Page 1

TASCAM

MMR-8 Version 4.0

TEAC Professional Division

MMR-8

Modular Multitrack Recorder

OWNER’S MANUAL

Page 2

Page 3

Page 4

Page 5

TASCAM MMR-8 Owner’s Manual

Chapter 1 General Information.........................................................................12

MMR-8 Introduction.......................................................................................................................12

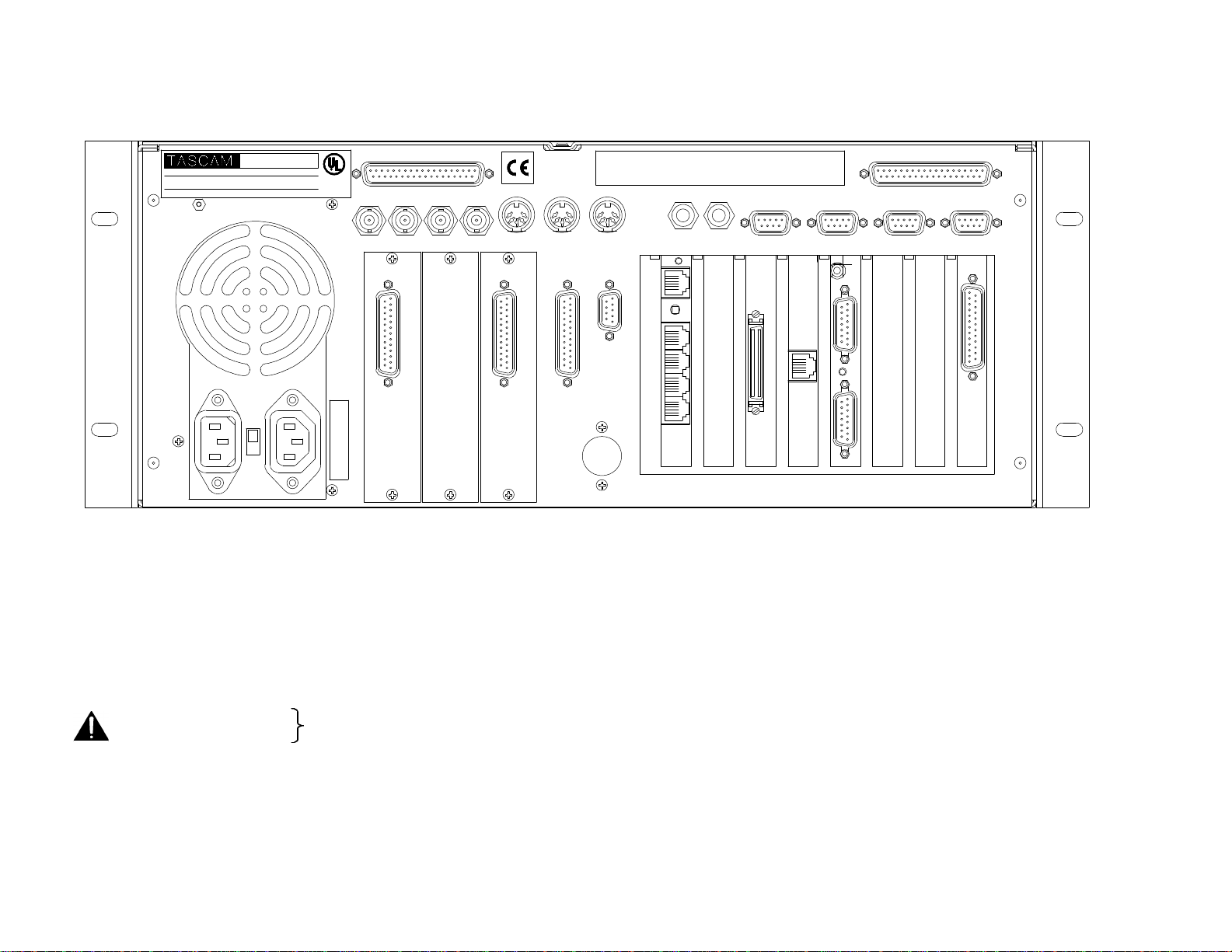

Hardware Overview ........................................................................................................................13

Internal Boards for Units with Serial Numbers up to 01608...........................................................................13

Internal Boards for Units with Serial Numbers of 01609 and above ............................................................... 13

Front Panel ..................................................................................................................................................14

Rear Panel ...................................................................................................................................................14

Accessory Products......................................................................................................................................15

ViewNet Audio.............................................................................................................................16

Functional Overview........................................................................................................................17

System Specifications.......................................................................................................................20

Chapter 2 Installation........................................................................................22

MMR-8 Materials Kit Box ..............................................................................................................22

General Guidelines ..........................................................................................................................23

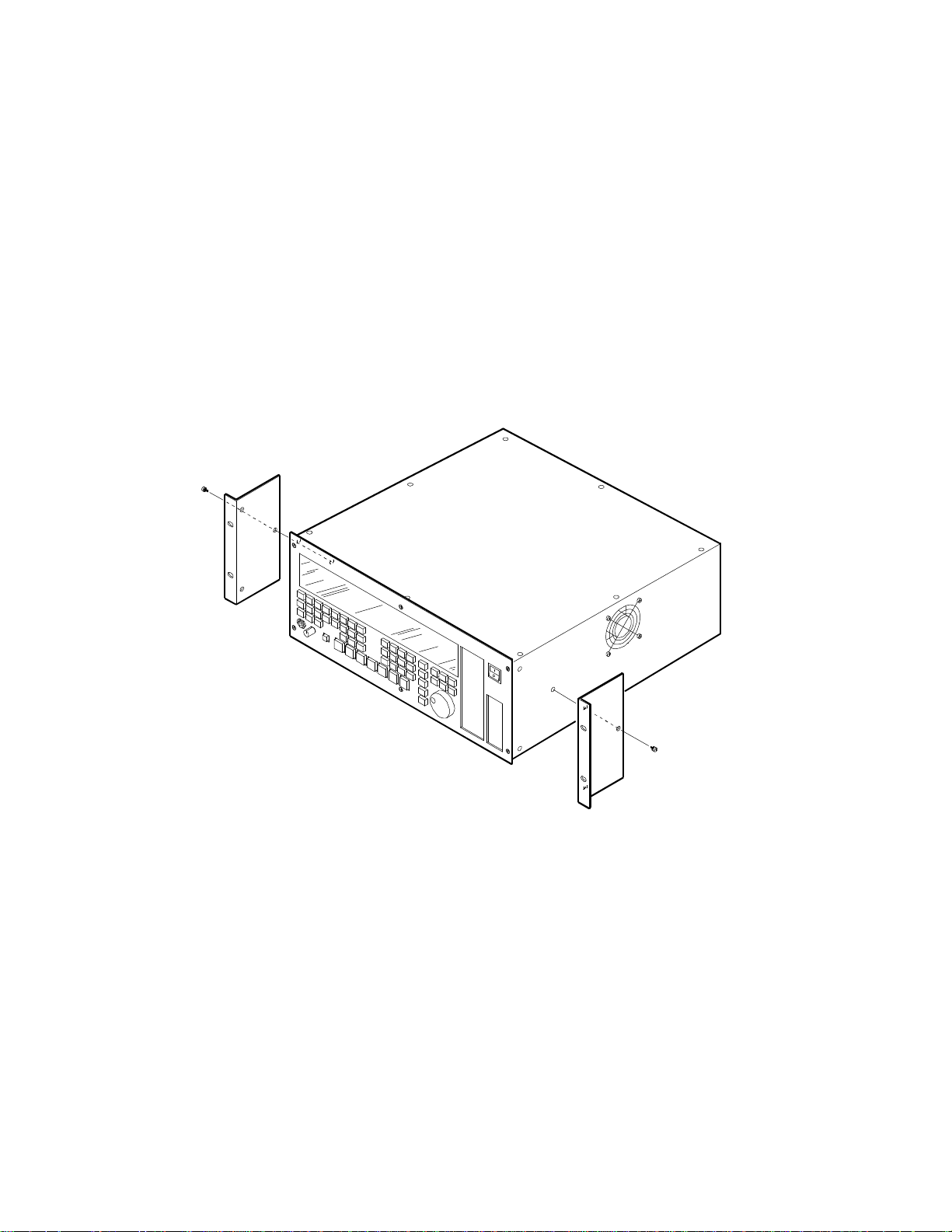

Mounting Rack Ears .................................................................................................................................... 23

Installing Multiple MMR Units.................................................................................................................... 24

AC Mains and Grounding (Earthing) Considerations.................................................................................... 25

Audio Cables ....................................................................................................................................25

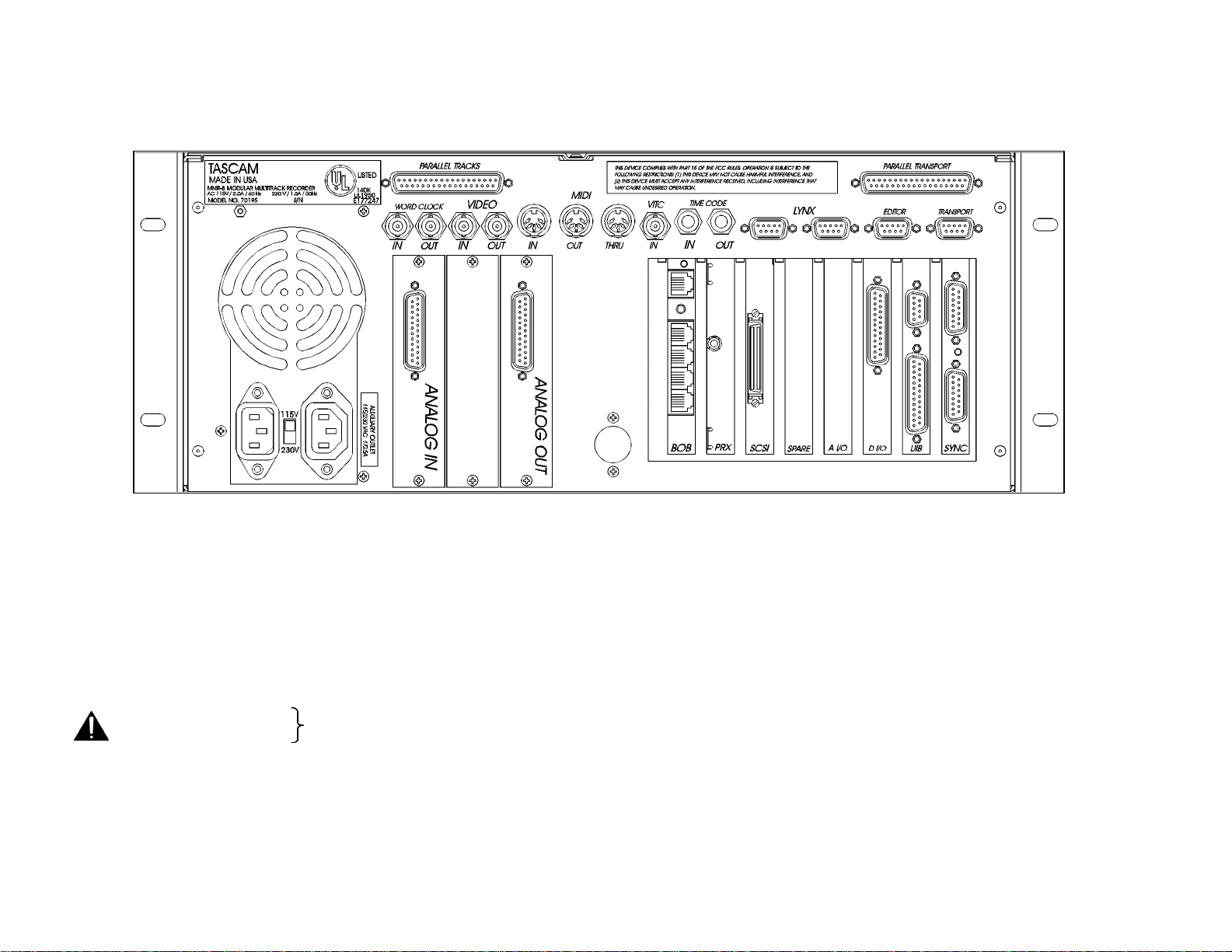

MMR-8 Back Panel Connections For Serial # Up To 01608..........................................................26

MMR-8 Back Panel Connections For Serial # 01609 And Above..................................................27

Audio Connections ...................................................................................................................................... 28

Analog In/Out Connections ...................................................................................................................... 28

Digital In/Out Connections ...................................................................................................................... 28

Monitoring Connections...........................................................................................................................28

Timecode and Video Reference Signals........................................................................................................ 29

Video In/Out............................................................................................................................................29

SMPTE/EBU Time Code In/Out..............................................................................................................29

Biphase Connections................................................................................................................................30

Digital Audio Sample Reference Connections .............................................................................................. 30

Word Clock.............................................................................................................................................30

AES/EBU Sample Rate............................................................................................................................ 30

MIDI Connections .......................................................................................................................................31

External Controllers & Bus Connections ......................................................................................................31

Lynx Bus / KCU Connection ................................................................................................................... 31

MMR Sync Bus Connections................................................................................................................... 31

Serial Transport Connection..................................................................................................................... 32

Serial Editor Connection..........................................................................................................................32

Parallel Transport ....................................................................................................................................32

Parallel Tracks.........................................................................................................................................32

Connecting External SCSI Media...................................................................................................33

SCSI Cables .....................................................................................................................................33

Cable Quality ............................................................................................................................................... 33

Cable Length and Device Support ................................................................................................................33

Cabling Wide and Narrow Devices in a System............................................................................................34

SCSI Termination ............................................................................................................................34

Kingston Frame Configuration.......................................................................................................34

MMR-8 TASCAM MMR-8 Owner’s Manual • Table of Contents

Page 6

6

Wide SCSI Cards and Kingston Frames.........................................................................................35

Removing the Narrow Host Adapter (Symbios SYM 8600SP)...................................................................... 35

Installing the Wide Host Adapter (Symbios SYM8751SP)............................................................................35

Wide Kingston Drive Frames....................................................................................................................... 36

Approved SCSI Drives ....................................................................................................................36

DVD RAM Support.........................................................................................................................37

LIMDOW Optical Drives................................................................................................................37

Remote Controllers for the TASCAM MMR-8 ..............................................................................38

Keyboard Operation (with MM-RC option)...................................................................................38

Using the PC Keyboard................................................................................................................................ 39

Powering Up the System..................................................................................................................40

Verifying MMR-8 Installation.........................................................................................................40

Software Updates ......................................................................................................................................... 41

Factory Default Settings..................................................................................................................42

Testing Your Installation.................................................................................................................42

Chapter 3 MMR-8 Keys and Status Displays ...................................................44

MMR-8 Keys & Definitions.............................................................................................................44

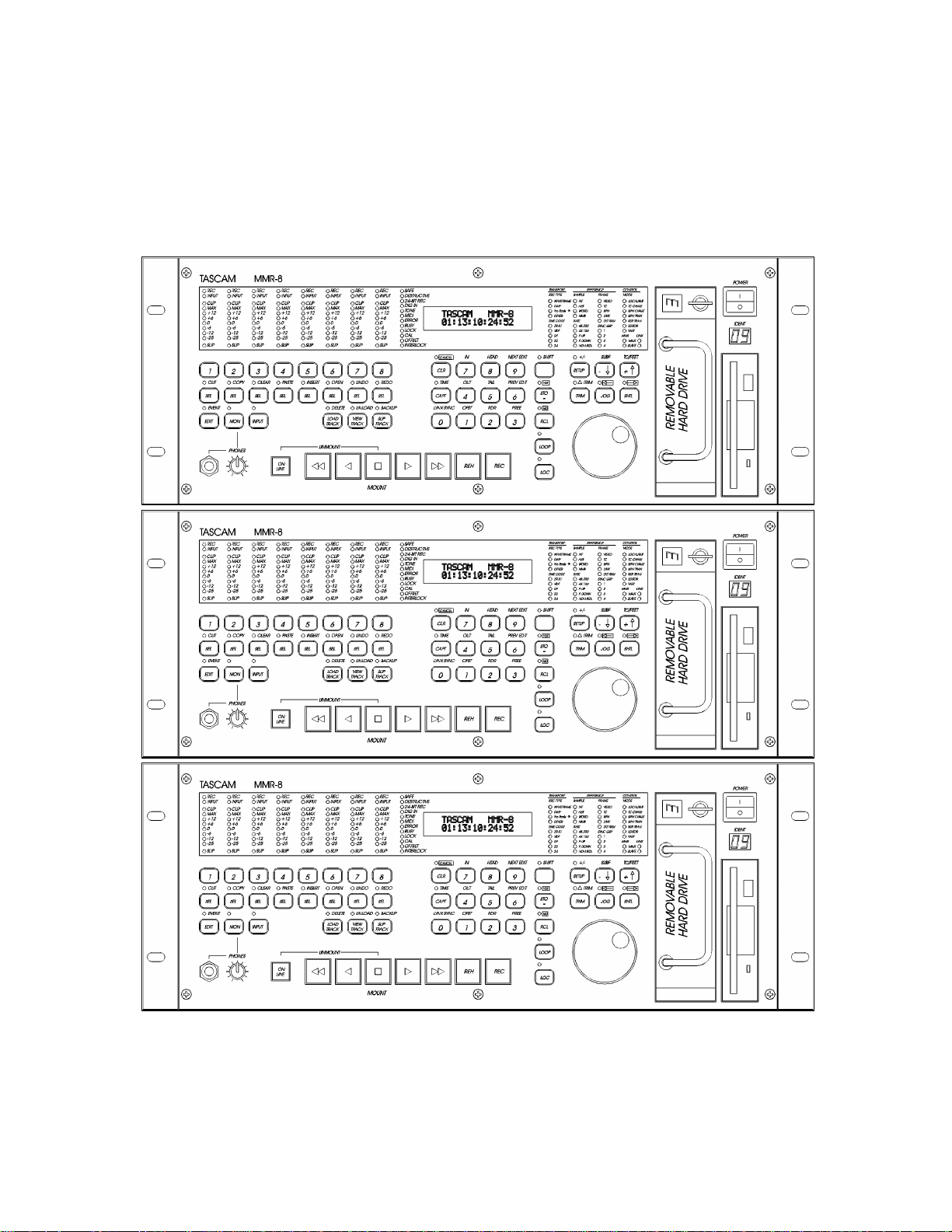

MMR-8 Front Panel ........................................................................................................................46

Front Panel Indicators, Switches, and Displays..............................................................................48

LED Indicators ............................................................................................................................................48

Configuration Settings .............................................................................................................................48

Active Mode/Key Indicators ....................................................................................................................48

Track Status and Metering .......................................................................................................................48

Meter LEDs ............................................................................................................................................. 48

Machine Status LEDs .............................................................................................................................. 49

Liquid Crystal Display (LCD)...................................................................................................................... 50

Normal State Display...............................................................................................................................50

Setup State Display..................................................................................................................................51

View Track State Display.........................................................................................................................51

Slip Track State Display...........................................................................................................................52

Load Track State Display.........................................................................................................................52

Backup State Display...............................................................................................................................53

Verify State Display.................................................................................................................................54

Error State Display...................................................................................................................................54

Front Panel Key Groups..................................................................................................................55

Transport Group...........................................................................................................................................55

Setup and Wheel Group ...............................................................................................................................56

Wheel..........................................................................................................................................................58

Track Group ................................................................................................................................................58

Keypad Group ............................................................................................................................................. 63

Chapter 4 MMR-8 Operation ............................................................................69

Loading and Mounting Drives ........................................................................................................69

Loading a Project.............................................................................................................................70

Loading Individual Tracks..............................................................................................................70

Viewing Tracks............................................................................................................................................71

Unloading Tracks.........................................................................................................................................71

TASCAM MMR-8 Owner’s Manual • Table of Contents MMR-8

Page 7

Deleting Tracks from the Disk......................................................................................................................71

Recording a New Project.................................................................................................................71

Default Record Drive...................................................................................................................................72

Disk Initialization and Low Format.............................................................................................................. 72

Formatting Macintosh Disks ........................................................................................................................ 72

Clip Names..................................................................................................................................................72

In & Out Points Set In Record......................................................................................................................72

Using the Backup Functions............................................................................................................73

Backup ........................................................................................................................................................73

Rename ....................................................................................................................................................... 74

TapeMode Convert ......................................................................................................................................74

Export..........................................................................................................................................................75

WaveFrame Export..................................................................................................................................75

OMF Export............................................................................................................................................ 75

To Import the MMP OMF Export File on Pro Tools................................................................................. 76

Crossfades in OMF..................................................................................................................................76

Tape Mode Export to OMF......................................................................................................................76

Pro Tools Export......................................................................................................................................76

Export As ....................................................................................................................................................77

Dynamic Backup Status Display...................................................................................................................77

Using Registers ................................................................................................................................77

Recalling Registers ......................................................................................................................................78

Capturing the Current Time Code ................................................................................................................. 78

Trimming Time Code Values....................................................................................................................... 78

Using the Entry Register ..............................................................................................................................78

Editing..............................................................................................................................................80

Local & Studio Monitoring .............................................................................................................85

Headphone Volume (LEVEL)......................................................................................................................85

Headphone Jack (PHONES).........................................................................................................................85

The Lynx Bus...................................................................................................................................85

Transport Control.........................................................................................................................................86

Track Record Arm/Select (MMR-8 Only).....................................................................................................86

Head/Tail.....................................................................................................................................................86

Slip Track/Region........................................................................................................................................86

Prev/Next.....................................................................................................................................................86

Undo/Redo...................................................................................................................................................86

Clear/Paste...................................................................................................................................................87

The MMR Bus .................................................................................................................................88

Chapter 5 MMR-8 Setup Menus.......................................................................89

The Setup State & the Setup Menus ...............................................................................................89

Setup Operation ...............................................................................................................................90

Setup Menu Chart...........................................................................................................................91

000 Basic Setup................................................................................................................................96

000 Control Mode........................................................................................................................................96

Local/Bus................................................................................................................................................ 96

Time Code Chase.....................................................................................................................................96

Biphase Chase .........................................................................................................................................96

Serial Transport.......................................................................................................................................97

Editor...................................................................................................................................................... 97

Varispeed ................................................................................................................................................97

Serial Editor Port Details..............................................................................................................................97

MMR-8 TASCAM MMR-8 Owner’s Manual • Table of Contents

Page 8

8

Record Ready Tallies...............................................................................................................................97

Sony P2 Chase and Offset Commands...................................................................................................... 97

Serial Editor Port Active When Not ONLINE .......................................................................................... 97

Automatic ONLINE.................................................................................................................................97

Local Machine Response to Serial Record Commands..............................................................................97

Program Speed Play.................................................................................................................................98

Editor Mode Operation Without Video Reference.....................................................................................98

Hybrid Protocol on Serial Editor Port.......................................................................................................98

001 Frame Reference ...................................................................................................................................98

Automatic................................................................................................................................................ 98

Video.......................................................................................................................................................98

002 Sample Reference..................................................................................................................................98

Automatic................................................................................................................................................ 98

AES/EBU Input.......................................................................................................................................98

Ext Wordclock......................................................................................................................................... 99

003 Timecode Type......................................................................................................................................99

004 Sample Rate..........................................................................................................................................99

006 Varispeed Rate......................................................................................................................................99

100 Bus Control .............................................................................................................................100

100 Sync Group.........................................................................................................................................100

110 MMR Bus Request.............................................................................................................................. 100

111 Ident Request ...................................................................................................................................... 100

112 Ident Assigned .................................................................................................................................... 100

120 Lynx Bus ............................................................................................................................................ 100

121 Lynx Bus Address............................................................................................................................... 100

122 Lynx Bus V500 Mode ......................................................................................................................... 100

200 Transport ................................................................................................................................ 101

200 Record Mode.......................................................................................................................................101

Non-Destructive.....................................................................................................................................101

Tape Mode ............................................................................................................................................ 101

201 All Safe ............................................................................................................................................... 102

202 Record Key......................................................................................................................................... 102

203 Rehearse Key ......................................................................................................................................102

210 Loop Mode.......................................................................................................................................... 102

211 Loop Record ....................................................................................................................................... 102

212 Pre-roll................................................................................................................................................ 102

213 Post-roll.............................................................................................................................................. 102

220 Next / Previous Mode..........................................................................................................................102

221 Edit Sync Mode................................................................................................................................... 103

230 Tape Mode Start.................................................................................................................................. 103

231 Tape Mode Length.............................................................................................................................. 103

240 Dailies Mode ....................................................................................................................................... 103

250 Slip Commit........................................................................................................................................ 103

300 Biphase.................................................................................................................................... 103

300 Biphase Frame Rate.............................................................................................................................103

301 Biphase Pulse Rate..............................................................................................................................104

302 Biphase Input...................................................................................................................................... 104

400 Remote.....................................................................................................................................104

400 Editor Device ......................................................................................................................................104

TASCAM MMR-8.................................................................................................................................104

Sony PCM-7030.................................................................................................................................... 104

Sony BVU-950...................................................................................................................................... 104

401 Editor Auto EE.................................................................................................................................... 104

402 Editor Edit Field.................................................................................................................................. 105

Auto...................................................................................................................................................... 105

Field 1...................................................................................................................................................105

TASCAM MMR-8 Owner’s Manual • Table of Contents MMR-8

Page 9

Field 2...................................................................................................................................................105

403 Editor Track Arm................................................................................................................................ 105

Digital Audio ......................................................................................................................................... 105

Analog A1-A4.......................................................................................................................................105

Local [enbl+any]....................................................................................................................................105

Local [enbl+Aud] .................................................................................................................................. 105

Local [enbl+A1] ....................................................................................................................................105

Local [enbl+A2] ....................................................................................................................................105

Local [enbl+A3] ....................................................................................................................................105

Local [enbl+A4] ....................................................................................................................................106

404 Editor Chase........................................................................................................................................106

410 Parallel Track Arm..............................................................................................................................106

Parallel I/O Details..................................................................................................................................... 106

Dedicated Record/Rehearse ON/OFF pins .............................................................................................. 106

Lock Tally Out ...................................................................................................................................... 106

Record Punch to Local Only .................................................................................................................. 106

420 MIDI Device ID.................................................................................................................................. 106

500 Audio....................................................................................................................................... 107

500 Input Source ........................................................................................................................................ 107

501 Auto Input........................................................................................................................................... 107

510 Crossfade............................................................................................................................................ 107

520 Meter Reference Level ........................................................................................................................ 107

521 Meter Calibrate ................................................................................................................................... 107

522 Clip LED on Play................................................................................................................................ 107

530 Reference Tone................................................................................................................................... 107

540 Gapless Punchout................................................................................................................................108

550 Remote Meter Source.......................................................................................................................... 108

600 Digital I/O ...............................................................................................................................108

600 Digital Input Ref Track........................................................................................................................108

602 Digital Input Delay..............................................................................................................................108

610 Digital Output Delay ........................................................................................................................... 108

700 Disk.......................................................................................................................................... 108

700 Disk Encoding.....................................................................................................................................108

701 Record Disk SCSI ID ..........................................................................................................................108

710 Disk Initialize...................................................................................................................................... 109

711 Disk Low Format ................................................................................................................................109

720 Disk Cleanup ...................................................................................................................................... 109

790 Drives Mounted...................................................................................................................................109

800 Tracks/Project......................................................................................................................... 109

800 Project Name.......................................................................................................................................109

810 Track Prefix ........................................................................................................................................109

900 System .....................................................................................................................................110

900 Store Settings...................................................................................................................................... 110

901 Recall Settings .................................................................................................................................... 110

910 Set MM:DD:YY [Date].......................................................................................................................110

911 Set HH:MM:SS [Time] ....................................................................................................................... 110

912 Change Password................................................................................................................................ 110

920 LED Brightness................................................................................................................................... 110

940 Machine Name....................................................................................................................................110

950 IP Address...........................................................................................................................................111

Setting the IP Address............................................................................................................................ 111

Format of IP Addresses..........................................................................................................................111

951 IP Net Mask........................................................................................................................................ 111

952 IP Gateway.......................................................................................................................................... 111

Important Rules for IP Addresses ...............................................................................................................111

980 Serial Number.....................................................................................................................................112

MMR-8 TASCAM MMR-8 Owner’s Manual • Table of Contents

Page 10

10

990 Software Version.................................................................................................................................112

995 Load Software.....................................................................................................................................112

Chapter 6 File Format Support........................................................................113

Show Project Format ..................................................................................................................... 113

Show Track Format, Drive ID ......................................................................................................113

Formatting Macintosh Disks......................................................................................................... 113

Delete and Disk Cleanup for Macintosh Volumes........................................................................114

Macintosh File System Errors.......................................................................................................114

Macintosh Files Created by the MMR ........................................................................................................ 114

Support for Pro Tools® Session Files ...........................................................................................115

Pro Tools Features Supported..................................................................................................................... 116

Pro Tools Features Not Supported.............................................................................................................. 116

Dynamic Voice Allocation ..................................................................................................................... 116

TDM Plug-Ins ....................................................................................................................................... 116

Voice Output Assignments..................................................................................................................... 117

Restrictions When Using the Pro Tools Session Format..............................................................................117

Pull Up / Pull Down ............................................................................................................................... 117

Frame and Sample Rates in Tape Mode..................................................................................................117

Limitations on Number of Tracks ........................................................................................................... 117

Session Start Time Restrictions..............................................................................................................117

Using TapeMode with ProTools Sessions ............................................................................................... 118

Pro Tools Volume and Mute Automation..................................................................................... 119

Volume Automation...................................................................................................................................119

Mute Automation ....................................................................................................................................... 119

Disabling Pro Tools Volume Automation................................................................................................... 120

Audio File Time Stamp Support ................................................................................................... 120

AIFF File Support .........................................................................................................................121

OMF Files ......................................................................................................................................121

Zaxcom DEVA Broadcast Wave File Support..............................................................................121

DEVA Files Naming Conventions.............................................................................................................. 122

Akai DD-8 Support........................................................................................................................122

Playback.................................................................................................................................................... 122

Export........................................................................................................................................................122

Editing File Formats not Written by The MM Series...................................................................122

Sonic Solutions File Support .........................................................................................................123

Using Sonic Lightspeed ............................................................................................................................. 123

Sonic SSP, USP, and HD System Support ..................................................................................................123

Sonic Fade Files......................................................................................................................................... 123

Format Chart ................................................................................................................................. 124

Chapter 7 MMR-8 System Applications.........................................................125

Film Post Production.....................................................................................................................125

Biphase Setup Menus ................................................................................................................................. 126

MMR-8 Film Connections ......................................................................................................................... 127

Video Post Production................................................................................................................... 127

The Lynx Bus ............................................................................................................................................127

TASCAM MMR-8 Owner’s Manual • Table of Contents MMR-8

Page 11

Chapter 8 Maintenance & Service.................................................................. 128

System Input Level Calibration Using the Meter LEDs............................................................... 128

MMR Input and Output Level Calibrations................................................................................................. 128

MOC Calibration Procedure.......................................................................................................................129

MIC Calibration Procedure ........................................................................................................................ 130

Adding External Drives to the System..........................................................................................131

Formatting Disks ...........................................................................................................................131

Using Removable Media................................................................................................................131

Chapter 9 Technical Support..........................................................................132

MMR-8 System Software ..............................................................................................................132

Appendix A: Control Panel Command Summary........................................................................133

Transport Group .................................................................................................................................... 133

Setup and Wheel Group......................................................................................................................... 133

Keypad keys.......................................................................................................................................... 134

Track Select Keys.................................................................................................................................. 136

Appendix B: TASCAM MMR-8 Drive Compatibility Chart ........................... 137

Approved SCSI Drives ............................................................................................................................... 137

Appendix C: WaveFrame Compatibility...................................................................................... 139

Appendix D: MMR-8 Cable Information .....................................................................................141

Parallel Tracks and Parallel Transport Connector Pinout.............................................................................141

MIDI IN/THRU/OUT Connector pinout..................................................................................................... 142

LYNX (Remote Controller) Connector pinout............................................................................................ 142

EDITOR Connector pinout......................................................................................................................... 142

TRANSPORT (Sony 9-pin) Connector pinout............................................................................................ 143

ANALOG INPUT & OUTPUT Connectors pinouts.................................................................................... 144

BIPH (Biphase) Connectors pinout............................................................................................................. 144

DIO (AES/EBU Digital Audio) Connector pinout....................................................................................... 145

SYNC (MMR-Bus) Connector pinout ........................................................................................................ 145

TIMECODE IN Connector......................................................................................................................... 146

TIMECODE OUT Connector.....................................................................................................................146

WORD CLOCK IN Connector ................................................................................................................... 146

WORD CLOCK OUT Connector...............................................................................................................146

VIDEO IN/OUT Connector........................................................................................................................146

SERIAL CONNECTORS .......................................................................................................................... 147

SCSI Connector......................................................................................................................................... 147

PRX Connector.......................................................................................................................................... 147

Appendix E: MMR-8 Glossary......................................................................................................148

Appendix F: Disk Time Chart ....................................................................................................... 154

Appendix G: Macintosh File System Error Messages..................................................................155

Macintosh File System Error Codes............................................................................................................ 156

Appendix H: MMR/MMP MIDI Machine Control Protocol .......................................................161

MMC Information Fields ........................................................................................................................... 162

MMR-8 MMC Signature............................................................................................................................ 163

MMP-16 MMC Signature ..........................................................................................................................163

MIDI Inquiry Message............................................................................................................................... 163

Index ..............................................................................................................................................164

MMR-8 Owner’s Manual Version 4.1 TRAINING

MMR-8 TASCAM MMR-8 Owner’s Manual • Table of Contents

Page 12

12

Chapter 1 General Information

This chapter presents the main features and capabilities of the MMR-8 hardware and a functional

overview of its Panel/Display states. MMR-8 product specifications are also included.

MMR-8 Introduction

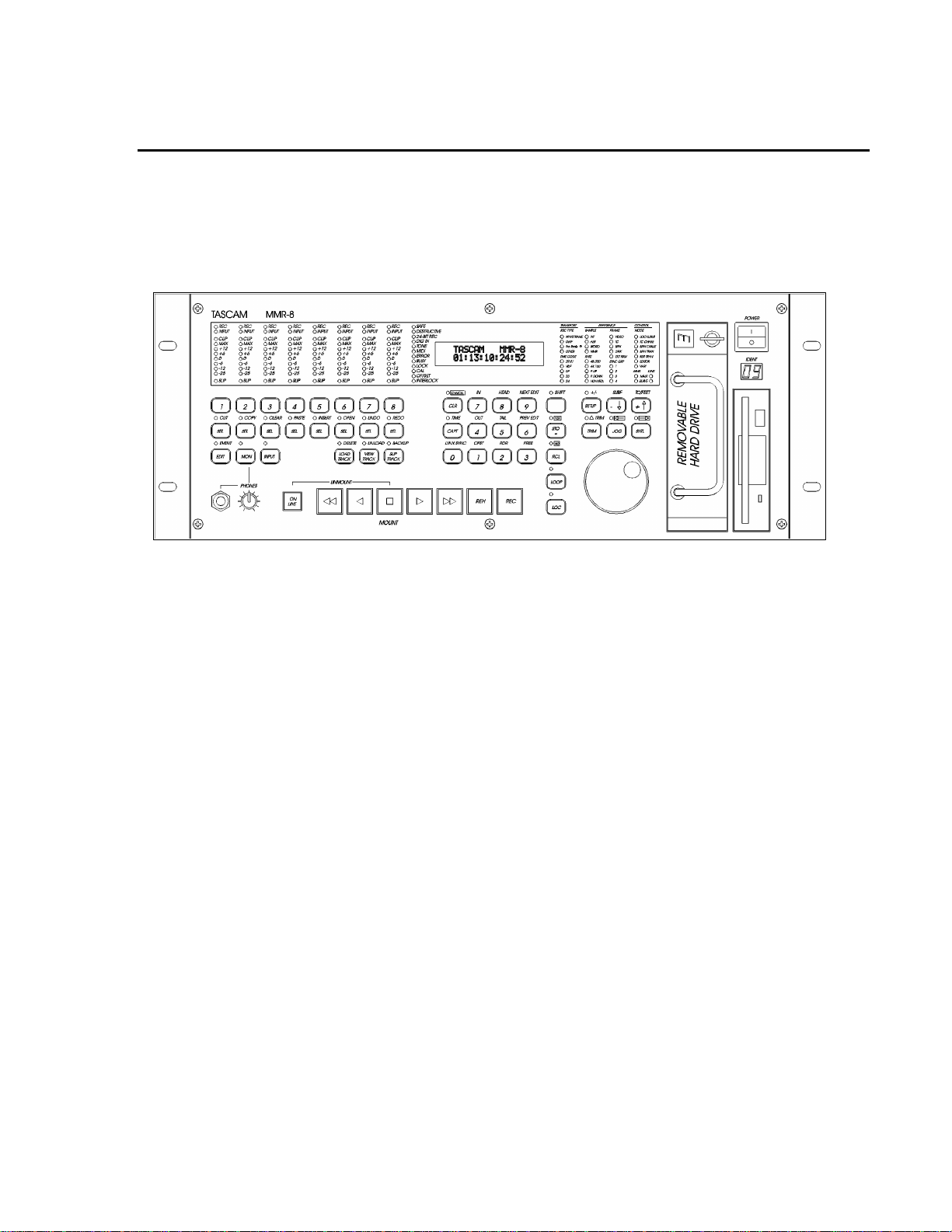

MMR-8 Front View

The MMR-8 is a non-linear digital replacement for the analog or digital tape machines found in recording

studios and broadcast facilities, and for magnetic film dubbers found in film and video post-production

facilities. The MMR-8 can play back and record eight tracks of material from one or more SCSI hard

drives or other removable media. Playback can be in exact or track-slipped synchronization to industrystandard film, video, and audio devices, whether they are mechanical tape-based or hard drive-based.

Audio files recorded on the MMR-8 consist of selectable linear 16-bit or linear 24-bit words at sample

rates of 48.0 kHz or 44.1 kHz, modifiable to a pull-up or pull-down rate, including conversion between

PAL, film, and video, making fourteen total discrete sampling rates. The analog I/O section uses

balanced +4 dBu analog connections on DB-25 connectors that are pin-compatible with the TASCAM

DA-88 and may use the same cables. The DIO (Digital I/O) connection provides digital audio inputs and

outputs which conform to the AES/EBU standard for direct digital recording and playback. The digital

I/O connector can use a standard DA-88 cable (the analog cable – not TDIF) to provide four stereo AES

inputs and four stereo AES outputs. See the Pin out drawing given in Appendix D for detailed

information. Any digital input can be selected as the sample clock reference source. Additionally, any one

of the four digital input signal pairs can be selected for routing through a sample rate converter.

MMR-8 TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information

Page 13

13

The MMR-8 will directly play back material created on many different digital audio workstation systems.

A format compatibility chart is given in the Functional Specifications section of this chapter. The disk

drive or drives containing edited Project (EDL and audio) files may be simply “unplugged” from the

workstation and then “hot-plugged” into the MMR-8, using the standard internal Kingston hard drive

carrier, or otherwise connected to the MMR-8’s external SCSI port. Optionally, files on a RAID may be

accessed via the external SCSI port as well. Once the drive(s) are mounted by the MMR-8, tracks from

one or more projects may be loaded as required for the mix session. Sound files of the same or different

audio file formats may be played back on the same unit simultaneously from one or more drives.

When the MMR-8 is turned on for the first time, the system default operating parameters are loaded, and

the machine boots into the Normal state (see the Functional Overview section in this chapter). There are

ten user settings files that may be stored to and recalled from the internal hard drive so that the MMR-8

setup parameters can be instantly reconfigured between mix sessions. The MMR-8’s operating parameters

can be manually changed at any time via Setup menu selections. Password protection may be used to

prevent some parameters from being changed inadvertently.

Hardware Overview

The MMR-8 comes standard with one removable Kingston drive carrier. The Kingston carrier can hold a

standard SCSI drive for recording and playback of audio tracks. An internal IDE hard drive holds the

operating system, the MMR-8 software, and the parameter settings files. Additional external SCSI drives

can be connected and accessed by the MMR-8. This allows loading tracks simultaneously from more than

one disk. A list of approved media drives is given in Appendix B.

The MMR-8 is based on a standard Intel Pentium™ processor-based PC motherboard, with

integral PCI and ISA bus slots running under an industry-standard operating system. The MMR-8

processing and interface boards plug directly into this PC motherboard. There is a Lithium battery

#CR2032 for the CMOS circuit on the motherboard. Caution: Battery May Explode if Mistreated. Do

Not Recharge, Disassemble or Dispose of in Fire. The MIC (analog-to-digital Input Converter) and

MOC (digital-to-analog Output Converter) boards are in their own shielded cage, connected to the AIO

(Analog I/O) card via ribbon cables. Very high quality 20-bit converters on all analog inputs and outputs

assure excellent audio fidelity. The MMR-8 uses 24-bit internal digital resolution for all digital audio

processing. Recorded audio is stored in standard linear 16-bit or 24-bit sound files.

Internal Boards for Units with Serial Numbers up to 01608

The PRX (DSP) card performs the audio processing for the MMR-8. A standard Symbios SCSI-2

controller card also plugs into the PCI bus. The Sync card, the UI/B (User Interface/Biphase) card, the

AIO (analog I/O) card, and the DIO (AES/EBU digital I/O) card are all plugged into the ISA bus. The

Biphase Operations Board (BOB) occupies a slot on the back panel to provide connections for the

system’s four Biphase inputs and one Biphase throughput. It is attached to the UI/B card via a ribbon

cable and is not plugged into a slot.

Internal Boards for Units with Serial Numbers of 01609 and above

Units with serial numbers of 01609 and above have a different set of internal processing boards.

Functionally, these units are identical to previous units. The change was made to facilitate a more

streamlined manufacturing process. Instead of separate boards for DSP processing, sync, remote control,

etc., these functions have been combined into a single board designated as the M2 board. Connectors on

the side of the M2 board have ribbon cables attached which break out to brackets and connectors serving

the same functions as the previous array of boards and connectors.

TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information MMR-8

Page 14

14

Front Panel

The MMR-8 front panel contains 45 soft-touch keys with most of the common dubber and audio playback

functions available through one or two keystrokes. There are also seven large illuminated motion control

buttons (Play, Stop, FF, Rew, Reverse Play, Record, Rehearse) for track playback and “play head”

locating, and an Online button for setting the MMR-8 offline (as a local machine) or online (as a

synchronized slave or a master machine). When the MMR-8 is the master and is online, then any number

of external SMPTE/EBU, MTC or biphase devices will follow the MMR-8. When the MMR-8 is set as a

slave, it can chase time code, biphase, a TimeLine Lynx™ module, or another MMR-8.

A 40-character (two line by 20-character) LCD (Liquid Crystal Display) serves as the MMR-8 status and

control text window. The top line typically shows the machine status and current time code or feet/frames

location, while the bottom line shows various time code registers (In, Out, memory, slip. etc.) and accepts

input from the front panel. The entire display may also alert the operator to any machine or user error

conditions. Text can be scrolled horizontally or vertically, using the Wheel or arrow keys, for entering

Panel/Display state and setup information, or for finding and loading tracks.

As with other 8-track recorders, there are dedicated front panel LED peak meters that always display

monitor level information for the track outputs whether in audio input or playback. Each meter contains

seven green, yellow and red LEDs plus a CLIP/Hold LED for easy at-a-glance level monitoring. An

additional 74 status LEDs instantly identify current synchronization modes, bus control modes, sample

and frame reference settings, record format settings, transport status, and front panel input status.

Rear Panel

The MMR-8 rear panel contains all the audio and synchronization connections. To minimize connector

footprint, female DB-25 connectors are used for the audio connections. The eight analog audio inputs are

on one female DB-25 and the eight analog audio outputs are on another female DB-25. Each analog

connector mounts on a separate card within the chassis, and is labeled Input or Output. The connectors are

pin-compatible with the TASCAM DA-88 analog audio connector.

The DIO card allows direct digital audio transfers into and out of the MMR-8. Because it uses standard

AES/EBU digital signal conventions, there are four stereo digital inputs and four stereo digital outputs

with odd-even track pairs. Tracks 1+2 are on the first AES/EBU connection, tracks 3+4 on the second

AES/EBU connection, and so on. All eight tracks (four pairs of in and out) are on a single female DB-25

connector. Any of the digital inputs can serve as a sample rate reference and any of the input pairs can

also be routed through an on-board sample rate converter. Note that this connector carries AES/EBU

digital signals and is NOT pin-compatible with the TASCAM DA-88 TDIF digital audio format

connector.

Built-in biphase control allows the MMR-8 to automatically lock to and chase biphase devices

without having to use an external biphase to SMPTE LTC adapter. Up to four biphase input

signals can be simultaneously connected to the MMR-8. The active biphase input is linked to the active

Sync Group assignment and is determined by menu selection (Setup Menu 100). A biphase throughput

connector passes through the selected incoming biphase signal. Software Setup Menu 300 bank

parameters (frame rate, pulses per frame, input type) allow various biphase devices to be used with the

MMR-8. The biphase connector is not intended for public telecommunications network connection.

MMR-8 TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information

Page 15

15

Video post-production work can be done with any industry-standard playback device. The MMR-8

supports SMPTE/EBU Linear Time Code, Word Clock, Video sync, MIDI Time Code, MIDI Machine

Control input, and Sony 9-pin serial in and out (P2- protocol).

Accessory Products

The TASCAM MM-RC is a dedicated remote control unit designed specially for use with the MMR-8

and the MMP-16 sixteen-channel player unit. It connects directly to the UI/B board on the MMR back

panel and allows control of any combination of up to 100 MMR-8 or MMP-16 units.

The TASCAM MMU-16 is a multi-segment digital meter unit which can display sixteen channels of

audio level information. Two connectors on the back of the MMU-16 allow it to be connected to one or

two MMR-8 units, or an MMP-16 sixteen channel player. The MMU-16 can also be connected to the

MM-RC for displaying detailed level information for the MMR-8 or MMP-16 unit being accessed by the

MM-RC. The MMU-16 comes with standard rack ears for mounting in a standard 19” equipment rack

and also with mounting brackets for attaching the unit to an MM-RC.

The TimeLine Lynx Keyboard Control Unit (KCU) can function directly as a remote controller for up to

six MMR-8s without the use of dedicated Lynx-2 modules, since the MMR-8 contains the functional

equivalent of an integrated Lynx-2 synchronizer. Optionally, Lynx-2 modules can also be connected to

the Lynx port of the MMR so that other transports connected to the Lynx bus may also be controlled from

a Lynx KCU connected to the MMR-8. TimeLine offers a special software version for the Lynx KCU

(KCU 900 software) which includes special MMR support for some editing and event slip commands.

Other remote controllers can also be used for controlling the transport and track arm functions of the

MMR-8 through the two Parallel ports or via Sony P2 protocol through the 9-pin serial Editor port.

TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information MMR-8

Page 16

16

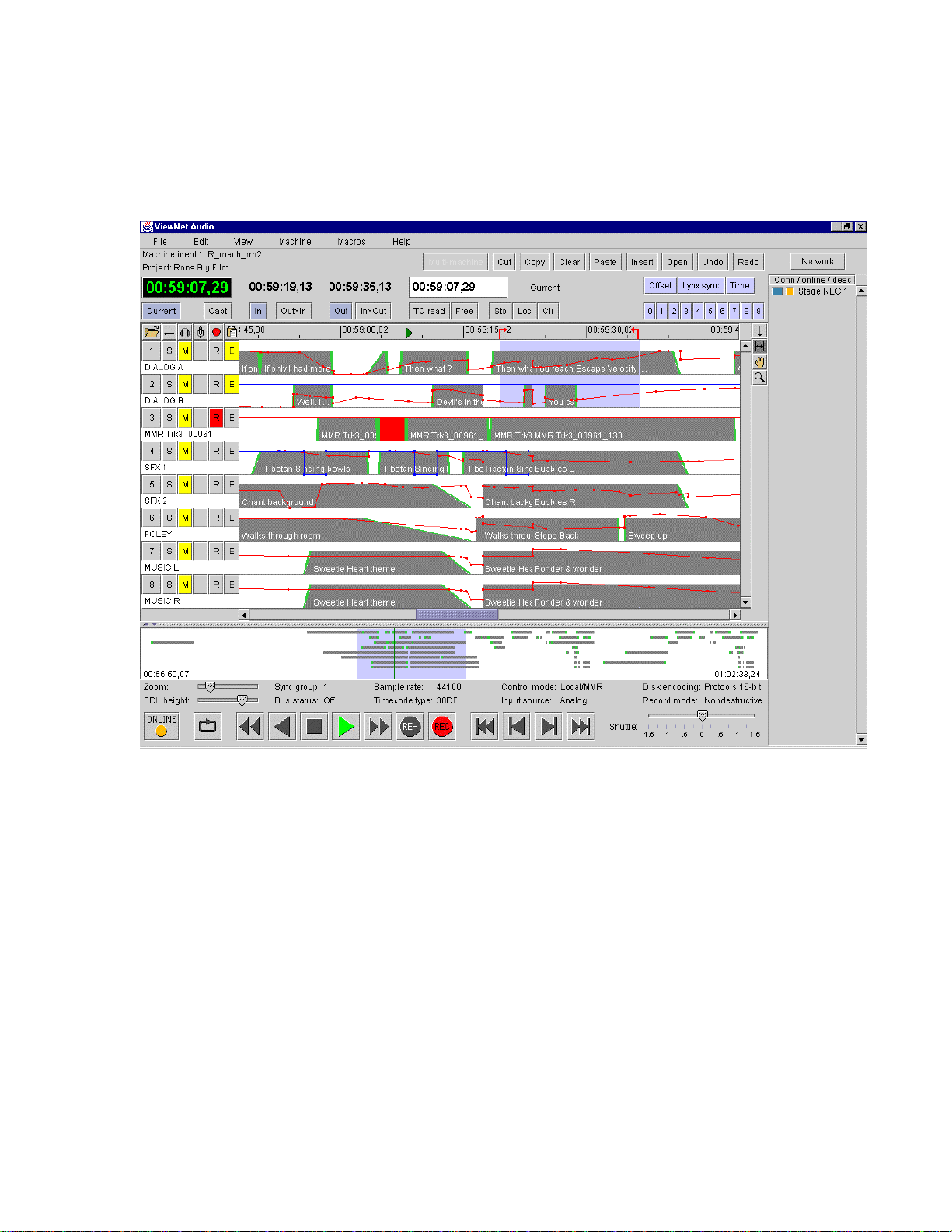

ViewNet Audio

TimeLine’s ViewNet Audio is a graphical interface network option for the MM Series modular multitrack

machines which provides a Fast Ethernet (100 Mbps) connection for the MM unit and the special

ViewNet Audio software application running on a computer attached to the network.

ViewNet Audio Project View Screen

ViewNet Audio is designed to allow system administration and control of setup parameters for all

machines from any computer on the network. Since ViewNet was written using the Java programming

environment, the software application can be run from computers running the Windows (95, 98, or NT),

Macintosh, or UNIX (Linux) operating systems. Administration and Server software is included with the

system to allow for setting levels of security in multi-room facilities. This helps to prevent operators from

accidentally controlling machines in other areas of the facility for which they do not have access

permission.

ViewNet provides a graphical editing environment for making changes to sound events at the mix. Multimachine edits and macros are also supported. Real time scrolling of sound events with clip names

provides a visual cue sheet for mixers. Complete access to all system setup parameters and the ability to

broadcast parameters to multiple sets of machines makes it easy for machine room operators to set up jobs

for different clients in different rooms. ViewNet is available from authorized TASCAM MM series

dealers and distributors.

MMR-8 TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information

Page 17

17

Functional Overview

The MMR-8 operates in any of eight different Panel/Display states (simply referred to as “states” for

convenience). These states are distinguished by the nature of the information displayed in the LCD

window and by which keys are functionally available while in that state. These MMR-8 Panel/Display

states are described here.

Normal state is the default Panel/Display state on power-up. In this state, the LCD shows the current

system play time in the top of the display, and shows the active register (last requested register or function

time) in the bottom of the display. All keys are active while in this state, and will respond by performing

an action, accessing a register, or changing to the state written on the key. Shifted key functions are also

available by first pressing the SHIFT key, then pressing the key which corresponds to the desired shifted

function. Once the SHIFT key is selected, pressing the appropriate key to activate the desired shifted

function completes the SHIFT operation. The SHIFT state can be cancelled by pressing SHIFT again, or

by pressing CLR, to return the system to normal key selection.

Pressing the SETUP key activates the Setup state. This state gives access to the system setup menus,

where most of the operating parameters of the MMR-8 can be altered. Some parameters are changeable

only under certain operating conditions (non-record, stopped, etc.), although all are viewable at any time

in the Setup state. Once in the Setup state, you may return to the Normal state by pressing the SETUP key

again, or by pressing CLR.

There are three types of Panel/Display states that deal with MMR-8 track operations. These are Load

Track, View Track, and Slip Track. Pressing the LOAD TRACK, TRACK, or SLIP keys puts the

MMR-8 into one of these Track states. The SEL keys for each MMR track are used in conjunction with

these keys to identify the specific track to be loaded, viewed, or slipped.

There are also three keys to the left of the Track state keys labeled EDIT, MON, and INPUT. These keys

do not change the state of the MMR display, but are used to determine what status is being indicated for

each MMR track by the track selection LEDs when the SEL keys are pressed while in the Normal state of

operation. One of these keys is always active as the current Track Mode. Since these keys function along

with the Track state keys to identify the function being specified by the SEL keys, the entire group of six

keys (EDIT, MON, INPUT, LOAD TRACK, TRACK, and SLIP) are also referred to as the Track Mode

keys.

The Track states supersede the Normal state since they change the display and make certain keys

unavailable until the Track state is exited or cleared. To exit a Track state and return the MMR-8 to the

Normal state, it is necessary to either complete the selected track operation (by pressing STO to load a

Project, for example), or press the selected Track state key again, or press the CLR key to cancel the

operation. After exiting a Track state, the system will return to the Normal state and the last selected

Track Mode (EDIT, MON, INPUT).

Pressing the LOAD TRACK key activates the Load Track state. This state allows for loading

WaveFrame projects, OMF Compositions, or Pro Tools Session files from any mounted disk volume.

This state also allows loading of individual tracks from a Project, Composition, or Session (hence the

name of this key and state), and moving of tracks from one MMR channel to another. The shifted function

of LOAD TRACK allows for deleting WaveFrame Projects or Tracks. The MMR-8 software does not

currently allow OMF Compositions and Pro Tools Session Files to be deleted.

TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information MMR-8

Page 18

18

The MMR Backup state is accessed via the Load Track state by pressing SHIFT+SLIP after choosing

(scrolling to) the desired Project while in the LOAD TRACK state. This state is similar to the Setup state

in that it has two menu choices which are accessed by using the Up/Down arrow keys or the Wheel. The

key choices available in the Backup state are the same as those in the Setup state, hence it exists at the

same level of the hierarchy of panel/display states as the Setup state.

Pressing the TRACK key activates the View Track state. This state allows for viewing the names of

loaded tracks, and unloading of tracks (the shifted function of the TRACK key) from the loaded track list.

Pressing the SLIP key activates the Slip Track state. This state allows for slipping one or more of the

already loaded tracks in time.

Verify state supersedes the Normal and Track states. The two most common Verify state functions are

confirmation (a Yes/No answer is required from the user) and password entry (a password must be

entered to complete the action request). Both of these requests override most other actions or do not allow

access to the Normal, Setup, or Track states until they are cleared or a valid response is entered. Verify

state, when cleared, usually drops the MMR-8 back into the previously active state.

Error state is the final level in the hierarchy of Panel/Display states. In this state, the ERROR status light

flashes and the user is asked to clear a condition by pressing the CLR key, or if that is impossible (as in

the case of a fatal error), to note the error information and possibly take some extraordinary action (such

as re-starting the MMR-8). Until the Error state is cleared, or a valid response is entered, access to the

Normal, Setup, or Track states is not allowed. The Error state, when cleared, may drop to another state, or

to any appropriate condition—depending on the type and severity of the error.

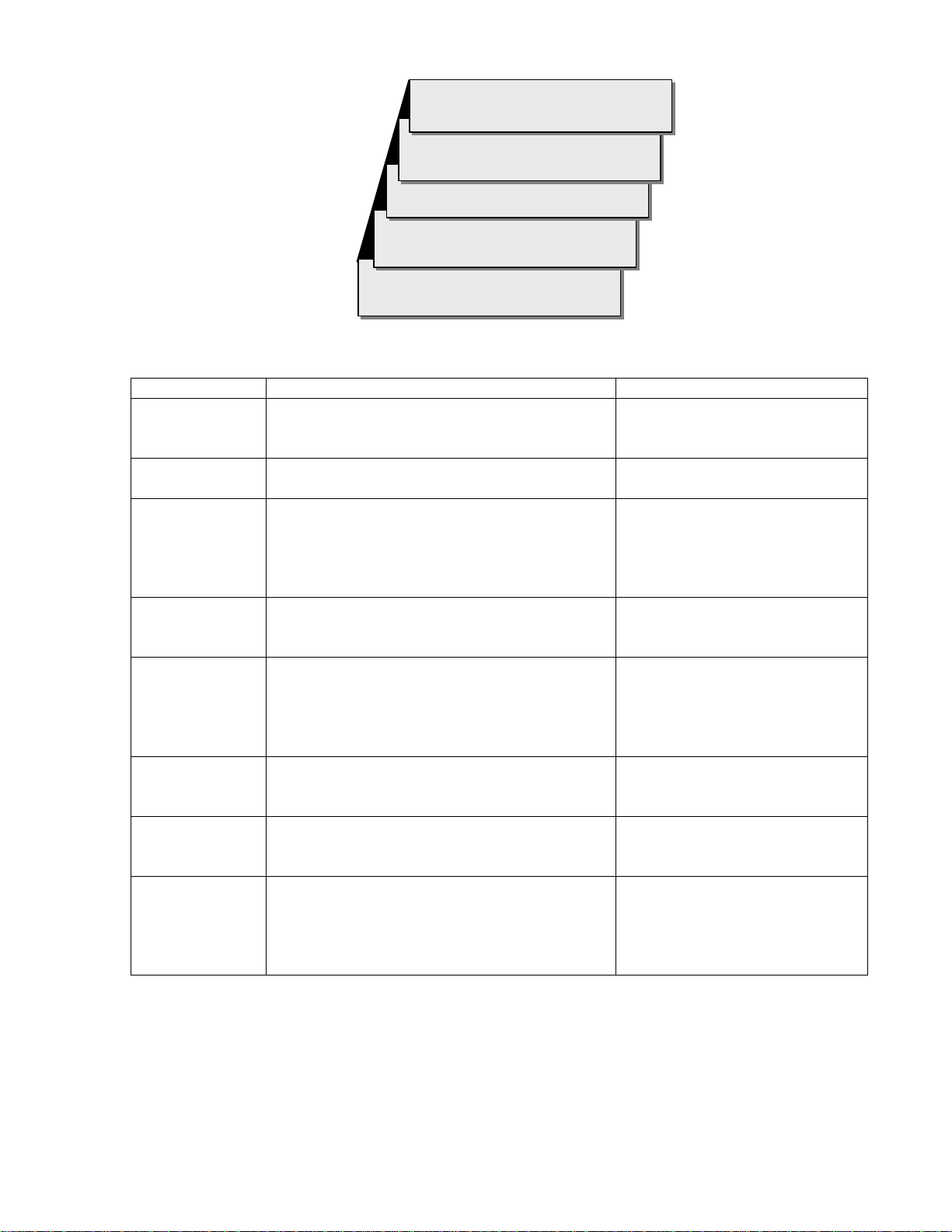

These states are hierarchical in the sense that some require a response or they require a state to be cleared

before certain keys or other states can be accessed. The Normal state is at the base of the hierarchy

because it is the default on startup and can always be accessed from any other state or by pressing the

CLR key as many times as is necessary to clear any other state. The track record arm function and the

transport keys can be accessed directly from any state, so the MMR can always record and playback,

regardless of what other functions or states are being accessed. The following diagram illustrates the

hierarchical relationship between the various states, based on the number of choices available from each

state.

MMR-8 TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information

Page 19

19

LLo

o

o

a

a

a

d

d

d

,

,

,

V

V

V

i

i

i

e

e

e

w

w

w

,

,

,

S

S

S

l

l

l

i

i

i

p

p

p

T

T

T

r

r

r

a

a

a

c

c

c

k

k

k

V

V

Vee

err

rii

iff

fyy

yEE

Err

rrr

roo

orr

r

S

e

t

u

p

,

B

a

c

k

u

S

e

t

u

p

,

S

e

N

N

N

MMR-8 Panel/Display State Hierarchy

STATE LCD WINDOW DISPLAY COMMENT

NORMAL

SETUP

LOAD TRACK

VIEW TRACK

SLIP TRACK

VERIFY

ERROR

BACKUP

Shows current play head time on top and selected

time register on bottom of display.

Shows setup menus and parameter choices for

each menu item.

Shows disk directory list of projects,

compositions, sessions, and their tracks. Shows

other levels for WaveFrame projects. Backup

state can be accessed only while viewing name of

project while in this state.

Shows the name of each loaded track. Use wheel,

arrows, or press appropriate SEL key to choose

which track to view.

Shows Current Play position on top, Slip register

value for each track below, allows for slipping

tracks in time. All SEL keys have a SLIP

register, so numbers can be stored, recalled, or

cleared directly.

Asks for a response (usually requires pressing

Yes or No) to clear state and return to previous

state.

Shows Error message, usually requires pressing

CLR to clear and return to previous state.

Menu with two choices: BeginBackup to

(device#) or TapeMode Convert to (device#).

Only currently mounted devices will appear as

choices.

B

t

u

p

,

B

o

r

m

a

o

r

m

a

o

r

m

a

p

a

c

k

u

p

a

c

k

u

p

l

l

l

Default at startup. Allows direct

access to SETUP and TRACK

states, all keys functional.

Press SETUP to enter state, press

TRIM to view parameters.

Press LOAD TRACK once to see

Project level, again to see

successive levels (tracks). Press

SHIFT+SLIP while in LOAD

TRACK to enter Backup state.

Press TRACK to enter state,

SHIFT+TRACK to unload track.

Press SLIP to enter state, use

wheel or arrows to change value,

or enter TC value on keypad &

press STO then SEL to enter

number directly.

Disallows most key entry or

switching to other states until

response is made.

Disallows most key entry or

switching to other states until

condition is cleared.

Accessed only via LOAD TRACK

state. Use Up/Down arrows or

wheel to choose Backup style,

press STO to begin backup

process.

MMR-8 Panel/Display State Chart

TASCAM MMR-8 Owner’s Manual • Chapter 1 • General Information MMR-8

Page 20

20

System Specifications

Analog Input and Output Level:+4 dBu balanced, +24 dBu clip, nominal levels trim pot adjustable

Headroom:20 dB above nominal input level

Analog Input / Output Impedance:10k, balanced / <75 ohms, balanced

Input / Output Adjustment Range: +10 dBu - +25 dBu, clipping / +18 dBu - +25 dBu, clipping

THD+N:<.004 % @ 1 kHz, @ clip level -0.5 dB

Dynamic range:>104 dB (10 Hz - 22 kHz, with A-weighted filter), including Record.

S/N ratio:>108 dB (10 Hz - 22 kHz, with A-weighted filter)

Crosstalk:<-85 dB (between any channels, 20 Hz - 20 kHz)

Frequency Response:20 Hz - 20 kHz ±0.1 dB

Digital Conversion / Quantization:20-bit ADC and 20-bit DAC conversion

Sample length, Recording:16-bit, linear or 24-bit, linear

Sample Length, Internal: 24 bit

Timing Reference sources:Internal, Internal Varispeed, Follow time code in, Follow biphase signal input

(any one of four inputs), Video (either NTSC or PAL), AES/EBU digital clock input (optional), Word

clock input, MMR bus, Lynx bus

Internal Sample Rates in Hz: 42294 (44x23/25), 42336 (44x24/25), 44056 (44100-), 44100, 44144

(44100+), 45938 (44x25/24), 45983 (44x25/23), 46034 (48x23/25), 46080 (48x24/25), 47952 (48000-),

48000, 48048, (48000+),50000 (48x25/24)50050 (48x25/23)

External Sample rates:32 kHz - 51 kHz (via external sync input)

Time Code Type & Rate:30 Non drop frame (NDF) @ 30 frames per second

30 Drop frame (DF) @ 30 frames per second

PAL @ 25 frames per second (PAL default setting)

Film @ 24 frames per second

NTSC @ 29.97 frames per second NDF (NTSC default setting)

29.97 Drop frame(DF) @ 29.97 frames per second

Display Modes:SMPTE/EBU time code, with or without subframes

Feet & Frames, with or without subframes

Time Code Memories:ten (numbered 0 - 9)

Time Code Registers:IN (punch in point)

OUT (punch out point)

HEAD (jump to beginning of project)

TAIL (jump to end of project)

NEXT EDIT (jump to next track edit)