Page 1

SYNTE

Date:2014/06/19

6A SERIES

Page 2

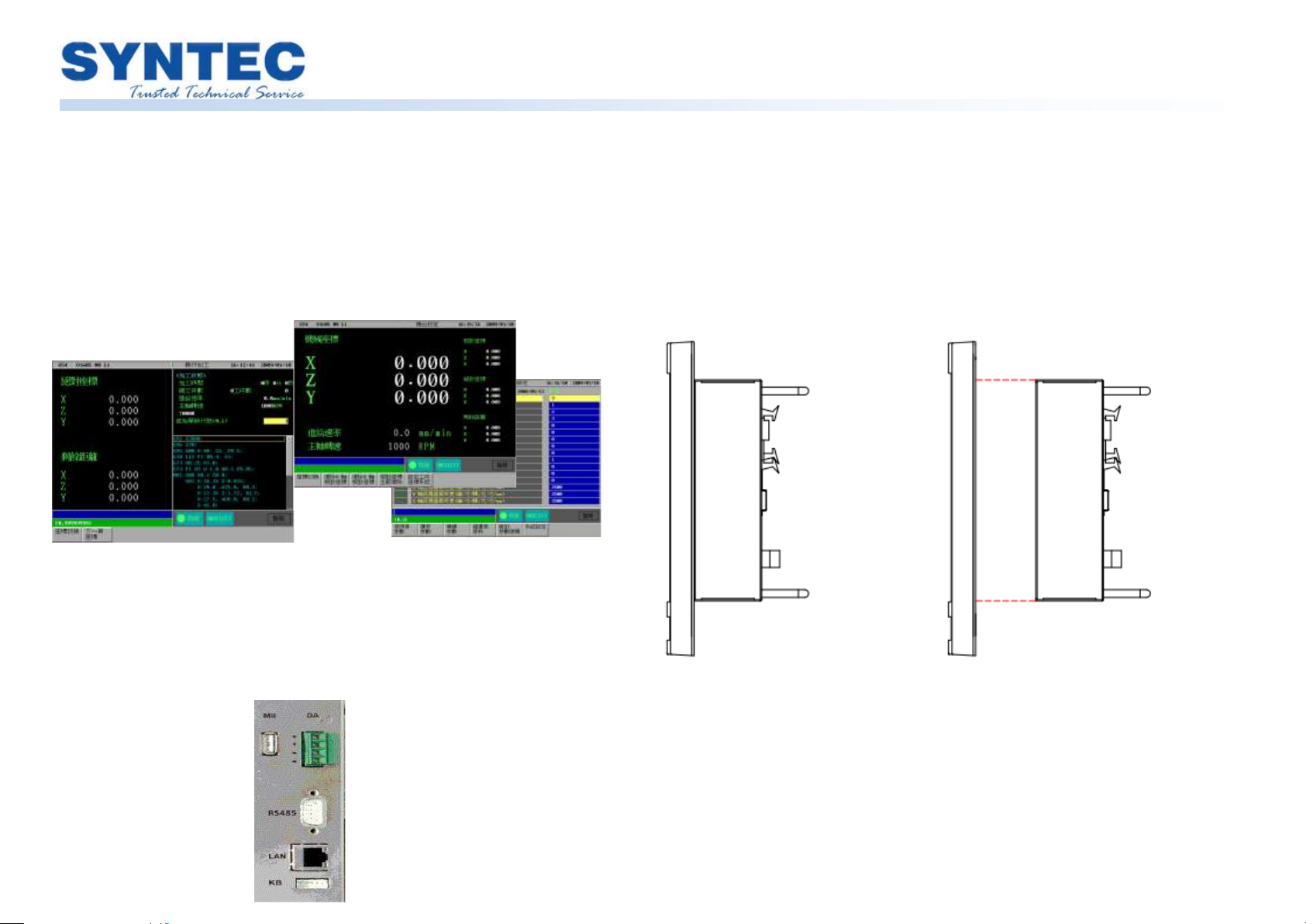

6A Controller

The 6A Architecture

6A Controller Description

The Syntec 6A Series controllers incorporate embedded

system architectures with 8-inch LCD displays and standard

keyboard panels. They include integrated servo axes, spindle

axes, MPG (manual pulse generator) axes, as well as USB ports

on the front panel. This series provides low prices, high

stability, easy operation, and high reliability.

3-axis servo positioning control

2 spindle DA (+/-10V) sets, including 1 encoder set

1 set of dedicated MPG (manual pulse generator) axes,

including 7 IN points

The 6TA and 6MA come standard with 32I/32O, while the 6CA

comes standard with 16I/16O

Standard keyboard panel

Dedicated port on the operation panel for matrix scanning

2 sets of USB ports on the front panel, supporting hot

plug-and-play

Adapter ( 100~240V AC 50/60Hz ) included

Operating environment temperature: 55°C

Page 3

6A Controller

Product Features

Easily Maintainable System Architecture

Complete System Functionality

The system provides complete lathing and milling

functionalities, a simple windows-based operating interface

that is easy to learn to use, and precise synchronous

movement interpolation, allowing users to easily produce

perfected work pieces.

Advanced Transmission Mechanism

In addition to the traditional RS-485 interface, the system also

has an advanced 10/100 MHz Ethernet port as well as

hot-swappable USB ports, which boost software transmission

speeds as well as enhance convenience and stability.

This next-generation controller is built using high-density

integration technologies and incorporates an extremely

well-thought-out design. Its compact and modular design

allows on-site personnel to easily perform maintenance with

just a single screwdriver.

Page 4

6A Controller

Multi-pocketed Complex Cutting cycle

-The user only needs to enter the external appearance

of the work piece, and the CNC will automatically

figure out the cutting path and cycle

-Can be used with A, R, and C

-Can perform multi-pocketed processing with one run

of the program

Graphical Dialogue

-X/Y axis single/dual-direction surface milling

cycles

-Track-type/square-type/round-type trench

rocessing cycles

-Round-hole/angled-line hole/curved-hole

checkerboard hole drilling cycles

Processing execution

-Integrated operation environment

-Processing parameter configuration

-Program coordinate and cutting tool

configurations are made on the same page

Hand Wheel Processing Simulation

The MPG can be used to control software processing speeds

Rotate the MPG forwards/backward to move the cutting tool

forwards/backwards along its path

Turn the MPG to fast and the cutting tool will move faster along its path

Turn the MPG to slow and the cutting tool will move slower along its path

Turn the MPG to stop and the machine will stop

On line ladder

-I, O, C, S inspection page

-Real-time Ladder display

-Search for components

-The PLC can issue alert messages in

Chinese and English

Alert records

-Records 200 alert messages in the alert history, with

dates, hours, minutes, seconds, and alert content

-Capable of further displaying reason for malfunction and

methods used for troubleshooting

Parameter Settings

-Parameter group configuration

-Comprehensive descriptions of the

meaning of parameters

-Password protection

-Supports user-defined parameters

Production Records

-Provides complete records for 100 completed processing

programs, including the program name, start time, total

processing time, as well as number of work pieces

-Monitors the production rate of programs in execution

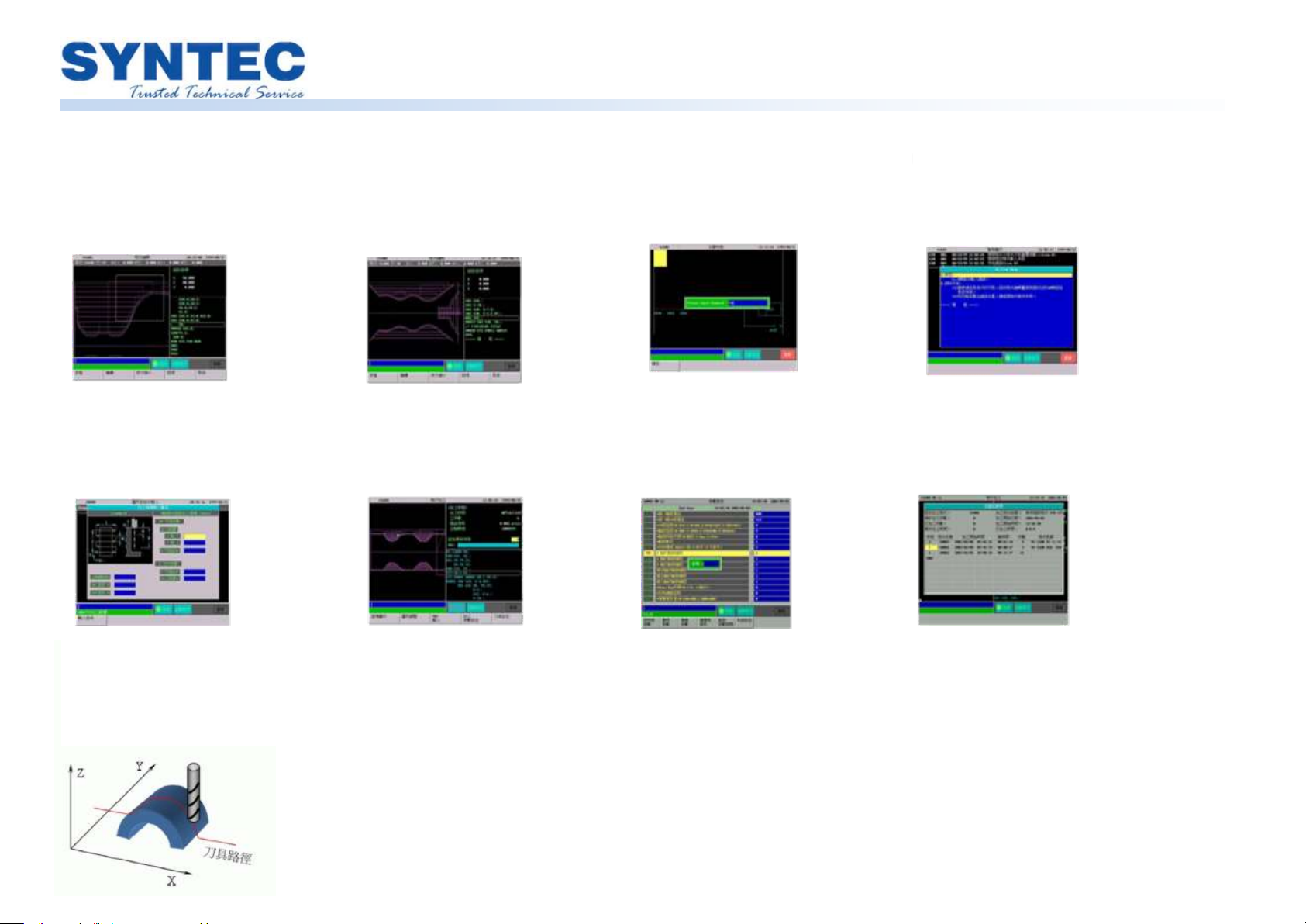

Simulation

– Syntax check

– 3D simulation and step simulation

– Magnify at any ratio

– Integrated environment that can also check

trajectory coordinates and program contects

User-Friendly Operation Interface

Thoughtful Diagnostic and Development Tools

Page 5

6A Controller

Logic Computation Command

Digit Function Command

Structural Process Control Command

MACRO Support

-Windows based Macro development environment

-Can communicate with the PLC via register bits

-Completely compatible with CNC operating

environments

-Open and store files

-Step simulation and three-view diagram

simulation

-System parameter and variable configuration

Ladder Support

-Windows based PLC software development

-Online Ladder display, making troubleshooting

easier

-PLC executes servo movement commands

-Editing Function Table

Open file, save file

Add Ladder footnote (Chinese and English)

Cut, copy, paste

Search,…

Syntax check

Contact point: normally open,

normally closed

Coil: normally open, normally

closed, positive edge, negative

edge, always return

Arithmetic commands:

Timer, counter

Data movement: MOV

Cutting tool commands: ROT

Software control commands:

JMP, JSR

Call subroutine

Directly execute PLC shaft

movement commandSpecify

PLC shaft for executing

movement program

instruction…………………..

Macro Syntax

Ladder Syntax

Complete Software Application Support

Page 6

6A Controller

External Appearance of the Product (6A-4012-M)

External Appearance of the Product (6A-4012-T2)

External Appearance of the Product (6A-4018-M2)

External Appearance of the Product (6A-4018-T3)

Page 7

6A Controller

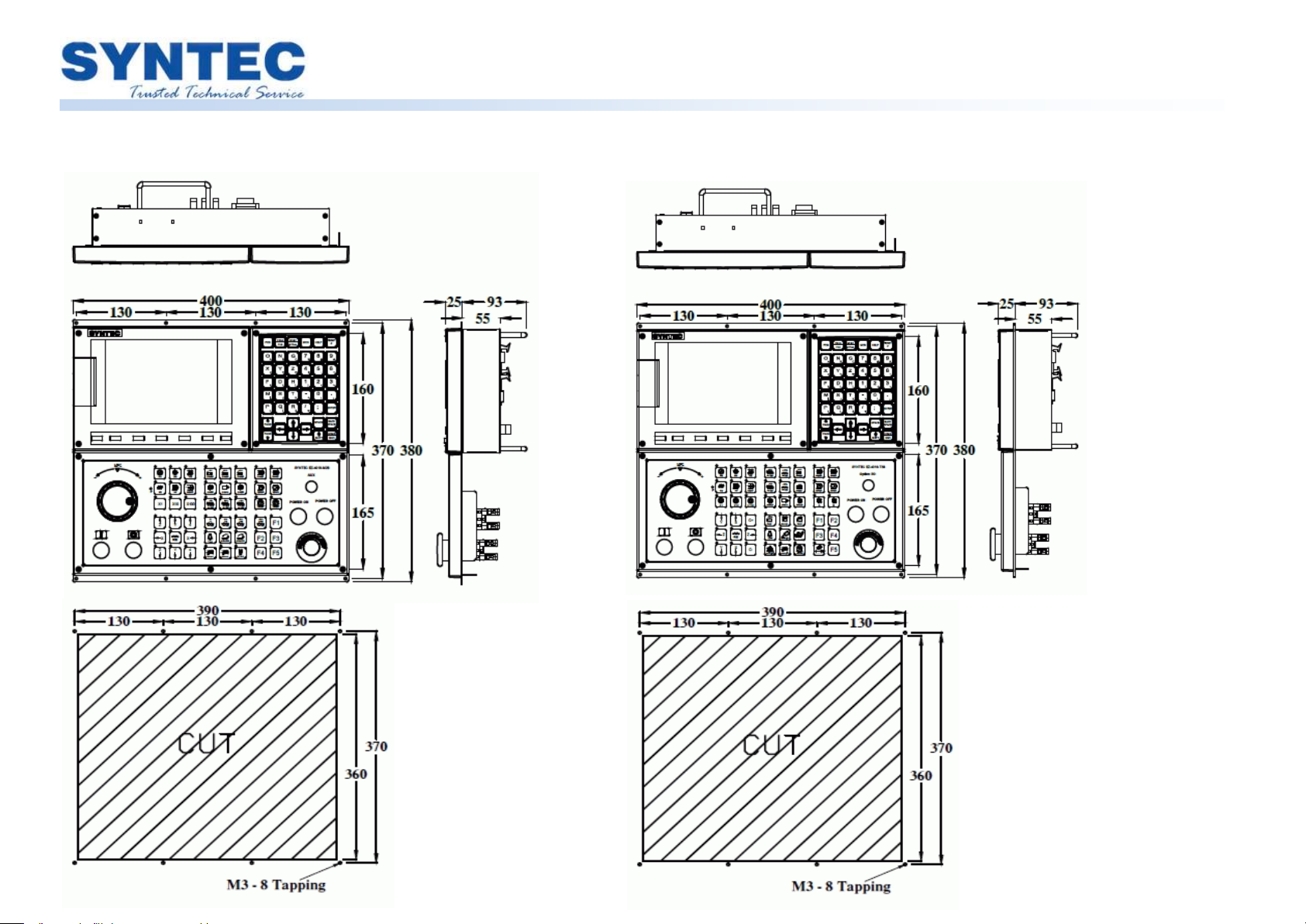

Structural Dimensions (6A-4012-M)

Structural Dimensions (6A-4012-T2)

Page 8

6A Controller

Structural Dimensions (6A-4018-M2)

Structural Dimensions (6A-4018-T3)

Page 9

6A Controller

WWiirriinngg--SSiiddee RRSS448855 FFrroonntt

SScchheemmaattiicc DDiiaaggrraam

m

Connector Interface Definitions

Please mind the voltage values as well as positive and negative

polarities

X1 Connector Definitions Y1 Connector Definitions

HK Connector Definitions Spindle Connector Definitions

P1~P3 Connector Definitions

SP Connector Definitions

RS485 Connector Definitions

MPG Connector Definitions

Page 10

6A Controller

Product Specifications

Model

6TA

6CA

6MA

Control command format

Generic

6CA

6MA

Largest main system axis group

2 1 2

Largest PLC axis group number

1 ─ 1

Standard control axis number

3

Maximum control axis number (optional)

3

Maximum spindle number

2 1 1

Maximum synchronous control axis number

(single axis group)

3 2 3

Smallest unit of control - mm

0.0001

Maximum number of work piece coordinate sets

32

Maximum number of tool compensation sets

96

Number of pre-read single-sections

64

100

100

Single-section processing time – number of single

sections / seconds

300

350

350

Hardware Specifications

I/O (standard)

32/32

16/16

32/32

I/O (optional)

─

DA

2

Display

8

RJ-45

1

VGA output

─

PS/2

─

RS232/RS422/RS485

─/─/1

CF card

─

USB

2

Compensation

Model

6TA

6CA

6MA

Backlash compensation

O

Pitch error compensation

O

Angle compensation

O

Temperature-rise compensation

O

Two-dimensional compensation

─

Operation

MPG simulation

O

Program idle

O

Selective stop

O

Single-section execution

O

Virtual MPG

O

Pause point activation

O

Break point activation

O

External offset settings

O

MPG offset function

─ O O

Program Input

Selective jump

O

B-stop / end of program

O

Interrupt-type MACRO (M96/M97)

─

M198 subroutine call

─

G code expansion

O

6A Series Product Specifications

O Standard

-

Not supported

△

Optional

Page 11

6A Controller

High-Speed, High-Precision

Model

6TA

6CA

6MA

Constant Jerk control

O

Cross-section S-curve acceleration and deceleration

─

Automatic corner deceleration

O

Circular radius speed limit

O

Multiple sets of high-speed high-precision

parameters

─

Fast user parameters

─

SPA function

─

Virtual circular radius function

─

High-speed high-precision control mode I (G05.1Q1)

─

High-speed high-precision control mode II

(G05P10000)

─

NURBS interpolation

─

Tool and Blade Management

Automatic blade calibration

─ O O

Tool and blade usage life management

O

Supportive Functions

Mechanical lock (R-bit)

O

Software cycle limit

O

Spindle rotation speed detection

O

Axial coupling function

─ O O

Dynamic axial coupling function

─

Feedback coupling function

─

Fast tapping retraction

O

Virtual axis function

─

Axis swapping function

─

Serial machine swapping function

─

Fast controller-based spindle positioning (C61)

─ O O

Frond and back Dipole architecture

─

Data backup and restoration (MB)

O

Boot screen customization

O

Favorites

─

Project protection function

─

Access privilege management

─

RemoteAP monitoring

O

Programming

Background editing

O

Editing protection

O

Data Transfer Function

NETWORK/FTP

O/O

DNC(Network)

O

DNC(USB)

─

Information Display

Graphical simulation

O

Optical scale missing pulse self-diagnostics

─

Five-Axis Function

Five-axis blade tip control (RTCP)

─

Smooth blade tip function (Smooth TCP)

─

Tilted-Surface

Characteristic coordinate system (tilted-surface

processing) (G68.2)

─

Characteristic coordinate system training

─

Page 12

6A Controller

G Code Commands

Model

6TA

Elliptical cutting (clockwise) (G02.1)

O

Parabolic cutting (clockwise) (G02.2)

O

Cylindrical interpolation (G07.1)

O

Activate polar coordinate interpolation (G12.1)

O

External radius / internal radius lathing and cutting cycle (G20)

O

Threaded lathing and cutting cycle (G21)

O

Threaded lathing and cutting mid-phase blade entry cycle (G21.2)

O

Edge and surface lathing and cutting cycle (G24)

O

Jumping function (G31)

O

Thread cutting (G33)

O

Variable-pitch thread cutting (G34)

O

Blade tip control (G43.4)

─

Polygonal cutting (G51.2)

O

Blade calibration for tilted surface processing (G53.1)

─

Operating coordinate system configuration (G54~G59.9)

O

Mirroring function (lathe) (G68)

O

Tilted surface processing (G68.2)

─

Duplex cutting cycles (G72~G78)

O

Fixed drilling cycles (G80,G83~G89)

O

Default absolute zero coordinated system (G92.1)

O

Inversed time feed (G93)

O

Equal surface cutting speeds (G96)

O

Spindle synchronization function (G114.1)

O

Spindle bearing function (G114.3)

O

Model

6CA

6MA

High-speed high-precision mode (G05)

─

Path smoothing mode (G05.1)

O

NURBS curve interpolation (G06.2)

─

Thread cutting (G33)

O

Automatic blade measurement command (G37)

─

Blade offset (G45~G48)

─

Tilted surface processing (G68.2)

─

High-speed pecking-type drilling cycle (G73)

O

Left-handed tapping cycle (G74)

O

Fine boring cycle (G76)

O

Drilling cycle (G81)

O

Suspended hole-bottom drilling cycle (G82)

O

Pecking-type drilling cycle (G83)

O

Tapping cycle (G84)

O

Drilling cycle (G85)

O

High-speed drilling cycle (G86)

O

Backside fine boring cycle (G87)

O

Semi-automatic fine boring cycle (G88)

O

Suspended hole-bottom boring cycle (G89)

O

Page 13

6A Controller

Model

6A

Operating environment

-10 ~ 55oC

Storage environment

-40 ~ 70oC

Cooling method

Natural cooling

Safety certification

CE

Operating voltage

100V~240V, 60Hz

Power consumption

Approximately 5W

6A Series Operating Environment

Loading...

Loading...