Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

CAUTION

OSYEXP Explosion Proof

Gate Valve Supervisory Switch

Specifications

Contact Ratings: One SPDT (Form C) Switch

15 A @ 125/250/480 VAC; 1/8 HP @ 125 VAC, 1/4 HP @ 250 VAC

1/2 A @ 125 VDC; 1/4 A @ 250 VDC

Dimensions: 7″L X 3.125″D X 4.875″H

Maximum Stem Extension: 2.875″

Bracket Span: 7″

Operating Temperature Range: –40° - 160°F (–40°C – 71°C)

Shipping Weight: 2-1/4 lb.

Enclosure Rating: UL Listed explosion proof switch enclosure for use in hazardous locations.

Class I, Groups C and D; Class II, Groups E. F and G

Important

Please Read Carefully And Save

This manual contains important information about the

installation and operation of supervisory switches. These

instructions apply to System Sensor switches for outside

screw and yoke valves only. Read all instructions carefully

before beginning installation.

To prevent ignition of hazardous atmospheres, disconnect

supply circuit before opening. Keep assembly tightly closed

when in operation. Do NOT leave unused wires exposed.

All supervisory switch installations must comply with local

codes and ordinances and the requirements of the authority having jurisdiction. Additional information is available

in National Fire Protection Association standards NFPA 13,

13D, 13R, 71, and 72.

General Installation Considerations

The OSYEXP Supervisory Switch can be mounted on open

yoke valves between 1/2″ and 12″ in diameter. The switch

is designed to supervise the open condition of the OS & Y

Gate Valve in hazardous locations.

All OSYEXP models are equipped with a ground screw

inside the switch housing for those applications where

grounding is required.

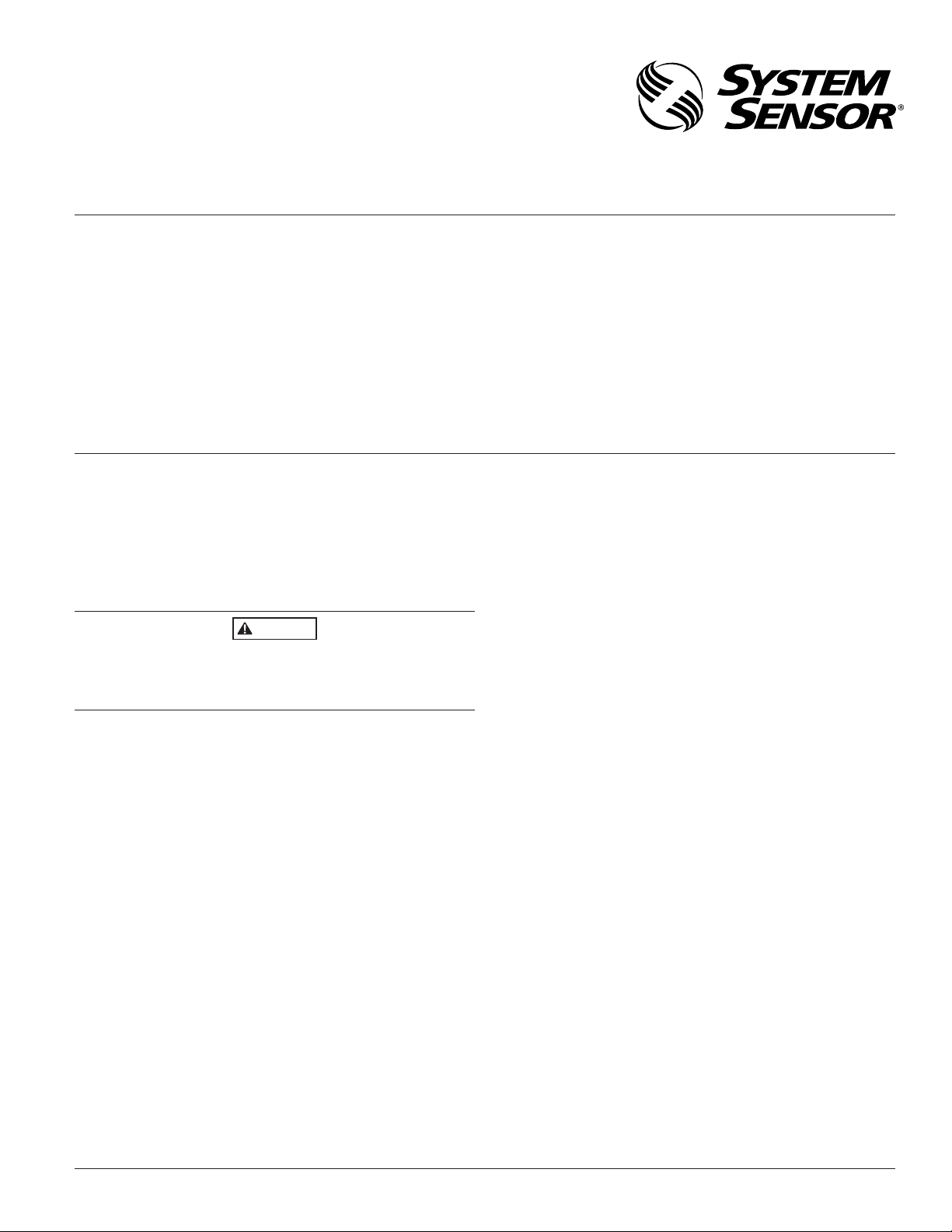

Narrow Yoke Valves

As Figure 1 suggests, installing the valve with mounting

bolts inside the yoke is recommended. However, some

valves may have yokes that are too narrow for this arrangement. If this is the case, the bolts can be positioned on the

outside of the yoke.

Limited Clearance Valves

The OSYEXP mounting bracket fits most of the open yoke

valves used in fire protection systems. However, some of

these valves, especially those less than 11/2″ in diameter,

have irregularly shaped yokes or such limited clearances

that the clamping bar cannot be installed properly and/or

it causes the valve to bind. If this is the case, the use of

the supplied J-bolts is required to attach the OSYEXP to the

valve (see J-Bolt Detail, Figure 1).

Installation Procedure

See Figures 2 and 3, as required, while performing the procedure that follows.

Perform step 1 on valves 11/2″ in diameter and smaller

only. Proceed directly to step 2 if the switch is being

installed on a valve larger than 11/2″ in diameter.

1. Remove and discard the two C-clips and roller from the

actuating lever.

2. Set the valve to its fully open position. Remove the

OSYEXP Supervisory Switch from the carton and adjust

the position of the retaining washers to provide sufficient bolt length for the yoke thickness of the valve.

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

D770-27-00 1 I56-1429-002R

Page 2

Figure 1:

Switch Housing

Actuating Lever

Mounting Bracket

Yoke

Retaining Washer

Nut

Hex Wrench

Clamping Bar

Carriage Bolt

Slide Clamping

Bar to remove

or install

W0182-00

J-Bolt Detail:

NOTE:

Larger gate valve shown (2″ through 12″). When installing supervisory switch to smaller gate valves (1/2″ through

11/2″), carriage bolts are to be located on outboard side of

yoke. On small valves with limited clearance, J-bolts may

be used.

W0207-00

D770-27-00 2 I56-1429-002R

Page 3

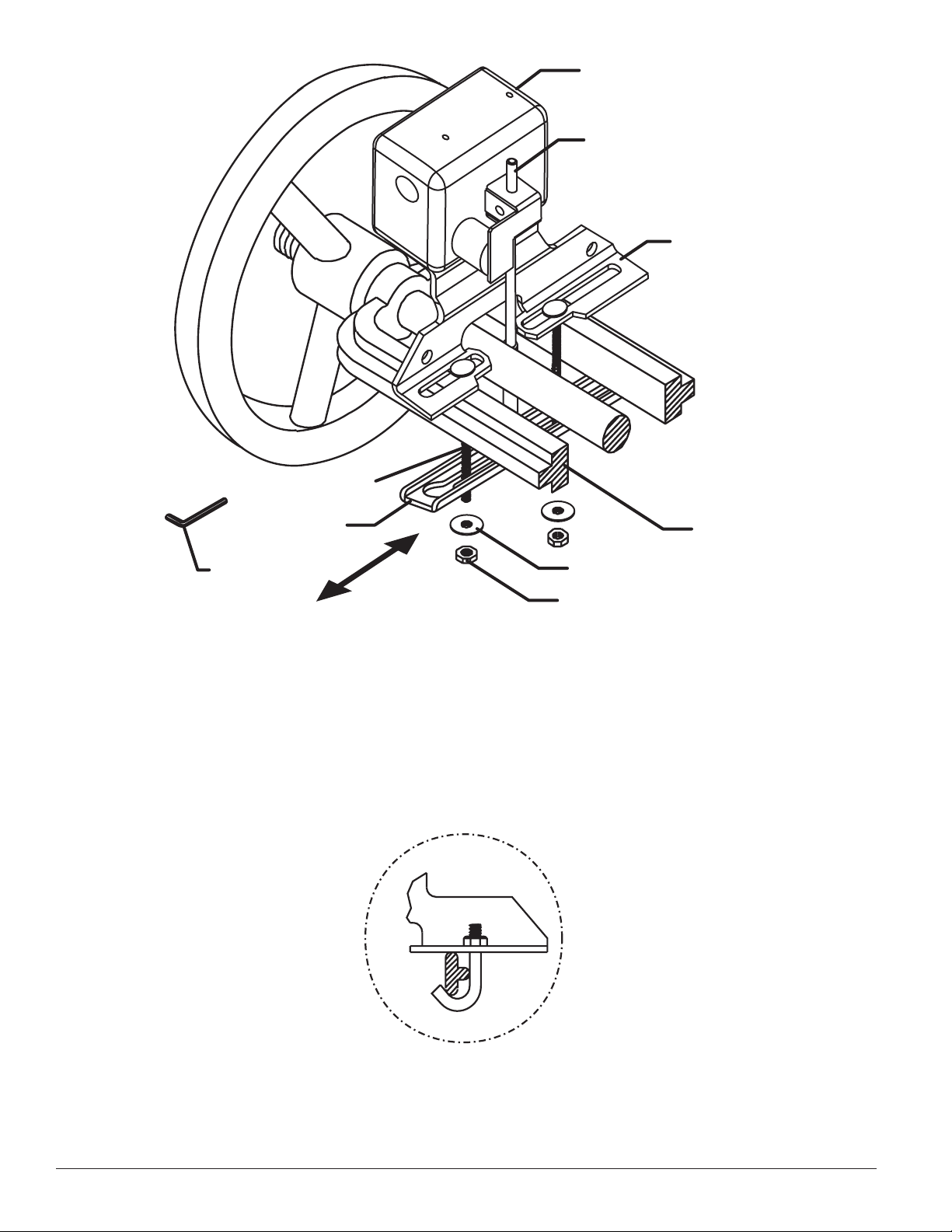

YOKE

GROOVE

CLAMPING BAR NOT SHOWN

THREADED VALVE

GLAND HEX NUT

OR BOLT

VALVE

STEM

GLAND

STEM HEX

Figure 2: 6. Mount the switch loosely with the actuating lever cen-

tered in the groove. When the switch is in position on

the valve, slide the open end of the clamping bar onto

the bolts and under the retaining washers, as indicated

in Figure 1.

7. Ensure that the actuating lever does not hit the clamping

bar at any point in its travel. If it does, adjust the length

of the lever by loosening the lever screw, sliding the

lever in or out, as needed, and retightening the screw.

8. Adjust the supervisory switch position on the valve so

that the switch is open when the actuating lever is in

W0209-00

the groove with the valve in the full open position. The

circuit should close when the valve is closed 1/5 of its

Position the switch on the valve with the bolts on the

inside (preferably) or outside of the yoke, depending on

clearances. Adjust the position of the OSYEXP as far as

possible from the valve gland and in a location where

the actuating lever contacts the unthreaded section of

the valve stem (if the valve stem is already grooved,

proceed directly to step 6).

3. When the switch is in position on the valve, slide the

open end of the clamping bar onto the bolts and under

the retaining washers. If necessary, adjust the length of

the actuating lever by loosening the lever screw. The

lever is properly adjusted when it clears the clamping

bar. Tighten the nuts by hand and slide the OSYEXP until

the switch trip point is found as the lever rests on the

valve stem. This approximates the final position of the

OSYEXP after the valve stem is grooved. Carefully check

all clearances of the bolts, actuator, mounting bracket,

travel or 2 full turns of the handle, whichever is less. The

switch produces an audible “click” when it closes. The

switch closure can also be tested electrically by using an

ohmmeter to test for continuity between its terminals.

9. Tighten the nuts securely with a wrench and check

the operation of the OSYEXP as in step 8. If necessary,

reposition the OSYEXP and test it again.

10. Wire the supervisory switch as shown in Figure 3.

NOTE: When removing the cover of the OSYEXP use

provided allen wrench in box.

11. Replace the OSYEXP cover.

12. Test the operation of the OSYEXP by closing the valve

the 1/5 of its travel distance or two full turns, whichever

is less. The circuit should indicate a closure during

this procedure. If it does not, readjust the supervisory

switch and actuator positions until the switch closes

when the valve is operated.

clamping bar, and OSYEXP cover. Adjust the position as

necessary. If clearance is a problem, refer to the Limited

Clearance Valves (page 1) section of this manual.

4. Mark the point on the valve stem where the actuating

lever contacts the valve stem.

Testing

Test the operation of all supervisory switches before they

are placed into service and at least semiannually, or as

required by the authority having jurisdiction.

5. Remove the OSYEXP by loosening the nuts and sliding

the clamping bar from beneath the retaining washers.

Remove the OSYEXP from the valve and set it aside.

(a) Valves 11/2″ in diameter and smaller only.

Use a 1/2″ untapered round file to file a groove 3/32″ deep

in the valve stem at the mark that was made in step 4.

NOTE: Notify the proper authorities that the supervi-

sory switch(es) is (are) undergoing maintenance

and, therefore, will be temporarily out of service.

Disable the system or zone undergoing testing to

prevent unwanted alarms.

Be sure to remove any burrs resulting from the filing

to avoid damaging the valve stem packing gland.

(b) Valves larger than 11/2″ inches in diameter only.

Use a 3/8″ untapered round file to file a groove 1/8″ deep

in the valve stem at the mark that was made in step 4.

Be sure to remove any burrs resulting from the filing

to avoid damaging the valve stem packing gland.

Test the operation of the OSYEXP by closing the valve the

1

/5 of its total travel distance or two full turns, whichever is

less. A contact closure must occur during this procedure.

If it does not, readjust the supervisory switch and actuator

positions until the switch closes when the valve operated.

D770-27-00 3 I56-1429-002R

Page 4

WARNING

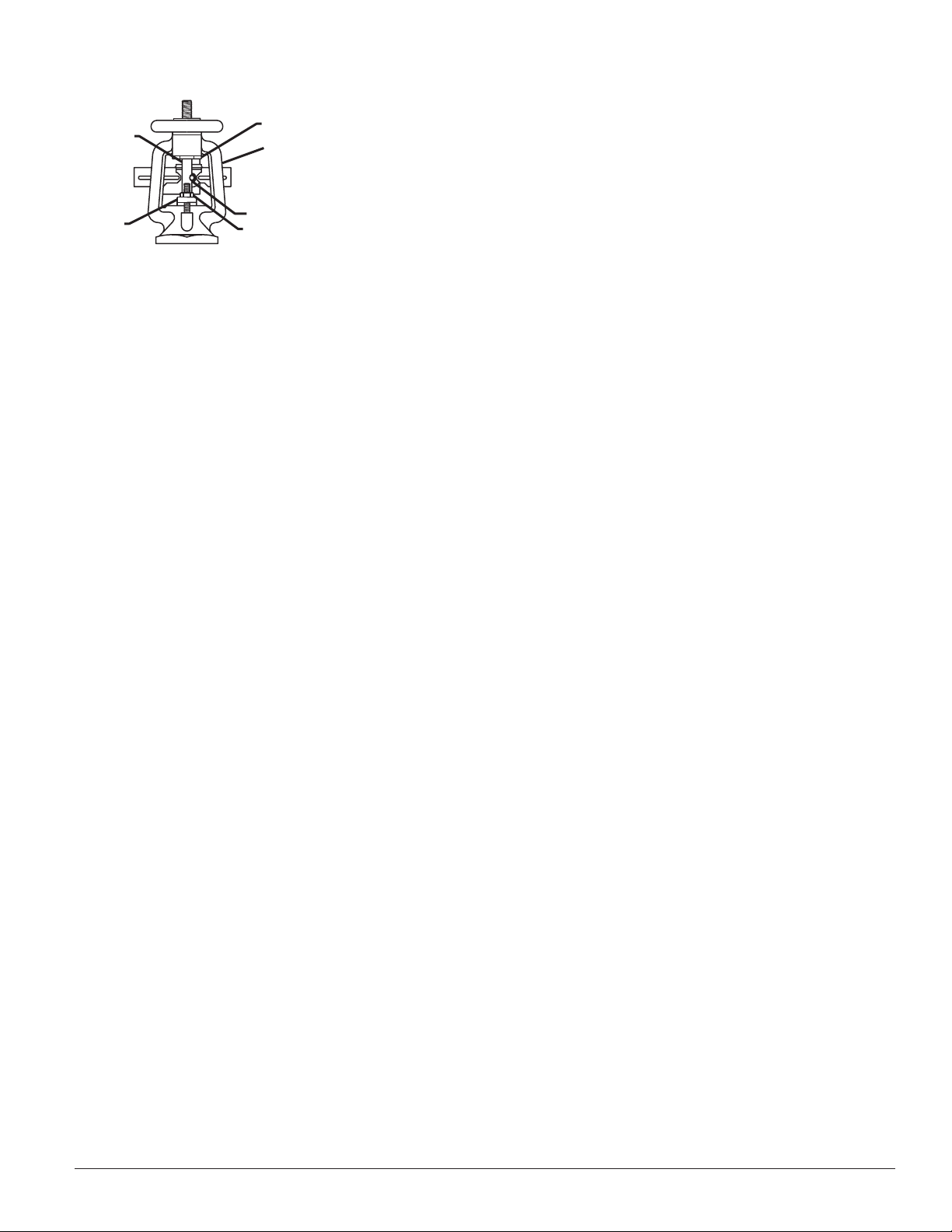

Figure 3. Supervisory switch wiring diagram:

To power source

compatible with bell

Local

Bell

COM

NO

NC

Typical Local Bell Connection

COM

NO

NC

COM

NO

NC

Sup. Switch

Sup. Switch

Typical Facp Connection

End of Line

resistor

To non-silenceable

intiating zone of

listed FACP

W0239-00

W0240-00 W0241-00

1. Alarms generated by the actuation of the activating lever

may not be received by a central station if telephone or

other communication lines to the detector are out of

service, disabled, or open.

2. Supervisory switch alarm devices have a normal service

life of 10-15 years.

System Sensor warrants its enclosed pressure switch to be free from

defects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this pressure switch. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obliga

tion of this Warranty shall be limited to the repair or replacement of any

part of the pressure switch which is found to be defective in materials or

workmanship under normal use and service during the three year period

commencing with the date of manufacture. After phoning System Sensor’s

toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor,

D770-27-00 4 I56-1429-002R

Break wire as shown for supervision of

connection. DO NOT allow stripped wire

leads to extend beyond switch housing.

DO NOT loop wires.

The Limitations of Supervisory Switch Alarm Devices

3. Supervisory switches are not a substitute for insurance.

Building owners should always insure property and lives

being protected.

Please refer to insert for the Limitations of Fire Alarm Systems

Three-Year Limited Warranty

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174.

Please include a note describing the malfunction and suspected cause

of failure. The Company shall not be obligated to repair or replace units

Return

which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In

-

no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s neg

ligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This Warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

©

-

System Sensor 2005

Loading...

Loading...