TB9400 Base Station

Installation and Operation Manual

MBC-00001-05 · Issue 5 · November 2013

Contact Information

Tait Communications

Corporate Head Office

Tait Limited

P.O. Box 1645

Christchurch

New Zealand

For the address and telephone number of regional

offices, refer to our website: www.taitradio.com

Copyright and Trademarks

All information contained in this document is the

property of Tait Limited. All rights reserved.

This document may not, in whole or in part, be copied,

photocopied, reproduced, translated, stored, or reduced

to any electronic medium or machine-readable form,

without prior written permission from Tait Limited.

The word TAIT and the TAIT logo are trademarks of

Tait Limited.

All trade names referenced are the service mark,

trademark or registered trademark of the respective

manufacturers.

Disclaimer

There are no warranties extended or granted by this

document. Tait Limited accepts no responsibility for

damage arising from use of the information contained

in the document or of the equipment and software it

describes. It is the responsibility of the user to ensure

that use of such information, equipment and software

complies with the laws, rules and regulations of the

applicable jurisdictions.

Enquiries and Comments

If you have any enquiries regarding this document, or

any comments, suggestions and notifications of errors,

please contact your regional Tait office.

Updates of Manual and Equipment

In the interests of improving the performance,

reliability or servicing of the equipment, Tait Limited

reserves the right to update the equipment or this

document or both without prior notice.

US7,649,893, US7,758,996, US7,937,661,

US8,301,682, US10/597339, US 29/401234, US 29/

401235, US61/218015, US61/236663, US61/323437.

This product may also be made under license under one

or more of the following U.S. Patents: 5,146,497,

5,148,482, 5,164,986, 5,185,795, 5,185,796,

5,271,017, 5,377,229 and 5,502,767.

The AMBE+2™ voice coding Technology embodied

in this product is protected by intellectual property

rights including patent rights, copyrights and trade

secrets of Digital Voice Systems, Inc. This voice

coding Technology is licensed solely for use within this

Communications Equipment. The user of this

Technology is explicitly prohibited from attempting to

decompile, reverse engineer, or disassemble the Object

Code, or in any other way convert the Object Code into

a human-readable form. Protected by U.S. Patents

5,870,405, 5,826,222, 5,754,974, 5,701,390,

5,715,365, 5,649,050, 5,630,011, 5,581,656, 5,517,511,

5,491,772, 5,247,579, 5,226,084 and 5,195,166.

Environmental Responsibilities

Tait Limited is an environmentally

responsible company which supports

waste minimization, material recovery and

restrictions in the use of hazardous

materials.

The European Union’s Waste Electrical and Electronic

Equipment (WEEE) Directive requires that this

product be disposed of separately from the general

waste stream when its service life is over. For more

information about how to dispose of your unwanted

Tait product, visit the Tait WEEE website at

www.taitradio.com/weee. Please be environmentally

responsible and dispose through the original supplier,

or contact Tait Limited.

Tait Limited also complies with the Restriction of the

Use of Certain Hazardous Substances in Electrical and

Electronic Equipment (RoHS) Directive in the

European Union.

In China, we comply with the Measures for

Administration of the Pollution Control of Electronic

Information Products. We will comply with

environmental requirements in other markets as they

are introduced.

Intellectual Property Rights

This product may be protected by one or more patents

or designs of Tait Limited together with their

international equivalents, pending patent or design

applications, and registered trade marks: NZ409837,

NZ409838, NZ415277, NZ415278, NZ508806,

NZ508807, NZ511155, NZ516280/NZ519742,

NZ520650/NZ537902, NZ521450, NZ524369,

NZ524378, NZ524509, NZ524537, NZ530819,

NZ534475, NZ534692, NZ537434, NZ547713,

NZ569985, NZ577009, NZ579051, NZ579364,

NZ580361/NZ601933, NZ584534, NZ586889,

AU2003281447, AU2004216984, AU2010212364,

AU11677/2008, AU13745/2008, CN 200930004199.5,

CN1031871, CN1070368, CN200930004200.4,

CN200930009301.0, CN201110141630,

CN201110253742.1, EU 000915475-0001,

EU000915475-0002, GB2413249, US5,745,840,

2 TB9400 Installation and Operation Manual

© Tait Limited November 2013

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Scope of Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Associated Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Publication Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Frequency Bands and Sub-bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.6 Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.7 Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7.1 Signal Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.7.2 Online and Offline Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.7.3 Intermodule Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.7.4 Power Management and Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.7.5 PMU Operation on DC Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.7.6 Front Panel Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 General Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.1 Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1.1 Unpacking and Moving the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1.2 Lethal Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1.3 AC Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.4 Explosive Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.5 Proximity to RF Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.6 High Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.7 LED Safety (EN60825-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.2 Equipment Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.1 Installation and Servicing Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.2 Preventing Damage to the PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.3 ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.2.4 Anti-tampering Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.1 Operating Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.2 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.3 Dust and Dirt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4 Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.4.1 Distress Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

TB9400 Installation and Operation Manual 3

© Tait Limited November 2013

2.4.2 Compliance Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.4.3 FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.4.4 Unauthorized Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2 Module Indicator LEDs and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2.1 Reciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2.2 PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2.3 PMU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Working with Base Stations from Your PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1 PC Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2 Connecting Your PC to the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2.1 Logging In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2.2 Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.2.3 Responding to Security Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.2.4 Connecting a Networked PC to a Base Station . . . . . . . . . . . . . . . . . . . 50

4.2.5 Troubleshooting Connection Problems . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.2.6 Finding a Lost or Forgotten IP Address. . . . . . . . . . . . . . . . . . . . . . . . . 52

4.3 Working with the Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3.1 Monitoring Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.3.2 Viewing Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.3.3 Viewing the Base Station and Network Identity . . . . . . . . . . . . . . . . . . 57

4.4 Basic Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.1 User Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.2 Taking the Base Station Offline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.3 Troubleshooting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.4 Working with Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.4.5 Configuring Single Base Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.4.6 Configuring Base Stations in a Channel Group. . . . . . . . . . . . . . . . . . . 60

4.4.7 Setting Up Custom Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.4.8 Disabling the Front Panel Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.4.9 Preparing to Download Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1 Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.1 Equipment Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.2 Grounding and Lightning Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.3 Equipment Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.4 Ambient Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1.5 Cabinet and Rack Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2 Unpacking and Moving the Subrack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3 Identifying the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.4 Initial Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4.1 Confirming Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4.2 Customizing the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4 TB9400 Installation and Operation Manual

© Tait Limited November 2013

5.4.3 Recommended Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4.4 Restricted Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.5 Changing the Root Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.4.6 Tuning the Reciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5 Installing the Base Station on Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.5.1 Base Stations for Trunked Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.5.2 Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.5.3 Mounting the Subrack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.6 Connecting Up the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.6.1 Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.6.2 Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.6.3 Connecting DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.6.4 Connecting the Auxiliary DC Power Output. . . . . . . . . . . . . . . . . . . . . 89

5.6.5 Connecting RF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.6.6 Connecting an External Frequency Reference . . . . . . . . . . . . . . . . . . . 91

5.6.7 Connecting a 1PPS Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.6.8 Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.6.9 Connecting General Purpose Inputs and Outputs . . . . . . . . . . . . . . . . . 93

6 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8 Replacing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.1 Saving the Base Station’s Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2 Preliminary Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.3 Replacing a Reciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.4 Replacing a Power Amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.5 Replacing a Power Management Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.6 Replacing the Module Guide Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.7 Replacing the Subrack Interconnect Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.8 Final Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Appendix A – Interface Pin Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

System Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Ethernet Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

PMU Auxiliary DC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix B – Inter-Module Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Dual 50W Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Single 50W Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

100W Base Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Receive-only Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

TB9400 Installation and Operation Manual 5

© Tait Limited November 2013

Appendix C – Identifying Front Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Tait Software License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Directive 1999/5/EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6 TB9400 Installation and Operation Manual

© Tait Limited November 2013

Preface

Scope of Manual

This manual provides information on installing and operating the TB9400

base station. It is intended for use by experienced technicians familiar with

installing and operating base station equipment. It also includes

configuration, maintenance and troubleshooting information.

Except where stated otherwise, the information in this manual generally

applies to both standard and receive-only base stations and reciters. References to power amplifiers (PAs) and transmitting obviously do not

apply to receive-only equipment.

Document Conventions

The TB9400 base station has a web interface with an accordion menu on

the left side of the screen. “Configure > Base Station > Channels” means

click Configure in the top-level menu, then in the expanded Configure

menu click Base Station, and finally click on the Channels tab on that page.

Within this manual, four types of alerts may be given to the reader. The

following paragraphs illustrate each type of alert and its associated symbol.

Warning This alert is used when there is a hazardous situation

which, if not avoided, could result in death or serious injury.

Caution This alert is used when there is a hazardous situation which,

if not avoided, could result in minor or moderate injury.

Notice This alert is used to highlight information that is required to

ensure procedures are performed correctly. Incorrectly performed procedures could result in equipment damage or malfunction.

This icon is used to draw your attention to information that may

improve your understanding of the equipment or procedure.

TB9400 Installation and Operation Manual Preface 7

© Tait Limited November 2013

Associated Documentation

The current set of TB9400 product documentation is provided in PDF

format on the product CD. Updates are made available on the Tait support

website. Printed copies of the documentation are available on request.

■ TB9400 Specifications Manual (MBC-00002-xx).

■ TaitNet P25 Trunked (TB9400) System Manual (MBA-00064-xx).

The characters xx represent the issue number of the documentation.

Technical notes are published from time to time to describe applications for

Tait products, to provide technical details not included in manuals, and to

offer solutions for any problems that arise. The product CD includes

technical notes that were available at the time of release. Look for new or

updated technical notes on the Tait support website.

Publication Record

Issue Publication Date Description

1 May 2012 First release

2 November 2012 General updates for version 1.15 release.

Information added on compliance standards,

marshalling duration, firmware download

procedure, and restricted port numbers.

3 May 2013 General updates for version 1.20 release

and the B3-band base station.

Front end tuning procedure added.

4 August 2013 General updates for version 1.25 release

and the H-band base station.

Information added for dual 50W and receiveonly base stations.

5 November 2013 General updates for version 1.30 release.

Minor updates for receive-only base station.

Directive 1999/5/EC Declaration of

Conformity added.

8 Preface TB9400 Installation and Operation Manual

© Tait Limited November 2013

1 Description

The Tait TB9400 base station is a robust state-of-the-art digital fixed

station that combines Tait’s proven strengths in reliability, high

performance and modular design with software-based configurability and

operation, digital signal processing and voice-over-IP technology.

The base station is designed for operation in a Project 25 trunked or trunked

simulcast radio network. The ability of the base station to link stations

using standard Internet Protocol communications, and to add features

through software options ensures that P25 systems designed with the

TB9400 are scalable in both size and functionality.

The base station combines industry-leading digital voice quality with

rugged design specifications and intuitive user interfaces. These products

have been designed to meet the demanding needs of the public safety and

public service sectors.

Its Ethernet interface provides built-in network connectivity, allowing the

TB9400 to join with other TB9400 base stations to form a channel group.

This network supports voice over IP and remote management of all base

stations via a web browser.

TB9400 Installation and Operation Manual Description 9

© Tait Limited November 2013

1.1 Features

The following are some of the features of the base station:

■ Fully compliant with the Project 25 Common Air Interface. Can

■ Linear power amplifier allows operation with Linear Simulcast

■ Integrated built-in voting facility. No external voter is needed.

■ Can be completely managed remotely from a PC running a web

■ An integrated wiring solution is provided for the system control bus and

■ Reciters (receiver/exciter modules) can be replaced without affecting

■ Rugged construction with generous heatsinks and fan-forced cooling

therefore interoperate with any similarly compliant radios.

Modulation (LSM). Future software upgrades will also allow

P25 Phase 2 operation (H-DQPSK modulation).

browser: configuration, alarm monitoring, fault diagnosis, feature and

firmware upgrades. Alarms can also be reported via SNMP traps,

allowing integration with an SNMP-based network management

system.

DC power connections to each module in the subrack.

the operation of other reciters in the same subrack.

for continuous operation from –30°C to +60° C (–22°F to + 140°F).

10 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

1.2 Modules

The base station consists of a subrack with up to two transmit/receive

channels, or up to four receive-only channels.

Receive-only base stations are currently available for operation only on

B3 band (148MHz to 174MHz

The single PMU (power management unit) supplies and manages power to

the whole subrack (refer to “Theory of Operation” on page 19). One reciter

and one PA (power amplifier) are needed for each transmit/receive channel.

The PA is not required for a receive-only base station. There is also a front

panel with user controls and fans. The modules are interconnected at the

front of the subrack. External connections to the modules are located at the

rear.

Modules come in different variants depending, for example, on the RF

band or the supply voltage.

Each module is inserted into the 4U subrack from the front and is secured

at the front with a metal clamp. Both clamp and module are easily removed

for rapid module replacement. The modules are secured laterally with

plastic guides that clip into the top and bottom of the subrack. These guides

can be easily repositioned to change the configuration of a subrack. The

heavier modules are also secured laterally by metal tabs at the rear of the

subrack.

The following provides a brief description of the available modules.

1

).

Reciter The reciter module comprises the

receiver, exciter and digital control

circuitry. The reciter provides the

Ethernet interface and system inputs

and outputs.

Receive-only reciters are not fitted

with the transmit circuitry or front

panel SMA connectors, and are

physically unable to transmit.

1. Refer to “Frequency Bands and Sub-bands” on page 17.

TB9400 Installation and Operation Manual Description 11

© Tait Limited November 2013

Power Amplifier

The PA amplifies the RF output from the reciter and is available in 50W

and 100W models.

The 50W model mounts vertically in the subrack, while the 100W model

mounts horizontally as it has a wider heatsink. The 100W PA is also fitted

with an airflow duct.

50W PA 100W PA

Both models are designed to operate on the 28VDC output provided by the

PMU. PAs are not required in a receive-only base station.

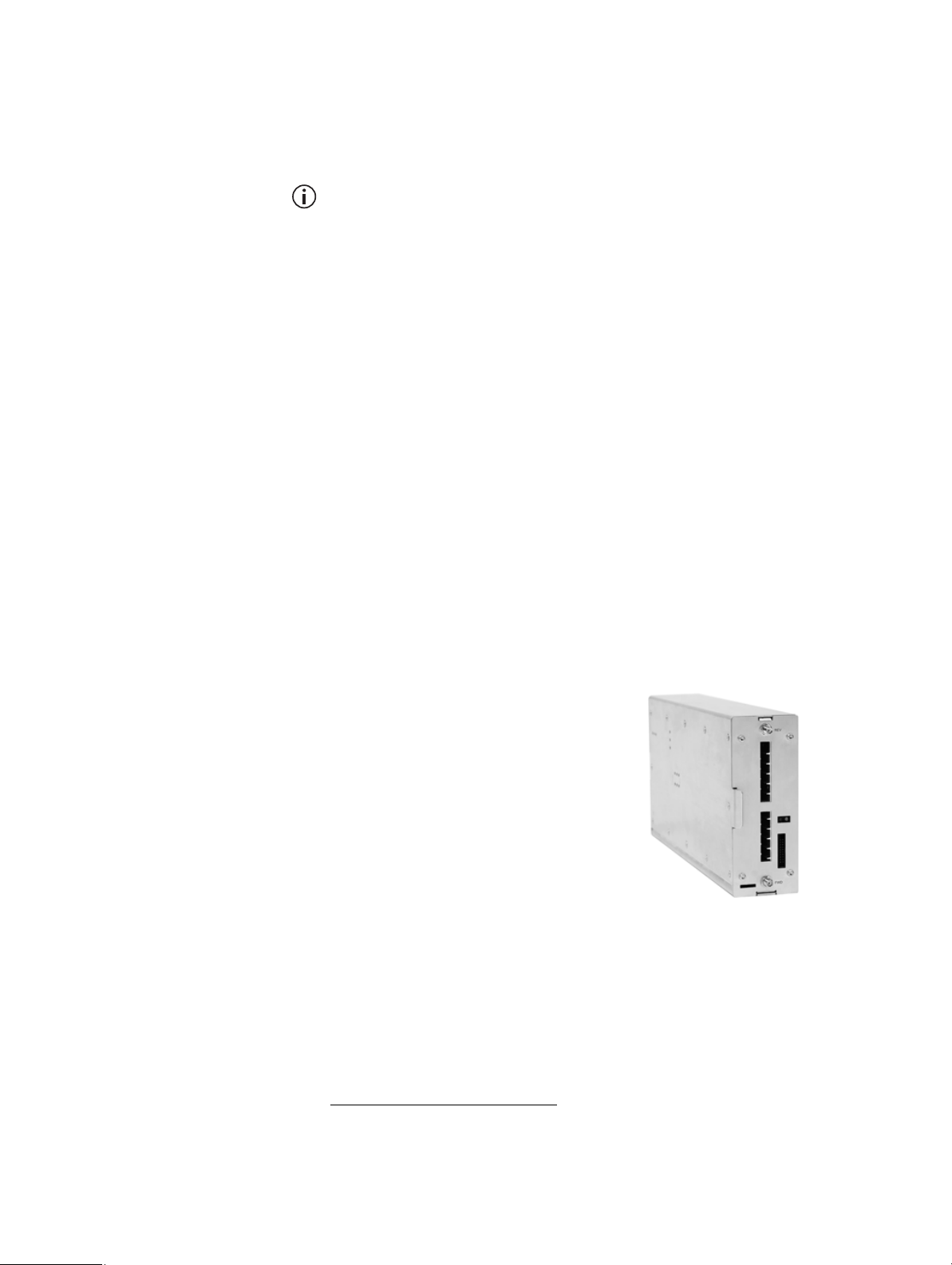

Power Management

Unit

The PMU provides the 28VDC

power supply for the modules in the

subrack. It can operate on

120/230VAC 50/60Hz nominal, and

12, 24 or 48VDC nominal. The input

voltage can be AC, DC, or both AC

and DC, depending on the model. The

PMU also has an auxiliary DC output

of 13.65VDC, 27.3VDC, or

54.6VDC, depending on the model.

AC and DC PMU shown

12 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

Front Panel

The front panel is mounted onto the subrack with two quick-release

fasteners. It incorporates the indicator LEDs, four-line LCD display, user

controls, ambient temperature sensor and cooling fans.

The indicator LEDS allow some monitoring of the operational status of the

base station. The user controls and display allow the technician to

configure the IP address of each module. Refer to “Front Panel” on page 36

for more information.

The microphone input and speaker are not used in this release of the

TB9400.

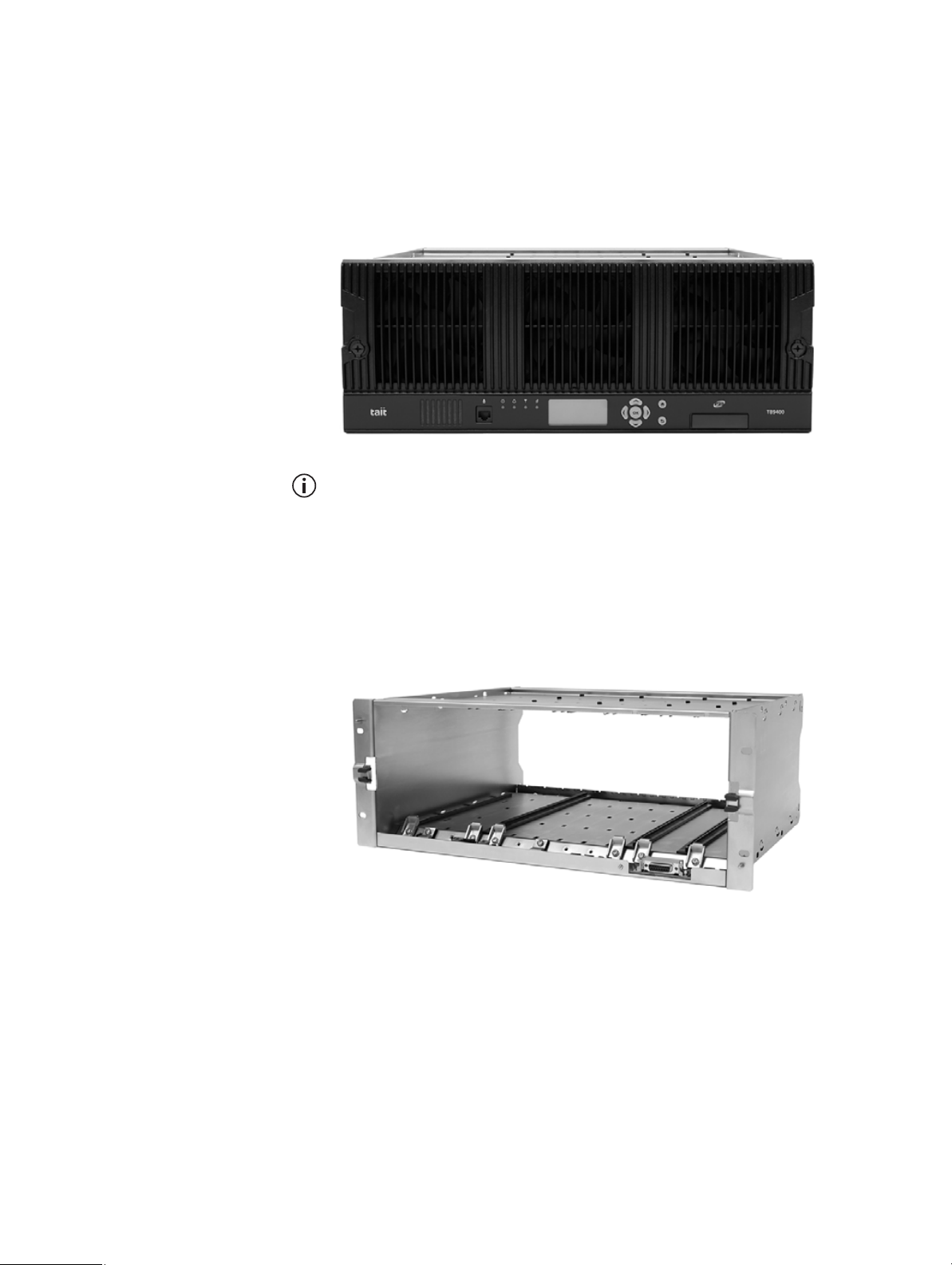

Subrack The 4U subrack is made of passivated steel and is designed to fit into a

standard 19 inch rack or cabinet. The subrack is fitted with an interconnect

board that connects the system control bus and power to the modules and

front panel. The position of a module in the subrack is defined by the socket

on the subrack interconnect board to which the module is connected by the

system control bus.

TB9400 Installation and Operation Manual Description 13

© Tait Limited November 2013

1.3 Mechanical Assembly

This section illustrates the main mechanical components of the base

station.

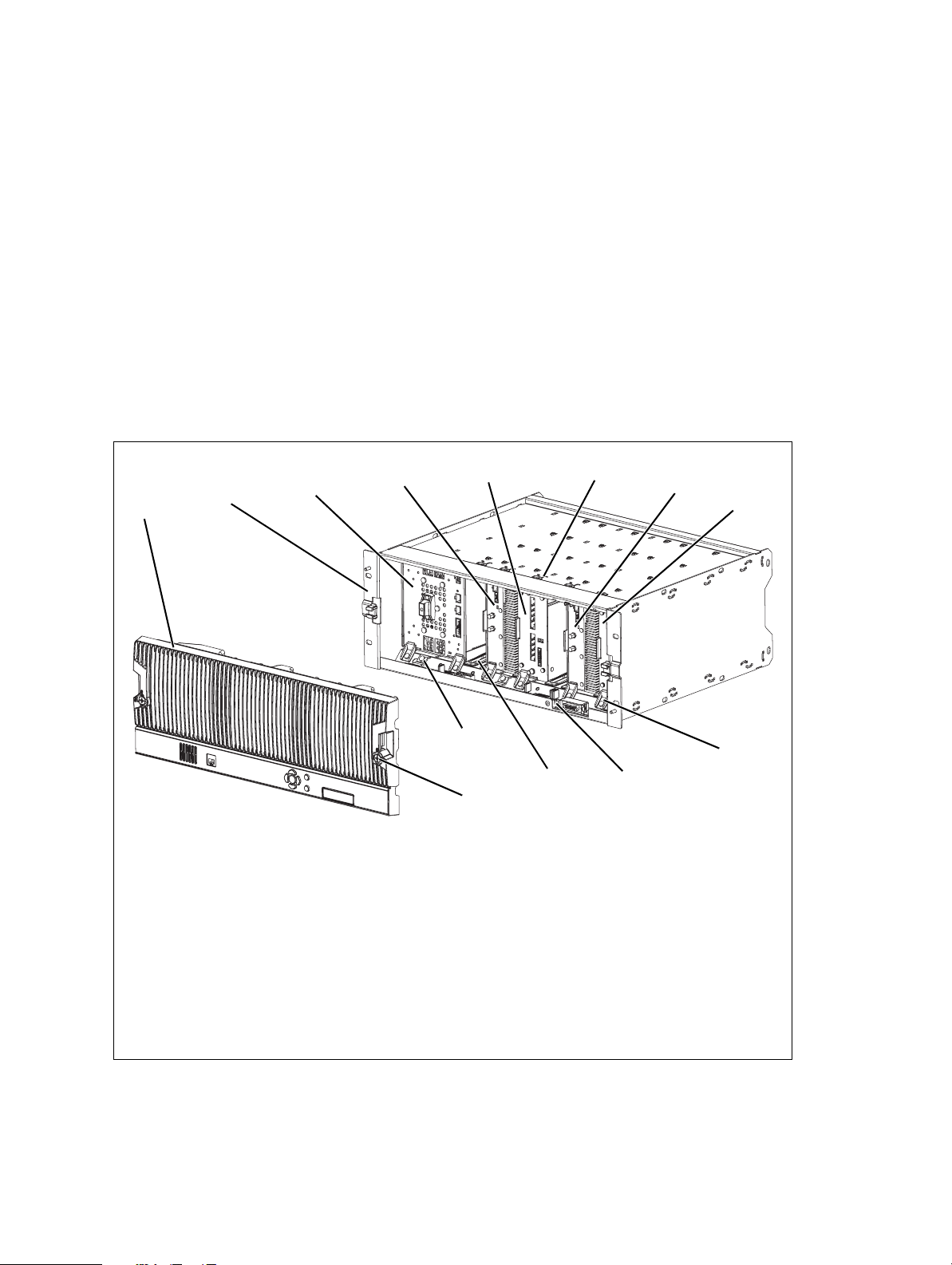

Figure 1.1 below shows the configuration for a typical dual 50W base

station. The subrack has six slots, numbered from right to left as viewed

from the front of the subrack. The PMU occupies slots 5 and 6, with the

reciter and PA pairs to the right of it in slots 1 to 4. Each PA is mounted

vertically with its heatsink facing its associated reciter. The PMU and each

reciter/PA pair have their own cooling fans.

The front panel can be easily removed from the subrack by undoing two

quick-release fasteners. Refer to “Replacing Modules” on page 99 for more

details.

Figure 1.1 Mechanical assembly - dual 50 W base station with front panel

b

c

.

g

d

e

f

1@

1!

1#

front panel

b

subrack

c

PMU

d

PA 2

e

reciter 2

f

cable retaining clip

g

PA 1

h

reciter 1

i

module retaining clamp

j

subrack interconnect board

1)

plastic guide rail

1!

subrack interconnect board retaining clamp

1@

front panel fastener

1#

h

i

j

1)

14 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

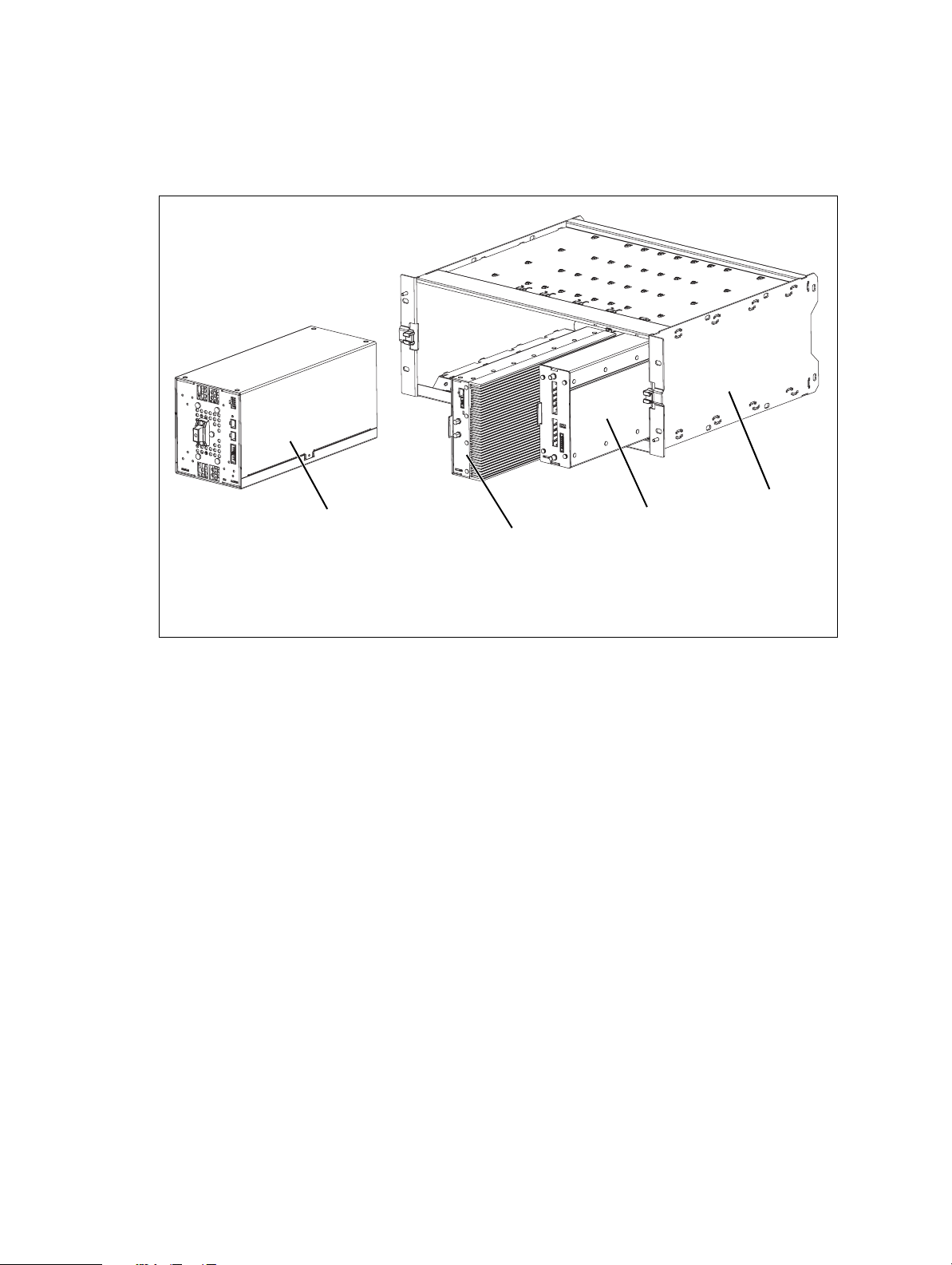

Figure 1.2 below shows the configuration for a typical single 50W base

station. The PMU again occupies slots 5 and 6, with the reciter in slot 1 and

PA in slot 2. The PA is mounted vertically with its heatsink facing the

reciter. The PMU and the reciter/PA pair have their own cooling fans.

Figure 1.2 Mechanical assembly - single 50W base station

b

c

PMU

50W PA

b

c

d

e

e

d

reciter

subrack

TB9400 Installation and Operation Manual Description 15

© Tait Limited November 2013

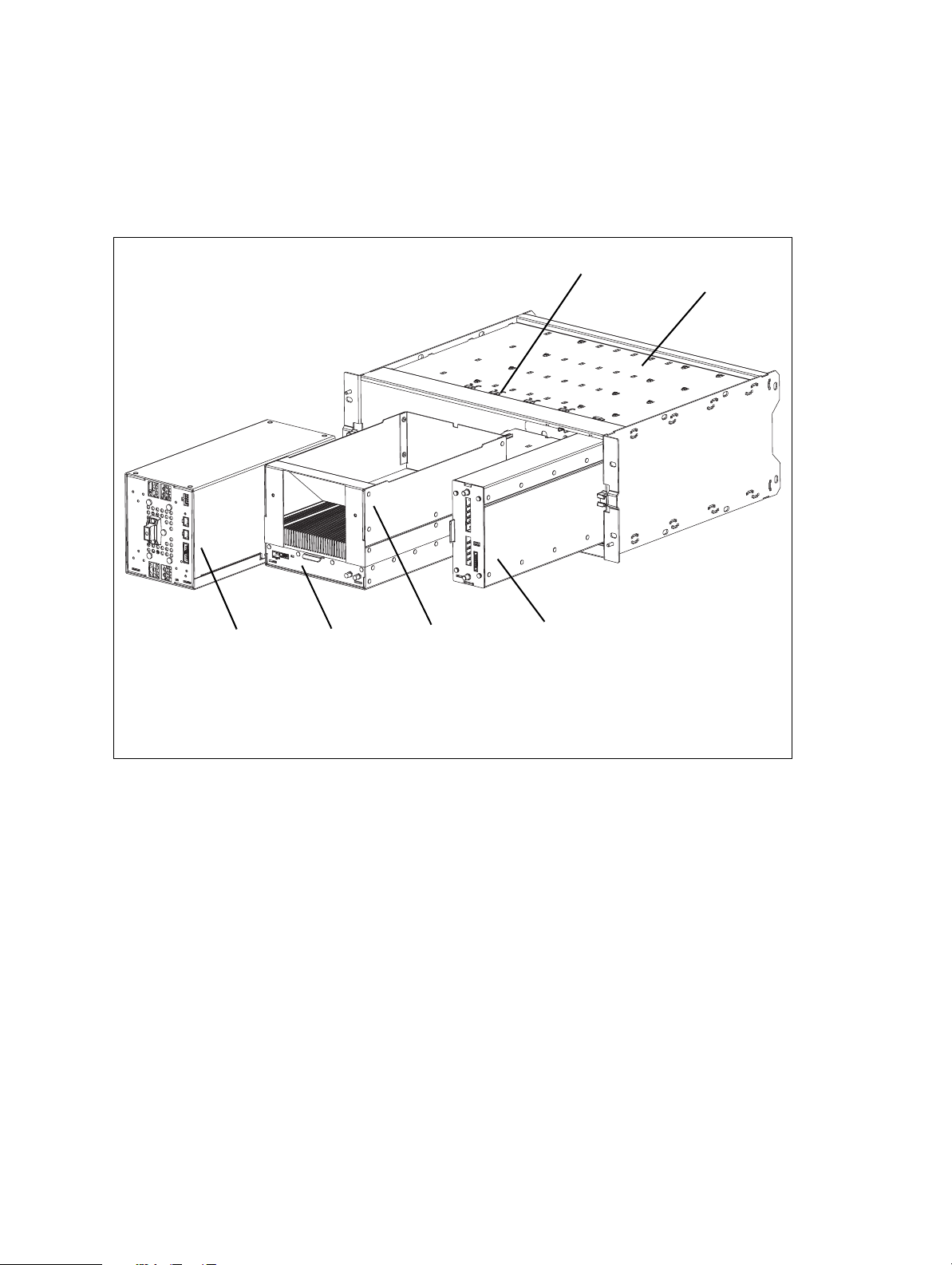

Figure 1.3 below shows the configuration for a typical 100 W base station.

The PMU occupies slots 5 and 6, with the PA directly beside it in slots 3

and 4. The reciter occupies slot 1. Unlike the 50W PAs, the 100 W PA is

mounted horizontally with the heatsink facing upwards. It is also fitted with

an airflow duct to channel the airflow from the cooling fan through the

heatsink fins.

Figure 1.3 Mechanical assembly - single 100W base station

g

f

PMU

b

PA

c

airflow duct

d

b

c

d

e

reciter

e

subrack

f

cable retaining clip

g

16 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

1.4 Frequency Bands and Sub-bands

Much of the circuitry in the base station is common to all frequency bands,

and is therefore covered by a single description in this manual. In some

cases the descriptions refer to specific bands or sub-bands, and these are

identified with the letters listed in the following table.

Frequency Identification Frequency Band and Sub-band

B band B3 = 148MHz to 174MHz

H band H1 = 400MHz to 440 MHz

H2 = 440MHz to 480MHz

K band K4 = 762MHz to 870MHz

a. The actual frequency coverage in this band is:

Transmit: 762MHz to 776 MHz, and 850 MHz to 870 MHz

Receive: 792MHz to 824MHz

1.5 Applications

The TB9400 is designed for operation in a Tait P25 trunked radio network.

It can operate as a single base station or as part of a simulcast channel

group, and as a traffic channel or control channel.

In a trunked simulcast network, the transmitters in the channel group are

synchronized and transmit simultaneously on the same frequency. Each

transmitter needs a highly accurate 1PPS pulse and an external frequency

reference, so that it can time transmissions with the required accuracy. We

also recommend using an NTP server at each site, as this will ensure a

common timestamp in logs across all units in the system.

The base station can be provided as a receive-only variant in systems that

need sites to enhance the receive coverage. The reciter in a receive-only

base station is physically unable to transmit.

a

For more information, refer to the appropriate Tait P25 System Manual.

TB9400 Installation and Operation Manual Description 17

© Tait Limited November 2013

1.6 Licenses

Some operational functions of the base station are controlled by licenses.

These functions will not work unless you purchase the appropriate feature

license and enable the feature set controlled by that license. The feature sets

currently available are listed below.

P25 Common Air

Interface

P25 Trunking

Operation

Networking with

Centralized Voter

Simulcast

Transmitter

Linear Simulcast

Modulation

Failsoft for P25

Trunking

Allows the base station to go into Online mode. Base stations are always

provided with this license.

Allows the base station to participate in a trunking system. Without this

feature, the base station cannot provide a control or a status connection to

a trunking site controller and it cannot function as a control or traffic

channel.

This feature is required in any base station that is used in a voted

configuration, such as simulcast. It also allows a base station to act as a

central voter.

This feature is required in base stations that have transmitters and belong

to a simulcast network.

Allows the base station to transmit using the LSM modulation scheme.

This scheme allows increased site separation in simulcast networks.

Allows trunked channels that become isolated from a site controller to

perform simple conventional operation and to interface to a digital dispatch

system. If a trunked channel consists of several base stations in a channel

group, only the central voter (normally the master) needs this license. It is

then able to become the failsoft repeater for that channel group.

P25 Phase 2

Operation

(not yet available)

18 Description TB9400 Installation and Operation Manual

This feature will allow the base station to operate in trunking mode using

two-slot TDMA as defined by the P25 Phase 2 standard.

© Tait Limited November 2013

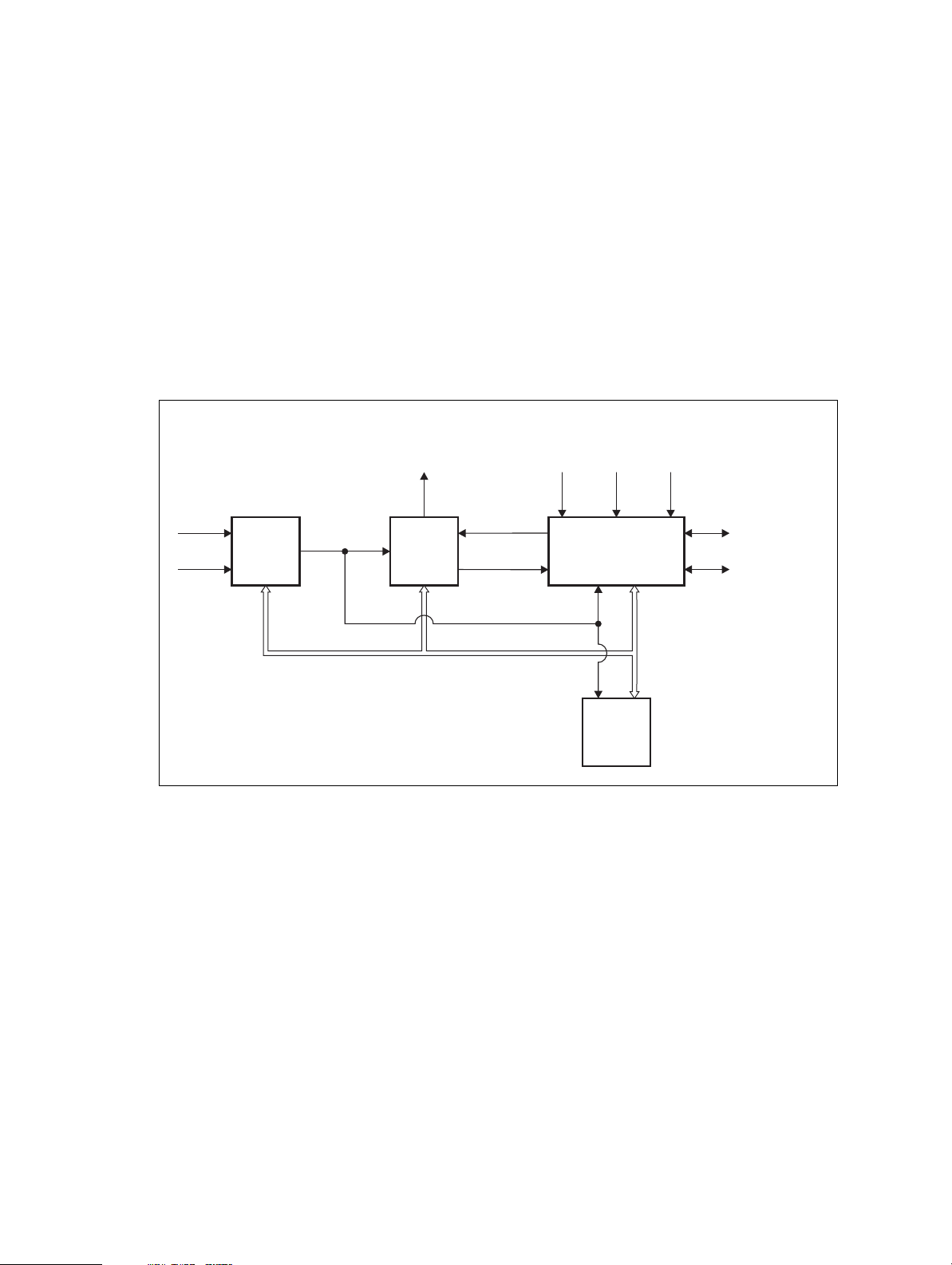

1.7 Theory of Operation

The reciter receives RF signals from its RF input and sends RF from its RF

output to the PA, along with a PA key signal. The PA sends an RF feedback

signal to the reciter for linearization and power control purposes. The

reciter also receives signals from, and sends signals to, the system

interface, the Ethernet interface, and the front panel (see Figure 1.4).

A system control bus interconnects the modules and carries alarm and

control signaling between the reciter and the other modules.

The Ethernet interface carries voice over IP and also allows maintainer

access via a web browser.

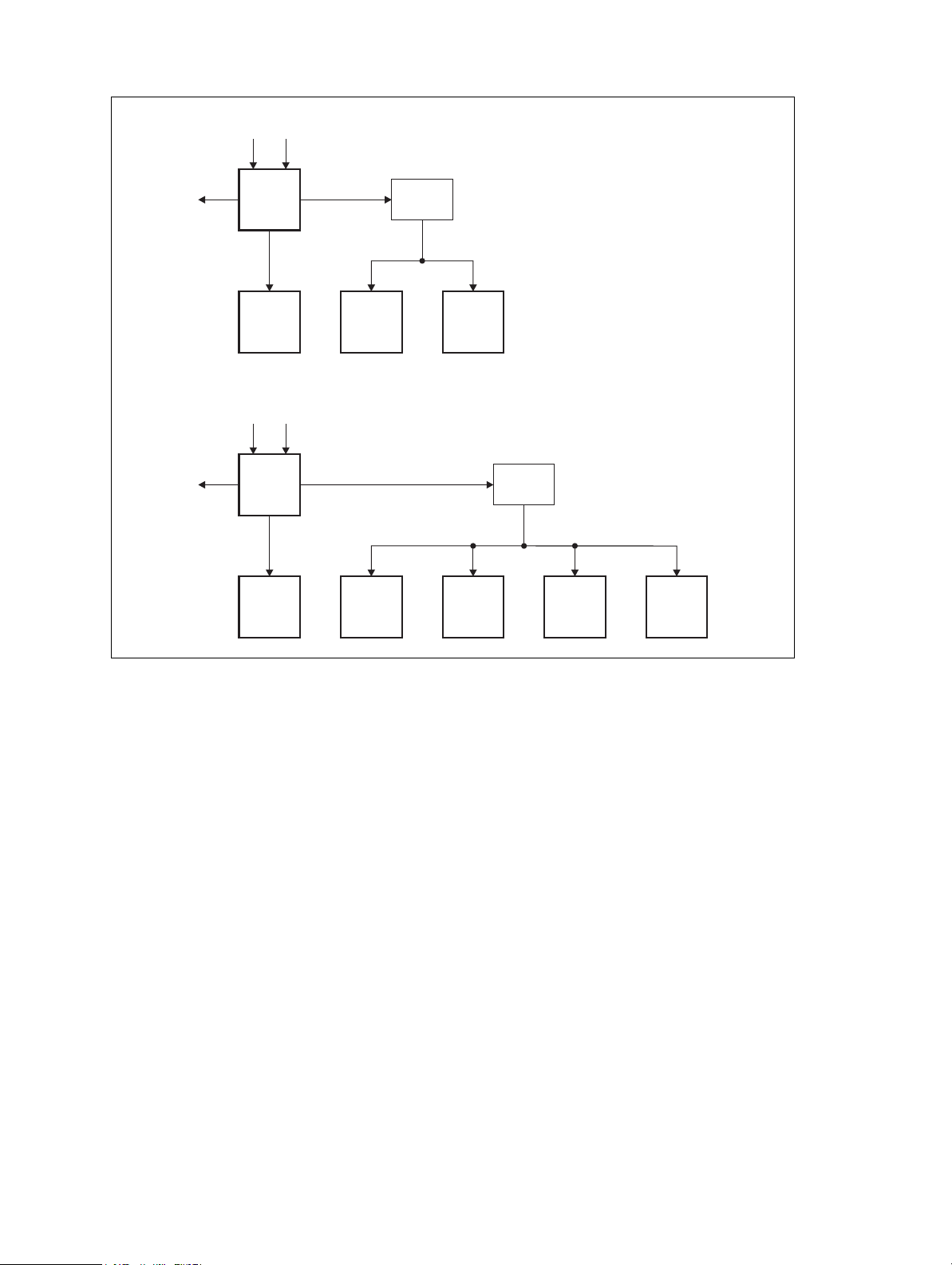

Figure 1.4 Base station high-level diagram

AC Input

DC Input

PMU

28VDC

RF To

Antenna

PA

System Control Bus

RF+PAKey

RF Feedback

RF From

Antenna

1PPS

Reciter

Front

Panel

External

Reference

Frequency

System Input

and Output

Ethernet Interface

to Network

TB9400 Installation and Operation Manual Description 19

© Tait Limited November 2013

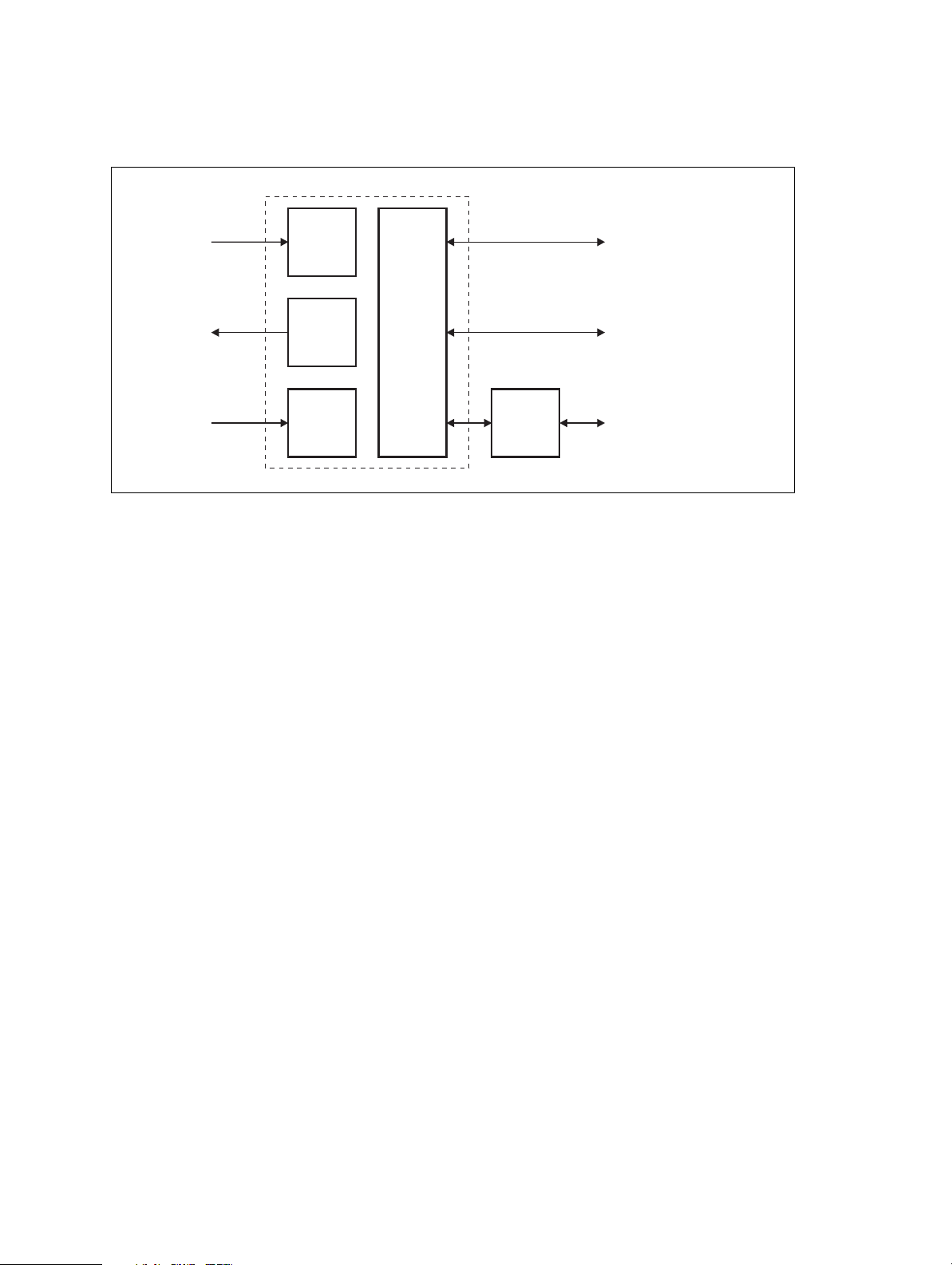

The reciter carries out signal processing and has overall control of the base

station. Its circuit boards are shown in Figure 1.5.

Figure 1.5 Reciter boards

RF Input

RF Output

RF Input

(feedback

from PA)

Receiver

Board

Transmit

Forward

Board

Transmit

Reverse

Board

Reciter

Control

Board

Front

Panel

System Input

and Output

Ethernet Interface

to Network

Maintainer Access

The receiver board contains all the receiver circuitry, while the exciter

circuitry is located on the transmit forward board.

The reciter control board converts information between analog and digital

and controls the maintainer’s access via the front panel. It performs the air

interface signal processing for digital P25 mode, gives the base station an

identity as a network element, and provides the physical connections for

the Ethernet and system interfaces.

20 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

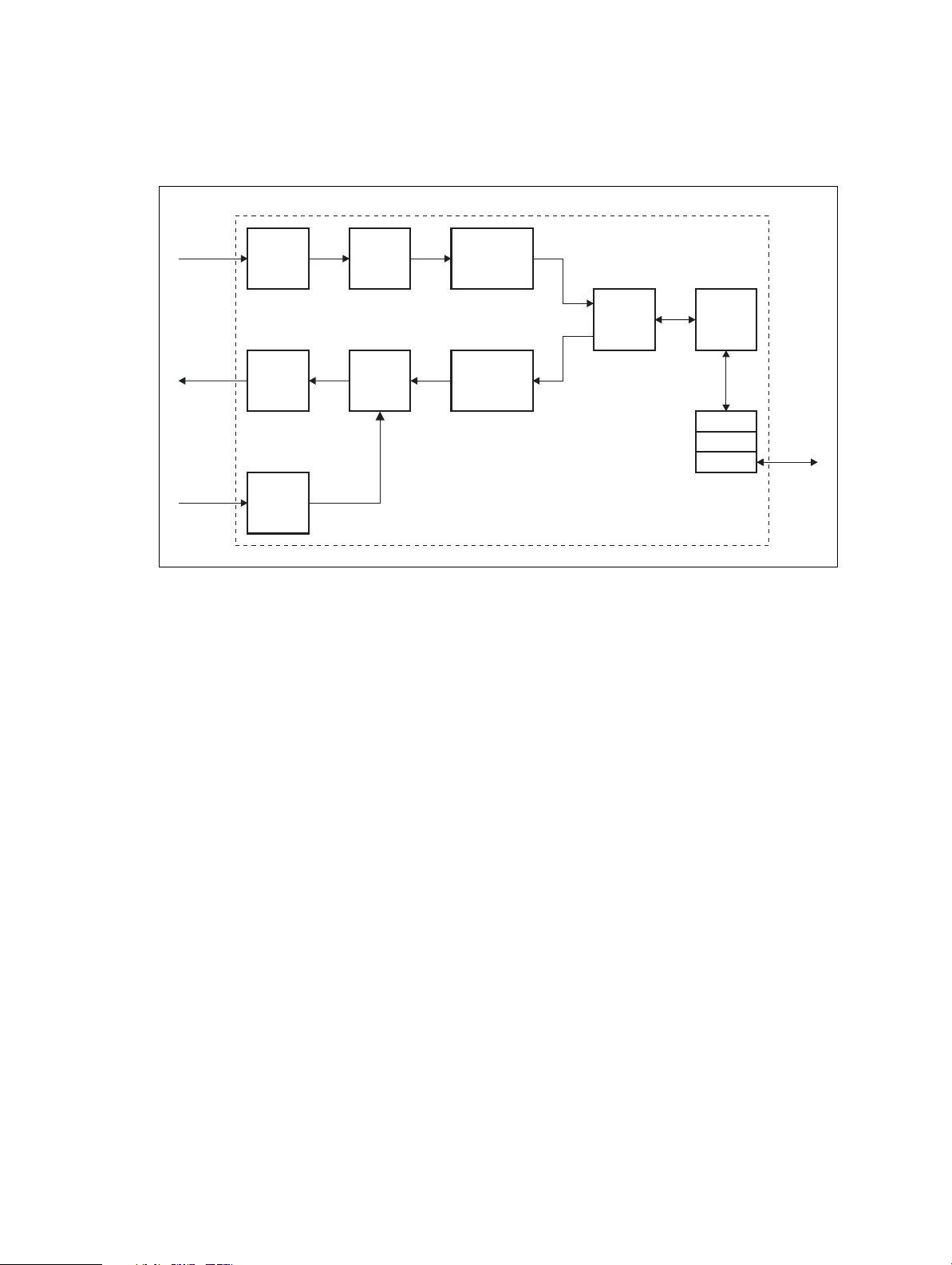

1.7.1 Signal Paths

Figure 1.6 gives an overview of signal paths within the reciter.

Figure 1.6 Reciter signal paths

Receive

RF Interface

ADC

DDC

Demodulator

Transmit

RF Interface

Transmit

RF Interface

(feedback

from PA)

DAC

ADC

Cartesian

Loop

P25

Modem

Modulator

Protocol

Reciter Control Board

Stack

Control

RTP

UDP

IP

Ethernet

Interface

Digital P25 signals from the receive RF interface pass through the digital

receiver and P25 modem to the control software in the RISC processor. The

control software passes the signal through the Ethernet interface to the site

controller, or to the central voter in a simulcast system.

Input to the Ethernet interface can be from the site controller, or from the

central voter in a simulcast system. These inputs are processed by the RISC

and passed through the P25 modem to the transmitter. If the base station is

itself a central voter, this input can also be a received signal, which is voted

on and sent back through the Ethernet interface to the site controller.

1.7.2 Online and Offline Modes

The base station normally operates in Online mode, but you can put it into

Offline mode via its web interface.

Online Mode In Online mode, the base station performs its normal functions.

Offline Mode Some procedures, such as activating firmware or running certain diagnostic

tests, require the base station to be in Offline mode. This takes the base

station out of service. However, the front panel is still operational and can

be used in the normal way.

TB9400 Installation and Operation Manual Description 21

© Tait Limited November 2013

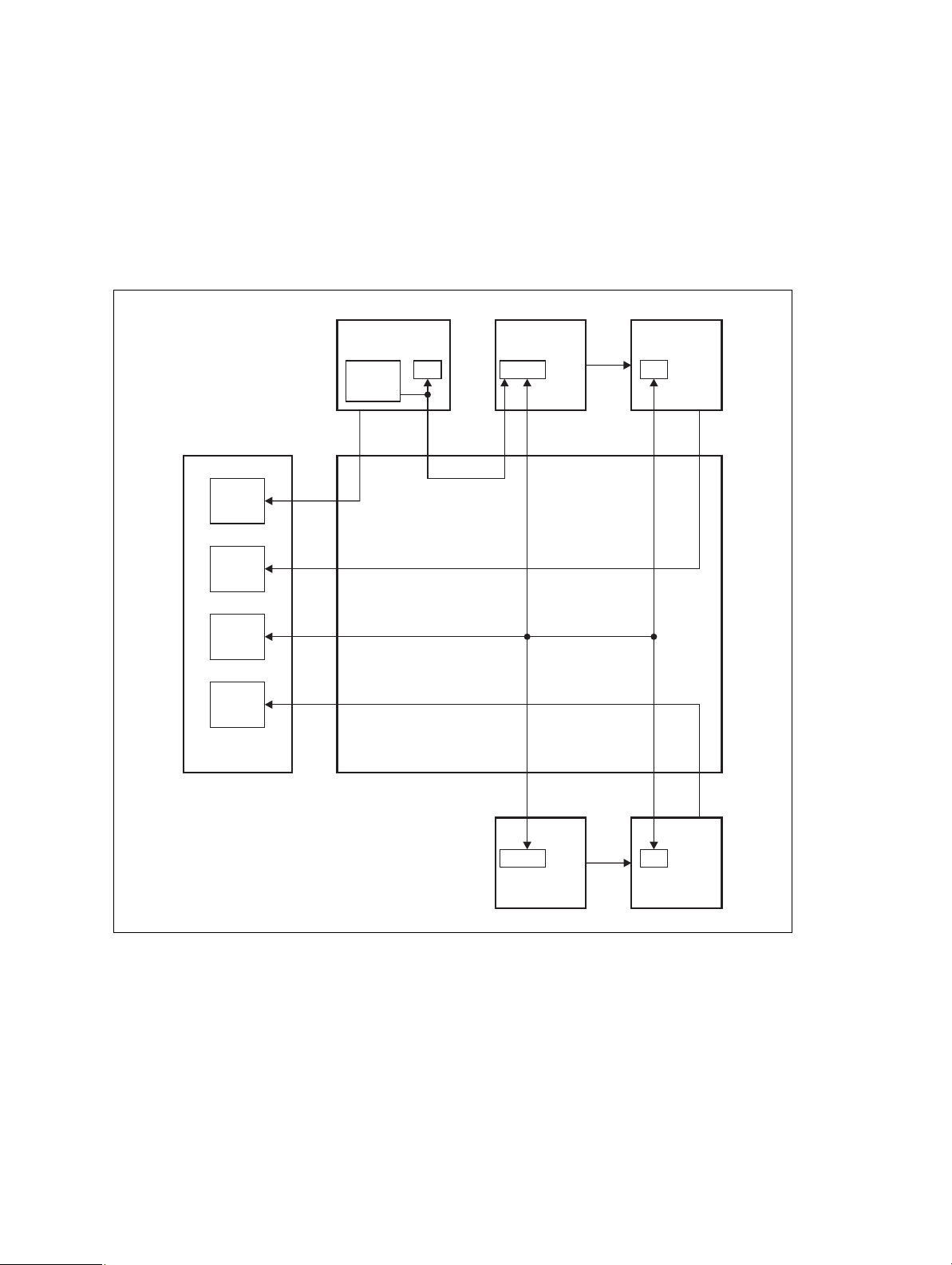

1.7.3 Intermodule Communications

A system control bus and a subrack interconnect board link the modules in

the subrack and carry alarm and control signaling between the reciter and

the other modules, as shown in Figure 1.7.

Specific configuration settings for dual base stations are described in

“Recommended Configuration Settings” on page 75.

Figure 1.7 Intermodule communication paths

Fan 3:

PMU

Fan 1:

Reciter 1/

PA 1

User

Controls

Fan 2:

Reciter 2/

PA 2

Front Panel

PMU

2

I C Current

Source

mP

2

Subrack Interconnect Board

2

IC

Reciter 1

mP

RS-485

PA 1

mP

RS-485IC

Fan

FanFan

RS-485RS-485 Fan

mP

Reciter 2

mP

PA 2

22 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

1.7.4 Power Management and Distribution

The PMU manages the supply of power to ensure uninterrupted operation

of the base station. A range of parameters is monitored and these can

trigger alarms that are sent to the reciter. Alarms can be monitored via the

web interface and reported via SNMP traps; they are also recorded in the

reciter’s internal log file.

AC to DC

Changeover

When the PMU has an AC and a DC module, the base station can be

powered by either the AC (mains) or the DC (battery) supply. The base

station will default to the AC supply if both supplies are provided. If the

AC supply becomes unavailable, a seamless changeover from the AC to

DC supply takes place, providing that the battery voltage is above the

configured minimum startup voltage. You can use a web browser to check

whether the base station is running on battery or mains power.

DC Operation When the base station is running off the DC supply and the battery voltage

falls below the configured minimum, the base station will enter battery

protection mode to protect the battery and base station equipment. The

standby power supply card maintains the power to the PMU

microprocessor, while the rest of the PMU is shut down. When the battery

voltage rises to the configured startup setting, power is resumed to the DC

supply. Refer to “PMU Operation on DC Input” on page 25 for more

detailed information.

Auxiliary Power

Control

Distribution Figure 1.8 shows how power is distributed to modules in the subrack. The

The output from the auxiliary power supply board can be used to power

other site equipment. The maximum output is 40W.

28VDC output from the PMU is fed directly to the PA in a single base

station, or directly to PA 1 in a dual base station, and to the other modules

via the subrack interconnect board. Power to the reciters and front panel is

current-limited by self-resetting fuses on the subrack board.

The AC converter has a series switch which breaks the phase input to the

converter. The DC input, however, has much higher current ratings. Its

switch does not disconnect power from the DC converter itself, but disables

the converter by switching off its control circuitry.

The outputs from both the AC and DC high power converters are added

together and fed to the modules via the high-current outputs. The auxiliary

output is also tapped off this summed output.

TB9400 Installation and Operation Manual Description 23

© Tait Limited November 2013

Figure 1.8 Subrack power distribution

Single

Dual

DC AC

Aux. DC 28V

Aux. DC 28V

PMU

28V

PA Reciter

DC AC

PMU

28V

Subrack

Board

Front

Panel

Subrack

Board

PA 1 PA 2 Reciter 1

Reciter 2

Front

Panel

24 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

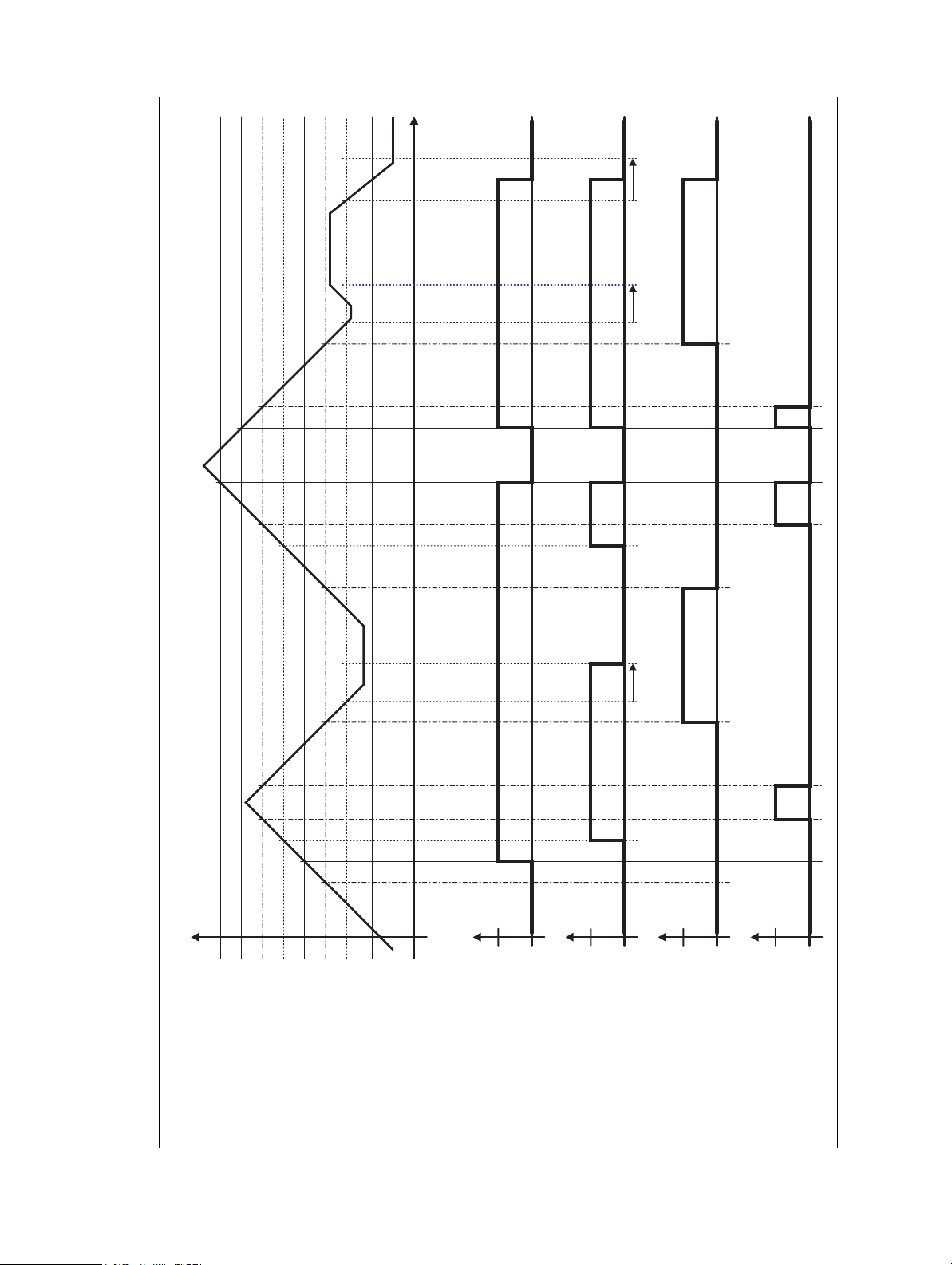

1.7.5 PMU Operation on DC Input

The operation of the PMU on DC input is controlled by three sets of

parameters:

■ user-programmable alarms

■ user-programmable startup and shutdown limits

■ battery protection limits

The voltage range for each of these parameters is provided in Table 1.1 on

page 26. Figure 1.9 on page 27 illustrates how these parameters interact,

and how they control the operation of the PMU over a range of DC input

voltages.

Alarms User-programmable alarms can be set for low or high battery voltage

(Configure > Alarms > Thresholds). The alarms will be triggered when the

set voltage levels are reached. These limits are subject to the tolerances of

the battery protection circuitry, as stated in “Battery Protection (Fail-safe)

Limits” in Table 1.1.

Startup and

Shutdown Limits

Battery Protection

Limits

The user-programmable startup and shutdown limits allow for adjustable

startup and shutdown voltages (Configure > Base Station >

Miscellaneous). These limits can be adjusted for different numbers of

battery cells, or for the particular requirements of the base station

operation. Once the limits are reached, the PMU will shut down. These

limits are subject to the tolerances of the battery protection circuitry, as

stated in “Battery Protection (Fail-safe) Limits” in Table 1.1.

Notice It is possible to set the startup voltage of the base station

below the nominal voltage of the battery. Continuing to use a battery for

extended periods when it is below its nominal voltage will severely

shorten its service life. For more information on battery management,

we recommend that you consult the battery manufacturer.

The battery protection limits are set in hardware at the factory, and cannot

be adjusted by the user. These limits will not be reached under normal

operation conditions, but are provided as “fail-safe” measures to protect the

battery from deep discharge. They also remove the need for low-voltage

disconnect modules.

TB9400 Installation and Operation Manual Description 25

© Tait Limited November 2013

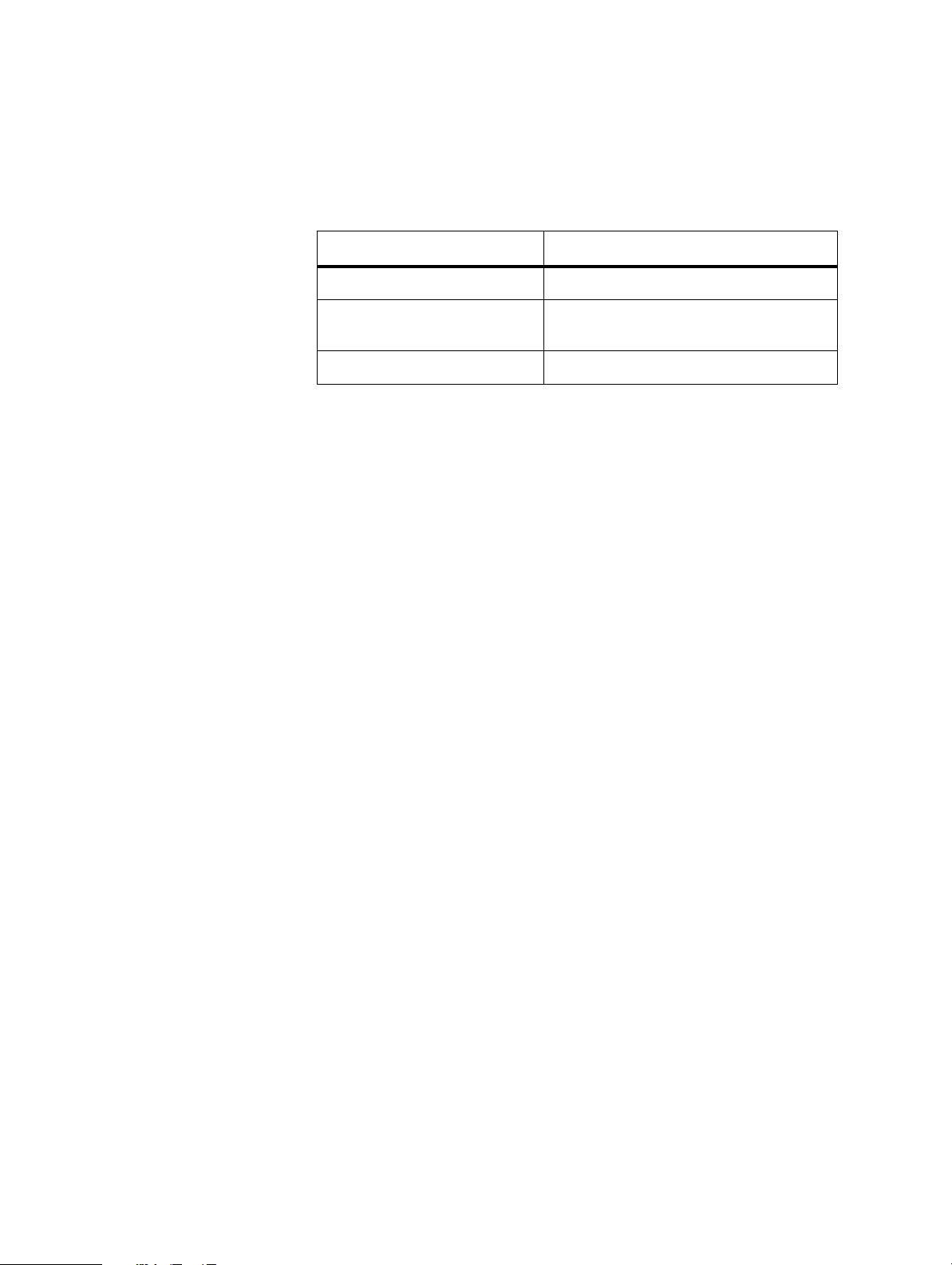

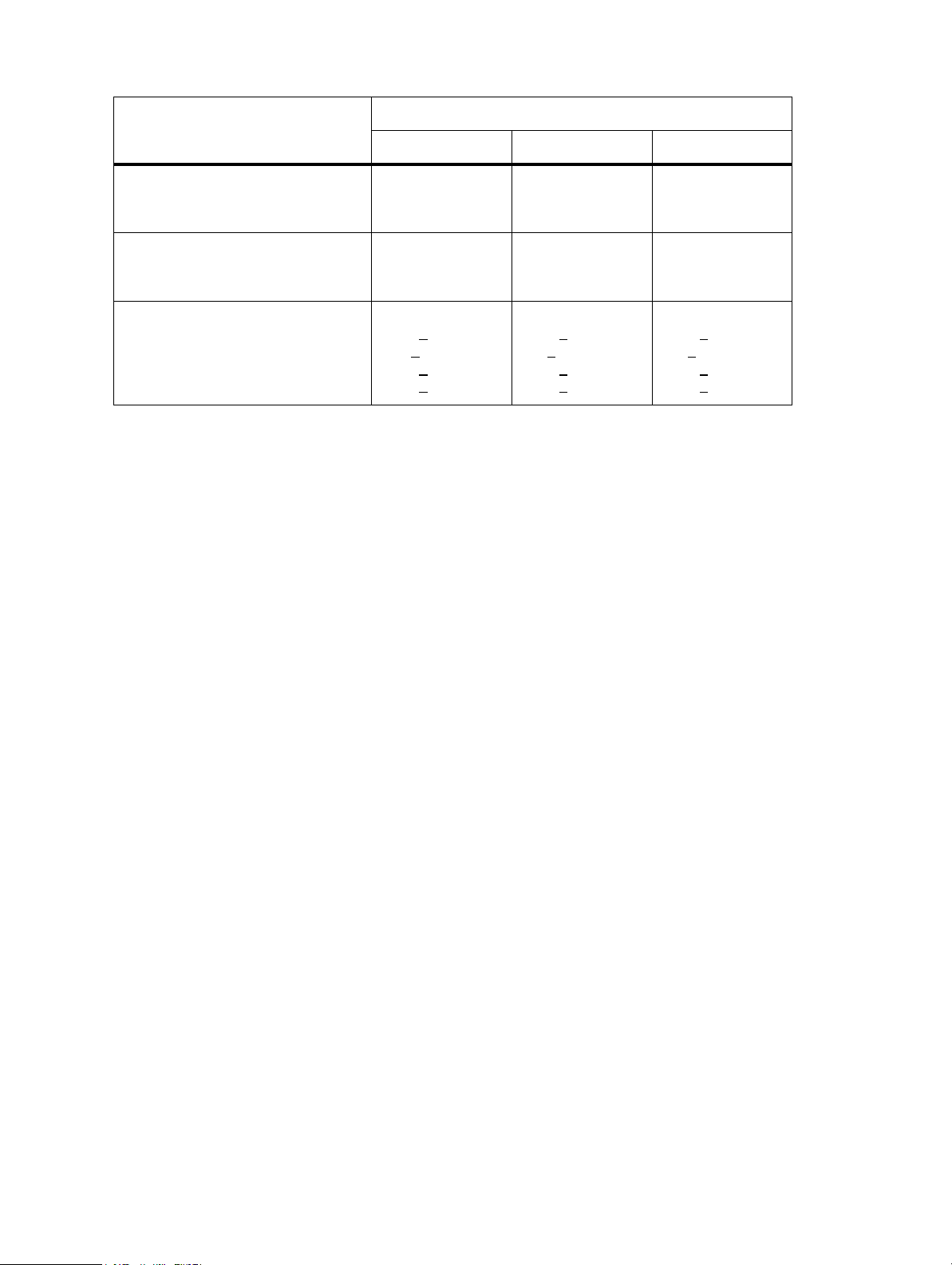

Table 1.1 PMU DC voltage limits

Parameter

User-programmable Alarms

Low Battery Voltage

High Battery Voltage

User-programmable Limits

Startup Voltage (after shutdown)

Shutdown Voltage

Battery Protection (Fail-safe) Limits

Startup Voltage

Undervoltage Shutdown

Overvoltage Shutdown

Overvoltage Shutdown Reset

a. The information in this table is extracted from the Specifications Manual. Refer to the latest issue of this manual

for the most up-to-date and complete PMU specifications.

b. Using the base station’s web interface.

b

b

a

Vol tage Range

12V PMU 24V PMU 48 V PMU

10V to 14V

14V to 17.5V

10.9V to 15V ±0.3V

10V to 13.5V ±0.3V

10.8V +0.2V

9.5V +0.3V

18.1V +

17.1V +

0.3V

0.3V

20V to 28V

28V to 35V

21.8V to 30V ±0.5V

20V to 27V ±0.5V

21.6V +

19V +0.5V

36.2V +

34.2V +

0.5V

0.5V

0.5V

40V to 56V

56V to 70V

43.6V to 60V ±1 V

40V to 54V ±1V

43.2V +

38V +1V

72.4V +

68.4V +

1V

1V

1V

26 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

Figure 1.9 PMU alarm thresholds and voltage limits when operating on DC

Time

DC Input Voltage

Overvoltage Shutdown (HW)

Overvoltage Shutdown Reset (HW)

High Battery Voltage Alarm (SW Alarm)

Startup Voltage (SW)

Startup Voltage (HW)

Shutdown Voltage (SW)

Undervoltage Shutdown (HW)

Low Battery Voltage Alarm (SW Alarm)

30s delay 30s delay 30s delay

Run

0V

Hardware Behaviour

Stop

Run

Software Control &

Hardware Combined

Stop

Software Alarm

Off

Active

Software Alarm

(Low Battery Voltage)

Off

Active

(High Battery Voltage)

TB9400 Installation and Operation Manual Description 27

© Tait Limited November 2013

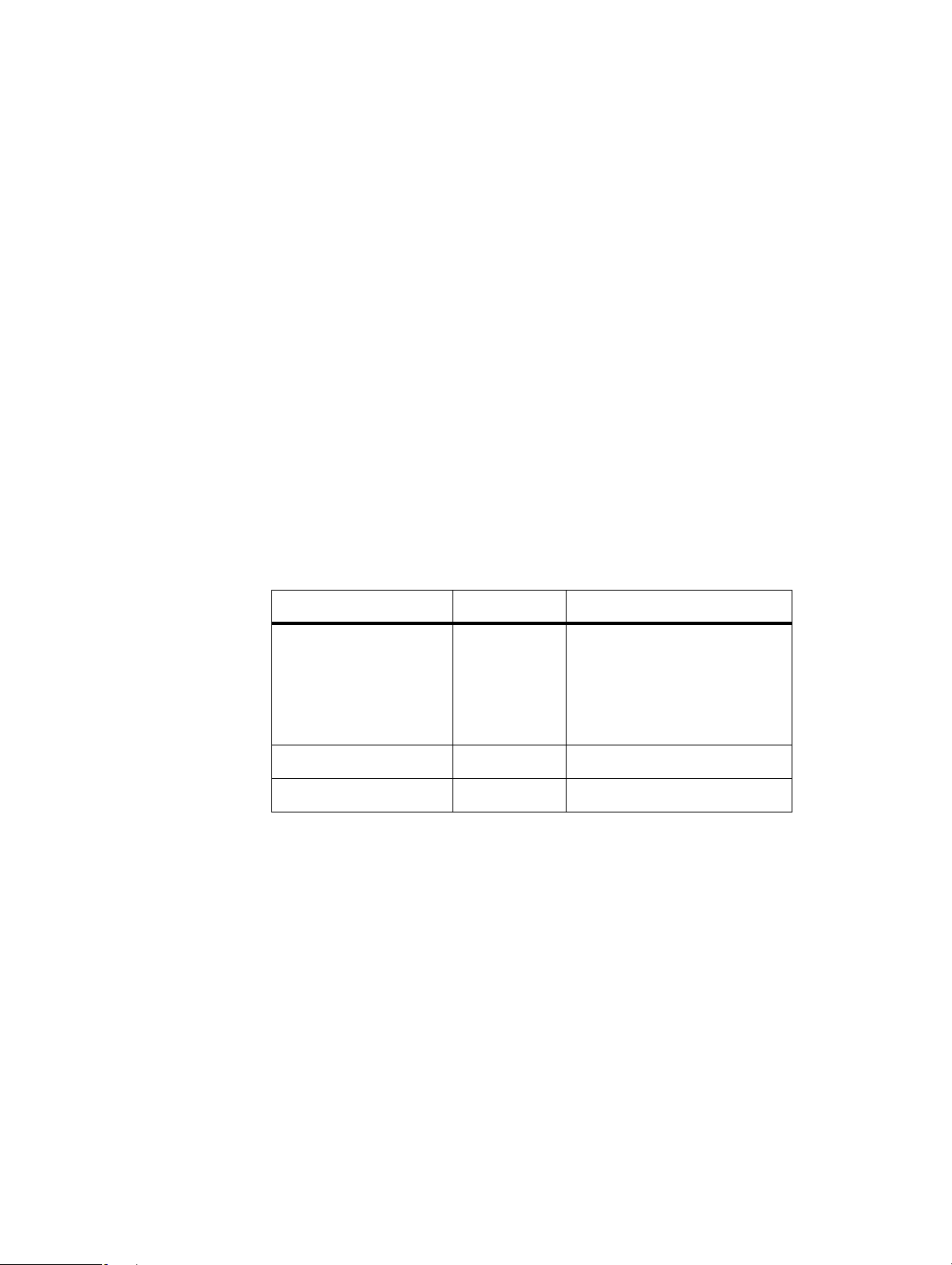

1.7.6 Front Panel Fans

The front panel is equipped with three fans. One fan is for the PMU and the

other two are for the reciter/PA pairs in a 50W base station, or for the PA

and reciter in a 100W base station. Front panel fans do not operate

continuously, but are switched on and off as needed. The PMU and PA

control their own fan. Reciters request the front panel to turn on their fan.

The reciter in slot 1can also carry out a fan test on all three fans.

Front panel fans are 3-wire fans (power, ground, and rotation detect). The

reciter can monitor whether the fans are rotating and generate an alarm if

the fan fails.

The fans turn on for a few seconds when the base station is powered up, and

also after the front panel is refitted to a base station which is powered up.

Configuring Fan

Control

The operation of the PA fan is configurable via the web interface; you can

specify the threshold temperature at which the fan will be turned on, and

set the fan to operate only when the PA is transmitting.

The PMU fan has fixed on/off thresholds and a defined set of duty cycles

based on the PMU temperature and load current, as described in the

following table.

PMU Temperature Current Fan Duty Cycle

<149°F (65°C) <4A

4A–6A

6A–8A

8A–12A

12A –14A

≥15A

149–167°F (65 – 75 °C) –– two minutes on, one minute off

>167°F (75°C) –– always on

always off

2 minutes on, 8 minutes off

2 minutes on, 5 minutes off

3 minutes on, 3 minutes off

4 minutes on, 1 minute off

always on

28 Description TB9400 Installation and Operation Manual

© Tait Limited November 2013

2 General Safety and Regulatory

Information

This chapter provides general information on safety precautions for

operating the base station.

TB9400 Installation and Operation Manual General Safety and Regulatory Information 29 © Tait Limited November 2013

2.1 Personal Safety

2.1.1 Unpacking and Moving the Equipment

To prevent personal injury and equipment damage, we recommend that two

people unpack and move the equipment.

Caution A subrack complete with modules can weigh up to 55lb

(25kg), or up to 62 lb (28 kg) complete with packaging. We recommend

that you have another person help you unpack and move the equipment.

The TBAA03-16 carrying handles will make it easier to move the

equipment once it has been unpacked. If necessary, remove the modules

from the subrack before moving it (refer to “Replacing Modules” on

page 99). In all cases follow safe lifting practices.

2.1.2 Lethal Voltages

Warning The PMU contains voltages that may be lethal. Refer

to the ratings label on the rear of the module.

The equipment must be installed so that the rear of the PMU is located in a

service access area which is accessible only by qualified personnel. The

PMU must be connected to the mains supply source by qualified personnel

in accordance with local and national regulations.

Disconnect the mains IEC connector and wait for five minutes for the

internal voltages to self-discharge before dismantling. The AC power

on/off switch does not isolate the PMU from the mains. It breaks only

the phase circuit, not the neutral.

The PMU should be serviced only by qualified technicians. There are no

user-replaceable parts inside. If the PMU is damaged and does not function

properly, stop the module safely and contact your regional Tait office

immediately.

All servicing should be carried out only when the PMU is powered through

a mains isolating transformer of sufficient rating.

30 General Safety and Regulatory Information TB9400 Installation and Operation Manual

© Tait Limited November 2013

Loading...

Loading...