Page 1

SYNTEC

Mill Controller Manual

By: SYNTEC

(For EZ Series)

Date: 2010/9/14

Version: 1.0

Page 2

No.

Modify Content

date

editor

New Vision

01

Mill Operation Manual-EN FOR EZ(5Keys)

2010/09/14

XuMing

V1.0

Version edit record

Page 3

Contents

1 CNC MILLING CONTROLLER INTERFACE ........................................... 1

1.1 CNC System Configuration .......................................................................................................... 1

1.2 Screen Sections .............................................................................................................................. 2

1.3 Main Menu Selections ................................................................................................................... 3

1.3.1 F1:Position .......................................................................................................................... 4

1.3.1.1 F1:Coor. Switch ........................................................................................................ 5

1.3.1.2 F2:1/2 Coor. .............................................................................................................. 5

1.3.1.3 F3:Clear Coor. ........................................................................................................... 5

1.3.1.4 F4:Clear All Relative ................................................................................................ 6

1.3.1.5 F5:Workpiece Coor. .................................................................................................. 6

1.3.1.5.1 F1:Coor. Latched .................................................................................................. 7

1.3.1.5.2 F2:Rel. Latched .................................................................................................... 7

1.3.1.5.3 F3:Aux. Latched ................................................................................................... 7

1.3.1.5.4 F5:Middle Point Func. .......................................................................................... 7

1.3.2 F2:Program ......................................................................................................................... 8

1.3.2.1 F1:Insert Cycle .......................................................................................................... 9

1.3.2.2 F2:Delete Line........................................................................................................... 9

1.3.2.3 F3:Edit Cycle .......................................................................................................... 10

1.3.2.4 F4:Simulation .......................................................................................................... 11

1.3.2.4.1 F1: STEP ........................................................................................................... 11

1.3.2.4.2 F2:Continue ........................................................................................................ 11

1.3.2.4.3 F3:Zoom ............................................................................................................. 12

1.3.2.4.4 F4:Graph reset .................................................................................................... 12

1.3.2.4.5 F5:Abort ............................................................................................................. 12

1.3.2.4.6 F5:Simu. Setting ................................................................................................. 12

1.3.2.5 F5:File Manager ...................................................................................................... 13

1.3.2.5.1 F1:New File ........................................................................................................ 14

1.3.2.5.2 F2:Copy File ....................................................................................................... 14

1.3.2.5.3 F3:Delete File ..................................................................................................... 14

1.3.2.5.4 F4:Import ............................................................................................................ 15

1.3.2.5.5 F5:Export ............................................................................................................ 16

1.3.2.5.6 F1:RS232 Import ................................................................................................ 17

1.3.2.5.7 F2 :RS232 Export .................................................................................................. 19

1.3.2.5.8 F3:Network Import ................................................................................................ 20

Page 4

1.3.2.5.9 F4:Multi Import ..................................................................................................... 20

1.3.2.5.10 F5:Multi Export .................................................................................................... 20

1.3.2.6 EDIT .......................................................................................................................... 20

1.3.2.6.1 EDIT sub function “F1 : Search” .......................................................................... 21

1.3.2.6.2 EDIT sub function “F2 : Replace” ........................................................................ 22

1.3.2.6.3 EDIT sub function “F3” : Go To Line” ................................................................. 23

1.3.2.6.4 EDIT sub function “F4”: copy line”...................................................................... 23

1.3.2.6.5 EDIT sub function “F5”: Insert line” .................................................................... 23

1.3.2.7 F2:Teach ................................................................................................................. 24

1.3.2.7.1 F1:Rapid Teach .................................................................................................. 24

1.3.2.7.2 F2:Line Teach .................................................................................................... 24

1.3.2.7.3 F3:Arc Teach ...................................................................................................... 24

1.3.2.7.4 F4:Cancel Middle ................................................................ ............................... 25

1.3.2.7.5 F5:Radius Teach ................................................................................................. 25

1.3.2.7.6 F1:Delete Line .................................................................................................... 25

1.3.2.7.7 F2:Coord Switch ................................................................................................ 25

1.3.2.7.8 F3:Point Teach ................................................................................................... 25

1.3.3 F3:DlgInput (ONLY for 940M) ........................................................................................ 26

1.3.4 F4:Monitor ........................................................................................................................ 26

1.3.4.1 F1:Coor ................................................................................................................... 26

1.3.4.2 F2:Graph Adjust ...................................................................................................... 27

1.3.4.2.1 F1:Zoom ............................................................................................................. 27

1.3.4.2.2 F2:Graph Reset ................................................................................................... 27

1.3.4.2.3 F5:Simu Setting .................................................................................................. 27

1.3.4.3 F3:MDI Input .......................................................................................................... 28

1.3.4.4 F4:SETTING ........................................................................................................... 29

1.3.4.5 F5:Tool Setting ....................................................................................................... 30

1.3.4.6 F5:Work Record ...................................................................................................... 31

1.3.5 F5:Alarm........................................................................................................................... 32

1.3.5.1 F1:Actual................................................................................................................. 33

1.3.5.2 F2:History ............................................................................................................... 33

1.3.5.3 F5: Save ..................................................................................................................... 33

1.3.6 F1:Parameter ..................................................................................................................... 34

1.3.7 F2:Diagnosis ..................................................................................................................... 35

1.3.7.1 F1:PLC State ................................................................................................ ........... 36

1.3.7.2 F2:System Data ....................................................................................................... 37

1.3.7.3 F3:Global Variable .................................................................................................. 38

1.3.7.4 F4:Coord Variable ................................................................................................... 39

Page 5

1.3.7.5 F5:System Manager ................................................................................................ 40

1.3.8 F3:Guidance ..................................................................................................................... 41

2 MACHINE OPERATION PANEL ............................................................ 42

2.1 2nd machine operation panel ....................................................................................................... 42

2.1.1 POWER ON ........................................................................................................................ 42

2.1.2 POWER OFF ....................................................................................................................... 42

2.1.3 Emergency STOP ................................................................................................................ 42

2.1.4 Home mode and Home function .......................................................................................... 42

2.1.5 Continues JOG (Rapid JOG) ............................................................................................... 42

2.1.6 Incremental JOG .................................................................................................................. 43

2.1.7 MPG JOG ............................................................................................................................ 43

2.1.8 AUTO mode NC file execute .............................................................................................. 43

2.1.9 MDI mode single block execute .......................................................................................... 43

2.1.10 MPG Simulation .................................................................................................................. 44

2.1.11 Dry Run ............................................................................................................................... 44

2.1.12 Single block ......................................................................................................................... 44

2.1.13 Option Stop.......................................................................................................................... 45

2.1.14 Option Skip.......................................................................................................................... 45

2.1.15 Spindle control .................................................................................................................... 45

2.1.16 Working led ......................................................................................................................... 46

2.1.17 Working Liquid ................................................................................................................... 46

2.1.18 Aux table backward ............................................................................................................. 46

2.1.19 Aux table forward ................................................................................................................ 46

2.2 Text key description: .................................................................................................................. 47

3 HOW TO OPERATE SYNTEC 900ME ................................................... 49

3.1 Manual function (JOG, INC_JOG, MPG) ................................................................................ 50

3.2 HOME .......................................................................................................................................... 51

3.3 Open a file (EDIT / FLOPPY / RS232) ..................................................................................... 52

3.4 Tool setting (G40/G41/G42, G43/G44/G49) ................................................................ .............. 53

3.5 Tool Length measurement (G43/G44/G49) ................................................................ ............... 54

3.6 Setting the Workpiece origin offset value (G54...G59)............................................................. 55

Page 6

3.7 Manual Data Input (MDI) .......................................................................................................... 56

3.8 Assigned an executing NC file (AUTO) ..................................................................................... 57

3.9 Graphic Simulation ..................................................................................................................... 58

3.10 How to check NC file in SYNTEC controller....................................................................... 59

3.11 Auto Center............................................................................................................................. 60

3.11.1 Manual Center ..................................................................................................................... 60

3.11.2 Auto center operation .......................................................................................................... 62

3.12 Z-axis Auto Tool ..................................................................................................................... 64

3.13 RS232 FUNCTION ................................................................................................................ 69

3.14 DNC Function ......................................................................................................................... 71

3.15 The software of SYNTEC controller replace the software of DNC to execute RS232

function 73

Page 7

Coor

1/2 Coor

Clear Coor

All Clear Relative

Workpiece Coor

Position

F1

Insert Cycle

Delete Line

Edit Cycle

Search

Replace

Go To Line

Copy Line

Insert Line

Edit

Rapid Teach

Line Teach

Arc Teach

Cancel Middle

Delete Line

Teach

Step

Continue

Zoom

Graph Reset

Abort

Simu. Setting

Simu.

New File

Copy File

Delete File

Import

Export

RS232 I mport

RS232 Export

File Manager

Program

F2

Dlginput

F3

Coor

Graph Adjust

MDI Input

Setting

Tool setting

Work Record

Monitor

F4

Actual

History

Save

Alarm

F5

System Param

Go to page One

Operation Setting

Param.

F6

PLC I Bit

PLC O Bit

PLC C Bit

PLC S Bit

PLC A Bit

PLC Register

PLC Timer

PLC Counter

PLC State

System Data

Global Data

Software Setup

Backup System

Install Local L.

Store Language

System Manger

Diagnosis

F7

Guidance

F8

CNC Mill

1 CNC Milling Controller Interface

1.1 CNC System Configuration

-1-

Page 8

1.2 Screen Sections

The screen of controller is shown as followings:

Meanings For Fields on the Display:

(1)Program Number

(2)Title

(3)Time

(4)Date

(5)Data Input

(6)Hint

(7)Status

(8)Function Key Switch

-2-

Page 9

1.3 Main Menu Selections

The following diagram is the main menu selections for SNC Mill

controller. To operate SNC Milling controller, users simply make the

selections by pressing function keys, F1~F5 located on the bottom of the

screen.

-3-

Page 10

1.3.1 F1:Position

This selection displays coordinate settings of current position. It can

also be used to reset the position of relative coordinate. Pressing function

key, F1, under the main menu to enter this selection (Note:This is the first

screen when the system is booted up)

Meaning of fields on the display------

X:X axis coordinate.

Y:Y axis coordinate.

Z:Z axis coordinate.

Feedrate:Feedrate of cutting tool at each machining, mm per minute (mm/min).

Spindle:RPM of spindle speed.

Machine(Relative coordinate of working platform)

The current position of cutting tool relative to working platform is shown as machine

coordinate on the display.

Relative

The current position of cutting tool relate to the previous location.

Absolute(Programming Coordinate)

The current position of the origin of user defined coordinate is shown as an absolute

position on the display.

Distance To Go:The distance of the cutting tool that need to move to the next position

show on position(+) and negative(-) direction.

-4-

Page 11

Function key selections:

1.3.1.1 F1:Coor. Switch

Function:Switch Coordinate Display。

Operation:Under the Position submenu, whenever users press F1 key, the values and

coordinate on the left corner of the display will toggle among the four different

coordinates with bigger fonts as shown in the following figure:

1.3.1.2 F2:1/2 Coor.

Function: Set the center point of work piece as coordinate origin.

Operation: Under the Position submenu, when the message line shows “X Input”(or

“Y Input” or “Z Input”), press “F2 1/2 Coordinating” and the origin of the coordinate

will move to the center point of work piece.

1.3.1.3 F3:Clear Coor.

Function:Reset the value of X(or Y or Z) axis relative coordinate to zero. (No effect

on other axes)

Operation:Under the Position submenu, when the message line shows “X Input”(or

“Y Input” or “Z Input”), press F3 to reset the value of X(or Y or Z) axis relative

coordinate to zero.

-5-

Page 12

1.3.1.4 F4:Clear All Relative

Function:Reset XYZ relative coordinate to zero.(No effect on other coordinates)

Operation :Under the Position submenu, pressing “F4” will reset XYZ relative

coordinate to zero.

1.3.1.5 F5:Workpiece Coor.

Function:Relative to machine coordinate setting for G54~G59.

Operation:Under the Position submenu, press "F5" key and the following screen will

show up. The users can begin to set the auto machine coordinate settings of G54~G59.

(The system needs to be in Ready Status)

1. “External Shift” : operator can set the all coordinate

G54..G59 at the same time .

2. CNC default G54 ,if user don‟t set any G54..G59 in the NC

file

-6-

Page 13

1.3.1.5.1 F1:Coor. Latched

Set the current machine coordinate to the input box

1.3.1.5.2 F2:Rel. Latched

Set the current relative coordinate to the input box

1.3.1.5.3 F3:Aux. Latched

Set the current relative coordinate to the input box

1.3.1.5.4 F5:Middle Point Func.

-7-

Page 14

1.3.2 F2:Program

This selection provides users with program file management and

editing. With a full screen editor, users can use arrow keys(↑、↓、←、→)

to move the cursor to anywhere on the screen for editing purpose. Press F2

under the main menu to enter this selection. The full screen editor is shown

as follows:

-8-

Page 15

Program Sub menu Key Selections:

1.3.2.1 F1:Insert Cycle

Function:Insert a block or cycle by conversation

Operation:Under Program submenu, press F1 to insert a line or cycle before cursor

position.(See Graphic Input Interface(900ME) User Guide)

1.3.2.2 F2:Delete Line

Function:Delete a line at cursor position.

operation: Under Program submenu, press F2 to delete a line where the cursor is

located.

-9-

Page 16

1.3.2.3 F3:Edit Cycle

Function:Edit an old block or cycle by conversation input

Operation: Under Program submenu, press F3 to edit a line where the cursor is

located.

-10-

Page 17

1.3.2.4 F4:Simulation

Function: Simulating the workpiece program can prove the accuracy of the editing

program.

Operation:Under Program submenu, press F4

F4 “simulation” sub Key Selections:

1.3.2.4.1 F1: STEP

Function: To simulate NC files STEP by STEP

Operation: Under Program submenu, press F4”Simulation” and then F1”Step” .The

operator can use this function ,to check NC file STEP by STEP

1.3.2.4.2 F2:Continue

Function: To simulation NC file one time .

Operation: Under Program submenu, press F4 “Simulation” and then

F2”Continue” .The operator can use this function to check NC file whole

picture ,when push button.

-11-

Page 18

1.3.2.4.3 F3:Zoom

Function: To enlarge the workpiece graph.

Operation: Under Program submenu, press F5 and then F3.The operator can use the

“←”,”↑”,”→”, ”↓” cursor to move the frame to the determined area. And use

“PageUp” “PageDn” to Enlarge this area .

1.3.2.4.4 F4:Graph reset

Function: To recover the zoomed workpiece graph.

1.3.2.4.5 F5:Abort

Function: To abort simulation action

1.3.2.4.6 F5:Simu. Setting

Function: To set simulation parameter

Operation: Under Program submenu, press and then F5.

Simulation Parameter description :

Path color : User can select cutting path color by this parameter

Cursor color : User can select cutting point color by this parameter

Drawing mode : User can select simulation plane by this parameter

Vertical / Horizontal angle : when XYZ drawing mode ,user can select 3D View angle

by these 2 parameter

Window range :

Mode (0: simulation ,1: direct draw)

-12-

Page 19

0 : When operator change his main screen to F4”Monitor” ,CNC would

automatically simulation at that screen

1 : When operator change his main screen to F4”Monitor” ,CNC would not

simulation at that screen but direct drawing the cutting cursor .

Xmin/Xmax, Ymin/Ymax ,Zmin/Zmax :

When “direct draw” mode ,operator must set draw window by these

parameter ,the best way : after simulation use simulation result which is

located at the top of this screen to X,Y,Z range .

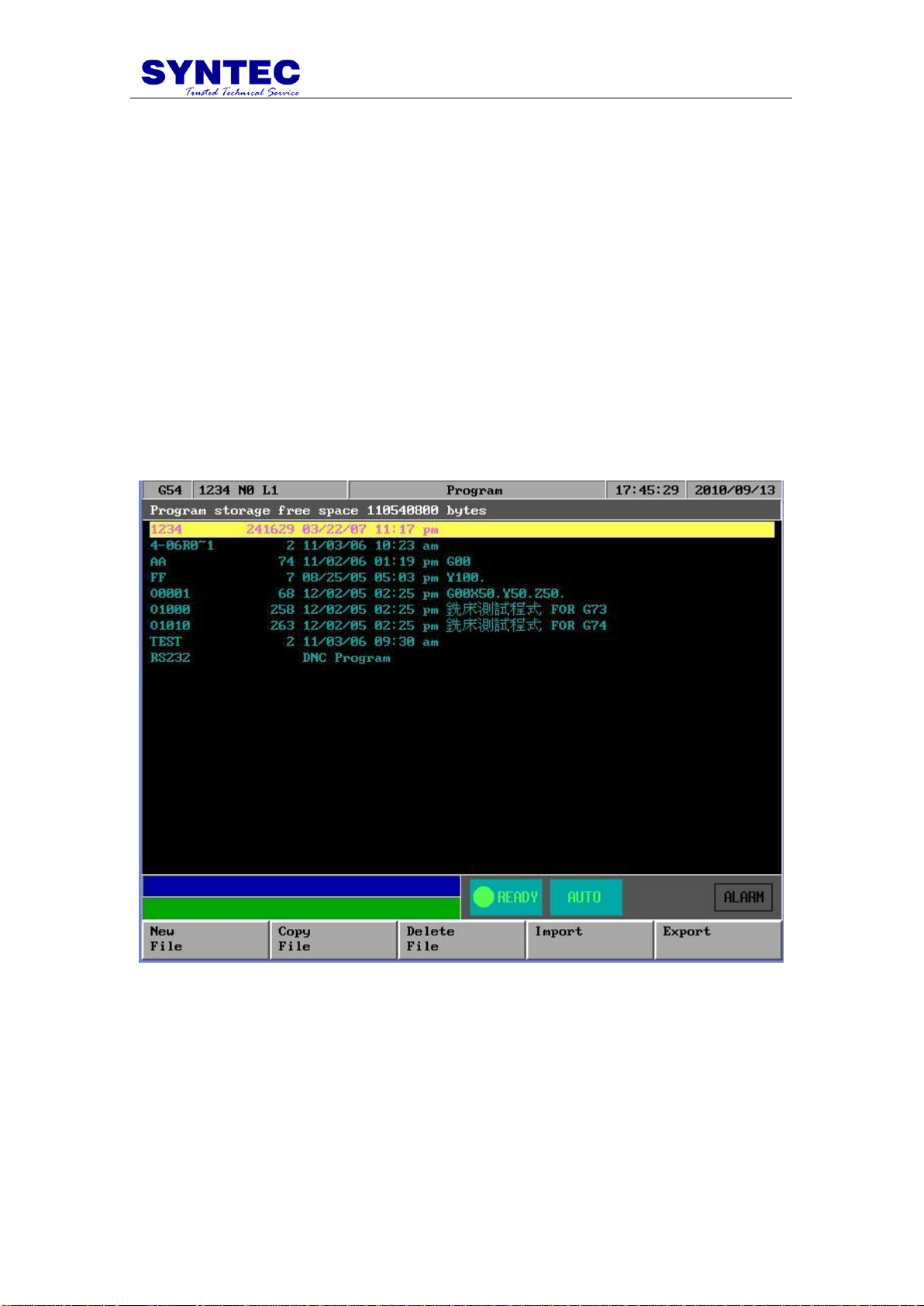

1.3.2.5 F5:File Manager

Under Program submenu, press F5 and the following diagram will

show up. Users can use arrow keys(↑、↓)to select file to be edited. After

pressing【ENTER】, content of the file will show up on the screen

-13-

Page 20

Key Selections:

1.3.2.5.1 F1:New File

Operation:

Step 1: A dialog box will prompt users with “New File ”. Type in

the new file name and press 【ENTER】.

Step 2: An empty screen shows up waiting users to type in a new

program.

1.3.2.5.2 F2:Copy File

Operation: After pressing F2, a dialog box will prompt users to type in a file name and

press 【ENTER】. The current file is then copy to the hard disk with a different file

name.

1.3.2.5.3 F3:Delete File

Operation: Select a file to be delete by pressing (↑、↓). A dialog box will pop up

to confirm this operation.

-14-

Page 21

1.3.2.5.4 F4:Import

Function:Input file from floppy.

Operation:Insert a disk to the floppy drive and then press F4. Select a file name by

pressing(↑、↓、←、→). Press【ENTER】to input the file from a floppy disk

.

P.S.

1. floppy disk file format is ASCI code

2. SYNTEC CNC also can accept *.zip format ,when import

from floppy disk ,cnc would unzip automatically

3. if NC file too big ,operator can use more than ONE floppy

disk to import nc FILE , separates a big file to some floppy

disks ,use the same file nmae ,then inport THIS file DISK

BY DISK ,operator choose appEnd but not overWRITE ,IT

IS VERY EASY TO INSATLL A BIG FILE

4. IF OPERATOR INSTALL EHTERNET ,IT IS MORE

EASY TO INSTALL A BIG FILE FROM NET .

-15-

Page 22

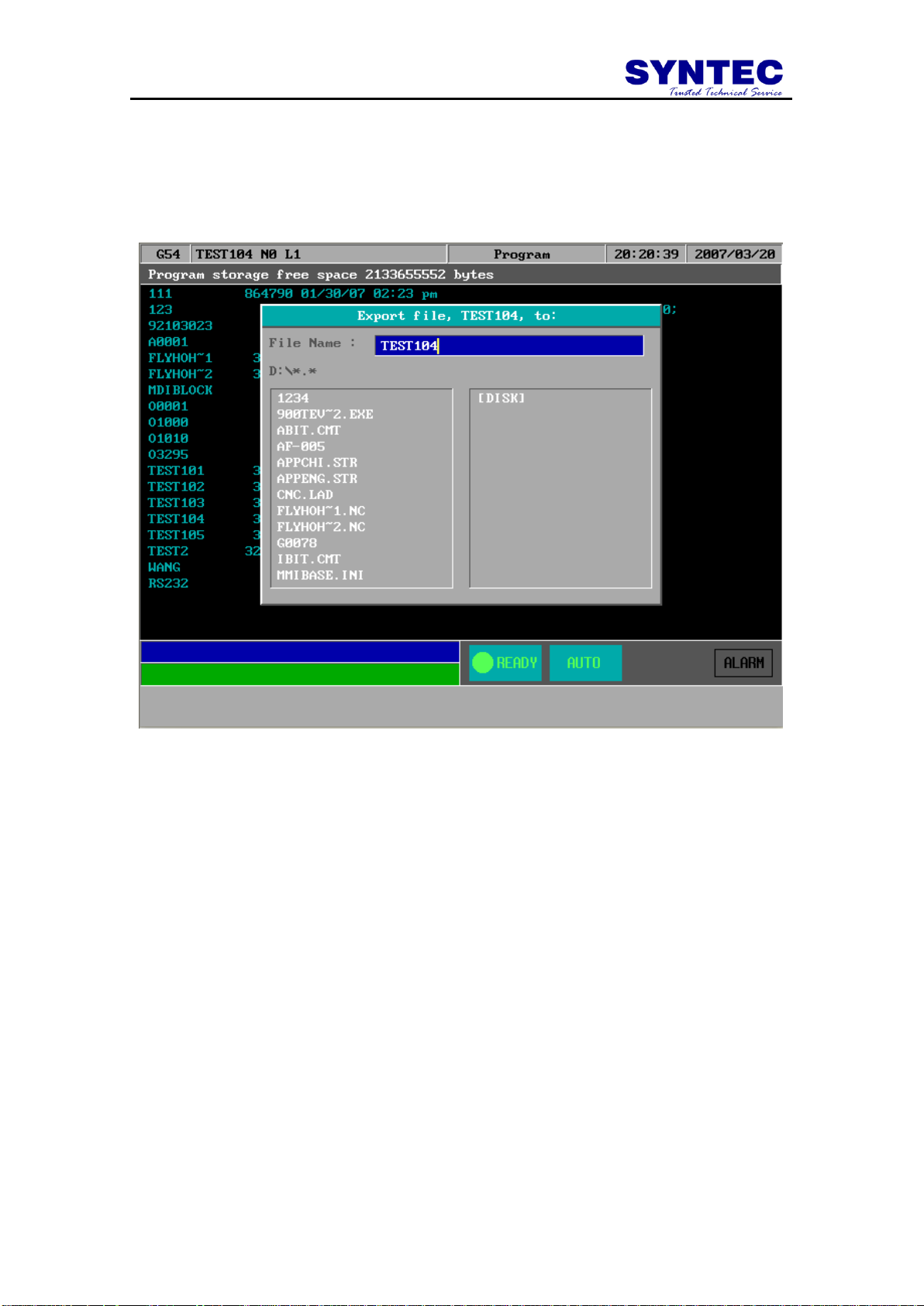

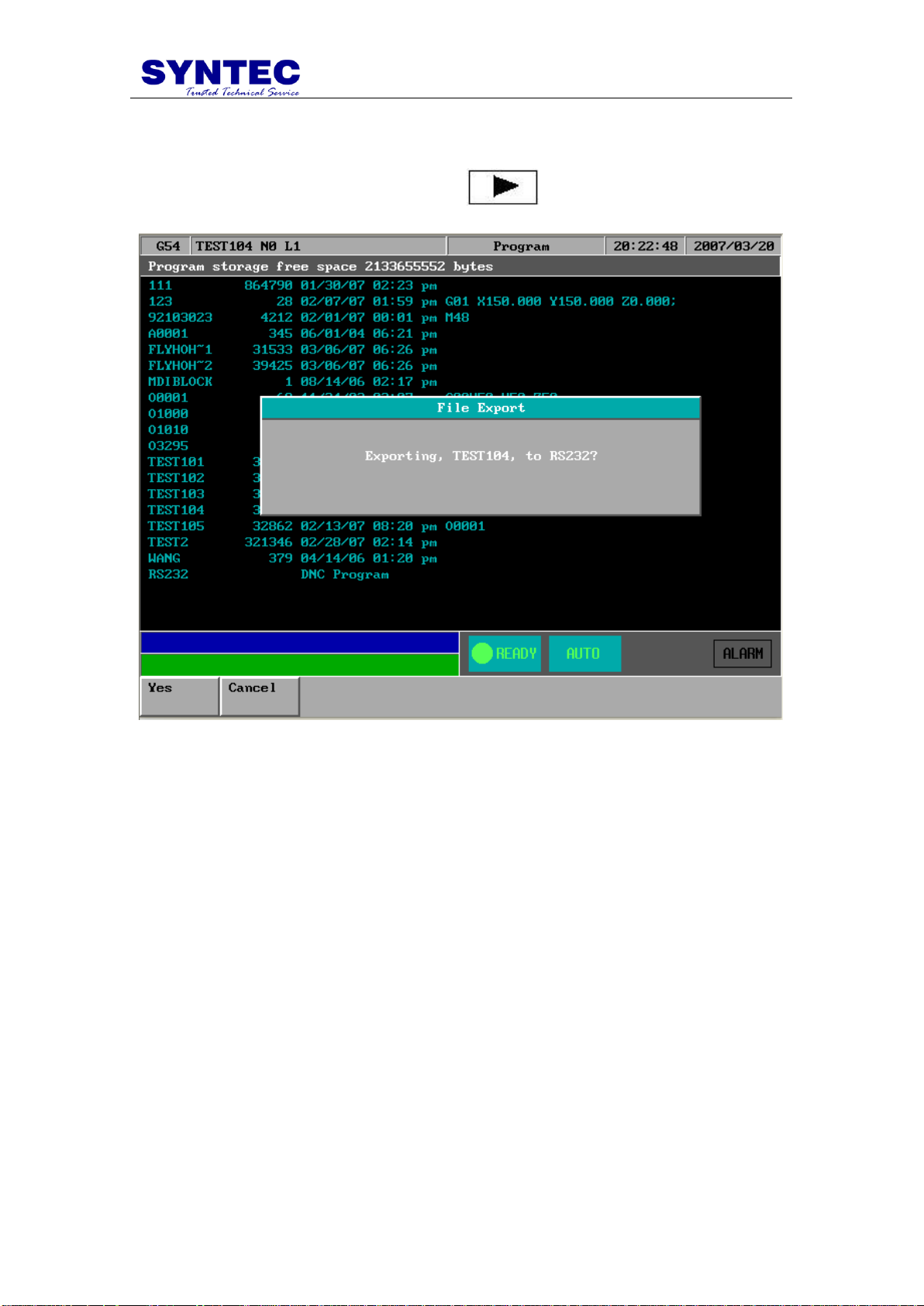

1.3.2.5.5 F5:Export

Function: Output file to floppy disk

Operation: Select a file by pressing(↑、↓、←、→)and then press F5. After following

the prompt in the dialog box, confirm this operation by pressing 【ENTER】.

-16-

Page 23

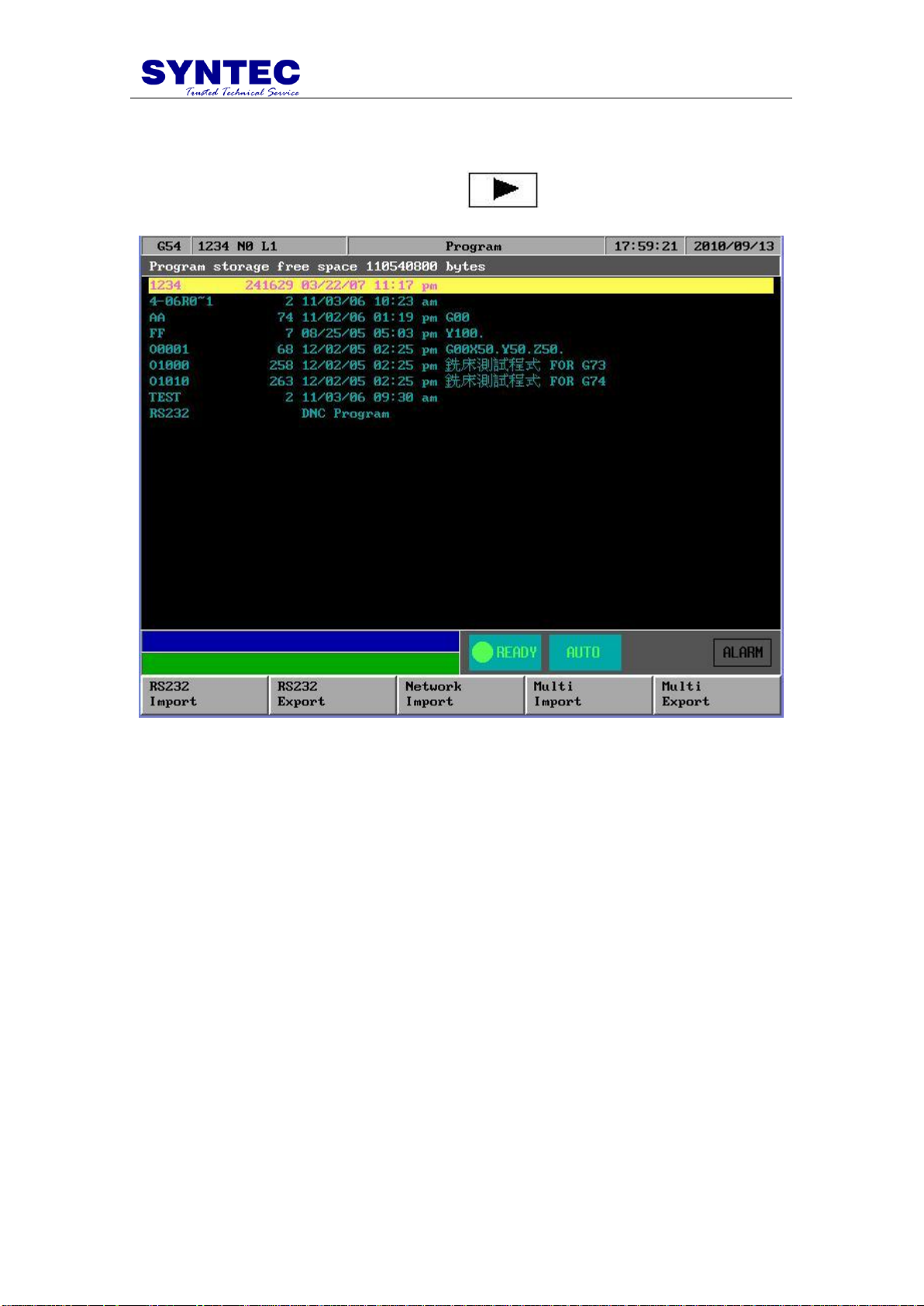

1.3.2.5.6 F1:RS232 Import

Function: use RS232 communication function to import NC files

Operation: Under Program submenu, press and then F1.Follow the

prompts in the dialog box and type in needed data.

-17-

Page 24

-18-

Page 25

1.3.2.5.7 F2 :RS232 Export

Function: Use RS232 communication function to Export NC files

Operation: Under Program submenu, press and then F2.

-19-

Page 26

1.3.2.5.8 F3:Network Import

Function: Use Net communication function to Import NC files

Operation: Under Program submenu, press and then F3.

1.3.2.5.9 F4:Multi Import

Function: Import multi NC files once time

Operation: Under Program submenu, press and then F4.

1.3.2.5.10 F5:Multi Export

Function: Export multi NC files once time

Operation: Under Program submenu, press and then F5.

1.3.2.6 EDIT

Function : Edit sub function “ Search “ “Replace” “Goto line” “Copy line” ”Insert

line”

Operation : Under Program submenu, press and then F1. User can use this

menu for more edit sub function

-20-

Page 27

1.3.2.6.1 EDIT sub function “F1 : Search”

Function:Search String。

Operation:Under Program submenu, press F5”EDIT” and then F1 “Search” to

search string. An dialog box will pop up asking users to input a string as shown in

the following figure. After keying in a string, press F1 to start searching.

-21-

Page 28

1.3.2.6.2 EDIT sub function “F2 : Replace”

Function:Replace String.

Operation:Under Program submenu, press F5 “EDIT” and then F2”Replace” to

replace string. An dialog box will pop up asking users to input the replacing string

and the new string as shown in the following figure. After keying in a string, press

F1 to start replacing.

-22-

Page 29

1.3.2.6.3 EDIT sub function “F3” : Go To Line”

Function:Go to a line number

Operation:Under Program submenu, press F4”EDIT” and then F3”GOTO line” to go

to the line number. A dialog box will pop up asking users to input a line number.

After keying in a number, press F1 to go to the desired line.

1.3.2.6.4 EDIT sub function “F4”: copy line”

Function:Copy a line from current cursor to next line

Operation:Under Program submenu, press F5 “EDIT” and then F4”Copy line” to go

to the next line.

1.3.2.6.5 EDIT sub function “F5”: Insert line”

Function:Insert a space line above current cursor line

Operation:Under Program submenu, press F5 “EDIT” and then F5”Insert line” to

Insert a new space line

-23-

Page 30

1.3.2.7 F2:Teach

Function: Teach present absolute coordinate to NC files

Operation:Under Program submenu, press and then F2.

Teach sub Key Selections:

1.3.2.7.1 F1:Rapid Teach

Function: Add “G00” code to NC files, G00 to current absolute coordinate,

1.3.2.7.2 F2:Line Teach

Function: Add “G01” code to NC files, G01 to current absolute coordinate,

1.3.2.7.3 F3:Arc Teach

Function: Add “G02” or “G03” code to NC files

1. 1st time press this key “arc teach “ ,CNC auto put current

value to Arc middle point

2. 2nd time press this key “arc teach “ ,CNC auto calculate

G02 or G03 ,and filled the complete code to NC files

-24-

Page 31

1.3.2.7.4 F4:Cancel Middle

Function: When arc teach ,user can use this key to abort middle point teach .

1.3.2.7.5 F5:Radius Teach

Function: Add “G02” or “G03” code to NC files by G_code menu and Arc Radius

1.3.2.7.6 F1:Delete Line

Function: When user use Teach function , user can use this key “Delete line “ to

delete line

Operation:Under Teach press and then F1.

1.3.2.7.7 F2:Coord Switch

Function: When the number of axis is more than 4-axis ,user can use this key to

switch absolute coordinate of other axis.

Operation:Under Teach press and then F2.

1.3.2.7.8 F3:Point Teach

Function: Add current absolute coordinate to NC files.

Operation:Under Teach press and then F2.

-25-

Page 32

1.3.3 F3:DlgInput (ONLY for 940M)

Pressing "F3" under the main menu to begin dialog box input as shown

in the following figure. After users follow the prompts shown on the dialog

box to key in every needed parameter, the CNC milling controller can start

milling a work piece immediately.

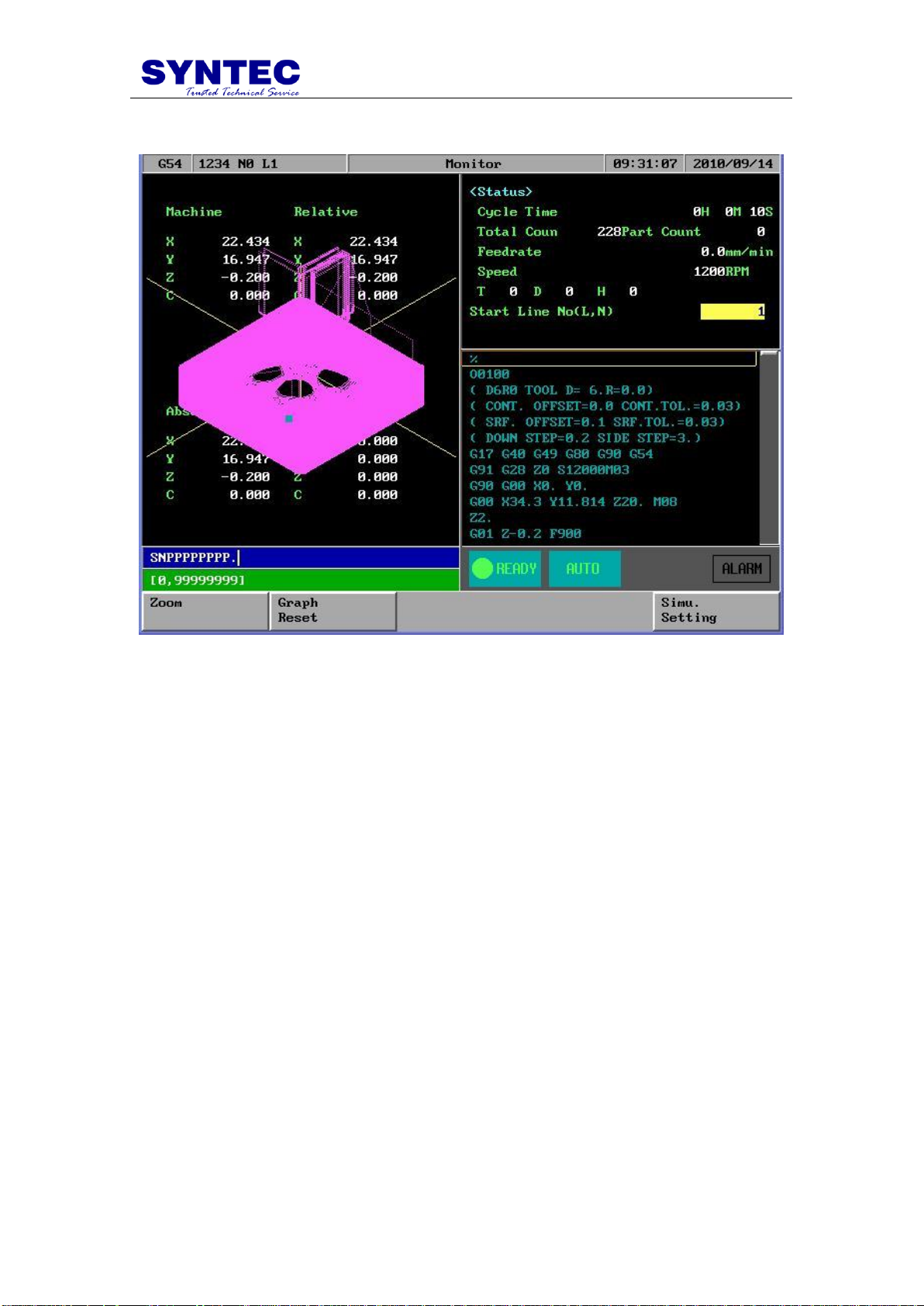

1.3.4 F4:Monitor

This selection displays machining speed, time, manual data input (MDI)

and some machine information such as coordinate, range or program at the

run time. Press F4 under the main menu to select this function.

Key Selections:

1.3.4.1 F1:Coor

Function: Toggle way of display among the four different coordinate systems,

graphical working paths display and the absolute coordinate. (Absolute coordinate

display at the upper right corner of the left half screen.)

Operation: Under Monitor submenu, press F1 to toggle coordinate display between

the four coordinates as shown as the following figure:

-26-

Page 33

1.3.4.2 F2:Graph Adjust

Key Selections:

1.3.4.2.1 F1:Zoom

Function: To enlarge the workpiece graph.

Operation: Under Monitor submenu, press F2 and then F1.The operator can use the

cursor to move the frame to the determined area.

1.3.4.2.2 F2:Graph Reset

Function: To recover the zoomed workpiece graph.

Operation: Under Monitor submenu, press F2”Graph Adjust” and then F2”Graph

Reset”

1.3.4.2.3 F5:Simu Setting

Function: To set simulation parameter

Operation: Under Monitor submenu, press F2”Graph Adjust” and then F5”Simu

Setting” .

-27-

Page 34

1.3.4.3 F3:MDI Input

Function:Manual Data Input

Operation:Users can operate SNC Milling Controller manually in MDI mode. Press

F3 under Monitor submenu and type in single-line G or M code. Press F1 (OK) to

confirm the input command. The typed-in command line will show on right upper

corner of the screen. Users simply press 【CYCLE START】on the machine panel to

execute the single-line command. The following figure shows an example of this

function.

-28-

Page 35

1.3.4.4 F4:SETTING

Function:To set the part count and also set required current

Operation:From this screen users can set the part count what he needs

1. When CNC execute M02 ,M30 ,M99 ,part count would add 1

automatically ,

2. When part count reach required part count ,CNC would stop

executing.

-29-

Page 36

1.3.4.5 F5:Tool Setting

Function:To set the tool compensation value

Operation:

Radius : G41/G42 tool radius Dn compensation (not diameter)

Radius wear : for small radius dimension adjust

Length : G43/G44 tool length Hn compensation

Length wear : for small length dimension adjust

-30-

Page 37

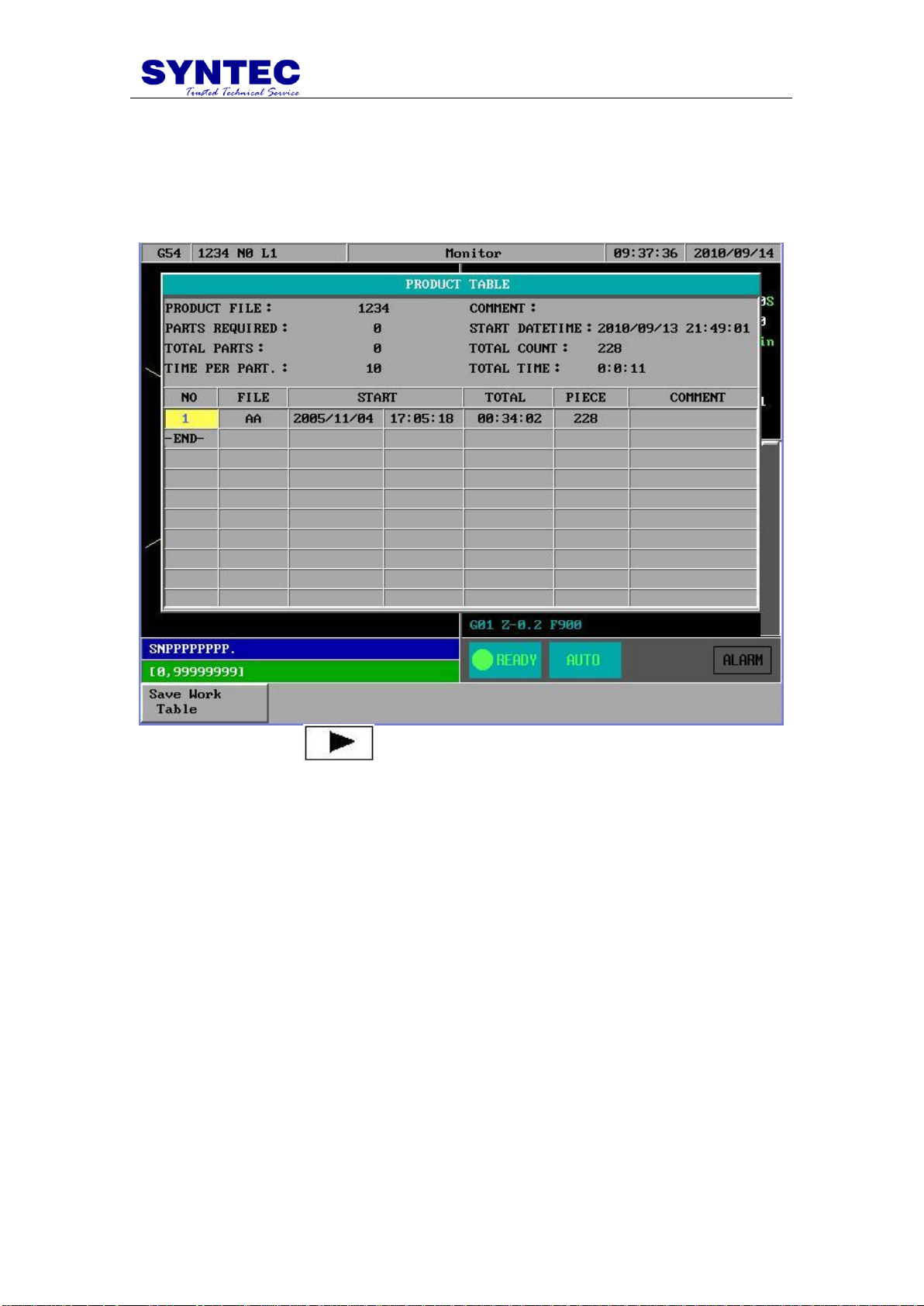

1.3.4.6 F5:Work Record

Function:This table can record 300 sets executed NC file ,this is very helpful to know

the end of user working history .

Operation: Under

Mo

nitor submenu, press and then F5.

-31-

Page 38

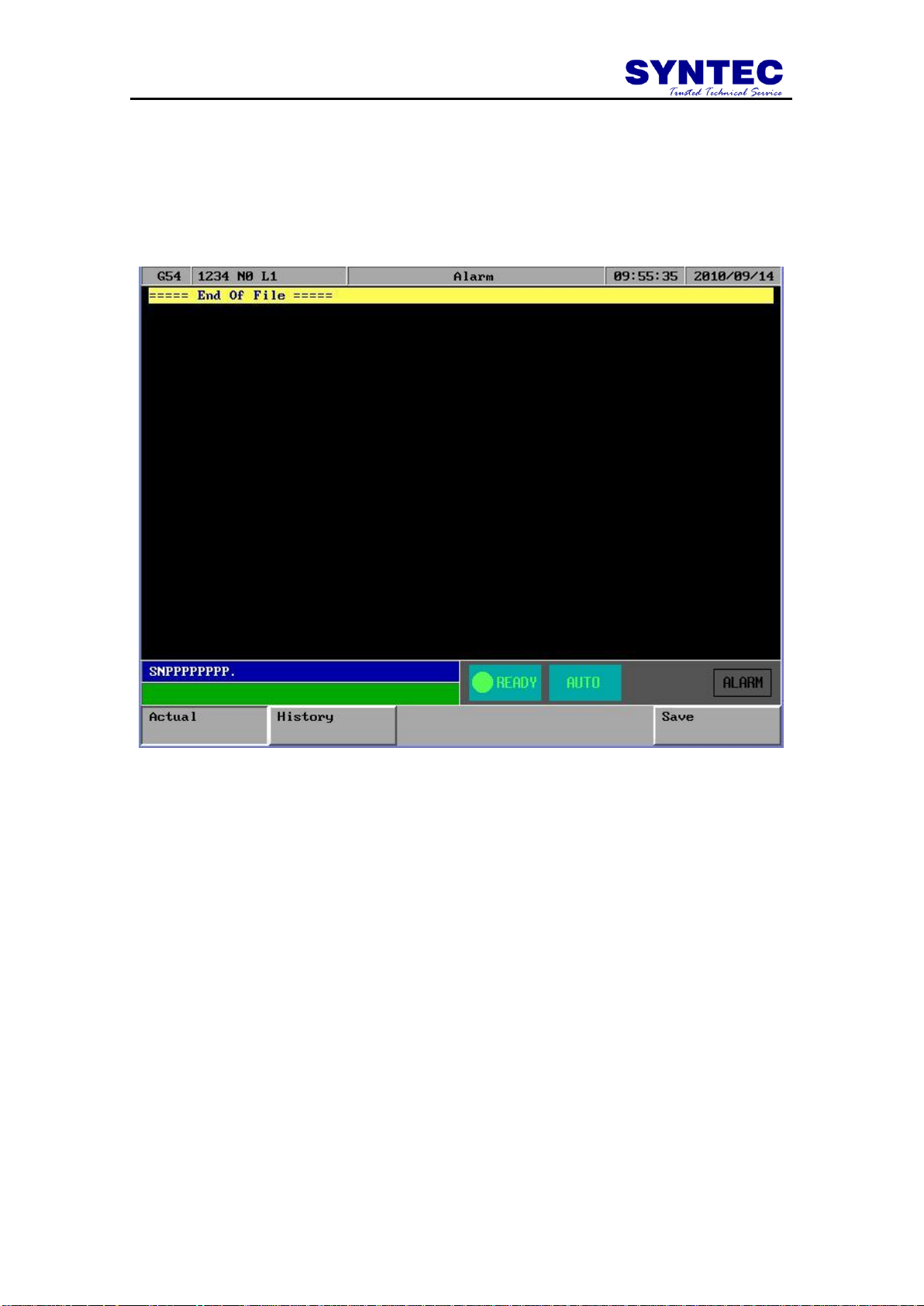

1.3.5 F5:Alarm

Whenever the system or the program stops running due to some errors,

there will be an alarm message shown on the screen. In order to clear the

errors, users can press F5 in the main menu for Alarm submenu as shown in

the following figure.

-32-

Page 39

Key Selections:

1.3.5.1 F1:Actual

Operation: Under the Alarm submenu, press F1 to show current alarm situation.

1.3.5.2 F2:History

Operation: Under the Alarm submenu, press F2 to show the alarm history of the

system.

1.3.5.3 F5: Save

Function:Save Alarm History To File.

Operation:Under the Alarm submenu, press F5 to save alarm history to a file as

shown in the following figure. A dialog box will prompt users to type in file name

to be saved. After selecting a disk drive by using (、、、), users press

【ENTER】to confirm this operation.

-33-

Page 40

1.3.6 F1:Parameter

Under the main menu, press and then F1 to enter this

function as shown in the following figure.

-34-

Page 41

1.3.7 F2:Diagnosis

This selection provides users with direct access to the memory area for

parameter checking, parameter settings and NC diagnosis function. It can

also be used to maintain and debug the control devices. Under the main

menu, press and then F2 to access this function as shown in the

following figure.

-35-

Page 42

Key Selections:

1.3.7.1 F1:PLC State

Function:for upgrade system software ,or Ladder ,system parameter …

-36-

Page 43

1.3.7.2 F2:System Data

Function:

-37-

Page 44

1.3.7.3 F3:Global Variable

-38-

Page 45

1.3.7.4 F4:Coord Variable

-39-

Page 46

1.3.7.5 F5:System Manager

-40-

Page 47

1.3.8 F3:Guidance

If users have any problem about SNC Mill controller, in addition to

user manual, users can also use this function for on-line help. Under the

main menu, press then F3 for on-line help.

-41-

Page 48

2 Machine operation panel

2.1 2nd machine operation panel

2.1.1 POWER ON

Turn on main power

2.1.2 POWER OFF

Turn off power

2.1.3 Emergency STOP

For safety reason ,press this button ,CNC would stop all

movement ,and also stop all main power . So ,people and machine safety is

guarantee .

2.1.4 Home mode and Home function

Description : When CNC power is on ,please do the home function

Operation :

1. Mode select to HOME mode

2. Press axis manual key X+,X-,Y+,Y-,Z+,Z-:

3. CNC would start the machine home function

2.1.5 Continues JOG (Rapid JOG)

Description : User can use this function to move the machine by press JOG key

Operation :

1. Mode select to CON JOG mode

2. Press axis manual key X+,X-,Y+,Y-,Z+,Z- ,work table

would move

3. Operator can use JOG% or G01% adjust Jog federate

4. When operator press manual key and rapid Key “〰” at the

same time

5. CNC would move the work table “RAPID speed”

6. Operator can use G00% Rapid Jog federate

G00 % : Adjust G00 % (F0 .25% .50% .100%)

G01 % : Adjust G01/G02 /G03 feedrate override %:

-42-

Page 49

2.1.6 Incremental JOG

Description : User can use this function to move the machine by press JOG key

Operation :

1. Mode select to INC JOG mode

2. Press axis manual key X+,X-,Y+,Y-,Z+,Z- ,work table

would move a fixed distance

3. Operator can set the incremental distance by G00 rotary

switch

4. , *1 : 1um ,*10 : 10um ,*100 : 100um

2.1.7 MPG JOG

Description : User can use this function to move the machine by MPG(Manual

Pulse Generator )

Operation :

1. Mode select to MPG mode

2. Select axis by hand box

3. Select incremental distance

4. Press axis manual key X+,X-,Y+,Y-,Z+,Z- ,work table

would move a fixed distance *1 : 1um , *10 : 10um ,

*100:100um , *1000 : 1000um

2.1.8 AUTO mode NC file execute

Description : User use this function to execute NC file

Operation :

1. mode select to AUTO mode

2. After Home function .AUTO mode is available

3. Set workpiece coor.(G54..G59) ,CNC default G54 ,if user

don‟t set any G54..G59 in the NC file

4. Set to “Tool Setting” ,to select tool radius and tool length .

5. Press “START” key to start the NC program .

6. Press “Feedhold” key to feedhold the NC program ,if it‟s

necessary

2.1.9 MDI mode single block execute

Description : User use this function to execute a block without NC file

Operation :

1. mode select to MDI mode

2. After Home function .MDI mode is available

3. Main function select F4”Monitor”

4. Press F3 “MDI Input”, screen would pop up a window.

5. After key in data ,press “ENTER” key to input the data

6. Press “START” key to start the MDI block.

7. If MDI block syntax is correct ,data in MDI menu would

disappear

-43-

Page 50

2.1.10 MPG Simulation

Description : User can use this function to check NC file

Operation :

1. Mode select to AUTO mode

2. Press this button ,and button led light “ON”

3. Press “START” key to start the NC file.

4. CNC would change machine status from “READY” to

“BUSY”

5. Machine is still not moving

6. Operator can use rotate MPG to start the NC file

7. MPG rotate faster ,machining speed is faster

8. When MPG stop ,CNC stop.

9. This function can “Enable” “ Disable” immediately

P.S. this function is very friendly for user to check his programs

2.1.11 Dry Run

Description : User can use this function to check NC file

Operation :

1. Mode select to AUTO mode

2. Press this button ,and button led light “ON”

3. Press “START” key to start the NC file.

4. CNC would change machine status from “READY” to

“BUSY”

5. This function can “Enable” “ Disable” immediately

2.1.12 Single block

Description : User can use this function to check NC file

Operation :

1. Mode select to AUTO mode

2. Press this button ,and button led light “ON”

3. Press “START” key to start the NC file.

4. CNC would execute NC file only one block and STOP

5. CNC would change machine status from “BUSY ” to

“B_STOP”

6. Press “START” again ,then CNC execute next block

7. This function is for user to check his NC file Block by Block

-44-

Page 51

2.1.13 Option Stop

Description : User can use this function to decide NC file M01 is STOP or not

Operation :

1. Mode select to AUTO mode

2. Press this button ,and button led light “ON”

3. Press “START” key to start the NC file.

4. When CNC execute “M01” ,CNC would STOP

5. CNC would change machine status from “BUSY ” to

“Feedhold”

6. This function uses to change tool or check workpiece

2.1.14 Option Skip

Description : User can use this function to decide NC file „/” is skip or not

Operation :

1. Mode select to AUTO mode

2. Press this button ,and button led light “ON”

3. Press “START” key to start the NC file.

4. When CNC execute “/” ,CNC would skip this block

5. If this key is not pressed ,CNC would execute this block

2.1.15 Spindle control

Spindle CW rotate

Spindle stop

Spindle CCW rotate

Spindle low speed: When spindle is rotate, press this key,

spindle would rotate with low speed

-45-

Page 52

2.1.16 Working led

ON/OFF working led

2.1.17 Working Liquid

Flush working liquid

2.1.18 Aux table backward

2.1.19 Aux table forward

-46-

Page 53

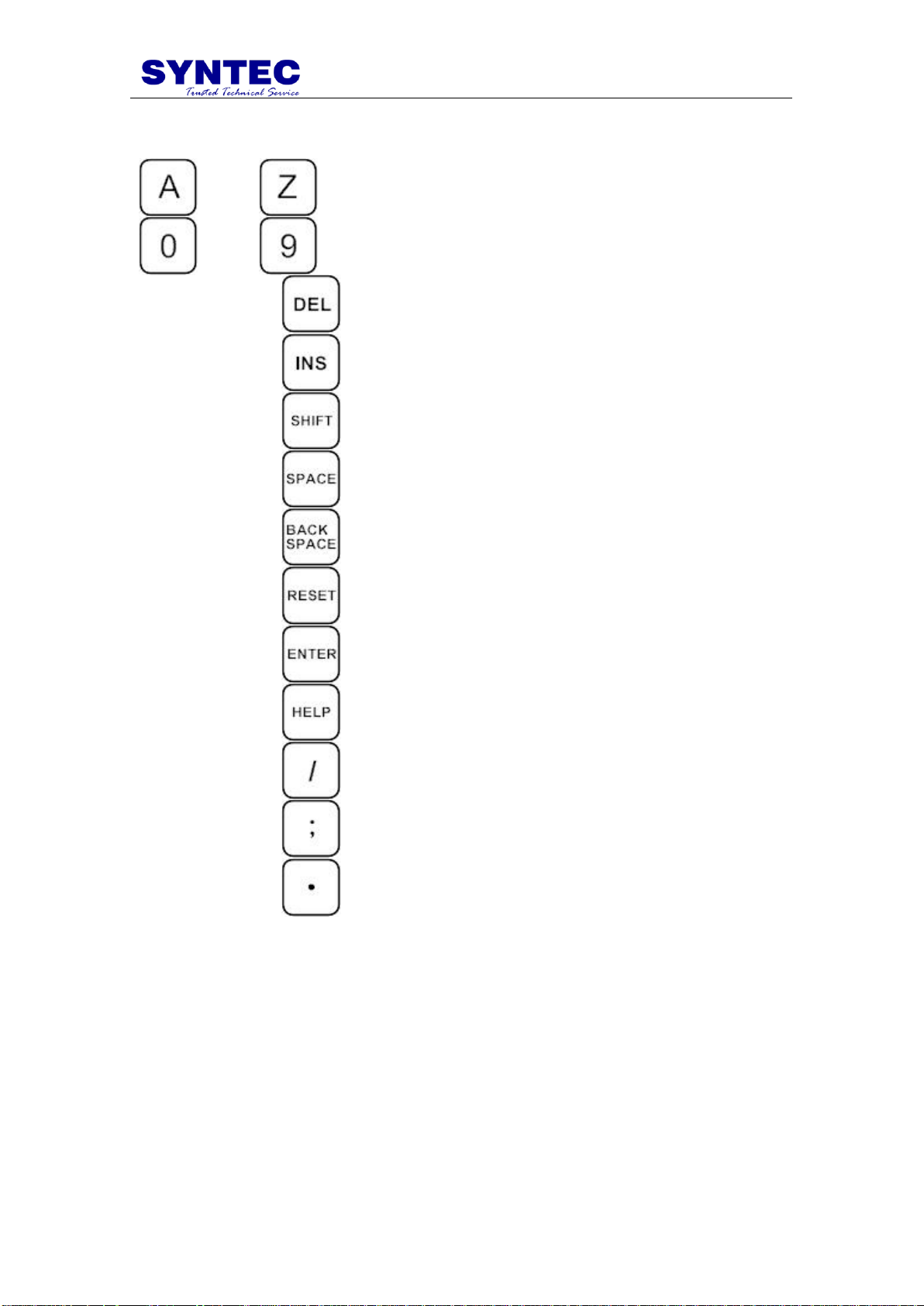

~

:

English 26 character key

~

:

numerical key

:

delete a character

:

Insert /replace mode switch

:

for select keyboard the other textkey

:

for select keyboard the other textkey

:

”Backspace” delete a character

:

”RESET “ abort the CNC status ,so please be careful to

use this key

:

to input current data to input box

:

press this key ,user can get help message about this

screen

:

for optional skip key input

:

end of block

:

decimal fraction

“(“, “)”, “[“, “]”, “|”, “!”, “&”, “$”, “#”, “<”, “>”, “=”, “%”, “@”, “*”, “:”, “,”, “+”, “-“

Above symbols are used for “Program Edit” mode.

2.2 Text key description:

-47-

Page 54

:

edit cursor Page Up /Page Down

:

edit cursor control key

-48-

Page 55

3 How to operate SYNTEC 900ME

This chapter is written for user task,when user operates this

controller ,operator can follow task description as below STEP by STEP ,so

very easy to use this controller ,TASK description as below :

1. Manuel function(JOG ,INC_JOG ,MPG)

2. HOME

3. Open a file (EDIT / FLOPPY /RS232 )

4. Tool setting (G40/G41/G42 ,G43/G44/G49)

5. Tool Length measurement (G43/G44/G49)

6. Setting the Workpiece origin offset value(G54..G59)

7. Manual Data Input(MDI )

8. Assigned an executing NC file (AUTO)

9. Graphic Simulation

10. How to check NC file in SYNTEC controller

11. Auto center

12. Auto Tool

-49-

Page 56

3.1 Manual function (JOG, INC_JOG, MPG)

When power on SYNTEC CNC, there are 3 mode to manual machine

1st CON_JOG :

1. Release emergency stop button ,CNC status “NOT READY”

change to “READY ”

2. Mode select switch rotate to JOG mode

3. Press axis direction key(X+,X-,Y+,Y-,Z+…) ,table would

move

4. Operator can use JOG% adjust JOG speed

5. Operator can press axis direction key and rapid key “~” at

the same time, machine will move by rapid speed

6. Rapid JOG speed can be adjusted by G00%

Incremental JOG :

1. Release emergency stop button ,CNC status “NOT READY”

change to “READY ”

2. Mode select switch rotate to INC JOG mode

3. Press axis direction key(X+,X-,Y+,Y-,Z+…) ,table will

move a fixed distance once

4. Operator can select incremental distance by G0%

(*1,*10,*100)

MPG incremental jog (MPG):

1. Release emergency stop button ,CNC status “NOT READY”

change to “READY ”

2. Mode select switch rotate to MPG INC JOG mode

3. Select movement axis

4. Select movement distance (*1,*10,*100)

5. Rotate MPG ,table would move .

-50-

Page 57

3.2 HOME

Because tool setting ,workpiece coordinate setting is based on Machine

zero point .So ,it is necessary to make sure where is machine zero (HOME).

When CNC bootup, execute HOME function is very important ,otherwise

SYNTEC CNC controller would not be allowed to start AUTO NC files

Procedure :

1. Release emergency stop button ,CNC status “NOT READY”

change to “ READY ”

2. Mode select switch rotate to HOME mode

3. Press axis direction key(X+,X-,Y+,Y-,Z+…) ,axis would

start HOMING

4. Home direction is defaulted in the CNC parameter

5. Home function can run 3 axis at the same time

6. After home function, machine coordinate would be zero .

7. After home function completed, software limit protection is

available .Therefore, please don‟t run machine too fast,

before HOME function.

-51-

Page 58

3.3 Open a file (EDIT / FLOPPY / RS232)

Procedure :

1. Press Group function key “Program”

2. Press submenu function key “File manage”

3. Screen display file system screen

4. Press F1 “New file” ,to open a new file

5. Press F2”copy file” ,to copy current file to target file

6. Press F3 “delete file“ ,to delete current file

7. Press F4 “Import” ,to import a new file from floppy disk

8. Press F5 “Export “ ,to export file to floppy disk

9. Press then F1 “RS232 Import” ,to import a new

file from RS232

10. Press then F2 “RS232 Export “ ,to export file to

RS232

11. Press then F3 “Network Import” ,to import a new

file from network

-52-

Page 59

3.4 Tool setting (G40/G41/G42, G43/G44/G49)

Procedure for setting Tool offset value :

1. Press Group function key “Monitor”

2. Press function key “Tool Setting”

3. Move the cursor to the compensation value to be set or

change using page keys and cursor keys

4. Type “A” or “I” key to selected input type is “Absolute”

or “Incremental”

5. Generally use Absolute type to input Tool radius and Tool

length

6. Use Incremental type to input radius wear and Length wear

for small value adjust

7. (Tool radius + radius wear ) is real G41/G42 compensation

value

8. (Tool length + length wear) is real G43/G44 compensation

value

-53-

Page 60

3.5 Tool Length measurement (G43/G44/G49)

Procedure :

1. Use manual operation to move the reference tool until it

touches the specified position on the machine.

2. Press Group function key “Position” and clear relative

coordinate to zero

3. Press Group function key “Monitor” and press “Tool

Setting” to this screen

4. Use manual operation to move the tool until it touches the

same specified position that have been measured. The

difference of measured that is between the length of the

reference tool and the tool is displayed in the relative

coordinates on the screen.

5. Move the cursor to the compensation number for the target

tool(the cursor can be moved in the same way as for setting

tool compensation values)

-54-

Page 61

3.6 Setting the Workpiece origin offset value

(G54...G59)

Procedure :

1. Press group function key “Position”

2. Press sub selection soft key “Workpiece coor.”

3. The screen for displaying the workpiece origin offset values

consists two pages . Display a desired page by Press

PageUp/PageDn key

4. Move the cursor to the workpiece origin offset to changed

the values.

5. “Extenal shift” input the value ,which can shift the whole

coordinate(G54..G59.8) simultaneous

6. F1”coor. Latched”: user can press this function key ,and

CNC would latch current machine coordinate to the screen

where sursor is located .

-55-

Page 62

3.7 Manual Data Input (MDI)

Procedure :

1. Mode select switch rotate to MDI mode

2. Press group function key “Monitor ”

3. Press sub selection soft key “MDI input”

.

4. The screen display the MDI input window

5. Key in MDI data at input bar and press “ENTER”

6. Press 2nd operation panel “START” to execute the current

block

7. If current block SYNTAX is correct ,the data in the window

would be disappear .

-56-

Page 63

3.8 Assigned an executing NC file (AUTO)

Procedure :

1. Mode select switch rotate to AUTO mode

2. Make sure CNC status is “READY”

3. Press group function key “Program ”,select NC file what

user want to execute

4. Press group function key “Monitor”,then executing file is

assigned automatically .

5. Please make sure CNC status is “READY”, that is the only

available status to assigned executing NC file .

-57-

Page 64

3.9 Graphic Simulation

Procedure :

1. Mode select switch rotate to AUTO mode

2. Press group function key “Program ”,select NC file what

user want to execute ,press sub menu “Simulation”

3. User can use “STEP” to check NC file step by step

4. Use “Continue” to simulation whole picture

5. Use “Zoom” check more detail

6. Use “Simulation setting” set simulation parameter

7. CNC status is “READY”, Press group function key

“Monitor”

8. that is the available status to assigned executing NC file .

-58-

Page 65

3.10 How to check NC file in SYNTEC controller

MPG simulation Procedure :

1. Mode select switch rotate to AUTO mode

2. Press group function key “Monitor”

3. Press “MPG simulation “key enable this function (led on)

4. Press “Start “ key ,CNC status from “READY” to “BUSY”

5. Machine table current status is static

6. Operator rotate MPGs ,then table is start moving along

cutting path

7. MPG rotates more fast ,table moves more fast ,MPG

stop ,table is stop from monitor screen ,operator can see the

cutting cursor move along simulation path

8. Operator also can press “Single Block” key ,enable single

block function when “MPG simulation “ function is

ON ,then user can use two function simultaneous ,check

NC file STEP by STEP ,with” MPG simulation “ function .

9. “ MPG simulation “ can control table forward ,also can

control backward too ,but NC file would stop at M,S,T code

when backward .

-59-

Page 66

3.11 Auto Center

Specification:

It is usually used to look for the center of the coordinate which is the

origination of the executing procedure. So it needs to touch both sides of the

tool. The center workpiece can be calculated by system after getting their

coordinate, then the operator chooses a group of workpiece coordinate

(G54~G59.9) as the origination of the executing procedure.

Here we supply the operation introduction of manual center and auto

center as follows.

3.11.1 Manual Center

Operator moves tool to touch the edge of the workpiece by rotating

MPG, the center coordinate can be calculated by system after pressing

function key.

Operation:

1. To enter center submenu, press F1”Positon”=>F5”workpiece

2.

3. To change middle function to manual center, input 0(manual

Coor”=>F5”Middle Func”.

center) in center submenu, then press enter, manual center

submenu can be displayed as follows.

4. Take the tool to touch Px1 spot in the figure by handwheel,

press F1”Px1”,the X machine coordinate value of Px1 can be

-60-

Page 67

noted in the screen and calculate X intermediate machine

coordinate with Px2, the value can be displayed in Pxm and

X-axis of Aux coordinate.

5. Take the tool to touch Px2 spot in the figure by handwheel,

press F2”Px2”,the X machine coordinate value of Px2 can be

noted in the screen and calculate X intermediate machine

coordinate with Px1, the value can be displayed in Pxm and

X-axis of Aux coordinate.

6. Take the tool to touch Py1 spot in the figure by handwheel,

press F3”Py1”,the Y machine coordinate value of Py1 can be

noted in the screen and calculate Y intermediate machine

coordinate with Py2, the value can be displayed in Pxm and

Y-axis of Aux coordinate.

7. Take the tool to touch Py2 spot in the figure by handwheel,

press F4”Py2”,the Y machine coordinate value of Py2 can be

noted in the screen and calculate Y intermediate machine

coordinate with Py1, the value can be displayed in Pxm and

Y-axis of Aux coordinate.

8. Press “Esc” to exit “Auto Center” and return to “Workpiece

Coor” submenu.

9. In “Workpiece Coor” submenu move cursor to the location

of the workpiece coordinate which will be set, press F3

“AUX Latched”. At this time the system will set the value

of the AUX coordinate into the filed in accordance with the

axis where the cursor stop.

-61-

Page 68

3.11.2 Auto center operation

Auto center function is different to manual center function .The

operator only need to input the size of the workpiece and set the border

coordinates of the workpiece. Move the tool to the start point and press

startup, the system will find the center coordinate automatically.

Operation:

1. To enter center submenu, press F1”Positon”=>F5”workpiece

Coor”=>F5”Middle Func”.

2. To change middle function to auto center, input 1(auto center)

in middle function submenu, then press enter, auto center

submenu can be displayed as follows.

3. Choose the quadrant to process and input workpiece data, the

description of the field to input an follows.

Workpiece length I: the workpiece actual length in X-axis direction

Workpiece width J: the workpiece actual width in Y-axis direction

Safe distance H: this is the length more than the distance between the start point of the

tool P2 and workpiece, regardless of X-axis direction or Y-axis direction.

Feed rate: detection rate of auto center.

Z-axis safe height: this is the height that the tool will not encounter the workpiece

when it moves above the workpiece,P1 in the figure as follows.

-62-

Page 69

4. Move to Z-axis Safe Height Teach, the location of P1 as

displayed in the figure. Press F5 “Z safe height teach”, the

value of Z-axis machine coordinate will be noted

simultaneously as the safe height when tool moves above the

workpiece.

5. Move the tool down to P2 under the surface of work piece as

the start point of auto center.

6. Press F2”Start”, the tool will be moved to touch the

workpiece according to the data which has been set and the

value will be displayed on the screen. Finally the center

coordinate of the workpiece in XY-axis direction can be

calculated.

7. Press “Esc” to exit “center function” back to workpiece

coordinate submenu.

8. Move the cursor to the location of the workpiece coordinate

which will be set in workpiece coordinate submenu. Press

F3”AUX Latched” and the system will set the AUX

coordinate Pxm or Pym into the workpiece coordinate

system according to the axis that the cursor stops.

-63-

Page 70

3.12 Z-axis Auto Tool

Specification:

Z-axis auto tool function measures the location of tool point of

different tool number through the tool calibrator on the machine, then

operator makes the distance that the location of the tool point to the datum

plane of the workpiece is fixed to amend the processing datum plane.

Operator can teach the distance into workpiece coordinate system as the gist

of the tool offset when processing.

Operation:

After starting, F1”Positon”=>F5”workpiece Coor”=> =>F1”

Tool Tip Measure”

-64-

Page 71

Auto tool length measurement

It needs to measure the length of the tool again when change another

tool in order to compensate the correct tool length to the processing path.

1. Coordinate workpiece number P:0: auxiliary point,1: 1:G54,

2:G55, 3:G56, 4:G57, 5:G58, 6:G59, 7:G59.1 …;

2. Measurement rate F: set auto tool bottom detection of the

first time and rebounding speed of every time.

3. Use reference point coordinate: set whether to re-move to the

reference point and then auto tool or not.

“0” the current location ,as the start point of auto tool and

directly do bottom detection.

”1”The system will first complete the following steps and then

do auto tool.

I. Z-home

II. XY-axis move to the location of the second reference

III. Z-axis down to the start point of auto tool.

4. Reference point X in X-axis direction: this field can first

move spindle to new auto tool position coordinate and then

through【XY machine coordinate teach】to correct the

location of the auto tool reference point in X-axis(if no

correction system, the previous value will be set as the preset

value);

5. Reference point Y in Y-axis direction: this field can first

move spindle to new auto tool position coordinate and then

through【XY machine coordinate teach】to correct the

location of the auto tool reference point in Y-axis(if no

correction system, the previous value will be set as the preset

value);

6. Start point Z in Z-axis direction: this field can first move

spindle to the new location of auto tool start point in Z-axis

and then through【Z machine coordinate teach】to set Z-axis

start point of auto tool ;

7. Z-axis lowest machine coordinate H: the height to down

Z-axis that the spindle will not hit the tool calibrator, press

function key 【Z machine coordinate teach】to set the value;

point

-65-

Page 72

Start

Bottom detection and

execute auto tool

No use of

reference point

coordinate

Use reference coordinate

XY reference point

Z-axis startint point

No correction

Z-axis lowest point

correction

Setting completed

Correct XY coordinate

as new reference point

Correction

Start auto tool

Setting completed

-66-

Page 73

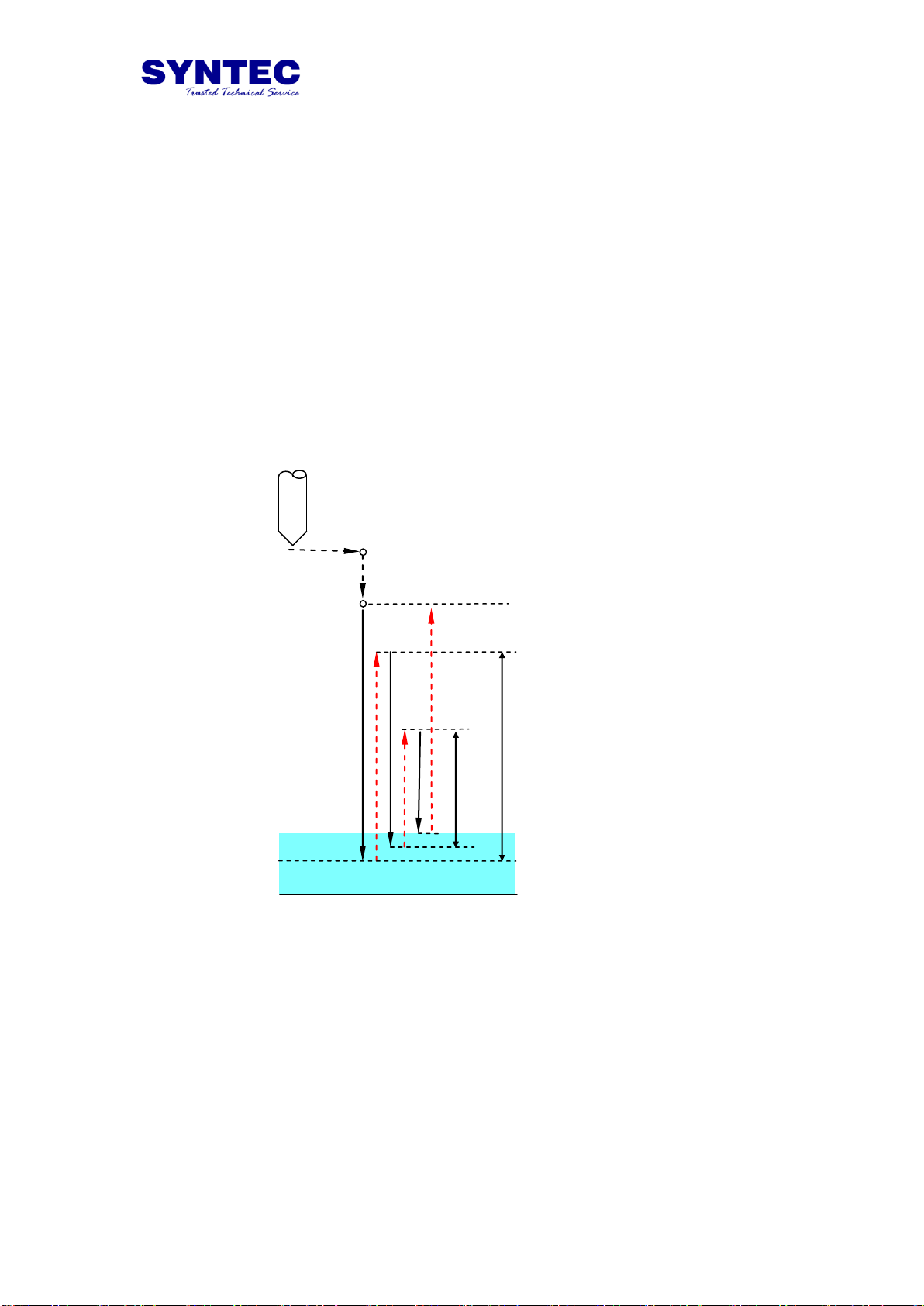

d:the value of error

5mm

3mm

Z-axis starting point

Auto tool measurement action

XY reference point

Z-axis lowest point

d

Tool calibrator

Delta z set:

of the workpiece and the tool calibrator when change another workpiece and

the system will note the value to external shift. The value can automatically

combine and calculate with the tool length measured to produce the correct

path.

Delta z set is mainly used to measure the distance between the surface

1. Delta z value: display the height delta value between the

surface of the workpiece and the tool calibrator, correspond

to Z-axis set value in external shift.

2. Operation: first do tool length measurement then set delta

Step 1: take tool tip to top of workpiece

Step 2: press F3,【delta z set】

-67-

Page 74

Tool calibrator action specification:

1. First move the spindle to XY-axis tool calibrator reference

point

2. Z-axis moves to start point ar 7000mm/min

3. Z-axis moves to【Z-axis min coordinate】that the operator

input at measuring speed and stops immediately while

touching tool calibrator.(if don‟t touch the tool calibrator

after arriving at the lowest coordinate, there will be an

alarm[Z min coordinate set error alarm] immediately)

4. Back Z-axis 5mm at the speed measured

5. Z-axis moves down 6mm at 50mm/min and will stop moving

and note Z-axis machine coordinate if touch the tool

calibrator in the process.( if don‟t touch the tool calibrator

after moving 6mm, there will be an alarm[Auto tool length

measurement error alarm] immediately)

6. Back Z-axis 3mm at the speed measured

7. Z-axis moves down 4mm at 50mm/min and will stop moving

and note Z-axis machine coordinate if touch the tool

calibrator in the process.( if don‟t touch the tool calibrator

after moving 4mm, there will be an alarm[Auto tool length

measurement error alarm] immediately)

8. Judge if the error noted in 0.01mm,input the min unit integer

into Z-axis coordinate that operator chooses after averaging;

if the error exceeds 0.01mm,there will be an alarm [Auto tool

length measurement error alarm] immediately

9. G90 G53 Z0. back tool to Z-axis original point of machinery.

-68-

Page 75

Param.

Controller

Meaning of parameter

3901

0

Dc protocol role, 0:CNC, 1:Device or PC

3903

1

File transfer port number(1:Com1, 2:Com2)

3921

2

Com1 baud(0:24;1:48;2:96;3:192;4:384..)

3922

8

Com1 data bit number

3923

0

Com1 exchange code type (0:ASCII;1:EIA;2:ISO)

3924

0

Com1 control code (0:No;1:DC2;2:DC4;3:DC2DC4)

3925

1

Com1 End-of-block output code(0:EOB;1:CR+EOB)

3926

0

Com1 DC3 control code parity (0:Off;1:On)

3927

2

Com1 flow control(0:No;1:CrsRts;2:XonXoff)

3928

1

Com1 parity check(0:No;1:Odd;2:Even)

3929

1

Com1 stop bit number(1:1 bit;2:2 bit)

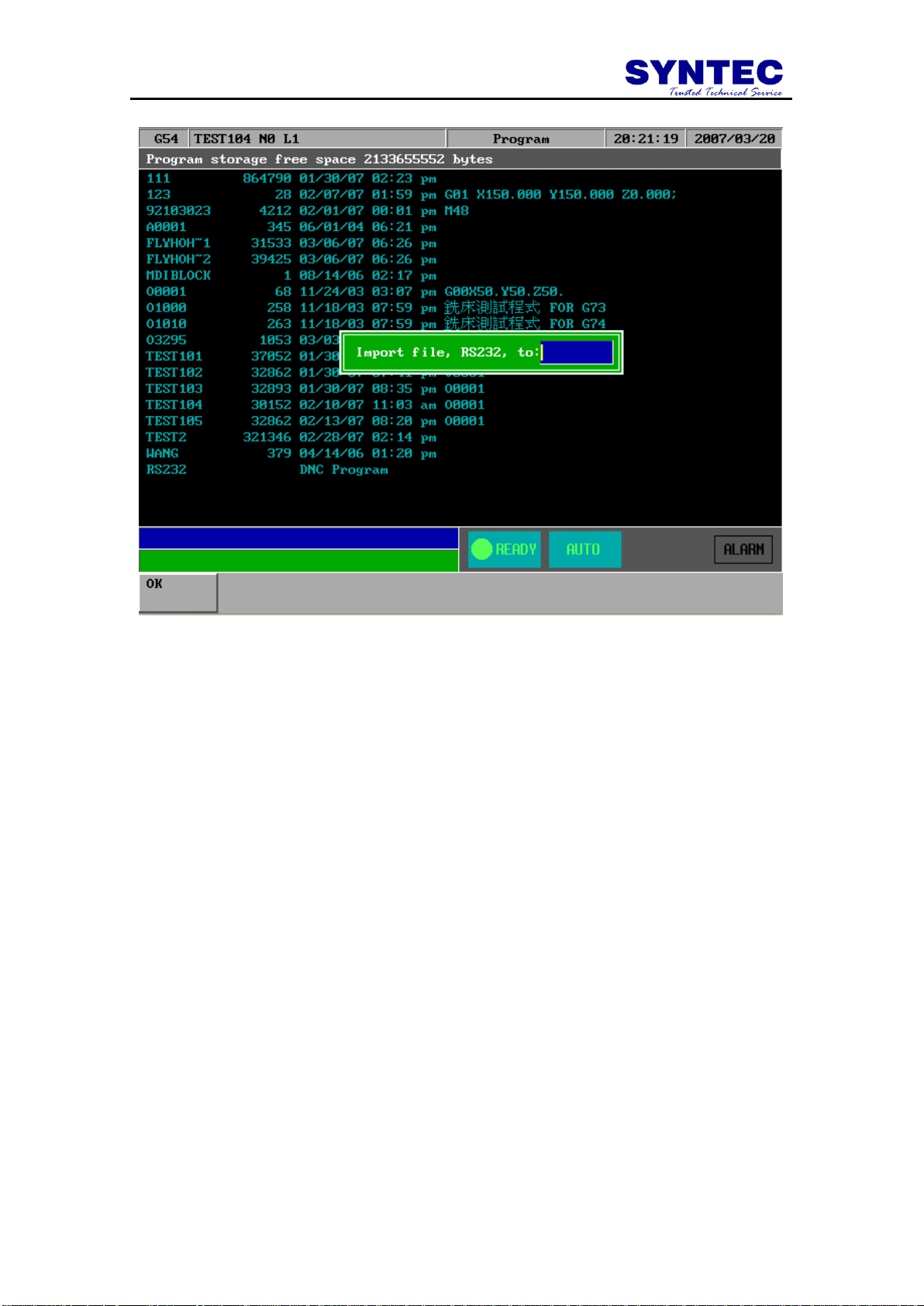

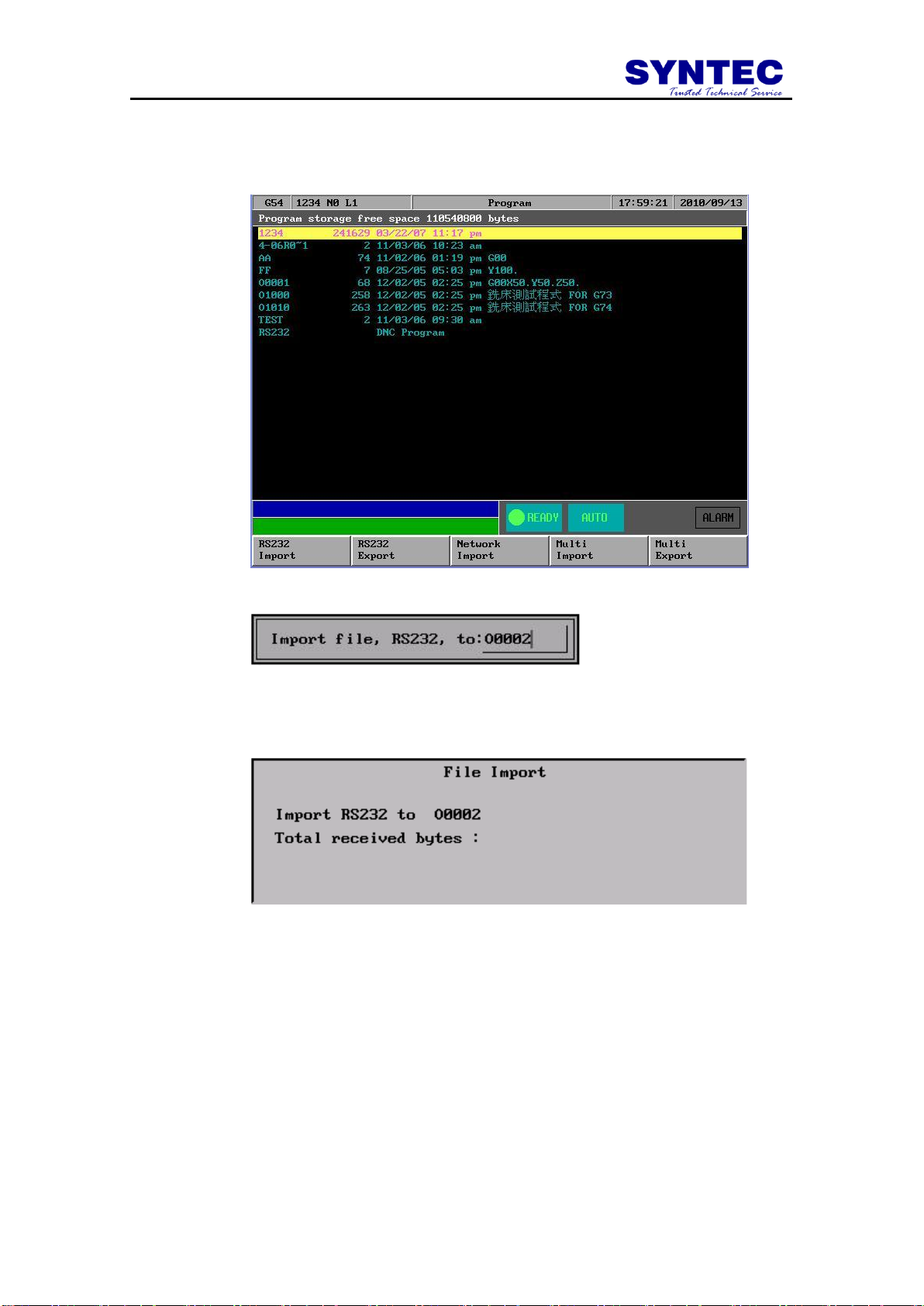

3.13 RS232 FUNCTION

DNC SOFTWARE CONTROLLER (SYNTEC NC

CONTROLLER SOFTWARE)

DESCRIPTION:

Users can uses software of CAD/CAM transfer data to controller by

RS232 cable. Let user can select be transferred NC file to working.

Operation:

1. Step I:The hardware line link to COM1

2. Step II:Parameter of SYNTEC software system setting

(Suggest value of default)

3. Step III:Turn on the controller power. The RS232 file input

is ready.

-69-

Page 76

Operation has been stated as follows.

I. Press [program] [file manage] to file manage submenu.

And than to press [=>] show up as follow:

II. press [RS232 Import].show up as follow:

III. After input the file name, Press [Ok] . Then the program

will wait for receive state. The transfer state will has

shown on transfer process.

4. Step IV:Executing DNC software. Does the RS232 transfer

setting adjust is the same controller, or controller adjust is the

same of DNC software. Executing the send function of DNC

software. It can be transferred into which the file of output.

Attention:

When operating. The file input should be doing firstly. Let controller

stay on the receive file state. And then to set up transfer file function of

DNC software. It can be sure transfer correctly.

-70-

Page 77

Param.

Controller

Meaning of parameter

3901

0

Dc protocol role, 0:CNC, 1:Device or PC

3903

1

File transfer port number(1:Com1, 2:Com2)

3921

2

Com1 baud(0:24;1:48;2:96;3:192;4:384..)

3922

8

Com1 data bit number

3923

0

Com1 exchange code type (0:ASCII;1:EIA;2:ISO)

3924

0

Com1 control code (0:No;1:DC2;2:DC4;3:DC2DC4)

3925

1

Com1 End-of-block output code(0:EOB;1:CR+EOB)

3926

0

Com1 DC3 control code parity (0:Off;1:On)

3927

2

Com1 flow control(0:No;1:CrsRts;2:XonXoff)

3928

1

Com1 parity check(0:No;1:Odd;2:Even)

3929

1

Com1 stop bit number(1:1 bit;2:2 bit)

3.14 DNC Function

DNC SOFTWARE CONTROLLER (SYNTEC NC

CONTROLER SOFTWARE)

DESCRIPTION:

When user is use the CAD/CAM software. The controller doesn‟t

capacity in saving the too large size program in working. Use this function

to execute that aside transfer and aside working.

Operation:

1. Step I:The hardware line link to COM1

2. Step II:Parameter of SYNTEC software system setting

(Suggest value of default)

3. Step III:Executing DNC software. Does the RS232 transfer

setting adjust is the same of controller, or controller adjust is

the same of the DNC software. Executing the send function

of DNC software. It can be transferred into the file of output.

4. Step IV:Turn on controller power. Into system by press

[program] [file manage] to file manage submenu. Select the

RS232 DNC Program is a working file. It is shown as

follows.

-71-

Page 78

5. Step Ⅴ:press “monitor”. Controller will read into file to

working by RS232

Attention:

software output wait controller to reading firstly. And select RS232 DNC

Program is working file on controller. Finish, Setup working. It can be sure

transfer correctly.

When operating. It should be doing that the working file from DNC

-72-

Page 79

Param.

Controller

Meaning of parameter

3901

0

Dc protocol role, 0:CNC, 1:Device or PC

3903

1

File transfer port number(1:Com1, 2:Com2)

3921

2

Com1 baud(0:24;1:48;2:96;3:192;4:384..)

3922

8

Com1 data bit number

3923

0

Com1 exchange code type (0:ASCII;1:EIA;2:ISO)

3924

0

Com1 control code (0:No;1:DC2;2:DC4;3:DC2DC4)

3925

1

Com1 End-of-block output code(0:EOB;1:CR+EOB)

3926

0

Com1 DC3 control code parity (0:Off;1:On)

3927

2

Com1 flow control(0:No;1:CrsRts;2:XonXoff)

3928

1

Com1 parity check(0:No;1:Odd;2:Even)

3929

1

Com1 stop bit number(1:1 bit;2:2 bit)

3.15 The software of SYNTEC controller replace

the software of DNC to execute RS232

function

PC(SYNTEC software end of PC) controller

DESCRIPTION:

The SYNTEC controller software made user transfer into controller

working by RS232 that CAD/CAM generate or writing file. But the

SYNTEC controller software can‟t offer the DNC software that aside

transfer and aside working function.

Operation:

1. Step I:The hardware line link to COM1

2. Step II: Parameter of SYNTEC software system setting

(suggest setting value. Exception of 3910 other all the same)

3. Step III:Turn on the controller power. The RS232 file input

is ready. Operation has been stated as follows.

-73-

Page 80

Operation has been stated as follows.

I. Press [program] [file manage] to file manage submenu,

And than to press [=>]show up as follow:

II. press [RS232 Import].Show up as follow:

III. After input the file name. Press [Ok].Then the program

will enter into waiting for receive state. The transfer

state will be shown on transfer process.

-74-

Page 81

4. Step IV:Upper End of PC. Executing c:\cnc\cnc into the

controller simulation software. Does RS232 file output.

Operation has been stated as follows.

I. Press [program] [file manage] to file manage submenu.

Than to press [=>] key to appearing. And press up/down

key select that want output of file. Such as O1000.

II. press[RS232 Import].show up as follow:

III. After press [Ok] .Start transfer program. And appearing

state of transfer.

-75-

Page 82

Attention:

1. When operating. The file input should be doing firstly. Let

controller stay on the receive file state ,and to setup transfer

file function of DNC software. It can be sure transfer

correctly.

2. 2、Be careful. SYNTEC controller software can offer RS232

file transfer function. But can‟t offer DNC software that

aside transfer and aside working function.

3. 3、The most our must be careful. When PC executing. We

suggest that add up /M /P parameter behind batch of cnc. Let

controller software can execute simulation controller of

function on PC. The /M is operate plate of simulation. User

can setup working from keyboard. The /P will simulate ISR

and cover off Interrupt. Convenient software can execute

upper the Windows. But will be invalid of transfer

function if behind batch of cnc add up /P parameter.

-76-

Loading...

Loading...