Suzuki VX800 1990-1993 Service Manual 03 Engine

CONTENTS

COMPRESSION CHECK

ENGINE COMPONENTS REMOVABLE WITH

THE ENGINE IN PLACE

ENGINE REMOVAL AND REINSTALLATION

ENGINE REMOVAL

ENGINE REINSTA L LA TION

ENGINE DISASSEMBL Y

ENGINE COMPONENTS INSPECTION A ND SERVICING

CYLINDER HEAD COVER

CYLINDER HEAD

CYLINDER

PISTON

PISTON RING

PISTON PIN AND PIN BORE

CONROD

..............................................................

................................................................. .3_31

..............................................................

.................................................. .3_ 1

.................................................. .3_ 2

....................... .3_ 3

.................................................. .3_ 3

...................................... .3_ 4

..................................................

.........................................

.....................................................

........................................................

....................................

.3_ 5

...... 3-20

.3_20

.3_24

.3_30

.3_32

3-33

.3_34

CRANKSHAFT

CLUTCH

GENERATOR

STARTER CLUTCH

OIL PUMP

TRANSMISSION

ENGINE REASSEMBLY

CAMSHAFT TIMING

VALVE ROCKER ARM AND SHAFT

..................................................................

........................................................

.......................................................... .3_41

..................................................

..............................................................

.....................................................

..................................................

................................................

.3_37

3-39

3-4 1

.3_42

.3_42

.3_44

3-57

.......................... .3_50

3-I ENGINE

COMPRESSION CHECK

The compression of a cylinder is good indicator of its internal condition. The decision to overhaul the

cylinders is often based on the results of a compression test. Periodic maintenance records kept at your

dealership should include compression readings for each maintenance service.

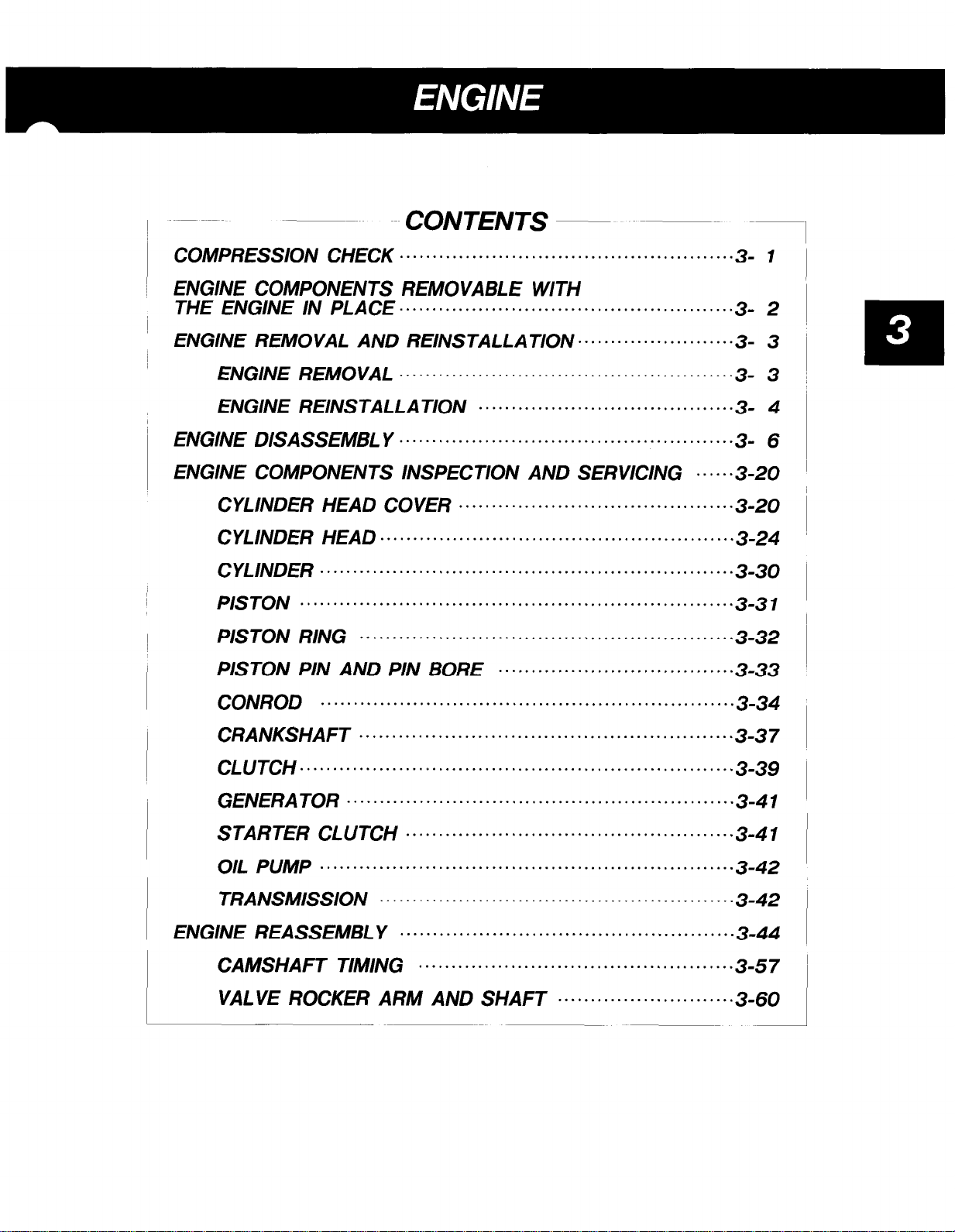

COMPRESSION

I

Low compression pressure can indicate any of the following conditions:

Overhaul the engine in the following cases:

*

* Difference in compression pressure between two cylinders is more than 200 kPa (2 kg/cm2, 28 psi).

*

Standard

1300 - 1600 kPa

13 - 16 kg/cm’

184 - 227 psi

Excessively worn cylinder wall

Worn-down piston or piston rings

Piston rings stuck in the grooves

Poor seating of valves

Ruptured or otherwise defective cylinder head gasket

Valve clearance out of adjustment

Starter motor cranks too slowly

Compression pressure in one of the cylinders is less than 1100 kPa (I 1 kg/cm’, 156 psi).

All

compression pressure are below 1300 kPa (13 kg/cm’,

1100 kPa (11 kg/cm2, 156 psi).

Limit

1100 kPa 200 kPa

(Difference in cylinders

184 psi) even when they measure more than

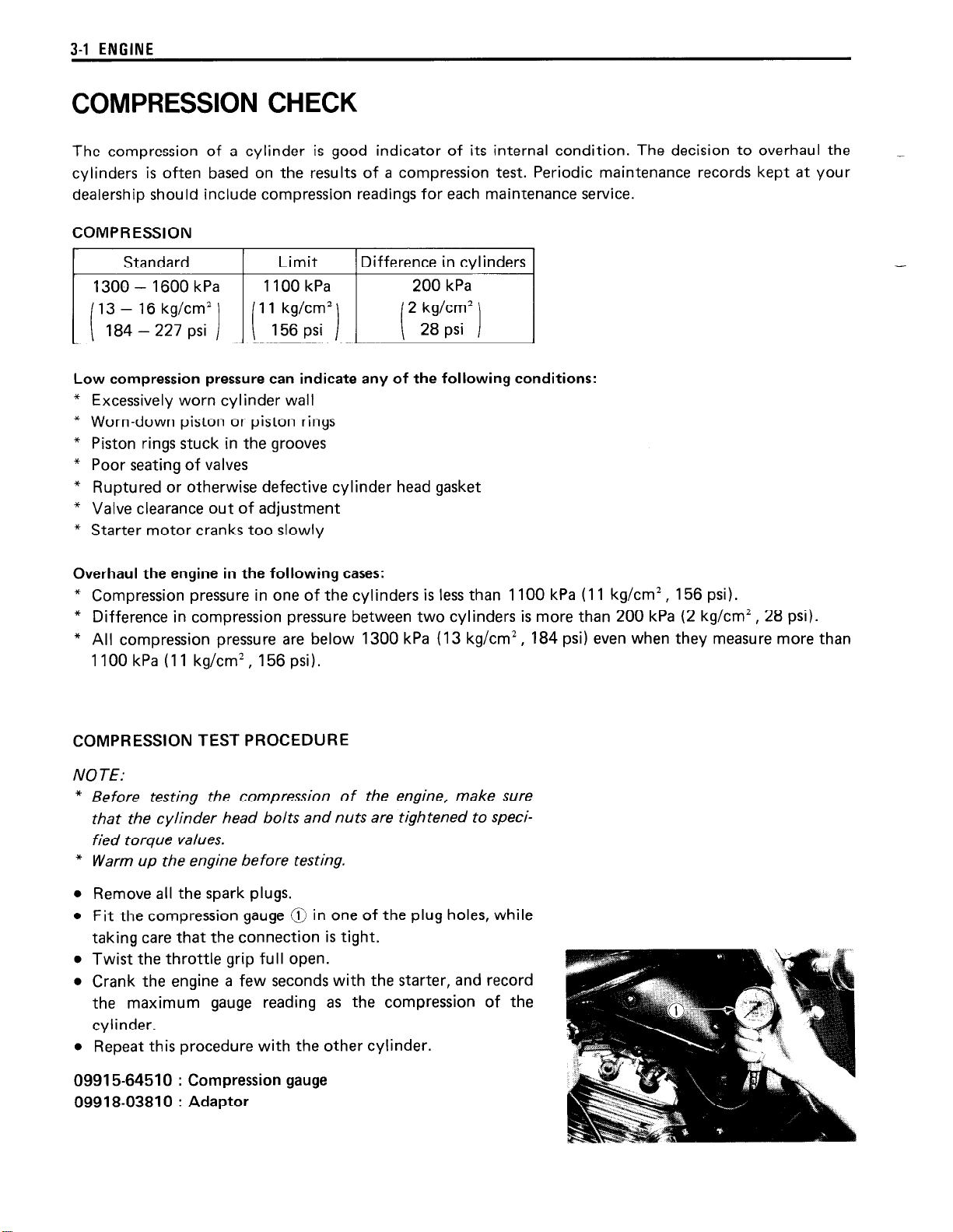

COMPRESSION TEST PROCEDURE

NOTE:

Before testing the compression of the engine, make sure

that the cylinder head bolts and nuts are tightened to speci-

fied torque values.

Warm up the engine before testing.

Remove all the spark plugs.

Fit the compression gauge 0 in one of the plug holes, while

taking care that the connection is tight.

Twist the throttle grip full open.

Crank the engine a few seconds with

the maximum gauge reading as th

cylinder.

Repeat this procedure with the other

09915-64510 : Compression gauge

09918-03810 : Adaptor

the starter,

re compress ion of the

cylinder.

and record

B

!z

2

m

s

ii

d

v)

z

0

$

?

z

4

m

z

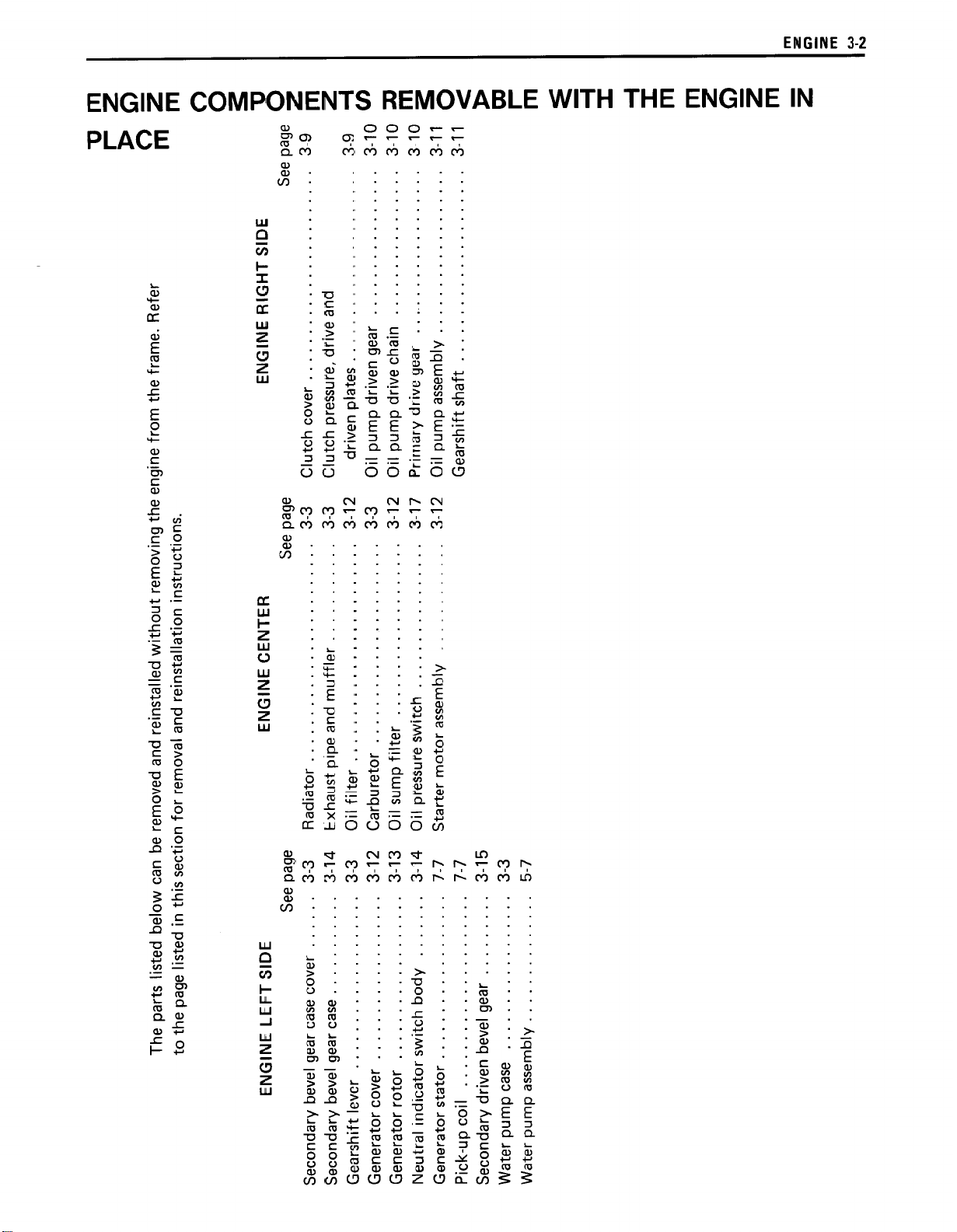

engine from the frame. Refer

ENGINE RIGHT SIDE

3-9

See page

Clutch cover . . . . . . . . . . . . . . . . . . . . . . .

3-3

See page

Clutch pressure, drive and

3-3

driven plates . . . . . . . . . . . . . . . . . . . . . 3-9

3-12

3-10

Oil pump driven gear . . . . . . . . . . . . . . . .

3-3

Oil pump drive chain . . . . . . . . . . . . . . . . 3-10 3

3-12

3-10

. . . . . . . . . . . . . . . . . .

Primary drive gear

3-l 7

3-11

Oil pump assembly . . . . . . . . . . . . . . . . . .

3-l 2

3-11 <

Gearshift shaft . . . . . , . . . . . . . . . . . . . . .

The parts listed below can be removed and reinstalled without removing the

to the page listed in this section for removal and reinstallation instructions.

ENGINE CENTER

........................

Radiator

See page

...... 3-3

...........

......................

........................

Exhaust pipe and muffler

Carburetor

Oil filter

3-l 2

3-14

3-3

............

................

...................

Oil sump filter

Oil pressure switch

Starter motor assembly

7-7

3-l 3

....... 3-14

7-7

......... 3-15

3-3

5-7

ENGINE LEFT SIDE

Secondary bevel gear case cover

Secondary bevel gear case ...........

Generator rotor ..................

Gearshift lever ...................

Generator cover ..................

Neutral indicator switch body

Generator stator ..................

Pick-up coil .....................

Secondary driven bevel gear

Water pump assembly ..............

Water pump case .................

3-3 ENGINE

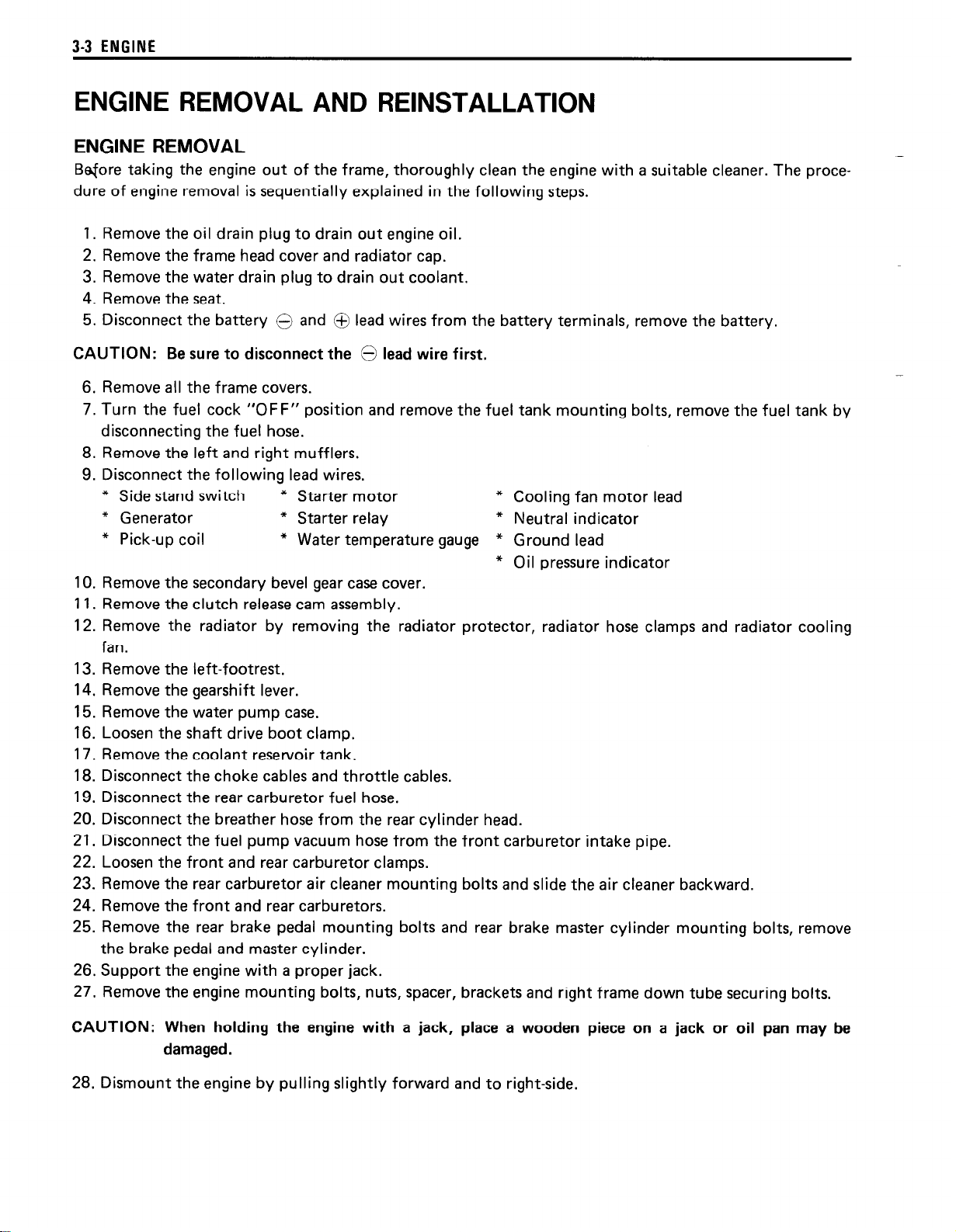

ENGINE REMOVAL AND REINSTALLATION

ENGINE REMOVAL

Bafore taking the engine out of the frame, thoroughly clean the engine with a suitable cleaner. The proce-

dure of engine removal is sequentially explained in the following steps.

1. Remove the oil drain plug to drain out engine oil.

2. Remove the frame head cover and radiator cap.

3. Remove the water drain plug to drain out coolant.

4. Remove the seat.

5. Disconnect the battery 0 and 0 lead wires from the battery terminals, remove the battery.

CAUTION: Be

6. Remove all the frame covers.

7. Turn the fuel cock “OFF” position and remove the fuel tank mounting bolts, remove the fuel tank by

disconnecting the fuel hose.

8. Remove the left and right mufflers.

9. Disconnect the following lead wires.

* Side stand switch

* Generator

* Pick-up coil

10. Remove the secondary bevel gear case cover.

11. Remove the clutch release cam assembly.

12. Remove the radiator by removing the radiator protector, radiator hose clamps and radiator cooling

fan.

13. Remove the left-footrest.

14. Remove the gearshift lever.

15. Remove the water pump case.

16. Loosen the shaft drive boot clamp.

17. Remove the coolant reservoir tank.

18. Disconnect the choke cables and throttle cables.

19. Disconnect the rear carburetor fuel hose.

20. Disconnect the breather hose from the rear cylinder head.

21. Disconnect the fuel pump vacuum hose from the front carburetor intake pipe.

22. Loosen the front and rear carburetor clamps.

23. Remove the rear carburetor air cleaner mounting bolts and slide the air cleaner backward.

24. Remove the front and rear carburetors.

25. Remove the rear brake pedal mounting bolts and rear brake master cylinder mounting bolts, remove

the brake pedal and master cylinder.

26. Support the engine with a proper jack.

27.

Remove the engine mounting bolts, nuts, spacer, brackets and right frame down tube securing bolts.

sure to disconnect the @ lead wire first.

* Starter motor

* Starter relay

* Water temperature gauge * Ground lead

* Cooling fan motor lead

* Neutral indicator

* Oil pressure indicator

_

-

CAUTION: When holding the engine with a jack, place a wooden piece on a jack or oil pan may be

damaged.

28. Dismount the engine by pulling slightly forward and to right-side.

ENGINE 3-4

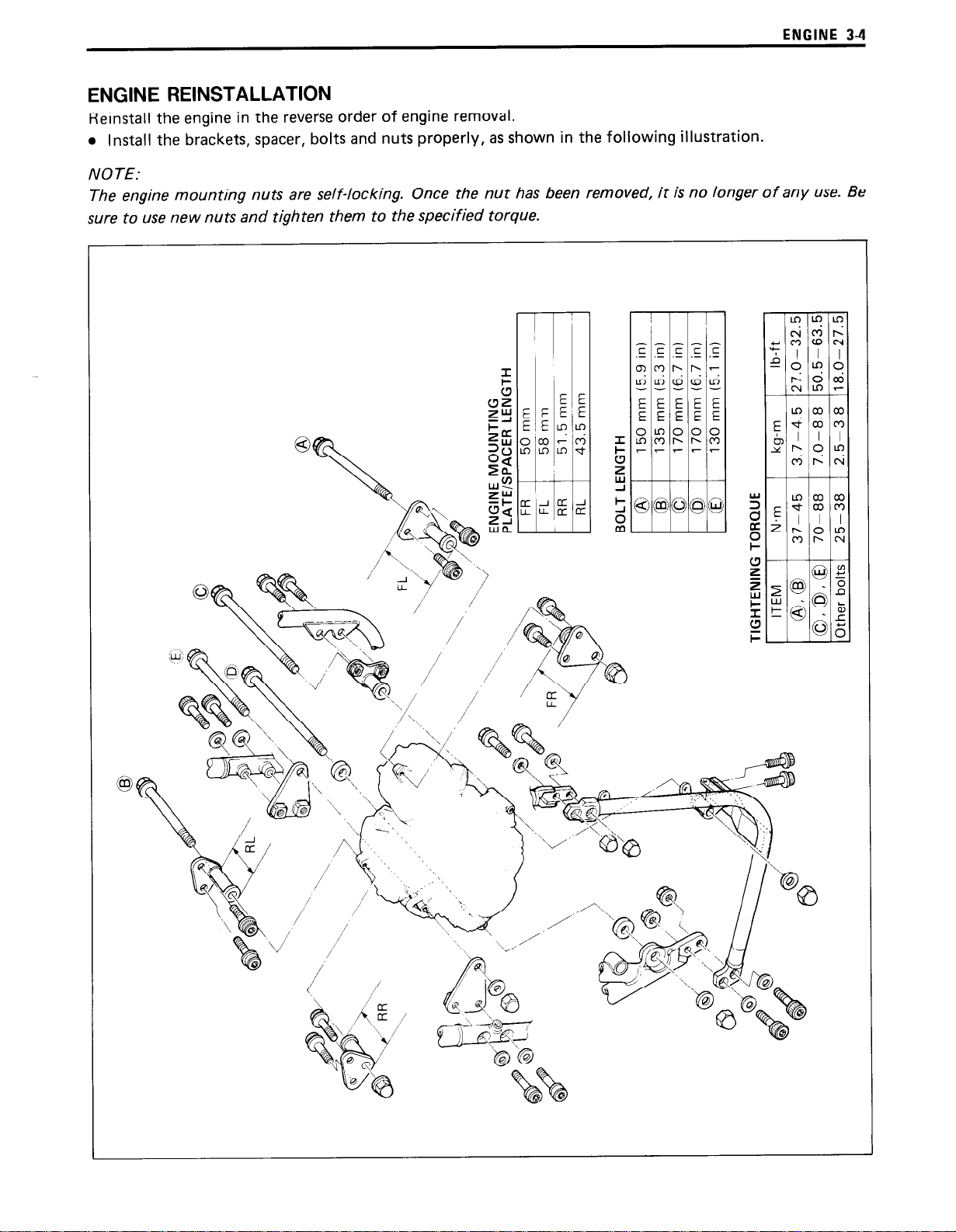

ENGINE REINSTALLATION

Reinstall the engine in the reverse order of engine removal.

l

Install the brackets, spacer, bolts and nuts properly, as shown in the following illustration.

NOTE:

The engine mounting nuts are self-locking. Once the nut has been removed, it is no longer of any use. Be

sure to use new nuts and tighten them to the specified torque.

1

3-5 ENGINE

l

After remounting the engine, route wiring harness, cables

and hoses properly by referring to the sections, for wire

routing, cable routing and hose routing. (See pages 9-12

through 23.)

l

Adjust the following items to the specification.

*

Filling coolant

*

Clutch cable play

*

Throttle cable play . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

*

Idling adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

*

Balancing carburetors

*

Rear brake pedal height

0

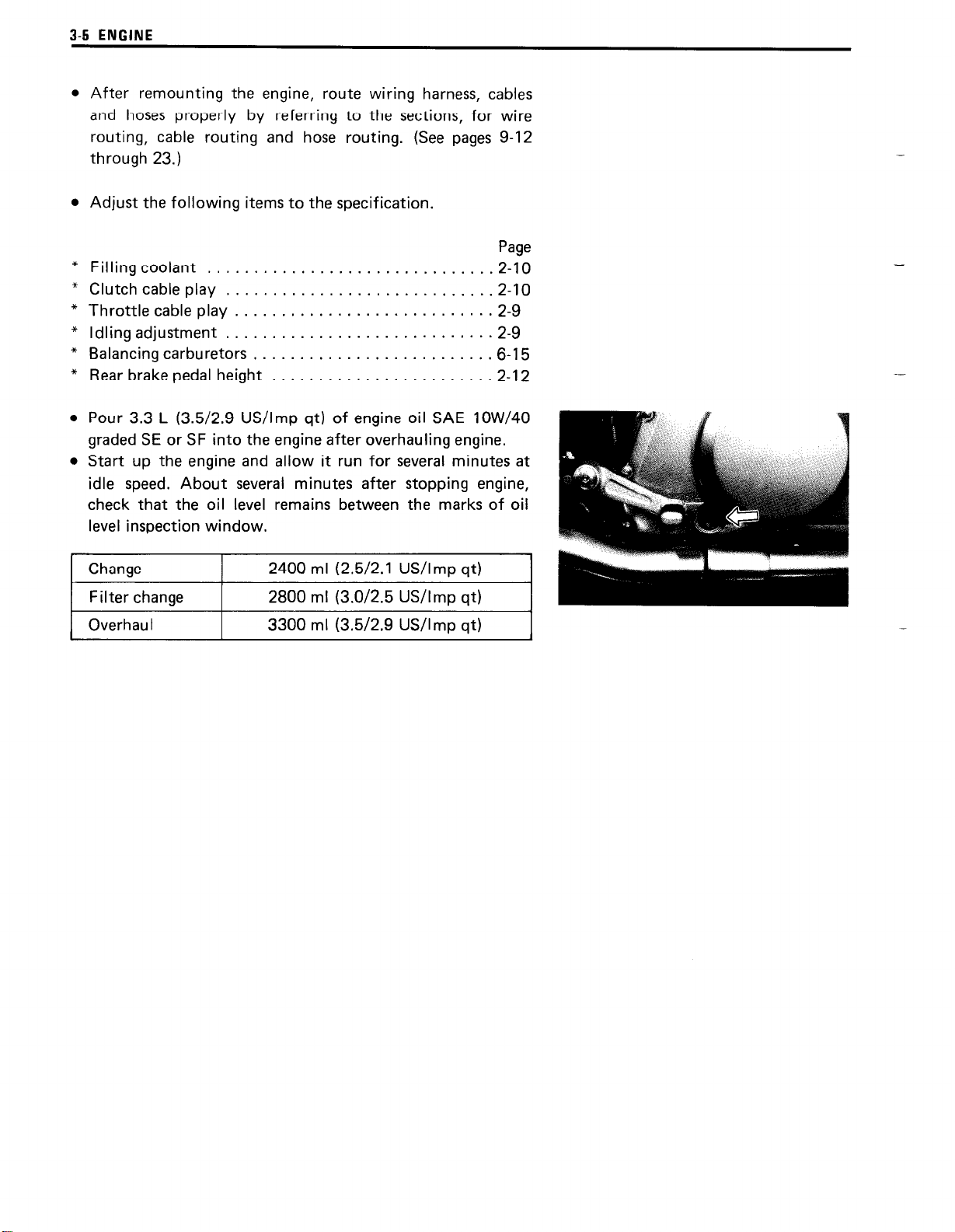

Pour 3.3 L (3.5/2.9 US/Imp qt) of engine oil SAE lOW/40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

. . . . . , . . . . . . . . . . . . . . . . . . . . . . .2-10

, . . . . . . . . . . . . . . . . . . . . . . . . .6-15

. . . . . . . . . . . . . . . . . . . . . . . .2-l

graded SE or SF into the engine after overhauling engine.

l

Start up the engine and allow it run for several minutes at

idle speed. About several minutes after stopping engine,

check that the oil level remains between the marks of oil

level inspection window.

Change

Filter change

Overhau I

I

I

2400 ml (2.5/2.1 US/Imp qt)

2800 ml (3.0/2.5 US/Imp qt)

3300 ml (3.V2.9 US/Imp qt)

Page

2

-

-

1

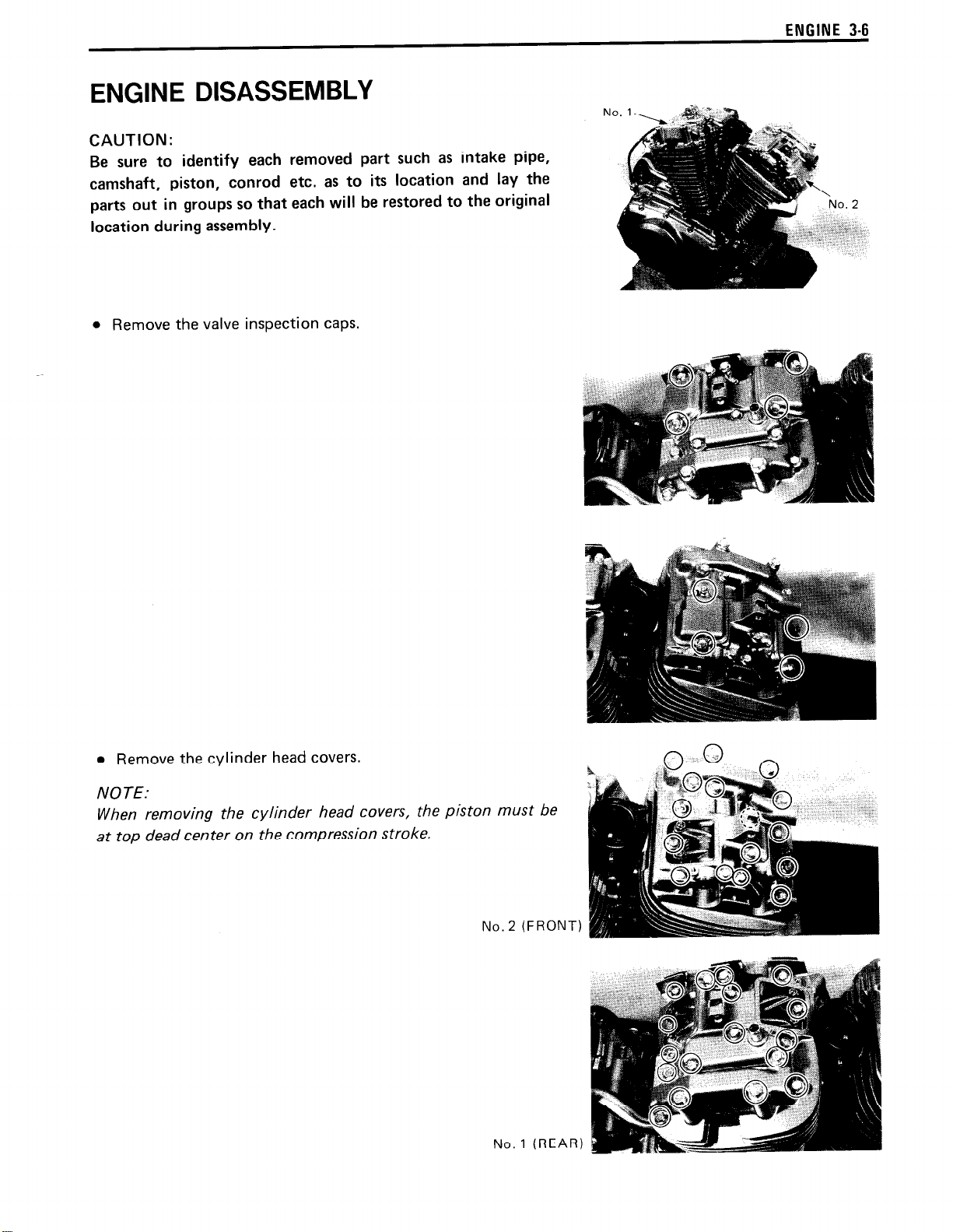

ENGINE DISASSEMBLY

CAUTION:

Be sure to identify each removed part such as intake pipe,

camshaft, piston, conrod etc. as to its location and lay the

parts out in groups so that each will be restored to the original

location during assembly.

l

Remove the valve

inspection caps.

ENGINE 3-6

l

Remove the cylinder head covers.

NOTE:

When removing the cylinder head covers, the piston must be

at top dead center on the compression stroke.

No. 2 (FRONT)

No. 1 (REAR)

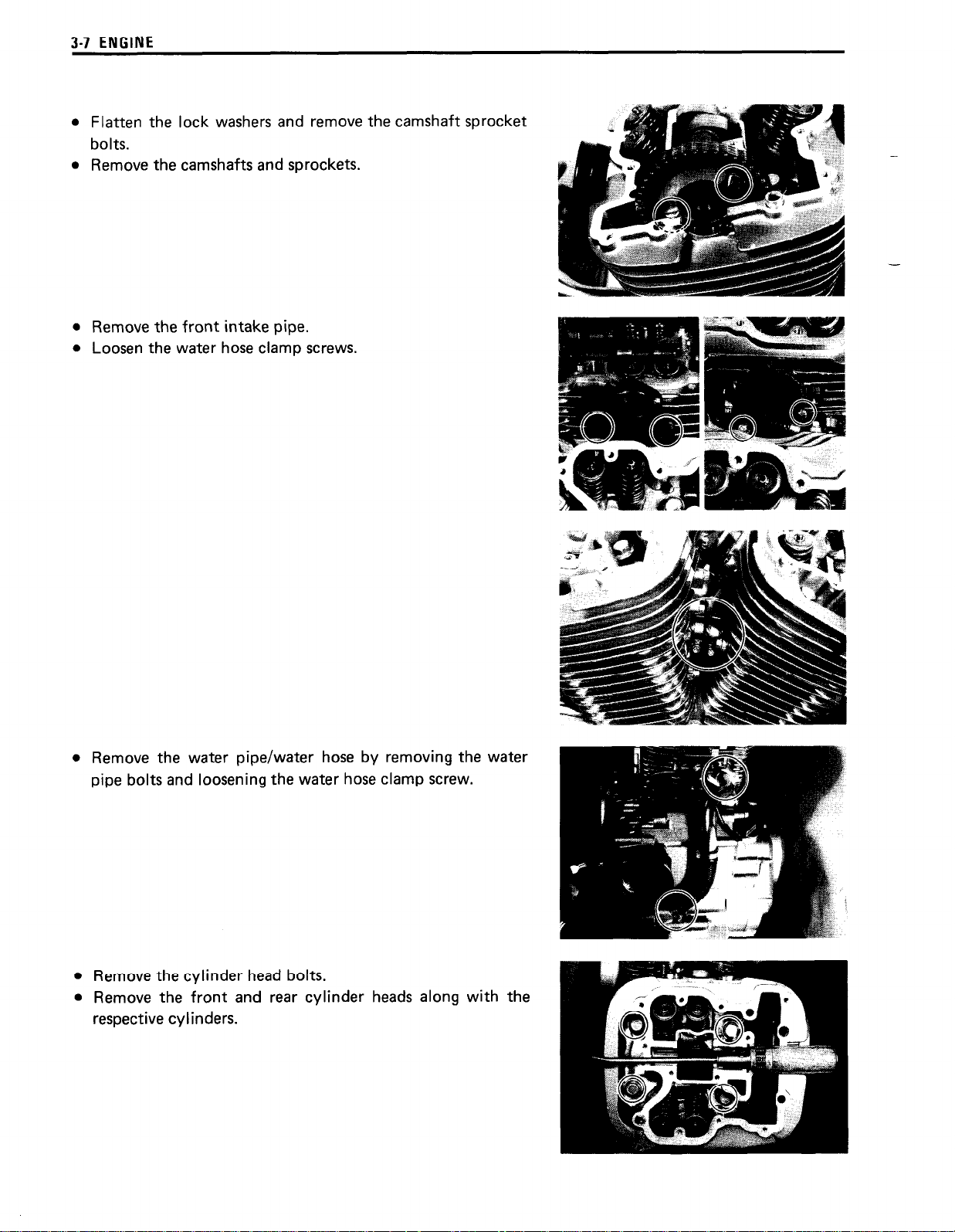

l

Flatten the lock washers and remove the camshaft sprocket

bolts.

l

Remove the camshafts and sprockets.

l

Remove the front intake pipe.

l

Loosen the water hose clamp screws.

l

Remove the water pipe/water hose by removing the water

pipe bolts and loosening the water hose clamp screw.

l

Remove the cylinder head bolts.

l

Remove the front and rear cylinder heads along with the

respective cylinders.

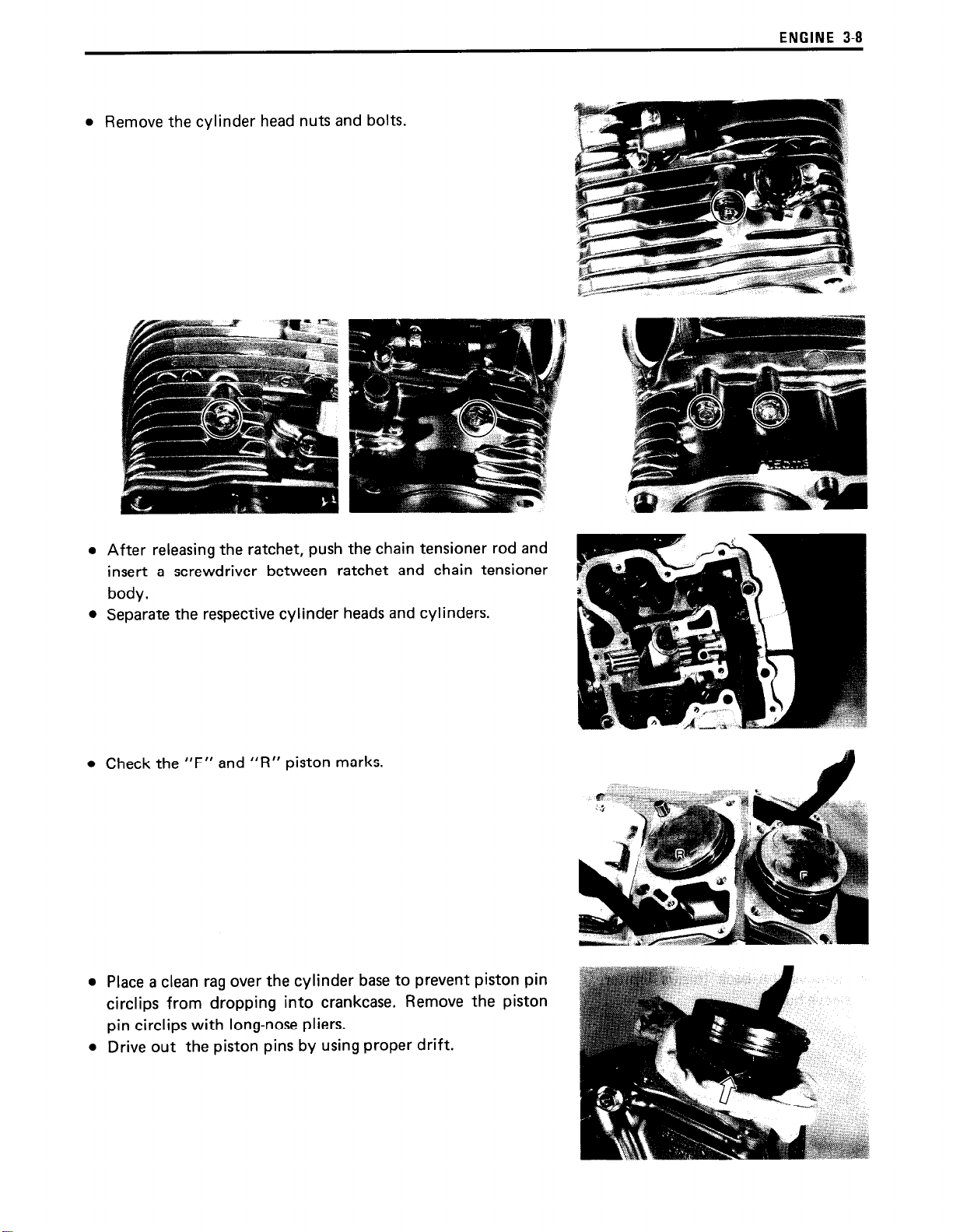

Remove the cylinder head nuts and bolts.

ENGINE 3-8

After releasing the ratchet, push the chain tensioner rod and

insert a screwdriver between ratchet and chain tensioner

body.

Separate the respective cylinder heads and cylinders.

l

Check the “F” and “R” piston marks.

Place a clean rag over the cylinder base to prevent piston pin

circlips from dropping into crankcase. Remove the piston

pin circlips with long-nose pliers.

Drive out the piston pins by using proper drift.

3-9 ENGINE

l

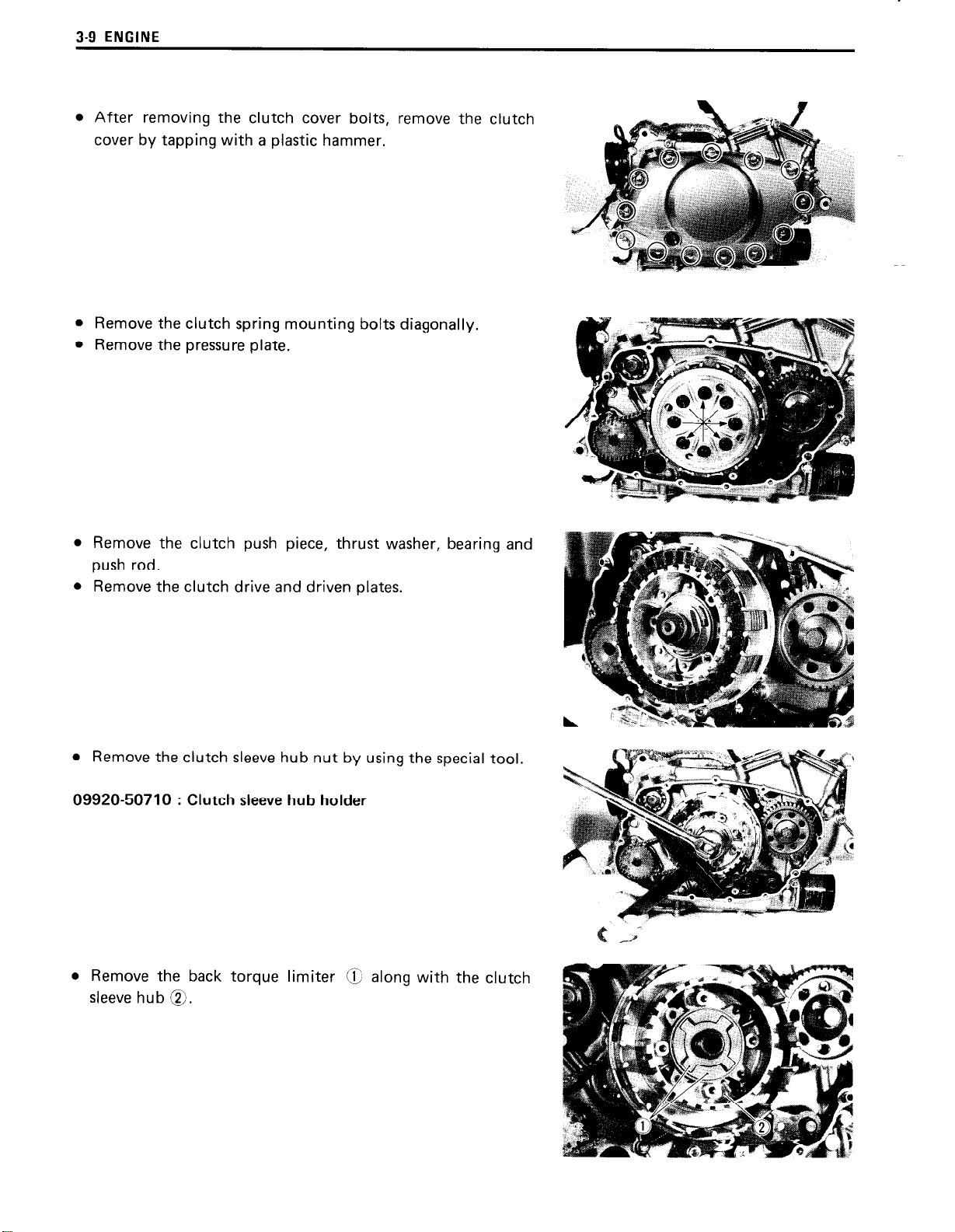

After removing the clutch cover bolts, remove the clutch

cover by tapping with a plastic hammer.

l

Remove the clutch spring mounting bolts diagonally.

l

Remove the pressure plate.

l

Remove the clutch push piece, thrust washer, bearing and

push rod.

l

Remove the clutch drive and driven plates.

l

Remove the clutch sleeve hub nut by using the special tool.

09920-50710 :

l

Remove the back torque limiter (c along with the clutch

Clutch sleeve hub holder

sleeve hub 0.

l

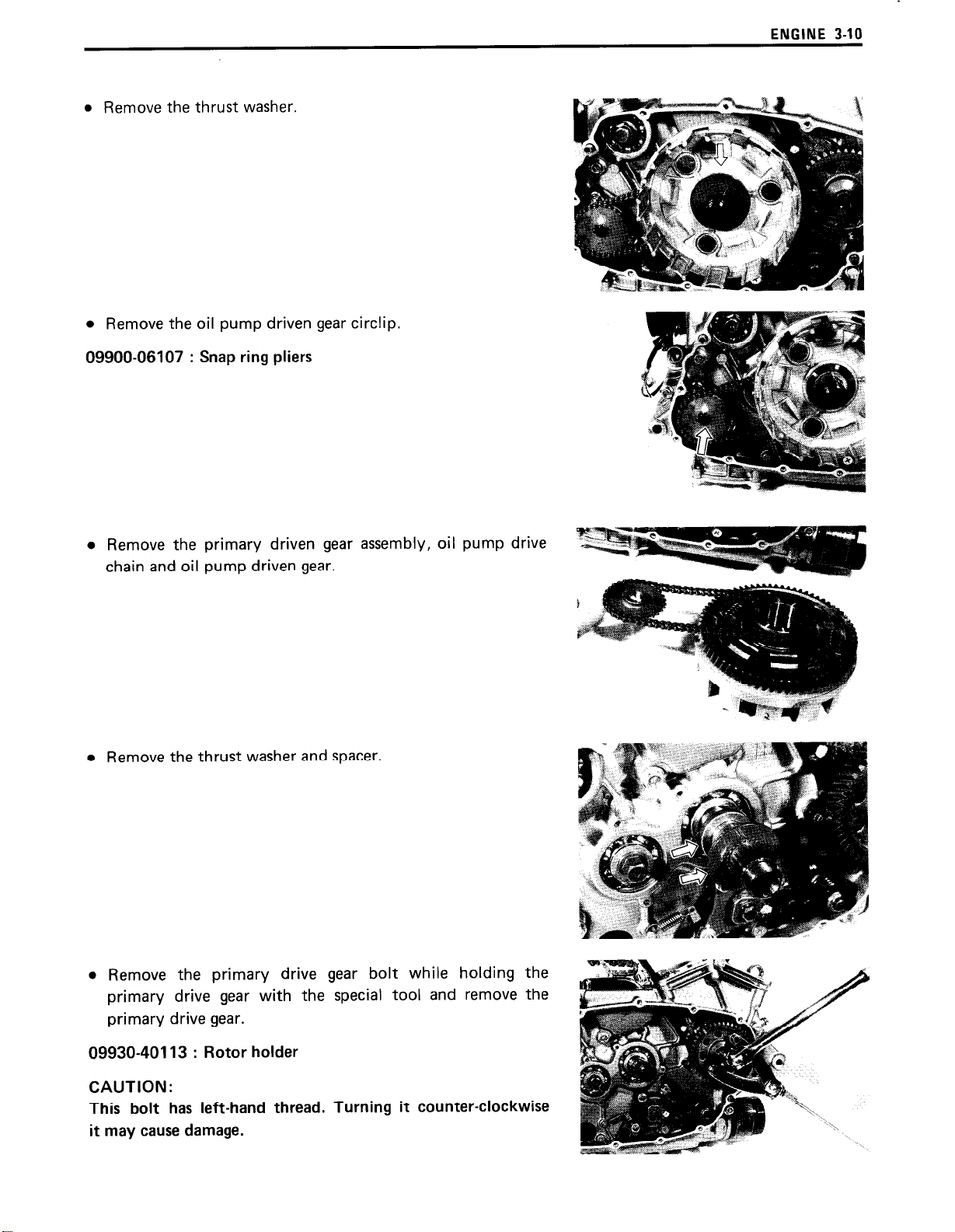

Remove the thrust washer.

l

Remove the oil pump driven gear circlip.

09900-06107 : Snap ring pliers

ENGINE 3-10

l

Remove the primary driven gear assembly, oil pump drive

chain and oil pump driven gear.

l

Remove the thrust washer and spacer.

l

Remove the primary drive gear bolt while holding the

primary drive gear with the special tool and remove the

primary drive gear.

09930-40113

CAUTION

:

Rotor holder

:

This bolt has left-hand thread. Turning it counter-clockwise

it may cause damage.

l

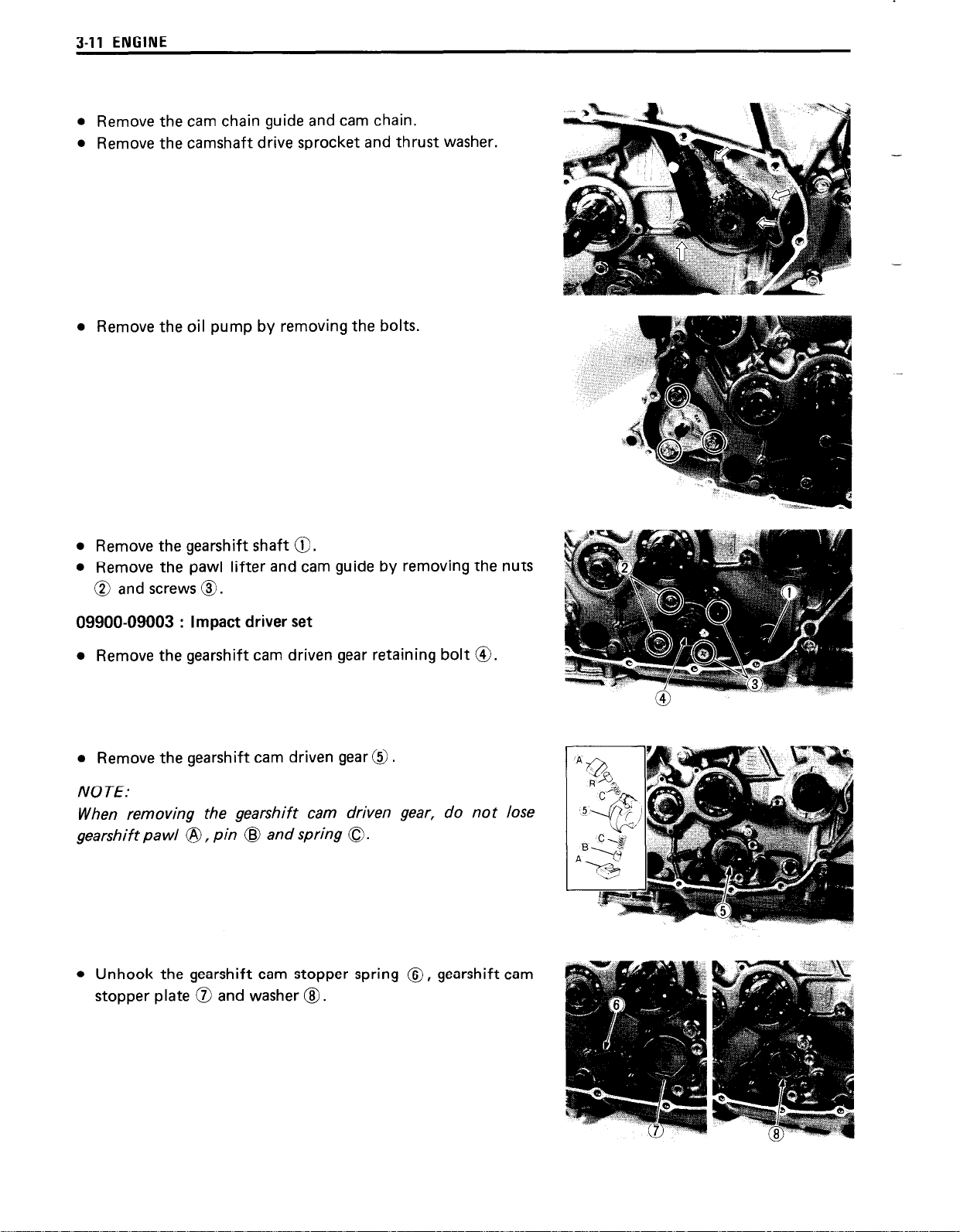

Remove the cam chain guide and cam chain.

l

Remove the camshaft drive sprocket and thrust washer.

l

Remove the oil pump by removing the bolts.

l

Remove the gearshift shaft 0.

l

Remove the paw1 lifter and cam guide by removing the nuts

@ and screws 0.

-

-

09900-09003

l

Remove the gearshift cam driven gear retaining bolt @.

l

Remove the gearshift cam driven gear 0.

:

Impact driver set

NOTE:

When removing the gearshift cam driven gear, do not lose

gearshift pawl

l

Unhook the gearshift cam stopper spring 0, gearshift cam

@ ,

pin @ and spring 0.

stopper plate @ and washer 8.

l

Remove the oil sump filter cap and oil sump filter.

l

Remove the oil filter by using the special tool.

09915-40611 : Oil filter wrench

ENGINE 3-12

l

Remove the starter motor cover.

l

Remove the starter motor.

l

Remove the generator cover.

3-13 ENGINE

l

Remove the starter driven gear and its idle gear.

l

Loosen the rotor bolt.

NOTE:

When removing the rotor, do not remove the rotor bolt after

loosening the bolt. The rotor bolt is used in conjunction with

the rotor remover.

l

Remove the rotor by using the special tool.

(For U.S.A. models)

09930-30720

:

Rotor remover

(For the other models)

09930-34970

l

Remove the key (iJ.

l

Remove the starter driven gear.

l

Remove the cam chain guide and cam chain.

:

Rotor remover

l

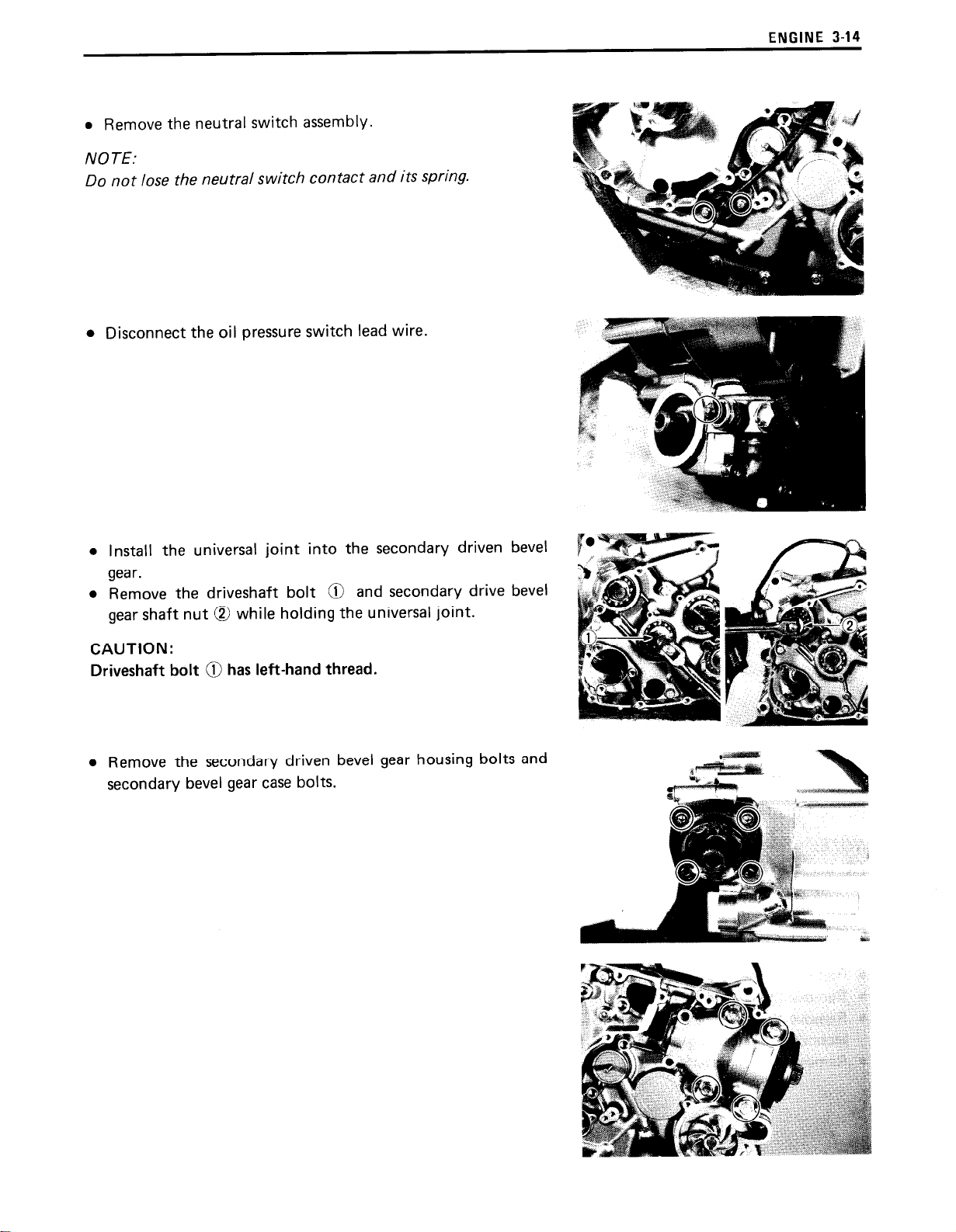

Remove the neutral switch assembly.

NOTE:

Do not lose the neutral switch contact and its spring.

l

Disconnect the oil pressure switch lead wire.

ENGINE 3-14

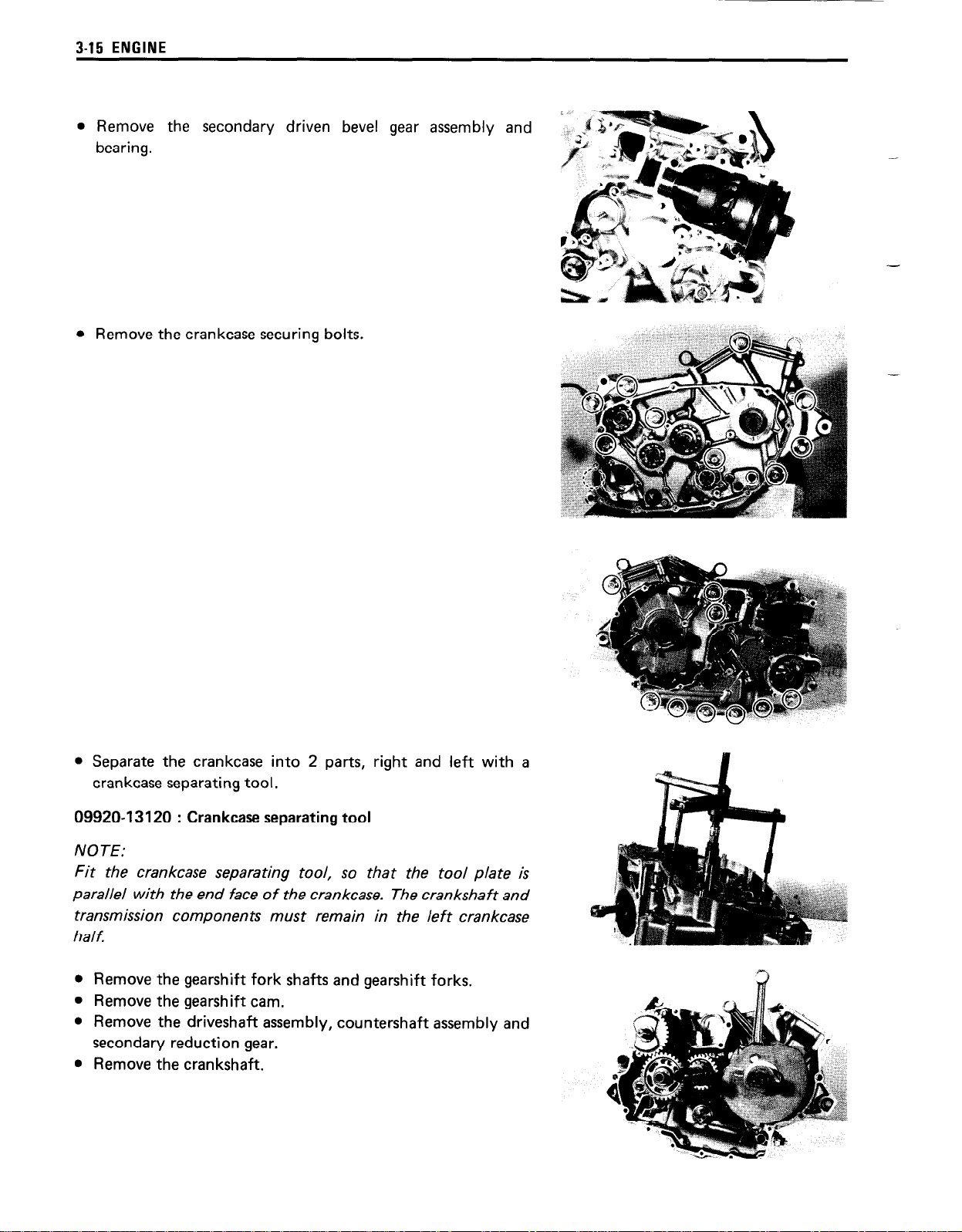

Install the universal joint into the secondary driven

gear.

Remove the driveshaft bolt @ and secondary drive

gear shaft nut @ while holding the universal joint.

CAUTION:

Driveshaft bolt 0

l

Remove the secondary driven bevel gear housing bolts and

has left-hand thread.

secondary bevel gear case bolts.

bevel

bevel

l

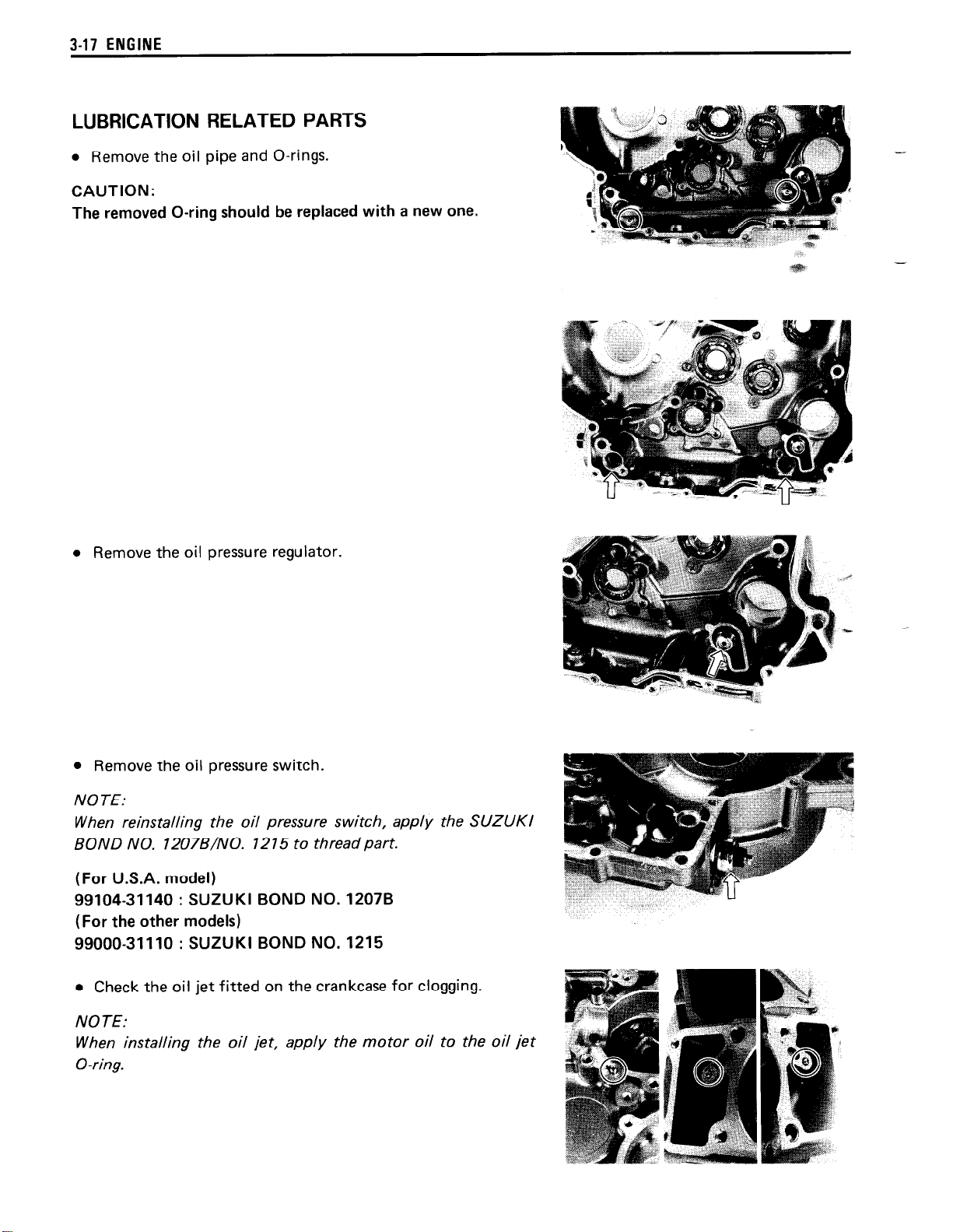

Remove the secondary driven bevel gear assembly and

bearing.

l

Remove the crankcase securing bolts.

l

Separate the crankcase into 2 parts, right and left with a

crankcase separating tool.

09920-13120 : Crankcase separating tool

NOTE:

Fit the crankcase separating tool, so that the tool plate is

parallel with the end face of the crankcase. The crankshaft and

transmission components must remain in the left crankcase

half

Remove the gearshift fork shafts and gearshift forks.

Remove the gearshift cam.

Remove the driveshaft assembly, countershaft assembly and

secondary reduction gear.

Remove the crankshaft.

l

Loosen the secondary drive bevel gear housing bolts and

remove the secondary drive bevel gear assembly.

TRANSMISSION

DISASSEMBLY

l

Disassemble the transmission gears as shown in the illustration.

ENGINE 3-16

Reduction drive gear

Low driven gear

4th driven gear

3rd driven gear

Driveshaft

Top driven gear

2nd driven gear

CountershaftlLow

drive gear

4th drive gear

3rd drive gear

(@ Top drive gear

@ 2nd drive gear

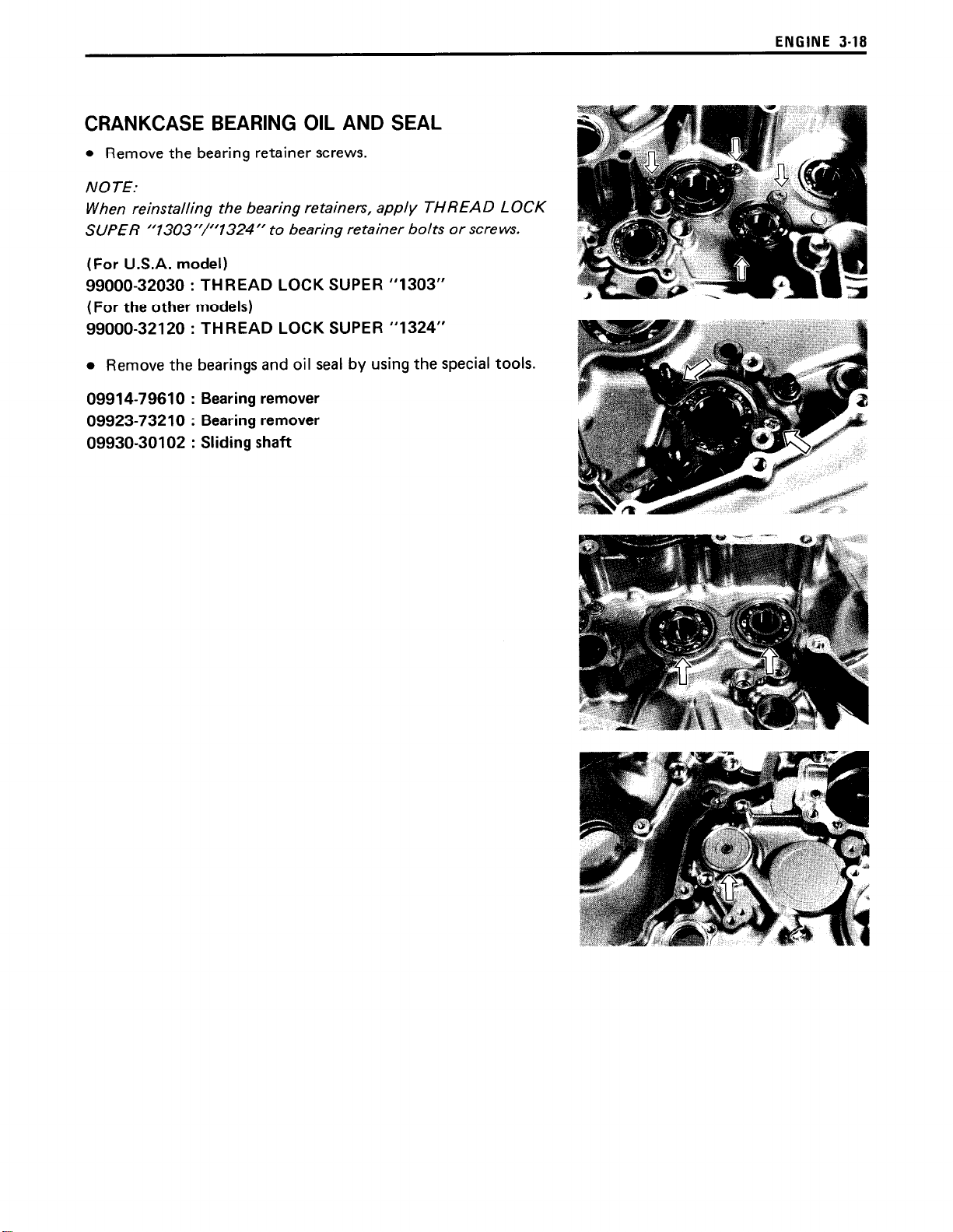

LUBRICATION RELATED PARTS

l

Remove the oil pipe and O-rings.

CAUTION:

The removed O-ring should be replaced with a new one.

l

Remove the oil pressure regulator.

l

Remove the oil pressure switch.

NOTE:

When reinstalling the oil pressure switch, apply the SUZUKI

BOND NO. 1207B/NO. 1215 to thread

part.

(For U.S.A. model)

99104-31140 : SUZUKI BOND NO. 1207B

(For the other models)

99000-31110 : SUZUKI BOND NO. 1215

l

Check the oil jet fitted on the crankcase for clogging.

NOTE:

When installing the oil jet, apply the motor oil to the oil jet

O-ring.

CRANKCASE BEARING OIL AND SEAL

l

Remove the bearing retainer screws.

NOTE:

When reinstalling the bearing retainers, apply THREAD LOCK

SUPER “1303”/“1324” to bearing retainer bolts or screws.

(For U.S.A. model)

99000-32030 : TH READ

(For the other models)

99000-32120 : THREAD

l

Remove the bearings and oil seal by using the special tools.

09914-79610 : Bearing remover

09923-73210

:

Bearing remover

09930-30102 : Sliding shaft

LOCK SUPER “1303”

LOCK SUPER “1324”

ENGINE 3-18

Loading...

Loading...