Page 1

About This Manual

Table Of Contents

Index

Copyright

LS 400Xi

Feedback

Product Reference Guide

70-33848-01

Revision A

August 1998

Page 2

1998

by Symbol Technologies, Inc. All rights reserved.

No part of this publication may be reproduced or used in any form, or by any electrical or

mechanical means, without permission in writing from Symbol. This includes electronic or

mechanical means, such as photocopying, recording, or information storage and retrieval

systems. The material in this manual is subject to change without notice.

The software is provided strictly on an “as is” basis. All software, including firmware,

furnished to the user is on a licensed basis. Symbol grants to the user a non-transferable and

non-exclusive license to use each software or firmware program delivered hereunder (licensed

program). Except as noted below , such license may not be assigned, sublicensed, or otherwise

transferred by the user without prior written consent of Symbol. No right to copy a licensed

program in whole or in part is granted, except as permitted under copyright law. The user

shall not modify , merge, or incorporate any form or portion of a licensed program with other

program material, create a derivative work from a licensed program, or use a licensed

program in a network without written permission from Symbol. The user agrees to maintain

Symbol’s copyright notice on the licensed programs delivered hereunder, and to include the

same on any authorized copies it makes, in whole or in part. The user agrees not to

decompile, disassemble, decode, or reverse engineer any licensed program delivered to the

user or any portion thereof.

Symbol reserves the right to make changes to any software or product to improve reliability ,

function, or design.

Symbol does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any

Symbol Technologies, Inc., intellectual property rights. An implied license only exists for

equipment, circuits, and subsystems contained in Symbol products.

Symbol, Spectrum One, and Spectrum24 are registered trademarks of Symbol T echnologies,

Inc. Other product names mentioned in this manual may be trademarks or registered

trademarks of their respective companies and are hereby acknowledged.

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, New York 11742-1300

http://www.symbol.com

i

Page 3

Contents

About This Manual

Notational Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Related Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Symbol Support Center. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Chapter 1. The LS 400Xi Scanner

Scanning Made Easy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter 2. Set Up

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installing the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Switching Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Battery Box Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Changing the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Recharging a Nickel-Cadmium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Connecting to a Host - 1D Scanning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

RS-232C (LS 4004i) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Keyboard Wedge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

IBM 468X/9X (LS 4005i) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Connection to a Host - PDF Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Chapter 3. Scanning

Scanning 1-D Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Aiming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Scan the Entire Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

i

Page 4

LS 400Xi Product Reference Guide

Hold at an Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Scanning PDF417 (2-D) Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

What If.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Nothing happens when you follow the operating instructions?. . . . . . . . . . . . . . . . . . . . . . . . .3-4

Symbol is decoded, but not transmitted to the host terminal?. . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Scanned data is incorrectly displayed on the terminal? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Chapter 4. Maintenance & Specifications

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Required Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

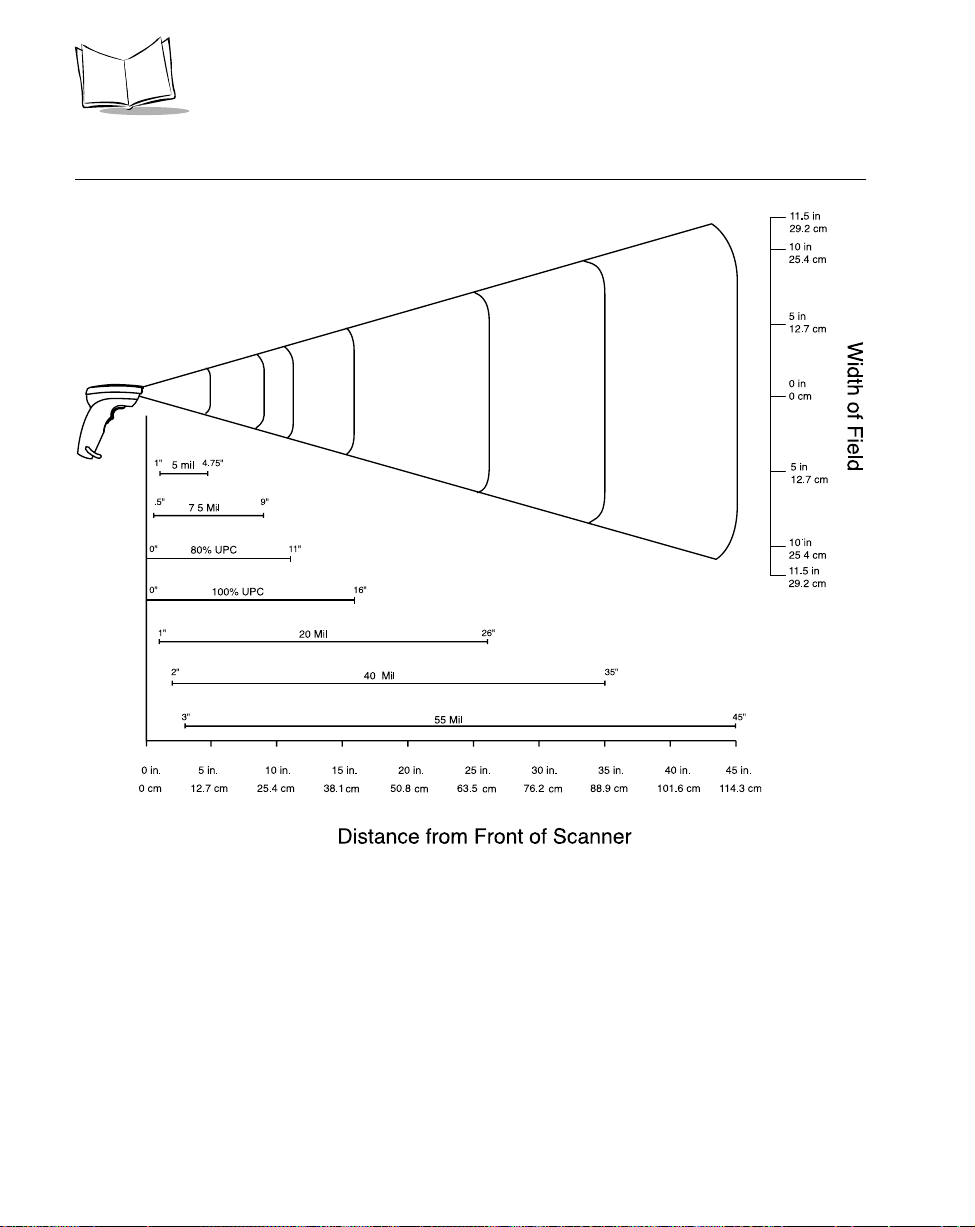

LS 400Xi 1-D Decode Zone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

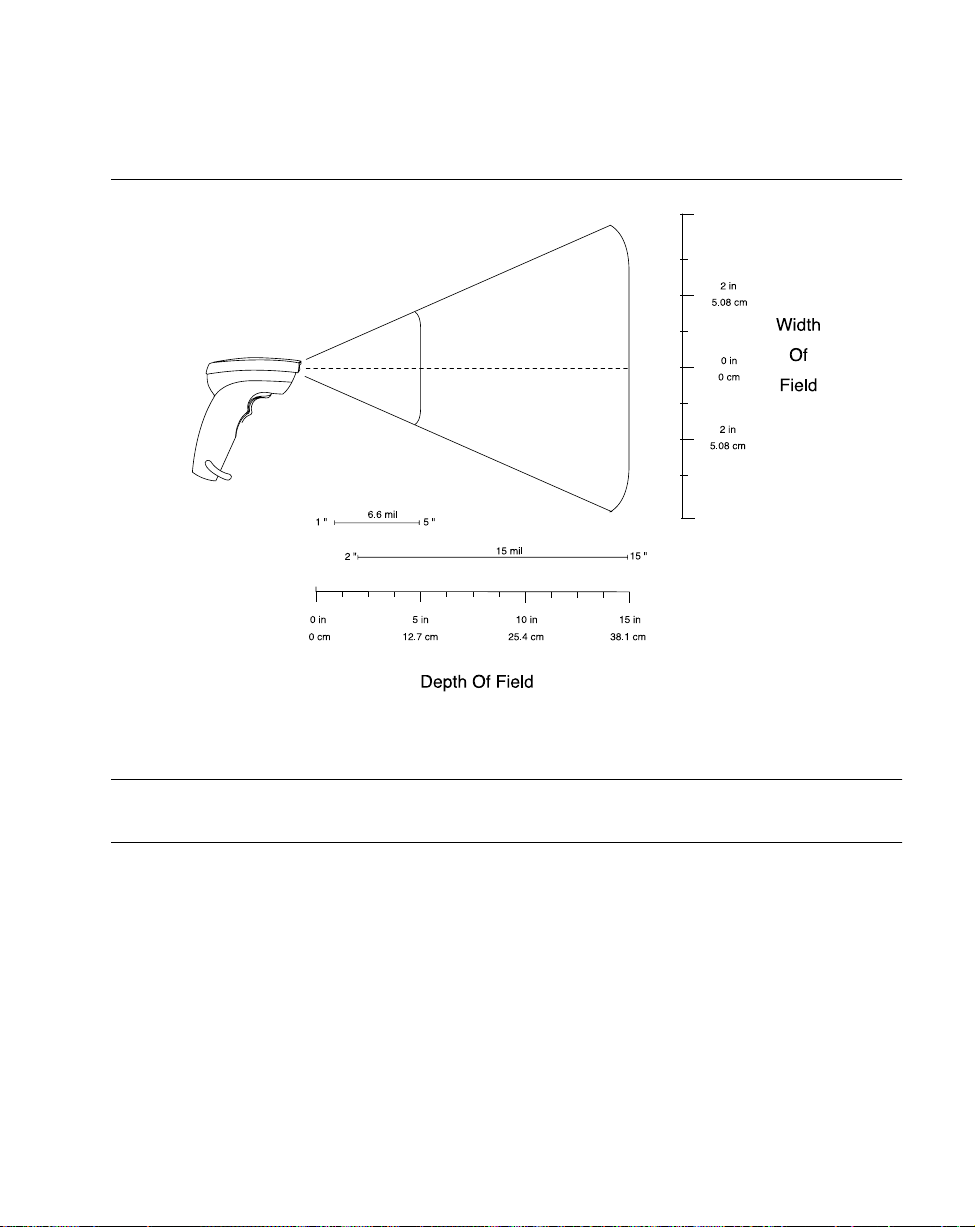

LS 400Xi 2-D Decode Zone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Beeper Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Chapter 5. Parameter Menus

Operational Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Set Default Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Host Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

IBM 46XX Host Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

RS-232C Host Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Beeper Tone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Beeper Volume. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Laser On Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Beep After Good Decode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Transmit “No Read” Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

PDF Decode Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Linear Code Type Security Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Linear Security Level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Linear Security Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Linear Security Level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Linear Security Level 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Bi-directional Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Enable/Disable UPC-E/UPC-A/UPC-E1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Enable/Disable EAN-8/EAN-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

Enable/Disable Bookland EAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

Decode UPC/EAN Supplementals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Decode UPC/EAN Supplemental Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

ii

Page 5

Contents

Transmit UPC-A/UPC-E/UPC-E1 Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

UPC-A Preamble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

UPC-E Preamble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

UPC-E1 Preamble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Convert UPC-E to UPC-A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Convert UPC-E1 to UPC-A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

EAN Zero Extend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

Convert EAN-8 to EAN-13 Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

UPC/EAN Security Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

UPC/EAN Security Level 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

UPC/EAN Security Level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

UPC/EAN Security Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

UPC/EAN Security Level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

UPC/EAN Coupon Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Enable/Disable Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Enable/Disable UCC/EAN-128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

Lengths for Code 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

Enable/Disable Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Enable/Disable Trioptic Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Convert Code 39 to Code 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Code 32 Prefix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Set Lengths for Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Code 39 Check Digit Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Transmit Code 39 Check Digit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Enable/Disable Code 39 Full ASCII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

Code 39 Buffering (Scan & Store) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

Buffer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Clear Transmission Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Transmit Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Overfilling Transmission Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Attempt to Transmit an Empty Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

Enable/Disable Code 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

Set Lengths for Code 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

Enable/Disable Interleaved 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Set Lengths for Interleaved 2 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

I 2 of 5 Check Digit Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

Transmit I 2 of 5 Check Digit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

Convert I 2 of 5 to EAN-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

Enable/Disable Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

Set Lengths for Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Enable/Disable Codabar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

Set Lengths for Codabar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65

CLSI Editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

NOTIS Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

iii

Page 6

LS 400Xi Product Reference Guide

Enable/Disable MSI Plessey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-69

Set Lengths for MSI Plessey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

MSI Plessey Check Digits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Transmit MSI Plessey Check Digit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-73

MSI Plessey Check Digit Algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-74

Enable/Disable PDF417. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-75

Transmit Code ID Character . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-76

Symbol Code ID Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-76

Pause Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-78

Prefix/Suffix Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-79

Scan Data Transmission Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-80

RS-232C Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-82

Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-82

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-84

Check Receive Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-85

Hardware Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-86

Software Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-88

Host Serial Response Time-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-90

RTS Line State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-90

Stop Bit Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

ASCII Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Beep on <BEL>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-92

Intercharacter Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-92

Numeric Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-93

Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-95

Appendix A. Programming Reference

UCC/EAN-128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

AIM Code Identifiers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Index

Feedback

iv

Page 7

About This Manual

The

LS 400Xi Product Reference Guide

troubleshooting, maintenance, and programming of the LS 400Xi scanner.

Notational Conventions

The following conventions are used in this document:

t

LS 400Xi refers to both the LS 4004i and the LS 4005i, unless specifically noted.

t

Bullets (•) indicate:

s

action items

s

lists of alternatives

s

lists of required steps that are not necessarily sequential

t

Sequential lists (e.g., those that describe step-by-step procedures) appear as

numbered lists.

t

References to other sections, chapters, or manuals appear in italics.

Related Publications

provides general instructions for setup, operation,

t

LS 400Xi Quick Reference Guide

p/n 70-33849-xx

Service Information

If you have a problem with your equipment, contact the Symbol Support Center. Before

calling, have the model number , serial number, and several of your bar code symbols at hand.

Call the Support Center from a phone near the scanning equipment so that the service person

can try to talk you through your problem. If the equipment is found to be working properly

i

Page 8

LS 400Xi Product Reference Guide

and the problem is symbol readability, the Support Center will request samples of your bar

codes for analysis at our plant.

If your problem cannot be solved over the phone, you may need to return your equipment

for servicing. If that is necessary, you will be given specific directions.

Note:

Symbol Technologies is not responsible for any damages incurred

during shipment if the approved shipping container is not used.

Shipping the units improperly can possibly void the warranty. If the

original shipping container was not kept, contact Symbol to have

another sent to you.

Symbol Support Center

For service information, warranty information or technical assistance contact or call the

Symbol Support Center in:

United States Canada

Symbol Technologies, Inc.

One Symbol Plaza

Holtsville, NY 11742-1300

1-800-653-5350

International Asia/Pacific

Symbol Technologies International

Symbol Place

Winnersh Triangle, Berkshire RG41 5TP UK

United Kingdom

0800 3282424 (Inside UK)

+44 118 945 7529 (Outside UK)

Symbol Technologies Canada, Inc.

2540 Matheson Boulevard East

Mississauga, Ontario, Canada L4W 422

(905) 629-7226

Symbol Technologies Asia, Inc.

230 Victoria Street #04-05

Bugis Junction Office Tower

Singapore 188024

337-6588 (Inside Singapore)

+65-337-6588 (Outside Singapore)

ii

Page 9

Chapter 1

The LS 400Xi Scanner

Scanning Made Easy

Symbol Technologies, the world leader in hand-held laser scanning, now offers 21st century

technology while maintaining compatibility with today’s existing systems. The LS 400Xi

hand-held laser scanner offers the best performance in retail and light industrial applications.

Advanced ergonomic design ensures comfortable use for extended periods of time.

The LS 400Xi hand-held laser scanner offers the best performance in retail and light

industrial applications. It uses a 650nm laser diode for improved scan line visibility, and has

a scan rate of approximately 100 scans/second. These factors make the LS 400Xi even more

aggressive than ever on 1-D bar codes, and also offer the added dimension of entry level PDF

scanning.

The LS 400Xi is intended for applications where 1-D scanning is a priority, with an

occasional need to scan PDF symbols. The product is ideal for applications such as point-ofsale where the majority of scanning is items with UPC or EAN/JAN bar codes, with an

occasional scan of a PDF symbol on a courtesy card, a coupon, etc.

1-1

Page 10

LS 400Xi Product Reference Guide

Here’s what the LS 400Xi offers you:

t

The LS 4004i (RS-232C)

- This scanner contains onboard discrete RS-232C

communications for connecting to RS-232C asynchronous terminals and host

systems. It also accommodates any of the Synapse™ “Smart Cables” which allows

you to connect to a wide variety of host systems.

t

The LS 4005i (IBM 468X/469X)

line of IBM 468X/469X terminals. It also accommodates the full line of Synapse

Smart Cables.

- This scanner is fully compatible with the entire

1-2

Page 11

Chapter 2

Set Up

Unpacking

Remove the scanner from its packing and inspect it for damage. If the scanner was damaged

in transit, call the

KEEP THE PACKING. It is the approved shipping container and should be used if you ever

need to return your equipment for servicing.

Cables

Installing the Cable

1.Switch off all devices connected to the LS 400Xi.

Symbol Support Center

at one of the telephone numbers listed on page ii.

2-1

Page 12

LS 400Xi Product Reference Guide

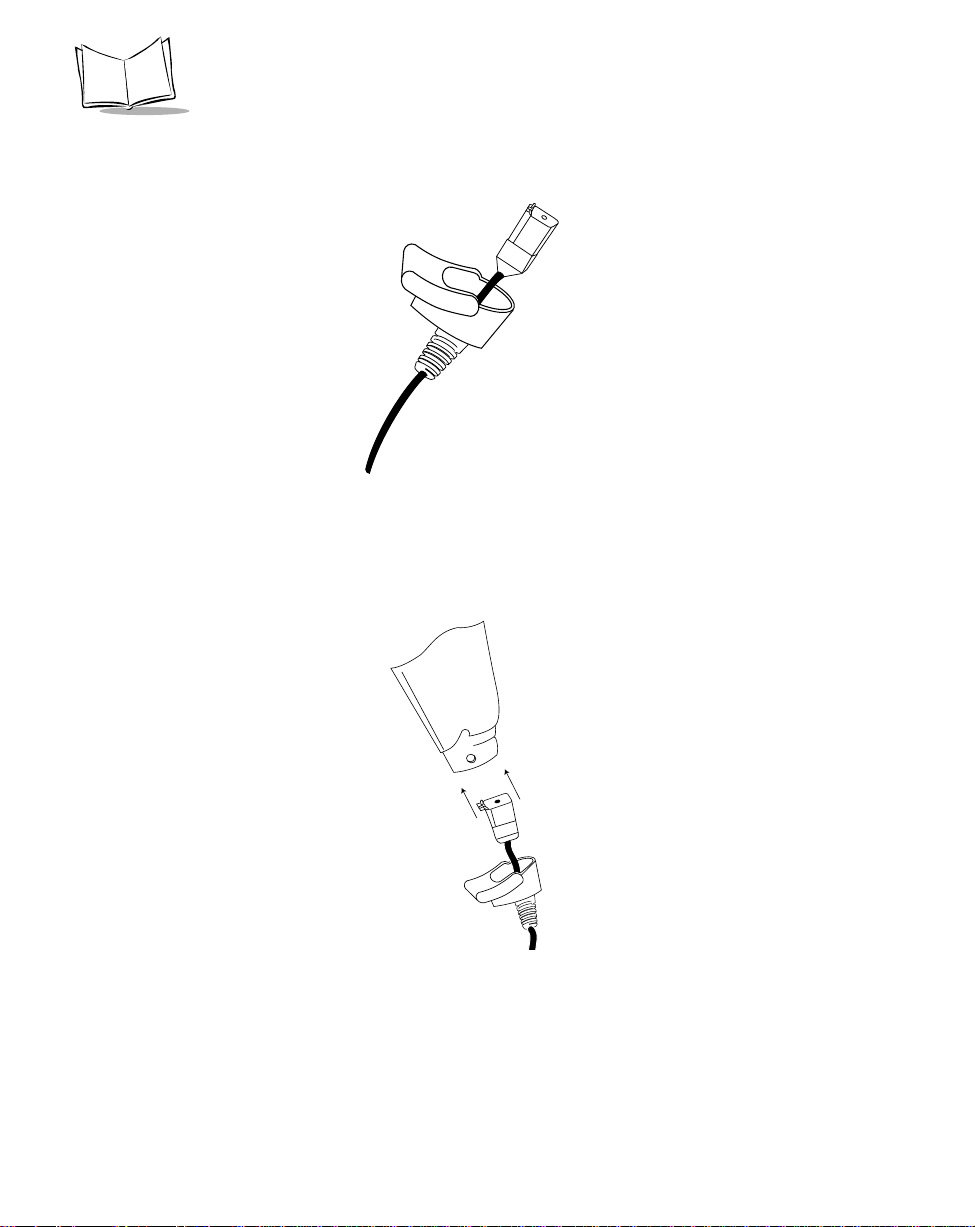

2. Pull the boot up over the cable until just the connector is protruding (Figure 2-1).

Figure 2-1. Scanner Cable

3. Plug the modular connector on the cable into the receptacle in the bottom of the LS

400Xi handle (Figure 2-2). Listen for a click.

Figure 2-2. Plugging in the Modular Connector

4. Gently tug the cable to ensure the connector is properly secured.

2-2

Page 13

5. Slide the boot up while observing its orientation until it is securely in place (Figure

2-3).

Figure 2-3. Boot Securely in Place

6. Make certain the semi-circular key on the boot slides inside the handle assembly , and

that the boot snaps into place.

7. Gently pull the boot to be sure it is properly seated.

Switching Cables

Different cables are required for different hosts. To change the scanner cable:

1. Slide the boot down over the cable.

2. Unplug the modular connector by depressing the connector clip (through the access

hole), and remove existing cable.

3. Follow steps for

Installing the Cable on page 2-1

.

Set Up

Power Options

Three power options are available:

t

External power supply

t

Battery box

t

Direct host power (IBM Series - LS 4005i only)

Available power options are host dependent.

2-3

Page 14

LS 400Xi Product Reference Guide

Battery Box Operation

When using the LS 400Xi with a battery box, you can use either an alkaline battery

(recommended), or a nickel-cadmium rechargeable battery.

Changing the Battery

1. To open the battery box, push up on the flanges at one end of the pack.

2. Remove the old battery.

3. Insert the new or recharged 9-volt battery into the battery box. Match the

positive (+) and negative (-) terminals on the battery with the corresponding

terminals in the battery box.

Recharging a Nickel-Cadmium Battery

Remove the battery from the battery box and place it in the recharging unit (not supplied by

Symbol).

To recharge the battery, follow the instructions supplied with the recharging unit.

2-4

Page 15

Set Up

Connecting to a Host - 1D Scanning

With some terminal types, the LS 400Xi is unable to answer host terminal polls until the

appropriate host type is selected. If the appropriate host type is not selected, the connected

host may generate an error message. T o correct this situation, select the proper parameter set

and initialize the host terminal. See

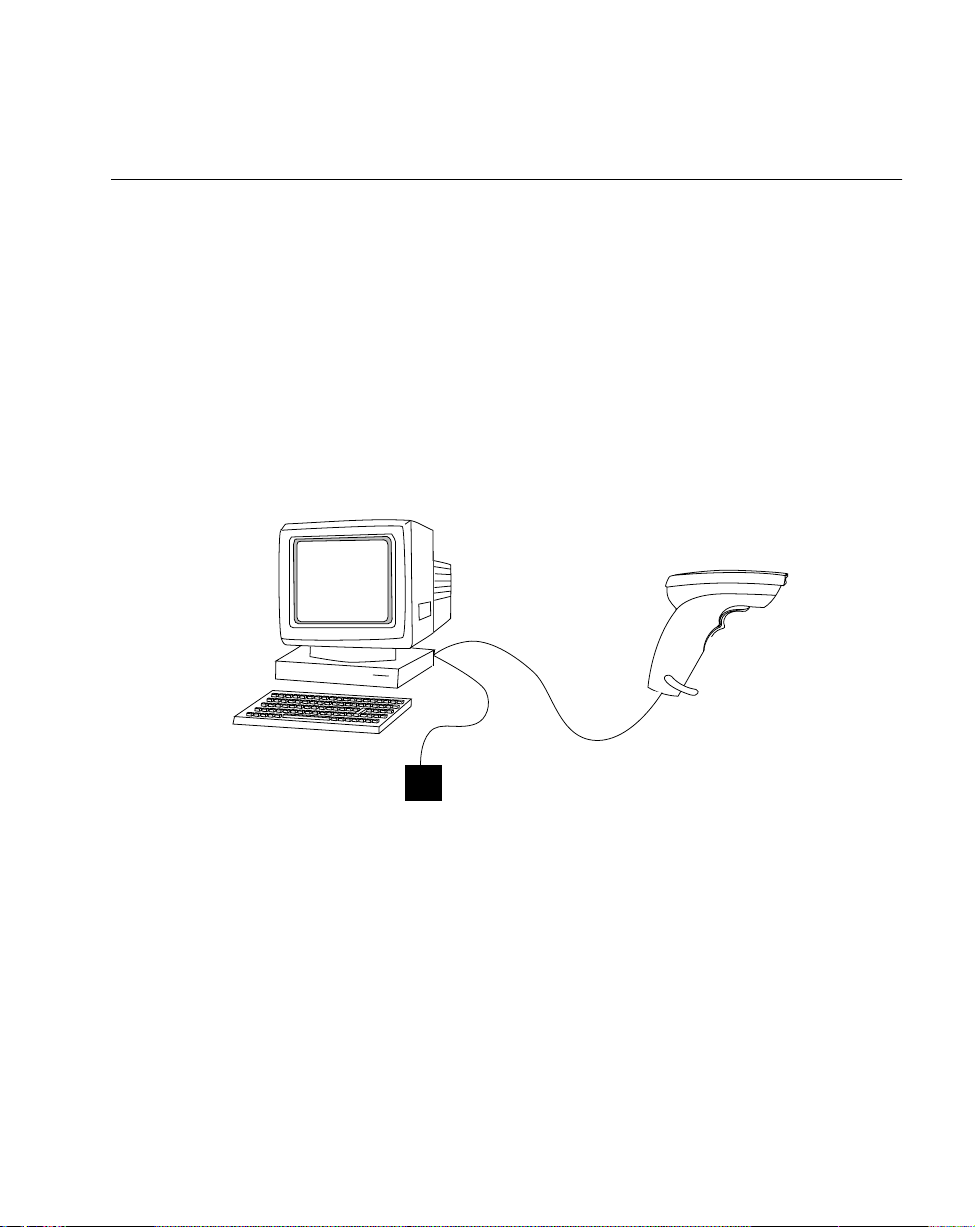

RS-232C (LS 4004i)

Direct RS-232

For direct RS-232 connection, plug the LS 4004i interface cable directly into the scanner port

on the back of the host. If necessary, connect a power supply to the host.

Chapter 5

Host

for more information.

Interface

Cable

Power Supply

(as required)

Figure 2-4. Direct RS-232 Configuration

LS 4004i

2-5

Page 16

LS 400Xi Product Reference Guide

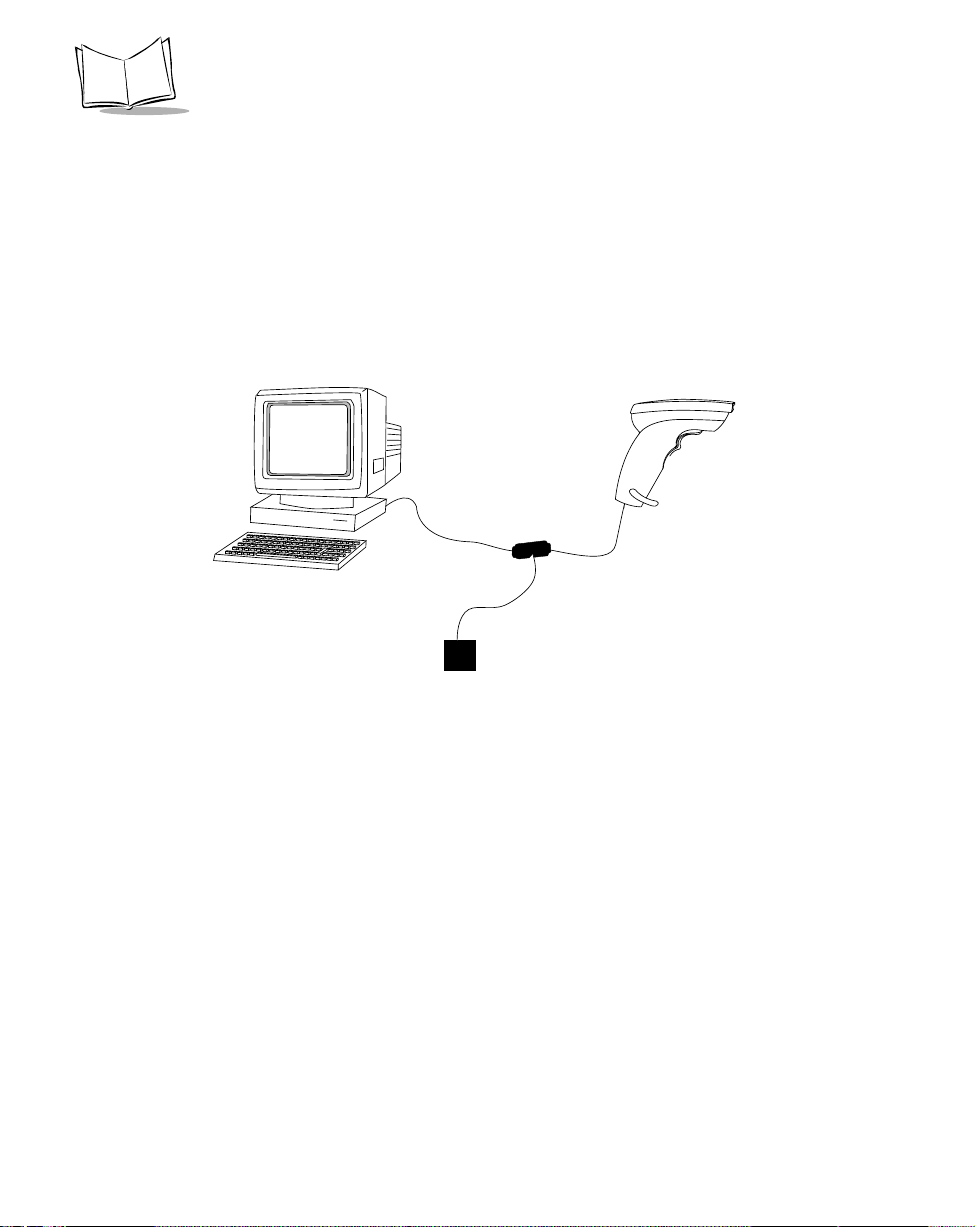

RS-232 via Synapse

To set up your RS-232 system via Synapse:

1. Connect the Synapse Smart Cable to the host.

2. Connect the Synapse Adapter cable to the Synapse cable, and the other end to the

scanner.

3. If necessary, plug a power supply into the power port on the Synapse cable.

Host

Synapse

Cable

Power Supply

(as required)

Synapse

Adapter

Cable

LS 4004i

Figure 2-5. RS-232 via Synapse Configuration

External Power Operation with Single-Piece Cable

1. Plug the scanner into the appropriate port on the host device.

2. Connect the power supply to the power port on the cable. Depending upon the cable

being used, this is located on a “lump” on the cable or the cable’s host connector.

Battery Operation

1. Insert a 9-volt battery into the battery box. Refer to

2-4

.

2. Plug the 9-pin connector at the end of the scanner’s coil cord into one end of the

battery box.

Battery Box Operation on page

2-6

Page 17

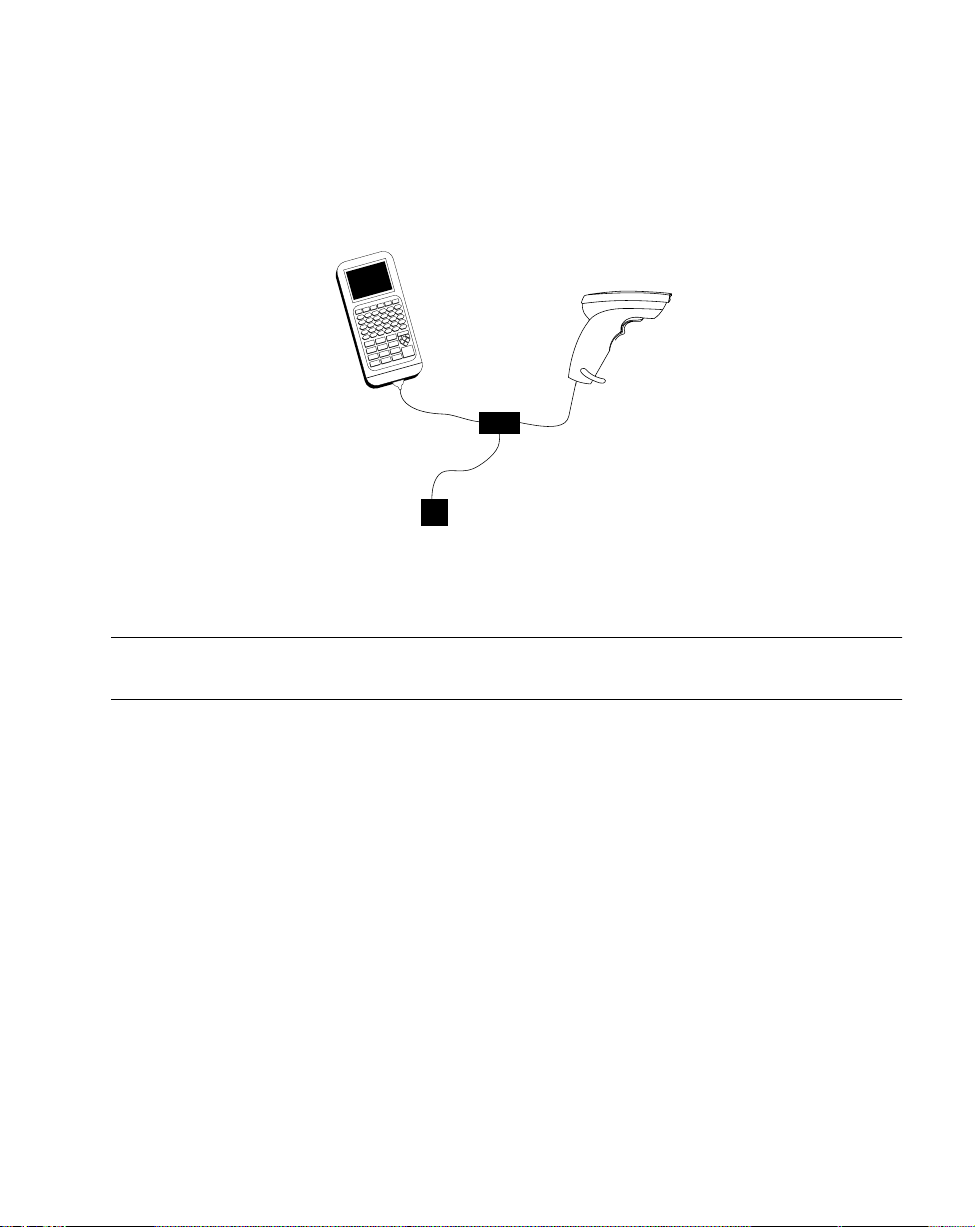

Set Up

3. An output cable from the battery box connects the LS 4004i to the RS-232C input

device. Connect one end of this cable to the battery box and the other end to the

appropriate port on the host device (Figure 2-6).

Portable

Terminal

Output Cable

Battery Box

Power

Supply

(Optional)

LS 4004i

Figure 2-6. RS-232C Batter y Operation

Note:

Coil cables that terminate in a 25-pin D-type connector have a power

receptacle on the side of the connector assembly.

Ke yboard Wedge

To setup the keyboard wedge configuration:

1. Connect the keyboard connector on the Synapse cable to the host keyboard.

2. Connect the host connector on the Synapse cable to the keyboard interface port on

the host.

3. Connect the Synapse scanner connector to the scanner.

2-7

Page 18

LS 400Xi Product Reference Guide

4. If necessary, plug a power supply into the power port on the Synapse cable.

Host

Synapse

“Smart”

Cable

Power Supply

(as required)

LS 4004i

Figure 2-7. Keyboard Wedge Configuration

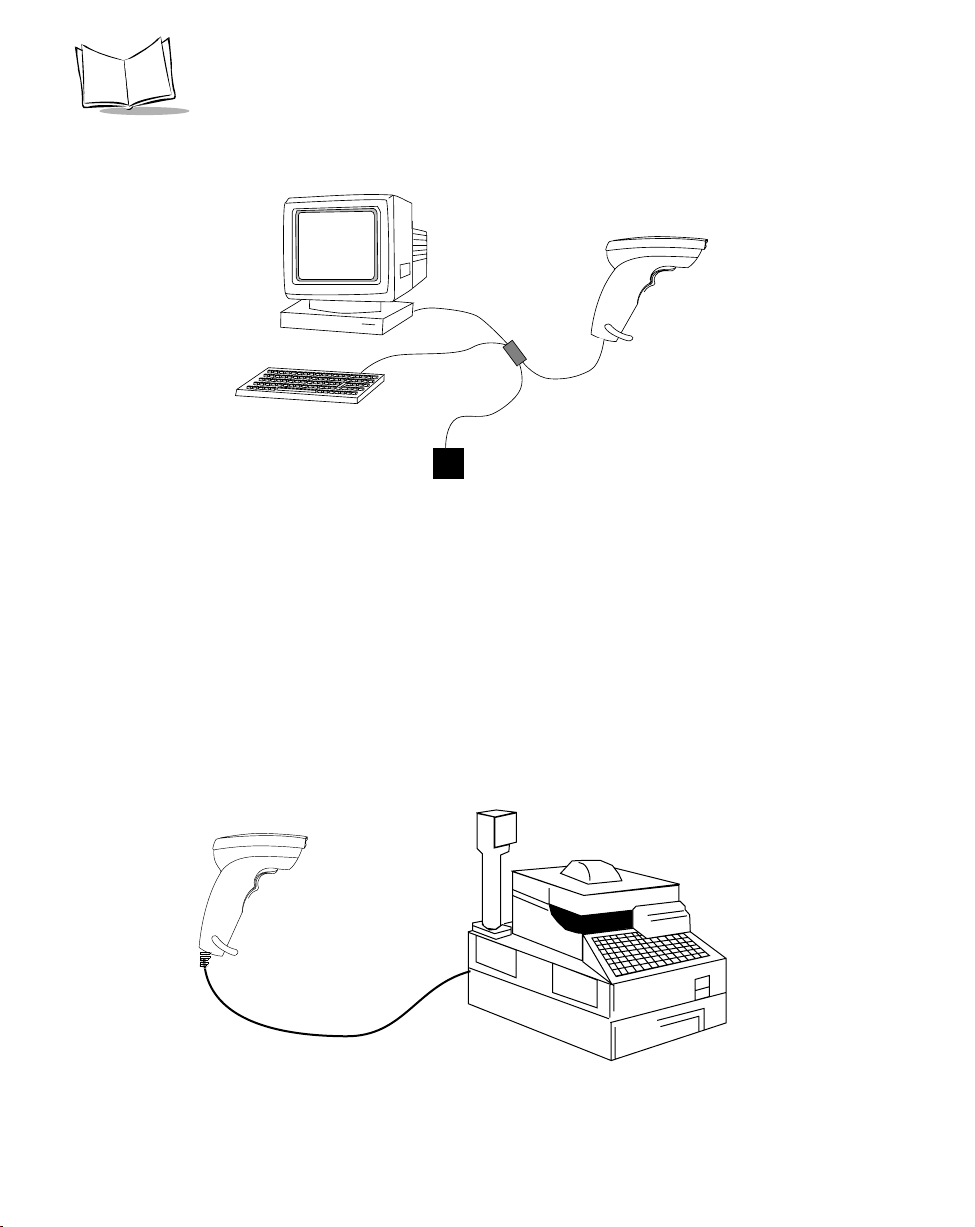

IBM 468X/9X (LS 4005i)

Plug the SDL modular connector at the end of the selected scanner cable into the appropriate

port (5, 5B, 9B, 9C, 9E, or 17). Check that the connection is secure. No additional power

connections are necessary . Figures 2-9 through 2-12 show the rear of the IBM terminals with

the covers removed. Note that the unit may be connected to one hardware port, and

configured for a different software port using the bar codes in IBM 46XX Host Types on

page 5-8. The hardware ports available determine how the unit is connected to the host,

while the software port configuration determines how it communicates.

LS 4005i

IBM 4683/84/93/94 Cash Register

2-8

Figure 2-8. Typical System Configuration

Page 19

Set Up

Port 5B

Port 9B

Port 17

Figure 2-9. IBM 4683 Rear Panel With Cover Removed

9B

5B

17

Figure 2-10. IBM 4684 Rear Panel With Cover Removed

2-9

Page 20

LS 400Xi Product Reference Guide

5

9C

9B

Figure 2-11. IBM 4693 Rear Panel With Cover Removed

Port 9E

Figure 2-12. IBM 4694 Rear Panel With Cover Removed

2-10

Page 21

Connection to a Host - PDF Scanning

Currently, PDF417 can only be interfaced with the following host types:

t Direct RS-232 (refer to page 2-5)

t RS-232 via Synapse (refer to page 2-6)

t Keyboard Wedge (refer to page 2-7).

The RS-232 Host Types that support PDF417 are:

t Standard RS-232C

t PDT 330

Refer to Host Type on page 5-8 for more information.

Note: PDF417 is not enabled by default. Scan the parameter bar code

ENABLE PDF417 on page 5-75 to enable PDF417 scanning

capabilities.

Set Up

2-11

Page 22

Chapter 3

Scanning

Scanning 1-D Bar Codes

To scan a 1-D bar code:

1. Make sure all connections are secure, and the symbol you want to scan is within the

scanning range (refer to Technical Specifications on page 4-2).

2. Aim the scanner at the symbol and press the trigger. The scanning beam remains on

for approximately 3.0 seconds (default) or until a successful decode.

The scanner has read the symbol when:

t You hear a short, high tone beep (if the beeper is enabled).

t The yellow LED on the rear of the scanner turns green.

The green LED stays lit for two seconds or until the next trigger pull.

3-1

Page 23

LS 400Xi Product Reference Guide

Aiming

Scan the Entire Symbol

t Cross every bar and space of the symbol with the scan beam.

t Hold the scanner further away for larger bar codes.

t Hold the scanner closer for symbols with bars that are close together.

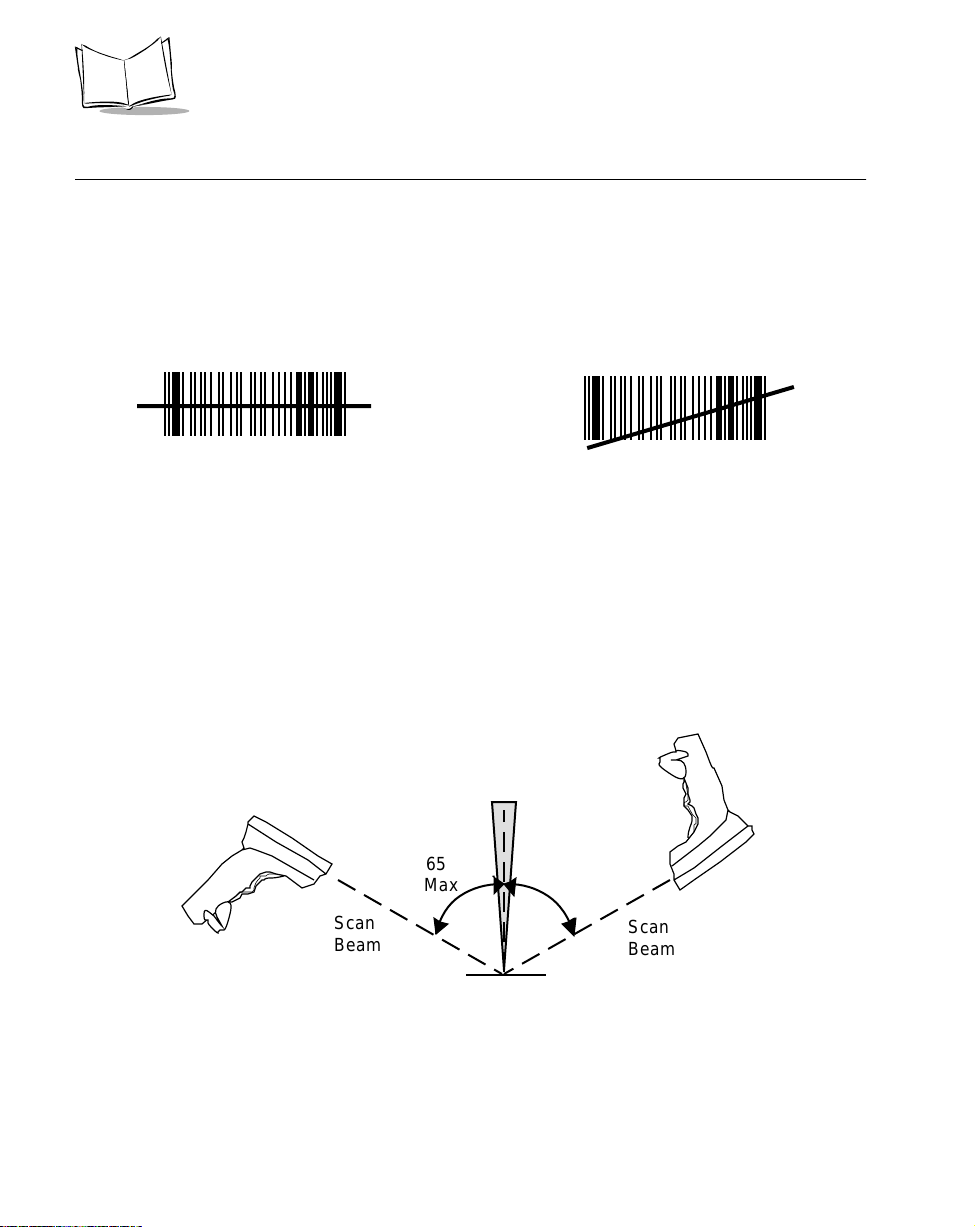

Right Wrong

012345

012345

Hold at an Angle

Do not hold the scanner directly over the bar code. Laser light reflecting directly back into

the scanner from the bar code is known as specular reflection. This strong light can “blind”

the scanner and make decoding difficult. The area where specular reflection occurs is known

as a “dead zone.”

You can tilt the scanner up to 65° forward or back and still achieve a successful decode

(Figure 3-1.) Simple practice quickly shows what tolerances to work within.

Shaded area represents

dead zone (±2°)

65°

Max

Scan

Beam

Bar Code

65°

Max

Scan

Beam

3-2

Figure 3-1. Maximum Tilt Angles and Dead Zone

Page 24

Scanning

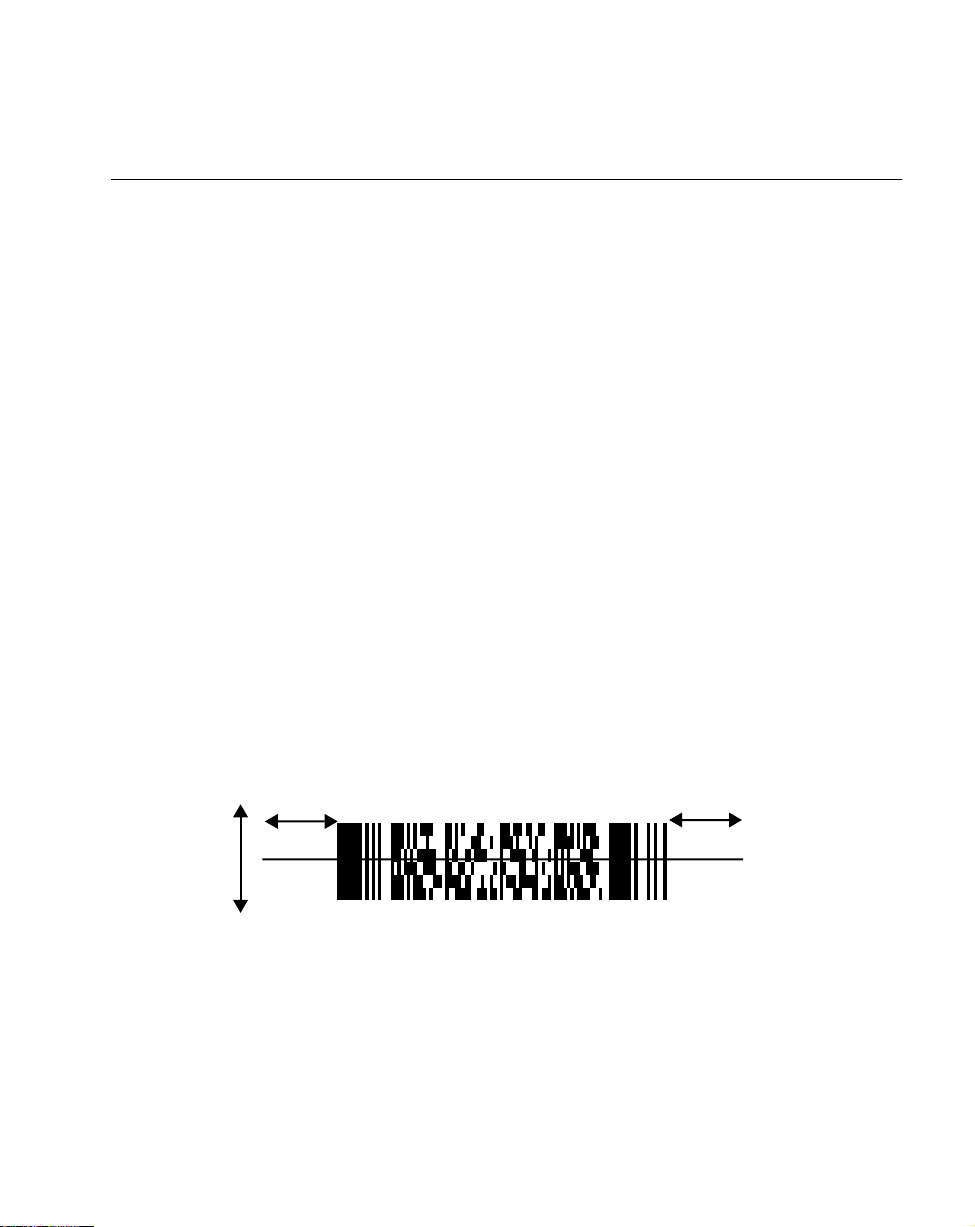

Scanning PDF417 (2-D) Bar Codes

Before scanning a PDF bar code, enable PDF417 scanning by using the parameter bar code

in ENABLE PDF417 on page 5-75.

1. Aim the scanner at the PDF bar code and press the trigger.

2. Hold the trigger down and keep the scan line parallel to the rows of the symbol.

3. Manually raster the scan line by slowly moving the scanner up and down so it scans

the entire bar code.

If PDF Decode Feedback is enabled, an audible feedback “clicking” lets you know the bar

code is being decoded. If this parameter is enabled but there’ s no clicking noise when you’re

scanning the bar code, it’s not being scanned properly.

t Check that PDF417 scanning is enabled.

t Make sure the scan line extends at least 1/2” past the left and right edges of the bar

code.

t Hold the scanner closer for denser symbols, farther away for larger symbols.

t Make sure you scan the top and bottom rows of the symbol.

t Be patient - it may take a few swipes to decode the symbol.

The bar code has been completely decoded when you hear a tone, followed by a short, high

tone beep. The yellow LED on the rear of the scanner turns green. The green LED stays lit

for two seconds or until the next trigger pull.

1/2”

1/2”

3-3

Page 25

LS 400Xi Product Reference Guide

What If...

Nothing happens when you follow the operating instructions?

You Should

t Check the system power. Is there a battery in the battery box?

t Be sure the scanner is programmed for the terminal in use.

t Make sure the scanner is programmed to read the type of bar code you are scanning.

t Check for loose cable connections.

t Check the symbol to make sure it is not defaced.

t Try scanning test symbols of the same code type.

Symbol is decoded, but not transmitted to the host terminal?

You Should

t Be sure the proper host type is selected (See Chapter 5).

Scanned data is incorrectly displayed on the terminal?

You Should

t Make sure the system is programmed for the correct keyboard type.

t Make sure the CAPS LOCK key is off.

t Be sure the proper host is selected.

t Be sure editing options (e.g., UPC-E to UPC-A Conversion) are properly

programmed.

Note:If after performing these checks the symbol still does not scan, contact

your distributor or call the Symbol Support Center. See page ii for

the telephone number.

3-4

Page 26

Chapter 4

Maintenance & Specifications

Maintenance

Cleaning the exit window is the only maintenance required.

t Do not allow any abrasive material to touch the window.

t Remove any dirt particles with a damp cloth.

t Wipe the window using a damp cloth, and if necessary, a non-ammonia based

detergent.

t Do not spray water or other cleaning liquids directly into the window.

Accessories

Required Accessories

LS 400Xi scanners are sent as a package with required accessories. Optional accessories are

available at extra cost.

Optional Accessories

Optional accessories include various stands and holders, which are supplied at extra cost.

Additional units of standard accessories may also be purchased at extra cost.

4-1

Page 27

LS 400Xi Product Reference Guide

Technical Specifications

Table 4-1. Technical Specifications

Item Description

Power Requirements*

IBM 46XX/Synapse

RS-232C/Synapse

Low Power

Decode Capability The LS 400Xi can be programmed to decode the following

Beeper Operation User-selectable: Enabled, Disabled

Scan Repetition Rate 100 scans/sec (bidirectional)

4.8 to 14 VDC (max) 200 mA @ 5V typical

4.8 to 14 VDC (max) 180 mA @ 5V typical

4.8 to 14 VDC (max) 2 mA @ 5V typical

code types: UPC/EAN, Bookland EAN, Code 39, Code

39 Full ASCII, Trioptic Code 39, Code 93, Codabar,

Interleaved 2 of 5 , Code 128, EAN 128, Discrete 2 of 5,

MSI Plessey, and PDF417. Set code length(s) for any linear

code type. The LS 400Xi can auto-discriminate between all of

the above code types except for Code 39 and Code 39 Full

ASCII. Transmission of decoded information will depend on

the capabilities of the attached terminal.

Scan Angle 30°

Roll (Skew) Tolerance ± 10˚ from normal

Pitch ± 65˚ from normal

Yaw ± 60˚ from normal

1-D Decode Depth of Field See LS 400Xi 1-D Decode Zone on page 4-4

2-D Decode Depth of Field See LS 400Xi 2-D Decode Zone on page 4-5

Print Contrast Minimum 20% absolute dark/light differential, measured at 675 nm.

*For direct host power connection, make sure the host terminal supplies sufficient power for the

specified operation. Symbol is not responsible for damage to host equipment or system misoperation due to an insufficient power condition.

4-2

Page 28

Maintenance & Specifications

Table 4-1. Technical Specifications (Cont’d)

Item Description

Ambient Light Immunity

Artificial Lighting

Sunlight

Operating Temperature 32° to 104°F 0° to 40°C

Storage Temperature -40° to 140°F -40° to 60°C

Humidity 5% to 95% (non-condensing)

Coil Cable Length 9-12 ft. 274-365 cm (depending on host)

Durability 4-ft. drop to concrete 1.2 m

Dimensions

Height

Length

Width

Laser Classifications CDRH Class II

200 ft. candles 2153 lux

8000 ft. candles 86112 lux

(@8 in. (20 cm) on low density bar

codes)

6.3 in. 16 cm

5 in. 12.7 cm

2.8 in. 7.1 cm

IEC Class 1

IEC 825 Class 2

Laser Power .92 mW ±5%

4-3

Page 29

LS 400Xi Product Reference Guide

LS 400Xi 1-D Decode Zone

4-4

Figure 4-1. LS 400Xi 1-D Decode Zone

Page 30

LS 400Xi 2-D Decode Zone

Maintenance & Specifications

4.2 in

10.67 cm

4.2 in

10.67 cm

Figure 4-2. LS 400Xi 2-D Decode Zone

Note: The measurements above are for 6.6 mil, 100 character PDF bar code

and 15 mil, 64 character PDF bar code.

4-5

Page 31

Pin-outs

LS 400Xi Product Reference Guide

Table 4-2. Pin-outs

Pin LS 4004I LS 4005I LS 4005I with EAS

1 Reserved Reserved Reserved

2 Power Power Power

3 Ground Ground Ground

4 Synapse Data Synapse Data Synapse Data

5 Synapse Clock Synapse Clock Synapse Clock

6 RxD B IBM SERIAL B IBM SERIAL

7 TxD A IBM SERIAL A IBM SERIAL

8 DTR Not used Shield

9 CTS Not used EAS 1

10 RTS Not used EAS 2

4-6

Page 32

Maintenance & Specifications

Beeper Indications

Table 4-3. Beeper Indications

Beeper Sequence Indication

Standard Use

Short high tone A bar code symbol was decoded (if decode beeper is

enabled).

Low tone, followed by short high tone A PDF417 bar code symbol was decoded (if decode

beeper is enabled).

Clicking A PDF417 bar code symbol is being decoded (if PDF

Decode Feedback is enabled).

4 Beeps - long low tone A transmission error has been detected in a scanned

symbol. The data is ignored. This occurs if a unit is not

properly configured. Check option settings.

5 Beeps - low tone Convert or format error

Lo/hi/lo tone ADF transmit error

Hi/hi/hi/lo tone RS-232 receive error

Parameter Menu Scanning

Short high tone Correct entry scanned or correct menu sequence

performed.

Lo/hi tone Input error, incorrect bar code or “Cancel” scanned,

wrong entry , incorrect bar code programming sequence;

remain in program mode.

Hi/lo tone Keyboard parameter selected. Enter value using bar code

keypad.

Hi/lo/hi/lo tone Successful program exit with change in the parameter

setting.

4-7

Page 33

LS 400Xi Product Reference Guide

Table 4-3. Beeper Indications (Cont’d)

Code 39 Buffering

Hi/lo tone New Code 39 data was entered into the buffer.

3 Beeps - long high tone Code 39 buffer is full.

Lo/hi/lo tone The buffer was erased, or there was an attempt to

transmit an empty buffer. When the Code 39 buffer was

empty, the scanner read a command to clear or to

transmit a Code 39 buffer.

4 Beeps - long low tone Error in data transmission.

Lo/hi tone A successful transmission of buffered data.

4-8

Page 34

Chapter 5

Parameter Menus

Operational Parameters

The LS 400Xi is shipped with the settings shown in the Default Table on page 5-2. These

default values are stored in non-volatile memory and are preserved even when the scanner is

powered down. You can change these default values by scanning the appropriate bar codes

included in this manual. These new values replace the standard default values in memory . The

default parameter values can be recalled by scanning the SET ALL DEFAULTS bar code on

page 5-7.

Note: The ability to scan PDF417 bar codes is not enabled by default. You

must program the scanner to read PDF417 bar codes by scanning the

ENABLE PDF417 bar code on page 5-75.

Even if the default parameters suit your needs, you must still select a terminal type. The

scanner automatically identifies the host type on power-up (provided the host is powered-up

before the scanner is attached to it). You must then select the appropriate terminal type for

that host. For example, if the scanner is connected to an IBM 4683, after you hear the powerup beeps, select the proper port from the choices on page 5-8. The same applies to all other

host types.

5-1

Page 35

LS 400Xi Product Reference Guide

The following table lists the defaults for all parameters. If you wish to change any option,

scan the appropriate bar code(s).

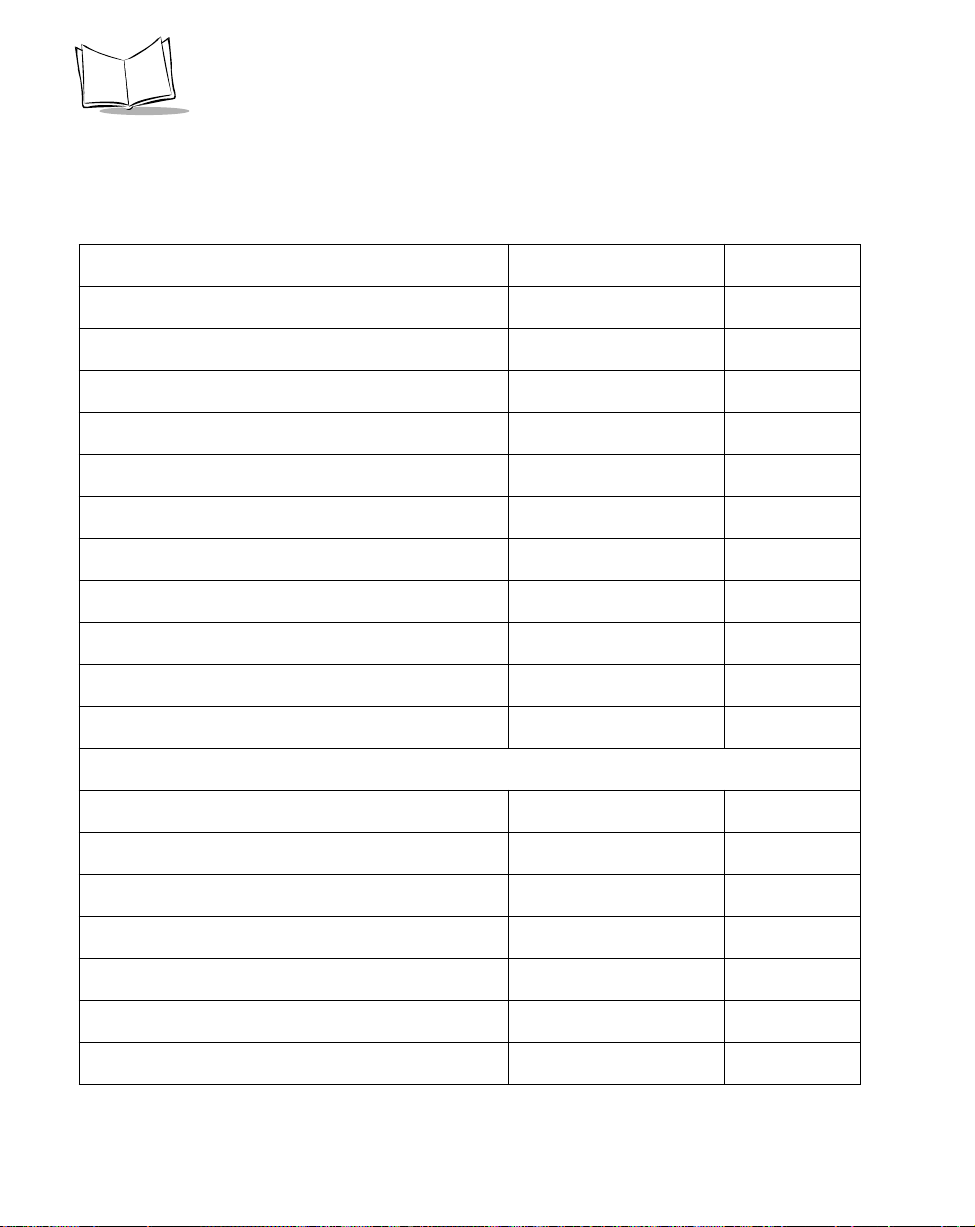

Table 5-1. Default Table

Parameter Default Page Number

Set Default Parameter All Defaults 5-7

Host Type See page 5-1 5-8

Beeper Tone High Frequency 5-12

Beeper Volume High 5-13

Laser On Time 3.0 seconds 5-14

Power Mode Low Power 5-15

Beep After Good Decode Enable 5-16

Transmit “No Read” Message Disable 5-17

PDF Decode Feedback Enable 5-18

Linear Code Type Security Levels 1 5-19

Bi-directional Redundancy Disable 5-21

UPC/EAN

UPC-A Enable 5-22

UPC-E Enable 5-22

UPC-E1 Disable 5-22

EAN-8 Enable 5-23

EAN-13 Enable 5-23

Bookland EAN Disable 5-24

Decode UPC/EAN Supplementals Ignore 5-25

5-2

Page 36

Parameter Menus

Table 5-1. Default Table (Cont’d)

Parameter Default Page Number

Decode UPC/EAN Supplemental Redundancy 7 5-26

Transmit UPC-A Check Digit Enable 5-27

Transmit UPC-E Check Digit Enable 5-27

Transmit UPC-E1 Check Digit Enable 5-27

UPC-A Preamble System Character 5-28

UPC-E Preamble System Character 5-29

UPC-E1 Preamble System Character 5-30

Convert UPC-E to A Disable 5-31

Convert UPC-E1 to A Disable 5-32

EAN-8 Zero Extend Disable 5-33

Convert EAN-8 to EAN-13 Type Type is EAN-8 5-34

UPC/EAN Security Levels 0 5-35

UPC/EAN Coupon Code Disable 5-37

Code 128

Code 128 Enable 5-38

UCC/EAN-128 Disable 5-39

Code 39

Code 39 Enable 5-40

Trioptic Code 39 Disable 5-41

Convert Code 39 to Code 32 Disable 5-42

Code 32 Prefix Disable 5-43

5-3

Page 37

LS 400Xi Product Reference Guide

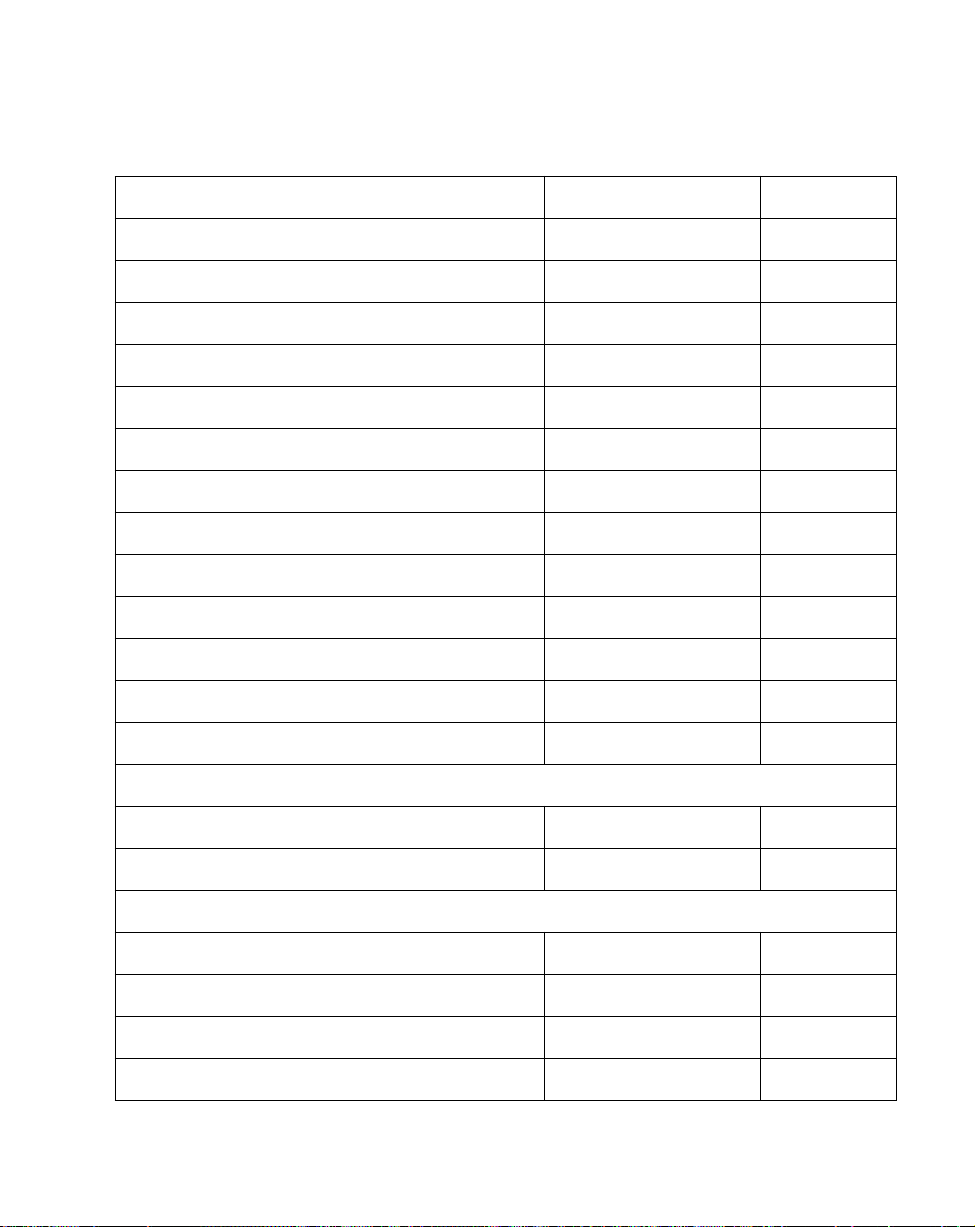

Table 5-1. Default Table (Cont’d)

Parameter Default Page Number

Set Length(s) for Code 39 2 to 55 5-44

Code 39 Check Digit Verification Disable 5-46

Transmit Code 39 Check Digit Disable 5-47

Code 39 Full ASCII Conversion Disable 5-48

Buffer Code 39 Disable 5-49

Code 93

Code 93 Disable 5-52

Set Length(s) for Code 93 4-55 5-53

Interleaved 2 of 5

Interleaved 2 of 5 Enable 5-55

Set Length(s) for I 2 of 5 14 5-56

I 2 of 5 Check Digit Verification Disable 5-58

Transmit I 2 of 5 Check Digit Disable 5-59

Convert I 2 of 5 to EAN 13 Disable 5-60

Discrete 2 of 5

Discrete 2 of 5 Disable 5-61

Set Length(s) for D 2 of 5 12 5-62

5-4

Page 38

Parameter Menus

Table 5-1. Default Table (Cont’d)

Parameter Default Page Number

Codabar

Codabar Disable 5-64

Set Lengths for Codabar 5-55 5-66

CLSI Editing Disable 5-67

NOTIS Editing Disable 5-68

MSI Plessey

MSI Plessey Disable 5-69

Set Length(s) for MSI Plessey Any Length 5-71

MSI Plessey Check Digits One 5-72

Transmit MSI Plessey Check Digit Disable 5-73

MSI Plessey Check Digit Algorithm Mod 10/Mod 10 5-74

PDF

Enable/Disable PDF Disable 5-75

Data Options

Transmit Code ID Character None 5-77

Pause Duration 0 5-78

Prefix/Suffix Values 7013

(<CR/LF> for serial)

Scan Data Transmission Format Data as is 5-80

5-79

5-5

Page 39

LS 400Xi Product Reference Guide

Table 5-1. Default Table (Cont’d)

Parameter Default Page Number

RS-232C

RS-232 Host Type Standard 5-11

Baud Rate 9600 5-83

Parity None 5-85

Check Receive Errors Do Not Check 5-85

Hardware Handshaking None 5-87

Software Handshaking None 5-88

Host Serial Response Time-out 2 Sec. 5-90

RTS Line State Low 5-90

Stop Bit Select 1 5-91

ASCII Format 8-Bit 5-91

Beep on <BEL> Disable 5-92

Intercharacter Delay 0 5-92

5-6

Page 40

Parameter Menus

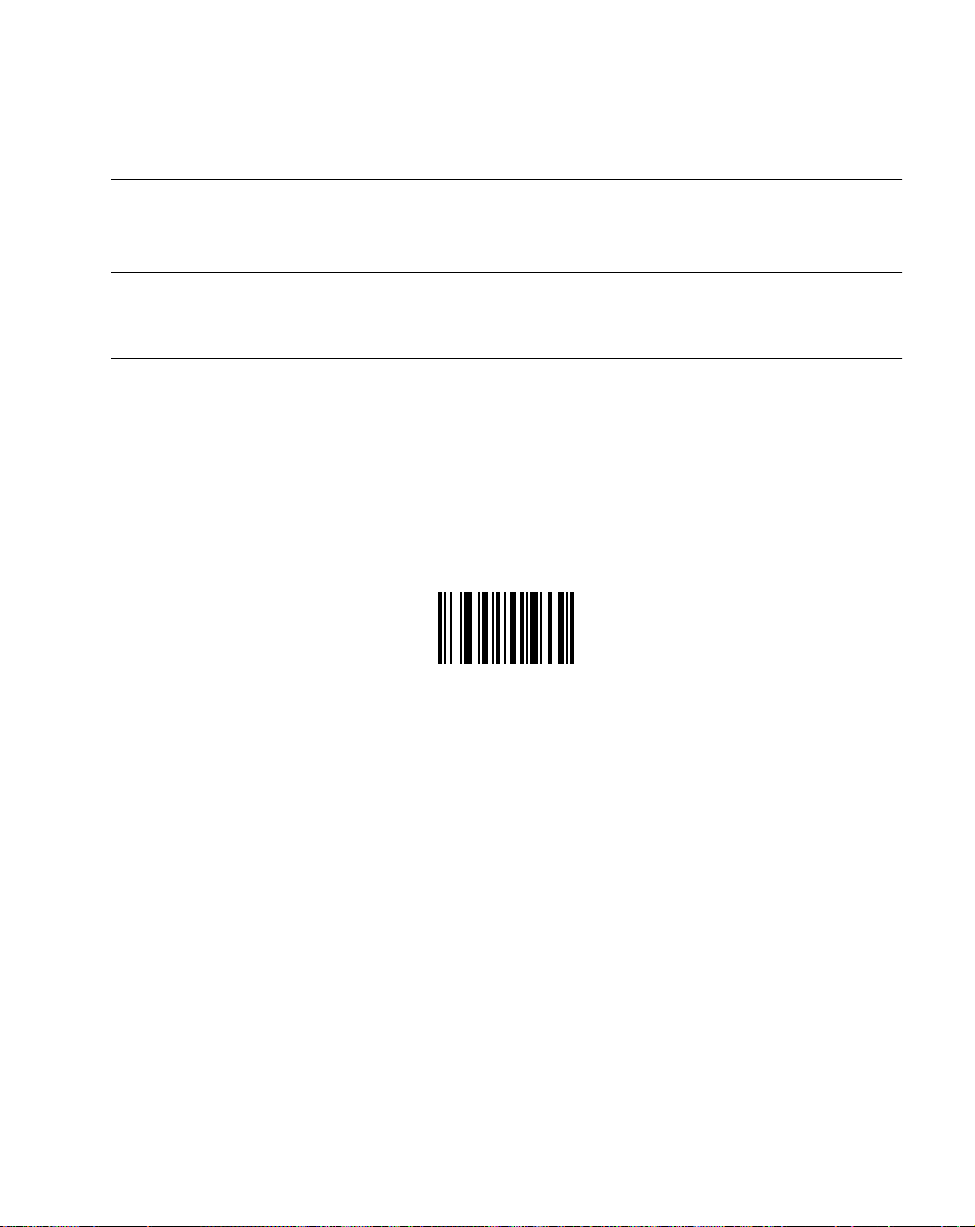

Set Default Parameter

Scanning this bar code returns all parameters to the default values listed in T able 5-1 on page

5-2.

Note: The ability to scan PDF417 bar codes is not enabled by default. You

must program the scanner to read PDF417 bar codes by scanning the

ENABLE PDF417 bar code on page 5-75.

SET ALL DEF AUL TS

5-7

Page 41

LS 400Xi Product Reference Guide

Host T ype

If you are using a Synapse cable, Synapse auto-detects your host so no host bar codes need to

be scanned. Otherwise, use the following selections to select your host.

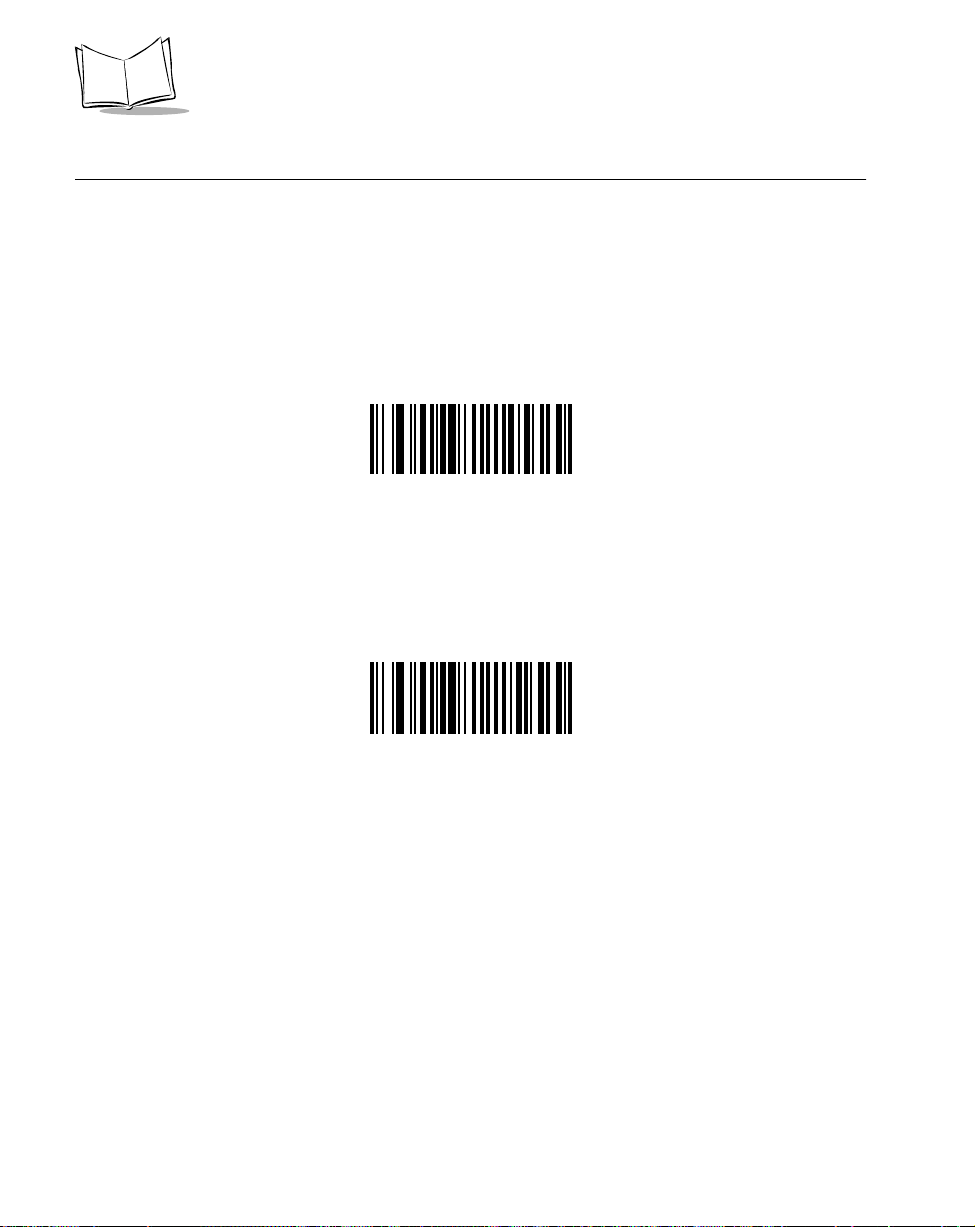

IBM 46XX Host Types

To select one of the following as a POS Interface, scan the appropriate bar code below.

Note: To properly communicate with 468X/9X terminals, the driver

corresponding to the port being used must be loaded and enabled

when you are configuring your terminal system. See your terminal’s

operating manual for details.

Port 5B

5-8

Port 9B

Port 17

Page 42

Parameter Menus

RS-232C Host Types

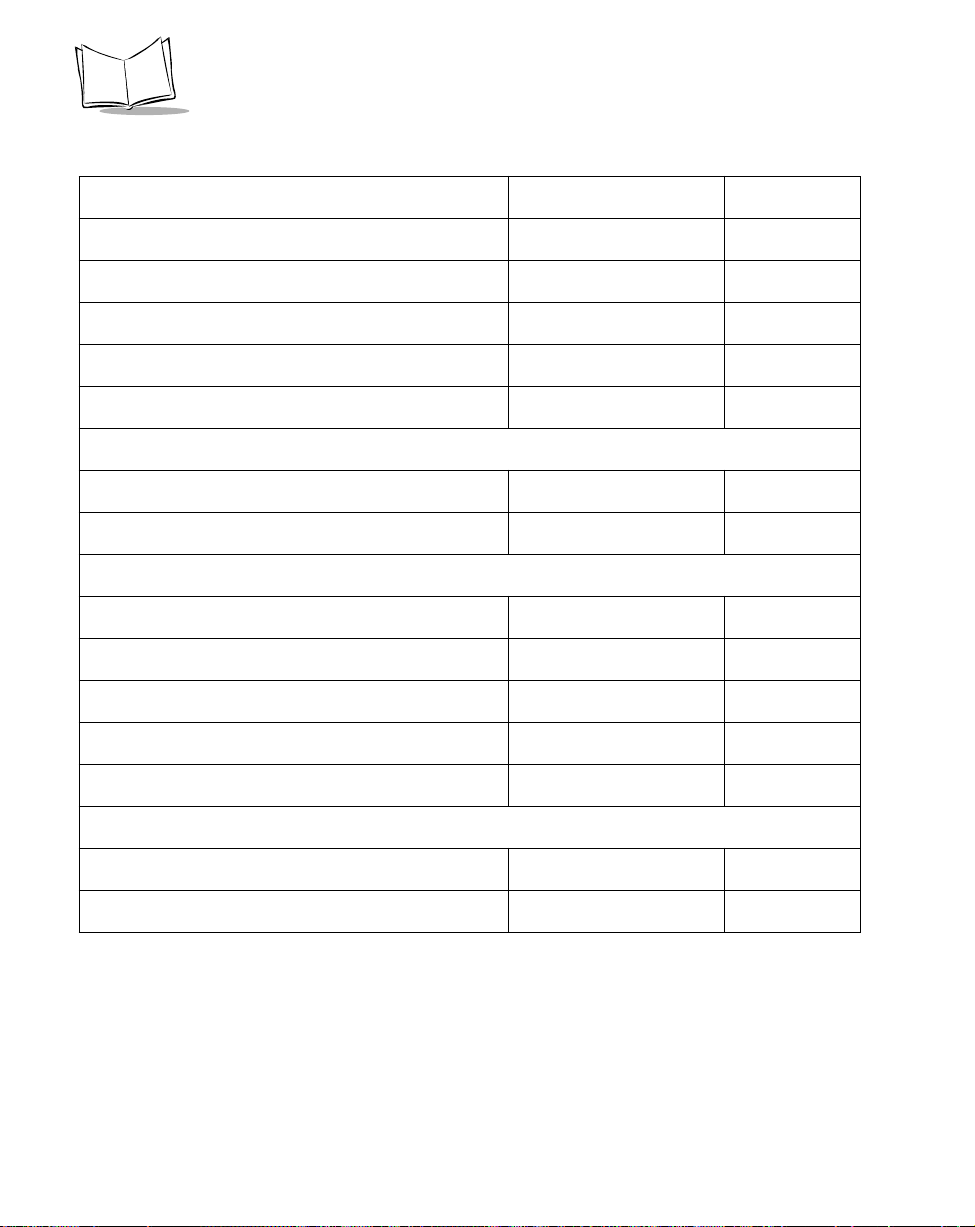

Three RS-232C hosts are set up with their own parameter default settings (Table 5-2).

Selecting the ICL, Fujitsu, or Nixdorf RS-232C terminal sets the defaults listed below . These

defaults take precedence over standard defaults. So if you select Fujitsu RS-232C, then select

the standard defaults, the Fujitsu defaults still take precedence.

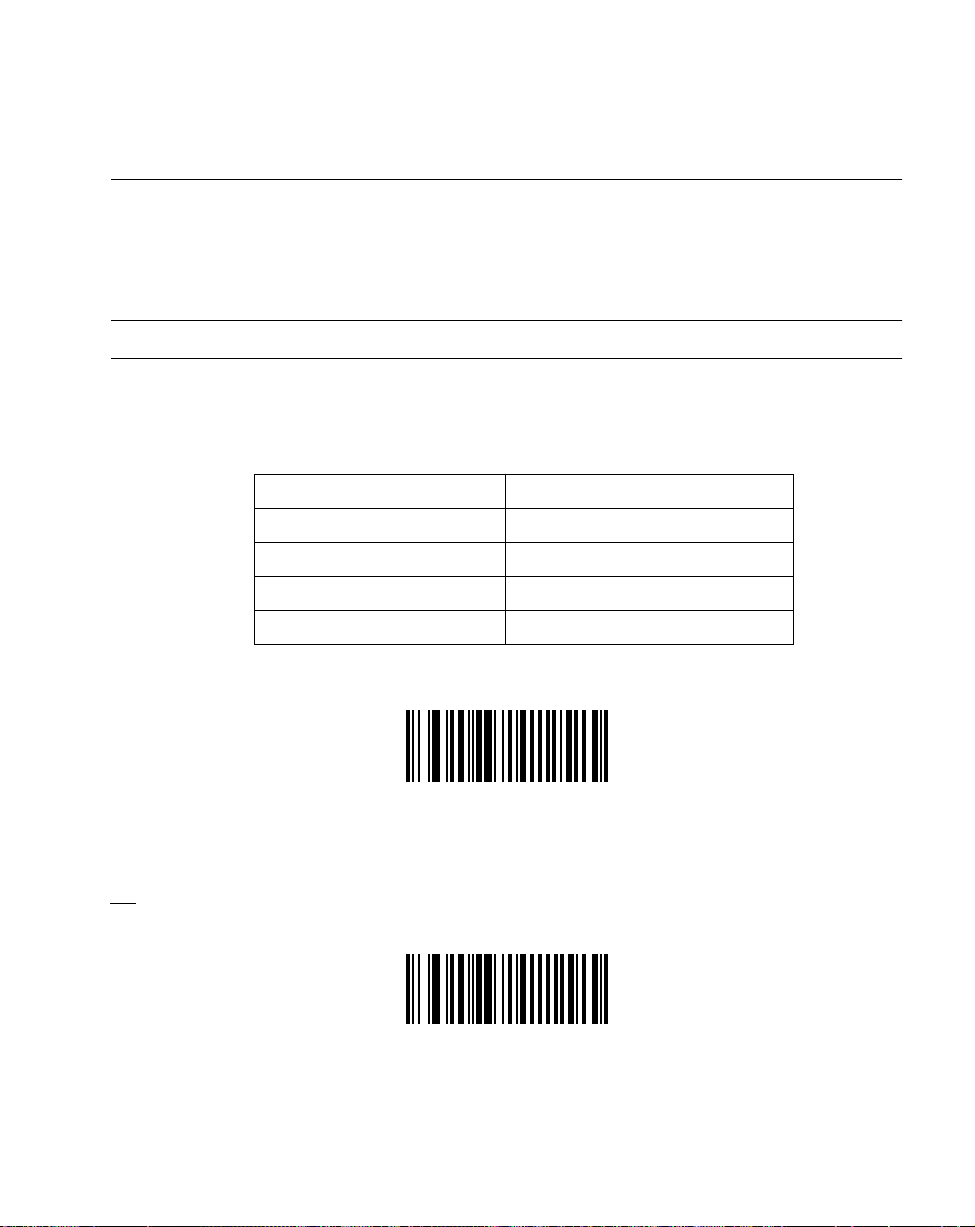

Table 5-2. Terminal Specific RS-232C

Parameter Standard ICL FUJITSU NIXDORF

Mode A/

Mode B

Transmit Code ID No Yes Yes Yes Yes

Data T ransmission Format Data as is Data/Suffix Data/Suffix Data/Suffix STX/Data/

Suffix CR/LF

(7013)

Baud Rate 9600 9600 9600 9600 19200

Parity None Even None Odd Even

Hardware Handshaking None RTS/CTS

Software Handshaking None None None None ACK/NAK

Serial Response Time-out 2 Sec. 9.9 Sec. 2 Sec. 9.9 Sec. 9.9 sec.

Stop Bit Select One One One One One

ASCII Format 8-Bit 8-Bit 8-Bit 8-Bit 7-Bit

Beep On <BEL> Disabled Disabled Disabled Disabled Disabled

RTS Line State Low High Low *Low = No

*In the Nixdorf Mode B, if CTS is Low , scanning is disabled. When CTS is High, the user can scan

bar codes.

CR (1013) CR (1013) CR (1013) None

None RTS/CTS

Option 3

Option 3

data to send

PDT

3300**

ETX/LRC

RTS/CTS

Standard

Low

**If Nixdorf Mode B or PDT 3300 is scanned without the scanner connected to the proper host,

it may appear unable to scan. If this happens, scan a different RS-232 host type within 5 seconds

of cycling power to the scanner.

5-9

Page 43

LS 400Xi Product Reference Guide

RS-232C Host Types (Cont’d)

Selecting the ICL, Fujitsu, or Nixdorf RS-232C terminal enables the transmission of code ID

characters as listed in Table 5-3 below. These code ID characters are not programmable and

are separate from the Transmit Code ID feature. The Transmit Code ID feature should not

be enabled for these terminals.

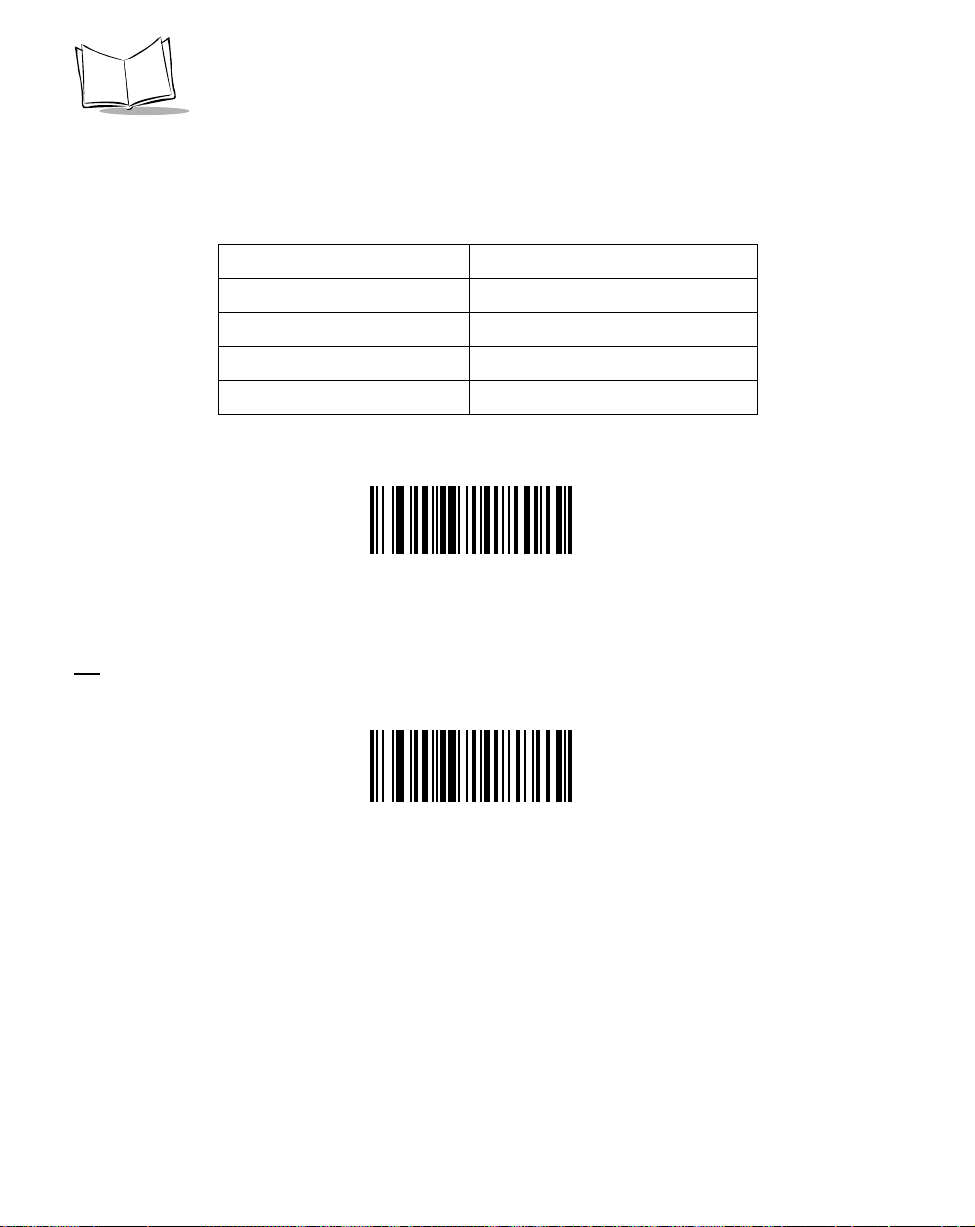

Table 5-3. Terminal Specific Code ID Characters

ICL FUJITSU NIXDORF

UPC-A “A” “A” “A”

UPC-E “E” “E” “C0”

EAN-8 “FF” “FF” “B”

EAN-13 “F” “F” “A”

Code 39 “C” <len> None “M”

Codabar “N” <len> None “N”

Code 128 “L” <len> None “K”

I 2 of 5 “I” <len> None “I”

Code 93 None None “L”

D 2 of 5 “H” <len> None “H”

UCC/EAN 128 “L” <len> None “P”

MSI/Plessey None None “O”

Bookland EAN “F” “F” “A”

Trioptic None None None

5-10

Page 44

Parameter Menus

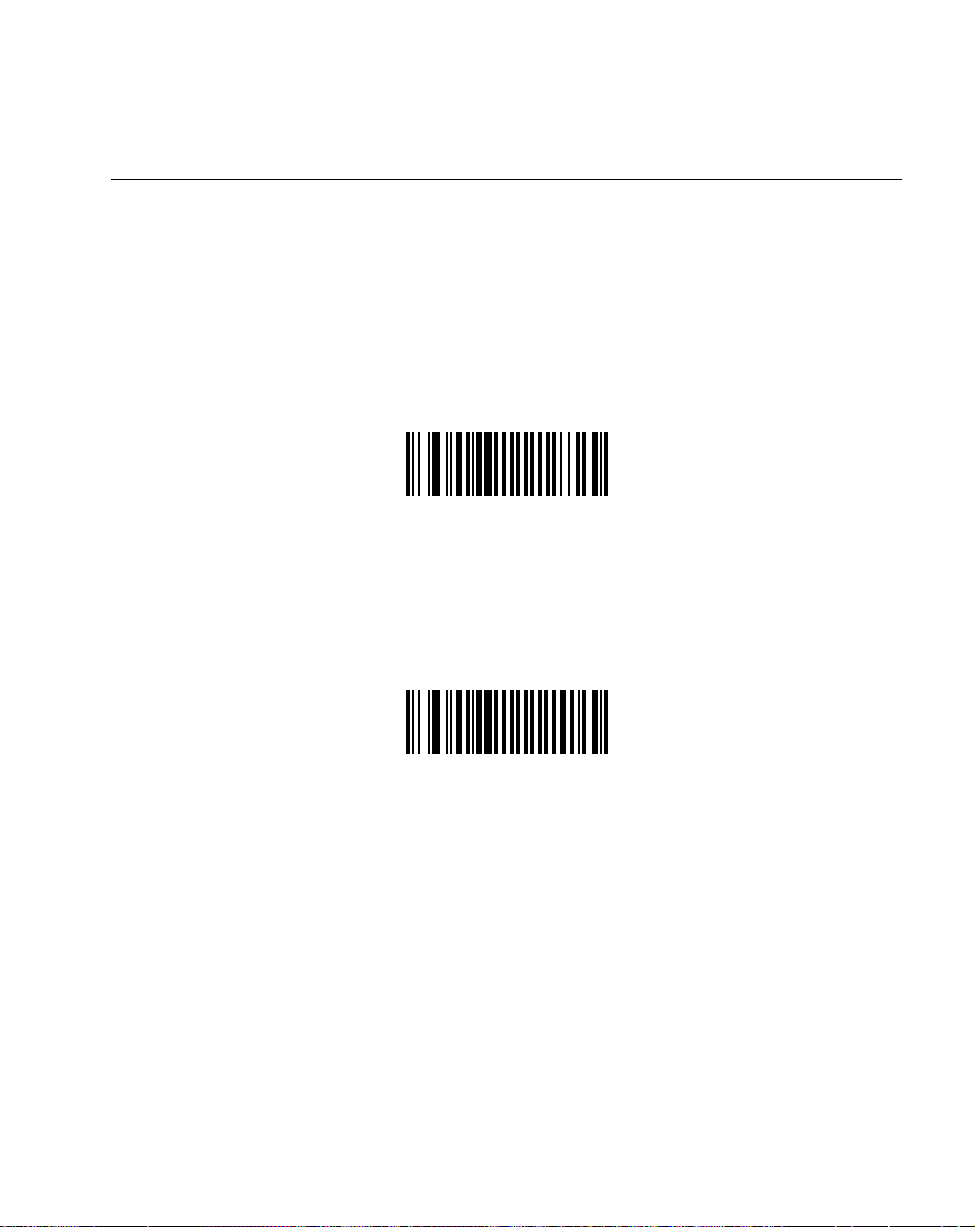

RS-232C Host Types (Cont’d)

T o select an RS-232C host interface, scan one of the following bar codes. If you are scanning

PDF417 bar codes, only Standard RS-232C or PDT 3300 may be selected.

STANDARD RS-232C

ICL RS-232C

NIXDORF RS-232C Mode A

NIXDORF RS-232C Mode B

FUJITSU RS-232C

PDT 3300

5-11

Page 45

LS 400Xi Product Reference Guide

Beeper T one

To select a decode beep frequency (tone), scan the LOW FREQUENCY, MEDIUM

FREQUENCY, or HIGH FREQUENCY bar code.

LOW FREQUENCY

5-12

MEDIUM FREQUENCY

HIGH FREQUENCY

Page 46

Parameter Menus

Beeper Volume

To select a beeper volume, scan the LOW VOLUME, MEDIUM VOLUME, or HIGH

VOLUME bar code.

LOW V OLUME

MEDIUM VOLUME

HIGH VOLUME

5-13

Page 47

LS 400Xi Product Reference Guide

Laser On Time

This parameter sets the maximum time decode processing continues during a scan attempt.

It is programmable in 0.1 second increments from 0.5 to 9.9 seconds.

T o set a Laser On T ime, scan the bar code below . Next scan two numeric bar codes beginning

on page 5-93 that correspond to the desired time on. Single digit numbers must have a leading

zero. For example, to set an On Time of .5 seconds, scan the bar code below, then scan the

“0” and “5” bar codes. If you make an error , or wish to change your selection, scan CANCEL

on page 5-95.

5-14

LASER ON TIME

Page 48

Parameter Menus

Power Mode

This parameter determines whether or not power remains on after a decode attempt. When

in low power mode, the scanner enters into a low power consumption mode to preserve

battery life after each decode attempt. When in continuous power mode, power remains on

after each decode attempt.

CONTINUOUS ON

LOW POWER

5-15

Page 49

LS 400Xi Product Reference Guide

Beep After Good Decode

Scan a bar code below to select whether or not the unit beeps after a good decode. If DO

NOT BEEP is selected, the beeper still operates during parameter menu scanning and

indicates error conditions.

BEEP AFTER GOOD DECODE

5-16

DO NOT BEEP AFTER GOOD DECODE

Page 50

Parameter Menus

Transmit “No Read” Message

Scan a bar code below to select whether or not a “No Read” message is transmitted. When

enabled, if a symbol does not decode, “NR” is transmitted. Any prefixes or suffixes which

have been enabled are appended around this message. When disabled, if a symbol does not

read, nothing is sent to the host.

ENABLE NO READ

DISABLE NO READ

5-17

Page 51

LS 400Xi Product Reference Guide

PDF Decode Feedback

Scan a bar code below to select whether or not the unit “clicks” during PDF417 decoding to

indicate proper alignment, motion, and distance.

ENABLE PDF DECODE FEEDBACK

5-18

DISABLE PDF DECODE FEEDBACK

Page 52

Parameter Menus

Linear Code Type Security Level

The LS 400Xi offers four levels of decode security for linear code types (e.g., Code 39,

Interleaved 2 of 5). Higher security levels are selected for decreasing levels of bar code quality .

As security levels increase, the scanner’s aggressiveness decreases. Select the security level

appropriate for your bar code quality.

Note: This does not apply to Code 128.

Linear Security Level 1

The following code types must be successfully read twice before being decoded:

Code Type Length

Codabar All

MSI Plessey 4 or less

D 2 of 5 8 or less

I 2 of 5 8 or less

LINEAR SECURITY LEVEL 1

Linear Security Level 2

All code types must be successfully read twice before being decoded.

LINEAR SECURITY LEVEL 2

5-19

Page 53

LS 400Xi Product Reference Guide

Linear Security Level 3

Code types other than the following must be successfully read twice before being decoded.

The following codes must be read three times:

Code Type Length

MSI Plessey 4 or less

D 2 of 5 8 or less

I 2 of 5 8 or less

Codabar 8 or less

LINEAR SECURITY LEVEL 3

Linear Security Level 4

All code types must be successfully read three times before being decoded.

LINEAR SECURITY LEVEL 4

5-20

Page 54

Parameter Menus

Bi-directional Redundancy

This parameter is only valid when a Linear Code Type Security Level (see page 5-19) has

been enabled. When this parameter is enabled, a bar code must be successfully scanned in

both directions (forward and reverse) before being decoded.

ENABLE BI-DIRECTIONAL REDUNDANCY

DISABLE BI-DIRECTIONAL REDUNDANCY

5-21

Page 55

LS 400Xi Product Reference Guide

Enable/Disable UPC-E/UPC-A/UPC-E1

To enable or disable UPC-E, UPC-A or UPC-E1, scan the appropriate bar code below.

ENABLE UPC-E

DISABLE UPC-E

5-22

ENABLE UPC-A

DISABLE UPC-A

ENABLE UPC-E1

DISABLE UPC-E1

Page 56

Parameter Menus

Enable/Disable EAN-8/EAN-13

To enable or disable EAN-8 or EAN-13, scan the appropriate bar code below.

ENABLE EAN-8

DISABLE EAN-8

ENABLE EAN-13

DISABLE EAN-13

5-23

Page 57

LS 400Xi Product Reference Guide

Enable/Disable Bookland EAN

To enable or disable Bookland EAN, scan the appropriate bar code below.

ENABLE BOOKLAND EAN

DISABLE BOOKLAND EAN

5-24

Page 58

Parameter Menus

Decode UPC/EAN Supplementals

Supplementals are additionally appended characters (2 or 5) according to specific code

format conventions (e.g., UPC A+2, UPC E+2, EAN 8+2). Three options are available.

t If UPC/EAN with supplemental characters is selected, UPC/EAN symbols without

supplemental characters are not decoded.

t If UPC/EAN without supplemental characters is selected, and the LS 400Xi is

presented with a UPC/EAN plus supplemental symbol, the UPC/EAN is decoded

and the supplemental characters ignored.

t An autodiscriminate option is also available. If this option is selected, choose an

appropriate Decode UPC/EAN Supplemental Redundancy value from the next page.

A value of 5 or more is recommended.

Note: In order to minimize the risk of invalid data transmission, it is

recommended that you select whether to read or ignore supplemental

characters.

DECODE UPC/EAN WITH SUPPLEMENTALS

IGNORE UPC/EAN WITH SUPPLEMENTALS

AUTODISCRIMINATE UPC/EAN SUPPLEMENTALS

5-25

Page 59

LS 400Xi Product Reference Guide

Decode UPC/EAN Supplemental Redundancy

With Autodiscriminate UPC/EAN Supplementals selected, this option adjusts the number of

times a symbol without supplementals is decoded before transmission. The range is from two

to twenty times. Five or above is recommended when decoding a mix of UPC/EAN symbols

with and without supplementals, and the autodiscriminate option is selected.

Scan the bar code below to select a decode redundancy value. Next scan two numeric bar

codes beginning on page 5-93. Single digit numbers must have a leading zero. If you make an

error, or wish to change your selection, scan CANCEL on page 5-95.

DECODE UPC/EAN

SUPPLEMENTAL REDUNDANCY

5-26

Page 60

Parameter Menus

Transmit UPC-A/UPC-E/UPC-E1 Check Digit

Scan the appropriate bar code below to transmit the symbol with or without the UPC-A,

UPC-E or UPC-E1 check digit.

TRANSMIT UPC-A CHECK DIGIT

DO NOT TRANSMIT UPC-A CHECK DIGIT

TRANSMIT UPC-E CHECK DIGIT

DO NOT TRANSMIT UPC-E CHECK DIGIT

TRANSMIT UPC-E1 CHECK DIGIT

DO NOT TRANSMIT UPC-E1 CHECK DIGIT

5-27

Page 61

LS 400Xi Product Reference Guide

UPC-A Preamble

Three options are given for lead-in characters for UPC-A symbols transmitted to the host

device: transmit system character only, transmit system character and country code (“0” for

USA), and no preamble transmitted. The lead-in characters are considered part of the symbol.

NO PREAMBLE

(<DATA>)

5-28

SYSTEM CHARACTER

(<SYSTEM CHARACTER> <DATA>)

SYSTEM CHARACTER & COUNTRY CODE

(< COUNTRY CODE> <SYSTEM CHARACTER> <DATA>)

Page 62

Parameter Menus

UPC-E Preamble

Three options are given for lead-in characters for UPC-E symbols transmitted to the host

device: transmit system character only, transmit system character and country code (“0” for

USA), and no preamble transmitted. The lead-in characters are considered part of the symbol.

NO PREAMBLE

(<DATA>)

SYSTEM CHARACTER

(<SYSTEM CHARACTER> <DATA>)

SYSTEM CHARACTER & COUNTRY CODE

UPC(< COUNTRY CODE> <SYSTEM CHARACTER> <DATA>)

5-29

Page 63

LS 400Xi Product Reference Guide

UPC-E1 Preamble

Three options are given for lead-in characters for UPC-E1 symbols transmitted to the host

device: transmit system character only, transmit system character and country code (“0” for

USA), and no preamble transmitted. The lead-in characters are considered part of the symbol.

NO PREAMBLE

(<DATA>)

5-30

SYSTEM CHARACTER

(<SYSTEM CHARACTER> <DATA>)

SYSTEM CHARACTER & COUNTRY CODE

(< COUNTRY CODE> <SYSTEM CHARACTER> <DATA>)

Page 64

Parameter Menus

Convert UPC-E to UPC-A

This parameter converts UPC-E (zero suppressed) decoded data to UPC-A format before

transmission. After conversion, data follows UPC-A format and is affected by UPC-A

programming selections (e.g., Preamble, Check Digit).

Scanning DO NOT CONVERT UPC-E TO UPC-A allows you to transmit

UPC-E (zero suppressed) decoded data.

CONVERT UPC-E TO UPC-A

(ENABLE)

DO NOT CONVERT UPC-E TO UPC-A

(DISABLE)

5-31

Page 65

LS 400Xi Product Reference Guide

Convert UPC-E1 to UPC-A

This parameter converts UPC-E1 decoded data to UPC-A format before transmission. After

conversion, data follows UPC-A format and is affected by UPC-A programming selections

(e.g., Preamble, Check Digit).

Scanning DO NOT CONVERT UPC-E1 TO UPC-A allows you to transmit UPC-E1

decoded data.

CONVERT UPC-E1 TO UPC-A

(ENABLE)

5-32

DO NOT CONVERT UPC-E1 TO UPC-A

(DISABLE)

Page 66

Parameter Menus

EAN Zero Extend

If this parameter is enabled, five leading zeros are added to decoded EAN-8 symbols to make

them compatible in format to EAN-13 symbols.

Disabling this parameter returns EAN-8 symbols to their normal format.

ENABLE EAN ZERO EXTEND

DISABLE EAN ZERO EXTEND

5-33

Page 67

LS 400Xi Product Reference Guide

Convert EAN-8 to EAN-13 Type

When EAN Zero Extend is enabled, this parameter gives you the option of labeling the

extended symbol as either an EAN-13 bar code, or an EAN-8 bar code. This affects T ransmit

Code ID Character.

When EAN Zero Extend is disabled, this parameter has no effect on bar code data.

TYPE IS EAN-8

5-34

TYPE IS EAN-13

Page 68

Parameter Menus

UPC/EAN Security Level

The LS 400Xi offers four levels of decode security for UPC/EAN bar codes. Increasing levels

of security are provided for decreasing levels of bar code quality. There is an inverse

relationship between security and scanner aggressiveness, so be sure to choose only that level

of security necessary for any given application.

UPC/EAN Security Level 0

This is the default setting which allows the scanner to operate in its most aggressive state,

while providing sufficient security in decoding “in-spec” UPC/EAN bar codes.

UPC/EAN SECURITY LEVEL 0

UPC/EAN Security Level 1

As bar code quality levels diminish, certain characters become prone to misdecodes before

others (i.e., 1, 2, 7, 8). If you are experiencing misdecodes of poorly printed bar codes, and

the mis-decodes are limited to these characters, select this security level.

UPC/EAN SECURITY LEVEL 1

5-35

Page 69

LS 400Xi Product Reference Guide

UPC/EAN Security Level 2

If you are experiencing misdecodes of poorly printed bar codes, and the misdecodes are not

limited to characters 1, 2, 7, and 8, select this security level.

UPC/EAN SECURITY LEVEL 2

UPC/EAN Security Level 3

If you have tried Security Level 2, and are still experiencing misdecodes, select this security

level. Be advised, selecting this option is an extreme measure against misdecoding severely out

of spec bar codes. Selection of this level of security significantly impairs the decoding ability

of the scanner. If this level of security is necessary, you should try to improve the quality of

your bar codes.

5-36

UPC/EAN SECURITY LEVEL 3

Page 70

Parameter Menus

UPC/EAN Coupon Code

When enabled, this parameter decodes UPC-A, UPC-A with 2 supplemental characters, UPCA with 5 supplemental characters, and UPC-A/EAN 128 bar codes. Autodiscriminate UPC/

EAN With Supplemental Characters must be enabled.

ENABLE UPC/EAN COUPON CODE

DISABLE UPC/EAN COUPON CODE

5-37

Page 71

LS 400Xi Product Reference Guide

Enable/Disable Code 128

To enable or disable Code 128, scan the appropriate bar code below.

ENABLE CODE 128

5-38

DISABLE CODE 128

Page 72

Parameter Menus

Enable/Disable UCC/EAN-128

To enable or disable UCC/EAN-128, scan the appropriate bar code below. (See Appendix A

for details on UCC/EAN-128.)

ENABLE UCC/EAN-128

DISABLE UCC/EAN-128

Lengths for Code 128

No length setting is required for Code 128. The default setting is Any Length.

5-39

Page 73

LS 400Xi Product Reference Guide

Enable/Disable Code 39

To enable or disable Code 39, scan the appropriate bar code below.

ENABLE CODE 39

5-40

DISABLE CODE 39

Page 74

Parameter Menus

Enable/Disable Trioptic Code 39

T rioptic Code 39 symbols always contain six characters. To enable or disable Trioptic Code

39, scan the appropriate bar code below.

ENABLE TRIOPTIC CODE 39

DISABLE TRIOPTIC CODE 39

Note: Trioptic Code 39 and Code 39 Full ASCII cannot be enabled

simultaneously . If you get an error beep when enabling T rioptic Code

39, disable Code 39 Full ASCII and try again.

5-41

Page 75

LS 400Xi Product Reference Guide

Convert Code 39 to Code 32

Scan the appropriate bar code below to enable or disable converting Code 39 to Code 32.

Note: Code 39 must be enabled in order for this parameter to function.

ENABLE CONVERT CODE 39 TO CODE 32

5-42

DISABLE CONVERT CODE 39 TO CODE 32

Page 76

Parameter Menus

Code 32 Prefix

Scan the appropriate bar code below to enable or disable adding the prefix character “A” to

all Code 32 bar codes.

Note: Convert Code 39 to Code 32 must be enabled for this parameter to

function.

ENABLE CODE 32 PREFIX

DISABLE CODE 32 PREFIX

5-43

Page 77

LS 400Xi Product Reference Guide

Set Lengths for Code 39

Lengths for Code 39 may be set for any length, one or two discrete lengths, or lengths within

a specific range. The length of a code refers to the number of characters (i.e., human readable

characters), including check digit(s) the code contains. If Code 39 Full ASCII is enabled,

Length Within a Range or Any Length are the preferred options.

One Discrete Length - This option allows you to decode only those codes containing a

selected length. For example, if you select Code 39 One Discrete Length, then scan 1, 4, only

Code 39 symbols containing 14 characters are decoded. Numeric bar codes begin on page

5-93. If you make an error or wish to change your selection, scan CANCEL on page 5-95.

CODE 39 - ONE DISCRETE LENGTH

T wo Discrete Lengths - This option allows you to decode only those codes containing two

selected lengths. For example, if you select Code 39 Two Discrete Lengths, then scan 0,

2, 1, 4, only Code 39 symbols containing 2 or 14 characters are decoded. Numeric bar

codes begin on page 5-93. If you make an error or wish to change your selection, scan

CANCEL on page 5-95.

CODE 39 - TWO DISCRETE LENGTHS

5-44

Page 78

Parameter Menus

Set Lengths for Code 39 (Cont’d)

Length Within Range - This option allows you to decode a code type within a specified

range. For example, to decode Code 39 symbols containing between 4 and 12 characters,

first scan Code 39 Length Within Range. Then scan 0, 4, 1, and 2 (single digit numbers must

always be preceded by a leading zero). Numeric bar codes begin on page 5-93. If you make

an error or wish to change your selection, scan CANCEL on page 5-95.

CODE 39 - LENGTH WITHIN RANGE

Any Length - Scanning this option allows you to decode Code 39 symbols containing any

number of characters.

CODE 39 - ANY LENGTH

5-45

Page 79

LS 400Xi Product Reference Guide

Code 39 Check Digit Verification

When enabled, this parameter checks the integrity of a Code 39 symbol to ensure it complies

with specified algorithms. Only those Code 39 symbols which include a modulo 43 check

digit are decoded when this parameter is enabled.

ENABLE CODE 39 CHECK DIGIT

5-46

DISABLE CODE 39 CHECK DIGIT

Page 80

Transmit Code 39 Check Digit

Scan a bar code below to transmit data with or without the check digit.

TRANSMIT CODE 39 CHECK DIGIT

(ENABLE)

Parameter Menus

DO NOT TRANSMIT CODE 39 CHECK DIGIT

(DISABLE)

5-47

Page 81

LS 400Xi Product Reference Guide

Enable/Disable Code 39 Full ASCII

To enable or disable Code 39 Full ASCII, scan the appropriate bar code below.

When enabled, the ASCII character set assigns a code to letters, punctuation marks,

numerals, and most control keystrokes on the keyboard.

The first 32 codes are non-printable and are assigned to keyboard control characters such as

BACKSPACE and RETURN. The other 96 are called printable codes because all but SPACE

and DELETE produce visible characters.

Code 39 Full ASCII interprets the bar code special character ($ + % /) preceding a Code 39

character and assigns an ASCII character value to the pair. For example, when Code 39 Full

ASCII is enabled and a +B is scanned, it is interpreted as b, %J as ?, and $H emulates the

keystroke BACKSPACE. Scanning ABC$M outputs the keystroke equivalent of ABC

ENTER. Refer to Table A-3 in Appendix A.

The scanner does not autodiscriminate between Code 39 and Code 39 Full ASCII.

ENABLE CODE 39 FULL ASCII

DISABLE CODE 39 FULL ASCII

Note: Trioptic Code 39 and Code 39 Full ASCII cannot be enabled

simultaneously . If you get an error beep when enabling T rioptic Code

39, disable Code 39 Full ASCII and try again.

5-48

Page 82

Parameter Menus

Code 39 Buffering (Scan & Store)

When you select the scan and store option, all Code 39 symbols having a leading space as a

first character are temporarily buffered in the unit to be transmitted later. The leading space

is not buffered.

Decode of a valid Code 39 symbol with no leading space causes transmission in sequence of

all buffered data in a first-in first-out format, plus transmission of the “triggering” symbol.

See the following pages for further details.

When the scan and transmit option is selected, decoded Code 39 symbols without leading

spaces are transmitted without being stored in the buffer.

Scan and Store affects Code 39 decodes only . If you select scan and store, we recommend that

you configure the scanner to decode Code 39 symbology only.

BUFFER CODE 39

(ENABLE)

DO NOT BUFFER CODE 39

(DISABLE)

While there is data in the transmission buffer, deleting Code 39 buffering capability via

the parameter menu is not allowed. The buffer holds 200 bytes of information.

To allow disabling of Code 39 buffering, first force the buffer transmission (see Transmit

Buffer) or clear the buffer . Both the CLEAR BUFFER and TRANSMIT BUFFER bar codes

are length 1. Be sure Code 39 length is set to include length 1.

5-49

Page 83

LS 400Xi Product Reference Guide

Buffer Data

To buffer data, Code 39 buffering must be enabled, and a symbol must be read with a space

immediately following the start pattern.

t Unless symbol overflows the transmission buffer, the unit gives a lo/hi beep to

indicate successful decode and buffering. See Overfilling Transmission Buffer.

t Unit adds the message, excluding the leading space to the transmission buffer.

t No transmission occurs.

Clear Transmission Buffer

To clear the transmission buffer, read a symbol which contains only a start character , a dash

(minus), and a stop character.

t Unit issues a short hi/lo/hi beep to signal that the transmission buffer has been erased,

and no transmission has occurred.

t Unit erases the transmission buffer.

t No transmission occurs.

5-50

CLEAR BUFFER

Page 84

Parameter Menus

Transmit Buffer

To transmit the buffer, read a symbol containing either the first or second condition:

1. Only a start character, a plus (+), and a stop character.

t The unit signals that the transmission buffer has been sent (a lo/hi beep).

t Unit sends the buffer.

t Unit clears the buffer.

TRANSMIT BUFFER

2. A Code 39 bar code with leading character other than a space.

t The unit signals a good decode and buffering of that decode has occurred by giving

a hi/lo beep.

t Unit transmits the buffer.

t Unit signals that the buffer has been transmitted with a lo/hi beep.

Overfilling T ransmission Buffer

If the symbol just read results in an overflow of the transmission buffer:

t Unit indicates that the symbol has been rejected by issuing three long, high beeps.

t No transmission occurs. Data in buffer is not affected.

Attempt to Transmit an Empty Buffer

If the symbol just read was the transmit buffer symbol and the Code 39 buffer is empty:

t A short lo/hi/lo beep signals that the buffer is empty.

t No transmission occurs.

t The buffer remains empty.

5-51

Page 85

LS 400Xi Product Reference Guide

Enable/Disable Code 93

To enable or disable Code 93, scan the appropriate bar code below.

ENABLE CODE 93

5-52

DISABLE CODE 93

Page 86

Parameter Menus

Set Lengths for Code 93

Lengths for Code 93 may be set for any length, one or two discrete lengths, or lengths within

a specific range. The length of a code refers to the number of characters (i.e., human readable

characters), including check digit(s) the code contains.

One Discrete Length - This option allows you to decode only those codes containing a

selected length. For example, if you select Code 93 One Discrete Length, then scan 1, 4, only

Code 93 symbols containing 14 characters are decoded. Numeric bar codes begin on page

5-93. If you make an error or wish to change your selection, scan CANCEL on page 5-95.

CODE 93 - ONE DISCRETE LENGTH

Two Discrete Lengths - This option allows you to decode only those codes containing

two selected lengths. For example, if you select Code 93 Two Discrete Lengths, then

scan 0, 2, 1, 4, only Code 93 symbols containing 2 or 14 characters are decoded.

Numeric bar codes begin on page 5-93. If you make an error or wish to change your

selection, scan CANCEL on page 5-95.

CODE 93 - TWO DISCRETE LENGTHS

5-53

Page 87

LS 400Xi Product Reference Guide

Set Lengths for Code 93 (Cont’d)

Length Within Range - This option allows you to decode a code type within a specified

range. For example, to decode Code 93 symbols containing between 4 and 12 characters,

first scan Code 93 Length Within Range. Then scan 0, 4, 1, and 2 (single digit numbers must

always be preceded by a leading zero). Numeric bar codes begin on page 5-93. If you make

an error or wish to change your selection, scan CANCEL on page 5-95.

CODE 93 - LENGTH WITHIN RANGE

Any Length - Scanning this option allows you to decode Code 93 symbols containing any

number of characters.

5-54

CODE 93 - ANY LENGTH

Page 88

Parameter Menus

Enable/Disable Interleaved 2 of 5

To enable or disable Interleaved 2 of 5, scan the appropriate bar code below.

ENABLE INTERLEAVED 2 OF 5

DISABLE INTERLEAVED 2 OF 5

5-55

Page 89