JANDBERG

Serles

6OOOX

SER\/IGE

MANUAL

TANDBERGS

:'.:'-"-!,..,r/

g

/r

l

i.- I

:t(.;iJ,i

l.

l

i

,

3(r

RADIOFABRIKK

A/S

-\

CONTENTS

7.0

Mechanical

1.0

1.1

1.2 Brakes

I

I

I

tt

I

t'>,

1.3 Pressure Pad Adjustment

1.4

2.0

Alignment

2.1 Demagnetizing

2.2 Bias-

Tape Path

3.0

3.1 Visual

3.2 Mechanical Adjustment of Tape

Head Alignment

4.0

Model

4.1 Playback Head

4.2

4.3 Bias Head

4.4 Erase Head

4.5 Model6021X

Head Alignment

5.0

Model

5.1

5.2

5.3 Bias Head

5.4 Erase Head

5.5 Model

6.0 Track

6.1 Model

6.2

Adjustments

Clutches

1.1.1 Take-up T\rrntable

1.1.2

Supply

End

Stop

1.4.1 Tape Feeler Tension

1.4.2 Adjustment

and

2.2.1 Oscillator Frequency

2.2.2

Erase

2.2.3 Bias

6041X

Height

4.1.1

Azimuth

4.1.2

Record

4.2.1 Height Adjustment by

4.2.2

4.3.1 Vertical Adjustment

Height Adjustment

4.3.2

4.3.3

4.4.1 Height Adjustment

4.4.2

6041X

Playback

5.1.1 Height Alignment

5.1.2 Azimuth Alignment

Record

5.4.1 Height Adjustment

5.4.2 Azimuth Adjustment

Control

6.1.1 Record Head

6.1.2

6.1.3 Playback Head

Model

6.2.1 Erase Head

6.2.2

6.2.3 Playback tlead

T\rrntable

Mechanism

of Tape Feeler

Erase Circuits

Voltage

Current

Check

Tandberg Test Tapes

with

Adjustment

Adjustment

Head

Visual Inspection

Height

Adjustment

Measurement

Track

Horizontal Adjustment

Azimuth Adjustment

Without

Head

Head

6021X

6041X

Erase Head

6021X

Record

Head

by

Tandberg Test Tapes,

Path

Adjustment

7.1.1 Playback Level

7.1.2

7.1.3

7.1.4

7.1.5

7.1.6 Distortion

7.1.7

7.1.8

7.2

Tape Speed

7.2.1

7.2.2

8.0

9.0 Modifications

10.0 Lubrication

11.0 Illustrations

12.0

13.0 Transistor

14.0 Block

15.0

7.2.3

Adjustment

Tandberg

8.1 Playback

Record/Playback Curves

8.2

8.3

Readjustment

Indicators

8.4 Distortion

8.5

Control

8.5.1 Playback Amplifier

8.5.2

8.6 Pick-up

8.7 Limiter

8.7.1

8.7.2

9.1 Modification

to 230/115V

Modification

9.2

to Two-Track

9.3 Important

Introduced

Spare Parts

Tape

12.1

12.2

12.3

Printed Wiring Boards and

and Control of the Amplifiers

Adjustment

Record Level

Record/Playback Curves

Indicator Adjustment

Indicator Adjustment

and Amplifier Modes

Control of the Playback

Using Frequency Meter

Using Transformer

Voltmeter

Using Tape of Known

of the Amplifiers, without

Test Tapes

and Record Level

of Playback and Record Amplifiers

Record Amplifier

Amplifier

Adjustment of Limiting Threshold

Adjustment of Release Time

with

List for Tandberg

Recorder 6000X

Mechanical Parts

Screws,

Electrical Components

12.3.1 Transistors

12.3.2 Diodes

12.3.3 Rectifier

1

12.3.5 Poientiometers

12.3.6 Heads

12.3.7 Transfonners

Washers, Nuts and Circlips

2.3.4

Trimming

and Diode

Diagram

Adjustment

of Bias Current

Adjustment

in Record Mode

in Playback

Control 10

Record Levels

of

Curve

230/115V

from

Hz

60

operation

from Four-Track

Venion

Electrical Modifications

in

Series 6000X

Reference

Capacitor

Identification

6000X

Series

Amplifier I

or Counter 10

and Vacuum

Length

Adjustment

and

50 Hz

Part

Numbers

lViring Diagram

Ttrbe

9

I

9

9

I

9

I

9

10

10

10

10

10

10

10

11

11

11

11

12

72

12

t2

13

13

13

I4

1.7

77

2L

21

2L

22

22

9'

,t

22

22

23

23

24

^

1.0

MECHANICAL ADJUSTMENT

1.1

Clutches

1.1.1

Take-up Turntable

Normal

Set

the operating

with

the motor running.

between the

table

and friction disc

(0.02"-0.035").

fig.

1.1.

Forward

polyurethane

drive

lever

to

991009 lays between

If necessary, adjust

normal forward

Ensure that

friction

drive

pads

the clearance

under

screw A as

position

the turn-

0,5-0,9

shown in

mm

0,5-0.9

mm

{0.02"-0.35")

1

991 034

L

-

I

Control

Note:

The

presents

of Winding

All

controls

with the tape recorder

tion

control is

with

and

accomplished

two

optional modes

Torque

and measurements

empty

30 mm

reels

as

of

radius

placed

only.

shown

control.

must be carried out

in

horizontal

in

fig.

Force:

4O-80g

posi-

1.2, which

991017

Fig.1.1

il

-

991013

80

.rl

mm radius

Force:

15-30g

.arl

4

While measuring,

rotation. The instrument should

slow

movement in a straight

der.

Fig. 1.2 Control of winding force.

Fast Forward

Control of Fast Winding

Set

the operating lever

The control is

presents

Winding

two optional

the reel should be allowed

line

Torque

fast

to

accomplished as

modes of control,

forward

shown

follow the

tape

towards

Normal forward

the

winding

in fig.

1.3, which

to have a

recor-

drive

position.

Notc:

mode.

After a

operation,

20-30V"

longer

an increase

considered

is

period

normal.

as

of

of

the

continuous

torque by

+i

I

mm radius

\

30

80 mm radius

^

Force:

90-2509

\

\F

't\

Fig. 1.3 Control of

If the torque deviates

figure, check and, if

2673738.

spring

fast winding

necessary, alter the

torque. Fast forward winding mode

from

the specifications in the

pressure

of

Ensure that there is a clearance between the studs on

friction disc 991010

and

lever

991013.

See fig. 1.4.

min 0,1

(0.091")

mm

1.1.2 Supply Turntable

Tape

Control

of

Set the operating

The

control

presents

is accomplished

optional modes

two

Tightening

lever to normal

Tension

forward drive

as shown

of

control.

30 mm radius

in

fig.

position.

which

1.5,

991017

Fig. 1.4

991013

991OlO

261805

80 mm radius

Force:

O-99o

the

While measuring,

movement in a

straight

reel should

the

line towards

be

allowed

the tape recorder.

to

have a slow

rotation. The

instrument should

follow

F

Fig. 1.5 Control of tape

tightening tension.

Normal forward drive mode.

Fast

Reverse

Control

Set

the

The

control

presents

Winding

of Fast

operating

is

accomplished

two

optional

Force:

240-67

Reverse

lever

modes

0g

Winding

to fast

as

of

30

Torque

reverse

shown in

control.

mm radius

winding position.

fig.

1.6,

which

Force:

90-250g

80 mm

J

radius

1F{

Fig.

1.6 control

If the

figure,

spring 261805.

The

reverse

measured

1a--dius!

(fig.

1.2

See

Set the

Check

tumtable

screw

Set the

reverse

between

parts

(0.02"-0.04").

The

torque

check

difference

Winding

at

30 mm

If

necessary,

1.7),

or spring

Brakes

fig.

1.8.

operating

that the

is

approx.

D.

operating

winding

screw

on

operating

adjustment prosedure

of fast

reverse

deviates

and, if

See fig.

between

Torque

clearance

respectively.

C

If

necessary,

1.7.

should

radius),

alter

2673738

lever

to

1 mm

lever

to fast

and the

arm

991012

necessary,

winding

from

the specifications

Fast

Winding

be lesi

g (measured

or 50

p.esiu.e

the

(fig.

1.1).

normal

between

is

(0.04").

forward

Ensure

bottom

lays

adjust

equal for

forward

the

of

screw

torque.

alter the

Torque

than

of

brake

If

necesiary,

that

the

between

both turntables.

pressure

180 g (force

spring

drive

pad^

winding

the

hinged

0,b-1

C.

Fast

at

position.

clearance

reverse

in

the

and Fast

g0

mm

261g0b

and

the

adjust

or fast

delrin

mm

of

winding

Set

the operating

pressure

The

g (2.8

80

pressure

adjust

pair

of

Fig.

1.7

mode

pad

pressure

the

pliers.

of the

oz) !

arm

See fig.

lever

pad

tO 7o,

254025.

by

bending

1.12.

to

normal forward

against

the

measured

See fig.

the

tape rest

on

the

1.11.

spring

position.

drive

slould

end

If

necessary,

268062

be

of the

with-a

.)fl

1.3

Pressure

Set the

between

254844

fig.

1-.!. If

arm

254025

Pad

operating

pressure

the

should

be approx.

necessary,

with

Adjustment

lever

to neutral position.

pad

990325

6,5 mm

adju,st

of

the

pliers.

a

pair

and

(1/4")

clearance

See fig.

The

clearance

the

tape rest

as

shown in

by bending

1.10.

the

Fig.

1.8

991Ol7

(0.02"-0.04")

i)c

Mechanisrn

StoP

End

1.4

A

251489

-

(1/4").

mm

6,5

1.9

Fig.

;

I

TaPe

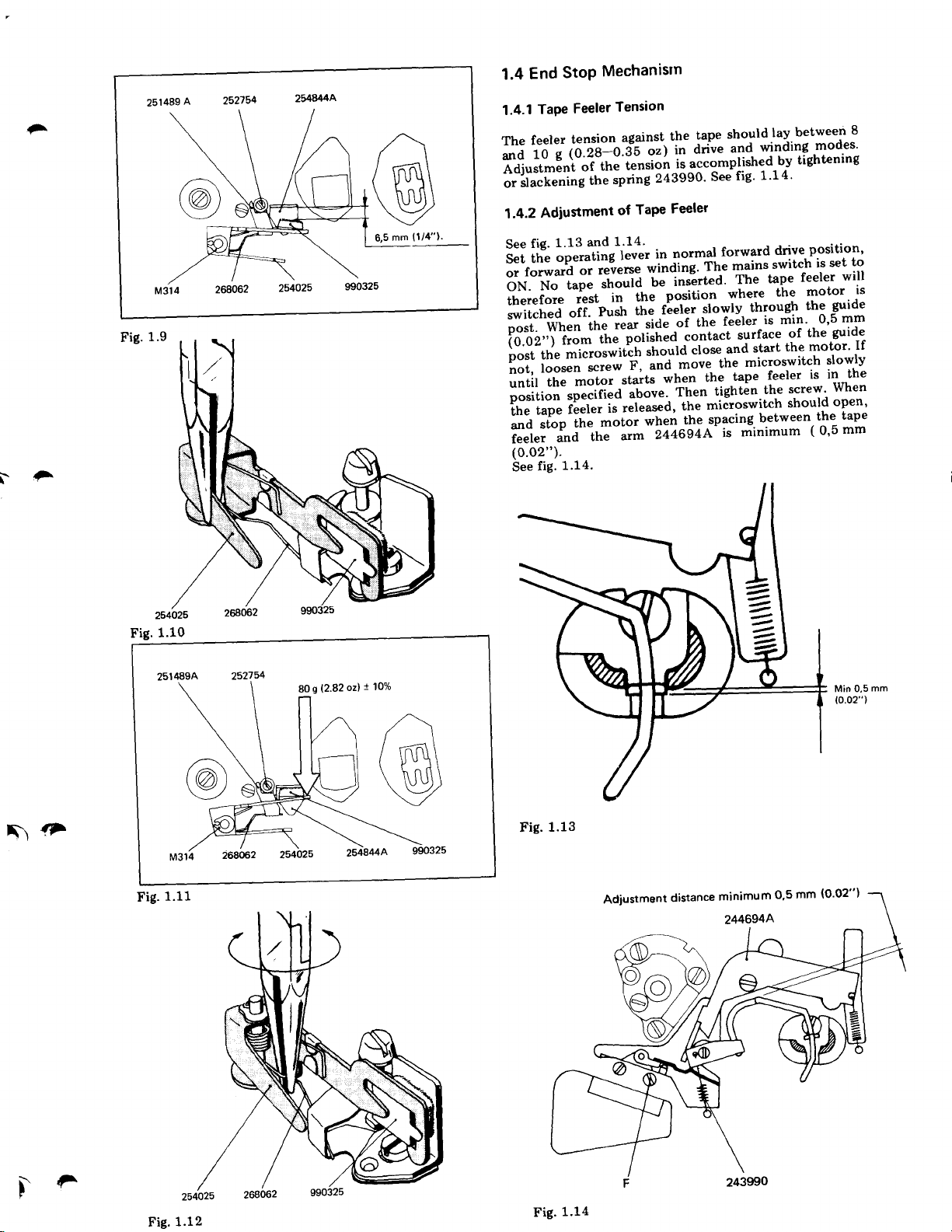

1.4.1

feeler

The

i;';

;;

Adiustment

;'"i;t;;;iline.p'l"g

Adlustment

1.4.2

1.13

fig.

See

S.;

or

bN."ff;di

ir,i;"i';"

ffi;;

oost.

id;t";'ii"*

i"".","1t*'-"";#qt.l""F*iml*n3iiil".n';"i

operating

il:

forward

"T;-i;

When

loosen

not,

the

until

",i.iirJii""i""iri"a

fi;;';;;;

and

feeler

(0.02").

See

stop

fig.

ii"r"t

and

1.14.

Tension

Feeler

the

of

and

reverse

or

.r'"ura

p.ro

the

ttt"

screw

against

of

1.14'

lever

rear

startJ-

tension

to.ie-o.fs

oii.

motor

it

motor

the

arm

the

tape

the

a'ii"

in

o')

tensioit

porislea-"ontact

released,

ii accomptishgd-u.v

243eeo'

Feeler

TaPe

normal

in

winding'

;;-;;e;hd'

*,J-poiiti"rr

tt'"

tla"

r'.i

"u"u"'

when

244694A-

t!"tet

"f

when

irten

the

the

the

Th-e

slowlv-

the

microswitch

see

forward

tighten

spacing.

shouldlay.between

winding

and.

1'14'

fig'

mains.switch

tape

rhe

Yh:T"--ll3

through

feeler-is

surface

feeler

tape

the

-

between

minimum

is

tightening

drive

reeler

min'

of

screw'

should

modes'

position'

set

is

motor

guide

the

0'5

guide

the

is in

When

open'

the

(

0'5

8

to

will

is

mm

the

tape

mm

F\

1.10

Fig.

1

80

g

(2.82

oz)

t0%

Min 0,5

{0.02")

mm

@

1.13

!f

1.11

Fig.

Fig.

DF

Fig.

1.12

Fig.

1.14

2.0

ALIGNMENT

-

It is-important

heads

on.the

results

on

tape recorder

the tape

ponse

2.1

Demagnetize

the

2.2

2.2.1

Connect

kHz),

oscillator

erase

by mens

2.2.2

Set the

VTVM

low-capacitance

Then

headhalf.

Set

check

The

recording

recording

2.2.3

Set

the

of a VTVM.

R407.

adjust

tape

new

polished

and the

Demagnetizing

heads.

Bias-

Oscillator

head. Adjust

Era* Voltage

check that

the

deviation from

Btas Current

the

voltage

path.

the

and

calibrated

a

frequency

by

means

of C404.

tape recorder

to

upper

tape recorder

the voltage

should

on

channel R.

recorder

tape

across

Adjust

Check

to 22Y

by

the

that

tape

tapes,

approx.

signal-to-noise

Erase

Frequency

probe.

the

contact

recorder

the

tape should

5 times

before

heads

measuring

and

Circuits

long

meter

half of

the same voltage

across

not exceed

upper

means

wave receiver

or frequency

pick-up

of

a

the

oscillator frequency

for

stereo recording

the

The

for recording

upper half

the voltage

for

stereo recording

half of the

the

voltage

voltage

of R410. Demagnetize

between

good.

is

ratio.

adjacent

voltage

across lower

To

be run

at normal

the

parts

placed

loop

erase head

should

appears

on channel

of the erase

measured

10V.

Proceed

bias head

to 22Y

the

tape

obtain

optimum

through

speed

friquency

before

(tuned

counter

to

around

to 8b.b kHz

and connect

by

means

be 80-120V.

across lower

in

similarly

and measure

by means

means of

by

head-half

heads

and

the

the

to

have

res-

aligning

256.5

the

to

the

of a

L

and

head.

stereo

for

and

and

IHMD

Fig.

3.1 Tape

3.2

Mechanical

Prior

essential

ment

Set the operating

screw holding

position

the

a

the

screw. The

the_ upper

247941.

Put

a tape free

way and

position,

99033.1

tapg

ls

$ightly

located

Align

pressure

perfectly.

path

to the

through

running

guide

electrical

to make the

the

latch 215563

determined

spring

and lower

from

set the operating

Adjust the

with

a screw

touching

adjacent to the

evenly through

post

roller

spring

2, 3,

adjustment

screws

adjustment

adjustment

tape

path.

lever

on-e of the

run

to neutral

to

by

spring

pressure

points

damages

lever

azimuth

driver

as shown in fig.

capstan.

and

4 similarly.

234478

flanges

of tape

without

allow the latch

will

of

on the

to normal forward

position

the

to make

path

of the

sideways

position.

284478.

now

be equal

pressure

recorder

pressure

of

rest of

the tape

of the tape

If necessary,

the

Unscrew

Then tighten

roller

3.2, until

heads,

it

move-

to settle in

against

pivot

in

normal

drive

roller

path,

post

adjust

tape

-<l

is

the

the

1

run

3.0 TAPE

3.1

Visual

Load

the recorder

lever

dowly

that

the

screws (C)

tape

head

Operate

runs

without

Check

cor:ect.

flanges

forward

tape

bias

against

parallel

is

the start/stop

within

flickering

that

It

of

the

drive,

must,

however,

PATH

Check

with

normal

record

button,

of the

on

neither

tolerated

posts

drive

by

no means

a t-ape,

head

head.

when

to

the

head neither

on

the record

the

record

to the

the rims

height positioning

can

be

guide

or

as the

and

forward

touches

base

Also

head.

and check

pressure

side

of

that

the recorder

mechanism

bulge

move

position.

drive

the height

plate,

nor

check

pressure

of the

guide

the

the tape

is

at the

the

operating

adjustment

presses

thit

the

that the

wheel

rubber

wheel.

posts

touches

is in

normal

engaged.

flanges.

Checi

the

bias

tape

the

The

ln

is

rll'\

Fig.

3.2

Azimuth

adjustment

pressure

of

roller

--

(?4;

$'rF

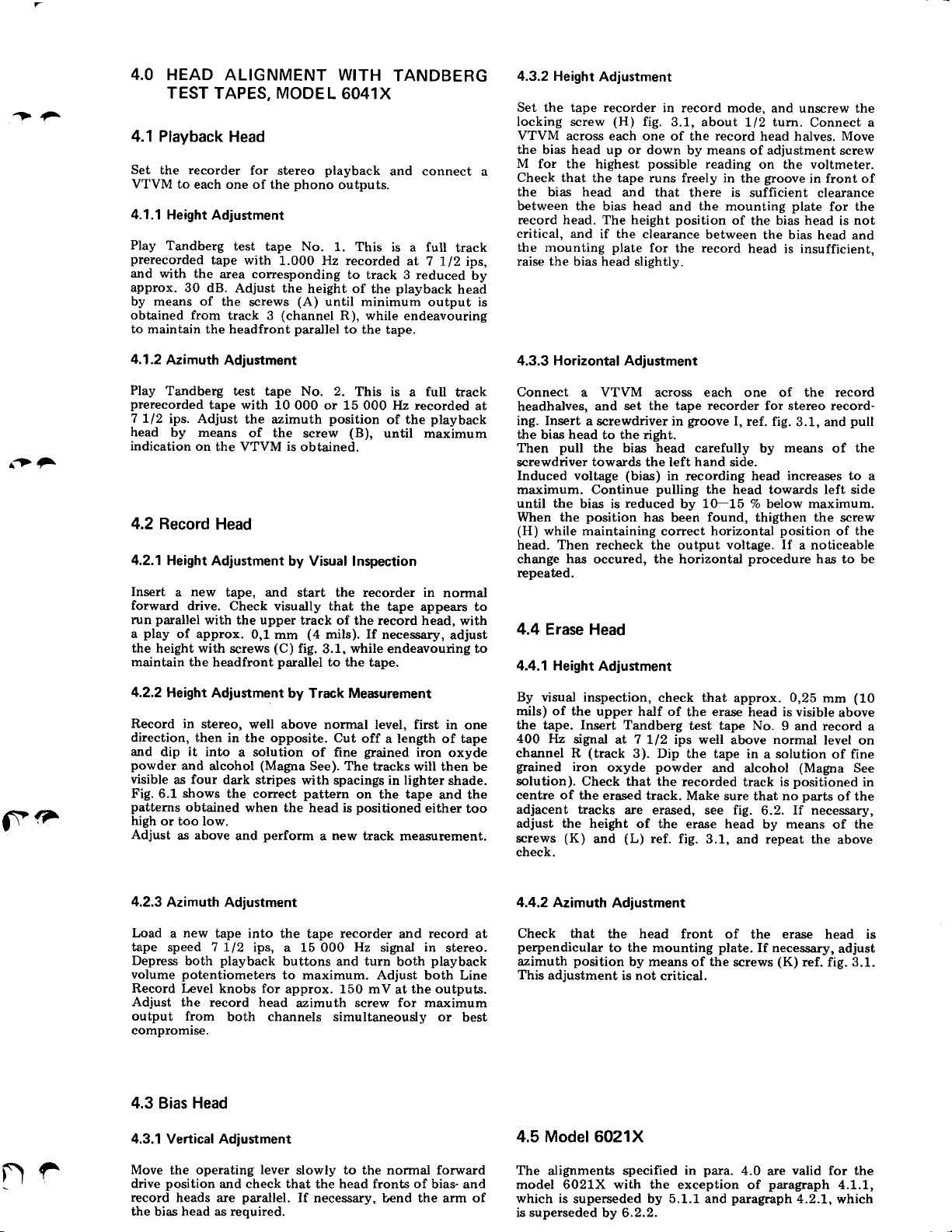

4.0

HEAD ALIGNMENT WITH

TEST TAPES, MODEL

4.1 Playback

Set

the

VTVM to

4.1.1

Height Adiustment

Play

Tandberg

prerecorded

and with the

approx.

by means

obtained from

to

maintain the headfront

4.1.2

Azlmuth

Play

Tandberg

prerecorded

7 tl2

ips. Adjust

head

by means

indication

4.2 Record

4.2.1

Height

Insert a new

forward

parallel

run

play

a

of approx.

the

height with screws

maintain the headfront

4.2.2Heighl

Record

direction, then

and

dip

powder

visible

Fig.6.1

patterns

high

Adjust

and

as

or too low.

as

Head

recorder

each one of the

30 dB.

of

on

drive.

in

stereo,

it

four

shows

obtained

above

for stereo

phono

test tape No.

tape with

area corresponding

the

track 3

Adjustment

tape with 10

the VTVM

Head

Adiustment

tape, and start the recorder in

Check visually that

with the upper

Adiustment

in the opposite. Cut

into

alcohol

dark stripes

the

1.000 Hz recorded

Adjust the

screws

test tape No. 2.

the azimuth

of the

0,1 mm

well above

a solution

(Magna

correct

when the head is

and

height of

(A)

(channel

parallel

000 or 15

screw

is

obtained.

by Visual Inspection

track of the record head,

(4

(C)

fig.

parallel

by Track Meaurement

See). The

with spacings in lighter

pattern

perform

TANDBERG

6041X

playback

outputs.

1. This

to track

the

until minimum

R),

while endeavourlng

to

the tape.

This is a full

000 Hz

position

(B),

the tape appears to

If

mils).

while

3.1,

to the tape.

normal level, first in

off

grained

fine

of

a

tracks will

on the tape

positioned

new track

connect

and

is a full

at

3 reduced

playback

recorded

of the

until

necessary,

endeavouring

a length of tape

iron

measurement.

track

7 ll2

ips,

by

head

output is

track

playback

maximum

normal

with

adjust

one

oxyde

then

shade.

and the

either

too

4.3.2 Height

Set

the

locking screw

VTVM

the

bias

M

a

at

to

be

for the

Check that

the bias head

between the

record head. The height

critical, and

the mounting

raise the

4.3.3 Horizontal Adjustment

Connect

headhalves,

ing. Insert

the

bias head to the right.

Then

screwdriver towards the left hand side.

Induced voltage

maximum. Continue

until the

When the

(H)

while maintaining correct

head.

change

repeated.

4.4

Erase Head

4.4.1 Height

By

visual inspection,

mils) of the

the tape. Insert Tandberg

4OO Hz

channel R

grained

solution).

centre of the

adjacent tracks

adjust the height

screws

check.

Adjustment

tape recorder

(H)

across each one

head

highest

the tape runs freely in

bias head slightly.

a VTVM across each one of the record

and

a screwdriver in

pull

the

bias

position

Then

recheck the output

has

occured, the horizontal

upper half of

signal

(track

iron

Check that

(K)

and

fig.

up or down

possible

and that

head

bias

if the clearance

plate

for

set the tape

bias head carefully

(bias)

pulling

is reduced

has

Adjustment

check that

at 7 Ll2 ips well

3). Dip

oxyde

erased track.

powder

the recorded

are

erased, see fig.

of the

(L)

ref.

in record mode,

3.1, about

record

of the

means

by

reading

there

the

and

position

between

record

the

recorder

groove

in recording head

the head towards left side

10-15 7o

by

found,

been

horizontal

the erase head is visible

test tape No.

the tape in

and

Make sure

erase

fig. 3.1,

and unscrew the

turn.

1/2

head

of adjustment screw

on

groove

the

is

sufficient

mounting

of

bias

the

the

head is insufficient,

for stereo record-

I,

ref. fig.

by

below

thigthen

voltage. If

above

head

position

procedure

approx.

normal

a solution

alcohol

is

track

that

6.2.

by means

and repeat the

Connect a

halves. Move

the

voltmeter.

in front

clearance

plate

for

head is

bias

head and

3.1, and

means

increases to

a noticeable

0,25

9 and record

(Magna

positioned

parts

no

If necessary,

pull

of

maximum.

the

screw

of

has to be

mm

above

level on

fine

of

of

of

above

of

the

not

the

a

the

(10

a

See

in

the

the

D

{^

4.2.3

Azimuth

Load a new

tape speed 7 Ll2

Depress

volume

Record

Adjust

output from

compromise.

4.3

Bias

4.3.1

Vertical Adiustment

Move

the operating

position

drive

record

heads are

the bias head as required.

Adiustment

tape into

ips, a 15 000

playback

both

potentiometers

l,evel knobs for

the record head

both channels simultaneously or

Head

lever

and check that

parallel.

the tape

buttons and turn

to maximum. Adjust

approx. 150 mV

recorder

Hz

signal in

azimuth

slowly to the normal forward

If

screw for

head fronts of

the

necessary,

and

both

the outputs.

at

bend

record

playback

both Line

maximum

bias- and

the arm of

at

stereo.

best

4.4.2 Azimuth

Check

perpendicular

azimuth

This

adjustment

that

the

to

position

Adlustment

head

the

mounting

by means

not

is

critical.

front of

plate.

the

of

4.5 Model 6021X

The

alignments specified

model 6021X with the exception

which is

is superseded

supenseded by 5.1.1 and

by 6.2.2.

in

para.

erase

the

If necessar5r,

(K)

screws

4.0

are

paragraph

of

paragraph

ref.

valid

4.2.1,

head is

adjust

3.1.

fig.

for the

4.1.1,

which

5.0 HEAD

ALIGNMENT

TANDBERG

MODEL

5.1 Playback

Head

TEST

6041X

WITHOUT

TAPES,

a similar

dip

and alcohol

visible.

distributed

Readjust the

the azimuth

recording on

it into a mixture of

(Magna

The

spaces

equidistant across

alignment.

between

height

4 and 2.

tracks

glained

fine

See solution)

the recorded

position,

if necessary,

Cut the

iron oxyde

to make

the tape, ref.

the recording

tracks

and

tape

powder

should

fig.6.1.

recheck

and

be

back

meters.

Head

the

Alignment

the

of

screws

run

for channel

Alignment

a standard

head

until

Head

instructions

instructions

5.1.1 Height

The height

adjustment

the tape shall

lamination

5.1.2 Azimuth

Play

VTVM connected

playback

the

fig. 3.1,

ref.

output

5.2 Record

Follow the

5.3 Bias

Follow

playback head

(A), ref. fig. 3.1.

with the upper

flush

L.

azimuth

to each

the

by

maximum

given

given

is aligned by

alignment

output. Adjust the

azimuth

reading

under

under

the height

The upper

part

adjustment screw

obtained

is

paragraph

paragpaph

edge of

the head

of

tape

position

4.2.

4.3

with

on

6.1.2

Insert a

Hz signal

ing level in mono

and dip

a

prereeorded

of

(B)

the

fig.6.2. Adjust

necessarv.

6.1.3

Record a 1.000

500 Hz

recording levels.

track 2

should

signal

signal is heard.

The Erase

Playback

be heard. Raise

is heard. Lower

Head

full-track

from a

it into

(channel

generator, well

the

track is

the

Head

Hz signal on

on

signal

Turn the

Recheck the azimuth

prerecorded tape and

on

track

Magna

in the

vertical

track 3

R)

at

the

the

above

(channel

3

See

solution.

centre of the

position

tape

maximum

playback

playback

of the

1

track

(channel

around

head

position.

(channel

volume.

head

record

optimum

R). Cut

R)

the

Check'that

erased area,

erase head

L) and

at

optimum

play

and

No signal

if

1.000

the

if the 500

a 1'000

record'

tape

the

ref'

if

,-t

a

back

Hz

Hz

Head

Erase

5.4

screws

mils)

Azimuth

azimuth

adjustment

with

position

6021X

Adjustment

of

of the ferite

should

Adjustment

the

with the exception of

CONTROL

5.4.1 Height

The height

adiustment

min

tfO

erase head

the

5.4.2

Align the

azimuth

parallel

azimuth

Model 6021X

5.5

The alignments

model

is superseded by

6.2.2.Paragraph

TRACK

6.0

Model 6041X

6.1

is

the erase

of

specified in

4.2.

5.4.1 is superseded by 6.2.1.

head

(K

mounting

L) ref.

and

visible above

be

position

screws

the erase

Paragtaph 4.2.1

aligned

fig. 3.1.

the upper

for

core

of

(K).

plate for the heads.

head is

paragraph 5.0

the

the erase

The erase head should

not critical.

paragraph

is superseded by

by

Approx.

tape.

head

are

height

the

0'25

track of

by

valid for

5.2 which

the

be

The

-

-

Fig. 6.1

-

-

Too

high

Correct

Track measurement

Too high

:

:

of record

head

Too

Too

low

tn

low

Record Head

6.1.1

Record a 1.000

optimum

3 for approx. 5 seconds.

Hz signal

recording

level in stereo

from

Turn

generator

a

the

on tracks 1 and

A-test

tape around and

well

above

make

Fig. 6.2

Correct

Track measurement

of erase

tro

head

6.2

Model

6021X

7.1.3 Record Level Adjustment

l)a

6.2.1 Erase

The

screws

in stereo well above

full-track

See solution and check

symmetrically across the

record heads, if necessary.

6.2.2 Record Head

The

adjustment

stereo

prerecorded

check that the tracks

across the

6.2.3

Head

height of

height of the record

well above optimum recording

Playback

the erase head is aligned by the

(K

L) ref. fig. 3.1. Record a 1.000

and

prerecorded

screws

tape.

tape. Readjust the

Head

optimum recording level on a

tape. Dip the tape in the

(C).

Dip

the tape in Magna

adjustment

Hz

signal

that the tracks are distributed

tape. Readjust the erase

head is aligned

Record

are distributed

a 1.000 Hz signal in

level

on a

See

erase and the record

symmetrically

Magna

and

by the height

full-track

solution and

heads,

the

Insert a new tape

in

A-test. Adjust the recording levels for

indication of

playback

current

channel)

7.1.4 Record/Playback

para.

Ref.

playback

7.1.5

Indicator Adjustment

Setting of levels,

Adjust R124 for a 0

indicator

indicator.

Release

output voltage is still 1.5 V for

1.5V at both

buttons

means of R108

by

until an

8.2 for

curves.

and set

both

record a4OOHz

and

(B-test)

output voltage

the same as

F-224 for

playback

(left

Curves

adjustment

dB

buttons and check that the

phono

outputs. Depress the

and adjust the

channel)

of 1.5 V is obtained.

and control

in Record

paragraph

in

reading on left record level

the same

channels.

both

signa.latT

R208

and

of record/

Mooe

7.1.3.

reading

l12ips

VTVM

a

recording

(right

right

on

rF

il

'

^

{T--\

The height

adjustment

the upper edge of the lamination for

the

azimuth

7.0 ADJUSTMENT AND

of the

screws

position

playback

(A).

head is

The tape shall run

if necessary.

aligned by

parallel

channel L. Readjust

CONTROL OF THE

AMPLIFIERS.

7.1.1 Playback Level Adiustment

Connect a VTVM

tum the

recorder for 7 tl2 ips

No.

reading on both vacuum tube

7.1.2 Adlustment of Bias Current

Insert

Connect a

generator

for

to maximum and adjust the

150 mV deflection on

stereo recording. Adjust

on left channel VTVM, and R410 to maximum

channel

Note:

playback

4 and adjust R150

a new

VTVM

to Line

Hz

1.000

The

ally tuned

tances

upper

and 0.5

VTVM.

2-track model

C40?,

C408

bias-

and erase heads,

are

track.

each one of the

to

volume controls

playback

(L)

voltmeters.

reel of

good quality

Line Output terminals, and

to

Input terminals and set the

volt. Set the Output Level Controls

VTVM. Set the tape recorder

R407

bias- and erase

given

is also

and C126.

pF.

in

phono

to maximum. Set the

of

and R250

Record Level Controls

maximum deflection

to

equipped with individu-

heads. The values

C226

respectively. The

Upper

ouq)uts, and

Tandberg test tape

(R)

(Low

tape

labelled

are

number refers to

the height

with

for 1.5V

Noise).

signal

generator

to

for

on right

of

on the

capaci-

7.1.6 Distortion

Connect signal

meter to outputs.

Adjust

indicators.

distortion

indicator,

7.1.7 Indicator

Set the

check that the vacuum

phono

level

7.1.8 Control

Play

prerecorded

250-1 0. 000-5. 000ips

standard.

5 kHz:

tolerances t

two channels should

Record Level controls to

Modes.

tape recorder

output.

indicators read

back Tandberg

tape speed. The

generator

Record in B-test on both channels.

Check distortion

exceeds 37o, readjust recording level

paras.

ref.

The

+

1

7.1.3

Adjustment

Adjust P"422

0 dB.

Playback Amplifier

of

tape

with

1. 000-

output

2 dB. The

- +

tolerances

3 dB. The

be less than

400 Hz,

and

in stereo

tube

test No.

the following frequencies:

1 0 O- 5 O-

tape

difference in level

0.5 V and distortion

0 dB deflection on

to be

7.1.5.

in Playback and

voltmeters read

(L)

conforms

less

preamplifier

R445

and

This

3.

recorded

25OHz

with

10 kHz:

are:

other

3dB.

frequencies

is a full

than 37o. lf

(R)

between the

and

Amplifier

mode,

and

1.5V on

until

both

track

7 7

at

the N.A.B.

+

-

0

4

dB,

have

2

|

7.2Tape

7.2.1

Connect

and

7

ll2 ips

is indicated

Tolerance:

7.2.2

Connect a transformer 115/0.5 V

Hz

shown

(mains

Hz)

60

Deviation

the VTVM.

adequate meter

Clock

needle.

Read

this

Brake left hand turntable

too high

is

low tape speed.

Speed Control

Using Frequency

a frequency

play

back Tandberg

tape

speed.

%.

in

11.7o

Transformer

Using

VTVM

and a

in fig.

7.1. Play back Tandberg

frequency

at 7 712 ips tape speed.

from correct tape speed will

Turn the

the time

the speed deviation

particular

time from the

or too low. Increased deviation indicates

Meter

meter

Difference from

to the

50 Hz) or

deflection.

for

Output

10 comolete excursions of

or Counter.

or counter to

test

tape No. 11

Vacuum

and

phono

Output

No.

Level Control

per

in

nomogram in

slightly

phono

Output

(1.000

Hz)

correct tape speed

Tube Voltmeter

230/0.5

or

and the mains as

test

(mains

a

19

give

cent corresponding to

to

decide if tape speed

V,

50/60

No. 10 a

tape

frequency

a beat across

to

obtain

the

meter

|ig.7.2.

too

8.0

ADJUSTMENT

WITHOUT TANDBERG

Playback

8.1

at

Connect a

generator

channels and tuned

tape recorder is

The

112 ips

7

Noise).

Adjust the

output meters are 1.5

the

maximum. Replace

to

distortion rneter

(B-test).

reading

Replace the

meter and depress the

Adjust the

shows

terminal

stereo

Adjust R150

reading

the

Release

A-test) and check

still are 1.5 V.

shows

3 % distortion. Connect a

B-test"

on the output meters are 1.5

playback

THE AMPLIFIERS

OF

TEST TAPES

Record Level Adjustment

and

VTVM to each output

is connected

speed.

tape

recording

Adjust the recording current

and

the

and depress the

3 % distortion.

VTVM for channel R

recording current

proceed

(channet

volume controls ate set

push-buttons

that the reading

to

Hz.

to 400

for

up

set

Insert a

gain

controls until

V with

VTVM for channel

the

push

button

the recording as

L) and R250

Playback L and

terminal.

the Line Input of

stereo

good

the

playback

playback

R208 until the

by

VTVM to each

(channel

on the output

The signal

both

recording A-test, at

quality

the reading on

playback

R108

by

the distortion

with

discribed above

V. Make sure that

to maximum.

tape

controls

L with a

push

button

until

(B-test).

R

reading

output

R) until

(Stereo

R

meters

(Low

the

the

^+

I

I

i

in

+,1

2,A

play

1,5

Tandberg

l7o"

n ( rr

-:'-

50

or

Fig.7.1

r,0

, , ,

, l,

.,,J

20 25

At 3314 ips,

mains frequency). Proceed

accuracy.

tolerance:t

Speed

115

V) 60 Hz

230V,50H2

2,5

,0

1,.,,r.,,1,,,,1,,

I

F\9.7

test

for

as

'

60 Hz

0,5

I

I I I | | | |

40 50

l0

.2

tape

No. 10

7 1/2 ips to

lU

nr rreu

gL

0/3

SPeeddeviotion('A)

I I

hme

torr0

excursrons-

60 66

b

find

I

rn

seconds

complete

(50

speed

Hz

8.2 Record/Playback

Connect a

and R.

voltage,

kHz must be

voltmeters.

Set

30 dB below

reading as

Then

check

voltage

R407

If the voltage

to 1.000

means of R407 and

respectively.

reference level,

cies between

t

Perform the same

between

1 7/8

the output

frequency

In order

a band

the tape

record a

that

is too

for

2

from

dB

ips between

reference levels.

channel L and

Hz and adjust

40 and 20.000

differ by

VTVM to

recorder

optimum

the

is

Then

50 and

reference level.

levels

each

to

avoid

stop

or a

inserted

for 3 314

16.000

output

high, increase

low, alter

too

go

and recheck

16.000 Hz do not deviate

check

50

and

of the two channels

more than

Curves

phono

one of

interference

low

between the output and

(0

dB).

Hz signal at

voltage is within

R410

for maximum output

R410

back

for 7 112

Hz, and

9.000

the

from the oscillator

pass

filter

ips

stereo

Use

the

the

current by means

bias

for

channel

the input signal frequency

for channels L

400 Hz, reestablish the

to

the output level at

tps

then finally check

Hz. Ref.

3 dB.

outputs L

tuned

recording, level

output

same

!

2 dB.

R.

voltage by

more than

frequencies

at

level

4OO

should not at any

to 85.5

the

VTVM

level and

If the

of

and

frequen'

for

Hz.

R

4

7.2.3

Using Tape of Known Length

Insert

it

Tnloranne

tape of known length

a

back. Time taken

ips:

7

1/2

3

ips:120 seconds

3/4

ips:240 seconds

1 7/8

. 'l

7^

60 seconds

for

the whole

450"

(1144

length strould

cm) and

be:

play

8.3

Readjustment

Indicators

For readjustments of

paragraph

8.4

Ref.

7.1.3 and

Distortion

para.

7.1.6 for

of Recording

recording levels and

?.1.4.

adjustment and control

Levels and

indicators

of distortion.

ref.

'l

8.5

Control

of Playback

and Record Amplifiers

6

R12

(R226)

Irf

F\,

t

If

A

the specified

exceeded,

8.5.1 Playback

Connect

resistor

fig.8.1.

a signal

and a

tolerances for frequency respons€ are

playback

the

check

Amplifier

generator

100 uF capacitor

and record

in

series

playback

and

with a I kohm

amplifiers.

head, see

30

(24

)

VTVM

8.3

Fig.

Signa

generato

Fio A 1

(R235)

R'.r3s

Connect

playback

Set the

correct

rator

to

V,

i.e. 150 mV.

to

fie.8.2.

VTVM

also

volume

tape recorder

signal level,

Hz

4OO

+

1.

Fig.

'

,

\

-

.F"i!.'ulgu.'"'utor'and10dBdownbymeansofRecord

F

"

'

Connect

shown

each

oscillator.

with

below

Level

deflection.

fig.

Playback

8.2

Record

.5.2

channel.

input selectors to Line

8.4'

AnrPlifier

a VTVM

in

fig. 8.3 and

Short-circuit trimming

Set

0

indicator

dB

bontrols. Use

Check the

each

to

control to

apply oscilloscope. Tune the

and adjust the level

Check

curves

of the Line Outputs

maximum.

for

the

frequency response

stereo

playback.

to 20 dB below 1.5

ELEC'IRONIC

to each one of the head-halves

a signal

the tape recorder

generator

position.

deflection

400 Hz

frequency response

as

to

capacitor C404

for stereo

Set

i.e.

20

refurence

the

and set

To

ensure

gene-

according

DlV.

A

OI t,f,iV;F()T'{(]i-";}JC.

Hil-r-t/"'.."-ri:

862

i',1A5!-ivlLl-

6.t:.t

as

for

Input

Line

recording,

level 30 dB

dB

on

according

in

down on .,oi-

VTVM

to

S l@ ?@

mHr

Fig. 8.4 Recording

8.6 Pick-up

Set the

pick-up

unoperated

Controls

Adjust

VTVM

voltmeters connected

frequency

with the RIAA

SERVICT

Amplifier

input selector

selector

(stereo

to maximum.

with Record Level

(1.5

response conforms

CENTER

i'-';/').

t. i ;:

;:;.{zf

:li .

':'i

-,6i

"l

Fig. 8.5

'-

f

.

-+1

- I

'-

-

| 1---

.-

=1

-

-r-hi-i

?0

RIAA curve

curves

position MAGN.

in

amplifier

:

-

V

curve shown

1-

"i-l

'

1.,

-,

r'0

for magnetic

Curve

position PICK UP and

in

Set signal

Controls

dB).

20

the

to

within a

fie. 8.5.

in

-:

*

--

.-i

I

mode

).

generator

to 150

Check by

phono

Leave

Output

output that the

tolerance

-:

pick-up

the

buttons

all

Volume

4OO Hz.

to

mV output on

means of

of 2 dB

8.7.2 Adiustment

Release

of

Time

r00

2o

frequency

500

response

Fig.

to

8.6

DIN

50

Total

45511

8.7 Limiter

Set

8.7.1 Adjustment of Limiting

Set

Hz signals into

the level

button and adjust both R320

indicators. Increase

indicator reading does not

2

dB.

both

the

volume

input

to

controls to maximum.

outputcontrolsto maximum.

and

the

Line lnputs

on

0 dB

the

the input

increase

rm

?0m 5000

tolerances according

Threshold

in

amplifier

indicators. Depress LIMIT

+-

for

20

by

10000

mode

dB reading on

1

dB

and check

more than

m000 50000

Feed 400

and set

the

that

approx.

Connect

phono

and set signal

Depress

20

Then

mine

for

normal

See fig.

an oscilloscope

output. Feed 400 Hz signals into the line input,

dB.

abruptly decrease the level

by means of

the output

levels

LIMIT

level on indicator.

8.7. Adjust

button, and increase the signal level by

sigrral to

LITIIT

with

calibrated time scale

for

0 dB reading on

by 20 dB, and deter-

the oscilloscope

return

time to 0.7 s by means of R311.

the

Fig.

pattern

to approx. 1

8.7

to

the

the indicators.

the

time taken

below

dB

.+

+

MODIFICATIONS

9.0

230V to

9.1-9.2

motor

Motor

from

Hz

pulley, part

pulley, part

23O/115V 50

operation

l15V

operation, while motor

changed.

paper

part

uF, oil

be

No.:

SVo

No.: 263184.

No.:

paper

and description below.

capacitor,

1,5

motor capacitor,

Hz to

Connect

245777.

320V. Clamp

247452.

57. 320V.

part

Motor

Motor

No.:

9.1 Modification

2301115V 60

The transformer must be rewired when changing from 50

FIz

to 60 Hz

pulley

and motor capacitor have to

shown in

as

230V connections

230V, 50 Hz: Motor

230V,

or

fig.

capacitor: 2 uF, oil

for

Hz:

60

capacitor:

Clamp for

2631,84.

Fig.

9.1

230 V motor

257746

transformer connections

and

fl

-t'

q

115V connections

motor

part

pulley,

pulley, part

for motor,

pulley

number,

257746

115V, 50 Hz: Motor

v

115V, 60

When

tor, specify

capacitor: 8 uF, oil

for

Hz: Motor

capacitor: 6,5

Clamp

ordering motor

the

part

capacitor,

uF, oil

part

or

No.:

paper

5 % 220Y. Clamp

part

No.:

No.:

paper

No.:

clamp for

991040.

Vo

5

MoLor

Motor

22OY.

245777.

247452.

206773.

motor capaci-

Part

Record head

Playback

Erase

Bias

head

head

head

c726

c226

c407

c408

The numbers indicating the heads

for

heads.

the

Four-Track

c04-1

1R

c03-10P

D84-l8E

D90-038

pF

250

pF

250

pF'

3300

pF

3300

Two-Track

F82-07R

F83-11P

D87-20E

D92-04B

Add capacitance

I

until value

\

labeled

l'

J

are

on

is obtained

ordering numbers

head

9.3 lmportant

Introduced

From

serial number 2803700 output

altered from 10

specifications 45511. The following components

modified:

i

transformer connections

Fig. 9.2 1l-5 V motor

Modification from Four-Track to

9.2

and

Two-Track

Version

The

following components

modifying from

total capacitance is

four-track

labeled on two-track heads.

have to

to two-track.

be

changed when

The value

of

R423 changed

R428

changed

R429 changed

R432 changed

R434

changed

R435

changed

R436 changed

R437 changed

From

serial number 2803010

cations were introduced

Restistors R314

by capacitors

were introduced from base to emitter of

(10

C327

Electrical Modifications

in Series 6000X

kohm

from

from 22

from

from

from

from 10

from 82 kohm to

from

kohm) were omitted and

(2

uF). Resistors R346

5 kohm

to

kohm to 10

22

kohm

kohm to 10

22

kohm to 10

22

kohm

82

kohm

kohm to 5,6

10

in

limiter circuit:

the

impedance

to meet

kohm

kohm

10

to

to

to

the

kohm

kohm

47 kohm

5,6 kohm

47 kohm

kohm

following modifi-

Q305.

(100

were

DIN

were

replaced

kohm)

)F

F

1O.O LUBRICATION

l\'lotor:

The

The motor should be

3000 hours

every

The upper

Teresso oil 43 or 4? from

with a

and

the

lubricated after

of

use.

lower bearing

should

Esso.

approximately

lubricated

be

The Self

The turntables,

are

usually not

necessary

Teresso oil 43

Note: Utmost

Lubricating

mounted

be

to lubricate

only one

Excessive oil might seriously

drive.

Bearings:

the flywheel

in

self lubricating

lubricated.

or

from

47

must be taken while

care

fractional drop

the

Esso.

and

the speed

If,

however,

bearings

of oil

transfer-wheel

bearings and

it

should be

for any

affect the

reason, use

lubricating.

for each bearing.

should

Use

friction

ILLUSTRATIONS

1.0

1

WITH

REFERENCE

PART

NUMBERS

,a

264355/

260131

261+60'

262674

/

26'1655

262674

261355

265026

"62944

2607QO

264665

991007

l

.-.......--..-

_-_.

--_\

--<-264564

a.

--

----_

vEPTlcALPoslTloN'269772

260929

206296

2629

26i655

-263to9

--

260641

264169

261303

/262061

,/

\

A1

.f

EA(

QOSE

NUT

/-'

F

'i,

264494

2697A6

261149

+

991026

264E30

zsoao+

etortf

TAfl$StsBrs

218195

Fig.

2o2E5r

261970

11.1.

'1"

ToP

alal

t'

2667774

exterior

r <^A )QR

t

vtew

s

l,-

I

1".*.

i,@

\-@

ortouru

I

264190

O

240275

'g

{N(

259754

259600

264786

264494

2697A6

\

261A3c-

264119

9911u^26

+'r7\

t

99C305 215771

^

eeo23 3

,rLsz

\

(5oHz)

262969

991o^41

242331 / 99C2C4

9?1013

!7

2 697EF)

264973

991OO8

991Q14

991a17

260045

260153

261345

250828

-

----

-

-

269786

264973

202151

991034

991011

991013

990312

264270

263709

263932

261593

991030

259681

r

p

1o1/1o4

I

106/107

265096

990325

i

p

201/204/

I

206/2C7

252754

25i<8eA

26cJ42A

Fig.

zs<a<+a\

\

228244

18E-D84

12631e3 \250131

260131

11.3.

Top

11Q-CO4 10p-CO3

zszzs, I zszzs+

view

26116C^

with

covers removed

|

D3k

262532

262854

263c26

zaorz=lggpzrl

2416944

24e551

"12309

243013

242503

26O290

991A11

rs

254025

2s'1130

Fig.

c4B-D92

219234 261511

11.4. Tape path

and

\ 260577

pressure

2413124

1

23o185 990334

roller

arm

991003

264003

263134

991002

20E222

260620

262782

991012

262531

263,184

(1,5

-2f

9100 0

f )

9

991019

f

212036

26457E

<oa)at

-

)A7AA A

211539

991001

260289

1o51.0<

2697E6

264973

991014

262193

--;:r

991004

r

"'df

990233

^

'

991004

213997

\_'-

r

\L.

2a5771

"4rt52

(SOHz\

6oHz)

262236

Fig.

9903

11.5.

.1

257746

Bottom

2322

26

,ur"uo

|

lil/

{/t/

view

262969

f

,",

u, /

3

990201

,r,o,

991

"/,

034

*

.l

"t'1"

151

}r

269786

'%,

i:_26a973

t:t

f

1

(l

260124

D_1o1/1O4/

I

1o6/1o7

268e3?

2ol/2o1/

a

2A6i207

264932

261453

Fig. 11.6.

2598

Top

260131

61

view

460\ 2601

261

93

26

with upper

ff660

I

mounting

wJ

.l\

p

I

I

12

plate removed

31-4

261647

\

2634

86

26

1

120

?63309

263522

259881

,l

J

261865

248cJ27

2c2151

207977

26O706

261c94

^

262509

^

Fig.

11.7.

Upper

12.0

SPARE

The

numbers

identical

:lgr" 9".

not

available

12.1

Mechanical

with

the

as

PARTS

of

the

mechanical

the

numbers

figures

without

spare parts.

parts:

LIST

"n

e*istin!

FOR

TANDBERG

parts

on

tfi" p-"rt.

in-ihe'j*t.

the

figures

i.r'.io.".

990346

mounting

TAPE

are

p""t"

ti.t

.."

214342A

991027

plate

seen

from

RECORDER

Note:

Appty part

parts.

242sO3

underneath

6OOOX.

reference

24399o

numbers

244691

when

A

ordering

263952A

spare

l

I

I

I

I

I

rn

201957

202008

202t5t

202309

203250

206296

206713

207977

208222

208724

209306

21

1339

21

1418

21

2036

212066

21

5953

216599

217783

2t8767

2L9234

2l

9816

Shaft

Mains

cable

Microswitch

Shaft

Mains

cable

Window

Clamp

Roller

Transformer

Clamp

Spring

Pulley

Shaft

Holder

Nut

Pulley

Fin

Retainer

Nut

Shaft

Flange

Pressure

115

V,

7FT

Eceentric

230

Y

22Ocm

Counter

Motor

capacitor

Eccen.

segment

Microphone

Mains

cable

Transfer

Revolution

Lever

Operating

Cabinet

Turntable

Cooling

Tape

Turntable

Pressure

Ttrrntable

wheel

reel

roller

pad

arm

segment

w/plug

T301

arm

counter

lever

shaft

arm

housing

6,buF

assembly

L&R

224r85

224796

228244

Screw

Support

Connector

Vertical mounting

Sound-on-Sound

Microphone

feet

switch

f

230183

230629B

234960

237 482

240275

2402764

240406

2408794

242309

242337

242503

243013

243150

243990

2443424

2446944

245354

245777

24623t

24669L

247395

247452

24794L

248027

248157

248495

249306

249551

249737

2511 30

2574894

252tt5

252172

252496

252754

254025

2548444

255886

256864

2575t7

257746

259529

259600

259758

259773

259881

Shield

Roller

Washer

Spring

Connector

Screw

Spring

Plate

Spring

Spring

Arm

guide

Tape

Arm

Spring

Arm

I-cver

Suppressor

Pulley

Clamp

Washer

Clip

Pulley

Shaft

Insulator

Bushing

Connector

Suppressor

Guide

Clip

Link

Arm

Switch

Bearing

Clamp

guide

Tape

Arm

Support

Push

button

Connector

Drive

belt

Motor

Lamp

Selector switch

Connector

Plate

Jack

switch

Playback

Stop arm

Speed selector

Support,

Radio-P.up-Line

End

Record-playback

Ttansfer wire

End stop, transfer arm

Cam disc arm

End stop

Right

Bias head

End stop arm

End

End

Start-stop

Motor, 5O

End

Rec.

mm

9

Motor,60 Hz

Pressure roller

End

Adj. tape

26V

End

End stop lever

12.5 mm

Pressurc

Tape rest

Equalization

Flywheel

Adj.

Pressure

Pressure

Assy.

Remote

Counter

tLll23O

Counter and meter.

Pick-up

Phono

Fastening,

Microphone, US

head

erase head

stop

switch

stop

stop

switch

Hz

stop switch

potm.

(3/8")

stop switch

guide

stop switch

(112")

pad

arm

pad

pad/tape

control

V 50/60

printboard

shaft

head adj.

wires

Hz

version

24

f,

+

V 1W

260045

260t24

260131

260153

260289

260290

260361

260421

260476

260577

260620

260641

260700

260706

260735

260828

260850

260929

Meter

Transfer

Button

Arm

Side

Tape support

Friction ring

Washer

Spring

Bearing

Panel

Knob

Knob

Eccentric

Screw

Bracket

Lever

arm

plate

arm

:","_"i_o]11",..-

Record

Input switch

Limi ter-playback-stop

Input switch control,

Right

Neut.

Clutch L&R

Neoprene,

Input

Flutter filter

Front

Operating lever

Cueing

Tape

Support,

Start/stop solenoid

Rear

? nin<

and

position

start/stop

switch

control

guide

input

playback

switchr

indicator

level

right

solenoid

f

260965

261051

26L072

261094

261216

261302

261303

261345

26t453

26t460

261525

261647

261655

261805

84 1

261

261885

261913

26t970

261992

261999

262064

262157

262153

262215

262236

262244

262258

262322

262402

26248r

262509

262537

262532

262545

26267 4

262739

262782

262833

262854

262969

262983

262984

263026

263105

263734

263184

263278

263335

263486

263493

263522

263688

263709

263817

263838

26387

263888

263896

263932

264003

264054

264083A

264L26

264L62

264769

264L90

2642L2

264226

264370

264355

264420

264427

264485

Spring

Socket

Tension spring

Guide

Adj. screw

Terminal connector

Screw

Input

Input switch

Button

Stud

Transfer

Screw

spring

Coil

spring

Coil

Screw

Spacer

Cover

Disc

Spacer

Cabinet

Spacer

plate

Slide

Shield

Clamp

Steel ball

Roller

Knob

Contact

Arm

Lamp

Armature

Guide

Holder

Knob

Spring

Frame

Spring

Arm

Plate

Terminal

Screw

Control arm

plate

Side

Bracket

Clamp

Bracket

Plate

Transfer arm

Button

Spring

Screw

Button

Switch

Spacer

Bushing

4

Power

Shield

Guide

plate

Side

Spring

Tube

Spacer

Tape

plate

Top

Holder

Screw

Guide

Counter

Knob

Sleeve

Wafer

Insulator

switch

arm

post

spring

shield

plate

plug

switch

brake

arm

Cueing

Lamp meter

Pressure roller

Operating

Clutch-and-breake levers

pins

7

front

Cover

Control

Stop

control

Record,

Lifting arm

Control

rear,

Oover

Left clutch disc

Clutch and brake levers

End stop, feeler arm

Pick-up

Bottom

Thrust, bearing

Push button

Teak

Push

button

Stainless steel

Line input

Support, motor

Transfer

Flutter

Speed selector

Counterlamp

Tape

brake

Start/stop

Push

buttons

Speed selector

Upper,

Lower, operating lever

Main

board holder

Pull rod

selector

Speed

Speed selector

pins

3

Cabinet 5/8"

Switch. Sound-on-Sound

Right

PC

boards

Motor capacitor

Power

switch

Retainer,

Sound-on-Sound switch

Record left

Upper, operating

Topplate. 3 x

Power

switch

Sound-on-Sound

Function

Plastic,

Without

Radio connector

Power

switch button

Left

Bias head

Friction disc

Neoprene,

Insure rubber

Front

plug, rear

Mains

Start/stop

Slidearm

Lower,

Slide

arm

Sound-on-Sound switch

Motor terminal

cover

pc.

lever,

arm, left

right

channel

Sound-on-Sound switch

japanned

switch

flywheel

assy.

assy.

board

arm input switch

filter

holder

solenoid

rec/output

arm spring

lever

1.5-2uF

flywheel

selector switch-

operating lever

button

arm

start/stop

solenoid adj.

rec/out level contr.

damping

bearing,

lever

8 mm countersunk

solenoid

panel

control

Iower

small

264514

264542

264564

264578

264593

264645

264664

264830

264866

264894

264909

264930

264973

265096

265462

266072

266309

266496

266777 A

2673738

268062

268134

268932

269772

269786

990204

990233

990228

990305

990312

990325

990334

990346

991000

991001

991002

991003

991004

991005

991006

991007

991008

991009

991010

991011

991012

991013

991014

991015

991017

991018

991019

991020

991021

99t022

991023

991024

991025

991026

991027

991028

991029

99r030

991031

991 032

991034

991035

991038

991039

991040

991041

991043

Spring

Spring

Cabinet

Bracket

Bushing

Screw

Terminal

Foot

Spring

Holder

Post

Bracket

Stay

Tape

Tlansformer

Cover

Sleeve

Coil

Panel

Coil spring

Spring

Shield

Switch

Cabinet

Plate

Parallel

Ttansfer

Spring

Arm

Flywheel

Pressure

Pressure

Bracket

Main amplifier board

Power

Output

Input

Pick-up input

Line input

Cover

Cover

Turntable

Clutch

Clutch

Pressure

Start/stop

LeVer

Lever

Releasing

Arm

Arm

Bracket

Bracket

Spring

Spring

Spring

Spring

Housing

Foot

Bearing

Plate

Termnal strip

0perating

Lamp

Sound-on-Sound

Turntable

Disc

Cover

Cover

Clamp

Drivebelt

Holder

plug

plate

guide

arm

wheel

pad

roller

w/shaft

supply board

amplifier/osc. board

preamp

holder

board

roller

solenoid

arm

lever

board

board

arm

switch

slide

Usage

Pressure

Sound-on-Sound

Rosewood

Operating

Stop, operating

Vert.

4

Insert

Tape

Mains

Spring

Braking

Rear comers

Left

Power,

Rear

End stop lever

Start-stop

Rear

Right

Pressure

Start-stop

Input

Walnut

Fastening

Complete

Pressure

Tlansfer

With capstan

End

Compl.

Compl.

Compl.

Compl.

Compl.

Pressure

Heads

Supply

Disc, right

Disc, left

Assy.

Compl.

Clutch

Braking

With

Clutch and braking slide

Cueing

Sound-on-Sound assy.

Start/stop

Turntable, brake left

Turntable, brake

Flywheel, brake

Capstan, thrust

Turntable bearing

Plastic with rubber inserts

Upper flywheel, compl.

Record

Motor

With ball

Counter

Take-up

Tape

Pressure

Heads

Motor

Rubber

Tlansfer

roller

lever

mount

pins

rubber

brake

arm

cord

prcssure

lever

T1,

115-230V

solenoid

friction

pad

solenoid

selector

rear

roller

wheel

stop

roller arm

pulling

solenoid

interlock

tightening. Take

Roller

Capacitor,

wheel

arm

disc

arm

cover

rod

switch

lever

roller

right

Arm

8

arm

up tumtable

ptF

control arm

Valid below

Valid

below

Valid

below

Valid

below Ser. No.

No.

Ser.

No. 2806200

Ser.

Ser. No.

$-

f,

2806200

+

2806200

2806200

12.2 Screws,

Washers,

Nuts

and

Circlips.

Screws

^

214270 2,6x4 mm

210556

3 x 3

2tgt62 3

2t7280 4

269255 3 x 4

215951

204809 3 x 8

217632

251936 3 x 10

261303 3 x 10

214336

210622 3 x

206908 3 x

263336 3 x

214772

2t39I2 4 x

234529

204875 4 x

232367

200944

237267

227899

278675

269298

12.3

213767

Electrical

i

3 x 5

3 x

10

3 x

12

18

2O

30

4 x 4

5

4

x 7

18

3/16" nr.

t14"

1l+"

rl4"

3/8"

rl2"

314"

4

A

4

o

4

2

A

Components

230542

215320 3,2

237833 3,2

239651 3,2

231878

232826 3,2

201980 3,2

204ro5 3,5

235937

204013 4,2

214895 4,2

217752 4,3

202332

271216 4,75

231310

200299

277856 5,2

27 4930

209408 16

202072

Nuts

Washers

2,3 mm

3,2

4

4,3

5

5,2

6,2

5132"

mm

"

"

"

"

236346

208431

201003

2L7

540

2r3826

Circlips

2mm

D

I,

6"