Page 1

2U Autoloader 6.4® LTO3

User Reference Manual

Document No: DOCSP 301283

Date: Aug., 2005

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 1 of 79

Page 2

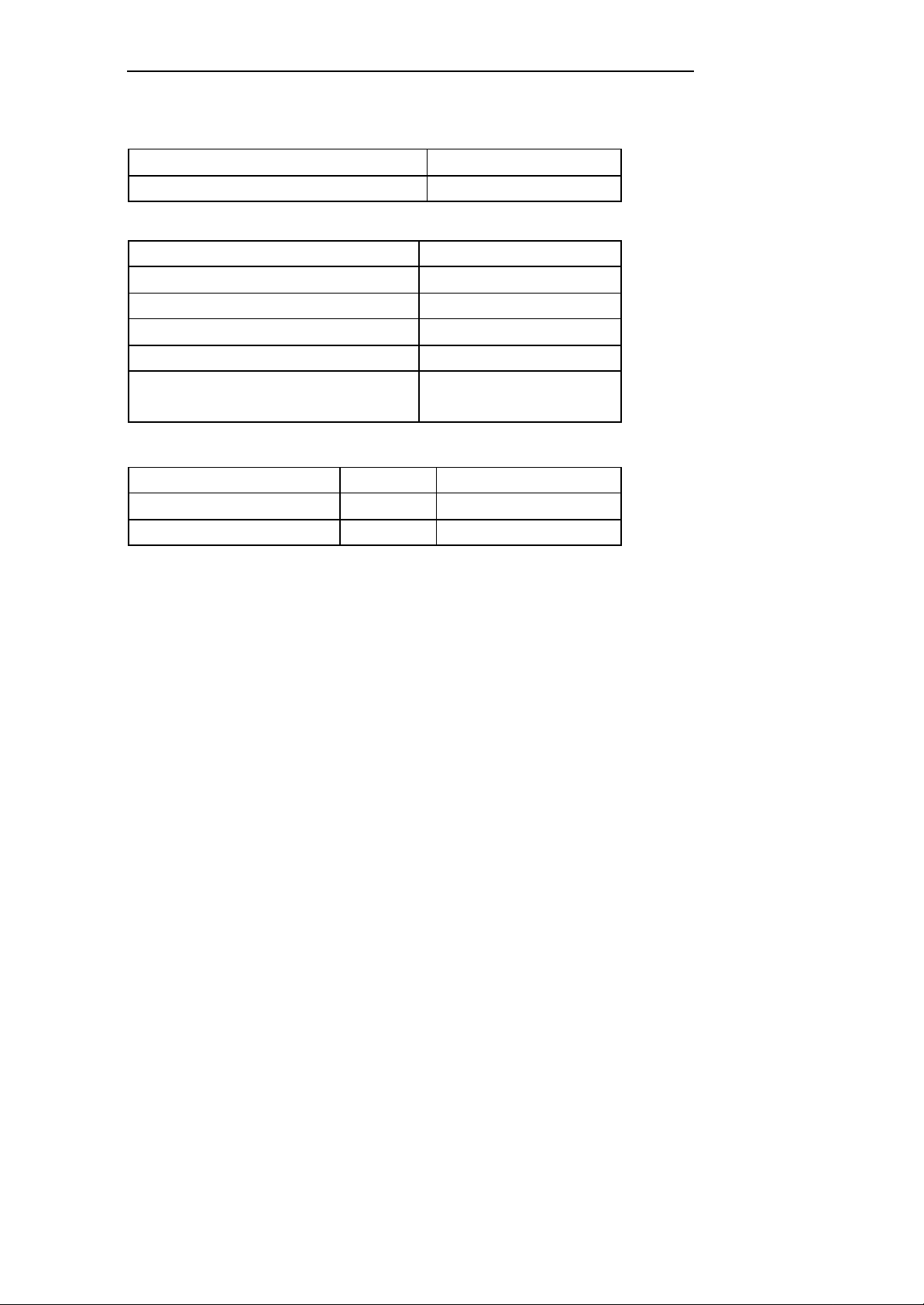

Product Overview

product name P/N description

LTO3 AUTOLOADER 6.4 8330 7071 00 1 drive & 8 slots, 2U,

Accessories

product name description

SCSI cable

Terminator

Power cord (1x EU version, 1x US version)

Manual CD & Quick Reference Guide

BCR (customer installable) LTO 3 only

BCR Installation Guide LTO 3 only

Options

product name P/N description

Remote Management Card 433023 Web Administration Tool

RackMount Kit 433026

Warnings

Precautions

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 2 of 79

Page 3

SERVICE & SUPPORT INFORMATION:

Europe TANDBERG Data GmbH

Feldstr. 81

D-44141 Dortmund

Germany

Phone: 0049 – (0)231 – 5436 142

Fax: 0049 – (0)231 – 5436 143

USA INOSTOR Inc. (A TANDBERG DATA COMPANY )

13000 Gregg Street

Poway

CA 92064

USA

Phone: 001 – (0)858 – 726 0277

Fax: 001 – (0)858 – 726 0278

ASIA TANDBERG Data Pte. Ltd. (main office for ASIA)

20 Bendemeer Road

#04-05 Cyberhub

Singapore 339914

Phone: 0065 – (0)6396 – 0786

Fax: 0065 – (0)6396 – 0787

Japan TANDBERG Data Inc.

Shinkawa –nittei Annex Bldg. , 7th floor

22-4, Shinkawa 1-chome

Chuo-ku

Tokyo 104

Japan

Phone: 0081 – (0)3 5566 – 2871

Fax: 0081 – (0)3 5566 – 2875

Warnings

Precautions

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 3 of 79

Page 4

Warnings

Precautions

1 Warnings

IMPORTANT

!

!

DANGER

n Heed warnings – All warnings on the product and in the operating instructions should be adhered

to.

n Follow instructions – All operating and use instructions should be followed.

n Ventilation – The product should be situated so that its location or position does not interfere with

proper ventilation.

n Heat – The product should be situated away from heat sources such as radiators, heat registers,

furnaces, or other heat producing appliances.

n Power sources – The product should be connected to a power source only of the type directed in

the operating instructions or as marked on the product.

n Power cord protection – The AC line cord should be routed so that it is not likely to be walked on

or pinched by items placed upon or against it, paying particular attention to the cord at the wall

receptacle, and the point where the cord exits from the product.

n To complete the disconnection of the electricity, please remove the power (electric) cable and the

SCSI cable from their connections in the back of the autoloader. The plugs should be placed near

the autoloader for easy access.

n Object and liquid entry – Care should be taken to insure that objects do not fall and liquids are not

spilled into the product's enclosure through openings.

n Servicing – The user should not attempt to service the product beyond that described in the

operating instructions. All other servicing should be referred to qualified service personnel.

All safety and operating instructions should be read before this product is

operated, and should be retained for future reference. This unit has been

engineered and manufactured to assure your personal safety. Improper use can

result in potential electrical shock or fire hazards. In order not to defeat the

safeguards, observe the following basic rules for its installation, use and

servicing.

High voltage!

Risk of electric shock.

Do not remove cover (or back). No user-serviceable parts inside. Refer

servicing to qualified service personnel.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 4 of 79

Page 5

Warnings

Precautions

1.1 Precautions

n Do not use oil, solvents, gasoline, paint thinners or insecticides on the unit.

n Do not expose the unit to moisture, to temperatures higher than 60 °C (140 °F) or to extreme low

temperatures.

n Keep the unit away from direct sunlight, strong magnetic fields, excessive dust, humidity and

electronic/electrical equipment, which generate electrical noise.

n Hold the AC power plug by the head when removing it from the AC source outlet; pulling the cord

can damage the internal wires.

n Use the unit on a firm level surface free from vibration, and do not place anything on top of the

unit.

1.2 Product Warranty Caution

The 1x8 autoloader by Tandberg is warranted to be free from defects in materials, parts, and

workmanship and will conform to the current product specification upon delivery. For the specific

details of your warranty, see your sales contract or contact the company from which the autoloader

was purchased.

The warranty for the autoloader shall not apply to failures of any unit when:

n The autoloader is repaired or modified by anyone other than the manufacturer's personnel or

approved agent.

n The autoloader is physically abused or used in a manner that is inconsistent with the operating

instructions or product specification defined by the manufacturer.

n The autoloader fails because of accident, misuse, abuse, neglect, mishandling, misapplication,

alteration, faulty installation, modification, or service by anyone other than the factory service

center or its approved agent.

n The autoloader is repaired by anyone, including an approved agent, in a manner that is contrary to

the maintenance or installation instructions supplied by the manufacturer.

n The manufacturer's serial number tag is removed.

n The autoloader is damaged because of improper packaging on return.

CAUTION

CAUTION

Rough Handling at Shipping!

Damaging of the autoloader and loosing warranty.

If you are returning the autoloader for repair, package it in its original

packaging (or in replacement packaging obtained from your vendor).

Untrained or unauthorized personnel!

Damaging of the autoloader and loosing warranty.

If problems with the autoloader occur, contact your maintenance

organization.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 5 of 79

Page 6

Warnings

User Guide

1.3 User Guide

This specification describes the functional, performance, and environmental specifications of the

autoloader.

Contents of this User Reference Manual

n Quick Start Guide

n Features and Physical Description

n Installation and Setup

n Operation and Maintenance

n Troubleshooting and Diagnostics

n Analysis Procedures

n SCSI Interface Specification

n Product Specifications

To configure and operate the ThinStor®Plus LTO3 Autoloader via the OCP and the RMU see

ThinStor®Plus LTO3 Autoloader – Operator's Manual.

Conventions used in this specification

This specification uses the following conventions:

NOTE: Notes provide additional information or suggestions about the topic or procedure being

!

!

In this document you may find the following 3 steps of warnings:

discussed.

IMPORTANT

DANGER

WARNING

CAUTION

Information next to the word Important helps you complete a procedure or avoid

additional steps.

Usage:

Imminently hazardous situation.

Will result in death or serious injury if not avoided.

Usage:

Potentially hazardous situation.

Could result in death or serious injury if not avoided.

Usage:

Potentially hazardous situation.

May result in minor or moderate injury or property-damage-only accidents

if not avoided. Example: losing data, or damaging the autoloader or the

tape drive

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 6 of 79

Page 7

Contents

2 Contents

1 Warnings ............................................................................................................................4

1.1 Precautions................................................................ ................................................ 5

1.2 Product Warranty Caution...........................................................................................5

1.3 User Guide.................................................................................................................6

2 Contents................................................................................................ ............................. 7

3 Tables............................................................................................................................... 10

4 Figures ................................................................ ............................................................. 11

5 Quick Start Guide ................................................................................................ ............. 12

6 Features and Physical Description................................ ................................................... 14

6.1 Equipment Description .............................................................................................. 14

6.2 Features ................................................................................................ .................. 15

6.3 Component Descriptions................................................................ ........................... 16

7 Installation and Setup ................................ ...................................................................... 20

7.1 Installing the Optional Remote Management Unit (RMU) ............................................. 20

7.1.1 Contents of the Kit: .......................................................................................... 20

7.1.2 Required Tools:............................................................................................... 20

7.1.3 Mounting Instructions:................................................................ ...................... 20

7.2 Installing the Optional Bar Code Reader (BCR).......................................................... 21

7.2.1 Contents of the Kit: .......................................................................................... 21

7.2.2 Required Tools:............................................................................................... 21

7.2.3 Mounting Instructions:................................................................ ...................... 22

7.2.4 Configuration of the Barcode Reader ................................ ................................ 23

7.2.5 Barcode Labels............................................................................................... 23

7.2.6 Removing the Barcode Reader......................................................................... 23

7.3 Installing the Autoloader as a Desktop Unit................................................................. 24

7.3.1 Checks Before Installation:............................................................................... 24

7.3.2 Connecting Power................................................................ ........................... 24

7.4 Installing the Autoloader in a Rack................................................................ ............. 25

7.4.1 Prepare the Autoloader for Installation.............................................................. 25

7.4.2 Install the Support Rails in the Rack.................................................................. 25

7.4.3 Install the Rack Front Mount Brackets on the Autoloader.................................... 27

7.4.4 Secure the Autoloader to the Rack ................................................................ ... 27

7.4.5 Connecting Power................................................................ ........................... 28

7.5 Running Library Verify Test ....................................................................................... 28

7.6 Connecting the Autoloader to the Server .................................................................... 29

7.6.1 Connecting to RMU ......................................................................................... 29

7.6.2 Connecting to SCSI bus................................ ................................................... 29

8 Operation and Maintenance ................................ ............................................................. 30

8.1 General Guidelines ................................................................................................ ... 30

8.2 Powering on the System ................................................................ ........................... 30

8.3 Using the Operator Panel and Menu Options.............................................................. 32

8.4 Operational Modes................................................................................................ ... 33

8.4.1 Automatic Mode .............................................................................................. 33

8.4.2 Random Mode................................................................................................. 33

8.4.3 Sequential Mode................................ ............................................................. 34

8.4.4 Loop Mode................................ ...................................................................... 34

8.4.5 Autoload Mode................................................................ ................................ 34

8.4.6 Menu Structure and Options OCP User Interaction Mode ................................... 35

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 7 of 79

Page 8

Contents

8.5 Configuration............................................................................................................ 36

8.6 Operation ................................................................................................................. 36

8.6.1 Monitoring Autoloader Operation and Status..................................................... 36

8.7 Performing Autoloader and Tape Drive....................................................................... 36

8.7.1 Importing and Exporting Cartridges................................................................... 36

8.7.2 Bulk Exchange ................................................................ ................................ 37

8.7.3 Load and unload a Cartridge ............................................................................ 37

8.7.4 Write Protected Media..................................................................................... 37

8.7.5 Cleaning the Tape Drive .................................................................................. 37

8.8 Shipping................................................................ ................................................... 39

9 Troubleshooting and Diagnostics.................................................................................... 40

9.1 General Guidelines ................................................................................................ ... 40

9.2 Reacting on Lightening Error LED/Error Code............................................................. 40

9.2.1 Viewing Drive Error Codes via the OCP ............................................................ 41

9.2.2 Viewing Drive Error Codes via Serial Communication................................ ........ 41

9.2.3 Viewing Drive Error Codes vi a the RMU............................................................ 41

9.3 Determining a Problem.............................................................................................. 41

9.4 Error Messages and Error Codes ............................................................................... 43

9.4.1 Error Code Description.................................................................................... 43

9.4.2 Example for an Error/Event Log:....................................................................... 43

9.4.3 Not Ready Errors 01h – 0Fh................................................................ ............. 44

9.4.4 Unit Attention 10h – 1Fh ................................................................ .................. 44

9.4.5 Recovered Errors 20h – 2Fh ............................................................................ 45

9.4.6 Hardware Errors 30h – 4Fh................................ .............................................. 45

9.4.7 Illegal Request Errors 50h – 6Fh ...................................................................... 46

9.4.8 Aborted Command Errors 70h – 73h ................................................................. 47

9.4.9 Additional Errors 7ah – 7Fh................................ .............................................. 47

9.4.10Robotic Control Errors 81h – 8Fh ..................................................................... 48

9.4.11Function Errors 90h – 9Fh................................................................................ 49

9.4.12Low Level Axis Errors A0h – AFh ..................................................................... 50

9.4.13Electronic Hardware Errors B0h – B9h.............................................................. 51

9.4.14Drive Errors BAh – BFh .................................................................................... 51

9.4.15Barcode Errors C0h – CFh............................................................................... 52

9.4.16Network Errors D0h – D5h ............................................................................... 52

9.4.17Subcode Descriptions................................................................ ...................... 52

9.4.18Drive Error Code Descriptions ................................ .......................................... 55

9.5 Access Protocol................................................................................................ ........ 56

10 Analysis Procedures................................................................................................ ........ 57

10.1 Power/External Fan Analysis..................................................................................... 57

10.2 RMU Analysis................................ ........................................................................... 57

10.3 BCR Analysis................................ ........................................................................... 58

10.4 Media-Related Problems................................................................ ........................... 58

11 SCSI Interface Specification................................ ............................................................. 59

11.1 Cable and Terminator Requirements................................ .......................................... 59

11.1.1SCSI Cable Requirements............................................................................... 59

11.1.2SCSI Terminator Requirements................................................................ ........ 60

11.2 SCSI Communications.............................................................................................. 60

11.2.1SCSI Messages.............................................................................................. 61

11.2.2SCSI Commands................................ ............................................................. 62

11.3 Elements and Element Addresses ................................................................ ............. 65

11.3.1Elements................................................................................................ ........ 65

11.3.2Element Addresses......................................................................................... 65

12 Product Specifications................................................................ ..................................... 67

12.1 Size and Weight ....................................................................................................... 67

12.2 Performance Specifications....................................................................................... 67

12.3 Power Specifications................................................................................................. 69

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 8 of 79

Page 9

Contents

12.4 Environmental Specifications..................................................................................... 70

12.4.1Shock and Vibration......................................................................................... 71

12.5 Shipping Specifications................................ ............................................................. 72

12.6 Safety and Regulatory Agency Compliance................................ ................................ 73

13 Index................................................................................................ ................................ 77

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 9 of 79

Page 10

Tables

3 Tables

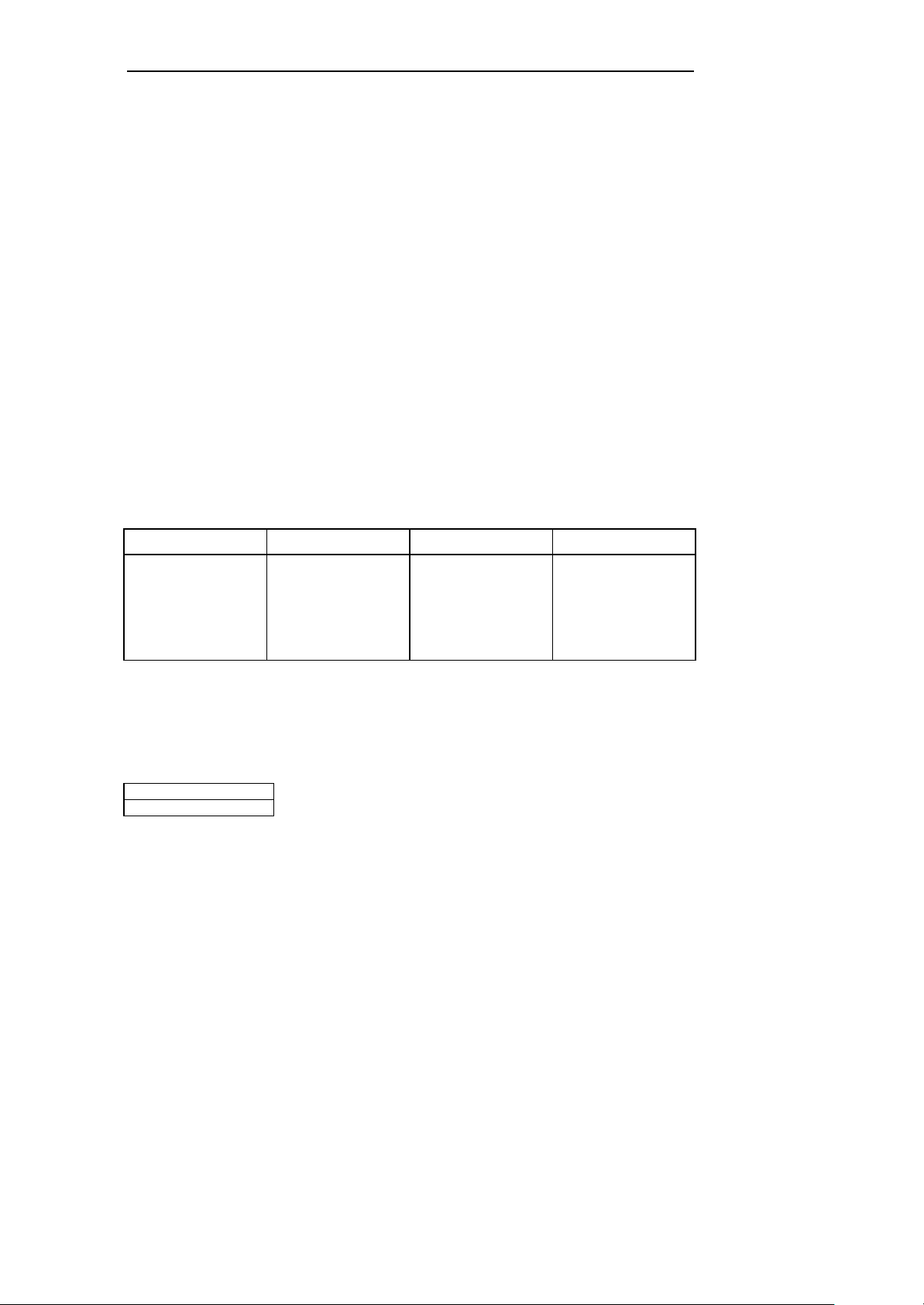

Table 1 Autoloader features................................................................................................ ... 15

Table 2 SCSI interface................................................................ .......................................... 15

Table 3 Data cartridge capaci ties in gigabytes (GB) ................................................................ 19

Table 4 Ultrium Gen3 support ................................................................ ................................ 19

Table 5 Inventory Status characters.......................................................................................31

Table 6 SCSI messages supported by the autoloader .............................................................62

Table 7 SCSI commands supported by the autoloader............................................................63

Table 8 Status byte descriptions............................................................................................64

Table 9 Supported sense keys...............................................................................................64

Table 10 Element addresses ................................................................................................ ... 66

Table 11 Dimensions and weight ................................ ............................................................. 67

Table 12 Autoloader storage capacity................................................................ ...................... 67

Table 13 AC power specifications ............................................................................................69

Table 14 Environmental specifications .....................................................................................70

Table 15 Acoustic noise limits................................ ..................................................................70

Table 16 Shock limits................................................................ .............................................. 71

Table 17 Vibration specifications..............................................................................................72

Table 18 Shipping weight and dimensions ................................................................................ 72

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 10 of 79

Page 11

Figures

4 Figures

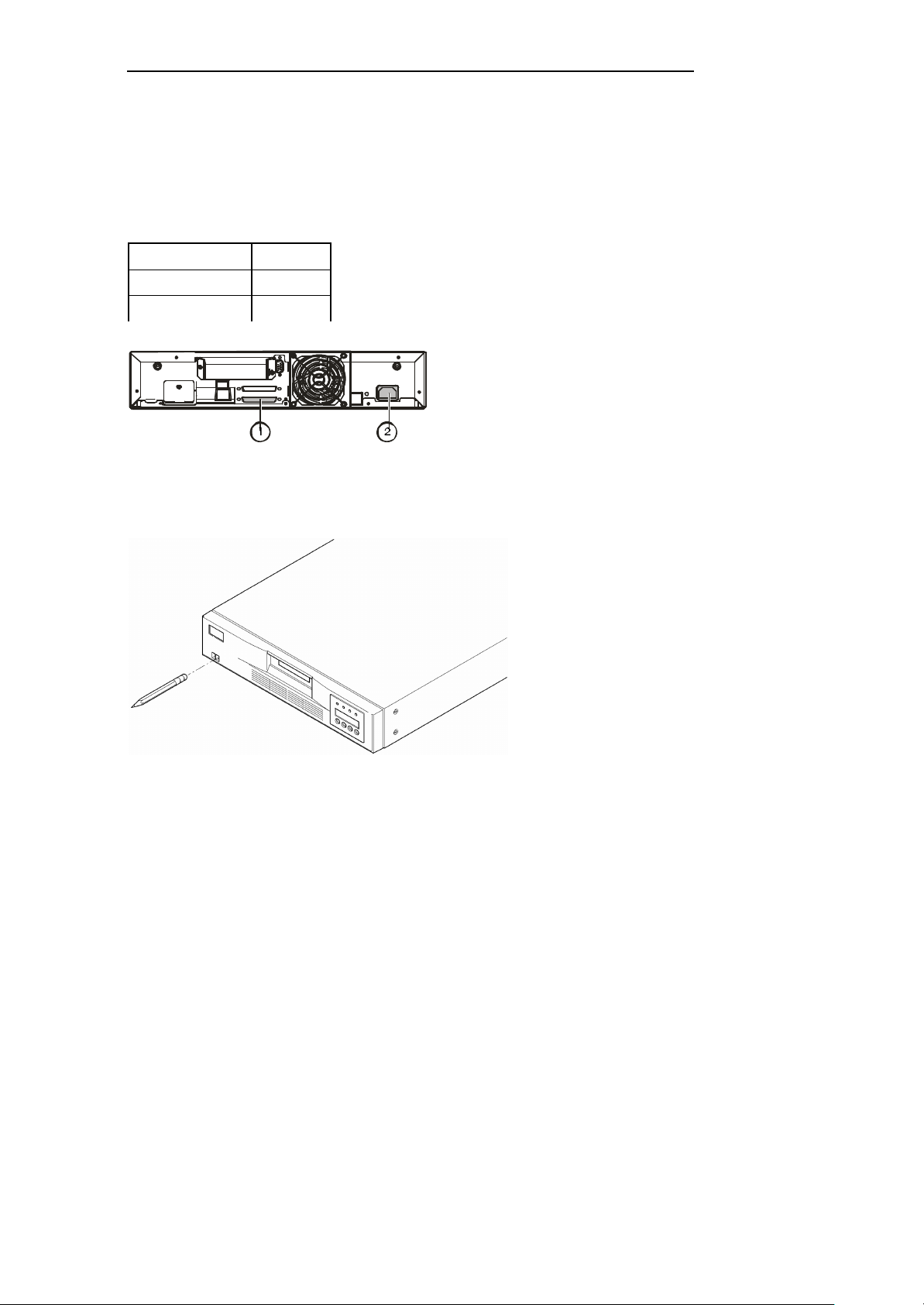

Figure 1 AC line cord, SCSI terminator....................................................................................12

Figure 2 Power switch ............................................................................................................12

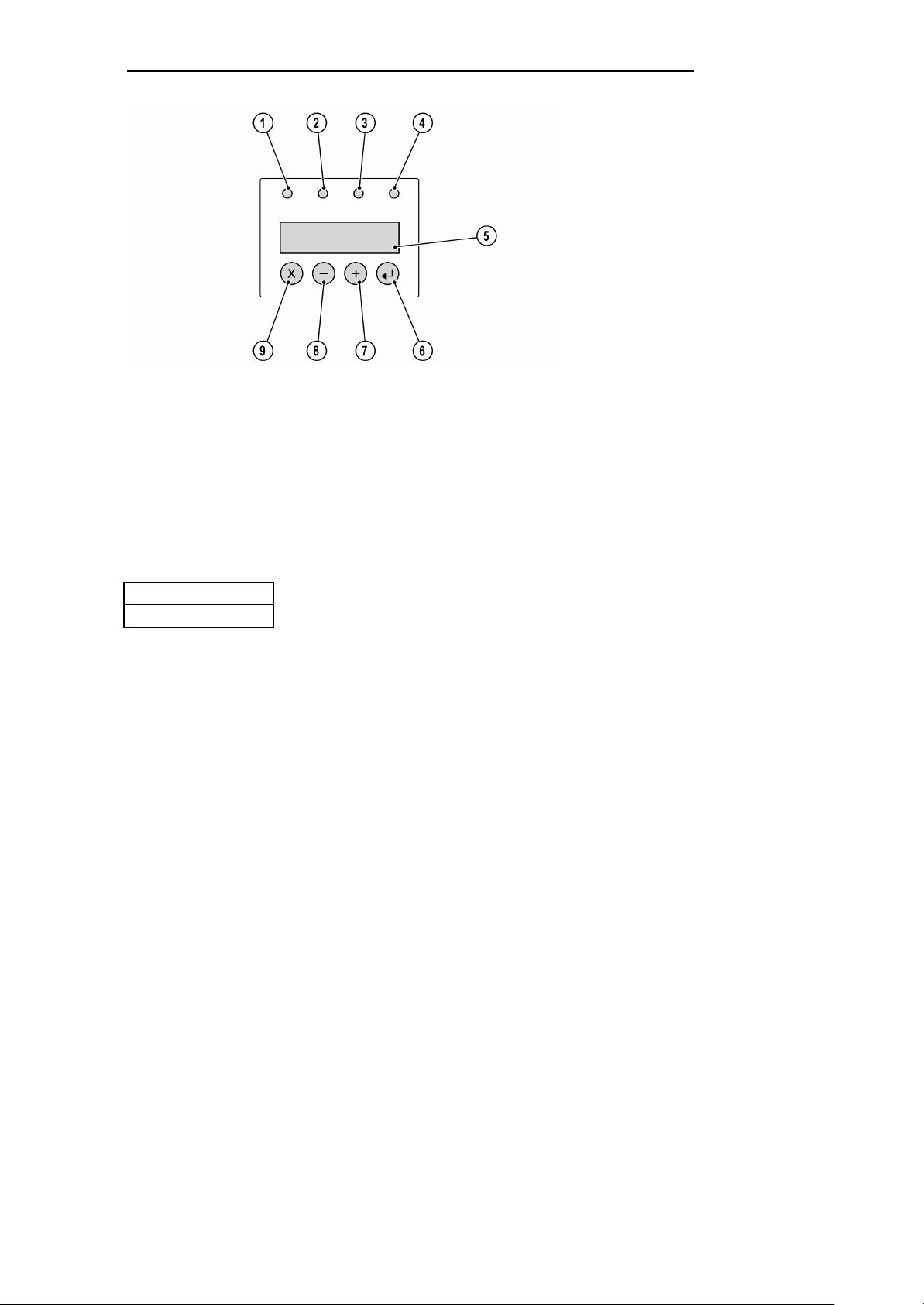

Figure 3 Operator panel.........................................................................................................13

F igure 4 Autoloader...............................................................................................................14

Figure 5 Front panel components............................................................................................16

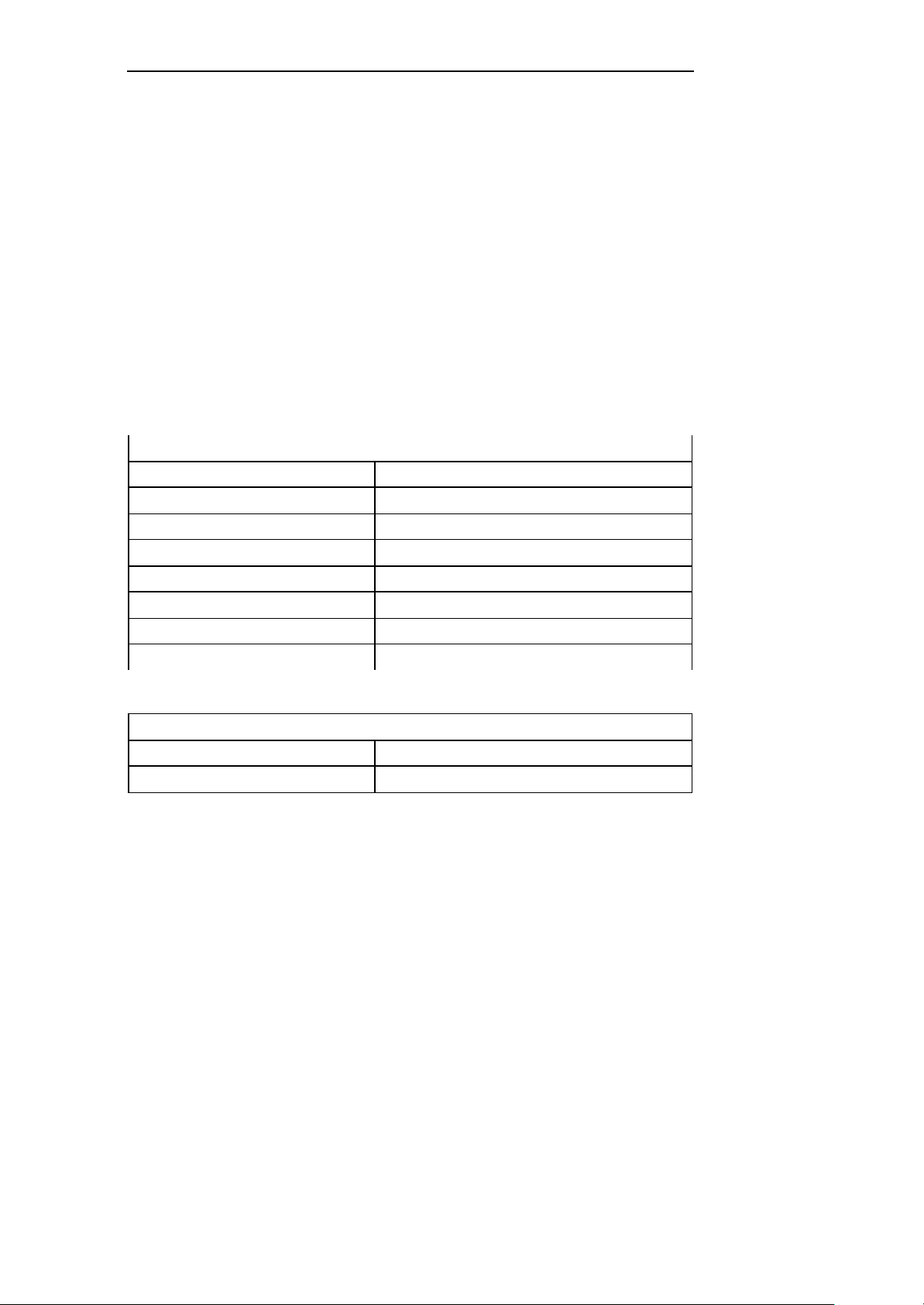

Figure 6 Back panel components............................................................................................17

Figure 7 Internal components.................................................................................................17

Figure 8 Location of the protective covering for the RMU rail.....................................................21

Figure 9 Positioning of the LAN card.......................................................................................21

Figure 10 Location of the cover plate for the BCR rail.................................................................22

Figure 11 Connecting of the BCR..............................................................................................22

Figure 12 EIA identification.......................................................................................................25

Figure 13 Attaching cage cilp nuts to a rack with square holes....................................................26

Figure 14 Attaching expanding rails to the rack................................ .......................................... 26

Figure 15 Mounting position of rack mount bracket, left side.......................................................27

Figure 16 Installing the Autoloader in a rack .............................................................................. 27

Figure 17 SCSI receptacles ................................ ...................................................................... 29

Figure 18 LEDs.......................................................................................................................31

Figure 19 Operator panel.........................................................................................................32

Figure 20 Interaction Mode, overview ................................ ........................................................ 35

Figure 21 Default element addresses (identical to the element indexes.......................................66

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 11 of 79

Page 12

5 Quick Start Guide

Defaults

NOTE: The following defaults have been set at the factory.

LDR SCSI ID 0

DRV SCSI ID 5

Operating Mode Sequential

Figure 1 AC line cord, SCSI terminator

1. Install AC line cord, first to autoloader (receptacle 2), then to AC outlet.

2. Install SCSI terminator on autoloader (receptacle 1).

Quick Start Guide

Figure 2 Power switch

3. Use the eraser end of a pencil or something similar to press the left side of the power switch. The

autoloader powers up.

Install data cartridges in slots 1-8:

4. Place cartridge in the cartridge access port.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 12 of 79

Page 13

Figure 3 Operator panel

5. Press any button on the operator panel to change to interaction mode.

6. Choose the "Go Offline" menu and press <Enter>.

7. Choose the "Commands" menu and press <Enter>.

8. Choose "Import", press <Enter>

9. Enter the number of the cartridge slot and press <Enter>.

The cartridge is placed in the chosen slot.

10. Repeat step 4 to 7, until all cartridges are imported.

Drive empty

12345678 SEQ

11. Power up your host computer.

12. Verify your backup software.

Quick Start Guide

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 13 of 79

Page 14

Features and Physical Description

Equipment Description

6 Features and Physical Description

6.1 Equipment Description

The autoloader provides automated data storage, archival, backup, and retrieval for a range of

systems, from desktop workstations to small office local area networks.

This chapter describes the autoloader. It includes the following topics:

n Autoloader features

n Component descriptions

n Autoloader accessories

n Related products

Figure 4 Autoloader

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 14 of 79

Page 15

Features and Physical Description

Features

6.2 Features

The autoloader includes the following features:

n A carousel encircles the tape drive and positions the specified cartridge slot in front of the tape

drive. A robotic cartridge loader moves the cartridges between the cartridge slots and the tape

drive.

n Storage for up to 8 data cartridges. Cartridges are stored in cartridge slots mounted on the

carousel. One of these cartridge slots can contain a cleaning cartridge.

n A cartridge access port for importing or exporting a single cartridge f rom the autoloader.

n An LCD allows you to monitor autoloader operations, select configuration options, and control the

cartridge loader and carousel from the front panel.

n The autoloader and the tape drive each include independent Small Computer System Interface

(SCSI) controllers. Each supports independent sets of SCSI messages and commands. The

autoloader and the enclosed tape drive use a wide, low -voltage differential (LVD) SCSI interface.

NOTE: Also the LVD SCSI interface is compatible with single-ended (SE) SCSI.

The autoloader is designed as a standalone unit, but can be mounted in a standard 19-inch rack if

desired. Rack mount kits are available from the manufacturer.

Physical characteristics and features

Drive technology IBM LTO Ultrium 3

Total drives 1

Total storage elements 8

Cartridge access port 1

LCD display size and type Two-line x 32 character, ASCII

LCD user interface Four-button keypad

Maximum capacity 3.2 TB native/6.4 TB compressed

Maximum sustained data transfer rate 80 MB/s native/280 MB/s compressed

Table 1 Autoloader features

Parallel SCSI communication interface

Low-voltage differential (LVD) + SE yes

Maximum SCSI bus connections 1

Table 2 SCSI interface

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 15 of 79

Page 16

Features and Physical Description

Component Descriptions

6.3 Component Descriptions

The following sections describe the major components of the autoloader.

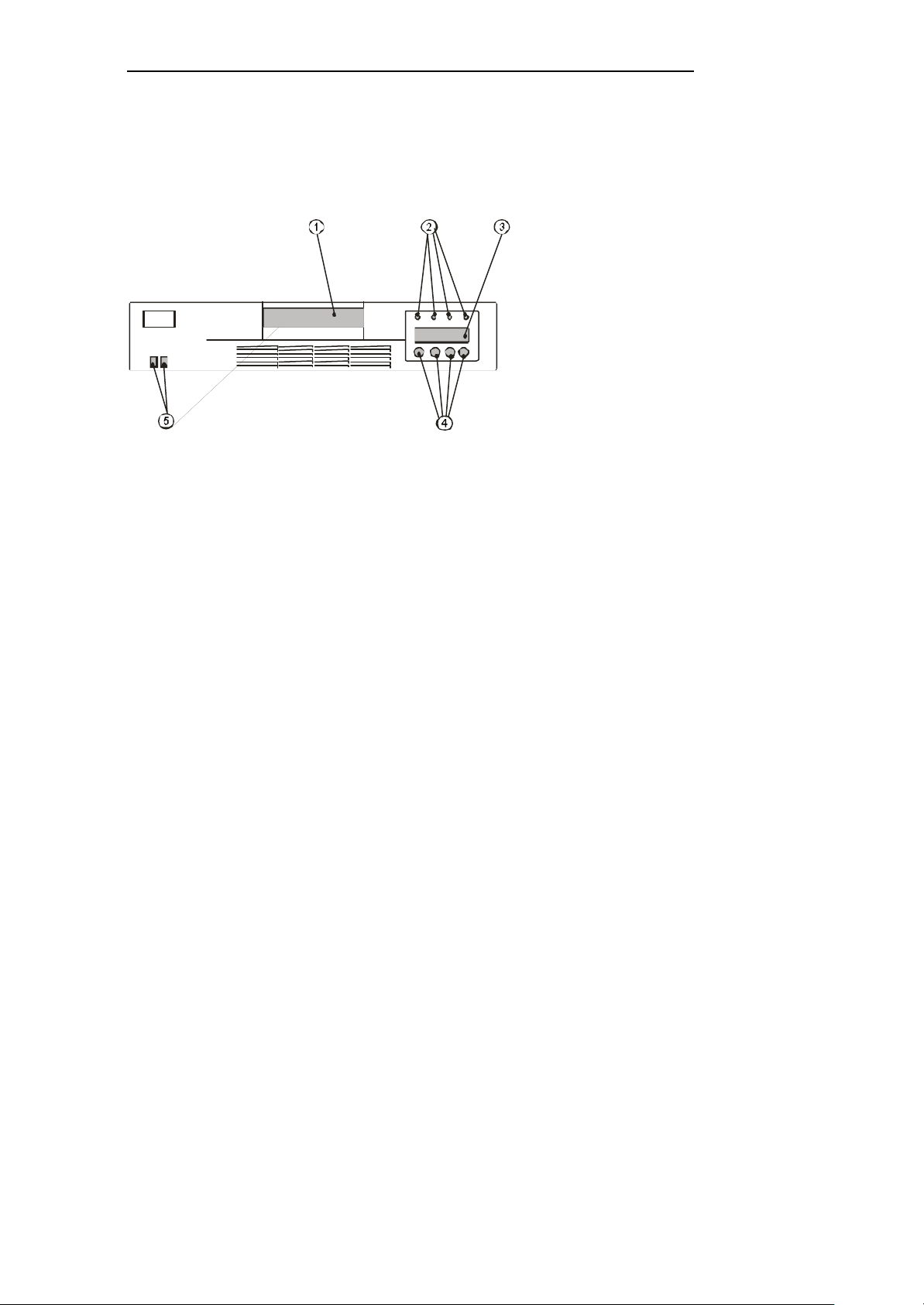

Front Panel Components

Figure 5 Front panel components

( 1 ) Cartridge access port

The cartridge access port allows you to insert or remove cartridges from the autoloader.

Operator Panel

( 2 ) 4 Status LEDs

( 3 ) Liquid crystal display, 16 characters per line, two lines

( 4 ) Four button keypad

For more information about the operator panel and menu operations, see page 32.

( 5 ) Power switch

The power switch allows you to turn power on and off for the autoloader and the enclosed tape

drive. The switch is recessed into the front panel to prevent the autoloader from being accidently

turned off during operation.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 16 of 79

Page 17

Features and Physical Description

Component Descriptions

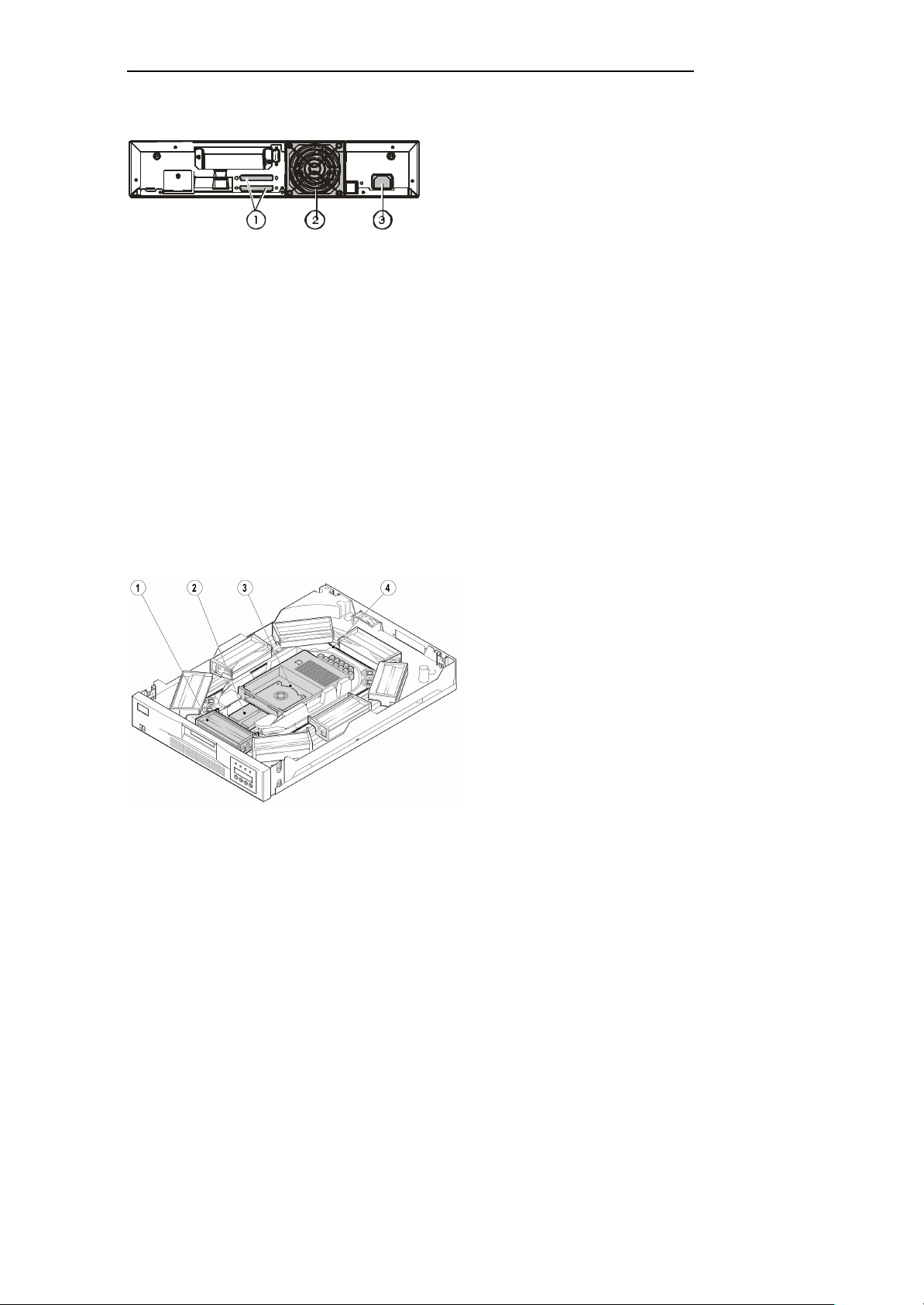

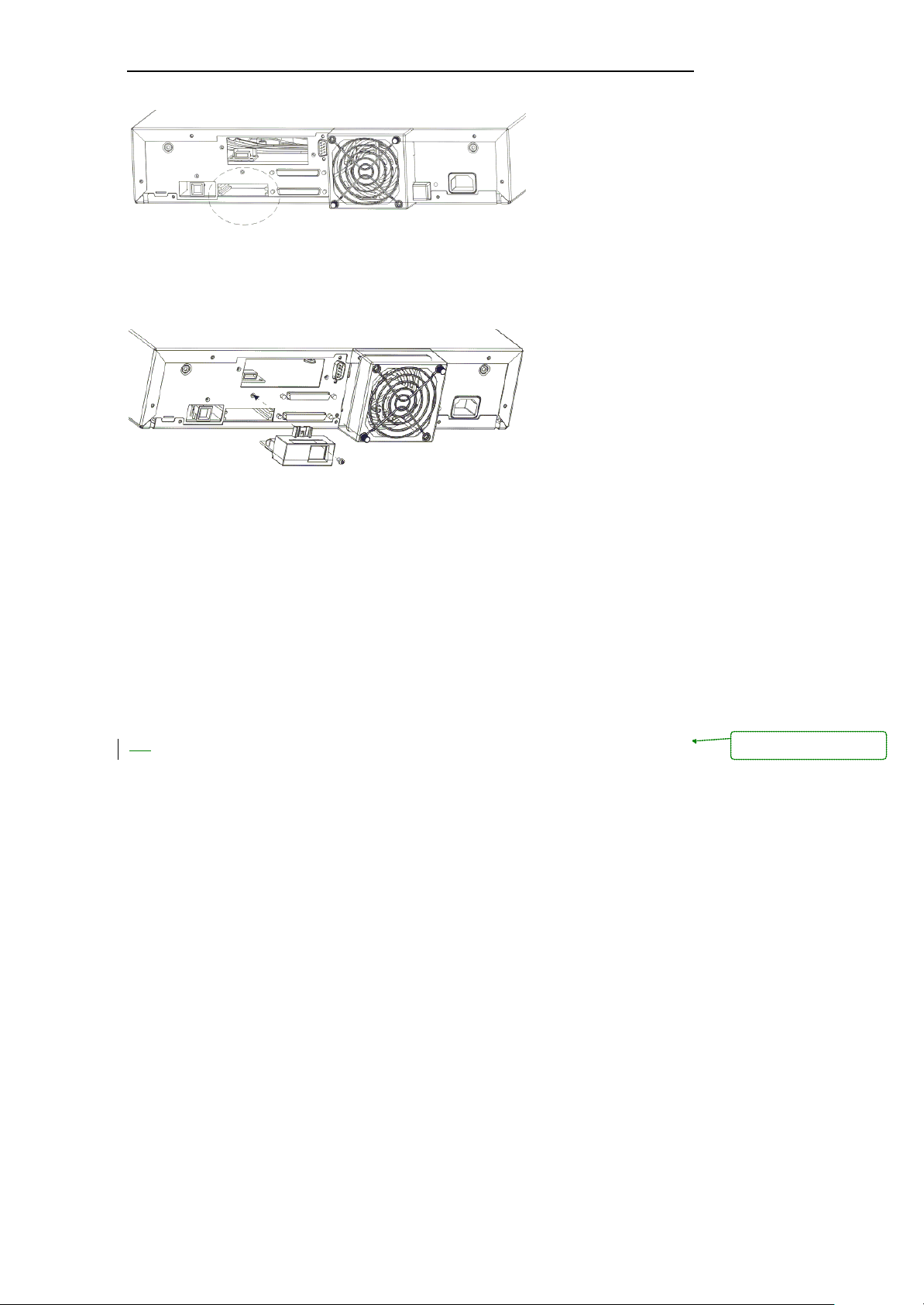

Back Panel Components

Figure 6 Back panel components

( 1 ) SCSI Connectors

The autoloader has two wide SCSI connectors for connecting the autoloader and tape drive to a

single SCSI bus. The connectors can accommodate either of the following:

– A shielded male, high-density wide (68-pin) SCSI cable

– A wide external terminator

The wide SCSI configuration allows up to 16 devices (including one or more initiators) to be

attached to a single SCSI bus. See SCSI Interface Specification on page 59 for more information

about the SCSI interface.

( 2 ) Fan

The system fan provides cooling for the autoloader and the tape drive.

( 3 ) Power cord connection

The power cord connection provides AC power and chassis grounding to the autoloader and the

tape drive.

Internal Components

Figure 7 Internal components

( 1 ) Cartridge slot

( 2 ) Cartridge loader

( 3 ) Tape drive

( 4 ) Carousel

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 17 of 79

Page 18

Features and Physical Description

Component Descriptions

Tape Drive

The autoloader contains one tape drive. The tape drive can sustain a maximum data transfer rate of

280 MB per second (compressed) and can store up to 800 GB of compressed information on a single

data cartridge (assuming an average compression ratio of 2:1).

Cartridge Slots and Carousel

The carousel stores up to eight data cartridges. The carousel consists of a drive chain, guides, and

gears that move the cartridges into position in front of the tape drive. Each cartridge is installed in a

cartridge slot that ensures that the cartridge is properly aligned to be inserted into the tape drive.

If desired, you can use one cartridge slot to hold a cleaning cartridge.

Cartridge Loader

The cartridge loader moves cartridges between the cartridge slots and the tape drive. When a

cartridge slot is positioned in front of the tape drive, the loader grips the sides of the cartridge and

slides it forward or backward between the slot and tape drive. The loader then releases the cartridge

and pushes it firmly into the drive or slot.

Enclosure

The autoloader is housed in a 2 rack-units (ru) high desktop enclosure with a black, textured finish. A

paint kit is available from your vendor for touching up nicks and scratches on the finish.

Autoloader Accessories and Related Pro ducts

The following accessories and products, – available from the manufacturer, are intended for use with

the autoloader:

n 230 V AC power cord

n One Wide SCSI-3 cable

n One LVD Wide SCSI terminator

n Autoloader CD (includes all of the produc t documentation)

n LTO tape data cartridges

n LTO tape Packs

n LTO tape cleaning cartridges

n Rack mount kit

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 18 of 79

Page 19

Features and Physical Description

Component Descriptions

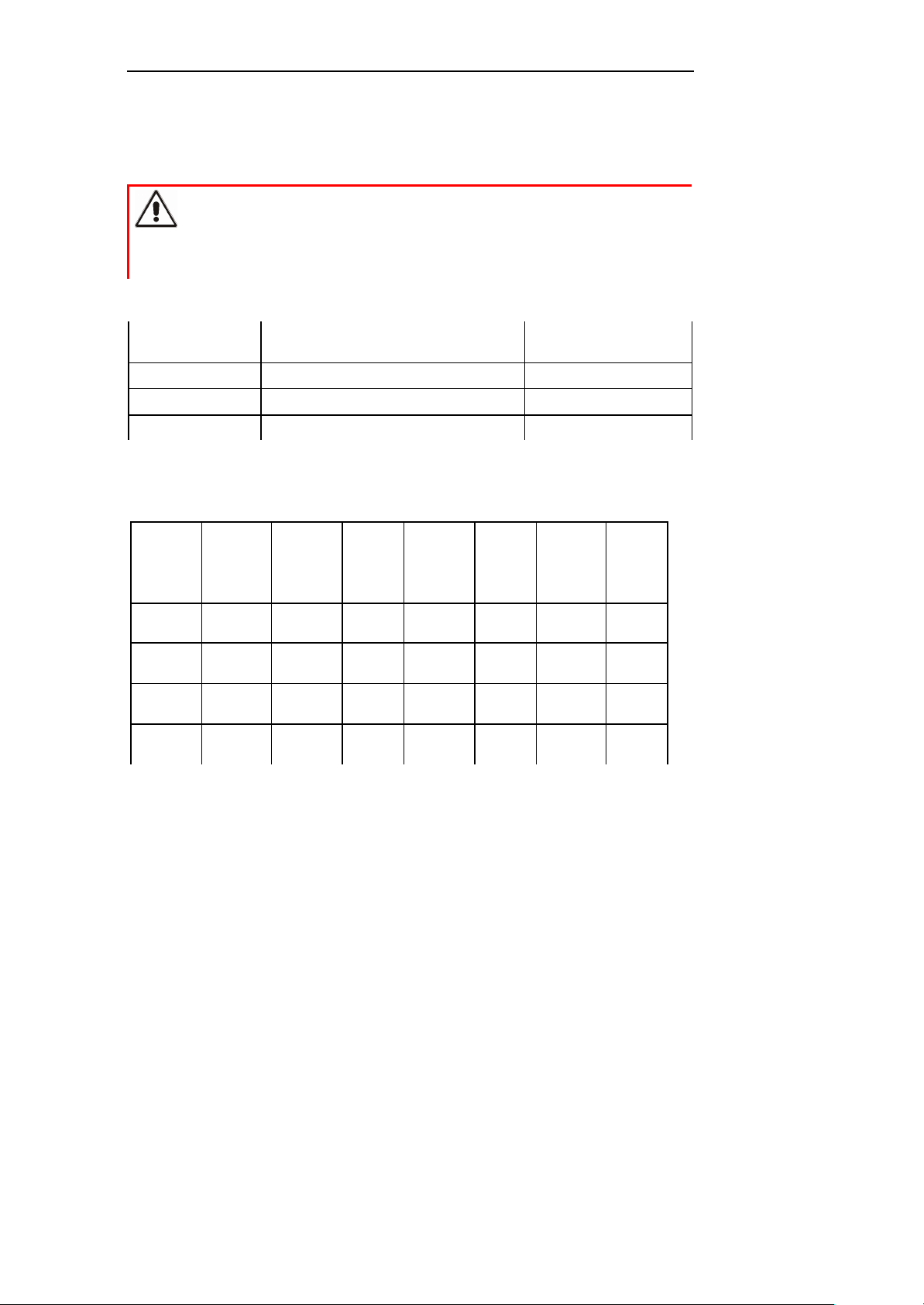

Data Cartridges

The tape drive reads and writes to LTO tape data cartridges. The capacity and transfer rates are listed

in 0.

CAUTION

LTO tape

Cartridge type

Ultrium 1 100GB 200GB 580

Ultrium 2 200GB 400GB 580

Ultrium 3 400GB 800GB 680

Table 3 Data cartridge capacities in gigabytes (GB)

1) Assuming a 2:1 compression ratio. Actual compressed capacity varies depending on the type of data being

recorded.

Wrong tapes!

Damages of the tape drive.

Use only LTO tape data cartridges.

Capacity (native) Capacity

(compressed)1)

Tape length (meters)

Gen 3

Native

Capacity

400 GB

(680m)

200 GB

(580 m)

100 GB

(580 m)

50 GB

(290 m)

Table 4 Ultrium Gen3 support

Format Write Read Write Read Write Read

Ultrium 3 yes yes no no no no

Ultrium 2 yes yes yes yes no no

Ultrium 1 yes yes yes yes yes yes

Ultrium 1 yes yes yes yes yes yes

drive

Gen 2

drive

Gen 1

drive

Cleaning Cartridges

Following a regular cleaning schedule for your tape drive will maximize the reliability of your drive and

the life of your LTO tape data cartridges. To clean your tape drive, use only LTO tape Cleaning

Cartridges, available from the manufacturer.

Rack Mount Kit

If you want to mount the autoloader in a rack, you can purchase a rack mount kit from the

manufacturer. The kit includes instructions and all the hardware you need to mount the autoloader in a

standard 19-inch EIA rack. The autoloader occupies 2 rack units.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 19 of 79

Page 20

Installation and Setup

Installing the Optional Remote Management Unit (RMU)

7 Installation and Setup

This chapter describes:

n Installing the Optional Remote Management Unit (RMU)

n Installing the Optional Bar Code Reader (BCR)

n Installing the Autoloader as a Desktop Unit

n Installing the Autoloader in a Rack

n Running Library Verify Test

n Connecting the Autoloader to the Server

7.1 Installing the Optional Remote Management Unit

(RMU)

7.1.1 Contents of the Kit:

n LAN Card.

Formatiert: Nummerierung und

Aufzählungszeichen

7.1.2 Required Tools:

n T10 Torx wrench or small flat-blade screwdriver.

7.1.3 Mounting Instructions:

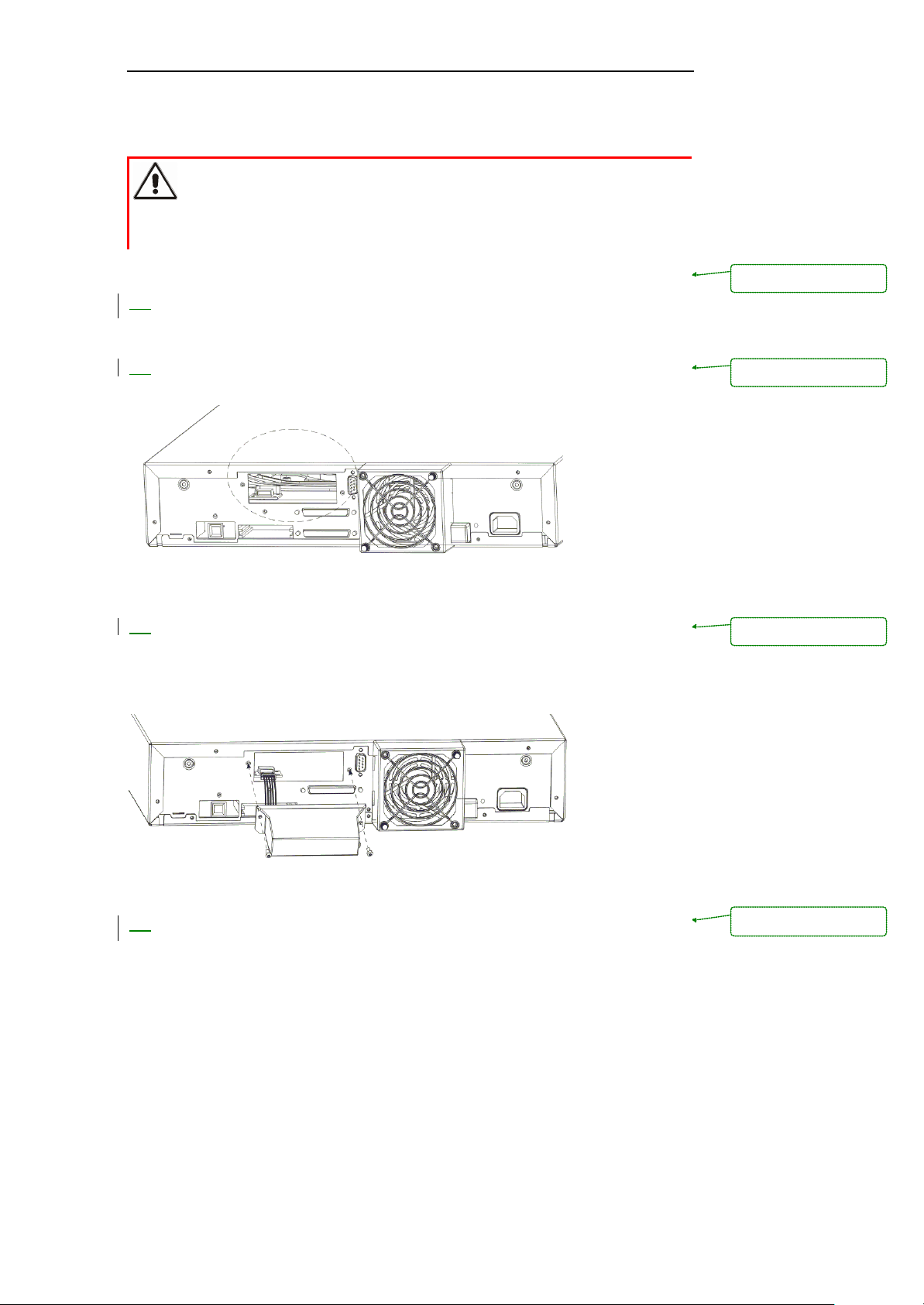

CAUTION

The LAN card is to be mounted on the rear of the device.

1. Power off the autoloader.

2. Remove the protective covering (located on the autoloader’s rear panel) (see Figure 8 ). Save the

screw.

Electro static discharge!

Destruction of the ESD sensitive components.

Please touch unit cover or rear panel before installing the RMU.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 20 of 79

Page 21

Installing the Optional Bar Code Reader (BCR)

Figure 8 Location of the protective coveri ng for the RMU rail

3. Align the LAN card in the rails and insert into the unit.

4. Fix the unit with the supplied screw (see Figure 9 ).

Figure 9 Positioning of the LAN card

Installation and Setup

5. Attach the Ethernet cable to the RMU and HOST system.

6. Power ON the autoloader and wait for initialization to complete.

7. Configure the RMU via OCP, see ThinStor®Plus LTO3 Autoloader – Operator's Manual.

7.2 Installing the Optional Bar Code Reader (BCR)

7.2.1 Contents of the Kit:

n Barcode reader.

7.2.2 Required Tools:

n Flat-blade screwdriver; small.

Formatiert: Nummerierung und

Aufzählungszeichen

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 21 of 79

Page 22

Installation and Setup

Installing the Optional Bar Code Reader (BCR)

7.2.3 Mounting Instructions:

CAUTION

The barcode reader is to be mounted on the rear side of the autoloader.

1. Power down the autoloader.

2. Disconnect the power cord from the outlet. Remove the SCSI cable(s) and power cord from the

rear panel of the autoloader.

3. Remove the cover plate from the rear panel (see Figure 10). Save the screws! Save and store the

cover plate; you may use this plate later after removing the barcode reader.

Electro static discharge!

Destruction of the ESD sensitive components.

Please touch unit cover or rear panel before installing the RMU.

Formatiert: Nummerierung und

Aufzählungszeichen

Formatiert: Nummerierung und

Aufzählungszeichen

Figure 10 Location of the cover plate for the BCR rail

4. Orient the barcode reader before the slot. There is only one correct orientation. Check whether the

holes align.

5. Connect the cable to the barcode controller outlet.

6. Attach the barcode reader with the screws (see Figure 11).

Figure 11 Connecting of the BCR

7. Reconnect the SCSI cables and power cord to the autoloader.

8. Power on the autoloader.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 22 of 79

Formatiert: Nummerierung und

Aufzählungszeichen

Formatiert: Nummerierung und

Aufzählungszeichen

Page 23

Installation and Setup

Installing the Optional Bar Code Reader (BCR)

7.2.4 Configuration of the Barcode Reader

1. Enable Barcode Reader through the Operator Panel. Select menu item

CONFIGURATION/BARCODE READER and set BCR CHANGE TO „ON”.

2. The barcode reader is controlled through the host software.

3. The autoloader and host system will sense the presence of the barcode reader.

7.2.5 Barcode Labels

The barcode reader can only operate, if barcode labels are present on the tape cartridges. Please

make sure that only barcode labels according to the appropriate barcode label specification are used!

7.2.6 Removing the Barcode Reader

1. Disable Barcode Reader through the Operator Panel. Select menu item

CONFIGURATION/BARCODE READER and set BCR CHANGE TO "OFF"

2. Power down the autoloader.

3. Disconnect the power cable from the outlet. Remove the SCSI cable(s) and power cable from the

rear panel.

4. Unscrew the screws that fix the barcode reader to the rear panel.

5. Unplug the barcode reader connector from the controller outlet.

6. Replace the cover panel on the rear panel.

Formatiert: Nummerierung und

Aufzählungszeichen

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 23 of 79

Page 24

Installation and Setup

Installing the Autoloader as a Desktop Unit

7.3 Installing the Autoloader as a Desktop Unit

WARNING

7.3.1 Checks Before Installation:

If you install the autoloader as a desktop unit, position the autoloader in a location that is away from

dust, dirt, and debris, and is convenient to the server (host) to which it will be attached. The only

restrictions are the length of the power cord and the length of the SCSI cable.

For a desktop installation, position the autoloader in the following recommended locations:

n Away from high-traffic areas, especially if the floor is carpeted.

n Out of copy rooms to avoid toner and paper dust. Do not store paper supplies near any unit.

n Away from moving air, such as doorways, open windows, fans, and air conditioners.

n Off the floor.

n In a horizontal position on a flat surface.

n Where a tape cartridge can be easily inserted into the I/O Door.

Weights on the autoloader!

Destruction of the autoloader's chassis.

The autoloader should not be stacked. Do not place anything on top of

the autoloader.

7.3.2 Connecting Power

1. Plug the power cord into the receptacle at the rear of the autoloader

2. Plug the other end of the power cord into a grounded electrical outlet.

3. Power on the autoloader.

The autoloader will verify the drive configuration and status, build a valid cartridge inventory log , and

calibrate the robotic cartridge loader.

The OCP’s green READY/ACTIVITY LED (light -emitting diode) will blink during this initialization

process.

When the autoloader completes the Power-On Self Test (POST) for the drive and the library, the

green READY/ACTIVITY LED will stop blinking.

The autoloader will be in automatic mode (the default mode) and SEQ will appear in the lower right

corner of the OCP display.

For information about the autoloader’s modes of operation, see ThinStor®Plus LTO3 Autoloader –

Operator's Manual. If a failure occurred, the red ERROR LED will light up and an error message will

be displayed on the OCP. See Troubleshooting and Diagnostics on page 40.

4. If the power on is successful, run the Library Verify test (see Running Library Verify Test on

page 28).

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 24 of 79

Page 25

Installation and Setup

4.45cm

(1.75in.)

(1.75in.)

Installing the Autoloader in a Rack

7.4 Installing the Autoloader in a Rack

You have to install the autoloader into a standard 19-inch rack.

Required Tools:

n Phillips screwdriver, size 2

n Torx wrench, T10 (part of kit)

7.4.1 Prepare the Autoloader for Installation

CAUTION

If the Autoloader is already in operation as a standalone unit, prepare it for Installation in the rack as

follows:

1. Power off the Autoloader using the POWER button on the front panel.

2. Remove the power cord and any cables or terminator attached to the Autoloader. Note the

configuration of the cables and terminator for reconnecting them after installing the Autoloader in

the rack.

Disrupting communication between the server (host) and other

devices on the SCSI bus!

Incomplete data storage.

Make sure there is no SCSI activity on the bus before you power of the

autoloader.

7.4.2 Install the Support Rails in the Rack

1. Remove the two support rails from the kit and note how they will be positioned in the rack. When

the rails are properly installed, the shelf flanges will face inward to support the autoloader.

NOTE: The autoloader requires 2 EIAs of rack space for installation.

2. Identify the 2 EIAs required by the autoloader for rail placement.

4.45cm

Figure 12 EIA identification

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 25 of 79

Page 26

Installation and Setup

Installing the Autoloader in a Rack

3. Install the cage clip-nuts (for racks with square mounting holes) from the back side of each rail.

Figure 13 Attaching cage cilp nuts to a rack with square holes

NOTE: To ensure proper installation of the Autoloader in your rack, it is very important to install the

clip-nuts in the correct positions on each rail.

4. Count the holes on the other three rack rails, up or down, to determine the position of the top or

bottom clip-nut.

5. From the front of the rack, position one of the rails on the appropriate side.

6. Position the front flange so that it is on the outside of the strip of mounting holes in the rack (see

Figure 14).

Figure 14 Attaching expanding rails to the rack

7. Using a #2 Phillips screwdriver, attach the rail to the rack with screws and washers from the kit.

8. Slide the rail pieces apart to match the depth of your rack.

9. Using a #2 Phillips screwdriver, attach the rail to the outside of the rack with screws and washers

supplied with the rack mount kit.

10. Repeat steps 5 through 9 to install the second rail.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 26 of 79

Page 27

Installation and Setup

Installing the Autoloader in a Rack

7.4.3 Install the Rack Front Mount Brackets on the Autoloader

1. Determine on which side of the autoloader the rack mount brackets will be attached (see

Figure 15). The oval hole for attaching the bracket to the rack will be on the bottom of the arm of

the bracket.

Figure 15 Mounting position of rack mount bracket, left side

2. Using the Torx wrench, Remove the two screws on each side of the autoloader cover.

3. Position the correct bracket, as determined in Step 1, on each side of the autoloader and secure

by reusing the original screws (see Figure 15).

7.4.4 Secure the Autoloader to the Rack

1. From the front of the rack, position the autoloader on the shelf flanges between the support rails.

Slide it toward the rear of the rack un til the brackets contact the rack’s mounting holes.

NOTE: Make sure that the tabs on the back of each shelf flange are fully engaged in the slots at the

Figure 16 Installing the Autoloader in a rack

2. Place one screw and washer from the rack mount kit into the hole in the front of each bracket.

rear of the autoloader.

Take care that the screws line up with the holes containing the remaining installed clip-nuts. Use a

#2 Phillips screwdriver to tighten the screws.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 27 of 79

Page 28

Installation and Setup

Running Library Verify Test

7.4.5 Connecting Power

1. Connect the PCC cable (included with your rack mount kit) to the rear of the autoloader.

2. Connect the other end of the PCC cable to your rack’s power strip.

3. Power on the power strip.

4. Power on the autoloader.

The autoloader will verify the drive configuration and status, build a valid cartridge inventory log, and

calibrate the robotic cartridge loader.

The OCP’s green READY/ACTIVITY LED (light -emitting diode) will blink during this initialization

process.

When the autoloader completes the Power-On Self Test (POST) for the drive and the library, the

green READY/ACTIVITY LED will stop blinking.

The autoloader will be in automatic mode (the default mode) and SEQ will appear in the lower right

corner of the OCP display.

For information about the autoloader’s modes of operation, see ThinStor®Plus LTO3 Autoloader –

Operator's Manual. If a failure occurred, the red ERROR LED will light up and an error message will

be displayed on the OCP. See Troubleshooting and Diagnostics on page 40.

5. If the power on is successful, run the Library Verify test (see Running Library Verify Test on

page 28).

7.5 Running Library Verify Test

1. Press Enter on the OCP at the ONLINE screen.

2. Press Next four times to navigate to the Diagnostic Menu.

3. Press Enter to navigate to the LOADER DIAG menu item.

4. Press Enter to access LIBRARY VERIFY.

5. Press Enter to begin the verification.

6. On the OCP display, you will be asked to insert a cartridge.

7. When the I/O Door opens, insert a blank cartridge or a scratch cartridge.

The I/O Door will close automatically.

While the test is running, the OCP will display library status.

8. If the test PASSED, proceed to the next step.

9. If the test FAILED, see Determining a Problem on page 41.

10. Press Enter.

11. When prompted by the OCP display, remove the cartridge.

12. Press Enter to end the test.

13. Power off the autoloader.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 28 of 79

Page 29

Installation and Setup

Connecting the Autoloader to the Server

7.6 Connecting the Autoloader to the Server

The autoloader has to be attached to a SCSI/LVD system.

Cabling is required for the tape drive interface and the RMU, if installed, in order for your server (host)

to communicate with the autoloader. The following sections include information on options cabling and

drive interface connections.

7.6.1 Connecting to RMU

NOTE: If you are plugging the RMU directly into a PC, use a special crossover Ethernet cable (not

1. Plug an Ethernet cable into the RMU mounted on the rear of the autoloader.

2. Plug the other end of the Ethernet cable into your network switch or hub.

7.6.2 Connecting to SCSI bus

A SCSI cable is required for each server connection to a SCSI bus. An LVD SCSI terminator may be

included in your ship group.

!

!

Connecting to a SCSI-LVD System

1. Plug the SCSI cable into the top SCSI receptacle (1) on the rear panel of your autoloader.

Figure 17 SCSI receptacles

supplied).

IMPORTANT

Be sure to install the appropriate SCSI host bus adapter and software on your

server (host). For more information, see your server (host) documentation and

application software.

2. Plug the LVD SCSI terminator (or another SCSI cable connecting to another SCSI device) into the

bottom SCSI receptacle (2) on the rear panel of your autoloader.

3. Connect the SCSI cable to your server (host).

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 29 of 79

Page 30

Operation and Maintenance

General Guidelines

8 Operation and Maintenance

This chapter describes the requirements for using the autoloader, including information about:

n General Guidelines

n Powering on the System

n Powering on the System

n Using the Operator Panel and Menu Options

n Operational Modes

n Configuration

n Operation

n Performing Autoloader and Tape Drive

n Shipping

8.1 General Guidelines

Do not open the front door of the autoloader unless you must perform interaction mode commands, or

change media.

Use only the recommended types of media cartridges.

Clean the drive whenever necessary.

CAUTION

Disrupting data storage!

Incomplete data storage.

Never insert or remove cartridges from the cartridge slot unless

READY/ACTIVITY is lit.

8.2 Powering on the System

Switch on power at the POWER button located on the front panel, after the power cord and the SCSI

cabel are connected. The autoloader will power up.

If an RMU is installed, look on the rear panel of the autoloader and verify that the RMU’s green LED is

on. If the green LED is not on, check the connection to the RMU, see Installing the Optional Remote

Management Unit (RMU) on page 20. Otherwise call the Technical Support.

When the autoloader powers up, or resets, it goes through several internally controlled processes that

allows it to get initialized and running. While those processes are happening, the operator panel shall

have appropriate information displayed to keep the user informed. When the autoloader finishes

coming alive, it will display the Current Drive mount status in the ‘Home Screen’. It also indicates that

sequential mode is ON by posting the SEQ string.

If the drive is empty, the following status will be displayed:

Drive empty

12345-78 SEQ

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 30 of 79

Page 31

Operation and Maintenance

Powering on the System

If the autoloader detects that a cartridge is loaded when it first comes alive, the following status will be

displayed on the operator panel:

Drive loaded

12345-78 SEQ

In this example, there is no cartridge in slot 6. Inventory status will be displayed as an 8-character

string, with 4 blank spaces on each side.

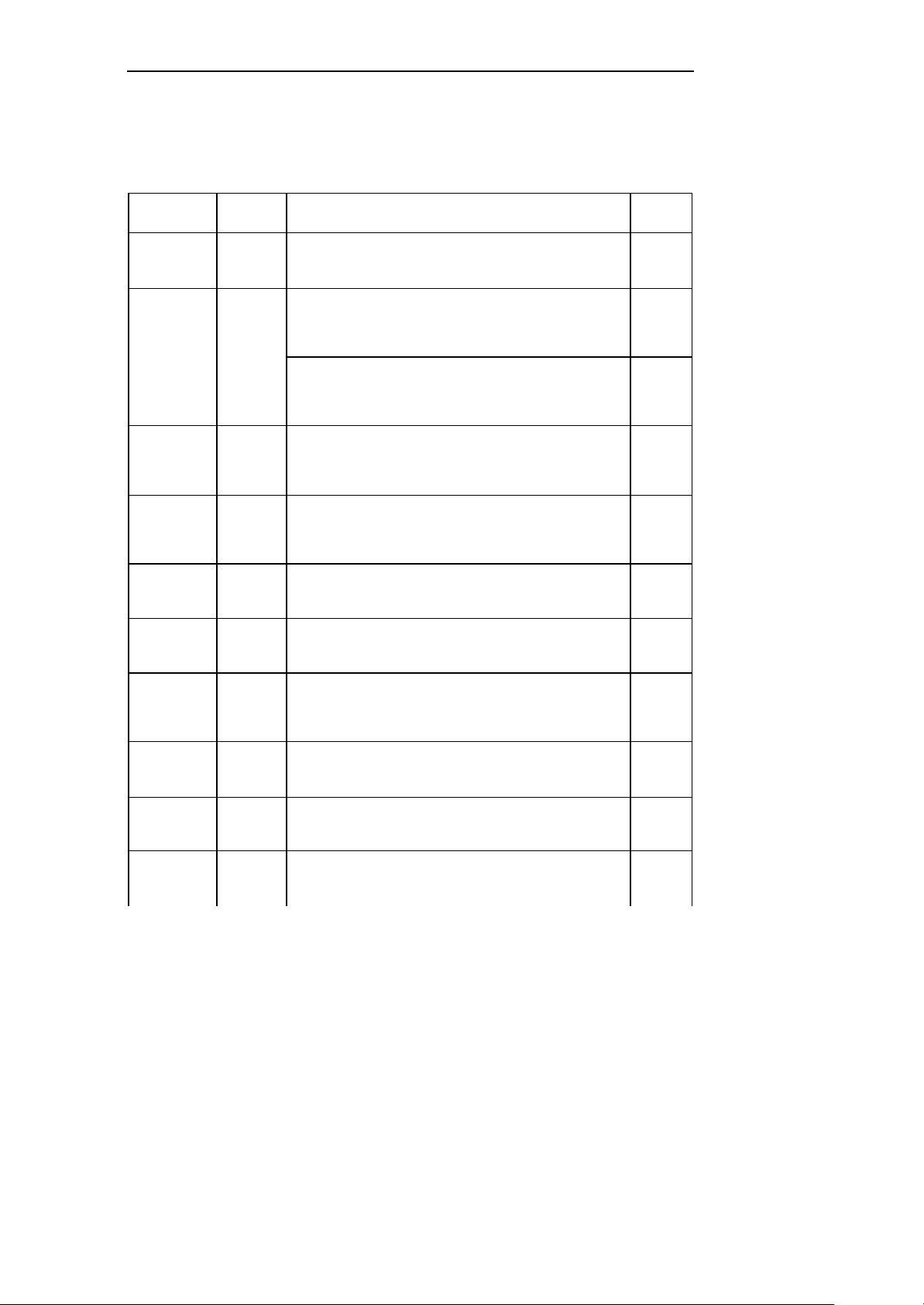

Inventory status characters

Current Drive Status/Activity Drive loaded

Inventory Status

The inventory status characters will be represented as follows:

Character Meaning

1 … 8 Slot Full – uses the slot numbers 1 to 8

– Slot Empty – a dash is displayed as place holder

1/(0xff) A cartridge that is being loaded, unloaded, imported, exported, or is loaded

in the drive, will be represented by the slot number alternating with the block

(0xff) character. The alternating rate should be approximately 1-second per

cycle, 50% duty cycle.

12!45-78 SEQ

! A cartridge that has been identified as faulty (and Media Attention LED is on)

Table 5 Inventory Status characters

will be repre sented by an exclamation point. An invalid cartridge will be

identified the same way.

LEDs

Figure 18 LEDs

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 31 of 79

Page 32

Operation and Maintenance

Using the Operator Panel and Menu Options

The 4 LEDs (1 -4) are updated during power up and reset sequences. Upon power up or software

reset, the autoloader will illuminate all LEDs as soon as power on self-test (POST) allows. This will

help the user to verify if all LEDs are functional.

When mechanical initialization starts, all LEDs will be extinguished and the READY/ACTIVITY LED (1)

will flash at a reasonable rate of approximately 1-second per cycle, 50% duty cycle.

When the mechanical initialization is complete, the READY/ACTIVITY LED (1) will stop flashing and

be constantly illuminated.

If an autoloader failure occurs, the READY/ACTIVITY LED (1) will be turned off and the error LED (4)

will be illuminated. The operation panel will also display an appropriate error code to help identify the

failure.

8.3 Using the Operator Panel and Menu Options

Figure 19 Operator panel

( 1 ) READY/ACTIVITY, Green LED

It is lit any time the unit is powered on and able to function. It should blink whenever there is

autoloader or drive activity.

( 2 ) CLEAN DRIVE, Amber LED

It will be lit when the drive is to be cleaned. The LED will be turned off after the drive is cleaned

successfully.

( 3 ) MEDIA ATTENTION, Amber LED

It will be lit when there has been a failure that indicates that there is a piece of media that is bad,

marginal or invalid. It will be cleared when all invalid cartridges have been exported from the

autoloader.

( 4 ) ERROR, Red LED

It should be lit when there is an unrecoverable autoloader or drive failure. A message is

displayed at the same time on the screen. It will be cleared when the error state is resolved.

( 5 ) CD display, consisting of two lines with 16 characters per line

The screen displays actions and status information, menu items or error messages equivalent to

the operation mode.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 32 of 79

Page 33

Operation and Maintenance

Operational Modes

( 6 ) ENTER, button [↵]

It is used in interaction mode. Push the enter button to go to a sub menu or to force a robotic

action.

( 7 ) NEXT, button [+]

It is used in interaction mode to navigate through menu items.

( 8 ) PREVIOUS, button [–]

It is used in interaction mode to navigate through menu items.

( 9 ) CANCEL, button [X]

It is used in interaction mode. Push the CANCEL button to cancel a user action and return to the

last menu item.

8.4 Operational Modes

The operational modes affect how the autoloader loads cartridges into the drive. The different modes

can be selected at the configuration menu in the OCP. They are stored persistent in the NVRAM and

are valid also after Power ON.

There are 2 basic modes that the OCP operates in. First is the User Interaction mode. This mode is

employed when a user is pushing buttons on the OCP (Operator Control Panel). The second mode is

the System Driven mode. This is the normal mode of operation. In this mode, the OCP displays status

associated with the actions that were caused from commands issued via the Drive’s serial interface.

Actions like loading, rewinding or moving tape will be displayed. When an OCP button is pressed and

released, the OCP automatically transitions to User Interaction mode. User Interaction mode will

continue until 3 minutes after a user stops pushing buttons, or the requested robotic action stops;

whichever is longer. At this time the OCP will return to System Driven mode.

If necessary, the OCP will automatically transition to the System Driven mode. When this occurs, the

LTO3 Autoloader must remember what the User was doing before the display mode changed.

Therefore the next button pressed will only transition the OCP to the User Interaction mode from the

System Driven mode.

In case of activated User security feature the User Interaction Mode is restricted to the Information and

Login menu item, until a login with correct PIN is done.

For User Interaction mode display information and rules see ThinStor®Plus LTO3 Autoloader –

Operator's Manual.

8.4.1 Automatic Mode

Automatic Mode is the default setting and allows the autoloader to switch between Random and

Sequential Mode depending on the SCSI command received. In this mode Sequential Mode is

activated after Power On.

Every MOVE MEDIUM, READ ELEMENT STATUS or INITIALIZE ELEMENT STATUS command

disables Sequential Mode and activates Random Mode. The unit will switch back to Sequential Mode

with every OCP initiated Load Command.

8.4.2 Random Mode

In Random Mode the Media Exchanger SCSI target is visible on the SCSI bus, i.e. the autoloader

allows the host application software to select any cartridge in any order. Cartridges can be moved by

MOVE MEDIUM commands in random order. Unload commands to the drive should not be executed.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 33 of 79

Page 34

Operation and Maintenance

Operational Modes

8.4.3 Sequential Mode

In Sequential Mode the Media Exchanger is no longer visible on t he SCSI bus. Cartridge

replacements are initiated by an ‘Unload’ command sent to the drive.

Sequential Mode presumes that the first cartridge was previously loaded to the drive, i.e. the operator

determines the first cartridge to load by loading the desired cartridge into the drive using the ‘Load

Cartridge’ menu item on the OCP. When the first tape is unloaded with a drive ‘Unload’ command, the

autoloader removes the cartridge from the drive and puts it in its original slot. After that, the next

cartridge in order will be moved into the drive. This queue stops if the last cartridge has been ejected

und unloaded to the slot.

NOTE: If Sequential Mode is activated (menu item CONFIGURATION/CHANGE LDR

MODE/TO:SEQUENTIAL), the media exchanger is not logically connected the SCSI bus

and does not respond to SCSI commands. Every SCSI command (except INQUIRY and

REQUEST SENSE) sent to the media exchanger is rejected with a Check Condition (sense

key 02/04/8E). For further details please see the Media Exchanger SCSI Command

Specification.

In Sequential Mode the display shows the following screen where the string ‘SEQ’ indicates that

Sequential Mode is activated:

Drive empty

12345-78 SEQ

To further determine how you want cartridges loaded into the drive while in Sequential Mode, you can

set Loop Mode and Autoload Mode from the OCP.

8.4.4 Loop Mode

Loop Mode is a special type of Sequential Mode. The cartridges exchange queue will not terminate

with the last cartridge but restart with the first cartridge. This mode allows endless backup operation

without user interaction.

8.4.5 Autoload Mode

This is also an option of Sequential Mode and could be combined with Loop Mode. The first cartridge

will be loaded automatically if the unit powers up with an empty drive. In this case user interaction via

OCP is not required.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 34 of 79

Page 35

Operation and Maintenance

Operational Modes

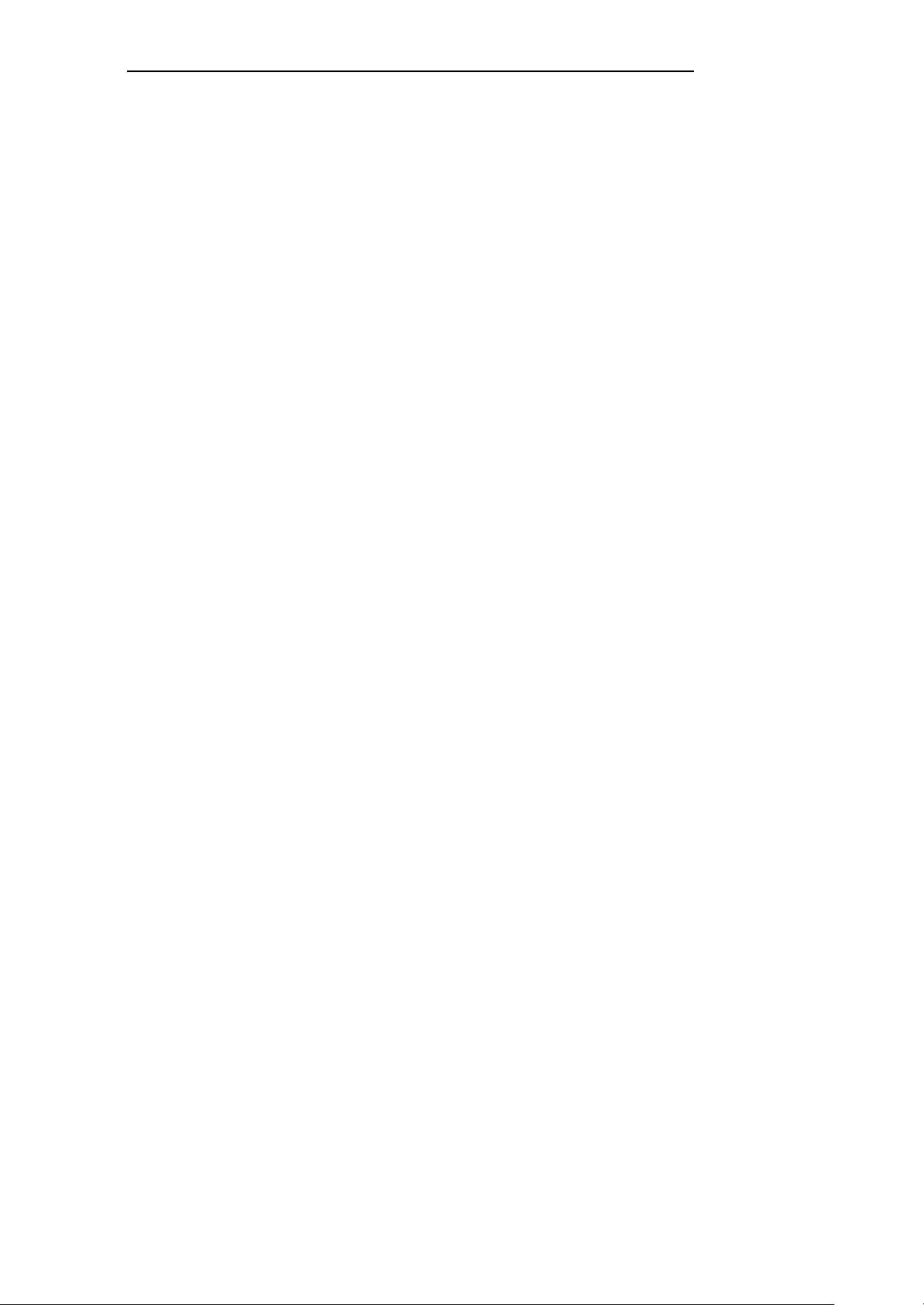

8.4.6 Menu Structure and Options OCP User Interaction Mode

ANY

KEY

INFORMATION

(INV. STATUS)

CANCEL

ENTER

LOADER INFO.

(INV. STATUS)

DRIVE INFO.

(INV. STATUS)

(-)

(+)

(-)

(-)

(-)

(+)

CANCEL

IMPORT

(INV. STATUS)

EXPORT

(INV. STATUS)

LOAD

CARTRIDGE

(INV. STATUS)

UNLOAD

CARTRIDGE

(INV. STATUS)

CLEAN DRIVE

(INV. STATUS)

RE-INVENTORY

(INV. STATUS)

COMMANDS

(INV. STATUS)

ENTER

BULK EXCHANGE

(INV. STATUS)

(+)

NOTES:

1. CANCEL, from any LCD display in

row, will return to Curent Status, Home

Screen.

2. CANCEL, from all lower LCD displays,will

return to the Respective LCD display, detailed

in the top ROW.

3. ENTER, from all lower LCD displays

will invoke operation depicted on LCD.

Figure 20 Interaction Mode, overview

(+)

(-)

CONFIGURATION

(INV. STATUS)

CANCEL

ENTER

(-)

RESET

(INV. STATUS)

(-)

(+)

CHANGE SCSI ID

(Inv. Status)

(-)

(+)

HI SPEED SCSI

MAX SPEED

(-)

(+)

DRIVE FW

UPGRADE

FROM FMR TAPE

(-)

(+)

CHANGE LDR

MODE

AUTOMATIC

(-)

(+)

LOOP MODE

OFF

(-)

(+)

AUTOLOAD MODE

OFF

NET PARAMETER

(INV. STATUS)

BARCODE

READER

OFF

PROTECTION

MODE

OFF

SERIAL NUMBER

0123456789

(+)

(+)

(+)

(+)

(-)

(+)

(+)

(-)

(-)

(+)

(+)

(+)

(+)

(+)

(-)

(-)

(-)

(-)

(+)

(-)

(-)

(-)

(-)

DIAGNOSTIC

(INV. STATUS)

CANCEL

ENTER

LOADER DIAG.

(INV. STATUS)

DRIVE DIAG.

(INV. STATUS)

(+)

(-)

(INV. STATUS)

GO ONLINE

ARE YOU SURE ?

(-)

(+)

GO ONLINE

CANCEL

ENTER

ENTER

Drive Empty

(INV. STATUS)

See Note 2 & 3

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 35 of 79

Page 36

Operation and Maintenance

Configuration

8.5 Configuration

For most installations, the default configuration of the autoloader does not need to be changed. For

further information see ThinStor®Plus LTO3 Autoloader – Operator's Manual. However, if necessary,

you can use the operator panel to make the following changes to the autoloader configuration:

You can change the SCSI IDs for the autoloader and the tape drive using the 'Configuration'.

IMPORTANT

!

!

The autoloader and the tape drive must each have unique SCSI IDs. It is your

responsibility to make sure you do not assign duplicate IDs within a bus.

8.6 Operation

After you install and configure the autoloader and install your application software on the host

computer, the autoloader performs most operations automatically. Operator intervention includes the

following activities:

n Monitoring autoloader operation and status

n Performing autoloader and tape drive operations

8.6.1 Monitoring Autoloader Operation and Status

During normal operation, the 'Status screen' is displayed on the LCD. You can use this screen to

monitor autoloader activities. By default, the 'Status screen displays the current operating status of the

autoloader and tape drive.'

To set the operator panel to user interaction mode, press a key. This mode allows you to use the

[Enter] or [Cancel] and [+] or [–] buttons to display options for issuing commands to the autoloader,

viewing information screens, and configuring the autoloader.

8.7 Performing Autoloader and Tape Drive

The 'Commands' screen provides options for importing and exporting cartridges, loading and

unloading a cartridge from the tape drive, cleaning the tape drive, and updating the cartridge

inventory.

8.7.1 Importing and Exporting Cartridges

The Import command under the Library Commands menu allows you to place a cartridge into a

specific cartridge slot through the cartridge access port.

When you issue an Import command, the cartridge carousel moves the specified cartridge slot into

position in front of the cartridge access port and slides the door open. You can then push the cartridge

into the slot through the door. The cartridge loader then grasps the cartridge, pulls it into the

autoloader, and closes the door.

The 'Export' command allows you to remove a cartridge from a specific cartridge slot through the

cartridge access port. When you issue an 'Export' command, the cartridge carousel moves the

specified cartridge slot into position in front of the cartridge access port and slides the door open. The

cartridge loader then pushes the cartridge far enough out through the door to allow you to remove it.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 36 of 79

Page 37

Operation and Maintenance

Performing Autoloader and Tape Drive

8.7.2 Bulk Exchange

The menu item Bulk Exchange was designed to make the autoloader more user friendly. This item

enables a user to import or export a specific amount of cartridges e.g. this item makes sense if a user

wants to exchange a complete set of cartridges. Bulk Exchange operation starts with slot #1. If a

cartridge is available this cartridge will be exported. It’s up to the user to import a new cartridge or to

move to the next slot #2. The same procedure then takes place for slot #2 to slot #8.

8.7.3 Load and unload a Cartridge

The load cartridge command under the 'Commands' menu allows you to load the cartridge in the

specified slot into the tape drive. When you issue a 'Load cartridge' command, the cartridge carousel

moves the specified cartridge slot into position in front of the tape drive. The cartridge loader then

extracts the cartridge from the cartridge slot and inserts it into the tape drive.

The 'Unload cartridge' command causes the tape drive to unload the tape from the tape path and eject

the cartridge. After the cartridge is ejected, the cartridge carousel moves the slot from which the

cartridge originated into position in front of the tape drive. The cartridge loader then extracts the

cartridge from the tape drive and returns it to the cartridge slot.

8.7.4 Write Protected Media

If the drive detects a write protected media, an internal bit is set and the autoloader posts the “WP”

string on the display indicating a write protected media is loaded in the drive.

The display shows the following status:

Drive loaded

12345-78 WP

As soon as the write protected media is ejected, the drive resets the internal bit and the “WP” string on

the display is cancelled.

8.7.5 Cleaning the Tape Drive

The tape drive contains an automatic cleaning mechanism that allows it to clean itself as necessary. In

addition, the tape drive requires regular cleaning with a LTO tape cleaning cartridge to maintain

optimal performance.

To clean the tape drive, use LTO tape cleaning cartridges only.

CAUTION

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 37 of 79

Wrong cleaning cartridge!

Damages of the tape drive and loosing warranty.

Use only LTO tape cleaning cartridges. Using other types of cleaning

cartridges will void your warranty.

Carefully follow all instructions and recommendations provided with the

cleaning cartridge.

Page 38

Operation and Maintenance

Performing Autoloader and Tape Drive

NOTE: The tape drive can also report its cleaning requirements to the application software. Your

application may notify you when the tape drive needs cleaning. See your application

documentation for more information.

To clean the tape drive, select the 'Clean drive' option from 'Commands' menu on the operator panel.

When you use this option, the autoloader imports a cleaning cartridge through the cartridge access

port and inserts it into the tape drive.

When the cleaning is complete, the tape drive ejects the cleaning cartridge and the autoloader returns

it to the cartridge a ccess port for removal.

Alternatively, you can store a cleaning cartridge in one of the cartridge slots. You use the 'Load' option

from the 'Commands' menu to move the slot containing the cleaning cartridge into position and load

the cartridge into the tape drive. When the cleaning is complete, the tape drive ejects the cleaning

cartridge and the autoloader returns it to the slot from which it originated. Although this alternative

allows you to always have the cleaning cartridge in the autoloader, it has following disadvantages:

n You have to remember which slot your cleaning cartridge is in.

n The autoloader's data-storage capacity is reduced by one cartridge.

n Some software applications may not support reserving a slot for a cleaning cartridge.

Your backup software might offer additional possibilities for cleaning the tape drive. For details please

see the relevant section of the corresponding documentation.

Updating the Cartridge Inventory

After you import or export a data cartridge, you can update the cartridge inventory using the 'Re inventory' option under the 'Commands' menu. The autoloader checks for the presence of a cartridge

in each cartridge slot.

Resetting the Autoloader

A reset causes the autoloader to perform its power-on self-test (POST) and check for the presence of

the data cartridges. The autoloader can be reset in any of the following ways:

n Power-on reset. Powering the autoloader off (or unplugging it), then back on again resets the

autoloader and the tape drive.

n Bus device reset message. Issuing a bus device reset message from the SCSI application

program can reset either the autoloader or the tape drive.

n SCSI bus reset. A RST (reset) pulse occurring on the SCSI bus for a minimum of 25 µs causes

the autoloader and tape drive to be reset. A SCSI bus reset immediately clears all devices on the

bus, resets their associated equipment, and terminates all pending I/O processes.

Resetting the tape drive does not cause a cartridge loaded in the drive to be ejected. If a cartridge is in

the tape drive during a reset, make sure that it is safe to overwrite the loaded cartridge before

performing a backup. If you perform a backup without checking the loaded cartridge, you may lose

important data from a previous backup.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 38 of 79

Page 39

Operation and Maintenance

Shipping

Performing Routine Maintenance and Service

The autoloader requires no routine maintenance. If necessary, you can use touch-up paint on the

housing. Touch-up paint is available for covering nicks and scratches on the f inish. Contact your

vendor to order touch-up paint. All other parts can be serviced only by the manufacturer, an approved

maintenance organization, or by self-maintenance contract customers.

CAUTION

IMPORTANT

!

!

Cleaning solvents or lubricants!

Malfunction of mechanical assemblies.

Do not clean or lubricate any of the autoloaders mechanical assemblies.

All parts have to be serviced only by the manufacturer, an approved

maintenance organization, or by self-maintenance contract customers.

The autoloaders warranty does not apply to failures of the autoloader when it is

repaired by untrained or unauthorized service personnel.

8.8 Shipping

If you need to ship the autoloader, use the original shipping carton and packing materials (or

replacement packaging obtained from the vendor) to prevent damage. The shipping carton and

packing materials are not intended to be used for shipping items other than or in addition to the

autoloader.

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 39 of 79

Page 40

Troubleshooting and Diagnostics

General Guidelines

9 Troubleshooting and Diagnostics

9.1 General Guidelines

The autoloader includes features to support troubleshooting and diagnostic operations.

If an autoloader error occurs, the red error LED is on, an error message and error code are displayed

on the Status Screen.

Additionally, the autoloaders internal 'TapeAlert' firmware constantly monitors the autoloaders

operation for problems. 'TapeAlert' is an industry-standardized method for reporting errors and

potential difficulties to the software application.

To check if the autoloader is operational the system offers a system test. It is accessible via the item

“Diagnostic” in the system menu. See ThinStor®Plus LTO3 Autoloader – Operator's Manual.

Preconditions:

n tape drive empty

n at least one slot contains a cartridge

n no drive may contain a cleaning cartridge

Mode of operation:

Depending on the firmware revision either you are asked to select the number of cycles or only an

endless test is offered. During the test in an arbitrary sequence cartridges are moved, mounted and

dismounted. Thus most of the autoloader’s functions are tested. The test can be stopped anytime by

pressing the “Cancel” button.

9.2 Reacting on Lightening Error LED/Error Code

1. If the red error LED is on and an error message and error code are displayed on the Status

Screen note the code or information.

2. Press Enter to attempt recover and initialization. Cycling power may also be necessary.

3. If possible, running the Library Verify test in the Diagnostic Menu (see ThinStor®Plus LTO3

Autoloader – Operator's Manual).

NOTE: If the Media Attention LED turns on red, this is an indication that a drive error occurred

AUTOLOADER LTO3 – User Reference Manual Rev. 1.01 TANDBERG DATA

Page 40 of 79

pointing to the me dia as the possible problem. For instance, if during the Library Verify