Page 1

TB9400 Base Station/Repeater

Installation and Operation Manual

MBC-00001-20 · Issue 20· November 2018

Page 2

Contact Information

Tait Communications

Corporate Head Office

Tait International Limited

P.O. Box 1645

Christchurch

New Zealand

For the address and telephone number of regional

offices, refer to our website: www.taitradio.com

Copyright and Trademarks

All information contained in this document is the

property of Tait International Limited. All rights

reserved. This document may not, in whole or in part,

be copied, photocopied, reproduced, translated, stored,

or reduced to any electronic medium or machinereadable form, without prior written permission from

Tait International Limited.

The word TAIT and the TAIT logo are trademarks of

Tait International Limited.

All trade names referenced are the service mark,

trademark or registered trademark of the respective

manufacturers.

Disclaimer

There are no warranties extended or granted by this

document. Tait International Limited accepts no

responsibility for damage arising from use of the

information contained in the document or of the

equipment and software it describes. It is the

responsibility of the user to ensure that use of such

information, equipment and software complies with the

laws, rules and regulations of the applicable

jurisdictions.

Enquiries and Comments

If you have any enquiries regarding this document, or

any comments, suggestions and notifications of errors,

please contact your regional Tait office.

US640974, US640977, US698339, US 702666,

US7758996, US8902804, US9107231, US9504034,

US9559967.

The AMBE+2™ voice coding Technology embodied

in this product is protected by intellectual property

rights including patent rights, copyrights and trade

secrets of Digital Voice Systems, Inc. This voice

coding Technology is licensed solely for use within this

Communications Equipment. The user of this

Technology is explicitly prohibited from attempting to

decompile, reverse engineer, or disassemble the Object

Code, or in any other way convert the Object Code into

a human-readable form.

Environmental Responsibilities

Tait International Limited is an environmentally

responsible company which supports waste

minimization, material recovery and restrictions in the

use of hazardous materials.

The European Union’s Waste Electrical and Electronic

Equipment (WEEE) Directive requires that this

product be disposed of separately from the general

waste stream when its service life is over. For more

information about how to dispose of your unwanted

Tait product, visit the Tait WEEE website at

www.taitradio.com/weee. Please be environmentally

responsible and dispose through the original supplier,

or contact Tait International Limited.

Tait International Limited also complies with the

Restriction of the Use of Certain Hazardous Substances

in Electrical and Electronic Equipment (RoHS)

Directive in the European Union.

In China, we comply with the Measures for

Administration of the Pollution Control of Electronic

Information Products. We will comply with

environmental requirements in other markets as they

are introduced.

Updates of Manual and Equipment

In the interests of improving the performance,

reliability or servicing of the equipment, Tait

International Limited reserves the right to update the

equipment or this document or both without

prior notice.

Intellectual Property Rights

This product may be protected by one or more patents

or designs of Tait International Limited together with

their international equivalents, pending patent or

design applications, and registered trade marks:

NZ409837, NZ409838, NZ415277, NZ415278,

NZ530819, NZ534475, NZ547713, NZ577009,

NZ579051, NZ579364, NZ586889, NZ610563,

NZ615954, NZ700387, NZ708662, NZ710766,

NZ711325 , NZ726313, NZ593887, AU2015215962,

AU339127, AU339391, AU2016259281,

AU2016902579, EU000915475-0001, EU 0009154750002, GB2532863, US 14/834609 Div. no 1, US15/

346518 Div.no 2, US15/350332, US15/387026 Div.,

US20150085799, US20160044572, US20160057051,

2 TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Scope of Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Associated Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Publication Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.3 Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Frequency Bands and Sub-bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.6 Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7 Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.7.1 Signal Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.7.2 Online and Offline Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.7.3 Intermodule Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.7.4 Power Management and Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.7.5 PMU Operation on DC Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.7.6 Front Panel Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2 General Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.1 Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.1.1 Unpacking and Moving the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . 32

2.1.2 Lethal Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.1.3 AC Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1.4 Explosive Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1.5 High Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1.6 LED Safety (EN60825-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1.7 Proximity to RF Transmissions / A proximité des émissions RF . . . . . 34

2.2 Equipment Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2.1 Installation and Servicing Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2.2 Preventing Damage to the PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2.3 ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2.4 Anti-tampering Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.1 Operating Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.2 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.3 Dust and Dirt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4 Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.1 Distress Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.2 Compliance Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.3 FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.4 Unauthorized Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

TB9400 Installation and Operation Manual 3

© Tait International Limited November 2018

Page 4

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2 Module Indicator LEDs and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2.1 Reciter and Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2.2 PA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.3 PMU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.1 Equipment Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.2 Grounding and Lightning Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.3 Equipment Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.4 Ambient Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.5 Cabinet and Rack Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.2 Unpacking and Moving the Subrack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.3 Identifying the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4 Initial Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4.1 Confirming Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4.2 Working with Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.4.3 Customizing the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.4 Recommended Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.5 Restricted Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.6 Changing the Root Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.4.7 Tuning the Reciter and Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5 Installing the Base Station on Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.5.1 General Installation Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.5.2 Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.5.3 Mounting the Subrack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.6 Connecting Up the Base Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.6.1 Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.6.2 Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.6.3 Connecting DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.6.4 Connecting the Auxiliary DC Power Output. . . . . . . . . . . . . . . . . . . . . 75

4.6.5 Connecting RF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.6.6 Connecting an External Frequency Reference. . . . . . . . . . . . . . . . . . . . 77

4.6.7 Connecting a 1PPS Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.6.8 Ethernet Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.6.9 Connecting General Purpose Inputs and Outputs . . . . . . . . . . . . . . . . . 80

5 Working with Base Stations from Your PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.1 PC Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.2 Connecting Your PC to the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.2.1 Logging In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.2.2 Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.2.3 Security Certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.2.4 Local Connection to a Base Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.2.5 Troubleshooting Connection Problems . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.2.6 Finding a Lost or Forgotten IP Address. . . . . . . . . . . . . . . . . . . . . . . . . 86

5.2.7 Setting Up Authentication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

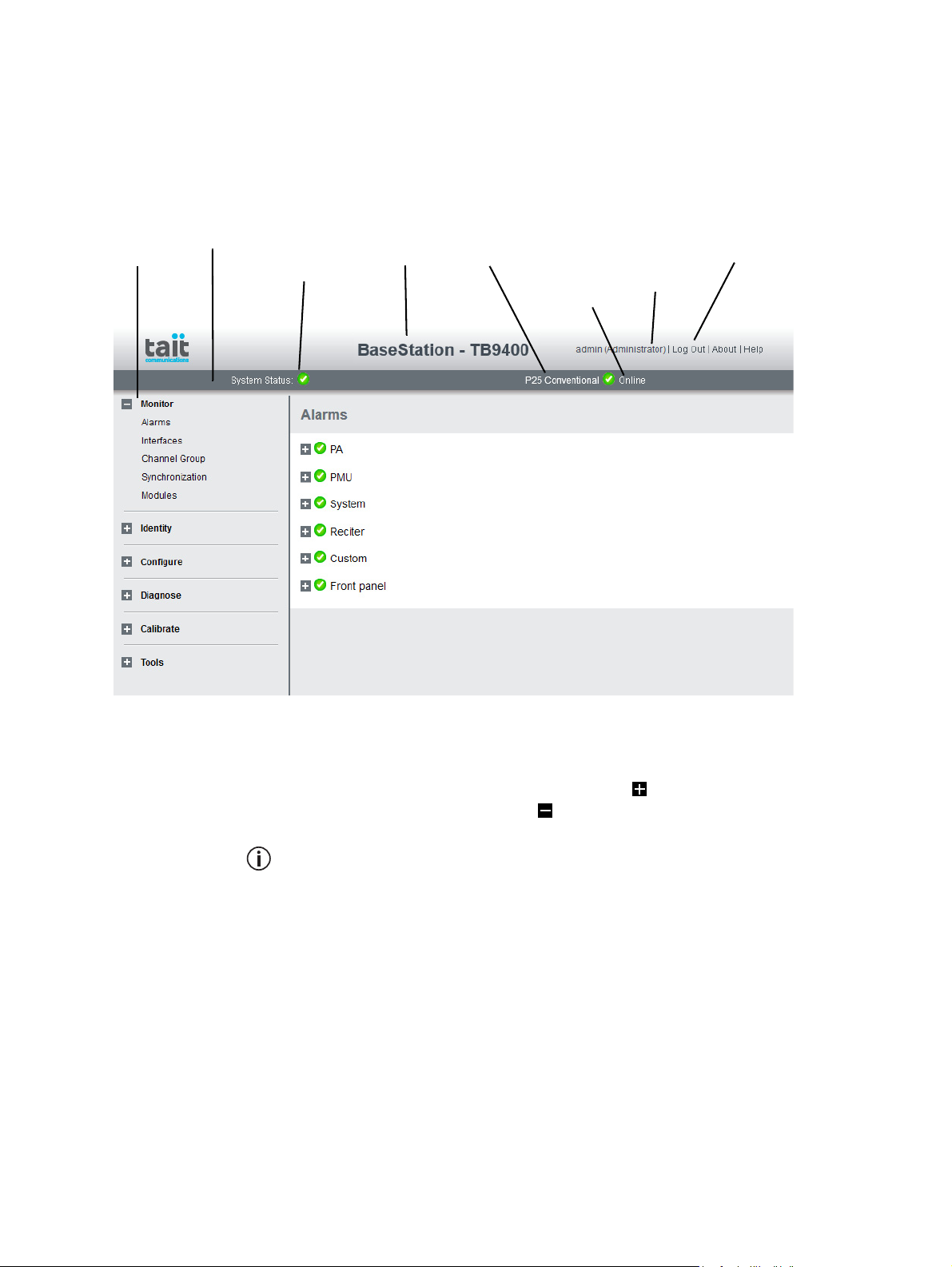

5.3 Working with the Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4 TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 5

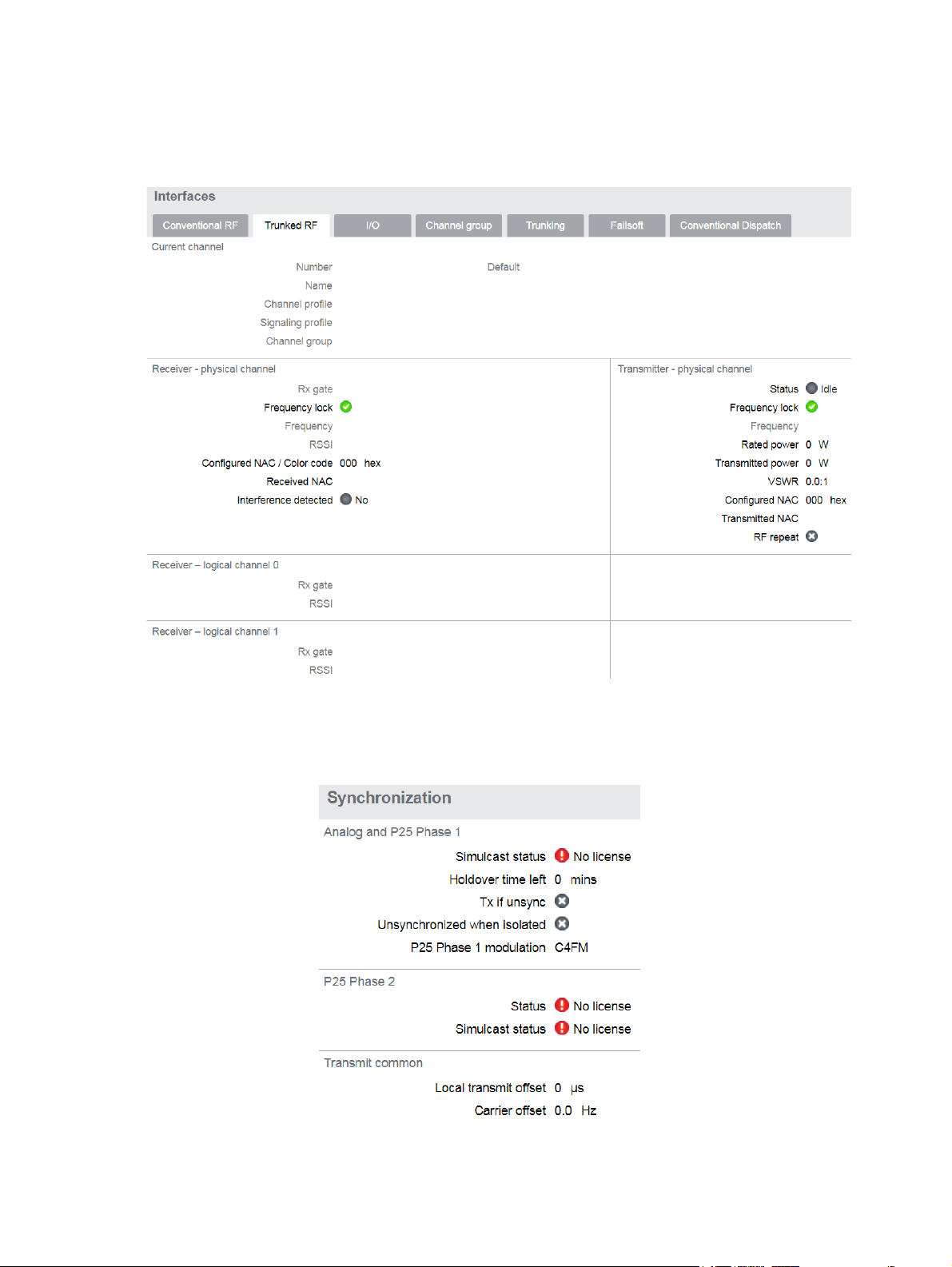

5.3.1 Monitoring Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

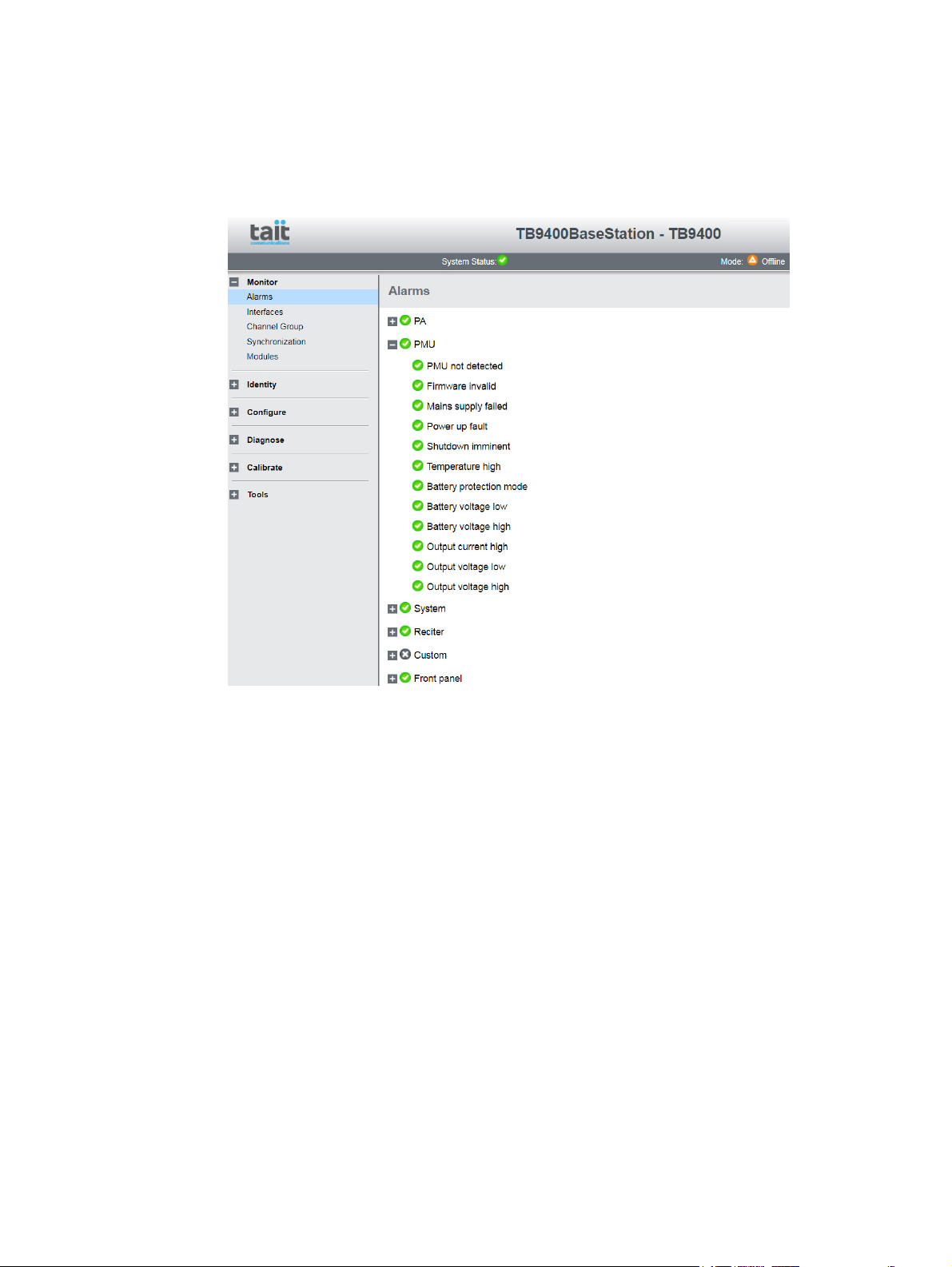

5.3.2 Troubleshooting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.3.3 Viewing Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.3.4 Viewing the Base Station and Network Identity . . . . . . . . . . . . . . . . . . 94

5.4 Basic Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.4.1 User Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.4.2 Taking the Base Station Offline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.4.3 Troubleshooting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.4.4 Disabling the Front Panel Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.4.5 Preparing to Download Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5.4.6 Working with Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.4.7 Setting Up Custom Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.4.8 Subaudible Signaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.4.9 Checking for Interference on a Receive Channel . . . . . . . . . . . . . . . . . 99

5.4.10 Configuring Single Base Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.4.11 Configuring Receive-Only Base Stations . . . . . . . . . . . . . . . . . . . . . . 100

5.4.12 Configuring Base Stations in a Channel Group. . . . . . . . . . . . . . . . . . 100

6 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8 Replacing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.1 Saving the Base Station’s Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2 Preliminary Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.3 Replacing a Reciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.4 Replacing a Power Amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

8.5 Replacing a Power Management Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

8.6 Replacing the Module Guide Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

8.7 Replacing the Subrack Interconnect Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

8.8 Final Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Appendix A – Interface Pin Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

System Interface Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Ethernet Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

PMU Auxiliary DC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

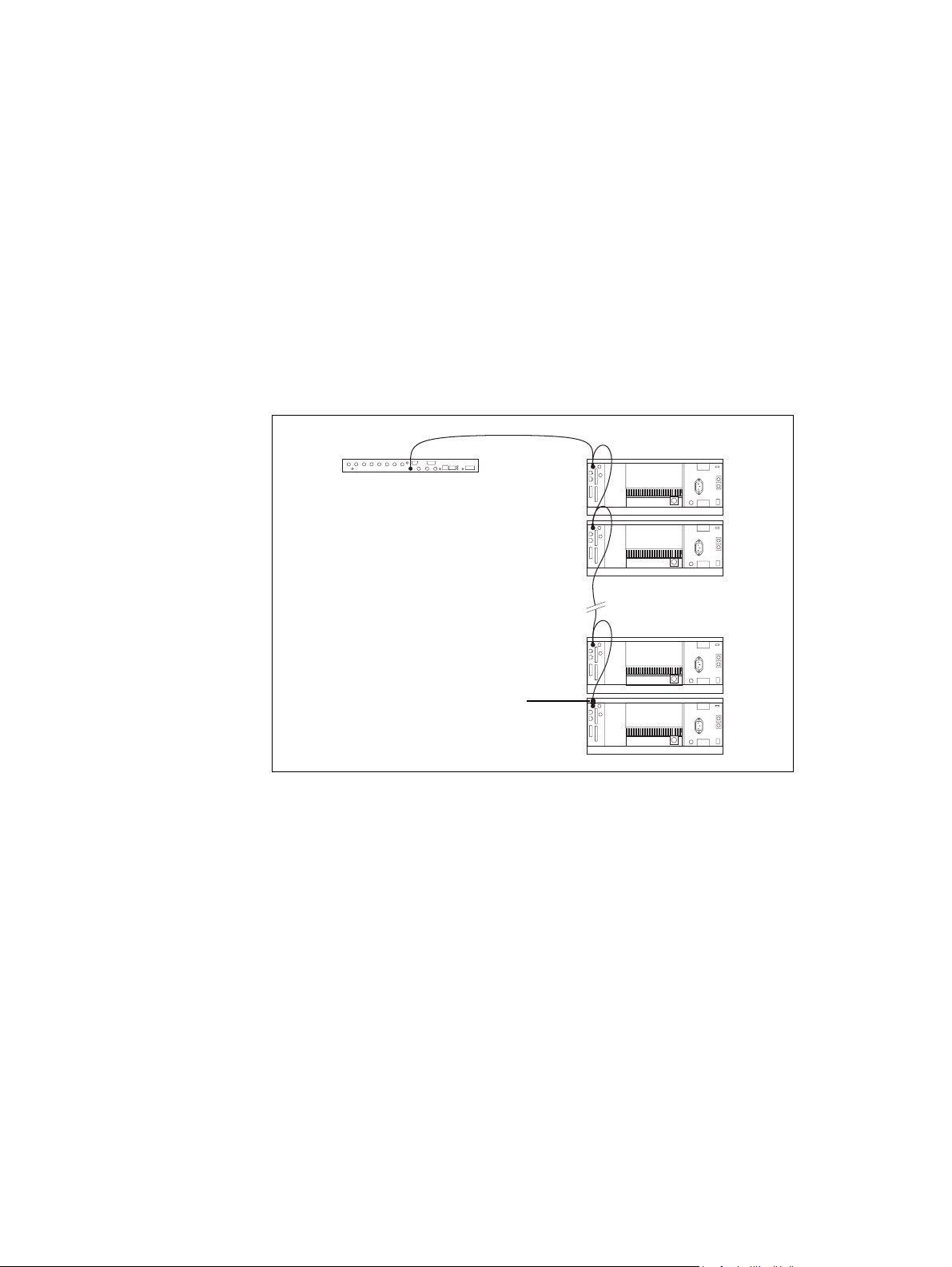

Appendix B – Inter-Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Dual 50W Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Single 50W Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

100W Base Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Receive-only Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Appendix C – Identifying Front Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Tait Software License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Simplified EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

TB9400 Installation and Operation Manual 5

© Tait International Limited November 2018

Page 6

Preface

Scope of Manual

This manual provides information on installing and operating the TB9400

base station. It is intended for use by experienced technicians familiar with

installing and operating base station equipment. It also includes

configuration, maintenance and troubleshooting information.

Except where stated otherwise, the information in this manual generally

applies to both standard and receive-only base stations and reciters.

When “reciter” is referred to, this generally applies also to the receiver

(receive-only reciter). References to power amplifiers (PAs) and transmitting obviously do not apply to receive-only equipment.

Unless mentioned specifically, this manual will use the term “base station”

to refer to both base station and repeater.

Document Conventions

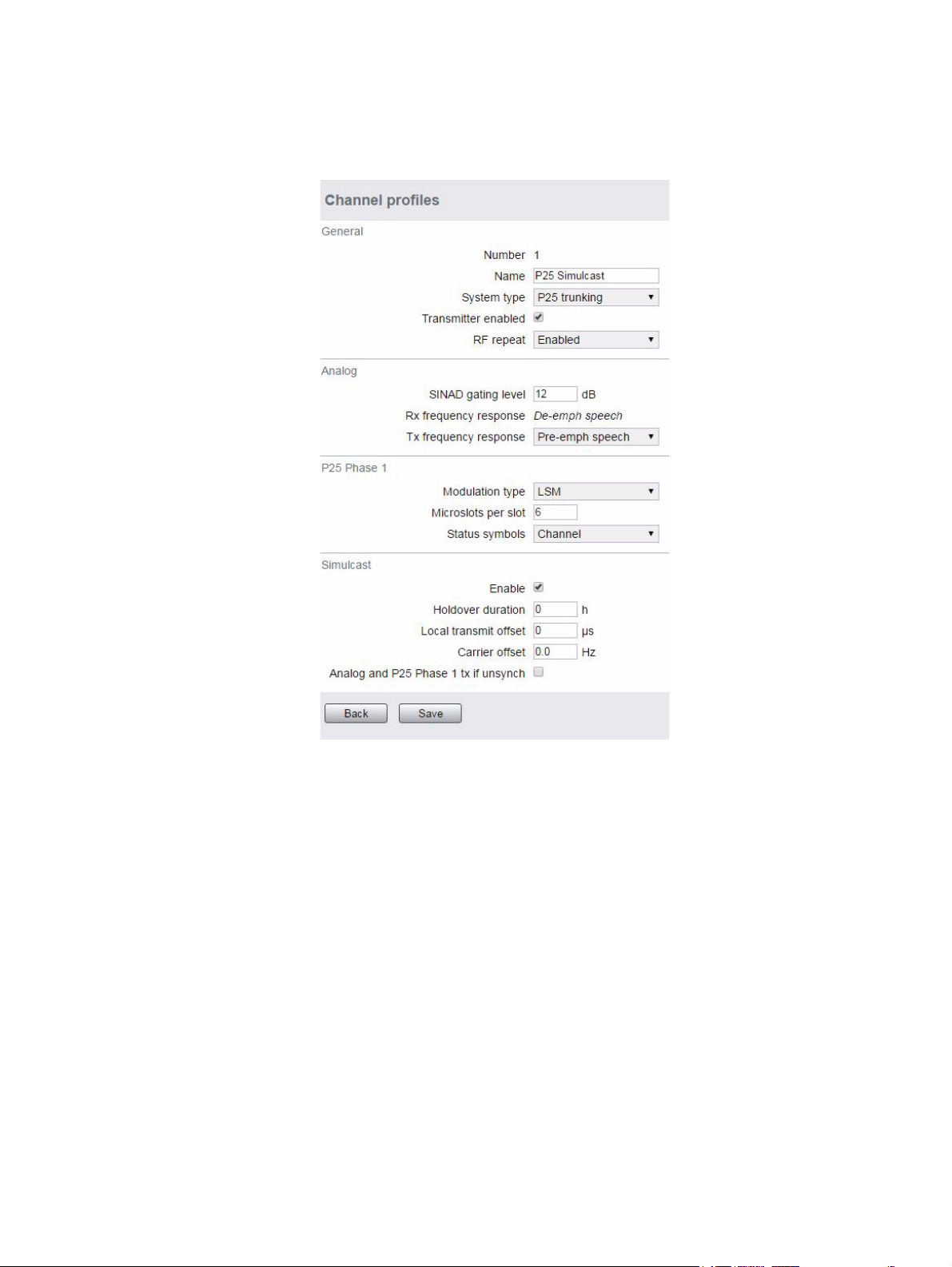

The TB9400 base station has a web interface with an accordion menu on

the left side of the screen. “Configure > Base Station > Channels” means

click Configure in the top-level menu, then in the expanded Configure

menu click Base Station, and finally click on the Channels tab on that page.

Within this manual, four types of alerts may be given to the reader. The

following paragraphs illustrate each type of alert and its associated symbol.

Warning This alert is used when there is a hazardous situation

which, if not avoided, could result in death or serious injury.

Caution This alert is used when there is a hazardous situation which,

if not avoided, could result in minor or moderate injury.

Notice This alert is used to highlight information that is required to

ensure procedures are performed correctly. Incorrectly performed procedures could result in equipment damage or malfunction.

This icon is used to draw your attention to information that may

improve your understanding of the equipment or procedure.

6 Preface TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 7

Associated Documentation

The following associated documentation for this product is available on the

Tait support website.

■ TB9400 Specifications Manual (MBC-00002-xx)

■ TN9400 P25 Trunked Network Maintenance Manual (MNC-00001-xx)

■ TaitNet P25 Trunked Networks with TB9400 Base Stations System

Manual (MBA-00064-xx)

■ TaitNet Analog Conventional Networks with TB9400 Base Stations

System Manual (MND-00001-xx)

■ Safety and Compliance Information (MBA-00012-xx)

The characters xx represent the issue number of the documentation.

Technical notes are published from time to time to describe applications for

Tait products, to provide technical details not included in manuals, and to

offer solutions for any problems that arise. Technical notes are available in

PDF format from the Tait support website. For more information contact

your regional Tait office.

TB9400 Installation and Operation Manual Preface 7

© Tait International Limited November 2018

Page 8

Publication Records

Issue Publication Date Description

20 November 2018 General updates for the 2.55 release

Advice for configuring subaudible signaling.

19 July 2018 General updates for the 2.50 release

Addition of B2 band.

Clarified that HH band is nominally 378 - 420. All frequencies can be used

except for the range at 406 - 406.1 (exclusive).

Updated type designators.

Smaller updates throughout.

18 March 2018 General updates for the 2.45 release

Publication Record now shows most recent manual issue at top of table

Added note about fill-in receiver to “8.4 Replacing a Power Amplifier”

Clarified “Bands and Sub-Bands” table

Updated section 5.2.4 “Connecting a Networked PC to a Base Station”

Added site controller table to the “1.6. Licenses” section

HH band is now released as 50W and receive only

17 November 2017 General updates for the 2.40 release.

Added definition of “integral voter” to Glossary on page 122

Added solution to Internet Explorer black screen in Connecting Your PC to

the Base Station on page 82.

Added notice regarding fan operation to Front Panel Fans on page 31.

Added information on cancelling a firmware package to Subaudible

Signaling on page 99.

Updated information on downloading firmware packages Setting Up a

Central Package Server on page 97.

Added notice regarding the base station resetting to Setting the IP Address

on page 84.

Added new HH band information throughout.

16 July 2017 General updates for version 2.35 release.

General minor wording and content changes throughout

Added P25 Conventional Simulcast Repeater to Features on page 10

Central voter and satellite licences listed as alternatives Licenses on

page 19.

Updated description for the ‘Digital Fixed Station’ Interface in Licenses on

page 19.

Updated the “Licenses and applicability” table for Central Voter, IP

Networking Satellite, and Simulcast.

Added new H3 band information throughout.

Screenshots have been updated in various places.

8 Preface TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 9

1 Description

The Tait TB9400 base station is a robust state-of-the-art digital fixed

station that combines Tait’s proven strengths in reliability, high

performance and modular design with software-based configurability and

operation, digital signal processing, and voice-over-IP technology.

The TB9400 operates as a transceiver in Project 25 trunked, trunked

simulcast, and P25 conventional networks. It is capable of either P25 Phase

1 FDMA operation, or 6.25kHz equivalent P25 Phase 2 TDMA operation.

The TB9400 can also operate in an analog conventional simulcast or

non-simulcast multi-site network.

The TB9400 combines industry-leading digital voice quality with rugged

design specifications and intuitive user interfaces. These products are

designed to meet the needs of the public safety and public service sectors.

The ability of the base station to link stations using standard Internet

Protocol communications, and to add features through software options

ensures that P25 systems designed with the TB9400 are scalable in both

size and functionality.

Its Ethernet interface provides built-in network connectivity, allowing the

TB9400 to join with other TB9400 base stations to form a channel group.

This network supports voice-over-IP and remote management of all base

stations via a web browser.

TB9400 Installation and Operation Manual Description 9

© Tait International Limited November 2018

Page 10

1.1 Features

The following are some of the features of the base station:

■ Fully compliant with the P25 Common Air Interface. Can therefore

■ Supports P25 Phase 1 operation with either C4FM or LSM modulation

■ Supports P25 Phase 2 operation.

■ Analog conventional repeater operation.

■ Analog conventional simulcast operation on an IP backbone requiring

■ Integrated built-in voting facility. No external voter is needed.

■ Can be completely managed remotely from a PC running a web

■ An integrated wiring solution is provided for the system control bus and

■ Reciters (receiver/exciter modules) can be replaced without affecting

■ Rugged construction with generous heatsinks and fan-forced cooling

interoperate with any similarly compliant radios.

on the transmitter

no audio calibration or training.

browser: configuration, alarm monitoring, fault diagnosis, feature and

firmware upgrades. Alarms can also be reported via SNMP traps,

allowing integration with an SNMP-based network management

system.

DC power connections to each module in the subrack.

the operation of other reciters in the same subrack.

for continuous operation from –22°F to +140°F (–30°C to +60°C).

10 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 11

1.2 Modules

The base station consists of a subrack with up to two transmit/receive

channels, or up to four receive-only channels.

The single PMU (power management unit) supplies and manages power to

the whole subrack (refer to “Theory of Operation” on page 22). One reciter

and one PA (power amplifier) are needed for each transmit/receive channel.

The PA is not required for a receive-only base station. There is also a front

panel with user controls and fans. The modules are interconnected at the

front of the subrack. External connections to the modules are located at the

rear.

Modules come in different variants depending, for example, on the RF

band or the supply voltage.

Each module is inserted into the 4U subrack from the front and is secured

at the front with a metal clamp. Both clamp and module are easily removed

for rapid module replacement. The modules are secured laterally with

plastic guides that clip into the top and bottom of the subrack. These guides

can be easily repositioned to change the configuration of a subrack. The

heavier modules are also secured laterally by metal tabs at the rear of the

subrack.

The following provides a brief description of the available modules.

Subrack The 4U subrack is made of passivated steel and is designed to fit into a

standard 19 inch rack or cabinet. The subrack is fitted with an interconnect

board that connects the system control bus and power to the modules and

front panel. The position of a module in the subrack is defined by the socket

on the subrack interconnect board to which the module is connected by the

system control bus.

TB9400 Installation and Operation Manual Description 11

© Tait International Limited November 2018

Page 12

Front Panel

The front panel is mounted onto the subrack with two quick-release

fasteners. It incorporates the indicator LEDs, four-line LCD display, user

controls, ambient temperature sensor and cooling fans.

The indicator LEDS allow some monitoring of the operational status of the

base station. The user controls and display allow the technician to

configure the IP address of each module. Refer to “Front Panel” on page 38

for more information.

The base stations have different front panel ducting arrangements

depending on PA type and power. Front panels may not be interchangeable.

The microphone input and speaker are not used in this release of the

TB9400.

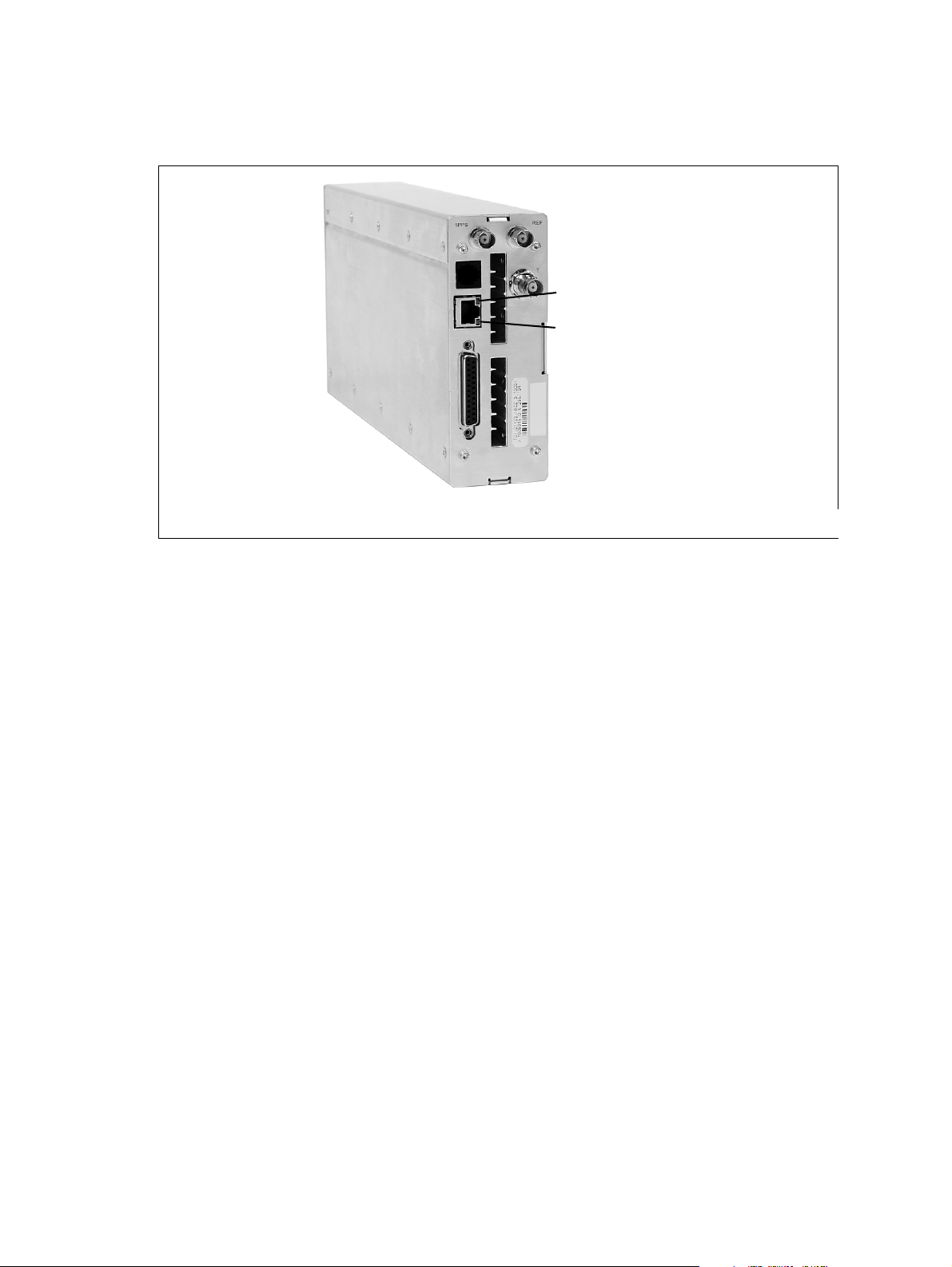

Reciter The reciter module comprises the receiver, exciter and digital control

circuitry. The reciter provides the Ethernet interface and system inputs and

outputs.

Receiver modules (receive-only reciters) are not fitted with the transmit

circuitry or front panel SMA connectors, and are physically unable to

transmit.

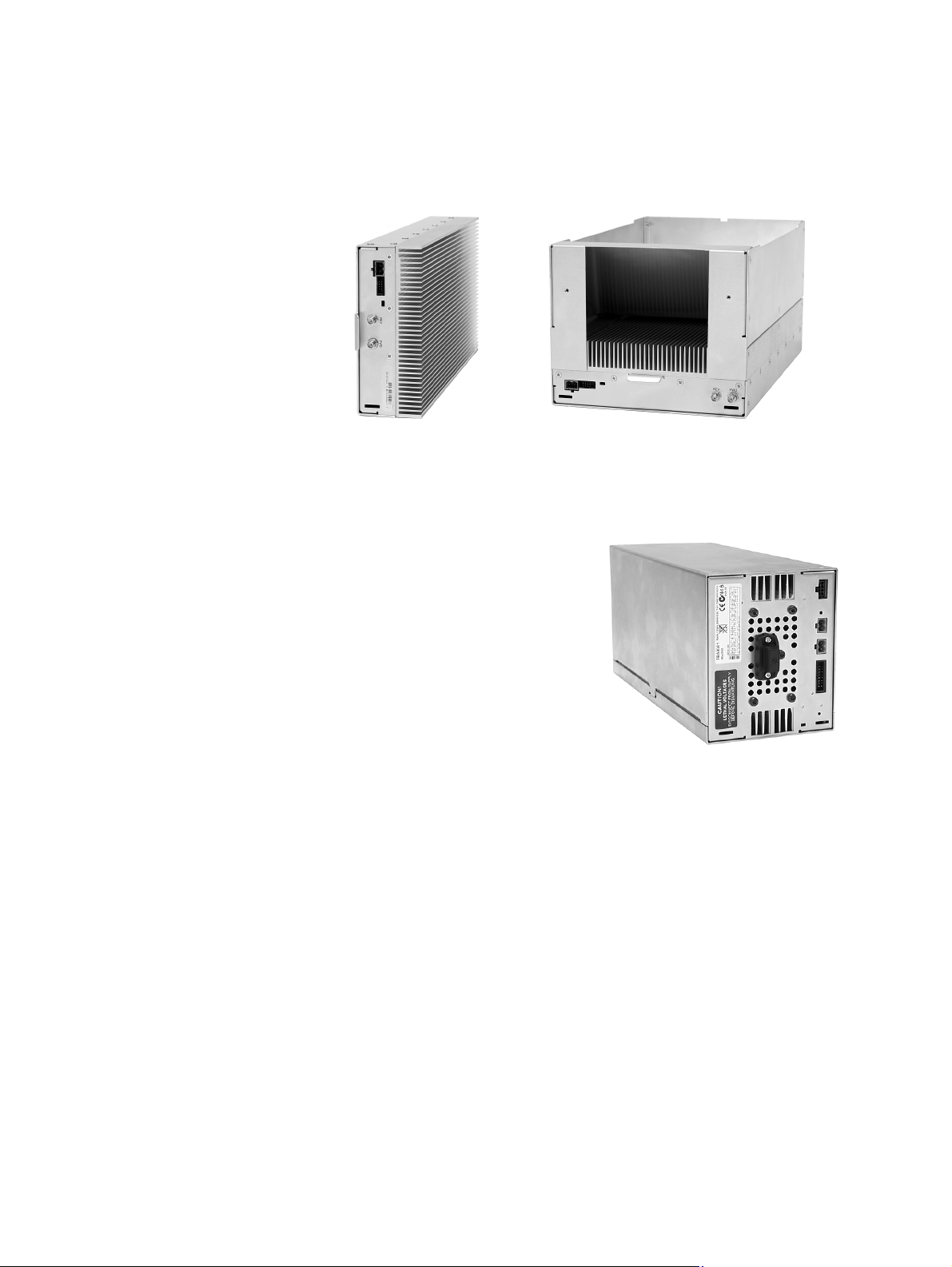

reciter receiver

12 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 13

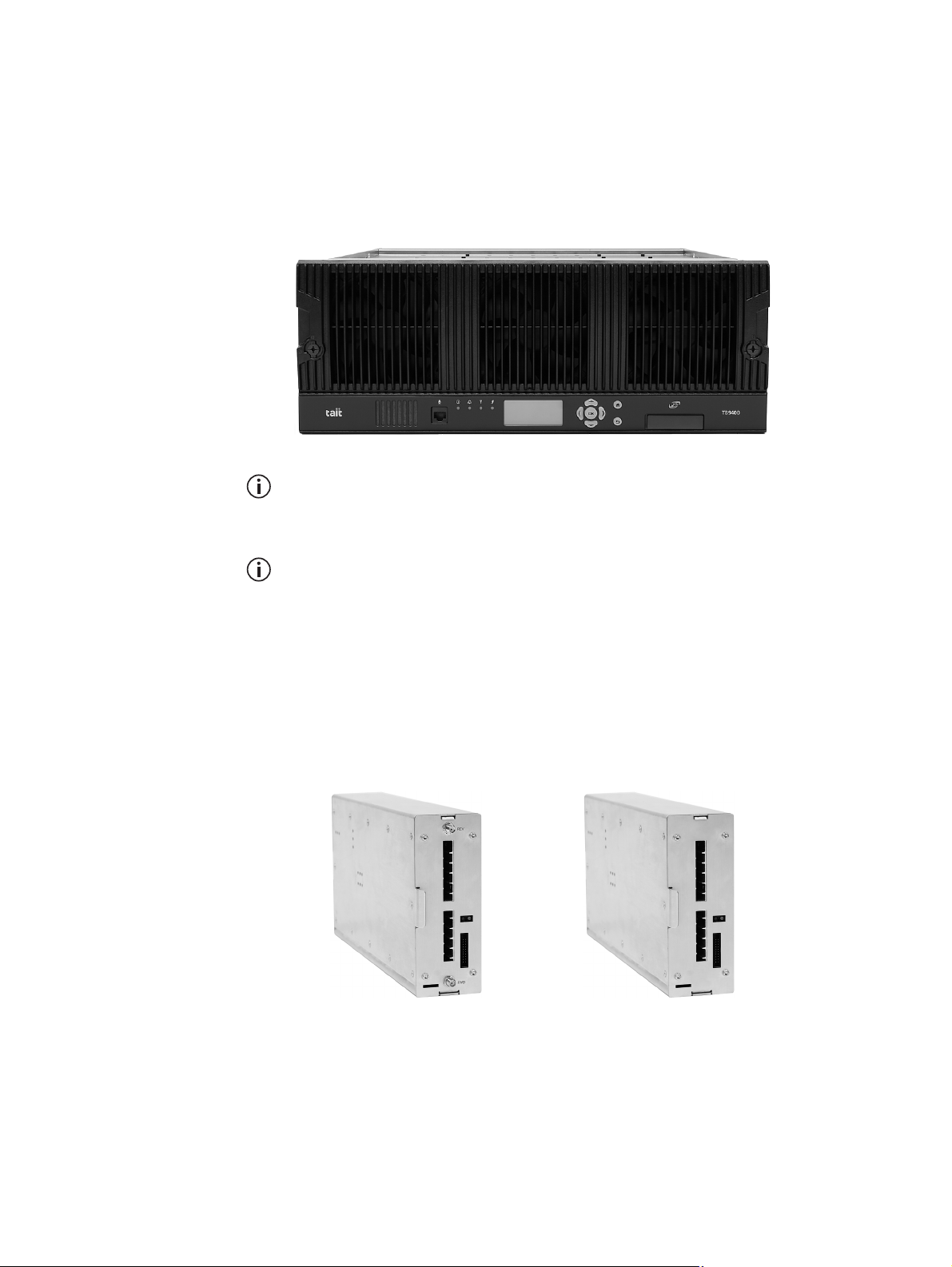

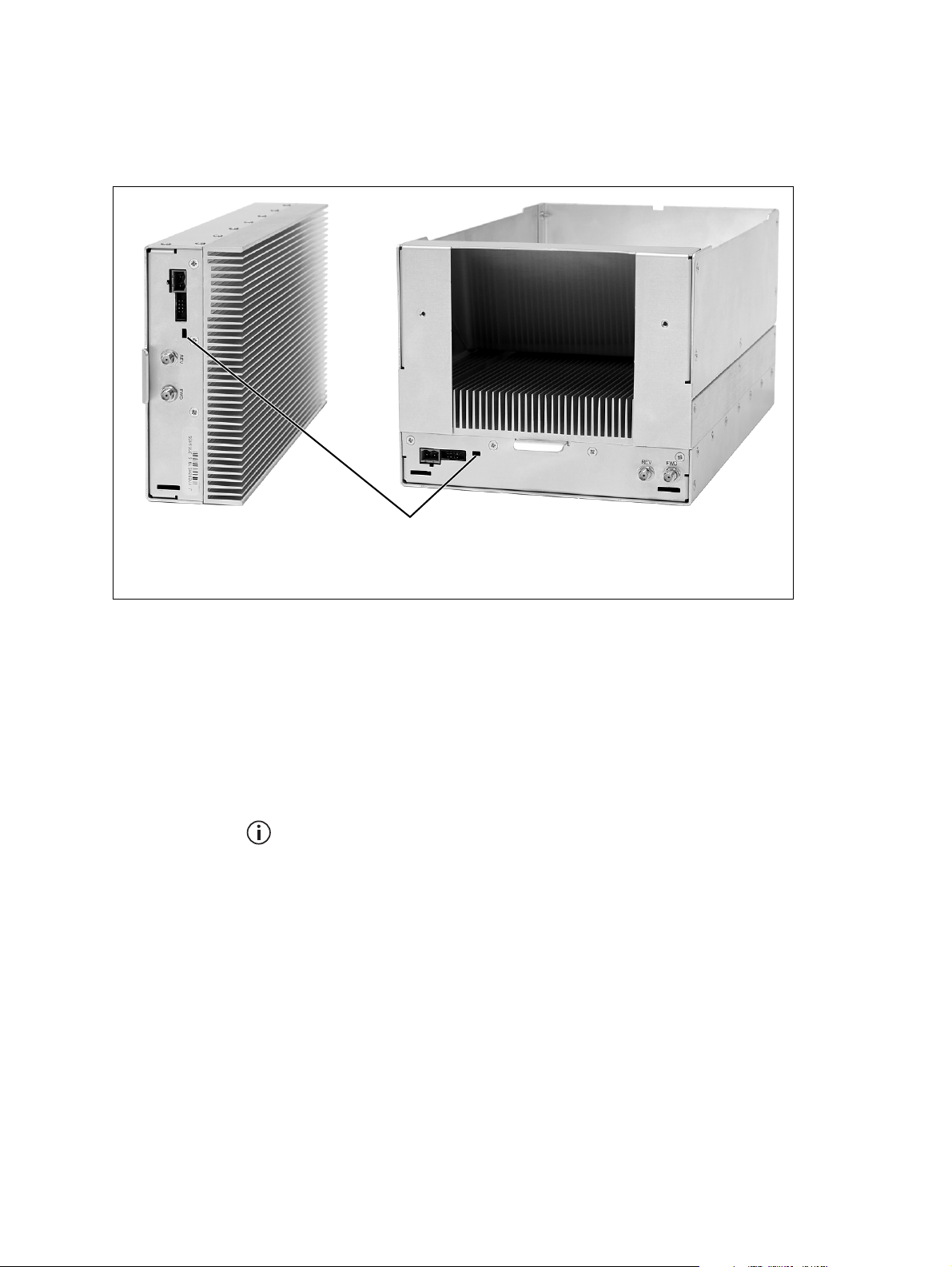

Power Amplifier

The PA amplifies the RF output from the reciter and is available in 50W

and 100W models.

The 50W model mounts vertically in the subrack, while the 100W model

mounts horizontally as it has a wider heatsink. The 100W PA is also fitted

with an airflow duct.

50W PA 100W PA

Both models are designed to operate on the 28VDC output provided by the

PMU. PAs are not required in a receive-only base station.

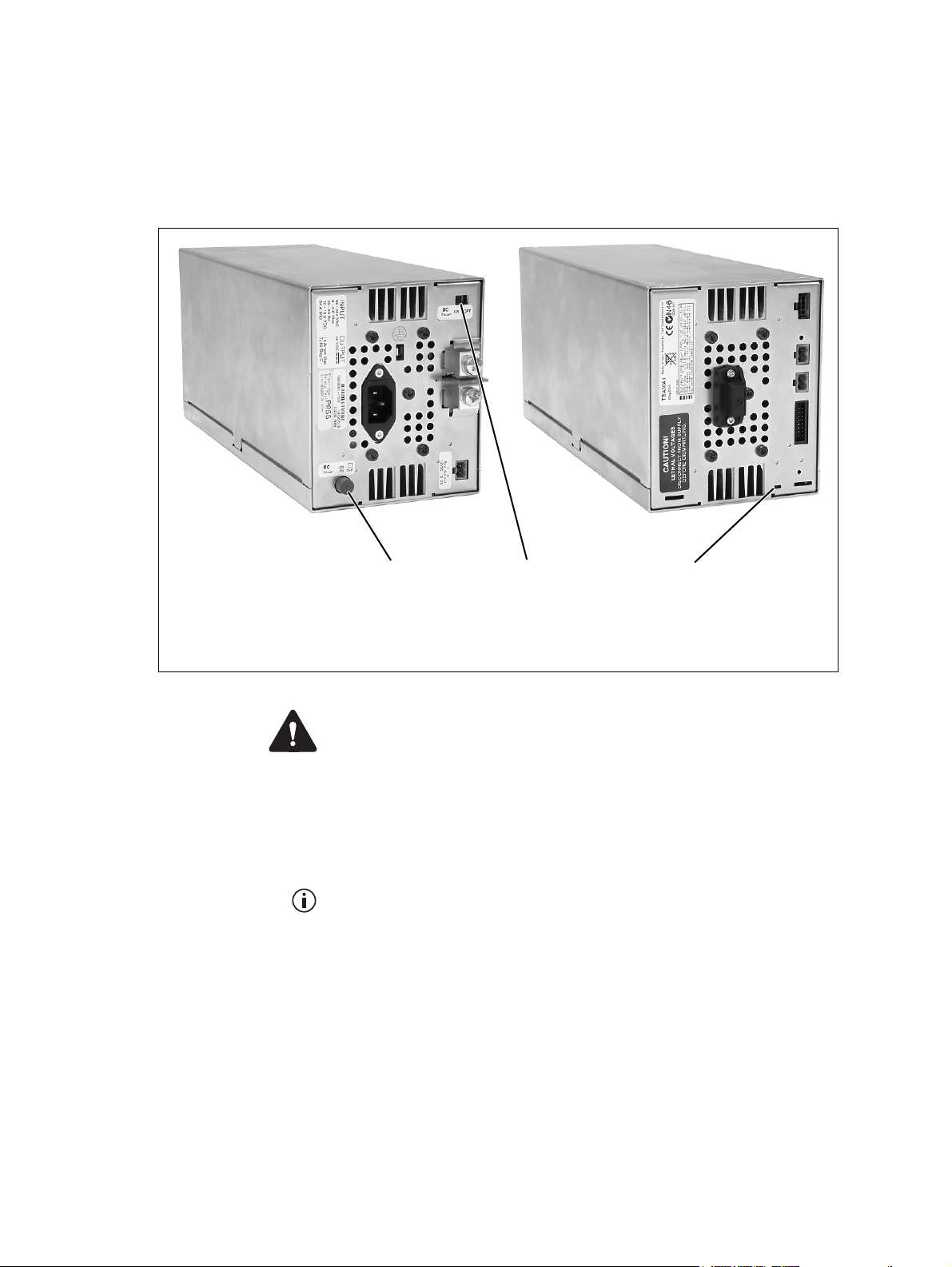

Power Management

Unit

The PMU provides the 28VDC

power supply for the modules in the

subrack. It can operate on

120/230VAC 50/60Hz nominal, and

12, 24 or 48VDC nominal. The input

voltage can be AC, DC, or both AC

and DC, depending on the model. The

PMU also has an auxiliary DC output

of 13.65VDC, 27.3VDC, or

54.6VDC, depending on the model.

AC and DC PMU shown

TB9400 Installation and Operation Manual Description 13

© Tait International Limited November 2018

Page 14

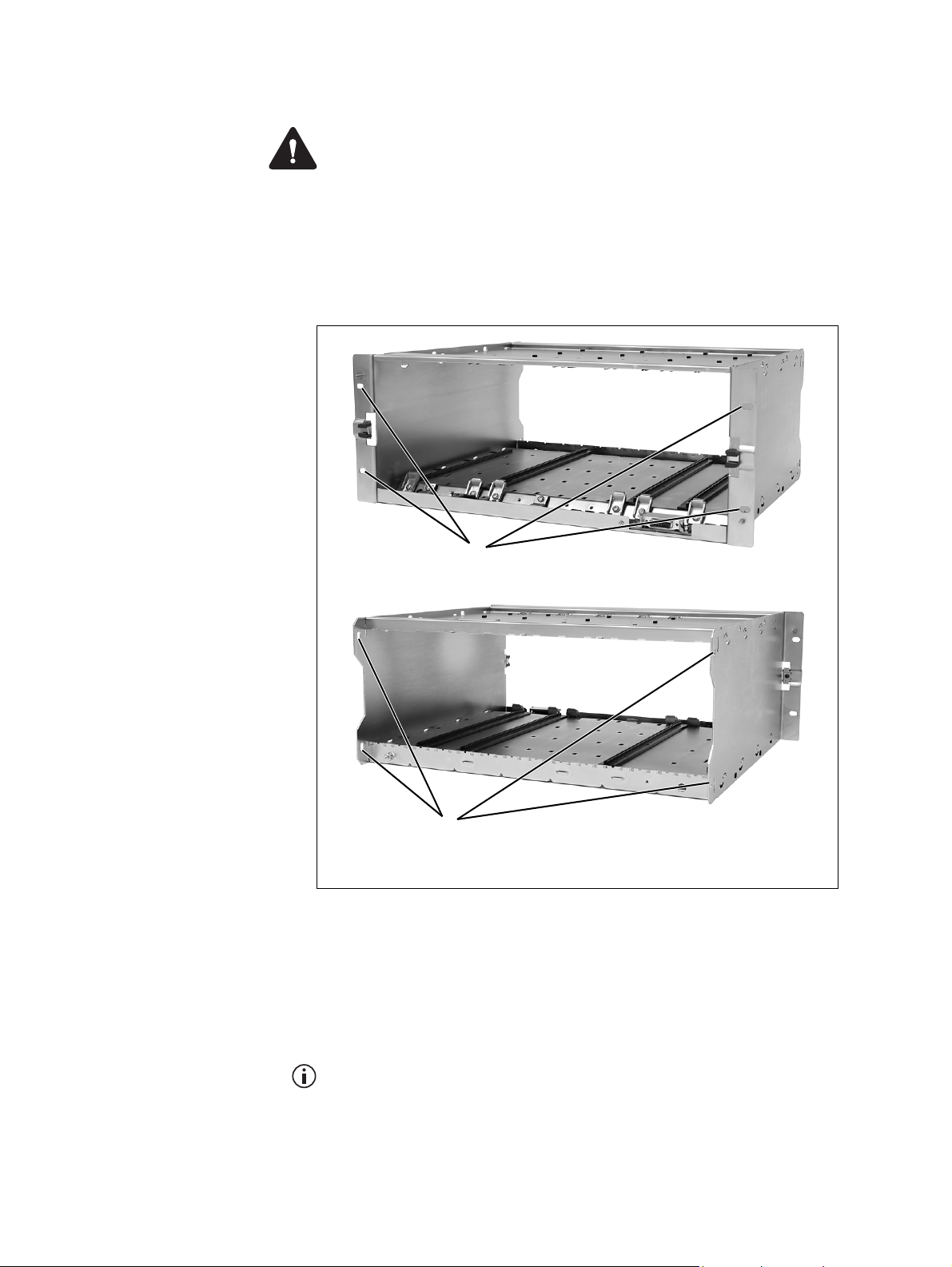

1.3 Mechanical Assembly

This section illustrates the main mechanical components of the base

station.

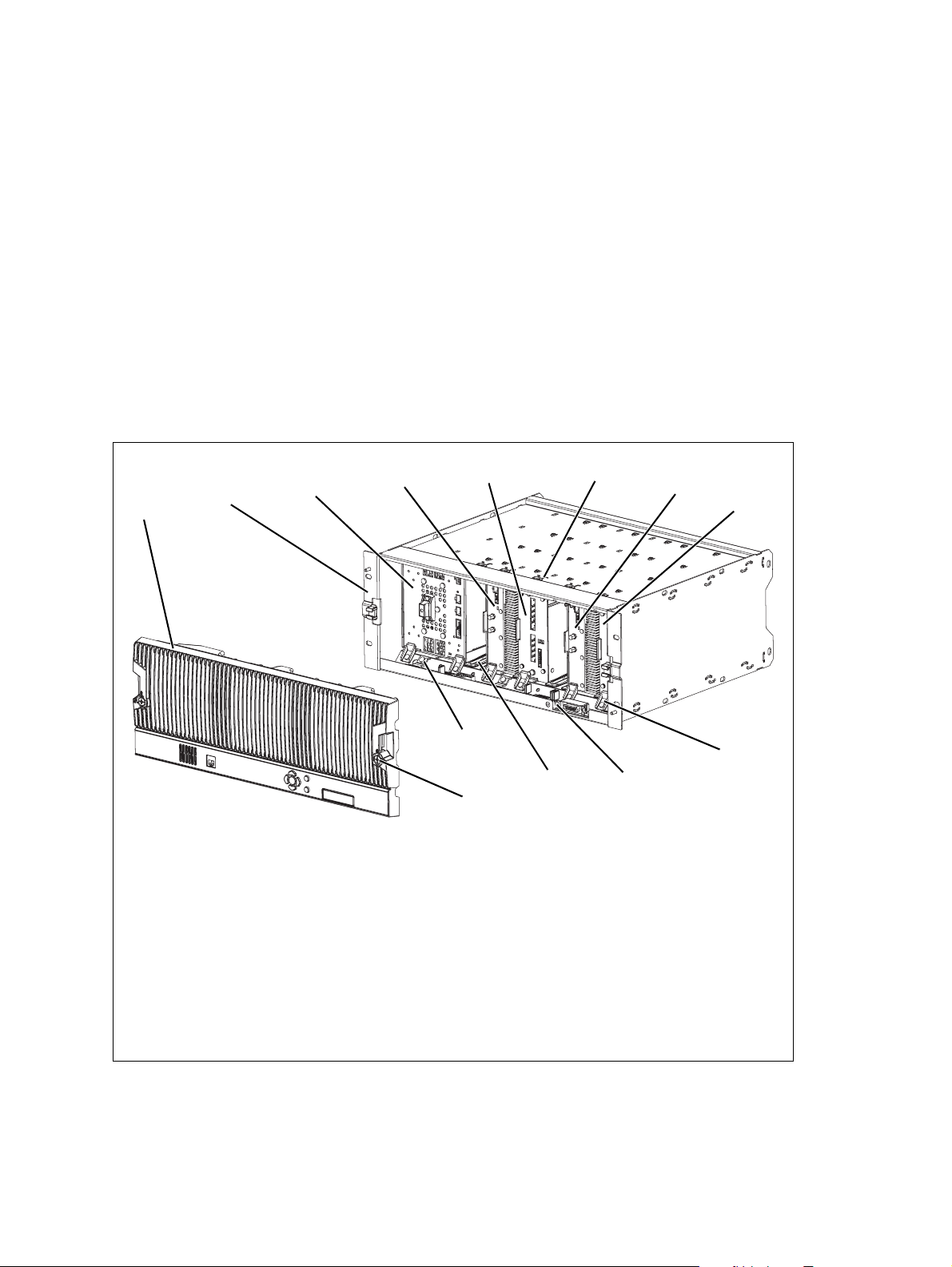

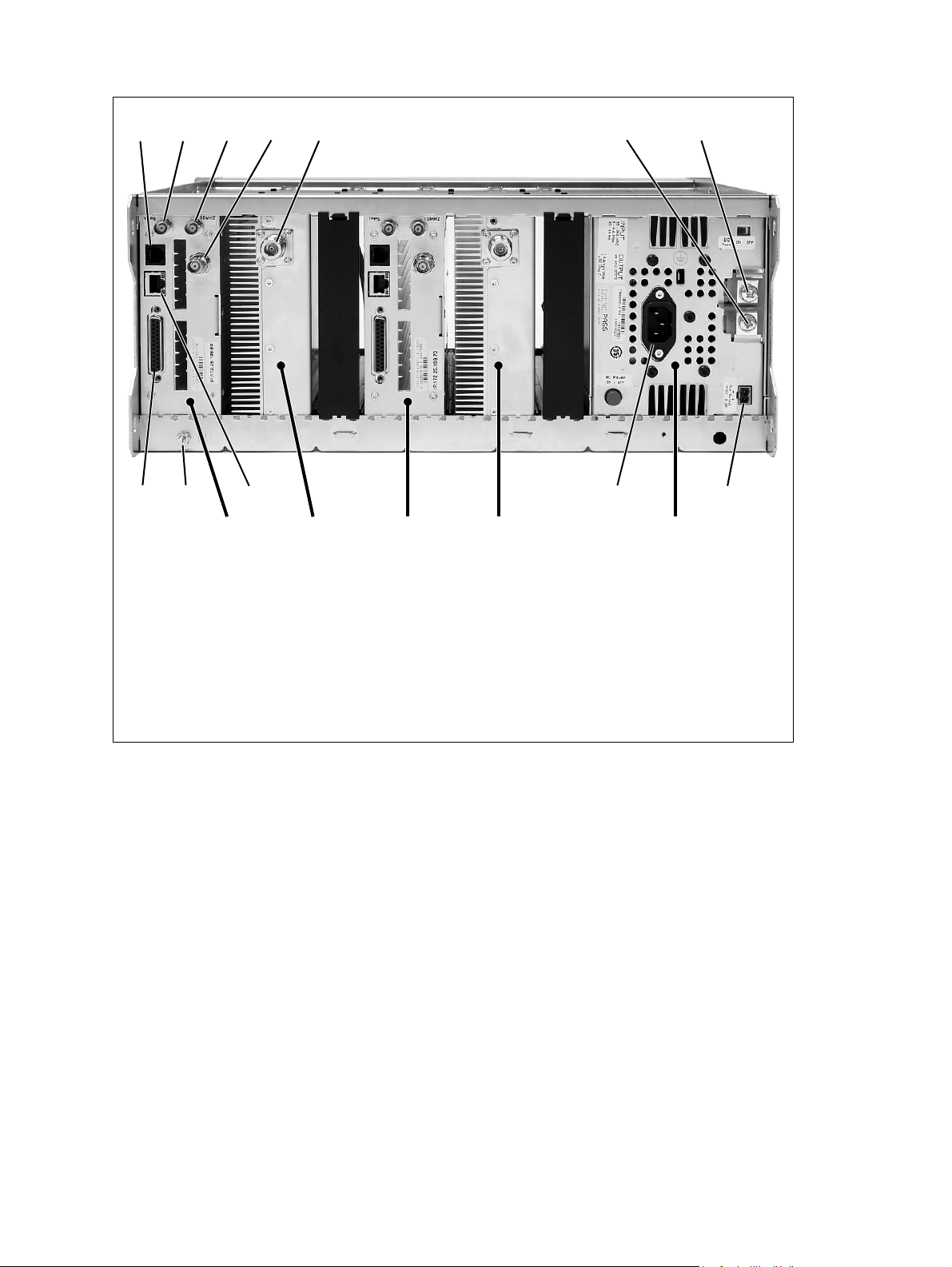

Figure 1.1 below shows the configuration for a typical dual 50W base

station. The subrack has six slots, numbered from right to left as viewed

from the front of the subrack. The PMU occupies slots 5 and 6, with the

reciter and PA pairs to the right of it in slots 1 to 4. Each PA is mounted

vertically with its heatsink facing its associated reciter. The PMU and each

reciter/PA pair have their own cooling fans.

The front panel can be easily removed from the subrack by undoing two

quick-release fasteners. Refer to “Replacing Modules” on page 105 for

more details.

Figure 1.1 Mechanical assembly - dual 50W base station with front panel

b

c

.

g

d

e

f

1@

1!

1#

front panel

b

subrack

c

PMU

d

PA 2

e

reciter 2

f

cable retaining clip

g

PA 1

h

reciter 1

i

module retaining clamp

j

subrack interconnect board

1)

plastic guide rail

1!

subrack interconnect board retaining clamp

1@

front panel fastener

1#

h

i

j

1)

14 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 15

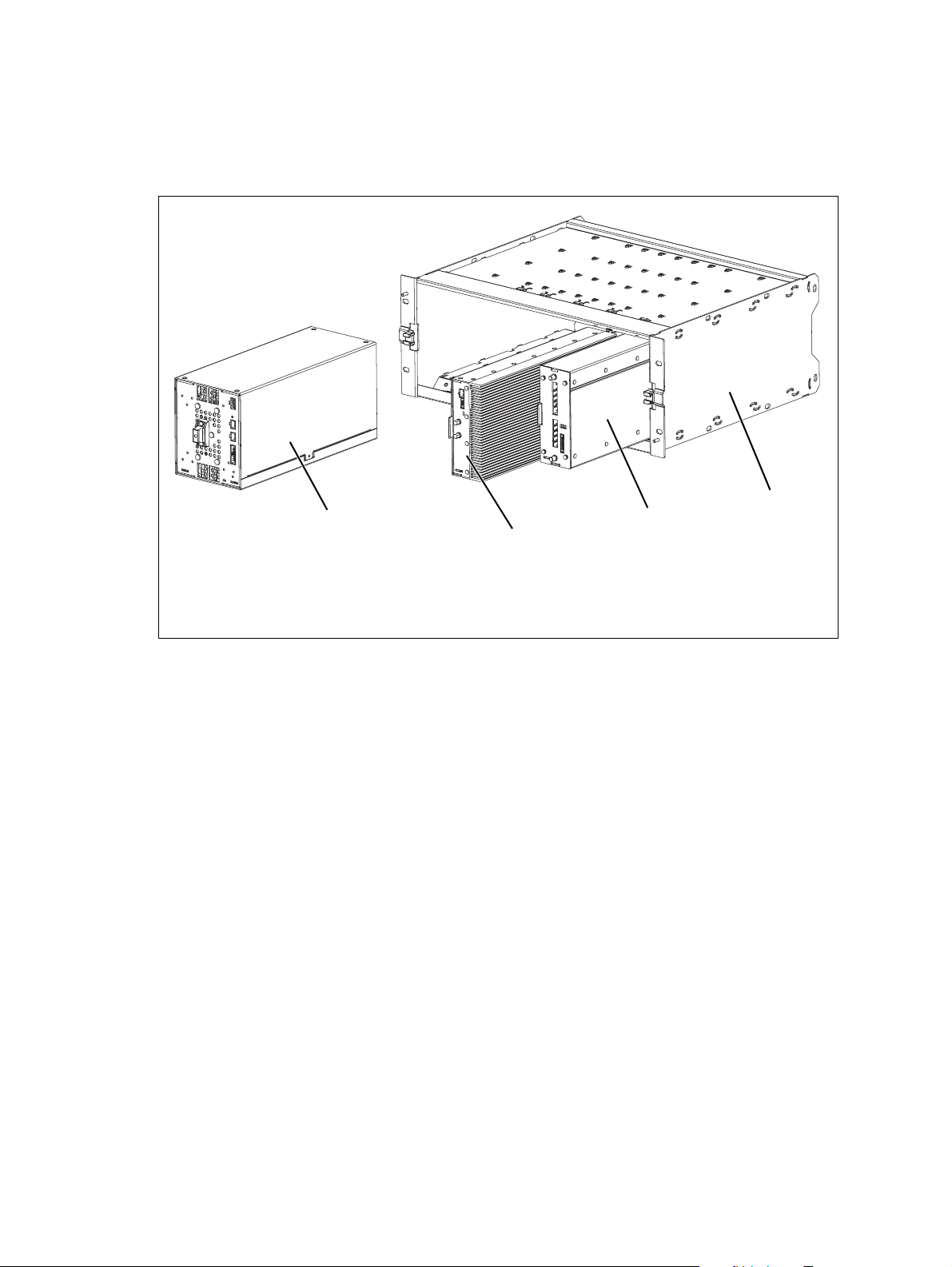

Figure 1.2 below shows the configuration for a typical single 50W base

station. The PMU again occupies slots 5 and 6, with the reciter in slot 1 and

PA in slot 2. The PA is mounted vertically with its heatsink facing the

reciter. The PMU and the reciter/PA pair have their own cooling fans.

Figure 1.2 Mechanical assembly - single 50W base station

b

c

PMU

50W PA

b

c

d

e

e

d

reciter

subrack

TB9400 Installation and Operation Manual Description 15

© Tait International Limited November 2018

Page 16

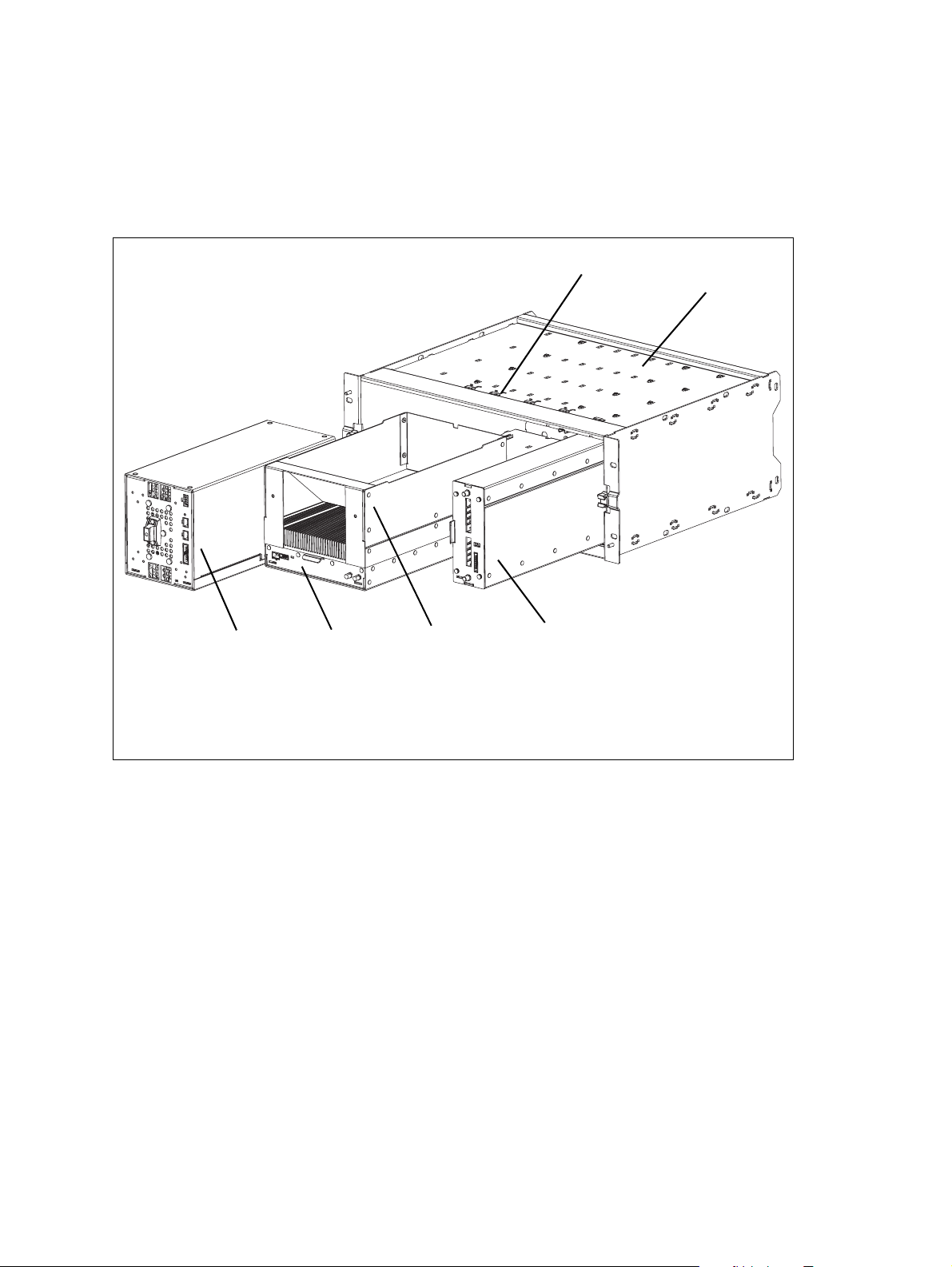

Figure 1.3 below shows the configuration for a typical 100 W base station.

The PMU occupies slots 5 and 6, with the PA directly beside it in slots 3

and 4. The reciter occupies slot 1. Unlike the 50W PAs, the 100W PA is

mounted horizontally with the heatsink facing upwards. It is also fitted with

an airflow duct to channel the airflow from the cooling fan through the

heatsink fins.

Figure 1.3 Mechanical assembly - single 100W base station

g

f

PMU

b

PA

c

airflow duct

d

b

c

d

e

reciter

e

subrack

f

cable retaining clip

g

16 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 17

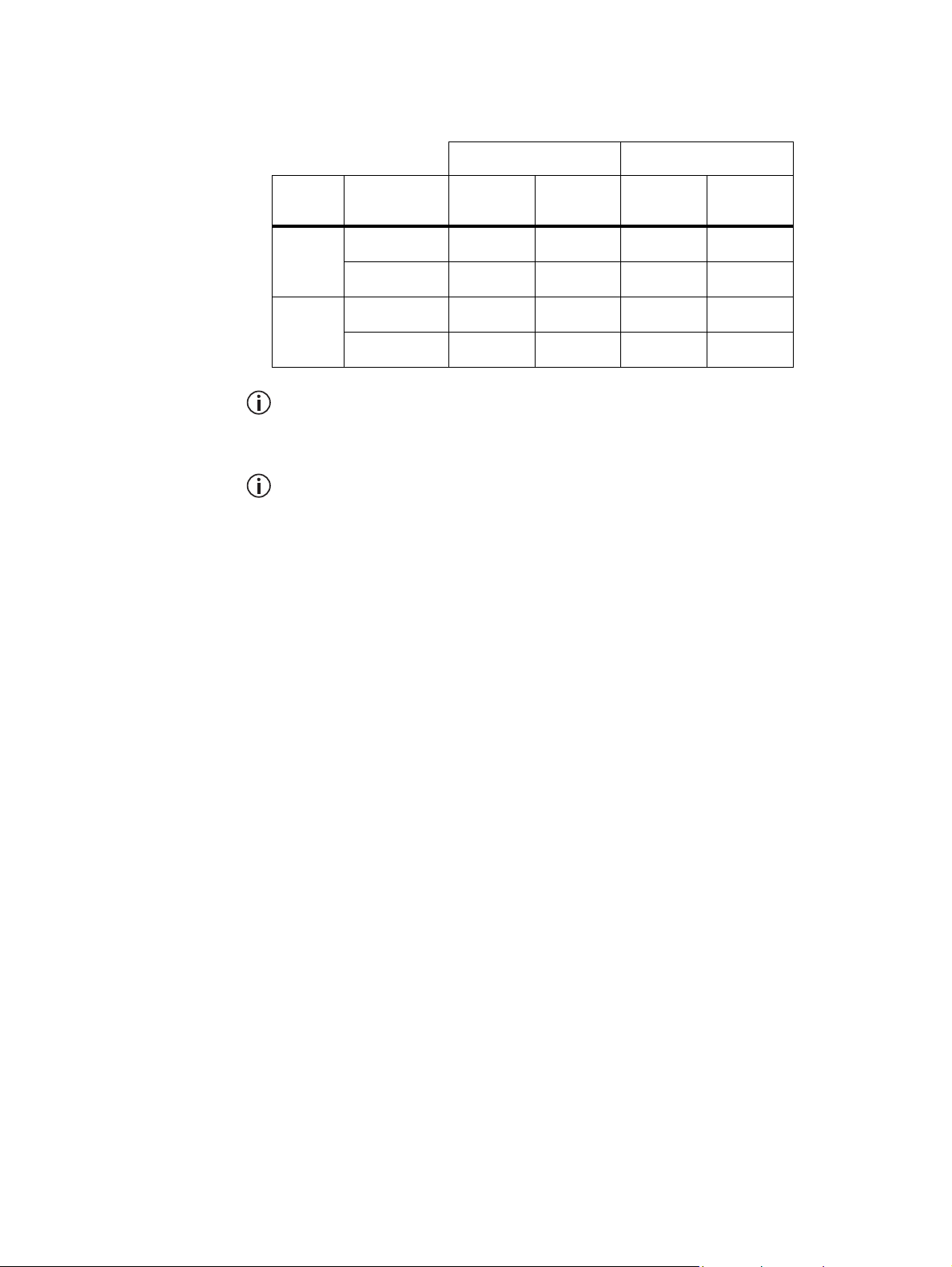

1.4 Frequency Bands and Sub-bands

Much of the circuitry in the base station is common to all frequency bands,

and is therefore covered by a single description in this manual. In some

cases the descriptions refer to specific bands or sub-bands, and these are

identified with the letters listed in the following table.

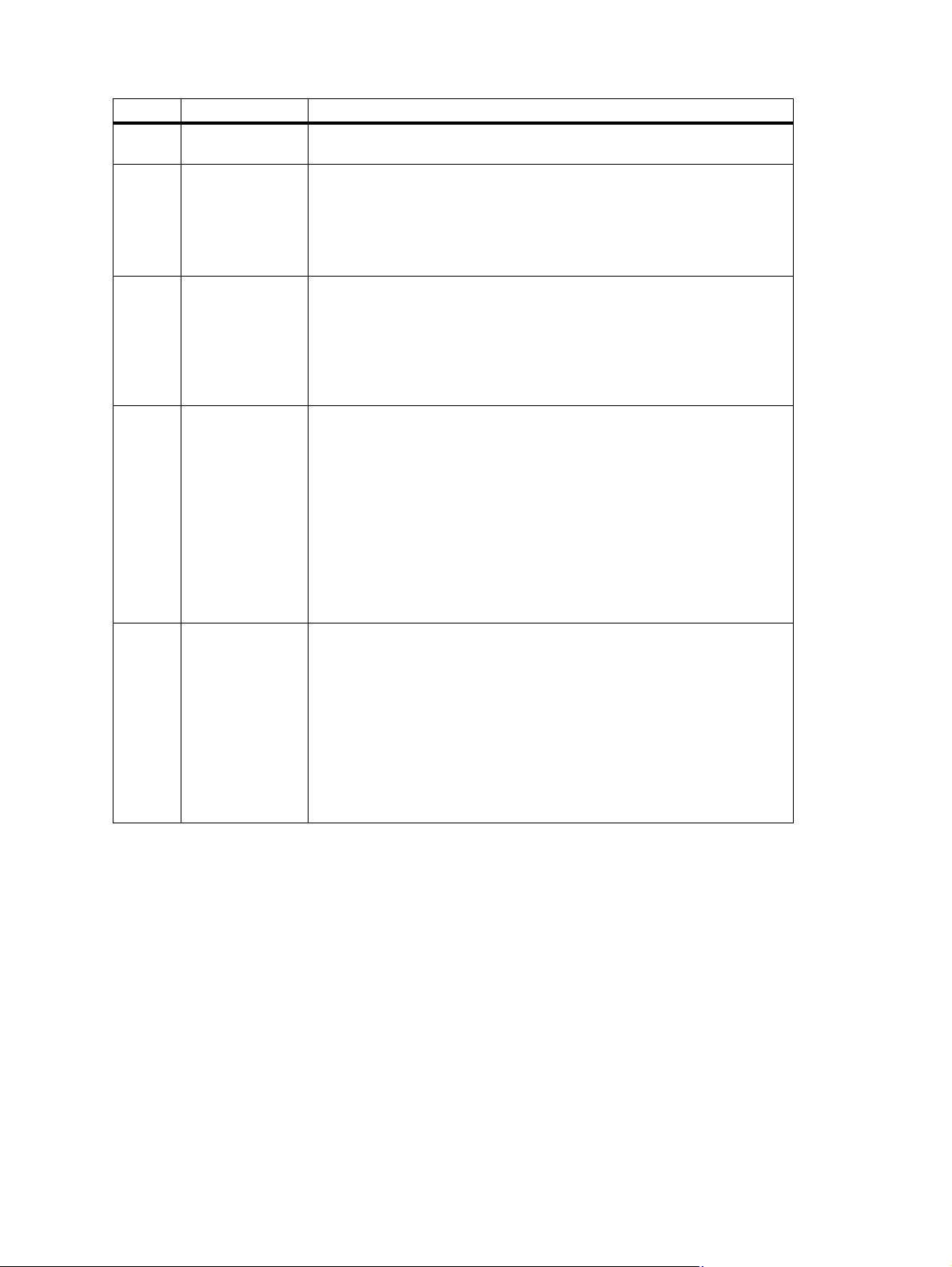

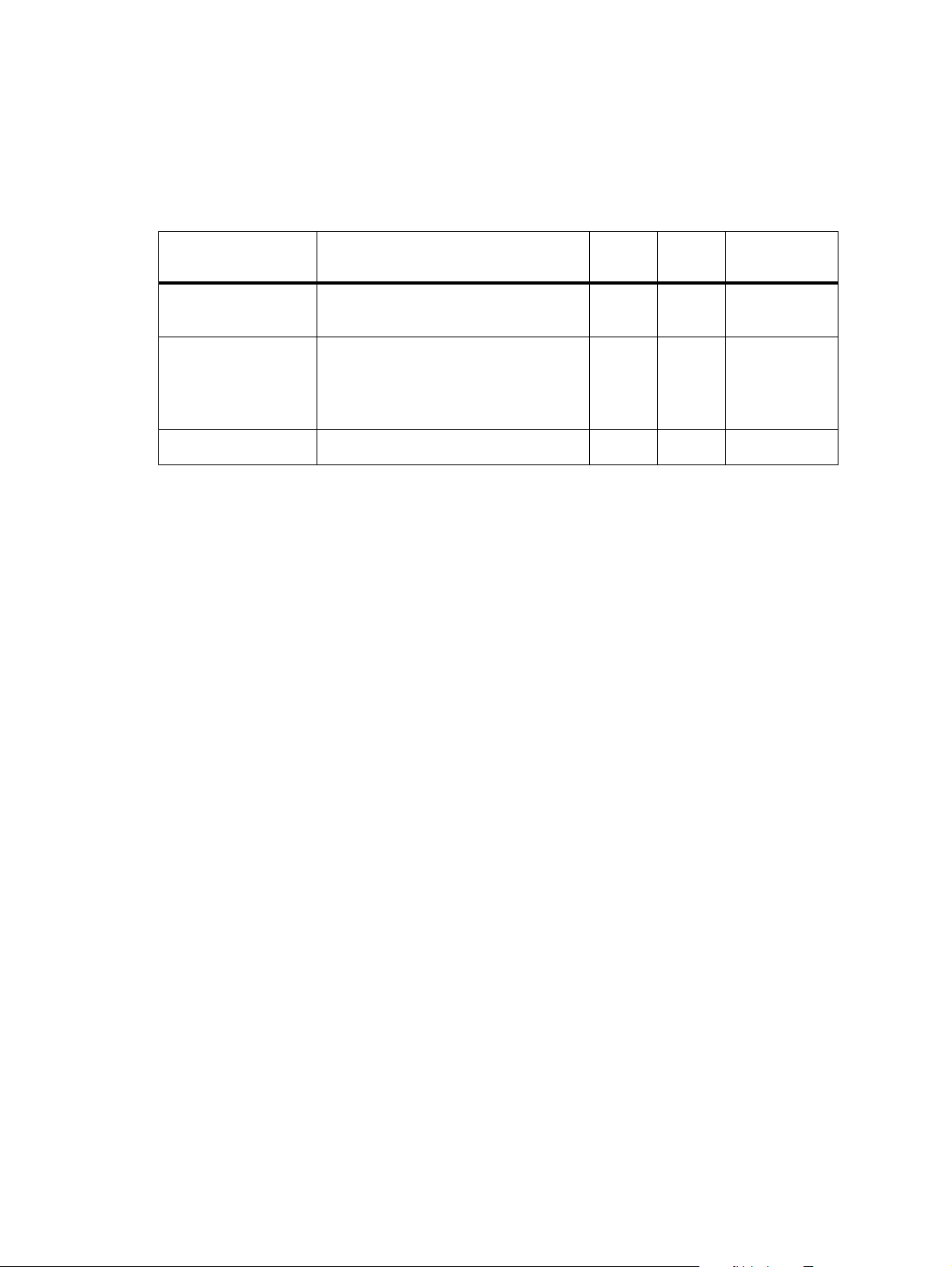

Frequency

Identification Frequency Band and Sub-band 50W 100W Receive-only

B band B2 = 136MHz to 156MHz

B3 = 148MHz to 174MHz

H band HH = 378MHz to 420MHz

H1 = 400MHz to 440 MHz

H2 = 440MHz to 480 MHz

H3 = 470MHz to 520 MHz

K band K4 = 762 MHz to 870MHz

a. The actual frequency coverage in this band is:

Transmit: 762MHz to 776 MHz, and 850 MHz to 870 MHz

Receive: 794MHz to 824MHz

In Brazil, for K band, the TB9400 is considered to be configured as a base

station with retransmission of received signals.

✓

✓

✓

✓

✓

✓

a

✓✓ ✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

TB9400 Installation and Operation Manual Description 17

© Tait International Limited November 2018

Page 18

1.5 Applications

The TB9400 operates in P25 trunked networks (Phase 1 or Phase 2), P25

conventional networks and analog conventional networks. It operates as a

stand-alone repeater/base station, or as part of a channel group, providing

receiver voting and simulcast transmission. All air interfaces and system

types support simulcast operation.

In P25 Phase 2 operation, a single TB9400 base station can provide two

traffic channels, since each radio frequency (physical channel) provides

two logical channels (timeslots). However, it can provide only one control

channel, since control channels are still P25 Phase 1.

In a trunked simulcast network, the transmitters in the channel group are

synchronized and transmit simultaneously on the same frequency. Each

transmitter needs a highly accurate 1PPS pulse and an external frequency

reference, so that it can time transmissions with the required accuracy. Also

required is an NTP source that is derived from the same source as the 1PPS

signal. This will ensure a common timestamp in logs across all units in the

system. An external frequency reference, along with an NTP source and

1PPS signal derived from the same GPS source, are also essential for all

reciters for P25 Phase 2 operation.

In a P25 conventional network, the TB9400 operates as a single or wide

area conventional repeater, with receiver voting and optional simulcast.

Dispatch connection is via two distinct interfaces:

■ P25 standard DFSI connection (up to three connections simultaneously)

■ Tait P25 Console Gateway, supporting conversion between P25 and

analog consoles with MDC1200 signalling

In an analog conventional network it can operate as a repeater with

CTCSS

The base station can also operate as part of an analog conventional

simulcast network and is fully IP-connected. The base station also features

an internally integrated voter, and therefore requires no external voter.

The base station can be provided as a receive-only variant in systems that

need sites to enhance the receive coverage. The receiver module in a

receive-only base station is physically unable to transmit.

For more information on these applications, refer to the Help and

appropriate Tait System Manual.

1

or DCS subaudible signaling.

1. Private Line (PL).

18 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 19

1.6 Licenses

Some operational functions of the base station are controlled by licenses.

These functions will not work unless you purchase the appropriate feature

license and enable the feature set controlled by that license. The feature sets

currently available are listed below.

Base stations can operate in distinct network tiers according to the feature

licences on the base station.

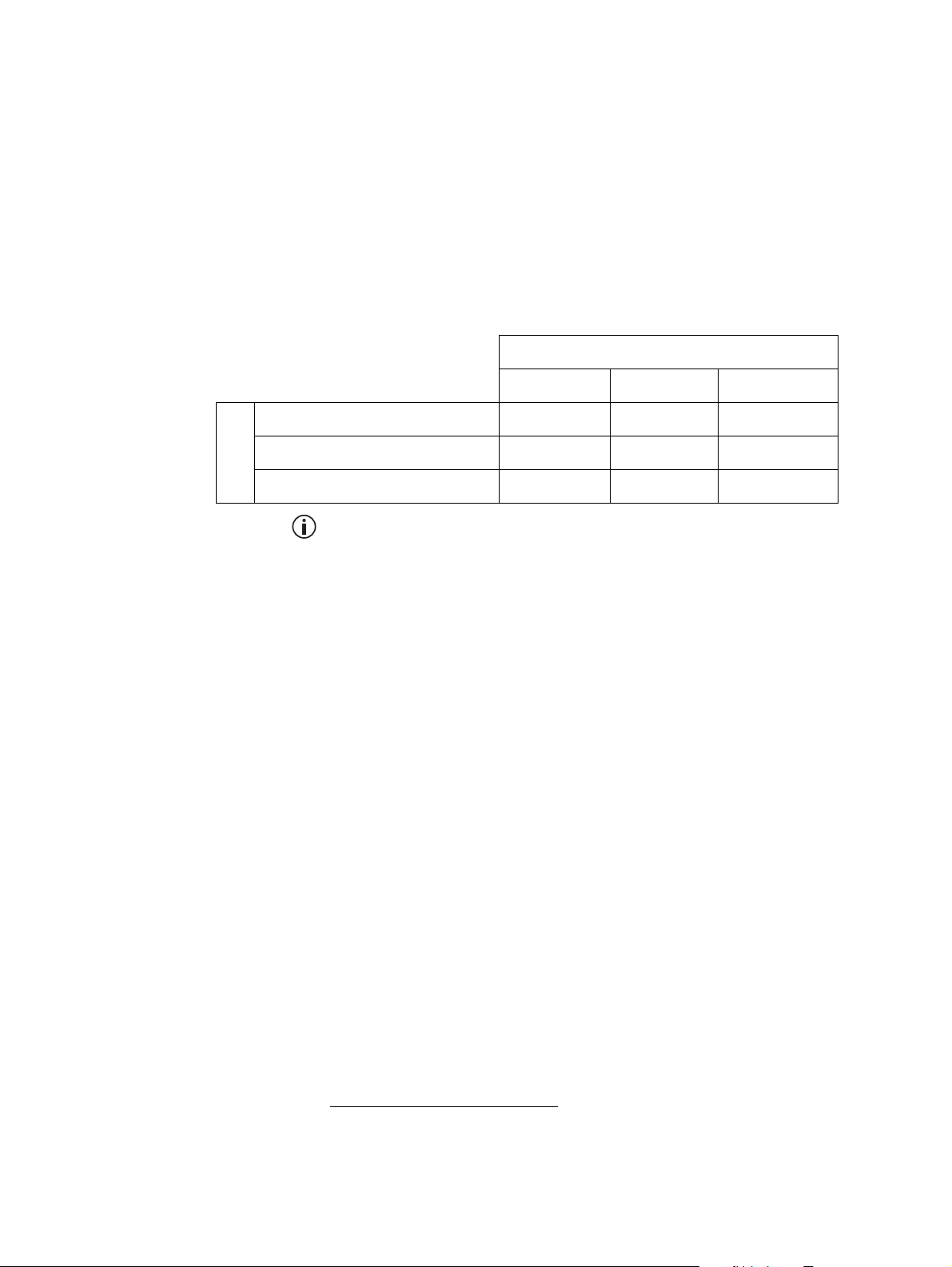

The compatibility rules are defined in the following table:

P25 Access Trunking Operation Compatible Not operate Not operate

P25 Express6 Trunking Operation Compatible Compatible Not operate

Site controller

Access Express6 Full system

P25 Trunking Operation Compatible Compatible Compatible

Base station

Analog Air Interface

(TBAS041 - Default

Licence)

P25 Common Air

Interface

(TBAS050)

P25 Trunking

Operation

(TBAS056)

Digital Fixed Station

Interface (TBAS060)

Central Voter

(TBAS061)

The central voter and satellite licences listed below are alternatives.

This is the licence that accompanies the base station. A base station with

this license can operate as a repeater in an analog conventional network.

Allows a base station to transmit and receive P25 Phase 1 C4FM digital

voice transmissions.

Allows a base station to become a trunking master, functioning as an

interface between the trunking site controller and the channel group.

Allows a base station (master or satellite) to have a TCCP connection

(control or status) to a trunking site controller.

Allows the base station to integrate with dispatch consoles supporting

DFSI (Digital Fixed Station Interface).

P25 and analog. This feature allows a base station to act as a central voter.

Simulcast

(TBAS062)

TB9400 Installation and Operation Manual Description 19

© Tait International Limited November 2018

This feature is required in base stations that have transmitters and belong

to a P25 Phase 1 simulcast or analog simulcast network

in the central voter of a simulcast channel.

1. Not needed for receive-only base stations.

2

1

. It is also required

Page 20

P25 Trunking

Failsoft

(TBAS063)

Linear Simulcast

Modulation

(TBAS065)

P25 Phase 2

Trunking

(TBAS066)

P25 Phase 2

Simulcast

(TBAS069)

Allows trunked channels that become isolated from a site controller to

perform simple conventional operation and to interface to a digital dispatch

system. If a trunked channel consists of several base stations in a channel

group, only the central voter (normally the master) needs this license. It is

then able to become the failsoft repeater for that channel group.

P25 only. Allows the base station to transmit using the LSM modulation

1

scheme

. This scheme allows increased site separation in simulcast

networks. Also requires the Simulcast license (TBAS062).

This feature allows the base station to operate in trunking mode using

two-slot TDMA as defined by the P25 Phase 2 standards.

This feature is required in base stations that have transmitters and belong

1

to a P25 Phase 2 simulcast network

of a P25 Phase 2 simulcast channel

. It is also required in the central voter

2

. Also requires the P25 Phase 2

Trunking (TBAS066) and Simulcast (TBAS062) licenses. Tait also

recommends adding the Linear Simulcast Modulation (TBAS065) license

as it provides improved RF performance.

P25 Access

Trunking Operation

(TBAS070)

IP Networking

Satellite

(TBAS071)

P25 Express6

Trunking Operation

(TBAS072)

Enables single site P25 trunking.

All system types and all air interface types. This feature allows a base

station to be part of a channel group without requiring the Central Voter

(TBAS061) license.

Enables P25 trunking with up to 6 sites.

2. The central voter in a simulcast channel needs the respective Phase 1 or

Phase 2 simulcast license. Normally, a transceiver member of a simulcast

channel will have a simulcast license, so this constraint should not be an

issue.

20 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 21

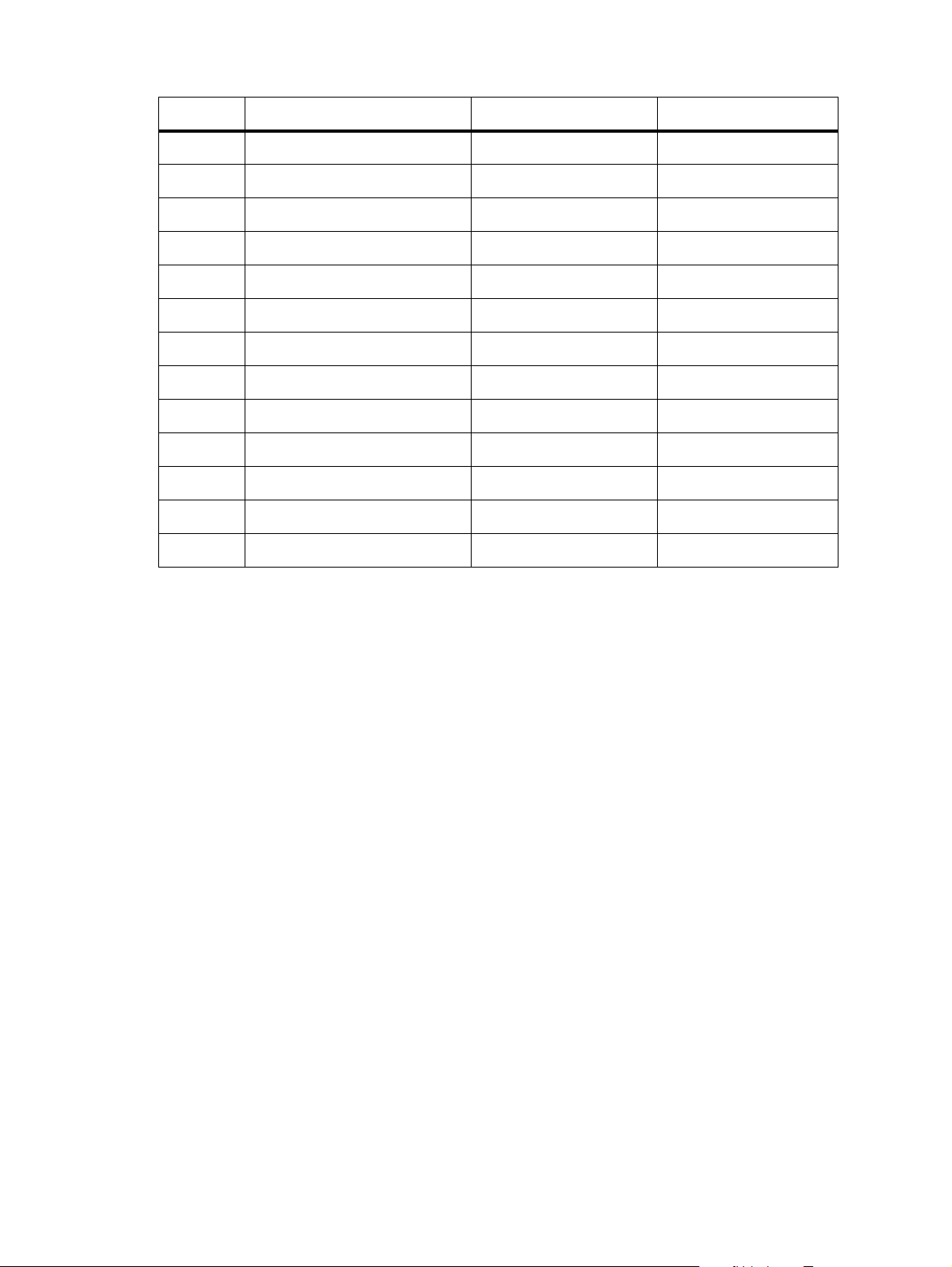

Table 1.1 Licenses and applicability

Licence Name Air Interface System Type

TBAS041 Analog Air Interface Analog Conventional

TBAS060 Digital Fixed Station Interface Analog & P25 Phase 1 Conventional

TBAS061 Central Voter Analog & P25 Phase 1 & 2 Trunked, Conventional

TBAS071 IP Networking Satellite Analog & P25 Phase 1 & 2 Trunked, Conventional

TBAS062 Simulcast Analog & P25 Phase 1 & 2 Trunked, Conventional

TBAS050 P25 Common Air Interface P25 Phase 1 & 2 Trunked, Conventional

TBAS065 Linear Simulcast Modulation P25 Phase 1 & 2 Trunked, Conventional

TBAS056 P25 Trunking Operation P25 Phase 1 & 2 Trunked

TBAS063 P25 Trunking Failsoft P25 Phase 1 & 2 Trunked

TBAS066 P25 Phase 2 Trunking P25 Phase 1 & 2 Trunked

TBAS070 P25 Access Trunking Operation P25 Phase 1 & 2 Trunked

TBAS072 P25 Express6 Trunking Operation P25 Phase 1 & 2 Trunked

TBAS069 P25 Phase 2 Simulcast P25 Phase 2 Trunked

TB9400 Installation and Operation Manual Description 21

© Tait International Limited November 2018

Page 22

1.7 Theory of Operation

The reciter receives RF signals from its RF input and sends RF from its RF

output to the PA, along with a PA key signal. The PA sends an RF feedback

signal to the reciter for linearization and power control purposes. The

reciter also receives signals from, and sends signals to, the system

interface, the Ethernet interface, and the front panel (see Figure 1.4).

A system control bus interconnects the modules and carries alarm and

control signaling between the reciter and the other modules (refer to

“Intermodule Communications” on page 25 for more details).

The Ethernet interface carries voice over IP and also allows maintainer

access via a web browser.

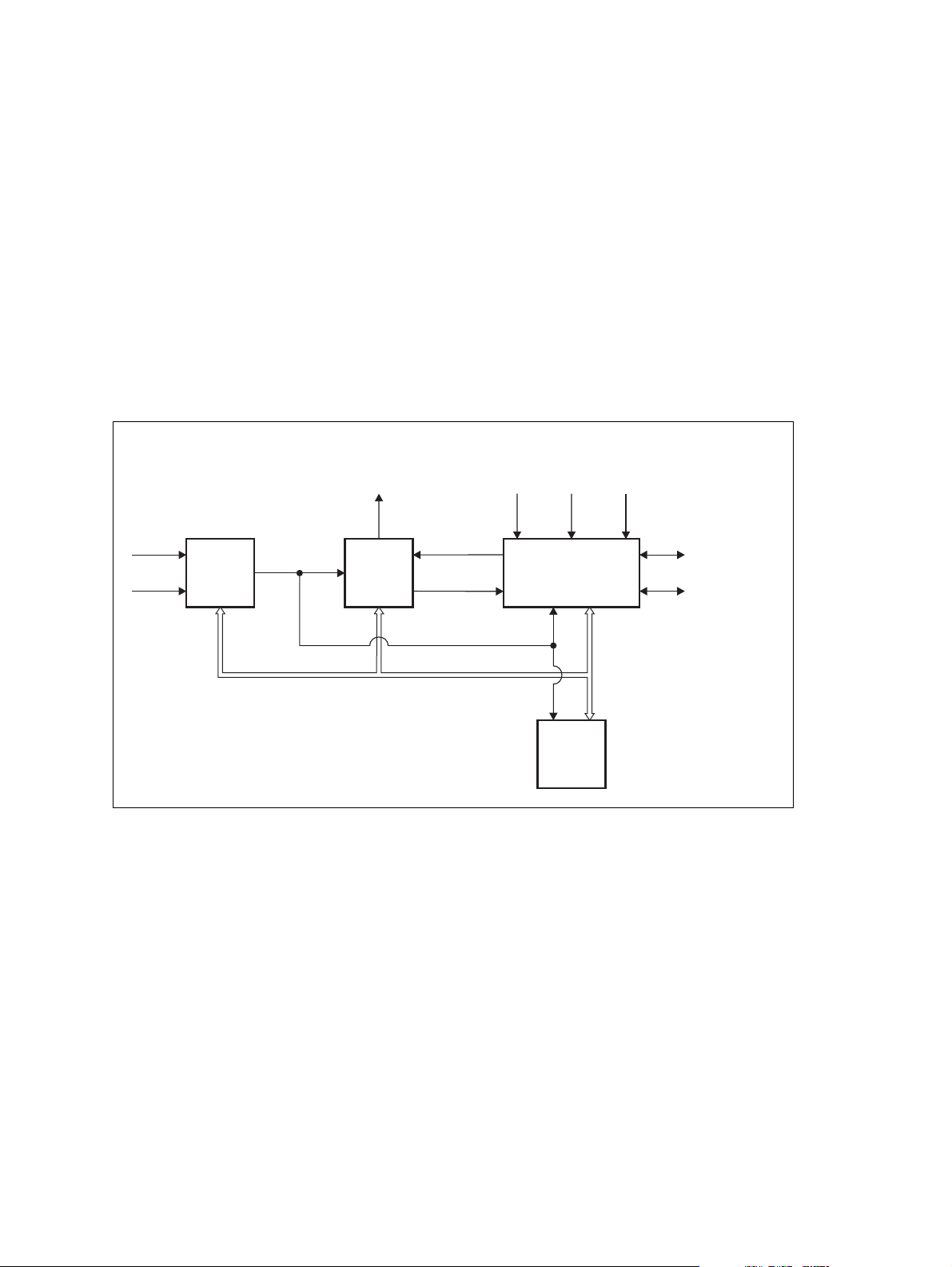

Figure 1.4 Base station high-level diagram

RF To

Antenna

AC Input

DC Input

A receive-only base station has a receiver instead of a reciter,

and does not have a PA.

PMU

28VDC

PA

System Control Bus

RF+PAKey

RF Feedback

RF From

Antenna

1PPS

Reciter

Front

Panel

External

Reference

Frequency

System Input

and Output

Ethernet Interface

to Network

22 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 23

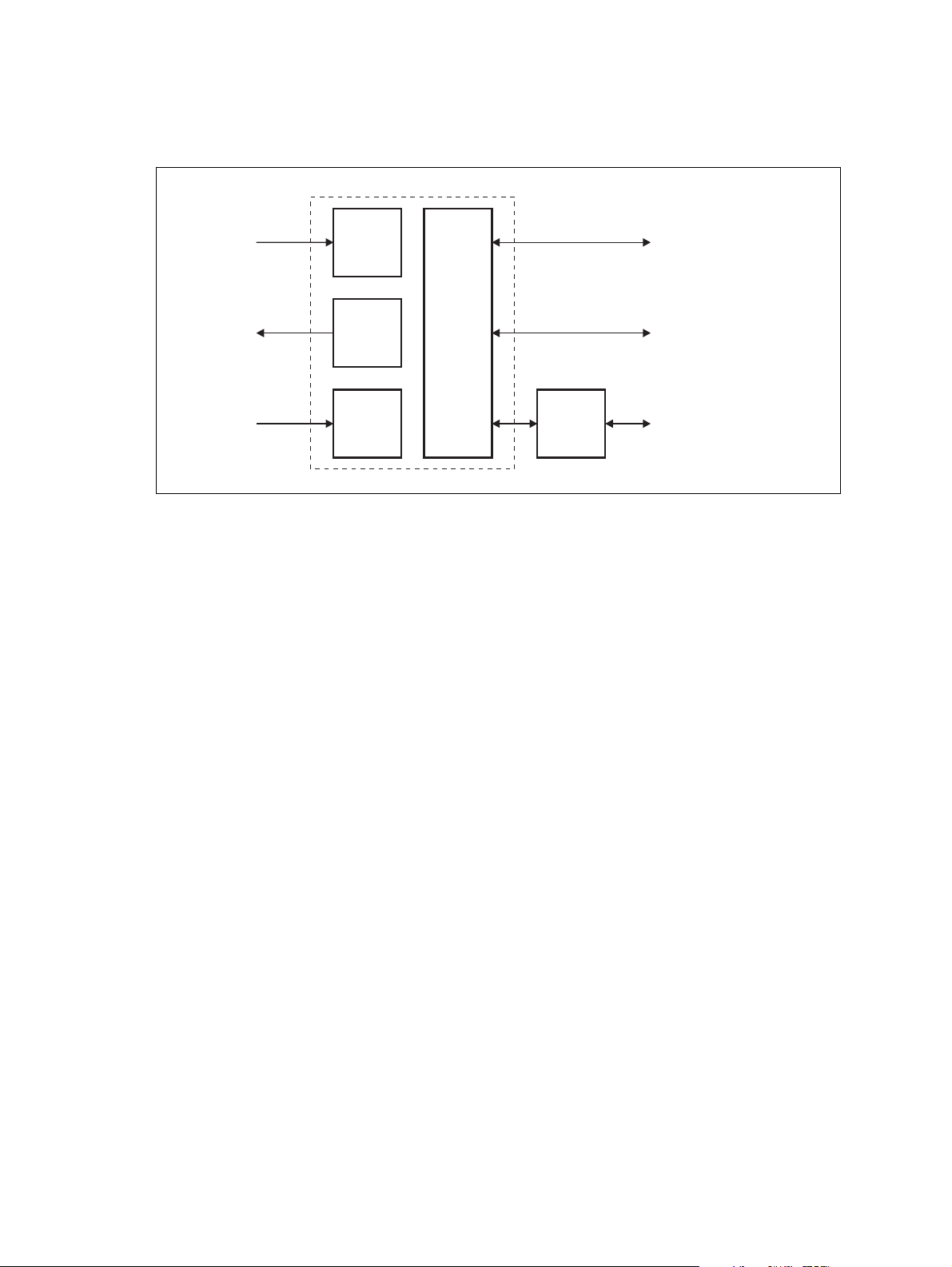

The reciter carries out signal processing and has overall control of the base

station. Its circuit boards are shown in Figure 1.5.

Figure 1.5 Reciter boards

RF Input

RF Output

RF Input

(feedback

from PA)

Receiver

Board

Transmit

Forward

Board

Transmit

Reverse

Board

Reciter

Control

Board

Front

Panel

System Input

and Output

Ethernet Interface

to Network

Maintainer Access

The receiver board contains all the receiver circuitry, while the exciter

circuitry is located on the transmit forward board.

The reciter control board converts information between analog and digital

and controls the maintainer’s access via the front panel. It performs the air

interface signal processing for digital P25 operation, gives the base station

an identity as a network element, and provides the physical connections for

the Ethernet and system interfaces.

TB9400 Installation and Operation Manual Description 23

© Tait International Limited November 2018

Page 24

1.7.1 Signal Paths

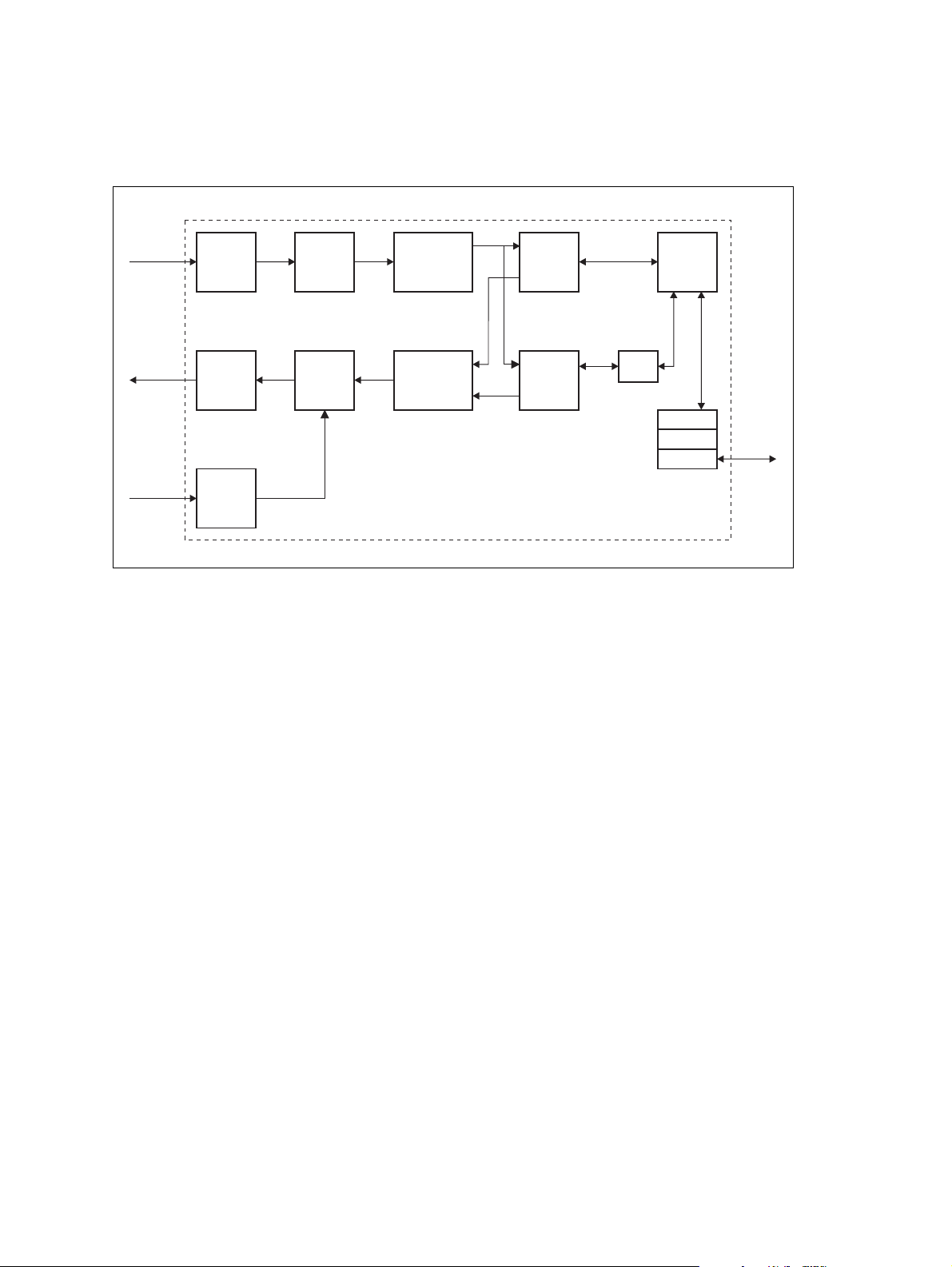

Figure 1.6 gives an overview of signal paths within the reciter.

Figure 1.6 Reciter signal paths

Receive

RF Interface

Demodulator

P25

Modem

ControlADC DDC

Transmit

RF Interface

Transmit

RF Interface

(feedback

from PA)

DAC

ADC

Cartesian

Loop

Modulator

FM

Baseband

Audio

G.711

Protocol

Stack

Reciter Control Board

RTP

UDP

IP

Ethernet

Interface

Digital P25 signals from the receive RF interface pass through the digital

receiver and P25 modem to the control software in the control processor.

The control software passes the signal through the Ethernet interface to the

site controller (P25 trunked networks), to the console gateway

(conventional networks), or for a satellite, to the central voter in a simulcast

system.

Input to the Ethernet interface can be from the site controller (P25 trunked

networks), from the console gateway (conventional networks), or from the

central voter in a simulcast system. These inputs are processed by the

control processor and passed through the P25 modem to the transmitter. If

the base station is itself a central voter, this input can also be a received

signal, which is voted on and sent back through the Ethernet interface to the

site controller.

1.7.2 Online and Offline Modes

The base station normally operates in Online mode, but you can put it into

Offline mode via its web interface.

Online Mode In Online mode, the base station is in service and performs its normal

functions of transmitting and receiving radio signals.

24 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 25

Offline Mode

Offline mode allows a maintenance engineer to carry out tasks that can not

be done while the base station is in service - such as activating firmware or

running diagnostic tests.

1.7.3 Intermodule Communications

A system control bus and a subrack interconnect board link the modules in

the subrack and carry alarm and control signaling between the reciter and

the other modules, as shown in Figure 1.7.

Specific configuration settings for dual base stations are described in

“Recommended Configuration Settings” on page 58.

Figure 1.7 Intermodule communication paths

PMU

2

I C Current

Source

mP

2

2

IC

Reciter 1

mP

RS-485

PA 1

mP

RS-485IC

Fan

FanFan

Fan 3:

PMU

Fan 1:

Reciter 1/

PA 1

User

Controls

Fan 2:

Reciter 2/

PA 2

Front Panel

Subrack Interconnect Board

mP

Reciter 2

RS-485RS-485 Fan

mP

PA 2

TB9400 Installation and Operation Manual Description 25

© Tait International Limited November 2018

Page 26

1.7.4 Power Management and Distribution

The PMU manages the supply of power to ensure uninterrupted operation

of the base station. A range of parameters is monitored and these can

trigger alarms that are sent to the reciter. Alarms can be monitored via the

web interface and reported via SNMP traps; they are also recorded in the

reciter’s internal log file.

AC to DC

Changeover

When the PMU has an AC and a DC module, the base station can be

powered by either the AC (mains) or the DC (battery) supply. The base

station will default to the AC supply if both supplies are provided. If the

AC supply becomes unavailable, a seamless changeover from the AC to

DC supply takes place, providing that the battery voltage is above the

configured minimum startup voltage. You can use a web browser to check

whether the base station is running on battery or mains power.

DC Operation When the base station is running off the DC supply and the battery voltage

falls below the configured minimum, the base station will enter battery

protection mode to protect the battery and base station equipment. The

standby power supply card maintains the power to the PMU

microprocessor, while the rest of the PMU is shut down. When the battery

voltage rises to the configured startup setting, power is resumed to the DC

supply. Refer to “PMU Operation on DC Input” on page 28 for more

detailed information.

Auxiliary Power

Control

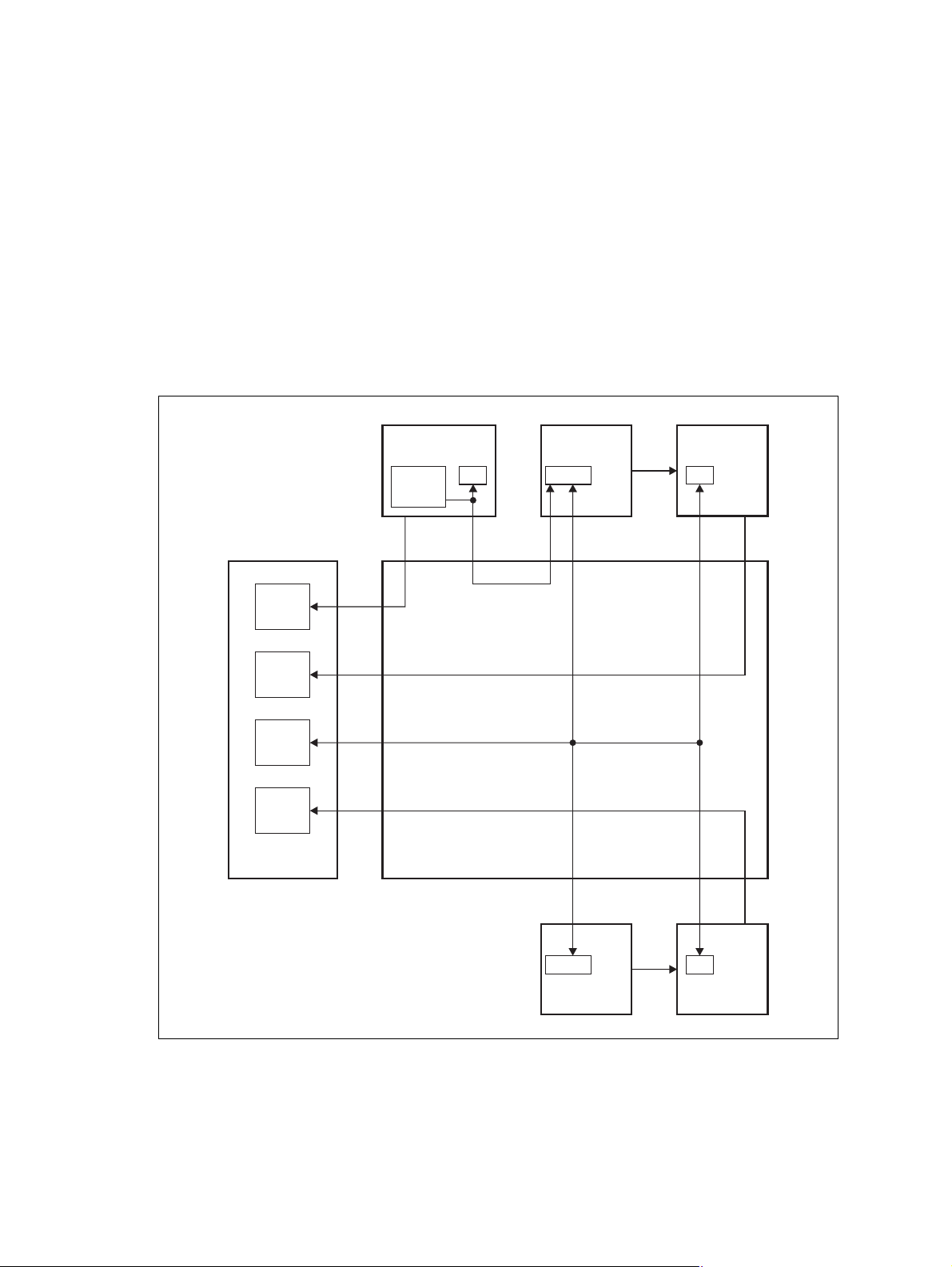

Distribution Figure 1.8 shows how power is distributed to modules in the subrack. The

The output from the auxiliary power supply board can be used to power

other site equipment. The maximum output is 40W.

28VDC output from the PMU is fed directly to the PA in a single base

station, or directly to PA 1 in a dual base station, and to the other modules

via the subrack interconnect board. Power to the reciters and front panel is

current-limited by self-resetting fuses on the subrack board.

The AC converter has a series switch which breaks the phase input to the

converter. The DC input, however, has much higher current ratings. Its

switch does not disconnect power from the DC converter itself, but disables

the converter by switching off its control circuitry.

The outputs from both the AC and DC high power converters are added

together and fed to the modules via the high-current outputs. The auxiliary

output is also tapped off this summed output.

26 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 27

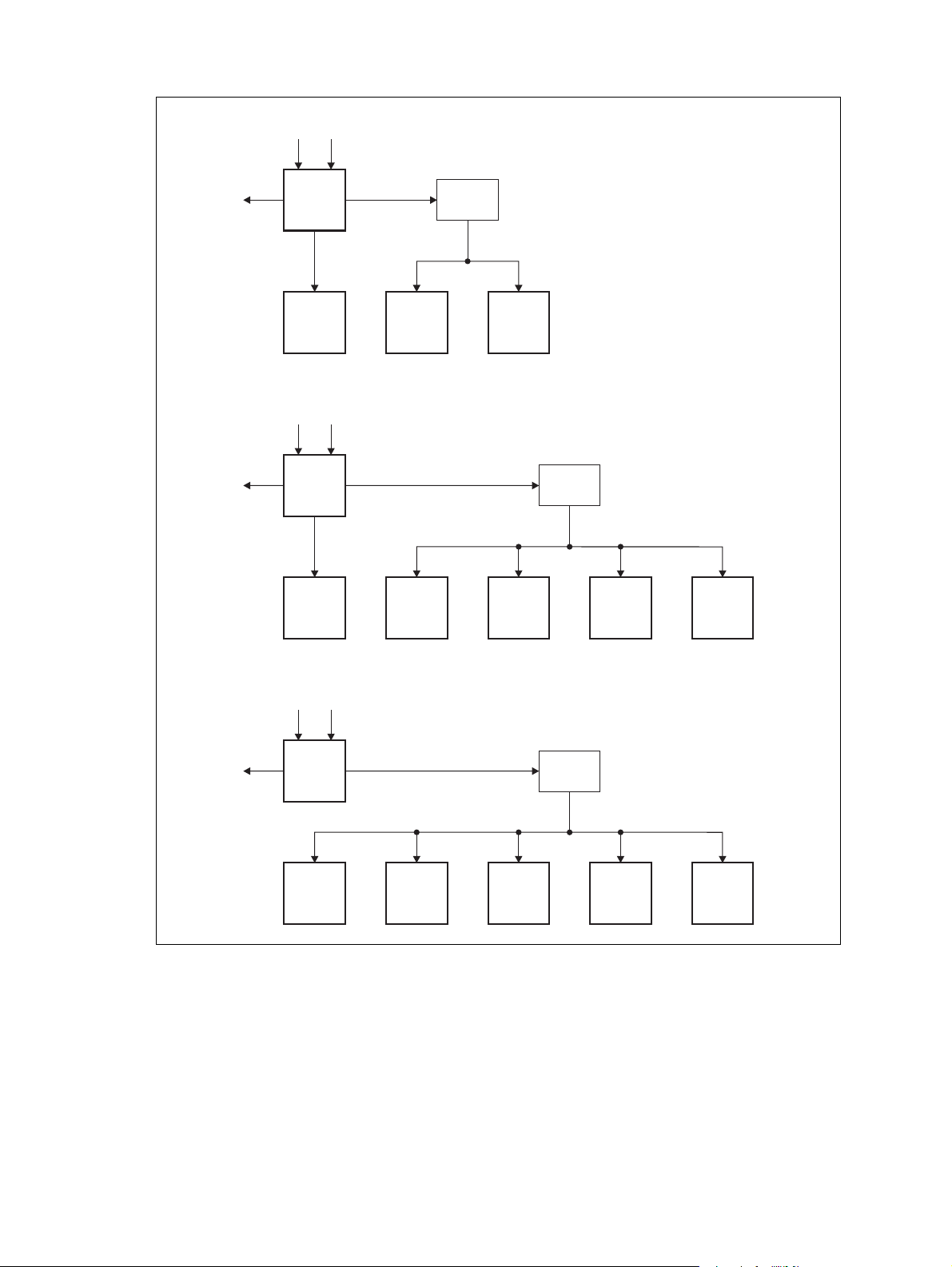

Figure 1.8 Subrack power distribution

Single

Dual

DC AC

Aux. DC 28V

Aux. DC 28V

PMU

28V

PA Reciter

DC AC

PMU

28V

Subrack

Board

Front

Panel

Subrack

Board

Receive-only

PA 1 PA 2 Reciter 1

DC AC

Aux. DC 28V

PMU

Receiver 1

Receiver 3

Subrack

Board

Reciter 2

Receiver 4Receiver 2

Front

Panel

Front

Panel

TB9400 Installation and Operation Manual Description 27

© Tait International Limited November 2018

Page 28

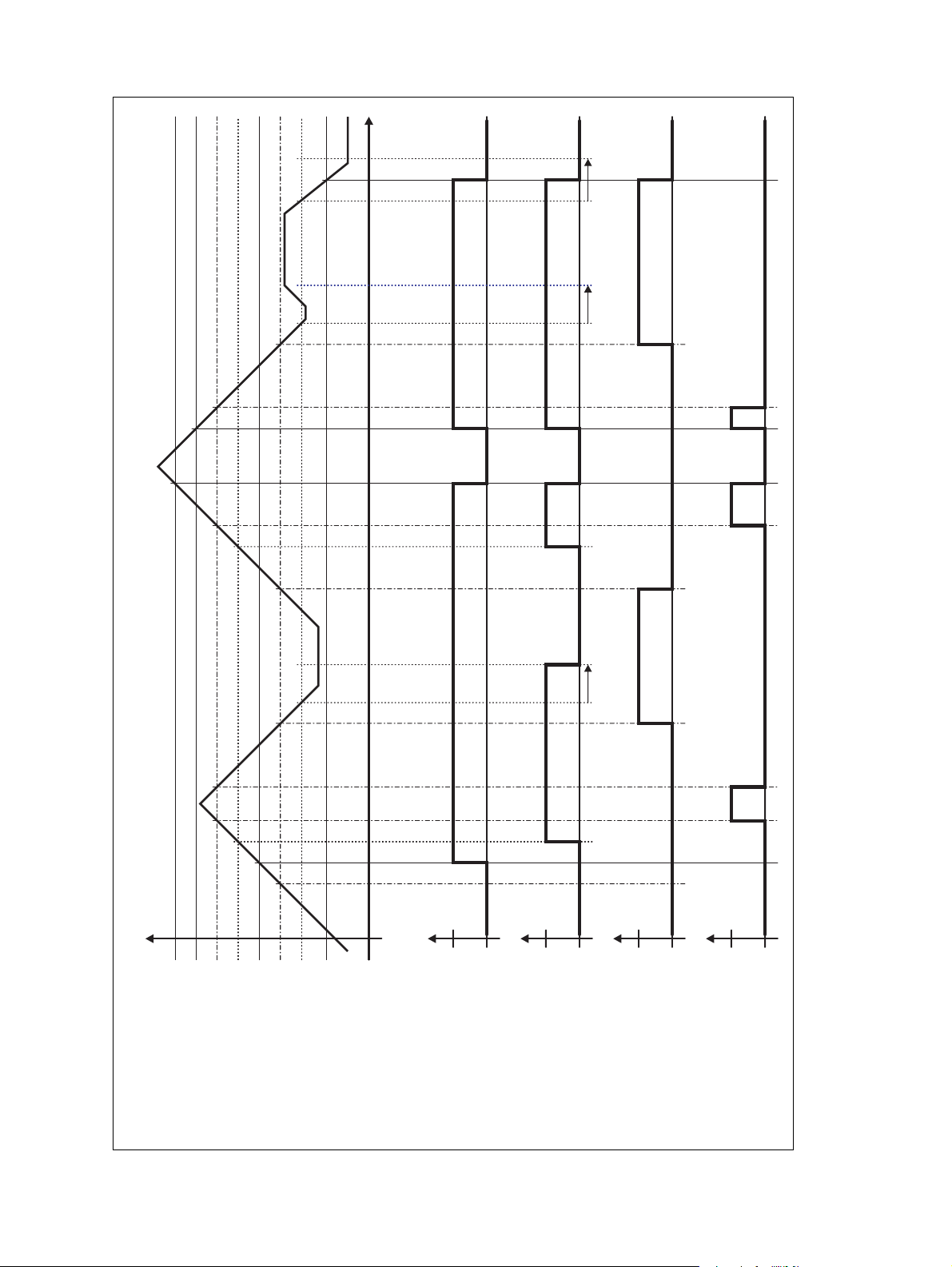

1.7.5 PMU Operation on DC Input

The operation of the PMU on DC input is controlled by three sets of

parameters:

■ user-programmable alarms

■ user-programmable startup and shutdown limits

■ battery protection limits

The voltage range for each of these parameters is provided in Table 1.2 on

page 29. Figure 1.9 on page 30 illustrates how these parameters interact,

and how they control the operation of the PMU over a range of DC input

voltages.

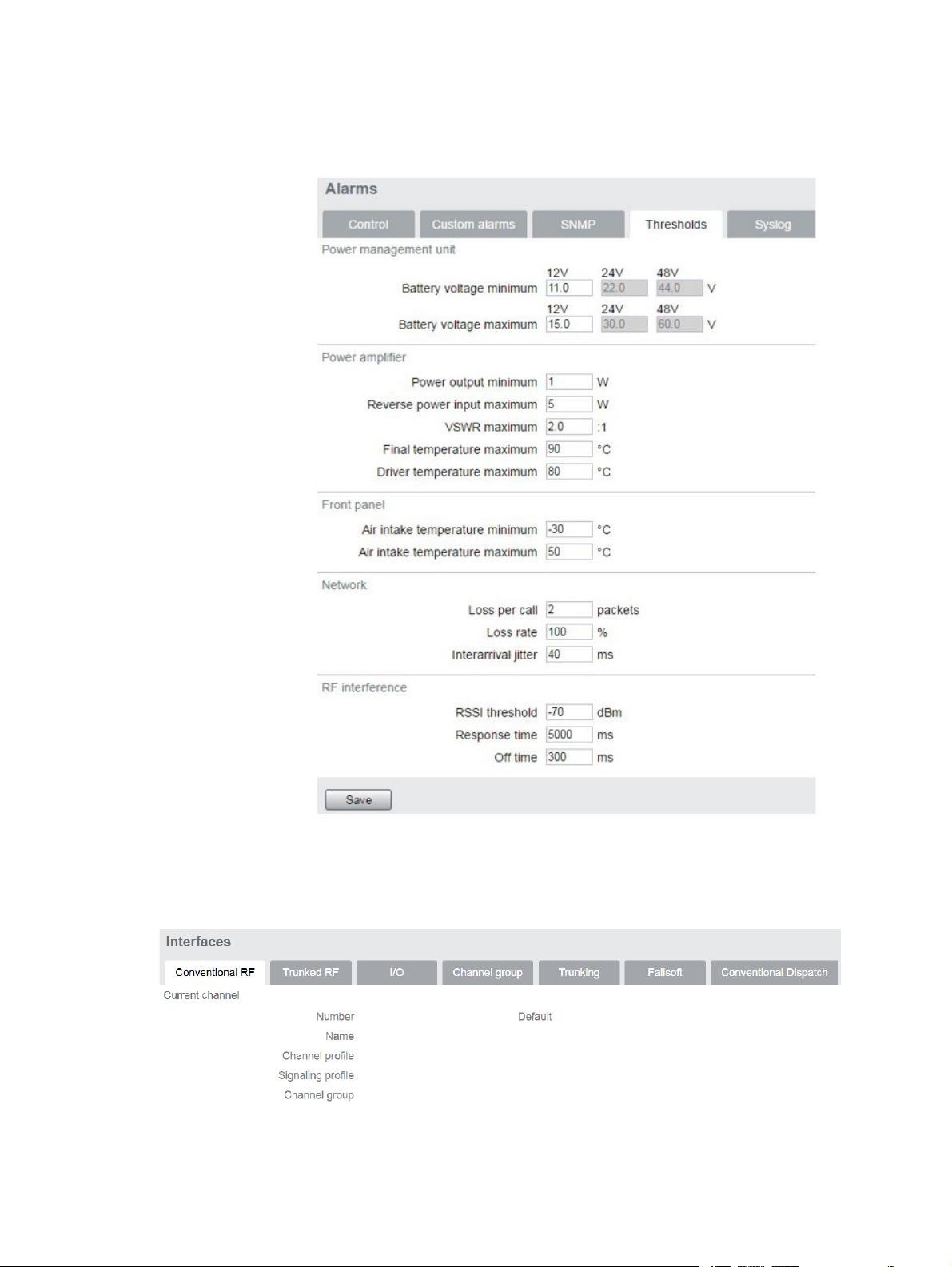

Alarms User-programmable alarms can be set for low or high battery voltage

(Configure > Alarms > Thresholds). The alarms will be triggered when the

set voltage levels are reached. These limits are subject to the tolerances of

the battery protection circuitry, as stated in “Battery Protection (Fail-safe)

Limits” in Table 1.2.

Startup and

Shutdown Limits

Battery Protection

Limits

The user-programmable startup and shutdown limits allow for adjustable

startup and shutdown voltages (Configure > Base Station >

Miscellaneous). These limits can be adjusted for different numbers of

battery cells, or for the particular requirements of the base station

operation. Once the limits are reached, the PMU will shut down. These

limits are subject to the tolerances of the battery protection circuitry, as

stated in “Battery Protection (Fail-safe) Limits” in Table 1.2.

Notice It is possible to set the startup voltage of the base station

below the nominal voltage of the battery. Continuing to use a battery for

extended periods when it is below its nominal voltage will severely

shorten its service life. For more information on battery management,

we recommend that you consult the battery manufacturer.

The battery protection limits are set in hardware at the factory, and cannot

be adjusted by the user. These limits will not be reached under normal

operation conditions, but are provided as “fail-safe” measures to protect the

battery from deep discharge. They also remove the need for low-voltage

disconnect modules.

28 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 29

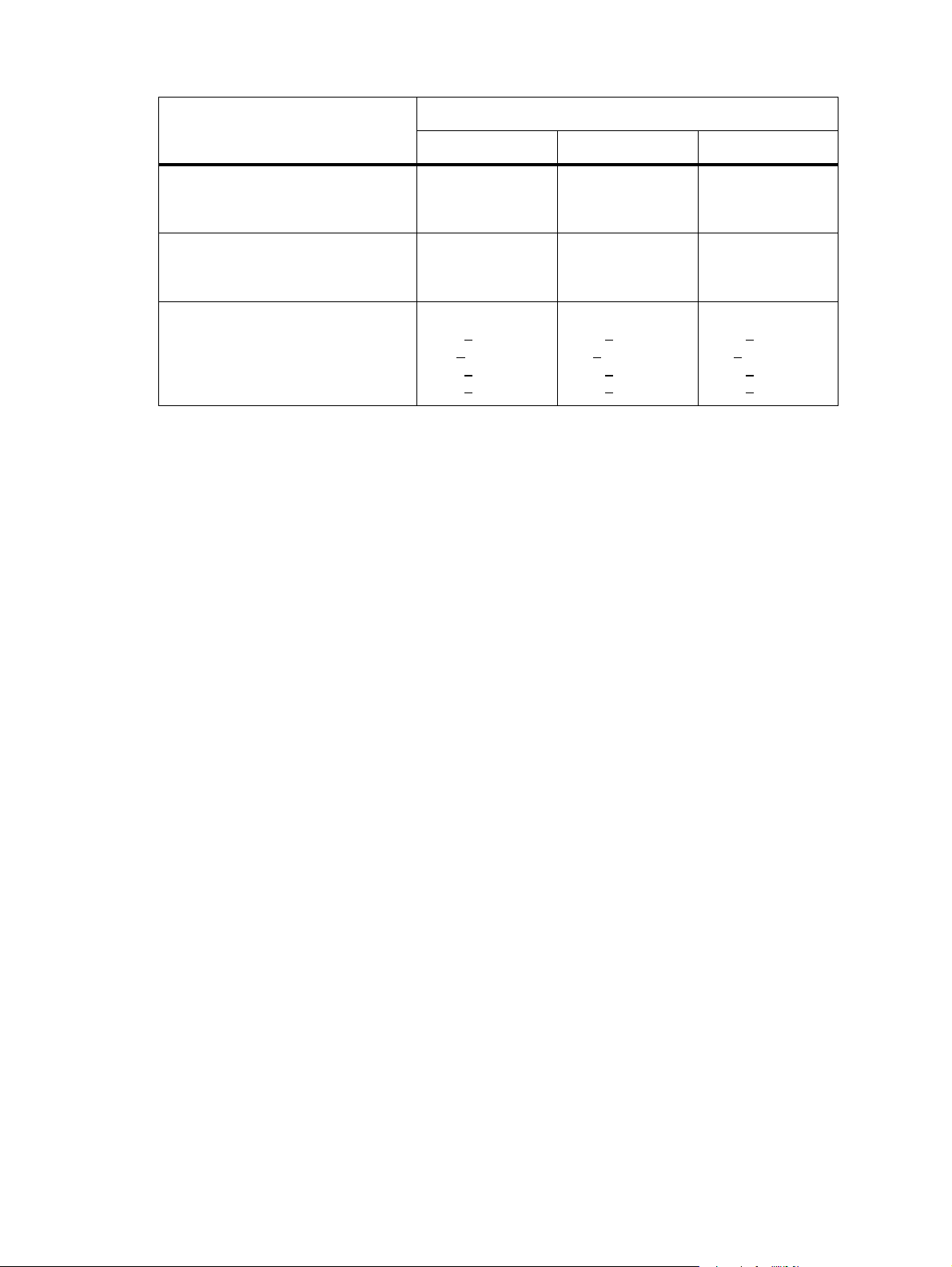

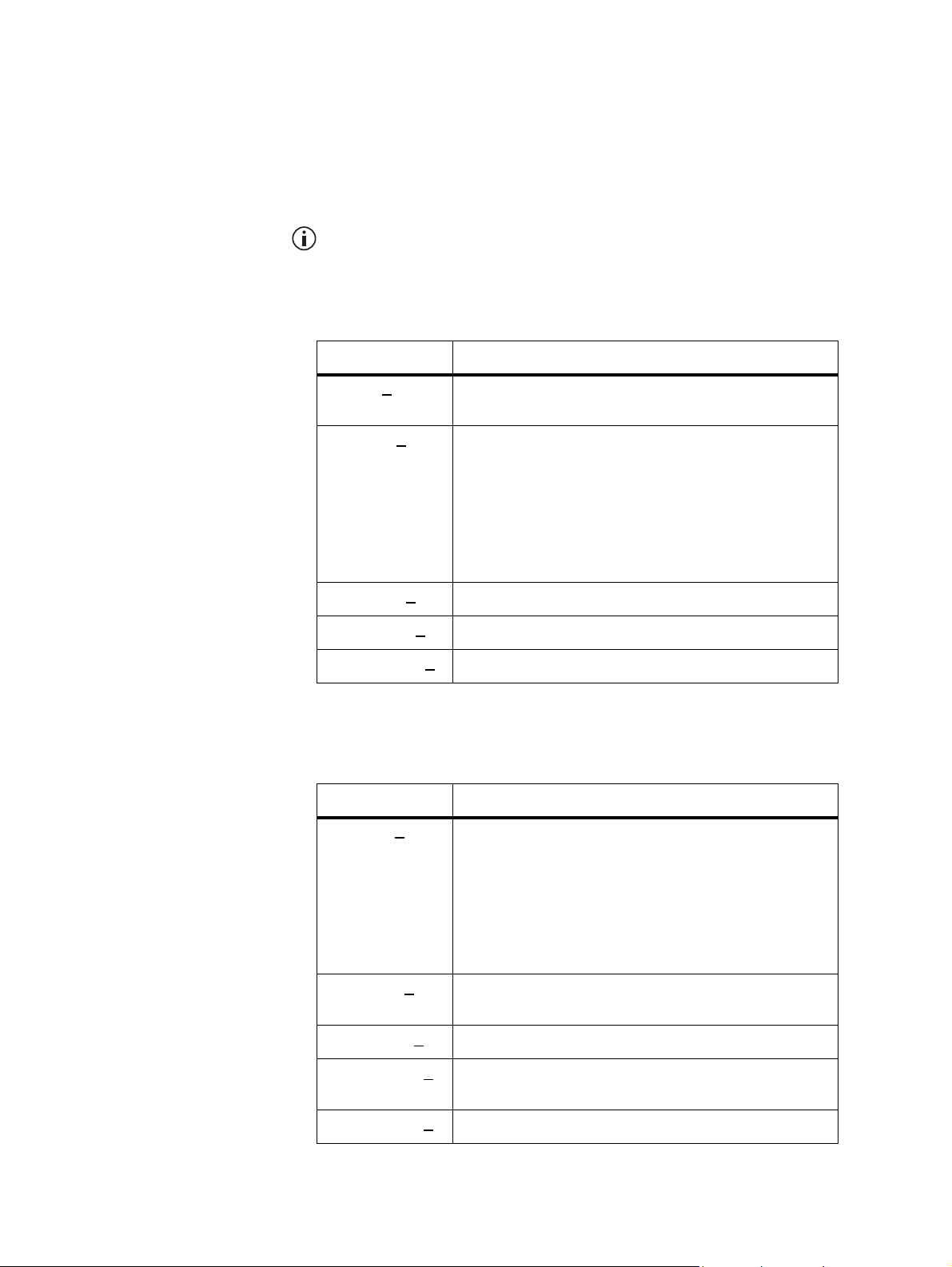

Table 1.2 PMU DC voltage limits

Parameter

User-programmable Alarms

Low Battery Voltage

High Battery Voltage

User-programmable Limits

Startup Voltage (after shutdown)

Shutdown Voltage

Battery Protection (Fail-safe) Limits

Startup Voltage

Undervoltage Shutdown

Overvoltage Shutdown

Overvoltage Shutdown Reset

a. The information in this table is extracted from the Specifications Manual. Refer to the latest issue of this manual

for the most up-to-date and complete PMU specifications.

b. Using the base station’s web interface.

b

b

a

Voltage Range

12V PMU 24V PMU 48 V PMU

10V to 14V

14V to 17.5V

10.9V to 15V ± 0.3 V

10V to 13.5V ± 0.3 V

10.8V +0.2 V

9.5V +0.3 V

18.1V +

17.1V +

0.3V

0.3V

20V to 28V

28V to 35V

21.8V to 30V ±0.5V

20V to 27V ±0.5V

21.6V +

19V +0.5V

36.2V +

34.2V +

0.5V

0.5V

0.5V

40V to 56V

56V to 70V

43.6V to 60V ±1V

40V to 54V ±1V

43.2V +

38V +1V

72.4V +

68.4V +

1V

1V

1V

TB9400 Installation and Operation Manual Description 29

© Tait International Limited November 2018

Page 30

Figure 1.9 PMU alarm thresholds and voltage limits when operating on DC

Time

DC Input Voltage

Overvoltage Shutdown (HW)

Overvoltage Shutdown Reset (HW)

High Battery Voltage Alarm (SW Alarm)

Startup Voltage (SW)

Startup Voltage (HW)

Shutdown Voltage (SW)

Undervoltage Shutdown (HW)

Low Battery Voltage Alarm (SW Alarm)

30s delay 30s delay 30s delay

Run

0V

Hardware Behaviour

Stop

Run

Software Control &

Hardware Combined

Stop

Software Alarm

Off

Active

Software Alarm

(Low Battery Voltage)

Off

Active

(High Battery Voltage)

30 Description TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 31

1.7.6 Front Panel Fans

The front panel is equipped with three fans. One fan is for the PMU, and

the other two are for the reciter/PA pairs in a 50W base station, or for the

PA and reciter in a 100W base station, or for the receivers in a receive-only

base station (refer to “Appendix C – Identifying Front Panels” on

page 121). Front panel fans do not operate continuously, but are switched

on and off as needed. The PMU and PA control their own fan. Reciters

request the front panel to turn on their fan. The reciter in slot 1can also

carry out a fan test on all three fans.

Front panel fans are 3-wire fans (power, ground, and rotation detect). The

reciter can monitor whether the fans are rotating and generate an alarm if

any of the fans fail.

The fans turn on for the duration of time the base station takes to boot

from power up. The fans also turn on for a few seconds after the front

panel is refitted to a base station that is powered up.

Configuring Fan

Control

The operation of the PA fan is configurable via the web interface; you can

specify the threshold temperature at which the fan will be turned on, and

set the fan to operate only when the PA is transmitting.

Notice If a fan is not operational, the fan alarm will only be raised

when the fan is turned on, not at system start-up. To avoid discovering

a fan fault after leaving the site, Tait recommends running a diagnostics

fan test.

The PMU fan has fixed on/off thresholds and a defined set of duty cycles

based on the PMU temperature and load current, as described in the

following table.

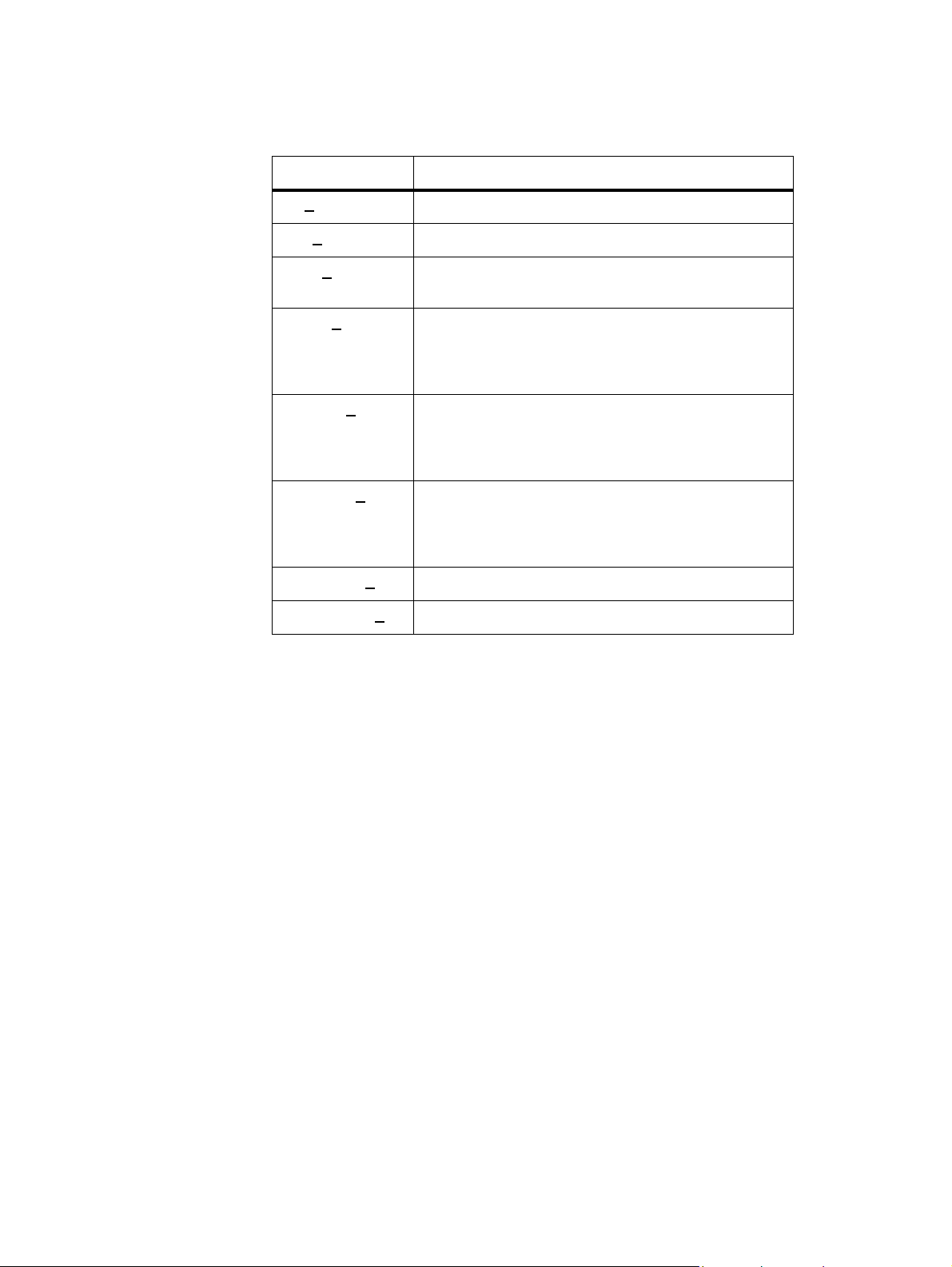

PMU Temperature Current Fan Duty Cycle

<149°F (65°C) < 4 A

4A–6A

6A–8A

8A–12A

12A–14A

≥15A

>149°F (65°C) –– always on

always off

2 minutes on, 8 minutes off

2 minutes on, 5 minutes off

3 minutes on, 3 minutes off

4 minutes on, 1 minute off

always on

TB9400 Installation and Operation Manual Description 31

© Tait International Limited November 2018

Page 32

2 General Safety and Regulatory

Information

This chapter provides general information on safety precautions for

operating the base station.

2.1 Personal Safety

2.1.1 Unpacking and Moving the Equipment

To prevent personal injury and equipment damage, we recommend that two

people unpack and move the equipment.

Caution A subrack complete with modules can weigh up to 55lb

(25kg), or up to 62lb (28kg) complete with packaging. We recommend

that you have another person help you unpack and move the equipment.

The TBAA03-16 carrying handles will make it easier to move the

equipment once it has been unpacked. If necessary, remove the modules

from the subrack before moving it (refer to “Replacing Modules” on

page 105). In all cases follow safe lifting practices.

2.1.2 Lethal Voltages

Warning The PMU contains voltages that may be lethal. Refer

to the ratings label on the rear of the module.

The equipment must be installed so that the rear of the PMU is located in a

service access area which is accessible only by qualified personnel. The

PMU must be connected to the mains supply source by qualified personnel

in accordance with local and national regulations.

Disconnect the mains IEC connector and wait for five minutes for the

internal voltages to self-discharge before dismantling. The AC power

on/off switch does not isolate the PMU from the mains. It breaks only

the phase circuit, not the neutral.

The PMU should be serviced only by qualified technicians. There are no

user-replaceable parts inside. If the PMU is damaged and does not function

properly, stop the module safely and contact your regional Tait office

immediately.

All servicing should be carried out only when the PMU is powered through

a mains isolating transformer of sufficient rating.

32 General Safety and Regulatory Information TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 33

2.1.3 AC Power Connection

English (en) The PMU must be connected to a grounded mains

Norsk (no) Apparatet må tilkoples jordet stikkontakt.

Suomi (fi) Laite on liitettävä suojamaadoitus-koskettimilla

Svenska (sv) Apparaten skall anslutas till jordat uttag.

2.1.4 Explosive Environments

socket-outlet.

varustettuun pistorasiaan.

Warning

caps or in an explosive atmosphere. Operating the equipment in

these environments is a definite safety hazard.

Do not operate the equipment near electrical blasting

2.1.5 High Temperatures

Take care when handling a PMU or PA which has been operating recently.

Under extreme operating conditions (+140°F [+60°C] ambient air

temperature) or high duty cycles, the external surfaces of the PMU and PA

can reach temperatures of up to +176°F (+80°C).

2.1.6 LED Safety (EN 60825-1)

This equipment contains Class 1 LED Products.

TB9400 Installation and Operation Manual General Safety and Regulatory Information 33

© Tait International Limited November 2018

Page 34

2.1.7 Proximity to RF Transmissions / A proximité des émissions RF

To comply with the RF Field Limits for Devices Used by the General

a

Public for (Uncontrolled Environment)

, a safe separation distance of at

least 12 feet (3.6 metres) from the antenna system should be maintained.

This figure is calculated for a typical installation, employing one 100W

base station transmitter. Other configurations, including installations at

multi-transmitter sites, must be installed so that they comply with the

relevant RF exposure standards.

a. Reference Standards

Health Canada’s Safety Code 6: Limits of Human Exposure to

Radiofrequency Electromagnetic Energy in the Frequency Range from

3kHz to 300GHz

USA Federal Communications Commission OET bulletin 65

(47CFR 1.1310)

IEEE C95.1 2005: Standard for Safety Levels with Respect to Human

Exposure to Radio Frequency Electromagnetic Fields, 3kHz to

300GHz

Pour respecter les limites imposées au champ RF au niveau des

équipements utilisés par le grand public (environnement non contrôlé)

a

une distance de séparation de sécurité d’au moins 3.6 mètres du bloc

d’antenne devrait être observée.

,

Ce nombre est calculé pour une installation typique, ayant un émetteur de

station de base de 100W. D’autres configurations, incluant les installations

ayant des sites de plusieurs émetteurs, doivent être installées de façon à se

conformer aux normes pertinentes des expositions RF.

a. Normes de référence

Code de sécurité 6 de Santé Canada: Limites d'exposition humaine à

l’énergie électromagnétique radioélectrique dans la gamme de

fréquences de 3kHz à 300GHz

Commission fédérale des communications (FCC) des Etats Unis

d’Amérique bulletin OET numéro 65 (47CFR 1.1310)

IEEE C95.1 2005: Norme pour les niveaux de sécurité compatibles avec

l'exposition des personnes aux champs électromagnétiques de

radiofréquence 3kHz à 300GHz

34 General Safety and Regulatory Information TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 35

2.2 Equipment Safety

2.2.1 Installation and Servicing Personnel

The equipment should be installed and serviced only by qualified

personnel.

2.2.2 Preventing Damage to the PA

The base station has been designed to operate safely under a wide range of

antenna loading conditions. Transmitting into a low VSWR will maximize

the power delivered to the antenna.

Notice Do not remove the load from the PA while it is transmitting.

Load transients (switching or removing the load) can damage the PA output

stage. See “Connecting RF” on page 76 for recommendations.

2.2.3 ESD Precautions

Notice This equipment contains devices which are susceptible to

damage from static charges. You must handle these devices carefully

and according to the procedures described in the manufacturers’ data

books.

We recommend you purchase an antistatic bench kit from a reputable

manufacturer and install and test it according to the manufacturer’s

instructions. Figure 2.1 shows a typical antistatic bench set-up.

You can obtain further information on antistatic precautions and the

dangers of electrostatic discharge (ESD) from standards such as ANSI/

ESD S20.20-1999 or BS EN 100015-4 1994.

Figure 2.1 Typical antistatic bench set-up

common point ground

(building ground or

mains ground)

dissipative rubber

bench mat

conductive wrist strap

TB9400 Installation and Operation Manual General Safety and Regulatory Information 35

© Tait International Limited November 2018

Page 36

2.2.4 Anti-tampering Devices

All network elements should be physically secured, where possible. This

includes the use of locked cabinets and the use of seals on connectors.

All network connectors should be sealed with the stick-on type of seal. The

purpose of the seals is to detect unauthorized tampering. The seal should

reveal if any of the connectors have been unplugged or if any unauthorized

equipment has been plugged in.

The seals must be difficult to remove without breaking, and must bridge

between the cable and equipment side (plug and socket) of the connection.

Seals must cover any unused network sockets. This includes the Ethernet

connector on the rear panel, any spare switch ports, and the console port on

the router and switch.

The seals must be difficult to reproduce. A sticker initialed or signed by the

technician should satisfy this.

Seals must be replaced if they need to be disturbed during maintenance.

2.3 Environmental Conditions

2.3.1 Operating Temperature Range

The operating temperature range of the equipment is –22°F to +140°F

(–30°C to +60°C) ambient temperature. Ambient temperature is defined as

the temperature of the air at the intake to the cooling fans.

2.3.2 Humidity

The humidity should not exceed 95% relative humidity through the

specified operating temperature range.

2.3.3 Dust and Dirt

For uncontrolled environments, the level of airborne particulates must not

exceed 100µg/m

3

.

36 General Safety and Regulatory Information TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 37

2.4 Regulatory Information

2.4.1 Distress Frequencies

The 406 to 406.1MHz frequency range is reserved worldwide for use by

Distress Beacons. Do not program transmitters to operate in this frequency

range.

2.4.2 Compliance Standards

This equipment has been tested and approved to various national and

international standards. Refer to the latest issue of the Specifications

Manual for a complete list of these standards.

2.4.3 FCC Compliance

This equipment complies with:

■ CFR Title 47 Part 15 Class B (except PMU):

Radiated and conducted emissions, and electromagnetic susceptibility specifications of the Federal Communications Commission

(FCC) rules for the United States.

Operation is subject to the following two conditions:

a. This device may not cause harmful interference, and

b. This device must accept any interference received, including

interference that may cause undesired operation.

■ CFR Title 47 Part 15 Class A (PMU only):

Radiated and conducted emissions, and electromagnetic susceptibility specifications of the Federal Communications Commission

(FCC) rules for the United States.

Operation is subject to the following two conditions:

a. This device may not cause harmful interference, and

b. This device must accept any interference received, including

interference that may cause undesired operation.

2.4.4 Unauthorized Modifications

Any modifications you make to this equipment which are not authorized by

Tait may invalidate your compliance authority’s approval to operate the

equipment.

The manufacturer is not responsible for any radio or TV interference

caused by unauthorized modifications to this equipment. Such

modifications could void the user’s authority to operate the equipment.

TB9400 Installation and Operation Manual General Safety and Regulatory Information 37

© Tait International Limited November 2018

Page 38

3 Operation

This section describes the user controls and indicator LEDs on the front

panel and on the base station modules.

3.1 Front Panel

The user controls and indicator LEDs on the front panel are shown in

Figure 3.1. They allow some manual control over the base station and

monitoring of its operational status.

Notice If there is more than one reciter in a subrack, inputs from all

reciters are summed to drive the front panel LEDs.

Figure 3.1 Operating controls on the control panel

b c

d

e

b

speaker

b

microphone connector

c

power LED

d

alarm LED

e

Speaker and

Microphone

Connector

Power LED The green power LED is lit when power is supplied to the subrack.

Alarm LED The red alarm LED will flash at a rate of 2 to 5Hz when an alarm has been

c

de

The speaker and microphone connector are not currently used.

generated by any of the base station modules. It will continue to flash until

the alarm is canceled or the fault is fixed. Note that only those alarms which

are enabled using the web interface will cause this LED to flash.

gi

f

receive LED

f

transmit LED

g

keypad

h

display

i

h

38 Operation TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 39

LED Description

Flashing One or more faults are present.

On (steady) A base station is in Offline mode, and no faults are present.

Off A base station is in Online mode, and no faults are present.

Receive LED

f

The amber receive LED indicates whether the base station is receiving a

valid RF signal (on one or both logical channels in P25 Phase 2 operation).

LED Description

On (steady) A base station is receiving a valid RF signal.

Off A base station is not receiving a valid RF signal.

Transmit LED The amber transmit LED is lit while the transmitter is transmitting.

g

Keypad The keypad is used to navigate the base station’s menus, enter text, and to

h

adjust the contrast of the display. The complete list of menu items is

provided in “Menu Map” on page 41.

If required, the keypad can be disabled in the web interface to prevent

access to the base station via the front panel menus (see “Subaudible

Signaling” on page 99).

TB9400 Installation and Operation Manual Operation 39

© Tait International Limited November 2018

Page 40

Key Name Function

i

Display

OK

left and right

arrow keys

scroll keys

OK

home

return ■ Returns to the previous menu.

■ Move the cursor to the left or right when entering text. Moving the

cursor beyond the end of a line will return it to the other end of the same

line.

■ Decrease or increase the contrast in the Display Contrast screen.

■ Scroll up and down through a list of menu items.

■ Scroll up and down through the list of available characters when

entering text.

■ Increase or decrease the contrast in the Display Contrast screen.

■ Selects the highlighted menu item.

■ Confirms any adjustments made and exits to the previous menu.

■ When setting the IP address, moves the cursor down one line. When all

the IP addresses are confirmed, exits to the previous menu.

■ Returns to the home screen from any other menu.

■ Moves the cursor up one line in the IP address screen. When the top

line is reached, pressing again returns to the previous menu.

The display is used in conjunction with the keypad to access the base

station’s menus. It allows the technician to configure the IP address of each

reciter (refer to “Setting the IP Address” on page 84), and to set the contrast

of the display (see below).

After the base station is powered up, the display shows “Please wait...”

while the base station is starting up, followed by the home screen when the

start-up process is complete. The home screen shows four lines of userdefined text, which can be entered via the web interface (Identity > Identity

> Base Station Identity).

From the home screen press an arrow key, a scroll key or OK to go to the

base station menu. The display returns to the home screen from any other

screen 30 seconds after the last key press. Press any key to turn on the

backlight. The backlight turns off 30 seconds after the last key press.

If the keypad has been disabled, pressing an arrow key, a scroll key or

OK will cause the display to show “Keypad Disabled”.

Set the display contrast as follows:

1. From the base station menu select Modules > Front Panel > Contrast.

2. To increase the contrast, press the right arrow or scroll up key. To

decrease the contrast, press the left arrow or scroll down key.

When the contrast is set to the required level, press OK to save the changes

and exit the menu.

40 Operation TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 41

Menu Map

Home Screen

The menu map below shows the menu items available in this release of the

base station.

Notice The menu map shown is for a single base station. The menu

items available in your base station will depend on which modules are

present in the subrack, and whether the keypad has been disabled (refer

to “Subaudible Signaling” on page 99).

Base Station

Modules

Modules

Reciter 1

Front Panel

Reciter 1

View Reciter 1 Address

Edit Reciter 1 Address

Front Panel

Contrast

View Reciter 1 Address

IP: 172.025.198.043

MASK: 255.255.000.000

GW: 172.025.002.251

Edit Reciter 1 Address

IP: 172.025.198.043

1

MASK: 255.255.000.000

GW: 172.025.002.251

Contrast

TB9400 Installation and Operation Manual Operation 41

© Tait International Limited November 2018

Page 42

3.2 Module Indicator LEDs and Switches

Additional status information is displayed by LEDs in individual modules.

The PMU also has switches that let you turn the AC and DC modules off.

3.2.1 Reciter and Receiver

Front View The indicator LEDs on the front of the reciter or receiver are visible

through a slot in its front panel.

Figure 3.2 Indicator LEDs on the front of the reciter and receiver

b

Reciter Receiver

indicator LEDs

b

These LEDs provide the following information about the state of the reciter

or receiver:

■ steady green - the reciter or receiver is powered up

■ flashing red - one or more alarms have been generated; you can use the

web interface to find out more details about the alarms.

42 Operation TB9400 Installation and Operation Manual

© Tait International Limited November 2018

Page 43

Rear View

Figure 3.3 Indicator LEDs on the rear of the reciter and receiver

The indicator LEDs on the rear of the reciter and receiver are on the

Ethernet connector.

b

c

10Base-T Ethernet Connector LED (green)

b