Page 1

Tandberg 420LTO

Half Height LTO2 Tape Drive

Quick Installation Guide

Revision 1 – February 2005

Page 2

Mechanical Installation

For mechanical mounting specifications, please refer to Figure 1.

Allowed mounting position is either horizontal with the indicator LEDs to the

right, or vertical with the LEDs up.

The drive occupies a half-size 5.25-inch slot with standard holes for mounting

screws on both sides of the drive chassis and at the bottom of the drive.

Figure 1 Mounting specifications

Important!

Mounting screw

requirements

• Only M3 (metric) screws must be used for mounting the drive

• Maximum permitted screw penetration: 3.0 mm

• Minimum required screw penetration: 2.0 mm

• Screw torque, mounting screws: 0.5 Nm

• Screws are supplied with all the Tandberg 420LTO drive

variants

Do not use longer screws or higher screw torque

than specified!

Figure 2 Allowed mounting orie nt at i o n s

2

Page 3

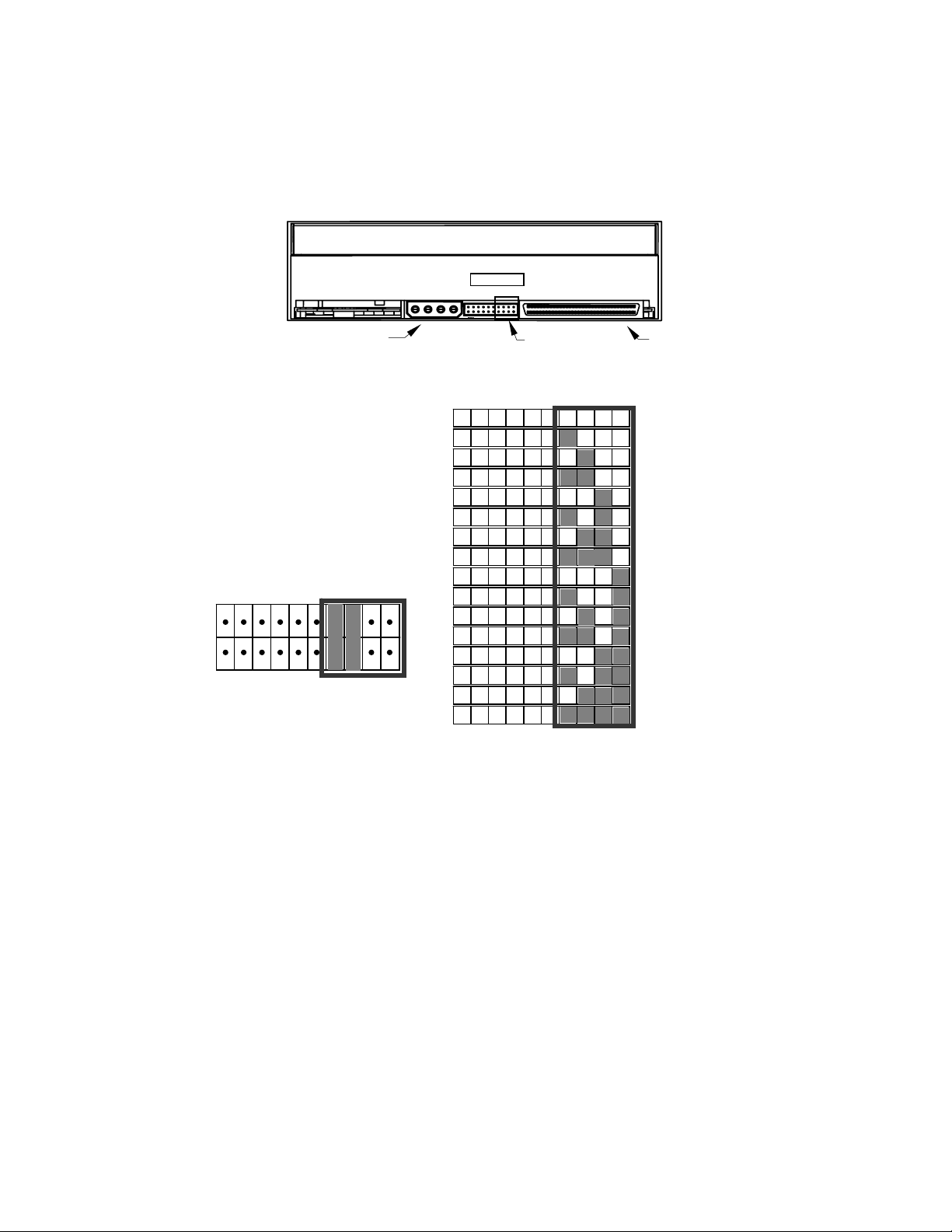

SCSI Identification

Make sure that the drive unit has the proper SCSI-ID before it is connected to a

computer system.

Refer to manuals for host computer and application software to obtain the correct

ID. For correct mounting of ID-jumpers at the rear of the drive, please refer to

Figure 3 and Table 1.

External drives have a thumb-wheel switch to set the SCSI-ID (see Figure 6).

Power Connector

Figure 3 Drive connectors

The factory default drive

number setting is SCSI ID = 2.

If the drive has to be set up

with a different unit number,

the straps (on the Service

Connector) have to be

connected according to

Table 1.

Example: SCSI ID = 3

Service Connector

SCSI Connector

SCSI ID=0

SCSI ID=1

SCSI ID=2

SCSI ID=3

SCSI ID=4

SCSI ID=5

SCSI ID=6

SCSI ID=7

SCSI ID=8

SCSI ID=9

SCSI ID=10

SCSI ID=11

SCSI ID=12

SCSI ID=13

SCSI ID=14

SCSI ID=15

Table 1 Service Connector strap settings

for SCSI ID (Dark = Strap mounted)

3

Page 4

SCSI Cable

Host

Internal Terminator Connector

Last SCSI Device

-

Figure 4 SCSI cable

• Internal SCSI-LVD/SE-cable with 5 co nnectors (Ordering no. 43 32 63)

• Internal, removable SCSI-LVD/SE-terminator (Ordering no. 43 20 53)

• External, removable SCSI-LVD/SE-terminator (Orderin g n o. 43 20 52)

• External SCSI 68HD/VHDCI 320MBs (Ordering no. 43 32 64)

10 cm

Termination

The SCSI-bus cable must be terminated in both ends according to SCSI

specifications. If the tape drive is the last device on the bus, the bus must be

terminated within 10 cm of the tape drive connection.

Tandberg 420LTO has a combined SCSI-LVD/SE interface embedded. The PC-98

Specification specifies that the termination of the SCSI-bus system is a part of the

SCSI-cable and not a part of the SCSI-device.

As a result, termination cannot be turned on or off directly on the tape drive itself.

For internal devices, a SCSI-cable with an integrated terminator or a separate

terminator applied to the end connector of the cable, 10 cm from the last device,

must be used.

External devices must be terminated with an external terminator on the last device

on the SCSI-bus.

Software Installation

For Software Application support and software drivers, please see

www.tandberg.com/ > SUPPORT > LTO Support and www.tandberg.com/ >

SUPPORT > Software Compatibility

For installation of Backup Application software, refer to the software vendor’s

software application user guide supplied with the software or on the software

vendor’s web.

4

Page 5

Front LED Indicators

Figure 5 Light Emitting Diodes (LED)

Drive State

LED-test.

The LEDs are turned ON one-by-one.

Power-On Self-Test starts in parallel

with the LED-test .

Cartridge not loaded. OFF OFF ON / OFF OFF

Cartridge loaded, no activity ON OFF ON / OFF OFF

Cartridge loaded, activity ON Flashing ON / OFF OFF

Cleaning OFF Flashing ON OFF

Cartridge loading or unloading OFF Flashing ON / OFF OFF

Unrecoverable drive failure ON / OFF OFF ON / OFF Flashing

Over temperature OFF OFF ON / OFF ON

Media Error (wrong, write protected or

harmed media)

READY LED

(Green left)

ON ON ON ON

OFF Flashing ON / OFF Flashing

ACTIVITY LED

(Green)

CLEAN LED

(Amber)

FAULT LED

(Amber right)

Table 2 Front LED behavior during normal operation

For a complete description of LED behavior see Tandber g 4 20LTO Reference

Manual.

5

Page 6

Media and Capacities

Drive Model Media Name Tape Length Capacity

Tandberg

420LTO

LTO Ultrium Generation 2 (Native format)

LTO Ultrium Generation 1 (Read/Write compatible)

609 m

609 m

(Native)

200 GByte

100 GByte

Table 3 Media alternatives

External Tabletop Enclosure

ON/OFF Switch

Cooling Fan SCSI_ID Switch

SCSI Interface Connectors Power Connector

Figure 6 External tabletop enclosure, rear side

Power Requirements

Tandberg 420LTO in external tabletop enclosure:

AC Input: 100 VAC / 0.6 A or 240 VAC / 0.3 A, 50-60 Hz

Tandberg 420LTO as standalone:

DC Input (typical operation): 5 VDC / 2.1 A, 12 VDC / 0.6 A

Heat Dissipation

Tandberg 420LTO as standalone:

Operating: 18 W

Sleep mode with cartridge inserted: 9 W

6

Page 7

Total customer satisfaction is of the utmost importance

to Tandberg Data.

We guarantee that this product left our premises defect free.

If you are not satisfied with the quality of this product,

please contact your distributor or the nearest

Tandberg Data office to have the problem solved!

For more documentation and information, please see our website

www.tandberg.com.

7

Page 8

Tandberg Data

International headquarters

Tandberg Data ASA, Kjelsåsveien 161, Oslo, P.O. Box 134 Kjelsås, N-0411 Oslo, Norway.

Tandberg Data GmbH, Feldstrasse 81, D-44141 Dortmund, Germany.

Tandberg Data S.A.S., 16/18 Ave. Morane-Saulnier, F-78941 Vélizy Cedex, France.

Fax: +33 1 34 65 02 89 (for technical support: 00800-07867243).

Tandberg Data (Asia) Pte. Ltd, 20 Bendemeer Road, #04-05 Cyberhub, Singapore 339914,

Tandberg Data (Japan) Inc., Eitaibashi Eco-Piazza Bldg. 8th floor 29-13, Shinkawa 1-chome,

Tandberg Data (UK) Ltd., Registered Office, High Street Redbourne, Herts AL3 7LW, UK

Specifications subject to change without notice. All trademarks are the property of their respective owners.

Tel: +47 22 18 90 90. Fax: +47 22 18 95 50.

www.tandberg.com

Worldwide subsidiaries

Inostor Inc., 13000 Gregg Street, Poway, CA 92064, U.S.A.

Tel: +1 858 726 0277. Fax: +1 858 726 0278.

Tel: +49 231 5436 0. Fax: +49 231 5436 111.

Tel: +33 1 39 26 01 01/00800-82632374.

Tel: +65 6396 0786. Fax: +65 6396 0787.

Chuo-ku Tokyo 104-033, Japan

Tel: +81 3 5566 2871. Fax: +81 3 5566 2875.

Tel: 00800-82632374. Fax: 00800-07867243.

©2005 Tandberg Data ASA. All Rights reserved.

Part No. 433261-01. February 2005.

Loading...

Loading...