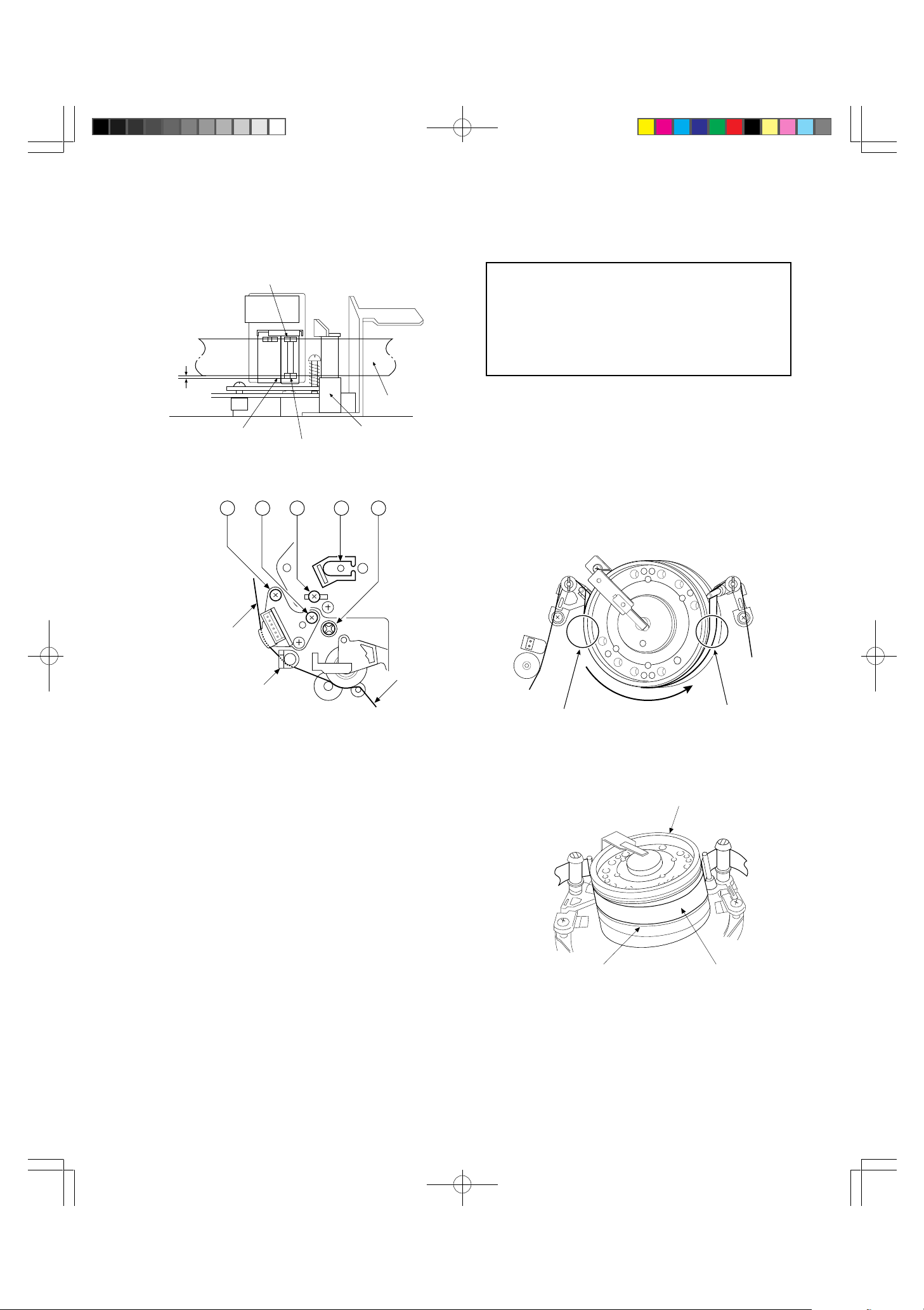

3. AUDIO/CTL HEAD

v

4. T APE TRANSPORT SYSTEM

3-1. T APE TRANSPORT ADJUSTMENT

Audio Head

Approx.

0.06mm

Reference line

CTL Head

Audio/CTL Head Adjustment

A DB EC

Tape

Take-up Guide Pole

CHECKS AND ADJUSTMENT

The tape transport system has been precisely

aligned at the factory and normally does not

require readjustment. The following steps are

therefore necessary only in cases of frequent use

or when replacing parts which have an effect on

the tape transport system.

4-1. T APE TRANSPORT CHECK

1. Using an ordinary cassette tape, switch back and

forth between PLAY and STOP modes several times.

2. During PLAY mode, observe the input and output

portions of the tape (A and B in the figure below) of

the head drum lead. Confirm that the tape slips

neither upward nor downward with respect to the

lead as shown in Figure “Drum Lead Check-1”.

Tape

e[v

e[

Tape

Take-up Guide

“«ŁKCh

1. Using an ordinary cassette tape, set to CUE mode.

2. Turn screw C and adjust for smooth transport at the

take-up guide.

3-2. AUDIO/CTL HEAD HEIGHT AND

AZIMUTH ADJUSTMENT

1. Connect the noise meter to the audio output.

2. Play the test tape (1 KHz color bar signal), turn screw

A back and forth a little at a time to set maximum

audio output level. (Rotate in a clockwise direction to

adjust the settings.)

3. Play the test tape, (8 KHz stair step signal), turn

screw B back and forth a little at a time to adjust the

azimuth so that the audio output level will reach a

maximum.

4. Play the test tape (1 KHz color bar signal), and make

sure that there is no significant change in the audio

output level. If a large change remains, turn screw C

back and forth a little at a time to adjust so that the

level change will reach a minimum.

5. When all adjustment is finished, lock up screw B.

A:hß B:ho

Tape Transport Check

Upper Drum Ass'y

ªhAZu

Drum Lead (lower)

h[hiӧj e[v

Drum Lead Check-1

Drum OutputDrum Input

Tape

9

MV-8080G_5(6~16) 97.12.11, 9:36Page 9 Adobe PageMaker 6.0J/PPC

Page 12

NOTES:

1. If the tape slips upward; sound is produced by

contact between the tip of rotating heads and

the edge of the tape.

2. If the tape slips downward; the tape curls or

wrinkles (or makes noise) at its connection

with the lead face of the drum lead.

3. During loading, play, and unloading of the

cassette tape, observe the tape at the supply

guide roller, and take-up guide roller.

4. Make sure that there are no curls or wrinkles as

shown in the figure below.

Incorrect

Tape

Correct

4-2. GUIDE ROLLER HEIGHT

ADJUSTMENT

1. Slightly loosen the tight-screw of the supply and takeup guide rollers as shown in the figure below.

2. Using an ordinary cassette tape, set to PLAY mode.

3. With a standard screwdriver, slightly turn the supply

guide roller (no more than 180° at a time), and adjust

so that at the drum input portion, the tape travels

smoothly along the drum lead without slipping

upwards or downwards.

4. Similarly, adjust the take-up roller for the drum output.

hCo[¯æ

Turn with a

standard screwdriver

Guide

roller

AB C

Guide Roller

5. Observe the tape as it wraps around the drum

during PLAY and separates from the drum

during STOP.

6. As shown in the figure below, make sure that

there is no damage to C and D and that there

is no contact noise between the head tips and

tape edge.

Upper Drum Ass'y

e[v

Ło

Supply Guide Roller

KCh[

Tape

ªhAZu

“«Ł

Take-up

KCh[

Guide Roller

Guide Roller

KCh[

¯ŁlW

Tight Screw

Adjusting Guide Roller Height

NOTES:

1. Loosen the tight-screw only enough to allow

the guide rollers to be rotated. Loosening it

anymore than that may rotate the roller

inadvertently as a result of tape motion.

2. Rotate the roller carefully to avoid damage to

the tape.

3. When the adjustment is completed, tighten the

screw and set by locking up the screw.

D

Drum Lead

h[h

C

Drum Lead Check-2

7. If a defect is detected during check, perform

the follwoing procedure for adjusting Guide

Roller height.

10

MV-8080G_5(6~16) 97.12.11, 9:36Page 10 Adobe PageMaker 6.0J/PPC

Page 13

4-3. TAPE TRANSPORT CHECK AT

v

THE T AKE-UP GUIDE

In general, no adjustment will be necessary for the takeup guide. However, adjustments or checks will be

necessary when replacing the Audio/CTL Head or parts

affecting the tape transport system after a long period of

operation.

1. Using an ordinary cassette tape, set to PLAY mode.

2. Turn Audio/CTL Head screw C as shown in the

figure below and adjust for smooth transport at the

Take-up Guide.

A DB EC

X|WVAWXg¡

X position Adjusting Jig

Tape

e[v

e[

Tape

Take-up Guide

“«ŁKCh

5. INTERCHANGEABILITY

ADJUSTMENT

Before using the test tape, make sure that the tape

transport is normal using an ordinary cassette tape.

Also, make sure that the switching point (Refer to P.5)

is adjusted. If they are not, do the following checks after

adjusting.

5-1. PRELIMINARY CHECKS

1. FM Envelope Waveform Check

1. Connect the CH-1 oscilloscope to TP of PB ENV and

CH-2 to TP of CTL. At this time, trigger the

oscilloscope externally with the signal (RF Switching

Pulse) from TP of RFS.

2. Play the test tape (Stairstep).

3. Use the Channel ∞/5 buttons to tune the tracking to

center position. Adjust point 4 (X value adjustment

point: test point reference P.6) so that the FM

envelope output at TP of PB ENV reaches a maximum.

4. Using the Channel ∞/5 buttons. Perform the following

3 steps (5-7) by moving the TP of CTL waveform in

both positive (+) and negative (–) directions in 3 ms

increments.

5. Refer to the figure below. Read the level of portion

(a) of the waveform. If the waveform is serrated at

point (a), adjust the level so that the serrations are as

smooth as possible (refer to the second figure).

ce

a

abd

Ideal FM envelope

FM Waveform (Maximum Output)

Minimum levelMaximum level

Normal Waveform Examples

11

MV-8080G_5(6~16) 97.12.11, 9:36Page 11 Adobe PageMaker 6.0J/PPC

Page 14

6. As shown in the equation below, read the FM

waveform value at point (b) and make sure that:

b

> 0.75 or 20 log > –2.5 dB

=

a

b

=

a

7. Read the values at points (c) and (d) [drum input and

output] and make sure that:

c

> 0.75 and > 0.75 or

=

a

20 log = –2.5 dB and

20 log = –2.5 dB

c

a

e

a

d

=

a

NOTES:

1. Read the minimum levels for (b), (c), and (d).

2. If above checks yield normal results, proceed

to page MA-8 section “ADJUSTMENT”.

3. If defects are noted, perform the following FM

envelope waveform adjustment.

2. FM ENVELOPE WAVEFORM

ADJUSTMENT

1. As in the previous section, observe the FM waveform

and press the CHANNEL ∞/5 buttons. Waveform

alterations must be nearly parallel to each other as

shown in Figure “Normal Waveform Examples” on

page P.11.

2. If the waveform changes as shown in the figure

below, adjustment is necessary.

5-2. ADJUSTMENT

1. Connect the TP of PB ENV to the oscilloscope

CH-1. At this time, trigger the oscilloscope externally

with the signal (RF Switching Pulse) from TP of RFS.

2. Play the test tape (Stairstep).

1. DRUM INPUT ADJUSTMENT

1. Observe the FM envelope output wave at the TP of

PB ENV with the oscilloscope and press the

CHANNEL ∞/5 buttons in both positive (+) and

negative (–) directions.

2. A of the following figure shows incorrect waveforms.

With a standard screwdriver, adjust the transport

guide roller to flatten the peak of the FM envelope

waveform as shown in B.

NOTES:

1. If the guide roller rotates freely, tighten the

screw slightly.

2. Be sure to adjust the guide roller only by small

increments at a time to avoid damaging the

test tape.

In addition to observing the waveform, make

sure that there is no slipping of the tape or

curling at the drum lead.

AB

Drum input

Abnormal Waveform Example

Supply Guide Roller

Tight Screw

Tape

Supply Guide Roller

Drum Input Adjustment

12

MV-8080G_5(6~16) 97.12.11, 9:36Page 12 Adobe PageMaker 6.0J/PPC

Page 15

2. DRUM OUTPUT ADJUSTMENT

1. Adjust the take-up guide roller so that the FM

envelope output flattens as shown in D of the figure

below.

CD

Drum output

Drum Output Adjustment

NOTES:

1. Fine adjustments are not required at this time.

It is sufficient if the tape is engaged with the

guide and that the servo operates properly

(control signal picked up).

2. If the tape separates from the take-up guide or

wrinkling occurs, screw C must have been

excessively tightened with respect to screw A

and screw B, which is causing the Audio/CTL

Head to incline forward or backward. Use care

in adjusting screws B and C, and screw A

evenly and observe that wrinkles are not

produced at the take-up guide.

2. If the tape separates from the guide or wrinkling

occurs at the take-up guide, adjust by turning screw

C of the Audio/CTL Head as shown in the figure

below.

AB E

Take-up

“«Ł

Guide Roller

KCh[

¯ŁlW

Tight Screw

e[v

Tape

“«Łe[vKCh

Take-up Guide

DC

Tape

e[v

Take-up Guide

3. As shown in the figure below, adjust screws B and

C and screw A to align the Audio/CTL Head

height with the tape.

Audio Head

5-3. INTERCHANGEABILITY

ADJUSTMENT

1. Observe the FM envelope output waveform at the

oscilloscope and press to adjust the CHANNEL ∞/5

buttons in both positive(+) and negative(-) directions.

Maximum

AC

DB

Minimum FM Output (Incorrect Examples)

2. If there are waveforms as shown in A or B in the

above figure, adjust the supply guide roller height so

that the waveform appears as shown by E, F, or G

in the figure below. At this time, if the waveform

fluctuates, adjust to the point of minimum fluctuation.

Taper

Parallel

Taper

Approx.

0.06mm

Reference line

CTL Head

Tape

Take-up Guide Pole

E

F

G

Audio/CTL Head Height

Minimum FM Output (Correct Examples)

13

MV-8080G_5(6~16) 97.12.11, 9:36Page 13 Adobe PageMaker 6.0J/PPC

Page 16

3. If the FM waveform appears as shown by C or D in

the above figure, adjust the take-up guide roller

height to obtain a waveform such as shown in E, F,

or G.

At this time, if the waveform fluctuates, adjust to the

point of minimum fluctuation.

4. Vary the tracking control from maximum to minimum

FM output.

Perform fine adjustment of supply and take-up guide

rollers so that waveform variation appears as shown

in E, F, or G.

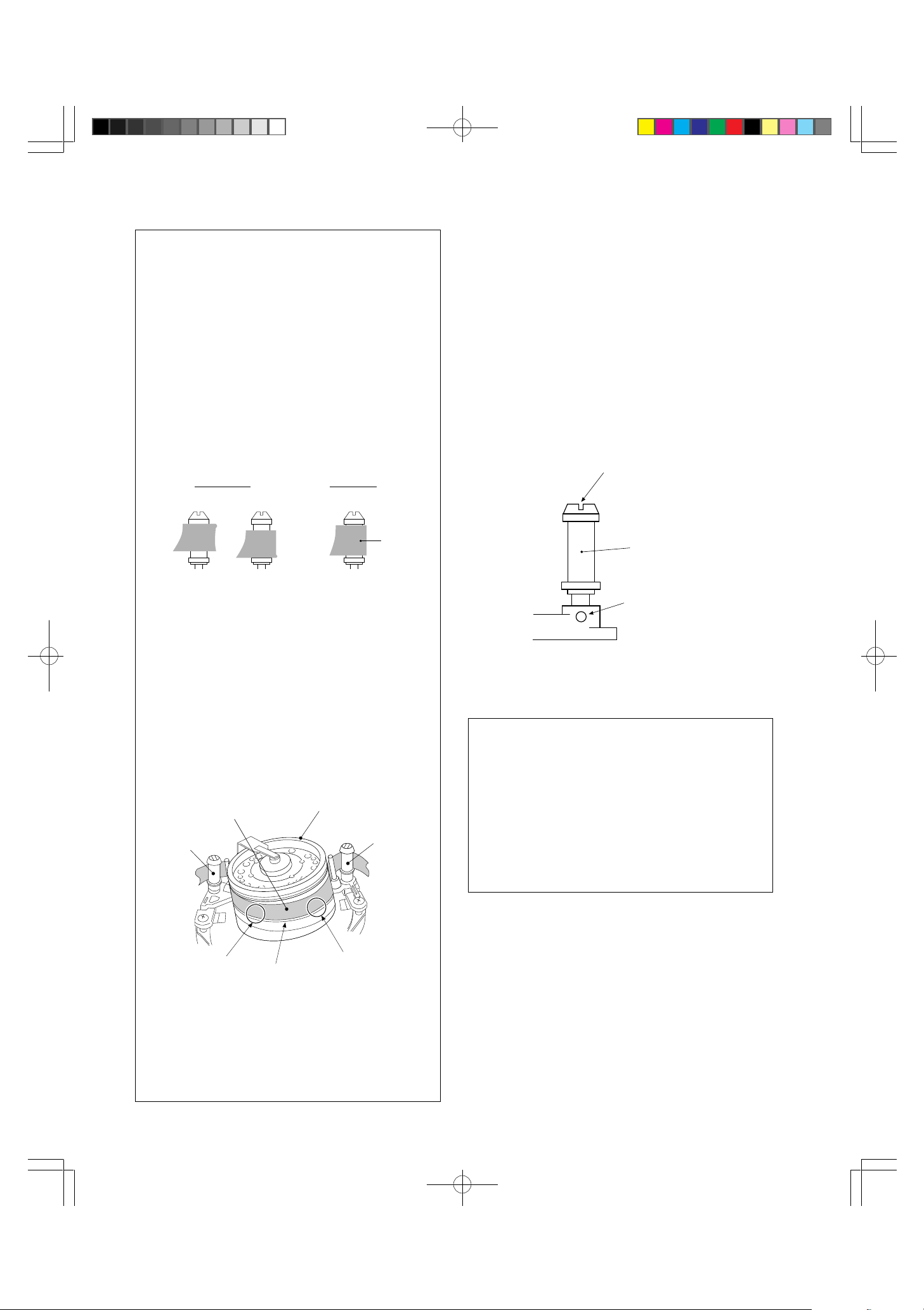

6. RG POST HEIGHT ADJUSTMENT

E

Tape

5-4. AUDIO/CTL HEAD HEIGHT,

AZIMUTH AND SLANT

Refer to 3-2 (P.9) for details regarding AUDIO/CTL

HEAD HEIGHT AND AZIMUTH ADJUSTMENT.

5-5. SETSCREW TIGHTENING

1. Check for maximum FM output waveform, maximum

audio output, and be sure that there is no wrinkling on

the tape or other transport irregularities. When

finished, secure the guide rollers. (This must be

performed in STOP mode.)

2. Because the guide rollers are easily moved, use care

when securing.

3. After tightening the screws, perform the final interchangeability check.

5-6. FINAL INTERCHANGEABILITY

CHECK

Perform preliminary checks referring to section “PRELIMINARY CHECKS” on page P.11.

Take-Up Guide

RG Post

1) Use a blank tape and set the VCR to REV mode.

2) Adjust the RG Post height adjusting screw E so that

the tape runs along the lower flange of the Take-Up

Guide.

14

MV-8080G_5(6~16) 97.12.11, 9:36Page 14 Adobe PageMaker 6.0J/PPC

Page 17

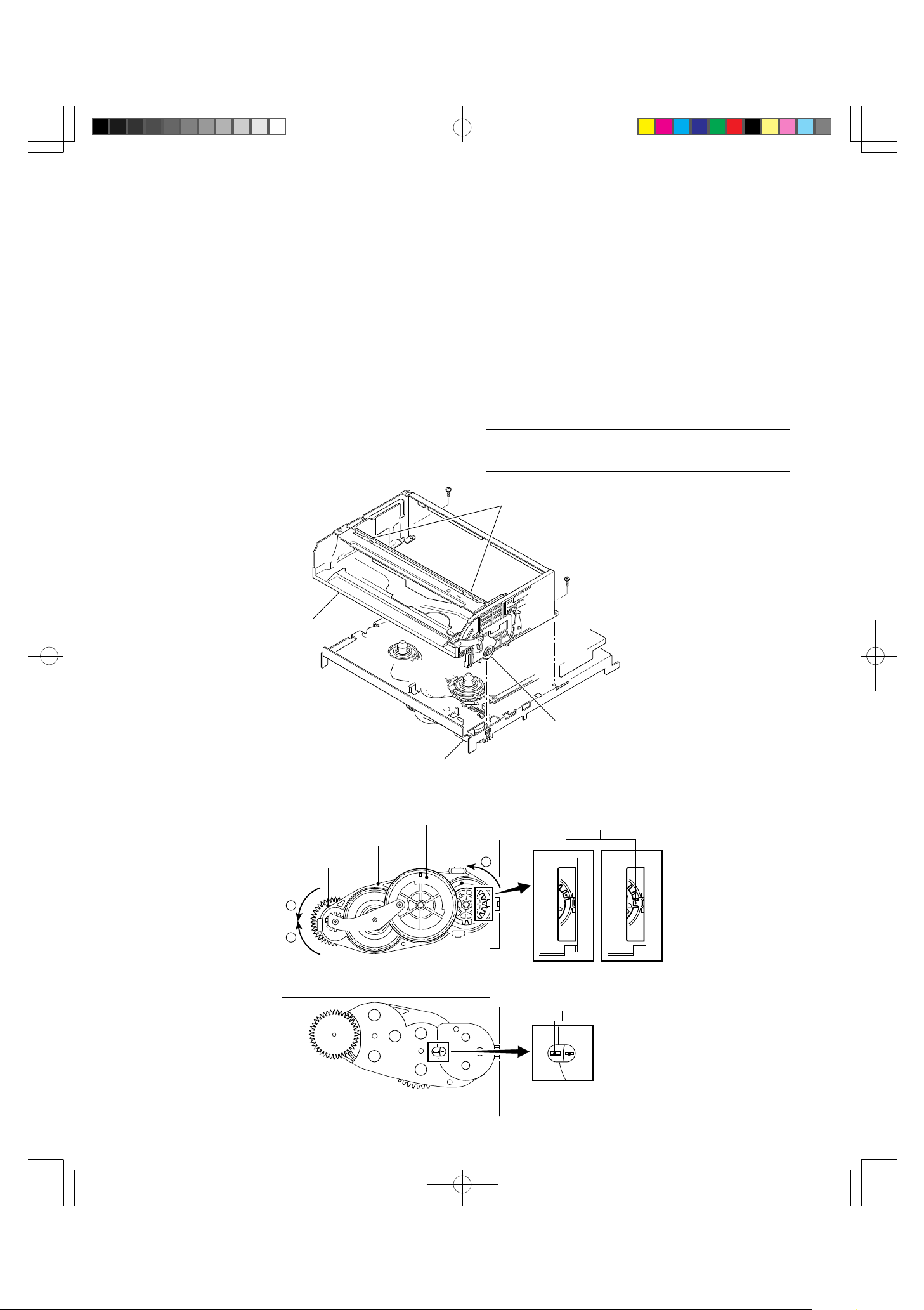

7. FRONT LOADING ASSEMBLY ATTACHMENT

To attach the Front Loading Assembly, follow the procedures below.

1) Twist the loading motor with your finger until it is in

EJECT mode.

2) Twist the FD Pinion Gear counterclockwise until it

stops. (The FD Face Gear is loose. )

3) Twist the FD face Gear counterclockwise until it

stops, then apply gentle pressure in the

counterclockwise direction.

4) In the position at step 2) , rotate the FD Pinion Gear

clockwise. After about 3 1/2 turns, the FD Pinion Gear

should begin to interlock with the FD Relay Gear.

Now twist the FD Pinion Gear until it stops. (The

assembly should now resemble Fig. 2)

5) Twist the FD Pinion Gear about 1/3 of a turn

counterclockwise so that the Lift Gear R attachment

position is horizontal making attachment easier, as

shown in Fig. 3. Also, the FD Relay Gear and FD

Face Gear eye marks should be aligned when the

MD is viewed from the back. (Fig. 4)

6) Attach the front assembly.

Insert the first Lift Gear R between the first and

second gear of the front assembly. (Fig. 3)

Note: Do not touch the CSP plate of the Front Loading

Assembly. (Take care not to distort it.)

CSP plate

Front Loading A'ssy

FD Gear Case

FD Pinion Gear

2

4

Fig. 1 View from above the MD

FD Gear Case

FD Relay Gear

FD Face Gear

Lift Gear R

Align first gear on Lift Gear R.

3

Fig. 2

Fig. 3

Eye mark

Fig.4 MD Rear View

15

MV-8080G_5(6~16) 97.12.11, 9:36Page 15 Adobe PageMaker 6.0J/PPC

Page 18

PERIODIC MAINTENANCE

The following procedures are recommended for maintaining optimum performance and reliability of this video

cassette recorder.

CLEANING

For cleaning, use a lint-free cloth or gauze dampened

with alcohol.

TAPE TRANSPORT SYSTEM

1. The following components should be cleaned after

every 500 hours of use.

• Impedance Roller

• Tension Post

• Transport Slide Post

• Supply Guide Roller

• Take-up Slide Post

• Take-up Guide Roller

• Video Head & Drum System

• Drum Ground

• Drum Motor Shaft

• Audio/CTL Head

• Pinch Roller

• Capstan

• Reverse Guide Post

• Full Erase Head

• Tape Guide

• F Post

REEL DRIVE SYSTEM

1. The following components should be cleaned after

every 1000 hours of use.

TOP BOTTOM

• Take-up Reel Table Ass’y • Capstan Motor Pulley

• Supply Reel Table Ass’y • Clutch Pulley

• T Soft Brake Ass'y • Drive Belt

• T Main Brake Ass'y • C Brake

• S Main Brake Ass'y

• BT Band Ass'y

2. The above revolving parts are of rubber or come in

direct contact with rubber parts. Dust on rubber

accumulates and interferes with proper operation.

3. Avoid using excessive alcohol when cleaning rubber

parts.

2. Since the above parts come in direct contact with

video tape, they tend to collect dust particles. If

allowed to accumulate, dust may lead to damage to

the video tape and above parts.

3. After cleaning with alcohol, allow the parts to dry

thoroughly before using a cassette tape.

NOTE:

• When cleaning the two video heads on the

upper drum, do not clean them with a vertical

stroke.

• Use only a gentle back and forth motion in the

direction of the tape path.

16

MV-8080G_5(6~16) 97.12.11, 9:36Page 16 Adobe PageMaker 6.0J/PPC

Page 19

SERVICE SCHEDULE FOR MAIN COMPONENTS

The following table lists the parts which should receive periodic servicing at the recommended intervals.

Ref. No Part No.

Description

1000 2000 3000 4000 5000

1 62D806501603 Cylinder Ass’y for 59277 ●●

1 62D806501603 Cylinder Ass’y for 59311 ●●

90 62D806506301 Pinch Roller Arm Ass'y ●●

116 62D806508303 BT Band Ass’y ●●

128 62D806509302 Clutch Ass’y ●●

131 62D80650920 Drive Belt ●●

132 62D806510301 T Main Brake Ass’y ●●

133 62D806510302 S Main Brake Ass’y ●●

134 62D806510303 T Soft Brake Ass'y ●●

61 62D62041520 A/C & E Head for 59277 ●

61 62D62040324 Audio/CTL Head for 59311 ●

80 62D806505301 T Reel Ass’y

81 62D806505302 S Reel Ass’y

100 62D60030360 Capstan Motor Ass’y

Periodic Service Schedule (operating hours)

142 62D806511303 Loading Motor Ass'y

Standard Service Periods Check and replace if necessary

● Replace

NOTE:

Cleaning and replacement of the belts should be undertaken every 2 years even if the unit is not used frequently.

17

MV-8080G_6(17~18) 97.12.11, 9:49Page 17 Adobe PageMaker 6.0J/PPC

Page 20

Page 21

CASSETTE DECK MECHANISM 59277, 59311

Ref. No. TN Part No. ST Part No. Description

1 8065-01-603 62D806501603 CYLINDER ASS’Y

2 8065-01-305 62D806501305 V OUT PWB ASS’Y

3 6809-70-243 62D680970243 FPC4 CONNECTOR (C)

4 9P12-26-064 62D9P1226064 TAMS SCREW,2.6X6MM

5 8065-01-501 62D806501501 DRUM EARTH ASS’Y

6 9P04-26-041 62D9P0426041 TAPPING SCREW,2.6X4MM

7 8065-01-2316 62D806501316 DRUM MOTOR ASS’Y

8 9P02-26-151 62D9P0226151 TAMS SCREW 2.6X15

9 8065-01-315 62D806501315 ROTOR SCREW ASS’Y

10 9P04-30-051 62D9P0430051 TAPPING SCREW 3.0X5

20 8065-02-301 62D806502301 F POST METAL ASS’Y

21 8065-02-303 62D806502303 TAPE GUIDE BASE ASS’Y

22 8063-02-23 62D80630223 CASSETTE GUIDE BOSS

23 8065-02-21 62D80650221 TAPE PROTECT

24 8065-02-304 62D806502304 TAPE GUIDE ASS’Y

30 8065-03-502 62D806503502 LOADING LEVER KASIME

31 8063-03-305 62D806303305 LOADING PLATE L ASS’Y

32 8065-03-305 62D806503305 LOADING PLATE R ASS’Y

33 9W06-50-110 62D9W0650110 HL WASHER,4.5X7X0.5(CUT)

34 8065-03-303 62D806503303 L BLOCK L ASS’Y

35 8065-03-304 62D806503304 L BLOCK R ASS’Y

36 8063-03-09 62D80630309 ROLLER POST

37 8065-03-04 62D80650304 LOADING GEAR

38 8065-03-05 62D80650305 L GEAR PLATE

39 8065-03-11 62D80650311 L GEAR PLATE COLLOR

40 9W02-50-100 62D9W0250100 P.WASHER,2.1X5X0.5(CUT)

41 9W02-50-110 62D9W0250110 P.WASHER,2.6X6X0.5(CUT)

42 8065-03-10 62D80650310 L GEAR PLATE SPRING

43 8065-03-01 62D80650301 LD CATCHER

44 9P04-26-051 62D9P0426051 SCREW,2.6X5MM

45 8065-03-306 62D806503306 HEAD CLEANING ASS’Y

46 8063-03-29 62D80630329 CLEANING ROLLER ASS’Y

47 9W02-30-050 62D9W0230050 P.WASHER,1.6X3.8X0.3(CUT)

48 9C17-20-233 62D9C1720233 CAMERA SCREW 2 X2.3MM

60 8065-04-302 62D806504302 ACE HEAD BASE ASS’Y

61 6204-15-20 62D62041520 ACE HEAD HVMZA1220

60 8065-04-303 62D806504303 AC HEAD BASE ASS’Y

61 6204-03-24 62D62040324 AC HEAD HVMZB1030

62 8000-06-04 62D80000604 AZIMUTH SPRING

63 8000-06-26 62D80000626 AZIMUTH SPRING SCREW

64 9P09-30-061 62D9P0930061 SCREW,3X6MM(FIXING)

65 9P01-26-072 62D9P0126072 SCREW,2.6X7MM

66 8065-04-301 62D806504301 FE HEAD BASE ASS’Y

67 6209-15-04 62D62091504 VTR1X2ERS11107

*

68 8063-04-306 62D806304306 IMPEDANCE ROLLER ASS’Y

69 9W02-30-050 62D9W0230050 P.WASHER,1.6X3.8X0.3(CUT)

LOWER DECK (59277) FOR REC/PB

UPPER DECK (59311) FOR P.B. ONLY

LOWER DECK (59277) FOR REC/PB

19

MV-8080G_7(19~21) 97.12.11, 9:51Page 19 Adobe PageMaker 6.0J/PPC

Page 22

CASSETTE DECK MECHANISM 59277, 59311

Ref. No. TN Part No. ST Part No. Description

70 9W06-30-040 62D9W0630040 HL WASHER,1.55X4.5X0.3(CUT)

71 8065-04-02 62D80650402 HEAD BASE SPRING

80 8065-53-01 62D806505301 T REEL ASS’Y

81 8065-05-302 62D806505302 S REEL ASS’Y

82 9W03-30-110 62D9W0330110 NYLON WASHER 2.5X5X0.3

90 8065-06-301 62D806506301 PINCH ROLLER ARM ASS’Y

91 8065-06-05 62D80650605 PINCH ROLLER

92 9B01-26-041 62D9B0126041 SCREW,2.6X4MM

93 8065-06-501 62D806506501 PINCH ROLLER KASIME

94 8065-06-04 62D80650604 PINCH ROLLER SPRING

100 6003-03-60 62D60030360 CAPSTAN MOTOR (F2QTB10)

101 9P07-26-061 62D9P0726061 TAPPING SCREW P 2.6X6

102 8065-07-301 62D806507301 C BRAKE ASS’Y

103 9W02-50-100 62D9W0250100 P.WASHER,2.1X5X0.5(CUT)

104 8065-07-02 62D80650702 C BRAKE SPRING

110 8065-08-301 62D806508301 TENSION ARM ASS’Y

111 8063-08-04 62D80630804 BT ARM METAL

112 8065-08-02 62D80650802 BT SPRING

113 8065-08-06 62D80650806 BT LEVER

114 9W02-50-110 62D9W0250110 P.WASHER,2.6X6X0.5(CUT)

115 8065-08-302 62D806508302 TENSION ARM SEMI ASS’Y

116 8065-08-303 62D806508303 BT BAND ASS’Y

120 8065-09-303 62D806509303 SUB PLATE ASS’Y

121 9C04-26-503 62D9C0426503 CAMERA SCREW(TAPPING)S 2.6X5

122 9P04-20-041 62D9P0420041 TAPPING SCREW 2.0X4

123 8065-09-304 62D806509304 RF CLUTCH ASS’Y

124 9W02-50-110 62D9W0250110 P.WASHER,2.6X6X0.5(CUT)

125 8065-10-09 62D80651009 SS BRAKE SPRING

126 8065-10-07 62D80651007 TS BRAKE SPRING

127 8065-10-10 62D80651010 TS BRAKE LEVER

128 8065-09-302 62D806509302 CLUTCH ASS’Y

129 8065-09-301 62D806509301 CLUTCH PULLY ASS’Y

130 9W02-30-060 62D9W0230060 P.WASHER,2.1X5X0.3(CUT)

131 8065-09-20 62D80650920 DRIVE BELT

132 8065-10-301 62D806510301 T MAIN BRAKE ASS’Y

133 8065-10-302 62D806510302 S MAIN BRAKE ASS’Y

134 8065-10-303 62D806510303 T SOFT BRAKE ASS’Y

135 8065-11-13 62D80651113 REVERSE LEVER

136 8065-09-307 62D806509307 GEAR PLATE ASS’Y

137 8065-10-05 62D80651005 MAIN BRAKE SPRING

138 8065-10-08 62D80651008 S SOFT BRAKE ARM

139 8065-11-14 62D80651114 REVERSE LEVER PIN

140 8065-11-302 62D806511302 CAM GEAR ASS’Y

141 8065-11-301 62D806511301 CAM PLATE ASS’Y

142 8065-11-303 62D806511303 LOADING MOTOR ASS’Y

143 8065-11-11 62D80651111 MOTOR HOLDER

20

MV-8080G_7(19~21) 97.12.11, 9:51Page 20 Adobe PageMaker 6.0J/PPC

Page 23

CASSETTE DECK MECHANISM 59277, 59311

Ref. No. TN Part No. ST Part No. Description

144 9P02-26-051 62D9P0226051 TAMS SCREW 2.6X5

145 9F22-26-081 62D9F2226081 ADJUST SCREW 2.6X8

146 8065-11-04 62D80651104 M GEAR

147 8065-11-305 62D806511305 M GEAR PLATE ASS’Y

148 8065-11-07 62D80651107 M RELAY GEAR

149 9W06-30-100 62D9W0630100 HLW(C) 2.6X6X0.3

150 8065-11-08 62D80651108 M SLIDE PLATE

151 8065-11-17 62D80651117 R LEVER SPRING PLATE

152 9P04-26-051 62D9P0426051 SCREW,2.6X5MM

153 8065-11-03 62D80651103 CAM DRIVE GEAR

154 8065-11-10 62D80651110 WORM WHEEL

155 8065-11-15 62D80651115 OPEN ANGLE

156 8065-11-16 62D80651116 AH ADJUST NUT

160 8065-13-01 62D80651301 OPTICAL LEADER

161 8065-13-303 62D806513303 RS LEADER

162 8065-13-04 62D80651304 REC SWITCH LEVER

*

163 8065-13-05 62D80651305 REC LEVER SPRING

*

164 8065-13-06 62D80651306 IN SWITCH SLIDER

165 8065-13-07 62D80651307 IN SW SLIDER SPRING

166 8065-13-302 62D806513302 BASE PWB ASS’Y

167 8065-13-11 62D80651311 DM LEAD PWB

168 8065-13-12 62D80651312 CM LEAD PWB

169 9P04-26-051 62D9P0426051 SCREW,2.6X5MM

180 8065-15-09 62D80651509 FD SLIDE PLATE

181 8065-15-10 62D80651510 FD SLIDE PLATE SP

182 8065-15-301 62D806515301 FD GEAR CASE ASS’Y

190 8065-16-301 62D806516301 FRONT LOADING ASS’Y

191 9B03-26051 62D9B0326051 SCREW,2.6X5MM

192 9P04-26-051 62D9P0426051 SCREW,2.6X5MM

200 8065-17-501 62D806517501 RG ARM KASIME

201 8065-17-03 62D80651703 RG ADJUST NUT

202 8065-17-04 62D80651704 RG LEVER

203 8065-17-05 62D80651705 RG ARM SPRING

LOWER DECK (59277) FOR REC/PB

21

MV-8080G_7(19~21) 97.12.11, 9:51Page 21 Adobe PageMaker 6.0J/PPC

Page 24

DECK 1

DECK 2

LOADING DRIVER

IC1601

TA7291S

I/R SENS UNIT

MD1701

DECK

TN6500

DECK

SW

SERVO AMP

IC1501

LA7116

SENSOR

NORMAL AUDIO

IC1401

LA7286

BIAS OSC

Q1401

VIDEO

HEAD AMP

IC1102

LA7411

POWER

CPU

IC1701

CXP88132

KEY

SWITCH

DISPLAY

PB EQ

REC EQ

I HDL

HQ PB

Y-EQ

HQ PB

C-BPF

HQ LIMITER

IC1301

AN6326N

IC1801

PH530090

IC1802

KIA431

Q1804

IC2D03

LA7016

AUDIO

SWITCH

IC

IC2D02

TEA6420

CCD 1HDL

IC1202

LC89970N

VIDEO Y/C

PROCESS

IC1201

LA7437

VIDEO

AMP

IC1302

AN304

IC1803

KIA7809P

Q2801

VIDEO

SWITCH

IC

IC2D01

TEA6415C

OSD IC

IC2C01

LC74781

FRONT

JACK

KEY

SWITCH

IC2D04

LA7016

CPU

IC2701

CXP87360

32MHz

12MHz

12MHz

RESET IC

IC2702

PST9129

LOADING DRIVER

IC2601

TA7291S

DECK

SW

SENSOR

SERVO AMP

IC2501

LA7116

NORMAL AUDIO

IC2401

LA7286

BIAS OSC

Q2401

IC2703

AT24C02.10PC

CCD 1 HDL

IC2202

LC89970N

VIDEO Y/C

PROCESS

IC2201

LA7437

P.B. EQ

REC EQ

HQ

REC

EQ

VIDEO

HEAD AMP

LA7411

TUNER

CONVERTER

DECK

TN6500

FSS-OUT

21PIN

JACK

#8

AC IN

–

30V

FL

SW+11V

+

12V

SW+11V

+

12V

+

30V

+

5V

+

5V

DEC-IN

P1802

DECORDER

P1801

AUDIO/VIDEO

SW1C

IC2301

BU4053BC

+

9V

MV-8080G_8(22~27) 97.12.11, 9:53Page 22 Adobe PageMaker 6.0J/PPC

2. BLOCK DIAGRAM

– 22 –

Page 25

3. TERMINOLOGY REFERENCE

CAD-Code Numerical Value

RAIRIF IRI = 1.1 Ω

R RA821F 821 = 82 X 10

C CA200C 200 = 20 X 10

L 330J 330 = 33 X 10

RA180F 180 = 18 X 10

RC102F 102 = 10 X 10

RC103F 103 = 10 X 10

RC104F 104 = 10 X 104 = 100 KΩ

CLIR5H 1R5 = 1.5 pF

CA333B 333 = 33 X 10

CA104F 104 = 10 X 10

ESI/50H 1/50 = 1µF/50V

IR5J IR5 = 1.5 µH

181J 181 = 18 X 10

68NJ 68N = 68 X 10

The following terms have been changed as a result of the use of a new CAD system.

Description Ref. No. CAD Code

♦ IC IC101 LA3373, MT

♦ Transistor Q101 2SC2785T. E. F

♦ Diode D101 1S2835T

♦ Resistor R101 RC102F

R102 RA1R1

♦ Capacitor C101 CA200C

(Chip)

♦ Capacitor C101 SL1R5H or S or Z

(Ceramic)

♦ Capacitor C101 ES1/50H or F or Z

(Electrolytic)

0

= 18 Ω

1

= 820 Ω

2

= 1 KΩ

3

= 10 KΩ

0

= 20 pF

3

= 33000 pF = 0.033 µF

4

= 0.1 X 106 pF = 0.1 µF

0

= 33 µH

1

= 180 µH

–9

H = 68 NH = 0.068 µH

No Connection

Description (LA3373)

Circuit Ref. Number

Head Name

Rank

No Connection

Description (2SC2785)

Circuit Ref. Number

Head Name

No Connection

Description (1S2835)

Circuit Ref. Number

Head Name

Tolerance

F: ±1 %

G: ±2 %

J: ±5 % (No Mark)

K: ±10%

M: ±20%

H: No Connection

Resistance (10 x 102 = 1000 ohms)

Carbon Resistor 1/6W

Circuit Ref. Number

Head Name

Resistance (1.1 ohm)

Decimal Point Mark

Chip Resistor 2125 Type 1/10W

Temperature Characteristic

C: CH, CJ, CK

U: UJ

S: SL

B: B

D: D

Capacitance (20 x 100 = 20pF)

Chip Capacitor 2125 Type

Circuit Ref. Number

Head Name

No Connection

Capacitance (1.5pF)

Decimal Point Mark

Characteristic (Ceramic SL)

No Connection

Voltage Proof (50V)

Capacitance (1µF)

Electrolytic SSM Type

– 23 –

MV-8080G_8(22~27) 97.12.11, 9:53Page 23 Adobe PageMaker 6.0J/PPC

Page 26

Description Ref.No. CAD Code

♦ Hybrid IC IC102 HIC* * * * * * Code No. (3 ~ 8 Column → 11* * * * * *0)

♦ CR Component CR101 CR* * * * * * Code No. (3 ~ 8 Column → 11* * * * * *0)

♦ In-Line Block IB101 IB* * * * * * Code No. (3 ~ 8 Column → 11* * * * * *0)

♦ Surge Absorber D102 Z* * * * * * Code No. (3 ~ 8 Column → 13* * * * * *0)

♦ LED LD101 LED* * * * * * Code No. (3 ~ 8 Column → 14* * * * * *0)

♦ LCD H101 LCD* * * * * * Code No. (3 ~ 8 Column → 14* * * * * *0)

♦ FIP H102 FIP* * * * * * Code No. (3 ~ 8 Column → 14* * * * * *0)

♦ Pilot Lamp PL101 PL* * * * * * Code No. (3 ~ 8 Column → 14* * * * * *0)

♦ Neon Bulb NE101 NE* * * * * * Code No. (3 ~ 8 Column → 14* * * * * *0)

♦ Trimmer Cap. C102 CT* * * * * Code No. (5 ~ 9 Column → 1591* * * * *)

♦ CFC Assy C103 CFC* * * * * Code No. (5 ~ 9 Column → 1501* * * * *)

♦ Coil L101 L* * * * * * Code No. (3 ~ 8 Column → 17* * * * * *0)

♦ Filter F101 F* * * * * * Code No. (3 ~ 8 Column → 17* * * * * *0)

Description Type Capacitance Limit No Marked Tolerance

CK, CJ, CH, UJ 1PF ∼ 5PF C (±0.25PF)

Chip CH, SL 12PF ∼ 470PF J (±5%)

Ceramic

Semi-Conductor SR 0.001µF ∼ 0.068µFK

Mylar (M) 0.001µF ∼ 0.1µFJ

TF 0.1µF ∼ 0.47µFJ

PS, NPS 470PF ∼ 1000PF G (±2%), J

ALSICON (AS) 0.1µF ∼ 0.22µFM

Tantalum (TA) 0.15µF ∼ 10µFM

Electrolytic General 0.1µF ∼ 220µFM

CH, UJ 6PF ∼ 10PF D (±0.5PF)

SL, B 680PF ∼ 0.022µF K (±10%)

D 0.033µF ∼ 0.1µF M (±20%)

1PF ∼ 5PF C

General 12PF ∼ 270PF J

B 100PF ∼ 680PF K

BC 0.1µF ∼ 0.2µF Z (–20% ∼ +80%)

6PF ∼ 10PF D

Head Description

ET Electrolytic Tuner

MT Manual Tuner

PT Push Button Tuner

K Relay

MC Microphone

SP Speaker

IC IC, Hybrid IC

IB In-Line Block

CR CR Component

Q Transistor

D Diode, Surge Absorber

LD LED

H LCD

H FIP

CAD Code *Capacitor

CA* * * * Chip Capacitor 2125 Type

CB* * * * Chip Capacitor 3216 Type

SL* * * Ceramic Capacitor SL Type

B* * * Ceramic Capacitor B Type

F* * * Ceramic Capacitor F Type

CH* * * Ceramic Capacitor CH Type

LH* * * Ceramic Capacitor LH Type

PH* * * Ceramic Capacitor PH Type

RH* * * Ceramic Capacitor RH Type

SH* * * Ceramic Capacitor SH Type

TH* * * Ceramic Capacitor TH Type

UJ* * * Ceramic Capacitor UJ Type

SR* * * Semi-Conductor Cap. SR Type

BC* * * Semi-Conductor Cap. BC Type

M* * * Mylar Capacitor

TF* * * TF Capacitor

NP* * * NPS Capacitor

AS* * / * * ALSICON Capacitor

TA* * / * * Tantalum Capacitor

ES* * / * * Electrolytic Cap. SSM Type

ESL* * / * * Electrolytic Cap. SSM-L Type

ESH* * / * * Electrolytic Cap. SSM-H Type

ESB* * / * * Electrolytic Cap. Bi-Polar

EG* * / * * Electrolytic Cap. GSM Type

EE* * * * Electrolytic Cap. SEM Type

Head Name Description

NE Neon Bulb

PL Pilot Lamp

C* Capacitor

R* * Resistor

L Transformer

L Coil, Inductor

F Ceramic Filter, Crystal

W Printed Circuit Board

BL Block PC Ass'y

P Connector Post

TP Check Pin

AJ Antenna Jack

SW Switch

VR Volume

CAD Code *Capacitor

EA* */* * Electrolytic Cap. Aibis Type

EL* */* * Electrolytic Cap. LSM Type

EH* */* * Electrolytic Cap. HPW Type

CT* * * * * Trimmer Capacitor

CAD Code * *Resistor

RA* * * Chip Resistor 2125 Type

RB* * * Chip Resistor 3216 Type

RC* * * Carbon Resistor 1/6W S Type

RD* * * Carbon Resistor 1/4W U Type

RU* * * Carbon Resistor 1/6W U Type

RF* * * Carbon Resistor 1/2W S Type

RK* * *F Metal Film Resistor 1/4W S ±1%

RL* * *F Metal Film Resistor 1/6W S ±1%

RP* * * Metal Oxide Resistor 1W S Type

RQ* * * Metal Oxide Resistor 2W S Type

RM* * * Cement Resistor 5W S Type

RV* * * Variable Resistor Vertical Type 6φ

RV* * *A Variable Resistor Vertical Metal 6φ

RV* * *B Variable Resistor Down Type 6φ

RV* * *C Variable Resistor Vertical 6φ 4 pin

PR* * * Printed Resistor (on PC Board)

– 24 –

MV-8080G_8(22~27) 97.12.11, 9:53Page 24 Adobe PageMaker 6.0J/PPC

Page 27

5. IC, TRANSISTOR LEAD IDENTIFICATION

SPS-1118C

GND

IN

EC

OUT

PST9129T

TOP VIEW

1 18

AN6326N

9 10

TYPE NUMBER

E

C

B

B

C

E

B

C

E

OUT

GND

IN

2SD1858T

2SA124

2SA1048T

2SC124

2SC2120T

2SC2458T

DTC124EST

KRA103MT

KTA1267T

KTC3199T

2SC4908

2SD2396

BA12T

KIA7809PI

FRONT VIEW

5

1

FRONT VIEW

8

1

FRONT VIEW

9

1

TOP VIEW

1

2

4

3

LA7213

LA7016

TA7291S

PHOTOCOUPLER

PS2561

TOP VIEW

1 20

10 11

TOP VIEW

1 22

11 12

TOP VIEW

1 24

12 13

TOP VIEW

1 42

21 22

TEA6415C

LC89970

LA7116

LA7286

LA7411

LA74781-9155

TEA6420

LA7437

REF

TOP VIEW

TOP VIEW

2SD1581T

B

C

E

1 8

4 5

AT24C02-10PC

80 51

81

100

1 30

50

CXP8XXXX

31

TOP VIEW

2SC1959

B

C

E

2SD2132T

1 14

7 8

AN304

SDA5650

TOP VIEW

1 16

KIA431AT

K

A

8 9

BU4053BC

– 25 –

MV-8080G_8(22~27) 97.12.11, 9:53Page 25 Adobe PageMaker 6.0J/PPC

Page 28

X

A

B

E

F

L

K

Y

D

D

37

44

18

22

19

12

11

1

4

13

3

13

21

6

20

25

26

27

28

29

30

31

36

35

34

33

20

18

26

31

31

28

27

27

27

31

43

47

46

45

47

31

31

30

30

30

32

MV-8080G_8(22~27) 97.12.11, 9:53Page 26 Adobe PageMaker 6.0J/PPC

6. UPPER CABINET EXPLODED VIEW (DECK UNIT 1)

✽ Never touch the gold plated part on the Base PWB Ass'y

X as oil or other dirt will cause the electrical connection to

deteriorate.

The spring connection point Y of the connector will also

be distorted if touched.

Therefore, never touch these parts.

– 26 –

✽Attach the Face Plate with the Dust

Cover pushed open.

Page 29

Y

E

F

H

J

A

B

J

L

K

H

X

2

31

48

31

31

28

31

31

6

31

30

30

31

31

31

41

28

49

49

31

39

23

9

7

5

17

8

10

16

15

24

42

8

18

19

12

14

20

26

29

31

35

34

20

18

26

31

33

43

17

42

13

13

40

38

MV-8080G_8(22~27) 97.12.11, 9:53Page 27 Adobe PageMaker 6.0J/PPC

✽ Never touch the gold plated part on the Base PWB Ass'y

LOWER CABINET EXPLODED VIEW (DECK UNIT 2)

X as oil or other dirt will cause the electrical connection to

deteriorate.

The spring connection point Y of the connector will also

be distorted if touched.

Therefore, never touch these parts.

– 27 –

Page 30

7. PARTS LIST FOR CABINET & CHASSIS

Ref. No. Part No. Description

1 59311

2 59277

UPPER DECK MECHANISM (TN6500-116M) FOR P.B. ONLY

LOWER DECK MECHANISM (TN6500-105M) FOR REC/PB

3 21046281 COVER (TOP)

4 21046200 COVER (MID)

5 21046191 COVER (BOTTOM)

6 21175910 BKT (BAR-F)

7 21176050 BKT A

8 21176060 BKT B

9 21176070 BKT C

10 21176080 BKT D

11 21234880 SHIELD PLATE

12 21234720 S.PLATE (AUD)

13 21234850 S.PLATE (GND)

14 2953310A DPBB-3X10SSA

15 22128820 REAR PANEL (2-SCART)

16 22128830 REAR PANEL (PAL-R)

17 22128170 HOLDER (CHASSIS)

18 22151730 SPACER DECK-S

19 22151740 SPACER DECK-L

20 22151840 SPACER (DECK-N)

21 22329050 FPASSY TWIN TOP 11

22 22704140 CHASSIS (PAL-DECK1) UPPER

23 22704150 CHASSIS (PAL-DECK2) LOWER

24 25351020 CUSHION

25 28004430 INSULATOR

26 2952305A DPBS-3X5SSA

27 2952308A DPBS-3X8SSA

28 2953306A DPBB-3X6SSA

29 2952235A DPBS-2.3X5SSA

30 2953310C DPBB-3X10SSC

31 2953312A DPBB-3X12SSA

32 See inside cover POWER CORD

33 194916LA0 N801 FLEXIBLE WIRE 21P

34 196A00700 N702 QS-CONN AMP11

35 196311700 QS-CONN -8283-02

See inside cover UPPER VIDEO CIRCUIT BOARD (MV-8080G)

36 MAIN CIRCUIT BOARD (WITH POWER SECTON)

37 HEAD CIRCUIT BOARD

38 SCART CIRCUIT BOARD

See inside cover LOWER VIDEO CIRCUIT BOARD (MV-8080G)

39 MAIN CIRCUIT BOARD (WITH TUNER)

40 HEAD CIRCUIT BOARD

41 196311300 N2401 QS-CONN -8283-02

42 21234910 S.PLATE (GND-F)

43 194001090 N1201, N2201 FLEXIBLE WIRE-9P

44 106012100 MD1701 MODULE, TFMX5380SN

45 22128210 MP1008 HOLDER (FIP-L)

46 22128231 MP1009 HOLDER (FIP-R)

47 22128410 MP1007 HOLDER (LED)

48 22128251 MP2007 HOLDER (RCA)

49 21291220 PLATE SPRING (PCB)

28

MV-8080G_9(28-) 97.12.11, 9:58Page 28 Adobe PageMaker 6.0J/PPC

Page 31

Page 32

Page 33

Page 34

Page 35

9. PC BOARD ASS’Y (UPPER MAIN) PARTS LIST

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

C1201,C1215 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1202,C1358 15714R00E CAPACITOR,CHIP,4PF 50V

C1203 15717R00E CAPACITOR,CHIP,7PF 50V

C1204 15713900E CAPACITOR,CHIP,39PF 50V

C1205 15711210E CAPACITOR,CHIP,120PF 50V

C1207,C1318 15785610E CAPACITOR,CHIP,560PF 50V

C1211,C1430 15714700E CAPACITOR,CHIP,47PF 50V

C1216,C1218 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1217 15712010E CAPACITOR,CHIP,200PF 50V

C1219 15783310E CAPACITOR,CHIP,330PF 50V

C1220,C1355 15713300E CAPACITOR,CHIP,33PF 50V

C1221,C1223 157C2230E CI-2125F223Z25-CT

C1222,C1227 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1224,C1228 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C1225,C1230 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1226,C1229 155347625 CE-SSM47M16-FT

C1231,C1232 157C2230E CI-2125F223Z25-CT

C1233,C1238 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C1234,C1501 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1235,C1236 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1237,C1241 157C2230E CI-2125F223Z25-CT

C1239,C1410 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1240,C1504 15711010E CAPACITOR,CHIP,100PF 50V

C1242,C1245 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C1243,C1246 157A4730E CAPACITOR,CHIP,0.047UF 25V

C1247,C1249 157A4730E CAPACITOR,CHIP,0.047UF 25V

C1248,C1407 157C2230E CI-2125F223Z25-CT

C1250 15782210E CAPACITOR,CHIP,220PF 50V

C1263 157C1050E CAPACITOR,CHIP,1UF 16V

C1264 15715R00E CAPACITOR,CHIP,5PF 50V

C1273,C1274 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1301,C1302 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1303 15715600E CAPACITOR,CHIP,56PF 50V

C1304,C1306 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1305,C1311 1553107G5 CAPACITOR,ELECTROLYTIC,100UF 16V

C1309,C1310 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1312,C1313 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1314,C1317 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1315 15711200E CAPACITOR,CHIP,12PF 50V

C1319 15716800E CAPACITOR,CHIP,68PF 50V

C1321,C1322 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1323,C1325 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1324,C1411 1553107G5 CAPACITOR,ELECTROLYTIC,100UF 16V

C1351,C1424 157A1030E CAPACITOR,CHIP,0.01UF 25V

33

MV-8080G_9(28-) 97.12.11, 9:58Page 33 Adobe PageMaker 6.0J/PPC

Page 36

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

C1352 15718200E CAPACITOR,CHIP,82PF 50V

C1353,C1431 15784710E CAPACITOR,CHIP,470PF 50V

C1360,C1361 15714R00E CAPACITOR,CHIP,4PF 50V

C1406,C1510 155647425 CAPACITOR,ELECTROLYTIC,0.47UF 50V

C1408,C1723 1553476G5 CAPACITOR,ELECTROLYTIC,47UF 16V

C1409,C1509 157F1220E CAPACITOR,CHIP,1200PF 50V

C1412 157A1520E CAPACITOR,CHIP,1500PF 50V

C1416,C1426 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C1418 155447525 CAPACITOR,ELECTROLYTIC,4.7UF 25V

C1421,C1521 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1422 157F5620E CAPACITOR,CHIP,5600PF 50V

C1423 157F2720E CAPACITOR,CHIP,2700PF 50V

C1425,C1713 155347625 CE-SSM47M16-FT

C1502,C1503 157A1020E CAPACITOR,CHIP,1000PF 50V

C1505,C1506 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1507 157C2230E CI-2125F223Z25-CT

C1508,C1513 157A1020E CAPACITOR,CHIP,1000PF 50V

C1511,C1520 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1512,C1515 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1514,C1517 157A1020E CAPACITOR,CHIP,1000PF 50V

C1516 155147625 CAPACITOR,ELECTROLYTIC,47UF 6.3V

C1602,C1702 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1703,C1720 157A1020E CAPACITOR,CHIP,1000PF 50V

C1704,C1712 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1705,C1710 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1706,C1707 15712000E CAPACITOR,CHIP,20PF 50V

C1711,C1721 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1714,C1715 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1718 1556225K5 CAPACITOR,ELECTROLYTIC,2.2UF 50V

C1719,C1790 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1791,C1793 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1794,C1829 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1801 150908900 CC-CFJC22E104M

C1802 150908850 CC-ECKDNA332M250

C1803 15CK47620 CE-HPC47M400

C1804 157A2230E CAPACITOR,CHIP,0.022UF 25V

C1805 157A3320E CAPACITOR,CHIP,3300PF 50V

C1806 157A2730E CAPACITOR,CHIP,0.027UF 25V

C1807 157F8220E CAPACITOR,CHIP,8200PF 50V

C1808 150908015 CC-SL560J1000-FT

C1809 150907710 CC-B103K500

C1810 157A3330E CAPACITOR,CHIP,0.033UF 25V

C1811,C1826 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1812 1553107G5 CAPACITOR,ELECTROLYTIC,100UF 16V

C1813,C1815 1556477M0 CAPACITOR,ELECTROLYTIC,470UF 50V

C1814 1556477W0 CAPACITOR,ELECTROLYTIC,470UF 50V

34

MV-8080G_9(28-) 97.12.11, 9:58Page 34 Adobe PageMaker 6.0J/PPC

Page 37

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

C1816,C1819 1556477M0 CAPACITOR,ELECTROLYTIC,470UF 50V

C1820,C1821 1556477M0 CAPACITOR,ELECTROLYTIC,470UF 50V

C1822 1556477M0 CAPACITOR,ELECTROLYTIC,470UF 50V

C1817 1556226G5 CAPACITOR,ELECTROLYTIC,22UF 50V

C1818 155633525 CAPACITOR,ELECTROLYTIC,3.3UF 50V

C1823,C1828 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C1824 150908210 CC-KC472M250

C1825 155647425 CAPACITOR,ELECTROLYTIC,0.47UF 50V

C1827 157A1030E CAPACITOR,CHIP,0.01UF 25V

C1832 1553476G5 CAPACITOR,ELECTROLYTIC,47UF 16V

C1840 150909350 CC-ECKDNA221M250

C1F00,C1F01 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F02,C1F03 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F04,C1F05 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F06,C1F07 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F08,C1F09 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F10,C1F11 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F12,C1F13 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F14,C1F15 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F16,C1F17 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F18,C1F19 157B1040E CAPACITOR,CHIP,0.1UF 25V

C1F20 157B1040E CAPACITOR,CHIP,0.1UF 25V

D1202,D1204 131002101 DIODE,1SS254T

D1205,D1501 131002101 DIODE,1SS254T

D1502,D1809 131002101 DIODE,1SS254T

D1702 141024800 LED,RED

D1703 141024700 LED-GREEN

D1707 134014131 DIODE,ZENER,MTZJ3.9T-B

D1708,D1709 134013921 DIODE,ZENER,MTZJ4.7T-B

D1801,D1802 132015202 DIODE,RL204-H11

D1803,D1804 132015202 DIODE,RL204-H11

D1805 132014606 DIODE,EG01C-FT

D1810,D1817 131002101 DIODE,1SS254T

D1811,D1814 131003001 DIODE,1SS244T

D1812,D1813 132013508 DIODE,RU2YX-PF

D1815 132013508 DIODE,RU2YX-PF

D1816 132015408 DIODE,RK44LF-M1

D1818 131003001 DIODE,1SS244T

D1819 134015131 DIODE,ZENER,MTZJ6.8T-B

D1820 134019511 DIODE,ZENER,MTZJ33T-A,B

D1821 134015021 DIODE,ZENER,MTZJ6.2T-B

D1822,D1824 131002101 DIODE,1SS254T

D1823 132015308 DIODE,RM4LF(015-301)

D1825,D1827 131002101 DIODE,1SS254T

D1826 134016621 DIODE,ZENER,MTZJ11T-A

D1828 134014511 DIODE,ZENER,MTZJ5.6T-C

35

MV-8080G_9(28-) 97.12.11, 9:58Page 35 Adobe PageMaker 6.0J/PPC

Page 38

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

D1831,D1832 131002101 DIODE,1SS254T

F1201 1764139B0 X'TAL,HC49U-4.433619MHZ

F1301 177500290 GDL-ADL-CP144E

F1701 1764134B0 X'TAL,HC-49U-S12.00MHZ

FB1801,FB1802 177103140 CORE-BP53RA451650M

FB1803,FB1804 177103140 CORE-BP53RA451650M

FH1801,FH1802 26N20110 FUSE HOLDER CNT47

H1701 143002100 FIP,SVV-7SS06

IC1201 111729300 IC,LA7437

IC1202 112285300 IC,LC89970

IC1301 111749400 IC,AN6326N

IC1302 111750400 IC,AN304

IC1401 111717300 IC,LA7286

IC1501 111380300 IC,LA7116

IC1601 111718200 IC,TA7291S

IC1701 See inside cover IC,CXP88132

IC1704 111779600 IC,BA12T

IC1801 145300900 PHOTOCOUPLER,PS2561-1-MDHW-V

IC1802 111737A07 IC-KIA431AT-RT

IC1803 111743A00 IC,KIA7809PI

J600,J602 165200006 RESISTOR,CHIP,0OHM 1/10W

J601,R1722 165100006 RESISTOR,CHIP,0OHM 1/8W

J603,J604 165200006 RESISTOR,CHIP,0OHM 1/10W

J605,J606 165200006 RESISTOR,CHIP,0OHM 1/10W

J607,J608 165200006 RESISTOR,CHIP,0OHM 1/10W

J609,J610 165200006 RESISTOR,CHIP,0OHM 1/10W

J611,J612 165200006 RESISTOR,CHIP,0OHM 1/10W

J613,J614 165200006 RESISTOR,CHIP,0OHM 1/10W

J615,R1259 165200006 RESISTOR,CHIP,0OHM 1/10W

J8AB 198300101 JUMPER 5MM (INSERT)

L1201,L1214 172012227 L-LF-5.0-470J-ST

L1202,L1221 172019427 COIL,LF-5.0-390J-ST

L1203,L1352 172012127 L-LF-5.0-100J-ST

L1204,L1306 172012527 L-LF-5.0-101J-ST

L1212,L1301 172025234 COIL,EL0305RA-101J-FT

L1213,L1701 172024634 COIL,EL0305RA-100J-FT

L1302,L1303 172026027 COIL,LF-5.0-8R2J-ST

L1305,L1308 172025234 COIL,EL0305RA-101J-FT

L1307 1720234C4 COIL,FLR50T50-561J-FT

L1351 172010127 L-LF-5.0-680J-ST

L1353 172012527 L-LF-5.0-101J-ST

L1355 172012227 L-LF-5.0-470J-ST

L1801 173006180 COIL,ELF18D290A

L1802,L1803 172022944 COIL,LHL06TB220K-FT

L1804,L1805 172022944 COIL,LHL06TB220K-FT

L1806,L1807 172022944 COIL,LHL06TB220K-FT

36

MV-8080G_9(28-) 97.12.11, 9:58Page 36 Adobe PageMaker 6.0J/PPC

Page 39

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

LD1790 141014900 LED,SLR-932A

LD1791,LD1792 141023500 LED,SLR-981A

MD1701 106012100 MODULE,TFMX5380SN

MP1001 21234760 SHIELD PLATE (DECK)

MP1002,MP1003 22127580 HOLDER (1)

MP1004,MP1005 22127590 HOLDER (2)

MP1006 22127600 HOLDER (5)

MP1007,MP1012 22128410 HOLDER (LED)

MP1008 22128210 HOLDER (FIP-L)

MP1009 22128231 HOLDER (FIP-R)

MP1010 21144830 HEATSINK (IC)

MP1011 2912308A APPM-3X8SSA

P1201 198130529 POST-09FE-BT-VK-N

P1701 1981299AS POST-TVK-A28X-B1

P1702 19813202L POST-21FE-ST-VK-N

P1704 1981270G2 POST-00-8283-0212-0

P1801 1981251GB POST-00-8283-1111-0

P1802 198130722 POST-B2P3-VH

PQ1790,PQ1791 120013100 TRANSISTOR,SPS-1118C

PQ1792,PQ1793 120013100 TRANSISTOR,SPS-1118C

Q1201,Q1202 123245811 TRANSISTOR,2SC2458T-Y,GR

Q1203,Q1206 123245811 TRANSISTOR,2SC2458T-Y,GR

Q1205 120002401 TRANSISTOR,DTA124EST

Q1301 121104811 TRANSISTOR,2SA1048T-GR

Q1304,Q1305 123245811 TRANSISTOR,2SC2458T-Y,GR

Q1306,Q1501 120002201 TRANSISTOR,DTC124EST

Q1351,Q1352 123245811 TRANSISTOR,2SC2458T-Y,GR

Q1353,Q1780 123245811 TRANSISTOR,2SC2458T-Y,GR

Q1790,Q1805 123245811 TRANSISTOR,2SC2458T-Y,GR

Q1802 124213201 TRANSISTOR,2SD2132T-V,W

Q1803 123490800 TRANSISTOR,2SC4908

Q1804 124158101 TRANSISTOR,2SD1581T-L,M

Q1807 124239600 TRANSISTOR,2SD2396-J,K

R1201,R1206 165268106 RESISTOR,CHIP,680OHM 1/10W

R1202,R1203 165268206 RESISTOR,CHIP,6.8KOHM 1/10W

R1204 165256106 RESISTOR,CHIP,560OHM 1/10W

R1205,R1207 165247106 RESISTOR,CHIP,470OHM 1/10W

R1208,R1303 165239106 RESISTOR,CHIP,390OHM 1/10W

R1209,R1219 165268106 RESISTOR,CHIP,680OHM 1/10W

R1211 165212206 RESISTOR,CHIP,1.2KOHM 1/10W

R1213,R1221 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1214,R1507 165239206 RESISTOR,CHIP,3.9KOHM 1/10W

R1215,R1218 165222206 RESISTOR,CHIP,2.2KOHM 1/10W

R1216,R1311 165215206 RESISTOR,CHIP,1.5KOHM 1/10W

R1217,R1355 165247206 RESISTOR,CHIP,4.7KOHM 1/10W

R1220 165227206 RESISTOR,CHIP,2.7KOHM 1/10W

37

MV-8080G_9(28-) 97.12.11, 9:58Page 37 Adobe PageMaker 6.0J/PPC

Page 40

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

R1222 165282306 RESISTOR,CHIP,82KOHM 1/10W

R1223,R1226 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1224,R1314 165218206 RESISTOR,CHIP,1.8KOHM 1/10W

R1225,R1705 165282206 RESISTOR,CHIP,8.2KOHM 1/10W

R1227,R1313 165233106 RESISTOR,CHIP,330OHM 1/10W

R1257,R1302 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1258,R1308 165247306 RESISTOR,CHIP,47KOHM 1/10W

R1301,R1307 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1304,R1305 165239106 RESISTOR,CHIP,390OHM 1/10W

R1306,R1310 165200006 RESISTOR,CHIP,0OHM 1/10W

R1309,R1708 165247306 RESISTOR,CHIP,47KOHM 1/10W

R1315,R1354 165222106 RESISTOR,CHIP,220OHM 1/10W

R1316,R1317 165239106 RESISTOR,CHIP,390OHM 1/10W

R1318,R1409 165227306 RESISTOR,CHIP,27KOHM 1/10W

R1319,R1405 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1320,R1429 165200006 RESISTOR,CHIP,0OHM 1/10W

R1351,R1360 165268206 RESISTOR,CHIP,6.8KOHM 1/10W

R1352,R1358 165247106 RESISTOR,CHIP,470OHM 1/10W

R1353 165215206 RESISTOR,CHIP,1.5KOHM 1/10W

R1356,R1357 165239106 RESISTOR,CHIP,390OHM 1/10W

R1359,R1419 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1361 165268106 RESISTOR,CHIP,680OHM 1/10W

R1407,R1719 165233206 RESISTOR,CHIP,3.3KOHM 1/10W

R1408 165215406 RESISTOR,CHIP,150KOHM 1/10W

R1410 161322404 RESISTOR,CARBON,220KOHM 1/6W

R1417,R1738 165256206 RESISTOR,CHIP,5.6KOHM 1/10W

R1418,R1501 165212306 RESISTOR,CHIP,12KOHM 1/10W

R1420,R1512 165233406 RESISTOR,CHIP,330KOHM 1/10W

R1421 165218106 RESISTOR,CHIP,180OHM 1/10W

R1426 165210106 RESISTOR,CHIP,100OHM 1/10W

R1431,R1711 165200006 RESISTOR,CHIP,0OHM 1/10W

R1502,R1503 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1504,R1514 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1505 165210406 RESISTOR,CHIP,100KOHM 1/10W

R1506,R1509 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1508,R1703 165247206 RESISTOR,CHIP,4.7KOHM 1/10W

R1510,R1701 165233106 RESISTOR,CHIP,330OHM 1/10W

R1511,R1731 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1515,R1710 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1601,R1602 16131R004 RESISTOR,CARBON,1OHM 1/6W

R1603 16131R004 RESISTOR,CARBON,1OHM 1/6W

R1702,R1749 165227106 RESISTOR,CHIP,270OHM 1/10W

R1704 165212406 RESISTOR,CHIP,120KOHM 1/10W

R1706,R1714 165282206 RESISTOR,CHIP,8.2KOHM 1/10W

R1707 165256306 RESISTOR,CHIP,56KOHM 1/10W

R1709,R1715 165247306 RESISTOR,CHIP,47KOHM 1/10W

38

MV-8080G_9(28-) 97.12.11, 9:58Page 38 Adobe PageMaker 6.0J/PPC

Page 41

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

R1712,R1729 165200006 RESISTOR,CHIP,0OHM 1/10W

R1713 169172199 RESISTOR,SEMI-FIXED,RH0638C-223B-RT

R1716,R1717 165247306 RESISTOR,CHIP,47KOHM 1/10W

R1718,R1740 165247306 RESISTOR,CHIP,47KOHM 1/10W

R1720,R1721 165247206 RESISTOR,CHIP,4.7KOHM 1/10W

R1723,R1736 165222206 RESISTOR,CHIP,2.2KOHM 1/10W

R1724 165212306 RESISTOR,CHIP,12KOHM 1/10W

R1725,R1726 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1727,R1787 165247206 RESISTOR,CHIP,4.7KOHM 1/10W

R1728,R1730 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1732,R1734 165239306 RESISTOR,CHIP,39KOHM 1/10W

R1735 165218206 RESISTOR,CHIP,1.8KOHM 1/10W

R1737 165233206 RESISTOR,CHIP,3.3KOHM 1/10W

R1739 165215306 RESISTOR,CHIP,15KOHM 1/10W

R1741,R1742 165247306 RESISTOR,CHIP,47KOHM 1/10W

R1743 165247306 RESISTOR,CHIP,47KOHM 1/10W

R1745,R1746 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1747,R1748 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1750,R1754 165200006 RESISTOR,CHIP,0OHM 1/10W

R1751,R1782 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1755,R1821 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1757,R1760 165200006 RESISTOR,CHIP,0OHM 1/10W

R1763 165247106 RESISTOR,CHIP,470OHM 1/10W

R1777,R1778 165247006 RESISTOR,CHIP,47OHM 1/10W

R1779,R1780 165247006 RESISTOR,CHIP,47OHM 1/10W

R1790,R1792 165256406 RESISTOR,CHIP,560KOHM 1/10W

R1791,R1794 165247006 RESISTOR,CHIP,47OHM 1/10W

R1793,R1795 165256206 RESISTOR,CHIP,5.6KOHM 1/10W

R1796,R1797 165247006 RESISTOR,CHIP,47OHM 1/10W

R1798,R1832 165247006 RESISTOR,CHIP,47OHM 1/10W

R1802 16C34R71A RESISTOR4.7OHM 3W

R1803,R1804 161382304 RESISTOR,CARBON,82KOHM 1/6W

R1805,R1806 161382304 RESISTOR,CARBON,82KOHM 1/6W

R1810 16431211A RESISTOR120OHM 3W

R1811 165239206 RESISTOR,CHIP,3.9KOHM 1/10W

R1812 16311R20A RESISTOR,METAL FILM,1.2OHM 1/2W

R1813 161347104 RESISTOR,CARBON,470OHM 1/6W

R1814 161327204 RESISTOR,CARBON,2.7KOHM 1/6W

R1815,R1816 161368304 RESISTOR,CARBON,68KOHM 1/6W

R1817,R1818 161368304 RESISTOR,CARBON,68KOHM 1/6W

R1819 16D38231A RESISTOR82KOHM 3W

R1820 165222106 RESISTOR,CHIP,220OHM 1/10W

R1822 165C30206 RESISTOR,CHIP,2KOHM 1/10W

R1823 165282106 RESISTOR,CHIP,820OHM 1/10W

R1824 165C20206 RESISTOR,CHIP,2KOHM 1/10W

R1825,R1838 165200006 RESISTOR,CHIP,0OHM 1/10W

39

MV-8080G_9(28-) 97.12.11, 9:58Page 39 Adobe PageMaker 6.0J/PPC

Page 42

UPPER MAIN CIRCUIT BOARD (WITH POWER SECTION)

Ref. No. Part No. Description

R1826,R1829 165247206 RESISTOR,CHIP,4.7KOHM 1/10W

R1827 16133R904 RC-S6-3R9J-ST

R1828,R1830 165210206 RESISTOR,CHIP,1KOHM 1/10W

R1833 165247006 RESISTOR,CHIP,47OHM 1/10W

R1834 165218306 RESISTOR,CHIP,18KOHM 1/10W

R1835 165210306 RESISTOR,CHIP,10KOHM 1/10W

R1836,R1837 165247206 RESISTOR,CHIP,4.7KOHM 1/10W

R1839,R1843 165200006 RESISTOR,CHIP,0OHM 1/10W

R1840,R1842 165222206 RESISTOR,CHIP,2.2KOHM 1/10W

R1844 165200006 RESISTOR,CHIP,0OHM 1/10W

SW1701,SW1702 23A11520 SWITCH SOR-142HS

SW1703,SW1704 23A11520 SWITCH SOR-142HS

SW1705,SW1706 23A11520 SWITCH SOR-142HS

SW1790 23M10070 LEAF SW 10480 MLB0

T1801 174401580 TRANSFORMER,SWT-ZTS4071VA

Z1801 26GA022 MINI FUSE T1.6A250V

Z1804 100008305 ICP-N50(T104)-RT

2805261 CUSHION (3)

40

MV-8080G_9(28-) 97.12.11, 9:58Page 40 Adobe PageMaker 6.0J/PPC

Page 43

Page 44

Page 45

14. PC BOARD ASS’Y (LOWER MAIN) PARTS LIST

LOWER MAIN CIRCUIT BOARD (WITH TUNER)

Ref. No. Part No. Description

C2201,C2215 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2202 15714R00E CAPACITOR,CHIP,4PF 50V

C2203 15717R00E CAPACITOR,CHIP,7PF 50V

C2204 15713900E CAPACITOR,CHIP,39PF 50V

C2205 15711210E CAPACITOR,CHIP,120PF 50V

C2207,C2310 15785610E CAPACITOR,CHIP,560PF 50V

C2213,C2312 15714700E CAPACITOR,CHIP,47PF 50V

C2216,C2218 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C2217 15712010E CAPACITOR,CHIP,200PF 50V

C2219 15783310E CAPACITOR,CHIP,330PF 50V

C2220 15713300E CAPACITOR,CHIP,33PF 50V

C2221,C2223 157C2230E CI-2125F223Z25-CT

C2222,C2227 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C2224,C2228 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C2225,C2230 157B1040E CAPACITOR,CHIP,0.1UF 25V

C2226,C2425 155347625 CE-SSM47M16-FT

C2229,C2408 1553476G5 CAPACITOR,ELECTROLYTIC,47UF 16V

C2231,C2232 157C2230E CI-2125F223Z25-CT

C2233,C2238 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C2234,C2272 155310625 CAPACITOR,ELECTROLYTIC,10UF 16V

C2235,C2236 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2237,C2241 157C2230E CI-2125F223Z25-CT

C2239,C2410 157B1040E CAPACITOR,CHIP,0.1UF 25V

C2240,C2504 15711010E CAPACITOR,CHIP,100PF 50V

C2242,C2245 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C2243,C2246 157A4730E CAPACITOR,CHIP,0.047UF 25V

C2247,C2249 157A4730E CAPACITOR,CHIP,0.047UF 25V

C2248,C2407 157C2230E CI-2125F223Z25-CT

C2250 15782210E CAPACITOR,CHIP,220PF 50V

C2263 157C1050E CAPACITOR,CHIP,1UF 16V

C2264 15715R00E CAPACITOR,CHIP,5PF 50V

C2266,C2273 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2267,C2269 15712200E CAPACITOR,CHIP,22PF 50V

C2268,C2271 15781210E CAPACITOR,CHIP,120PF 50V

C2270 157F3910E CAPACITOR,CHIP,390PF 50V

C2274,C2301 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2302,C2305 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2307,C2311 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2308,C2516 155147625 CAPACITOR,ELECTROLYTIC,47UF 6.3V

C2309 151115005 CAPACITOR,CERAMIC,15PF 50V

C2401 153C47305 CAPACITOR,MYLAR,0.047UF 100V

C2402,C2403 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2404 155005325 CAPACITOR,ELECTROLYTIC,47UF 16V BP

C2406,C2510 155647425 CAPACITOR,ELECTROLYTIC,0.47UF 50V

43

MV-8080G_9(28-) 97.12.11, 9:58Page 43 Adobe PageMaker 6.0J/PPC

Page 46

LOWER MAIN CIRCUIT BOARD (WITH TUNER)

Ref. No. Part No. Description

C2409 15714700E CAPACITOR,CHIP,47PF 50V

C2411,C2A02 1553107G5 CAPACITOR,ELECTROLYTIC,100UF 16V

C2412,C2417 157B1040E CAPACITOR,CHIP,0.1UF 25V

C2414,C2424 157A1030E CAPACITOR,CHIP,0.01UF 25V

C2415,C2705 15784710E CAPACITOR,CHIP,470PF 50V

C2416,C2426 155610525 CAPACITOR,ELECTROLYTIC,1UF 50V

C2418 155447525 CAPACITOR,ELECTROLYTIC,4.7UF 25V

C2419,C2A62 155633525 CAPACITOR,ELECTROLYTIC,3.3UF 50V

C2420,C2421 157B1040E CAPACITOR,CHIP,0.1UF 25V

C2422 157F5620E CAPACITOR,CHIP,5600PF 50V

C2423 157F2720E CAPACITOR,CHIP,2700PF 50V

C2427,C2514 157A2220E CAPACITOR,CHIP,2200PF 50V