Page 1

7265

Programmer's Manual

Matrix printer

Page 2

Table of Contents

Chapter 1. Introduction............................................................................................................1

Chapter 2. ANSI......................................................................................................................2

Control Code Summary .......................................................................................................3

Control Code Comparison, 7 Bit/8 Bit..................................................................................4

8-bit Control Codes..............................................................................................................4

Escape Sequence Summary ...............................................................................................6

Printer Handshaking............................................................................................................8

Printer Control .....................................................................................................................9

Graphics Rendition (Fonts and Modes) .............................................................................15

NATIONAL CHARACTER SET......................................................................................16

Forms Setup......................................................................................................................20

Superscript/Subscript.........................................................................................................21

Vertical Movement.............................................................................................................22

Margins..............................................................................................................................25

Horizontal Movement.........................................................................................................26

Tabs...................................................................................................................................28

Dot Graphics......................................................................................................................29

Sample Basic Program for Dot Coding ..........................................................................30

Graphics Control Functions............................................................................................31

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom

i

Page 3

Table of Contents

Chapter 3. ANSI Bar Codes....................................................................................................33

Before You Begin - Set the Form Length.............................................................................34

Setting Bar Code Parameters..............................................................................................35

General Rules for Assigning Parameters.........................................................................36

Bar Code Command Sequences .....................................................................................37

Element Widths................................................................................................................39

Other Parameters.............................................................................................................40

Delimiters.............................................................................................................................42

Horizontal Tab Delimiter...................................................................................................44

Horizontal Position - Relative Delimiter............................................................................45

Calculating Characters per Inch ..........................................................................................47

Bar Code Style Characteristics............................................................................................48

Interleaved 2 of 5 (Style 0)...............................................................................................48

Bidirectional/Industrial 2 of 5 (Styles 1 and 3)..................................................................48

Matrix 2 of 5 (Style 2).......................................................................................................49

Code 3 of 9 (Style 4) ........................................................................................................49

EAN-8 (Style 5)................................................................................................................50

EAN-13 (Style 6)..............................................................................................................50

Code 11 (Style 7).............................................................................................................51

Codabar A/t, B/n, C/*, D/e (9, 10, 11, 12).........................................................................52

UPC-A (Style 13)..............................................................................................................52

UPC-E (Style 14)..............................................................................................................53

Code 93 (Style 15)...........................................................................................................54

Code 128 (Style 16) .........................................................................................................54

MSI (Style 19) ..................................................................................................................55

POSTNET (Style 50)........................................................................................................56

Calculating the Checksum for Code 3 of 9 ..........................................................................58

Calculating the Checksum for CODE 93..............................................................................58

Code 93 Checksums for Full ASCII..................................................................................60

Chapter 4. ANSI Oversized Font.............................................................................................63

Control Function Summary..................................................................................................64

Oversized Control Functions ...............................................................................................64

Oversized Versus Expanded ...............................................................................................66

Setting the Expansion..........................................................................................................66

Device Timeout with Very Large Characters .......................................................................67

What is a Character Cell ?...................................................................................................68

Oversized Character Dimensions – 0

Oversized Character Dimensions - 270

o

...............................................................................69

o

...................................................................................70

Vertical Position-Relative in Oversized................................................................................70

Implementing the Line Feed Function - 0

Line Spacing and Intercharacter Spacing – 270

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom

o

..........................................................................71

o

................................................................72

ii

Page 4

Table of Figures

Figure 2-1 Default Character Set for ANSI Emulation, 00 to 7F

........................................5

Figure 2-2 Default Character Set for ANSI Emulation, 80 to FF..............................................6

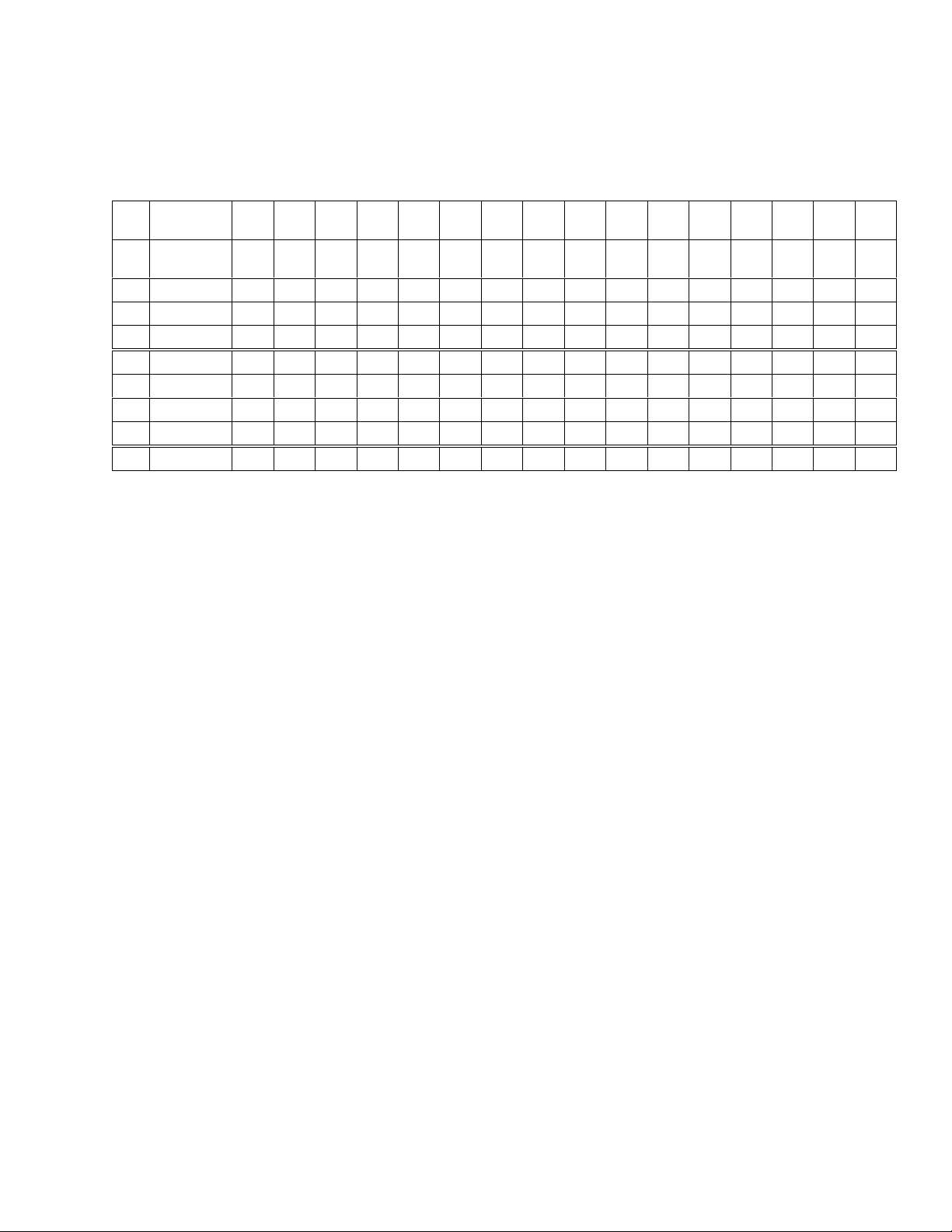

Figure 2-3 National Character Substitutions 0 - 18 ...............................................................17

Figure 2-4 Effects of Character Spacing Parameters............................................................22

Figure 2-5 Dot Column Coding..............................................................................................29

Figure 2-6 Dot Graphics Example ........................................................................................30

Figure 3-1 Parts of a Bar Code ............................................................................................35

Figure 3-2 Effects of Rotation Parameters ............................................................................40

Figure 3-3 Comma, Space, and Asterisk Delimiters..............................................................43

Figure 3-4 Horizontal Tab Delimiter.......................................................................................44

Figure 3-5 Horizontal Position-Relative Delimiter..................................................................45

Figure 3-6 Vertical Bar Code Sumbols.................................................................................46

Figure 4-1 Expanded and Oversized.....................................................................................66

Figure 4-2 Character Cells ....................................................................................................68

Figure 4-3 Vertical Character Dimensions.............................................................................69

Figure 4-4 Sideways Character Dimensions .........................................................................70

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom

iii

Page 5

Chapter 1.

Introduction

The TallyGenicom 7265 provides rugged, versatile impact printers useful in a variety of

applications. Flexibility of use is guaranteed by the wide range of software emulations and

programming options. The current printer characteristics are the result of years of application

experience. It is a hallmark of TallyGenicom products that they may be used with a broad

range of systems, hardware, emulations, and protocols.

All trademarks and registered trademarks are property of their respective holders.

CENTRONICS of GENICOM LLC Epson of Epson America, Incorporated

DEC of COMPAQ Corporation GENICOM of TallyGenicom LP

IBM and Proprinter of International Business Machines Corporation

The information in this manual is believed to be accurate and correct. However, TallyGenicom

makes no claim as to its absolute accuracy and reserves the right to make improvements to this

document from time to time.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 1 Introduction

1

Page 6

ANSI

The TallyGenicom im ple m entation of ANSI X3.64 is the native control protocol for the 7265

printer, as it is for a variety of other TallyGenicom impact matrix printer families. The control

functions presented here are a superset of ANSI control sets familiar to our customers. For the

most part, ANSI drivers written for other TallyGenicom printers should only need to be modified as

features introduced on the 7265 Series printers are exercised. Examples of such new features

include user-defined formats, alternate paper paths, user-defined character substitutions, and

remote selection of emulations.

Enabling the application to select among emulations provides access to some of the 7265

features not supported in emulated products. Toward this end, the printer can be commanded to

maintain the current status of fonts, pitches, tabs, margins and so forth across emulation

changes. Although some minute differences due to translations from, say, columns to decipoints

may be discernible when switching from one emulation to another, the printer is quite predictable

when switching from another emulation to ANSI and then back again.

The 7265 is a decipoint machine. Locations and dimensions such as tabs, margins, absolute and

relative positions, and form lengths are described in ANSI control sequences in units of 1/720

inch. If you have the choice of describing your page in one or another of the supported

emulations, consider that ANSI gives you more flexible control of locations of objects on the page.

In this chapter we include spaces between characters in escape sequences for clarity. ESC H,

for instance, is easier to read than is ESCH. Where the space character forms a component of a

control sequence, then it is designated by <SP> .

Listed below are the control codes interpreted by this printer, along with page numbers where you

can find detailed descriptions.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom

2

Page 7

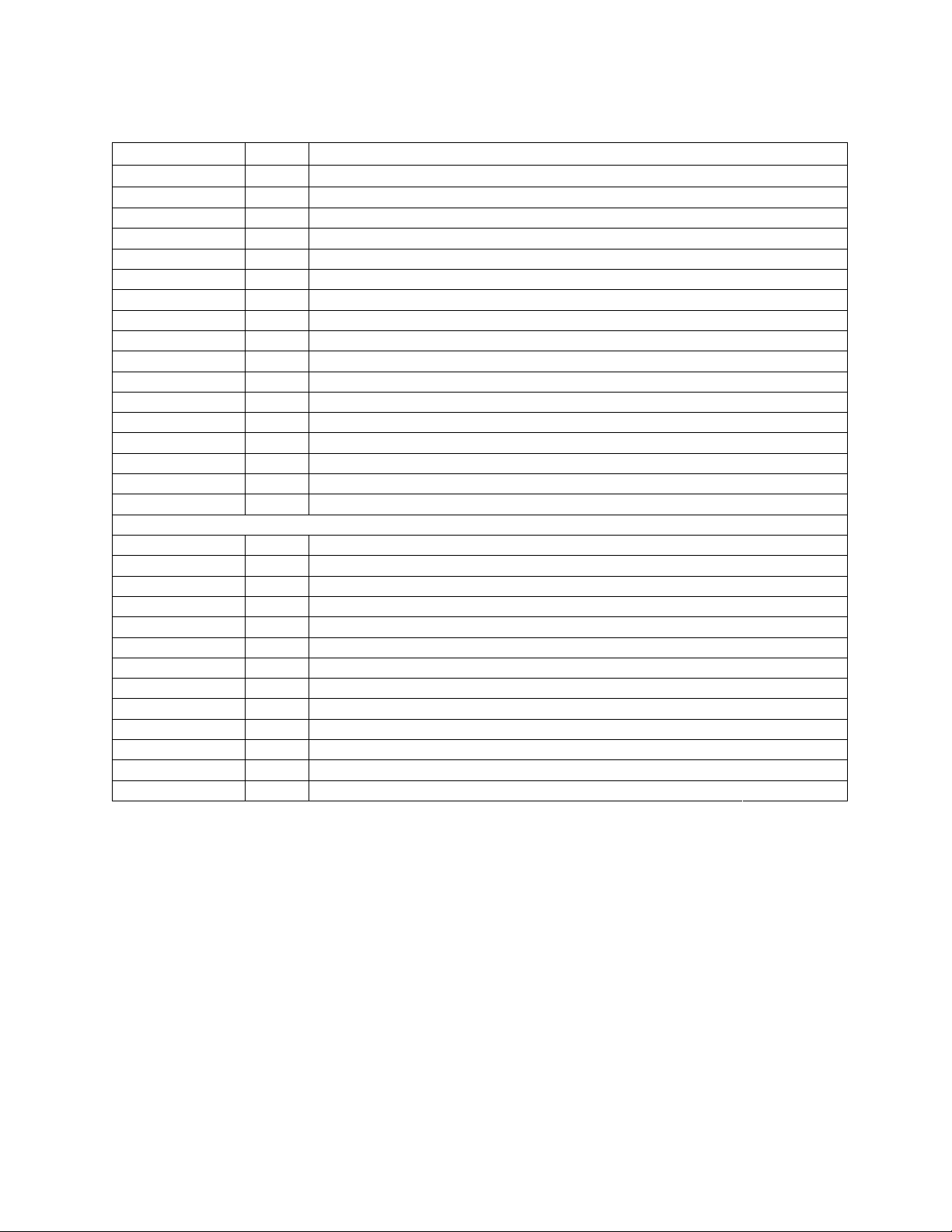

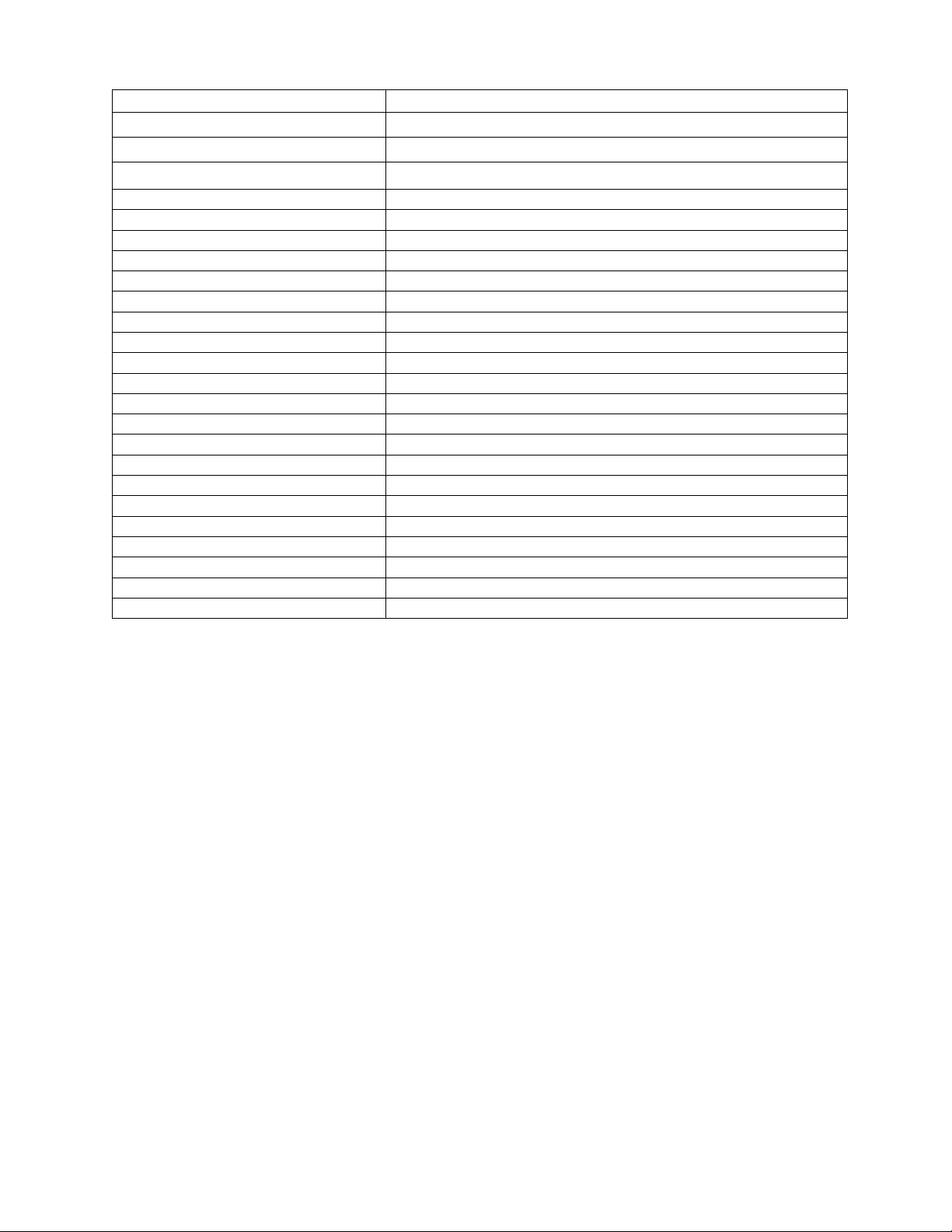

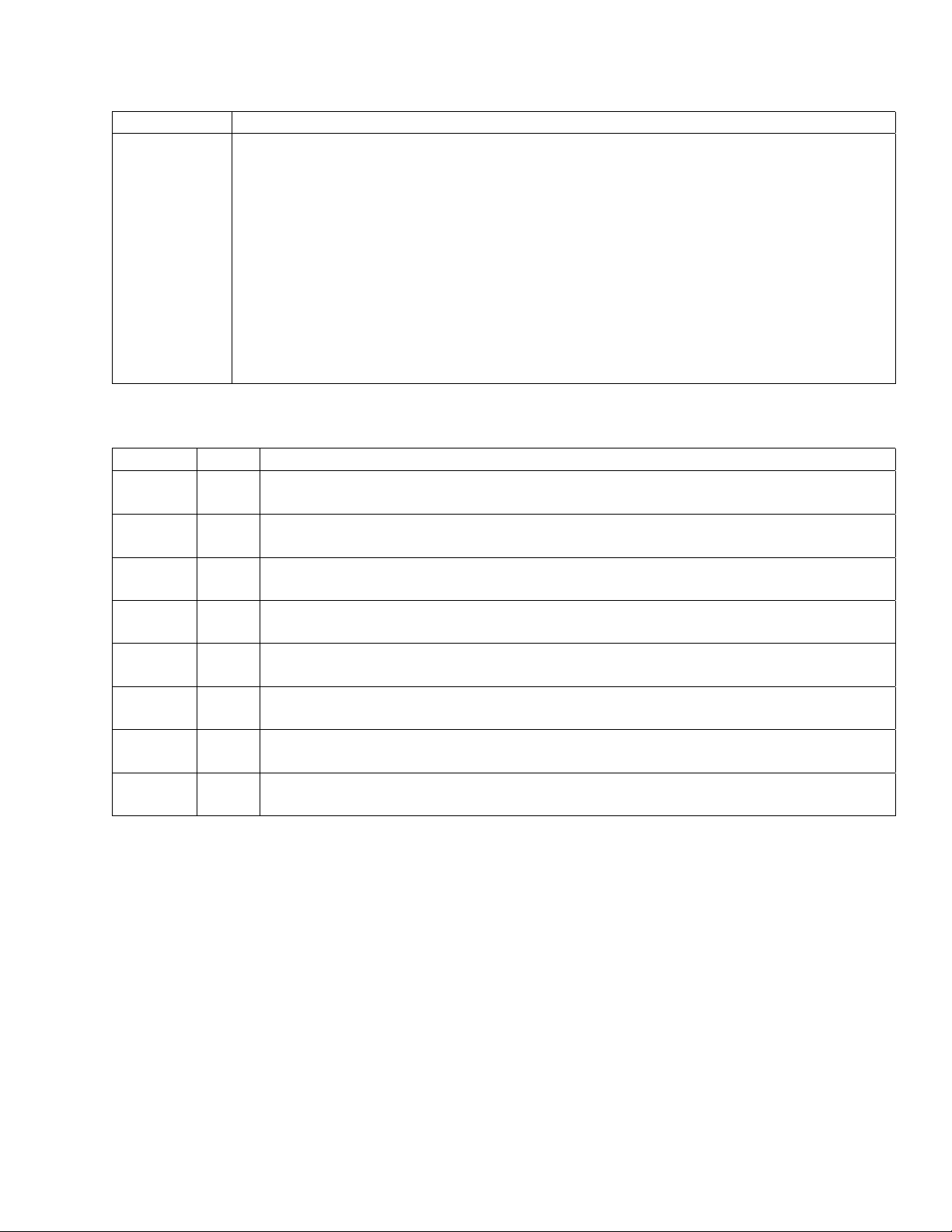

Control Code Summary

Code Hex Description

ETX 03 ETX/ACK Communication Protocol

ACK 06 ETX/ACK Communication Protocol

BEL 07 Sound Beeper

BS 08 Backspace

HT 09 Horizontal Tab

LF 0A Line Feed

VT 0B Vertical Tab

FF 0C Form Feed

CR 0D Carriage Return

SO 0E Barcode / Oversized On

SI 0F Barcode / Oversized Off

DC1(XON) 11 Printer Ready

DC3(XOFF) 13 Printer Busy

ESC 1B Escape

DEL 7F Delete

If 8-bit control code interpretation is enabled ...

IND 84 Index

NEL 85 Next Line

HTS 88 Set Horizontal Tab

VTS 8A Set Vertical Tab

PLD 8B Partial Line Down

PLU 8C Partial Line Up

RI 8D Reverse Index

DCS 90 Device Control String

PU1 91 Private Use 1

CSI 9B Control String Introducer

ST 9C String Terminator

OSC 9D Straps and Options Introducer

Some of the control codes are interpreted when encountered within a graphics data sequence.

Interpretations relative to graphics are shown on page 31.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

3

Page 8

ompar ison, 7 Bi t/ 8 Bi t

8 B i t Hex Description 7 Bit Hex

IND 84 Index ESC D 1B 44

NEL 85 Next Line ESC E 1B 45

HTS 88 Set Horizontal Tab ESC H 1B 48

VTS 8A Set Vertical Tab ESC J 1 B 4A

PLD 8B Partial Line Down ESC K 1B 4B

PLU 8C Partial Line Up ESC L 1B 4C

RI 8D Reverse Index ESC M 1B 4D

DCS 90 Device Control String ESC P 1B 50

PU1 91 Private Use 1 ESC Q 1B 51

CSI 9B Control String Introducer ESC [ 1B 5B

ST 9C String Terminat or ESC \ 1B 5C

OSC 9D Straps and Options Introducer ESC ] 1B 5D

8-bit Control Codes

ANSI assigns control functions to characters 80 hex through 9F hex and calls these characters

C1 codes. You can set the printer to either interpret 80 hex - 9F hex as control codes or not. The

ISU default status of this option is disabled.

You can toggle the status of the 8-bit control code enable from the Emulations Options Menu or

with escape sequences. The pertinent escape sequences are the ANSI private use sequences

described on page 12. In 8-bit mode, all of the lower contro l codes and ESC sequences remain

active. For example, you can use either PLD or ESC K for subscript printing. In 7-bit mode, only

ESC K is available.

If 8-bit control code interpretation is disabled, then the printer processes characters 80 hex

through 9F hex according to IBM PC character sets 1 or 2, depending on which is currently

selected. The default is character set 1. You can toggle the character set selection from the

Emulation Options Menu.

If 8-bit control code interpretation is disabled and character set 1 is active, then the printer strips

the most significant bit of characters 80 hex through 9F hex. For example, if you send 8A hex

when 8-bit control code interpretation is disabled and character set 1 is active, then the printer

treats 8A hex as 0A hex and performs a line feed.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom

4

Page 9

0 123 456 7

00 NUL@P`p

1 DC1 !1AQaq

2“2BRbr

3 ETX DC3 #3CScs

4$4DTdt

5 ENQ %5EUeu

6 ACK &6FVfv

7 BEL ‘7GWgw

8 BS (8HXhx

9 HT )9IYIy

A LF *:JZjz

B VT ESC +;K[k{

C FF ,<L\ l|

D CR -=M]m}

E SO .>N^n~

F SI /?O_oDEL

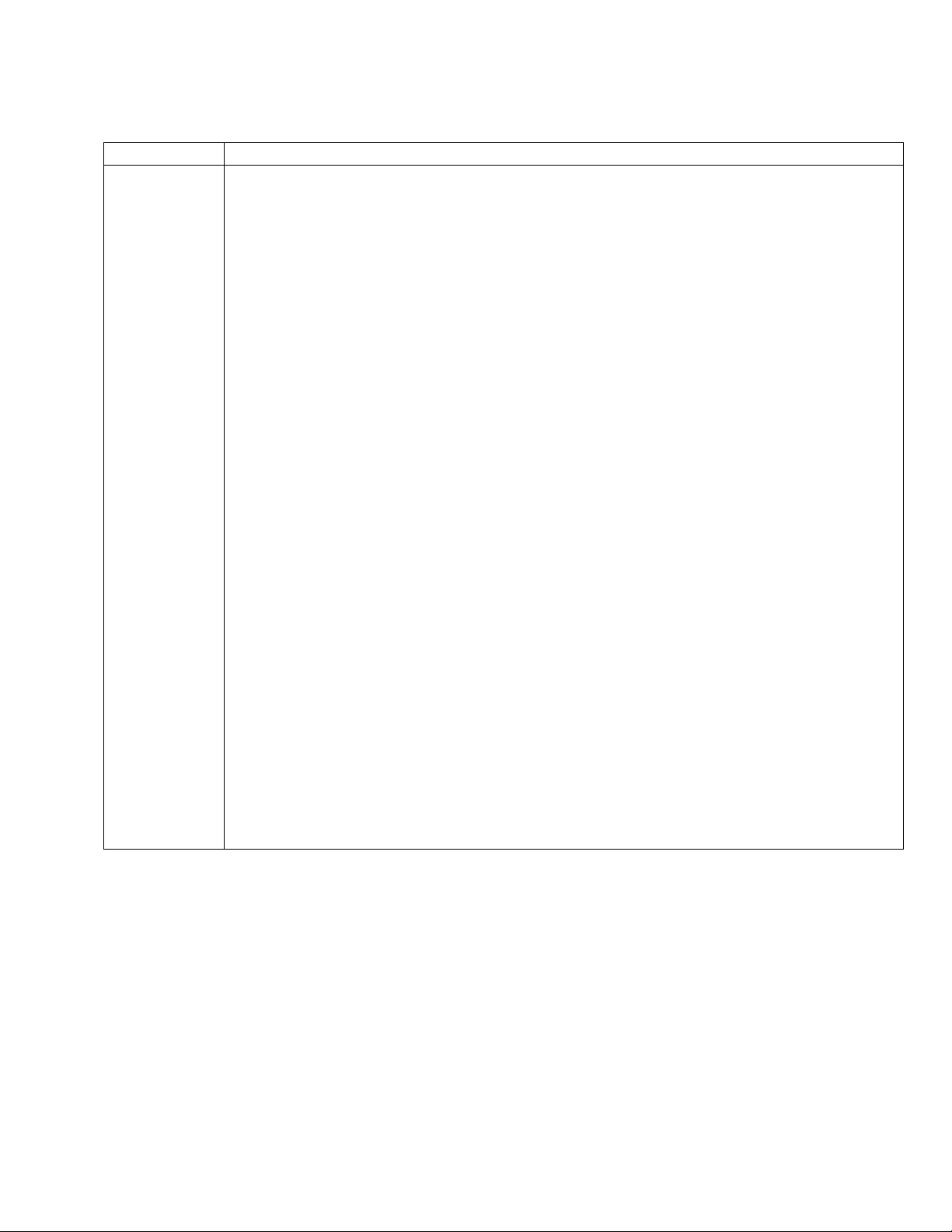

Figure 2-1 Default Character Set for ANSI Em ulati on, 00 to 7F

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom

5

Page 10

Code is Hexadecimal, Ordered Column|Row

89ABCDEF

0 DCS á

1 PU1 í

2ó

3ú

4 IND ñ

5 NEL Ñ

6a

7o

8 HTS ¿

9

A VTS

B PLD CSI

C PLU ST

D RI OSC

AB CD

¬ EFG

½ IJK

¼ MN Oæ P

¡ QR Sز

!"#

%& '

()*

,-#

/01

345

789

:;<

>?@

$

±

+

.

2

6

÷

=

º

•

H

L

E

F

« TUVW

» XYZ[

Figure 2-2 Default Character Set for ANSI Emulation, 80 to FF

Escape Sequence Summary

In this chart, the 7-bit representation is given. Use the Comparison Chart on page 4 to convert

7 bit to 8 bit sequences.

Code Description

ESC H Set Horizontal Tab

ESC J Set Vertical Tab

ESC K Subscript Printing

ESC L Superscript Printing

ESC P Enter Dot Graphics

ESC c Restore to Initial State

ESC \ Exit Dot Graphics Modes

ESC [(p1);(p2)<SP>B Graphic Size Modification

ESC [(p1);(p2)<SP>G Line/Character Spacing

!

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

6

Page 11

Code Description

ESC [(p1);(p2)<SP>~ Select Emulation

ESC [(p)` Horizontal Position Absolute

ESC [(p)a Horizontal Position Relative

ESC [(p)d Vertical Position Absolute

ESC [(p)e Vertical Position Relative

ESC [(p1);(p2)f Vertical and Horizontal Position Absolute

ESC [(Ps)g Clear Tabs

ESC [(p1);...(pn)h Set Auto CR on LF

ESC [>(p1);...(pn)h Set Mode (GENICOM)

ESC [(p)j Horizontal Position Backwards

ESC [(p)k Vertical Position Backwards

ESC [(p1);...(pn)l Reset Auto CR on LF

ESC [>(p1);...(pn)l Reset Mode (GENICOM)

ESC [(P1);...(Pn)m Fonts and Print Modes (SGR)

ESC [(p1)p Select Paper Path

ESC [(p1)q Select Graphics Density

ESC [(p1);(p2);(p3)r Forms Setup

ESC [(p1);(p2)s Sets Left and Right Margins

ESC [(p1)t ENA/DIS Oversized/Expanded/Bar Code

ESC [(p1);(p2);...(p22)u Set Horizontal Tabs at Certain Positions

ESC [(p1);(p2);...(p12)v Set Vertical Tabs at Certain Positions

ESC [(p1);(p2);…} Set Bar Code Parameters

ESC [(p)x National Character Sets

7265 Programmer’

Copyright © 2004 TallyGenicomenico Chapter 2 ANSI

Manual 7

Page 12

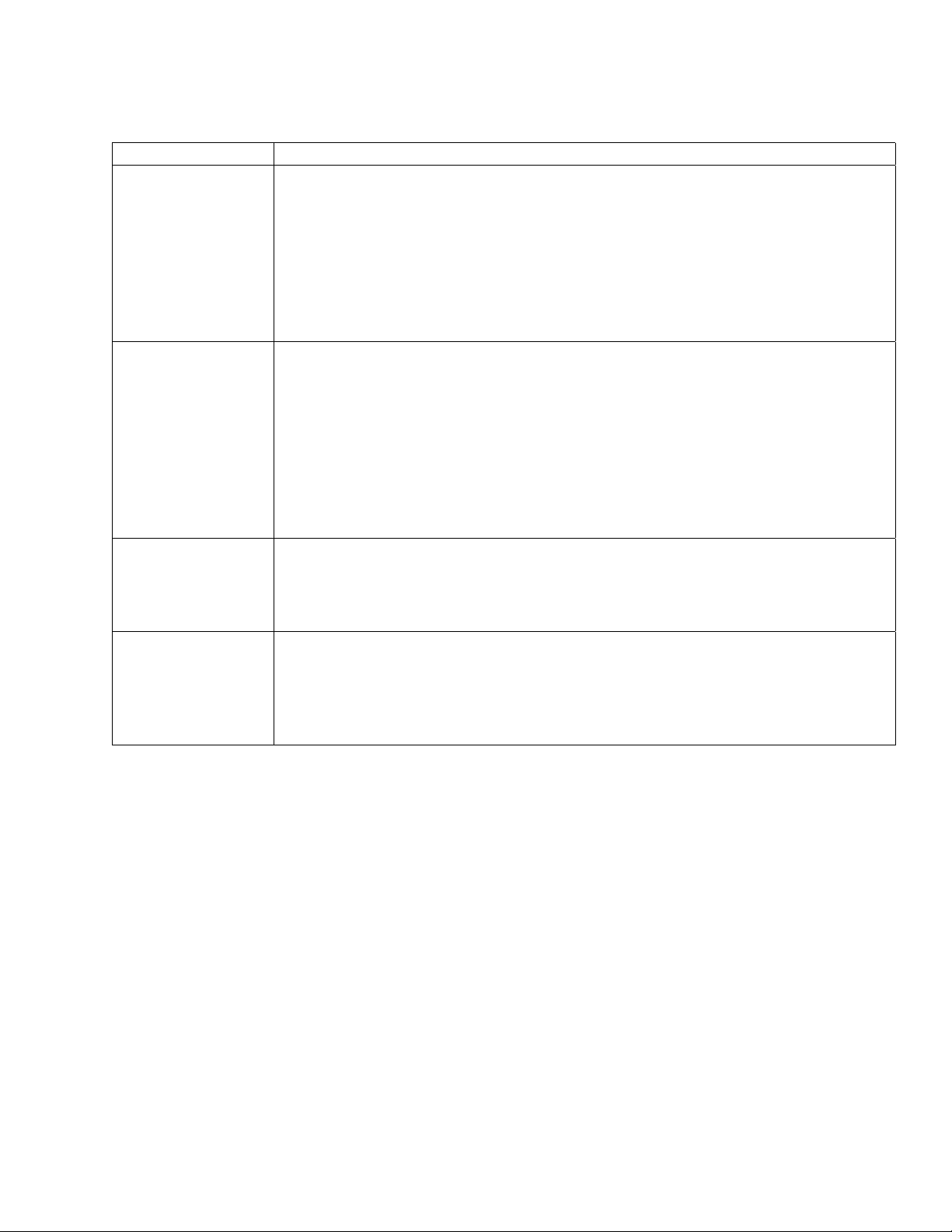

Pr inter Handshaking

Commands Description

DC1 PRINTER READY

In serial interface, if the printer is strapped for XON/XOFF handshaking, then

the printer sends DC1 to the host to signal that the printer is ready to accept

data.

In parallel interface, if the printer is strapped for select/ deselect by received

DC1/DC3 codes, then the host sends DC1 to the printer to set the printer

online.

Dec 17 Hex 11

DC3 PRINTER NOT READY

In serial interface, if the printer is strapped for XON/XOFF handshaking, then

the printer sends DC3 to the host to signal that the printer cannot, for the

moment, accept any more data.

In parallel interface, if the printer is strapped for select/ deselect by received

DC1/DC3 codes, then the host sends DC3 to the printer to set the printer to

Standby. In Standby, the printer will accept and acknowledge data from the

interface, but will discard all data received.

Dec 19 Hex 13

ETX ETX/ACK COMMUNICATION PROTOCOL

In serial interface, if the printer is strapped for ETX/ACK handshaking, then the

host sends the ETX control code at the end of a block of data.

Dec 3 Hex 03

ACK ETX/ACK COMMUNICATION PROTOCOL

In serial interface, if the printer is strapped for ETX/ACK handshaking, then the

printer sends an ACK in response to and ETX from the host to indicate that it is

ready to receive more data.

Dec 6 Hex 06

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

8

Page 13

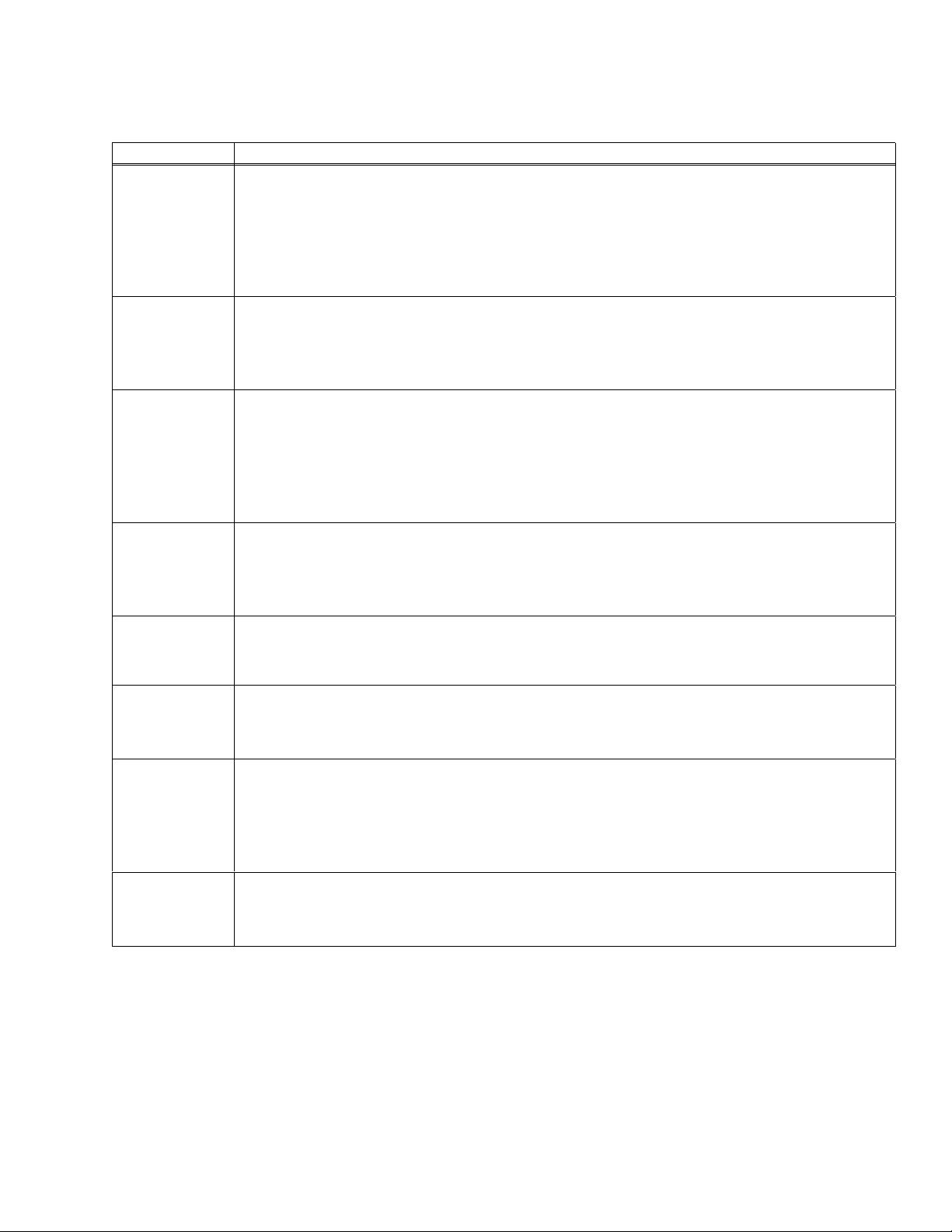

Printer Control

Commands Description

SO SHIFT OUT

You can strap the printer to start either barcode (page 37) or oversized (page 64)

mode, whichever is enabled, on receipt of SO. The ISU status of SO/SI control is

disabled. You can enable SO/SI control from Software Options on the printed menu,

or from the host via the Straps and Options control sequence. See page 14.

Dec 14 Hex 0E

SI SHIFT IN

If the printer is strapped to turn on barcode or oversized on receipt of SO, then SI

turns barcode (page 37) or oversized (page 64) mode off.

Dec 15 Hex 0F

ESC ESCAPE

Introduces an escape sequence. The printer evaluates characters following the ESC

character to determine if the sequence is valid. If the sequence is valid, then the

printer responds to the command. If the sequence is not valid, then the printer aborts

the process, discarding at least the first character following ESC.

Dec 27 Hex 1B

ESC P

(DCS)

ESC [

(CSI)

ESC \

(ST)

ESC ]

(OSC)

DEVICE CONTROL STRING

The control function introducer for the device control string structure, which is used to

frame graphics.

Dec 144 Hex 90

The CSI character is the control function introducer for the ANSI control sequence.

Control sequences are multi-character control functions that accept parameters.

Dec 155 Hex 9B

STRING TERMINATOR

Terminates the DCS and the OSC sequence.

Dec 156 Hex 9C

The OSC character is the introducer for straps and options.

Dec 157 Hex 9D

BEL BEEPER

Dec 7 Hex 07

9

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

Page 14

Commands Description

DEL DELETE

DEL is a printable character, or is a valid graphics data byte if received

in dot graphics

Dec 127 Hex 7F

ESC [(p1);

(p2)<SP>~

SELECT EMULATION

If p2 is 0, which is the default, then the current settings in the printer remain in effect

through the emulation change to the extent that selected features are supported in

the target emulation. This affects such things as, font selection, character pitch,

margins, tabs, and so forth. If p2 is 1, then the status of such parameters reverts to

defaults dependent on the selected emulation.

p1 selects

0 GENICOM ANSI

1 Tally ANSI

2-21 Reserved

22 Epson FX286e

mode.

p2 selects

0-1 full reset

Example: Select Epson emulation with full reset:

Dec 27 91 50 50 59 49 32 126 Hex 1B 5B 32 32 3B 31 20 7E

ESC [(p1)p SELECT PAPER PATH

p1 selects

08 unload current path

10 unload current path and load tractor 2

12 unload current path and load tractor 1

Forms in the current path should be torn off before changing paper paths. If

you send a command to change paper paths and there is more paper

downstream of the print head than 1/2 times the current form length or six

inches, whichever is greater, then the printer returns paper to the position that

was current before the command was received, and a fault condition is set.

If you send a command to change paper paths and the target path is the

current path, then the printer executes a form feed. If you load tractor 2

when tractor 2 is not installed, the command will be ignored.

Example: Unload tractor 1 and load tractor 2:

Dec 27 91 49 48 112 Hex 1B 5B 31 30 70

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

10

Page 15

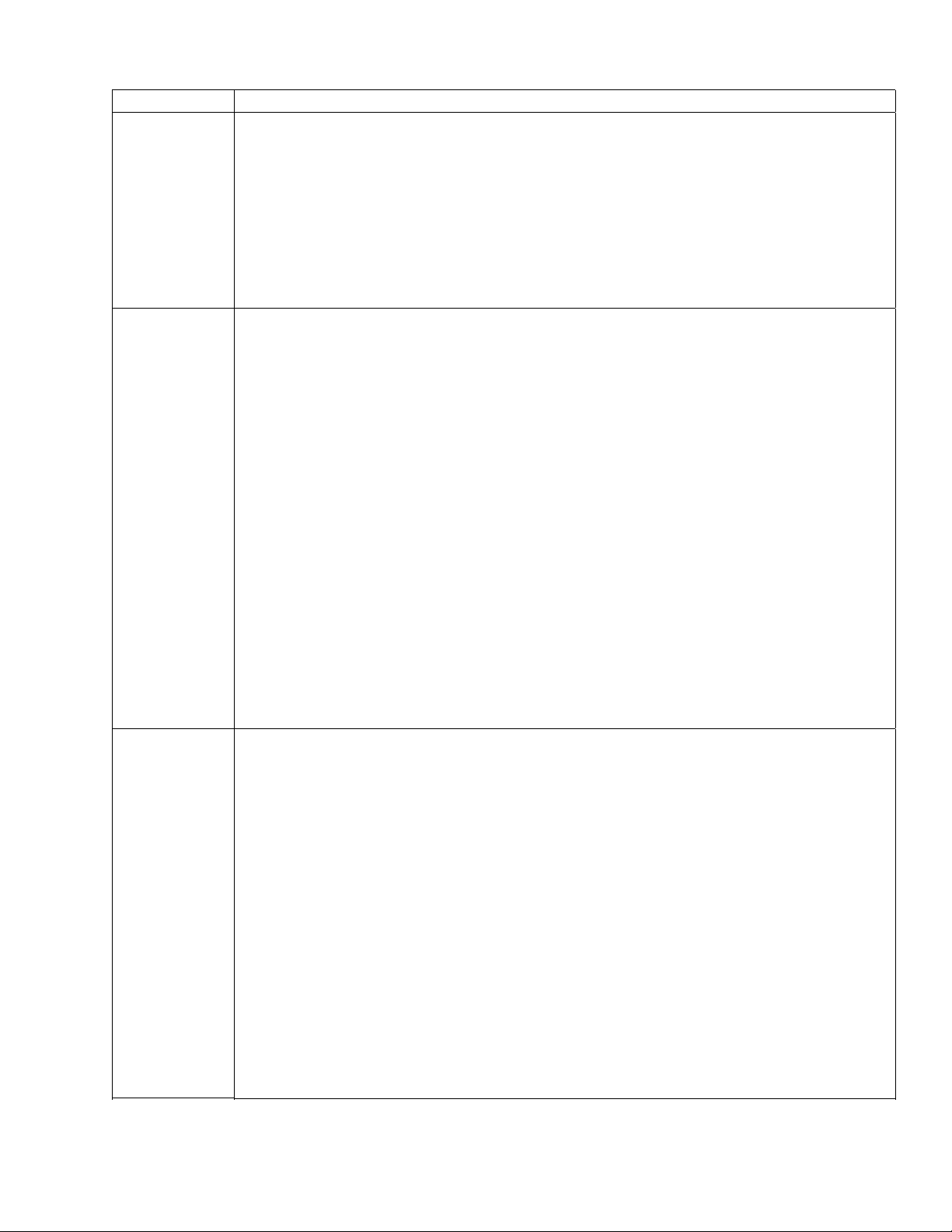

Commands Description

ESC c RESET TO INITIAL STATE

Recalls the user format presently assigned to the current paper path.

Dec 27 99 Hex 1B 63

ESC [(p1)t ENABLE/DISABLE OVERSIZED/EXPANDED/BAR CODE MODES

p1 Effect Page

0 reset special modes

1 select oversized printing 4-2

2 select expanded printing 4-2

3 select bar code 3-6

Oversized printing and bar codes are explained in separate chapters. When

expanded printing is selected, the current font is expanded horizontally and vertically

in 100% increments according to expansion factors specified by ESC

[(p1);(p2)<SP>B (see page 11). The range of expansion is 1x through 8x.

Example: select expanded printing

Dec 27 91 50 116 Hex 1B 5B 32 74

ESC [(p1);

(p2)<SP>B

GRAPHIC SIZE MODIFICATION

Sets the size of expanded and oversized characters. The effect of this command on

oversized is explained in a separate chapter.

When expanded print is selected, the argument units for parameters p1 and p2 are

percentages of the vertical and horizontal dimensions of the current font. Parameter

p1 controls the vertical expansion and p2 controls the horizontal expansion. The

argument limits for expanded print are 800;800 (8x the parent font size).

Oversized enables much larger expansions. Parameters are rounded down to the

nearest 100.

Note: This printer goes into expanded mode immediately on receiving this

command. Any text between this sequence and a countermanding ESC [(p1)t

sequence (see page 11) is printed according to the specified expansion.

If height and width are different values, the height will be set the same as the width.

ESC [(p1);

...(pn)h

SET MODE (ANSI)

p Effect

20 auto CR on LF

Dec 27 91 50 48 104 Hex 1B 5B 32 30 68

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

11

Page 16

Commands Description

ESC [(p1);

...(pn)l

RESET MODE (ANSI)

Resets mode(s) set by ESC [(p1);..(pn)h.

p Effect

20 reset auto CR on LF

Example: reset auto CR on LF

Dec 27 91 50 48 108 Hex 1B 5B 32 30 6C

ESC [>

(p1);..(pn)h

ESC [>

(p1);..(pn)l

SET MODE (GENICOM)

This is an ANSI private use sequence.

p Effect

1 proportional print

2 reserved

3 80 hex - 9B hex interpreted as C1 control codes

4 bold mode accomplished by overstrike

5 select character set 2

Example: set proportional print

Dec 27 91 62 49 104 Hex 1B 5B 3E 31 68

RESET MODE (GENICOM)

Resets modes set by ESC [>(pn)h. See the previous command. The parameter

definitions are the same.

Example: reset proportional print

Dec 27 91 62 49 108 Hex 1B 5B 3E 31 6C

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

12

Page 17

Commands Description

ESC [(p1);

(p2);<SP>{

PAPER SHEAR

If the paper shear option is installed, then note that the appropriate strap must be set

in the hardware options menu in order for the paper shear to work.

Parameter p1 = 1 selects the paper shear.

Parameter p2 = 1 executes a cutting sequence: If the vertical position is not at top-of-

form, then a form feed is executed. Paper is advanced to the shear position and cut.

Next, it is advanced an inch to eject the sheet that has been cut off; then it is

retracted to the top margin on the following form. The horizontal position following a

shear is the left margin. The shear position should be set from the control panel so

that paper is cut precisely at the perforation. If a non-zero top print reference is

needed, then set the top print reference first and then set the shear position.

Dec 27 91 49 59 49 32 123 Hex 1B 5B 31 3B 31 20 7B

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

13

Page 18

Commands Description

ESC ]6;4;

(p3);(p4)

ESC \

STRAPS AND OPTIONS

This command enables downline control of options found at various places in the

printer menus. This includes the Emulation and Software Options menus, as well as

the User-defined Options menu. For details and descriptions, see the User’s

Manual.

p3 = 0 reset

1set

p4 =

4 auto cr on lf

5 auto lf on cr

6 auto cr on vt

14 auto wrap

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

14

Page 19

Graphics Rendition (Fonts and Modes)

Command Description

ESC [(p1);

...(pn)m

SELECT GRAPHICS RENDITION

Selects print modes and fonts.

p1 Printing Mode

0 normal printing - resets all modes (but does not affect font selection)

1 set bold print

4 set underline

5 set doublewide

6 set proportional

*

10 and 11 Gothic DP

12 Gothic LQ

13 Courier DP

14 Courier LQ

15 Gothic Italic DP

16 Gothic Italic LQ

17 Courier Italic DP

18 Courier Italic LQ

19 Wide Gothic DP

*

22 cancel bold

24 cancel underline

25 cancel doublewide / expanded

26 cancel proportional

30 select black ribbon color

31 select red ribbon color

32 select green ribbon color

33 select yellow ribbon color

34 select blue ribbon color

35 select magenta ribbon color

36 select cyan ribbon color

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

15

Page 20

NATIONAL CHARACTER SET

Command Description

ESC [(p)x SELECT NATIONAL CHARACTER SET

p Character Set

0 USA

1 Germany

2 French A

6 Italian

7 United Kingdom

8 Spanish

9 Danish/Norwegian A

16 Swedish/Finnish D

If a parameter value (p) is not recognized, then the default character set (0 - USA) is

selected.

To use substitutions that have characters in the 80 hex to 95 hex range, first disable

8-bit control code processing, either by escape sequence or from the Emulation

Options Menu. Next, enable character set 2, either by the Straps and Options control

sequence on page 14 or from the Emulation Options menu. This causes ASCII

codes 80 hex - 9F hex to be mapped to printable characters instead of control codes.

Example: To select the United Kingdom character set:

Dec 27 91 55 120 Hex 1B 5B 37 78

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

16

Page 21

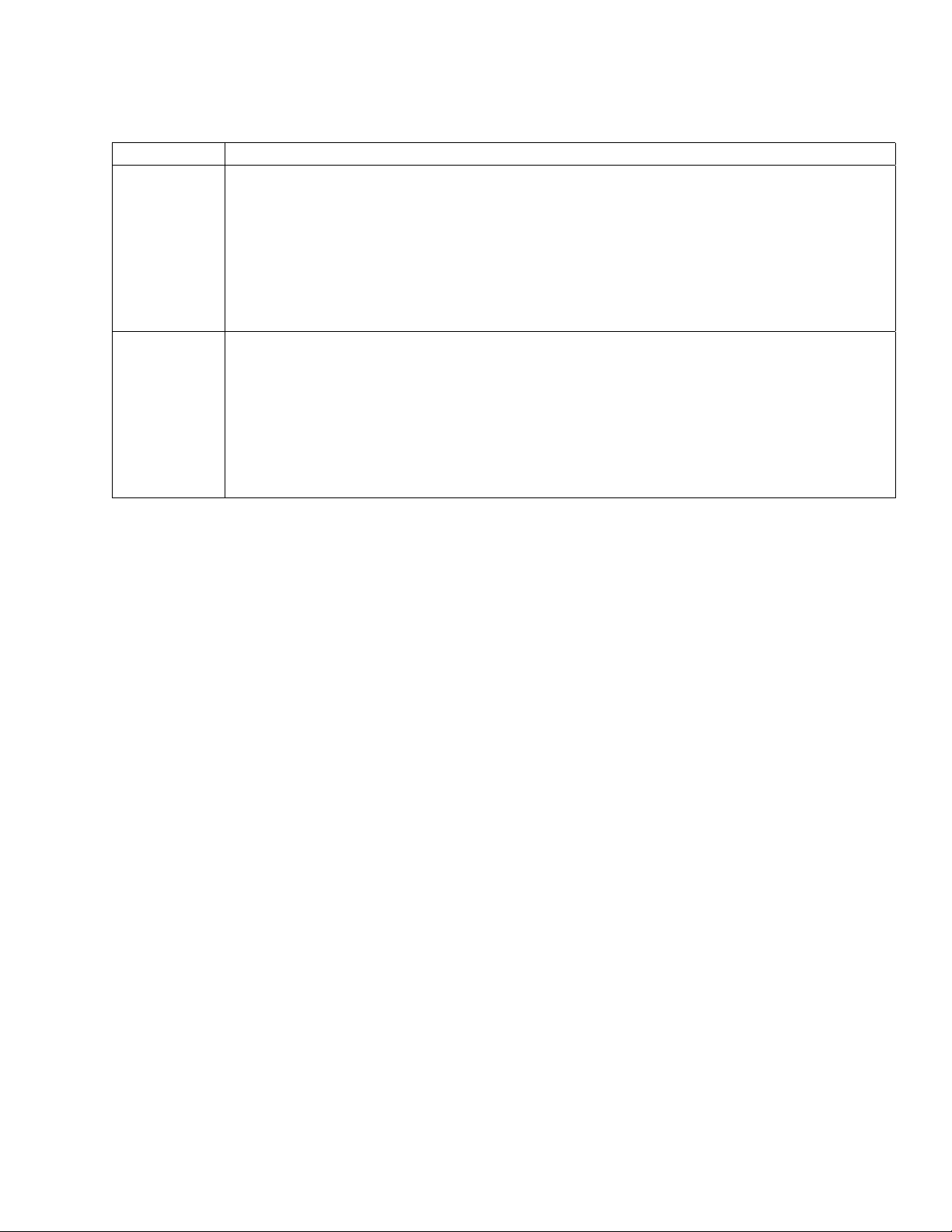

D/N = Danish/Norwegian S/F = Swedish/Finnish

Code D

Location H352336243826422A6440915B925C935D945E9660

Character

p

Set

0USA

1Germany

2 French A

6Italian

7UK

8 Spanish

9D/N A

16 Swedish

#$&* @[ \ ] ^` {

#$&* §ÄÖÜ^` äöüߢ¥

£$&* à° ç§^` éùè¨ ¢¥

£

$&*

£

$&*@[\]^`{

^

$&* @í Ñ¿^` ¨ ñ} ~¢¥

§°ç é

#$&* @ÆØÅ^` æøå~¢¥

¤

&*

É

ÄÖÅ

^

Üé

1237B1247C1257D1267E1559B157

!

}~¢¥

ùàòè ì

!

}~¢¥

¢¥

äöåü¢¥

9C

Figure 2-3 National Character Substitutions 0 - 18

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

17

Page 22

Line/Character Spacing

Command Description

ESC [(p1); (p2)

<SP> G

LINE/CHARACTER SPACING

Sets the vertical and horizontal pitch in decipoints. Parameter (p1) is the

spacing between lines and (p2) is the spacing between characters.

Unspecified parameters remain at their current values. This command

does not affect oversized printing selected by ESC [1t.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

18

Page 23

Commands Description

ESC [(p1);

(p2) <SP> G

LINE/CHARACTER SPACING

p1 = line spacing parameter p2 = character spacing parameter

If you select doublewide printing (ESC [5m), then the printer doubles character

spacing set by this command. If the designed pitch of the current font is 10 cpi and

doublewide is set, then a character spacing argument of 72 results in a pitch of 5 cpi,

at which horizontal segments of line-draw characters are contiguous.

Example: ESC [90;60 <sp> G

sets the vertical spacing to 8 lines per inch and the horizontal spacing to 12

characters per inch. (720 divided by 8 = 90, and 720 divided by 12 = 60).

Dec 27 91 52 48 59 54 48 32 71

Hex 1B 5B 39 30 3B 36 30 20 47

p2 CPI

120 6

The quick brown fox jumped

90 8

72 10

60 12

51 14

45 16

40 18

36 20

The quick brown fox jumped over

The quick brown fox jumped over the lazy

The quick brown fox jumped over the lazy dog’s back.

The quick brown fox jumped over the lazy dog’s back.

The quick brown fox jumped over the lazy dog’s back.

The quick brown fox jumped over the lazy dog’s back.

The quick brown fox jumped over the lazy dog’s back.

Figure 2-4 Effects of Character Spacing Parameters

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

19

Page 24

Forms Setup

Command Description

ESC [(p1);

(p2);(p3);(p4)

;(p5)r

FORMS SETUP

Sets top of form and sets form length, as well as top and bottom margins, in decipoints.

Parameter

p1 is form length 720ths ,

p2 is the top margin,

p3 sets the length of white space between the baseline of the last allowed

line and the end of form.

p4 is the top print reference, and

p5 is the left print reference

Any parameter not specified is assigned its default value. Maximum form length is

15840 decipoints (22 inches).

Default Values

p1 7920 decipoints 11-inch form

p2 0 decipoints 0-inch top margin

p3 0 decipoints 0-inch bottom margin

p4 0 decipoints 0-inch top print reference

p5 0 decipoints 0-inch left print reference

Example:

Set 8-inch form length, one-inch top margin, one-inch bottom margin

Dec 27 91 53 55 54 48 59 55 50 48 59 55 50 48 114

Hex 1B 5B 35 37 36 30 3B 37 32 30 3B 37 32 30 72

Note: Before you send this command, verify that the top print reference is zero in the

target paper path. One way to do this is to park and then load paper in the target path.

The top edge of the paper should line up with the top of the print head. If not, then set

the top print reference to zero from the menu and save the change to the format

associated with the target paper path. You must once again park and load paper in the

target path in order for the new print reference to take effect.

Next, send a command to set the vertical position-absolute to zero. If you do not do

this, then the printer establishes top-of-form at the current top margin, and form

registration is lost.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

20

Page 25

Superscript/Subscript

Command Description

ESC K

(PLD)

ESC L

(PLU)

NOTE: The partial line up does not respect top of form; that is, following a form feed, ESC L causes a partial line

movement upward. Also, partial line down does not respect bottom of form; that is, when printing the last line on

the form, ESC L causes a partial line movement downward.

SUBSCRIPT PRINTING

Moves paper 1/2 line below the current line for subscript printing. ESC K is used to

return to the original line following ESC L (superscript).

If 8-bit control code processing is enabled then

Dec 139 Hex 8B

otherwise

Dec 27 75 Hex 1B 4B

SUPERSCRIPT PRINTING

Moves paper 1/2 line above the current line for superscript printing. ESC L is used to

return to the original line following ESC K (subscript).

If 8-bit control code processing is enabled then

Dec 140 Hex 8C

otherwise

Dec 27 76 Hex 1B 4C

When printing the last line on a form, do not send a line feed (LF) code to move directly from superscript to

subscript. The LF code will be acted upon as the bottom of form terminator.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

21

Page 26

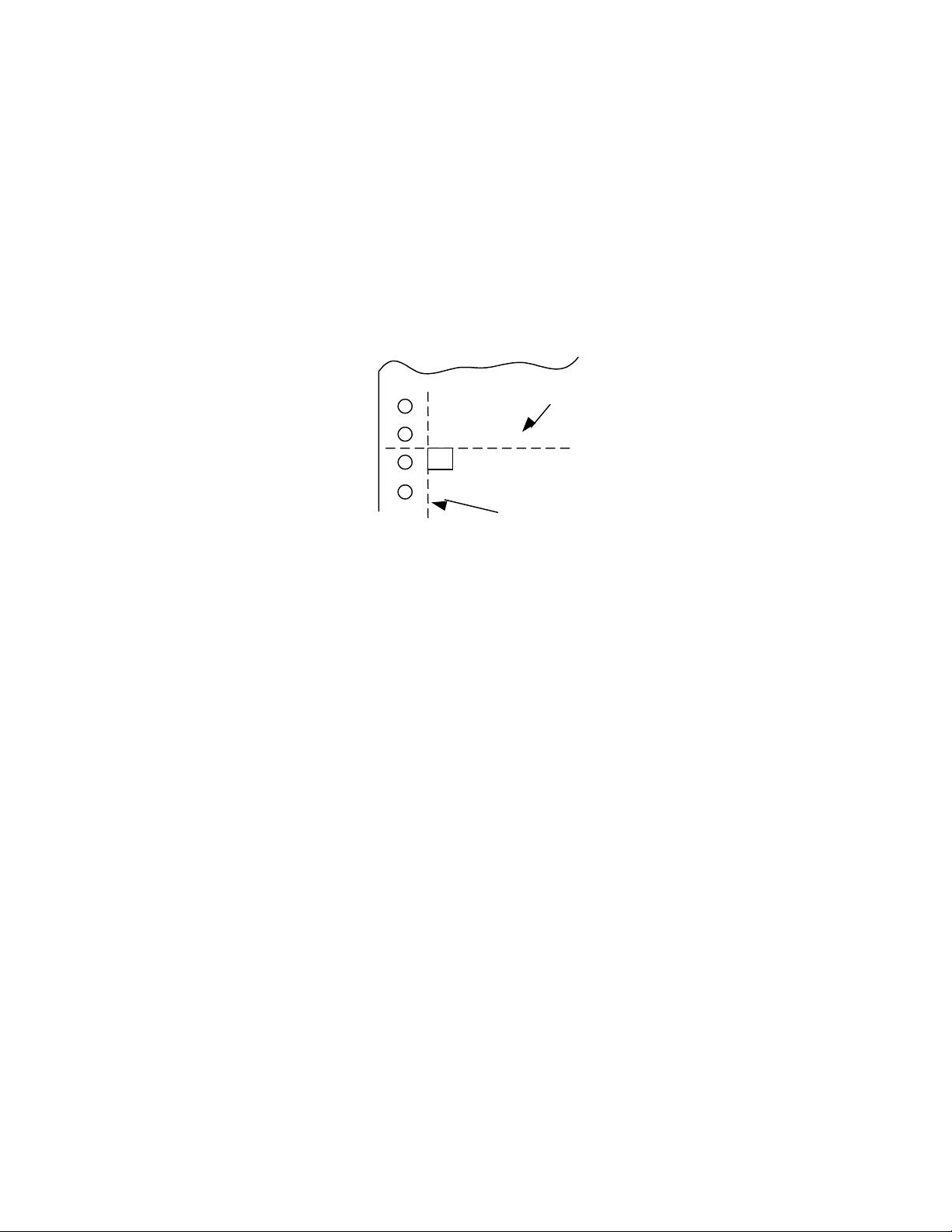

Vertical Movement

p

Absolute positions are calculated from the top and left print references without respect to margin

settings. The top of a character cell located at vertical position-absolute 0 is at top print reference.

The left edge of a character cell located at horizontal position-absolute 0 is at the left print

reference. If the default left print reference is current, and if the left tractor position(s) are as

shipped, then this is about 0.6 inches from the left edge of the paper.

Top and left print references are adjustable from the printer menu.

To

Shee

A

Extreme

Left Position

Character Printed at Zero Position

CAUTION: Do not attempt reverse paper motion across a perforation, since this may cause the

paper to snag on the print head. Vertical position accuracy is not specified for reverse paper

moves greater than 1.5 inches.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

22

Page 27

Vertical Movement

Commands Description

LF LINE FEED

Advances the paper one line according to the spacing currently in effect.

Dec 10 Hex 0A

VT VERTICAL TAB

Advances paper to the next vertical tab setting. If the current print position is at or

beyond the last tab setting, the paper advances to the top of form. If no tabs are set,

then VT is processed according to the status of emulation option strap 14.

Dec 11 Hex 0B

FF FORM FEED

Advances the paper to the top margin on the next form.

Dec 12 Hex 0C

ESC D

(IND)

ESC E

(NEL)

ESC M

(RI)

INDEX

Advances the paper to the next line. The current column is not changed, regardless

of the status of auto CR on LF.

Dec 132 Hex 84

NEXT LINE

The next line character advances the paper to the next line. The current column is

reset to the left margin. Auto CR on LF has no effect.

Dec 133 Hex 85

REVERSE INDEX

Moves the paper back one line.

Dec 141 Hex 8D

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

23

Page 28

Commands Description

ESC [(p)e VERTICAL POSITION RELATIVE

Advances paper p decipoints. This command enables printing below the bottom

margin of the current form and above the top margin of the following form. The

example below advances the paper 4 1/4 inches.

Example: ESC [3060e

Dec 27 91 51 48 54 48 101 Hex 1B 5B 33 30 36 30 65

ESC [(p)k VERTICAL POSITION BACKWARDS

Moves the vertical position backwards to (p) decipoints above the current position.

The horizontal position does not change.

If the target position is above the top margin, then the vertical position is the top

margin. If no top margin is set, and the target position is above top-of-form, then the

vertical position is top-of-form.

NOTE: The printer economizes vertical motion with vertical logic seeking, so this

command may cause reverse paper motion in some instances and not in others.

Reverse paper motion can cause problems with some forms.

Example: ESC [1080k moves the vertical position up by 1.5 inches.

Dec 27 91 49 48 56 48 107 Hex 1B 5B 31 30 38 30 6B

ESC [(p)d VERTICAL POSITION ABSOLUTE

Moves the current print position to p decipoints from the top of the form.

The following example advances the paper to 2 inches below top of form.

Example: ESC [1440d

Dec 27 91 49 52 52 48 100 Hex 1B 5B 31 34 34 30 64

ESC[(p1);

(p2)f

VERTICAL AND HORIZONTAL POSITION ABSOLUTE

Moves the print position to any coordinate on the page. Coordinates are measured

in decipoints. Parameter p1 is the vertical coordinate, which is measured from the

top print reference. Parameter p2 is the horizontal coordinate, which is measured

from the left print reference. The computation of absolute positions is not influenced

by margin settings. Top and left print references are adjustable from the control

panel.

You can print characters beyond the left, top, and bottom margin setting, but no

printing is allowed beyond the right margin.

EXAMPLE: ESC [1440;2160f

Prints the next character 2 inches from the top print reference and 3 inches from the

left print ref erence.

Dec 27 91 49 52 52 48 59 50 49 54 48 102

Hex 1B 5B 31 34 34 30 3B 32 31 36 30 66

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

24

Page 29

Margins

Use the Forms Setup command, page 2-39, to set vertical margins.

Commands Description

ESC [(p1);6 (p2)s SET LEFT AND RIGHT MARGIN

Sets the left and right margin in decipoints; p1 is the left margin and p2 is the

right. Distances are measured from the left print reference. This command

takes effect following the next line terminator (you cannot set margins for the

current line).

EXAMPLE: Set the left margin at 0.4 inch and right margin at 6.9 inches,

making a 6.5-inch print line.

Dec 27 91 50 56 56 59 52 57 54 56 115

Hex 1B 5B 32 38 38 3B 34 39 36 38 73

ESC [s ASSIGN MARGIN DEFAULTS

Assigns the default parameters. Sets the left margin to zero, right margin to

maximum print line width of the printer. This command takes effect following the

next line terminator.

Dec 27 91 115 Hex 1B 5B 73

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

25

Page 30

Horizontal Movement

Commands Description

HT HORIZONTAL TAB

Causes the current print position to move to the next tab stop. If no tabs are set, then

the current position moves one space. If tab(s) are set but no tab(s) are set between

the active print position and the right margin, then following characters on the line are

either discarded or printed on the next line, depending on the status of auto wrap.

Dec 9 Hex 09

CR CARRIAGE RETURN

Initiates printing and returns the current print position to the left margin.

Dec 13 Hex 0D

ESC [(p)a HORIZONTAL POSITION RELATIVE

Advances the current print position by the distance specified. Parameter p is

specified in decipoints.

Example: ESC [1080a advances the print position 1.5 inches.

Dec 27 91 49 48 56 48 97 Hex 1B 5B 31 30 38 30 61

ESC [(p)j HORIZONTAL POSITION BACKWARDS

Moves the horizontal position (p) decipoints left of the current position.

Actual distance between symbols separated by this command is the argument (p)

minus the current horizontal pitch (text or graphics). For example, if you print an

uppercase E at 10 cpi, move backwards by (p), and print another uppercase E, then

the distance between leading edges of the two characters is (p) - 72 decipoints. If you

print graphics at 72 dpi, move backwards by p, and print another graphics column,

then the distance between the two graphics columns is (p) – 10 decipoints.

This command enables printing left of the left margin. Any data located left of the left

print reference is discarded.

Example: ESC [1080j moves the horizontal position back by 1.5 inches.

Dec 27 91 49 48 56 48 106 Hex 1B 5B 31 30 38 30 6A

7265 Programmer’s Manual 26

Copyright © 2004 TallyGenicom Chapter 2 ANSI

Page 31

Commands Description

ESC [(p)` HORIZONTAL POSITION ABSOLUTE

Causes the print position to move (in decipoints) a specified distance from the left

print reference.

Example: ESC [360` Move print head ½” from left print reference.

Dec 27 91 51 54 48 96 Hex 1B 5B 33 36 30 60

BS BACKSPACE

Prints the data in the print buffer, then moves the print position one character position

to the left.

Dec 8 Hex 08

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

27

Page 32

Tabs

This printer stores tab stops in NVRAM while power is off. Therefore, all tab stops should be cleared before new

stops are set.

Commands Description

ESC H

(HTS)

ESC [(p1)

(p2);..(p22)u

ESC J

(VTS)

ESC [(p1);

(p2);.. (p12)v

ESC [(Ps)g CLEAR TABS

SET HORIZONTAL TAB AT CURRENT POSITION

If 8-bit control code processing is enabled then both

Dec 136 Hex 88

otherwise only

Dec 27 72 Hex 1B 48

SET HORIZONTAL TABS AT SPECIFIED POSITIONS

Sets up to 22 stops at one time. The value of p1, p2, etc. are in

decipoints (1 inch = 720 decipoints).

Dec 27 91 55 50 48 59 50 56 56 48 117

Hex 1B 5B 37 32 30 3B 32 38 38 30 75

The above example sets tabs at 1 inch and 4 inches. Existing tab stops ar e not

cleared. Margin settings have no effect on the positions of tab stops.

SET VERTICAL TAB AT CURRENT POSITION

If 8-bit control code processing is enabled then both

Dec 138 Hex 8A

otherwise only

Dec 27 74 Hex 1B 4A

SET VERTICAL TABS AT SPECIFIED POSITIONS

Sets vertical tabs at positions p1, p2, p3, etc. Up to 12 stops can be set at one

time. Tab stops are measured in decipoints from the top print reference.

Example: Set tab stops at 4 and 7 inches.

Dec 27 91 50 56 56 48 59 53 48 52 48 118

Hex 1B 5B 32 38 38 30 3B 35 30 34 30 76

Ps Effect

0 clear horizontal tab at current print position

1 clear vertical tab at current position

3 clear all horizontal tabs

4 clear all vertical tabs

Example: Clear all horizontal tabs

Dec 27 91 51 103 Hex 1B 5B 33 67

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

28

Page 33

Dot Graphics

Dot graphics allows you to print individual dots at any position on the page and thus to print

pictures as well as text. When you enter dot graphics, the printer defaults to a dot density of 72

dpi horizontally and vertically, and a line spacing of 12 lpi. Exiting from dot graphics returns the

printer to its prior lpi setting. You can also choose a density of 144 dpih x 72 dpiv. The printer

powers up in low density. The density remains as last set until it is changed, or until power is

turned off.

Each byte of graphics data defines one column of dots that is six dots high. You can think of the

least significant six bits in the byte as controlling the topmost six wires of the print head, with the

first bit controlling the top wire and the sixth bit controlling the sixth wire down. If you wanted to

fire all six wires, then you would send a byte with a decimal value of 63. Byte values of 0 through

31 decimal are interpreted as control codes, so you have to add 64 to any graphics data byte less

than 32 decimal.

You would expect to be able to simply add the value 64 decimal to every graphics data byte; in

other words, just set the seventh bit. This is risky because some variations within the 3000

product family interpret decimal 127, the Delete character, within a graphics sequence. The effect

is to delete everything following the last line terminator. The safest course is:

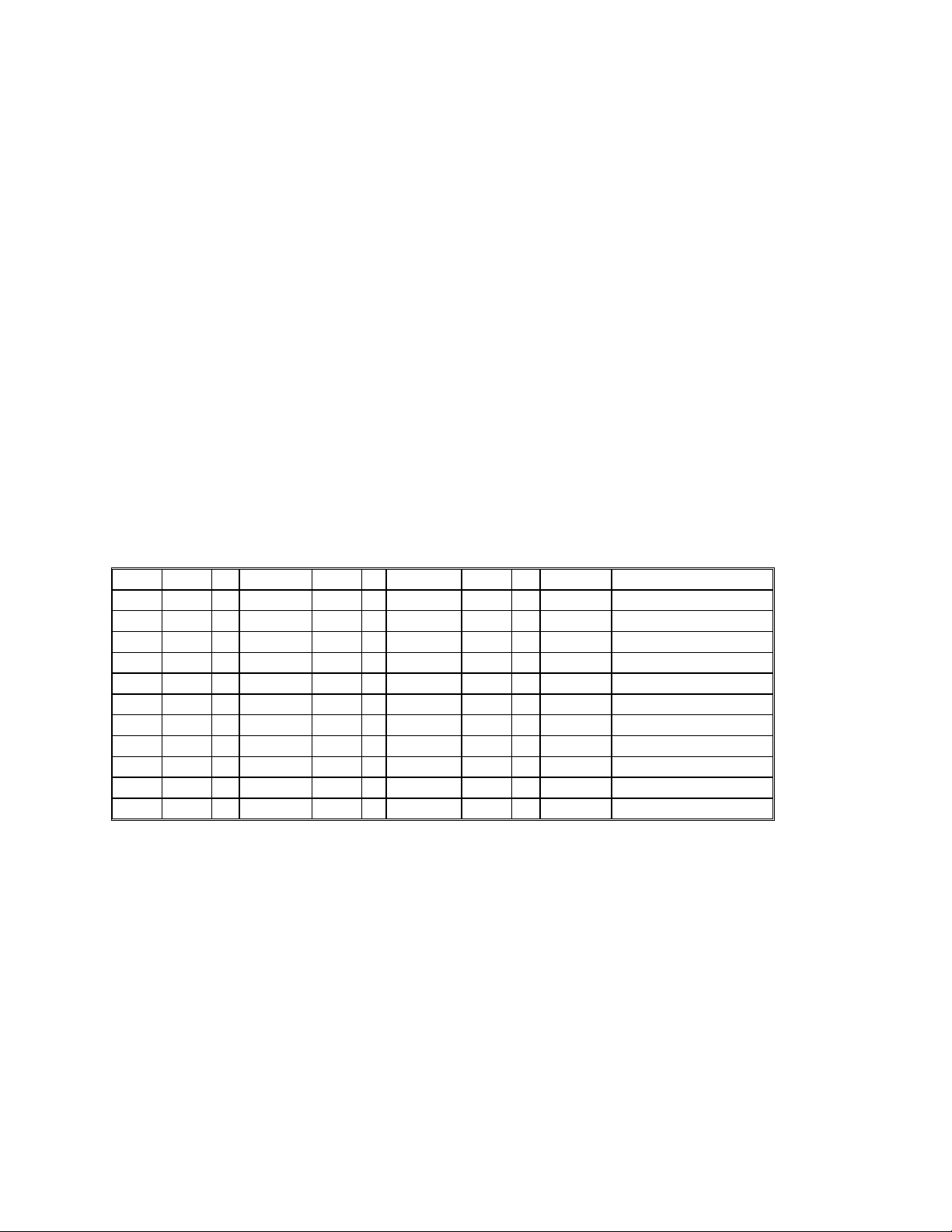

byte_val < 32 then byte_ val = byte_val + 64

WEIGHT WIRE

11

22

43

84

16 5

32 6

!!

!!

!!

!!!!!

!!

!

65 66 68 72 88 40 88 72 68 66 65

Figure 2-5 Dot Column Coding

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

29

Page 34

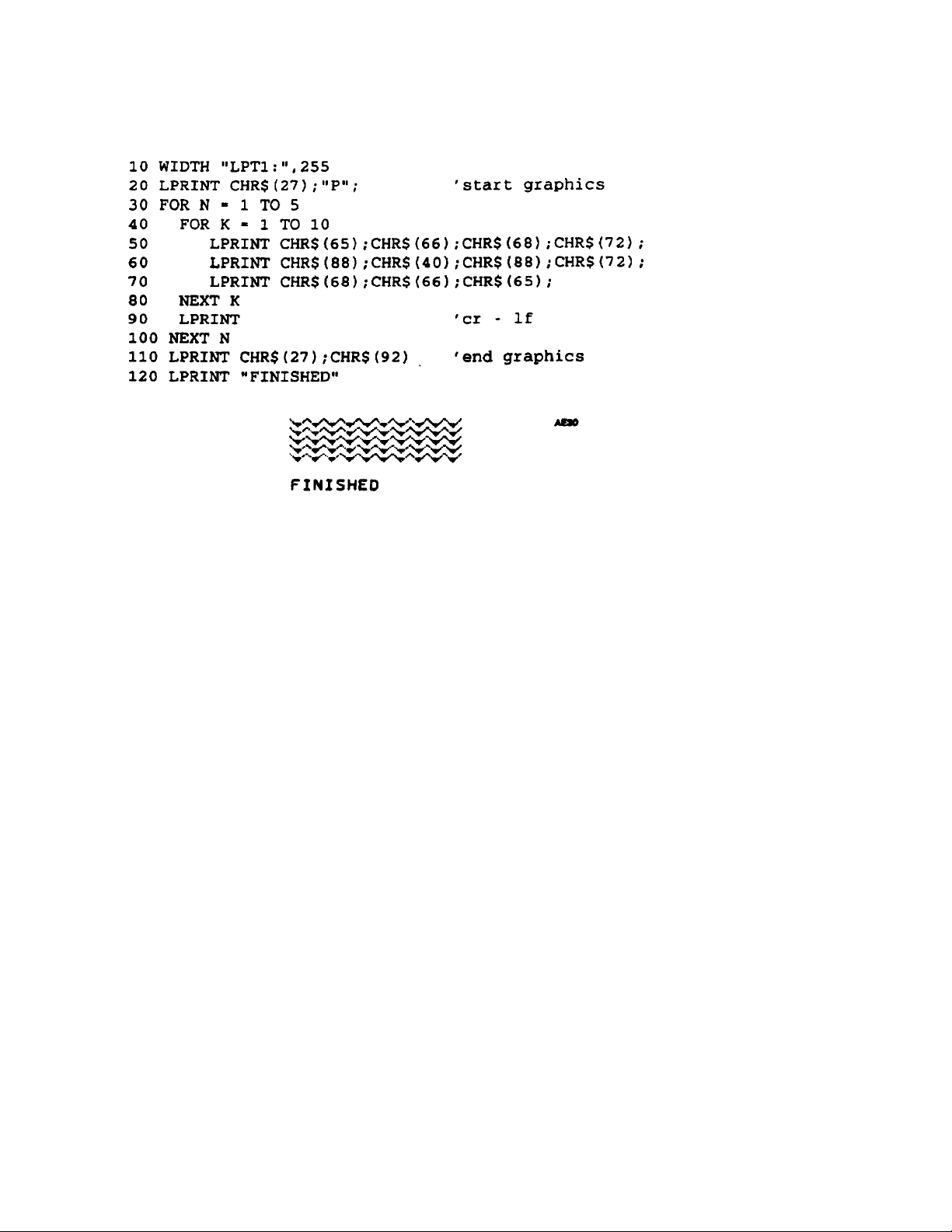

Sample Basic Program for Dot Coding

Figure 2-6

Dot Graphics Example

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

30

Page 35

Graphics Control Functions

The set of control codes that are interpreted while in graphics mode are shown in the following

charts. Bytes less than 32 decimal that are not interpreted as control codes are ignored. The

printer processes valid escape sequences within a graphics data sequence. This is potentially

useful, for instance, in the cases of the absolute and relative position commands. A valid escape

sequence that is not applicable to graphics mode, such as bold printing mode, will be

implemented for text on exiting graphics. If the printer receives a nonvalid escape sequence while

in graphics mode, then it drops out of graphics mode.

Commands Description

BEL BELL

Causes the beeper to sound for about 1/2 second.

Dec 7 Hex 07

HT HORIZONTAL TAB

Causes the print head to move to the next tab stop.

Dec 9 Hex 09

LF

(NEL)

VT VERTICAL TAB

FF FO RM FEED

CR CARRIAGE RETURN

IND INDEX

RI REVERSE INDEX

ESC P ENTER DOT GRAPHICS MODE

ESC \ EXIT DOT GRAPHICS MODE

LINE FEED

Graphics next line. Causes printing to move to the left margin on the following line.

If 8-bit control code processing is enabled, then NExt Line does the same thing.

Dec 10 or 133 Hex 0A or 85

Causes printing to move to the left margin at the next vertical tab stop.

Dec 11 Hex 0B

Causes printing to move to the top left margin on the following form.

Dec 12 Hex 0C

Causes printing to move to the left margin on the current line. This permits

overprinting the current line.

Dec 13 Hex 0D

If 8-bit control code processing is enabled, then a line feed is performed at the

graphics vertical pitch. The horizontal position stays the same.

Dec 132 Hex 84

If 8-bit control code processing is enabled, then a reverse line feed is performed at

the graphics vertical pitch. The horizontal position stays the same.

Dec 141 Hex 8D

Also sets line spacing to 1/12 inch so that LF produces contiguous graphics lines.

Dec 27 80 Hex 1B 50

Also restores line spacing to its previously set value.

Dec 27 92 Hex 1B 5C

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

31

Page 36

Commands Description

ESC [(p1)q GRAPHICS DENSITY

Sets the graphics density. The printer powers up with a graphics density of 72 x 72

dpi; changes are not stored in NVRAM.

p1 horizontal density vertical density

0 72 dpi 72 dpi

1 144 dpi 72 dpi

Dec 27 91 48 113 Hex 1B 5B 30 71

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 2 ANSI

32

Page 37

Chapter 3.

ANSI Bar Codes

This chapter describes the characteristics and lists ANSI control sequences for 23 resident bar

code styles. You have to be in ANSI emulation to print the resident bar codes. You can adjust

various bar code attributes including rotation, height, print density, status of the human-readable

line, and element widths. Subject to some constraints based on style and rotation, the humanreadable font is also selectable. For some styles, the printer will calculate checksum characters

for you.

To print a bar code symbol, you need to:

1) Set the printer to ANSI emulation.

2) Send the escape sequence to set the user-adjustable attributes. Always do this at least

once.

3) Send the control sequence to turn on bar code.

4) Send the ASCII representation of symbol data you want to encode.

5) Send the control sequence to turn off bar code.

6) Send a line terminator at some point thereafter.

In bar code parlance, a module is the narrowest nominal width of measure, while an element is a

single bar or space. A character is a group of elements that represents a number, letter, or

punctuation mark. A symbol is a group of characters that can stand alone in terms of being

interpreted by the reader. A symbol always comprises one or more data characters framed by

white spaces known as quiet zones. The symbol frame almost always includes start and stop

characters. Depending on the style, some bar code symbols can also include check characters,

center characters, and guard bars.

Among printers that generate bar codes internally and that also support any user-adjustment of

bar code widths, some enable the specification of module width, while others, such as this one,

enable the adjustment of element widths. From the programmer's point of view, adjustable

module widths tend to guarantee that the ratio among element widths remains correct, while

adjustable element widths afford more flexibility.

When we ship the printer, the ratios among element widths in a given bar code style are within

generic specifications for that style. You can restore these default element widths by performing

an initial setup (ISU) as described in the User's manual. Since this printer lets you specify

element widths independently of each other, it is possible to print bar codes that are outside of

generic specifications, or outside of the limits of your particular reading system, or both. You need

to know the requirements of your system before you program your printer.

Bar codes printed with this printer are suitable for readers designed for low- or medium-density

bar code symbols. Avoid readers with apertures smaller than 7 mils. If bar codes are to be read

with an infrared reader, then you must use a special carbon ribbon.

The examples given in this section use the Code 3-of-9 format.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

33

Page 38

Before You Begin - Set the Form Length

Programmers tend not to trust form feeds and sometimes use line feeds instead to move from

one form to another. If there is any advantage to that approach, it is that the vertical move will not

depend on the current form length. When printing bar codes on labels, you can greatly simplify

your task by setting a form length that exactly matches the length of your physical form and then

using form feeds to make vertical moves between labels or rows of labels.

If you print nothing but text, then the vertical position following each line feed lies on a grid that is

evenly spaced according to the line feed increment. If you print a bar code symbol, then positions

established by subsequent line feeds may not be on that grid. The vertical position following a bar

code symbol becomes the origin for a subsequent line feed; this new origin must be computed

based on bar code height, and the status of the human-readable line.

If you do not initialize your vertical position with a form feed for each row of labels, then printed

objects may creep cumulatively up or down with respect to the top of your physical form.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

34

Page 39

Setting Bar Code Parameters

The ANSI control sequence that sets bar code parameters has the format:

Command Description

ESC

[p1;p2;p3;p4;p

5;p6;p7;p8;p9;

p10;p11;p12;p

13}

Set Up Bar Code Parameters

Determines bar code parameters to be used when bar code mode is enabled.

See following sections.

Dec 27 91 (p1) 59 (p2) 59…(p13)125

Hex 1B 5B (p1) 3B (p2) 3B…(p13) 7D

Bar Code Height

Parameter p2

0123456789

0123456789

01234567890123456789

0123456789

Human Readable

Line Parameter p3

Wide Bar Width

Parameter p5

Narrow Space

Width Parameter p6

Figure 3-1 Parts of a Bar Code

Narrow Bar Width

Parameter p4

Wide Space Width

Parameter p7

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

35

Page 40

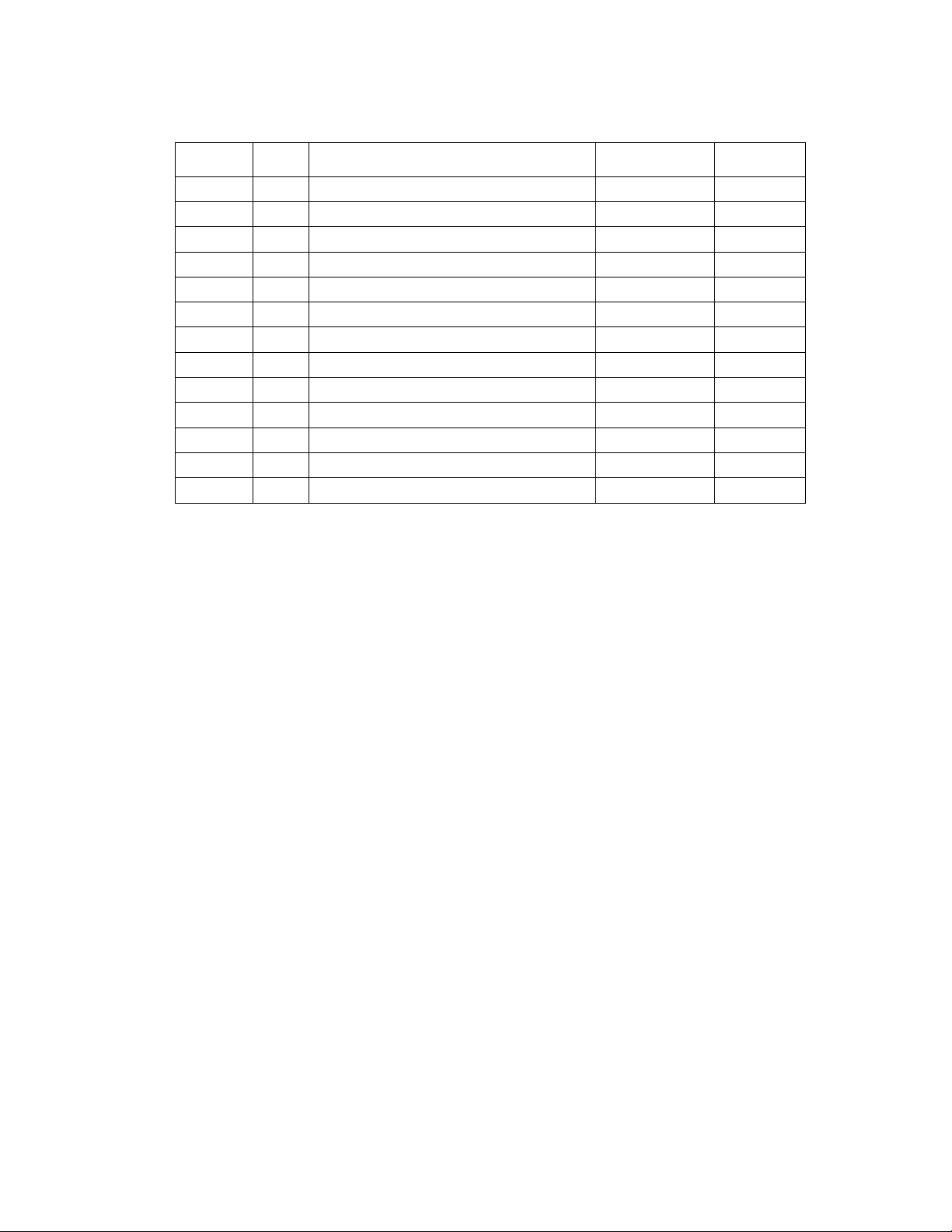

Values of all the adjustable bar code parameters are stored in NVRAM while power is off. You

can restore the bar code attributes to the factory settings by performing an ISU on the printer.

pn Attribute

p1 style

p2 height

p3 human readable line enable

p4 narrow bar width

p5 wide bar width

p6 narrow space width

p7 wide space width

p8 N / A

p9 rotation

p10 horizontal print density

p11 check character

p12 human readable font

p13 height (in 1/24” increments)

General Rules for Assigning Parameters

You can send the sequence to modify bar code parameters any time except when bar code

mode is active.

If you assign a parameter value outside the permissible range, then that parameter value

reverts to the default value.

Values for narrow bars must be less than values for wide bars. Values for narrow spaces

must be less than values for wide spaces. The ratio between wide and narrow elements

should be about 3:1.

As with other ANSI escape sequences that take multiple parameters, you can use the semicolon

as a place holder when you want to change a higher-numbered parameter while leaving lowernumbered parameters alone. For example, to set the horizontal print density to 60 dpi without

changing any other bar code attributes, you could send:

ESC [;;;;;;;;;0;;}

Semicolons that trail the last specified parameter are optional. For example, to turn off the

human-readable line without changing any other parameters, you could send:

ESC [;;0}

Or, you could send:

ESC [;;0;;;;;;;;;}

Note: The term “default” is misleading when applied to bar code parameters. This printer stores

bar code parameters in nonvolatile RAM while power is off; except for an ISU or an out-of-range

argument, you might never see the effects of the factory defaults. For this reason, your

application should probably initialize all 12 parameters one time before any symbols are sent.

This is particularly true when other bar code applications are sharing the printer.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

36

Page 41

Bar Code Command

Sequences

Command Description

ESC [3t ENABLE BAR CODES

Enables Bar Codes with the characteristics set by ESC [(p1);(p2)…}.

ESC [3t selects Bar Code mode and

activates Bar Code printing.

Dec 27 91 51 116 Hex 1B 5B 33 74

ESC [0t CANCEL OVERSIZED/EXPANDED/BAR CODE MODES

Dec 27 91 48 116 Hex 1B 5B 30 74

SO

SHIFT OUT

Turns off bar code printing, then enters bar code mode again.

Dec 14 Hex 0E

SI

SHIFT IN

SI

turns bar code printing off.

Dec 15 Hex 0F

7265 Programmer’s Manual 37

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

Page 42

p1 - Bar Code Style

This printer supports the following styles:

p1 Style

0 Interleaved 2 of 5

1 Bidirectional 2 of 5

2 Matrix 2 of 5

3 Industrial 2 of 5

4 Code 3 of 9 (default)

5 EAN-8

6 EAN-13

7 Code 11

9 Codabar a/t (see note)

10 Codabar b/n (see note)

11 Codabar c/* (see note)

12 Codabar d/e (see note)

13 UPC-A

14 UPC-E

15 Code 93

16 Code 128 (subsets A, B, and C)

17 Reserved

18 Reserved

19 MSI

p2 – Height

50 POSTNET

Note: Each of the four Codabar styles will accept any combination of valid start-stop characters

that you send. If you do not send any start-stop characters, then the printer generates start-stop

characters according to the style in force.

Height of the bar code in 1/12-inch increments. The default is ¾ inch, which corresponds to an

argument of 9.

Caution: In some versions of the printer, the last non-zero value of p13 supplants all subsequent

values of p2 until you ISU that printer. (See page 41.)

7265 Programmer’s Manual 38

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

Page 43

p3 - Human Readable Enable

An argument of 1 turns on the human-readable line, while 0 turns it off. The default is on. When

the human readable line is enabled, it is printed in the font specified by parameter p12. There is

0.1" between the bottom edge of the bar code and the top of the characters in the human-

readable line.

Element Widths

The default element widths are the narrowest that we recommend for consistent readability.

The argument units for horizontal bar code element widths are 1/120 inch. The print wire diameter

is 1/72 inch; a printed dot is about 1/60 inch in diameter. This is the finest line that the printer can

make. The printer accepts an element width of 1 as a valid argument, but the actual width of the

resulting element is 1/60 inch, the same as if you had specified a width of 2.

If the element width argument is greater than 2, then the printer rounds down odd numbers. A

width argument of 5 produces the same result as a width argument of 4.

p4 - Narrow Bar Width

Argument units are 1/120 inch if the bar code is horizontal (0o or 180o rotation) or 1/144 inch if the

bar code is vertical (90

p5 - Wide Bar Width

Argument units are 1/120-inch increments if the bar code is horizontal or 1/144 inch if the bar

code is vertical. The default is 6.

p6 - Narrow Space Width

Argument units are 1/120-inch increments if the bar code is horizontal or 1/144 inch if the bar

code is vertical. The default is 2.

p7 - Wide Space Width

Argument units are 1/120-inch increments if the bar code is horizontal or 1/144 inch if the bar

code is vertical. The default is 6.

Wide space and wide bar are both set to the smaller of the two values. This sets the proportion

of the large to small the same for spaces as it is for bars.

o

or 270o rotation). The default is 2.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

39

Page 44

Other Parameters

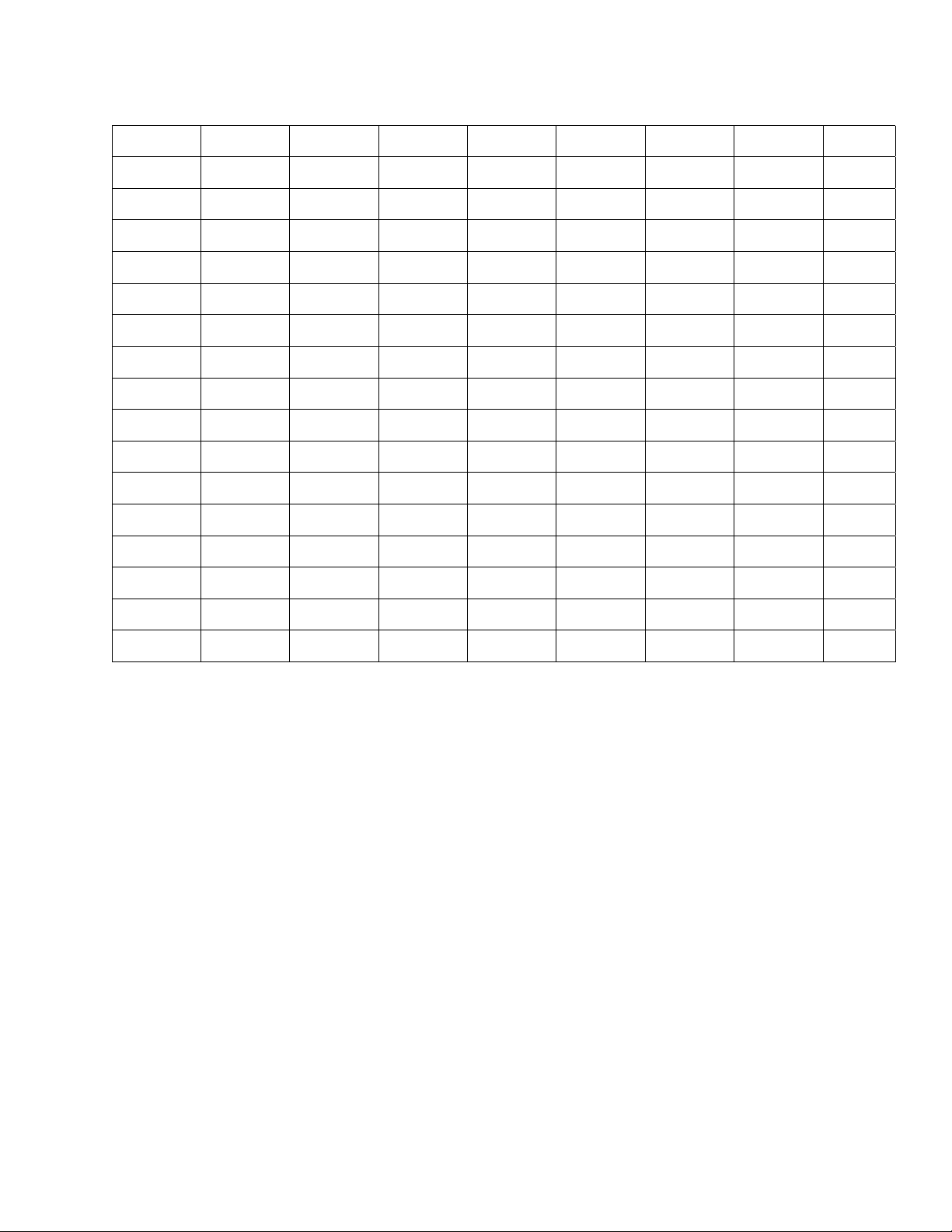

p9 – Rotation

Sets the absolute rotation in 90 degree increments. If parameter p12 = 0, then the humanreadable font is shown in the following table:

p9 Rotation HR Font if p12 = 0

0 no rotation (default) current font

1 no r otat ion special bar code HR font

2o270 rotation special bar code HR font

3 no rotation special bar code HR font

4 270o rotation special bar code HR font

Rotation 0

*1234*

1234

*1234*

1234

Rotation 1

*1234*

1234

Rotation 2

1234

*1234*

Rotation 3

Figure 3-2 Effects of Rotation Parame ters

Rotation 4

*1234*

1234

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

40

Page 45

p10 - Horizontal Resolution

A value of 0 is 60 dots per inch, while a value of 1 is 1/120 dots per inch. The default depends on

the style in force. EAN and UPC styles default to 1. All other styles default to 0.

Note: This parameter affects bar codes printed at 0

resolution, then bar codes are darker and are printed at a somewhat slower speed.

p11 - Check Character Enable

N / A

p12 - Human Readable Font

N / A

p13 - Height in 1/24-inch Increments

Normally, bar code height is specified in 1/12-inch increments by p2. Only specify p13 if your job

requires the associated higher resolution of bar code height. A non-zero value of p13 supplants

the value of p2.

Caution: In some versions of the printer, a non-zero value of p13 supplants all subsequent

values of p2 until you ISU that printer. To be on the safe side, if you do not plan to use p13, then

set p13 to 0. NOTE: Bar code height is limited to 10 inches.

o

or 180o rotation only. If you select the higher

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

41

Page 46

Delimiters

A bar code delimiter is a character or control function that tells the printer where one bar code symbol ends and

an adjacent symbol begins. Different bar code styles accept different delimiters, which might be spaces,

commas, asterisks, horizontal tabs, or horizontal position-relative commands. Valid delimiters for the various

styles are listed in the Bar Code Style Characteristics section.

There is always a minimum one-fourth inch of white space called the quiet zone on either side of a bar code

symbol, so there is always an irreducible half-inch space between adjacent symbols, no matter which delimiter is

used. The space character occupies an additional tenth of an inch. Neither the comma nor the asterisk imposes

any additional space between symbols. Asterisks are valid delimiters in Code 3 of 9 (style 4) only, and are

normally used in pairs.

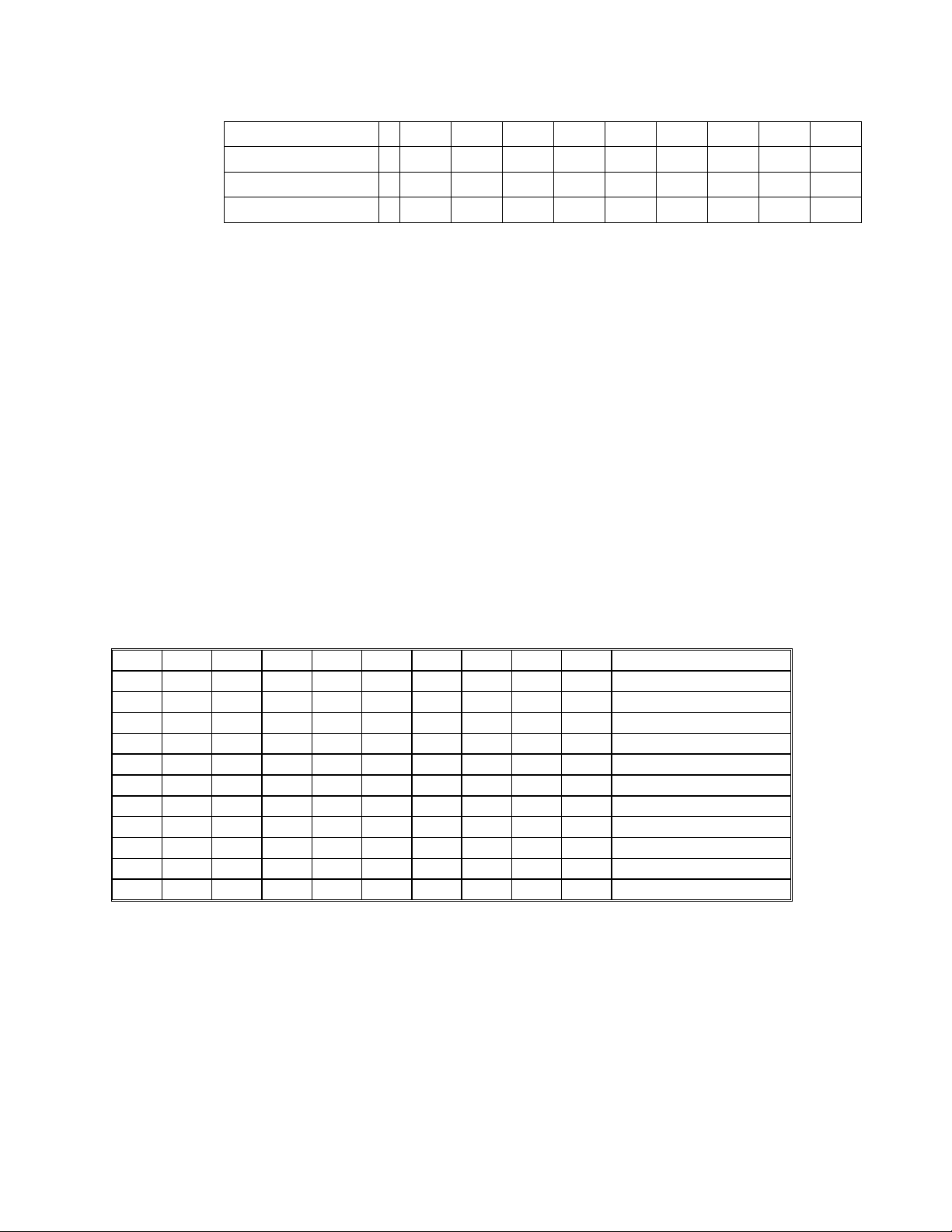

110 LPRINT CHR$(27);"[0;9;1}"; 'height 3/4", hr = on, interleaved 2 of 5

120 LPRINT CHR$(27);"[3t"; 'turn on bar code

140 LPRINT "001234,001234"; 'comma delimiter

150 LPRINT CHR$(27);"[0t"; 'turn off bar code

160 LPRINT "comma delimiter"

170 LPRINT

180 LPRINT CHR$(27);"[3t"; 'turn on bar code

190 LPRINT "001234 001234"; 'space delimiter

200 LPRINT CHR$(27);"[0t"; 'turn off bar code

210 LPRINT "space delimiter"

220 LPRINT

230 LPRINT CHR$(27);"[4}"; 'style 4 = 3 of 9

240 LPRINT CHR$(27);"[3t"; 'turn on bar code

250 LPRINT "*1234**1234*"; 'asterisk delimiter

260 LPRINT CHR$(27);"[0t"; 'turn off bar code

270 LPRINT

280 LPRINT "asterisk delimiters are used in pairs"

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

42

Page 47

!#/E"

!#/E"

Interleaved 2 of 5, comma delimiter

!#/E"

Interleaved 2 of 5, space delimiter

*1234*

*1234* *1234*

Asterisk delimiters are used in pairs, 3 of 9

Figure 3-3 Comma, Space, and Asterisk Delimiters

!#/E"

*1234*

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

43

Page 48

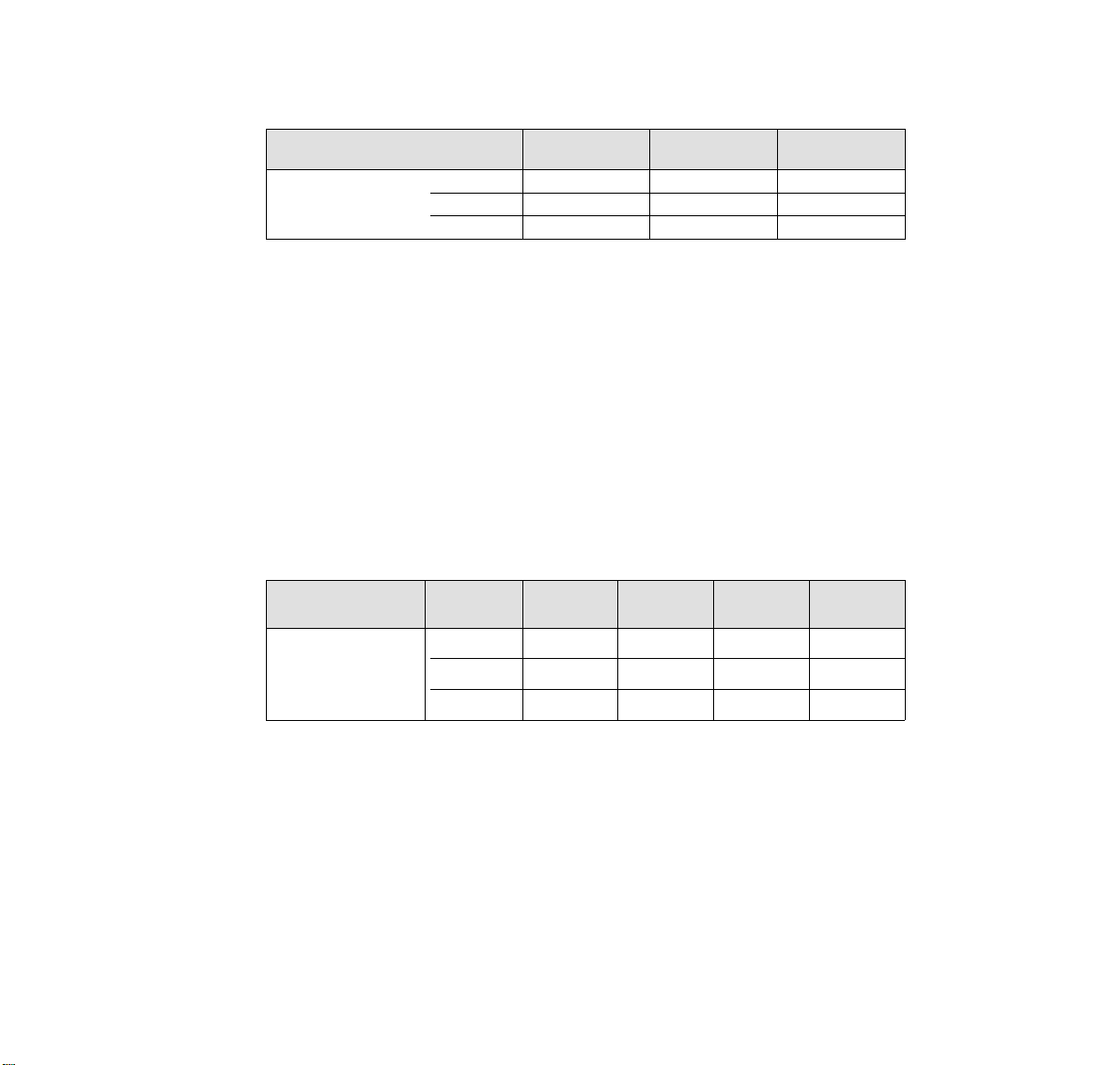

Horizontal Tab Delimiter

The HT control code (09) is a valid delimiter in all bar code styles. The leading quiet zone of a subsequent

symbol begins at the first tab stop right of the trailing quiet zone of the current symbol. This is evident in the

sample, where the quiet zone of the second symbol begins at the third tab stop.

Since this printer stores tabs in nonvolatile RAM while power is off, and since the control sequence that sets

horizontal tabs does not clear existing tabs, you should clear all tabs before setting tabs. Note also that new tab

stops do not take effect until you send a line terminator; in other words, you cannot set tabs for the current line.

The superfluous tab stops in the following example are included to show you how the function works. If you use

horizontal tabs for delimiters, then set no more tab stops than you plan to use.

100 LPRINT CHR$(27);"[4;9;1}"; ‘3 of 9

110 LPRINT CHR$(27);"[3g"; 'clear all h_tabs

120 'set horizontal tabs at 1/2-inch intervals

130 LPRINT CHR$(27);"[360;720;1080;14 40; 180 0;21 60 u"

150 FOR K = 1 TO 6 'show where the tabs are

160 LPRINT CHR$(9);"T";

170 NEXT K

180 LPRINT

190 LPRINT CHR$(27);"[3t"; 'turn on bar code

200 LPRINT "1234";CHR$(9);"1 234 ";

210 LPRINT CHR$(27);"[0t"; 'turn off bar code

TTTTTT

*1234*

Figure 3-4 Horizontal Tab Delimiter

*1234*

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

44

Page 49

Horizontal Position - Relative Delimiter

The horizontal position-relative command is a valid delimiter in all bar code styles except POSTNET.

ESC [(Pn)a

The argument units for this command are decipoints (1/720 inch), which the printer rounds off to the nearest

1/120 inch. This command is a valid delimiter even when issued with an argument of zero.

110 LPRINT CHR$(27);"[4;9;1}"; 'height 3/4", hr = on

120 LPRINT CHR$(27);"[3t"; 'turn on bar code

140 LPRINT "1234"; 'send a symbol

150 LPRINT CHR$(27);"[720a"; 'hp_relative 1 inch

160 LPRINT "1234"; 'send a symbol

170 LPRINT CHR$(27);"[0t"; 'turn off bar code

180 LPRINT "hp_rel delimiter"

*1234 *1234

1234 1234 hp_rel delimiter

Figure 3-5 Horizontal Position-Relative Delimiter

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

45

Page 50

Delimiters and Vertical Bar Codes

If you rotate a bar code 90o or 270o, then space imposed by delimiters is not rotated, but is applied horizontally, as

the sample shows. The symbol dimensions that used to be horizontal are shortened to 120/144 of what they used

to be; this includes the quiet zones.

100 LPRINT CHR$(27);"[4;9;1}"; ‘3 of 9

110 LPRINT CHR$(27);"[3g"; 'clear all h_tabs

120 'set horizontal tabs at 1/2-inch intervals

130 LPRINT CHR$(27);"[360;720;1080;14 40; 180 0;21 60 u"

140 LPRINT CHR$(27);"[0;9;1;;;;;;2}";

150 FOR K = 1 TO 6 'show where the tabs are

160 LPRINT CHR$(9);"T";

170 NEXT K

180 LPRINT

190 LPRINT CHR$(27);"[3t"; 'turn on bar code

200 LPRINT "1234";CHR$(9);"5678" ;

210 LPRINT CHR$(27);"[0t" 'turn off bar code

220 LPRINT CHR$(27);"[3t"; 'turn on bar code

230 LPRINT "2345";CHR$(9);"6 789 ";

240 LPRINT CHR$(27);"[0t" 'turn off bar code

TTTTTT

!1234! !2345!

Figure 3-6 Vertical Bar Code Symbols

!5678! !6789!

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

46

Page 51

Calculating Characters per Inch

We show characters per inch at the default element widths and 0o/180o rotation for each style in

the following chapter. All of our numbers ignore the quiet zones; you need to allow 1/2 inch per

symbol for the horizontal rotations.

Defining characters per inch for fixed-length codes is straightforward in that the start-stop and

center characters always take up the same portion of length of the symbol. The styles that have

center characters are all fixed-length.

For variable-length codes, net characters per inch depends on the number of data characters in

the symbol. The overhead imposed by start-stop characters is the same whether a symbol

represents 1 data character or 10, so the net cpi is greater for longer symbols. We show the

overhead imposed by start-stop characters separately for the variable length codes.

The default element widths are the narrowest that we recommend. If you use wider element

widths and maintain a 3:1 ratio of wide elements to narrow elements, then you can extrapolate

characters-per-inch for wider symbols. If you depart from the 3:1 ratio, then it's simpler for you to

print test symbols and derive formulae based on what you measure than it is for us to tell you how

to do the computation for each style.

One way to determine the combined length of start-stop characters for a variable-length symbol is

to print two symbols, one with twice as many data characters as the other. Measure the shorter

symbol and call this L1; measure the longer symbol and call this L2. The combined length of the

start-stop characters is:

d = (2 x L1) - L2

To summarize, when using our cpi figures to predict the length of a symbol, remember:

• Allow for two quiet zones per symbol.

• For variable-length symbols, allow the combined start-stop character length for each symbol.

• If you use a check character, then allow for the check character.

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

47

Page 52

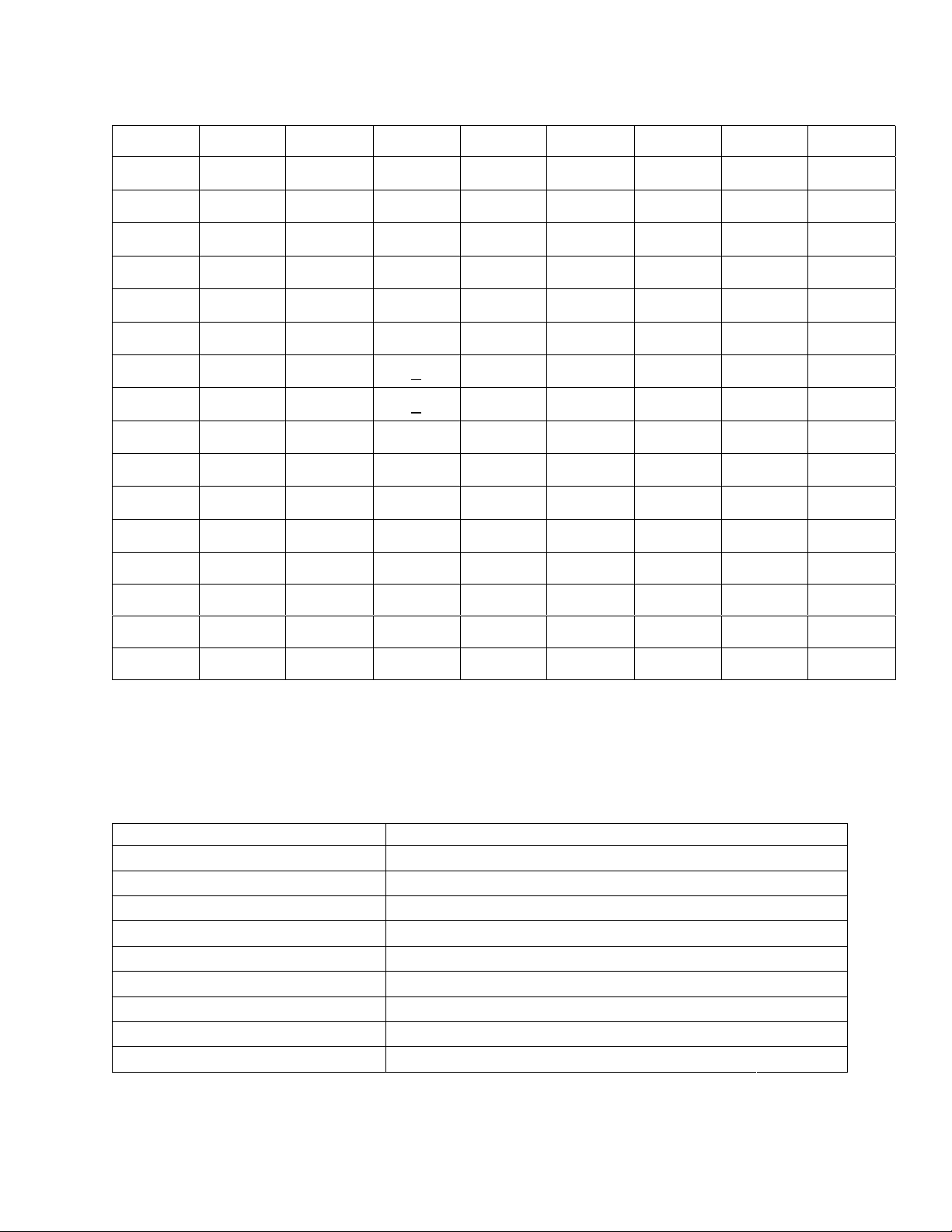

Bar Code Style Characteristics

The following pages show specific information about the various styles. A NULL character is a

combination of bars and spaces unique to a particular style that is printed when a nonvalid

character is encountered in received bar code symbol data. A null character in the symbol shows

up as a diamond in the human-readable line if the HRL is enabled.

Interleaved 2 of 5 (Style 0)

1 Bars per unit (2 characters): 5 dark bars and 5 light bars

2 Character set: 0 through 9

3 Start character: 2 dark bars and 2 light bars Stop character: 2 dark bars and 1

light bar

4 Center character code: None

5 NULL character: Yes

6 Intercharacter gap: None

7 Characters per symbol: Variable

8 Check digit: None.

9 Delimiters: Space, comma, horizontal tab, hp_relative

10 HR characters: Currently selected font, special HR font, special OCR-A/O CR-B

font (120 DPI only)

11 CPI at default element widths: 6.857

12 Combined start-stop character length: 0.167"

Bidirectional/Industrial 2 of 5 (Styles 1 and 3)

1 Bars per character: 5 dark bars and 4 light bars

2 Character set: 0 through 9

3 Start/Stop characters: 2 dark bars and 1 light bar

4 Center character code: None

5 NULL character: Yes

6 Intercharacter gap: None

7 Characters per symbol: Variable

8 Check digit: None

9 Delimiters: Space, comma, horizontal tab, hp_relative

10 HR characters: Currently selected font, special HR font, special OCR-A/O CR-B

font (120 DPI only)

11 CPI at default element widths: 4.3

12 Combined start-stop character length: Style 1 = 0.319", Style 3 = 0.139"

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

48

Page 53

Matrix 2 of 5 (Style 2)

1 Bars per character: 3 dark bars and 2 light bars

2 Character set: 0 through 9

3 Start/Stop characters: 3 dark bars and 2 light bars

4 Center character code: None

5 NULL character: Yes

6 Intercharacter gap: None

7 Characters per symbol: Variable

8 Check digit: None

9 Delimiters: Space, comma, horizontal tab, hp_relative

10 HR characters: Currently selected font, special HR font, special OCR-A/O CR-B

font (120 DPI only)

11 CPI at default element widths: 6.0

12 Combined start-stop character length: 0.278"

Code 3 of 9 (Style 4)

1 Bars per character: 5 dark bars and 4 light bars

2 Character set: 0 through 9, upper case letters A through Z characters - . $ / + %

and the space character

3 Start/Stop characters: Yes

4 Center character code: None

5 NULL character: Yes

6 Intercharacter gap: None

7 Characters per symbol: Variable

8 Check digit: None

9 Delimiters: Comma, asterisk (use in pairs--one before the bar code symbol and

one following it), horizontal tab, hp_relative

10 HR characters: Currently selected font, special HR font, special OCR-A/O CR-B

font (120 DPI only)

11 CPI at default element widths: 3.78

12 Combined start-stop character length: 0.514"

72655 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

49

Page 54

EAN-8 (Style 5)

1 Bars per character: 2 dark bars and 2 light bars

2 Character set: 0 through 9

3 Start/Stop characters: 2 dark bars and 1 light bar

4 Center character code: Yes

5 NULL character: Yes

6 Intercharacter gap: None

7 Characters per symbol: 8

8 Check digit: The check digit can be

supplied by the data source.

9 Delimiters: Space, comma, horizontal tab, hp_relative

10 HR characters (without guard bars): Currently selected font, special HR font,

special OCR-A/OCR-B font (120 DPI only), HR characters (with guard bars):

OCR-B font

11 CPI at default element widths: 7.385

EAN-13 (Style 6)

1 Bars per character: 2 dark bars and 2 light bars

2 Character set: 0 through 9

3 Start/Stop characters: 2 dark bars and 1 light bar

4 Center character code: Yes

5 NULL character: Yes

6 Intercharacter gap: None

7 Characters per symbol: 13

8 Check digit: The check digit can be

supplied by the data source.

9 Delimiters: Space, comma, horizontal tab, hp_relative

10 HR characters (without guard bars): Currently selected font, special HR font,

special OCR-A/OCR-B font (120 DPI only), HR characters (with guard bars):

OCR-B font

11 CPI at default element widths: 8.283

7265 Programmer’s Manual

Copyright © 2004 TallyGenicom Chapter 3 ANSI Bar Codes

50

Page 55

Code 11 (Style 7)

1 Bars per character: 3 dark bars and 2 light bars

2 Character set: 0 through 9 and the dash character

3 Start/Stop characters: Yes

4 Center character code: None

5 NULL character: Yes