Page 1

Administrator’s Manual

6800 Series Printer s

Page 2

READ THIS SOFTWARE LICENSE AGREEMENT BEFORE USING THIS PRINTER

Software License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE USING THIS PRINTE R. USING THIS PRINTE R INDICATES

YOUR ACCEPTANCE OF THESE TERMS AND CONDITIONS. IF YOU DO NOT AGREE TO THESE TERMS AND CONDITIONS,

PROMPTLY RETURN THE PRINTER AND ALL ACCOMPANYING HARDWARE AND WRITTE N MATERIA LS TO THE PLACE YOU

OBTAINED THEM, AND YOUR MONEY WILL BE REFUNDED.

Definitions.

“Software” shall mean the digitally encod ed, machine-readable data and program. The term “Software Product” in clude s the Software

resident in the printer and its documentation. The Software Product is licensed (not sold) to you, and TallyGenicom. either owns or licenses

from other vendors who own, all copyright, trade secret, patent and other proprietary rights in the Software Product.

License.

1.

Authorized Use. You agree to accept a non-exclusive license to use the Software resident in the printer solely for your own customary

business or personal purposes.

2.

Restrictions.

a.

To protect the proprietary rights of TallyGenicom, you agree to maintain the Software Product and other proprietary information

concerning the typefaces in strict confidence.

b.

You agree not to duplicate or copy the Software Product.

c.

You shall not sublicense, sell, lease, or otherwise transfer all or any portion of the Software Product separate from the printer,

without the prior written consent of TallyGenicom.

d.

You may not modify or prepare derivative works of the Software Product.

e.

You may not transmit the Software Product over a network, by telephone, or electronically using any means; or reverse engineer,

decompile or disassemble the Software.

f.

You agree to keep confidential and use your best efforts to prevent and protect the contents of the Software Product from

unauthorized disclosure or use.

3.

Transfer. You may transfer the Software Product with the printer, but only if the recipient agrees to accept the terms and conditions of

this Agreement. Your license is automatically terminated if you transfer the Software Product and printer.

Limited Software Product Warranty

TallyGenicom warrants that for ninety (90) days after delivery, the Software will perform in accordance with specifications publi sh ed by

TallyGenicom. TallyGenicom does not warrant that the Software is free from all bugs, errors and omissions.

Remedy

Your exclusive remedy and the sole liability of TallyGenicom in connection with the Software is replacement of defective software with a copy

of the same version and revision level.

Disclaimer of Warranties and Limitat ion of Remedies

1.

THE PARTIES AGREE THAT ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRA NTIE S OF

FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY ARE EXCLUDED. TallyGenicom does not warrant that

the functions contained in the Software will meet your requirements or that the operation of the Software will be uninterrupted

or error free. TallyGenicom reserves the right to make changes and/or improvements in the Software w ithout notice at any

time.

2.

IN NO EVENT WILL TALLYGENICOM BE LIABLE FOR LOST PROFITS, LOST DATA, BUSINE S S INTERRUP TIONS, OR

ANY OTHER DIRECT, INDIRECT, INCIDENTAL OR CONSEQ UENTI A L DAMA GES ARIS ING OUT OF THE USE OF OR

INABILITY TO USE THIS PRODUCT, EVEN IF TALLYGENICOM HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES, OR ANY DAMAGES CAUSED BY THE ABUSE OR MANIPULATION OF THE SOFTWARE. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, SO

THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

3.

TallyGenicom will not be liable for any loss or damage caused by delay in furnishing a Software Product or any other

performance under this Agreement.

4.

Our entire liability and your exclusive remedies for our liability of any kind (including liability for negligence except liability for

personal injury caused solely by our negligence) for the Software Product covered by this Agreement and all other

performance or nonperformance by us under or related to this Agreement are limited to the reme dies specified by this

Agreement.

5.

California law governs this Agreement.

Termination of License Agreement

This License shall continue until terminated. This license may be terminated by agreement between you and TallyGenicom or by

TallyGenicom. If you fail to comply with the term s of this Licen se and su c h failur e is not corre cted within thirty (30) days after notice.

When this License is terminated, you shall return to the pla ce you obta ined them, the printer and all copies of the Software and

documentation.

U.S. Government Restricted Rights

Use, duplication or disclosure by the Government is subject to restrictions as set forth in the Rights in Technical Data and Computer

Software clause at FAR 242.227-7013, subdivision (b) (3) (ii) or subparagraph (c) (1) (ii), as appropriate. Further use, duplication or

disclosure is subject to restrictions applicable to restricted rights software as set forth in FAR 52.227-19 (c) (2).

Page 3

Acknowledgement of Terms and Conditions

YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT, AND AGREE TO BE BOUND BY ITS

TERMS AND CONDITIONS. NEITHER PARTY SHALL BE BOUND BY ANY STATEMENT OR REPRESENTATION NOT

CONTAINED IN THIS AGREEMENT. NO CHANGE IN THIS AGREEMENT IS EFFECTIVE UNLE SS WRITTE N A ND SIGNED BY

PROPERLY AUTHORIZED REPRESENTATIVES OF EACH PARTY. BY USING THIS PRINTE R, Y O U AGREE TO ACCEPT THE

TERMS AND CONDITIONS OF THIS AGREEMENT.

This document contains proprietary information protected by copyright. No part of this document

may be reproduced, copied, translated, or incorporated in any other material in any form or by any

means, whether manual, graphic, electronic, mechanical, or otherwise, without the prior written

consent of TallyGenicom.

TallyGenicom makes no representations or warranties of any kind regarding this material, including,

but not limited to, implied warranties of merchantability and fitness for a particular purpose.

TallyGenicom shall not be held responsible for errors contained herein or any omissions from this

material or for any damages, whether direct or indirect, incidental or consequential, in connection

with the furnishing, distribution, performance, or use of this material. The information in this manual

is subject to change without notice.

COPYRIGHT 2013 PRINTRONIX, LLC.

Trademark Acknowledge ments

IBM, AS/400, and Proprinter are registered trademarks, and Intelligent Printer Data Stream and IPDS are

trademarks of International Business Machines Corporation.

Printronix, PGL, LinePrinter Plus, and IGP are registered trademarks, and 6805, 6810, 6805Z, 6810Z,

6805Q, 6810Q, 6815Q, 6820Q, and SureStak are trademarks of Printronix, LLC.

ANSI is a registered trademark of the American National Standards Institute, Inc.

Centronics is a registered trademark of Genicom Corporation.

CSA is a registered certification mark of the Canadian Standards Association.

Dataproducts is a registered trademark of Dataproducts Corporation.

EIA is a registered service mark of the Electronic Industries Association.

Epson is a registered trademark of Seiko Epson Corporation.

Ethernet is a trademark of Xerox Corporation.

IEEE is a registered service mark of the Institute of Electrical and Electronics Engineers, Inc.

QMS is a registered trademark, and Code V is a trademark of Quality Micro Systems, Inc.

TallyGenicom brand is owned by Printronix, LLC.

TUV is a registered certification mark of TUV Rheinland of North America, Inc.

UL is a registered certification mark of Underwriters Laboratories, Inc.

Page 4

Table of Contents

Introduction .................................................................... 9

Printer Overview .................................................................................................. 9

TallyGenicom 6800 Series Cartridge Ribbon Printers (CRP) ....................... 9

Consumable Monitoring with PrintNet Enterprise ............................................. 10

Protocols and Emulations .................................................................................. 10

Taking Care of your Printer ............................................................................... 11

Conventions in this Manual ............................................................................... 11

Warnings and Special Information .................................................................... 11

Related Documents ........................................................................................... 11

Setting Up The Printer ................................................. 13

Before You Begin .............................................................................................. 13

Power Requirements ......................................................................................... 13

Select a Site ...................................................................................................... 13

Printer Dimensions ............................................................................................ 14

Printer Component Locations ............................................................................ 17

Operating The Printer .................................................. 19

Powering on the Printer ..................................................................................... 19

Operating Modes ............................................................................................... 19

The Control Panel .............................................................................................. 20

Control Panel Keys ..................................................................................... 21

Cancel a Print Job ....................................................................................... 23

Operational Procedures ..................................................................................... 23

Reload Paper .............................................................................................. 23

Unload Paper .............................................................................................. 30

Integrated Print Management System ............................................................... 31

Output Darkness ......................................................................................... 32

Loading a Used Ribbon Cartridge .............................................................. 32

Lighter Or Darker Print ................................................................................ 32

Changing Ribbon Cartridge ........................................................................ 32

Configuration Menus .................................................... 37

Configuration Overview ..................................................................................... 37

Changing Parameter Settings ..................................................................... 37

Saving Parameter Settings ......................................................................... 37

Default and Custom Configur atio ns ............................................................ 37

Navigating the Menus ................................................................................. 38

Top Level Menu Overview ................................................................................. 39

Changing Parameters Example .................................................................. 40

Auto Save Configuration ............................................................................. 42

Page 5

Saving Your New Configuration .................................................................. 42

6800 CRP Main Menu ....................................................................................... 48

Quick Setup ....................................................................................................... 49

Operator Menu .................................................................................................. 51

Font Submenu ............................................................................................ 52

Forms Submenu ......................................................................................... 57

Vertical Format Units (VFU) Submenu ....................................................... 61

Config Menu ...................................................................................................... 62

Printer Submenu ......................................................................................... 62

Codes Submenu ......................................................................................... 65

Graphics Submenu ..................................................................................... 69

Configurations Submenu ............................................................................ 73

Host Interface Submenu ............................................................................. 75

USB I/O Submenu ...................................................................................... 76

Serial I/O Submenu ..................................................................................... 77

Parallel I/O Submenu .................................................................................. 80

Intellifilter Submenu .................................................................................... 81

Main File Mgmt Submenu ........................................................................... 82

SD File Mgmt Submenu .............................................................................. 83

CST/PAA Submenu .................................................................................... 84

PTX_SETUP Option Submenu ................................................................... 84

TCP/IP Menu ..................................................................................................... 84

Ethernet Address ........................................................................................ 85

Ethernet Params ......................................................................................... 86

Test Menu .......................................................................................................... 87

Pattern Submenu ........................................................................................ 88

Fault Override Submenu ............................................................................. 89

Diag Submenu ............................................................................................ 90

Interfaces ..................................................................... 91

Overview ............................................................................................................ 91

RS-232 Serial Interface ..................................................................................... 93

USB ................................................................................................................... 94

Centronics Parallel Interface ............................................................................. 94

Centronics Parallel Interface Signals .......................................................... 95

IEEE 1284 Parallel Interface ............................................................................. 95

Compatibility Mode ..................................................................................... 95

Nibble Mode ................................................................................................ 95

Byte Mode ................................................................................................... 95

Signals ........................................................................................................ 95

Ethernet ............................................................................................................. 97

Reprogramming the Security Key ................................ 99

Reprogramming the Security Key ..................................................................... 99

Page 6

How to Program the Security Key ............................................................... 99

Downloading Firmware .............................................. 101

Firmware File Types (.prg) and (.exe) ............................................................. 102

WebPanel Download ....................................................................................... 102

Automatic Download (.exe) ............................................................................. 105

Manual Two-Key Download Sequence ........................................................... 107

Manual Three-Key Download Sequence......................................................... 107

Sending Firmware in Download Mod e ............................................................ 108

Sending Firmware via Ethernet (FTP) ...................................................... 108

Sending Firmware via USB ....................................................................... 109

Sending Firmware via Parallel .................................................................. 113

Sending Firmware via Serial ..................................................................... 113

Downloading Files to the Main File System .................................................... 114

Filename Extensions Not Shown in Menus ..................................................... 114

WebPanel File Download ................................................................................ 115

PTX_SETUP Download................................................................................... 116

Manual Two-Key Download ............................................................................ 116

Downloading Files to the SD Card .................................................................. 117

Demo Facility ................................................................................................... 117

Downloading a Demo File ......................................................................... 117

Configuring the Printer to run a Demo File ............................................... 118

Starting a Demo File ................................................................................. 118

Pausing a Demo File ................................................................................. 118

Stopping a Demo File ............................................................................... 118

Deleting a Demo File ................................................................................ 118

Troubleshooting ......................................................... 119

Cleaning Requirements ................................................................................... 119

Exterior Cleaning ...................................................................................... 119

Interior Cleaning ........................................................................................ 119

Diagnosing Problems ...................................................................................... 121

Bar Code Verification ................................................................................ 121

Printing a Hex Dump ................................................................................. 122

Most Frequent Problems and Solutions .......................................................... 124

Diagnostics for EXX, BAD NVM, or ILL NVM Errors ....................................... 124

Fault Messages ......................................................................................... 125

Printer Specifications ................................................. 143

Ribbon Cartridge Specifications ...................................................................... 143

Paper Specifications ........................................................................................ 143

Labels .............................................................................................................. 143

Printer Weight and Dimensions ....................................................................... 144

Environmental Characteristics ......................................................................... 144

Page 7

Acoustic Noise Level ....................................................................................... 144

Electrical Characteristics ................................................................................. 145

Interfaces .................................................................................................. 145

Printing Speed ................................................................................................. 145

ASCII Character Set .................................................. 147

Zero Tear Pedestal Printer ......................................... 149

Overview .......................................................................................................... 149

Operation ......................................................................................................... 149

Position the Paper Input and Adjust the Paper Guides ............................ 149

Load Paper................................................................................................ 151

Position the Paper Out Sensor ................................................................. 153

Set the Tear Bar Distance ......................................................................... 154

ZTP SETTINGS Menu ..................................................................................... 156

Performance Considerations ........................................................................... 157

How to Set the ZTP Printer to Help Mitigate Paper Jams ........................ 158

Quick Change Memory Card (QCMC) ....................... 159

Overview .......................................................................................................... 159

Installing the QCMC ........................................................................................ 160

Saving the Printer’s Configuration to the QCMC ............................................. 161

Copying the QCMC “Snapshot” Image to a Second Printer............................ 162

PTX_SETUP Commands ........................................... 165

Overview .......................................................................................................... 165

The PTX_SETUP Commands ......................................................................... 165

Commands ................................................................................................ 165

Customer Support ...................................................... 171

TallyGenicom Customer Support Center ........................................................ 171

TallyGenicom Supplies Department ......................................................... 171

Corporate Offices ...................................................................................... 172

Communication Notices ............................................. 173

Notices ............................................................................................................. 173

Communication Statements ............................................................................ 174

Software License Agreement .......................................................................... 179

Page 8

Page 9

Introduction

Printer Overview

This chapter provides a general overview of your printer and the conventions used within this manual.

TallyGenicom 6800 Series Cartridge Ribbon Printers (CRP)

TallyGenicom® is pleased to announce the TallyGenicom 6800™ Series Line Matrix printers, the latest

generation product from a long heritage of high quality extending over 30 years. TallyGenicom® is a

global leader for design and manufacturing with the ability to deliver unsurpassed service and support.

The TallyGenicom 6800™ Line Matrix Printing Platform extends the series of technology innovations that

cement TallyGenicom’s reputation of world class printing. Line matrix printing is TallyGenicom’s flagship

technology, and it remains the workhorse solution for supply-chain and back-office printing applications

because of its reliability, lower cost of ownership and flexibility of printing applications.

• Most reliable printer ever – Durability provides more up time and lower operating costs

• High capacity ribbon cartridge – Darker, easy to read images, last longer, and costs less to operate

than other print technologies

• Integrated print management system – provides precise control over print quality, print costs, and job

planning

• Cabinet, pedestal, or zero tear pedestal (ZTP) styles – best user access and forms handling flexibility

• Unsurpassed ease of use – larger graphics LCD simplifies operation and enhances productivity

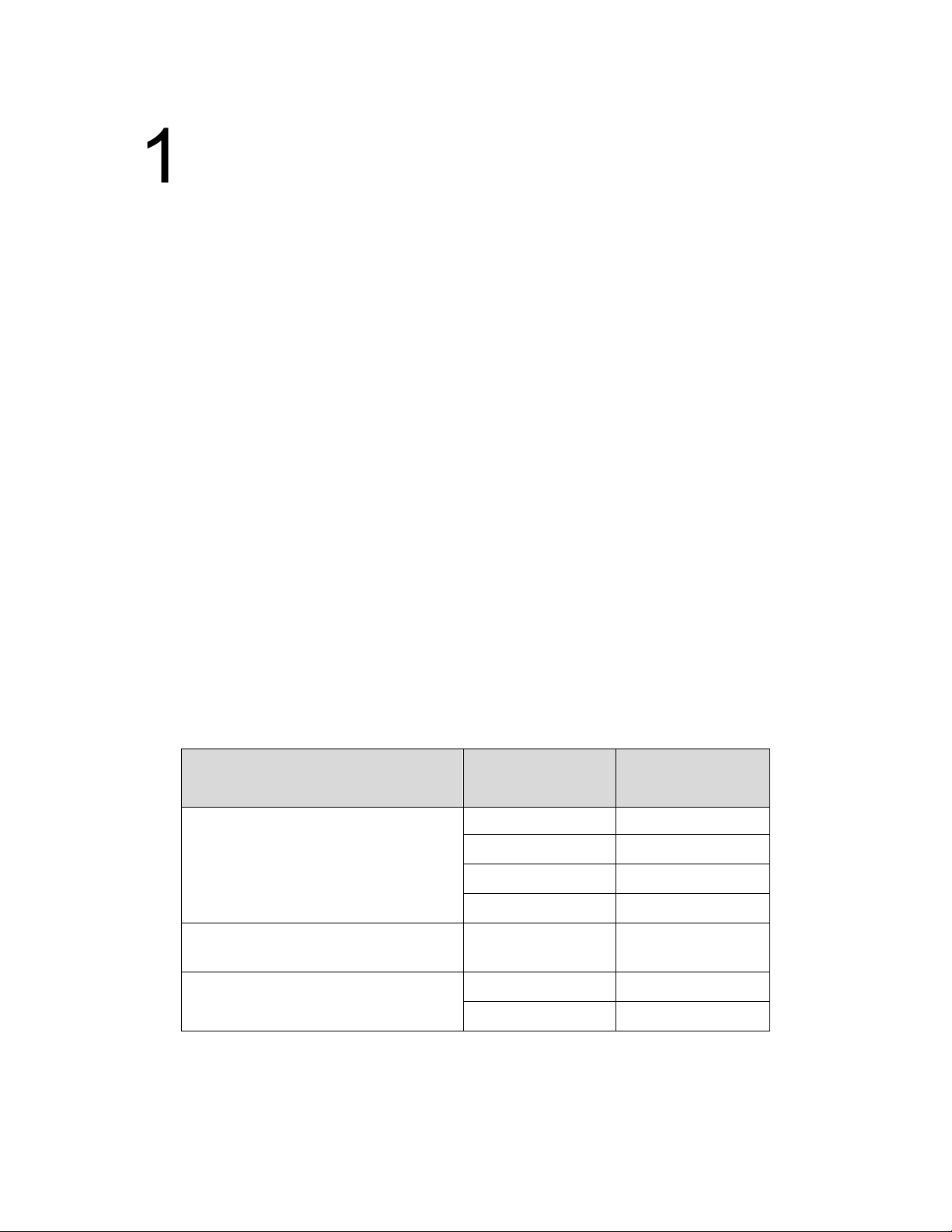

Table 1 6800 Series Models and Configurations

Number Model

LMPPLS

(Line Matrix Printer Pedestal Low Speed)

LMPCLS

(Line Matrix Printer Cabinet Low Speed)

Configuration

Number

6805 500

6805Z 500

6810 1000

6810Z 1000

6810Q 1000

Print Speed (Lines

per Minute)

LMPCHS

(Line Matrix Printer Cabinet High Speed)

6815Q 1500

6820Q 2000

9

Page 10

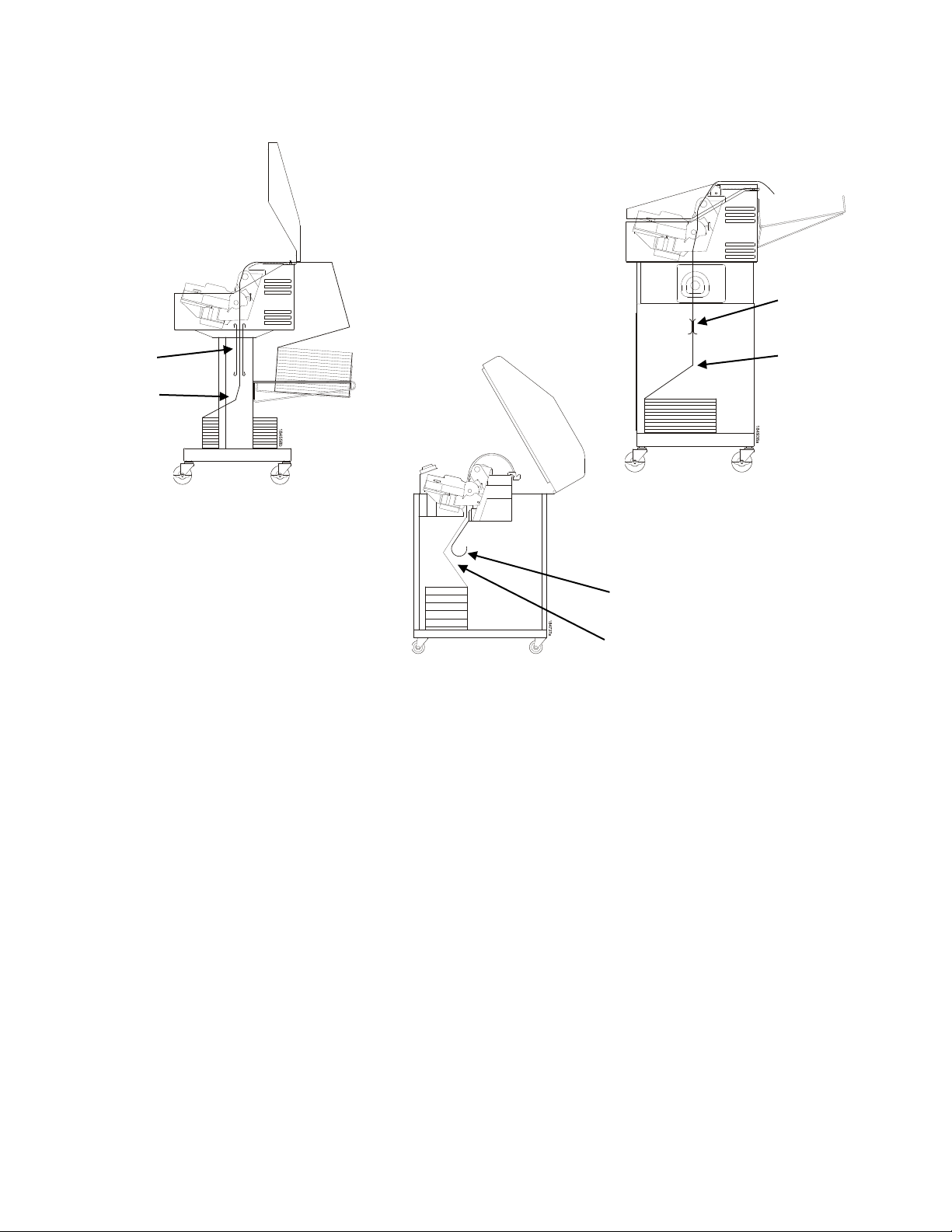

Five printer configurations are available:

Cabinet (68XXQ)

• The enclosed cabinet models provide for near silent operation, making these printers perfectly

suitable for use in the quietest of office environments.

• Provides the best paper handling for large print runs. All paper input and outp ut i s contai ned insi de

the cabinet and protected from bumping and contamination.

• Highly effective combination of moveable fences and chains allows for precise stacking all the way up

to a full box of paper.

• Available in the following print speeds: 1000, 1500 and 2000 lpm models.

Pedestal (68XX)

• The pedestal model has a clamshell design that allows easy access to all controls providing faster

ribbon replacements and easier paper loading.

• Oversized casters are standard making movement easy.

• Available in the following print speeds : 500 and 1000 l pm models.

Zero Tear Pedestal (68XXZ)

• Special push tractor configuration enables printing from the very first to the very last line of a form and

then tear-off with no forms lost

• The elimination of wasted forms between jobs can yield significant savings.

• An ideal solution for supply-chain and back-office applications.

• Available in the following print speeds : 500 and 1000 l pm models.

Consumable Monitoring with PrintNet Enterprise

The Integrated Print Management System works with PrintNet Enterprise (PNE). PNE allows a system

administrator to remotely view the current consumable status of all printers. PNE can be configured to

deliver alerts on all consumable warnings. When a ribbon reaches the low state, PNE notifies the system

administrator remotely via an automated e-mail alert of the low condition. This allows corrective action to

be taken before the ribbon reaches its end of life. If the ribbon is not changed, an alert will again be

initiated once the ribbon reaches the 0% end point. Refer to your PrintNet Enterprise Remote

Management Software manual for details.

Protocols and Emulations

A protocol is a set of rules governing the exchange of information between the printer and its host

computer. These rules consist of codes that manipulate and print data and allow for machine-to-machine

communication. A printer and its host computer must use the same protocol. As used in this manual,

protocol and emulation mean the same thing.

Most impact printers use single ASCII character codes to print text, numbers, and punctuation marks.

Some characters, are defined as control codes. Control codes instruct the printer to perform specific

functions, such as underlining text, printing subscripts, setting page margins, etc. The difference between

most printer protocols is the characters used to create control codes and the ways in which these

characters are formatted.

When the printer executes the character and control codes of a particular printer protocol, it is emulating

that printer.

10

Page 11

Taking Care of your Printer

Your printer will produce high quality print jobs if it is well taken care of. Periodic cleaning, handling the

printer properly, and using the correct printer supplies such as ribbon and paper ensures optimum

performance. Chapter 8 explains how to clean the printer, and printer supplies are listed in Appendix A.

Conventions in this Manual

Control panel keys and indicators are highlighted in UPPERCASE BOLD PRINT.

Example: Press the CANCEL key, then press the ONLINE key.

Quotation marks (“ ”) indicate messages on the Liquid Crystal Display (LCD).

Example: Press the ONLINE key. “OFFLINE” appears on the LCD.

The + (plus) symbol represents key combinations.

Example: “Press + ” means press the (UP) key and the (DOWN) key at the same time.

Warnings and Special Information

Read and comply with all information highlighted under special headings:

WARNING A warning notice calls attention to a condition that could harm you.

CAUTION A caution notice calls attention to a condition that could damage the printer.

IMPORTANT Information vital to proper operation of the printer.

NOTE: A note gives you helpful tips about printer operation and maintenance.

Related Documents

• Quick Reference Guide — Explains how to set up the printer for basic operation (load ribbon cartridge

and media, and clear paper jams).

• Maintenance Manual — Explains how to maintain and repair the line matrix printer at the field service

level of maintenance.

• Integrated Network Interface Card User’s Manual

Information about network protocols, configuration, and network operation.

• 6800 Series Printers Emulations App l icati ons Manu al, Vol um e 1

Defines printer emulations.

• 6800 Series Printers Fonts and Character Sets App lic a tions Man ua l, Volume 3

Defines printer fonts and character sets.

• 6800 Series Printers Graphics Languages Applications Manual, Volume 4

Defines Code V, PGL, and MT660 IG printer graphics languages.

11

Page 12

12

Page 13

Setting Up The Printer

Before You Begin

Read this chapter carefully before installing and operating the printer. The printer is easy to install.

However, for your safety and to protect valuable equipment, perform all the procedures in this chapter in

the order presented.

Power Requirements

The printer must be connected to a power supply outlet that supplies 90 to 264 volts AC at its upper and

lower limits. These limits take into account normal voltage sags and surges created on the nominal line

voltage by other AC power loads associated with the AC distribution line. The printer automatically

senses and adjusts itself to conform to the correct voltage range.

Primary circuit protection is provided by the AC source protection device. Consult an electrician if printer

operation affects local electrical lines.

IMPORTANT Pri nter p ower should be supplied from a separate AC circuit protected at 20

amperes maximum for 100 - 240 volts at 50 or 60 Hertz.

Select a Site

Select a printer site that meets all of the following requirements:

• Permits complete opening of the printer cover and doors.

• For cabinet models, allows at least three feet of clearance behind the printer. (This permits air to

circulate freely around the printer and provides access to the paper stacking area.)

• For pedestal models, DO NOT place the side of the printer (inlet and exit air vents) against a wall or

other object. A minimum of 6 inch spacing is recommended.

• Has a standard power outlet that supplies 100-135 Volts AC or 178-240 Volts AC power, at 47 to 63

Hz.

• Is relatively dust-free.

• Has a temperature range of 10° C to 40° C (50° F to 104° F) and a relative humidity from 15% to 90%

non-condensing.

• Is located within the maximum allowable cable length to the host computer. This distance depends on

the type of interface you plan to use, as shown in Table 2.

13

Page 14

41.0 in

27.0 in

(68.6 cm)

27.0 in

83.0 in

(210.8 cm)

29.0 in

27.0 in

(68.6 cm)

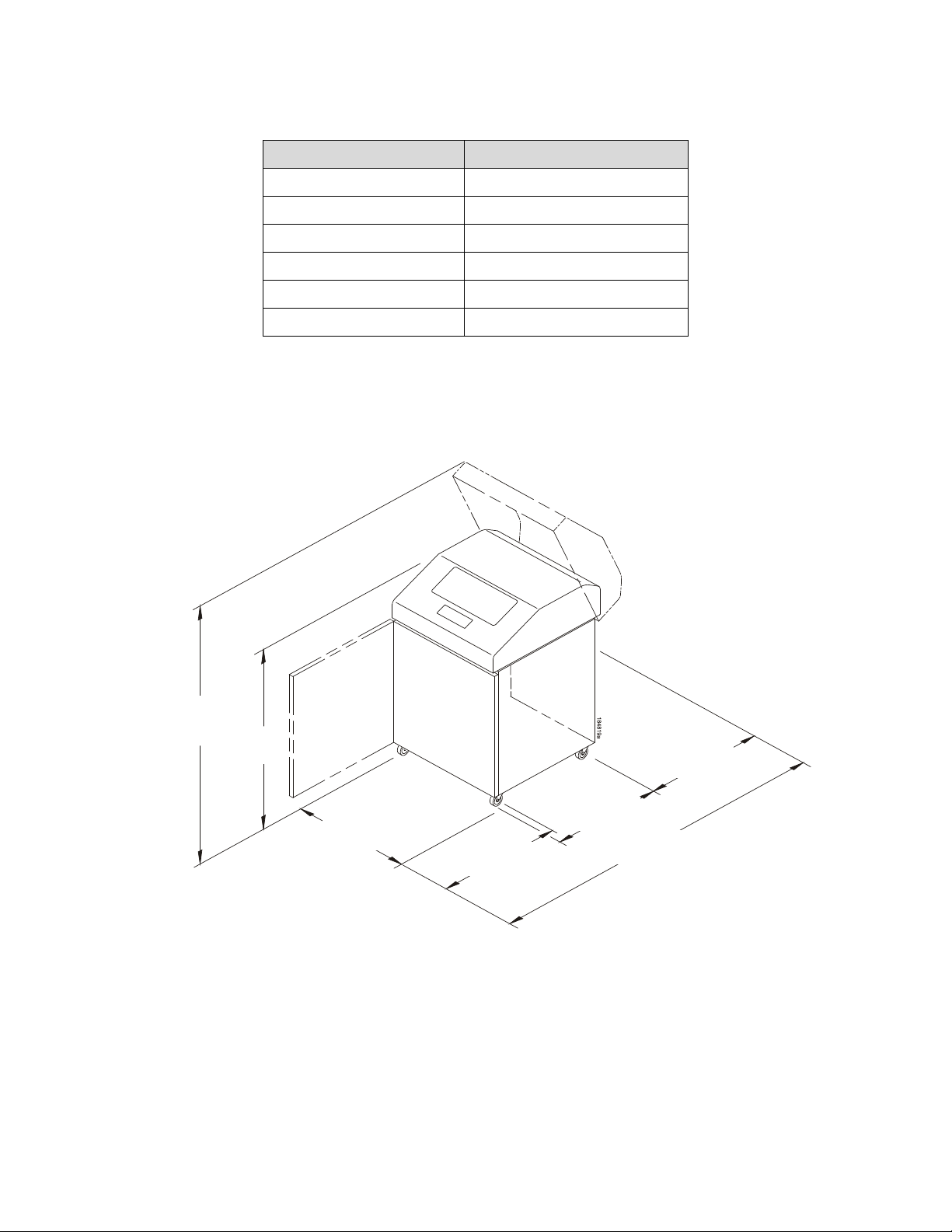

Table 2 Maximum Interface Connection Cable Length

Interface Type Maximum Cable Length

Centronics Parallel 5 meters (15 feet)

IEEE 1284 Parallel 10 meters (32 feet)

Serial RS-232 15 meters (50 feet)

USB 2.0 Universal Serial Bus 5 meters (15 feet)

Twisted Pair / Type 3 300 meters (985 feet)

Ethernet 10/100Base-T 100 meters (328 feet)

Printer Dimensions

57.5 in

(146.1 cm)

(104 cm)

(73.7 cm)

(68.6 cm)

Figure 1 Cabinet Model

14

Page 15

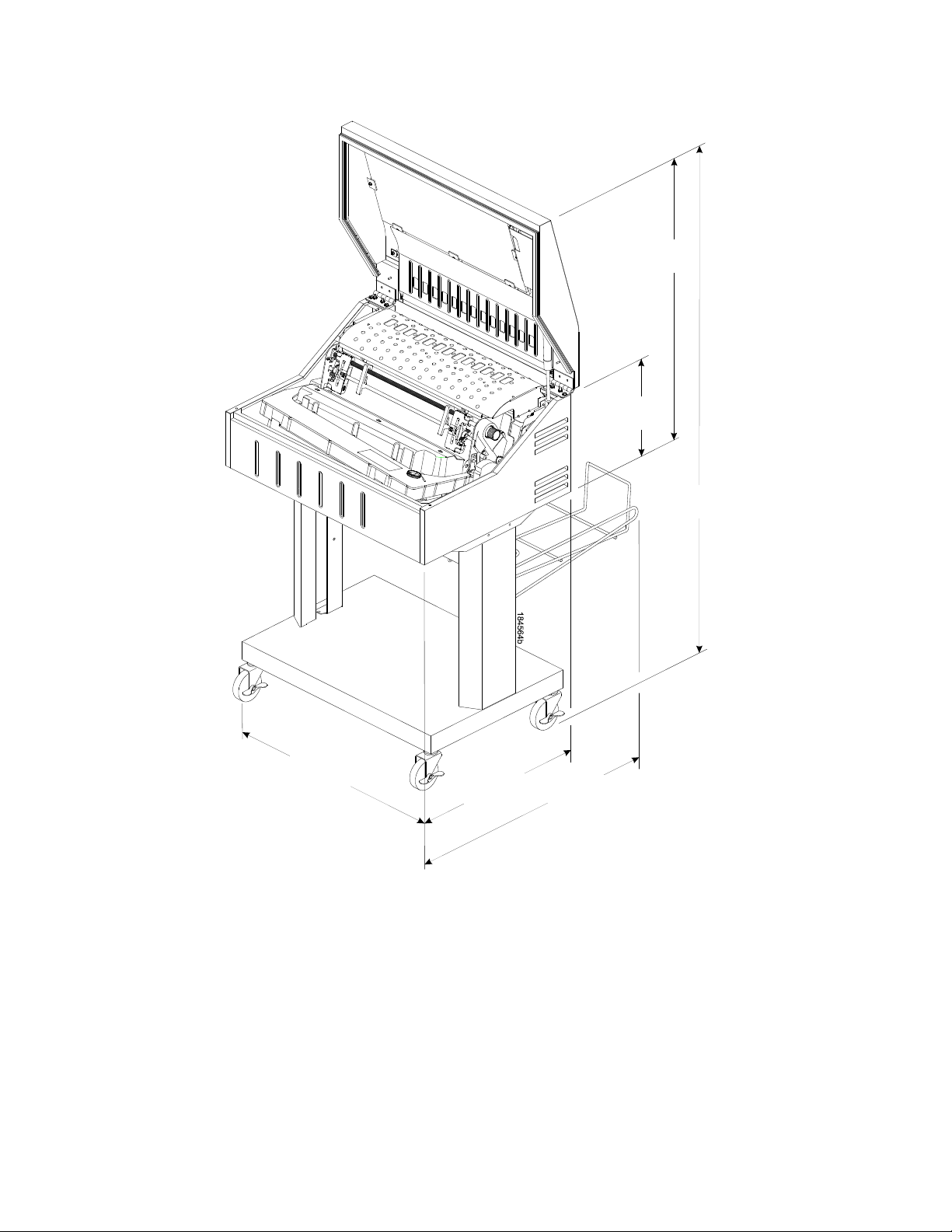

54.0 in

(28.9 cm)

29.5 in

(74.93 cm)

29.1 in

(73.9 cm)

19.1 in

(48.5 cm)

25.92 in

(65.8 cm)

11.36 in

(137.2 cm)

Figure 2 Pedestal Model

15

Page 16

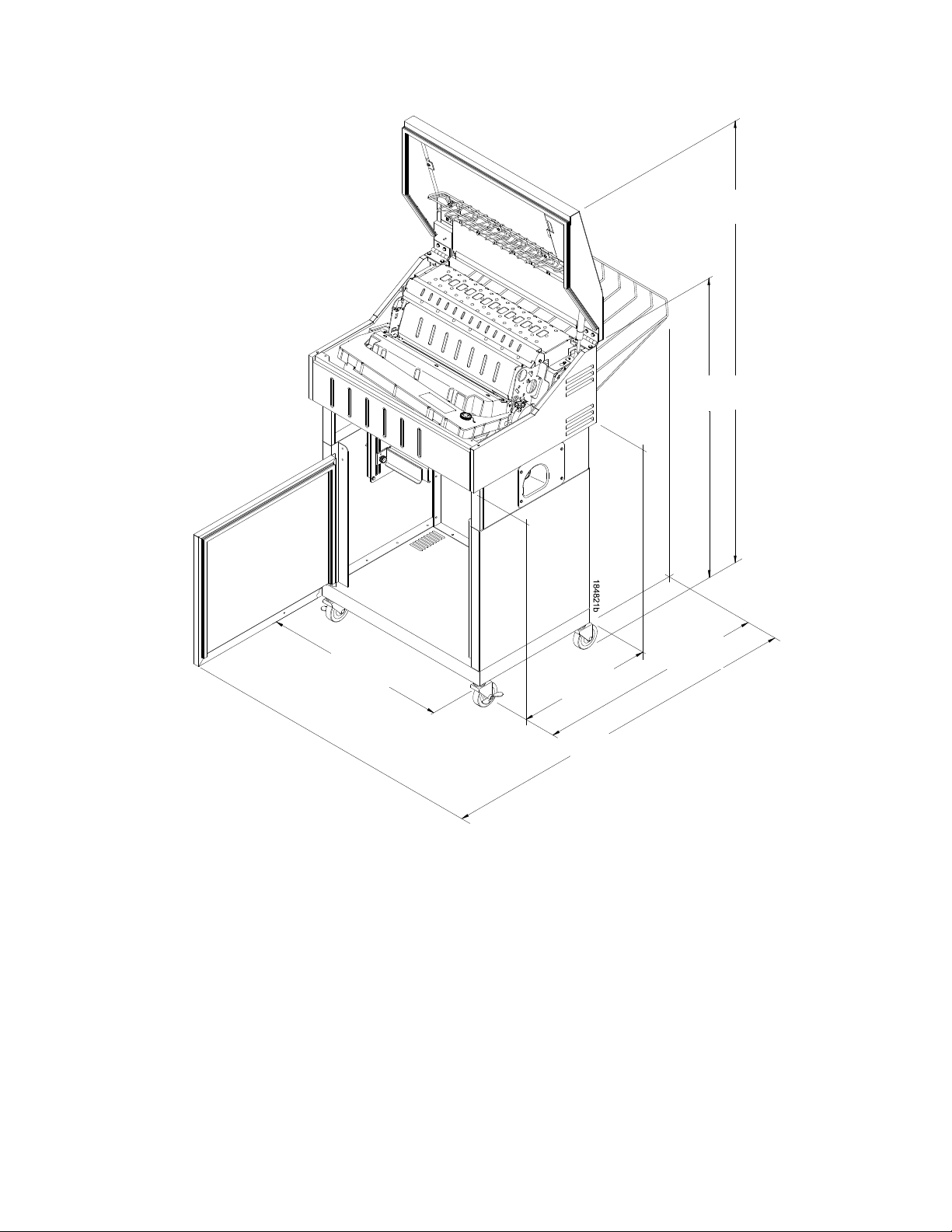

38.9 in

(98.8 cm)

19.1 in

(43.8 cm)

31.95 in

(81.2 cm)

25.92 in

(65.8 cm)

(106.7 cm)

60.1 in

(152.7 cm)

Figure 3 Zero Tear Pedestal Mode

42.0 in

16

Page 17

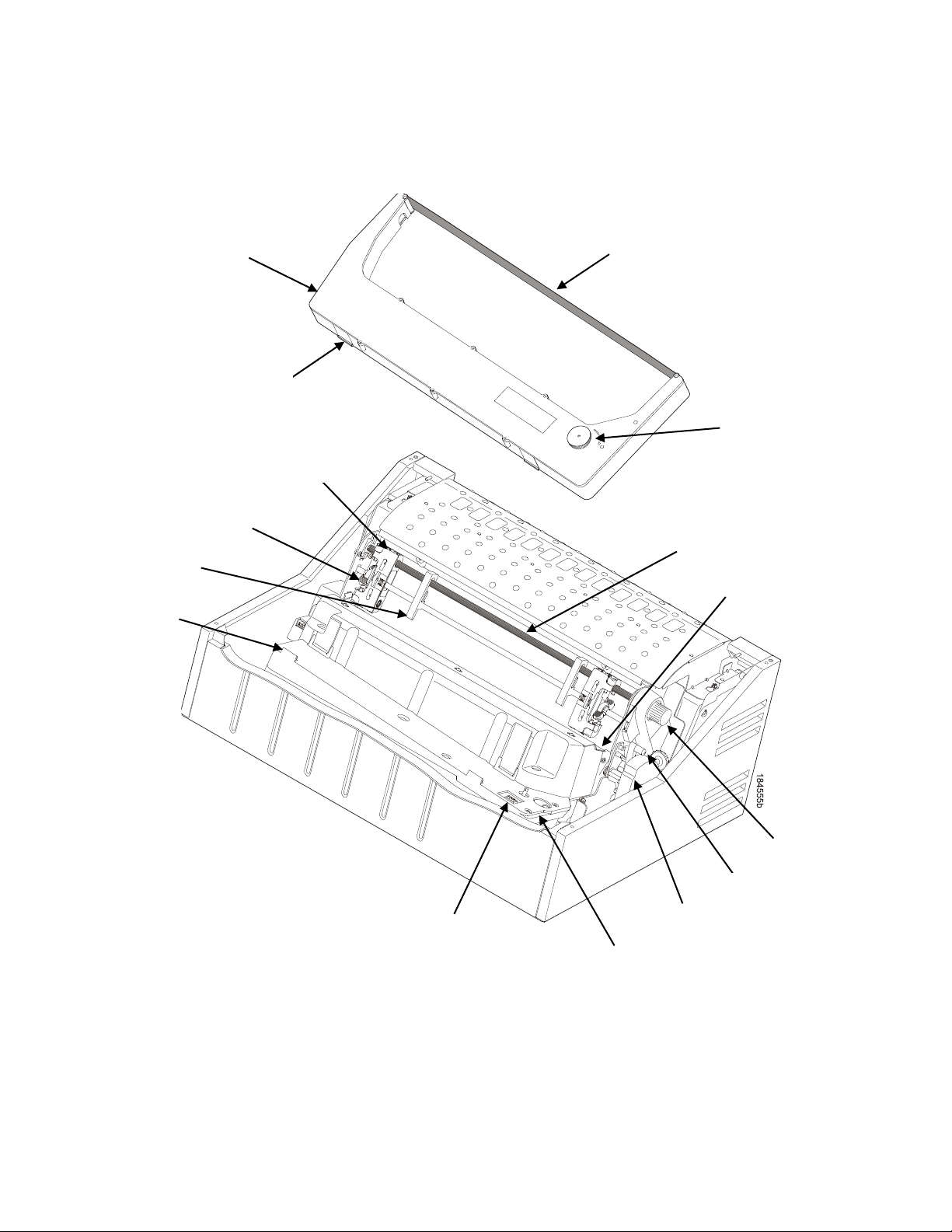

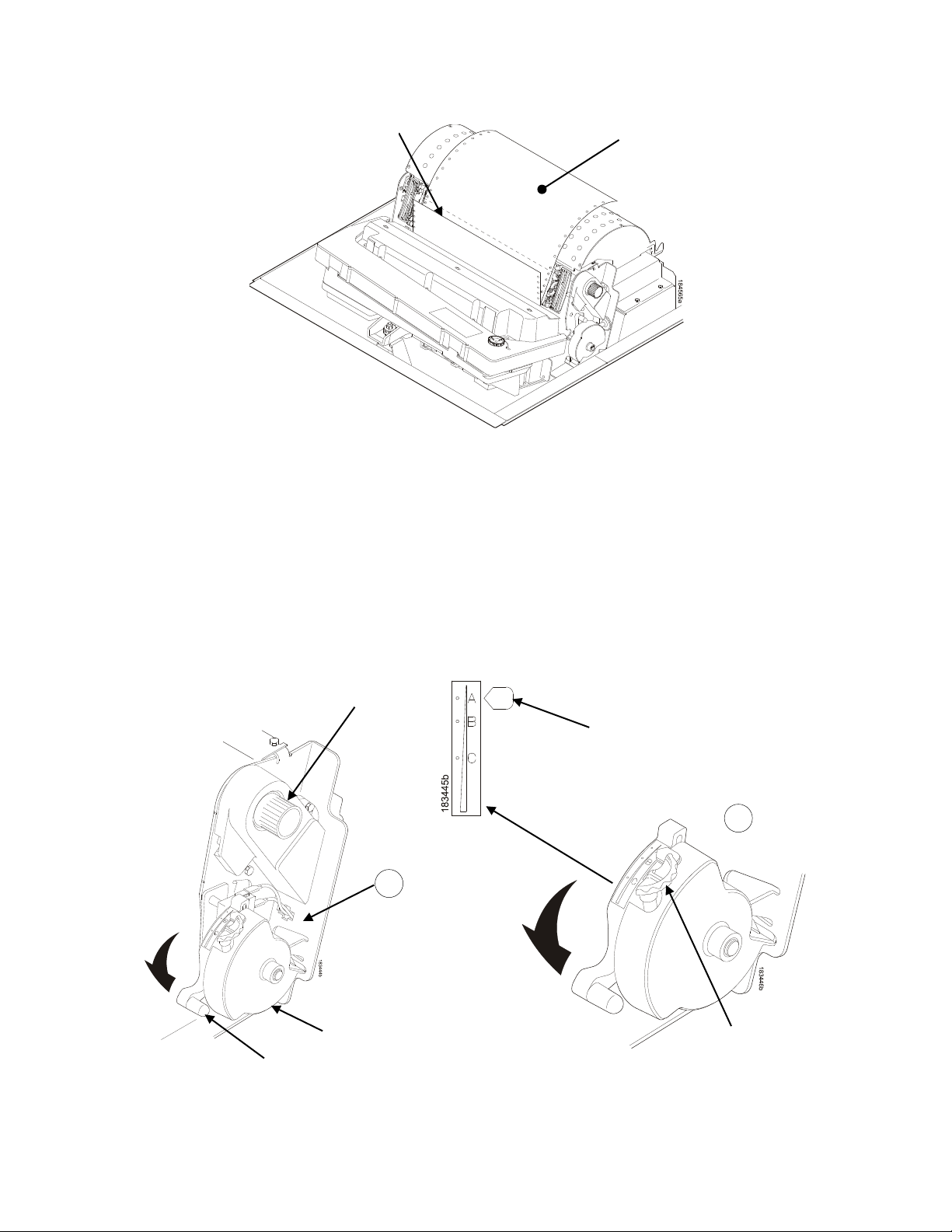

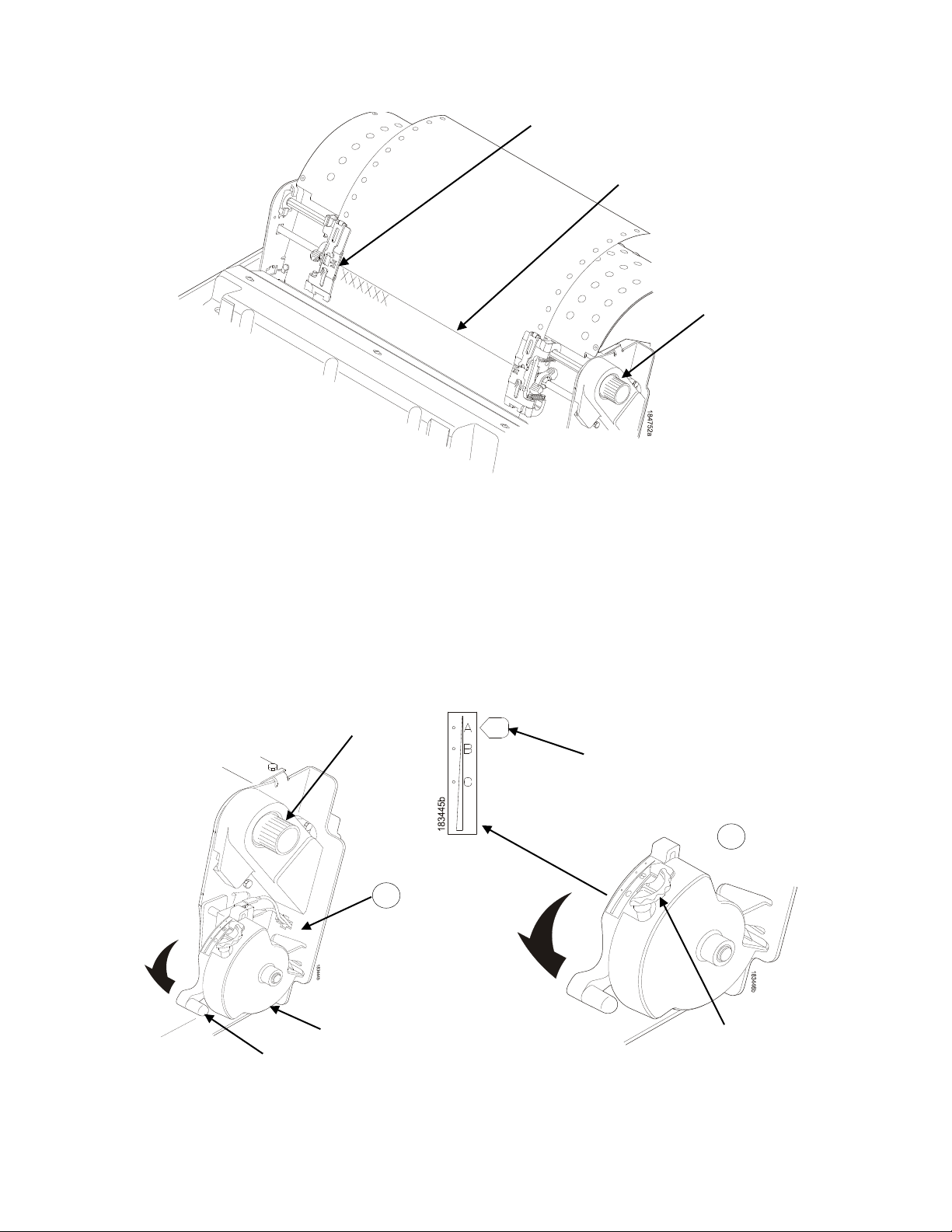

Ribbon

Cartridge

Tab (2)

Tractor (2)

Blue Tractor

Lock (2)

Paper

Support (2)

Tab Slot (2)

Ribbon Cartridge

Interface

Air Shroud

Assembly

Platen Stop

Platen Lever

Vertical Position

Knob

Hammerbank Cover

and Ribbon Mask

Splined Shaft

Ribbon

Tension Knob

Ribbon

Printer Component Locations

Figure 4 Printer Component Locations

17

Page 18

18

Page 19

Operating The Printer

Powering on the Printer

When you power on the printer, it executes a self-test. The default power-up state is offline. When the

self-test completes and the software has initialized successfully, the status indicator light is off, indicating

the printer is offline. When the printer is online, the default emulation type you have installed appears in

LCD display. The configuration name or ribbon life remaining is shown on the bottom of the LCD display.

If there is a fault during the self-test, the status indicator flashes and a specific fault message appears on

the display (such as “LOAD PAPER”). The alarm also sounds if it is configured to do so. See LCD

Message Troubleshooting Table on page 125 for information on fault messages and solutions.

Operating Modes

Online. In online mode, the printer can receive and print data sent from the host. Pressing the ONLINE

key toggles the printer from online to offline mode. The status indicator is lit in online mode.

Offline. In offline mode, you can perform operator functions, such as loading paper and setting top-of-

form. Pressing the ONLINE key toggles the printer from offline to online mode. The status indicator is off

in offline mode.

Menu. In offline mode, pressing ENTER moves the printer into Menu mode. In this mode, you can

navigate through all menus and change the printer configuration. To return to offline mode, press the

ONLINE key.

Fault. In fault mode, a condition exists which must be cleared before printing can continue. The status

indicator flashes, the alarm beeps (if configured to sound), and a descriptive fault message displays.

The current operating mode can be selected via control panel keys or can result from routine operations

such as powering on the printer.

19

Page 20

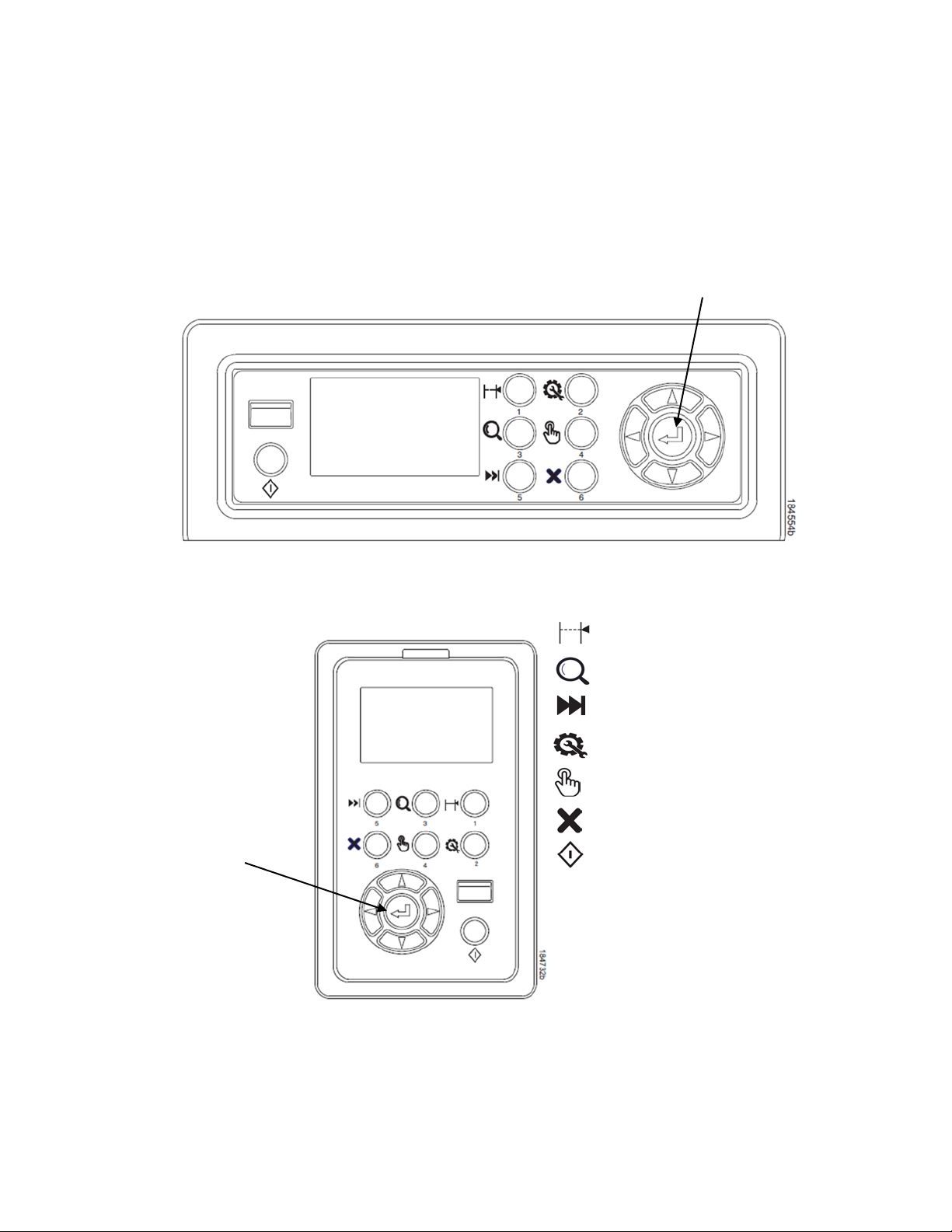

Enter

ENTER

TOF = Set TOF (Top of Form)

VIEW = View/Eject

ADVANCE = Paper Advance

CONFIG = Print Config

SELECT = Load Config/Print Mode

1

CANCEL = Cancel Job

ONLINE = Online/Clear

Legend:

The Control Panel

Figure 5 shows the keys, displays, and indicators as they appear on the control panel. The following

section provides the descriptions, and functions of the control panel keys.

Key combinations are indicated with the plus (+) sign. For example, “Press

key and the key at the same time.

Cabinet Model

Pedestal Model

Figure 5 Control Panel

NOTE:

1

Print Mode only available for H-Series printers.

+ ” means to press the

20

Page 21

Control Panel Keys

ONLINE

Toggles the printer between online and offline modes. The key performs the following in Online, Offline,

Fault, and Menu modes:

• Online Mode – sets the printer to Offline Mode.

• Offline Mode – sets the printer to Online Mode.

• Fault Mode – causes the printer to recheck the faults; if the faults are cleared, the printer toggles to

Offline Mode. If the fault condition is not corrected before pressing the ONLINE key, the fault

message reappears.

• Menu Mode – sets the printer to Offline Mode.

NOTE: When changing to Online Mode, if the user has changed menu items without saving the changes

in a configuration, the user will be prompted to save the changes.

ADVANCE

Performs advance to top-of-form, as defined by the current active form length. The key works both online

and offline.

• If online with data in the printer buffer, the data will print and then the paper will move to the next top-

of-form.

• In the fault state, pressing ADVANCE will advance the paper. The first press moves to the top of the

next available form. All subsequent presses advances one forms length as defined by the current

active forms length.

VIEW

When the printer is online or offline, pressing this key executes the view or eject function, depending on

whether the printer is a cabinet or a pedestal model.

If online with data in the printer buffer, the data prints and the key functions as described below.

If in a fault state, this key will be ignored.

• View Function — For cabinet and pedestal models, pressing the VIEW key for a short time (less

than 1/2 second) moves the last data printed to the tractor area for viewing. While in the view state,

the message "Printer in View" displays, pressing the UP or DOWN arrow keys moves the paper up or

down in 1/72 inch increments. This is done to align the image within a pre-printed form, for example.

Refer to the UP and DOWN key functions for additional details on the microstep feature. Pressing

VIEW a second time moves the paper back to the adjusted print position.

• Eject Function — For pedestal models only, if the View key is pressed for a long time (more than 1/2

second), the bottom of the last printed form will move to the tear bar position as set by the Tear Bar

Dist menu. The message "READY TO TEAR/EJECT To Return" displays. While in this position,

pressing the UP or DOWN arrow keys moves the paper up or down in 1/72 inch increments. Refer to

the Up and Down key functions for additional details on the microstep feature. When the VIEW key is

pressed a second time, the printer will move the paper either forward or backward to enable printing

on the next available form.

CANCEL

In offline mode, this key cancels all data in the print buffer. The print buffer is cleared without printing any

of the data and the current paper position moves to the next top-of-form. If this function is disabled, the

CANCEL key will be ignored.

21

Page 22

NOTE: Use of this key will cause loss of data.

TOF

Sets the top-of-form on the printer. This key is active only when the printer is offline and will not operate if

the printer is in a fault condition. The paper moves down to the print position and aligns to the top-of-form.

Refer to the User’s Setup Guide for com plete instr ucti ons on how to set the top-of-form.

CONFIG

In offline mode, CONFIG prints the current full configuration. This key requires a confirmation with the

ENTER key; pressing any other key will exit from this function. See Config Menu on page 62 for an

explanation of configuration menus.

SELECT

In offline mode, this key allows for fast selection of any of the previously stored configurations. Pressing

this key causes the printer to cycle through the following configuration load options: Factory, Cfg 1, Cfg 2,

Cfg 3,..., Cfg 8.

ENTER ( ↵ )

When navigating the configuration menus, the Enter key (referenced by the symbol ↵) selects the

currently displayed option value as the active value. An asterisk (*) appears next to the active value on

the display. ENTER is also used for starting and stopping printer tests and generating a configuration

printout.

NOTE: The ENTER key must be unlocked to execute the select function. See UP + DOWN, later in this

section.

• In Offline mode, pressing the Enter key places the printer in Menu mode. This will bring up a set of

icons to select.

• In Menu mode (at the icon menu level), pressing the Enter key moves down into the menu tree of the

highlighted icon.

• Within a menu tree: if the highlighted menu contains submenus instead of a selectable parameter,

pressing the Enter key will go into the submenu. If the highlighted menu is a display only menu, then

pressing the Enter key performs no function. If the highlighted menu has selectable parameters,

pressing the unlocked Enter key will select the displayed parameter. An asterisk (*) displays next to

the selected parameter.

• If the highlighted menu is an executable menu, pressing the unlocked Enter key will cause the

function associated with the executable menu to run. If the ENTER key is locked, pressing the Enter

key for highlighted menus that are executable or contain selectable parameters will cause the

message, THE

NOTE: Press the UP and Down keys at the same time to lock/unlock the

For special Network Address menus or String menus, pressing the Enter key will move down into a

special multiple segment setting menu. Exit this menu by pressing Enter again to save changes or Cancel

to exit without saving changes. This key is inactive in all other modes.

UP or DOWN ( or )

↵ KEY IS LOCKED, to display momentarily.

↵ key.

Moves up or down between levels in the configuration menus and makes vertical forms adjustment. In

Offline mode or after pressing VIEW, press or to adjust the paper up or down in 1/72 inch

increments for fine vertical forms alignment. When the printer is in Menu mode, press or to move

through levels in the configuration menus.

22

Page 23

UP + DOWN ( + )

Locks and unlocks the ENTER key.

PREV or NEXT ( or )

Moves between the options on the current level of configuration menu. In the configuration menu,

press to scroll backward or press to scroll forward through the menu selections on the same level.

PREV + NEXT ( + )

When both keys are pressed simultaneously, the printer will reset to the power-up configuration and reset

its internal state (in offline mode).

Ribbon Life Indicator

If the Panel Display menu is set to Ribbon Life, the bottom of the LCD displays the remaining life of the

currently installed ribbon. The default settings for this feature should match the requirements for most

applications; no special user setup is needed. If your particular application requires darker printing or can

tolerate lighter printing, the ribbo n end poi nt can be adj usted as appr o priat e. See Ribbon on page 51.

Cancel a Print Job

The procedure to cancel a print job depends on the printer emulation and your application software.

Contact your system administrator for additional information.

1. If the printer is online, press ONLINE to place the printer in offline mode.

2. From the host system, stop the print job.

NOTE: If the print job is not stopped from the host system before pressing CANCEL, the print job

continues with data missing when the printer returns to online mode. Exercise caution to prevent

unwanted data loss occurrences, as this function deletes unprinted data in the printer. This

function is active only in offline mode; the purpose of this function is to eliminate the necessity of

printing unwanted data when print jobs are canceled.

3. Press CANCEL.

4. Set the top-of-form. Refer to the Quick Reference Guide.

Operational Procedures

This section contains routine printer operating procedures on how to:

• reload paper

• unload paper.

Reload Paper

Do this procedure when “LOAD PAPER” displays. (This message occurs when the last

sheet of paper passes through the paper slot.) This procedure reloads paper without

removing the last sheet of the old paper supply, while retaining the current top-of-form

setting.

23

Page 24

Paper Slot

Wire Guide

(2)

Pedestal Model

Metal Paper Guide

(200

Paper Slot

Cabinet

Paper Slot

Wire Guide (2)

Zero Tear

Pedestal Model

Model

0 lpm only)

Figure 6 Paper Slot Location

1. Raise the printer cover. Raise the platen lever as far as it will go. (See Figure 4 on page 17 for the

location of the lever.)

NOTE: Do not open tractor doors or remove the existing paper.

2. Cabinet models: open the front door and align the paper supply with the label on the floor.

Pedestal models: place the paper supply on the floor of the printer, centered under the paper slot.

Zero Tear Pedestal models: open the front door and place the paper supply inside the printer, on

the floor of the cabinet.

3. Ensure the paper pulls freely.

4. Feed the paper up through the paper slot (see Figure 6). It may be easier to feed one corner of the

new paper up through the slot first. When this corner can be grasped from the top, rotate the paper

back to the normal position.

NOTE: If you are using thick, multi-part forms and are unable to load the new paper over the existing

paper, go to step 15.

5. Hold the paper to prevent it from slipping down and through the paper slot.

24

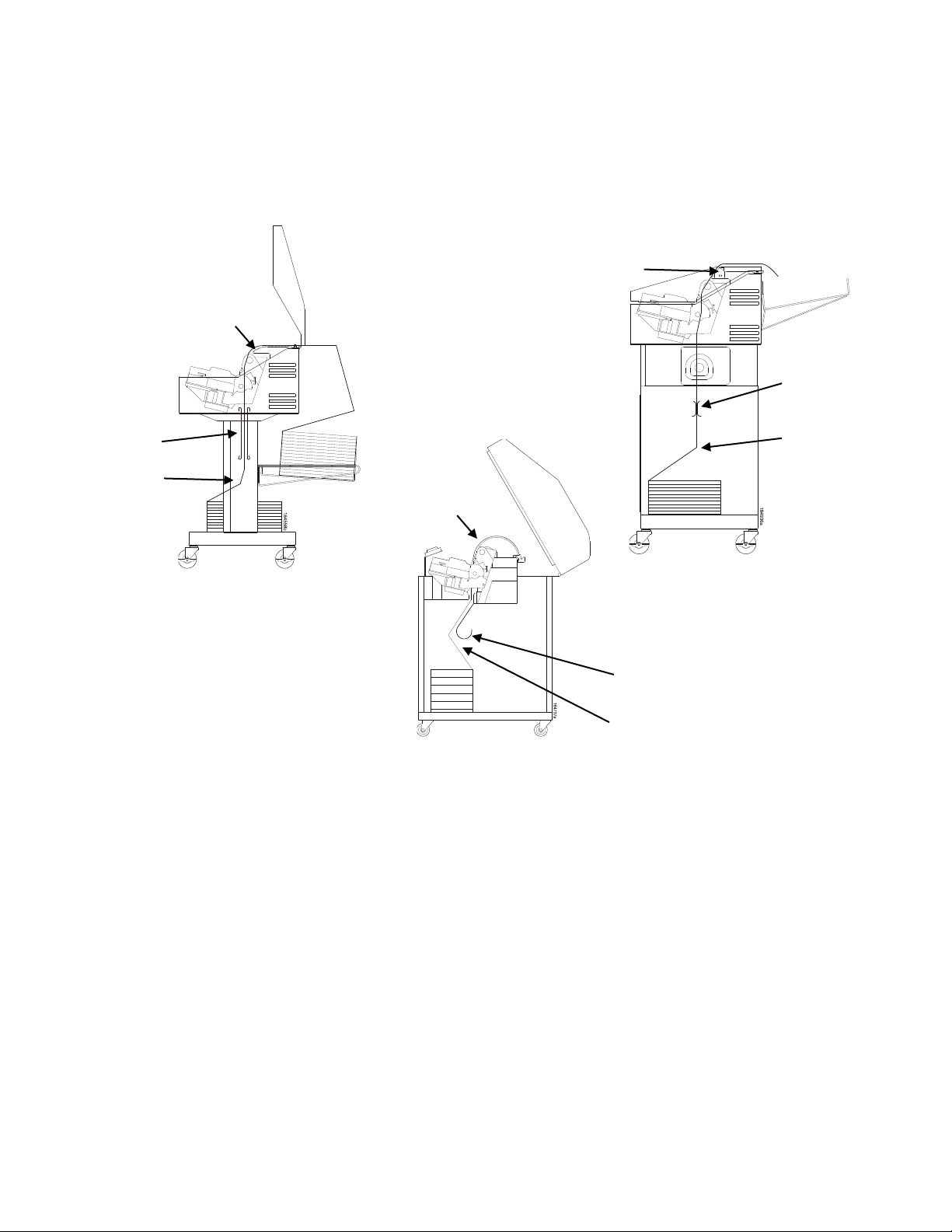

Page 25

Vertical Position

Knob

Platen Lever

Platen Stop

Platen Stop

Knob

Paper Thickness

Indicator

New Paper

Existing Paper

Figure 7 Loading New Paper into the Printer

6. Pull the new paper above and behind the ribbon mask, but in front of the existing paper. See Figure 4

on page 17 for the ribbon mask location. If necessary, gently press the existing paper back.

7. Align the top edge of the new paper with the top perforation of the existing paper.

8. Load the new paper over the existing paper. Open and load the tractors one at a time to prevent the

paper from slipping.

NOTE: Make sure that the top edge of the new paper lines up with the top horizontal perforation of the

last page.

A

A

Figure 8 Setting the Platen Lever

25

Page 26

Left Tractor Lock

Paper

Left T

9. Turn the platen stop knob clockwise or counterclockwise to match the paper thickness. (The A-B-C

scale corresponds approximately to 1-, 3-, and 6-part paper thickness).

NOTE: If you are using the same thickness of paper, there is no need to readjust.

10. Lower the platen lever until it stops.

11. Press ONLINE to remove the “LOAD PAPER” fault message from the display.

12. Press ADVANCE several times to make sure the paper feeds properly beyond the tractors and over

the lower paper guide. Feed sufficient paper to ensure the paper stacks correctly.

13. Close the printer top cover. Close the cabinet front door.

14. Press ONLINE to place the printer in online mode and resume printing.

NOTE: Perform steps 15 to 31 only if you are unable to load the new paper over the existing paper.

15. Open both tractor doors.

16. Remove the old paper from the tractors. Allow the paper to fall into the paper supply area.

17. Feed the new paper up through the paper slot. Hold the paper to prevent it from slipping down

through the paper slot (see Figure 6 on page 24).

ractor Door

Figure 9 Loading Paper on the Left Tractor

18. Pull the paper above and behind the ribbon mask. See Figure 4 on page 17 for the ribbon mask

location.

19. Load the paper on the left tractor.

20. Close the tractor door.

26

Page 27

Tractor Splined

Shaft

Tractor Lock

Tractor

Paper

Paper Scale

Tractor Door

Tractor Lock

Figure 10 Positioning the Left Tractor to Avoid Damage

CAUTION To avoid damage to the printer caused by printing on the platen, always position

the left tractor unit directly to the left of the “1” mark on the paper scale.

21. Normally, you should not need to adjust the position of the left tractor. If adjustment is necessary,

unlock the left tractor by placing the tractor lock in the middle position. Slide the tractor until it is

directly to the left of the number “1” on the paper scale and lock it. (You can also use the paper scale

to count columns.)

Figure 11 Loading Paper onto the Sprockets

27

Page 28

Paper Slot

Cabinet Model

Upper Paper

Guide

Paper Slot

Wire Guide

Upper Paper

Guide

Paper Slot

Wire Guide (2)

Pedestal Model

Upper Paper

Guide

22. Unlock the right tractor.

23. Load the paper onto the sprockets and close the tractor door. If necessary, slide the right tractor to

remove paper slack or to adjust for various paper widths. Then, lock the tractor.

Zero Tear

Pedestal Model

(2)

Metal Paper Guide

(2000 lpm only)

Figure 12 Using the Paper Guide to Orient the Paper

24. Press ADVANCE several times to make sure the paper feeds properly beyond the tractors and over

the lower paper guide. Feed sufficient paper to ensure the paper stacks correctly.

25. Cabinet models: Open the cabinet rear door. Make sure the paper is aligned with the label in the

output area (inside the cabinet). Close the front and rear doors.

28

Page 29

TOF Indicator

Perforation

Vertical

Position Knob

Vertical Position

Knob

Platen Lever

Platen Stop

Platen Stop

Knob

Paper Thickness

Indicator

Figure 13 Aligning the Perforation with the TOF Indicator

26. Align the top of the first print line with TOF indicator on the tractor by rotating the vertical position

knob. For best print quality, it is recommended that the top-of-form be set at least one print line or

more below the perforation.

NOTE: For exact positioning, perform a short press of the VIEW key to move the last data printed to the

tractor area for viewing. While in View mode “Printer in View” displays. Press the Up or Down

Arrow keys to move the paper vertically in small increments. Pressing the VIEW key a second

time moves the paper back to the adjusted print position. The key works both online and offline

provided that the printer is in View mode. (This procedure is applicable for both the cabinet and

pedestal models.)

A

A

Figure 14 Adjusting the Platen Lever

29

Page 30

Paper

Perforation

27. Turn the platen stop knob clockwise or counterclockwise to match the paper thickness. (The A-B-C

scale corresponds approximately to 1-, 3-, and 6-part paper thickness. Adjust unti l you have the

desired print quality).

NOTE: The platen stop allows you to set an optimum and consistent thickness that is not affected when

opening and closing the platen lever.

28. Lower the platen lever until it stops.

29. Press ONLINE to clear any fault messages (such as “LOAD PAPER”) from the LCD.

30. Press TOF. The top-of-form you have set moves down to the print position. If there is data in the

buffer, the paper moves forward to the last print position on the next page.

31. Press ONLINE and close the printer cover.

Unload Paper

1.

Press ONLINE to place the printer in offline mode and open the printer cover.

2.

For cabinet models, open the cabinet rear door.

Figure 15 Unloading the Paper from the Printer

3.

Tear off the paper at t he pe r f or ation.

4.

Allow the paper to fall to the back of the printer and into the paper stacking area.

5.

For pedestal models, remove the stacked paper from the paper tray.

6.

For cabinet models, remove the stacked paper from the rear cabinet floor.

7.

Close the cabinet rear door.

30

Page 31

Tractor Door

Platen Lever

Figure 16 Completely Removing the Paper

8.

To completely remove the paper from the printer:

a.

Raise the platen lever as far as it will go and open both tractor doors.

CAUTION Be careful when pulling any paper backward through the paper path, especially

when using a label stock. If you are not careful, labels can detach and adhere to

the printer within the paper path, where only an authorized service representative

can remove them.

b.

Open the cabinet front door.

c.

Gently pull the paper down through the paper slot. Allow the paper to fall into the paper supply

area.

d.

Remove the paper from the paper supply area.

Integrated Print Management System

The 6800 CRP has a feature that automatically monitors and communicates the status of the ribbon life to

help the operator know when to change ribbons. Using an ink delivery system called the Cartridge Ribbon

System (CRS), the printer can automatically detect when a new or used ribbon is loaded, and all ribbon

properties. The ribbon is contained in a plastic box (the cartridge) and feeds only in one direction. The

CRS contains an interface board that allows communication between the printer and the cartridge. Using

the CRS, the 6800 automatically detects when a new or used ribbon is installed and determines the

ribbon’s length, ink color, and expected yield. The ribbon life, starting from 100% when new and

decreasing to 0% when depleted, can be displayed on the control panel if configured by the Panel Display

Menu. See Figure 5 on page 20.

When the ribbon life reaches 2%, a warning message “RIBBON UNDER 2%/ Change RBN soon” appears

on the control panel display. The control panel status indicator lamp flashes. The printer will continue

printing in this condition until the ribbon life reaches 0% at which time, printing will stop. The ribbon may

be changed at any time while the printer is in the “CARTRIDGE AT END POINT/Change Cart” condition

31

Page 32

without losing data in the printer’s buffer. If a new ribbon is loaded, the system automatically detects the

change, clears the condition when the platen is closed, and restarts the life at 100%. If a partially used

ribbon is loaded, the system continues the life at the percentage indicated for the used ribbon.

You may also resume printing for approximately two more minutes without changing the ribbon by

pressing the ONLINE key twice. This may be done as many times as needed to complete the job in

progress.

Ribbon usage information is calculated by maintaining a count of impressions (dots) that is stored on the

ribbon cartridge and updated periodically so that the cartridge can be used on a different printer with the

information intact. This allows the system administrator to have precise control over print quality and

consumable costs. The accurate presentation of available ribbon life allows for efficient planning of print

jobs. For example, if the displayed ribbon life were low, you can install a new ribbon before printing a

large print job.

Output Darkness

By default the system is configured to meet most user requirements. However, some applications require

that the output remains darker than the nominal set point while some applications are less critical and

could tolerate a lighter final image. The system can easily adjust to this variability. A setting under the

QUICK SETUP or FORMS menu is available that allows the user to adjust the final output. The range is

as follows:

Normal (Default)

Darker +1 through +6

Lighter -1 through -10

The ribbon life indicator always cycles between 100% and 0%, but if a darker setting is selected, zero will

be reached more quickly. If a lighter setting is selected, the system will extend the amount of printing it

takes to reach zero.

Loading a Used Ribbon Cartridge

You can take the ribbon cartridge off the printer and reload it at a later time. The ribbon life gauge

automatically updates to reflect the correct remaining capacity.

NOTE: Since the ribbon usage information is stored on the ribbon cartridge, you can reload a partially

used cartridge onto a different printer.

Lighter Or Darker Print

The ribbon life value as determined by the Integrated Print Management System is factory set so that the

image quality at the end of the ribbon life is as good as it was when the ribbon was new. You may adjust

the ribbon end point for a lighter or darker image as required for your printing needs. See Ribbon End

Point on page 51.

Changing Ribbon Cartridge

Before changing the ribbon cartridge, determine whether at the end of ribbon life, you want to make the

print lighter (extend the ribbon life) or darker (shorten the ribbon life). If you want to make the print lighter

or darker, go to “Ribbon End Point” on page 51 and follow the procedures for adjusting the image density.

If you are satisfied with the print darkness, continue with the following steps.

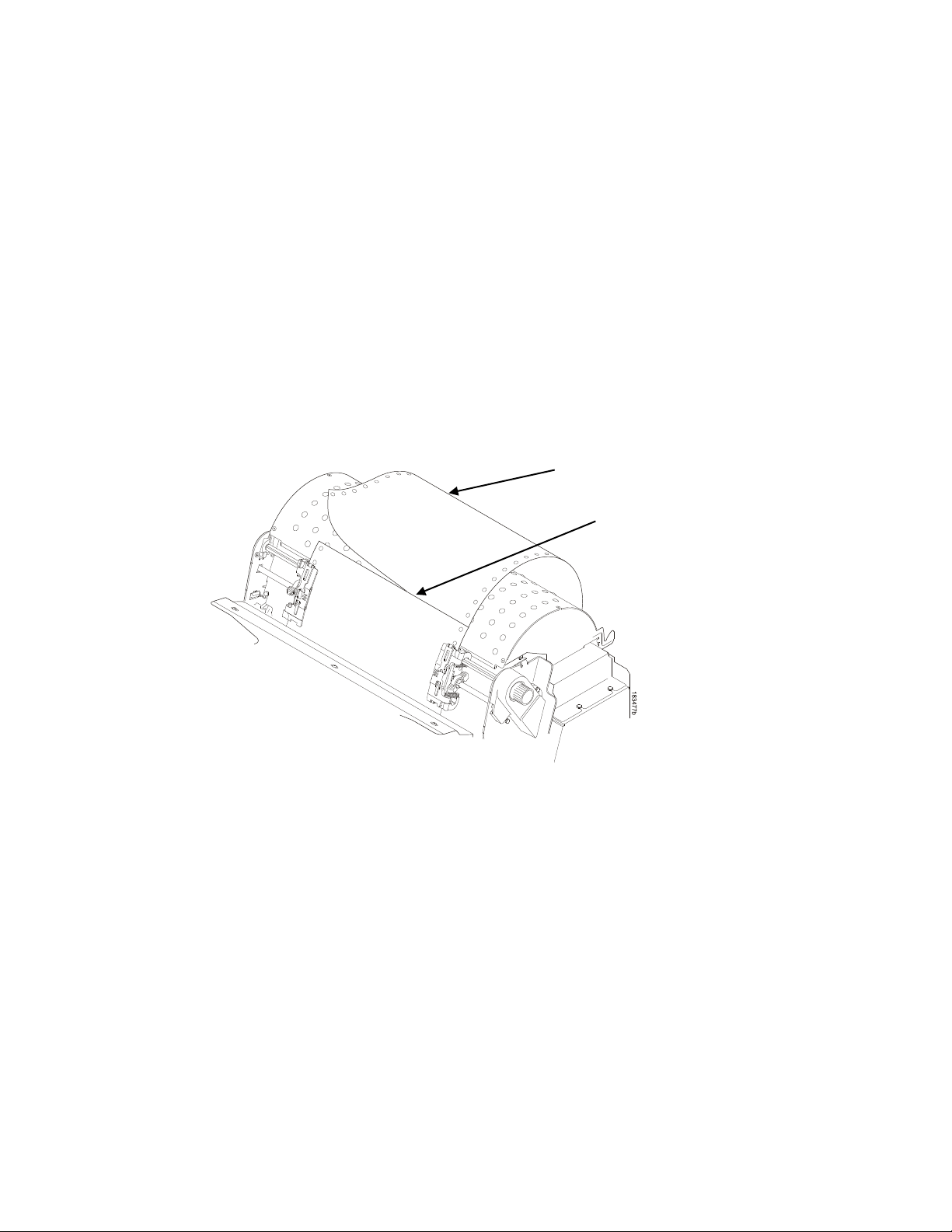

NOTE: Ribbon cartridge instructions and illustrations shown in the following section are for the pedes tal

model. Follow the same procedures for the cabinet model.

32

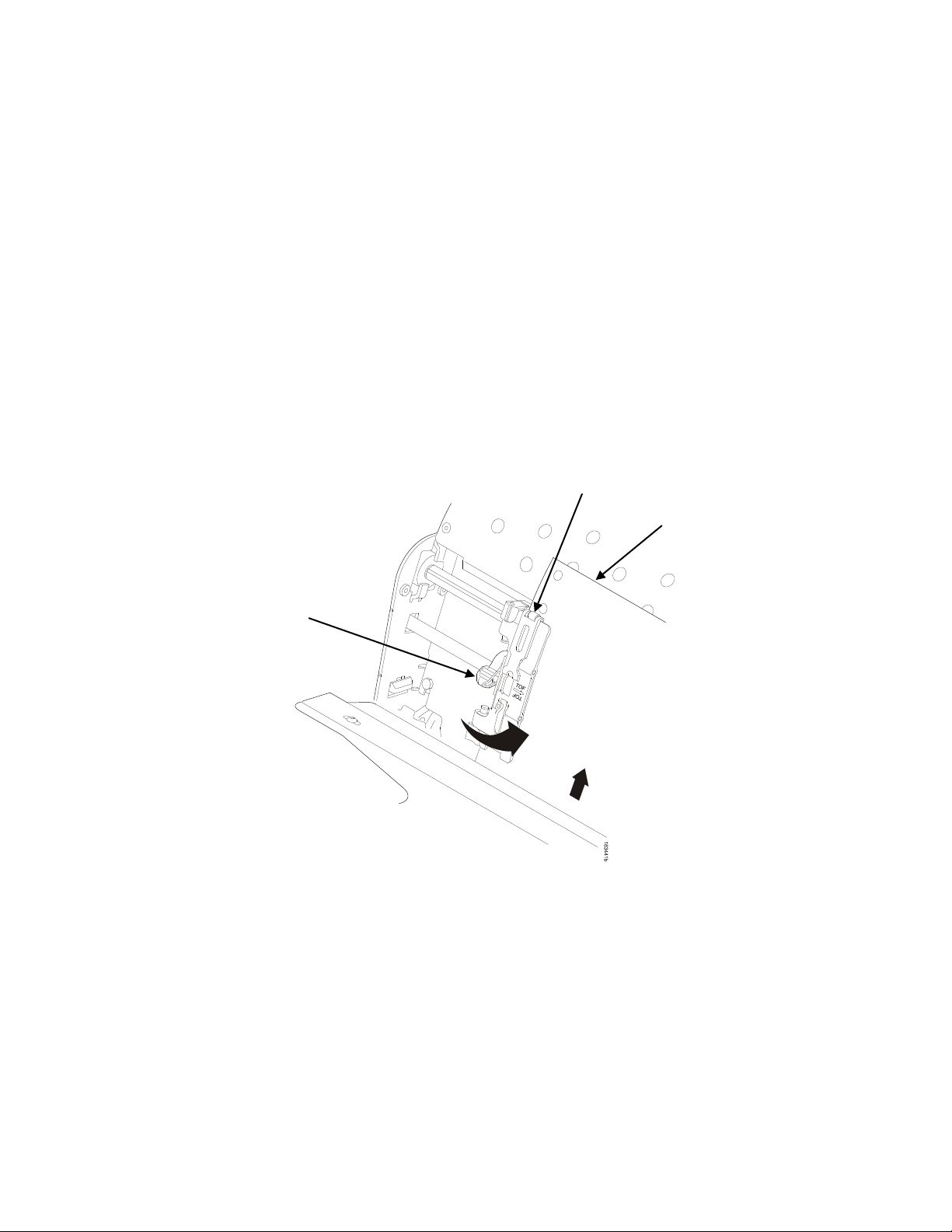

Page 33

Blue Tractor

Door (2)

Platen Lever

Figure 17 Preparing to Load the Ribbon

1. Open the printer cover.

2. Raise the platen lever as far as it will go.

3. Ensure the tractor doors are closed.

4. Remove the old ribbon cartridge and discard properly.

33

Page 34

184556b

Ribbon

Cartridge

Tab (2)

Tab Slot (2)

Air Shroud

Assembly

Ribbon

Tension Knob

Ribbon

Figure 18 Installing the Ribbon Ca rtridge

5. Remove the ribbon slack on the new ribbon cartridge by turning the ribbon tension knob clockwise.

CAUTION Do not turn the ribbon tension knob counterclo ckwise. This could damage the

ribbon cartridge.

6. Hold the cartridge at an angle, so that the rear side nearest you is lower than the side with the ribbon.

Find the two tabs on the outside of the cartridge and place them into the corresponding slots on the

air shroud assembly (see Figure 18).

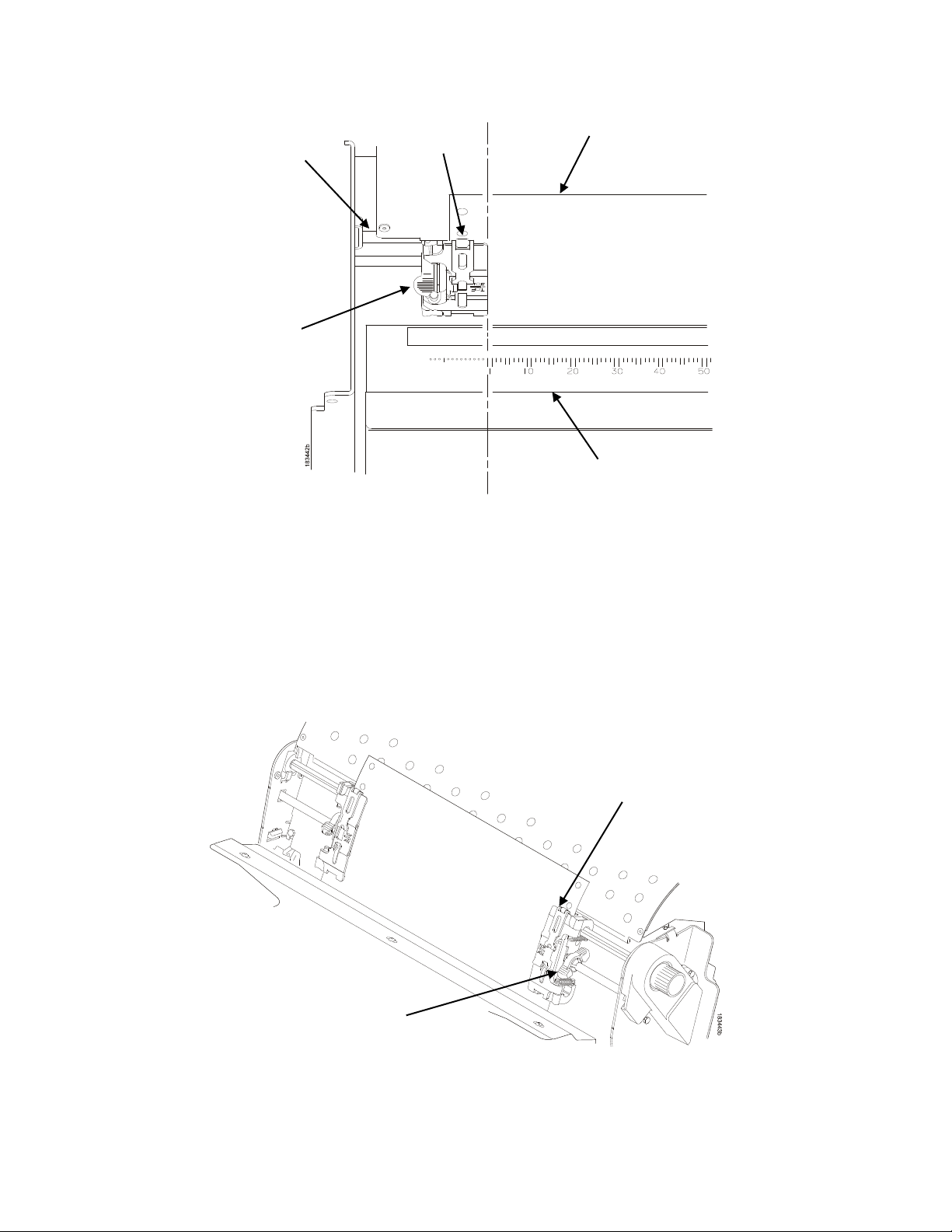

34

Page 35

Ribbon

Cartridge

Ribbon Cartridge

Ribbon Tension Knob

Hammerbank Cover

Ribbon

Mask

Ribbon

A

A

Figure 19 The Ribbon Cartridge Snapped in Place

7. Rock the cartridge downward, making sure that the ribbon goes between the guide and the mask

(see Figure 19). You will feel it snap into place .

CAUTION Make sure that the ribbon does not twist or fold over.

8. Turn the ribbon tension knob clockwise a few times to make sure the ribbon tracks correctly in the

ribbon path.

9. Close the platen lever.

10. Close the printer top cover.

11. Press the ONLINE key to return the printer to operation.

35

Page 36

36

Page 37

Configuration Menus

Configuration Overview

To print data, the printer must respond correctly to signals and commands received from the host

computer. Configuration is the process of matching the printer's operating characteristics to those of the

host computer and to specific tasks, such as printing labels or printing on different sizes of paper. The

characteristics which define the printer's response to signals and commands received from the host

computer are called configuration parameters.

You can configure the printer using the configuration menus and the control panel or by sending control

codes in the data stream from a host computer attached to the printer. This chapter provides an

introduction to configuring the printer and includes the configuration menus available (depending on

which emulation you have instal led in the prin ter) .

IMPORTANT Configuration directly affects printer operation. Do not change the configuration of

your printer until you are thoroughly familiar with the procedures in this chapter.

Changing Parameter Settings

You may change a printer parameter setting, such as line spacing or forms length, either by pressing

keys on the control panel or by sending emulation control codes in the data stream from a host attached

to the printer. The control panel allows you to configure the printer’s resident set of configuration menus.

An example procedure for using the control panel to change parameter settings begins on page 40.

When control codes are sent from a host attached to the printer, they override control panel settings. For

example, if you set the line spacing to 6 lpi with the control pan el, an d applic ati on software later changes

this to 8 lpi with a control code, the control code overrides the control panel setting.

Saving Parameter Set t in gs

The parameter settings that you have changed can be permanently stored in the printer’s memory as a

configuration. See Auto Save Configuration on page 42. and Saving Your New Configuration on page 42.

You may also save your new configurations using the PTX_SETUP command host control code. See

Appendix E on page 165.

Default and Custom Configurations

A configuration consists of a group of parameter settings, such as line spacing, forms length, etc. Your

printer provides a fixed default configuration and allows you to define several custom configurations for

use with particular print jobs. The factory default configuration can be loaded, but it cannot be altered.

Eight configurations can be modified for unique print job requirements. The “Save Config.” option allows

you to save eight groups of parameter settings in memory as custom configurations numbered from 1

through 8. An explanation on how to save a set of parameter values as a custom configuration using the

“Save Config.” menu option begins on page 42.

37

Page 38

Press to toggle between ONLINE and OFFLINE.

Press to enter the area of interest. This will take

Press to scroll through the available choices for the

ONLINE

ENTER

+

OR

CANCEL

OR

Navigating the Menus

To manipulate configurations review the following instructions about navigating through the menus.

You must be offline to move within the menus.

Press ENTER to enter Menu mode. Menus are

accessed only in Menu mode.

Scroll up, down, left, or right through the icons to

highlight the area of interest.

you into that section and list three menu selections,

with the middle selection highlighted.

Press to move up or down through the menu

selections. The highlighted menu is the active

selection.

highlighted menu. If the highlighted menu contains

submenus, these buttons have no effect and the

message “

Press to confirm selection. For normal menus, this

will change or execute the menu. If the selection

has submenus, the submenu will be entered.

Press simultaneously to lock and unlock the

ENTER key. Lock or Unlock settings of the ENTER

key at power is defined in the Panel Lock Menu.

The ENTER key is unlocked by default.

↵ for Submenu” will display.

38

Press to return to the previous menu level.

Page 39

Press to return to Offline mode. If changes were

ONLINE

made, the user will be prompted to save or discard

the configuration.

To experiment with navigating the menus, use the example on the next page as a tutorial.

Top Leve l Menu Overvie w

When entering Menu mode, the user will see top level menus represented as icons as shown below. Use

the navigation buttons up, down, right, and left to highlight the desired icon. As the user navigates, the

name of the top level menu displays on the top line of the LCD.

Table 3 provides brief descriptions of first level configuration menu options:

Table 3 Icon Level Menus

Menu Icon Menu Description

Quick Setup This menu allows quick access to the most

frequently changed or entered parameters during

printer installation.

Operator Menu This menu allows you to set fonts, forms, and

vertical format units (VFU) parameters.

Config Menu This menu allows you to select from Printer, Codes,

Graphics, I/O, Intellifilter, CST/PAA, and

PTX_SETUP options, as well as perform file and

configuration management.

TCP/IP Menu This menu allows you to select Ethernet Address

and Ethernet Parameters optio ns .

Test Menu This menu includes diagnostic tests, system memory,

software build part number, Feature File (if available),

shuttle type, and printer statistics.

Help Menu This m enu allo ws pri nting of the He lp Me nu to view

current options and the range of options allowed for

each setting.

39

Page 40

1.

ONLINE

ENTER

Forms

Operator

Menu

Font

Length

(lines)

Length

(inches)

OFFLINE

Quick

Setup

*= Factory Default

Unidirectional

Disable*

Enable

VFU

11*

(0.1-25.5)

66*

(1-255)

UNTIL

Changing Parameters Example

A configuration consists of several parameters. The default factory configuration has a starting set of

parameters. In the configuration menu above, and in all the configuration menus in this chapter, the

factory default values are indicated by an asterisk (*).

Your print jobs may require parameter values which vary from the default settings. This section provides

an example procedure for changing individual parameter values.

The following procedure shows how to change and save the setting for the Form Length option from the

default of 66 lines to 65 lines. Use these guidelines to navigate the configuration menus and change other

parameters.

40

Step Press LCD Notes

Make sure the printer is on.

2.

3.

Press to enter Menu mode.

4.

Page 41

ENTER

UNTIL

ENTER

ENTER

ONLINE

ONLINE

ENTER

Step Press LCD Notes

5.

6.

7.

8.

9.

The * indicates this choice is active.

Press until the desired selection or

value displays.

The * indicates this choice is active.

10.

Press ENTER to go back into the

menus or press ONLINE again to

go ONLINE.

11.

12A.

Configuration changes were

detected and you are prompted to

save the configuration permanently

or temporarily, to cancel changes,

or restore the Factory

Configuration.

Configuration changes have been

saved as Configuration 1, and will

be set as the Power-Up config. The

printer will then be brought online.

12B.

13.

The printer is ready for operation

Places the printer online after

permanently saving the

configuration changes as Config. 1.

41

Page 42

Auto Save Configuration

If the user makes a menu change and attempts to place the printer online without saving the changes to a

configuration, the following prompt displays:

The active option is highlighted. Use the Up and Down keys to scroll through the different options; the

keys will loop at the top and bottom options. The

performing the selected option, the printer will go to Online mode.

NOTE: Only the Up, Down, and Enter keys work at the Menu Changes Detected prompt.

• Save Permanently (factory default). This option causes the printer to save the configuration to the

active configuration and make the active configuration the Power-Up default configuration. If the

active configuration is the Factory Configuration, the printer will save the configuration to an open

configuration and make that open configuration the Power-Up default configuration.

↵ (Enter) key selects the highlighted option. After

If no open configuration is available, the user must decide which configuration to overwrite. In this

case the printer will display the Save Configuration menu, otherwise, the printer will go Online.

• Save Temporarily. Menu changes will be implemented, but will not be saved once the printer is

powered off.

• Cancel Changes. This option causes the printer to reload the Active Configuration, then go Online.

• Restore Factory. This option will cause the printer to reload the Factory Configuration, then go

Online.

NOTE: A printer fault during the Auto Save process causes the printer to Save Temporarily.

Saving Your New Configuration

The Save Config. option allows you to save up to eight custom configurations to meet different print job

requirements. Once you have changed all of the necessary parameters, you may save them as a

numbered configuration (Example 1 on page 43) or a named configuration (Example 2 on page 45) that

can be stored and loaded later for future use. If you do not save your configuration using the Auto Save,

or this option, all of your parameter changes will be erased when you power off the printer.

Once you have saved a custom configuration using this option, it will not be lost if you power off the

printer. You can load a configuration for a specific print job (see Load Config. on p age 74). You can also

modify and resave it. You may want to print your configurations and store them in a safe place, such as

inside the printer cabinet. If the Protect Configs. parameter is enabled and you try to resave an existing

configuration, the new configuration will not be saved until the existing configuration has been deleted

(see Delete Config. on page 74).

NOTE: Once you change active emulations, any changes to the previously selected emulation will be

gone unless they have been saved.

42

Page 43

1.

ONLINE

ENTER

ENTER

UNTIL

ENTER

OR

ENTER

UNTIL

Example 1

This example shows how to save a configuration as a numbered configuration, then later print it.

Step Press LCD Notes

Make sure the printer is on.

2.

3.

Shows the top level icons.

4.

5.

6.

7.

8.

9A.

Cycle through the choices.

Configuration is in the process of

being saved.

43

Page 44

CANCEL

ENTER

UNTIL

ENTER

ONLINE

UNTIL

Step Press LCD Notes

9B.

NOTE:

We recommend that you print the configuration. To print the configuration go to Step 10. To skip

this procedure and resume printer operation, go to Step 16.

10.

11.

12.

13.

The * indicates this choice is

active.

The Cancel Key will return back

one level.

14.

15.

16.

The selected configuration is

printed.

Press ENTER to go back into the

menus or press ONLINE again to

go ONLINE.

44

Page 45

1.

ONLINE

ONLINE

ENTER

UNTIL

ENTER

UNTIL

ENTER

Step Press LCD Notes

17.

18.

If you printed the configuration, store it in a safe place. The printer is ready for operation.

Example 2 This example shows how to save a configuration as a named configuration.

Step Press LCD Notes

Make sure the printer is on.

2.

3.

Shows the top level icons.

4.

5.

6.

7.

45

Page 46

UNTIL

ENTER

ENTER

OR

OR

ENTER

CANCEL

CANCEL

Step Press LCD Notes

8.

9.

10.

11.

12.

You will rename config. 2.

The LCD flashes.

Press the left or right key to

choose the character that is

highlighted.

13.

14.

15.

16.

Press the up key to select the next

character in the string. Press the

down key to go back to the

previous character and continue

editing as necessary.

Configuration 2 is renamed TEST.

Goes back up one level.

Goes back up another level.

46

Page 47

UNTIL

ENTER

ONLINE

ONLINE

Step Press LCD Notes

17.

18.

19A.

19B.

20.

TEST now appears as one of the

configuration choices.

Your configuration is saved as

TEST.

Press ENTER to go back into the

menus or press ONLINE again to

go ONLINE.

21.

Now you have the saved configuration for later use if needed.

47

Page 48

Pattern

Fault Override

Diag

OFFLINE

Host Interface

Emulation

Ribbon

Configuration

Clear

Font

Forms

VFU

Printer

Codes

Graphics

Configurations

Host Interface

USB I/O

Serial I/O

Parallel I/O

Intellifilter

Main File Mgmt

SD Fil e Mgmt

CST/PAA

PTX_SETUP Optio n

1

If Ethernet is installed.

2

3

TCP/IP

page 84

Operator

page 51

Ethernet Address

Ethernet Params

6800 CRP Main Menu

If Parallel is installed.

If SD is installed.

Test Menu

page 87

Help Menu

Quick Setup

page 49

Menu

Config Menu

page 62

Menu 1

2

3

Figure 20 6800 CRP Main Menu Configuration

48

Page 49

Buffers

All Configs

Current Configs

Reset

Quick Setup

Active Host

Paral

Serial Hotport

USB Hotport

Ethernet Hotport

Ser/Par Emul CPI

Lan Emulation

Length

Length (inches)

Ribbon End Point

* = Factory Default

1

2

Save Config.

Power

Quick Setup

(from page 48)

Host

Interface

Auto Switching*

Centronics2

Serial

IEEE 12842

USB

Ethernet1

lel Hotport2

Port Type

Trickle Time

Timeout

Report Status

Trickle Time

Timeout

Report Status

Timeout

Timeout

Switch Out On

Emulation

Tally ANSI* 10*

Genicom ANSI 12

P5000 13.33

P6000 15

P600 16.67

DEC LG01 17.14

HP2564C 20

IBM Proprinter 5

Epson FX-1180 6

MTPL 6.67

Tally ANSI* 8.33

Genicom ANSI 8.57

P5000 LPI

P6000 1.5

P600 2

DEC LG01 3

HP2564C 4

IBM Proprinter 5

Epson FX-1180 6*

MTPL 8

66* 10

1-255 12

11.0”*

00.1 – 25.5

1

7.5

(lines) 9

Ribbon

Darker +6

Darker +5

Darker +4

Darker +3

Darker +2

Darker +1

Normal*

Lighter -1

Lighter -2

Lighter -3

Lighter -4

Lighter -5

Lighter -6

Lighter -7

Lighter -8

Lighter -9