Suzuki VX800 1990-1993 Service Manual 02 Periodic maintenance

~ --CONTENTS_ ~~~_ ~~~ _ ~ ~

PERIODIC MAINTENANCE SCHEDULE

PERIODIC MAINTENANCE CHART

LUBRICATION POINTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2_

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 1

2- 1

2

MAINTENANCE AND TUNE-UP PROCEDURES ..................2- 3

BATTERY.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-

AIR CLEANERS

VALVE CLEARANCE

SPARK PLUGS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-

ENGINE OIL AND OIL FILTER

FUEL LINES

CARBURETORS

COOLING SYSTEM

CLUTCH

FINAL GEAR OIL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2_

. . . . . . . . . . . . . . . . . . . . . . . . 2_

. . . . . . . . . . . . . . . . . . . . . . . . 2-10

. . . . . . . . . .2_ 4

3

2- 5

B

2- 9

g

2- 10

2-11

7

BRAKES

TIRES

STEERING

FRONT FORKS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REAR SHOCK ABSORBERS

CHASSIS BOLTS AND NUTS

. . . . . . . . . . . . . . . . . . . . . . . .2_ 72

2- 14

. . . . . . . . . . . . . . . . . . . . . . . . 2-15

2- 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2_ 15

. . ..a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2_15

2-l

PERIODIC MAINTENANCE AND TUNE-UP PROCEDURES

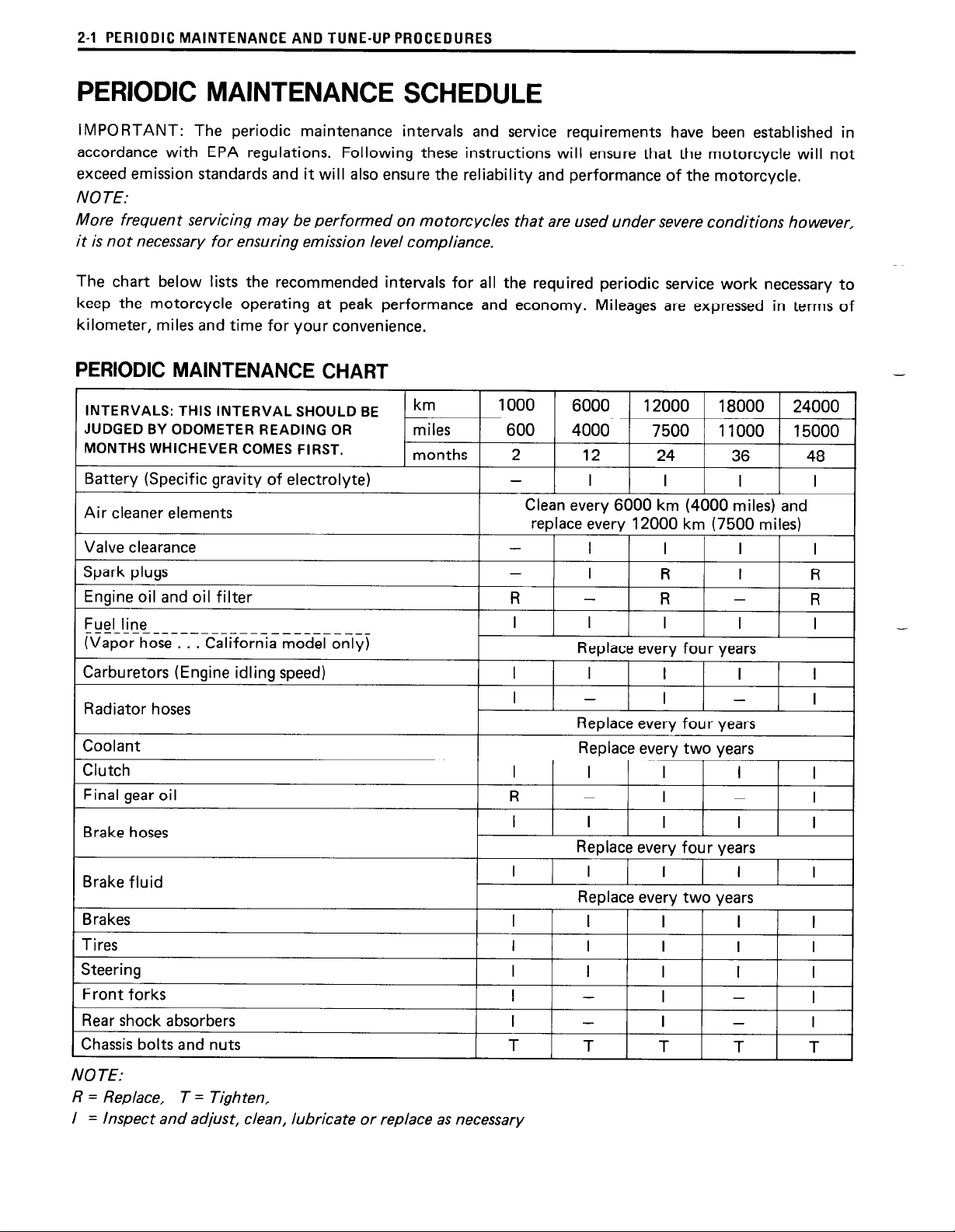

PERIODIC MAINTENANCE SCHEDULE

IMPORTANT: The periodic maintenance intervals and service requirements have been established in

accordance with EPA regulations. Following these instructions will ensure that the motorcycle will not

exceed emission standards and it will also ensure the reliability and performance of the motorcycle.

NOTE:

More frequent servicing may be performed on motorcycles that are used under severe conditions however,

it is not necessary for ensuring emission level compliance.

The chart below lists the recommended intervals for all the required periodic service work necessary

keep the motorcycle operating at peak performance and economy. Mileages are expressed in terms

kilometer, miles and time for your convenience.

to

of

-

PERIODIC MAINTENANCE CHART

INTERVALS: THIS INTERVAL SHOULD

JUDGED BY ODOMETER READING OR

MONTHS WHICHEVER COMES FIRST.

Battery (Specific gravity of electrolyte)

Air cleaner elements

Radiator hoses

BE km

miles

months

1000

600 4000

2

Clean every 6000 km (4000 miles) and

I

replace every 12000 km (7500 miles)

6000

12 24

12000

7500

-

18000 24000

11000 15000

36 48

-

Brake fluid

Brakes I I

Tires

Steering

Front forks

Rear shock absorbers

Chassis bolts and nuts

NOTE:

R = Replace,

= Inspect and adjust, clean, lubricate or replace as necessary

I

T = Tighten,

I I

I I

I

1

I

I I - I

T

I

Replace every two vears

I I

I I I

1

I

I

I

T T

I

I

I I I I

-

-

T T

I

I

I

I

PERIODIC MAINTENANCE AND TUNE-UP PROCEDURES 2-2

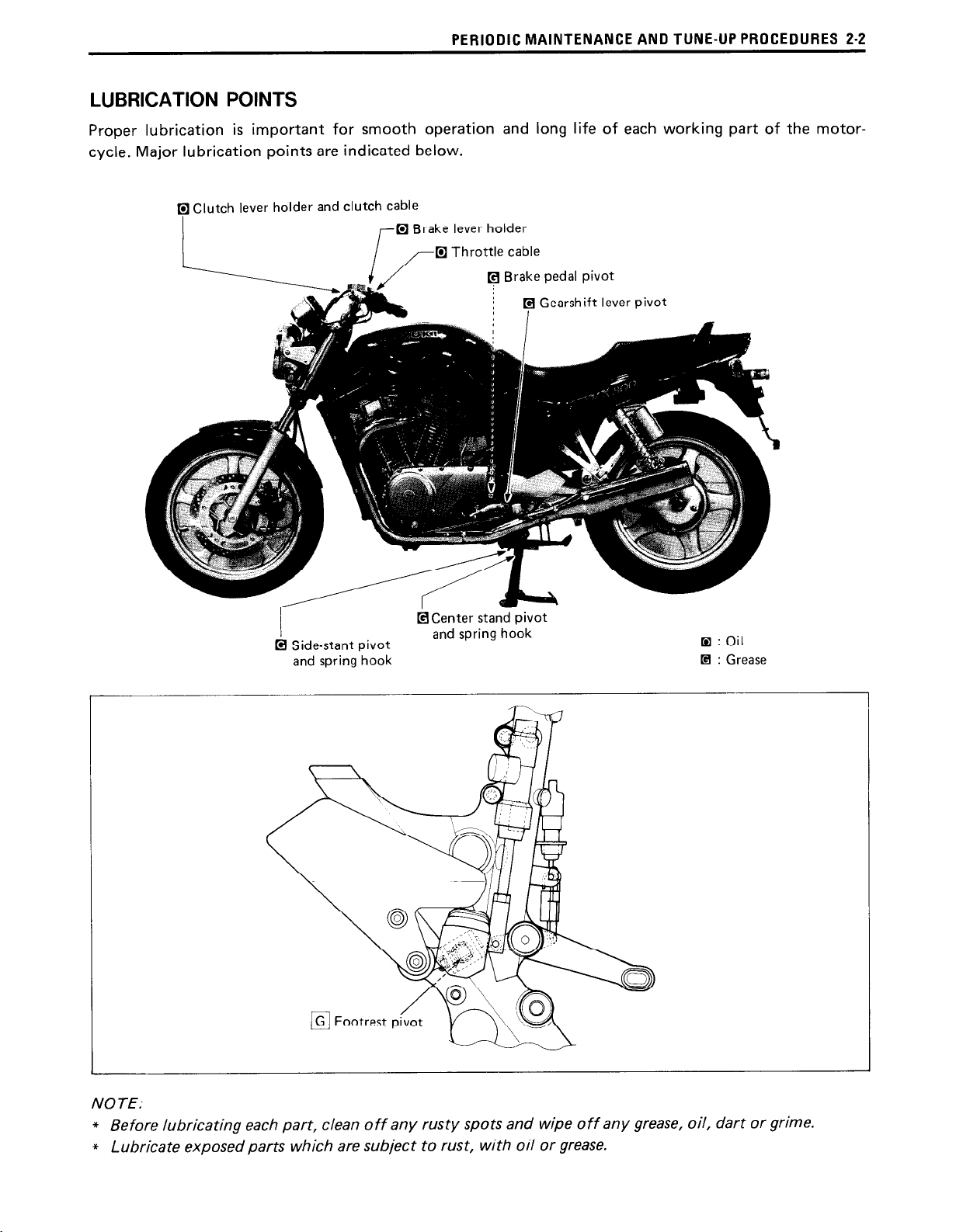

LUBRICATION POINTS

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated below.

q

Clutch lever holder and clutch cable

I

I

El Side-stant pivot

and spring hook

q

Footrest

ElCenter stand pivot

and spring hook

phot

q :

Oil

ra

NOTE:

*

Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dart or grime.

*

Lubricate exposed parts which are subject to rust, with oil or grease.

2-3

PERIODIC MAINTENANCE AND TUNE-UP PROCEDURES

MAINTENANCE AND TUNE-UP PROCEDURES

This section describes the servicing procedures for each item of

the Periodic Maintenance requirements.

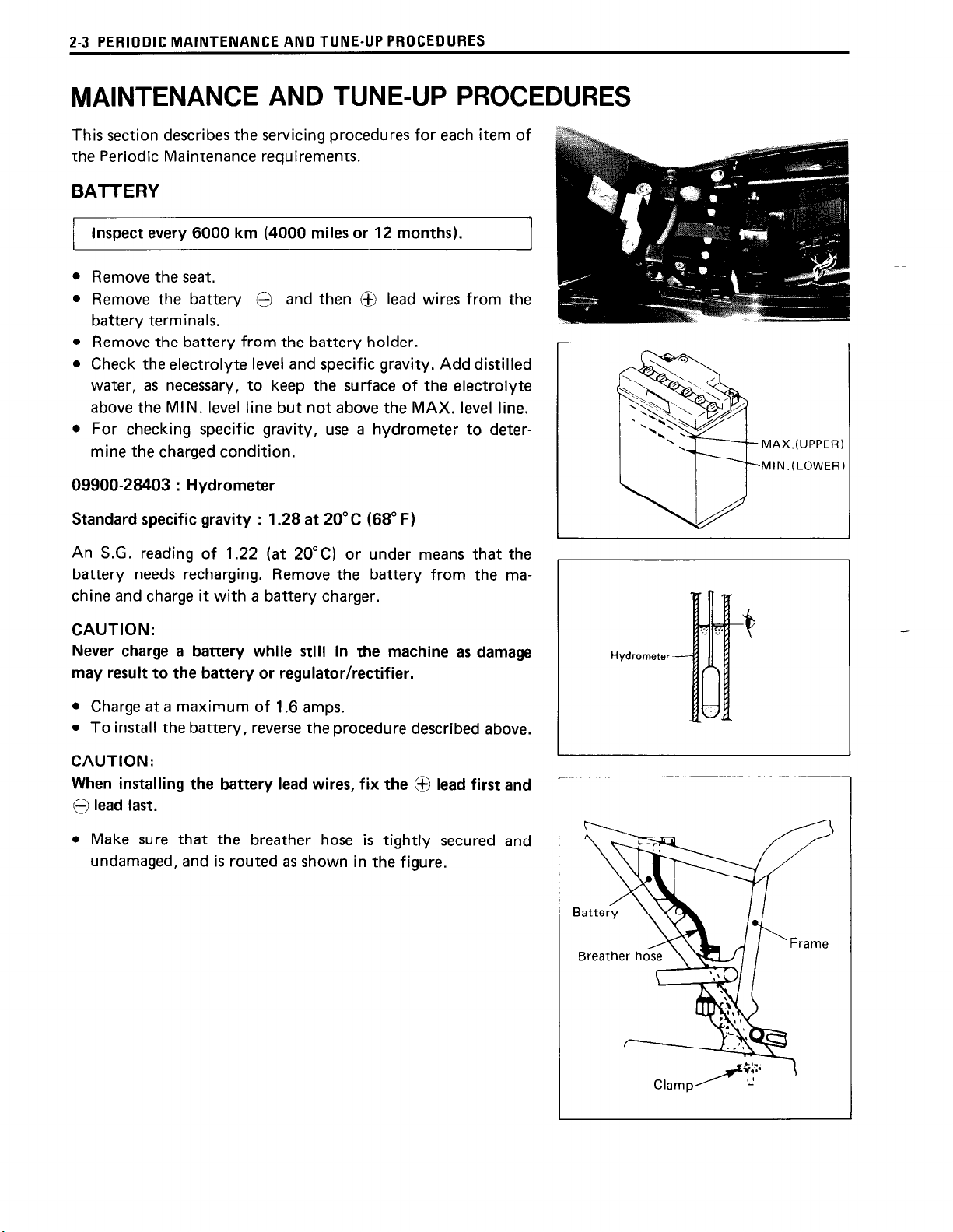

BATTERY

Inspect every 6000 km (4000 miles or 12 months).

Remove the seat.

Remove the battery 0 and then @ lead wires from the

battery terminals.

Remove the battery from the battery holder.

Check the electrolyte level and specific gravity. Add distilled

water, as necessary, to keep the surface of the electrolyte

above the MIN. level line but not above the MAX. level line.

For checking specific gravity, use a hydrometer to determine the charged condition.

09900-28403 : Hydrometer

Standard specific gravity : 1.28 at 20°C (68” F)

An S.G. reading of 1.22 (at 20°C) or under means that the

battery needs recharging. Remove the battery from the ma-

chine and charge it with a battery charger.

CAUTION:

Never charge a battery while still in the machine as damage

may result to the battery or regulator/rectifier.

I

-

MAX.(UPPER)

MIN.(LOWER)

Hydrometer

l

Charge at a maximum of 1.6 amps.

l

To install the battery, reverse the procedure described above.

CAUTION:

When installing the battery lead wires, fix the @ lead first and

0 lead last.

l

Make sure that the breather hose is tightly secured and

undamaged, and is routed as shown in the figure.

PERIODIC MAINTENANCE AND TUNE-UP PROCEDURES 2-4

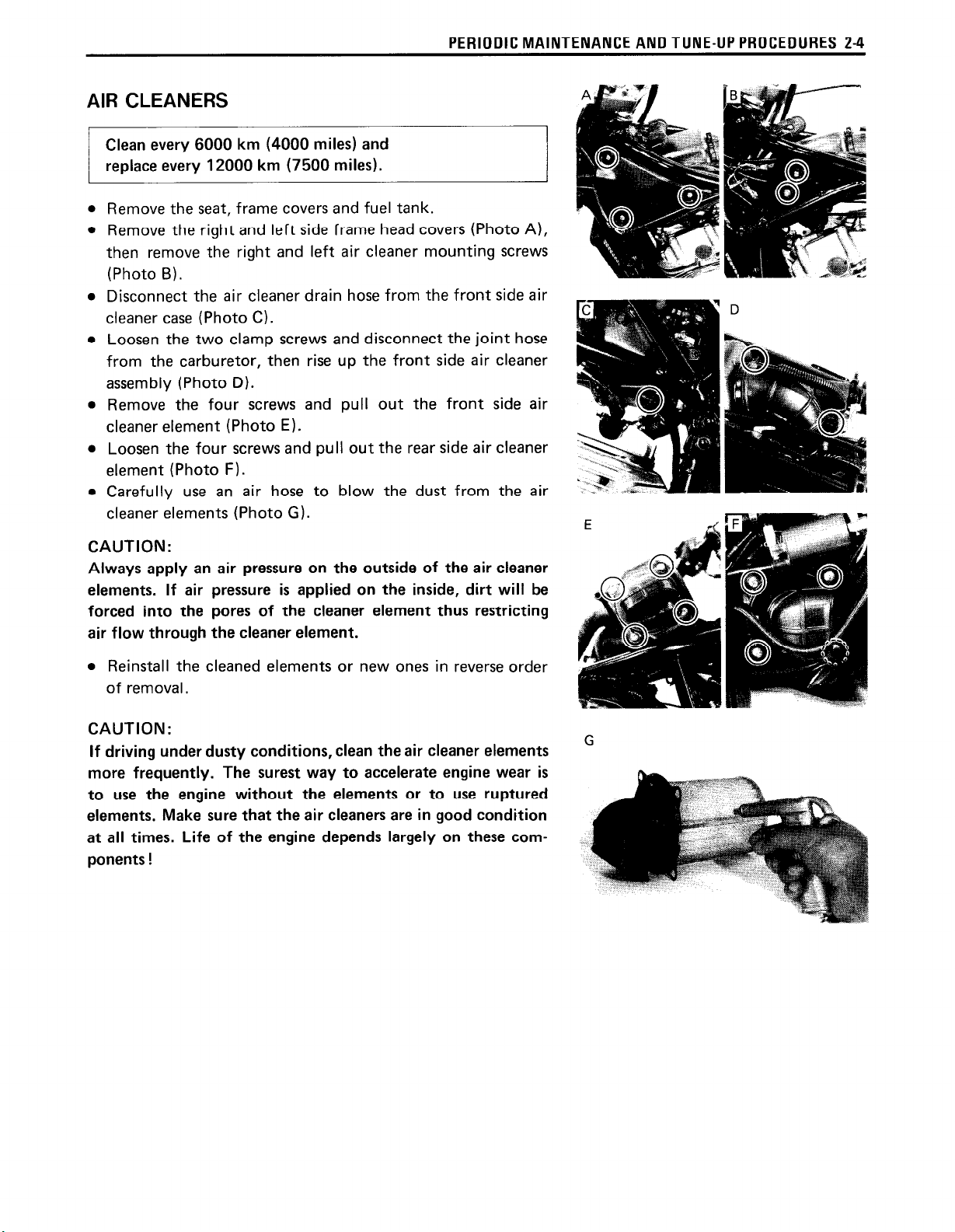

AIR CLEANERS

Clean every 6000 km (4000 miles) and

replace every 12000 km (7500 miles).

Remove the seat, frame covers and fuel tank.

Remove the right and left side frame head covers (Photo A),

then remove the right and left air cleaner mounting screws

(Photo 9).

Disconnect the air cleaner drain hose from the front side air

cleaner case (Photo C).

Loosen the two clamp screws and disconnect the joint hose

from the carburetor, then rise up the front side air cleaner

assembly (Photo D).

Remove the four screws and pull out the front side air

cleaner element (Photo E).

Loosen the four screws and pull out the rear side air cleaner

element (Photo F).

Carefully use an air hose to blow the dust from the air

cleaner elements (Photo G).

CAUTION:

Always apply an air pressure on the outside of the air cleaner

elements. If air pressure is applied on the inside, dirt will be

forced into the pores of the cleaner element thus restricting

air flow through the cleaner element.

l

Reinstall the cleaned elements or new ones in reverse order

of removal,

CAUTION:

If driving under dusty conditions, clean the air cleaner elements

more frequently. The surest way to accelerate engine wear is

to use the engine without the elements or to use ruptured

elements. Make sure that the air cleaners are in good condition

at all times. Life of the engine depends largely on these com-

ponents

!

2-5 PERIODIC MAINTENANCE AND TUNE-UP PROCEDURES

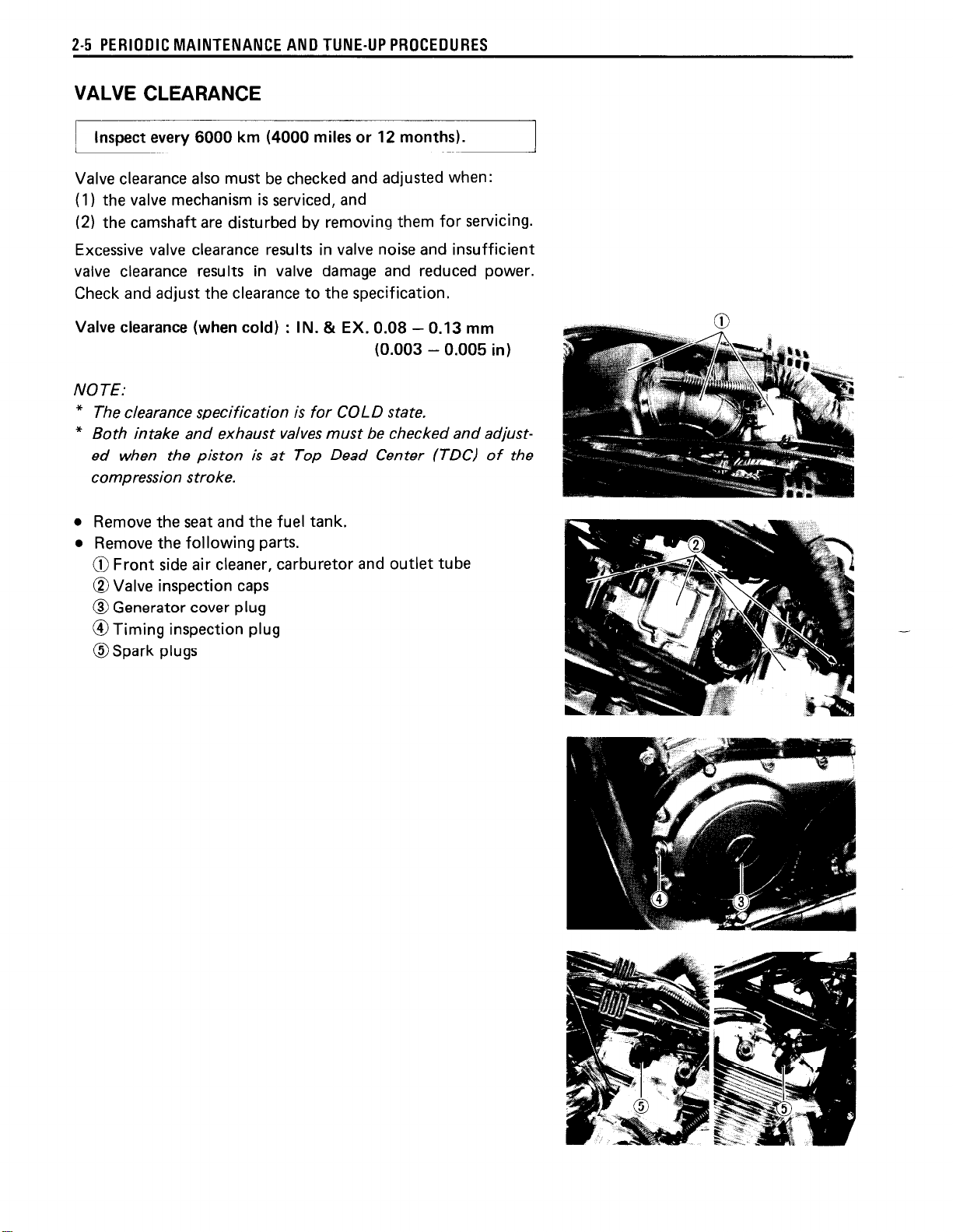

VALVE CLEARANCE

inspect every

6000

km (4000 miles or 12 months).

Valve clearance also must be checked and adjusted when:

(1)

the valve mechanism is serviced, and

(2) the camshaft are disturbed by removing them for servicing.

Excessive valve clearance results in valve noise and insufficient

valve clearance results in valve damage and reduced power.

Check and adjust the clearance to the specification.

Valve clearance (when cold) : IN. & EX. 0.08 - 0.13 mm

(0.003 - 0.005 in)

NOTE:

* The clearance specification is for COLD state.

* Both intake and exhaust valves must be checked and adjust-

ed when the piston is at Top Dead Center (TDCI of the

compression stroke.

l

Remove the seat and the fuel tank.

l

Remove the following parts.

@ Front side air cleaner, carburetor and outlet tube

@Valve inspection caps

@ Generator cover plug

@Timing inspection plug

@Spark plugs

-

Loading...

Loading...