TM8000 mobiles

TM8100 Mobile Radio

Service Manual

MM8100-02-00-812 Version 1.01

October 2003 © Tait Electronics Limited

Contact Information

Tait Radio Communications http://www.taitworld.com

Corporate Head Office

New Zealand

Tait Electronics Ltd

P.O. Box 1645

Christchurch

New Zealand

E-mail: info@taitworld.com

Website: http://www.taitworld.com

Technical Support:

E-mail: support@taitworld.com

Website: http://support.taitworld.com

Tait North America

Regional Head Office: United States of America

Tait North America Inc

E-mail: usa@taitworld.com

Canada

Tait North America Inc

E-mail: canada@taitworld.com

Latin America

Tait Latin America

E-mail: latinamerica@taitworld.com

Tait North Asia

Regional Head Office: Hong Kong

Tait Mobile Radio (Hong Kong) Ltd

E-mail: hongkong@taitworld.com

Beijing

Tait Mobile Radio (Hong Kong) Ltd

E-mail: beijing@taitworld.com

Tait South Asia

Regional Head Office: Singapore

Tait Electronics (Far East) Pte Ltd

E-mail: singapore@taitworld.com

Thailand

Tait Mobile Radio Ltd

E-mail: thailand@taitworld.com

Tait Oceania

New Zealand

Tait Communications Ltd

E-mail: headoffice@tcl.tait.co.nz

Australia

Tait Electronics (Aust) Pty Ltd

E-mail: australia@taitworld.com

Tait Europe

Regional Head Office: United Kingdom

Tait Mobile Radio Ltd

E-mail: teusales@tait.co.uk

2 TM8100 Mobile Radio Service Manual

Note

For the addresses and telephone numbers of the

above regional offices refer to the TaitWorld

website.

October 2003 © Tait Electronics Limited

Tait General Software Licence Agreement

This legal document is an Agreement between

you (the “Licensee”) and Tait Electronics Limited

(“Tait”). By using any of the Software or

Firmware items prior-installed in the related Tait

product, included on this CD or downloaded

from the Tait website, (hereinafter referred to as

“the Software or Firmware”) you agree to be

bound by the terms of this Agreement. If you do

not agree to the terms of this Agreement, do not

install and use any of the Software or Firmware.

If you install and use any of the Software or

Firmware that will be deemed to be acceptance of

the terms of this licence agreement.

The terms of this agreement shall apply subject

only to any express written terms of agreement to

the contrary between Tait and the Licensee.

Licence

TAIT GRANTS TO YOU AS LICENSEE THE NON-

EXCLUSIVE RIGHT TO USE THE SOFTWARE OR

FIRMWARE ON A SINGLE MACHINE PROVIDED YOU

MAY ONLY

1. COPY THE SOFTWARE OR FIRMWARE INTO ANY

MACHINE READABLE OR PRINTED FORM FOR

BACKUP PURPOSES IN SUPPORT OF YOUR USE OF

THE PROGRAM ON THE SINGLE MACHINE

PROGRAMS

TO LIMIT OR INHIBIT COPYING

“

COPY PROTECTED”), PROVIDED THE COPYRIGHT

NOTICE MUST BE REPRODUCED AND INCLUDED ON

ANY SUCH COPY OF THE SOFTWARE OR FIRMWARE

AND / OR

2. MERGE IT INTO ANOTHER PROGRAM FOR YOUR

USE ON THE SINGLE MACHINE

ANY SOFTWARE OR FIRMWARE MERGED INTO

ANOTHER PROGRAM WILL CONTINUE TO BE

SUBJECT TO THE TERMS AND CONDITIONS OF THIS

AGREEMENT

THE LICENSEE MAY NOT DUPLICATE, MODIFY,

REVERSE COMPILE OR REVERSE ASSEMBLE ANY

SOFTWARE OR FIRMWARE IN WHOLE OR PART

:

(CERTAIN

, HOWEVER, MAY INCLUDE MECHANISMS

, THEY ARE MARKED

(ANY PORTION OF

).

.

Title to Software

THIS AG REEMENT DOES NOT CONSTITUTE A

CONTRACT OF SALE IN RELATION TO THE

SOFTWARE OR FIRMWARE SUPPLIED TO THE

LICENSEE

OWN THE MAGNETIC OR OTHER PHYSICAL MEDIA

ON WHICH THE SOFTWARE OR FIRMWARE WAS

ORIGINALLY SUPPLIED

BEEN RECORDED OR FIXED

TERM OF THIS AG REEMENT THAT AT ALL TIMES

TITLE AND OWNERSHIP OF THE SOFTWARE OR

FIRMWARE

OTHERWISE

THIRD PARTIES WHO HAVE GRANTED LICENCES TO

TAIT

. NOT WITHSTANDING THE LICENSEE MAY

, OR HAS SUBSEQUENTLY

, IT IS A FUNDAMENTAL

, WHETHER ON THE ORIGINAL MEDIA OR

, SHALL REMAIN VESTED IN TAIT OR

.

Term and Termination

THIS LICENCE SHALL BE EFFECTIVE UNTIL

TERMINATED IN ACCORDANCE WITH THE

PROVISIONS OF THIS AGREEMENT

MAY TERMINATE THIS LICENCE AT ANY TIME BY

DESTROYING ALL COPIES OF THE SOFTWARE OR

FIRMWARE AND ASSOCIATED WRITTEN MATERIALS

THIS LICENCE WILL BE TERMINATED

AUTOMATICALLY AND WITHOUT NOTICE FROM

TAIT IN THE EVENT THAT THE LICENSEE FAILS TO

COMPLY WITH ANY TERM OR CONDITION OF THIS

AGREEMENT

ALL COPIES OF THE SOFTWARE OR FIR MWARE AND

ASSOCIATED WRITTEN MATERIALS IN THE EVENT OF

SUCH TER MINATION

;

Limited Warranty

THE SOFTWARE OR FIRMWARE IS SUPPLIED BY TAIT

AND ACCEPTED BY THE LICENSEE

WARRANTY OF ANY KIND EITHER EXPRESSED OR

IMPLIED

ANY IMPLIED WARRANTIES AS TO

MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE

ACKNOWLEDGES THAT THE SOFTWARE OR

FIRMWARE IS USED BY IT IN BUSINESS AND

ACCORDINGLY TO THE MAXIMUM EXTENT

PERMITTED BY LAW NO TER MS OR WARRANTIES

WHICH ARE IMPLIED BY LEGISLATION SHALL APPLY

TO THIS AGREEMENT

THAT THE FUNCTIONS CONTAINED IN THE

SOFTWARE OR FIRMWARE WILL MEET THE

LICENSEE

OPERATION OF THE SOFTWARE OR FIRMWARE WILL

BE UNINTERRUPTED OR ERROR

. THE LICENSEE AGREES TO DESTROY

.

, INCLUDING BUT NOT BEING LIMITED TO

. THE LICENSEE

. TAIT DOES NOT WARRANT

’S REQUIREMENTS OR THAT THE

. THE LICENSEE

.

“AS IS” WITHOUT

-FREE.

TM8100 Mobile Radio Service Manual 3

October 2003 © Tait Electronics Limited

Exclusion of Liability

TAIT’S ENTIRE LIABILITY AND THE LICENSEE’S

EXCLUSIVE REMEDY SHALL BE THE FOLLOWING

:

1. IN NO CIRCUMSTANCES SHALL TAIT BE UNDER

ANY LIABILITY TO THE LICENSEE

PERSON WHATSOEVER

SEQUENTIAL DAMAGE ARISING OUT OF OR IN CON-

NECTION WITH ANY USE OR INABILITY OF USING

THE SOFTWARE OR FIRMWARE

, FOR ANY DIRECT OR CON-

, OR ANY OTHER

.

2. TAIT WARRANTS THE OPERATION OF THE

SOFTWARE OR FIRMWARE ONLY WITH THE

OPERATING SYSTEM FOR WHICH IT WAS DESIGNED

USE OF THE SOFTWARE OR FIR MWARE WITH AN

OPERATING SYSTEM OTHER THAN THAT FOR

WHICH IT WAS DESIGNED MAY NOT BE SUPPORTED

BY TAIT

TAIT

, UNLESS OTHERWISE EXPRESSLY AGREED BY

.

General

THE LICENSEE CONFIRMS THAT IT SHALL COMPLY

WITH THE PROVISIONS OF LAW IN RELATION TO THE

SOFTWARE OR FIRMWARE

.

Law and Jurisdiction

THIS AGREEMENT SHALL BE SUBJECT TO AND

CONSTRUED IN ACCORDANCE WITH NEW ZEALAND

LAW AND DISPUTES BETWEEN THE PARTIES

CONCERNING THE PROVISIONS HEREOF SHALL BE

DETERMINED BY THE NEW ZEALAND COURTS OF

LAW

. PROVIDED HOWEVER TAIT MAY AT ITS

ELECTION BR ING PROCEEDINGS FOR BREACH OF

THE TER MS HEREOF OR FOR THE ENFORCEMENT

OF ANY JUDGEMENT IN RELATION TO A BREACH OF

THE TER MS HEREOF IN ANY JURISDICTION TAIT

CONSIDERS FIT FOR THE PURPOSE OF ENSURING

COMPLIANCE WITH THE TERMS HEREOF OR

OBTAINING RELIEF FOR BREACH OF THE TERMS

HEREOF

.

No Other Terms

THE LICENSEE ACKNOWLEDGES THAT IT HAS READ

THIS AG REEMENT

TO BE BOUND BY ITS TERMS AND CONDITIONS

LICENSEE FURTHER AGREES THAT SUBJECT ONLY

TO ANY EXPRESS WRITTEN TERMS OF AGREEMENT

TO THE CONTRARY BETWEEN TAIT AND THE

LICENSEE THIS IS THE COMPLETE AND EXCLUSIVE

STATEMENT OF THE AGREEMENT BETWEEN IT AND

TAIT IN RELATION TO THE SOFTWARE OR

FIRMWARE WHICH SUPERSEDES ANY PROPOSAL OR

.

PRIOR AGREEMENT

OTHER COMMUNICATIONS BETWEEN THE LICENSEE

AND TAIT RELATING TO THE SOFTWARE OR

FIRMWARE

, UNDERSTANDS IT AND AGREES

. THE

, ORAL OR WRITTEN AND ANY

.

No Dealings

THE LICENSEE MAY NOT SUBLICENSE, ASSIGN OR

TRANSFER THE LICENCE OR THE PROGRAM EXCEPT

AS EXPRESSLY PROVIDED IN THIS AGREEMENT

ATTEMPT OTHERWISE TO SUBLICENSE

TRANSFER ANY OF THE R IGHTS

OBLIGATIONS HEREUNDER IS VOID

, ASSIGN OR

, DUTIES OR

.

4 TM8100 Mobile Radio Service Manual

. ANY

October 2003 © Tait Electronics Limited

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Notes for Readers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Amendment Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

List of Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1 TM8100 Mobile Radio System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2 Radio Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3 Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4 Repair Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.5 Product Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1 Architecture of Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 Operation of Control-head Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.3 Operation in Receive Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.4 Operation in Transmit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5 Operation of Frequency Synthesizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Disassembly and Re-assembly of Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1 Detachment of Control Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.2 Disassembly of Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.3 Disassembly of Radio Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.4 Re-assembly of Radio Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.5 Re-assembly and Attachment of Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

TM8100 Mobile Radio Service Manual 5

October 2003 © Tait Electronics Limited

Preface

Scope of service manual This manual provides information to service technicians for carrying out

level-1 repairs of TM8100 mobile radios. Level-1 repairs entail the

replacement of faulty parts and circuit boards.

The manual does not cover level-2 repairs (repair of circuit boards, with

the exception of certain special items on the boards) and level-3 repairs

(repair of the special items).

The servicing procedures are moreover limited to the control head and

radio body of TM8100 mobile radios. Servicing of all accessories

associated with the radio is covered in the accessories manual.

Summary of service manual The service manual is divided into three sections. The first section

introduces the radio. The main products making up the radio system are

identified (in particular, the control head and radio body), the repair

levels are discussed, and the product codes of the control head and radio

body are given.

In the second section the functioning of the radio is described. The

description is limited to the control head and radio body. The

architecture of the radio, the operation of the control-head circuitry, the

functioning of the radio in the receive and transmit modes, and the

operation of the frequency synthesizer are described.

The third section provides information regarding the level-1 repair

procedures. The information is mainly limited to the procedures for

disassembling and re-assembling the radio. Only a brief outline is given

of the overall repair procedures themselves.

6 TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Notes for Readers

Enquiries and comments Any enquiries regarding this manual or the equipment that it describes,

as well as any comments, suggestions and notifications of errors, should

be addressed by e-mail to Technical Support (support@taitworld.com

or to the Technical Support Manager, Tait Electronics Limited, PO Box

1645, Christchurch, New Zealand. Orders for this manual can be placed

with your Tait Dealer.

)

Updates of manual

and equipment

In the interests of improving the performance, reliability or servicing of

the equipment, Tait Electronics Limited reserves the right to upgrade the

equipment or update this manual or both without prior notice.

Copyright All information contained in this manual is the property of Tait

Electronics Limited. All rights are reserved. This manual may not, in

whole or in part, be copied, photocopied, reproduced, translated, stored,

or reduced to any electronic medium or machine-readable form,

without prior written permission from Tait Electronics Limited. All

trade names referenced are the service mark, trade mark, or registered

trade mark of the respective manufacturers.

Disclaimer There are no warranties extended or granted by this manual. Tait

Electronics Limited accepts no responsibility for damage arising from use

of the information contained in the manual or of the equipment and

software it describes. It is the responsibility of the user to ensure that use

of such information, equipment and software complies with the laws,

rules and regulations of the applicable jurisdictions.

TM8100 Mobile Radio Service Manual 7

October 2003 © Tait Electronics Limited

Typographical Conventions

Conventions and alerts In this manual the names of electrical signals are typed in small capitals

using the standard sans-serif font of the document. For example:

TX INHIBIT

Alert notices that appear in the manual are selected from whichever of

the following are appropriate. These alert notices are in accordance with

the ANSI definitions.

Warning!! This alert notice is used when there is a

potential risk of death or serious injury.

Caution This alert notice is used when there is a risk of

minor to moderate injury to people.

Important This alert notice is used to warn about the risk of

equipment damage or malfunction.

Note This alert notice is used to highlight information that is

required to ensure that procedures are performed correctly.

8 TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Associated Documents

Basic manuals Together with this service manual, the following manuals are of concern

to service technicians. The pair of digits in the third field of the

document product code indicates the language of the document — 00

indicates an English and 03 a multi-lingual document.

MM8100-00-03-804

TM8100 mobile radio — User’s guide

MMAA00-00-00-812

TM8100 mobile radio — Accessories manual

PCB information packages Information on the circuit boards is supplied in the following separate

documents. The information consists of the BOMs (parts lists), grid

reference indexes, PCB layouts, and circuit diagrams.

MMAB12-H5-00-814

Main board (H5/H6) — PCB information package

MMAB12-B1-00-814

Main board (B1) — PCB information package

MMAC20-00-00-814

Control-head board — PCB information package

3DK manuals The following manuals are mainly of concern to third-party developers.

The manuals are supplied in soft-copy form on a 3DK resource CD.

MMAA30-00-00-807

TM8000 3DK hardware developer’s kit — Application manual

MMAA30-02-00-429

TM8000 3DK application board — Software programmer’s manual

MMAA30-02-00-812

TM8000 3DK application board — Service manual

MM8100-00-00-441

TM8100 Computer-controlled data interface — Protocol definition

TM8100 Mobile Radio Service Manual 9

October 2003 © Tait Electronics Limited

Amendment Record

Version Publication date Amended sections and pages

1.00 September 2003 First release

1.01 October 2003 Alert notice added in Section 3

Figures 3.5 to 3.8 updated

10 TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

List of Acronyms

3DK Third-party Developer’s Kit

AC Alternating Cur rent

ACP Adjacent Channel Power

ADC Analogue-to-digital Converter

AGC Automatic Gain Control

ALC Automatic Level Control

ASC Accredited Service Centre

BOM Bill of Materials

CODEC Coder-decoder

CSO Customer Service Organisation

DAC Digital-to-analogue Converter

DC Direct Current

DIN Deutsche Industrie Norm

DSP Digital Signal Processor

DTMF Dual-tone Multi-frequency

FCL Frequency Control Loop

FPGA Field-programmable Gate Array

IPN Internal Part Number

IC Integrated Circuit

IF Intermediate Frequency

IQ In-phase and Quadrature

ISC International Service Centre

LCD Liquid-crystal Display

LED Light-emitting Diode

LO Local Oscillator

PA Power Amplifier

PCB Printed Circuit Board

PLL Phase-locked Loop

RF Radio Frequency

RSSI Received Signal Strength Indication

SMT Surface-mount Technology

TCXO Temperature-compensated Crystal Oscillator

TEL Tait Electronics Limited

UHF Ultra-high Frequency

VCO Voltage-controlled Oscillator

VCXO Voltage-controlled Crystal Oscillator

VHF Very High Frequency

TM8100 Mobile Radio Service Manual 11

October 2003 © Tait Electronics Limited

12 TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

1 Introduction

Scope of section This section introduces the TM8100 mobile radio system. The main

items making up the system are first introduced. There follows

additional information on the radio body and control head — the two

items that are the prime concern of the service manual. Next is a

discussion of the repair levels that govern the servicing of the radio body

and control head. The section concludes with an explanation of the

product codes for these items.

1.1 TM8100 Mobile Radio System

Main items of system The TM8100 mobile radio system is a high-performance

microprocessor-controlled transceiver with a comprehensive range of

accessories. The system is designed primarily for installation in vehicles

but can also be used in desktop, remote-monitoring and similar

applications. The system consists of the following main items:

■ radio body

■ control head

■ audio accessories

■ mounting for radio

■ desktop power supply (optional)

The service manual covers the servicing of the radio body and control

head only. The accessories manual covers servicing of all the remaining

items.

Specifications for system The specifications for the system are not given in this manual, but will

be found instead on the TaitWorld website in the area reserved for

TM8000 products. This ensures that the latest specification data will

always be available to service technicians.

Radio body The radio body contains the transmitter, receiver and microprocessor

circuitry. The radio body also allows for the fitting of an internal options

board to provide additional functions. There are three standard external

connectors on the radio body: an RF connector, power connector, and

auxiliary connector. If an internal options board is fitted, there might or

might not be an associated external options connector. The auxiliary

and external options connectors allow for the connection of various

external devices.

TM8100 Mobile Radio Service Manual Introduction 13

October 2003 © Tait Electronics Limited

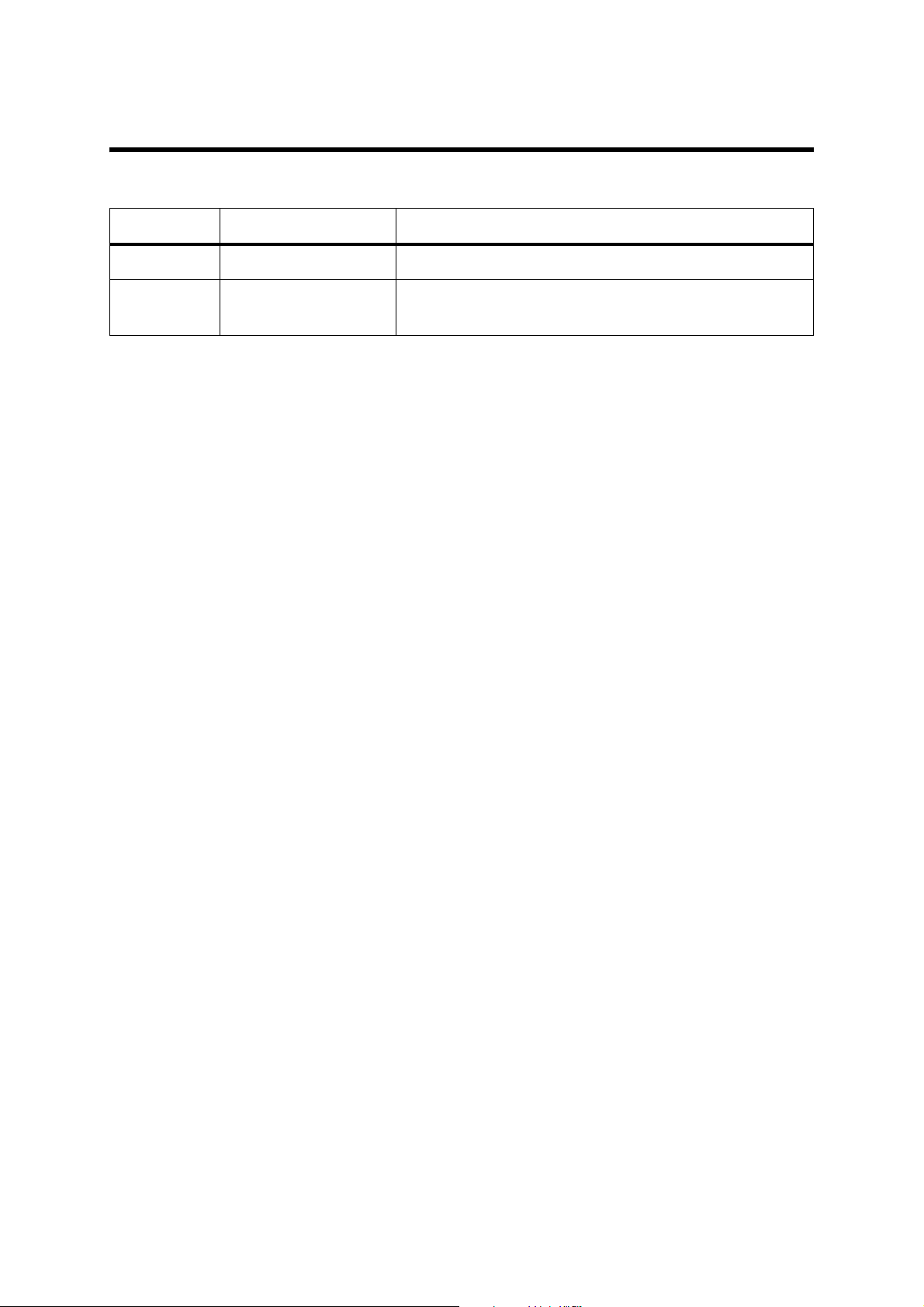

Figure 1.1 Illustrations of the TM8115 mobile radio showing both the front and rear

14 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

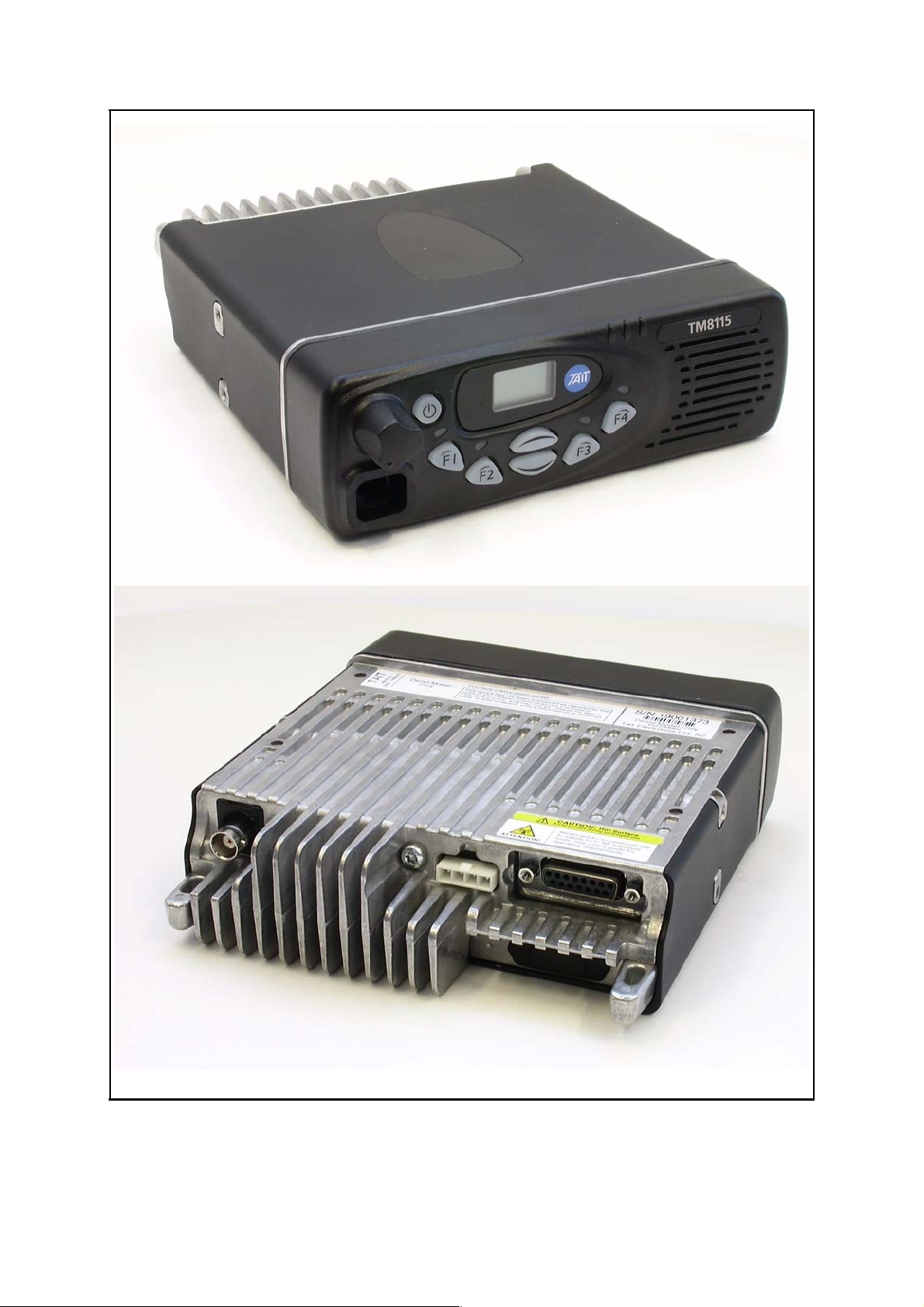

Figure 1.2 Illustration of the front of the TM8105 mobile radio

Control head

The control head is attached to the radio body. There is a choice of two

control heads:

■ two-digit-display control head

■ blank control head

The two-digit display control head provides the interface with the radio

user and includes a socket for the connection of a microphone. The

blank control head has no user interface but has a single external

connector called the programming connector; this is typically used for

programming and monitoring purposes. The radio is designated

TM8115 with the two-digit-display control head and TM8105 with the

blank control head. Illustrations of these radios are given in Figure 1.1

and Figure 1.2.

Audio accessories One or more audio accessories may be connected to the control head

and radio body. A microphone is the accessory usually required; other

accessories that are available are a handset, high-power remote speaker,

and hands-free kit. Various external devices may also be connected. The

user’s guide and accessories manual describe the audio accessories.

TM8100 Mobile Radio Service Manual Introduction 15

October 2003 © Tait Electronics Limited

RF ANTENNA

RF

CONNECTOR

DEVICE

EXTERNAL

FREE

HANDS-

EXTERNAL OPTIONS

CONNECTOR

AUXILIARY

RADIO BODY

KIT

CONNECTOR

FUSES

POWER

CONNECTOR

VEHICLE

HIGH-

POWER

BATTERY

REMOTE

SPEAKER

RADIO SYSTEM

CONTROL

HEAD

CONNECTOR

MICROPHONE

PHONE

MICRO-

MOUNTING

PLATE

HANGER

dwls

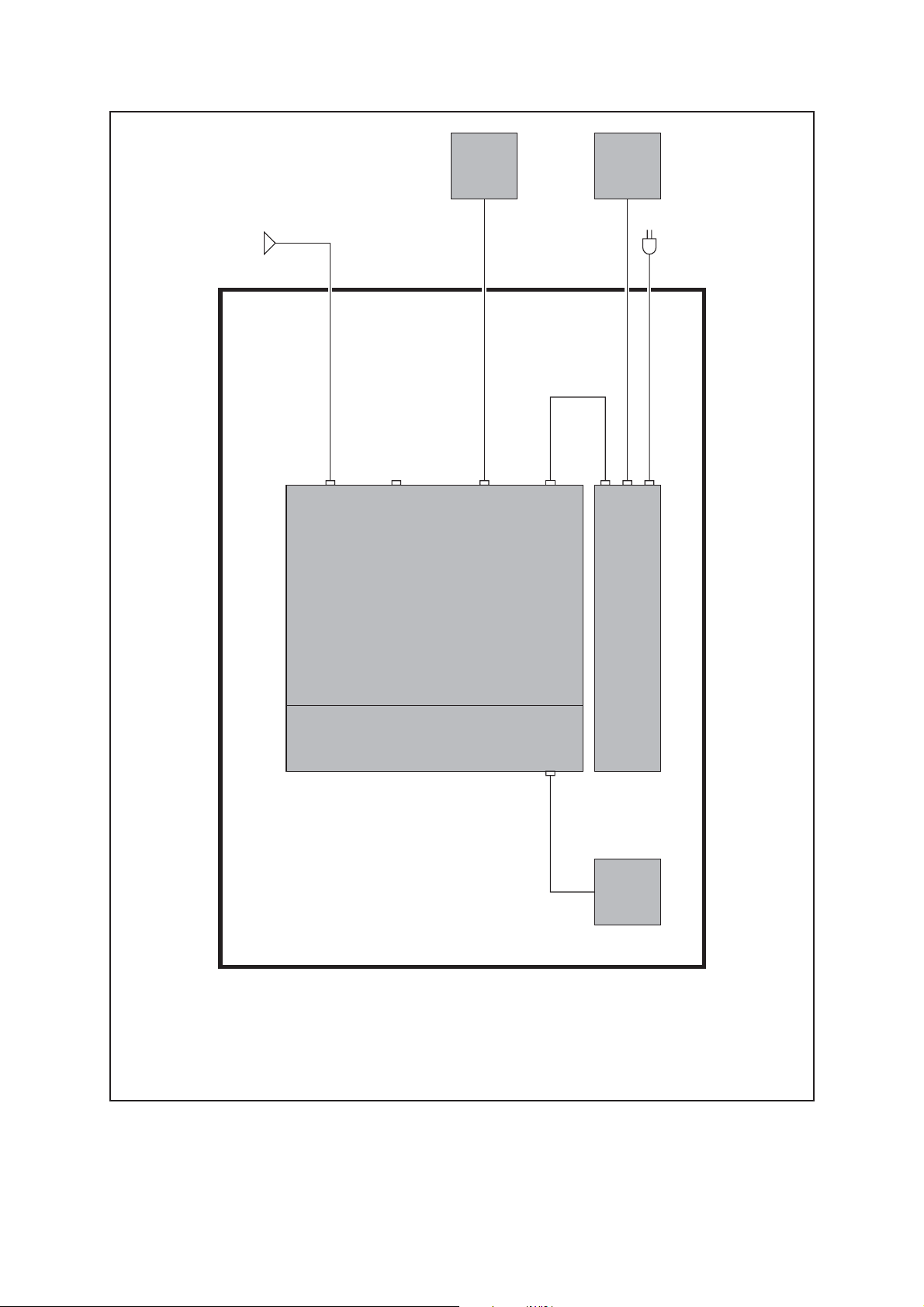

Figure 1.3 Block diagram of an example installation of the TM8115 mobile radio in a vehicle

16 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

RF ANTENNA

DEVICE

EXTERNAL

BACK-UP

BATTERY

AC MAINS

RF

CONNECTOR

RADIO SYSTEM

CONTROL

AUXILIARY

RADIO BODY

HEAD

EXTERNAL OPTIONS

CONNECTOR

CONNECTOR

POWER

CONNECTOR

CONNECTOR

MICROPHONE

DESKTOP POWER SUPPLY

OR

MICRO-

DESKTOP

HANDSET

PHONE

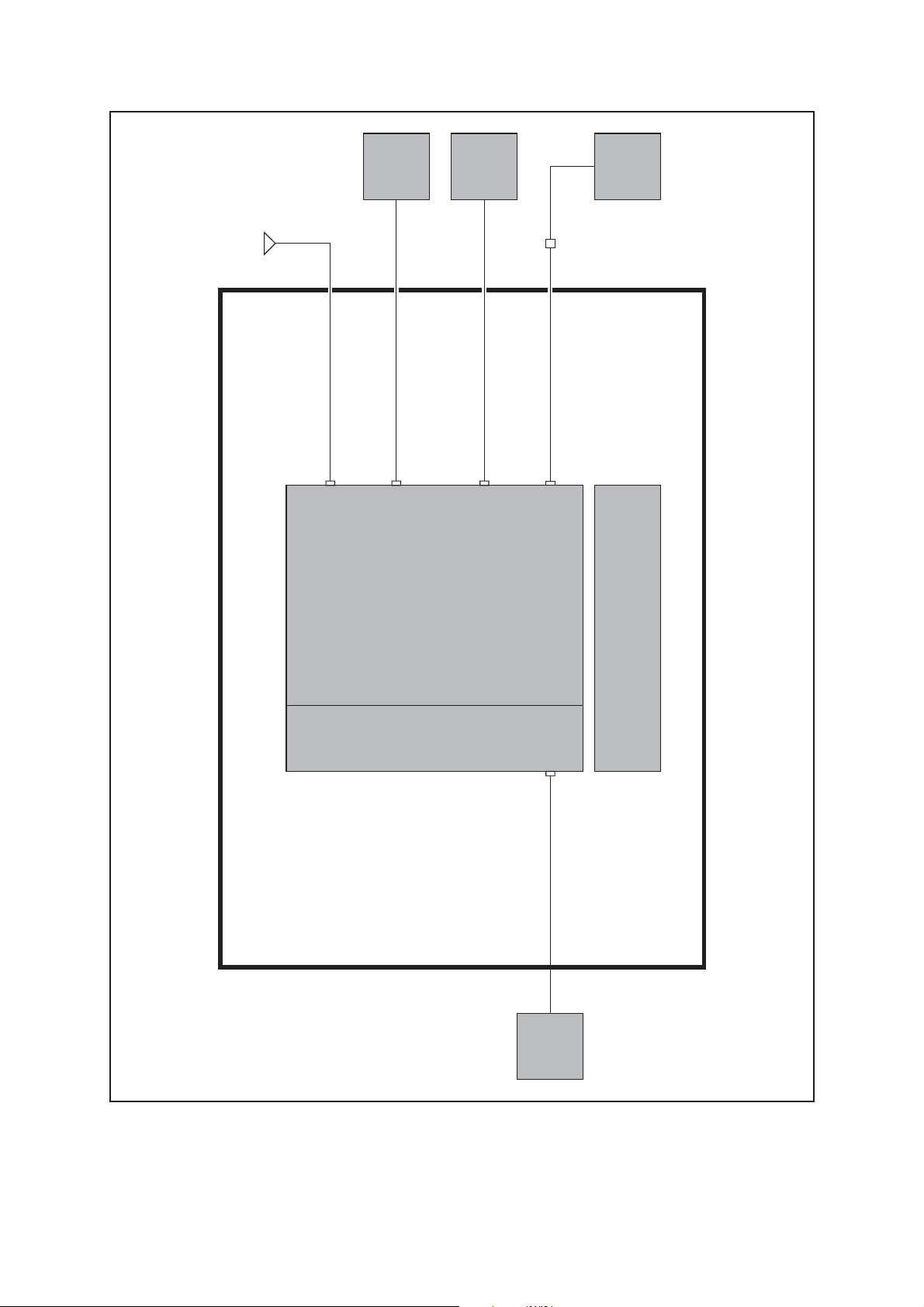

Figure 1.4 Block diagram of an example desktop installation of the TM8115 mobile radio

TM8100 Mobile Radio Service Manual Introduction 17

October 2003 © Tait Electronics Limited

dwls

RF ANTENNA

DEVICE

EXTERNAL

DEVICE

EXTERNAL

FUSES

VEHICLE

BATTERY

RF

CONNECTOR

EXTERNAL OPTIONS

RADIO SYSTEM

CONNECTOR

RADIO BODY

BLANK

CONTROL

HEAD

AUXILIARY

CONNECTOR

POWER

CONNECTOR

CONNECTOR

PROGRAMMING

MOUNTING

DEVICE

EXTERNAL

Figure 1.5 Block diagram of an example installation of the TM8105 mobile radio in a vehicle

18 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

dwls

Installation kits and

desktop power supply

The mounting hardware for the radio is in the form of a U-cradle. It is

supplied in an installation kit and provides for the installation of the radio

in a vehicle. Alternatively, the radio might be needed for desktop use, in

which case a desktop power supply is required. In some desktop

installations the U-cradle is used to attach the radio to the power supply.

The user’s guide and accessories manual describe the installation kit.

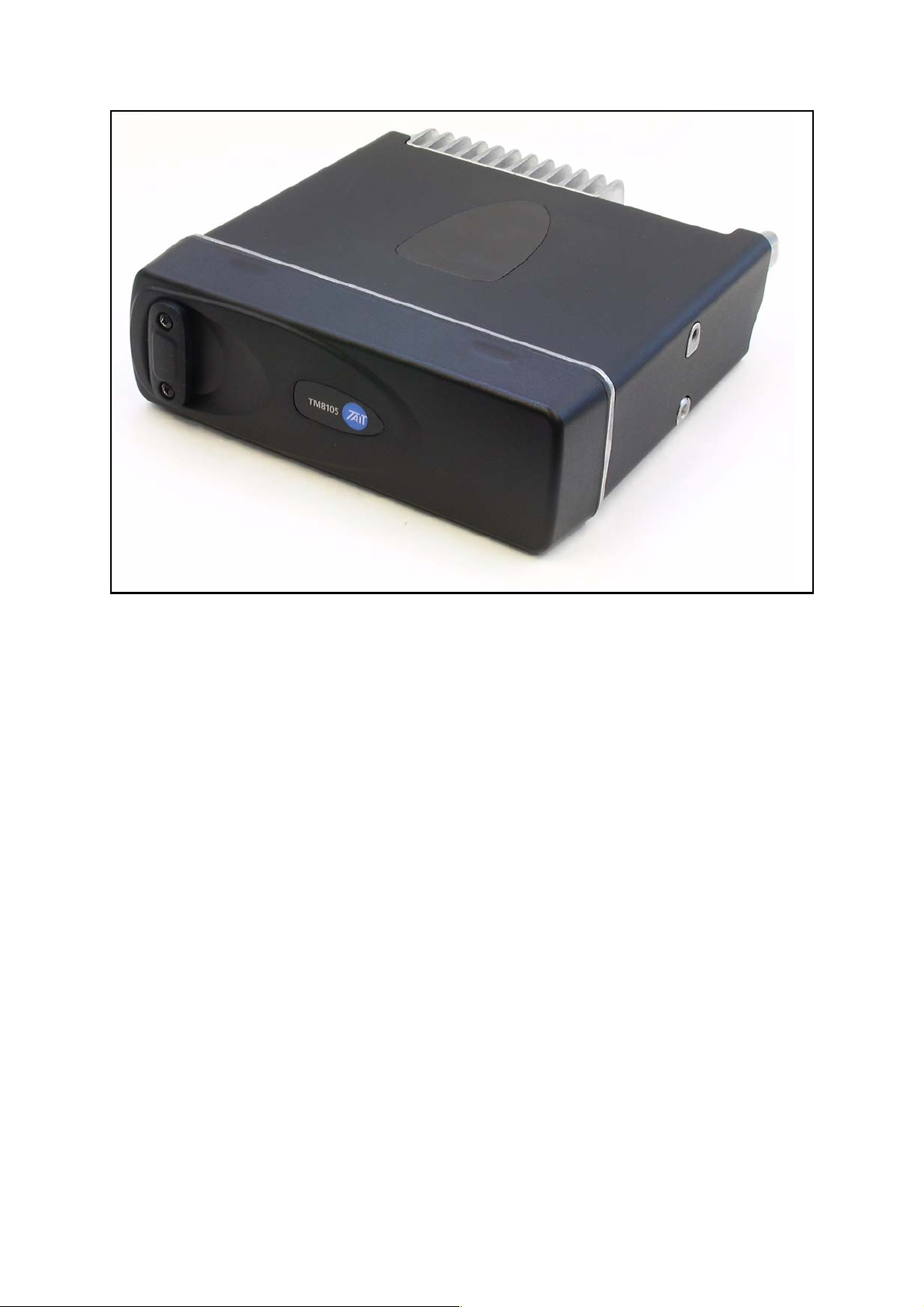

Block diagrams of system The block diagrams of Figure 1.3 to Figure 1.5 illustrate possible

configurations of the radio system. Figure 1.3 and Figure 1.4 show

example installations of the TM8115 radio (with two-digit-display

control head) in a vehicle and on a desktop. Figure 1.5 shows an example

of the TM8105 radio (with blank control head) installed in a vehicle.

Different audio accessories are shown connected to the radio. The

hands-free kit is connected to the auxiliary connector, and the remote

speaker to the power connector. The accessories that may be connected

to the microphone connector include the rugged microphone, as well as

a DTMF microphone, desktop microphone, and handset.

1.2 Radio Body

Main, digital and

internal options boards

The radio body consists of a rectangular case — or chassis — with a lid.

The case houses a main board with the receiver and transmitter circuitry,

and a digital board with the microprocessor that controls the radio.

There are different main boards available covering different frequency

bands and with different RF performances; refer to the product codes in

Figure 1.8. The digital board is reflow-soldered to the main board.

There is space in the lid for an optional internal options board. The

essentials of the arrangement are illustrated in the block diagram of

Figure 1.6.

Main-board assembly The rear edge of the main board is attached to a heat-transfer block. The

block is in thermal contact with the rear of the case, where there are

cooling fins for heat dissipation. Heat from the output stage of the

transmitter is conducted via the heat-transfer block to the rear and

radiated from the cooling fins. (The lower surface of the case is ridged

to augment the dissipation of heat.) The RF, auxiliary and power

connectors are fixed to the rear of the main board. They project through

apertures in the heat-transfer block and the rear of the case. The main

board, digital board, and heat-transfer block constitute a separate unit

called the main-board assembly.

Internal options boards Either Tait-designed or custom internal options boards may be fitted in

the radio body. Full details of the boards are given in the accessories

and 3DK manuals. Any internal options board that is fitted might or

might not include an external options connector. If included, the

connector will project through an aperture in the rear of the lid. If there

is no connector, the aperture is sealed with a bung.

TM8100 Mobile Radio Service Manual Introduction 19

October 2003 © Tait Electronics Limited

Figure 1.6 Block diagram of the radio body and control head of the TM8115 mobile radio

20 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Internal connections

There are three sets of internal connections to the main board; these use

the following connectors:

■ debug connector

■ control-head connector

■ internal options connector

The debug connector is for Factory use only. The control-head

connector is on the front edge of the main board; it is used to connect a

control-head loom from the control head to the main board. The

internal options connector is required when an internal options board is

fitted; it is used to connect an options loom between the two boards.

1.3 Control Head

Introduction The control head clips securely to the front of the radio body. The

control-head loom between the two is enclosed in the space between

them. For badging and branding purposes there are both a logo and a

label for the product model code on the front panel. The control head

may also be left unbadged. The essentials of the two-digit-display

control head are shown in the block diagram of Figure 1.6.

Two-digit-display control head The front panel of the two-digit-display control head is fitted with the

controls and indicators needed by the radio user; these comprise:

■ LCD screen

■ indicator LEDs

■ volume control

■ on/off key

■ function keys

■ channel-selection keys

In addition, there are the microphone connector and an internal speaker.

The necessary circuitry for the above items is mounted on a control-head

board fitted behind the front panel. The volume-control potentiometer

is fixed to the board; so is a control-head connector, which is used for

the control-head loom between the control head and radio body.

Options for control head The two-digit-display control head allows for an optional concealed

microphone or the use of a dynamic microphone. (A concealed

microphone is fitted behind the front panel next to the speaker.) With

either option a separate circuit board is required for the microphone.

This board is connected to the control-head board by means of two

connectors; the plugs of the connectors are mounted on the latter board

and the sockets on the former. Full details of the optional microphones

and circuit board are given in the accessories manual.

TM8100 Mobile Radio Service Manual Introduction 21

October 2003 © Tait Electronics Limited

Blank control head

The blank control head has none of the features of the two-digit-display

control head. The front panel of the blank control head is fitted only

with the single programming connector. The control-head loom is

permanently fixed to the rear of the programming connector. The space

inside the control head can be used for the fitting of an optional thirdparty circuit board, but is otherwise empty.

1.4 Repair Levels

Level-1 repairs The repairs that can be carried out on the TM8100 mobile radio are

grouped into categories — or levels — of increasing complexity. This

manual covers only level-1 repairs, which comprise the following:

■ replacement of control-head board

■ replacement of main-board assembly

■ replacement of other parts

The last-named parts include the connectors and volume-control

potentiometer on the control-head board, but not the connectors on the

main board.

Level-2 repairs It is important to distinguish level-1 repairs from the higher-level repairs,

which require greater skills and resources. Thus, level-2 repairs comprise

the following:

■ repair of control-head board

■ repair of main-board assembly, excluding special items

These repairs entail the replacement of faulty SMT components on the

boards, as well as the connectors on the main board. The special items

are the digital board and certain components on the main board.

(Repairs of the special items are level-3 repairs.)

Service centres The service centres that carry out repairs of TM8100 mobile radios can

be divided into three categories:

■ Dealers and Customers with appropriate facilities

■ ASCs, including CSOs

■ TEL and ISC

ASCs, the ISC and TEL may carry out both level-1 and level-2 repairs.

These are moreover the only service centres that may repair a radio that

is still under warranty — any repair by a non-accredited service centre

will void the warranty. After the expiry of the warranty, Dealers and

Customers with appropriate facilities may also carry out level-1 repairs,

but are strongly advised not to attempt level-2 repairs. Contact Technical

Support for details of the process by which service centres may achieve

accreditation.

22 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Figure 1.7 Scheme for the product codes assigned to products of the mobile radio product line

Restrictions regarding

level-3 repairs

Only TEL and the ISC should carry out level-3 repairs. The level of

technology employed in the TM8100 generation of radios is an order of

magnitude greater than in earlier generations. This greater sophistication

demands special equipment and techniques for level-3 repairs. Although

other service centres are strongly advised not to attempt such repairs,

those with sufficient resources and skilled technicians may wish to do so.

These service centres should contact Technical Support for assistance and

for the necessary documentation. TEL does not offer accreditation for

level-3 repairs to any service centres other than the ISC.

1.5 Product Codes

Introduction This subsection describes the product codes used to identify different

products of the mobile radio product line. The product-code scheme in

general is first explained, and then the product codes for the radio body

and control head in particular. The purpose is solely to enable service

technicians to identify the radio body and control head of a radio that has

been delivered for repair.

TM8100 Mobile Radio Service Manual Introduction 23

October 2003 © Tait Electronics Limited

Figure 1.8 Scheme for the product codes currently in use for the radio body of TM8100 mobile radios

Limitations on use

of product codes

General scheme for

product codes

The product codes discussed in this subsection are those in use at the time

of publication. For up-to-date information refer to the TaitWorld

website. The explanations of the product codes are to aid identification

only, and are not

to be used as the basis for sales orders. There are two

reasons for this: Firstly, an arbitrarily-constructed product code might

apply to a product that, for compliance reasons, is restricted to certain

markets. Secondly, a product with such a product code might not even

exist.

Individual products of the mobile radio product line are identified by

product codes with the format:

TMabcc–ddee

where a and b are uppercase letters representing the product family and

category of product respectively, and cc, dd and ee are characters that

identify the specific product. The characters ee are applicable to the

radio body only and identify different options. The product code

scheme is summarised in Figure 1.7.

24 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Figure 1.9 Scheme for the product codes currently in use for the control head of TM8100 mobile radios

Product families

and categories

Product codes

for radio body

Examples of different product families within the mobile radio product

line are the T700, T2000 and TM8100 radios. The TM8100 family is

however the first to which the above product-code scheme applies.

Examples of different product categories are radio bodies, control heads,

and accessories. These are the only categories identified to date. The

product codes for the TM8100 radio body and control head are discussed

below; those for the accessory items are described in the accessories

manual.

The product codes for the TM8100 radio body have the format:

TMABab–ccdd

where a identifies the architecture of the digital board, b identifies the

RF performance, cc is the letter-digit combination identifying the

frequency band, and dd identifies any options selected. The characters

dd are set to 00 for the default radio with no options added. For

universal options available to all Customers, the digits 01 to 99 are used

for dd. For custom options implemented for particular Customers, the

letters AA to ZZ are used. The digits and letters identifying the universal

and custom options are assigned sequentially. Figure 1.8 illustrates the

product codes in use at the time of publication.

TM8100 Mobile Radio Service Manual Introduction 25

October 2003 © Tait Electronics Limited

Product codes

for control head

The product codes for the TM8100 control head have the format:

TMACab–cc

where a identifies the type of control head, b identifies any options

selected, and cc identifies badging and branding options. By type is

meant whether the control head is a blank or two-digit-display control

head; allowance is made for additional types in the future. Only the

digits 1 to 9 are allowed for a (0 is not used), and the digits 0 to 9 for b;

the latter is set to 0 when no options are added. Both letters and digits

may be used for cc. The default for cc is 0T; on the two-digit-display

control head the Tait logo is then displayed next to the LCD screen, and

the product model code TM8115 is displayed above the speaker grill.

Figure 1.9 illustrates the product codes in use at the time of publication.

26 Introduction TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

2 General Description

Scope of section This section comprises a general description of the radio body and

control head of TM8100 mobile radios. Firstly, the architecture of the

radio is described. Secondly, the operation of the control-head circuitry

is summarised. Finally, the principles of operation of the radio are given

in three separate subsections.

2.1 Architecture of Radio

Introduction In this subsection the architecture of the radio is described. The different

circuit modules of the control-head, main and digital boards introduced

in Section 1 are identified. The optional circuit boards mentioned in

Section 1 are covered in other manuals.

Control head The two-digit-display control head houses a control-head board with the

circuitry needed for the controls and indicators on the front panel. There

is provision for an optional board for use with dynamic microphones or

with a concealed microphone inside the control head. There is also

provision for the fitting of an optional third-party circuit board in the

blank control head.

The operation of the control-head board is summarised in

Subsection 2.2. The circuit board for concealed and dynamic

microphones is described in the accessories manual. The fitting of thirdparty circuit boards in the blank control head is discussed in the

application manual for 3DK hardware developers.

Radio body The radio body houses a main board with the transmitter, receiver and

associated circuitry, and a digital board with the microprocessor and

associated circuitry. The digital board is reflow-soldered to the main

board. There is also provision for an internal options board to be

connected to the main board.

The different circuit modules of the main board are discussed below and

the operation of the circuitry is described in Subsection 2.3 to

Subsection 2.5. The different internal options boards are discussed in the

accessories manual and the 3DK manuals.

TM8100 Mobile Radio Service Manual General Description 27

October 2003 © Tait Electronics Limited

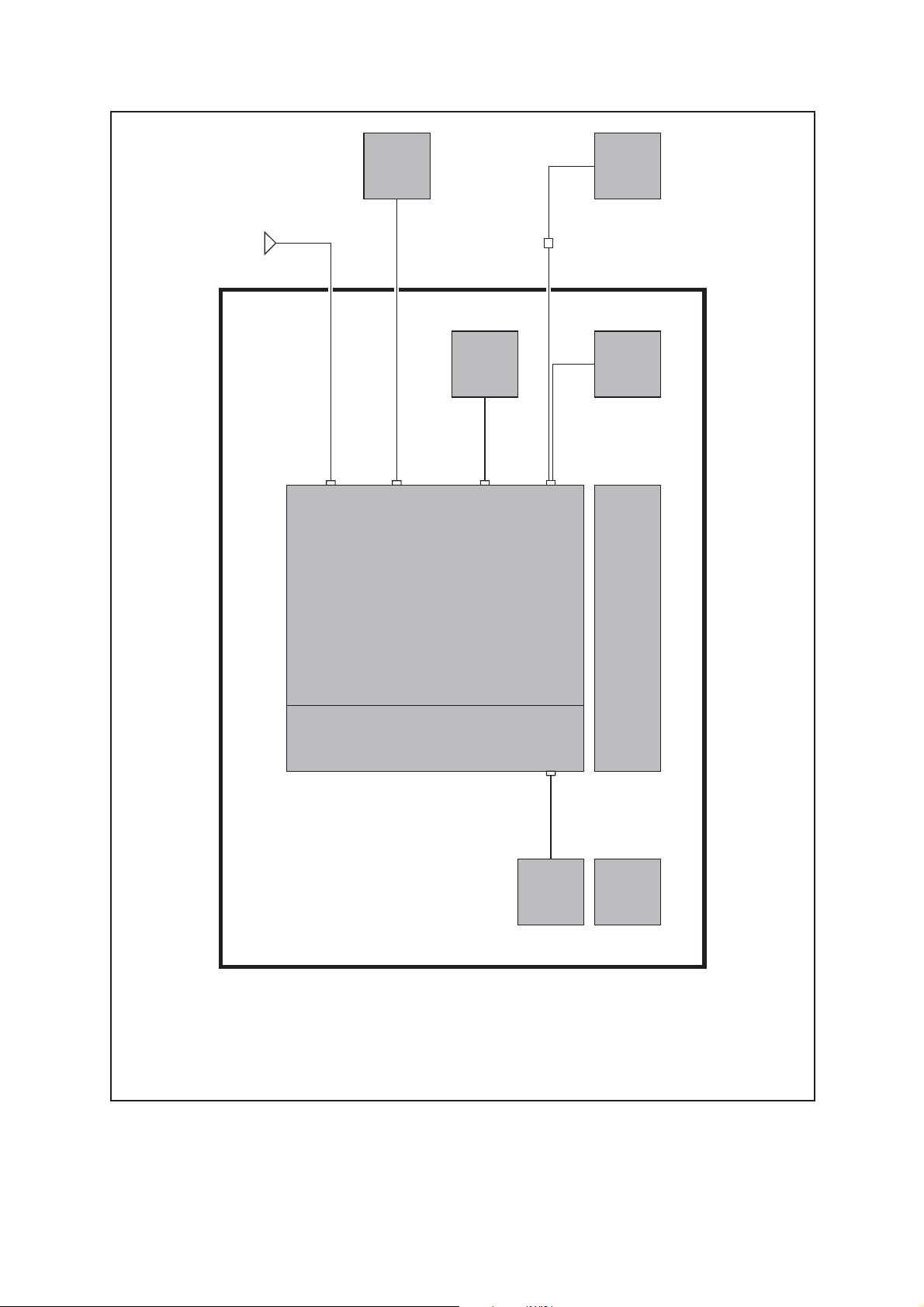

Figure 2.1 Block diagram of the main board of the radio body

28 General Description TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Modules of main board

The control-head, main and digital boards, and the connectors on the

boards, are illustrated in Figure 1.6 of Section 1. Figure 2.1 is a block

diagram showing the main and digital boards and the circuit modules of

the main board. These modules are:

■ transmitter

■ receiver

■ frequency synthesizer

■ CODEC and audio circuitry

■ power supply

■ interface circuitry

Software plays a prominent role in the functioning of the TM8100 radio.

For describing the operation of the radio the software must be included

with the above modules. This is considered further below.

Operation of radio Figure 2.2 is a simplified block diagram of the transceiver architecture

showing the hardware modules integrated with the software modules.

The same DSP device includes the software that controls the transceiver

and the software constituting the digital-signal-processing blocks in

Figure 2.2. The operation of the radio is then best described with

reference to Figure 2.2 and with a division into the following three parts:

■ operation in receive mode

■ operation in transmit mode

■ operation of frequency synthesizer

Operational descriptions of these three parts are given in Subsection 2.3

to Subsection 2.5 respectively.

2.2 Operation of Control-head Circuitry

User interface In this subsection the operation of the control-head circuitry is

summarised. The standard control head provides a user interface

consisting of:

■ two-digit seven-segment LCD

■ up and down channel-selection keys

■ four programmable function keys

■ on/off push-button key

■ LED indicators

■ volume control

■ internal speaker

■ microphone connector

The microphone connector may also be used for the connection of a

handset or programming lead. If required, a concealed microphone may

be fitted inside the control head.

TM8100 Mobile Radio Service Manual General Description 29

October 2003 © Tait Electronics Limited

Figure 2.2 Architecture of the TM8100 transceiver

30 General Description TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Connectors and circuit boards

There is an 18-way electrical interface between the control head and

radio body. The physical connection is via an 18-way loom. The control

head normally contains a single PCB assembly called the control-head

board. If a dynamic microphone is used or a concealed microphone

fitted, a small circuit board must be mounted on the control-head board.

The added board has the necessary amplification, filtering and switching

functions. The internal speaker is connected to the control-head board

via a lead with a mating connector so that it can be easily disconnected.

Control-head board The control-head board does not include a microprocessor. A

synchronous bi-directional serial interface provides communication of

key status, LCD and LED-indicator data between the radio body and the

control head. On the control-head board the serial data are converted to

or from parallel form by a number of shift registers for the keys and

indicators. For the LCD, the serial data are fed to a driver IC that

converts the serial data to a form suitable for the LCD itself. The keys

are scanned and the LCD and LED indicators updated approximately

every 50 ms.

2.3 Operation in Receive Mode

Receive path In this subsection the functioning of the radio in the receive mode is

described. As shown in Figure 2.2, the receive path exists in three

different domains:

■ hardware

■ custom logic

■ DSP

The front-end hardware amplifies and image-filters the received RF

spectrum, then down-converts the desired channel frequency to a first

intermediate frequency IF1 of 45.1 MHz (UHF) or 21.4 MHz (VHF)

where coarse channel filtering is performed. The first LO signal is

obtained from the frequency synthesizer. The output of the first IF is

then down-converted using an image-reject mixer to a low IF of 64 kHz.

Quadrature demodulator The LO for the image-reject mixer (quadrature demodulator) is

synthesized and uses the TCXO as a reference. This ensures good

centring of the IF filters and more consistent group-delay performance.

The quadrature demodulator device has an internal frequency division of

2 so the second LO operates at 2 x (IF1+ 64 kHz). The quadrature

output from this mixer is fed to a pair of AD Cs with high dynamic range

where it is oversampled at 256 kHz and fed to the custom logic device.

TM8100 Mobile Radio Service Manual General Description 31

October 2003 © Tait Electronics Limited

Custom logic

The remainder of the channel filtering is performed in custom logic.

Different filter shapes are possible to accommodate the various channel

spacings and data requirements. These filters provide the bulk of adjacent

channel selectivity for narrow-band operation. Each filter has a linear

phase response so that good group-delay performance for data is

achieved. The filters also decimate the sample rate down to 48 kHz.

Custom logic also performs demodulation, which is multiplexed along

with AGC and amplitude data and fed via a single synchronous serial port

to the DSP. The stream is demultiplexed and the demodulation data

stream processed further to meet audio requirements.

Automatic gain control The AGC is used to limit the maximum signal level applied to the image-

reject mixer and ADCs in order to meet the requirements for

intermodulation and selectivity performance. Hardware gain control is

performed by a variable gain amplifier within the quadrature

demodulator device driven by a 10-bit DAC. Information about the

signal level is obtained from the IQ data output stream from the ADCs.

The control loop is completed within custom logic. The AGC will

begin to reduce gain when the combined signal power of the wanted

signal and first adjacent channels is greater than about -70 dBm. In the

presence of a strong adjacent-channel signal it is therefore possible that

the AGC may start acting when the wanted signal is well below -70 dBm.

Noise squelch The noise squelch process resides in the DSP. The noise content above

and adjacent to the voice band is measured and compared with a preset

threshold. When a wanted signal is present, out-of-band noise content

is reduced and, if below the preset threshold, is indicated as a valid desired

signal.

Noise blanking Provision has been made for an optional noise blanker to remove

common sources of electrical interference such as vehicle ignition noise.

The noise blanker functions by sampling the RF input to the receiver for

impulse noise and momentarily disconnecting the first LO for the

duration of the impulse. The response time of the noise blanker is very

fast (tens of nanoseconds) and is quicker than the time taken for the RF

signal to pass through the front-end hardware, so that the LO is disabled

before the spike reaches the IF stage where it could cause crystal filter

ring. The noise blanker is fitted as standard for the VHF band.

Monitoring The lock-detect signal of the second LO synthesizer is monitored at least

every 100 ms. If the PLL fails to indicate lock within 10 ms of

programming, an error is reported by the control software. If an out-oflock condition occurs during run-time, then an audible indication will

be given and recovery repeatedly attempted.

32 General Description TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Calibration

The following items within the receiver path are calibrated:

■ Front-end tuning

■ AGC

■ Noise squelch

■ RSSI

Information on the calibration of these items is given in the on-line help

facility of the calibration application.

Audio processing Raw demodulated data from the receiver is processed within the DSP.

The sample rate at this point is 48000 samples per second with signal

bandwidth limited only by the IF filtering. Scaling (dependent on the

bandwidth of the RF channel) and noise-peak limiting are then applied

to normalise the signal level for the remaining audio processing. The

sample rate is decimated to 8000 samples per second and then low-pass

filtered at 3 kHz, before being passed to the subaudible decoders and on

for further filtering in the main path. High-pass filtering is then applied

to remove the subaudible signalling and rumble from the audio signal.

The filter cut frequency is made higher when subaudible signalling is

expected compared to when it is not. This allows full low-frequency

audio response on non-subaudible channels.

Signal source for speaker The output of the high-pass filter is where in-band signalling decoders

obtain their input signal. The signal is then de-emphasised. The next

process in the chain is a multiplexer to select a signal source to feed the

main path to the speaker. The sources are as follows:

■ receive path

■ confidence-tone generator

■ transmit confidence side-tone

The confidence-tone generator is activated for such events as key-presses

or alarms; the level from this block is a fixed proportion (in the order of

-10 dB) relative to full scale in the receive path. Regarding the transmit

confidence side-tone, the output of the transmit signalling encoders can

be fed to the speaker to give the user confidence that the signalling

message is being sent; the level from this block is a fixed proportion (in

the order of -10 dB) relative to full scale in the receive path.

Combined audio and

side-tone signal

The combined audio and side-tone signal is converted to analogue form

by a 16-bit DAC, and then bandpass filtered by a switched cap filter

(100 Hz to 3.3 kHz) to remove alias components. This is followed by a

programmable-gain amplifier with 45 dB range that performs volume

control and muting. The volume control is logarithmic, with steps of

1.5 d B. Here, a side-tone from an options board can be summed in with

the receive audio.

TM8100 Mobile Radio Service Manual General Description 33

October 2003 © Tait Electronics Limited

Output to speakers

After side-tone summation the audio is fed to an audio power amplifier

and to the control head via a buffer amplifier. The output configuration

of the audio power amplifier is balanced and drives an internal speaker

and, optionally, an external speaker. The speaker loads are connected in

parallel rather than being switched. The power delivered to each speaker

is limited by its impedance. The internal speaker has 16-ohm impedance

whereas the external speaker can be as low as 4 ohms.

2.4 Operation in Transmit Mode

RF power amplifier

and switching

In this subsection the functioning of the radio in the transmit mode is

described. Refer to Figure 2.2. The RF power amplifier is a four-stage

line-up with approximately 42 dB of power gain. The output of the

frequency synthesizer is first buffered to reduce kick during power

ramping. The buffer output goes to a broad-band exciter IC that

produces approximately 200 mW output. This is followed by an

LDMOS driver producing up to 2 W output that is power-controlled.

The final stage consists of two parallel LDMOS devices producing

enough power to provide 25 W at the antenna.

Output of RF power amplifier The output of the RF power amplifier passes through a dual-directional

coupler, used for power control and monitoring, to the PIN switch. The

PIN switch toggles the antenna path between the receiver and

transmitter in receive and transmit modes respectively. Finally, the output

is low-pass-filtered to bring harmonic levels within specification.

Power control The steady-state power output of the transmitter is regulated using a

hardware control loop. The forward power output from the RF power

amplifier is sensed by the directional coupler and fed back to the power

control loop. The PA output power is controlled by varying driver gate

bias voltage that has a calibrated maximum limit to prevent overdrive.

The reference voltage for the control loop is supplied by a 13-bit DAC.

The system driving the DAC supplies the steady-state voltage for a given

power level as determined by factory calibration. The bandwidth of the

loop is high to ensure that it does limit the ramping slope and has

approximately 25 dB power control range. At low power settings the

final bias is reduced to improve efficiency and maintain power control

range.

Ramping Power ramp-up consists of two stages:

■ bias

■ power ramping

The timing between these two stages is critical to achieving the correct

overall wave shape in order to meet the specification for transient ACP.

34 General Description TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Power

Bias

ramp

ll

Figure 2.3 Typical ramping waveforms

Power

ramp

Hi power

Lo power

Power

ramp

Bias

ramp

Time

Bias ramp-up

The steady-state final-stage bias level is supplied by an 8-bit DAC

programmed prior to ramp-up but held to zero by a switch on the DAC

output under the control of a

release by the

TX INHIBIT signal with the ramping shape being determined

TX INHIBIT signal. Bias ramp-up begins upon

by a low-pass filter. Owing to power leakage through the PA chain,

ramping the bias takes the PA output power from less than –10 dBm to

approximately 25 dB below steady-state power.

Power ramp-up The power ramp signal is supplied by a 13-bit DAC that is controlled by

custom logic. The ramp is generated using a look-up table in custom

logic memory that is played back at the correct rate to the DAC to

produce the desired waveform. The ramp-up and ramp-down

waveforms are produced by playing back the look-up table in forward

and reverse order respectively. For a given power level the look-up table

values are scaled by a steady-state power constant so that the ramp

waveform shape remains the same for all power levels. Typical ramping

waveforms are shown in Figure 2.3.

Inhibiting of transmitter The transmitter will be inhibited when any of the following conditions

exists:

■ frequency synthesizer out of lock

■ power supply voltage outside correct operating range

■ software inhibit present

The last-named signal would normally initiate the start of ramp-up.

TM8100 Mobile Radio Service Manual General Description 35

October 2003 © Tait Electronics Limited

Audio processing

The input to the transmitter path begins at the microphone input. There

are two microphone sources; a fist microphone connected to the control

head and an auxiliary microphone connected via the auxiliary or options

connector. Only electret-type microphones are supported. Support for

optional dynamic fist microphones is facilitated by a hardware amplifier

and filter in the control head.

Processing of

microphone signal

The CODEC performs microphone selection and pre-amplification.

The microphone amplifier consists of a by-passable amplifier with a fixed

gain of 20 dB followed by a programmable-gain amplifier with 0 to

22 dB gain giving up to 42 dB total control range. The amplified

microphone signal is converted to a digital stream by a 16-bit ADC and

then bandpass-filtered (0.1 to 3.2 kHz). The digital stream is transported

to the DSP for further processing.

Automatic level control The ALC follows, and is used to effectively increase dynamic range by

boosting the gain of the microphone pre-amplifier under quiet

conditions and reducing the gain under noisy acoustic conditions. The

ALC function resides in the DSP and controls the microphone preamplifier gain in the CODEC. The ALC has a fast-attack (about 10 ms)

and slow-decay (up to 2 s) characteristic. For the peak signal provided to

the DSP blocks that are next in the chain, this characteristic ensures that

the signal is regulated near full scale to maximise dynamic range.

Final processing

of audio signal

The audio is then high-pass filtered to remove any frequency

components that may exist in the subaudible signalling band and prevent

limiter overload. The encode signal for in-band signalling, if active, is

summed with the audio. Pre-emphasis is then applied, followed by a

limiter to remove transients that may have passed through the ALC. A

low-pass filter then removes unwanted limiter artefacts and also

interpolates the sample rate up to 48 kHz that is required for the interface

to the frequency synthesizer. At this point subaudible signalling, if active,

is summed with the audio. The final process is to scale the signal level

(and hence the deviation) to match the RF channel bandwidth and

compensate for subaudible signalling if added. The signal is then passed

to the frequency synthesizer where it is used as the modulation source.

36 General Description TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

2.5 Operation of Frequency Synthesizer

Control loops In this subsection the functioning of the frequency synthesizer is

described. Note that patents are pending for several aspects of the

synthesizer design. As may be seen from Figure 2.2, the frequency

synthesizer consists of two main parts:

■ RF PLL

■ FCL

The FCL generates a high-stability reference frequency that can be both

modulated and offset in fine resolution steps. The RF PLL has fastlocking capability but coarse frequency resolution. The FCL output is

the reference frequency input for the RF PLL. It is frequency-locked to

the TCXO, thereby acquiring the TCXO's frequency stability.

Modulation In dual-point modulation systems the modulation is applied to both the

frequency reference and the VCO in the RF PLL combining to produce

a flat modulation response down to DC. Reference modulation is

usually applied directly to the TCXO.

In the system employed in the TM8100 radio, the frequency reference is

composed of the 13 MHz TCXO and the FCL, which itself requires

dual-point modulation injection to allow modulation down to DC.

With another modulation point required in the RF PLL, this system

therefore requires triple-point modulation. The modulation cross-over

points occur at approximately 30 and 300 Hz as determined by the closed

loop bandwidths of the FCL and RF PLL respectively.

Frequency generation

and acquisition

The RF PLL is an integer-N type and has frequency resolution of

25 kHz. Higher resolution cannot be achieved owing to acquisitiontime requirements and so for any given frequency the error could

therefore be as high as ±12.5 kHz. This error is corrected by altering the

reference frequency to the RF PLL. The FCL supplies the reference

frequency and is able to adjust it up to ±300 ppm with better than

0.1 p pm resolution (equivalent to better than 50 Hz res o l ution at the RF

frequency). The FCL offset will usually be different for receive and

transmit.

Fast frequency settling Both the FCL and RF PLL employ frequency-acquisition speed-up

techniques to achieve fast frequency settling. The frequency-acquisition

process of the FCL and RF PLL is able to occur concurrently with

minimal loop interaction owing to the very large difference in frequency

step size between the loops.

TM8100 Mobile Radio Service Manual General Description 37

October 2003 © Tait Electronics Limited

Frequency-acquisition

of RF PLL

In the RF PLL the loop bandwidth is initially set high by increasing the

charge pump current and reducing time constants in the loop filter. As

a result settling to within 1 kHz of the final value occurs in under 3 ms.

In order to meet noise performance requirements the loop parameters

are then switched to reduce the loop bandwidth. There is a small

frequency kick as the loop bandwidth is reduced. Total settling time is

under 4.5 ms.

Frequency-acquisition

of FCL

The FCL utilises self-calibration techniques that enable it to rapidly settle

close to the final value while the loop is open. The loop is then closed

and settling to the final value occurs with an associated reduction in

noise. The total settling time is typically less than 4 ms.

Monitoring The lock detect signals of both the FCL and RF PLL are monitored by

the software. This is performed at least every 100 ms. If an out-of-lock

condition occurs during operation, then an audible indication will be

given and recovery repeatedly attempted.

Calibration The following items are calibrated in the frequency synthesizer:

■ Nominal frequency

■ Kvco

■ Kvcxo

■ VCO deviation

Calibration of the nominal frequency is achieved by adding a fixed offset

to the FCL nominal frequency; the TCXO frequency itself is not

adjusted. The items Kvco and Kvcxo are the control sensitivities of the

RF VCO (in MHz/V) and VCXO (in kHz/V) respectively. The latter

has temperature compensation.

38 General Description TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

3 Disassembly and Re-assembly of Radio

Introduction This section covers the disassembly and re-assembly procedures entailed

in level-1 repairs of the TM8100 radio. These procedures are:

■ detachment of control head

■ disassembly of control head

■ disassembly of radio body

■ re-assembly of radio body

■ re-assembly and attachment of control head

The procedures are detailed in Subsection 3.1 to Subsection 3.5

respectively. A brief outline of the overall level-1 repair procedure itself

is given below.

Important Observe anti-static precautions when servicing the

TM8100 radio in order to avoid damage caused by static

discharges.

Note The frequency ranges 156.8 MHz ± 375 kHz,

243 MHz ± 5 kHz, and 406.0 to 406.1 MHz are reserved

worldwide for use by distress beacons. Do not program

transmitters to operate in any of these frequency bands.

Outline of level-1

repair procedure

For level-1 repairs first determine whether the control head or radio

body is faulty. Do so by exchanging the control head for a spare control

head. (Detach the control head as described in Subsection 3.1.) If the

fault is rectified, the original control head is faulty; if not, the radio body

is faulty. In the case of a faulty two-digit control head, also exchange the

control-head loom for a spare loom. If the fault is rectified, the original

loom is faulty; if not, the control head itself is faulty. After thus isolating

the fault, repair a faulty control head and a faulty radio body as indicated

in the following two paragraphs respectively.

Control head is faulty If the control head is faulty, first inspect the control head for obvious

damage as described in Subsection 3.1. Replace any damaged part or

assembly; this might require removing the control-head board as

described in Subsection 3.2. If there is no obvious damage, replace the

control-head board. In either case, re-assemble the radio as described in

Subsection 3.5, and subject the radio to a final test.

TM8100 Mobile Radio Service Manual Disassembly and Re-assembly of Radio 39

October 2003 © Tait Electronics Limited

UNDERSIDE OF CHASSIS

RADIO

BODY

LEVER

POINT

CONTROL HEAD

INDICATION OF

LEVER POINT

DETAILS OF

LEVER POINT

bb

Figure 3.1 Lever points for detaching the control head from the radio body

Radio body is faulty

If the radio body is faulty, the main-board assembly will need

replacement. However, the control head should also be inspected for

damage as described above, and any damage rectified. Next, open the

radio body, remove the main-board assembly, and obtain a replacement

assembly. The procedure is described in Subsection 3.3 and includes

inspecting the radio body and rectifying any damage. Then re-assemble

the radio body as described in Subsection 3.4 and re-attach the control

head. If necessary, recalibrate the radio. Finally, reprogram and test the

radio.

40 Disassembly and Re-assembly of Radio TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

3.1 Detachment of Control Head

Detach control head Whether the control head or the radio body is faulty, the control head

needs to be detached from the radio body. Do so as follows:

1. Note which way up the control head is attached to the radio body.

The control head may be oriented with the underside of the radio

body either at the top or bottom. The configuration depends on

the Customer’s installation, and the radio will need to be returned

to the Customer with the same configuration.

2. Disconnect the radio from any test equipment or power supply.

3. Note the two points where the control head should be levered off

the radio body. As shown in Figure 3.1, these points are indicated

by dot-dash-dot marks on the underside of the radio body. The

lever point is between the rubber seal and the front panel of the

control head. (The seal is called the control-head seal.)

4. At each of the above lever points, insert the blade of a medium-

sized (about 5 mm) flat-bladed screwdriver and lever off the

control head.

5. After detaching the control head, disconnect the control-head

loom at the connector on the radio body. Refer to Figure 3.2.

6. Inspect the control head and loom as described below.

TM8100 Mobile Radio Service Manual Disassembly and Re-assembly of Radio 41

October 2003 © Tait Electronics Limited

CONTROL-HEAD LOOM

CONTROL-HEAD

SEAL

RADIO BODY

SEAL

SEAL LIPS

CONTROL HEAD

FRONT FACE OF RADIO BODY

df-cm-dwls

Figure 3.2 Details of the seal between the radio body and control head

CONTROL-HEAD SEAL

DETAILS OF

42 Disassembly and Re-assembly of Radio TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Inspect mechanical parts

Regardless of the reason for detaching the control head, it is advisable to

inspect the mechanical parts for damage. Check for and rectify any

damage as follows:

1. Inspect the control-head loom. If the loom has obvious physical

damage, replace it with a spare loom from Spares kit 1. The

product code and contents of the kit are listed in Subsection 3.2.

2. Inspect the control-head seal. Refer to Figure 3.2, which shows

a cross-section of the seal. Check for any sign of deformation, cuts

or tears. Pay particular attention to the two lips of the seal.

3. If the seal is damaged, replace it with a spare seal from Spares kit

7. This kit contains a set of these seals.

4. Inspect the control head for signs of damage. Check for cracked,

broken or burnt parts. In a two-digit-display control head the

parts to inspect are the volume-control knob, keypad, lens, spaceframe, speaker and, if fitted, concealed microphone. In a blank

control head inspect the programming connector and attached

loom.

5. If the inspection in Step 4 reveals no damage, continue with the

repair of the radio. If there is damage in a two-digit-display

control head, disassemble the control head and replace the

damaged part or assembly as described in the next subsection. If

there is damage in a blank control head, replace the complete

control head; for the relevant product code refer to

Subsection 1.5.

TM8100 Mobile Radio Service Manual Disassembly and Re-assembly of Radio 43

October 2003 © Tait Electronics Limited

POSITION OF CIRCUIT

BOARD FOR OPTIONAL

MICROPHONES

BOARD

CLIP 3

CONNECTORS FOR

OPTIONAL BOARD

CONNECTOR

CONTROL-HEAD

CONCEALED MICROPHONE

(IF FITTED)

CONTROL-HEAD

SCREW 3 GUIDE 4SCREW 2GUIDE 1GUIDE 2

PADS FOR LEADS TO

CONCEALED MICROPHONE

SPEAKER

SCREW 1 CLIP 1 CLIP 2

GUIDE 3

CONNECTOR

SPEAKER

Figure 3.3 Plan view of the control head showing the control-head board

44 Disassembly and Re-assembly of Radio TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

bb-dwls

3.2 Disassembly of Control Head

Introduction This subsection covers the disassembly of the two-digit-display control

head and the replacement of a damaged part or assembly. There are two

stages in the disassembly procedure:

■ remove control head board

■ replace damaged part or assembly

For the latter task the control-head board must first be removed. A

separate circuit board for a concealed or dynamic microphone might or

might not be mounted on the control-head board.

Remove control-head board The procedure for removing the control-head board is as follows. Refer

to Figure 3.3.

1. Pull off the knob from the volume-control potentiometer. Do not

use any tools to do so as this might cause damage.

2. If a circuit board for a concealed or dynamic microphone is fitted,

unplug it from the control-head board.

3. If a concealed microphone is fitted, unsolder the microphone leads

from the control-head board. The leads are soldered to pads on

the board as shown in Figure 3.3.

4. Note whether the speaker leads are connected to the control-head

board. If so, disconnect the leads. The radio will need to be

returned to the Customer in its original state.

5. Remove the screws securing the control-head board. The order

of removal is immaterial. The screws are labelled screw 1 to screw

3 in Figure 3.3; these numbers are also inscribed on the PCB. The

control-head board is now held down only by the clips labelled

clip 1 to clip 3 in Figure 3.3.

6. Pull upwards on the edge of the control-head board adjacent to

the speaker. At the same time push clip 1 and clip 2 by hand away

from the board. The board will lift up slightly.

7. Push clip 3 away from the control-head board while

simultaneously pressing on the shaft of the volume-control

potentiometer. The board will be freed from the space-frame.

Remove the board.

8. If the earlier inspections have not revealed any damaged parts,

continue with the repair of the radio. If there is damage, continue

with the disassembly of the control head and rectify the damage as

described below.

TM8100 Mobile Radio Service Manual Disassembly and Re-assembly of Radio 45

October 2003 © Tait Electronics Limited

Table 3.1 Contents of TMAA22-01 Spares kit 1 — parts of standard control head less control-head board

IPN Description Quantity

— Front-panel assembly (see below for constituent parts) 1

311-01054-xx Knob for volume-control potentiometer 1

— Control-head-loom assembly (see below for constituent parts) 1

346-10030-08 3 x 8 PT screw for control-head board 3

Parts of front-panel assembly

316-06786-xx Front panel 1

312-01095-xx Lens with Tait logo 1

365-01717-xx Label for TM8115 1

209-00011-xx Elastomeric strip 2

319-30073-xx Space-frame 1

008-00031-xx LCD 1

252-00011-xx Speaker 1

307-01024-xx Speaker membrane 1

311-03114-xx Keypad 1

262-00003-xx Short light pipe 2

262-00004-xx Long light pipe 2

Parts of control-head-loom assembly

219-02882-xx Control-head loom 1

240-00021-41 Female-female adaptor for control-head connector 1

Note

The characters xx in an IPN stand for the issue number. Items in the spares kit will always be the latest issue at the

time the spares kit is produced.

46 Disassembly and Re-assembly of Radio TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Front-panel assembly

and Spares kit 1

The assembly remaining after the removal of the control-head board is

called the front-panel assembly. A complete front-panel assembly is

included in Spares kit 1; the other parts in the kit are a control-head

loom, screws for the control-head board, and a volume-control knob.

The contents of the kit, including the parts of the front-panel assembly,

are listed in Table 3.1. The IPN of each spare part is given but, if

applicable, not

the issue number within the IPN. The latest issue of a

particular part is always supplied.

Repair of frontpanel assembly

There are two methods of repairing a damaged front-panel assembly:

■ replace complete front-panel assembly

■ replace damaged parts of front-panel assembly

Generally either method may be used. However, the latter method must

be used if a concealed microphone is fitted or custom labels have been

added to the front panel. The two methods are described separately

below:

Replace front-panel assembly To replace the complete front-panel assembly, discard the damaged

assembly and obtain a replacement assembly from Spares kit 1. Leave the

spare control-head loom, the screws, and the volume-control knob in the

kit. Continue with the repair of the radio. Later in the repair procedure

the control-head board will be fitted to the new front-panel assembly and

the complete control head will be assembled.

TM8100 Mobile Radio Service Manual Disassembly and Re-assembly of Radio 47

October 2003 © Tait Electronics Limited

APERTURE FOR SHAFT

OF VOLUME-CONTROL

ELASTOMERIC STRIPS

POTENTIOMETER

LCD

APERTURE FOR

MICROPHONE

CONNECTOR

KEYPAD

LIGHT PIPES FOR

STATUS LEDs

CONCEALED MICROPHONE

(IF FITTED)

SPACE-FRAME

CLIP 5 CLIP 3 CLIP 1

SPEAKER

CLIP 6 CLIP 4 CLIP 2

bb-dwls

Figure 3.4 Plan view of the control head with the control-head board removed

48 Disassembly and Re-assembly of Radio TM8100 Mobile Radio Service Manual

October 2003 © Tait Electronics Limited

Replace damaged parts —

disassembly task

To replace a damaged part, first disassemble the damaged front-panel

assembly as well as a spare assembly from Spares kit 1. Proceed as follows.

Refer to Figure 3.4.

1. Note the clips on the space-frame labelled clip 1 to clip 6 in

Figure 3.4. These clips need to be released to remove the spaceframe.

2. While pulling upwards on the space-frame at the corner where the

microphone connector is situated, release the clips in the order:

clips 1 and 2, 3 and 4, and then 5 and 6. To release each clip use

a medium-sized (about 5 mm) flat-bladed screwdriver to lever the

clip out of its recess. Pulling on the space-frame helps release the

clips.

3. Pull the space-frame out when all six clips have been released.

4. Remove the elastomeric strips, speaker, LCD, keypad and, if

fitted, concealed microphone.

Replace damaged parts —

replacement task

Replace any of the following parts that inspection has shown to be

damaged. Refer to the accessories manual regarding the replacement of

a concealed microphone that has been damaged.

■ elastomeric strips

■ space-frame

■ speaker

■ keypad

■ LCD

■ front panel

Obtain replacement parts from the disassembled spare front-panel

assembly. Discard the damaged parts and return unused spare parts to

Spares kit 1. Note that spare front panels include the speaker membrane,

lens and branding label; the LED light pipes are moulded into the panel.

If any part of the front panel is damaged, including the membrane, lens

and light pipes, replace the complete panel.

TM8100 Mobile Radio Service Manual Disassembly and Re-assembly of Radio 49

October 2003 © Tait Electronics Limited

LEVER POINT

DETAILS OF

LEVER POINT

bbbb

Figure 3.5 Lever points for removing the cover of the radio body

LOWER

SCREW

BOSS

UPPER

SCREW

BOSS

50 Disassembly and Re-assembly of Radio TM8100 Mobile Radio Service Manual