Suzuki VX800 1990-1993 Service Manual 08 Chassis

~~~~~ ~~ ~~~~~~ CONTENTS ~~

FRONT WHEEL

REMOVAL

INSPECTION AND DISASSEMBLY

REASSEMBLY AND REMOUNTING

FRONT BRAKE

BRAKE PAD REPLACEMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 5

CALIPER REMOVAL AND DISASSEMBLY .......+..........8- 6

CALIPER AND DISC INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 6

CALIPER REASSEMBLY AND REMOUNTING . . . . . . . . . . . . . . .8_ 7

MASTER CYLINDER REMOVAL AND DISASSEMBLY . ..8- 8

MASTER CYLINDER INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 8

MASTER CYLINDER REASSEMBLY AND

REMOUNTING

FRONT FORK

REMOVAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8s 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 10

DlSASSEMBL Y.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 11

INSPECTION

REASSEMBLY AND REMOUNTING

STEERING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 75

REMOVAL

DISASSEMBL Y

IN_CPFf?TlflN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . & 16

.m .V,

---m-m.

REASSEMBLY AND REMOUNTING

STEERING TENSION ADJUSTMENT

IGNITION SWITCH

REAR BRAKE

BRAKE PAD REPLACEMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 12

. . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_ I6

. . . . . . . . . . . . . . . . . . . . . . . . . . .8_ 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8_ 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_20

CALIPER REMOVAL AND DISASSEMBL Y . . . . ’ ’ . . . . . . . . . . . . B-2 1

CALIPER AND DISC INSPECTION

n 1 I ,m#-m mr 1 mmr.*m* ,I 1 .I_ mr..m. I.ITI..fi

CIHLlrKfl KtH33LIIVlCIL T UIVLJ

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_22

HtMLJUlV

I INU . . . . ’ . . . . . . . . . ’ 8-22

MASTER CYLINDER REMOVAL AND DISASSEMBLY . ..8-23

MASTER CYLINDER INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_24

MASTER CYLINDER REASSEMBLY AND

REMOUNTING

REAR WHEEL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_26

REMOVAL AND DlSASSEMBL Y.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_26

INSPECTION AND DISASSEMBLY

REASSEMBLY AND REMOUNTING

TIRE AND WHEEL

TIRE REMOVAL

INSPECTION

TIRE MOUNTING

RFA R _Cl I_CPFN_ClfIN A N/3 S WING

, .__, . VI_, I,._,_,. _..I _.I mn.-s .m .m.m

REMOVAL

INSPECTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_34

ARM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_38

REASSEMBLY AND REMOUNTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_28

. . . . . . . . . . . . . . . . . . . . . . . . . . .8_29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .&36

. . . . . . . . . . . . . . . . . . . . . . . . . . .8_38

FINAL INSPECTION AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . .8-39

REASSEMBLY INFORMATION

SUSPENSION SETTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_4I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8_40

FRONT WHEEL

-

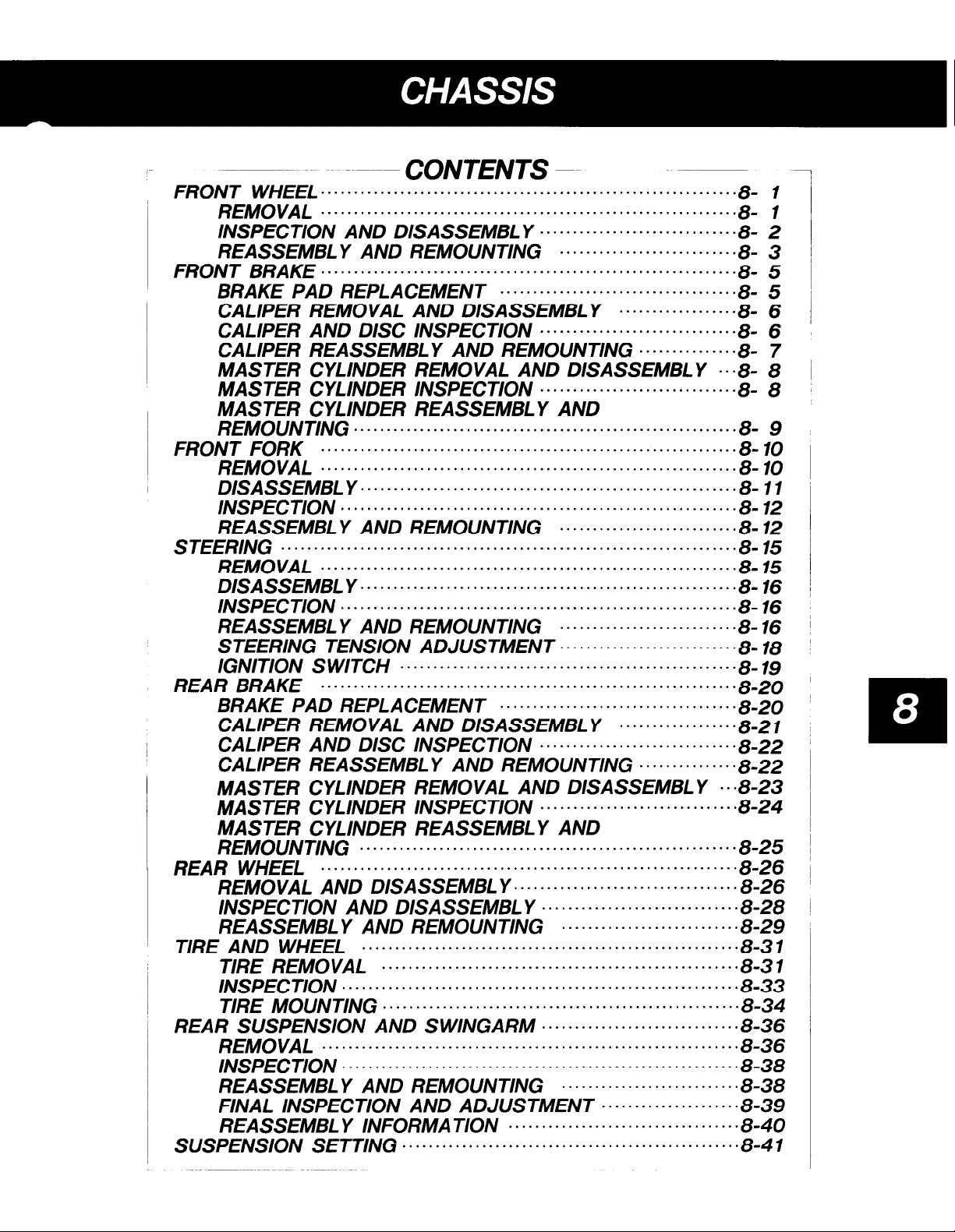

Th1360 : Apply THREAD LOCK SUPER “1360.”

Tightening torque

31

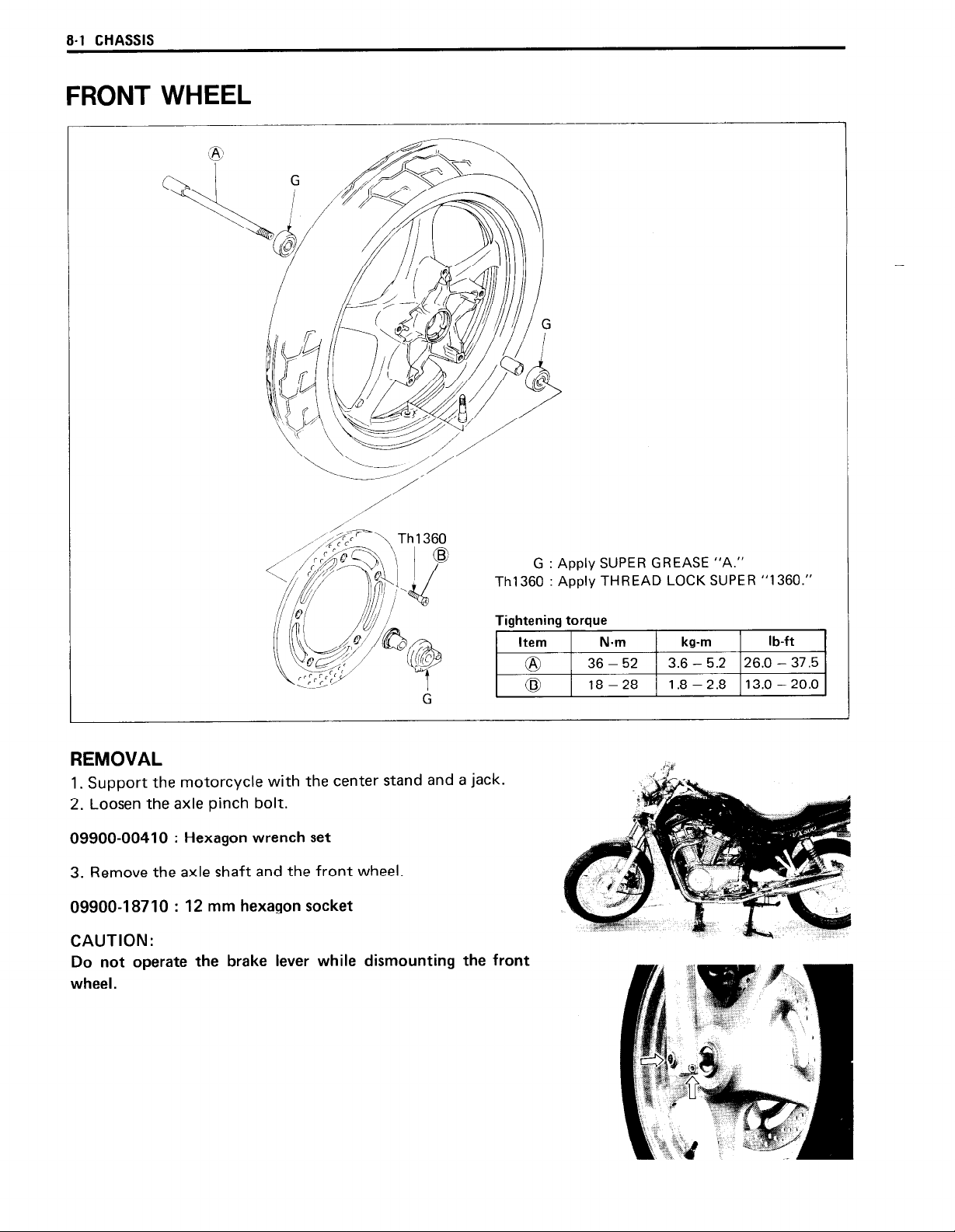

1. Support

2. Loosen the axle pinch bolt.

09900-00410 : Hexagon wrench set

3. Remove the axle shaft and the front wheel.

09900-l 8710 : 12 mm hexagon socket

CAUTION:

Do not operate the brake lever while dismounting the front

wheel.

the

motorcycle with

the center stand and a jack.

G : Apply SUPER GREASE “A.”

CHASSIS 8-2

INSPECTION AND

DISASSEMBLY

SPEEDOMETER GEAR BOX DUST SEAL

Inspect the lip of dust seal for damage.

TIRE

Refer to page 8-31.

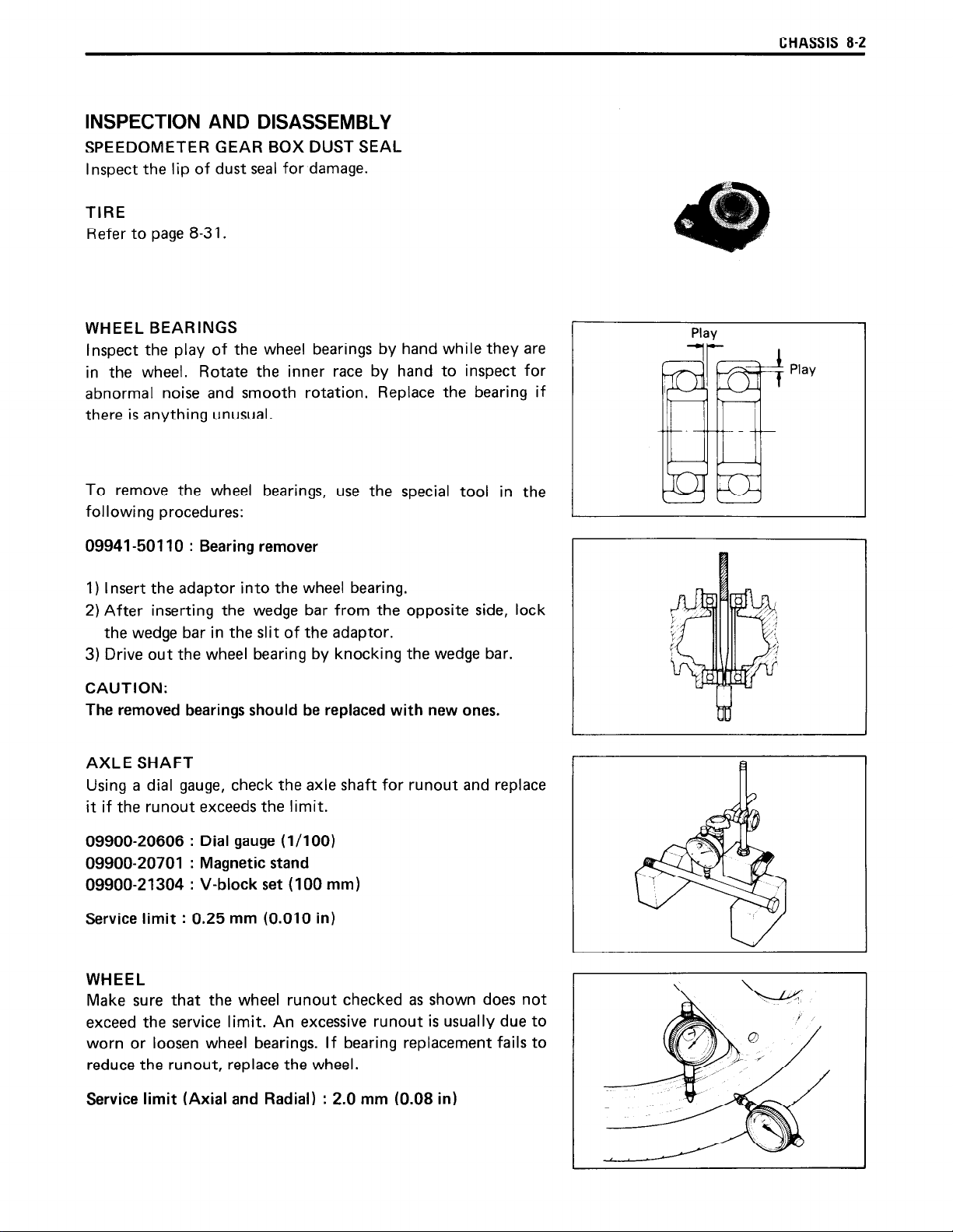

WHEEL BEARINGS

Inspect the play of the wheel bearings by hand whiie they are

in the wheel. Rotate the inner race by hand to inspect for

abnormal noise and smooth rotation. Replace the bearing if

there is anything unusual.

To remove the wheel bearings, use the

snecial tog! in the

-r--.-’

following procedures:

09941-50110 : Bearing remover

Plan

Play

I

1)

Insert the adaptor into the wheel bearing.

‘)\ II**-.. :,..-,+:,, +l-... . ..^ rl,.-. L.I” SC_, +L, P.,..,,;+, .-.:A,

L, H,K, 111se, LllllJ Lilt: ““a”ye “cl,

II”,,, LI,e: “cJIJ”S1K 31ve, 1”C.R

l--l,

the wedge bar in the slit of the adaptor.

3) Drive out the wheel bearing by knocking the wedge bar.

CAUTION:

The removed bearings should be replaced with new ones.

Using a dial gauge, check the axle shaft for runout and replace

it if the runout exceeds the limit.

09900-20606 :

Dial gauge (l/100)

09900-20701 : Magnetic stand

09900-21304 : V-block set (100 mm)

Service limit : 0.25 mm (0.010 in)

WHEEL

Make sure that

the wheel runout checked as shown does not

exceed the service limit. An excessive runout is usually due to

worn or loosen wheel bearings. If bearing replacement fails to

reduce the runout, replace the wheel.

I

Service limit (Axial and Radial) : 2.0 mm

(0.08

in)

8-3 CHASSIS

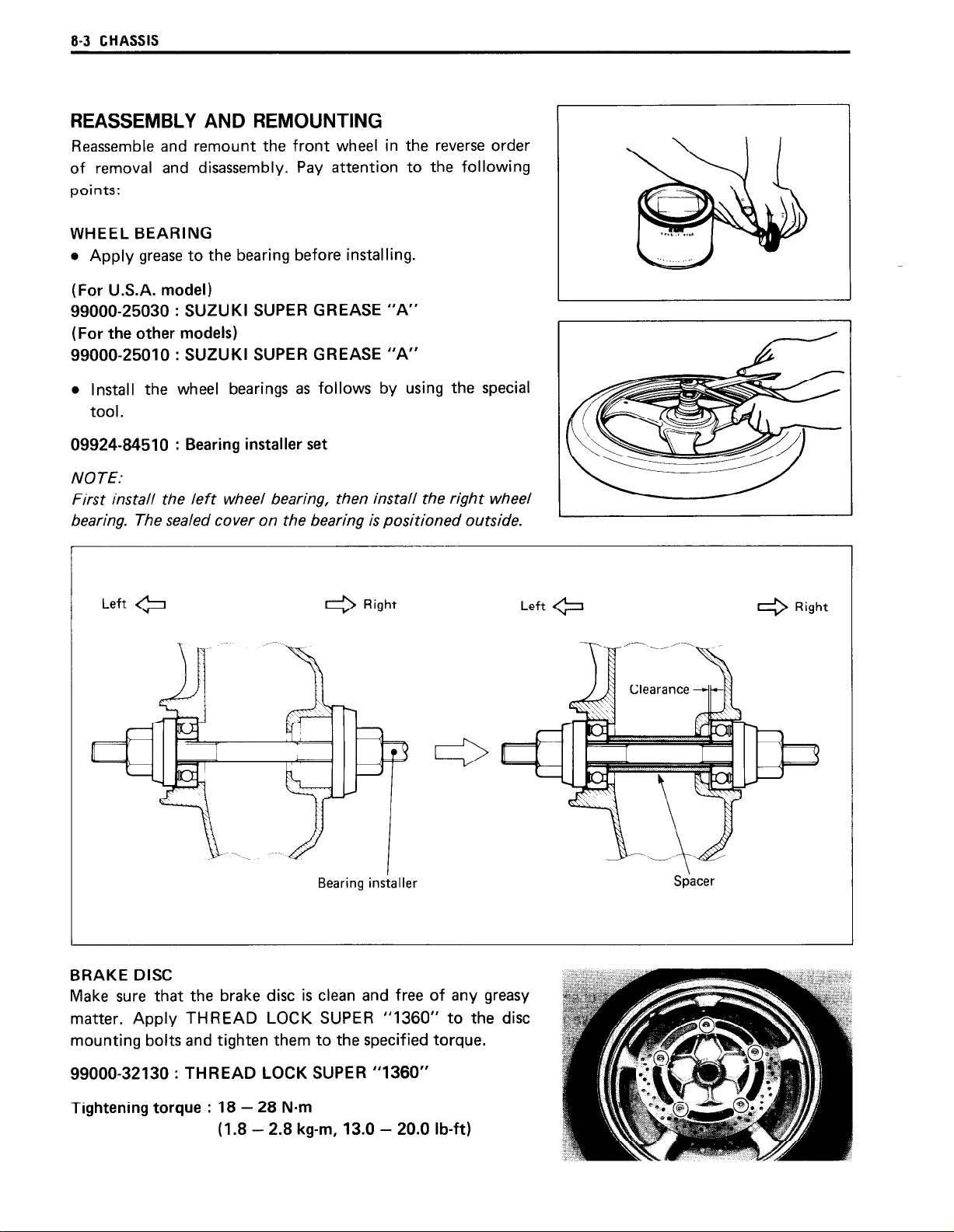

REASSEMBLY AND REMOUNTING

Reassemble and remount the front wheel in the reverse order

of removal and disassembly. Pay attention to the following

points:

WHEEL BEARING

l

Apply grease to the bearing before installing.

---‘-_

(For U.S.A. model)

99000-25030 : SUZUKI SUPER GREASE “A”

(For the other models)

99000-25010 : SUZUKI SUPER GREASE “A”

l

Install the wheel bearings as follows by using the special

tool.

09924-84510

:

Bearing installer set

NOTE:

First instaii the ieft wheei bearing, then instaii the right wheei

bearing. The sealed cover on the bearing is positioned outside.

Left +

I Right

Left +

4 Right

Bearing installer

BRAKE DISC

Make sure that the brake disc is clean and free of any greasy

matter. Apply THREAD LOCK SUPER “1360” to the disc

mounting bolts and tighten them to the specified torque.

99000-32130 : THREAD LOCK SUPER “1360”

Tightening torque : 18 - 28 N-m

(1.8 - 2.8 kg-m, 13.0 - 20.0 lb-ft)

Spacer

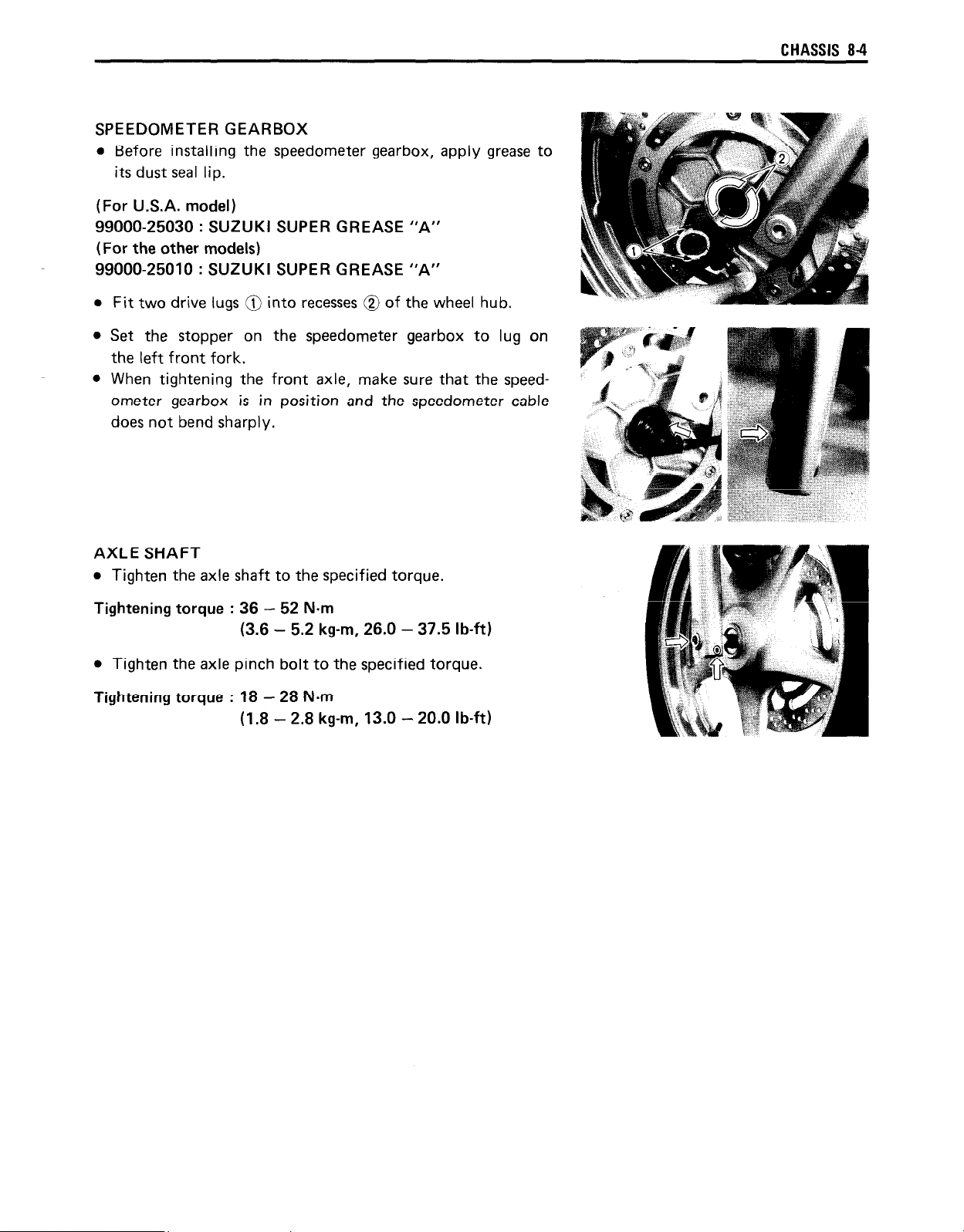

SPEEDOMETER GEARBOX

l

Before installing the speedometer gearbox, apply grease to

its dust seal lip.

(For U.S.A. model)

99000-25030 : SUZUKI SUPER GREASE “A”

(For the other models)

99000-25010 : SUZUK

I

SUPER GREASE “A”

CHASSIS 84

Fit two drive lugs @

into recesses @ of the wheel hub.

Set the stopper on the speedometer gearbox to lug on

the left front fork.

When tightening the front axle, make sure that the speedometer gearbox is in position and the speedometer cable

does not bend sharply.

AXLE SHAFT

l

Tighten the axle shaft to the specified torque.

Tightening torque : 36 - 52 N-m

(3.6 - 5.2 kg-m, 26.0 - 37.5 lb-ft)

l

Tighten the axle pinch bolt to the specified torque.

Tightening torque : 18 - 28 N.m

(1.8

- 2.8 kg-m, 13.0 - 20.0 lb-ft)

8-5 CHASSIS

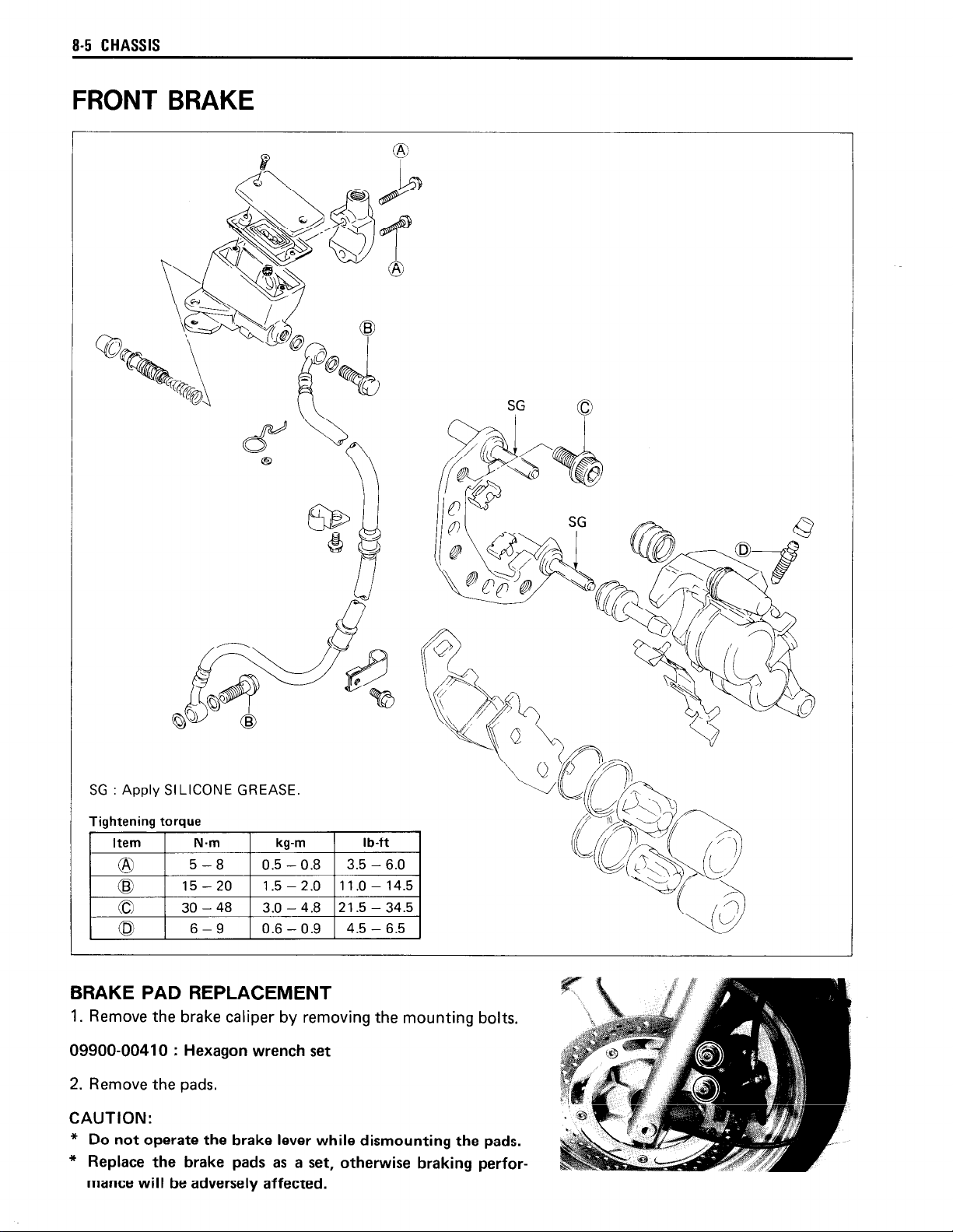

FRONT BRAKE

SG : Apply SILICONE GREASE.

SG

BRAKE PAD REPLACEMENT

1.

Remove the brake caliper by removing the mounting bolts.

09900-00410 : Hexagon wrench set

2. Remove the pads.

CAUTION:

* Do not operate the brake lever while dismounting the pads.

* Replace the brake pads as a set, otherwise braking perfor-

mance will be adversely affected.

CALIPER REMOVAL AND DISASSEMBLY

1. Disconnect the brake hose from the caliper by removing the

union bolt and catch the brake fluid in a suitable receptacle.

CAUTION:

Never reuse the

for long periods.

WARNING:

Brake fluid, if it leaks, will interfere with safe running and

discolor painted surfaces. Check the brake hose and hose joint

for cracks and oil leakage.

2.

Remove the caliper mounting bolts and take off the caliper.

3. Remove the pads.

brake

iiuid

ieft over from servicing and stored

CHASSIS 8-6

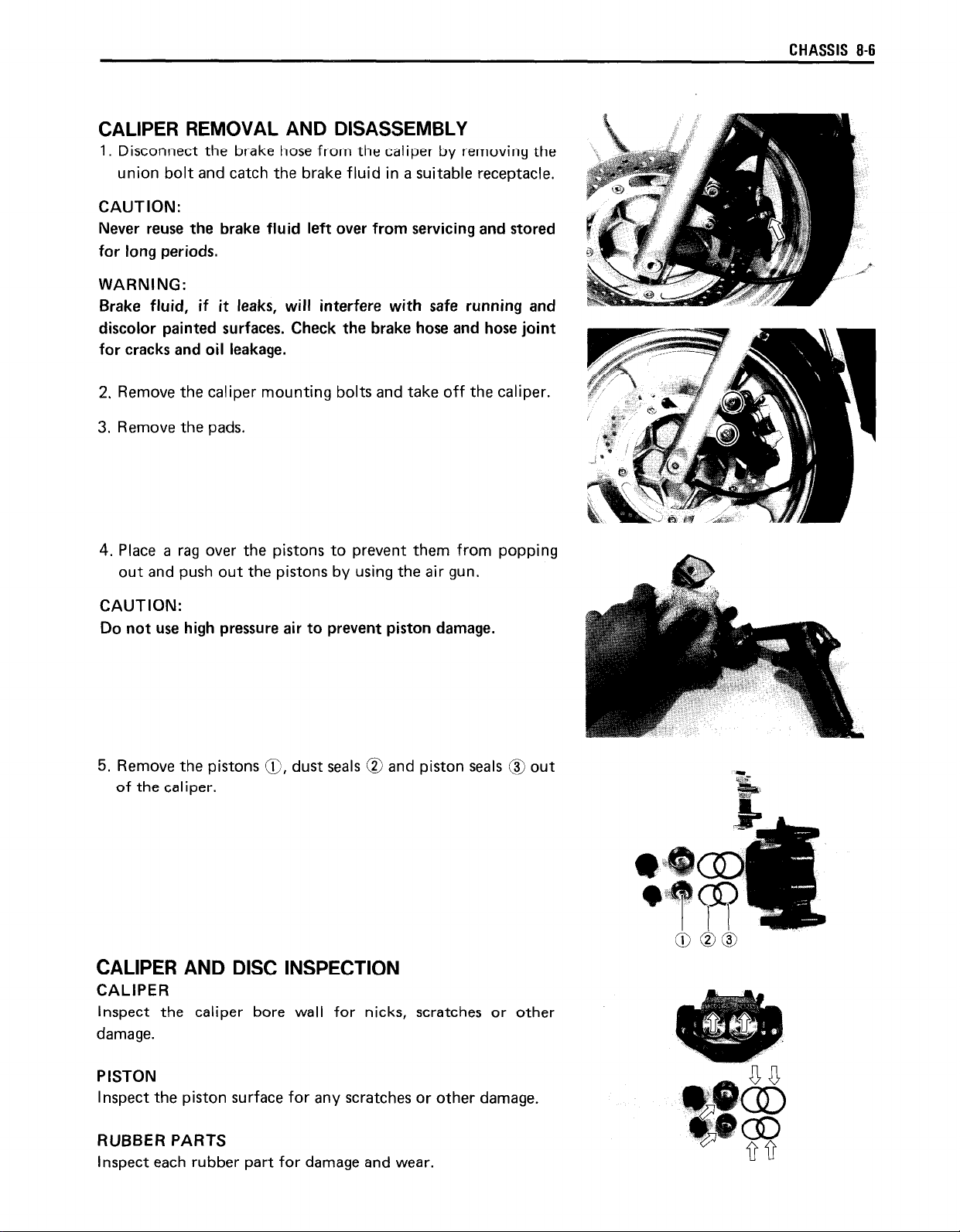

4. Place a rag over the pistons to prevent them from popping

out and push out the pistons by using the air gun.

CAUTION:

Do not use high pressure air to prevent piston damage.

5.

Remove the pistons 0, dust seals @ and piston seals @ out

of the caliper.

CALIPER AND DISC INSPECTION

CALIPER

Inspect the caliper bore wall for nicks, scratches or other

damage.

PISTON

Inspect the piston surface for any scratches or other damage.

8-7 CHASSIS

DISC

Using a micrometer, check the disc for wear, its thickness can

be checked with disc and wheel in place. The service limits for

the thickness of the discs are shown below.

09900-20205 : Micrometer (0 - 25 mm)

Service limit (Front) : 5.0 mm (0.20 in)

:

(Rear)

With the disc mounted on the wheel, check the disc for face

runout with a dial gauge, as shown.

09900-20606 : Dial gauge (l/100 mm)

09900-20701 : Magnetic stand

Service limit : 0.30 mm (0.012 in)

5.5 mm (0.22 in)

--

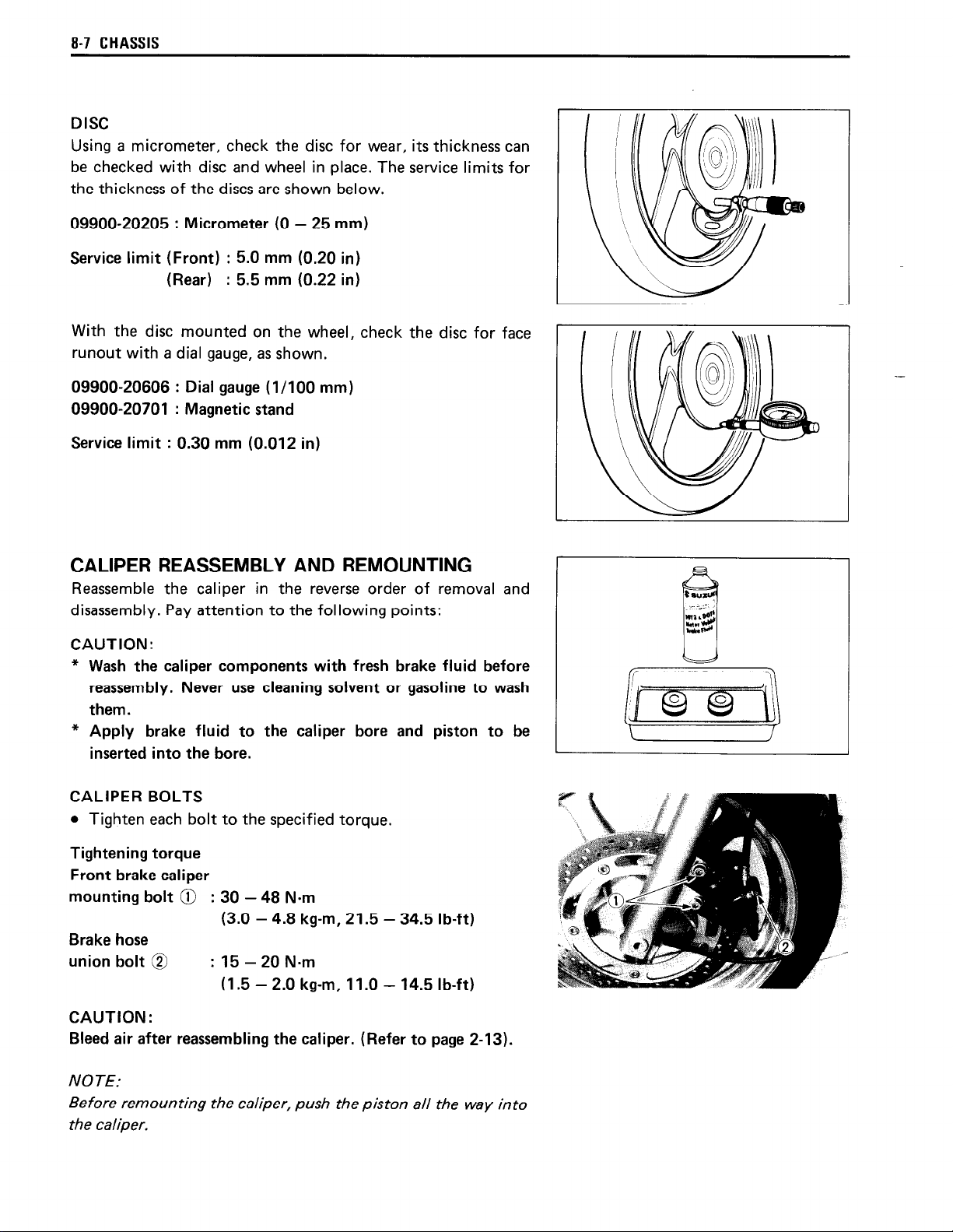

CALIPER REASSEMBLY

Reassemble the caliper in the reverse order of removal and

disassembly. Pay attention to the following points:

CAUTION

*

Wash the caliper components with fresh brake fluid before

reassembly. Never use cleaning solvent or gasoline to wash

them.

* Apply brake fluid to the caliper bore and piston to be

inserted into the bore.

CALIPER BOLTS

l

Tighten each bolt to the specified torque.

Tightening torque

Front brake caliper

mounting bolt @ : 30 - 48 N-m

Brake hose

union bolt @

CAUTION:

Bleed air after reassembling the caliper. (Refer to page 2-13).

:

(3.0 - 4.8 kg-m, 21.5 - 34.5 lb-ft)

:

15 - 20 N.m

(1.5 - 2.0 kg-m, 11.0 - 14.5 lb-ft)

AND REMOUNTING

NOTE:

Before remounting the caliper, push the piston all the way into

the caliper.

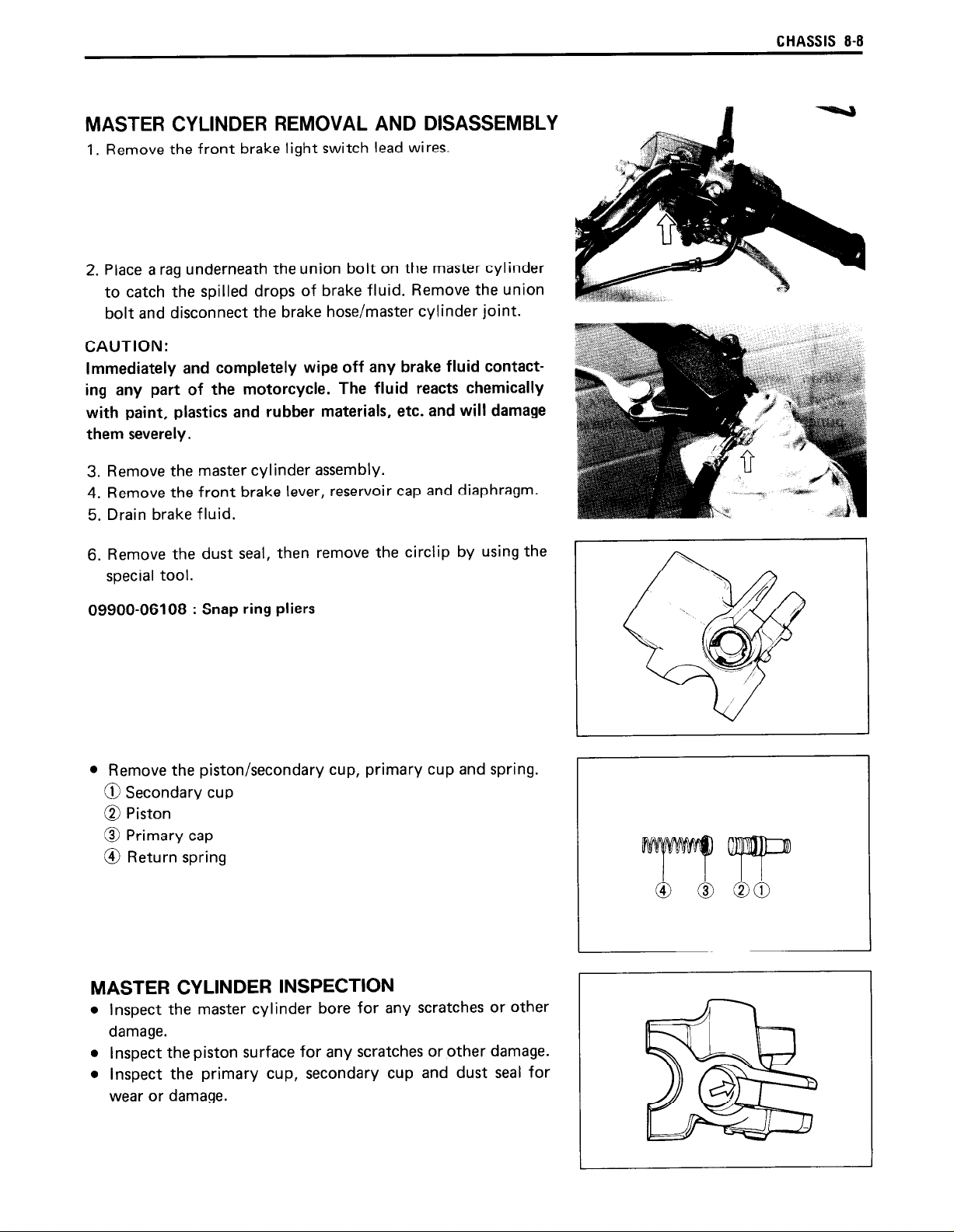

MASTER CYLINDER REMOVAL AND DISASSEMBLY

Remove the

1.

Place

2.

a rag underneath the union bolt on the master cylinder

to catch the spilled drops of brake fluid. Remove the union

bolt and disconnect the brake hose/master cylinder joint.

CAUTION:

Immediately and completely wipe off any brake fluid contacting any part of the motorcycle. The fluid reacts chemically

with paint, plastics and rubber materials, etc. and will damage

them severely.

3. Remove the master cylinder assembly.

4.

Remove the front brake lever, reservoir cap and diaphragm.

5. Drain brake fluid.

front brake light switch lead wires.

CHASSIS 8-8

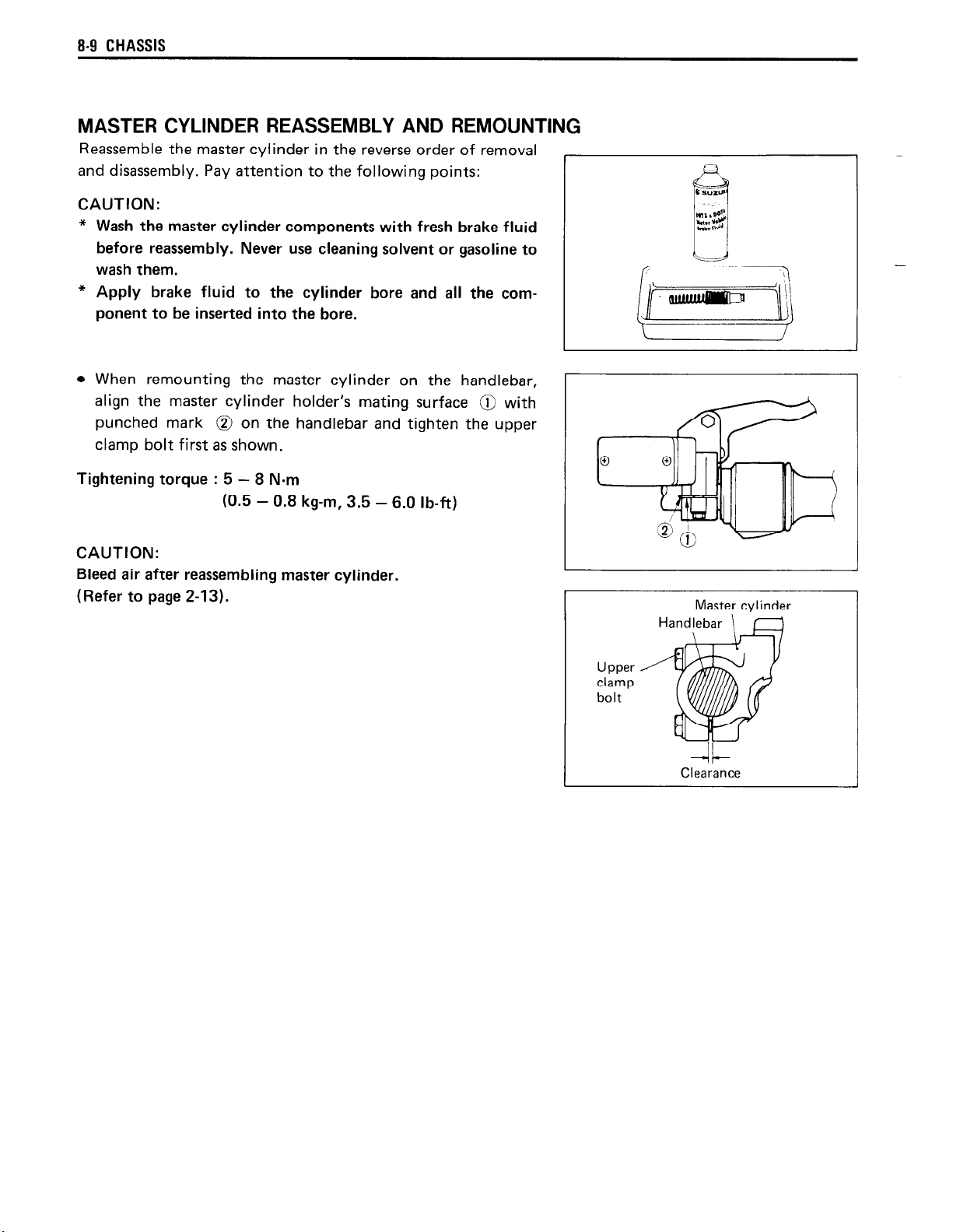

6.

Remove the dust seal, then remove the circlip by using the

special tool.

09900-06108 :

l

Remove the piston/secondary cup, primary cup and spring.

Snap ring pliers

@ Secondary cup

@ Piston

0 Primary cap

@ Return spring

MASTER CYLINDER INSPECTION

l

Inspect the master cylinder bore for any scratches or other

damage.

l

Inspect the piston surface for any scratches or other damage.

l

Inspect the primary cup, secondary cup and dust seal for

wear or damage.

I

8-9 CHASSIS

MASTER CYLINDER REASSEMBLY AND REMOUNTING

Reassemble the master cylinder in the reverse order of removal

and disassembly. Pay attention to the following points:

CAUTION:

Wash the master cylinder components with fresh brake fluid

before reassembly. Never use cleaning solvent or gasoline to

wash them.

Apply brake fluid to the cylinder bore and all the component to be inserted into the bore.

When remounting the master cylinder on the handlebar,

align the master cylinder holder’s mating surface @ with

punched mark @ on the handlebar and tighten the upper

clamp bolt first as shown.

Tightening torque : 5 - 8 N-m

(0.5 - 0.8 kg-m, 3.5 -

6.0

lb-It)

CAUTION:

Bleed air after reassembling master cylinder.

(Refer to page 2-13).

Master cylinder

Upper

clamp

bolt

Clearance

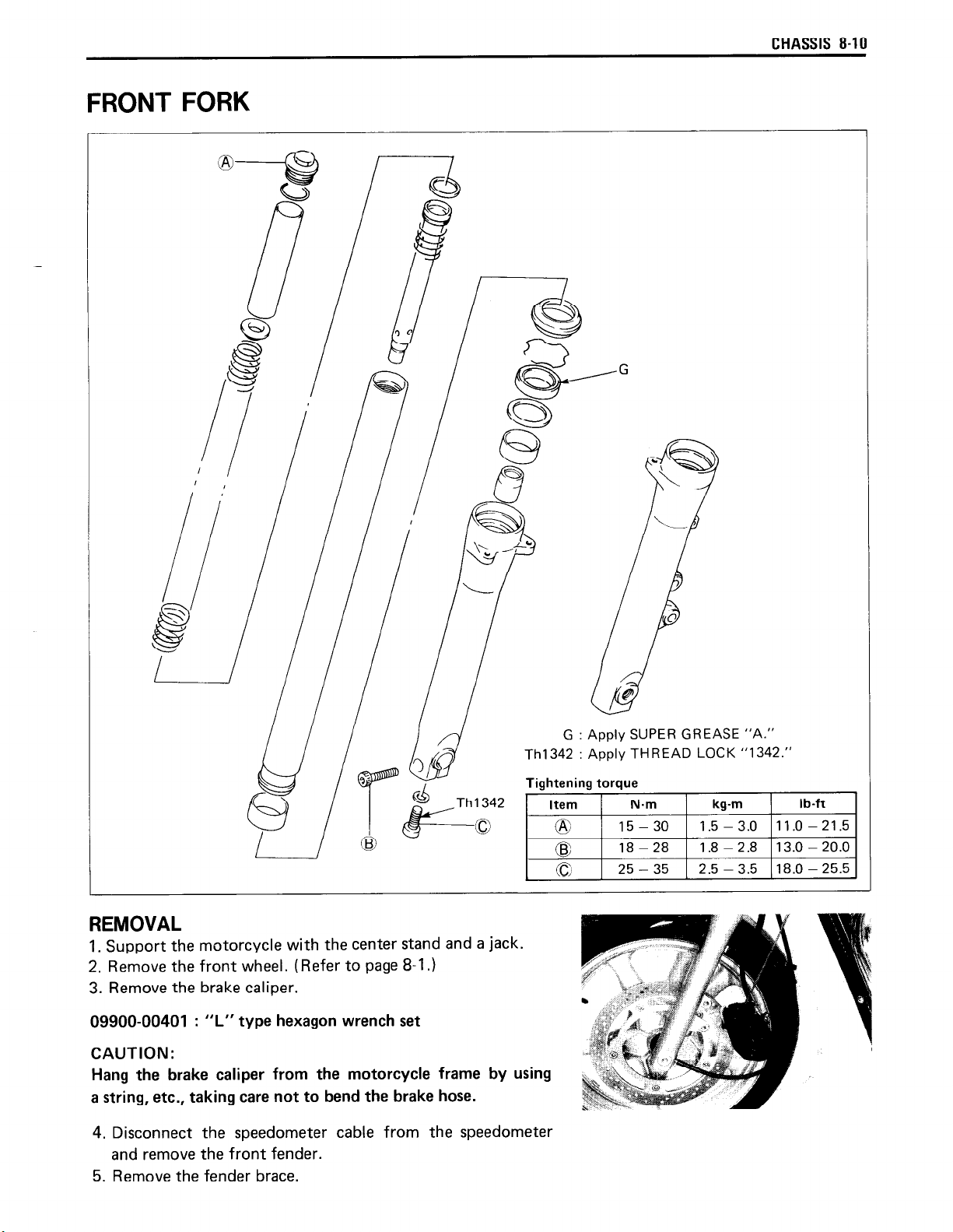

FRONT FORK

CHASSIS 8-l 0

Th1342 : Apply THREAD LOCK “1342.”

Tightening torque

I

,

REMOVAL

1. Support the motorcycle with the center stand and a jack.

2. Remove the front wheel. (Refer to page 8-l.)

3. Remove the brake caliper.

09900-00401

CAUTION:

Hang the brake caliper from the motorcycle frame by using

a string, etc., taking care not to bend the brake hose.

4. Disconnect the speedometer cable from the speedometer

and remove the front fender.

5. Remove the fender brace.

L” type hexagon wrench set

: ”

G : Apply SUPER GREASE “A.”

Item N.m

@I

0

15-30 1.5-3.0 11.0-21.5

18 -28 1.8-2.8 13.0-20.0

25 - 35 2.5 - 3.5 18.0 - 25.5

kg-m

lb-ft

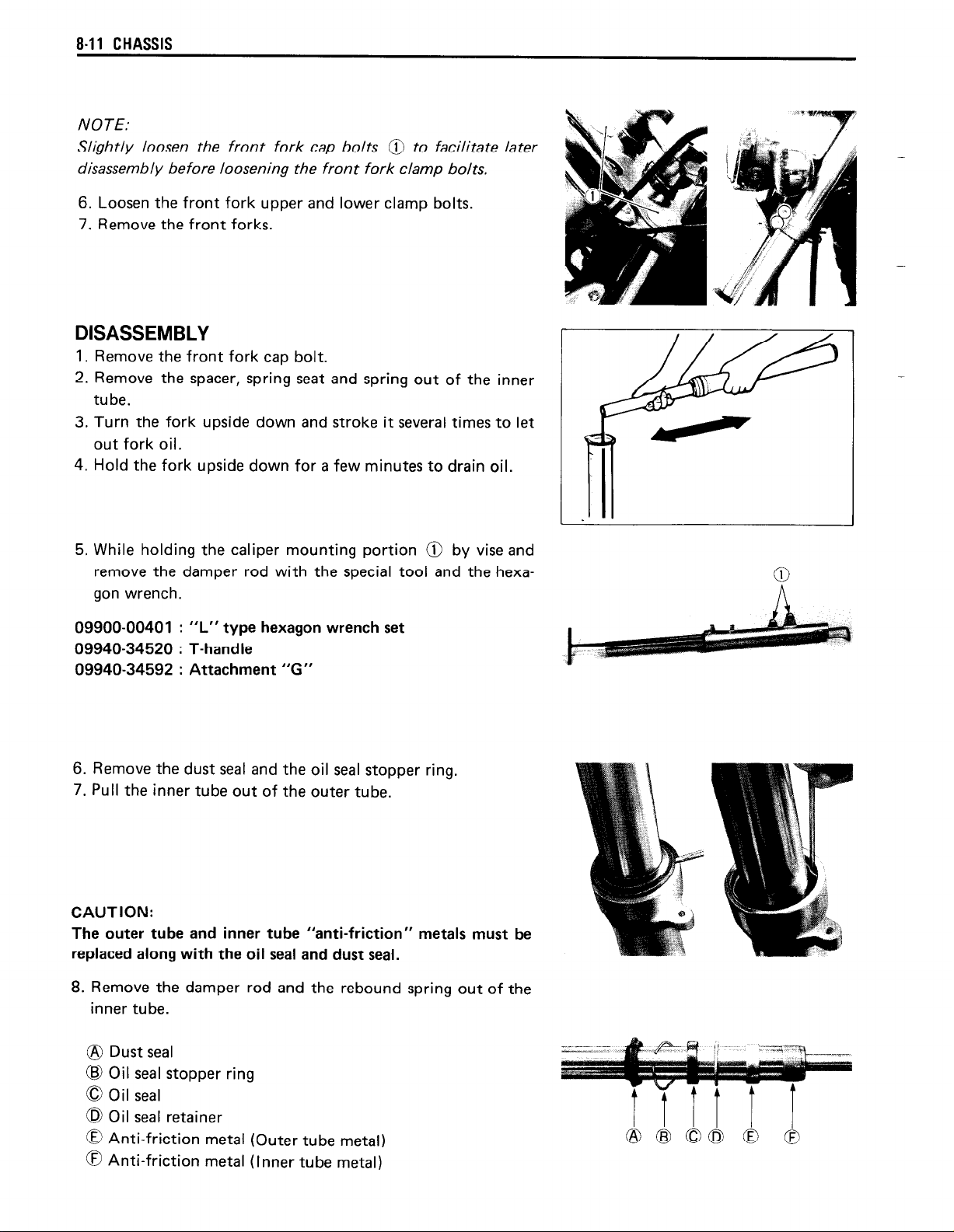

8-11 CHASSIS

NOTE:

Slightly loosen the front fork cap bolts @ to facilitate later

disassembly before loosening the front fork clamp bolts.

6. Loosen the front fork upper and lower clamp bolts.

7. Remove the front forks.

DISASSEMBLY

1. Remove the front fork cap bolt.

2. Remove the spacer, spring seat and spring out of the inner

tube.

3. Turn the fork upside down and stroke it several times to let

out fork oil.

4. Hold the fork upside down for a few minutes to drain oil.

5. While holding the caliper mounting portion @ by vise and

remove the damper rod with the special tool and the hexagon wrench.

09900-0040 1 : “L” type hexagon wrench set

09940-34520 : T-handle

09940-34592 : Attachment “G”

6. Remove the dust seal and the oil seal stopper ring.

7. Pull the inner tube out of the outer tube.

CAUTION:

The outer tube and inner tube “anti-friction” metals must be

replaced along with the oil seal and dust seal.

8. Remove the damper rod and the rebound spring out of the

inner tube.

@ Dust seal

@I Oil seal stopper ring

0 Oil seal

0 Oil seal retainer

@ Anti-friction metal (Outer tube metal)

6? Anti-friction metal (Inner tube metal)

INSPECTION

DAMPER ROD RING

Inspect the damper rod ring for wear or damage.

INNER AND OUTER TUBE

Inspect the inner tube sliding surface and outer tube sliding

surface for any scuffing.

CHASSIS 8-12

FORK SPRING

Measure the fork spring free length. If it is shorter than the

service limit, replace it with a new one.

Service limit

For E-01,03,28,33 models

For the other models

:

353 mm (13.9 in)

348 mm (13.7 in)

REASSEMBLY AND REMOUNTING

Reassemble and remount the front fork in the reverse order of

removal and disassembly. Pay attention to the following

points:

INNER TUBE METAL

l

Hold the inner tube vertically and clean the metal groove

and install the metal by hand as shown.

CAUTION:

Use special care to prevent damage to the “Teflon” coated

surface of the “anti-friction” metal when mounting it.

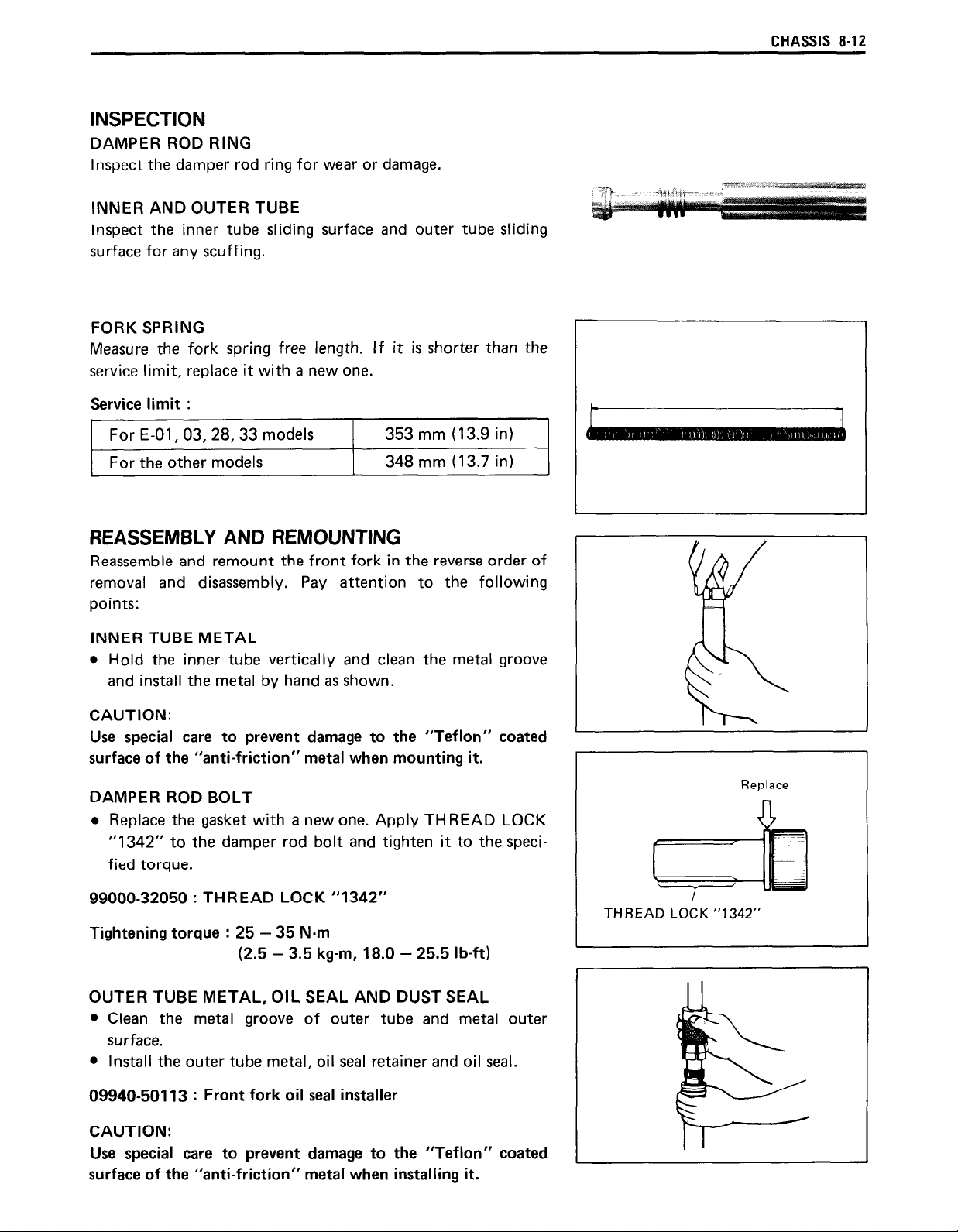

DAMPER ROD BOLT

l

Replace the gasket with a new one. Apply THREAD LOCK

“1342” to the damper rod bolt and tighten it to the speci-

fied torque.

1

Replace

99000-32050 : THREAD LOCK “1342”

Tightening torque : 25 - 35 N-m

(2.5 - 3.5 kg-m, 18.0 - 25.5 lb-ft)

OUTER TUBE METAL, OIL SEAL AND DUST SEAL

l

Clean the metal groove of outer tube and metal outer

surface.

l

Install the outer tube metal, oil seal retainer and oil seal.

09949-59113

CAUTION:

Use special care to prevent damage to the “Teflon” coated

surface of the “anti-friction” metal when installing it.

:

Front fork oil seal installer

THREAD LOCK “1342”

Loading...

Loading...