Page 1

OPERATOR’S

MANUAL

Model C606

Combination Freezer

Original Operating Instructions

059714-M

May, 2004 (Original Publication )

(Updated 8/5/2020)

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor: __________________________________________________________

Address:_________________________________________________________________

Phone: __________________________________________________________________

Service: _________________________________________________________________

Parts: ___________________________________________________________________

Date of Installation: ________________________________________________________

Information found on the data label:

Model Number:____________________________________________________________

Serial Number: ____________________________________________________________

Electrical Specs: Voltage__________________ Cycle__________

Phase__________________________________

Maximum Fuse Size: ______________________________________________________ A

Minimum Wire Ampacity: ___________________________________________________A

Note: Continuing research results in steady improvements; therefore, information in this manual is subject to change

without notice.

Note: Only instructions originating from the factory or its authorized transla tion repr esentative(s) are considered to be

the original set of instructions.

© 2004 Taylor Company

(Updated 8/5/2020)

059714-M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portio n of this wor k may be

a violation of copyright law of the United States of America and other countries, could result in the awarding of

statutory damages of up to $250,000 (17 USC 504) for infringement, and may result in further civil and criminal

penalties. All rights rese rved.

Taylor Company

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Section 1: To the Installer

Installer Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Air-Cooled Machines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Beater Rotation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Section 2: To the Operator

Section 3: Safety

Section 4: Operator Parts Identification

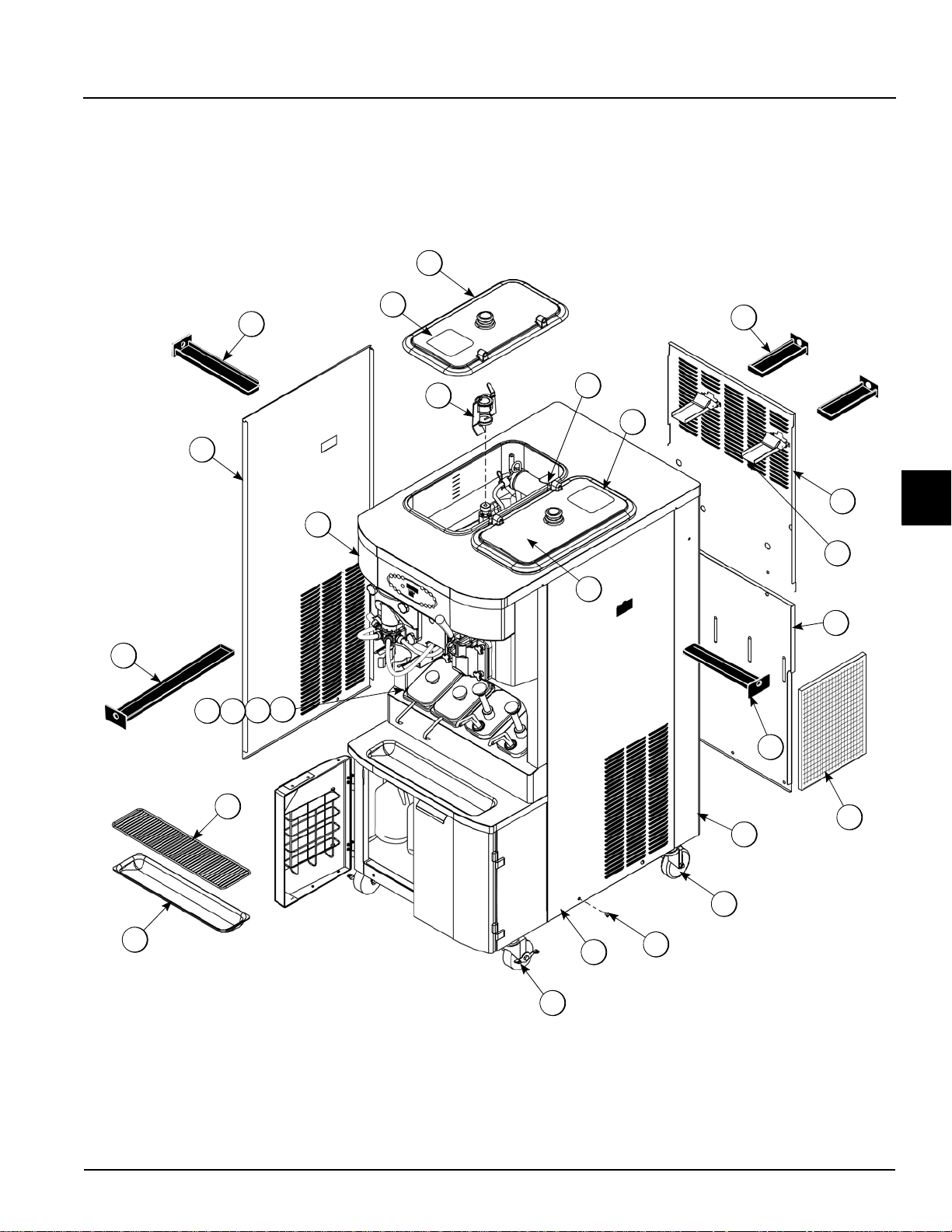

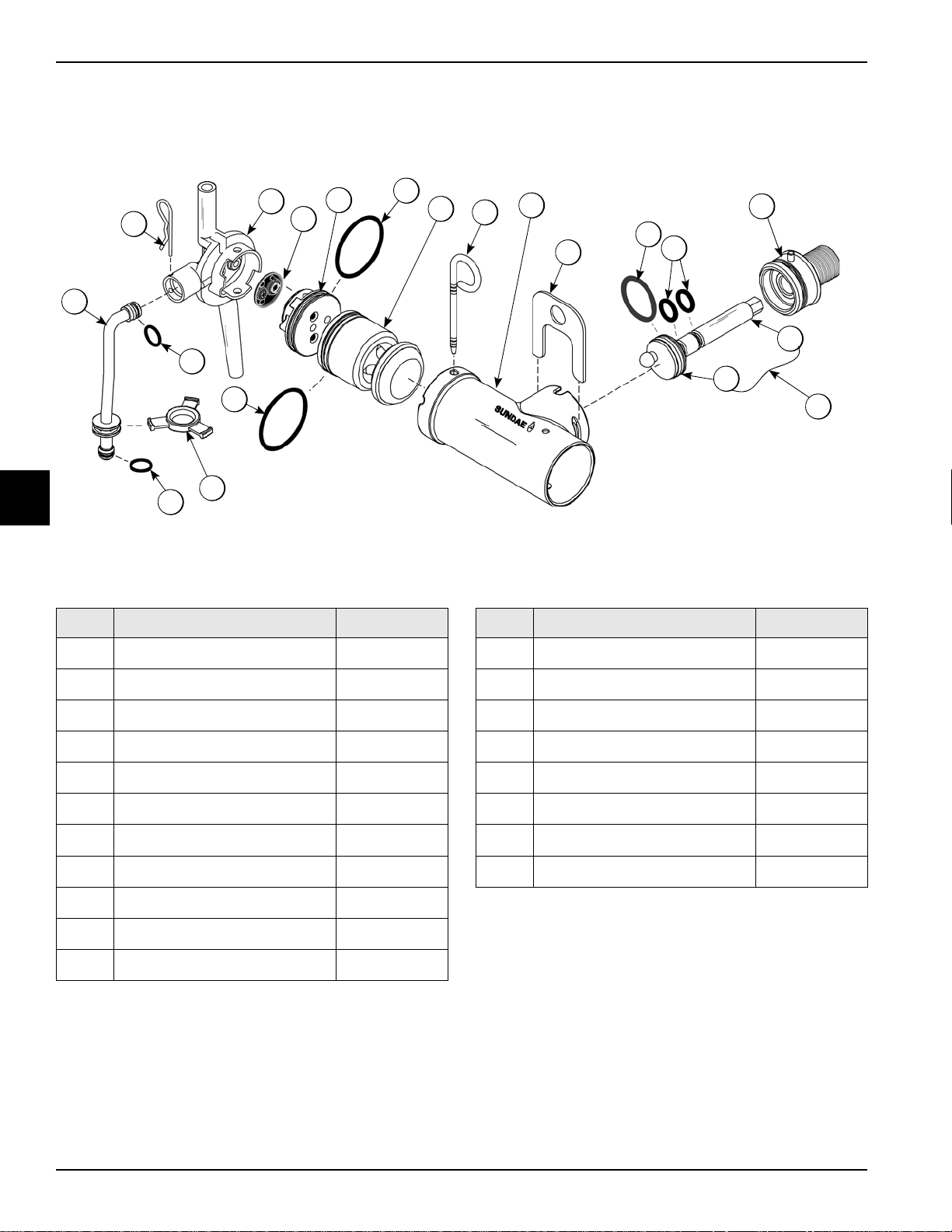

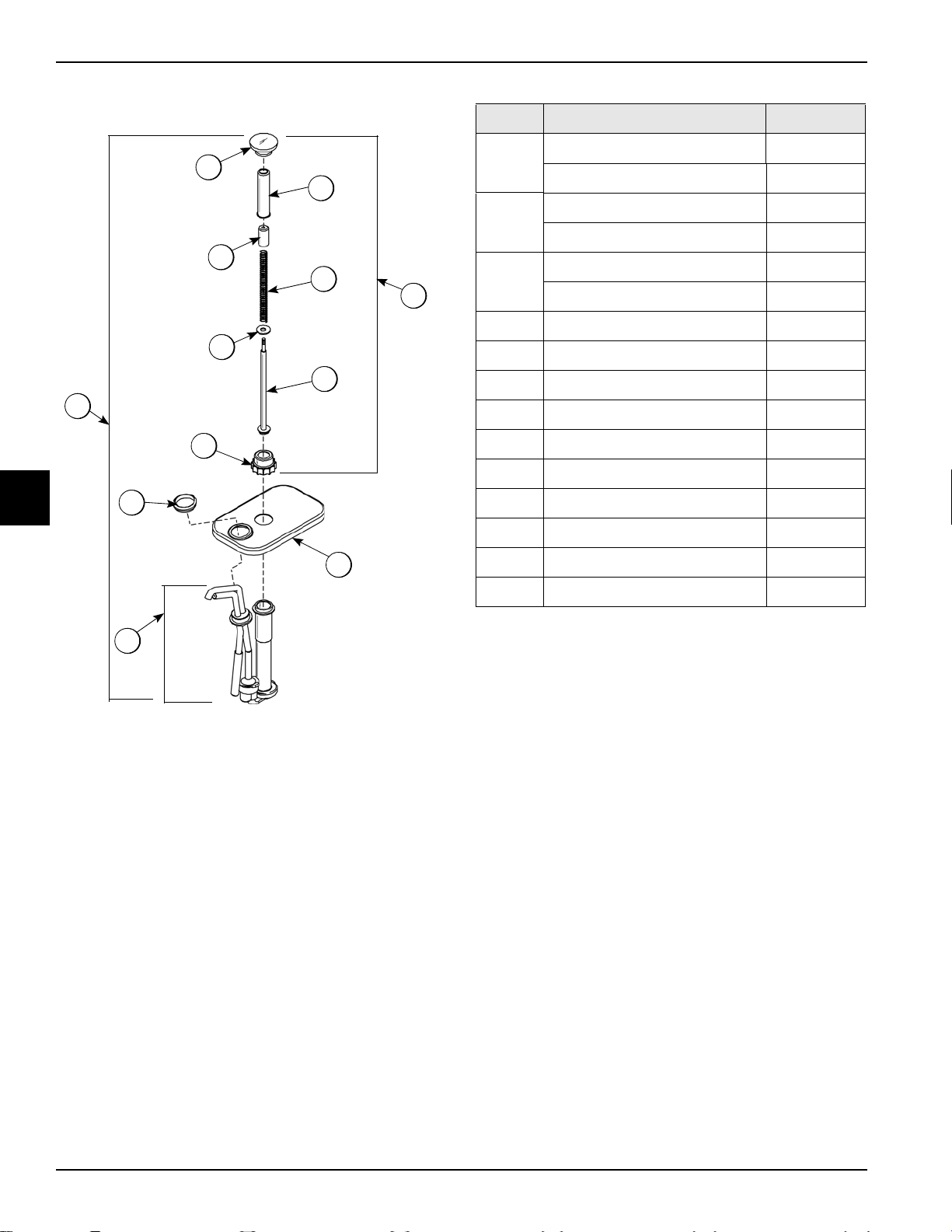

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

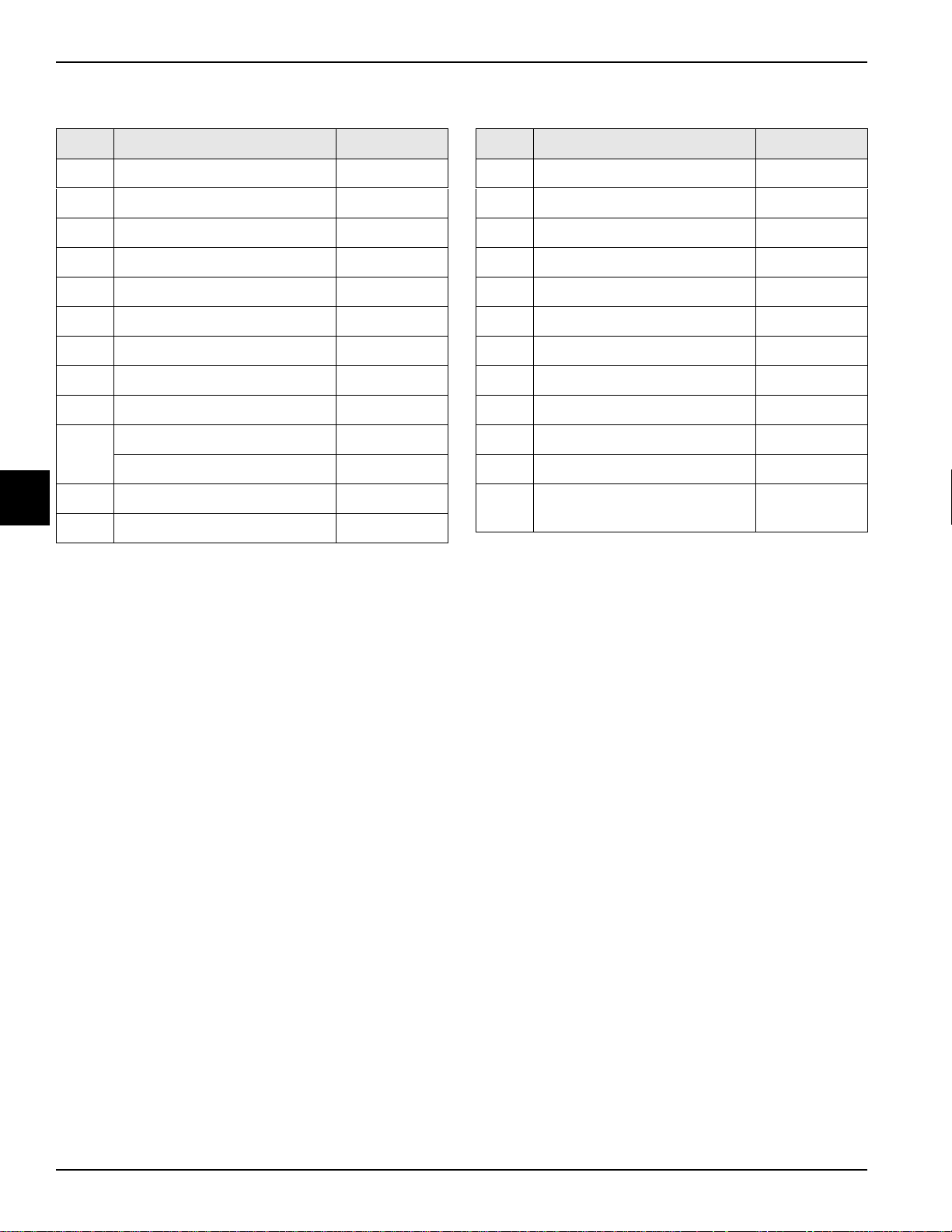

Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

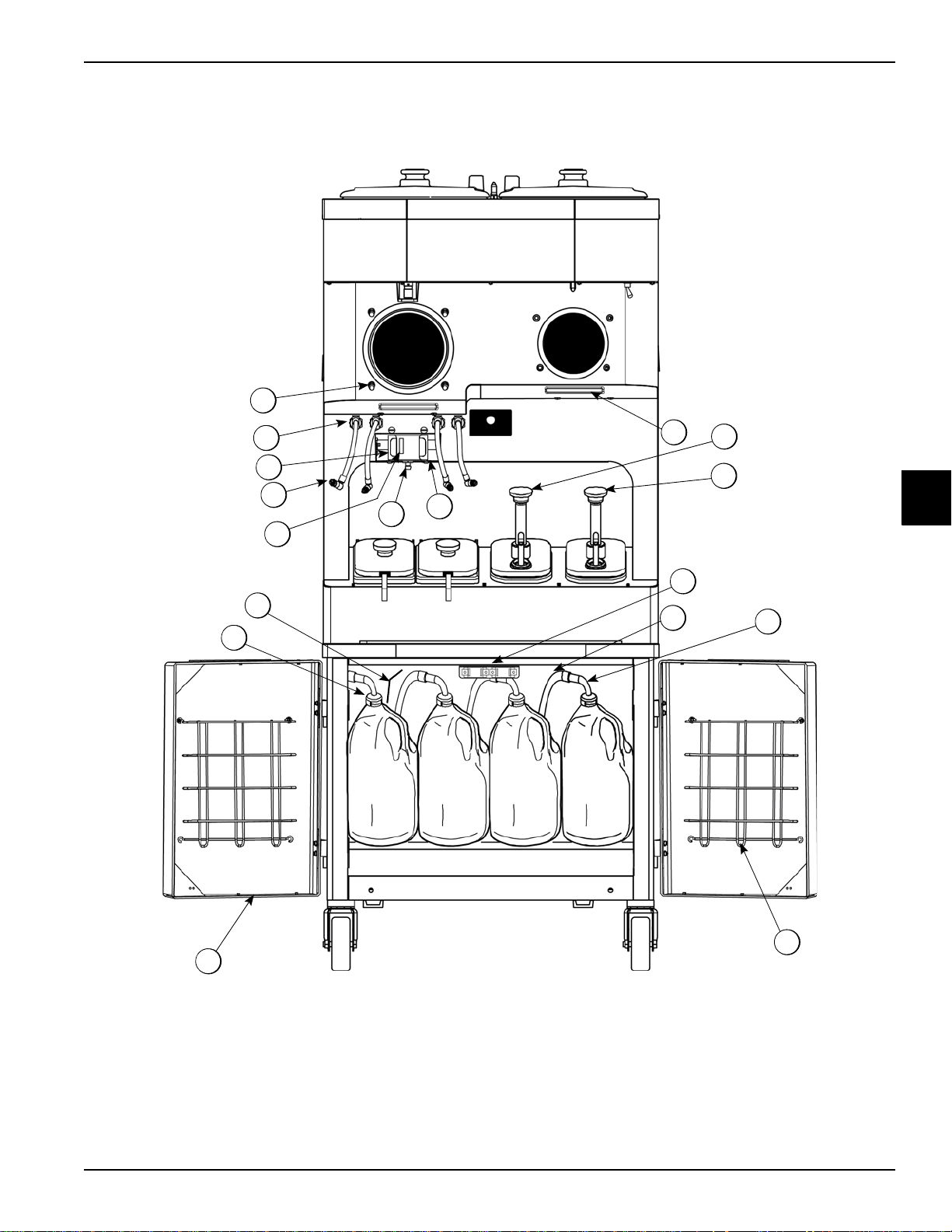

Syrup Cabinet View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Syrup Pump and Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

X57028-XX Pump A.—Mix Simplified - Shake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

X57029-XX Pump A.—Mix Simplified - Soft Serve. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

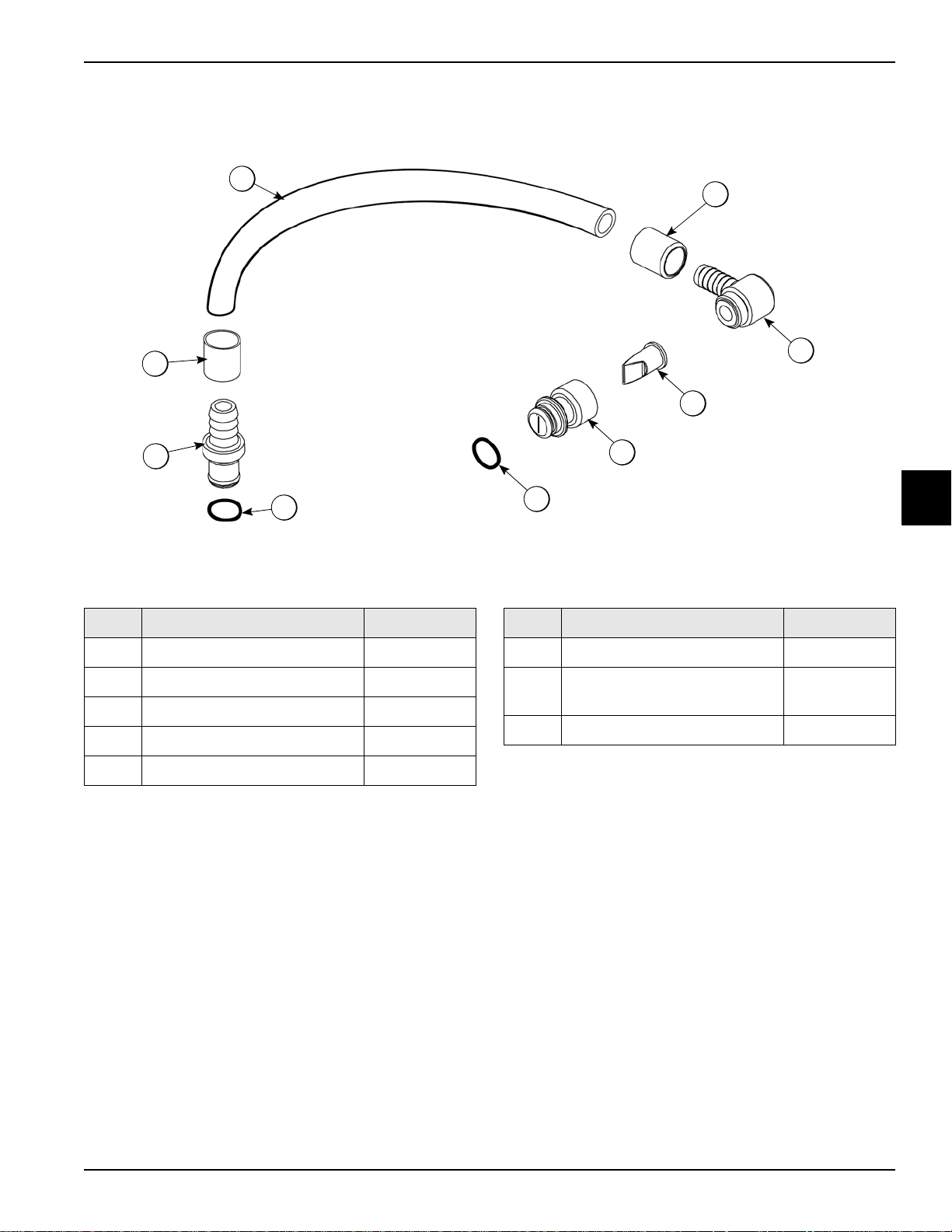

X59304 Syrup Line Assembly—Thin Viscosity Syrup. . . . . . . . . . . . . . . . . . . . . . . . . .4-9

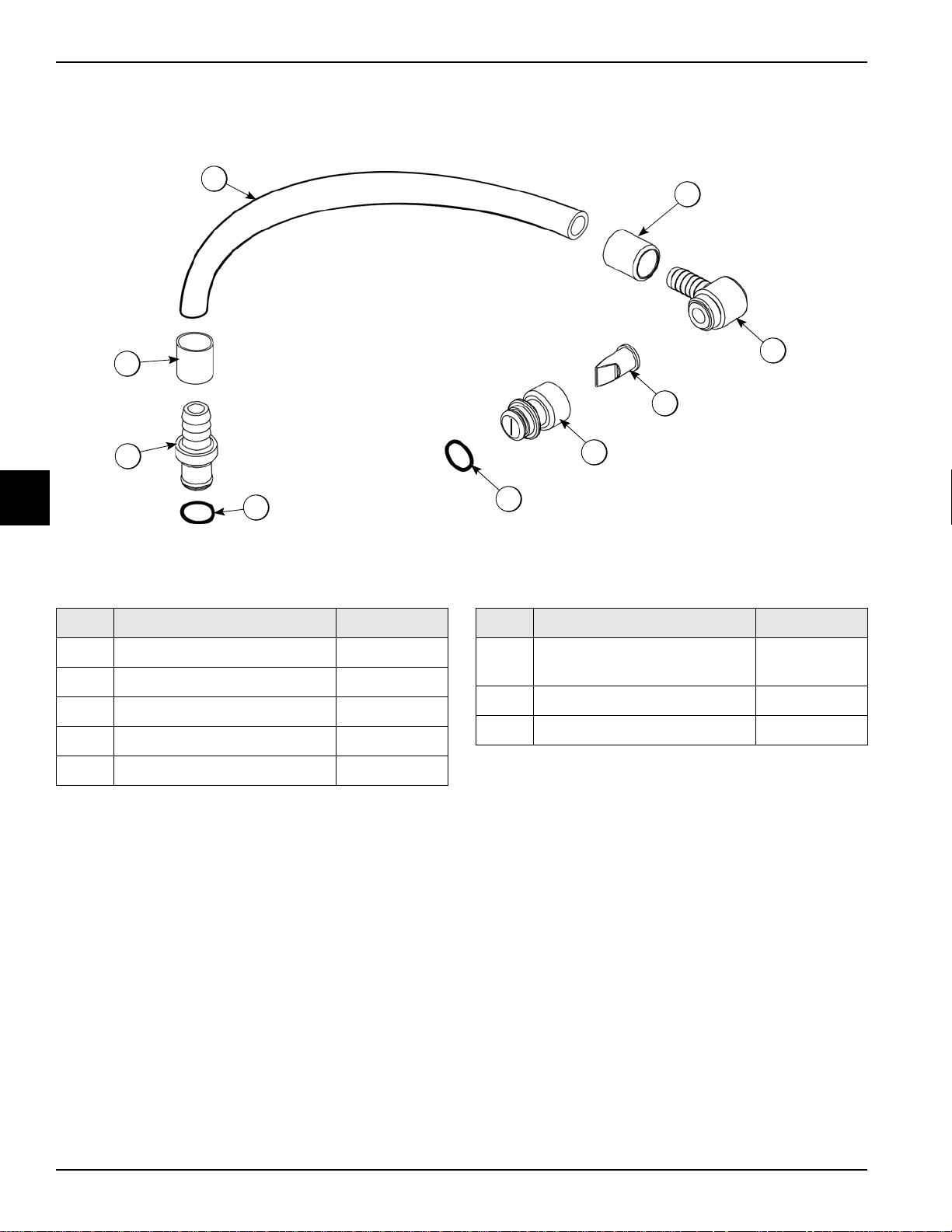

X56652 Syrup Line Assembly—Thick Viscosity Shake Syrup (Optional). . . . . . . . . .4-10

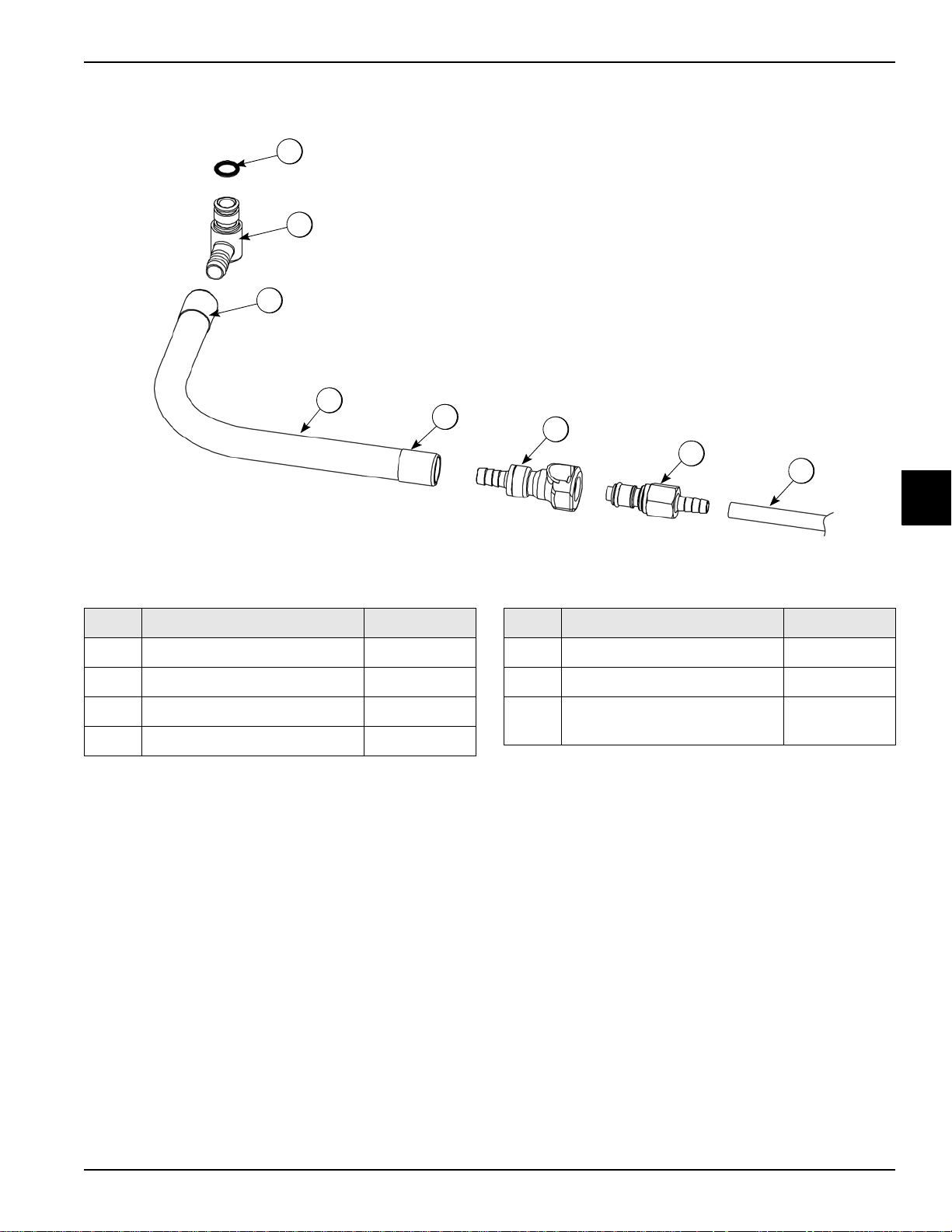

X58450 Syrup Line Assembly—Syrup-in-Bag Option. . . . . . . . . . . . . . . . . . . . . . . . .4-11

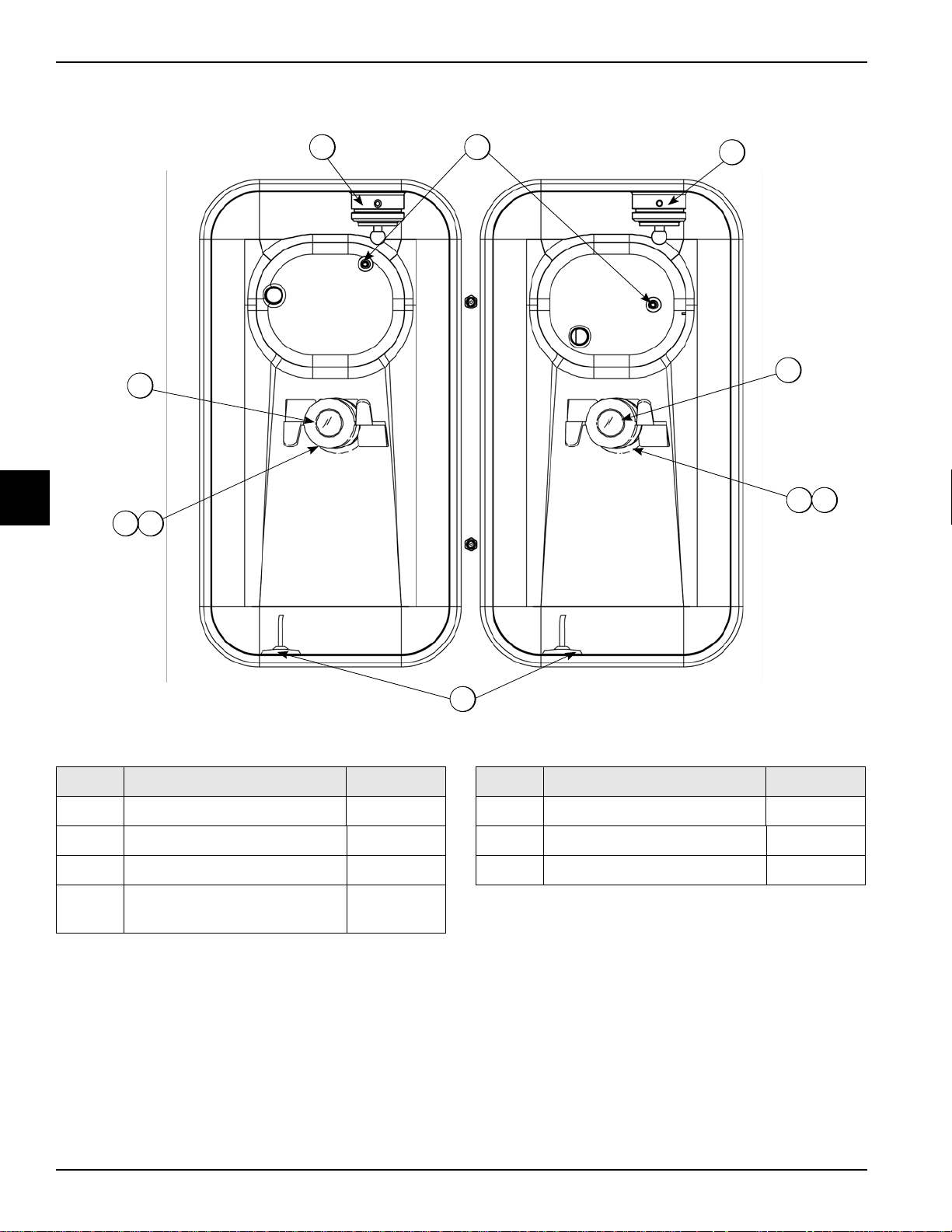

Mix Hopper—Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

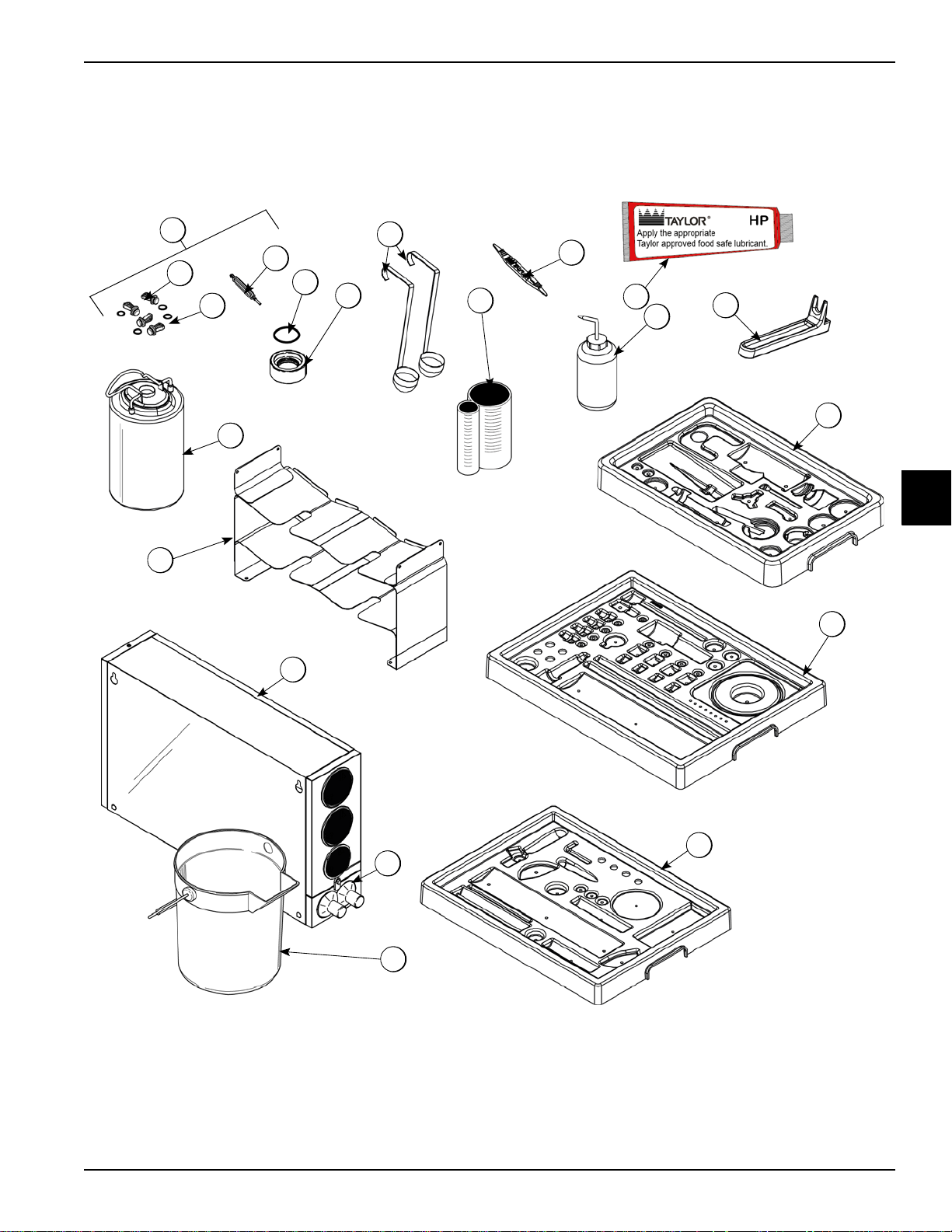

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

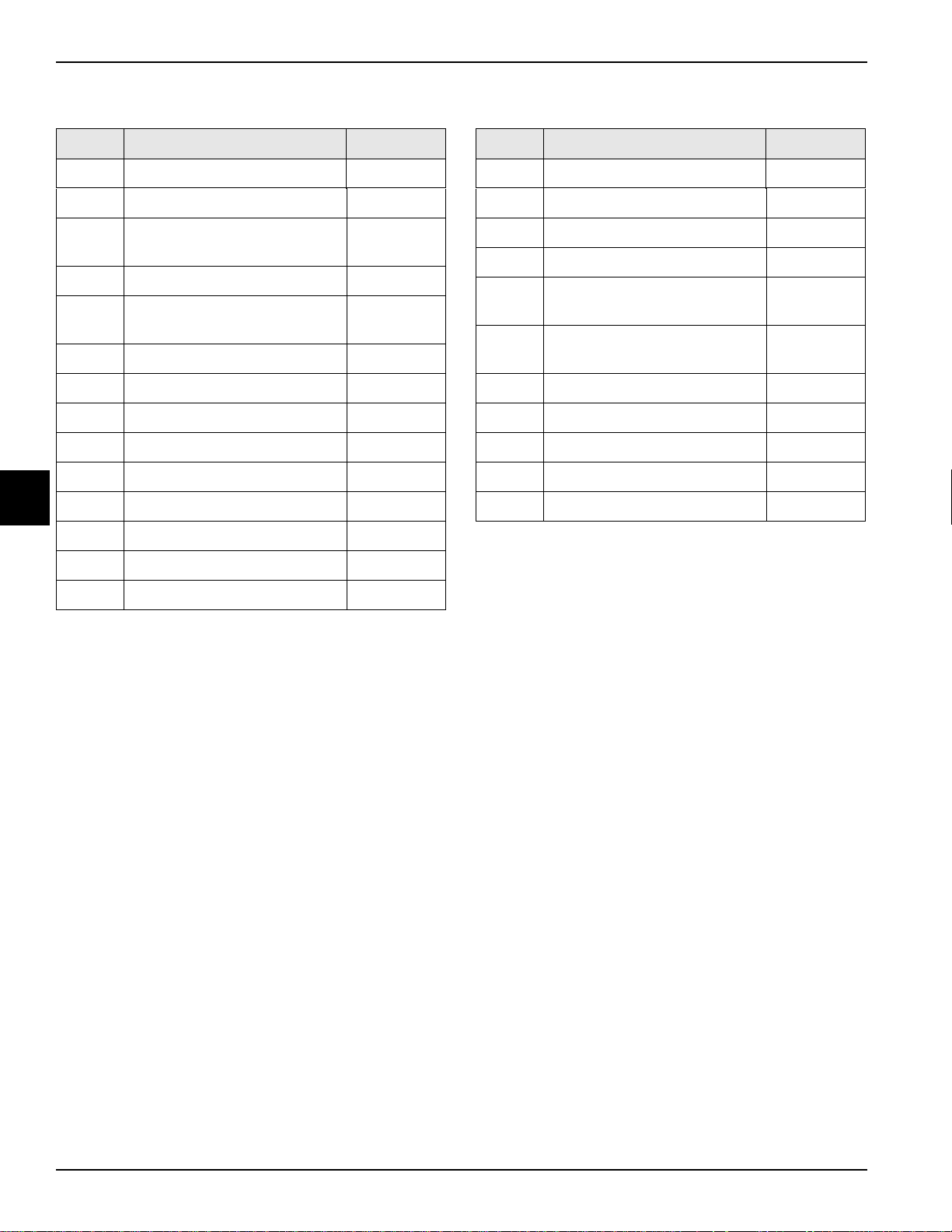

X44127 Brush Kit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

X53800-BRN/TAN Syrup Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

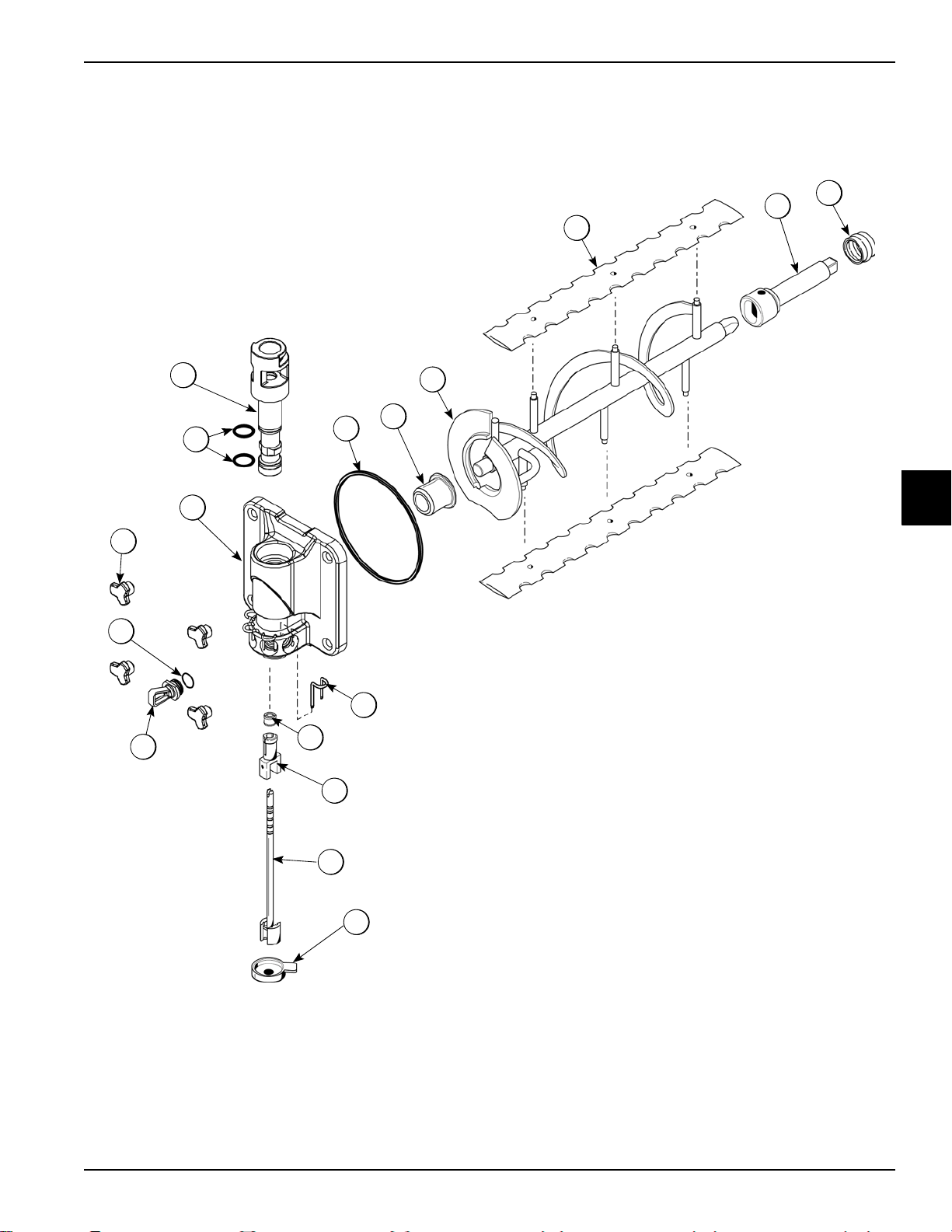

Beater Door Assembly—Shake Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Beater Door Assembly—Soft Serve Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

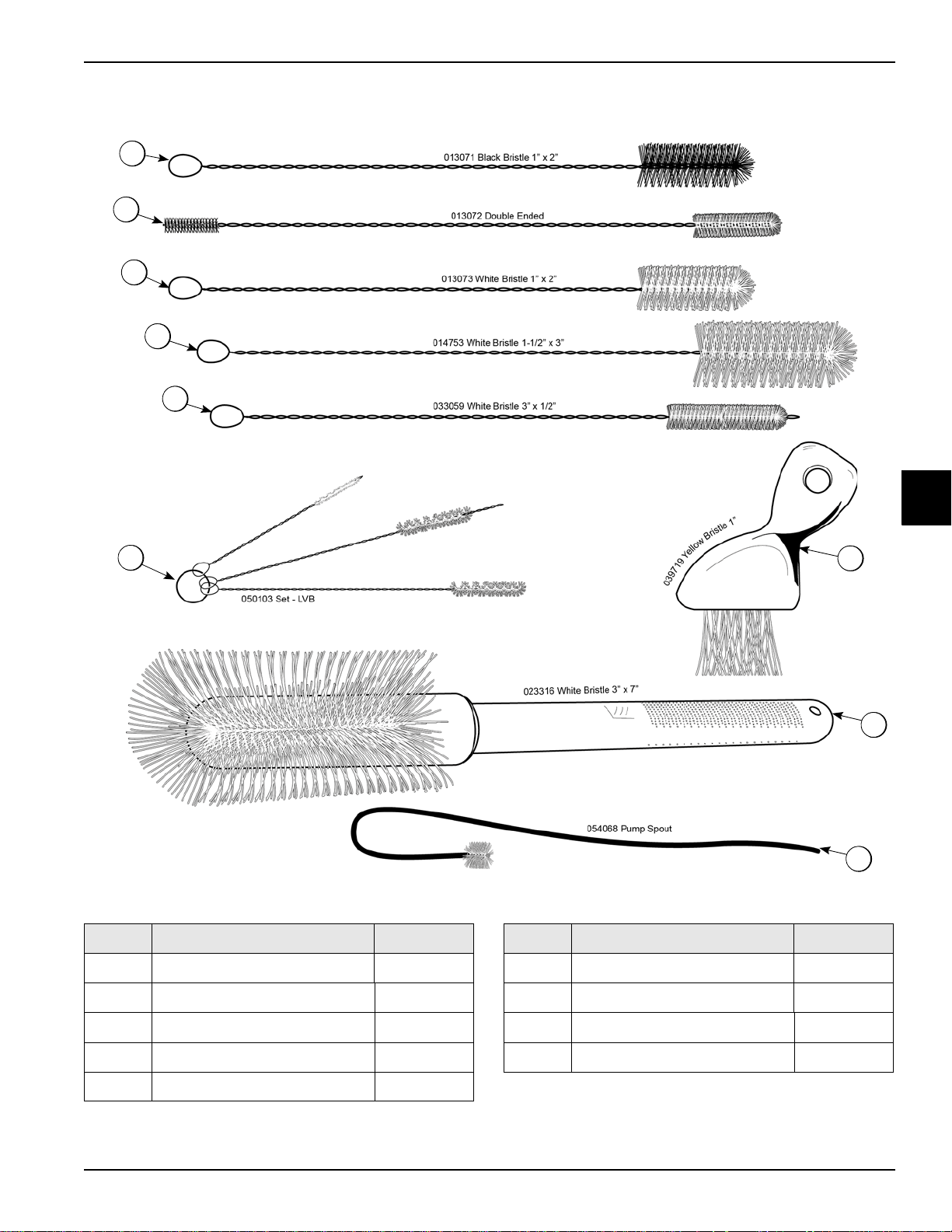

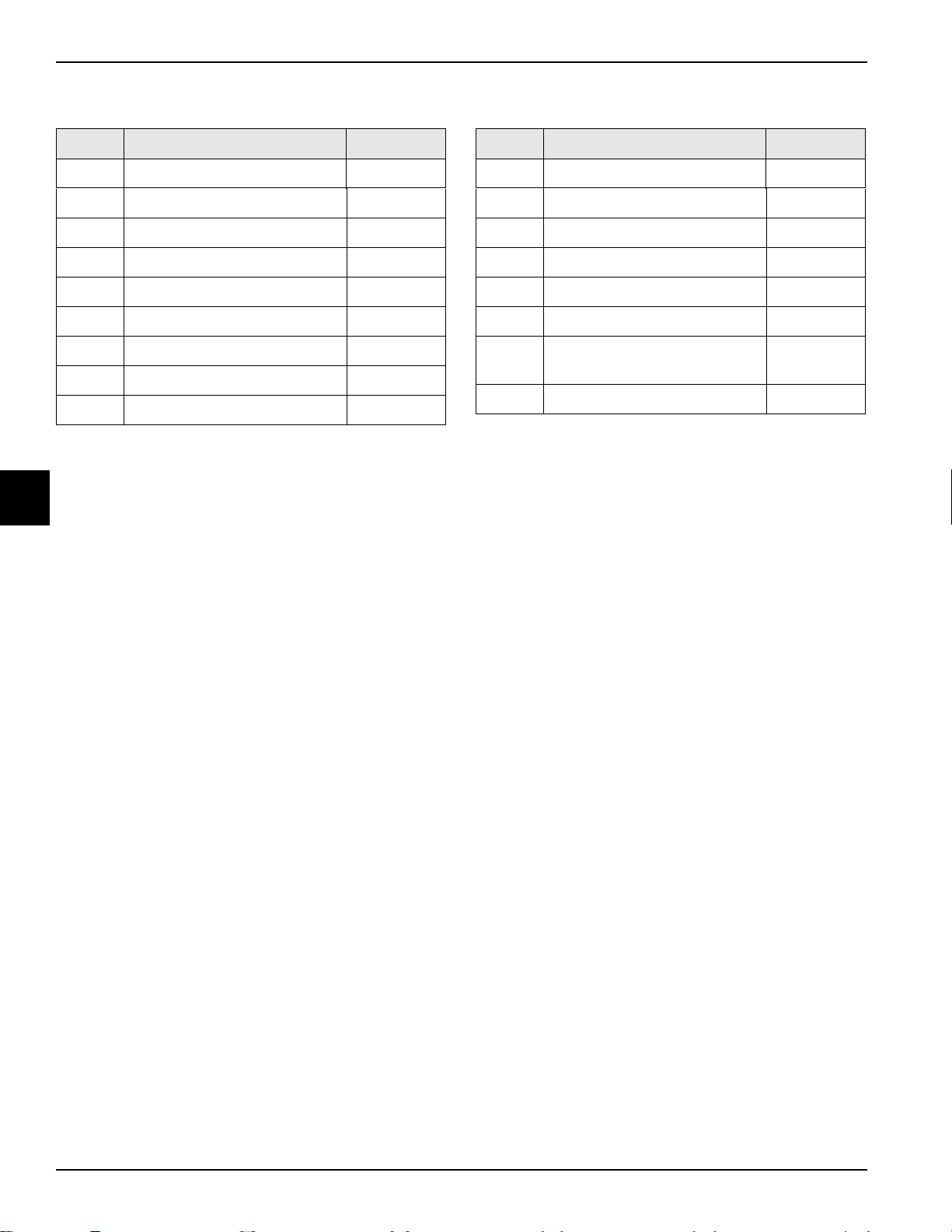

059088 Parts Tray—Shake Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

059087 Parts Tray—Soft Serve Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

056525 Parts Tray—Simplified Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Table of Contents

Section 5: User Interface

Symbol Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Vacuum Fluorescent Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Heat Cycle Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Reset Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Air/Mix Pump Reset Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Adjustable Draw Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Model C606 i

Page 4

Table of Contents

Shake Fill Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

VFD Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Manager's Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Section 6: Operating Procedures

Machine Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Sanitizing—Shake Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Sanitizing—Soft Serve Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Priming—Shake Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Priming—Soft Serve Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Daily Closing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Daily Opening Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Syrup System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Syrup Topping Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Manual Brush Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Draining Product from the Freezing Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Disassembly—Shake Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Disassembly—Soft Serve Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Brush Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

Syrup System—Scheduled Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Section 7: Operator Checklist

During Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting Bacterial Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Regular Maintenance Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Winter Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Section 8: Troubleshooting Guide

Section 9: Parts Replacement Schedule

Section 10: Limited Warranty

Section 11: Limited Warranty on Parts

ii Model C606

Page 5

Section 1

To the Installer

The following information has been included in the

manual as safety and regulatory guidelines. For complete

installation instructions, please see the Installation

Checklist.

Installer Safety

IMPORTANT! In all areas of the world,

machines should be installed in accordance with existing

local codes. Please contact your local authorities if you

have any questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and service

of Taylor

®

machines.

• Only Taylor service personnel should perform

installation, maintenance, and repairs on Taylor

machines.

• Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the industry

standards on lockout/tagout proced u re s bef or e

beginning any installation or repairs.

• Authorized service personnel must en su re tha t

the proper personal protective equipment (PPE)

is available and worn when required during

installation and service.

• Authorized service personnel must remove all

metal jewelry, rings, and watches before

working on electrical equipment.

All repairs must be performed by an authorized Taylor

service technician.

Site Preparation

Inspect the area where the machine will be installed

before uncrating it. Make sure that all possible ha zards to

the user and the machine have been addressed.

WARNING! Only install this machine in a

location where its use and maintenance is restric te d to

trained personnel. Failure to comply may result in

personal injury.

Air-Cooled Machines

Do not obstruct air intake and discharge openings.

Air-cooled machines require a min imum of 3 in. ( 76 mm)

of clearance around all sides to allow for adequate air

flow across the condensers. Install the deflector provided

to prevent recirculation of warm air. Failure to allow

adequate clearance can reduce the refrigeration capacity

and may cause permanent damage to the compressors.

For Indoor Use Only: This machine is designed to

operate indoors under normal ambient tempera tures of

70°F to

successfully performed in high ambient temperatures of

104°C (40°C) at reduced capacities.

75°F (21°C to 24°C). The freezer has

1

DANGER! The main power supply(s) to the

machine must be disconnected prior to performing any

installation, maintenance, or repairs. Failure to follow this

instruction may result in personal injury or death from

electrical shock or hazardous moving parts, as well as

poor performance or damage to the machine.

WARNING! This machine has many sharp

edges that can cause severe injuries.

To the Installer

Model C606

1-1

Page 6

TO THE INSTALLER

FOLLOW YOUR LOCAL ELECTRICAL CODES.

Water Connections

(Water-Cooled Machines Only)

An adequate cold water supply must be provided with a

hand shutoff valve. On the underside rear of the base

pan, two 3/8 in. Iron Pipe Size (IPS) water connections

for inlet and outlet have been provided for easy hookup.

Permanently connect the machine using 1/2 in. (12.7

1

mm) inside diameter water lines. (Flexible lines are

recommended, if local codes permit.) Depending on local

water conditions, it may be advisable to install a water

strainer to prevent foreign substances from clogging the

automatic water valve. There will be only one water in

and one water out connection. Do not install a hand

shutoff valve on the water out line! Water should always

flow in this order: first, through the automatic water valve;

second, through the condenser; and third, through the

outlet fitting to an open trap drain.

IMPORTANT! A backflo w preventio n device is

required on the incoming water connection side. Please

see the applicable national, state, and local codes for

determining the proper configuration. Water pressure to

the unit must not exceed 150 psi (1034 kPa).

WARNING! This machine must NOT be

installed in an area where a water jet or hose can be

used. NEVER use a water jet or hose to rinse or clean

the machine. Failure to follow this instruction may result

in electrocution.

Electrical Connections

In the United States, this machine is intended to be

installed in accordance with the National Electrical Code

(NEC), ANSI/NFPA 70-1987. The purpose of the NEC

code is the practical safeguarding of persons and

property from hazards arising from the use of electricity.

This code contains provisions considered necessary for

safety. In all other areas of the world, machine should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Each machine requires one power supply for each data

label on the machine. Check the data label(s) on the

freezer for branch circuit overcurrent protection or fuse,

circuit ampacity, and other electrical specifications. See

the wiring diagram provided inside the electrical box for

proper power connections.

IMPORTANT! An equipotential grounding lug is

provided with this machine. Some countries require the

grounding lug to be properly attached to the rear of the

frame by the authorized installer . The installation location

is marked by the equipotential bonding symbol (5021 of

IEC 60417-1) on both the removable panel and the

machine's frame.

WARNING! This machine must be properly

grounded. Failure to do so can result in severe personal

injury from electrical shock.

CAUTION! This machine must be installed on

a level surface to avoid the hazard of tipping. Extreme

care should be taken in moving this machine for any

reason. Two or more persons are required to safely move

this machine. Failure to comply may result in personal

injury or damage to the machine.

The authorized installer should inspect the machine for

damage and promptly report any damage to the local

authorized Taylor distributor .

This machine is made using USA hardware sizes. All

metric conversions are approximate.

1-2

Model C606

WARNING! Avoid injury .

• DO NOT operate the machine unless it is

properly grounded.

• DO NOT operate the machine with larger fuses

than specified on the machine's data label.

• All repairs should be performed by an

authorized Taylor service technician.

• The main power supplies to the machine must

be disconnected prior to performing installation,

repairs, or maintenance.

To the Installer

Page 7

TO THE INSTALLER

• For Cord-Connected Machines: Only

authorized Taylor service technicians or

licensed electricians may install a plug or

replacement cord on the machine.

• Machines that are permanently connected to

fixed wiring and for which leakage currents may

exceed 10 mA, particularly when disconnected

or not used for long periods, or during initial

installation, shall have protective devices to

protect against the leakage of current, such as a

GFI, installed by the authorized personnel to the

local codes.

• Stationary machines which are not equipped

with a power cord and a plug or another device

to disconnect the appliance from the power

source must have an all-pole disconnecting

device with a contact gap of at least 0.125 in.

(3 mm) installed in the external installation.

• Supply cords used with this machine shall be

oil-resistant, sheathed flexible cable not lighter

than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord

(code designation 60245 IEC 57) installed with

the proper cord anchorage to relieve conductors

from strain, including twisting, at the terminals

and protect the insulation of the conductors from

abrasion.

• If the supply cord is damaged, it must be

replaced by an authorized Taylor service

technician in order to avoid a hazard.

• Secure the supply cord ground lead to the

machine in a location where if the cord is pulled,

the main power leads will become taut before

the ground lead can break loose.

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

distributor for service.

fixed wiring and for which leakage currents may

exceed 10 mA, particularly when disconnected

or not used for long periods, or during initial

installation, shall have protective devices to

protect against the leakage of current, such as a

GFI, installed by the authorized personnel to the

local codes.

• Supply cords used with this machine shall be

oil-resistant, sheathed flexible cable not lighter

than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord

(code designation 60245 IEC 57) installed with

the proper cord anchorage to relieve conductors

from strain, including twisting, at the terminals

and protect the insulation of the conductors from

abrasion.

• If the supply cord is damaged, it must be

replaced by an authorized Taylor service

technician in order to avoid a hazard.

• Secure the supply cord ground lead to the

machine in a location where if the cord is pulled,

the main power leads will become taut before

the ground lead can break loose.

Beater Rotation

NOTICE! Beater rotation must be clockwise as

viewed looking into the freezing cylinder.

To correct the rotation on a three-phase machine,

interchange any two incoming power supply lines at the

freezer main terminal block only. To correct rotation on a

single-phase machine, exchange leads inside the beater

motor. (Follow the diagram printed on the motor.)

Electrical connections are made directly to the terminal

block provided in the main control box located behind the

service panel.

1

IMPORTANT!

• Stationary machines which are not equipped

with a power cord and a plug or another device

to disconnect the machine from the power

source must have an all-pole disconnecting

device with a contact gap of at least 0.125 in.

(3 mm) installed in the external installation.

• Machines that are permanently connected to

To the Installer

It is recommended that beater rotation adjustment be

performed by an authorized Taylor service technician.

Model C606

1-3

Page 8

TO THE INSTALLER

Refrigerant

CAUTION! This machine contains fluorinated

greenhouse gases (F-Gas) to provide refrigeration using

a hermetically sealed circuit or within foam insulation.

This machine's type of gas, quantity, Global Warming

1

Potential (GWP), and CO

is recorded on the machine's data-label. The refrigerant

used is generally considered nontoxic and

nonflammable. However any gas under pressure is

potentially hazardous and must be handled with caution.

NEVER fill any refrigerant cylinder completely with liquid.

Filling the cylinder to approximately 80% will allow for

normal expansion.

tonnes equivalent information

2

NOTICE! Taylor reminds technicians to be

aware of and in compliance with local government laws

regarding refrigerant recovery, recycling, and reclaiming

systems. For information regarding applicable local laws,

please contact your local authorized Taylor distributor.

IMPORTANT! Refrigerants and their

associated lubricants may be extremely moisture

absorbent. When opening a refrigeration system, the

maximum time the system is open must not exceed 15

minutes. Cap all open tubing to prevent humid air or

water from being absorbed by the oil.

CAUTION! Use only approved refrigerant

listed on the machine's data label or authorized through a

manufacturer's technical bulletin. The use of any other

refrigerant may expose users and operators to

unexpected safety hazards.

WARNING! Refrigerant liquid sprayed on to the

skin may cause serious damage to tissue. Keep eyes

and skin protected. If refrigerant burns should occur,

flush the area immediately with cold water. If burns are

severe, apply ice packs and contact a physician

immediately.

1-4

Model C606

To the Installer

Page 9

Section 2

To the Operator

The freezer you have purchased has been carefully

engineered and manufactured to give you dependable

operation. The Model C606, when properly op erated and

cared for, will produce a consistent quality product. Like

all machines, it will require cleaning and maintenance. A

minimum amount of care and attention is necessary if the

operating procedures outlined in this manual are followed

closely.

This Operator’s Manual should be read before operating

or performing any maintenance on the machine.

Your Taylor freezer will not eventually compen sat e an d

correct for any errors during the setup or filling

operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly

recommended that all personnel responsible for the

machine's operation thoroughly read and under stand this

manual.

If you require technical assistance, please contact your

local authorized Taylor distributor.

Note: Your Taylor warranty is valid only for authorized

Taylor parts purchased from an auth orized Taylor

distributor, and for required service work provided by an

authorized Taylor service technician. Taylor reserves the

right to deny warranty claims on machines or parts if

unapproved parts or incorrect refrigerant were installed in

the machine, system modifications were performed

beyond factory recommendations, or it is determined that

the failure was caused by abuse, misuse, neglect, or

failure to follow all operating instructions. For full details

of your Taylor warranty, please see the Limited Warranty

section in this manual.

Note: Constant research results in steady

improvements; therefore, information in this manual is

subject to change without notice.

IMPORTANT! If the crossed-out wheeled-bin

symbol is affixed to this machine, it signifies that this

machine is compliant with the EU Directives as well as

other similar end-of-life legislation in effect after August

13, 2005. Therefore, it must be collected separ ately after

its use is completed and cannot be disposed as unsorted

municipal waste.

The user is responsible for delivering the machine to the

appropriate collection facility, as specified by your local

code.

For additional information regarding applicable local

disposal laws, please contact the municipal waste facility

and/or local authorized Taylor distributor.

2

To the Operator

Model C606

2-1

Page 10

TO THE OPERATOR

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this machine are

warranted for the term stated in the Limited Warranty

section in this manual. However, due to the Montreal

Protocol and the U.S. Clean Air Act Amendments of

1990, many new refrigerants are being tested and

developed, thus seeking their way into the service

industry. Some of these new refrigerants are being

advertised as drop-in replacements for numerous

applications. It should be noted that in the event of

ordinary service to this machine's refrigeration system,

2

only the refrigerant specified on t he affixed data label

should be used. The unauthorized use of alternate

refrigerants will void your Taylor compressor warranty. It

is the machine owner's responsibility to make this fact

known to any technicians they employ.

It should be noted that Taylor does not warrant the

refrigerant used in its machine. For example, if the

refrigerant is lost during the course of ordinary service to

this machine, Taylor has no obligation to either supply or

provide its replacement either at billable or unbillable

terms. Taylor does have the obligation to recommend a

suitable replacement if the original refrigerant is banned,

obsoleted, or no longer available during the 5-year

warranty of the compressor.

Taylor will continue to monitor the industry and test new

alternates as they are being developed. Should a new

alternate prove, through our testing, that it would be

accepted as a drop-in replacement, then the above

disclaimer would become null and void.

T o find ou t the current status of an alternate refrigerant as

it relates to your compressor warranty, call the local

Taylor distributor or the Taylor factory. Be prepared to

provide the model and serial number of the machine in

question.

For Units Equipped with Taylor's Remote

Monitoring System

FCC / IC ID Label Placement:

• This hardware installation package includes a label

that must be placed on the unit immediately after the

installation of the IoT hardware device has been

completed.

• The label indicates the FCC ID and Industry Canada

ID for the wireless communication device. The label

must be placed on the outside surface of the

machine, in a manner that is visible and

unobstructed.

• It is recommended that this label be placed directly

adjacent to the product nameplate of this device.

FCC Compliance Statement:

• This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules.

• These limits are designed to provide reasonable

protection against harmful interference when the

equipment is operated in a commercial environment.

• This equipment generates, uses, and can radiate

radio frequency energy, and if not installed and used

in accordance with the instruction manual, may

cause harmful interference to radio communications.

• Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference at

his own expense.

Industry Canada Statement:

• This device complies with Industry Canada license-

exempt RSS standard(s).

• Operation is subject to the following two conditions:

a. This device may not cause interference.

2-2

Model C606

b. This device must accept any interference,

including interference that may cause undesired

operation of this device.

To the Operator

Page 11

Section 3

We at T a ylor are concerned about the safety of the

operator when they come in contact with the freezer and

its parts. Taylor has gone to extreme effo rts to design and

manufacture built-in safety features to protect both

operator and service technician. As an example, warning

labels have been attached to the freezer to further point

out safety precautions to the operat or.

DANGER! Failure to adhere to the following

safety precautions may result in severe personal injury or

death. Failure to comply with these warnings may also

damage the machine and/or its components. Such

damage may require component replacement and

service repair expenses.

NOTICE! DO NOT operate this machine

without reading this entire manual first. Failure to follow

all of these operating instructions may result in damage

to the machine, poor performance, health hazards, or

personal injury.

IMPORTANT! This machine is to be used only

by trained personnel. It is not intended for use, cleaning,

or maintenance by children or people with reduced

physical, sensory, or mental capabilities or lack of

experience and knowledge, unless given supervision or

instruction concerning the use of the machine by a

person responsible for their safety. Children should be

supervised to ensure that they do not play with the

machine.

IMPORTANT! An equipotential grounding lug is

provided with this machine. Some countries require the

grounding lug to be properly attached to the rear of the

frame by the authorized installer . The installation location

is marked by the equipotential bonding symbol (5021 of

IEC 60417-1) on both the removable panel and the

machine's frame.

Safety

WARNING! Avoid injury .

• DO NOT operate the machine unless it is

properly grounded.

• DO NOT operate the machine with larger fuses

than specified on the machine's data label.

• All repairs should be performed by an

authorized Taylor service technician.

• The main power supplies to the machine must

be disconnected prior to performing installation,

repairs, or maintenance.

• For Cord-Connected Machines: Only

authorized Taylor service technicians or

licensed electricians may install a plug or

replacement cord on the machine.

• Machines that are permanently connected to

fixed wiring and for which leakage currents may

exceed 10 mA, particularly when disconnected

or not used for long periods, or during initial

installation, shall have protective devices to

protect against the leakage of current, such as a

GFI, installed by the authorized personnel to the

local codes.

• Stationary machines which are not equipped

with a power cord and a plug or another device

to disconnect the appliance from the power

source must have an all-pole disconnecting

device with a contact gap of at least 0.125 in.

(3 mm) installed in the external installation.

• Supply cords used with this machine shall be

oil-resistant, sheathed flexible cable not lighter

than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord

(code designation 60245 IEC 57) installed with

the proper cord anchorage to relieve conductors

from strain, including twisting, at the terminals

and protect the insulation of the conductors from

abrasion.

• If the supply cord is damaged, it must be

replaced by an authorized Taylor service

technician in order to avoid a hazard.

• Secure the supply cord ground lead to the

machine in a location where if the cord is pulled,

the main power leads will become taut before

the ground lead can break loose.

3

Safety

Model C606

3-1

Page 12

SAFETY

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

distributor for service.

WARNING! Avoid injury.

• DO NOT allow untrained personnel to operate

this machine.

• DO NOT operate the machine unless all service

panels and access doors are fastened with

screws.

• DO NOT remove any internal operating parts

(including, but not limited to, freezer door,

beater , or scraper blades) unless all control

3

Failure to follow these instructions may result in severe

personal injury, especially to fingers or hands, from

hazardous moving parts.

switches are in the OFF position.

WARNING! This machine must NOT be

installed in an area where a water jet or hose can be

used. NEVER use a water jet or hose to rinse or clean

the machine. Failure to follow this instruction may result

in electrocution.

CAUTION! This machine is equipped with a

refrigerated cabinet, designed to maintain product

temperature at or below 41°F (5°C). Before replenishing

the mix supply, the product must be refrigerated at or

below 41°F (5°C). Failure to follow this instruction may

result in health hazards and poor freezer performance.

DO NOT run the machine without product. Failure to

follow this instruction can result in damage to the

machine.

WARNING! This machine has many sharp

edges that can cause severe injuries.

• DO NOT put objects or fingers near the shaver

or the pitcher blades.

• USE EXTREME CAUTION when removing

blades that are very sharp.

Failure to follow this instruction may result in

contaminated product or personal injury from blade

contact.

IMPORTANT! Access to the service area of

the machine is restricted to persons having knowledge

and practical experience with the machine, in particular

as far as safety and hygiene are concerne d.

DO NOT obstruct air intake and discharge openings. A

minimum of 3 in. (76 mm) air clearance on both sides of

the machine is required. It is recommended to place the

rear of the machine against the wall to prevent the

recirculation of warm air. Failure to follow this instruction

may cause poor freezer performance and damage to the

machine.

For Indoor Use Only: This machine is designed to

operate indoors, under normal ambient temperatures of

70°F to 75°F (21°C to 24°C). The machine has

successfully performed in high ambient temperatures of

up to 104°F (40°C) at reduced capacities.

Noise Level: Airborne noise emission does not exceed

78 dB(A) when measured at a distance of 39 in. (1.0 m)

from the surface of the machine and at a height of 62 in.

(1.6 m) from the floor.

NOTICE! Cleaning and sanitizing schedules

are governed by your federal, state, or local regula to ry

agencies and must be followed accordingly. Please refer

to the cleaning section of this manual for the proper

procedure to clean this machine.

3-2

Model C606

Safety

Page 13

Section 4

1

4

5

6

7

22

9

10

11

12

23

13

14

19

8

21

1a

20

18

1

1a

3

2

8

17

16

15

Exploded View

Operator Parts Identification

4

Operator Parts Identification

Figure 4-1

Model C606

4-1

Page 14

OPERATOR PARTS IDENTIFICATION

Exploded View

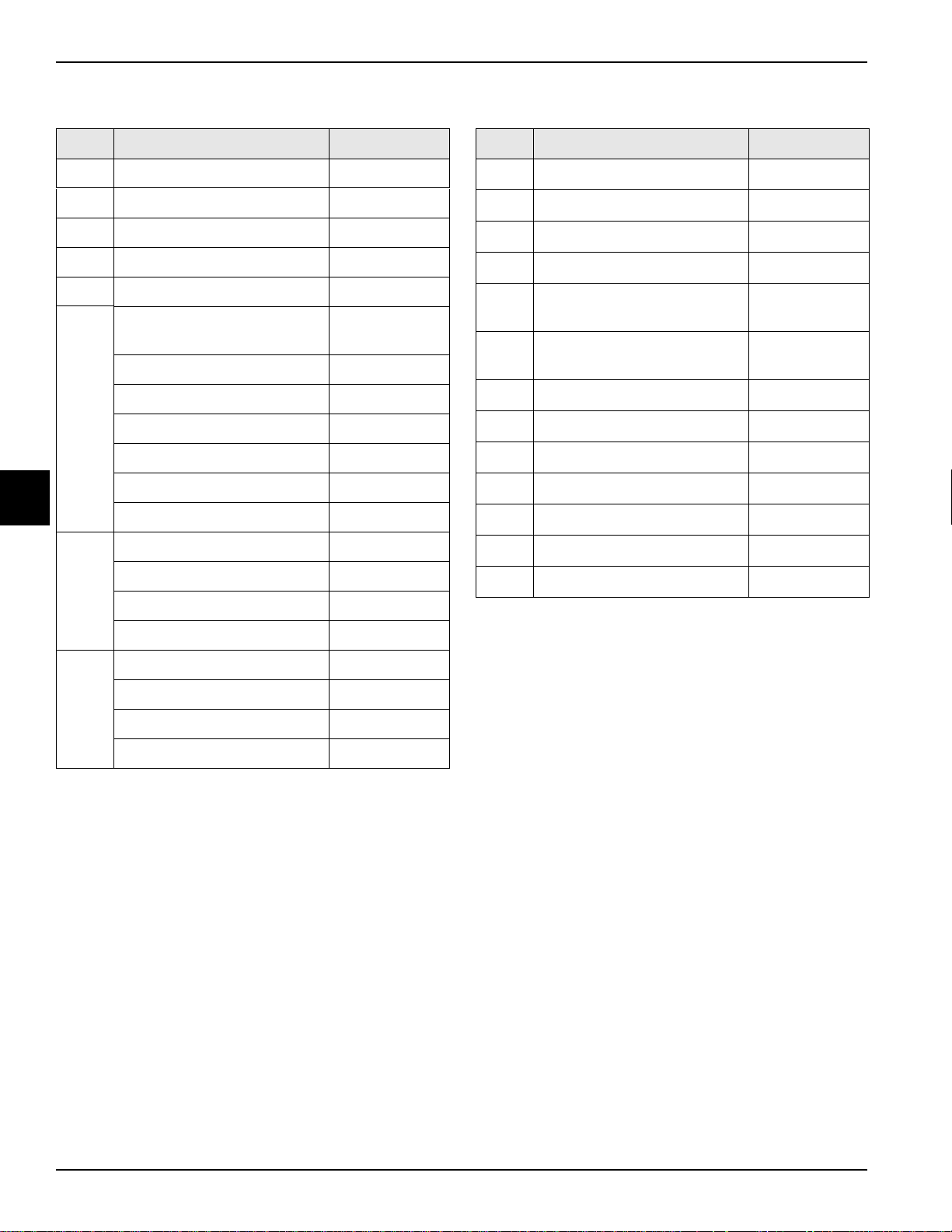

Item Description Part No.

1 Kit A.-Cover-Hopper X65368-SP

1a Label-Caution-Agitator 045191

2 Agitator A.-Mix Hopper-20 X44797

3 Pin-Retaining Hopper CVR 043934

4 Pan-Drip-Rear X56003

5 Panel-Rear-Upper 066724

6 Guide A.-Drip Pan-Mix Pump X48228

7 Panel-Rear-Lower 055959

8 Pan-Drip-Side X56005

Trim-Corner-Rear-R 056692

9

Trim-Corner-Rear-L 056693

4

10 Caster-4" 044106

11 Screw-1/4-20X3/8 011694

Item Description Part No.

12 Panel-Side Right 055950

13 Tray-Drip 033812

14 Shield-Splash 033813

15 Lid-Syrup Jar 042706

16 Jar-Syrup*Plastic 036573

17 Jar-Syrup*Stainless 036574

18 Ladle-1 oz 033637-1

19 Pan-Drip 19-1/2 Long 035034

20 Plate-DEC 056131-1

21 Panel-Side Left 055957

22 Filter-Air-18.00LX13.50HX.70 052779-3

23 Caster-4" SWV 3/4-10 Stem

w/ Brake

046437

4-2

Model C606

Operator Parts Identification

Page 15

Front View

12

11

10

6

7b

7c

8a

8

9

1

2

3

4

5

7

7a

9a

OPERATOR PARTS IDENTIFICATION

4

Operator Parts Identification

Figure 4-2

Model C606

4-3

Page 16

OPERATOR PARTS IDENTIFICATION

Front View

Item Description Part No.

1 Stud-Nose Cone 055987

2 Fitting-Panel Mount QD 056674

3 Clip-Spring-Cup Holder 068394

4 Line A.-Syrup Door X59304

5 Sensor A.-Pyroelectric X59268-SER

Kit A.-Syrup Door

(magnetic catch)

Screw-6-32X3/8 SLTD (4) 002201

Magnet-Catch Assy. (2) 016121

6

Nut-10-32 Flange Locknut (4) 020983

Screw-10-32X3/8 SLTD (4) 024298

Handle-Door Short (2) 065933

4

Bracket-Magnet Door (1) 065934

Fitting A.-Syrup Jug 36" X53353-BLU

Fitting A.-Syrup Jug 36" X53353-BRN

7

Fitting A.-Syrup Jug 36" X53353-RED

X65932

Consists of:

Item Description Part No.

Hose-Beverage 3/8"ID X 5/8 053052-36

7b

Tube A.-Syrup Pick Up X53175

7c

Ferrule-.625 ID NP Brass 053036

*7d

Fitting-Peristaltic Pump 054526

*7e

O-ring-.500 OD X .070W (50 to

*7f

bag)

Line A.-Syrup (for use with bag

*

syrup system)

Door A.-Cabinet X58607-SER

8

Basket-Door-Wire 059144

8a

Holder A.-25DCC PYR SNS X69102

*9

Screw-Adjustment-5/16-18 051574

*9a

Pump A.-Syrup-Heated- BRN X53800-BRN

10

Pump A.-Syrup-Heated- Tan X53800-TAN

11

Gasket-Drip Lip 036435

12

*Not Shown

024278

X58450

Fitting A.-Syrup Jug 36" X53353-WHT

Cap-Ultimate Syrup 053040-BLU

Cap-Ultimate Syrup 053040-RED

7a

Cap-Ultimate Syrup 053040-BRN

Cap-Ultimate Syrup 053040-WHT

4-4

Model C606

Operator Parts Identification

Page 17

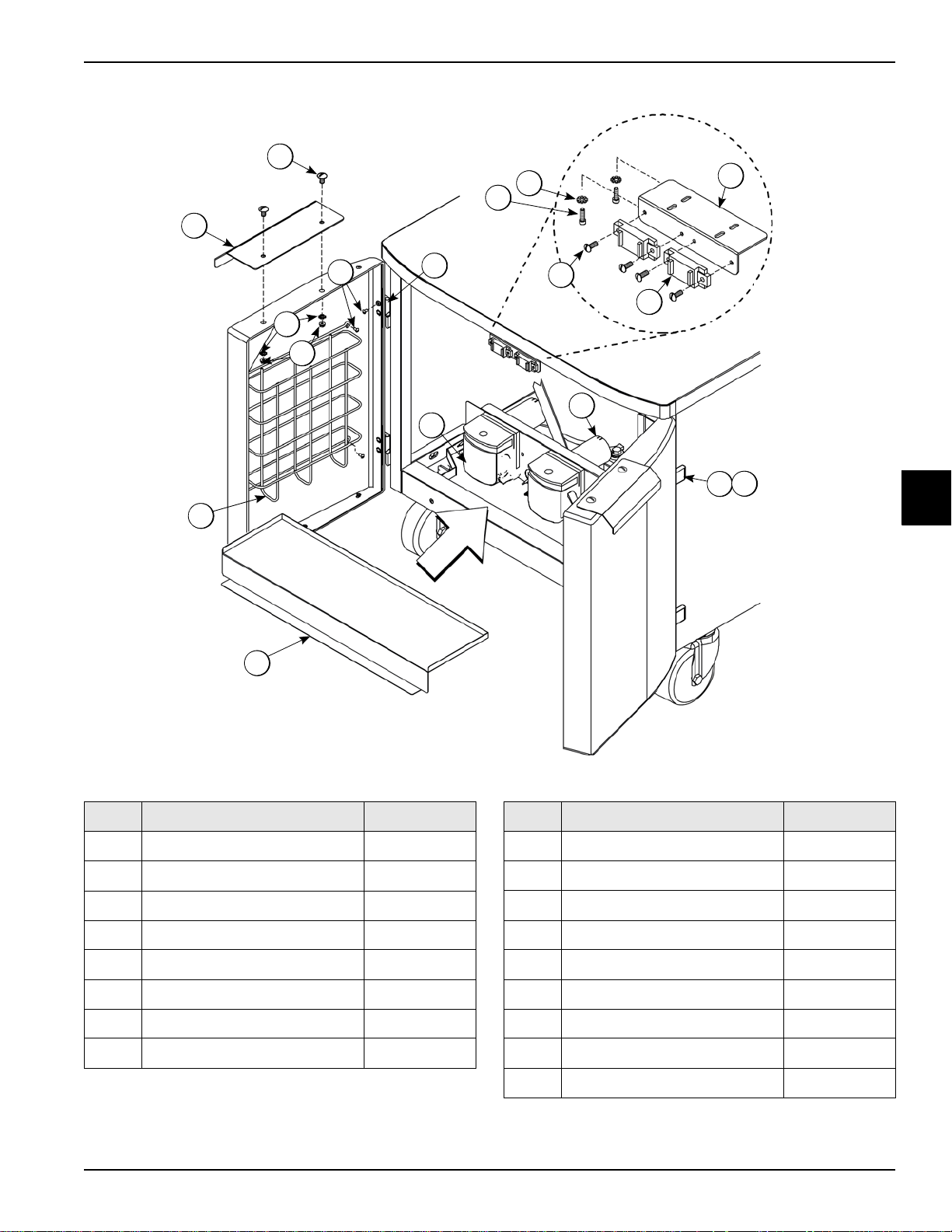

Syrup Cabinet View

11

9

4

1

6

12

7e

7a

7d

7b

7c

5

10

8a

8

3

2

OPERATOR PARTS IDENTIFICATION

Item Description Part No.

1 Shelf-Syrup 056016

2 Pump-Peristaltic 052916

3 Motor-Gear 161 RPM/ Short Shaft 058725-SER

4 Basket-Door-Wire 059144

5 Block-Hinge 058613

6 Block-Hinge 058614

Figure 4-3

Item Description Part No.

7c W asher-#4 Ext Tooth Lock 043075

7d Screw-6-32X3/8 SLTD BIND 002201

7e Bracket-Magnet Door 065934

8 Handle-Door Short 065933

8a Screw-10-32X3/8 SLTD TRUS 024298

9 Nut-10-32 Flange Locknut 020983

4

*7a Magnet-Catch Assy. 016121

7b Screw-4-40x3/8 Socket Cap 058317

Operator Parts Identification

*Prior to S/N K4091994, use 058630 Latch-Door-Magnetic.

Model C606

10 Screw-10-32X3/8 SLTD 006749

11 Washer-#8 Ext Tooth Lock 000964

12 Screw-8-32X1/4 SLTD Round 016540

4-5

Page 18

OPERATOR PARTS IDENTIFICATION

1

2

5

4

3

Syrup Pump and Tubes

4

Item Description Part No.

1 Pump-Peristaltic 052916

Kit A.-Peristaltic Pump Tube

(1 Tube Kit)

2

Kit A.-Peristaltic Pump Tube

(4 Tube Kit)

X54978

X54979

Figure 4-4

Item Description Part No.

3 Ferrule- .625 ID 053036

4 Fitting-Peristaltic Pump 054526

5 O-ring 1/2 OD x .070 024278

*6 Line A.-Syrup X62426-8

*Not Shown

4-6

Model C606

Operator Parts Identification

Page 19

X57028-XX Pump A.—Mix Simplified - Shake

13b

14

13d

13c

13a

12

1

10

9

8

7

6

5

11

4

3

2

13

4

OPERATOR PARTS IDENTIFICATION

Item Description Part No.

1–7 Pump Assembly-Mix Simplified

Shake

1 Cylinder-Pump Hopper Shake 057944

2 Pin-Retaining X55450

3 Piston-Pump-Simplified 053526

4 O-ring-2-1/8 OD X .139W-#225 020051

*5 Cap-Valve Body Shake 056873-10

6 Gasket - Simplified Pump Valve 086097

7 Adaptor - Mix Inlet - Shake Blue 054944

8 Pin-Cotter-Hairpin-1/8DIA 044731

9 Tube A.-Feed Tube-SHK X55973

X57028-10

Figure 4-5

*Standard Cap-Valve Body Shaft is -10. A vailable in other sizes.

X55973 Sleeve A.-Mix Pump

Item Description Part No.

10 Ring-Check-Feed-Tube 056524

11 O-ring-11/16ODX.103W-Red

(50 to bag)

12 Clip-Retainer-Mix Pump 044641

13 Shaft A.-Drive-Mix Pump-Hopper X41947

13a Crank-Drive-Hopper Mix Pump 039235

13b Shaft-Drive-Mix Pump- Hopper 041948

13c O-ring-1-3/4 OD X .139W

(25 to bag)

13d O-ring 1/2 ID X .139W (25 to bag) 048632

14 Sleeve A.-Mix Pump X44761

016132

008904

4

Operator Parts Identification

Model C606

4-7

Page 20

OPERATOR PARTS IDENTIFICATION

13b

14

13d

13c

13a

12

1

4

10

9

8

7

6

5

10

4

3

2

13

11

X57029-XX Pump A.—Mix Simplified - Soft Serve

4

Item Description Part No.

1–7 Pump A.-Mix Simplified S.S.

1

Cylinder-Pump Hopper Softserve

2

Pin-Retaining

3

Piston-Pump-Simplified

4

O-ring-2-1/8 OD X .139W-#225

5

Cap-Valve Body SS

6

Gasket-Simplified Pump Valve

7

Adaptor-Mix Inlet-SS-Red

8 Pin-Cotter-Hairpin-1/8DIA

9

Tube A.-Feed Tube-SS

X57029-12

057943

X55450

053526

020051

056874-12

086097

054825

044731

X55974

Figure 4-6

*Note: The Standard Pump is X57029-12. Overrun can be

changed higher or lower by substituting the valve body cap. The

higher the (-), the higher the overrun.

Item Description Part No.

11 Ring-Check-Feed-Tube

12 Clip-Retainer-Mix Pump

13 Shaft A.-Drive-Mix Pump- Hopper

13a

13b

13c

13d

14 Sleeve A.-Mix Pump *HT

Crank-Drive-Hopper Mix Pump

Shaft-Drive-Mix Pump- Hopper

O-ring-1-3/4 OD X .139W

O-ring 1/2 ID X .139W

056524

044641

X41947

039235

041948

008904

048632

X44761

10

O-ring-11/16ODX.103W-Red

016132

4-8

Model C606

Operator Parts Identification

Page 21

OPERATOR PARTS IDENTIFICATION

2

3

4

5

6

7

8

2

1

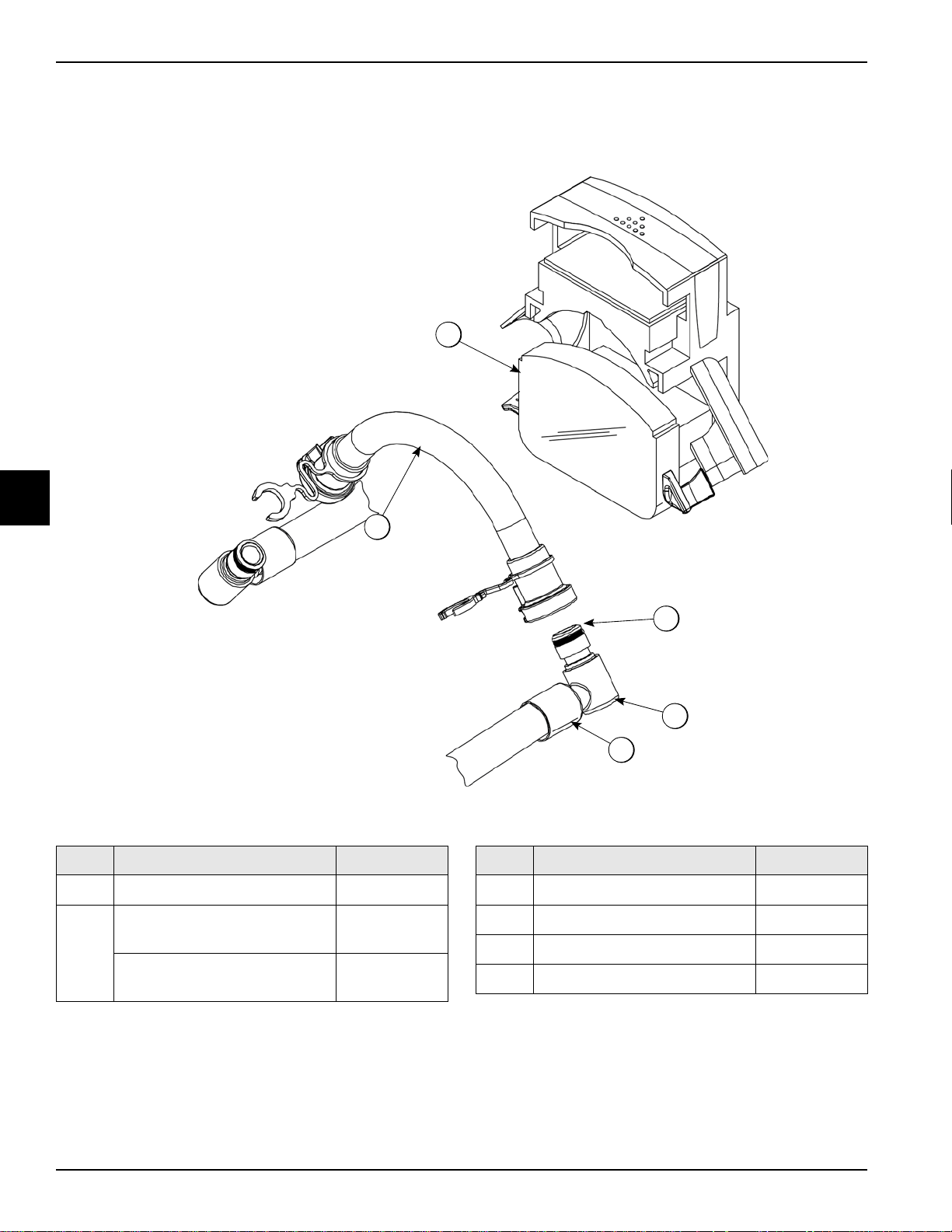

X59304 Syrup Line Assembly—Thin Viscosity Syrup

Item Description Part No.

1 Tube-Nylobrade 3/8IDX5/8 500038-9

2 Ferrule-.650 ID NP Brass 029834

3 Fitting-Syrup Elbow 056651

4 Valve-Check-Duckbill 500598

5 Fitting-Syrup Nose .075 Slot 056649

Figure 4-7

Item Description Part No.

6 O-ring-11mm ID X 2mm W Green 053890

7 O-ring-11mm ID X 2mm W Green

(25 to bag)

8 Insert-QD-CPC-3/8 Barb 056675

053890

4

Operator Parts Identification

Model C606

4-9

Page 22

OPERATOR PARTS IDENTIFICATION

2

3

4

5

6

7

8

2

1

X56652 Syrup Line Assembly—Thick Viscosity Shake Syrup (Optional)

4

Item Description Part No.

1 Hose-Beverage 053052-9

2 Ferrule-.625 ID 053036

3 Fitting-Syrup Elbow 056651

4 Valve-Check Duckbill 500598

5 Fitting-Syrup Nose (Large Slot) 056650

Figure 4-8

Item Description Part No.

6 O-ring-11 mm Green

(Syrup Hole Plug)

7 O-ring 500205

8 Fitting-Barb 056675

053890

4-10

Model C606

Operator Parts Identification

Page 23

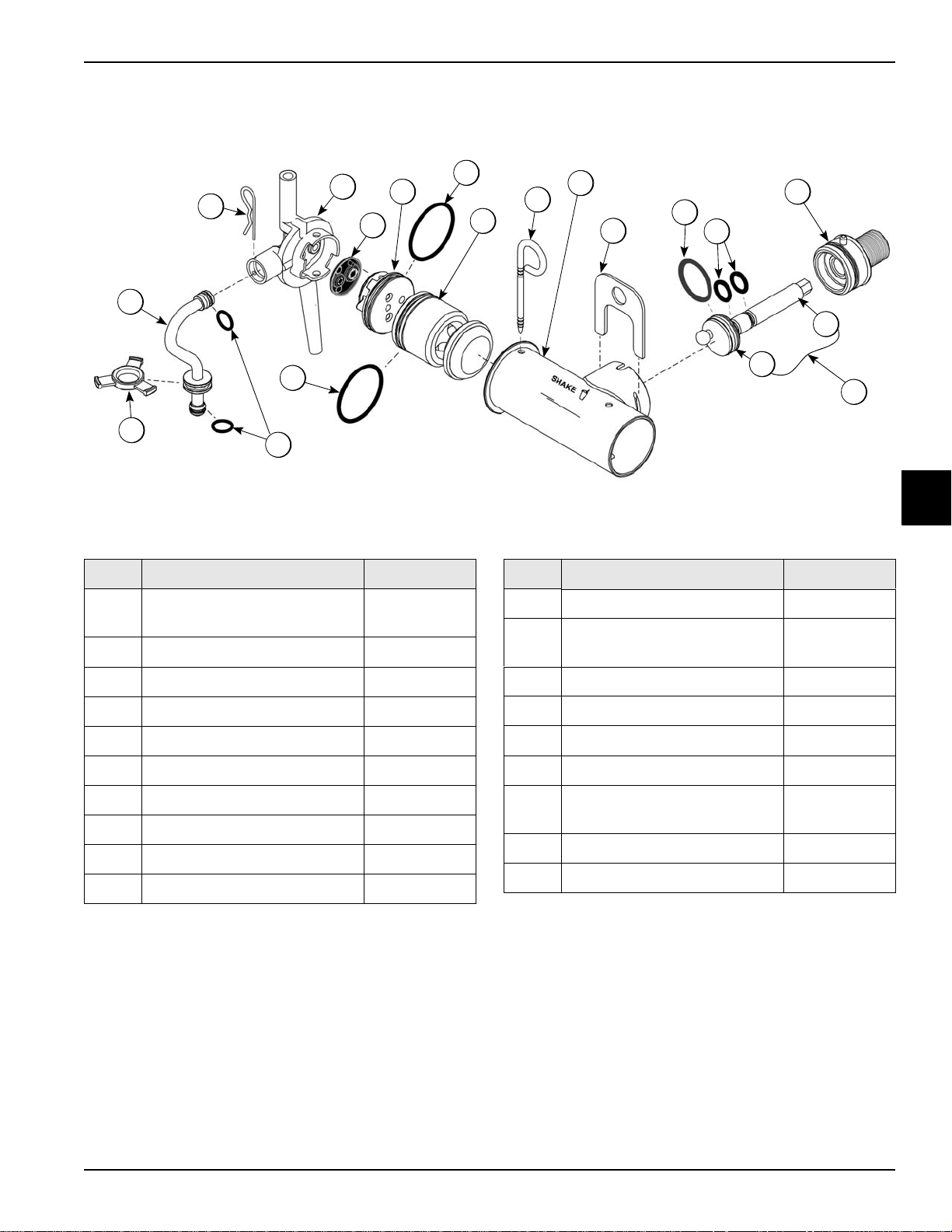

OPERATOR PARTS IDENTIFICATION

1

2

3

4

3

5

6

7

X58450 Syrup Line Assembly—Syrup-in-Bag Option

Item Description Part No.

1 O-ring 1/2 OD X .070 024278

2 Fitting-Male 054526

3 Ferrule- .625 ID NP Brass 053036

4 Hose-Beverage 3/8 ID 053052-36

Figure 4-9

Item Description Part No.

5 Coupling-QD Female 3/8 058451

6 Coupling-QD Male 1/4 Barb 058452

7 Tube-Vinyl 3/16 ID X 1/16 W

(R30314)

020940-8

4

Operator Parts Identification

Model C606

4-11

Page 24

OPERATOR PARTS IDENTIFICATION

1

21

6

3

4

6

5

4a

3a

Mix Hopper—Top View

4

Item Description Part No.

1 Sleeve A.-Mix Pump X44761

2 Probe A.Mix Out X41348

3 Housing A.-Agitator (Shake) X51664

3a4aMagnet A.-Agitator-Inner X41733

Figure 4-10

Item Description Part No.

4 Housing A.-Agitator (Soft Serve) X51661

5 Probe A.-Mix Low X42077

6 Cap-Magnet 080826

4-12

Model C606

Operator Parts Identification

Page 25

Accessories

10

11

12

8

9

7

6

4

2

3

1c

1a

1b

16

14

15

5

14a

13

1

OPERATOR PARTS IDENTIFICATION

4

Operator Parts Identification

Figure 4-11

Model C606

4-13

Page 26

OPERATOR PARTS IDENTIFICATION

Accessories

4

Item Description Part No.

1 Kit A.-Syrup Plug Kit TTS X58474

1a Plug-Syrup Port TTS 053867

1b O-ring-11mm ID X 2mm W Green

(25 to Bag)

1c Tool-Seal Install-Remove 035460

2 O-ring-1-11/16 OD X.139W

(25 to bag) (Draw Valve Cap)

3 Cap A.-V alve-Draw X54704

4 Ladle-1 oz-120D Bend 033637-1

5 Cup-Divided Syrup 017203

6 Tool-O-ring Removal 048260-WHT

7 Lubricant-Taylor Hi PERF 048232

8 Bottle-Wash-Plastic 044818

9 Tool-Mix Pump Shaft Removal 057167

10 Tray-Parts-Pump-SIMPL 056525

053890

041923

Item Description Part No.

12 Tray-Parts-SS Side 059087

13 Pail-10 qt. 013163

14 Dispenser A.-Cup-2 Cone X56121

14a Baffle-Rubber Cone 052193

15 Tray A.-Syrup (Optional Syrup in

Bag System)

16 Tank-Syrup 4qt. PSD (Optional 4

Tank Syrup System)

* Kit A.-Peristaltic Pump Tube X54978

* Kit A.-Topping Pump Spares X53795

* Kit A.-Tune Up Blade X49463-94

* Deflector-Blower Exhaust 047912

* Box-Tool 15 inch Plastic 058669

*Not Shown

X59143

056673

11 Tray-Parts-Shake Side 059088

4-14

Model C606

Operator Parts Identification

Page 27

X44127 Brush Kit Assembly

1

2

3

4

5

6

7

8

9

OPERATOR PARTS IDENTIFICATION

4

Item Description Part No.

Figure 4-12

Item Description Part No.

1 Black Bristle Brush 013071

2 Double End Brush 013072

3 White Bristle Brush (1” x 2”) 013073

4 White Bristle Brush (1-1/2” x 3”) 014753

5 White Bristle Brush (1/2” x 3”) 033059

Operator Parts Identification

Model C606

6 Brush Set (3) 050103

7 Yellow Bristle Brush 039719

8 White Bristle Brush (3” x 7”) 023316

9 Brush-Pump Spout 054068

4-15

Page 28

OPERATOR PARTS IDENTIFICATION

5

2f

2d

2b

2a

2c

2e

2g

1

3

4

2

X53800-BRN/TAN Syrup Pump

4

Item Description Part No.

Pump A.-Syrup-Heated X53800-BRN

1

Pump A.-Syrup-Heated X53800-TAN

Plunger A.-Brown X36576-BRN

2

Plunger A.-T an X36576-TAN

Knob-Plunger Brown- Syrup Pump 032762-BRN

2a

Knob-Plunger Tan-Syrup Pump 032762-TAN

2b Tube-Plunger 032757

2c Insert-Plunger 032758

2d Spring-Plunger-Syrup Pump 032761

2e Washer-Nylon 032760

2f Plunger 036578

2g Seal A. X33057

*2h Nut-Plunger 036577

3 Nut-Lock-Syrup Pump 039680

4 Pump A.-Syrup Heated Shallow X53798-SER

5 Lid 036579

Note: Shown for reference only. Not supplied with new

machines.

*Not Shown

Figure 4-13

4-16

Model C606

Operator Parts Identification

Page 29

Beater Door Assembly—Shake Side

2

1

3

4

17

16

8

7

9

10

13

11

12

14

15

6

5

OPERATOR PARTS IDENTIFICATION

4

Operator Parts Identification

Figure 4-14

Model C606

4-17

Page 30

OPERATOR PARTS IDENTIFICATION

Beater Door Assembly—Shake Side

4

Item Description Part No.

1 Seal-Drive Shaft 032560

2 Shaft-Beater 7 qt. 050985

3 Blade-Scraper 16” 041103

4 Beater A.-7 qt. Fluted Blade X50958

5 Bearing-Door Front 055605

6 O-ring 6” (Freezer Door) 033493

7 Door A.-Shake Side X55825SER2

8 Nut-Stud-Short 055989

9 O-ring Syrup Port 11 mm 053890

Item Description Part No.

10 Plug-Syrup Port 053867

11 Retainer-Syrup Valve 054554

12 Seal-Spinner Shaft 084696

13 Spinner 034054

14 Blade A.-Spinner X59331

15 Cap-Restrictor 033107

16 O-ring 1-1/16 OD X .139 W

(Draw V a lve)

17 V alve A.-Draw 059000

020571

4-18

Model C606

Operator Parts Identification

Page 31

Beater Door Assembly—Soft Serve Side

14

13

11

12

10

9

8

7

6

5

2

1

4

3

5

16

15

OPERATOR PARTS IDENTIFICATION

Item Description Part No.

1 Seal-Drive Shaft 032560

2 Shaft-Beater 032564

3 Beater A.-3.4qt-1 Pin X46231

4 Blade-Scraper-Plastic 9-13/16L 084950

5 Kit A.-Beater-Front Shoes-Bearing X50350

6 Baffle -Threadess Molded 087 708

7 Gasket-Door HT 4"-Double 048926

8 Pin-Handle-SS 055819

9 Door A.-1SP 3.4QT Threadless X87683

Figure 4-15

Item Description

10 Nut-Stud-Black-1.00 055989

1 1 Screw-Adjustment-5/16-24 056332

12 Nut-5/16-24 Finished Hex 029639-BLK

13 O-ring-1/4 OD X .070W 50 DURO

(25 to Bag)

14 Handle A.-Draw X56421-1

15 O-ring-7/8 OD X .103W

(100 to Bag)

16 V alve A.-Draw X55820

015872

014402

4

Operator Parts Identification

Model C606

4-19

Page 32

OPERATOR PARTS IDENTIFICATION

1

2 3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

6

059088 Parts Tray—Shake Side

4

Item Description Part No.

1 Beater A.-7 qt. X50958

2 Blade-Scraper-16” 041103

3 Shaft-Beater 7 qt. 050985

4 Seal-Drive Shaft 032560

5 Nut-Stud 055989

6 O-ring-Syrup Port 11mm ID Green 053890

7 Plug-Syrup Port 053867

8 Spinner 034054

9 Blade A.-Spinner X59331

10 Seal-Spinner Shaft 084696

Figure 4-16

Item Description Part No.

1 1 Cap-Restrictor 033107

12 V alve A.-Draw X57169

13 Valve-Check Duckbill 500598

14 Bearing-Door Front 055605

15 O-ring-1-1/16 OD (Draw Valve) 020571

16 Fitting-Syrup Nose See pages

17 Retainer-Syrup Valve 054554

18

4-9 and 4-10

O-ring 6”-Door 033493

Door A.-Shake X55825SER2

4-20

Model C606

Operator Parts Identification

Page 33

059087 Parts Tray—Soft Serve Side

9

8

76

5

4

3

2

1

14

13

12

11

10

OPERATOR PARTS IDENTIFICATION

Item Description Part No.

1 Handle A.-Draw X56421-1

2 Pin-Pivot 055819

3 Bearing-Front 050348

Figure 4-17

Item Description Part No.

8 Door A.-w/Baffle X57332-SER

9 Shoe-Front Helix- Front 084108

10 Drive Shaft 032564

4

4 Nut-Stud 055989

5 O-ring (Draw Valve) 014402

6 Gasket (Freezer Door) 048926

7 Valve A.-Draw X55820

Operator Parts Identification

Model C606

11 Seal-Drve Shaft 032560

12 Blade-Scraper-Plastic 9-13/16L 084950

13 Beater A. X46231

14 Shoe-Front Helix- Rear 084109

4-21

Page 34

OPERATOR PARTS IDENTIFICATION

5

4

3

2

1

16

15

14

13

12

11

10

9

7

8

6

056525 Parts Tray—Simplified Pump

4

Figure 4-18

Shake Side Soft Serve Side

Item Description Part No.

1 Clip-Mix Pump Retainer 044641

2 Cylinder-Pump-Hopper Shake 057944

3 Pin-Retaining X55450

4 Piston 053526

5 Pin-Cotter 044731

6 O-ring 2-1/8” OD - Red 020051

7 Cap-Valve 056873-XX

8 Gasket-Simplified Pump Valve 086097

9 Adaptor-Mix Inlet Shake-Blue 054944

10 Ring-Check .120 OD 056524

11 Shaft A.-Drive Mix Pump X41947

12 O-ring-Drive Shaft 048632

13 Tube A.-Feed-Hopper Shake X55973

Item Description Part No.

1 Clip-Mix Pump Retainer 044641

2 Cylinder-Pump-Hopper- Soft Serve 057943

3 Pin-Retaining X55450

4 Piston 053526

5 Pin-Cotter 044731

6 O-ring 2-1/8” OD - Red 020051

7 Cap-Valve 056874-XX

8 Gasket-Simplified Pump Valve 086097

9 Adaptor-Mix Inlet Soft Serve-Red 054825

10 Ring-Check .120 OD 056524

1 1 Shaft A.-Drive Mix Pump X41947

12 O-ring-Drive Shaft 048632

13 Tube A.-Feed-Hopper Soft Serve X55974

14 O-ring 1-3/4 008904

15 O-ring-11/16 OD - Red 016132

4-22

Model C606

14 O-ring 1-3/4 008904

15 O-ring-11/16 OD - Red 016132

16 Agitator A.-Mix Hopper X44797

Operator Parts Identification

Page 35

Section 5

4

3

2

1

16

15

13

12

11

10

9

8

7

5

6

14

User Interface

Item Description

1 Key—Shake

2 Display—Vacuum Fluorescent Menu (VFD)

3 Key—Menu (Entry/Exit)

4 Keys—Soft Serve

5 Indicator Light—Mix Out

6 Switch—Power

7 Standby—Soft Serve

8 Standby—Shake

Figure 5-1

Item Description

9 Keys—Topping Heaters

10 Display—LED (Brush Clean Countdown)

11 Key—Calibrate Menu

12 Key—Flavor Selection

13 Key—Vanilla Flavor

14 Key—Strawberry Flavor

15 Key—Chocolate Flavor

16 Indicator Light—Mix Low

Note: See “Manager's Menu” on page 5-7 for additional key

functions when the Calibration or Manager's Menu is displayed.

5

User Interface

Model C606

5-1

Page 36

USER INTERFACE

Symbol Definitions

To better communicate in the international arena,

symbols have replaced words on many of our operator

keys, switches, functions, and fault indicators. Your

Taylor machine is designed with these international

symbols.

The following chart identifies the symbol definitions:

= Auto

=Heat Cycle

= Wash

= Mix Pump

= Standby (Shake)

= Standby (Soft Serve)

= Flavor Selection

5

= Mix Low

Vacuum Fluorescent Display

The vacuum fluorescent display (VFD) is located on the

front control panel. During normal operation the display is

blank. The display is used to show menu options and

notifies the operator if a fault is detected. The display will

indicate the temperature of the mix in each hopper.

Indicator Lights

Mix Low—When the Mix Low indicator light is

illuminated, the mix hopper has a low supply of mix and

should be refilled as soon as possible.

Mix Out—When the Mix Out indicator light is

illuminated, the mix hopper has been almost completely

exhausted and has an insufficient supply of mix to

operate the freezer. At this time, the Auto mode is locked

out and the freezer will be placed in the Standby mode.

To initiate the refrigeration system, add mix to the mix

hopper and press the Auto key

automatically begin operation.

. The freezer will

Heat Cycle Key

= Mix Out

= Topping Heater-Left

= Topping Heater-Right

= Calibrate

= Menu Display

Power Switch

When placed in the ON position, the power switch allows

control panel operation.

When the Heat Cycle key is illuminated, the freezer

is in the process of a heat cycle. The Heat Cycle key ma y

be selected to start a heat cycle following a freezer soft

lock condition.

For some models, the Heat Cycle key can be selected to

manually start a heat cycle at any time.

Brush-Clean Countdown—Displays the number of days

before the next brush-cleaning is required. When the

display has counted down to 1, the machine must be

disassembled and brush-cleaned within 24 hours.

5-2

Model C606

User Interface

Page 37

USER INTERFACE

Reset Mechanism

The Reset button is located in the service panel at the

rear of the machine. (See Figure

beater motor from overloading. Should an overload

occur, the reset mechanism will trip. To properly reset the

freezer, place the power switch in the OFF position.

Press the Reset button firmly. Turn the power switch to

the ON position. Press the Wash key

the freezer's performance.

5-2.) It protects the

and observe

Adjustable Draw Handle

This machine features an adjustable draw handle to

provide the best portion control, giving a better,

consistent quality to your product and controlling costs.

The draw handle should be adjusted to provide a flow

rate of 5 oz. to 7-1/2 oz. (142 g to 213 g) of product by

weight per 10 seconds. To increase the flow rate, tighten

the screw. To decrease the flow rate, loosen the screw.

After setting the flow rate, tighten the jam nut to secure

the adjustment screw. (See Figure

5-3.)

Figure 5-2

CAUTION! DO NOT use metal objects to press

the reset button. Failure to follow this instruction may

result in electrocution.

If the beater motor is turning properly, press the Wash

key

resume normal operation. If the freezer shuts down

again, contact your authorized service tec hn i cian.

to cancel the cycle. Press the Auto key to

Air/Mix Pump Reset Mechanism

The Reset button for the pump is located in the service

panel at the rear of the machine. (See Figure

reset protects the pump from an overload condition.

Should an overload occur, the reset mechanism will trip.

To reset the pump, press the Reset button firmly.

5-2.) The

Figure 5-3

Shake Fill Level Adjustment

The portion control sensor located under the cup holder

can be adjusted to fill the cup to the desired level. If the

fill level is too low, or the cup is overfilling, it may be

necessary to adjust the sensor position. (See Figure

Figure 5-4

1. Using a crescent wrench, loosen the locking nut on

the screw adjuster below the sensor.

5-4.)

5

User Interface

2. Turn the adjustment screw clockwise to raise the fill

3. Once the desired fill level is achieved, tighten the

Model C606

level, or counterclockwise to lower the fill level.

locking nut.

5-3

Page 38

USER INTERFACE

VFD Screens

The vacuum fluorescent display (VFD) located in the

center of the control panel is normally blank during the

daily operation of the machine. The display is activated

when the Calibrate key

selected. The display screen will also alert the operator of

specific faults detected by the control.

or the Manager's Menu is

Power Up

When the machine is powered, the control system will

initialize to perform a system check. There are four types

of data that the system will check when the control is

initializing: Lamp Test, Lockout Data, Configuration Data,

and System Data.

Lamp Test: The control and software version is displayed

and all of the LEDs on the display panel are illuminated.

5

The SAFETY TIMEOUT screen will be displayed with the

alarm on, for 60 seconds or until any control key is

selected.

After the safety timeout has been completed and the

power switch is OFF, the status screen will display. When

the brush-clean requirements have been met, the

following screen will display:

If a brush-cleaning was not completed, the status screen

will display the current hopper temperature, barrel

temperature, and 5-minute brush-clean timer.

Power Switch ON

When the power switch is placed in the ON position, the

control panel keys become operative. The VFD will either

be blank or indicate that the machine has been cleaned.

Following the lamp test, three separate screens will

appear during initialization.

Initializing . . . . Lockout Data

Initializing . . . . Config Data

Initializing . . . . System Data

If the system detects corrupt data during the initializing,

the following display will alert the operator that the control

settings have changed:

Once the system has initialized, the number of days

remaining before the next required brush-cleaning is

indicated on the control panel, and the SAFETY

TIMEOUT screen is displayed with the alarm turned on.

Some models will continuously display the temperature

of each mix hopper when the power switch is in the ON

position.

5-4

Model C606

User Interface

Page 39

USER INTERFACE

Heat Treatment Cycle

The Heat Cycle keys on the control panel illuminate

throughout the heat treatment cycle. Two warning

messages will be displayed on the screen. DO NOT

DRAW will be displayed when the mix temperature is

below 130°F (54.4°C).

When the temperature of the mix is above 130°F

(54.4°C), the screen will display a message indicating

that hot product is in the machine.

Important! Do not attempt to draw product or

disassemble the machine during the he at trea tm e nt

cycle. The product is hot and under extreme pressure.

In the heat treatment cycle, the mix temperature in the

hoppers and freezing cylinders must be raised to 151°F

(66.1°C) within 90 minutes.

Heat Treatment Cycle Failure Messages

To comply with health codes, heat treatment system

freezers must complete a heat treatment cycle daily, and

must be disassembled and brush-cleaned a minimum of

every 14 days. Brush-cleaning is the normal disassembly

and cleaning procedure found in this manual. Failure to

follow these guidelines will cause the control to lock the

freezer out of the Auto mode.

Always comply with local guidelines for the maximum

number of days allowed between brush-clean cycles.

(See “BRUSH CLEAN CYCLE” on page 5-12.)

If the heat treatment cycle fails, the VFD will display a

failure message and return the freezer to the Standby

mode. A lock is defined as a special Standby mode of

operation which does not allow the machine to operate in

the Auto mode.

There are two types of freezer lock conditions that can

occur: hard lock and soft lock. A hard lock requires the

machine to be disassembled and brush-cleaned. A soft

lock can be corrected by either disassembling and

brush-cleaning the machine, or by starting another heat

treatment cycle.

Hard Lock: There are two causes of a hard lock failure.

• The brush-clean timer has elapsed (maximum se tting

of 14 days).

5

When the heating phase is complete, the freezer goes

into the holding phase of the cycle. The holding phase

will keep the temperature above 151°F (66.1°C) for a

minimum of 30 minutes.

The final phase of the heat treatment cycle is the cooling

phase. The freezer must cool the mix below 41°F (5°C)

within 2 hours.

When the entire heat cycle has been completed, the Heat

Cycle keys

machine will enter the Standby mode (Standby keys

and will illuminate). The machine can be

placed in Auto or left in Sta ndby.

will no longer be illuminated. The

Selecting the Wash key will display the

following screen.

• There has been a thermistor failure (freezing

cylinder, hopper, or glycol) during the heat treatment

process.

User Interface

Model C606

5-5

Page 40

USER INTERFACE

Selecting the Calibrate key will indicate which

thermistor caused the hard lock.

If the machine has hard locked and an attempt is made to

enter Auto mode, the machine will enter the Standby

mode and display the following message:

5

To restore the message that identified the reason for the

hard lock, turn the power switch to OFF for 5 seconds

and then return the power switch to the ON position. The

original message with the reason for the hard lock will be

displayed. The fault description can also be found in the

Manager's Menu.

The FREEZER LOCKED message will remain on the

display until the brush-clean requirements are fulfilled.

The freezer must be disassembled in order to activate

the 5-minute timer on the display screen. Once the timer

counts down to zero, the lockout is cleared.

If the reason for the soft lock has been corrected,

selecting the Heat Cycle key

initiates a heat

treatment cycle immediately . Selecting the W ash key

when the above message is displayed will hard lock the

machine, and brush-cleaning will be necessary.

The following are the variable messages for soft lock

failures that appear on the second line of the screen:

Table 5-1

POWER SWITCH

OFF

MIX OUT PRESENT There was a mix out condition present.

AUTO OR

STANDBY OFF

NO HEAT CYCLE

TRIED

The power switch was in the OFF position.

The machine was not in the Auto or

Standby mode.

A heat treatment cycle was not

attempted in the last 24 hours. (AUTO

HEAT TIME was advanced, a power

loss was experienced at the time the

cycle was to occur, or a heat cycle failure not due to a thermistor failure.)

If the following screen appears, a soft lock has occurred

during the heat treatment cycle:

Soft Lock: If a heat treatment cycle has not been

initiated within the last 24 hours, a soft lock failure will

occur. A soft lock allows the operator to cor rect the cause

of the soft lock. The operator has the option of either

starting another heat cycle or brush-cleaning the

machine.

When a soft lock occurs, the machine will go into the

Standby mode. The following message is displayed on

the screen. The reason for the soft lock is indicated on

the second line.

5-6

Model C606

A soft lock can also occur anytime during operation when

the hopper or freezing cylinder temperature rises above

59°F (15°C), rises and remains above 45°F (7°C) for

more than 1 hour, or rises and remains above

41°F (5°C) for more than 4 hours. If a produ ct ove r

temperature condition occurs during operation, the

following screen will appear:

User Interface

Page 41

USER INTERFACE

When one of these messages appears, automatic freezer

operation cannot take place until the freezer is

disassembled and brush-cleaned or has completed a

heat treatment cycle. Select the Heat Cycle key

start a heat cycle, or select the Wash key to

disassemble and brush-clean the machine.

Once the freezer is unlocked by starting a heat treatment

cycle, the Heat Cycle key

following message will be displayed on the screen:

If the Wash key is selected to clear the lockout by

brush-cleaning the machine, the FREEZER LOCKED

message will remain on the display until the brush-clean

requirements are fulfilled. The freezer must be

disassembled in order to activate the 5-minute timer on

the display screen. Once the timer counts down to zero,

the lockout is cleared.

will illuminate and the

to

Manager's Menu

The Manager's Menu is used to enter the operator

function displays. To access the Manager’s Menu, press

the center of the CONE symbol

(See Figure 5-5.)

Figure 5-5

The left (shake-side) Auto key , the Flavor Selection

key , and the Cone key will be illuminated when

the ACCESS CODE screen is displayed.

In the Menu program, the left (shake-side) Auto key ,

on the control panel.

5

To restore the message that identified the reason for the

soft lock, turn the power switch to OFF for 5 seconds,

and then return the power switch to the ON position. The

original message with the reason for the soft lock will be

displayed.

The FAULT DESCRIPTION can also be found in the

Manager's Menu.

Note: A record of heat cycle data and lockout history

can be found in the Manager's Menu.

Menu” on page 5-7.)

(See “Manager's Menu” on page 5-7.)

(See “Manager's

Flavor Selection key , and Calibr at ion key will

function as menu keys.

Auto —Increases the value above the cursor and is

used to scroll upward in text displays.

Flavor Selection —Decreases the value above the

cursor and is used to scroll downward in text displays.

Calibration —Advances the cursor position to the

right and is used to select menu options.

Note: You will not be able to dispense shakes while

accessing the Manager's Menu options, except when the

CURRENT CONDITIONS screen is displayed.

The soft serve side will continue operation in the mode it

was in when the Manager’s Menu was selected.

However, the soft serve side control keys will not be

illuminated and are nonfunctional when the Manager's

Menu or Calibration Menu is displayed.

User Interface

Model C606

5-7

Page 42

USER INTERFACE

The control keys for both sides are functional in the

Manager's Menu when the CURRENT CONDITIONS

screen is displayed.

page 5-19.)

(See “CURRENT CONDITIONS” on

Entering Access Code

With the ACCESS CODE screen on the display, use the

Auto

code number in the cursor position. When the correct

number is selected, press the Calibration key

move the cursor to the next number position.

The access code for the Manager Menu is 8309.

Continue to enter the proper access code numbers until

all four numbers are displayed, then press the Calibration

5

key

screen, provided the correct access code is entered.

If an incorrect number is entered for the access code, the

display will exit the Menu program when the Calibration

key

or Flavor Selection keys to set the first

. The Manager's Menu list will display on the

is selected. (See Figure 5-6.)

to

Menu Options

Press the Auto key or Flavor Selection key to

move up or down through the Menu. Select a Menu

option by aligning the option with the cursor on the left

side of the screen, then press the Calibration

key . Exit the Menu program by selecting EXIT

FROM MENU or pressing the Cone key .

The following menu options are listed in the Manager's

Menu:

• EXIT FROM MENU

• SYRUP CALIBRATION

• VERIFY CALIBRATION

• SERVINGS COUNTER

• SET CLOCK

• AUTO HEAT TIME

• AUTO START TIME

• STANDBY MODE

• BRUSH CLEAN CYCLE

• MIX LEVEL AUDIBLE

• FAULT DESCRIPTION

• LOCKOUT HISTORY

• FAULT HISTORY

• HEAT CYCLE SUMMARY

• HEAT CYCLE DATA

• SYSTEM INFORMATION

• CURRENT CONDITIONS

5-8

Figure 5-6

EXIT FROM MENU

Selecting EXIT FROM MENU exits the Manager's Menu

and returns the control panel keys to normal operation.

Model C606

User Interface

Page 43

USER INTERFACE

SYRUP CALIBRATION

Use the SYRUP CALIBRATION option to access the

calibration screen selections from the Manager's Menu.

The same functions found in the calibration menu are

displayed on the screen when this menu option is

selected.

Note: The UNFLAVORED DRAW option will only

appear on the screen when the shake side is in the Auto

mode.

VERIFY CALIBRATION

Use the VERIFY CALIBRATION to verify the amount of

syrup dispensed is within the proper specificat ion .

(See “Syrup System” on page 6-25.)

SERVINGS COUNTER

Use the SERVINGS COUNTER screen to check or reset

the number of servings dispensed from the machine.

Reset the SERVINGS COUNTER by selecting the Auto

key

Counters and Details selections will be displayed on the

next screen.

Select the Auto key to move the cursor to Reset

to move the cursor (>) to Next. The Reset

Remove the syrup valve from the dispensing door. With

the line fully primed with syrup, position the syrup valve

over the small chamber side of the divided syrup cup,

then select the corresponding flavor selection. Syrup will

flow into the cup and automatically stop. Place the cup on

a flat surface and check the amount of syrup dispensed.

If the level is not within the correct specification, the

flavor will need to be recalibrated.

on page 6-25.)

It is recommended to verify the calibration of each syrup

flavor and note any flavors that need to be recalibrated

before exiting the Manager's Menu to access the

CALIBRATION Menu.

Select the Calibration key to exit the VERIFY

CALIBRA TION screen and return to the Manage r's Menu

list.

(See “Syrup System”

Counters. Then select the Calibration key .

The display will ask, “Are you sure?” To reset the

counters, select the Auto key

Yes. Select the Calibration key to clear the left and

right counters and return to the SERVINGS COUNTER

screen. If you do not want to clear the serving counter,

move the cursor to No and select the Calibration key

to return to the SERVINGS COUNTER screen

without resetting the counters to zero.

Note: The SERVINGS COUNTER will automatically

reset to zero when the machine is brush-cleaned.

to move the cursor to

5

User Interface

Model C606

5-9

Page 44

USER INTERFACE

Access the Details screen by selecting Next in the

SERVINGS COUNTER screen. Move the cursor to

Details and then select the Calibration key

The counter menu will also display details for the number

of servings for each flavor (chocolate, strawberry , vanilla,

option, unflavored, and soft serve), and count the m ethod

that ended the draw for each flavor (pyroelectric sensor

detection, manually selecting a flavor key, draw safety

timeout, and other).

Example:

.

To change the date or time, select the SET CLOCK

option in the menu. Press the Auto key

the cursor from Exit to Change, then press the

Calibration key

Change the time by pressing the Auto or Flavor

Selection key with the cursor und er the ho u r

position. Move the cursor to the minutes by selecting the

Calibration key

entered, select the Calibration key to advance the

cursor to the month.

to select the Change option.

. Once the correct minutes are