Suzuki VX800 1990-1993 Service Manual 09 Servicing information

__ ~__~ _

~ TROUBLESHOOTING

CONTENTS_ __~~ ~_~ ~~~~ _

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . g_

1

1

,

) WIRING DIAGRAM

i CABLE, HARNESS AND HOSE ROUTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . g_

. . . . . . . . . . . . . . . . . . . . . . . . . . g-12 1

( SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .g_26

TIGHTENING TORQUE

’ SERVICE DATA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . g-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . g-29

_ __~ __~ ~ ~

g

~

(

I

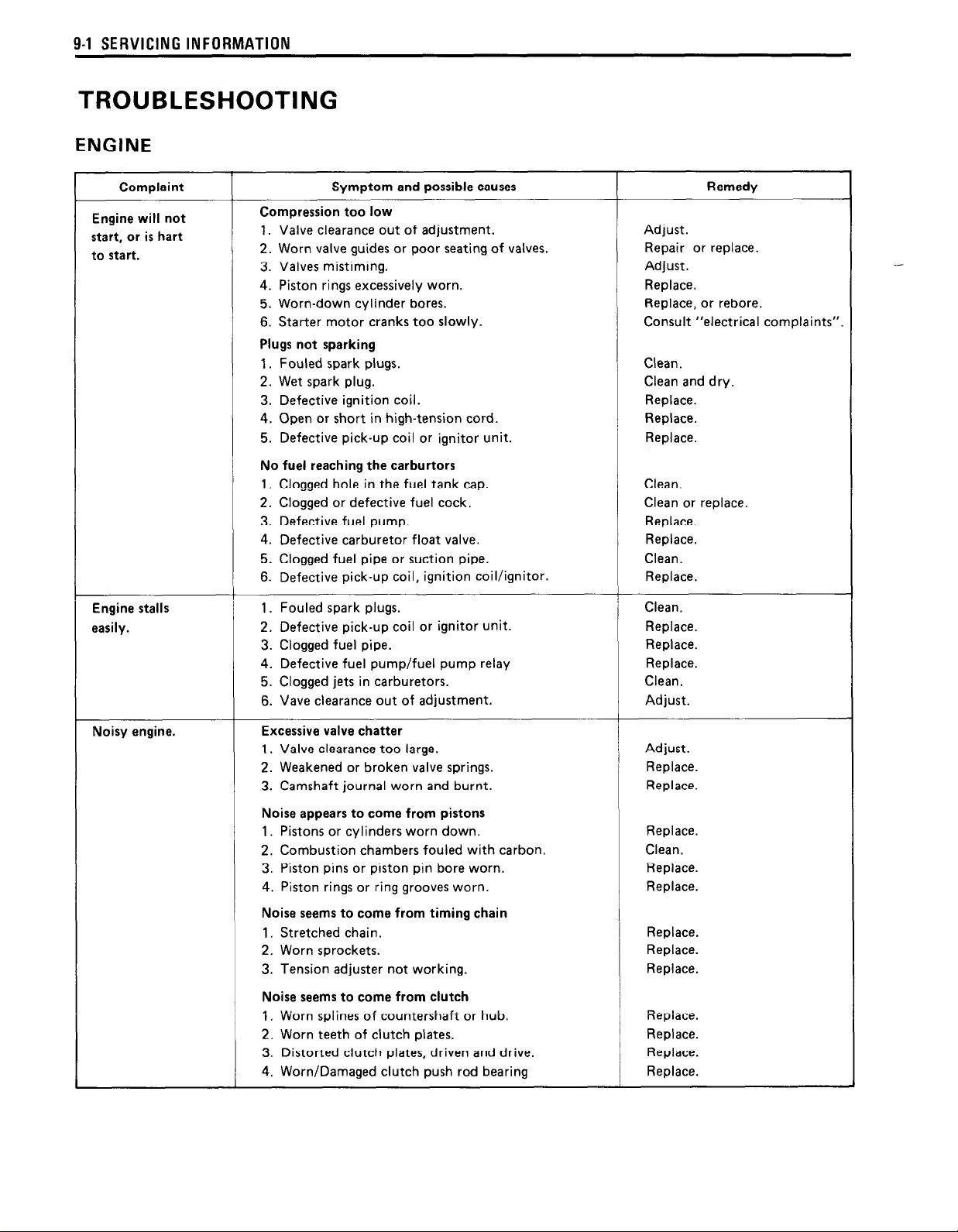

9-1 SERVICING INFORMATION

TROUBLESHOOTING

ENGINE

Complaint

Engine will not

start, or is hart

to start.

Engine stalls

easily.

Symptom and possible causes

Compression too low

1. Valve clearance out of adjustment.

2. Worn valve guides or poor seating of valves.

3. Valves mistiming.

4. Piston rings excessively worn.

5. Worn-down cylinder bores.

6. Starter motor cranks too slowly.

Plugs not sparking

1. Fouled spark plugs.

2. Wet spark plug.

3. Defective ignition coil.

4. Open or short in high-tension cord.

5. Defective pick-up coil or ignitor unit.

No fuel reaching the carburtors

1. Clogged hole in the fuel tank cap.

2. Clogged or defective fuel cock.

3. Defective fuel pump.

4. Defective carburetor float valve.

5. Clogged fuel pipe or suction pipe.

6. Defective pick-up coil, ignition coil/igniter.

1. Fouled spark plugs.

2. Defective pick-up coil or ignitor unit.

3. Clogged fuel pipe.

4. Defective fuel pump/fuel pump relay

5. Clogged jets in carburetors.

6. Vave clearance out of adjustment.

Remedy

Adjust.

Repair or replace.

Adjust.

Replace.

Replace, or rebore.

Consult “electrical complaints”.

Clean.

Clean and dry.

Replace.

Replace.

Replace.

Clean.

Clean or replace.

Replace.

Replace.

Clean.

Replace.

Clean.

Replace.

Replace.

Replace.

Clean.

Adjust.

Noisy engine.

Excessive valve chatter

1. Valve clearance too large.

2. Weakened or broken valve springs.

3. Camshaft journal worn and burnt.

Noise appears to come from pistons

1. Pistons or cylinders worn down.

2. Combustion chambers fouled with carbon.

3. Piston pins or piston pin bore worn.

4. Piston rings or ring grooves worn.

Noise seems to come from timing chain

1. Stretched chain.

2. Worn sprockets.

3. Tension adjuster not working.

Noise seems to come from clutch

1. ,I,_.._ __I!___ _z __.._r_.._L_lr __ L..L

worn sp~~nes 0~ counrersnarr or r~uo.

2. Worn teeth of clutch plates.

3. Distorted clutch plates, driven and drive.

4. Worn/Damaged clutch push rod bearing

Adjust.

Replace.

Replace.

Replace.

Clean.

Replace.

Replace.

Replace.

Replace.

Replace.

O^_L_^

naPlace.

Replace.

Replace.

Replace.

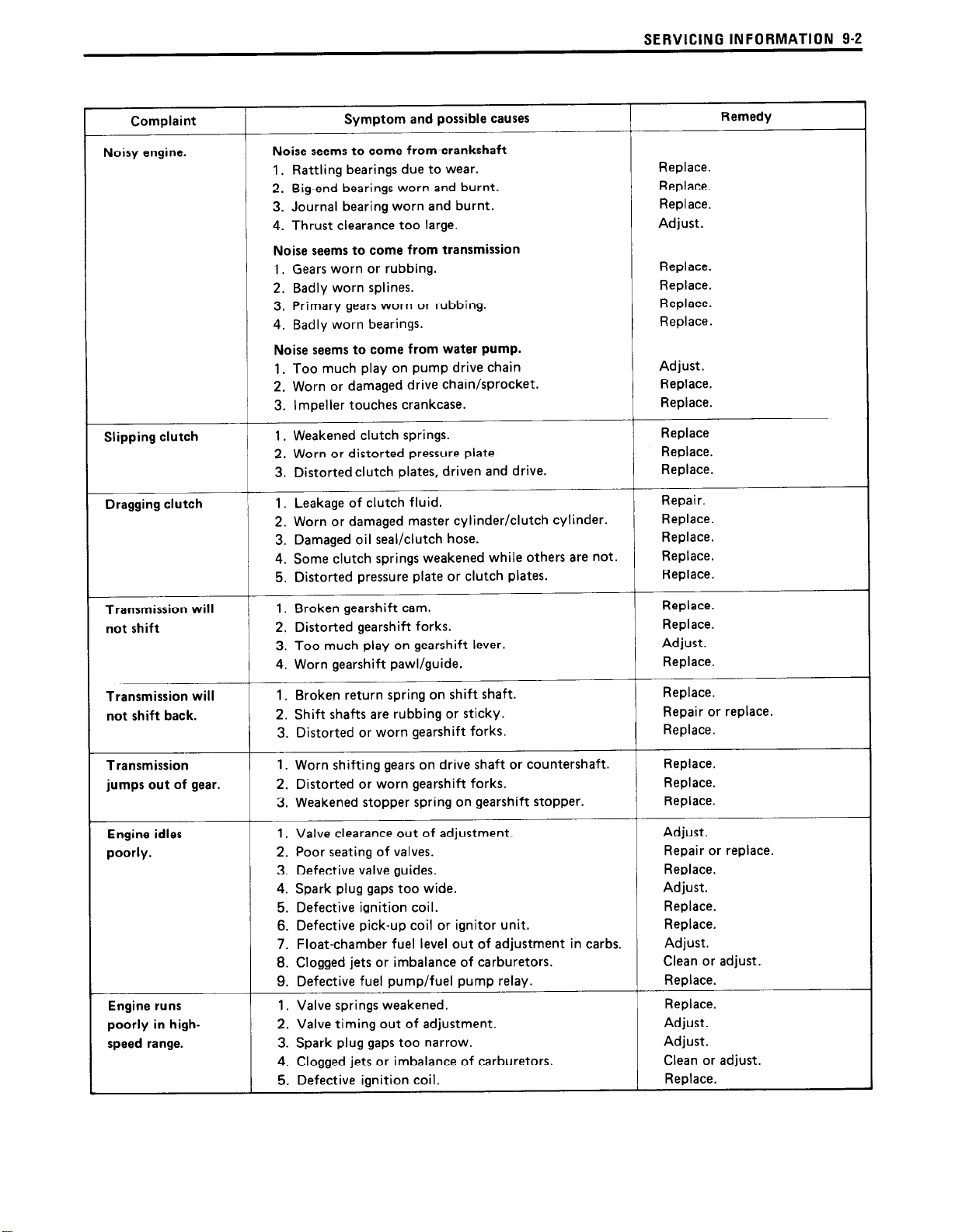

SERVICING INFORMATION 9-2

Complaint

_

Noisy engine.

_

Slipping clutch

_

Dragging clutch

_

Transmission will ,

not shift

_

Transmission will

not shift back.

I

Noise seems to come from crankshaft

1. Rattling bearings due to wear.

2. Big-end bearings worn and burnt.

3. Journal bearing worn and burnt.

4. Th!U? c!earance too !arge;

Noise seems to come from transmission

1.

Gears worn or rubbing.

2. Badly worn splines.

3. Primary gears worn or rubbing.

4. Badly worn bearings.

Noise seems to come from water pump.

1. Too much play on pump drive chain

2. Worn or damaged drive chain/sprocket.

3. Impeller touches crankcase.

1. Weakened clutch springs.

2. Worn or distorted pressure plate.

3. Distorted clutch plates, driven and drive.

1. Leakage of clutch fluid.

2. Worn or damaged master cylinder/clutch cylinder.

3. Damaged oil seal/clutch hose.

4. Some clutch springs weakened while others are not.

5. Distorted pressure plate or clutch plates.

1. Broken gearshift cam.

2. Distorted gearshift forks.

3. Too much play on gearshift lever.

4. Worn gearshift pawl/guide.

1. Broken return spring on shift shaft.

2. Shift shafts are rubbing or sticky.

3. Distorted or worn gearshift forks.

Symptom and possible causes

I

Replace.

Replace.

Replace.

Adjust.

Replace.

Replace.

Replace.

Replace.

Adjust.

Replace.

Replace.

Replace

Replace.

Replace.

Repair.

Replace.

Replace.

Replace.

Replace.

Replace.

Replace.

Adjust.

Replace.

Replace.

Repair or replace.

Replace.

Remedy

Transmission i. Worn shifting gears on drive shaft or countershaft. Repiace.

jumps out of gear.

Engine idles 1. Valve clearance out of adjustment.

poorly.

Engine runs

poor!y in highspeed range. 3. Spark plug gaps too narrow.

2. Distorted or worn gearshift forks.

3. Weakened stopper spring on gearshift stopper.

2. Poor seating of valves.

3. Defective valve guides.

4. Spark plug gaps too wide. Adjust.

5. Defective ignition coil. Replace.

6. Defective pick-up coil or ignitor unit.

7. Float-chamber fuel level out of adjustment in carbs.

8. Clogged jets or imbalance of carburetors.

9. Defective fuel pump/fuel pump relay.

1. Valve springs weakened.

2. Va!ve tjmjno not of adiustment.

4. Clogged jets or imbalance of carburetors.

5. Defective ignition coil.

J ---

_-,-__ .._.._.

Replace.

Replace.

Adjust.

Repair or replace.

Replace.

Replace.

Adjust.

Clean or adjust.

Replace.

Replace.

Adjust.

Adjust.

Clean or adjust.

Replace.

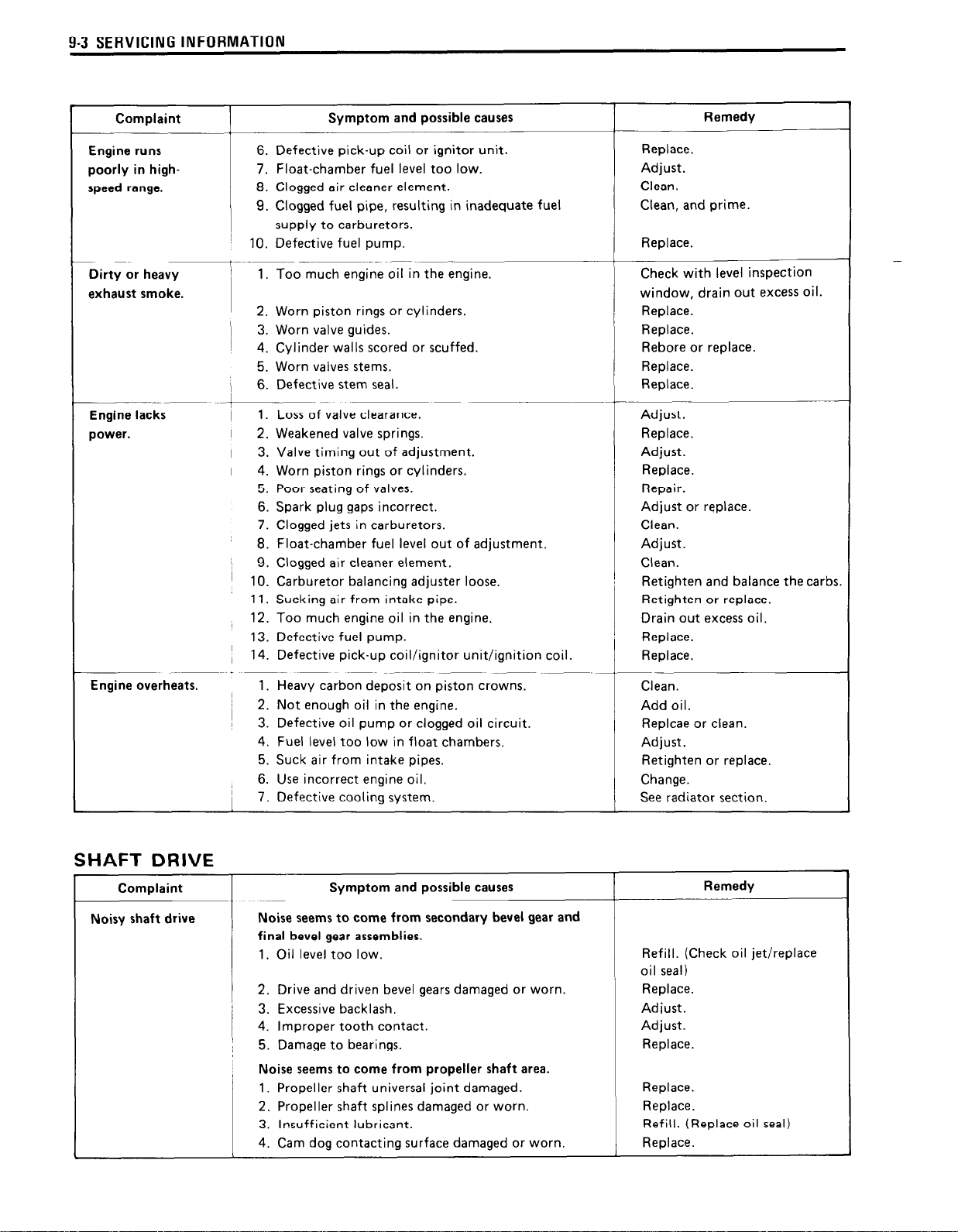

9-3 SERVICING INFORMATION

Complaint

c--:.... _...._

cllylllr; lull>

poorly in highspeed range.

Dirty or heavy

exhaust smoke.

Engine lacks

power.

Symptom and possible causes

c

nnf.-.r+:..r. ..:.-.L I,_ P.,.;, fir ;nn;+rrr *h-i+

“Izjl~LL,“~ I-“G”-“~ L”II “I 1xJ’“L”’ “#III.

Float-chamber

7u:

8.

Clogged air cleaner element.

Clogged fuel pipe, resulting in inadequate fuel

9.

supply to carburetors.

Defective fuel pump.

IO.

Too much engine oil in the engine.

1.

Worn piston rings or cylinders.

2.

3.

Worn valve guides.

Cylinder walls scored or scuffed.

4.

Worn valves stems.

5.

Defective stem seal.

6.

1.

Loss of valve clearance. Adjust.

Weakened valve springs.

2.

\,_I.._ *‘-:__ _..A _I _^I:.._..-^-& A-1:..“*

“dl”B llrnllly ““L “I cJ”,“sur,eIIl.

3.

4.

Worn piston rings or cylinders.

5.

Poor seating of valves.

6.

Spark plug gaps incorrect.

7.

Clogged jets in carburetors.

Float-chamber fuel level out of adjustment. Adjust.

8.

0

r,r\nn0r( q;” rln=n.,r al0m0n+ r,a?.n

“luyyr;” a,, \.IGcallIz, Gil~jlll~jlll, UlGcil I.

1;.

Carburetor balancing adjuster loose. Retighten and balance the cart

Sucking air from intake pipe.

11.

12.

Too much engine oil in the engine. Drain out excess oil.

Defective fuel pump. Replace.

13.

14.

Defective pick-up coil/igniter unit/ignition coil.

fuel level too low.

RaP.13.-CI

I ‘upa”Y.,.

Adjust.

Clean.

Clean, and prime.

Replace.

Check with level inspection

window, drain out excess oil.

Replace.

Replace.

Rebore or replace.

Replace.

Replace.

Replace.

H”,“SL.

Replace.

Repair.

Adjust or replace.

Clean.

Retighten or replace.

Replace.

Remedy

-

Engine overheats.

SHAFT DRIVE

Complaint

Noisy shaft drive

1. Heavy carbon deposit on piston crowns.

2. Not enough oil in the engine.

3. Defective oil pump or clogged oil circuit.

4.

Fuel level too low in float chambers.

5. Suck air from intake pipes.

6. Use incorrect engine oil.

7. Defective cooling system.

Symptom and possible causes

Noise seems to come from secondary bevel gear and

final bevel gear assemblies.

Oil level too low.

1.

i

Drive and driven bevel gears damaged or worn.

2.

3.

Excessive backlash.

Improper tooth contact.

4.

Damage to bearings.

5.

Noise seems to come from propeller shaft area.

I

1 Drnnallov chcaf* ~oni~~ovcal ;nint rlom~nd

I_ I ‘“p”“c’ 511(11L “lll”rlll”l ,““‘L “U”‘ayG”.

2. Propeller shaft splines damaged or worn.

3. Insufficient lubricant.

4. Cam dog contacting surface damaged or worn.

1

Clean.

Add oil.

Replcae or clean.

Adjust.

Retighten or replace.

Change.

See radiator section.

Remedy

Refill. (Check

oil seal)

Replace.

Adjust.

Adjust.

Replace.

RPnl.PP

I ‘“p,L”“U.

Replace.

Refill. (Replace oil seal)

Replace.

oil jet/replace

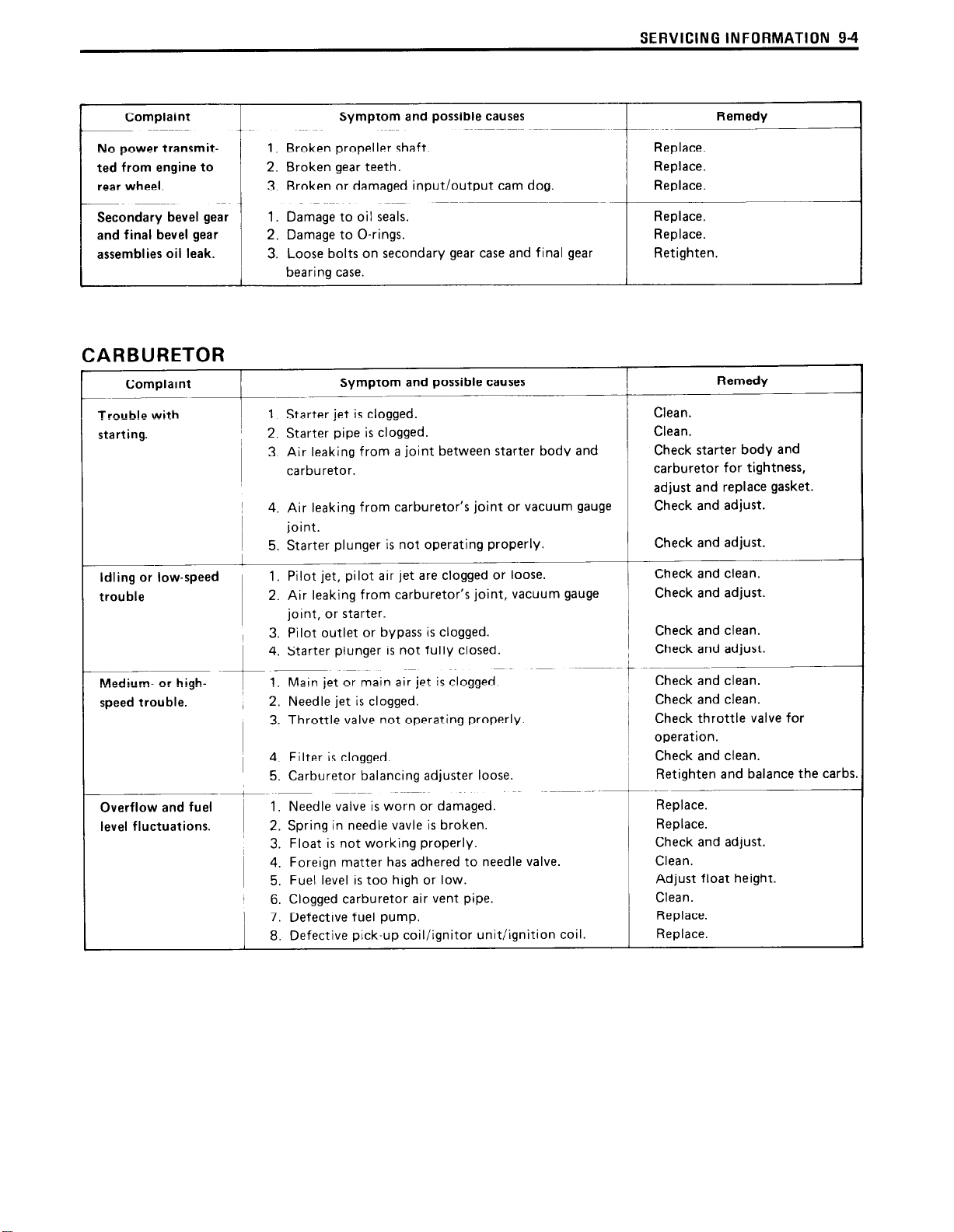

SERVICING INFORMATION 9-4

Complaint

No power transmitted from engine to

rear wheel.

Secondary bevel gear

and final bevel gear

assemblies oil leak.

CARBURETOR

Complaint

Trouble

starting.

with

Symptom and possible causes

Broken

1:

Broken gear teeth.

2.

Broken or damaged input/output cam dog.

3.

1.

Damage to oil seals.

Damage to O-rings.

2.

Loose bolts on secondary gear case and final gear

3.

bearing case.

I

I

1.

Starter jet

Starter pipe is clogged.

2.

Air leaking from a joint between starter body and

3.

carburetor.

Air leaking from carburetor’s joint or vacuum gauge

4.

joint.

Starter plunger is not operating properly.

5.

propeller shaft.

Symptom and possible causes

is clogged.

Remedy

r

Replace.

Replace.

Replace.

Replace.

Replace.

Retighten.

i-

1

Remedy

Clean.

Clean.

Check starter body and

carburetor for tightness,

adjust and replace gasket.

Check and adjust.

Check and adjust.

=l

j

1

Idling or low-speed

trouble

Mdi~~m. nr hinh-

. ..“..._... -. . ..=..

speed trouble.

Overflow and fuel

level fluctuations.

Pilot jet, pilot air jet are clogged or loose.

1.

Air leaking from carburetor’s joint, vacuum gauge

2.

joint, or starter.

Pilot outlet or bypass is clogged.

3.

Starter plunger is not fully closed.

4.

1-

Main iet nr main air jet

.

2.

/

3.

4.

5.

1~:

2.

3.

4.

5.

6.

7.

8.

I-- -’

Needle jet is clogged.

Throttle valve not operating properly.

Filter is clogged.

Carburetor balancing adjuster loose.

Needle valve is worn or damaged.

Spring in needle vavle is broken.

Float is not working properly.

Foreign matter has adhered to needle valve.

Fuel level is too high or low.

Clogged carburetor air vent pipe.

Defective fuel pump.

Defective pick-up coil/igniter unit/ignition coil.

is clogged.

Check and clean.

Check and adjust.

Check and clean.

Check and adjust.

Check and clean.

Check and clean.

Check throttle valve for

operation.

Check and clean.

Retighten and balance the carbs

Replace.

Replace.

Check and adjust.

Clean.

Adjust float height.

Clean.

Replace.

Replace.

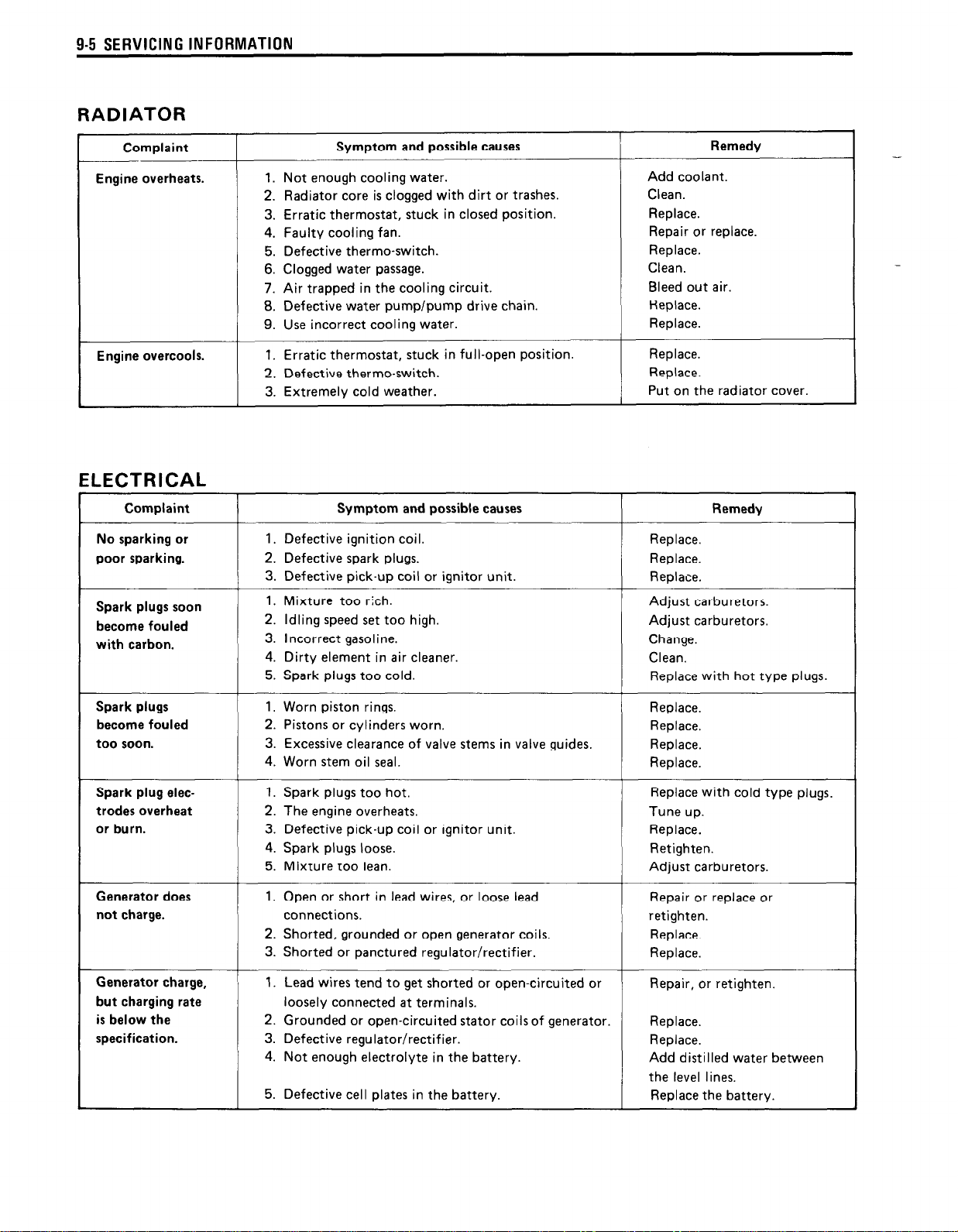

9-5 SERVICING INFORMATION

RADIATOR

Complaint

Engine overheats.

Engine overcools.

ELECTRICAL

Complaint

No sparking or

poor sparking.

Spark plugs soon

become fouled

with carbon.

Symptom and possible causes

1.

Not enough cooling water.

Radiator core is clogged

2.

Erratic thermostat, stuck in closed position.

3.

Faulty cooling fan.

4.

Defective thermo-switch.

5.

Clogged water passage.

6.

Air trapped in the cooling circuit.

7.

Defective water pump/pump drive chain.

8.

9.

Use incorrect cooling water.

Erratic thermostat, stuck in full-open position.

1.

Defective thermo-switch.

2.

Extremely cold weather.

3.

Symptom and possible causes

1. Defective ignition coil.

2. Defective spark plugs.

3. Defective pick-up coil or ignitor unit.

1. Mixture too rich.

2. Idling speed set too high.

3. Incorrect gasoline.

4. Dirty element in air cleaner.

5. Spark plugs too cold.

with dirt or trashes.

Remedy

Add coolant.

Clean.

Replace.

Repair or replace.

Replace.

Clean.

Bleed out air.

Replace.

Replace.

Replace.

Replace.

Put on the radiator cover.

Remedy

Replace.

Replace.

Replace.

Adjust carburetors.

Adjust carburetors.

Change.

Clean.

Replace with hot type plugs.

Spark plugs

become fouled

too soon.

Spark plug electrodes overheat

or burn.

Generator does

not charge.

Generator charge,

but charging rate

is below the

specification.

1. Worn piston rings.

2. Pistons or cylinders worn.

3. Excessive clearance of valve stems in valve guides.

4. Worn stem oil seal.

1. Spark plugs too hot.

2. The engine overheats.

3. Defective pick-up coil or ignitor unit.

4. Spark plugs loose.

5. Mixture too lean.

1. Open or short in lead wires, or loose lead

connections.

2. Shorted, grounded or open generator coils.

3. Shorted or panctured regulator/rectifier.

1. Lead wires tend to get shorted or open-circuited or

loosely connected at terminals.

2. Grounded or open-circuited stator coils of generator

3. Defective regulator/rectifier.

4. Not enough electrolyte in the battery.

5. Defective cell plates in the battery.

Replace.

Replace.

Replace.

Replace.

Replace with cold type plugs.

Tune up.

Replace.

Retighten.

Adjust carburetors.

Repair or replace or

retighten.

Replace.

Replace.

Repair, or retighten.

Replace.

Replace.

Add distilled water between

the level lines.

Replace the battery.

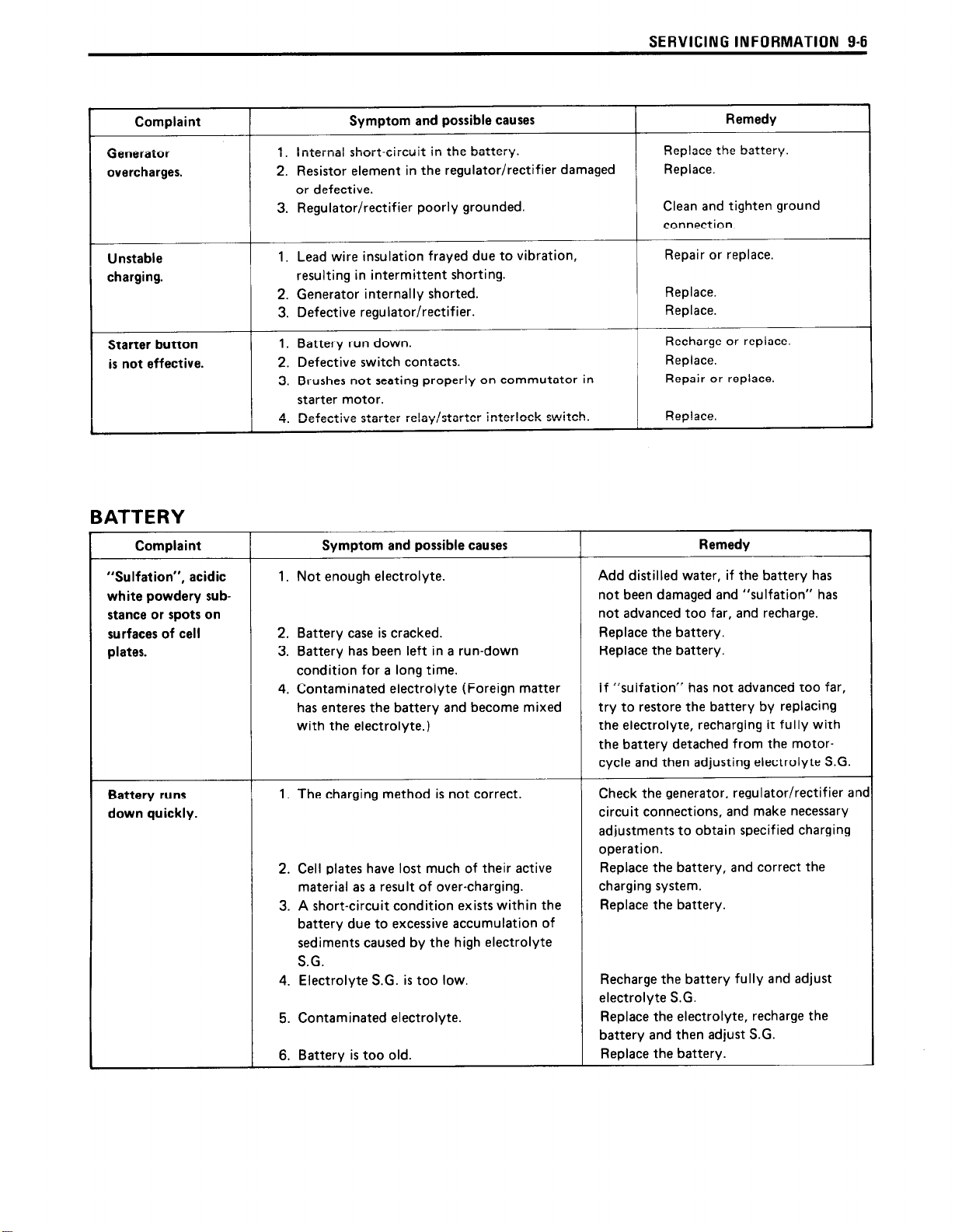

SERVICING INFORMATION 9-6

Complaint

~_-_“_*-_

“e”eriit”r

overcharges.

Unstable

charging.

Starter button

is not effective.

BATTERY

-_ _- - --- -

Complaint

Symptom and possible causes

‘I I-+rr.rr, ‘.b.,..+ r;,n,,;+ ;n +I.%- c\I++P.\,

I. 1111~‘111~, >,I”, L-LIIL”,L III LIIG “CILICI I.

2. Resistor element in the regulator/rectifier damaged

or defective.

3. Regulator/rectifier poorly grounded.

1. Lead wire insulation frayed due to vibration,

resulting in intermittent shorting.

2. Generator internally shorted.

3. Defective regulator/rectifier.

1. Battery run down.

2. Defective switch contacts.

3. Brushes not seating properly on commutator in

starter motor.

4,

nof-r+Tt.a r+Dr+-r rolQxr/c+~r+~r int~rlnrk

Y.zlczbLI”G JL(1, L-8 ,r,r;ly,aru, &.,I IEIL\1II”“I. I....-...

rwitrh

Symptom and possible causes

Remedy

R,z.nl=r~

I ‘my’“‘.. .I .I YY.LIl ,

the hrrttew

Replace.

Clean and tighten ground

connection.

Repair or replace.

Replace.

Replace.

Recharge or replace.

Replace.

Repair or replace.

RPnlarP

“-r-‘---’

Remedy

“Sulfation”, acidic

white powdery sub-

stance or spots on

surfaces of cell

plates.

Battery runs

down quickly.

1. Not enough electrolyte.

2. Battery case is cracked.

3. Battery has been left in a run-down

condition for a long time.

4. Contaminated eiectroiyte (Foreign matter

has enteres the battery and become mixed

with the electrolyte.)

1. The charging method is not correct.

2. Cell plates have lost much of their active

material as a result of over-charging.

3. A short-circuit condition exists within the

battery due to excessive accumulation of

sediments caused by the high electrolyte

S.G.

4. Electrolyte S.G. is too low.

5. Contaminated electrolyte.

6. Battery is too old.

Add distilled water, if the battery has

not been damaged and “sulfation” has

not advanced too far, and recharge.

Replace the battery.

Replace the battery.

If ..suifation” has not advanced too far,

** ”

try to restore the battery by replacing

the electrolyte, recharging it fully with

the battery detached from the motor-

cycle and then adjusting electrolyte S.G.

Check the generator, regulator/rectifier ant

circuit connections, and make necessary

adjustments to obtain specified charging

operation.

Replace the battery, and correct the

charging system.

Replace the battery.

Recharge the battery fully and adjust

electrolyte S.G.

Replace the electrolyte, recharge the

battery and then adjust S.G.

Replace the battery.

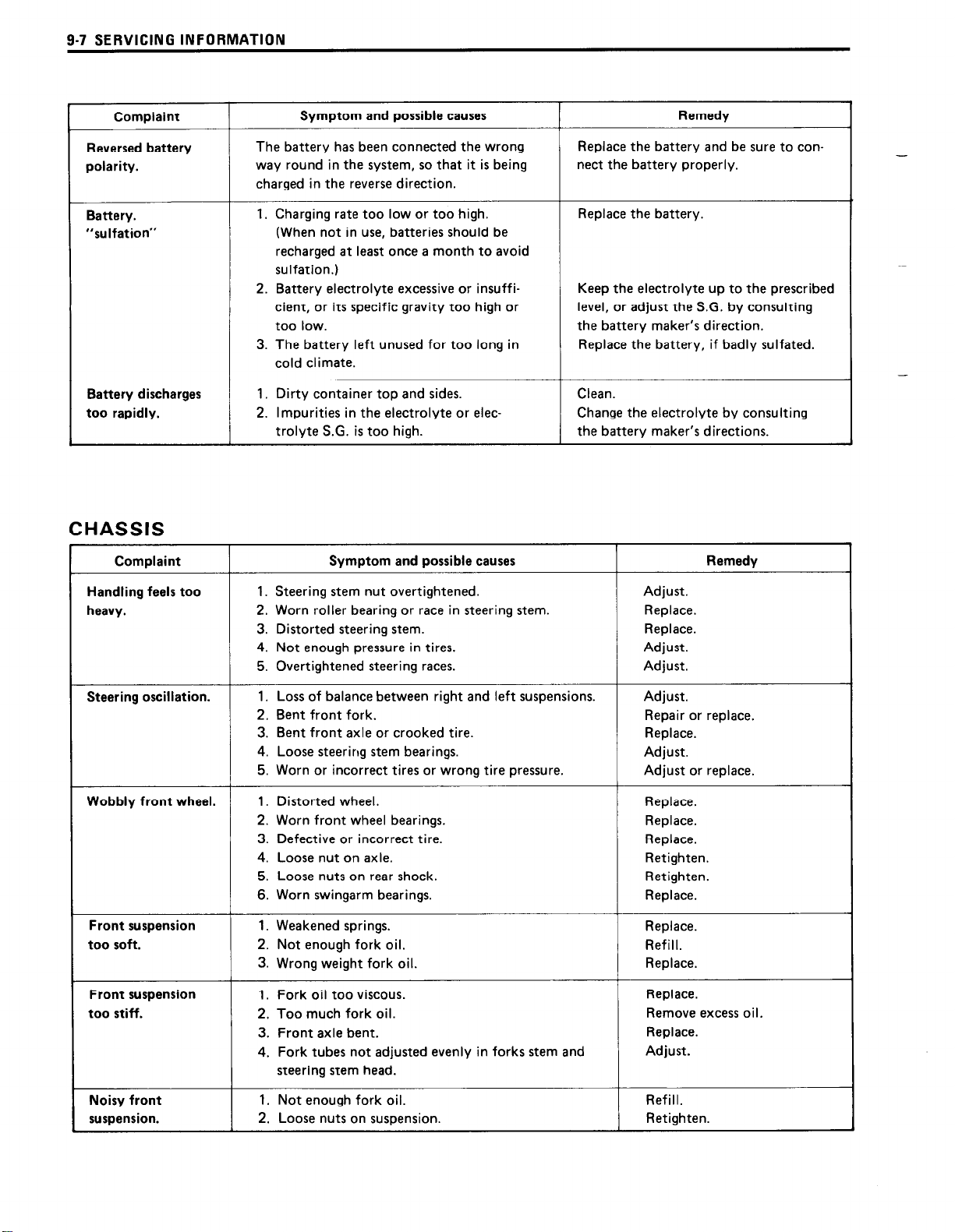

9-7 SERVICING INFORMATION

Complaint

Reversed battery

polarity.

Battery.

t

“sulfation”

Battery discharges

too rapidly.

CHASSIS

Complaint

_

Symptom and possible causes

The battery has been connected the wrong

way round in the system, so that it is being

charged in the reverse direction.

Charging rate too low or too high.

(When not in use, batteries should be

recharged at least once a month to avoid

sulfation.)

Battery electrolyte excessive or insufficient, or its specific gravity too high or

too low.

TL_ I-_**_-.. I_=* ..-.._-_I I__ *__ I___ !_

I ne uacrery IBTI unuseu ror 100 tony In

cold climate.

1. Dirty container top and sides.

2. Impurities in the electrolyte or electrolyte S.G. is too high.

Symptom and possible causes

Remedy

Replace the battery and be sure to connect the battery properly.

Replace the battery.

Keep the electrolyte up to the prescribed

level, or adjust the S.G. by consulting

the battery maker’s direction.

D--l___ *I__ l--r*__.

neplace Lilt: “aLLery, IT “auly s”lraIe”.

Clean.

Change the electrolyte by consulting

the battery maker’s directions.

:c L--l,. _..ll_r__i

Remedy

Handling feels too

L__....

neavy.

Steering oscillation.

Wobbly front wheel.

Front suspension

too soft.

Front suspension

too stiff.

1. Steering stem nut overtightened.

2. \*,-“- “^I,^” b.-..“:-- ^_ “^^^ :.. “*--“:-- ^+^-

“““Ill l”llll “tXY,ll&j “1 IdlrC III rrearlllg SUZ’III.

3. Distorted steering stem.

4. Not enough pressure in tires.

5. Overtightened steering races.

1.

Loss of balance between right and left suspensions.

2. Bent front fork.

3. Bent front axle or crooked tire.

4. Loose steering stem bearings.

5. Worn or incorrect tires or wrong tire pressure.

1. Distorted wheel.

2. Worn front wheel bearings.

3. Defective or incorrect tire.

4. Loose nut on axle.

5. Loose nuts on rear shock.

6. Worn swingarm bearings.

1. Weakened springs.

2. Not enough fork oil.

3. Wrong weight fork oil.

1. Fork oil too viscous.

2. Too much fork oil.

3. Front axie bent.

4. Fork tubes not adjusted evenly in forks stem and

steering stem head.

Adjust.

~,,I^,^

rltqJI.lUz.

Replace.

Adjust.

Adjust.

Adjust.

Repair or replace.

Replace.

Adjust.

Adjust or replace.

Replace.

Replace.

Replace.

Retighten.

Retighten.

Replace.

Replace.

Refill.

Replace.

Replace.

Remove excess oil.

I-- _I~__

Replace.

Adjust.

Noisy front

suspension.

1. Not enough fork oil.

2. Loose nuts on suspension.

Refill.

Retighten.

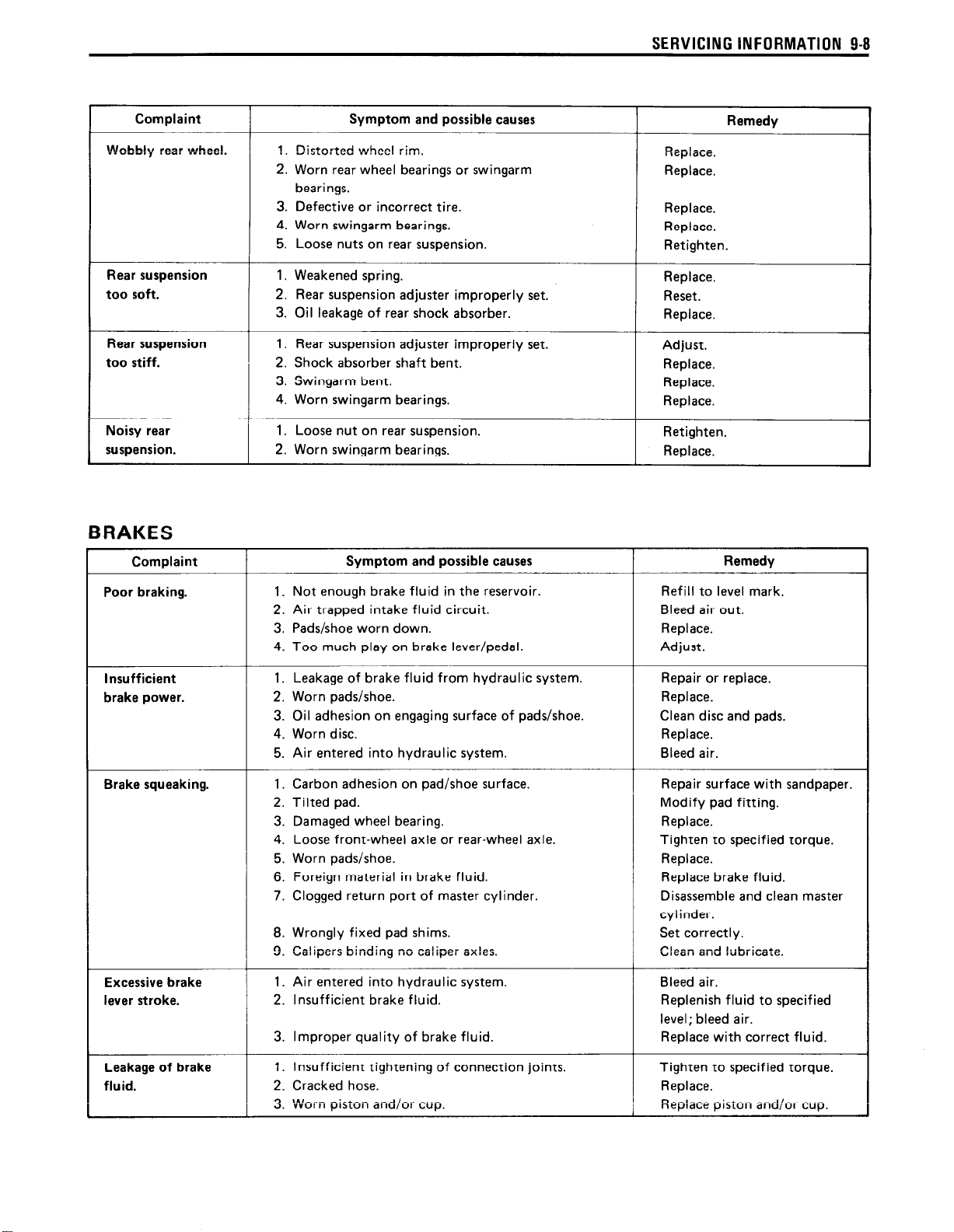

SERVICING INFORMATION 9-8

I

I

Complaint Symptom and possible causes

Wnhhlw ,PSP whmal

. . VI..,. , .““. . . . . ““..

Rear suspension

Rear suspension

BRAKES

Complaint

Poor braking.

1

nirtnrtOr(

I

YllLVl Lb” ..ll.,.,l I1111.

2.

Worn rear wheel bearings or swingarm

bearings.

3.

Defective or incorrect tire.

4.

Worn swingarm bearings.

5.

Loose nuts on rear suspension.

1. Weakened spring.

2. Rear suspension adjuster improperly set.

3. Oil leakage of rear shock absorber.

1. Rear suspension adjuster improperly set.

2. Shock absorber shaft bent.

3. Swingarm bent.

4. Worn swingarm bearings.

1. Loose nut on rear suspension.

2. Worn swingarm bearings.

_

1. Not enough brake fluid in the reservoir.

2. Air trapped intake fluid circuit.

3. Pads/shoe worn down.

4. Too much play on brake lever/pedal.

whool rim

Symptom and possible causes

Remedy

Replace.

Replace.

Retighten.

Replace.

Reset.

Replace.

Adjust.

Replace.

Replace.

Replace.

Retighten.

Replace.

Remedy

Refill to level mark.

Bleed air out.

Replace.

Adjust.

Insufficient

brake power.

Brake squeaking.

Excessive brake

lever stroke.

Leakage of brake

fluid.

Leakage of brake fluid from hydraulic system.

1.

2.

Worn pads/shoe.

3.

Oil adhesion on engaging surface of pads/shoe.

Worn disc.

4.

Air entered into hydraulic system.

5.

1.

Carbon adhesion on pad/shoe surface.

2.

Tilted pad.

3.

Damaged wheel bearing.

4.

Loose front-wheel axle or rear-wheel axle.

5.

Worn pads/shoe.

Foreign material in brake fluid.

6.

7.

Clogged return port of master cylinder.

1. Air entered into hydraulic system.

2. Insufficient brake fluid.

3. Improper quality of brake fluid.

1. Insufficient tightening of connection joints,

2. Cracked hose.

Repair or replace.

Replace.

Clean disc and pads.

Replace.

Bleed air.

Repair surface with sandpaper.

Modify pad fitting.

Replace.

Tighten to specified torque.

Replace.

Replace brake fluid.

Disassemble and clean master

cylinder.

Set correctly.

rla?.n .Y.nr( I,,hr;,.9+0

UlGiall cl,,” l”“, II.cILG.

Bleed air.

Replenish fluid to specified

level; bleed air.

Replace with correct fluid.

Tighten to specified torque.

Replace.

0-eI--_. ^:^&-_ __-I/_” ^.._

“epldue pJ’sl”rl dll”,“I cup.

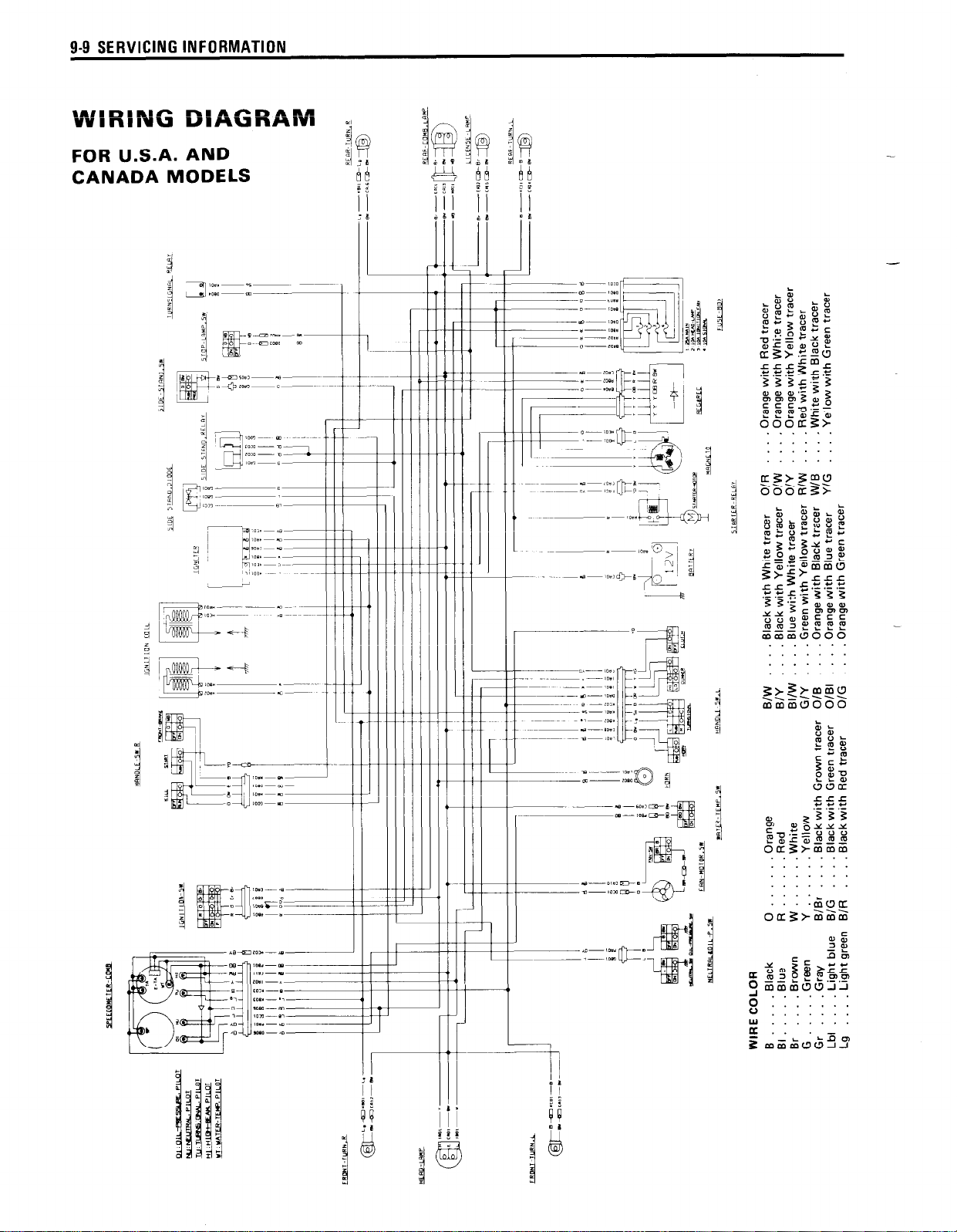

9-9 SERVICING INFORMATION

FOR U.S.A. AND

CANADA MODELS

I

”

r

r

-

.......

.......

.......

.......

. .

. . .

.&aa

oa3>iZGii5

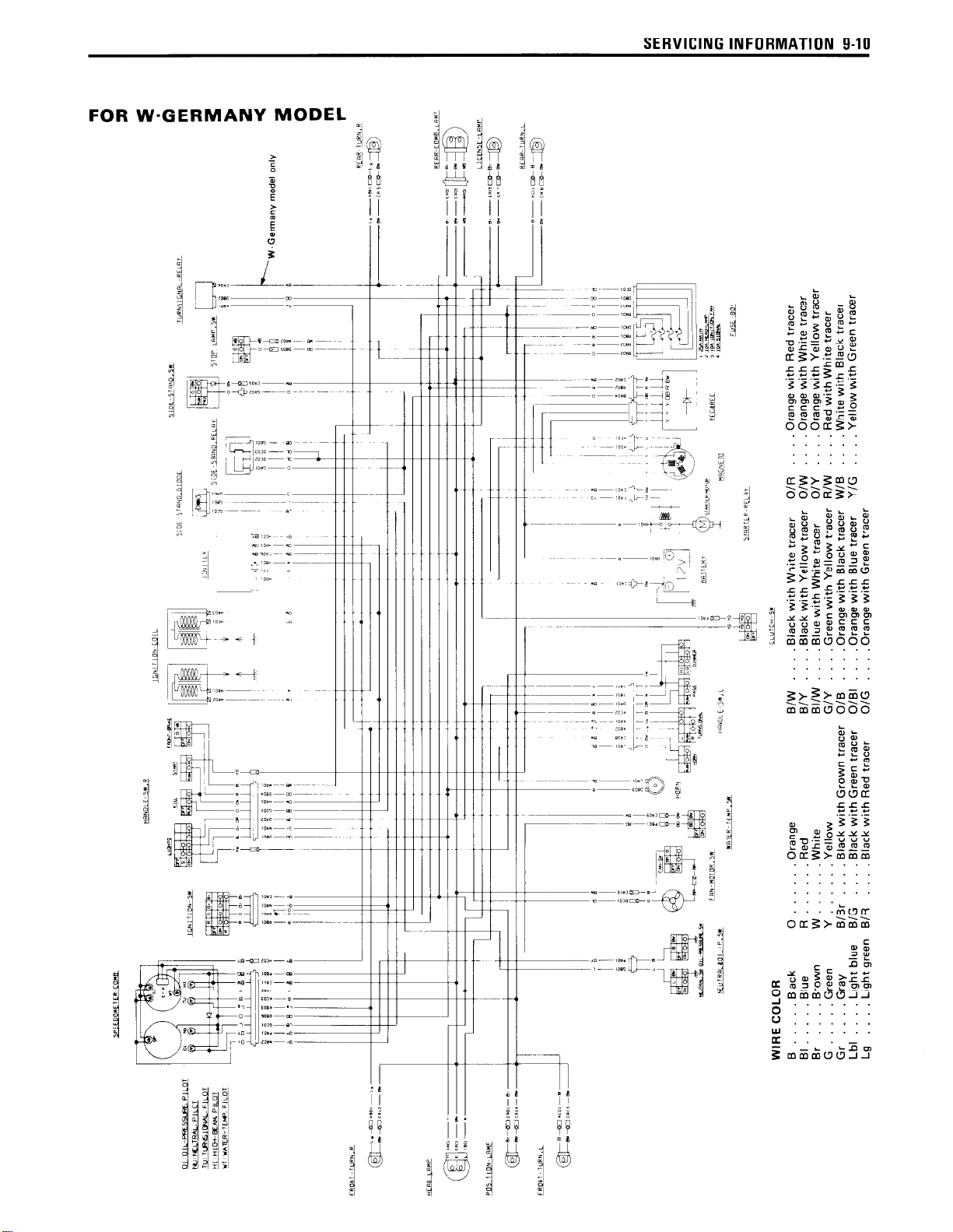

SERVICING INFORMATION 9-10

FOR W-GERMANY MODEL

I

!

I

t

%I el

......

......

......

......

g>p>rnSW

~i?i,Z~~ei

Orange with White tracer

,

O/R Orange with Red tracer

Black with Yellow tracer O/W

Black with White tracer

B/Y

B/W

Red

Orange

White

Orange with Yellow tracer

.

O/Y

Blue with White tracer

Green with Yellow tracer R/W Red with White tracer

BIIW

G/Y

Yellow

White with Black tracer

.

Y/G Yellow with Green tracer

Orange with Blue tracer

Orange with Black tracer W/B

OIBI

Black with Grown tracer O/B

Black with Green tracer

Orange with Green tracer

O/G

Black with Red tracer

R

0

Blue

Black

.

_ . .

BI

B

Y

w..

Br Brown

G . Green

Gr . Gray BlBr

B/G

Lbl Light blue

Lg Light green B/R

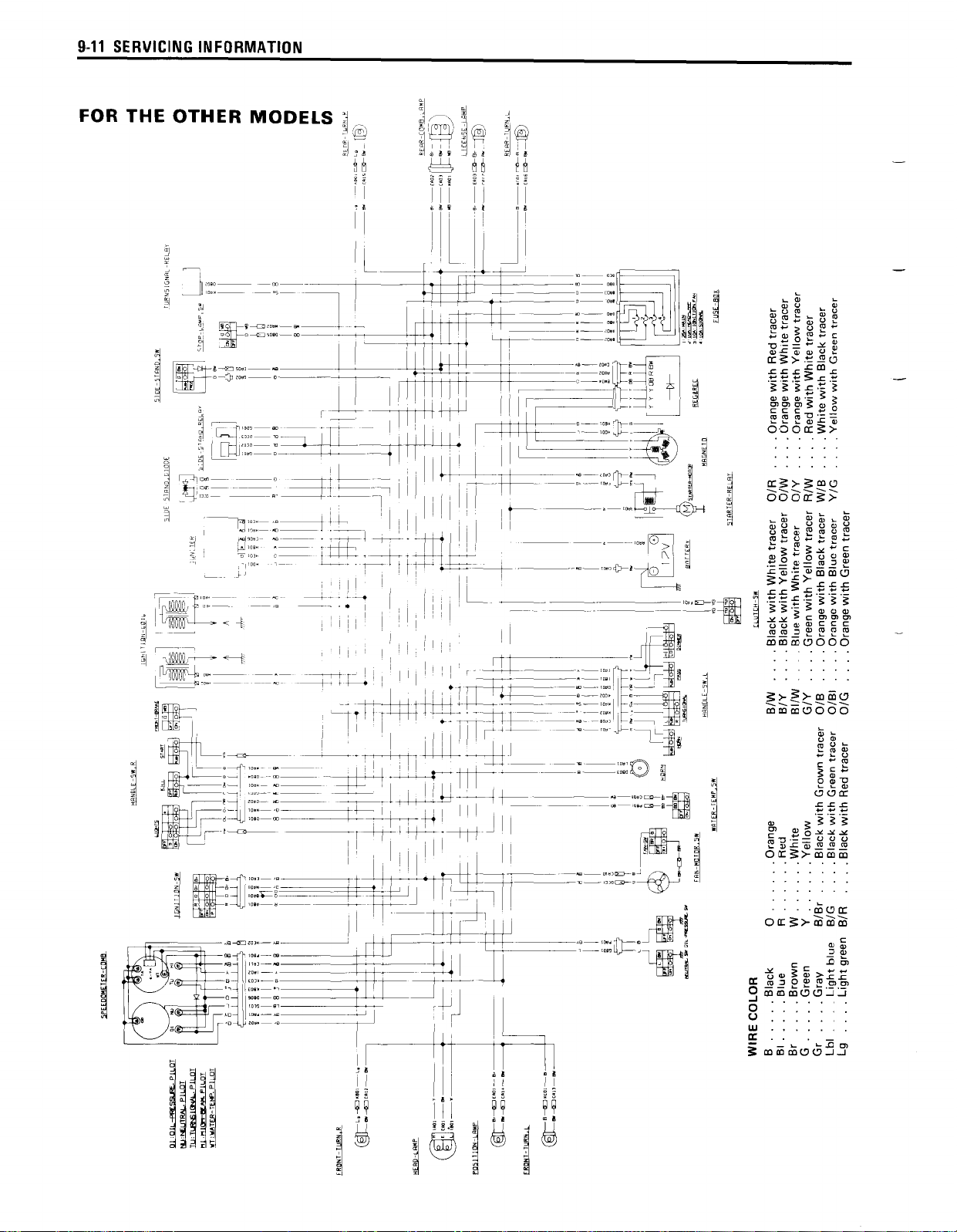

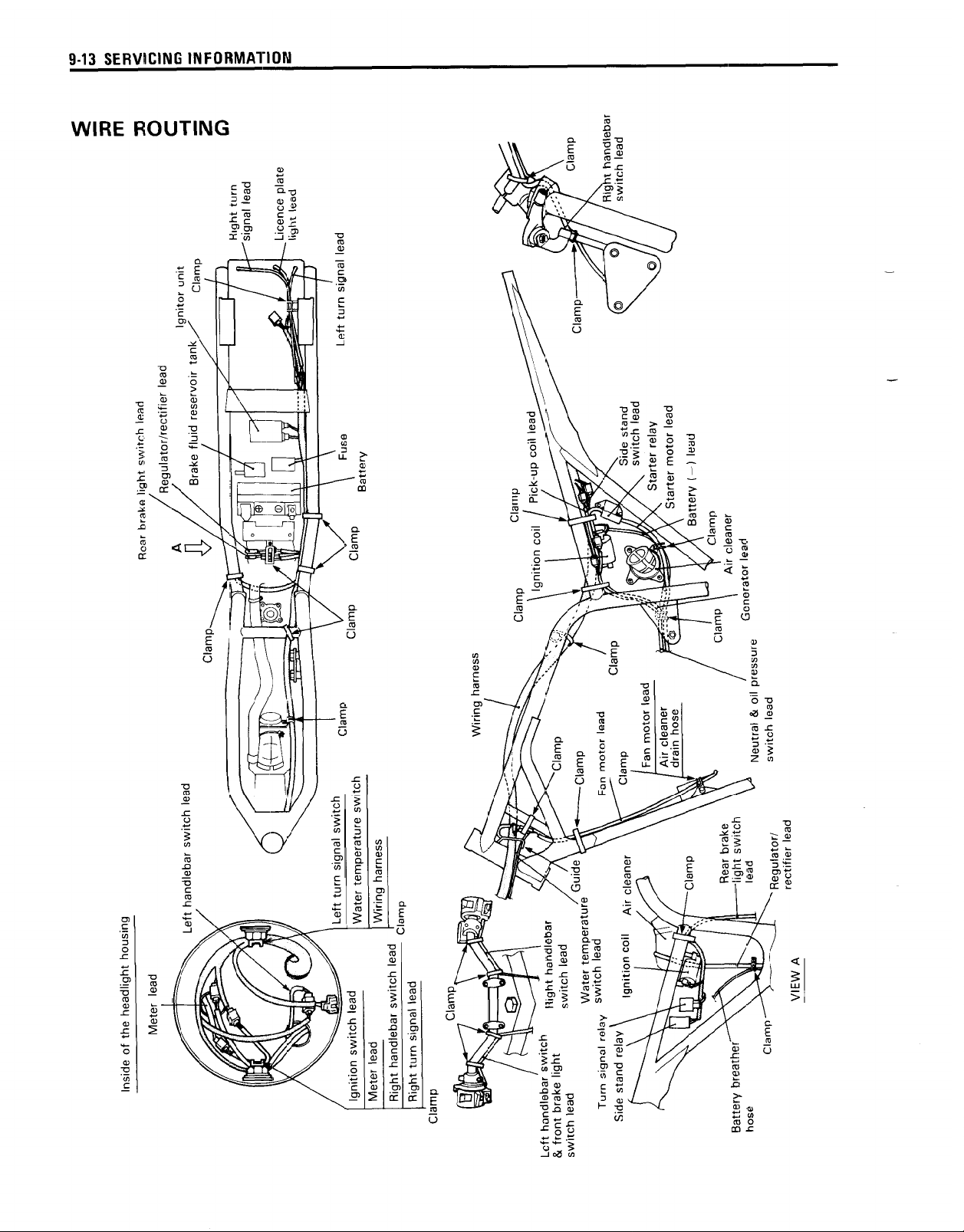

Carburetor

Air cleaner

_._.~ ~\

“lhtening

Clamp

pipe

It

VIEW D

\

hose (front carb.)

r cleaner hose

Breather hose

Fuel pump vacuum hose

Fuel pump & carburetor hose

‘Y

L Starter cable (rear carb.)

Carburetor

ti Throttle cable (rear carb.)

“le2

Air

hose /

Starter cable

Breather hose

tank water drain hose

Battery breather hose

diator overflow hose

Clam/p

Throttle

Air cleaner drain

hose (front)

Rear brake light switch lead

Regulator/rectifier lead

I

Wiring harness

rectifier lead

Inside of the headlight housing

Clamp

switch lead

light

& front brake

VIEW A

hose

switch lead

Loading...

Loading...