Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

+2

-1

+2

-1

+2

-1

+2

-1

2 COMM +

1 COMM -

+2

-1

+2

-1

+2

-1

+2

-1

3825 Ohio Avenue, St. Charles, Illinois 60174

MB500 Module Panel

1-800-SENSOR2, FAX: 630-377-6495

Specifications

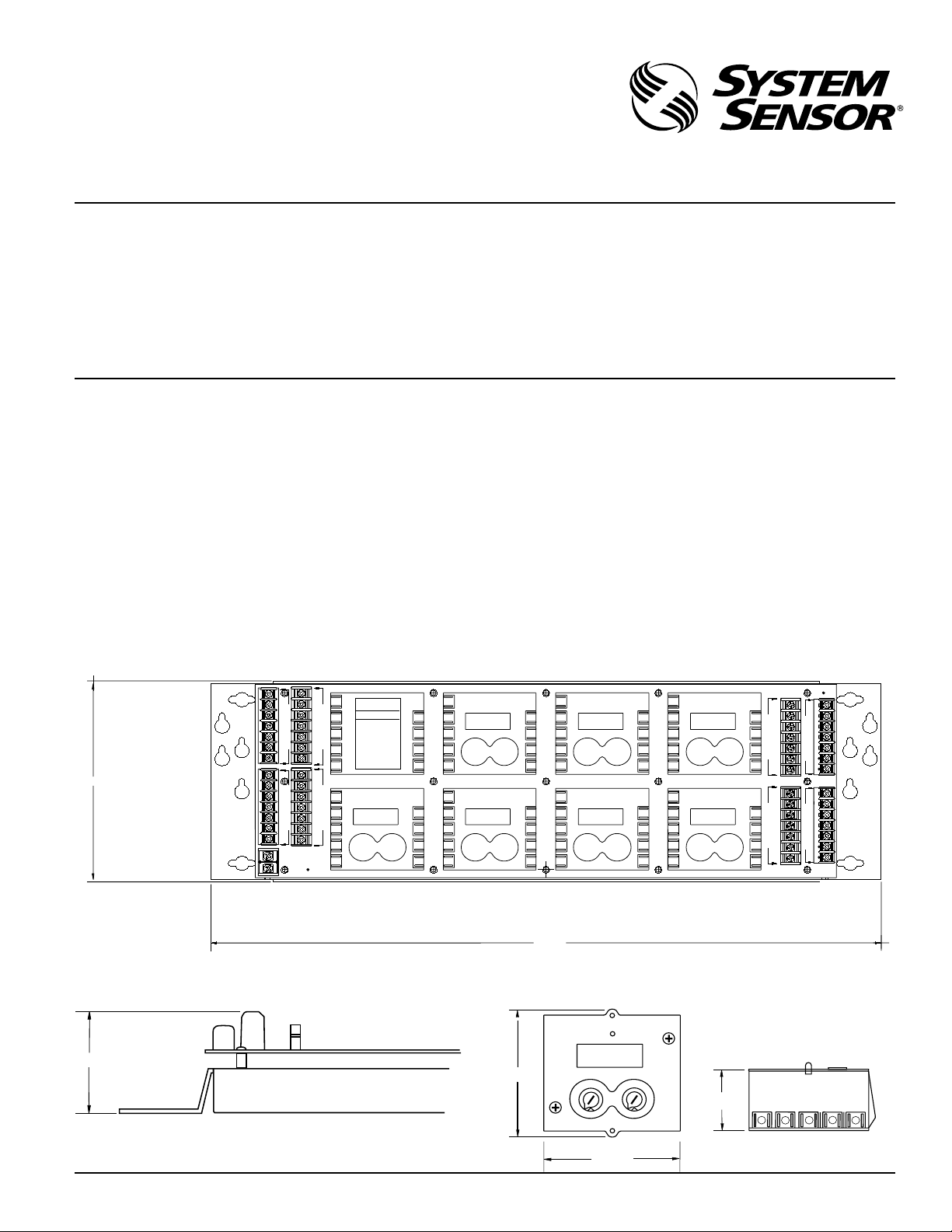

PANEL (Figures 1A and 1B) MODULE (sold separately; Figure 1C)

Depth: 2.17 inches (5.51 cm) Depth: 1.50 inches (3.81 cm)

Height: 6.13 inches (15.57 cm) Height: 2.70 inches (6.86 cm)

Width: 20.18 inches (51.26 cm) Width: 2.82 inches (7.16 cm)

Operating Temperature Range: 32° to 120°F (0° to 49°C)

Operating Humidity Range: 10% to 93% relative humidity, noncondensing

Construction of Bracket: 16-gauge galvanized steel

A Division of Pittway

NOTICE: This manual should be left with the owner/user

of this equipment.

General Description

Before installing this module panel, please thoroughly read

the system wiring and installation manuals. Also be aware

of the appropriate local and national standards and codes

of practice for the placement and installation of control

panels.

The MB500 Module Panel is for use with any listed enclosure suitable for fire-protection signaling applications. It

Figure 1A. MB500 module panel:

AB

9

DISCONNECT ALL POWER SOURCES

C = CONTROLM = MONITOR

MODULE TYPE ADDRESS

8

A C M ______

B C M ______

C C M ______

D C M ______

7

E C M ______

F C M ______

G C M ______

6

H C M ______

ALL MODULES MUST BE USED FOR

EITHER POWER - LIMITED OR

NON - POWER LIMITED APPLICATIONS. NO COMBINATION IS

ALLOWED.

5

WARNING

BEFORE SERVICING

-1

+2

3

4

9

8

7

6

5

E

9

8

7

3

6

2

1

5

-1

+2

54

4

5

6

3

6

3

7

7

2

8

8

1

0 9

0 9

E

4

9

8

7

6

5

6.13

9

8

M

O

7

D

U

6

L

E

5

A

4

3

9

M

8

O

7

D

U

6

L

E

5

E

4

3

2 COMM +

1 COMM -

9

8

M

O

7

D

U

6

L

E

5

B

4

3

9

8

M

O

7

D

U

6

L

E

5

F

4

3

provides a platform for the installation of up to 8 (two rows

of 4) standard monitor and/or control modules. Wiring and

mounting requirements of the modules are reduced by using the MB500.

The MB500 will support any combination of monitor and

control modules on one panel, but a combination of powerlimited and nonpower-limited modules is NOT permitted.

The monitor and control modules used with the MB500

meet the same electrical specifications as the individual

M500MB, M500CH, and M502M.

C

9

-1

+2

54

5

4

6

3

6

3

2

1

0 9

3

7

2

7

8

1

8

0 9

B

4

8

7

3

6

2

1

5

F

-1

+2

54

5

4

6

3

6

3

7

2

7

8

1

8

0 9

0 9

C

4

GH

9

-1

+2

54

5

4

6

3

6

3

2

1

0 9

3

7

2

7

8

1

8

0 9

F

4

8

7

3

6

2

1

5

-1

+2

54

4

5

6

3

6

3

7

7

2

8

8

1

0 9

0 9

G

4

D

9

8

7

5

4

3

6

3

6

2

7

2

1

8

1

0 9

0 9

D

5

9

8

7

5

4

3

6

3

6

2

7

2

1

8

1

0 9

0 9

H

5

9

9

8

8

M

-1

+2

54

6

3

7

8

4

-1

+2

54

6

3

7

8

4

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

C

D

4

4

3

3

9

9

8

8

M

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

G

H

4

4

3

3

20.18

A78-2621-00

Figure 1B. MB500 module panel height:

Figure 1C. Module dimensions:

2.17

2.7

4

3

2

1

0 9

A78-2622-00

D500-35-00 1 I56-917-02

5

6

7

8

2.82

54

3

6

7

2

8

1

0 9

1.50

9

8765

A78-2623-00

Page 2

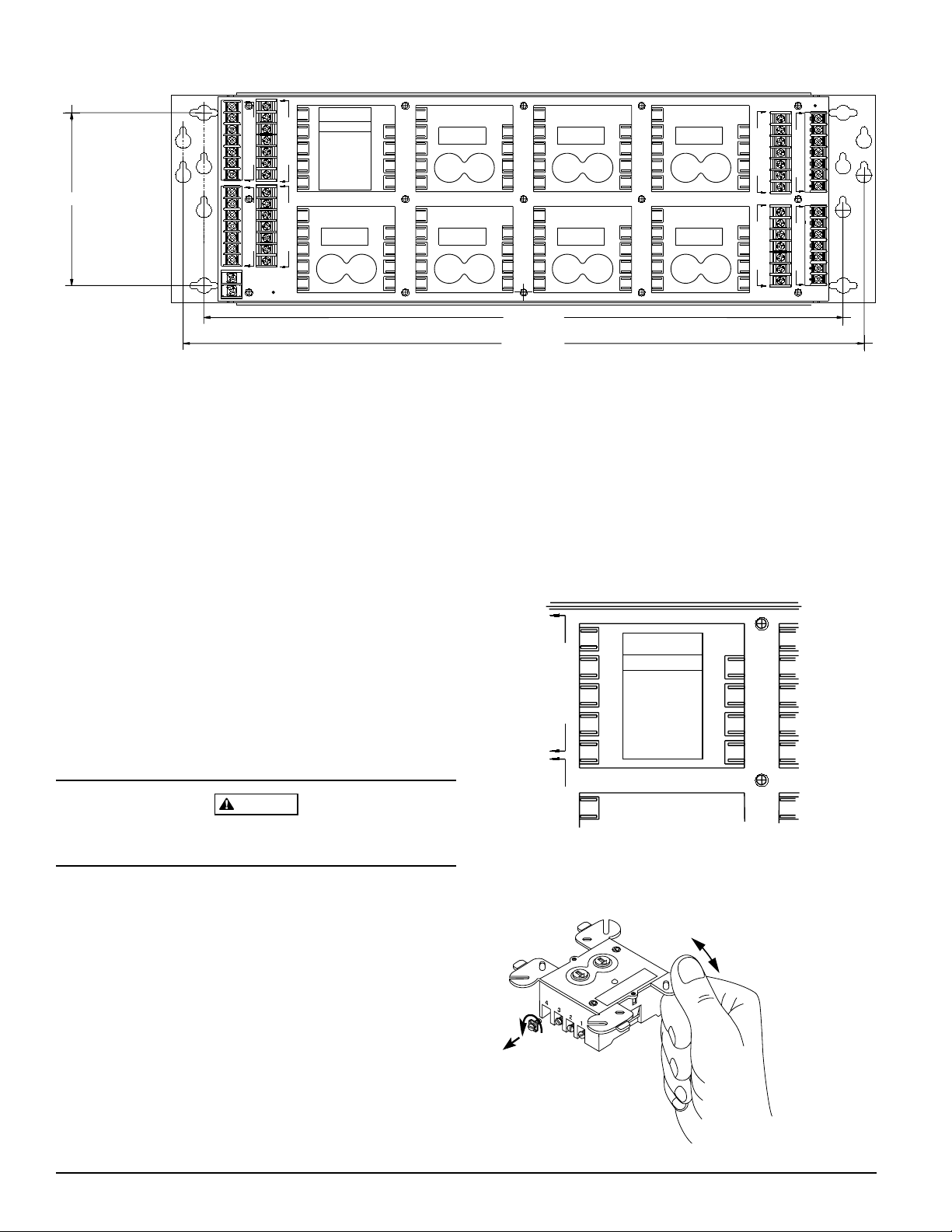

Figure 2. Mounting holes:

A

WARNING

DISCONNECT ALL POWER SOURCES

9

BEFORE SERVICING

C = CONTROLM = MONITOR

MODULE TYPE ADDRESS

8

A C M ______

B C M ______

C C M ______

D C M ______

7

E C M ______

F C M ______

G C M ______

6

H C M ______

ALL MODULES MUST BE USED FOR

EITHER POWER - LIMITED OR

NON - POWER LIMITED APPLICATIONS. NO COMBINATION IS

5

ALLOWED.

-1

+2

3

4

9

8

7

3

6

2

1

5

EF

9

8

7

3

6

2

1

5

-1

+2

4

5

54

6

6

3

3

7

2

7

8 1

8

0 9

0 9

E

4

9

8

7

3

6

2

1

5

5.000 (C)

9

8

M

O

7

D

U

6

L

E

5

4

3

9

M

8

O

7

D

U

6

L

E

5

E

4

3

2 COMM +

1 COMM -

9

8

M

O

7

D

U

6

L

E

5

BA

4

3

9

8

M

O

7

D

U

6

L

E

5

F

4

3

Mounting

1) Select the desired mounting location in a cabinet and

measure the mounting hole centers. The MB500 is

equipped with 3 sets of mounting holes for use depending on the mounting configuration:

A) 19 inch EIA standard with 18.312 inch (46.5 cm) cen-

ter-to-center mounting holes for horizontal mounting

B) 19.5 inch (49.5 cm) center-to-center mounting holes

for horizontal mounting

C) 5 inch (12.7 cm) center-to-center mounting holes for

vertical mounting

2) Hold the MB500 in place, mark the appropriate set of

mounting holes, and drill holes (if needed) in the

mounting surface.

3) Drive screws in place, allowing room for the MB500 to

slide over the screw heads.

4) Tighten screws to secure the MB500 to the mounting

surface.

WARNING

Remove power before installing modules and wiring the

MB500 panel.

Address Verification

Before installing the modules onto the panel, use the label

in position A (see Figure 3A) to record the type for each

module. Circle C (control) or M (monitor) to indicate the

type of module and record the address on the space provided.

B

-1

+2

4

5

54

6

6

3

3

7

2

7

8 1

8

0 9

0 9

B

4

-1

+2

4

5

54

6

6

3

3

7

2

7

8 1

8

0 9

0 9

F G

4

C

9

8

7

3

6

2

1

5

-1

+2

4

5

54

6

6

3

3

7

2

7

8 1

8

0 9

0 9

C

4

G

9

8

7

3

6

2

1

5

-1

+2

4

5

54

6

6

3

3

7

2

7

8 1

8

0 9

0 9

4

D

9

8

7

4

5

3

6

3

6

2

7

2

1

8 1

0 9

0 9

5

D

H

9

8

7

4

5

3

6

3

6

2

7

2

1

8 1

0 9

0 9

5

H

9

9

8

M

8

-1

+2

54

6

3

7

8

4

-1

+2

54

6

3

7

8

4

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

C

D

4

4

3

3

9

9

8

8

M

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

G

H

4

4

3

3

18.312 (A)

19.500 (B)

A78-2624-00

circuit board of the MB500 with the terminals on the individual modules, and plug a module into the panel at position A (see Figure 4). Repeat the procedure for positions B,

C, and so on, for up to 8 modules.

Figure 3A. Label each module:

9

8

7

6

5

4

9

M

O

D

8

U

L

E

7

B

6

3

5

9

8

M

O

7

9

D

U

A

WARNING

DISCONNECT ALL POWER SOURCES

BEFORE SERVICING

C = CONTROL M = MONITOR

MODULE TYPE ADDRESS

A C M ______

B C M ______

C C M ______

D C M ______

E C M ______

F C M ______

G C M ______

H C M ______

ALL MODULES MUST BE USED FOR

EITHER POWER - LIMITED OR

NON - POWER LIMITED APPLICATIONS. NO COMBINATION IS

ALLOWED.

E

-1

+2

3

4

Figure 3B. Remove module terminal screws and

break off mounting plate ears:

A78-2629-00

Module Mounting

Before placing the individual modules onto the MB500, remove the terminal screws on the modules and break off the

"ears" at the scored section on the module junction box

mounting plate (see Figure 3B). Now the modules can be

plugged into the board. Line up the clips mounted on the

D500-35-00 2 I56-917-02

A78-2625-00

Page 3

Wiring Installation

2 COMM +

1 COMM -

2 COMM +

1 COMM -

Once the control and/or monitor modules have been

plugged in, begin wiring the panel. Field wiring is completed using screw terminals accessible from the 6-inch

long sides of the MB500. The seven-position screw terminals accept 14- to 22-gauge wire and are two-tiered for easy

wiring. A two-position screw terminal block is used for the

common power wiring that exists between the modules

and accepts 12- to 18-gauge wire.

Figure 4. Mounting a module on the MB500:

Make wire connections by stripping about 1/4 inch (0.64

cm) of insulation from the end of the wire. Connect the

communication line to terminals 1 and 2. For specific module wiring, match the module location to the correct terminal strip. Refer to the control and/or monitor module

instruction manual for specific application wiring.

NOTE: The communication circuit to all modules is desig-

nated power limited. The remaining circuits must

be wired as either all power limited or all

nonpower limited. Refer to marking on individual

modules.

NOTE: When wiring modules for nonpower-limited appli-

cations, the wires to terminals 3-9 on each terminal

strip must be bundled together with wire ties and

routed through conduit, keeping them separated

from communication lines 1 and 2 (comm. - and

comm. +) by a minimum of

1

/4 inch at all points

(see Figures 5A and 5B). Communication line 1

and 2 wiring must also be routed through its own

conduit.

A78-2626-00

Figure 5A. Wiring the module panel in a cabinet for

nonpower-limited applications:

9

9

8

8

M

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

B

A

4

4

3

3

9

9

8

M

M

8

O

O

7

7

D

U

6

L

E

5

E

4

3

2 COMM +

1 COMM -

D

U

6

L

E

5

F

4

3

Figure 5B. Wiring multiple module panels in a cabinet

for nonpower-limited applications:

9

9

8

8

M

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

B

A

4

4

3

3

9

9

8

M

M

8

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

F

E

4

4

3

3

2 COMM +

1 COMM -

9

9

8

8

M

M

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

B

A

4

4

3

3

9

9

8

M

M

8

O

O

7

7

D

D

U

U

6

6

L

L

E

E

5

5

F

E

4

4

3

3

2 COMM +

1 COMM -

A78-2627-00

D500-35-00 3 I56-917-02

A78-2628-00

Page 4

Three-Year Limited Warranty

System Sensor warrants its enclosed module panel to be free from defects

in materials and workmanship under normal use and service for a period

of three years from date of manufacture. System Sensor makes no other

express warranty for this module panel. No agent, representative, dealer,

or employee of the Company has the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this

Warranty shall be limited to the repair or replacement of any part of the

module panel which is found to be defective in materials or workmanship

under normal use and service during the three year period commencing

with the date of manufacture. After phoning System Sensor’s toll free

number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

D500-35-00 4 I56-917-02

© System Sensor 1996

Loading...

Loading...