Tait TEL0061 PagingBoardFitInstruction

8 T800-32-0010 Fitting Instructions 419-83210-00 419-83210-00 T800-32-0010 Fitting Instructions 1

T800-32-0010 Paging Board

The T800-32-0010 PCB can be fitted to Tait T800 Series II transmitters to enable them to function as l ow-speed paging tran smitters. This pagin g board is

for transmitters that will be connected to an external frequency standard. It is

a DFSK Modulator, suitable for POCSAG or similar paging data formats. Reference frequency stability is determined by the stability of the external standard. The PCB is not designed for use with 66 to 88MHz equipment.

Newer T800 transmittters have a Micromatch connector in the audio processor compartment. This simplifies installation.

This fitting instruction describes how to fit the PCB into existing T800 transmitters. You need to be proficient in the soldering of SMD components. It

may be preferable to obtain a T800 transmitter already fitted with this board

from your Tait dealer or national sales office.

Parts Required

The T800-32-0010 kit should contain the following items:

1 x T800-32-0010 DFSK modulator board

1 x terminated coaxial cable

1 x T800-03-1000 auxiliary D-range kit

4 x M3 x 8 Taptite Pan To rx screws

1 x coaxial socket

1 x 47 ohm resistor SMD 0805

1 x terminated 8-way ribbon cable

1 x terminated 4-way ribbon cable

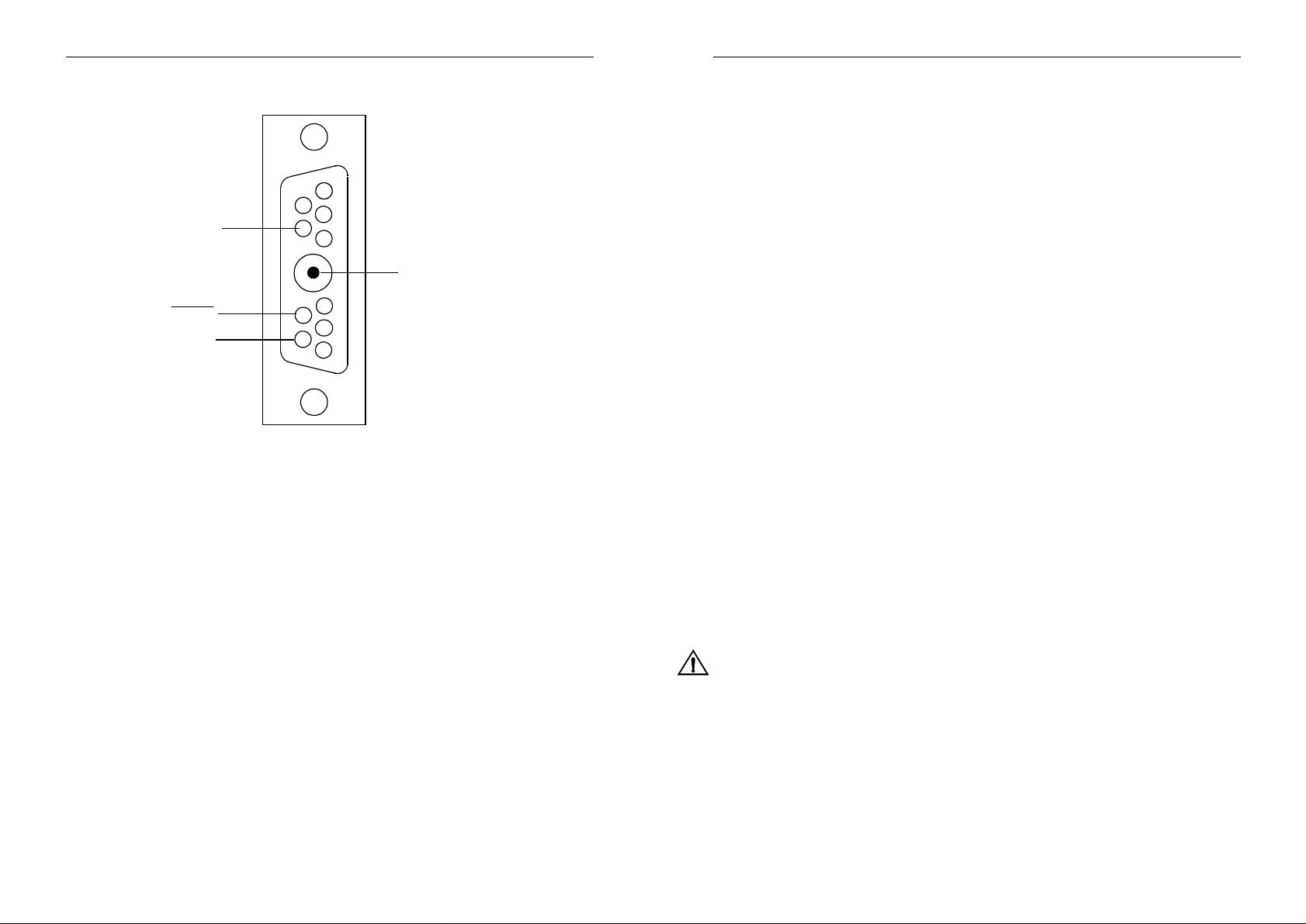

DATA

DATA

Lock detect

1

7

2

8

3

4

9

5

10

6

Figure 8 Pinouts for D-Range 2

Coaxial socket

(external

reference

frequency)

2004f_01

Installation

Caution:

1. Remove the TCXO module from the synthesiser compartment of the

2. Fit the miniature coaxial socket (=SK710) and 47 Ohm SMD resistor

The radio must be powered off for this modification. After modification, do not remove the co axial lead f rom the so cket unle ss the

radio is powered off.

T800 transmitter.

(=R705) to the PCB pads provided beneath the TCXO, as shown in Figure 1.

2 T800-32-0010 Fitting Instructions 419-83210-00 419-83210-00 T800-32-0010 Fitting Instructions 7

4. Using an AC-coupled oscilloscope set to 50 mV/div , observe the signal

at TP2. Adjust RV2 until the triangle wave amplitude has been minimised.

5. Apply 600 Hz to the DATA line. Use a modulation analyser to observe

the frequency deviation on the output of the transmitter . Adjust RV1 to

get 4.5 kHz deviation on the modulation analyser.

6. Observe the transmitter’s VCO control line using an AC-coupled oscilloscope set to at least 20 mV/div and 0.5ms/div. Vary the input frequency down to low frequencies (for example 100 Hz) and check that

the control line still has a good square wave.

You may have to re-adjust RV2 and RV1 alternately to achieve a square wave

Note:

on the VCO control line and a 4.5 kHz deviat ion. Fi gure 7 show s a typical 100

Hz VCO control line waveform with RV1 and RV2 set correctly.

Figure 1 Location Of Socket And SMD Resistor

Keep the angle of the coaxial socket steep to ensure that there is space for the

Note:

Micromatch cable as well as for the coaxial cable.

3. Remove the two screws and cover plate from the second D-range

mounting hole at the rear of the T800 chassis. (If the transmitter

already has a second D-range, this must be removed so that the Drange with a second Micromatch socket can be fitted.)

4. Remove R291, R289, and R296 from the audio processor

(shown in Figure 2).

Figure 7 100 Hz VCO Control Line Waveform

S5

S6

R291

S7

R289

R296

Figure 2 T800 Transmitter Audio Processor (older version without Micromatch connector) - Top Side

If the lower cut off frequency of an AC coupled oscilloscope is too high,

Note:

excessive distortion may be introduced which will result in 'sag' on the square

wave displayed. Determine if this is a problem by directly monitoring the

original square wave source and observe any sag.

If there is sag, switch the oscilloscope to DC and use a 10µF capacitor in

series with the scope probe (observing the correct polarity) to directly monitor

the VCO control line. Note that th e trace settling ti me will be ap proximately

one minute.

Loading...

Loading...