5 Installation

This chapter describes how to install the TB8100 BSS in a standard 19 inch

rack or cabinet. It also provides some general information on safety

precautions and site requirements. We recommend that you read the entire

chapter before beginning the installation.

5.1 Personal Safety

Lethal Voltages

Warning!! The PMU contains voltages that may be lethal.

The TB8100 BSS must be installed so that the rear of the PMU is located

in a service access area.

Refer to the ratings label on the rear of the

module.

Disconnect the mains IEC connector and wait for five minutes for

the internal voltages to self-discharge before dismantling. The AC

power on/off switch does not isolate the PMU from the mains. It

breaks only the phase circuit, not the neutral.

The PMU should be serviced only by qualified technicians. All servicing

should be carried out only when the PMU is powered through a mains

isolating transformer of sufficient rating. We strongly recommend that

the mains power to the whole of the repair and test area is supplied via an

earth leakage circuit breaker.

Explosive Environments

Warning!! Do not operate TB8100 BSS equipment near

Proximity to RF Transmissions

electrical blasting caps or in an explosive atmosphere. Operating the equipment in these environments is a definite safety hazard.

Do not operate the transmitter when someone is standing within 90cm (3ft)

of the antenna. Do not operate the transmitter unless you have checked that

all RF connectors are secure.

TB8100 Installation and Operation Manual Installation 59

© Tait Electronics Ltd March 2004

High Temperatures

Take care when handling a PMU or PA which has been operating recently.

Under extreme operating conditions (+60°C [+140°F] ambient air

temperature) or high duty cycles the external surfaces of the PMU and PA

can reach temperatures of up to +80°C (+176° F).

5.2 Equipment Safety

ESD Precautions

Important This equipment contains devices which are susceptible to

damage from static charges. You must handle these devices

carefully and according to the procedures described in the

manufacturers’ data books.

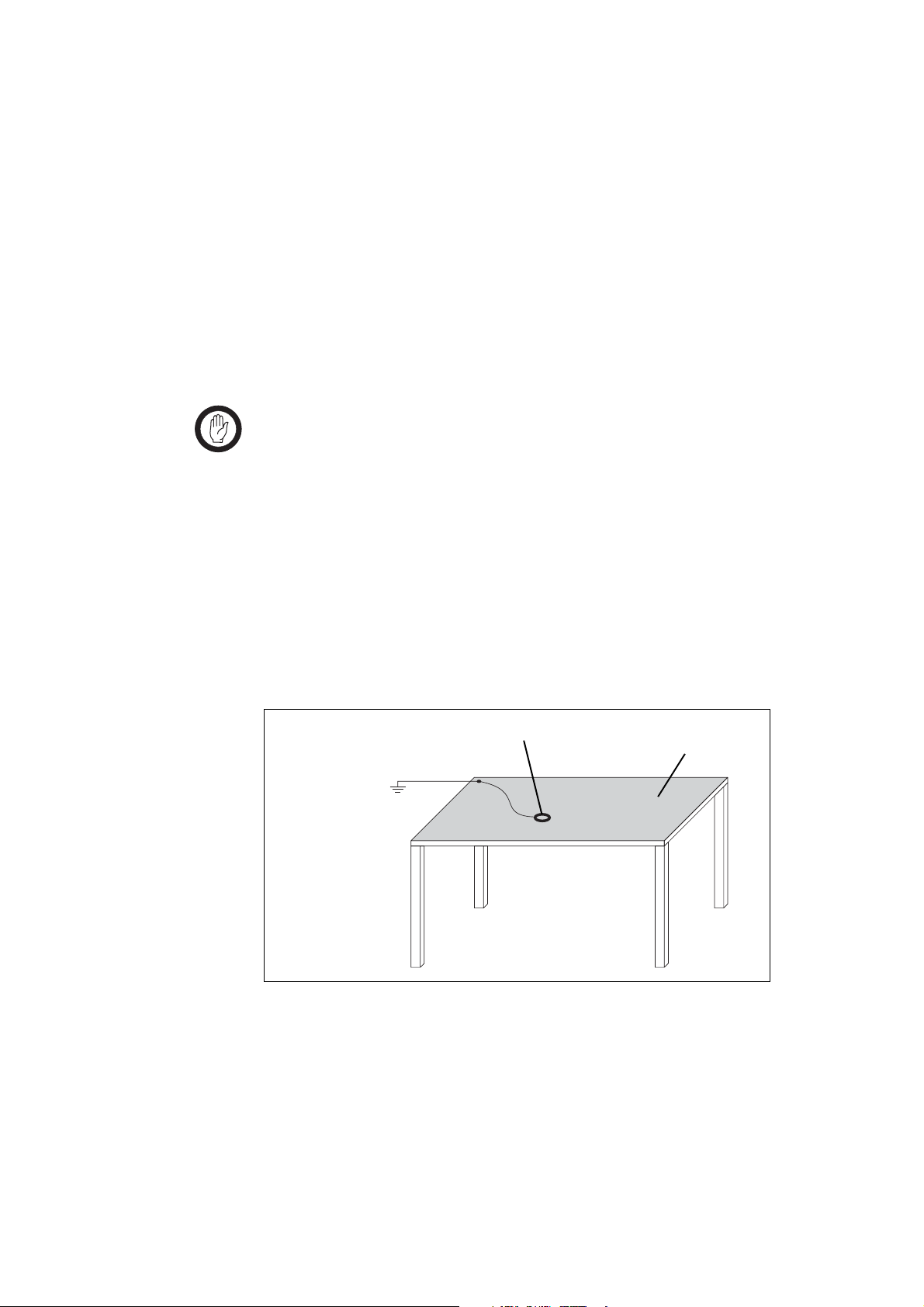

We recommend you purchase an antistatic bench kit from a reputable

manufacturer and install and test it according to the manufacturer’s

instructions. Figure 5.1 shows a typical antistatic bench set-up.

Aerial Load

You can obtain further information on antistatic precautions and the dangers

of electrostatic discharge (ESD) from standards such as ANSI/ESD

S20.20-1999 or BS EN 100015-4 1994.

Figure 5.1 Typical Antistatic Bench Set-up

conductive wrist strap dissipative rubber

bench mat

common point ground

(building ground or

mains ground via 1M

ohm series resistor)

The TB8100 BSS equipment has been designed to operate safely under a

wide range of aerial loading conditions. However, we strongly recommend

that the transmitter should always be operated with a suitable load to prevent

damage to the transmitter output power stage.

60 Installation TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

Equipment Grounding

To ensure safe operation the TB8100 BSS equipment must be correctly

grounded as described in these installation instructions.

Installation and Servicing Personnel

The TB8100 BSS should be installed and serviced only by qualified

personnel.

5.3 Regulatory Information

Distress Frequencies

The 406 to 406.1MHz frequency range is reserved worldwide for use by

Distress Beacons. Do not program transmitters to operate in this frequency

range.

FCC Compliance

This device complies with part 15 of the FCC Rules. Operation is subject

to the condition that this device does not cause harmful interference.

Unauthorised Modifications

Any modifications you make to this equipment which are not authorised by

Tait Electronics Ltd may invalidate your compliance authority’s approval to

operate the equipment.

5.4 Environmental Conditions

Operating Temperature Range

The operating temperature range of the TB8100 BSS is –30°C to + 60°C

(–22°F to +140°F) ambient temperature. Ambient temperature is defined

as the temperature of the air at the intake to the cooling fans.

Humidity

The humidity should not exceed 95% relative humidity through the

specified operating temperature range.

TB8100 Installation and Operation Manual Installation 61

© Tait Electronics Ltd March 2004

Dust and Dirt

For uncontrolled environments, the level of airborne particulates must not

exceed 100µg/m

3

.

5.5 Grounding and Lightning Protection

Electrical Ground

The TB8100 BSS modules are grounded by physical contact between the

module case and the subrack. To ensure a good ground connection you

must tighten each module retaining clamp securely (refer to “Final

Reassembly” on page 81 for the correct torque setting).

A threaded grounding connector is provided on the rear of the subrack for

connection to the site ground point (refer to “Connection” on page 83 for

more details).

Lightning Ground

It is extremely important for the security of the site and its equipment that

you take adequate precautions against lightning strike. While it is outside

the scope of this manual to provide comprehensive information on this

subject, the following guidelines apply:

■ install a suitable lightning rod at the top of the tower and connect it to a

secure ground point with appropriate conductors and connectors

■ position site buildings and equipment within the cone of protection

provided by the grounded tower

■ protect all cables entering the site to prevent lightning energy from

entering site buildings.

5.6 Recommended Tools

It is beyond the scope of this manual to list every tool that an installation

technician should carry. However, the following tools are specifically

required for installing the TB8100 BSS:

■ Pozidriv PZ3 screwdriver for the M6 screws used to secure the subrack

to the rack or cabinet, and also for the DC input terminals on the PMU

■ Pozidriv PZ2 screwdriver for the M4 screws used to secure the module

retaining clamps

■ 0.25in or 6mm flat blade screwdriver for the fasteners used to secure the

front panel to the subrack

■ 8mm AF spanner for the SMA connectors.

62 Installation TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

You can also obtain the TBA0ST2 tool kit from your nearest Tait Dealer or

Customer Service Organisation. It contains the basic tools needed to install,

tune and service the TB8100 BSS.

5.7 Ventilation

Always ensure there is adequate ventilation around the TB8100 BSS. Do

not operate it in a sealed cabinet. You must keep the ambient temperature

within the specified range, and we strongly recommended that you ensure

that the cooling airflow is not restricted.

Important The cooling fans are mounted on the front panel and will

only operate when the panel is fitted correctly to the front

of the subrack. To ensure adequate airflow through the

BSS, do not operate it for more than a few minutes with the

front panel removed (e.g. for servicing purposes).

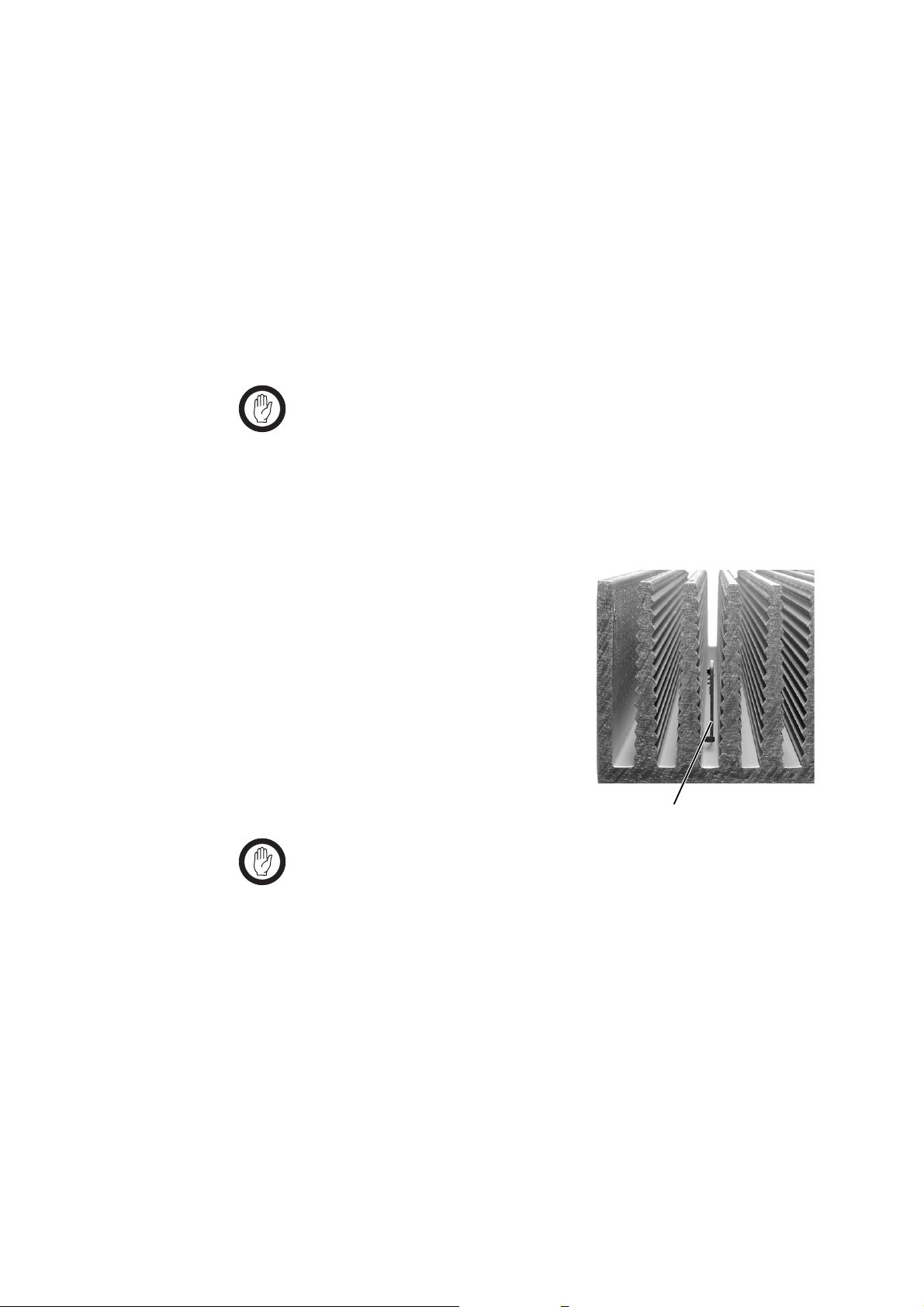

Ambient Air Temperature Sensor

The ambient air temperature reading

for the TB8100 BSS is provided by

the ambient air temperature sensor

PCB

b fitted to the PA control PCB.

The sensor PCB is inserted through

slots in the control PCB and heatsink

to be positioned between the heatsink

fins.

b

Important If the sensor PCB is to provide accurate ambient tempera-

ture readings, it must have forced airflow and must not

come into contact with the metal of the heatsink fins. Do

not stack PAs with the fins together. It is possible for

the fins on one heatsink to slide between the fins on the

other heatsink. This can damage the sensor PCB, and possibly result in the heatsink fins becoming locked together.

TB8100 Installation and Operation Manual Installation 63

© Tait Electronics Ltd March 2004

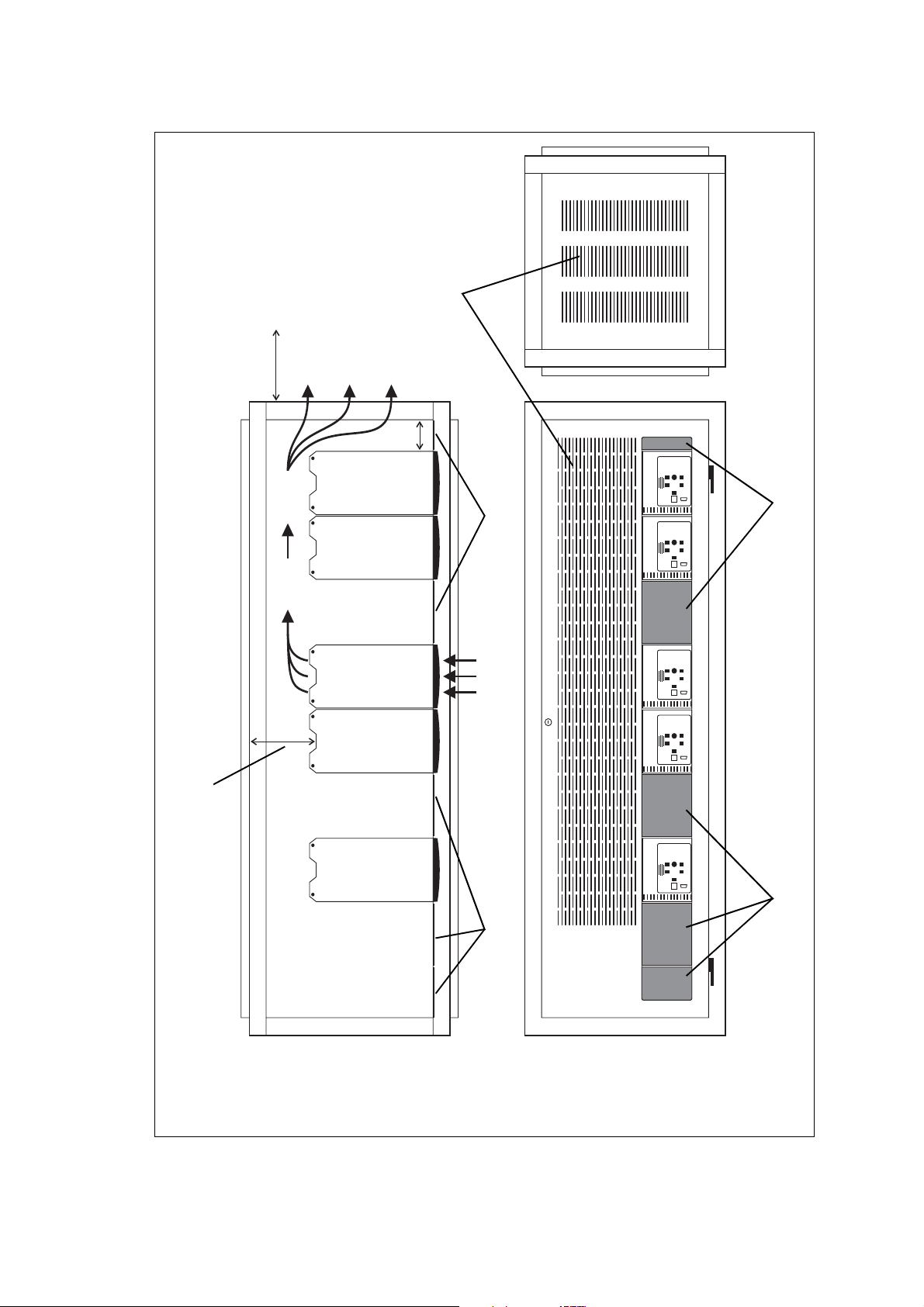

Cabinet and Rack Ventilation

Refer to Figure 5.2 on page 65.

The cooling airflow for the TB8100 BSS enters through the front panel and

exits at the rear of the subrack. For optimum thermal performance, the

heated air that has passed through a BSS must not be allowed to re-enter the

air intakes on the front panel. Any space at the front of the cabinet not

occupied by equipment should be covered by a blanking panel.

To allow enough cooling airflow through a cabinet-mounted BSS, we

recommend the following:

■ an area of at least 150cm

in front of the air intakes for the fans for each subrack; for example,

thirty 6x85 mm (0.25 x 3.3 in) slots will allow the recommended airflow

■ a vent in the top of the cabinet with an area of approximately 150cm

(23in2) per subrack, or a similar area of ventilation per subrack at the rear

of the cabinet behind each subrack

■ a 2U gap at the top of the cabinet.

Note The ventilation opening must be unrestricted. If the slots or holes

are covered with a filter, mesh or grille, the open area must be

increased to allow the same airflow as an unrestricted opening.

2

(23in2) of unrestricted ventilation slots or holes

2

Auxiliary Extractor

Fans

The maximum ambient temperature entering the cabinet must not exceed

+60°C (+140°F).

If the TB8100 BSS is installed in a rack or cabinet with other equipment

with different ventilation requirements, we recommend that the TB8100 be

positioned below this equipment.

The TB8100 BSS does not require auxiliary extractor fans mounted in the

top of the cabinet. If your cabinet is already fitted with fans, the following

procedures apply:

■ if there are six or more 120mm (4.75in) fans, each capable of extracting

■ if there are fewer than six fans, you must remove them and ensure the

3

160m

per hour (94.2CFM), they must run continuously

vent in the top of the cabinet has an area of approximately 150cm

2

(23in2) per subrack.

If you have any other configuration, the performance of your system will

depend on how closely you comply with the TB8100 BSS airflow

requirements described above.

64 Installation TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

Figure 5.2 Typical Cabinet Ventilation Requirements

b

20cm

(8in)

top view

side view

t17.5cm

(t7in)

front view

2U

c

c

e

d

c

c

ventilation slots

b

blanking panels

c

TB8100 Installation and Operation Manual Installation 65

© Tait Electronics Ltd March 2004

airflow entry

d

airflow exit

e

5.8 Installing the Base Station System

Caution A TB8100 subrack complete with modules can

weigh up to 28 kg (62lb), or up to 30 kg (66 lb) complete with packaging. We recommend that, once

the equipment is out of the carton, you remove the

modules from the subrack before moving the equipment again. Otherwise, have another person help

you with the lifting. In all cases follow safe lifting

practices.

Unpacking the Equipment

Unpacking the

TB8100 BSS

Figure 5.3 Unpacking the TB8100 BSS

The TB8100 BSS is packed in a strong corrugated cardboard carton with

top and bottom foam cushions. To prevent personal injury and damage to

the equipment, we recommend that two people unpack the BSS.

b

e

cd

f

g

1. Cut the tape securing the flaps at the top of the carton and fold them

flat against the sides

2. Rotate the carton carefully onto its side

ensuring that none of the flaps is trapped underneath.

66 Installation TB8100 Installation and Operation Manual

b.

hi

c and then onto its top d,

© Tait Electronics Ltd March 2004

3. Slide the carton upwards over the foam cushions and lift it away e.

Remove the cushion from the bottom of the BSS

f.

4. Rotate the BSS and cushion carefully over the rear of the BSS

Disposal of

Packaging

If you do not need to keep the packaging, we recommend that you recycle

it according to your local recycling methods. The foam cushions are CFCand HCFC-free and may be burnt in a suitable waste-to-energy combustion

facility, or compacted in landfill.

Mounting the Subrack

Caution We recommend that you remove the modules from

Figure 5.4 Subrack Mounting Points

that the BSS is the right way up with the cushion on top

the cushion from the top of the BSS

the subrack before lifting it (refer to “Replacing

Modules” on page 71), or have another person help

you with the lifting.

i.

g so

h. Remove

front view

b

rear view

c

main mounting holes - front

b

TB8100 Installation and Operation Manual Installation 67

© Tait Electronics Ltd March 2004

auxiliary mounting holes - rear

c

1. Remove the front panel, as described in “Preliminary Disassembly”

on page 71.

2. Fit the subrack into the cabinet or rack and secure it firmly with an

M6 screw, flat and spring washer in each of the four main mounting

holes

Note If you need extra mounting security, there are additional mount-

Auxiliary Support Bracket

TBA2140 auxiliary support brackets can be fitted to the rear of the TB8100

subrack to provide additional mounting security. Figure 5.5 below shows a

standard TBA2140 bracket

If you are not using a Tait cabinet, you may have to make your own brackets

to suit your installation.

Figure 5.5 Auxiliary Support Bracket

b, as shown in Figure 5.4 on page 67.

ing holes

port brackets.

c provided at the rear of the subrack for auxiliary sup-

b fitted in a typical Tait Electronics cabinet c.

b

c

Important Yo u must fit the auxiliary support brackets if you intend to

transport a cabinet fitted with a fully built-up TB8100 BSS.

We also recommend that you fit the brackets under the following

conditions:

■ when the installation is in an area prone to earthquakes

■ when third party equipment is installed hard up underneath the TB8100

BSS subrack.

68 Installation TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

Optional Slide Mounting Rails

You can also use TBA2141 slide mounting rails b when mounting the

TB8100 BSS in a cabinet, as shown in Figure 5.6 below. These rails will

support the BSS while you slide it into the cabinet.

However, you must still secure the BSS to the cabinet with four M6 screws

through the main mounting holes on the front of the subrack, as shown in

Figure 5.4 on page 67.

Figure 5.6 Optional Slide Mounting Rail - Rear View

c

b

Important The slide mounting rails are not suitable for transporting a

cabinet fitted with a fully built-up TB8100 BSS. In this

case, you must also fit the TBA2140 auxiliary support

brackets to the upper set of rear mounting holes

Cabling

General We recommend that you try to route all cables to and from the TB8100 BSS

along the side of the cabinet so the cooling airflow is not restricted.

DC Power Cabling DC power cables should be well supported so that the terminals on the

PMU and on the ends of the cables do not have to support the full weight

of the cables.

c.

TB8100 Installation and Operation Manual Installation 69

© Tait Electronics Ltd March 2004

Figure 5.7 below shows two recommended methods of securing these cables

to prevent straining either set of terminals.

Figure 5.7 DC Power Cabling

secure the cables to the

cabinet to support their

weight

70 Installation TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

7 Connection

Once the TB8100 BSS hardware is installed, you need to connect the

individual modules to each other, and to any ancillary equipment required

in your system. This chapter provides information on all the inputs and

outputs available on the TB8100 BSS.

7.1 Overview of Inputs and Outputs

This section identifies the main input and output connections for the

TB8100 BSS. Figure 7.1 below identifies the connections at the front of a

dual base station, and Figure 7.3 on page 85 identifies those at the rear.

Figure 7.2 on page 84 identifies the connections at the front of a single

100W base station. Figure 7.4 on page 85 and identifies the connections on

the control panel. Refer to the following sections in this chapter for more

details on these connections.

Figure 7.1 Dual 5 or 50W Base Station Inputs and Outputs - Front View

bcd e ghfgh

ddidiefd

28VDC high current output for PA

b

28VDC low current output for reciter

c

system control bus

d

RF input from reciter

e

PA 1 PA 2 reciter 2PMU

28VDC high current input cable from PMU

f

RF output to PA

g

28VDC low current input from PMU

h

DC output (for optional reciter fan only)

i

reciter 1

TB8100 Installation and Operation Manual Connection 83

© Tait Electronics Ltd March 2004

Figure 7.2 Single 100W Base Station Inputs and Outputs - Front View

bc de

hfgfi

PMU

28VDC high current output for PA

b

28VDC low current output for reciter

c

RF output to PA

d

28VDC low current input from PMU

e

PA re citer

system control bus

f

DC output (for optional reciter fan only)

g

28VDC high current input cable from PMU

h

RF input from reciter

i

84 Connection TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

Figure 7.3 Dual 5 or 50W Base Station Inputs and Outputs - Rear View

bc d fe

1)

system interface connector

b

external reference frequency input

c

RF output

d

–VDC input

e

+VDC input

f

bc

higidjj

PA 1PA 2reciter 1reciter 2 PMU

auxiliary 12VDC output

g

AC mains input

h

RF input

i

auxiliary 12VDC input for system interface

j

subrack ground connector

1)

Figure 7.4 Standard Control Panel Inputs and Outputs

c

b

d

DC outputs for fans mounted on front panel;

b

also used for fan rotation detectors (if fitted)

microphone connector

c

TB8100 Installation and Operation Manual Connection 85

© Tait Electronics Ltd March 2004

RS-232 programming port

d

Figure 7.5 Power Save Control Panel Outputs

b

c

DC outputs for fans mounted on front panel;

b

also used for fan rotation detectors (if fitted)

RS-232 programming port

c

7.2 Power Supply Connections

AC Power The TB8100 PMU is designed to accept a mains input of 88 to 264VAC at

45 to 65Hz. We recommend that a standard 3-wire grounded outlet is used

to supply the AC power. The socket-outlet must be installed near the

equipment and must be easily accessible. This outlet should be connected

to an AC power supply capable of providing a maximum of 600W. The

requirements of two typical AC supplies are given in the following table.

Nominal Supply Current Requirement

115VAC 8A 10A

230VAC 4A 6A

Your TB8100 BSS should come supplied

with a power supply cord to connect the

male IEC connector on the PMU to the

local AC supply. The pins of the IEC

connector on the PMU are identified at

right.

Circuit Breaker/Fuse

Rating

neutral

ground

rear view

phase

DC Power The TB8100 PMU is designed to accept a DC input of 10.3 to 15.5VDC

with negative or positive ground. There is a minimum DC start-up

threshold to prevent damaging a battery which has little capacity left.

You must connect the DC supply from the battery to the PMU via a fuse or

DC-rated circuit breaker with a rating of 60A. The DC input leads should

be of a suitable gauge to ensure less than 0.2 V drop at maximum load over

the required length of lead.

86 Connection TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

Terminate and insulate the DC input leads so they are protected from

accidentally shorting to the subrack if the PMU is removed before the leads

are disconnected.

Figure 7.6 Recommended DC Power Connection

Circuit Breaker

or Fuse

PMU

Battery

Reciter Auxiliary DC

Input

PMU Auxiliary DC

Output

The system interface PCB in the reciter has an auxiliary DC input

connector. DC from the auxiliary DC output on the PMU (see “PMU

Auxiliary DC Output” below) can be supplied to the +AUX_V pin on the

system interface connector via this input.

The pin allocations for the auxiliary DC input on the system interface PCB

are given in the following table. Note that pins 1 & 3 and pins 2 & 4 on this

connector are linked. Refer to “System Connections” on page 89 for the

pin allocations for +AUX_V on each system interface PCB.

Pin Description Links

1+V input

123

4

rear view

2 ground

3+V input

4 ground

The DC output from the PMU is 12VDC. Although this power output is

isolated, the negative side of the supply is grounded on the system interface

PCB to give a +V output.

The PMU can provide an auxiliary DC output when it is fitted with the

optional 40W auxiliary power supply PCB. This power supply is current

limited to 3A and is available on the auxiliary DC output connector on the

rear panel. DC from this output can be supplied to the +AUX_V pin on

the system interface connector on the reciter via the auxiliary DC input

connector on the system interface PCB (see “Reciter Auxiliary DC Input”

above).

The pin allocations for the auxiliary DC output on the PMU are given in

the following table. Note that pins 1 to 4 and pins 5 to 8 on this connector

are linked.

TB8100 Installation and Operation Manual Connection 87

© Tait Electronics Ltd March 2004

7.3 RF Connections

The RF input to the TB8100 BSS is via the lower BNC connector on the

rear panel of the reciter. The RF output is via the N-type connector on the

rear panel of the PA (refer to Figure 7.3 on page 85).

We recommend that you use dual-screened coaxial cable such as RG223 for

the BNC connections, and RG214 for the N-type connections.

5

rear view

Pin Description Links

1 +V output

2 +V output

1

26

37

48

3 +V output

4 +V output

5ground

6ground

7ground

8ground

88 Connection TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

7.4 System Connections

The reciter can be fitted with an optional system interface PCB which

provides the links between the reciter’s internal circuitry and external

equipment. This PCB is securely mounted to the reciter’s chassis and is

connected to the control PCB with a flexible connector. The system

interface PCB is fitted with industry-standard connectors and several

standard types are available for different applications.

The circuitry on the system interface PCB provides additional signal

processing so that the outputs meet standard system requirements. It also

enables the PCB to identify itself to the reciter control circuitry.

The system interface PCB is removable, which makes it possible to change

the application of a reciter by removing one type of PCB and fitting another.

Only one system interface PCB can be fitted to a reciter at any one time.

This section provides details on the system interface PCBs available at the

time of publication. Other types may be developed for future applications.

Figure 7.7 System Interface PCB

system interface PCB*

control PCB

*standard system interface PCB shown

Standard The standard system interface PCB is fitted to reciters bearing the product

code TBA4xxx-0A0x or TBA5xxx-0A0x. If purchased separately, it has the

product code TBA10A0. It provides:

■ non-isolated 600: balanced audio I/O

■ high impedance unbalanced audio I/O

■ Tx key

■ Rx gate

■ RSSI

■ Tx relay

TB8100 Installation and Operation Manual Connection 89

© Tait Electronics Ltd March 2004

■ digital I/O.

It is fitted with a 25-way female D-range connector and an auxiliary DC

input connector. The pin allocations are listed in the table below.

Pin Signal Name Signal Type Notes

B

C

D

E

F

G

H

I

J

1)

1!

1@

1#

rear view

1$

1%

1^

1&

1*

1(

2)

2!

2@

2#

2$

2%

1 Rx line out +

2 Rx line out –

3 Rx audio out audio output AC coupled

4 ground ground

5 Tx audio in audio input AC coupled

6 Tx line in +

7 Tx line in –

8 RSSI DC signal

9 Rx gate output open collector

10 Tx key input

11 digital out 1

12 digital out 2

13 +AUX_V power output

14 digital in 1

15 digital in 2

16 digital in 3

17 digital in 4

18 digital in 5

19 digital in 6

20 digital in 7

21 digital in 8

22 digital in 9

23 digital in 10

24 Tx relay output open collector

25 ground ground

audio output

audio input AC coupled line

output open collector

input 5V logic

non-isolated

AC coupled line

90 Connection TB8100 Installation and Operation Manual

© Tait Electronics Ltd March 2004

Isolated

This system interface PCB is fitted to reciters bearing the product code

TBA4xxx-0B0x or TBA5xxx-0B0x. If purchased separately, it has the

product code TBA10B0. It is the same as the standard model, except that

the balanced audio interfaces are galvanically isolated.

Isolated E&M This system interface PCB is fitted to reciters bearing the product code

TBA4xxx-0C0x or TBA5xxx-0C0x. If purchased separately, it has the

product code TBA10C0. It provides:

■ isolated balanced audio I/O

■ opto-isolated keying

■ opto-isolated gate output.

It is fitted with a 25-way female D-range connector and an auxiliary DC

input connector. The pin allocations are listed in the table below.

Pin Signal Name Signal Type Notes

B

C

D

E

F

G

H

I

J

1)

1!

1@

1#

rear view

1$

1%

1^

1&

1*

1(

2)

2!

2@

2#

2$

2%

1 Rx line out +

2 Rx line out –

3 Rx audio out audio output

4 audio ground ground

5 Tx audio in audio input

6 Tx line in +

7 Tx line in –

8 RSSI DC signal

9 Rx gate output open collector

10 Tx key input

11 digital out 1

12 digital out 2

13 +AUX_V power output

14 digital in 1

15 digital in 2

16 digital in 3

17 digital in 4

18 digital in 5

19 digital in 6

20 opto +/–

21 opto –/+

22 relay +/–

23 relay –/+

24 Tx relay output open collector

25 ground ground

audio output transformer isolated line

audio input transformer isolated line

output open collector

input 5V logic

isolated keying input

isolated gate output

TB8100 Installation and Operation Manual Connection 91

© Tait Electronics Ltd March 2004

Tai tN et

This system interface PCB is fitted to reciters bearing the product code

TBA4xxx-0T1x or TBA5xxx-0T1x. If purchased separately, it has the

product code TBA10T1. It is designed for use with MPT trunking systems.

It is fitted with a 15-way female D-range connector and an auxiliary DC

input connector. The pin allocations are listed in the table below.

Pin Signal Name Signal Type Notes

1 Rx line out +

2 Rx line out –

3 Rx audio out audio output

B

C

D

E

F

G

H

I

rear view

J

1)

1!

1@

1#

1$

1%

4 Rx gate output open collector

5 Tx key input

6 Tx audio in audio input

7 Tx line in +

8 Tx line in –

9 +AUX_V power output

10 digital out 3 output open collector

11 no connection

12 digital out 1

13 digital out 2

14 digital in 1 input 5V logic

15 ground ground

7.5 Service Kit Connections

The TB8100 service kit is connected to the BSS via the RS-232 serial port

on the control panel. This port is a 9-way female D-range connector. Use

a straight through cable, as supplied with the service kit, to connect your

programming computer to the BSS. The pin allocations for the serial port

are given in the following table. Note that pins 1, 4 & 6 and pins 7 & 8 are

linked. This port is also used for remote connection to the Service Kit or

Alarm Center software via a modem or radio modem.

audio output AC coupled line

audio input AC coupled line

output open collector

Pin Description Links

1 not connected

2 receive data

3 transmit data

b

cdef

hj

gi

front view

92 Connection TB8100 Installation and Operation Manual

4 not connected

5ground

6 not connected

7 not connected

8 not connected

9 not connected

© Tait Electronics Ltd March 2004

7.6 Microphone Connection

You can connect a microphone to the TB8100 BSS via the standard RJ45

socket on the control panel. If a standard TB8100 microphone has not been

supplied with your BSS, you should use an electret microphone. The pin

allocations for the microphone socket are given in the following table.

12345678

front view

Pin Description

1not connected

2not connected

3not connected

4 PTT and hookswitch

5 voice band (microphone) input

6 microphone ground

7not connected

8not connected

TB8100 Installation and Operation Manual Connection 93

© Tait Electronics Ltd March 2004

Loading...

Loading...