Page 1

M400-02-01 1 I56-511-02

MOD400R Test Module

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

General Description

The MOD400R Test Module is a tool testing the relative

sensitivity of 100, 200, 300, 400, and 500 Series smoke

detectors only. It CANNOT be used on 800 Series detectors.

It consists of a test module and interface cord for connecting the module to the detector being tested.

This battery powered module is equipped with two colorcoded banana jacks for the connection of any analog or digital DC voltmeter having a sensitivity of 10 kΩ/V or greater.

As an added convenience, two adhesive-backed Velcro

®

strips are also supplied for attaching the module to the

meter being used during testing.

Test module function is under the control of a 3-position

and a 2-position slide switch on the side of the unit.

Various combinations of positions of these two switches

enable the module to test conventional and analog ionization and photoelectronic smoke detectors as well as checking the battery. In addition, the 3-position switch, SW1, has

a center-OFF position for turning off the module. Therefore,

conserve battery life by always setting this switch to OFF

when the module is not in use.

MOD400R Setup

1. Connect a voltmeter having a sensitivty of 10 kΩ/V or

greater to the banana jacks on the side of the

MOD400R. Be sure to connect the positive test lead to

the red jack and the negative lead to the black.

2. Connect the interface cord to the RJ-11 telephone jack on

the bottom edge of the module.

3. Test the MOD400R battery as described in BATTERY

TESTING.

Smoke Detector Testing

Conventional Ion

1. Prepare the MOD400R for testing by performing the procedure in MOD400R SETUP.

2. Set the voltmeter to measure at least 3 VDC.

3. Make sure that power is applied to the detector to be

tested.

4. Set SW1 to its A position and the 2-position switch, SW2,

to CONV.

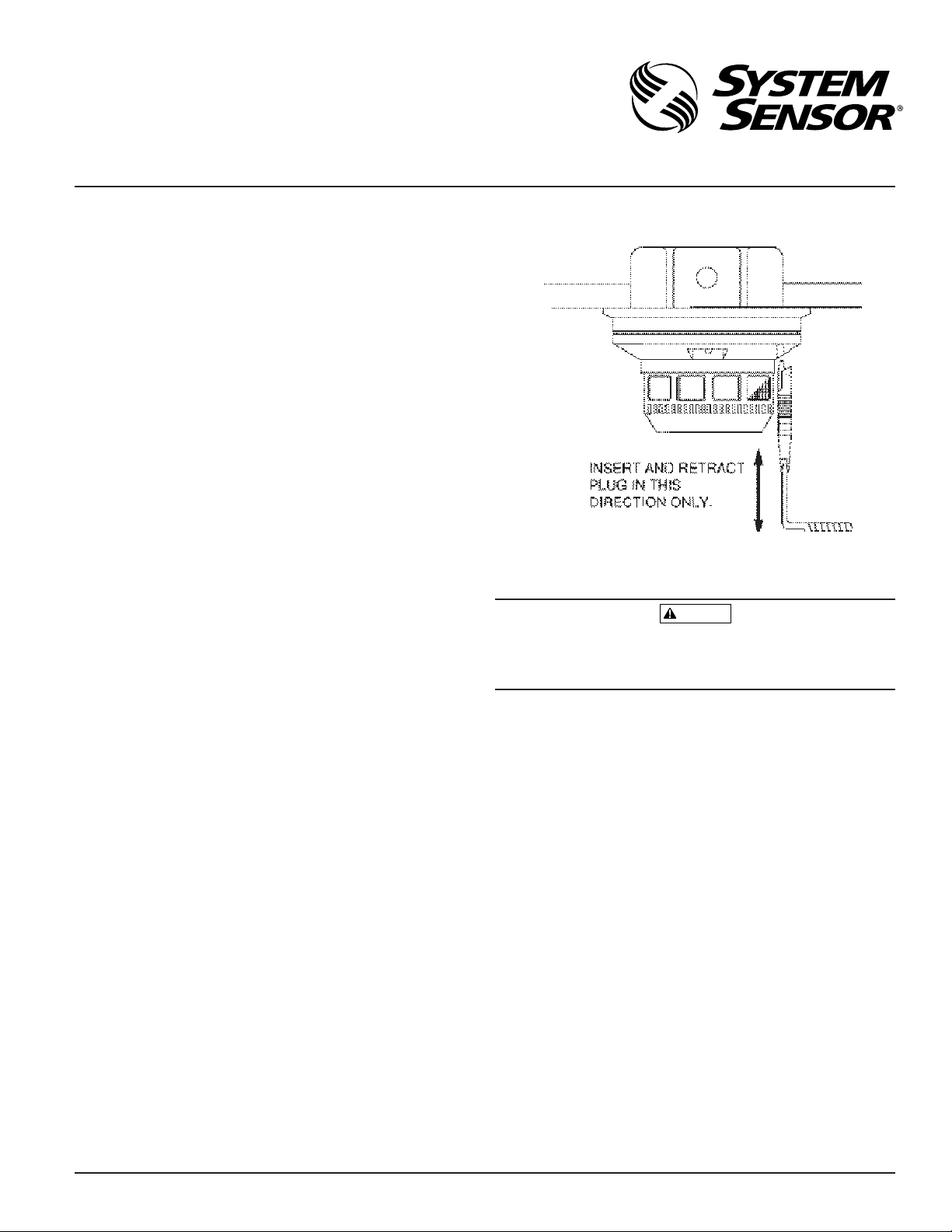

5. See Figure 1. Insert the test plug into the test module

socket on the detector.

The voltmeter should display a voltage that falls in the

MOD400(R) RANGE printed on the label on the back of

A78-2075-00

Failure to insert and retract this plug in the direction shown

may result in damage to the pins. Handle with care. Inspect

pins regularly for damage to ensure proper operation.

CAUTION

the detector. This corresponds to the NOMINAL SENS.

(sensitivity) on the label.

If the voltmeter displays a voltage outside the

MOD400(R) RANGE, it indicates that the detector

requires cleaning or repair.

6. Disconnect the MOD400R from the detector and set SW1

to OFF.

Conventional Photoelectronic Detectors

1. Prepare the MOD400R for testing by performing the procedure in MOD400R SETUP.

2. Set the voltmeter to measure at least 3 VDC.

3. Make sure that power is applied to the detector to be

tested.

4. Set SW1 to its B position and the 2-position switch, SW2,

to CONV.

5. See Figure 1. Insert the test plug into the test module

socket on the detector.

The voltmeter should display a voltage that falls in the

MOD400(R) RANGE printed on the label on the back of

Figure 1:

Page 2

M400-02-01 2 I56-511-02

© System Sensor 1996

Three-Year Limited Warranty

System Sensor warrants its enclosed MOD400R to be free from defects in

materials and workmanship under normal use and service for a period of

three years from date of manufacture. System Sensor makes no other

express warranty for this MOD400R. No agent, representative, dealer, or

employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this

Warranty shall be limited to the repair or replacement of any part of the

MOD400R which is found to be defective in materials or workmanship

under normal use and service during the three year period commencing

with the date of manufacture. After phoning System Sensor’s toll free

number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174.

Please include a note describing the malfunction and suspected cause of

failure. The Company shall not be obligated to repair or replace units

which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no

case shall the Company be liable for any consequential or incidental damages for breach of this or any other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by the Company’s negligence

or fault. Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not

apply to you. This Warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

the detector. This corresponds to the NOMINAL SENS.

(sensitivity) on the label.

If the voltmeter displays a voltage outside the

MOD400(R) RANGE, it indicates that the detector

requires cleaning or repair.

6. Disconnect the MOD400R from the detector and set SW1

to OFF.

Intelligent Sensors

NOTE: The MOD400R can be used to test the sensitivity of

only those sensors connected to control panels that

do NOT use drift compensation.

1. Prepare the MOD400R for testing by performing the procedure in MOD400R SETUP.

2. Set the voltmeter to measure at least 3 VDC.

3. Make sure that power is applied to the sensor to be tested.

4. Set SW1 to its B position and the 2-position switch, SW2

to INT.

5. See Figure 1. Insert the test plug into the test module

socket on the detector.

The voltmeter should display a voltage that falls in the

MOD400(R) RANGE printed on the label on the back of

the sensor. This corresponds to the NOMINAL SENS.

(sensitivity) on the label.

If the voltmeter displays a voltage outside the

MOD400(R) RANGE, it indicates that the sensor

requires cleaning or repair.

6. Disconnect the MOD400R from the detector and set SW1

to OFF.

Battery Testing

The MOD400R operates from a single 9 volt alkaline battery whose life expectancy is approximately one year.

However, it should be tested before each use of the

MOD400R to ensure accurate sensitivity measurements.

To test the battery:

1. Make sure that the MOD400R is NOT connected to any

detector or sensor.

2. Set a voltmeter having a sensitivity of at least 10 kΩ/V

to measure 9 VDC.

3. Connect the meter to the banana jacks on the side of the

MOD400R. Be sure to connect the positive lead to the

red jack and the negative lead to the black.

4. Set SW1 to its A position and read the meter. It should

indicate at least 5.5 VDC. If it does not, replace the 9 volt

alkaline battery.

The MOD400R is designed to “... assure that each smoke detector is within

its listed and marked sensitivity range ...” per NFPA 72. The MOD400R

CANNOT, however, initiate a detector/sensor alarm. Therefore, the

MOD400R meets only part of NFPA 72 testing standards.

Slight fluctuations in readings may be experienced on any device at any

given time and do not indicate a defect or sensitivity shift, provided the

The Limitations of the MOD400R

reading is within the specified range. These fluctuations are to be expected.

The MOD400R and its associated smoke detectors/sensors contain electronic parts and, though they are designed to last over 10 years, any of these

components can fail at any time. Therefore, it is recommended to test your

smoke detectors/sensors per NFPA 72 at least semiannually. Regular cleaning and testing of your fire detection system will measurably reduce your

product liability risks and minimize nuisance alarms.

WARNING

Loading...

Loading...