Page 1

N26704

280W

MULTI SANDER

INSTRUCTION MANUAL

AFTER SALES SUPPORT

TEL: 1300 922 271

EMAIL: service.australia@einhell.com

MODEL NUMBER RT-XS 28

Page 2

Multi Sander

What your 1 year warranty means

Great care has gone into the manufacture of this product and it should therefore provide you with years

of good service when used properly. In the event of product failure within its intended use over the

course of the rst 1 year after the date of purchase, we will remedy the problem as quickly as possible

once it has been brought to our attention. In the unlikely event of such an occurrence, or if you require

any information about the product, please contact us via our after sales support services, details of

which can be found in this manual and on the product itself.

Welcome Section

Congratulations on choosing to buy a TAURUS® product.

All products brought to you by TAURUS® are manufactured to the highest standards of performance and

safety, and, as part of our philosophy of customer service and satisfaction, are backed by our

comprehensive 1 Year Warranty.

We hope you will enjoy using your purchase for many years to come.

Table of Contents

1. Safety regulations

2. Layout

3. Proper use

4. Technical data

5. Before starting the equipment

6. Operation

7. Cleaning and maintenance

8. Disposal and recycling

9. Storage

2

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

Page 3

3

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

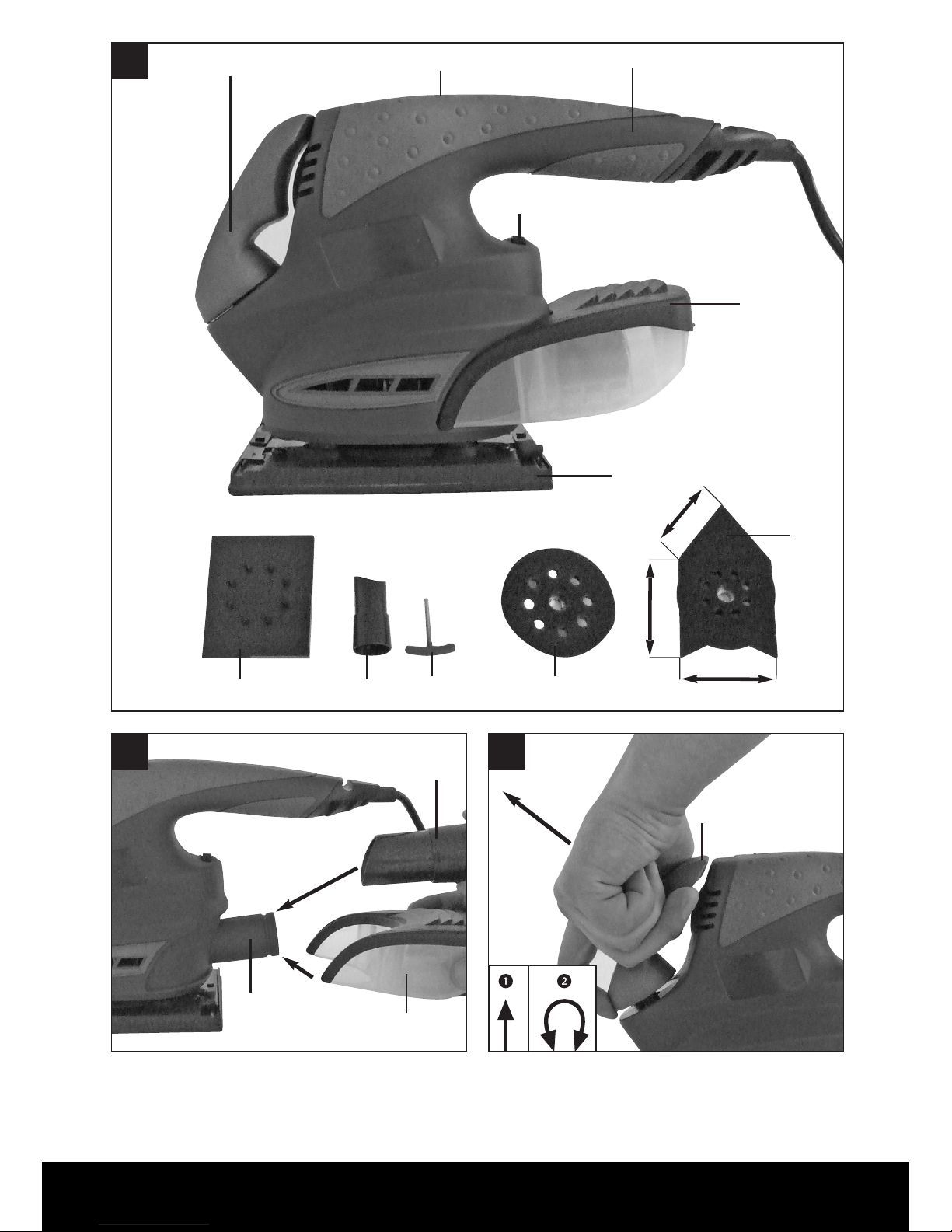

1

2 3

1

2

4

9 10 11 7

a

b

c

10

a

5

1

5

3

6

8

Page 4

4

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

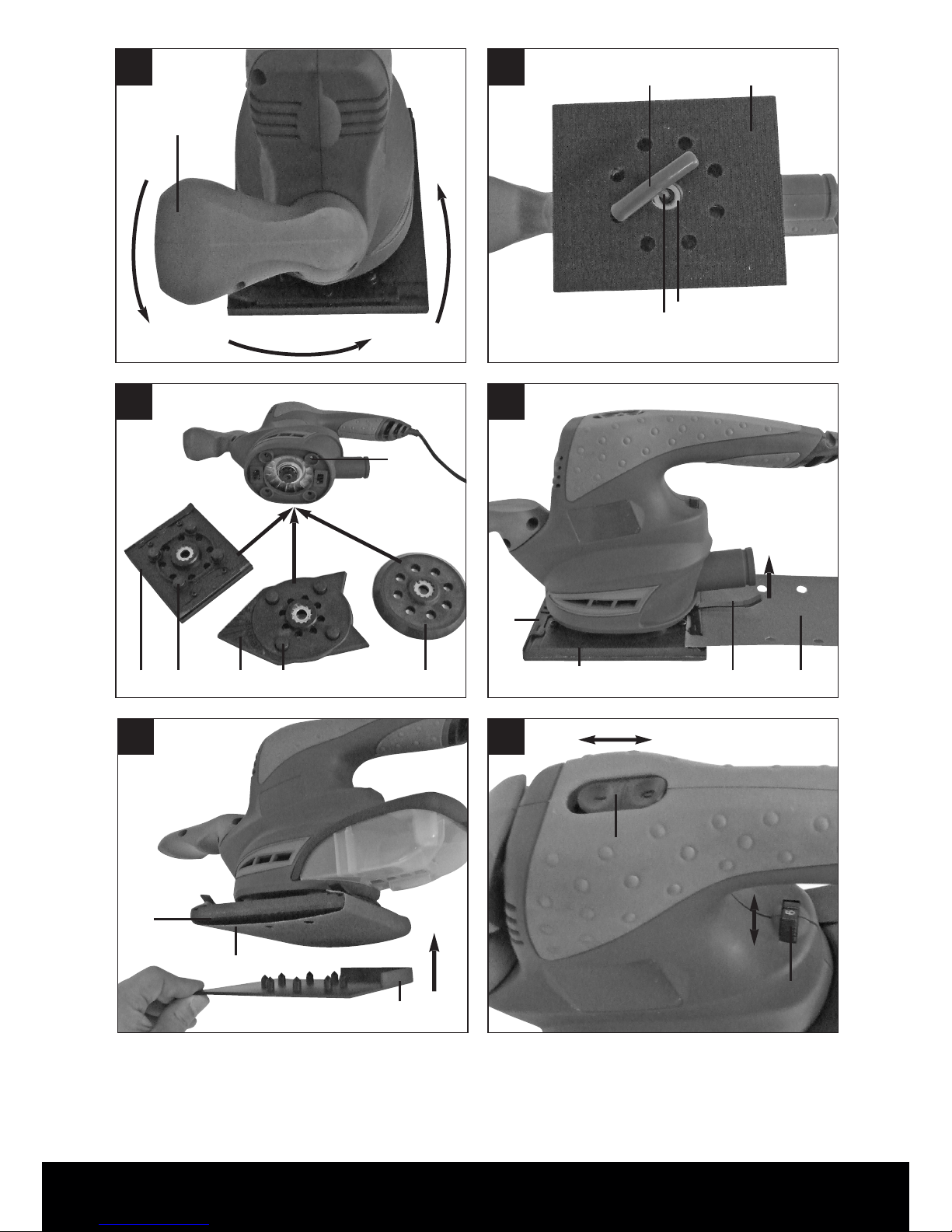

5

76

8

4

9

1

11 c

a

b

e

6 d 8 d 7

a

6 a

b

6

a

9

I 0

2

+

-

3

Page 5

5

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

GENERAL SAFETY RULES

SAVE THESE INSTRUCTIONS

1. Work area

a. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a. Power tools plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tool. Unmodied plugs and matching

outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk

of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

b. Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will

reduce personal injuries.

c. Avoid accidental starting. Ensure the switch is in

the off-position before plugging in. Carrying

power tools with your nger on the switch or

plugging in power tools that have the switch on

invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to rotating part of the power tool may

result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving

parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

4. Power tool use and cars

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c. Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g. Use the power tool, accessories and tool bits

etc. in accordance with these instructions and

in the manner intended for the particular type

of power tool, taking into account the working

conditions and the work to be performed. Use of

the power tool for operations different from

those intended could result in a hazardous

situation.

5. Service

a. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the

power tool is maintained.

WARNING! Read all instructions Failure to

follow all instructions listed below may result

in electric shock, re and/or serious injury. The

term ’’power tool’’ in all of the warnings listed

below refers to your mains-operated (corded)

power tool or battery-operated (cordless) power

tool.

Page 6

6

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

Important!

When using equipment, a few safety

precautions must be observed to avoid injuries

and damage. Please read the complete

operating manual with due care. Keep this

manual in a safe place, so that the information

is available at all times. If you give the

equipment to any other person, give them

these operating instructions as well.

We accept no liability for damage or accidents

which arise due to non-observance of these

instructions and the safety information.

1. Safety regulations:

The corresponding safety information can be found

in the enclosed booklet.

CAUTION

Read all safety regulations and instructions.

Any errors made in following the safety

regulations and instructions may result in an

electric shock, re and/or serious injury.

Keep all safety regulations and instructions

in a safe place for future use.

1. Keep your work area tidy. Untidiness in the

workplace can lead to risk of accidents.

2. Take into account inuences from the

surrounding environment. Do not expose

electrical appliances to rain. Do not use

electric tools in damp or wet environments.

Provide good lighting. Do not use electric

tools near ammable liquids or gases.

3. Protect against electric shock. Avoid bodily

contact with earthed parts, for example

pipes, heaters, ovens and fridges.

4. Keep other people away! Do not let other

people gain access to the tool or cable,

keep them away from your workplace.

5. Store the equipment safely and securely.

Unused equipment must be stored in a dry,

locked room, out of the reach of children.

6. Do not overburden the tool. It will work

better and safer when used within its quoted

capacity range.

7. Use the correct tool. Do not use weak tools

or attachments for heavy duty work. Never

use the electric tool for purposes other than

that for which it is designed, for example

do not use the hand-held circular saw to fell

trees or cut branches.

8. Wear suitable work clothes. Do not wear

loose clothing or jewellery. It could get

caught in moving parts. Rubber gloves and

non-slip shoes are recommended when

working outdoors. If you have long hair,

wear a hair-net.

9. Wear safety goggles. Use a dust mask when

working on dusty jobs.

10. Do not use the cable for purposes other

than that for which it is designed. Do not

carry the tool by the cable and do not use

it to pull the plug out of the socket. Do not

carry the charger by the cable and do not

use is to pull the plug out of the socket.

11. Secure the workpiece. Use clamps or a

vice to hold the workpiece securely. This is

safer than using your hand, and also makes

it possible to use the machine with both

hands.

12. Take care that your feet are a stable

distance apart. Avoid abnormal working

postures. Make sure you stand squarely and

keep your balance at all times.

13. Take good care of your tools. Keep

your tools sharp and clean to keep them

working safely and efciently. Observe the

maintenance instructions and the notes

about changing tools. Check the plug and

cable regularly, and if they are damaged,

have them replaced by a certied expert.

Check extension leads regularly andreplace

these if damaged. Keep handles dry, clean

and free from oil and grease.

14. Pull the power plug. When not in use, before

maintenance work or when changing tools,

such as saw blade, drill and machine tools of

any kind.

“Caution - Read the operating

instructions to reduce the risk of inquiry”

Wear ear-muffs.

The impact of noise can cause damage

to hearing.

Wear a breathing mask.

Dust which is injurious to health can be

generated when working on wood and

other materials.

Never use the device to work on any

materials containing asbestos!

Wear safety goggles.

Sparks generated during working or

splinters, chips and dust emitted by the

device can cause

loss of sight.

Page 7

7

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

15. Always remove keys and wrenches

after use. Before switching on, make sure

that all keys and wrenches have been

removed from the tool.

16. Avoid unsupervised operation.

Never carry mains-powered tools with your

nger on the switch. Make sure the switch is

OFF when connecting the tool to the mains.

17. Outdoor use of extension cables.

For outdoor use, only use approved and

appropriately labelled extension cables.

18. Be alert at all times.

Observe your work. Work carefully. Never

use the electric tool when you are

distracted.

19.

Check the appliance for damage.

Before using the equipment further, check

that safety equipment or slightly damaged

parts are in good working order and function

correctly. Check that the moving parts are

working correctly, that they do not jam, and

that no parts are damaged. Make sure that

all parts are tted correctly, to ensure that

the equipment remains safe to use.

Damaged safety devices and parts must be

repaired or replaced by experts in a

customer service workshop, unless

otherwise stated in the manual. Damaged

switches must be replaced by a customer

service workshop. Do not use equipment for

which the on-off switch does not correctly

function.

20. Important!

For your own safety, only use accessories

and auxiliaries which are stated in the

operating instructions or which have been

recommended or indicated by the

manufacturer. Use of any other attachments

or accessories than those stated in the

operating instructions or in the catalogue

could lead to personal injury.

21. Repairs should only be done by an

expert. This electric tool complies with the

pertinent safety regulations. Repair work

may only be carried out by an electrician.

Otherwise there is a risk of accidents for the

operator.

22. Attach the dust extraction system.

If there are apparatuses available for the

attachment of the dust extraction system,

make sure these are connected and used.

2. Layout

1. Additional handle

2. Operating switch

3. Speed controller

4. Handle

5. Dust container

6. Rectangular sanding/grinding plate

7. Eccentric sanding/grinding plate

8. Triangular sanding/grinding plate

9. Punch for sanding/grinding paper

10. Chip extractor adapter

11. Allen key

3. Proper use

The equipment is designed for the

grinding/sanding of wood, iron, plastic and

similar materials using the appropriate

grinding/sanding paper. The machine is not

suitable for wet grinding/sanding.

The equipment is to be used only for its

prescribed purpose. Any other use is deemed to

be a case of misuse. The user / operator and not

the manufacturer will be liable for any damage or

injuries of any kind caused as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or

industrial applications. Our warranty will be

voided if the machine is used in commercial,

trade or industrial businesses or for equivalent

purposes.

Page 8

8

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

Keep the noise emissions and vibrations to a

minimum.

• Only use appliances which are in perfect

working order.

• Service and clean the appliance regularly.

• Adapt your working style to suit the

appliance.

• Do not overload the appliance.

• Have the appliance serviced whenever

necessary.

• Switch the appliance off when it is not in

use.

• Wear protective gloves.

Residual risks

Even if you use this electric power tool in

accordance with instructions, certain residual

risks cannot be rules out. The following hazards

may arise in connection with the equipment’s

construction and layout:

1. Lung damage if no suitable protective dust

mask is used.

2. Damage to hearing if no suitable ear

protection is used.

3. Health damage caused by hand-arm

vibrations if the equipment is used over a

prolonged period or is not properly guided

and maintained.

Warning! The electric power tool generates an

electromagnetic eld during operation. Under

certain circumstances this eld may actively or

passively impede medical implants. To reduce

the risk of serious or fatal injuries, we recommend

persons with medical implants to consult their

doctor and the manufacturer of the medical

implant prior to using the equipment.

5. Before starting the

equipment

Before you connect the equipment to the mains

supply make sure that the data on the rating

plate are identical to the mains data.

Always pull the power plug before making

adjustments to the equipment.

5.1 Installing the dust container (Figure 2/Item 5)

• Slip the dust container (5) onto the

vacuumcleaner connector (a).

• The dust is extracted directly through

the grinding/sanding paper and the

grinding/sanding plate and into the dust

container.

4. Technical data

Mains voltage: 230 V ~ 50Hz

Power input: 280W

Orbits: 0 - 10,000rpm

Protection class:

Class II /

Weight: 2.2 kg

Rectangular sanding/grinding plate:

Grinding/sanding area: 140 x 115mm

Abrasive paper size

(Velcro fastening system)

140 x 115mm

Abrasive paper size

(Clamping system)

180 x 115mm

Eccentric sanding/grinding plate:

Grinding/sanding area: Ø 125mm

Abrasive paper size Ø 125mm

Triangular sanding/grinding plate:

Grinding/sanding area: 82 x 109 x 106mm

(a x b x c; Fig. 1)

Sound and vibration

Sound and vibration values were measured in

accordance with EN 60745

LpA sound pressure level 80 dB(A)

K

pA

uncertainty 3 dB

LWA sound power level 91 dB(A)

KWA uncertainty 3 dB

Wear ear-muffs.

The impact of noise can cause damage to

hearing.

Total vibration values (vector sum of three

directions) determined in accordance with EN

60745.

Vibration emission value ah = 14.495 m/s

2

K uncertainty = 1.5 m/s

2

Additional information for electric power tools

Warning!

The specied vibration value was established in

accordance with a standardized testing method.

It may change according to how the electric

equipment is used and may exceed the specied

value in exceptional circumstances.

The specied vibration value can be used to

compare the equipment with other electric power

tools. The specied vibration value can be used

for initial assessment of a harmful effect.

Page 9

9

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

• Place the rectangular sanding/grinding

plate (6) together with the tted sanding/

grinding paper (a) onto the punch (9) for

the sanding/grinding paper). (Fig. 8)

• Now punch the required holes into the

sanding/grinding paper.

• Remove the punch (9) from the sanding/

grinding plate (6).

• Check the correct position of the punch

holes in the sanding/grinding paper plate.

5.5.2 Fasting the sanding/grinding paper with

Velcro fastening system

The Velcro fastener enables easy changing of

sanding/grinding paper. Make sure that the

extraction holes on the sanding/grinding paper

and the sanding/grinding disk are aligned.

5.6 Triangular sanding/grinding plate (Fig. 6)

Fit the triangular sanding/grinding plate (8) to

use the equipment as delta sander/grinder.

Fastening the sanding/grinding paper:

The Velcro fastener enables easy changing of

sanding/grinding paper. Make sure that the

vacuum extraction holes on the sanding/grinding

paper and the sanding/grinding disk are aligned.

5.7 Eccentric sanding/grinding plate (Fig. 6)

Fit the eccentric sanding/grinding plate (7) to

use the equipment as eccentric sander/grinder.

Fastening the sanding/grinding paper:

The Velcro fastener enables easy changing of

sanding/grinding paper. Make sure that the

vacuum extraction holes on the sanding/grinding

paper and the sanding/grinding disk are aligned.

6. Operation

6.1 Switching the equipment ON/OFF

(Fig. 9/Item 2)

To switch on: Slide the ON/OFF switch (2)

forwards (position I)

To switch off: Slide the ON/OFF switch (2)

backwards (position 0)

6.2 Speed control (Fig. 7/Item 3)

To pre-select the speed turn the knurled screw

(3) on the switch.

Plus Direction: High Speed

Minus Direction: Lower Speed

5.2 Installing the dust extractor adapter

(Figure 2/Item 10)

Slip the dust extractor adapter (10) onto the

vacuum cleaner connector (a) as shown in Figure

2. Connect the dust extractor adapter to a

suitable dust extraction system.

Important.

For health safety reasons it is imperative that you

use a dust container or a dust extraction system.

5.3 Adjusting the additional handle (Fig. 3/4)

• The additional handle engages in 4 positions

(90° steps).

• Pull the additional handle upwards (1). (Fig.

3)

• Turn the additional handle (1) into the

required working position. (Fig. 4)

• Let go of the additional handle.

• Ensure that the additional handle is securely

engaged in the required position.

5.4 Fitting/removing the sanding/grinding

plates (Fig. 5/6)

• Use the Allen key (11) to remove the Allen

screw (a) and the washer (b) (Fig. 5).

• Then remove the sanding/grinding plate (c)

(Fig. 5).

• To assemble, proceed in reverse order.

• When tting the sanding/grinding plate

(6 / 8) make sure that the 4 rubber stoppers

(d) are inserted into the corresponding

mounts (e). (Fig. 6)

• Check that the sanding/grinding plate is

secure.

5.5 Rectangular sanding/grinding plate

(Fig. 6/7/8)

Fit the rectangular sanding/grinding plate (6) to

use the equipment as an orbital sander/grinder.

5.5.1 Fasting the sanding/grinding paper with a

clamping system)

Use of sanding/grinding paper with the

corresponding dimensions and perforations (Fig.

7):

• Press the lever (a) upwards.

• Insert the sanding/grinding paper (b) into

the open clamp and close the clamp.

• Lay the sanding/paper over the oscillating

plate so that the paper is taut and clamp it

again.

• Make sure that the perforations in the

sanding/grinding paper coincide with the

oscillating plate.

Use of sanding/grinding paper without the

appropriate dimensions and perforations (Fig.

7/8):

• Cut the sanding/grinding paper to t the

corresponding dimensions.

• Fit the sanding/grinding paper to the

sanding/grinding plate as described above.

Page 10

10

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

6.3 Working with the equipment:

Important. Never hold the workpiece you wish to

sand/grind in your hand. Secure the workpiece on a

sturdy surface or with a vise.

• Place the whole surface area of the sanding

disk on the material.

• Switch on the machine and move it with gentle

pressure over the workpiece completely

circular movements or moving it to and fro

and up and down.

• Use a coarse paper for coarse sanding and a

ner paper for nish sanding. You can nd the

best paper for the job by means of testing.

Important.

The dust generated when working with the machine

may be harmful.

• Always wear goggles and a dust mask when

carrying out sanding/grinding work.

• Everybody who uses the machine or enters the

workplace must wear a dust mask.

• Do not eat, drink or smoke at the workplace.

• Do not use the machine on paints which con-

tain lead.

7. Cleaning and maintenance

Always pull out the mains power plug before

starting any cleaning work.

7.1 Cleaning

• Keep all safety devices, air vents and the

motor housing free of dirt and dust as far as

possible.

• Wipe the equipment with a clean cloth or blow

it with compressed air at low pressure.

• We recommend that you clean the device im-

mediately each time you have nished using it.

• Clean the equipment regularly with a moist

cloth and some soft soap. Do not use cleaning

agents or solvents; these could attack the

plastic parts of the equipment. Ensure that no

water can seep into the device.

7.2 Carbon brushes

In case of excessive sparking, have the carbon

brushes checked only by a qualied electrician.

Important! The carbon brushes should not be rep

laced by anyone but a qualied electrician.

7.3 Maintenance

There are no parts inside the equipment which

require additional maintenance.

8. Disposal and recycling

The unit is supplied in packaging to prevent its

being damaged in transit. This packaging is raw

material and can therefore be reused or can be

returned to the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

9. Storage

Store the equipment and accessories out of

children’s reach in a dark and dry place at

above freezing temperature. The ideal storage

temperature is between 5 and 30 °C. Store the

electric tool in its original packaging.

Page 11

11

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

Page 12

m

After Sales Support TEL: 1300 922 271 EMAIL: service.australia@einhell.com

06/2011

Art.Nr: 44.191.33_11010

Loading...

Loading...