Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

RTC Remote Test Coil Kit for use

with the B404B and B404BT Bases

Specifications

Dimensions: 6.6"H x 2.75"W x 1.5"D

Weight: .11 lb.

Power Requirements

Alarm LED: 2.8 - 32 VDC, 10 mA max.

Test Coil: 15.5 - 32 VDC, 95 mA max.

Total Current: 105 mA max.

Test Switch: 10 VA @ 32 VDC

Reset Switch: 10 VA @ 32 VDC

Alarm Response Time: 40 seconds max.

Operating Temperature Range: -10°C to 60°C (14°F to 140°F)

Humidity: 95% RH, noncondensing

NOTICE: This manual should be left with the owner/user

of this equipment.

General Description

The System Sensor Model RTC Remote Test Coil Kit allows

for the remote testing of duct detectors using the B404B or

B404BT bases that are installed in inconvenient or difficultto-reach locations. Model RTC can be installed in almost

any convenient location and can be attached to a standard

2" X 4" electrical box.

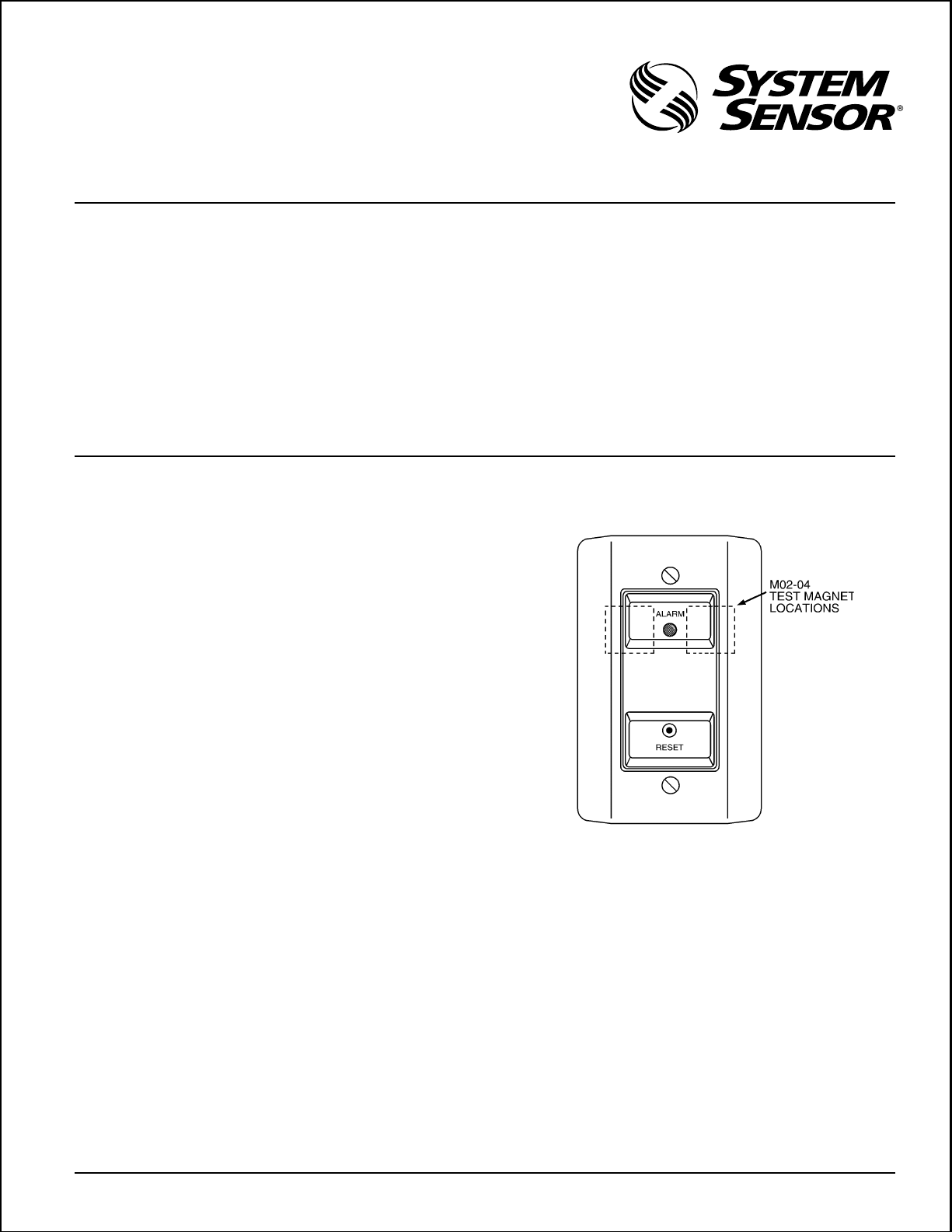

Figure 1:

A Division of Pittway

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

The National Fire Protection Association has published

standards and practices for the installation and use of this

device. As a result, System Sensor recommends that the installer be familiar with these standards and practices, local

codes, and any special requirements of the authority having jurisdiction.

RTC Contents

1 RTS451 Remote Test Station

2 #8 x 1/4" pan head screws for mounting bracket

1 Test Coil/Replacement Ring

1 Screw Pack (2 mounting Assembly screws)

1 Jumper with spade lugs

1 M02-04 Test Magnet

Installation

Installation of the Model RTC consists of attaching the test

station to the mounting surface, mounting the test coil on

the detector, and routing the necessary wiring between

them. This installation procedure assumes that the

associated detector base is already installed and ready for

operation.

A78-1995-00

F440-02-00 1 I56-648-03

Page 2

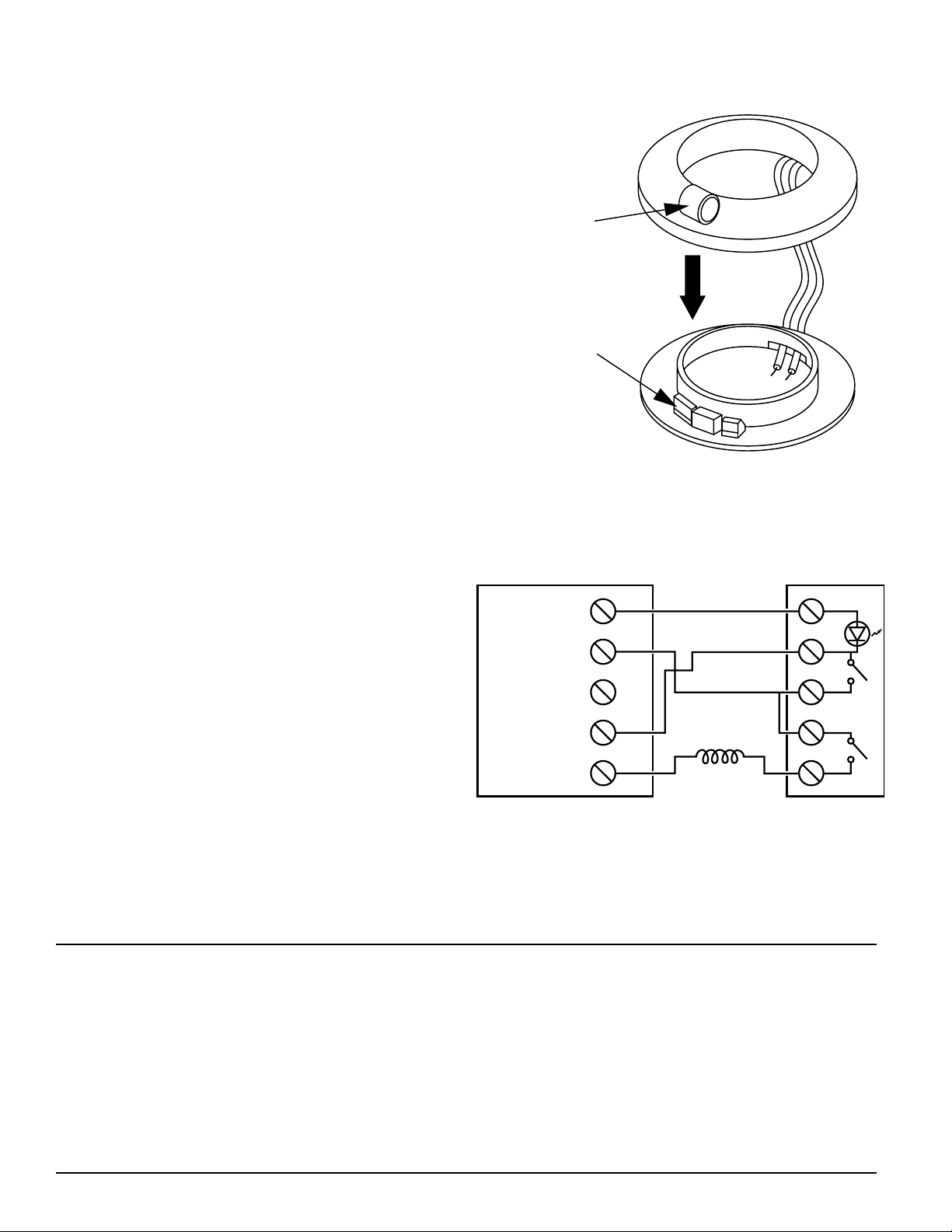

A. Test Coil Mounting

1. Remove the decorative ring from the B404B/B404BT

base by rotating it in either direction to release the

hooks. Separate the ring from the base.

2. Position the Test Coil/Replacement Ring Assembly on

the base, as shown in Figure 2. Be sure to position the

test coil directly over the 4-Position Terminal Block.

Otherwise, the coil may not activate the switch during

a test.

3. Route the the Test Coil/Replacement Ring Assembly

wires through the slot in the base as indicated in

Figure 2.

4. Rotate the ring in either direction until it snaps in

place. Dress all wiring, as needed.

B. Wiring

1. Route four wires from the B404B/B404BT to the test

station mounting location. Be sure to comply with all

applicable electrical codes when installing this wiring. This includes selecting the proper wire size and

routing through conduit, if necessary.

2. Connect the wiring to the B404B/B404BT Base and

RTS451 Test Station, as shown in Figure 3.

Figure 2. Ring Replacement:

TEST

COIL

4-POSITION

TERMINAL

BLOCK

A78-2513-00

C. Test Station Mounting

Attach the test station to a standard 2" X 4" electrical

box, using the screws supplied with the box.

Operation

Te s t

Position the painted side of the test magnet on the RTS451

Test Station on either the left or right side of the LED as

shown in Figure 1. The LED should light within 40 seconds, indicating that the detector being is latched in alarm.

Reset

Reset the detector by inserting a narrow bladed pocket

Figure 3. RTC Wiring Diagram:

B404B/B404BT RTS451

ANNUNCIATOR (+)

REMOTE

TEST COIL (+)

RTC (–)

1

2

3

4

5

TEST

COIL

1

2

3

RESET

4

5

ALARM

screwdriver, or other similar tool, into the RESET hole on

the front of the test station. Gently press until the LED

turns off.

Three-Year Limited Warranty

System Sensor warrants its enclosed remote test coil to be free from defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this remote test coil. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of

the remote test coil which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with the date of manufacture. After phoning System Sensor’s toll

free number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

F440-02-00 2 I56-648-03

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

© System Sensor 1997

Loading...

Loading...