Page 1

TB7100 bas e station

Installation and

Operation Ma nu a l

MBB-00001-02

Issue 2

December 2005

Page 2

Tait Contact Information

Tait Radio Communications

Corporate Head Office

Tait Electronics Ltd

P.O. Box 1645

Christchurch

New Zeala n d

For the address and telephone number of

regiona l of f ices, refer to th e TaitWorld

website:

Website: http://www.taitworld.com

Technical Support

For assistance with specific technical issues,

contact Technical Support:

E-mail: support@taitworld.com

Website: http://support.taitworld.com

To our European customers:

Tait Electronics Limited is an environmentally responsible company which

supports waste minimi zation and ma terial reco very. The European Union ’s

Waste Electrical and Electronic Equipment Directive requires that this

product be disposed of separately from the general waste stream when its

service life is over. Please be enviro nmentally responsible and dispose

through the original supplier, your local municipal waste “separate

collection” service, or contact Tait Electronics Limited.

2 TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Enquiries and Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Updates of Manual and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Associated Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Publication Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Frequency Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 RF Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 Power Supply Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4 Mechanical Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Product Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Mechanical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 UI Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Receiver Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Transmitter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 SI Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.6 AC Power Supply Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Receiver Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 RF Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.2 Digital Baseband Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.3 Audio Processing and Signalling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Transmitter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.1 Audio Processing and Signalling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.2 Frequency Synthesizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.3 RF Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 User Interface Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 System Interface Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.1 Internal Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.4.2 Serial Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4.3 General Purpose IO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4.4 Receiver Audio Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4.5 Tone On Idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4.6 Transmitter Audio Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

TB7100 Installation and Operation Manual 3

© Tait Electronics Limited May 2005

Page 4

3.4.7 Opto Isolated Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.8 Relay Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.9 Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.10 RSSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.11 Receiver Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.12 Receiver Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.5 Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1 Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.1 Lethal Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.2 Explosive Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.1.3 Proximity to RF Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.1.4 High Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2 Equipment Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2.1 ESD Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2.2 Antenna Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2.3 Equipment Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2.4 Installation and Servicing Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3 Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.1 Distress Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.2 FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.3 Unauthorised Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.4 Health, Safety and Electromagnetic Compatibility in Europe. . . . . . . . 44

4.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.1 Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.2 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.3 Dust and Dirt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5 Grounding and Lightning Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.1 Electrical Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.2 Lightning Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.6 Recommended Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.7 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.7.1 Cabinet and Rack Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.8 Installing the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.8.1 Unpacking the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.8.2 Identifying the Mechanical Configuration . . . . . . . . . . . . . . . . . . . . . 49

4.8.3 Power Supply Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.8.4 Setting the AC Mains Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.8.5 Mounting the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.8.6 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.8.7 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5 Replacing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.1 Removing the Base Station and Opening the Tray. . . . . . . . . . . . . . . . . . . . . . . 54

5.2 Replacing the UI Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3 Replacing the Receiver Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.4 Replacing the Transmitter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4 TB7100 Installation and Operation Manual

© Tait Electronics Limited May 2005

Page 5

5.5 Replacing the SI Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.6 Replacing the Transmitter and Receiver Fans . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.7 Replacing the Fan Power Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

5.8 Replacing the Temperature Sensor Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.9 Replacing the AC Power Supply Unit, Fan and Filter Module . . . . . . . . . . . . . .61

5.10 Replacing the Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.11 Final Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.1 External Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.2 Internal Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2.1 Transmitter and Receiver Connectors . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2.2 SI Board Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2.3 UI Board Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7 Preparation for Operat ion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.2 Mode of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.3 Line-controlled Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.3.1 Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.3.2 Test Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.3.3 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.3.4 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.3.5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.3.6 Receiver Audio Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.3.7 Receiver Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.3.8 Transmitter Audio Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.3.9 Transmitter Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

7.4 Talk Through Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.1 Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.2 Test Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.4.3 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.4.4 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.4.5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.4.6 Audio Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.4.7 Talk Through Repeater Functional Testing . . . . . . . . . . . . . . . . . . . . 91

7.4.8 Alternate Talk Through Repeater Configuration . . . . . . . . . . . . . . . . 92

7.5 RF Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.5.1 Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.5.2 Test Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.5.3 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.5.4 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.5.5 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.5.6 Audio Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.5.7 Programming for FFSK Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.5.8 Programming for THSD Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.5.9 Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

TB7100 Installation and Operation Manual 5

© Tait Electronics Limited May 2005

Page 6

7.6 Data Repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.6.1 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.6.2 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.6.3 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.6.4 Audio Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.6.5 Data Repeater Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.7 TaitNet Trunking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.8 Programmable Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.8.1 Connecting to the PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.8.2 TB7100 Programming Application . . . . . . . . . . . . . . . . . . . . . . . . . 105

7.8.3 Mandatory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.8.4 User-defined Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.8.5 Recommended Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

7.8.6 Function Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7.9 Additional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.10 Adding Subaudible Signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.10.1 Enabling Subaudible Signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.10.2 Testing Subaudible Signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.10.3 Multiple Subaudible Tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.11 Soft Off (Tx Tail Time) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7.11.1 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7.12 Tone On Idle (TOI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7.12.1 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.13 Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.13.1 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.14 Channel ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.14.1 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.15 Relay Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7.15.1 Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7.16 Channel Increment and Decrement by Function Keys . . . . . . . . . . . . . . . . . . . 123

7.17 Carrier Wave Identification (CWID). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.1 Station ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.2 Station ID 2/Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.3 Tone Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.4 ID Repeat Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.5 Speed (Words per Minute) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.6 Wait Period after Loss of COR/COS/CTCSS Input Before IDing. . 124

7.17.7 Transmit Key-Up Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.17.8 Transmit Time Out Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7.17.9 Transmit PTT Drop Out Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7.17.10Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8 Maintenance Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Directive 1999/5/EC Declaration of Co nformity . . . . . . . . . . . . . . . . . . . . . . . .141

6 TB7100 Installation and Operation Manual

© Tait Electronics Limited May 2005

Page 7

Preface

Scope of Manual

Welcome to the TB7100 Installation and Operation Manual. This manual

provides information on installing and operating the TB7100 base station.

Also included in this manual are a high-lev el cir cuit description, a functional

description and a maintenance guide.

Enquiries and Comments

If you have any enquiries regarding this manual, or any comments,

suggestions and notifications of errors, please contact Technical Support

(refer to “Tai t Contact Information” on page 2).

Updates of Manual and Equipment

In the interests of i mpr oving the performance, r eliability or servicing of the

equipment, Tait Electronics Limited reserves the right to update the

equipment or this manual or bot h without prior notice.

Copyright

All information contained in this manual is the property of

Tait Electronics Limited. All rights are reserved. This manual may not, in

whole or in part, be copied, photocop ied, repr oduced, tra nslated, stor ed, or

reduced to any electronic medium or machine-r eadable form, without prior

written permission from Tait Electronics Limited.

Disclaimer

There are no warranties extended or gr a nted by this manual .

Tait Electronics Limited accepts no responsibility for damage arising from

use of the information contained in the manual or of the equipment and

software it describes. It is the responsibility of the user to ensure that use of

such information, equipment and softwar e complies with the la ws, rules and

regulations of the applicab le jurisdictions.

TB7100 Installation and Operation Manual 7

© Tait Electronics Limited December 2005

Page 8

Document Conventions

“File > Open” means “click File on the menu bar, then click Open on the

list of commands that pops up”. “Channel Setup > Channels > Detailed”

means “in the navigation pane find the Channel Setup group, and select

Channels from it, on the Cha nnels page select the Detailed tab”.

Within this manual, four types of alerts are given to the reader: Warning,

Caution, Important and Note. The follo wing paragraphs illustrate each type

of alert and its associated symbol.

Warning!! This alert is used when there is a potential risk

Caution This alert is used when there is a risk of minor or

Important This alert is used to warn about the risk of equipment dam-

of death or serious injury.

moderate injury to people.

age or malfunction.

Note This alert is used to highlight information that is required to

ensure procedures are performed correctly.

Associated Documentation

The following associated documentation is available for this produc t:

■ MBB-00002-xx TB7100 Specifications Manual

■ MBB-00003-xx TB7100 Installation Guide

■ MBB-00005-xx TB7100 Service Manual

■ MBA-00013-xx TBA0STU/TBA0STP Calibration and Test Unit

The characters xx represent the issue number of the documentation.

All available documentation is provided on the CD (406-00047-xx)

supplied with the base station. Updates may also be published on the Tait

support website.

Technical notes are published from time to time to d escribe applications for

Tait products, to provide technical details not included in manuals, and to

offer solutions for any problems that arise.

Operation Manual

8 TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 9

Publication Record

Issue Publication Date Description

1 May 2005 First release

2 December 2005 Internal AC power supply, A4 and D1 bands

added.

TB7100 Installation and Operation Manual 9

© Tait Electronics Limited December 2005

Page 10

10 TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 11

1Introduction

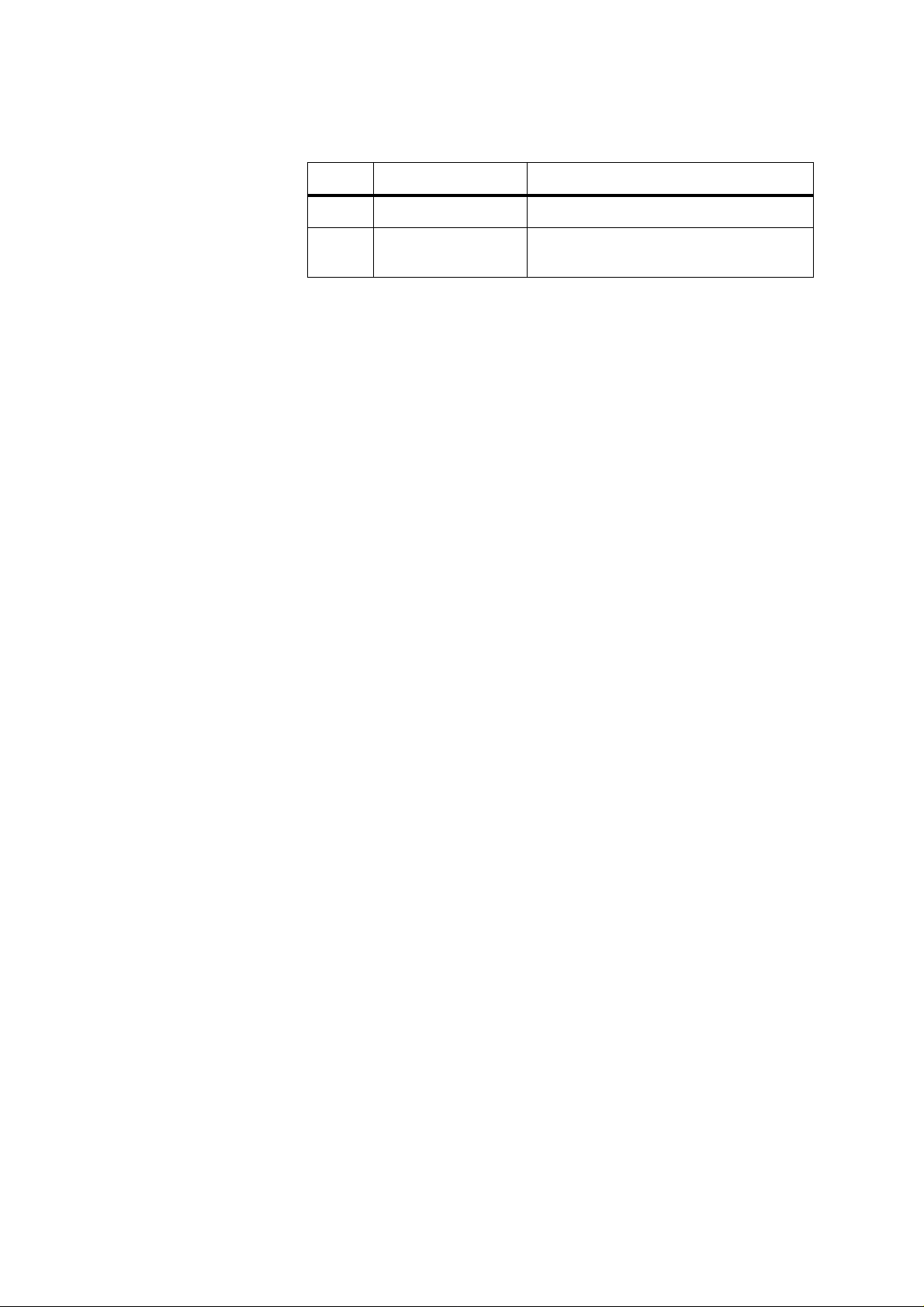

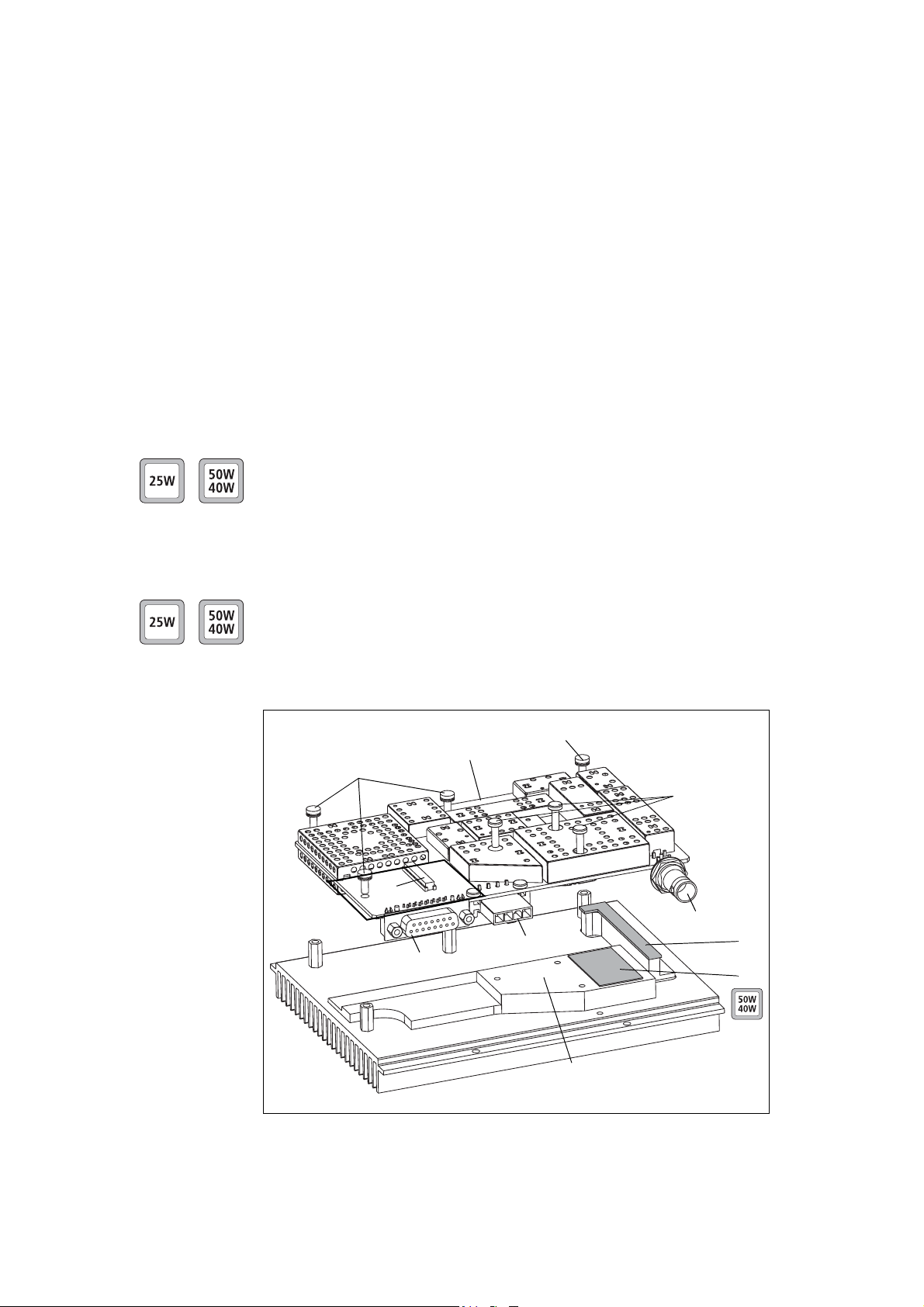

Figure 1.1 TB7100 base stations

Configuration with pr ovision for int ernal AC p ower supply*

Configuration without provision for internal AC power supply*

*cover removed

The TB7100 is a softw ar e and h ar dw ar e link- configur ed ba se stati on which

is designed for operation in a large variety of standard frequency ranges.

It makes extensive use of digital and DSP technology. Many operating

parameters such as channel spacing, audio bandwidth and sig na lling are

controlled by software.

This manual includes the information required for installing and operating

the base station.

This section describes the different options available for:

■ frequency bands

■ RF output power

■ power supply

■ mechanical configurations

■ product codes

For specifications, refer to the specifications manual or the area on the

Tait World website reserved for TB7100 products.

TB7100 Installation and Operation Manual Introduction 11

© Tait Electronics Limited December 2005

Page 12

1.1 Frequency Bands

The base station is available in the following frequency bands:

■ 66 to 88MHz (A4)

■ 136 to 174MHz (B1)

■ 216 to 266 MHz (D1)

■ 400 to 470MHz (H5)

■ 450 to 530MHz (H6)

■ 450 to 520MHz (H7)

The RF band of the base station is implemented by the frequency band of

the transmitter and receiver modules.

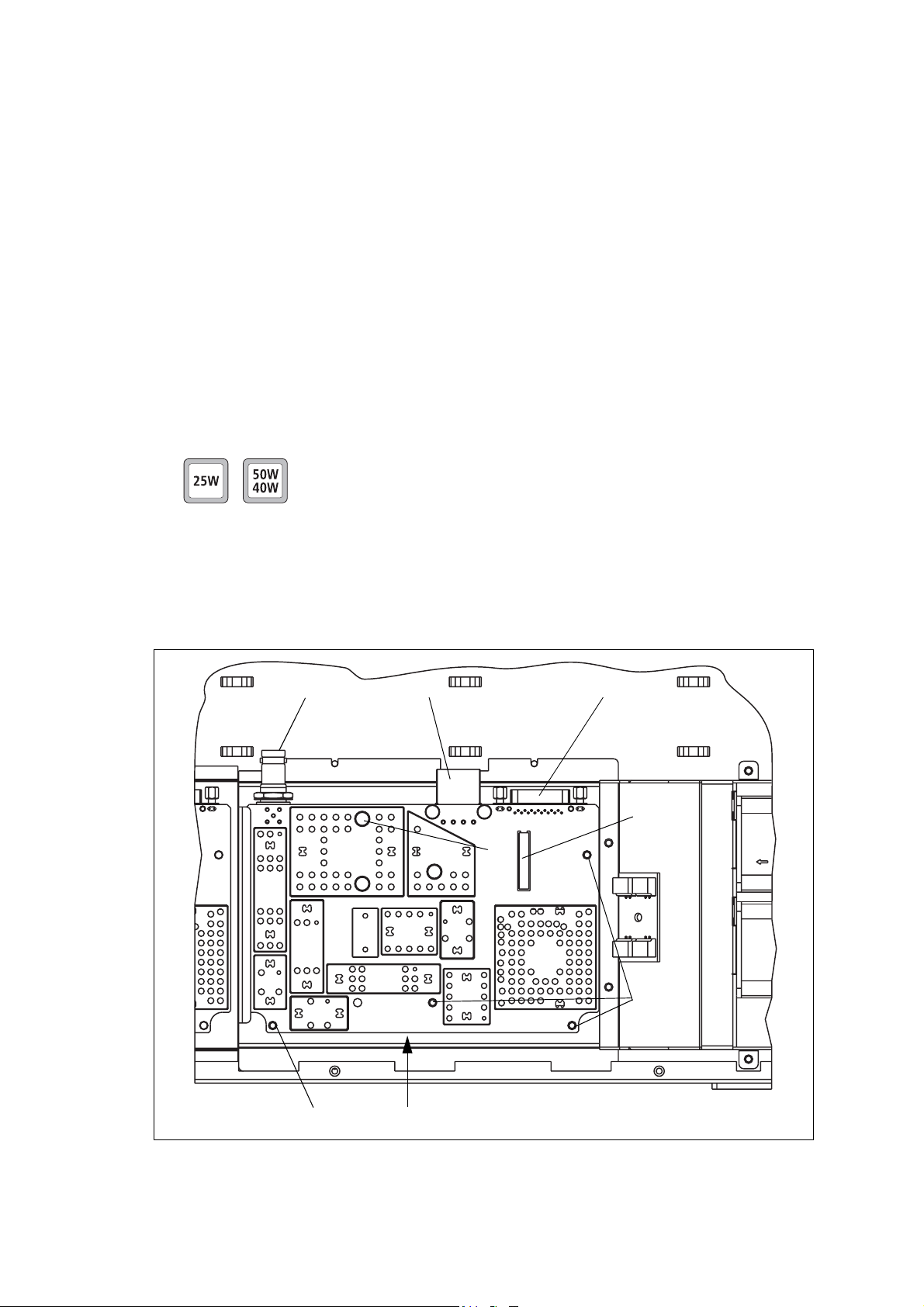

1.2 RF Output Power

The base station is available with 25W and 50W/40W RF output power.

The RF output pow er options ar e implemented by d ifferent transmitter and

receiver modules.

The 25W base station is available in the following frequency bands:

■ A4

■ B1

■ D1

■ H5

■ H6

The 50W/40W base station is available in the following frequency bands:

■ B1 (50 W)

■ H5 (40W)

■ H7 (40W)

12 Introduction TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 13

1.3 Power Supply Options

The base station is available with or without an internal AC power supply.

All base stations have an external DC input power connector which is used

as main power supply when no internal AC power supply is fitted.

When the internal AC power supply is fitted, the DC input can be used as

a DC backup pow er option. In case of AC mains failure the base station will

automatically and seamlessly switch to DC power input.

If no internal AC power supply is fitted, an external Tait T809-10-87xx

power supply can be used to supply the DC voltage required.

Warning!! The internal AC power supply unit contains

voltag es that ma y be lethal. Refer to the ratings

label on the rear of the bas e station. The internal

AC power supply contains no user-servicable

parts.

Important Wrong mains v oltage! Befor e connecting to the A C po w er

connector, ensure that the internal 115V/230V voltage

mains selector switch is set to the correct mains voltage.

1.4 Mechanical Configurations

The base station is available in two different mechanical configurations—

with or without provision for an internal AC power supply unit.

The mechanical configuration with provision for an internal AC power

supply has the following distinguishing features:

■ larger air intake on the right-hand side of the front panel

■ pro vis ion for A C con nector on the left-hand side o f the r ear p anel (r efer

to Figure 1.1 on page 11)

■ ground point on the right-hand side of the rear panel rather than on the

left-hand side

■ different SI board and internal cables.

The mechanical configuration without provis ion f or an internal AC power

supply unit cannot be upgraded with an internal AC power supply unit.

The product codes of the base station (see belo w) do not distinguish

between the mechanical configurations.

TB7100 Installation and Operation Manual Introduction 13

© Tait Electronics Limited December 2005

Page 14

1.5 Product Codes

This section describes the product codes used to identify products of the

TB7100 base station product line.

The product codes of the TB7100 base station product line has the format:

TBBaabb-cde-ff

where:

■ aa identifies the frequency band of the receiver:

A4=66 to 88MHz, B1=136 to 174MHz, D1=216 to 266 MHz,

H5=400 to 470MHz, H6=450 to 530MHz, H7=450 to 520MHz

■ bb identifies the frequency band of the transmitter:

A4=66 to 88MHz, B1=136 to 174MHz, D1=216 to 266 MHz,

H5=400 to 470MHz, H6=450 to 530MHz, H7=450 to 520MHz

■ c identifies the RF output power and digital architecture:

A=25W, level-1 digital architecture

B=35W to 50W, level-1 digital architecture

C=25W, level-2 digital architecture

D=35W to 50W, level-2 digital architecture

E=25W, level-3 digital architecture

F=35W to 50W, level-3 digital architecture

■ d identifies the power supply option:

0=DC only

1=internal AC power supply unit, factory preset to 115VAC

2=internal AC power supply unit, factory preset to 230VAC

■ e identifies the AC power cable:

1 = Australia/New Zealand

2 = United Kingdom

3 = Europe

4 = USA

■ ff identifies base station options:

00=no options

14 Introduction TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 15

2 Mechanical Description

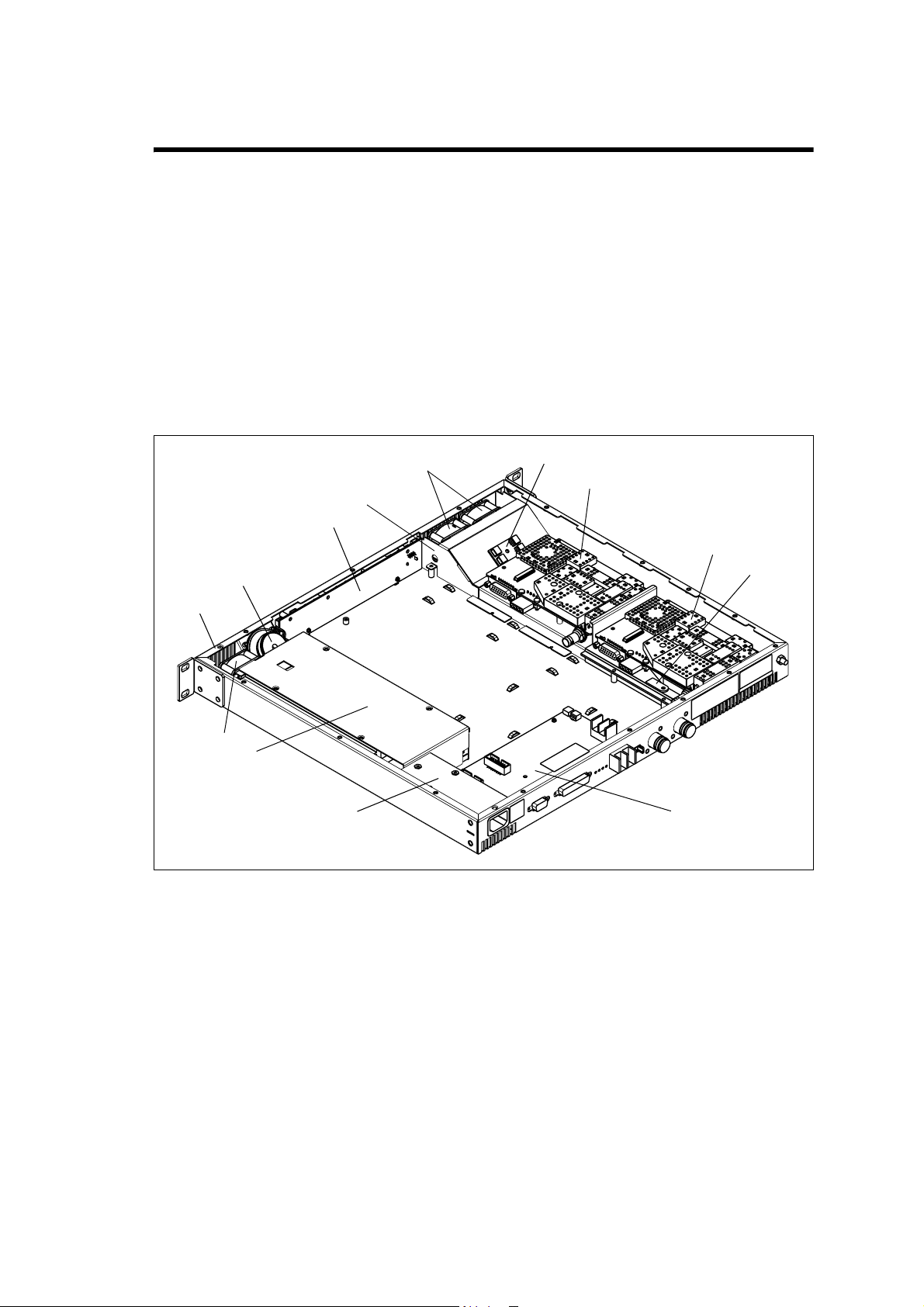

Overview The base station consists of the follo wing main modules:

■ tray b

■ UI board (user interface) d

■ receiver module h

■ transmitter module i

■ SI board (system interface) 1)

■ internal AC power supply unit 1@ (if fitted).

Figure 2.1 P arts of the base station (configuration with internal AC power supply unit shown)

b

1#

c

1@

f

g

h

e

d

i

j

1!

All modules and boards are mounted from above into the 1U tray

The modules are secured by scr ews or clips into s tandoffs on the tray chassis,

and are easily removed for replacement.

1)

b.

The base station includes two cooling fans

the receiver and transmitter modules, a speaker

panel, a fan power board

sensor board

If the internal AC po wer su pply unit

additional fan

The modules and components are interconnected by looms and cables.

TB7100 Installation and Operation Manual Mechanical Description 15

© Tait Electronics Limited December 2005

j mounted on the heatsink of the transmitter module i.

1# and an AC filter module 1!.

g mounted on the fan duct, and a temperature

f and a fan duct e in front of

c mounted behind the fr ont

1@ is fitted, the base station includes an

Page 16

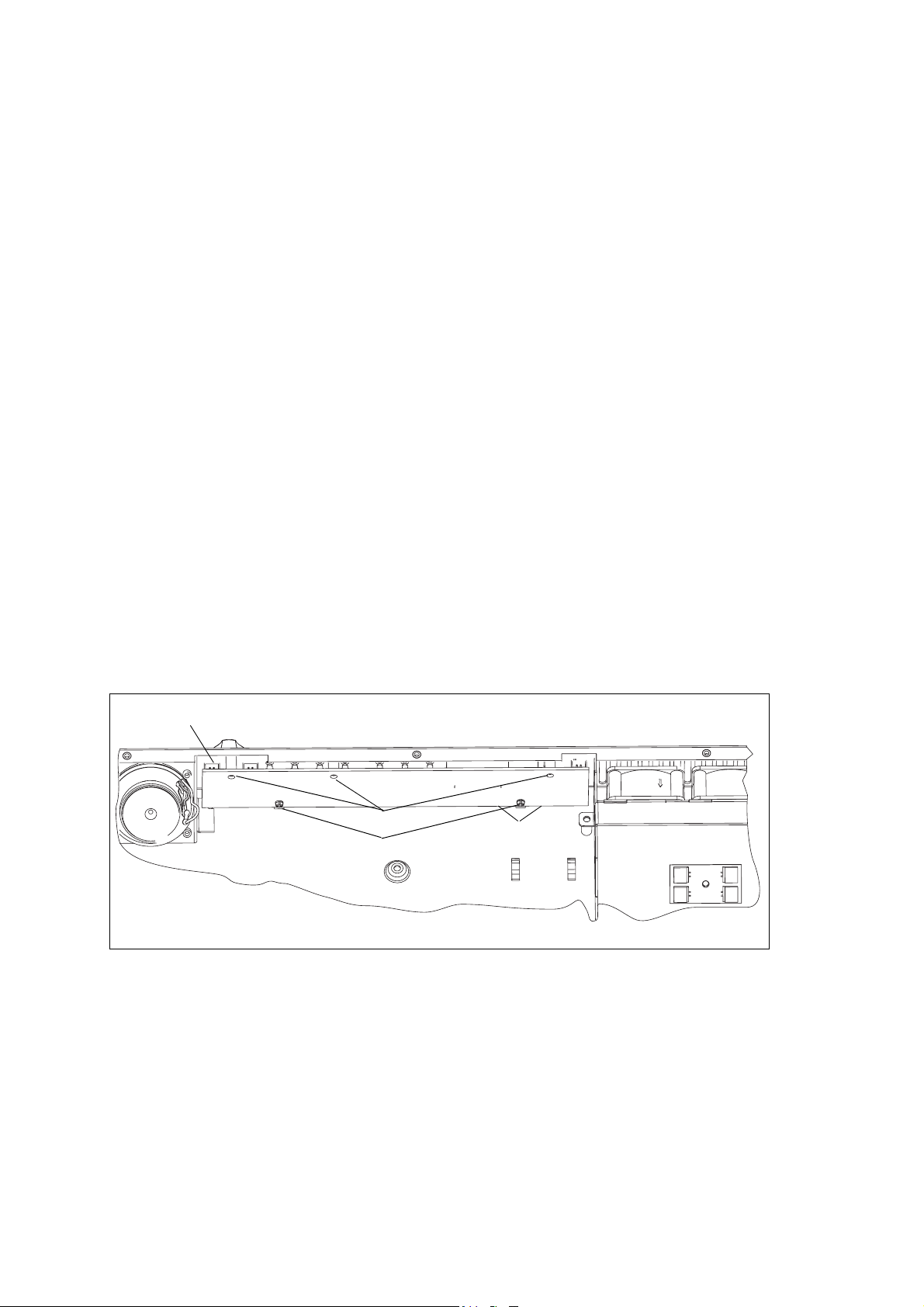

2.1 Tray

The 1U tray consists of a mild steel folded chassis and a flat cover (not

shown) which is fastened to the chassis with 15 Torx T10 screws. The tray

can be fitted into a standard 19 inch rack or cabinet using the two rack

mounting brackets.

The front panel ha s holes to accommodate the controls and the

microphone/programming connector of the UI board.

The rear panel has holes to accommodate the connectors and the fuse holder

of the SI board, the antenna connectors, and a gr ound terminal.

For more information on the connections, refer to “Connections” on

page 65.

2.2 UI Board

The UI board is mounted behind the front panel with three Torx T10

screws

transmitter and receiver modules via the two Micro-MaTch connectors

and the two UI cables (not shown). The UI board also has a speaker

connector

c and two spring clips D. The UI board is connected to the

e

b.

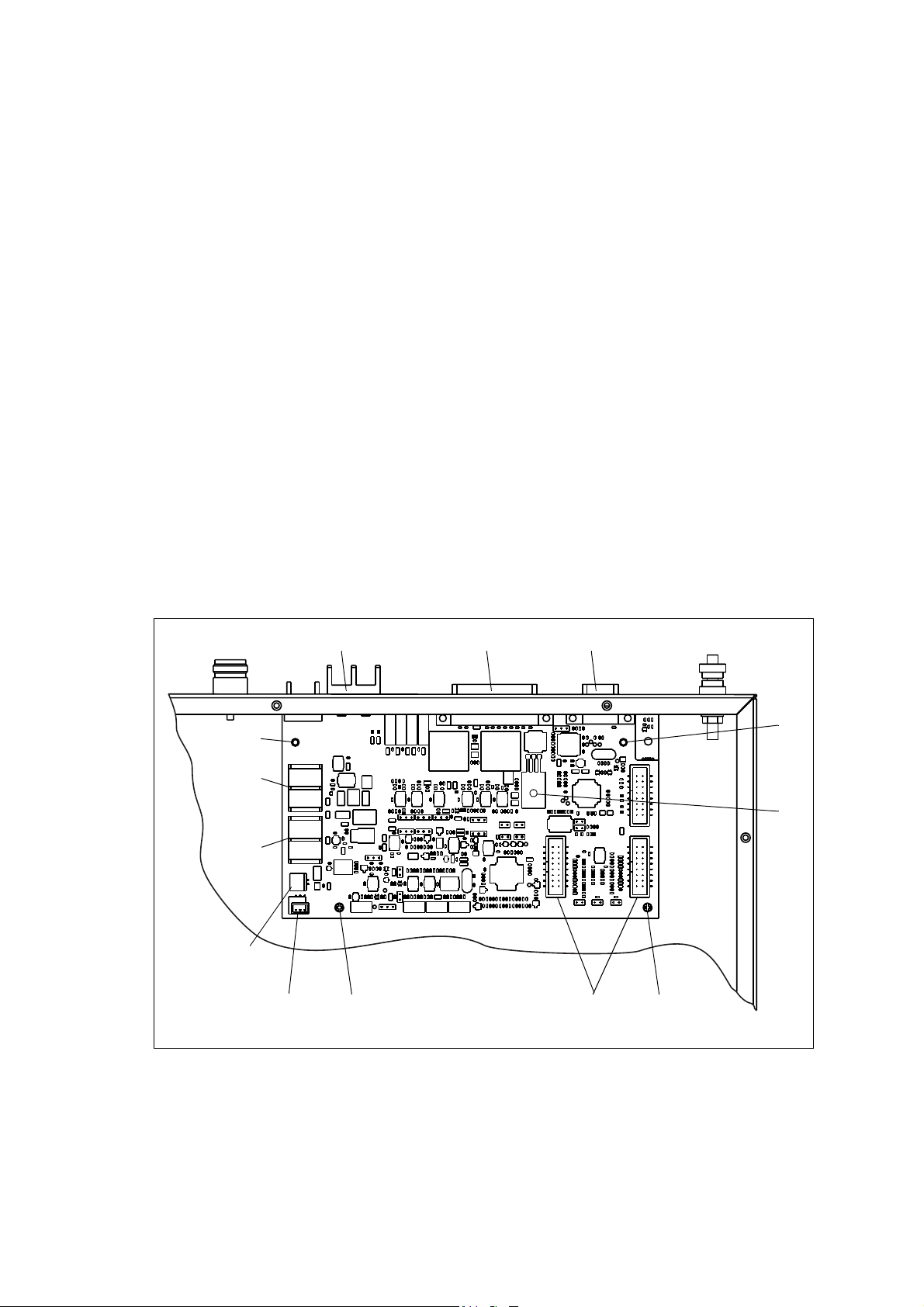

Figure 2.2 UI board

b

Cables not shown.

A volume knob is fitted to the shaft of the volume-control potentiometer.

c

e

d

16 Mechanical Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 17

2.3 Receiver Module

The receiver module is mounted in the front left of the tra y with five Torx

T10 screws

The receiver module is a printed circuit board in SMT design with

components on the top and bottom sides. A digital board is reflo w-sol dered

to the receiver. Most components are shielded by metal cans.

There are different boards for each frequency band and each RF output

power configuration.

g.

The RF

located on the bottom side of the boar d. The internal options connector

and a factory connector (not shown) for factory use are located on the top

side of the board.

For compliance reasons, there are different variants of the receiver module

for use in the 25W and 50W/40W base stations. The 25W version has a

white DC power connector

power connector.

For more information on the connectors, refer to “Connections” on

page 65.

Figure 2.3 Receiver module

b

b, D C po w er c, auxiliary d, and user interface f connectors are

e

C and the 50W/40W version has a black DC

cd

e

g

g

g

TB7100 Installation and Operation Manual Mechanical Description 17

© Tait Electronics Limited December 2005

f

Page 18

2.4 Transmitter Module

The transmitter module consisting of a transmitter board f mounted o n a

purpose-designed heatsink

four Torx T10 screws (not shown).

The transmitter board is a printed circuit board in SMT design with

components on the top and bottom sides. A digital board is r eflo w-soldered

to the board. Most components are shielded by metal cans. There are

different boards for each frequency band and each RF output power

configuration.

1) is mounted in the left rear of the tray with

The RF

located on the bottom side of the boar d. The internal options connector

and a factory connector (not shown) for factory use are located on the top

side of the board.

The 50W/40W version has a bla ck DC power connector

version has a white DC power connector. For more information on the

connectors, refer to “Connections” on page 65.

The board

b, DC po w er c, auxiliary d, and user interface f connectors are

e

C and the 2 5W

f is mounted to the heatsink 1) with seven Torx T10 screws

f and g.

An L-shaped gap pad

pad

j are fitted between the board f and the heatsink 1) to improve h eat

transfer.

Figure 2.4 Transmitter module

i and (with the 50W/40W version) a r ectangular gap

g

f

h

g

e

b

c

i

D

j

1)

18 Mechanical Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 19

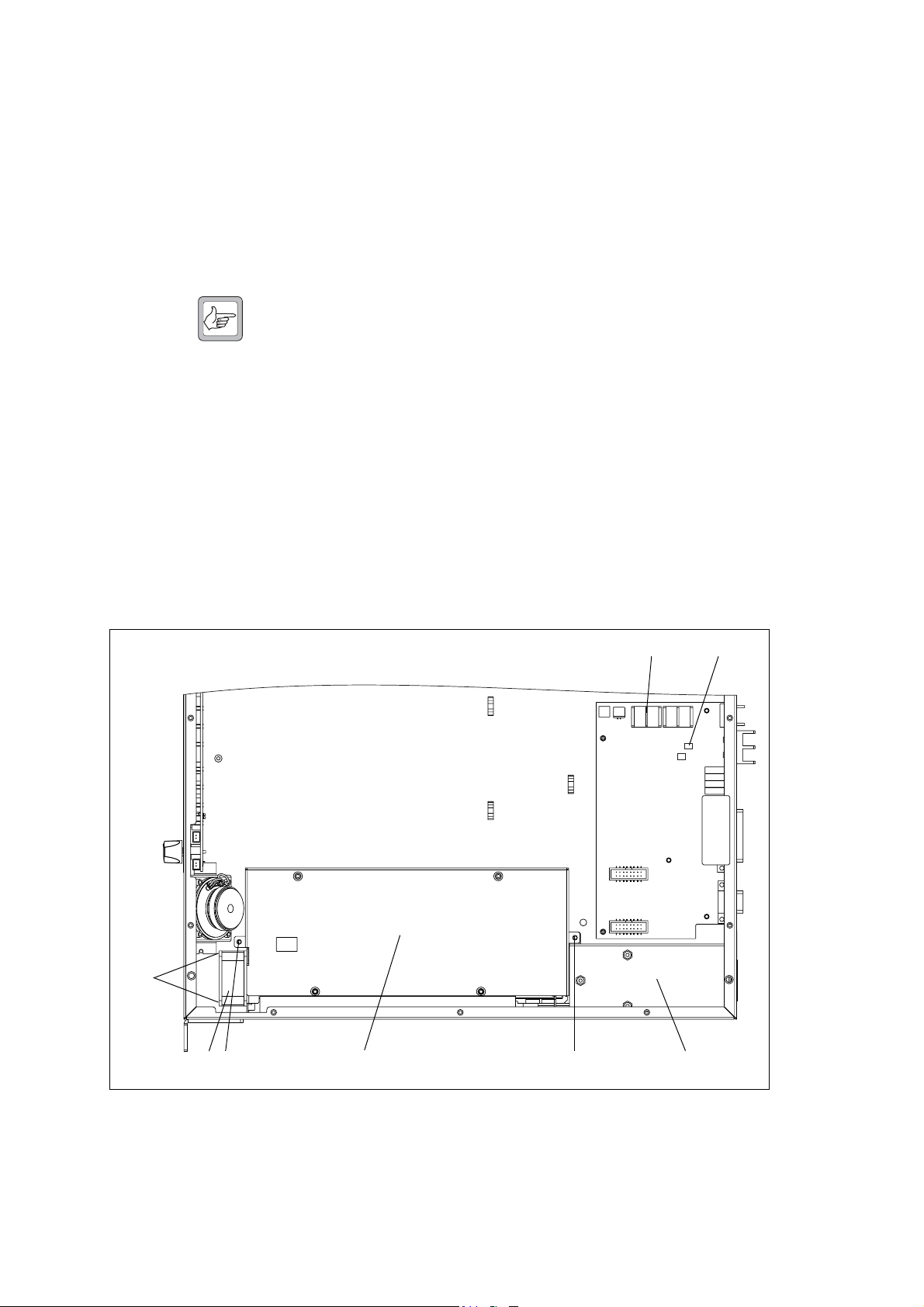

2.5 SI Board

The SI board is mounted in the rear right of the tray with two Torx T10

screws

The SI board has the follo wing external connectors:

■ 13.8 V DC power connector (labelled 12V DC) b

■ system connector (labelled SYSTEM) c

■ serial data connector (labelled IOIOI) D.

The SI board has the following internal connectors:

■ two syst em interface connectors e (to transmitter and receiver)

■ one DC input connector h, if fitted (from internal AC power supply)

■ one DC output connector i (to transmitter and receiver)

■ fan control connector f (to fan power board on fan duct)

■ temperature control connecto r g (to temperature sensor on transmitter

1), one Pozidriv scr ew j, an d two spring cli ps 1!.

heatsink).

Figure 2.5 SI board

1)

i

h

g

For more information on the connectors, refer to “Connections” on

page 65.

b

c d

1)

j

1!1! ef

TB7100 Installation and Operation Manual Mechanical Description 19

© Tait Electronics Limited December 2005

Page 20

2.6 AC Power Supply Unit

The base station ma y be fitt ed with an int ernal AC po w er supply unit f, an

AC filter module

The AC filter module has a stan dard A C connector that fit s into a pr o vision

on the rear of the tra y. The AC filter module slides into securing tabs on the

tray floor and is held in place by the AC power supply unit.

Note Mechanical configurations without the provision for a standard

AC connector cannot be upgraded with the internal AC power

supply unit.

d, and an additional fan g.

The AC power supply unit is held in place by two screws

attached to the AC power supply unit by two screws

The AC po w er supply unit is connected to the A C filter module via a cable

connector (not shown).

The DC output of the AC power supply unit is connected to the SI board

b. The AC pow er supp ly unit al so has a cable to provide a mains failure

signal to the SI board

power circuitry on the SI board to switch to DC external input.

Figure 2.6 AC power supply unit, filter module and fan

c. In case of a mains failure, this signal will cause the

e. The fan is

h.

bc

h

g

20 Mechanical Description TB7100 Installation and Operation Manual

e dfe

© Tait Electronics Limited December 2005

Page 21

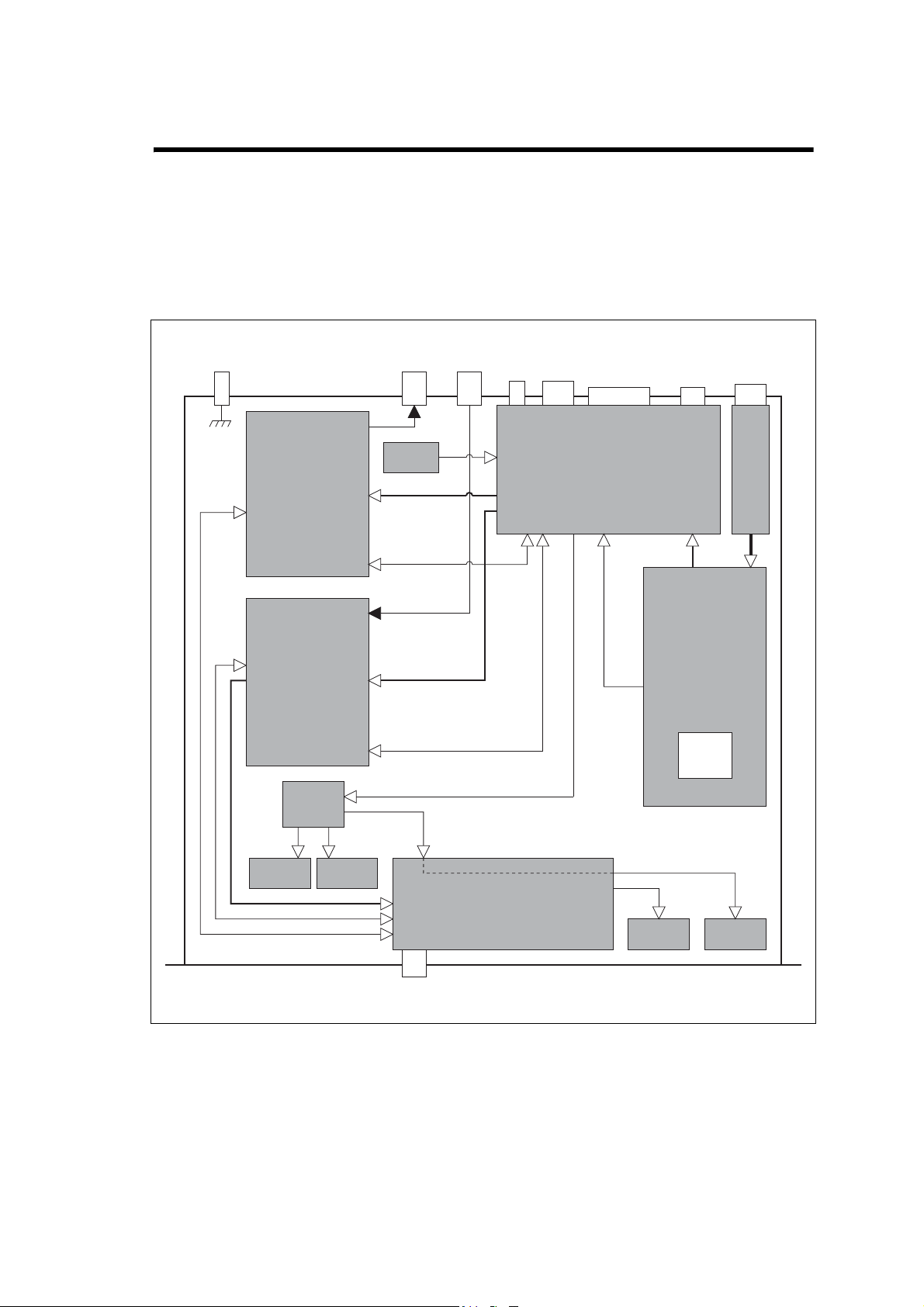

3 Functional Description

This section describes some principles of the base station operation.

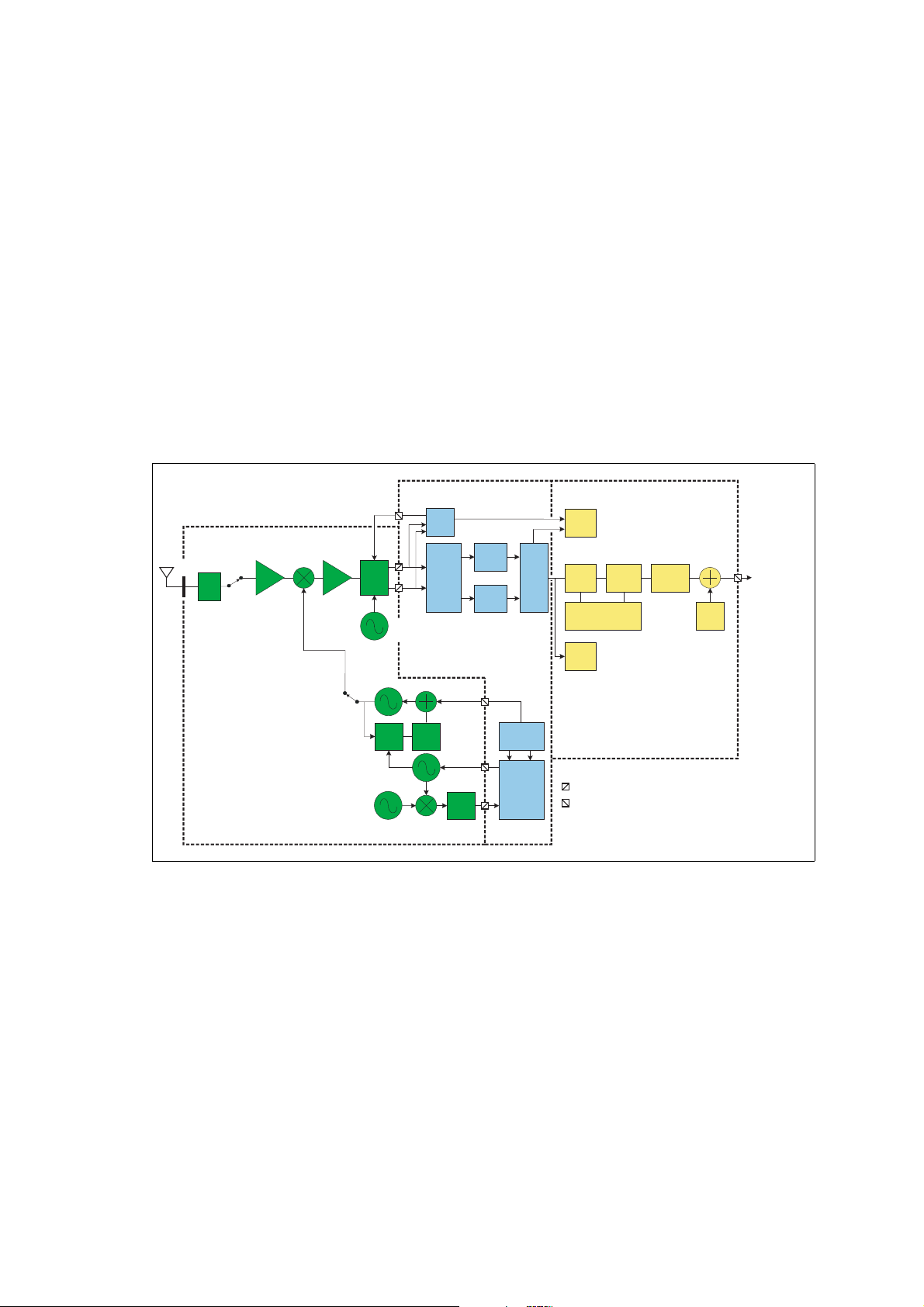

Figure 3.1 shows the high-level block diagram of the base station.

Figure 3.1 Base station high-level block diagram

Ground

Point

Transmitter

Module

Receiver

Module

Fan Power

Board

Tx/Ant

Connector

RF

Temperature

Sensor

Internal power

Transmitter/SI

RF

Internal power

Receiver/SI

Rx

Connector

Fuse

DC Input

Connector

System

Connector

SI Board

Mains fail signal

Serial Data

Connector

Internal power

AC

Power Supply

Unit

115V/230V

Selector

Switch

AC Input

Connector

Module

AC Input Filter

FanFan

Internal power

UI/Receiver

UI/Transmitter

Prog/Mic

Connector

UI Board

Speaker

Fan

TB7100 Installation and Operation Manual Functional Description 21

© Tait Electronics Limited December 2005

Page 22

The block diagram illustrates the main inputs and outputs for power, RF

and control signals, as well as the interconnection between modules:

■ pro gram data and audio fr om the PROG/MIC sock et on the UI boar d to and

from the transmitter and recei ver modules

■ audio and signalling from the SYSTEM connector to and from the

transmitter and receiver modules

■ RS-232 data from the serial data connector (IOIOI) to and from the

transmitter and receiver modules

■ fan power and control from the SI board

■ power distribution fr om the AC and DC power in put connecto rs to the

transmitter and receiver modules, and from the recei ver module to the

UI board.

The circuitry of the individual modules that make up the base station is

described in more detail in the following sections.

Frequency Bands

and Sub-bands

The circuitry of the transmitter and receiver modules is similar for all

frequency bands and is therefore covered by a single description in this

manual. Where the circuitry differs between bands, separate descriptions are

provided for each frequency band. For more information on frequency

bands, refer to the specifications man ual.

RS-232 Signals External data communications all occur directly between the connected

computer (or other electrical equipment) and the transmitter and receiver

modules over the RS-232 serial lines.

Fan Signals The power and ground signals for the fans are routed from the SI board to

the fans behind the front panel. These signals are electrically isolated from

all other system signals to ensur e fan noise is not transferred to other sensitiv e

system components.

If there is a fault in the fan circuitry , the transmitter module is protected fr om

overheating by its internal foldback circuitry.

Speaker Signal Received audio is sen t from the receiver module to the UI board.

The volume is controlled by the volume potentiometer on the UI board.

The audio signal is routed through the UI board to the speaker for

monitoring purposes.

Power and Ground The SI board provides power to the transmitter and receiver modules.

The receiver modules provides power to the UI board.

22 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 23

3.1 Receiver Operation

Parts of Receiver

Board

The main circuit parts of the receiver modules are:

■ receiver

■ frequency synthesizer

■ CODEC (coder-decoder) and audio circuitry

■ power supply

■ interface circuitry

Software plays a prominent role in the functioning of the radio.

When describing the operation of the radio the software m ust be included

with the above. This is considered further below.

These functional parts are described in detail below.

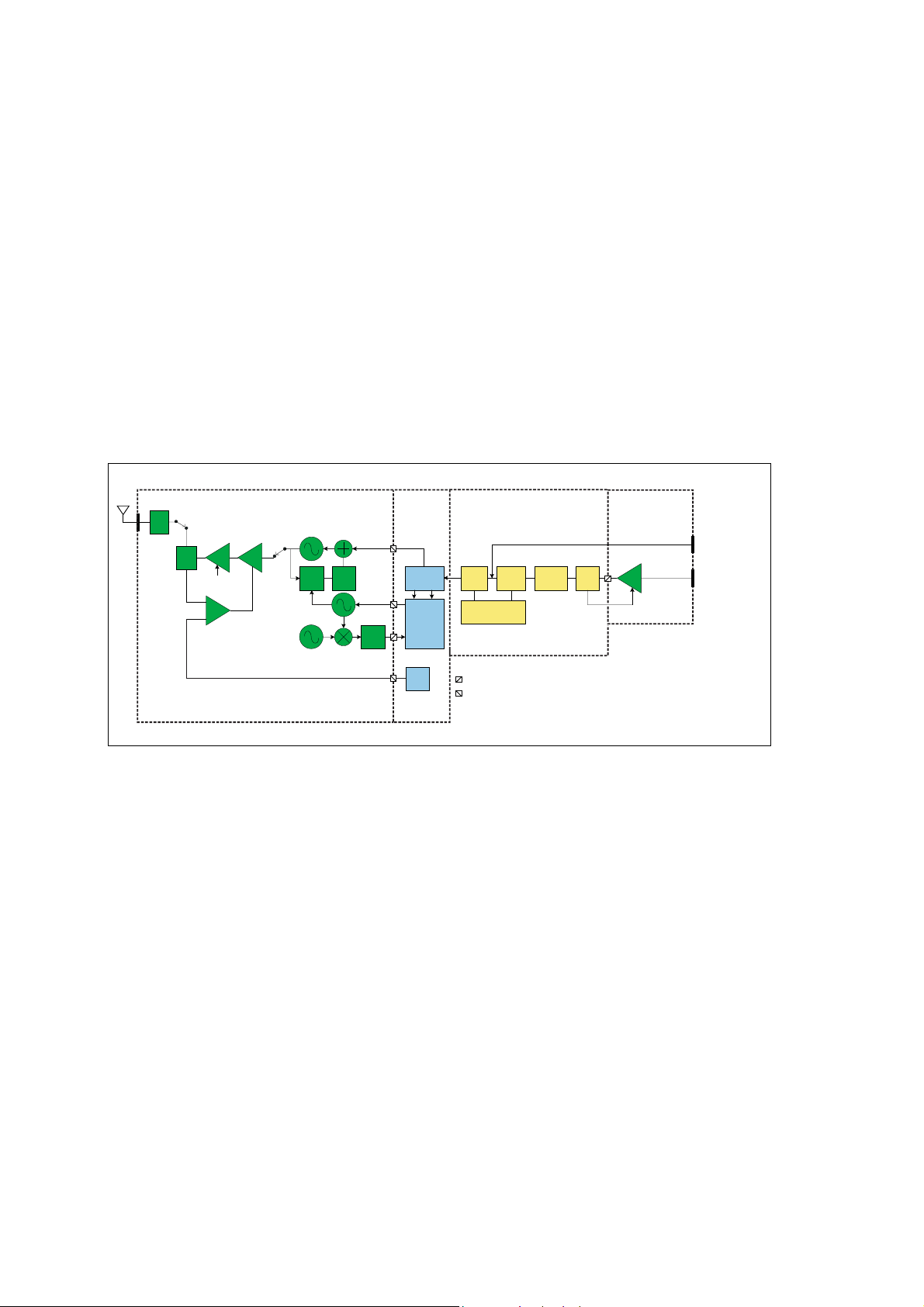

Figure 3.2 Receiver high-level block diagram

RX

2nd IF:

64 kHz

Second LO

UHF: 90.328 MHz

VHF: 42.928 MHz

AGC

Digital

down-

converter

IF:

UHF: 45.1 MHz

ANT

LPF

Front

end

VHF: 21.4 MHz

1st

IF

Phase

locked to

TCXO

Quad

Demod

VCO

Channel

LPF

Channel

LPF

CUSTOM-

LOGIC

BLOCK

Mag.

Demod

FM

RSSI

Audio

filtering

emphasis

Data and signalling

decoders

Squelch

De-

BLOCK

Optional

processing

DSP

Side

tones

System Interface

or User Interface

HARDWARE BLOCK

3.1.1 RF Hardware

Front End Circuitry

and First IF

The front-end hardware amplifies and image filters the received RF

spectrum, then down-converts the desired channel frequency to a first

intermediate frequency IF1 of 45.1MHz (UHF) or 21.4MHz (VHF) where

coarse channel filtering is performed. The first LO (local oscillator) signal is

obtained from the frequency synthesizer and is injected on the low side of

the desired channel frequen cy for all bands except A4. When r eceiving the

modulation to the freque ncy synthesizer is muted. The ou tput of the first IF

(intermediate frequency) stage is then down-converted using an imagereject mixer to a low IF of 64kH z.

TCXO:

13.000 MHz

PLL

VCXO

Loop

filter

Loop

filter

Triple-point

Equalisation

Frequency

control

KEY

Analogue-to-digital conversion

Digital-to-analogue conversion

NOTES

(1) Noise blanker not shown

TB7100 Installation and Operation Manual Functional Description 23

© Tait Electronics Limited December 2005

Page 24

Quadrature

Demodulator

Automatic Gain

Control

The LO for the image-reject mixer (quadratur e demodulator) is synthesized

and uses the TCXO (temperature-compensated crystal oscillator) as a

reference. This ensures good centring of the IF filters and more consistent

group-delay performance. The quadrature demodulator device has an

internal frequency division of 2 so the second LO operates a t

2 x (IF1 + 64kHz). The quadrature output from this mixer is fed to a pair

of ADCs (analog-to-digital con v erters) with high dynamic range where it is

oversampled at 256kHz and fed to the custom logic device.

The AGC (automatic gain contr ol) is used to limit the maximum signal lev el

applied to the image-reject mixer and ADCs in order to meet the

requirements for intermodulation and selectivity performance. Hardware

gain control is perfo rmed by a variable-gain amplifier within the quadrature

demodulator device driven by a 10-bit DAC (digital-to-analog converter).

Information about the signal level is obtained from the IQ (in-phase and

quadrature) data out put stream from the ADCs. The control loop is

completed within custom logic. The A GC will begin to reduce gain when

the combined signal power of the wanted signal and first adjac ent channels

is greater than about –70dBm. In the presence of a str ong adjacent-channel

signal it is therefore possib le that the AGC may st art acting when the wanted

signal is well below –70dBm .

3.1.2 Digital Baseband Processing

Custom Logic The remainder of the receiver processing up to demodulation is performed

by custom logic. The digitised quadrature signal from the RF hardware is

digitally down-converted to a zero IF, and channel filtering is performed at

base-band. Different filter shapes are possible to accommodate the various

channel spacings and data requirements. These filters provide the bulk of

adjacent channel selectivity for narrow-band operation. The filters have

linear phase response so that good group-delay performance for data is

achiev ed. The filters also decimate the sample rate do wn to 48kHz. Custom

logic also performs demodulation, which is multiplexed along with A GC

and amplitude data, and fed via a s ingle synchronous serial port to the DSP.

The stream is demultiplex ed a nd the demodulation data used a s an input for

further audio processing.

Noise Squelch The noise squelch process resides in the DSP. The noise content above and

adjacent to the voice band is measured and compared with a preset

threshold. When a wanted signal is presen t, out-of-band noise content is

reduced and, if below the preset threshold, is indicated as a valid wanted

signal.

Received Signal

Strength Indication

Received signal strength is measured by a process resident in the DSP.

This process obtains its input from the demodulator (value of RF signal

magnitude) and from the AGC (value of present gain). With these two

inputs and a calibration factor , t he RF sign al strength at the antenna can be

accurately calculated.

24 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 25

Calibration

The following items within the receiver path are calibrated in the Factory:

■ front-en d tuning

■ AGC

■ noise squelch

■ RSSI (received signal strength indication)

Information o n th e c al i b ration of these items is given in the on-line help

facility of the calibration application.

3.1.3 Audio Processing and Signalling

Audio Processing Raw demodulated data from the r eceiver is processed within the DSP. The

sample rate at this point is 48kHz with signal bandwidth limited only by the

IF filtering. Scaling (dependent on the bandwidth of the RF channel) is then

applied to normalise the signal level for the remaining audio pr ocessing.

The sample rate is decimated to 8kHz and bandpass audio filtering (0.3 to

3kHz) is applied. The base station takes the audio from the receiver mode

at Tap R4 by default; this point has no de-emphasis. This tap point can be

changed if required, for example, for trunking applications.

Data and Signalling

Decoders

The data and signalling decoders obtain their signals from various points

within the audio processing chain. The point used depends on the

bandwidth of the decoders and whether de-emphasis is required. Se veral

decoders may be active simultaneously.

Side Tones Side tones are summed in at the end of the audio-processing chain.

These are tones that pro vide some form of alert or giv e the user confidence

an action has been performed. The confidence tones may be generated in

the receiver. The side-tone level is a fixed proportion (in the order of

–10dB) relative to full scale in the receive path. By default, all audible

indicators are turned off.

CODEC The combined audio and side-tone signal is converted to analog form by a

16-bit DA C with integral anti-alias filtering. This is followed by a

programmable-gain amplifier with a range of 45dB in 1.5dB steps.

The amplifier performs muting. The DAC is part of the same CODEC

device (AD6521).

Output to Speakers The output of the CODEC is fed to an audio power amplifier and to the

UI board via a buffer amplifier. The output configu ration of the audio

power amplifier is balanced and drives an internal speaker. The power

delivered to the speake r is limited by its impedance. The speaker has 16Ω

impedance.

TB7100 Installation and Operation Manual Functional Description 25

© Tait Electronics Limited December 2005

Page 26

3.2 Transmitter Operation

Parts of T ransmitter

Board

The main circuit parts of the transmitter board are:

■ transmitter

■ frequency synthesizer

■ CODEC (coder-decoder) and audio circuitry

■ power supply

■ interface circuitry

Software plays a prominent role in the functioning of the board.

When describing the operation of the radio the software must be included

with the above. This is considered further below.

These functional parts are described in detail below.

Figure 3.3 Transmitter high-level block diagram

ANT

LPF

HARDWARE BLOCK

Dir.

Coup.

Drv

Fin

/Ex

Bias

Pwr

Crtl

TCXO:

13.000 MHz

VCO

Loop

PLL

filter

VCXO

Loop

filter

CUSTOM

LOGIC

BLOCK

Triple-point

Equalisation

Frequency

control

Ramp

control

Tap pointT8

Audio

filtering

emphasis

Data and signalling

encoders

KEY

Analog-to-digital conversion

Digital-to-analog conversion

DSP

BLOCK

Pre-

Optional

processing

ALC

HARDWARE

BLOCK

Mic

PGA

SYSTEM connector

PROG/MIC connector

3.2.1 Audio Processing and Signalling

Microphone Input The input to the transmitter path begins at either the SI board or the

PROG/MIC connector of the UI board. Only electret-type microphones are

supported. The audio input is then applied to tap point T8 on the

transmitter board (the tap point is user-selectable).

Analog Processing

of Microphone

Signal

26 Functional Description TB7100 Installation and Operation Manual

The CODEC (AD6521) performs microphone selection and ampli fication.

The microphone amplifier consi sts of an amplifier with a fix ed gain of 16dB

followed by a programmable-gain amplifier with 0dB to 22dB gain.

The amplified microphone signal is conv erted to a digital stream by a 16-bit

ADC with integral anti-alias filtering (0.1 to 3.2kHz). The digital stream is

transported to the DSP for further audio processing.

© Tait Electronics Limited December 2005

Page 27

Automatic Level

Control

DSP Audio

Processing

Data and Signalling

Encoders

The ALC (automatic lev el control) follo ws, and is used to effectiv ely increase

dynamic range by boosting the gain o f the micro phone pre-amplifier under

quiet conditions and reducing the gain under noisy acoustic conditions.

The ALC function resides in the DSP and controls the microphone

programmable-gain amplifier in the CODEC. The ALC has a fast-attack

(about 10ms) and slow-decay (up to 2s) characteristic. This characteristic

ensures that the peak signal level is regulated near full scale to maximise

dynamic range.

The output of the automatic level control provides the input to the DSP

audio-processing chain at a sample rate of 8kHz. Optional processing such

as encryption or companding is done first if applicable. Pre-emphasis, if

required, is then applied. The pre-emphasised signal is har d limited to

prev ent o v er deviation , and filtered to r emov e high -frequency components.

The sample rate is then interpolated up to 48kHz and scaled to be suitable

for the frequency synthesizer.

The data and signalling encoders inject their signals into various points

within the audio-processing chain. The injection point depends on the

bandwidth of the encoders and whether pre-emphasis is required.

3.2.2 Frequency Synthesizer

Main Parts of

Synthesizer

Frequency Control

Loop

The frequency synthesizer consists of two main parts:

■ FCL (frequency control loop)

■ RF PLL (phase-locked loop)

The FCL and RF PLL are described br iefly below. Note that patents are

pending for several aspects of the synthesizer desi gn.

The FCL consists of the following:

■ TCXO

■ mixer

■ loop filter

■ VCXO (voltage-controlled crystal oscillator)

■ frequency control block

The FCL provides the refere nce frequency for the RF PLL. It generates a

high-stability refer ence frequency that can be both modulated and offset in

fine resolution steps.

TB7100 Installation and Operation Manual Functional Description 27

© Tait Electronics Limited December 2005

Page 28

RF PLL

Operation of

Control Loop

The RF PLL consists of the following:

■ RF PLL device

■ loop filter

■ VCO (voltage-cont rolled oscillator)

■ VCO output switc h

The RF PLL has fast-locking capability but coarse frequency resolution.

The above combination of control loops creates improved frequency

generation and acquisition capabilities.

The RF PLL is a conventional integer-N design with frequency resolution

of 25 kH z. In transmit mode the loop locks to the transmit frequency.

Initially , the VCO generates an unr egulated frequency in the requir ed range.

This is fed to the PLL device (ADF4111) and divided down by a

programmed ratio to appr oximately 25kHz. The reference frequency input

from the FCL is also divided down to approximately 25kHz. The phase of

the two signals is compared and the error translated into a DC voltage by a

programmable charge pump an d dual-bandwidth loop filter . This DC signal

is used to control the VCO frequency and reduce the init ial error. The loop

even tually settles to a point that minimises the phas e error between divideddown reference and VCO frequencies. The net result is that the loop locks

to a programmed multiple of the reference frequency.

The FCL generates an output of 13.012±0.004MHz. Initially a VCXO

produces a quasi-regulated frequency in the required range. The VCXO

output is fed to a mixer where it is mixed with the 13.000MHz TCXO

frequency. The mixer, a fter low-pass filtering to remov e unwant ed products,

produces a nominal frequency of 12kHz. This is converted to digital form

and transported to the frequency-control block in custom logic.

The frequency-contr ol block compares the mixer output frequency with a

reference generated by the digital clock and creates a DC error signal. A

programmed offset is also added. This error signal is converted to analog

form and used to control the VCXO fr equency and r educe the i nitial error .

Once settled, the loop locks to the TCXO frequency with a programmed

offset frequency. The FCL output therefore acquir es the TCXO’s frequency

stability.

Modulation The full bandwidth modulation signal is obtained from the DSP in digital

form at a sample rate of 48kHz. In traditional dual-point modulation

systems the modulation is applied, in analog form, to both the frequency

reference and the VCO in the RF PLL, combining to produce a flat

modulation respon se dow n to DC. Reference m odulation is usually a pplied

directly to the TCXO.

28 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 29

In the system employ ed in th e transmitter boar d, the fr equency r efer ence is

generated by the FCL, which itself r equires dual-point modulation injection

to allow modu lation do wn to DC. W ith another modulati on point requi red

in the RF PLL, this system therefore requires triple-point modulation.

The modulation signals applied to the FCL are in digital form, whereas for

the RF PLL (VCO) the modulation signal is applied in analog form.

The modulation cross-over points occur at appro ximately 30 and 300Hz as

determined by the closed loop bandwidths of the FCL and RF PLL

respectively.

Frequency

Generation

Fast Frequency

Settling

Frequency

Acquisition

of RF PLL

The RF PLL has a fr equency resolution of 25kHz. Higher resolution cannot

be achieved owing to acquisition-time requirements and so for any given

frequency the error could be as high as ±12.5kHz. This error is corrected

by altering the reference frequency to the RF PLL. The FCL supplies the

reference fr equency and is able to adjust it up to ±300ppm with better than

0.1ppm resolution (equi valent to better than 50Hz resolution at the RF

frequency).

Both the FCL and RF PLL employ frequency-acquisition speed-up

techniques to achieve fast frequency settling. The frequency-acqui sition

process of the FCL and RF PLL is able to occur concurrently with minimal

loop interaction owing to the very large difference in frequency step size

between the loops.

In the RF PLL the loop bandwidth is initially set high by increasing the

charge pump current and reducing time constants in the loop filter. As a

result settling to within 1kHz of the final value occurs in under 4ms. In

order to meet noise performance requir ements the loop parameters are then

switched to reduce the loop bandwidth. There is a small frequency kick as

the loop bandwidth is reduced. Total settling time is under 4.5ms.

Frequency

Acquisition

of FCL

The FCL utilises self-calibration techniques that enable it to rapidl y settle

close to the final value while the loop is open. The loop is then closed and

settling to the final value occurs with an associated reduction in no ise.

The total settling time is typically less than 4 ms.

Calibration The following items are calibrated in the frequency synthesizer:

■ nominal frequency

■ KVCO

■ KVCXO

■ VCO deviation

Calibration of the nominal freq uency is achi e v ed b y addi ng a fixed offset to

the FCL nominal frequency; the TCXO frequency itself is not adjusted.

The items KVCO and KVCXO are the control s ensitivities of the RF VCO

(in MHz/V) and VCXO (in kHz/V) res pectively. The latter has temperature

compensation.

TB7100 Installation and Operation Manual Functional Description 29

© Tait Electronics Limited December 2005

Page 30

3.2.3 RF Power A mplifier

RF Power Amplifier

and Switching

(50W/40WVersion)

RF Power Amplifier

and Switching

(25W Version)

Output of RF

Power Amplifier

The RF power amplifier and exciter of the 50W/40W radio is a five-st age

line-up with approximately 40dB of power gain. The output of the

frequency synthesizer is first buffer ed to reduce kick during pow er ramping.

The buffer output goes to a discrete exciter that pr oduces appro ximately 300

to 400mW output. This is follo w ed b y an LDMOS driv er pr odu cing up to

8W output that is power-controlled. The final stage consists of two parallel

LDMOS devices pr oducing enoug h pow er to pro vi de 40 to 50W at the RF

connector.

The RF power amplifier of the 25 W version is a four-stage line-up with

appro ximately 37dB of power gain. The output of the frequency syn thesizer

is first buffered to reduce kick during power ramping. The b uffer output

goes to a broad-band exciter IC that produces appro ximately 200mW

output. This is follo wed by an LDMOS driver pr oducing up to 2W output

that is power-contro lled. The final stage consists of two parallel LDMOS

devices pro ducing enough power to provide 25W at the RF connector.

The output of the RF P A passes thr ough a dual-directiona l coupler, used for

power control and monitoring. Finally, the output is low-pass-filtered to

bring harmonic levels within specification.

Power Control The steady-state power output of the transmitter is regulated using a

hardwar e contr ol loop . The forw ard po w er output fr om the RF PA is sensed

by the directional coupler and fed back to the power control loop. The PA

output power is controlled by v arying the driv er gate bias voltage that has a

calibrated maximum limit to pre vent over drive. The power control signal is

supplied by a 13-bit DAC driven by custom logic.

Ramping Power ramp-up consists of two stages:

■ bias

■ power ramping

The timing between these two stages is critical to achieving the correct

overall wave shape in order to meet the specification for transient AC P

(adjacent channel power). A typical ramping waveform is shown in

Figure 3.4.

30 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 31

Figure 3.4 Typical ramping waveforms

Power

Power

Bias

ramp

Power

ramp

High power

powerLow

ramp

Bias

ramp

Time

Bias Ramp-up

The steady-state final-stage bias level is supplied by an 8-bit DAC

programmed prior to ramp-up but held to zero by a switch on the DAC

output under the contr ol of a

release by the

TX INHIBIT signal with the ramping shape being determined by

TX INHIBIT signal. Bia s ramp -u p begins upon

a low-pass filter. Owing to power leakage through the P A chain, ramping

the bias takes the PA output power from less than –2 0dBm for the

50W/40W version or –10dBm for the 25W version to approxima tely

25dB below steady-state power.

Power Ramp-up The power ramp signal is supplied by a 13-bit DAC that is controlled by

custom logic. The ramp is generated using a look-up table in custom logic

memory that is played back at the correct rate to the DAC to produce the

desired waveform. The ramp-up and ramp-down waveforms are produced

by playing ba ck the look-up tab le in forw ard and r e verse order respectively .

For a given power lev el th e look-up table values are scaled b y a steady-state

power constant so that the ramp waveform shape remains the same for all

power levels.

TB7100 Installation and Operation Manual Functional Description 31

© Tait Electronics Limited December 2005

Page 32

3.3 User Interface Operation

This section describes the programming/microphone connector and the

controls of the user inter face, and the function of the UI board.

Figure 3.5 shows the controls and indicators of the user interface.

Figure 3.5 User interface

status LEDs

2-digit LCD

programming/

microphone

connector

Programming/

Microphone

Connector

TX/RX Switch The TX/RX sw itch changes the LCD display to sho w either the t ransmitter or

Tx/Rx

switch

display

The PROG/MIC connector can be used to connect a handset or a pr ogramming

cable.

the receiv er channel. The

TX/RX switch also determines which board will be

volume controlfunction keys and LEDs

internal speaker

programmed by the programming or calibration applications.

The programming application is a pro gram on a PC that is connected to the

base station via the

PROG/MIC connector . Theprogramming application

enables the user to pro gram the base station with t he requ ired chann els and

subaudible signalling settings. The transmitter and receiver modules are

programmed individually according to the setting of the

TX/RX switch.

The calibration application is a program on a PC that is connected to the

base station via the

PROG/MIC connector. The transmitter and receiver

modules are designed to be totally electronically tuned. N o physical tuning

is required, as all tuning is done by electronic trimming. The calibration

application can assist in the tuning of:

■ AD6521 CODEC voltage reference

■ TCXO frequency

■ receiver front end

■ transmitter driver and final gate bias limit

■ transmitter power control

■ deviation and squelch.

32 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 33

Function Keys

Pressing the function keys will activate the functions assigned using the

programming application. Function keys may have functions assigned to

both short and long key presses. A short key press is less than one second,

and a long ke y press is more than one second.

Volum e Control and

Internal Speaker

Rotate the volume contr ol poten tiometer clockwise to incr ease the speak er

volume and counterclockwise to decrease the volume. By default, the base

station is programmed not to generate any audible indicators.

UI Board The UI board is connected to the receiver and transmitter modules via

separate 18-way ribbon cables. The internal speaker is connected to the

UI board via a cable with a mating connector for easy disconnection.

If an internal AC Power supply is fitted, a fan power signal is routed from

the fan powe r board to the fan via the UI board. For mor e information on

the connectors and their signals, refer to “UI Board Connectors” on

page 75.

Figure 3.6 on page 34 shows a block diagram of the UI board.

The UI board does not include a microprocessor. A synchronous bidirectional serial interface provides communication of key status, LCD and

LED-indicator data between the transmitter/receiver modules and the UI

board. The serial data is converted to or from a parallel form by a number

of shift registers for the function ke ys and indicators. For the LCD, the serial

data is fed to a driver IC that converts the serial data to a form suitable for

the LCD. The keys are scanned and the LCD and LED indicators updated

approximately every 50ms. The

TX/RX switch controls what is displayed on

the LCD and also whether the transmitter module or the receiver module

will be programmed.

TB7100 Installation and Operation Manual Functional Description 33

© Tait Electronics Limited December 2005

Page 34

Figure 3.6 UI board block diagram

UI Board

Speaker

Receiver

Module

Transmitter

Module

+13V8

+3V3

SpeakerAudio

Volume Level (DC)

Rx SPI Data

Rx Prog Data

Rx SPI Data

Rx Prog Data

PTT

MicAudio

+13V8

+3V3

Receiver

SPI Shift

Registers

Transmitter

SPI Shift

Registers

Electronic

Switching

Volume

Control

+3V3

Power

LED

Busy

LED

Function

Keys and

LEDs

Tx

LED

LCD

Tx/Rx

Switch

+13V8

Prog/Mic

Connector

Fan Power

Fan Power

Fan

Connector

Board

34 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 35

3.4 System Interface Operation

This section describes the functioning of the system interface. The system

interface provides:

■ internal power distribution

■ internal AC/external DC switching

■ serial data connection (THSD or FFSK)

■ fan control

■ general purpose IO

■ receiver audio processing

■ transmitter audio processing

■ opto-isolated keying

■ rela y output

■ received signal strength indication (RSSI)

■ receiver gate output

■ receiver inhibit input

■ 13.8VDC (1.5A) output

■ tone on idle (TOI).

These functional parts are described in detail below.

TB7100 Installation and Operation Manual Functional Description 35

© Tait Electronics Limited December 2005

Page 36

Figure 3.7 SI board block diagram

Transmitter

Module

13.8V

AUD IN

SI Board

13.8V

4.5V

3.3V

13.8V out

13.8V

13.8V

Mains fail signal

9V

Power Supplies

Fuse

13.8V

AC Power

Supply Unit

DC Power

Connector

AGND IN

13.8V out

9V 4.5V

RXAUDIO OUT

RX LINE OUT

Audio

TOITONE

TX INAUDIO

TX LINE IN

4.5V

System

Connector

9V

3.3V

Receiver

Module

Temperature

Sensor

Fan Power

Board

AUX IO

TX KEY

TX DATA

13.8V

AUD OUT

AUX IO

RX GATE

RSSI

RX DATA

Control

and

Signalling

13.8V

3.3V

Fan Control

TX KEY

RX INHIBIT

RELAY DRIVER

OPTO

DIG IO

TX DIG IO

RX DIG IO

RX GATE

RSSI

TXD

RXD

Serial Data

Connector

36 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 37

3.4.1 Internal Power Distribution

This section details ho w the i nput power feed is distributed throughout the

base station to powe r its various sub-systems. Refer to Figure 3.8 for more

information.

Figure 3.8 Powe r distribution

Prog/Mic

UI Board

Connector

Frequency

Synthesizer

Module

Receiver

CWID

SI Board

13.8V

Audio

9V

Power

Supply

Circuitry

13.8V

Mains fail signal

13.8V

CODEC

andAudio

6V

3.3V

Circuitry

Data

9V

Power

Circuitry

3.3V

Supply

Circuitry

3V

Fuse

4.5V

2.5V

Receiver

Control

Circuitry

Digital

Circuitry

Fan Control

Connector

DC Power

Board

Interface

Fan

Power

Board

Frequency

Synthesizer

Module

Transmitter

13.8V

Power

9V

CODEC

6V

Supply

Circuitry

andAudio

3.3V

Board

Digital

Transmitter

3V

2.5V

Interface

AC

Power

Source

AC Power

Supply Unit

DC

Power

Source

13.8V DC This is from either the DC input on the rear of the base station, or from an

optional internal AC po w er s upply unit. When AC mains is present, power

will not be drawn from the DC input. The DC power input of the base

station is protected by a r ear panel fuse . The 13.8V is distributed directly to

TB7100 Installation and Operation Manual Functional Description 37

© Tait Electronics Limited December 2005

Page 38

the receiver and transmitter boards and to the 13.8VDC output on the

SYSTEM connector, rated at 1.5A. The 13.8VDC is also used to power the

fans, via control circuitry.

Note The UI board obtains 13.8V and 3.3V from the receiv er module

and outputs 13V8_SW to the

3.3V, 4.5V, 9V, 13.8V The other voltages derived on the SI board are used only on the SI board.

PROG/MIC connector.

3.4.2 Serial Data

THSD Tait High Speed Data (THSD) is a proprietary protocol of Tait Electronics

Limited that can be used with the base station. This allows the base station

configured in either data r epeat er or data modem modes to pass data sp eeds

up to 12kbps on a narrow-band channel and 19.2kbps on a wide-band

channel. 1200-baud Fast Frequency Shift K eyed ( FFSK) data is also av ailable

as an option.

3.4.3 General Purpose IO

The transmitter and receiv er boards can be pr o grammed to act upon signals

from the SI board and also outputs signals for certain conditions.

These settings are discussed in “Preparation for Operation” on page 77.

3.4.4 Receiver Audio Processing

The SI board pr ovides an external 600Ω balanced 4-wire line for con necting

4-wire circuits of which two are used by the r eceiver for receive audio.

The SI board pr ovides an unbalanced audio output for connecting to other

devices. Output levels can be set via the rear panel.

3.4.5 Tone On Idle

The tone-on-idle (TOI) fr equency is generated by the SI board and fed

directly to the receiver line out. It is enabled using links on the SI board.

These settings are discussed in “Preparation for Operation” on page 77.

If enabled, the output of the TOI is switched by the receiver gate.

3.4.6 Transmitter Audio Processing

The SI board pr ovides an external 600Ω balanced 4-wire line for con necting

4-wire circuits of which two are used by the transmitter for transmit audio.

38 Functional Description TB7100 Installation and Operation Manual

© Tait Electronics Limited December 2005

Page 39

The SI board pro vides an unbalanced audio input and output for connecting

to other devices.

3.4.7 Opto Isolated Keying

External keying of the base station can be achieved using the current

regulated optically isolated keying connections.

3.4.8 Relay Out put

The SI board can pro vide a rela y output with a load voltage of 350V or load

current of 120mA continuous. The SI board can also provide a r ela y driver

output. Both these options ar e configurab le and these settin gs ar e di scuss ed

in “Preparation for Operation” on page 77.

3.4.9 Fan Control

There are three modes of operation for the fans. The modes are:

■ on continuous

■ on when transmitting

■ on at a pre-defined temperature.

The modes of operation are selected b y links on the SI board. These settin gs

are discussed in “Preparation for Operation” on page 77.

3.4.10 RSSI

A received signal strength indication (RSSI) voltage is developed by the

receiver module and applied directly to the SI board rear panel.

3.4.11 Receiver Gate

The receiver gate signal is used by the SI board to control TOI and a relay

output. The receiver gate output on the

external equipment such as TaitNet trunking controllers.

SYSTEM connector can be used for

3.4.12 Receiver Inhibit

The receiver inhibit input on the SYSTEM connector is used to control the

receiver gate signal. This may be used in linking applications to prevent

unwanted receiver audio signals from appearing at the SI board output

connector.

TB7100 Installation and Operation Manual Functional Description 39

© Tait Electronics Limited December 2005

Page 40

3.5 Fan Operation

The cooling fans are mounted behind the front panel. All fans in the chassis

must be of the same type.

Dissipation of Heat Heat needs to be dissipated from a number of components within the

internal AC pow er supply un it, transmitter and recei ve r modules, including

the following:

■ 9V r egulator

■ RF PA

■ driver for RF PA

■ audio PA

The mechanisms by which the heat is conducted away in each case are

described below.

Dissipation of Heat

from Transmitter

Dissipation of Heat

from Regulator and

Audio P A

Dissipation of Heat

from RF P A s and

Driver

Dissipation of Heat

from Internal AC

Power Supply Unit

The transmitter board is mounted directly onto a heatsink thr ough which

the forced air from the fans is ducted.

Heat from the audio PA and 9V regulator on the receiv er board is conducted

away by a small aluminium heatsink and mounting boss. The heatsink and

boss contact the underside of the board where the components are mounted

and thermal paste ensures a good thermal transfer between the two surfaces.