Suzuki VX800 1990-1993 Service Manual 07 Electrical system

CONTENTS

CHARGING SYSTEM

DESCRIPTION

INSPECTION

IGNITION SYSTEM

DESCRIPTION

INSPECTION .........................................................

STARTER SYSTEM

.........................................................

.................................................

.......................................................

...................................................

.......................................................

...................................................

7- 1

7- 1

7- 3

7- 5

7- 5

7- 6

7-

10

DESCRIPTION

REMOVAL AND DISASSEMBLY

INSPECTION

REASSEMBLY

STARTER REU Y INSPECTION

SIDE-S7AND/lGNl7lON INTERLOCK SYSTEM

DESCRIPTION .......................................................

INSPECTION

COMBINA T/ON METER

REMOVAL AND DISASSEMBLY

INSPECTION

LAMPS

HEXDLIGHT

TAIL/ BRAKE LIGHT

TURN SIGNAL LIGHT

SWITCHES

RELA Y

STARTER RELA Y

SIDE-S7A ND REU Y

TURN SIGNAL RELA Y

BA 7TERY

..................................................................

.............................................................

...................................................................

................................................................

.......................................................

.................................

.........................................................

.......................................................

..................................

.........................................................

..............................................

.................................

........................................................

.........................................................

................................................

..............................................

...................................................

...............................................

.............................................

..................

7- 10

7- 10

7- 11

7- 12

7- 13

7- 13

7- 13

7- 15

7- 16

7- 16

7-17

7- 18

7-18

7- 18

7- 19

7- 19

7-20

7-20

7-20

7-20

7-2 1

SPECIFICA TIONS

INITIAL CHARGING

SERVICING

RECHARGING OPERA T/ON BASED ON S. G. READING

SERVICE LIFE

..........................................................

..................................................

................................................

........................................................

7-2 1

7-2 1

7-2 1

...... 7-22

7-23

7-1 ELECTRICAL SYSTEM

CHARGING SYSTEM

DESCRIPTION

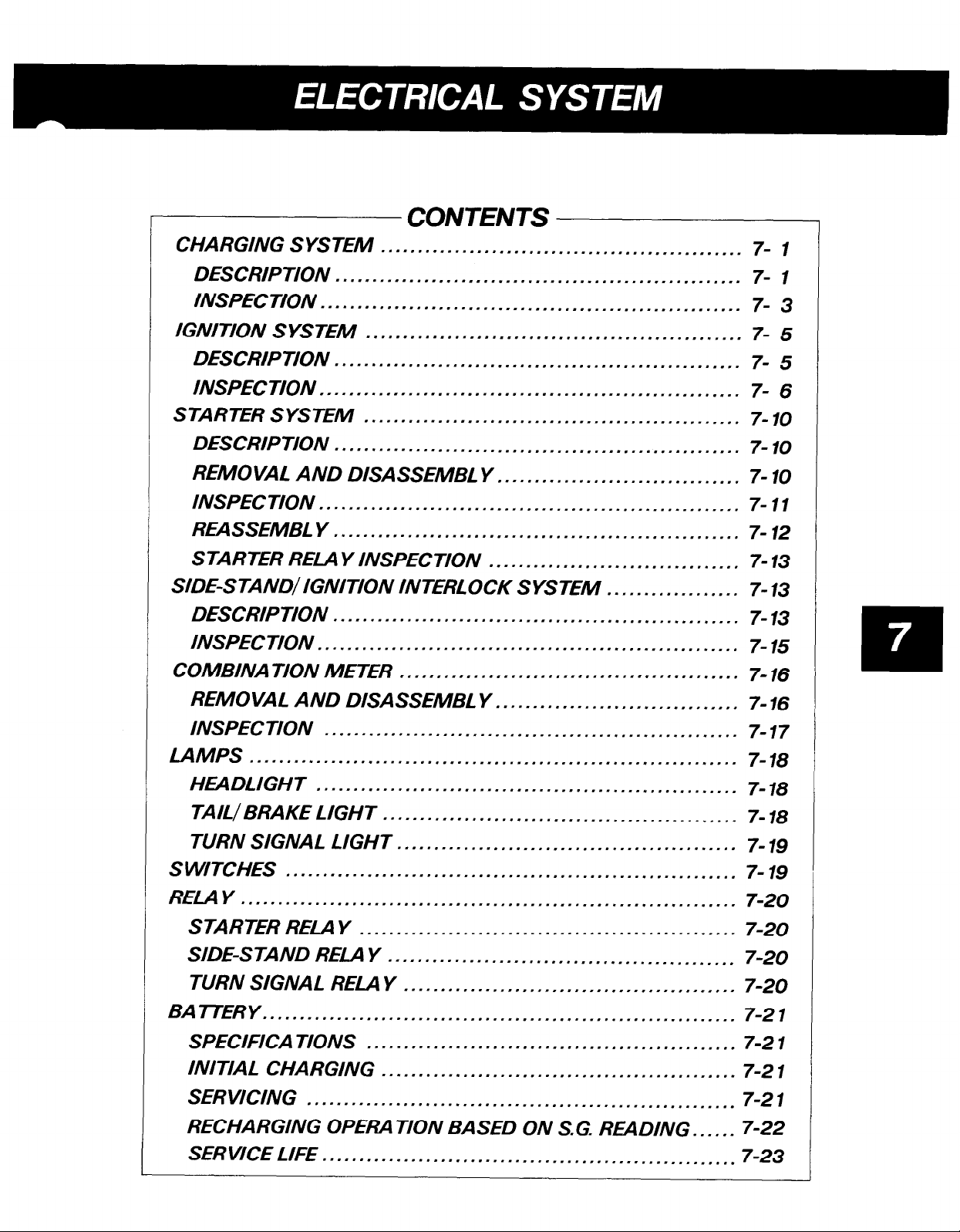

The circuit of the charging system is indicated in the figure, which is composed of an AC generator, regu-

lator/rectifier unit and battery.

The AC current generated from the AC generator is rectified by the rectifier and is turned into DC current,

then it charges the battery.

AC generator

I I

-1-1-1-1-----1--1-11

r

Regulator/Rectifier

1 1 T 1 T T 7 I TOW

SCR

Ignition switch

1

I

-

j 1 I-0 U.S.A. model only

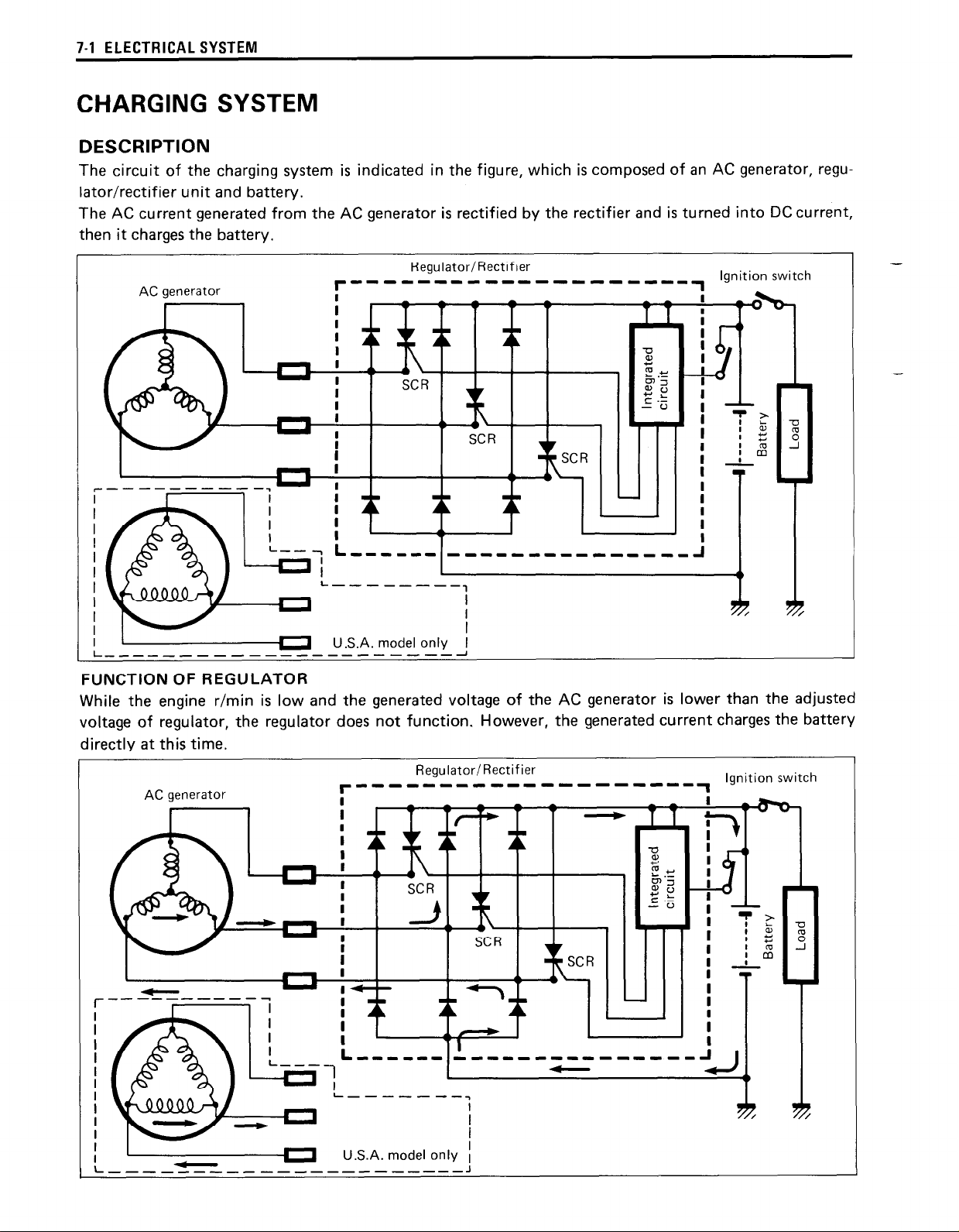

FUNCTION OF REGULATOR

While the engine r/min is low and the generated voltage of the AC generator is lower than the adjusted

voltage of regulator, the regulator does not function. However, the generated current charges the battery

directly at this time.

-------__-----

AC generator

r

-_--A

1-a-1-wmm1111---we--

Regulator/Rectifier

i

Ignition switch

1

A

b

I

::

:

2

rI

I

i

I

:

4J

I

T

/

i

I

I

L

1

_-------(

.S.A.

model only

,------- J

I

I

i

SCR

111

4

ELECTRICAL SYSTEM 7-2

When the engine r/min becomes higher, the generated voltage of the AC generator also becomes higher and

the voltage between the battery terminals becomes high accordingly. When it reaches the adjusted voltage

of the I.C. (Integrated Circuit) and it is turned “ON”,

probe and the SCR will be turned “ON”.

Then, the SCR becomes conductive in the direction from point @ to point @I. At this time, the current

generated from the AC generator gets through the SCR without charging the battery and returns to AC

generator again. At the end of this state, since the AC current generated from AC generator flows to point

@ , the reverse current tends to flow to SCR. Then, the circuit of SCR turns to the OFF mode and begins

to charge the battery again. Thus these repetitions maintain charging voltage and current to the battery

constant and protect it from overcharging.

a signal will be sent to the SCR (Thyristor) gate

Regulator/Rectifier

AC generator

---------1---1-11---

n

a---_-----

r

I

i v U.S.A. model only

Ignition switch

1

I

1

@

i

17

I

7-3 ELECTRICAL SYSTEM

INSPECTION

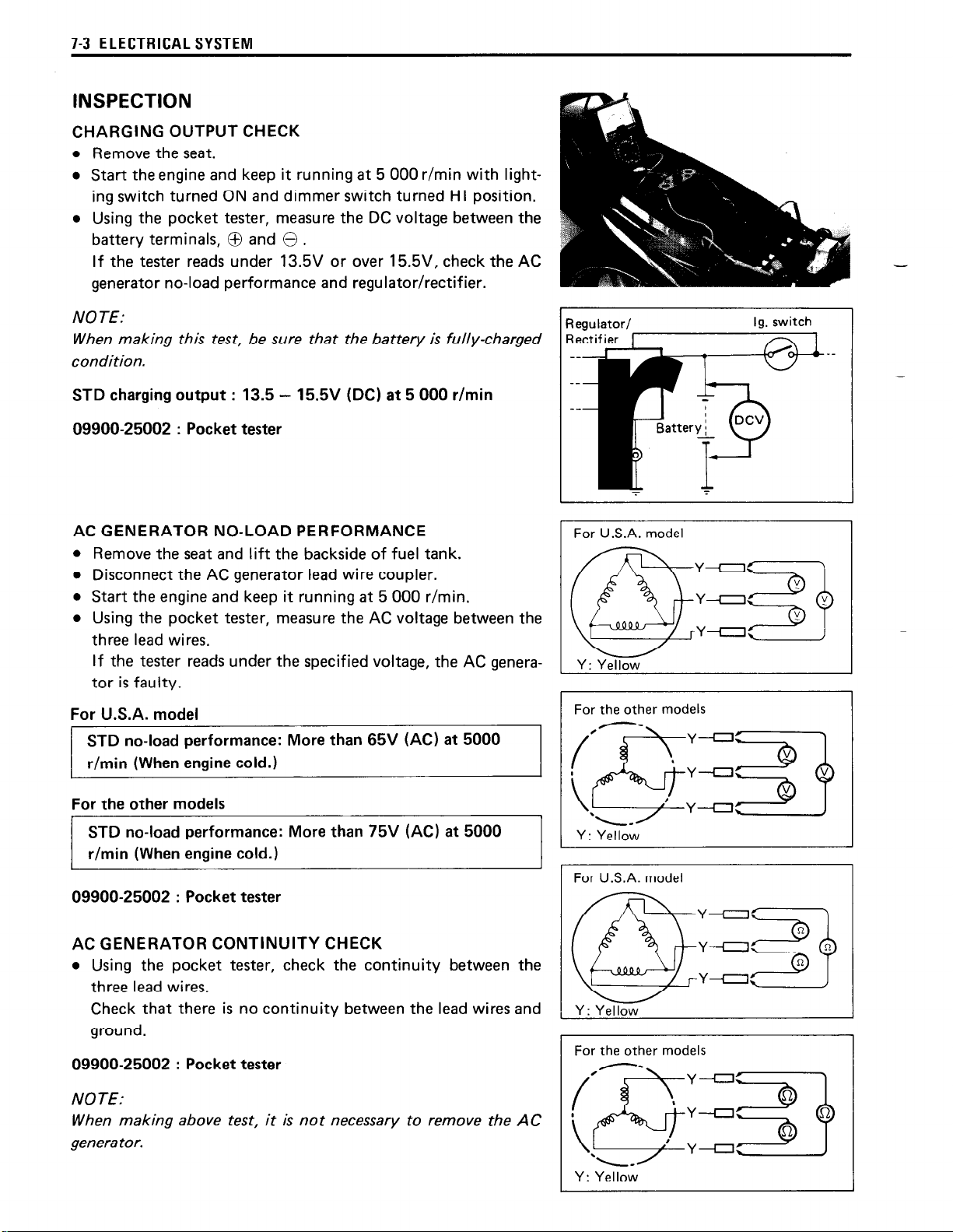

CHARGING OUTPUT CHECK

Remove the seat.

Start the engine and keep it running at 5 000 r/min with light-

ing switch turned ON and dimmer switch turned HI position.

Using the pocket tester, measure the DC voltage between the

battery terminals, 0 and 0

If the tester reads under 13.5V or over 15.5V, check the AC

generator no-load performance and regulator/rectifier.

.

NOTE:

When making this test, be sure that the battery is fully-charged

condition.

STD charging output : 13.5 - 15.5V (DC) at 5 000 r/min

09900-25002 : Pocket tester

AC GENERATOR NO-LOAD PERFORMANCE

Remove the seat and lift the backside of fuel tank.

Disconnect the AC generator lead wire coupler.

Start the engine and keep it running at 5 000 r/min.

Using the pocket tester, measure the AC voltage between the

three lead wires.

If the tester reads under the specified voltage, the AC genera-

tor is faulty.

For U.S.A. model

STD no-load performance: More than 65V (AC) at 5000

r/min (When engine cold.)

r

3egulatorf

3ectifier

-_

-_

__

For U.S.A. model

1 For the other models

I--

0

T

lg. switch

f

I

For the other models

STD no-load performance: More than 75V (AC) at 5000

r/min (When engine cold.)

09900-25002 : Pocket tester

AC GENERATOR CONTINUITY CHECK

l

Using the pocket tester, check the continuity between the

three lead wires.

Check that there is no continuity between the lead wires and

ground.

09900-25002

NOTE:

When making above test, it is not necessary to remove the AC

generator.

:

Pocket tester

Y:

Yellow

For U.S.A. model

@ii=+

Y: Yellow

For the other models

Y: Yellow

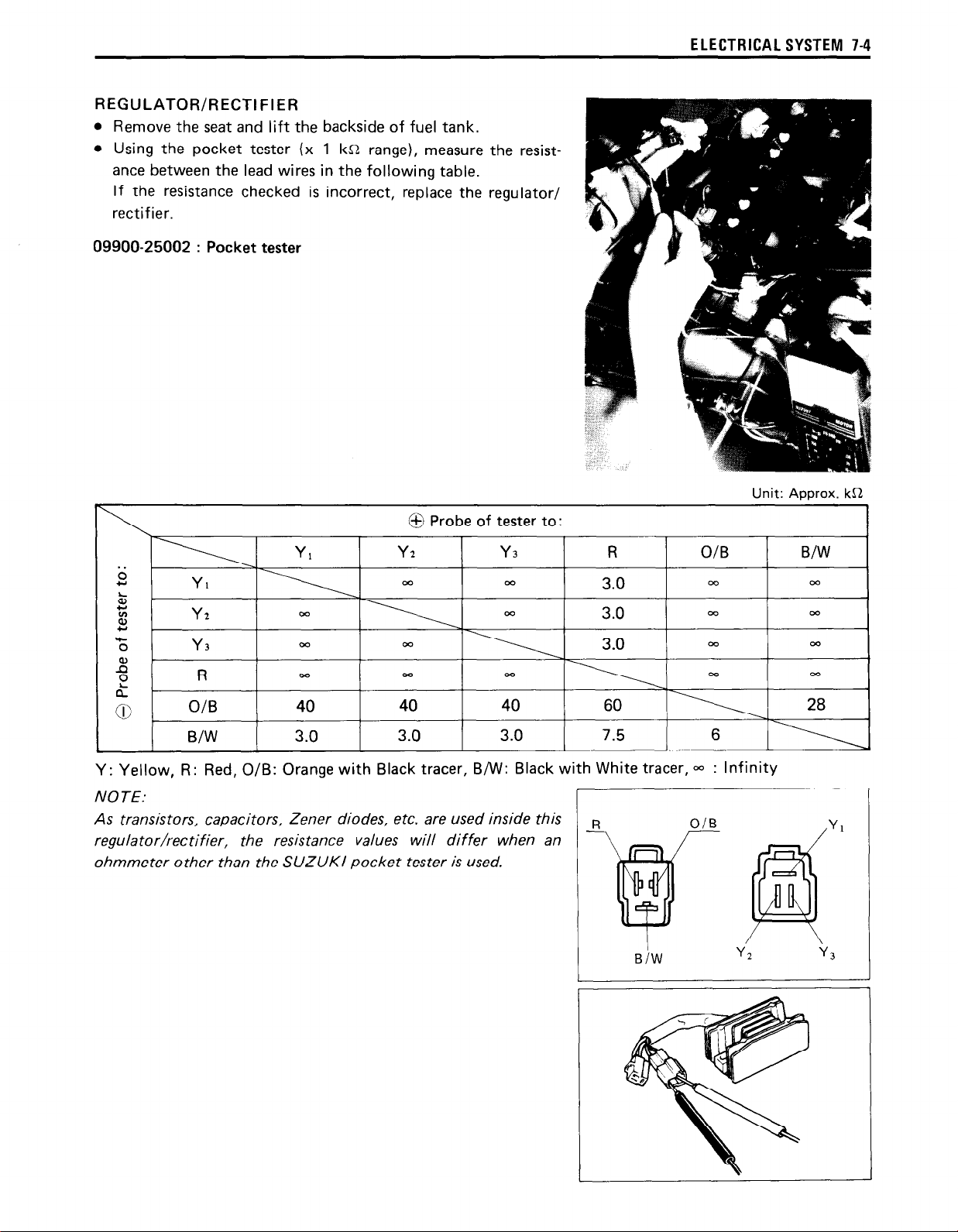

REGULATOR/RECTIFIER

l

Remove the seat and lift the backside of fuel tank.

l

Using the pocket tester (x 1 kn range), measure the resist-

ance between the lead wires in the following table.

If the resistance checked is incorrect, replace the regulator/

rectifier.

ELECTRICAL SYSTEM 7-4

09900-25002 : Pocket

\

Y3 00 00 100 m

R co 00 m 00

O/B

tester

@ Probe of tester to:

Y3

m

m

40 40 40 60

R

3.0

3.0

. I

.

O/B

00

00

Unit: Approx. kR

B/W

m

00

B/W 3.0 3.0 3.0 7.5

Y: Yellow, R: Red, O/B: Orange with Black tracer, B/W: Black with White tracer, m : Infinity

NOTE:

As transistors, capacitors, Zener diodes, etc. are used inside this R

O/B

regulator/rectifier, the resistance values will differ when an

ohmmeter other than the SUZUKI pocket tester is used.

V

B/W

Y2

7-5 ELECTRICAL SYSTEM

IGNITION SYSTEM

DESCRIPTION

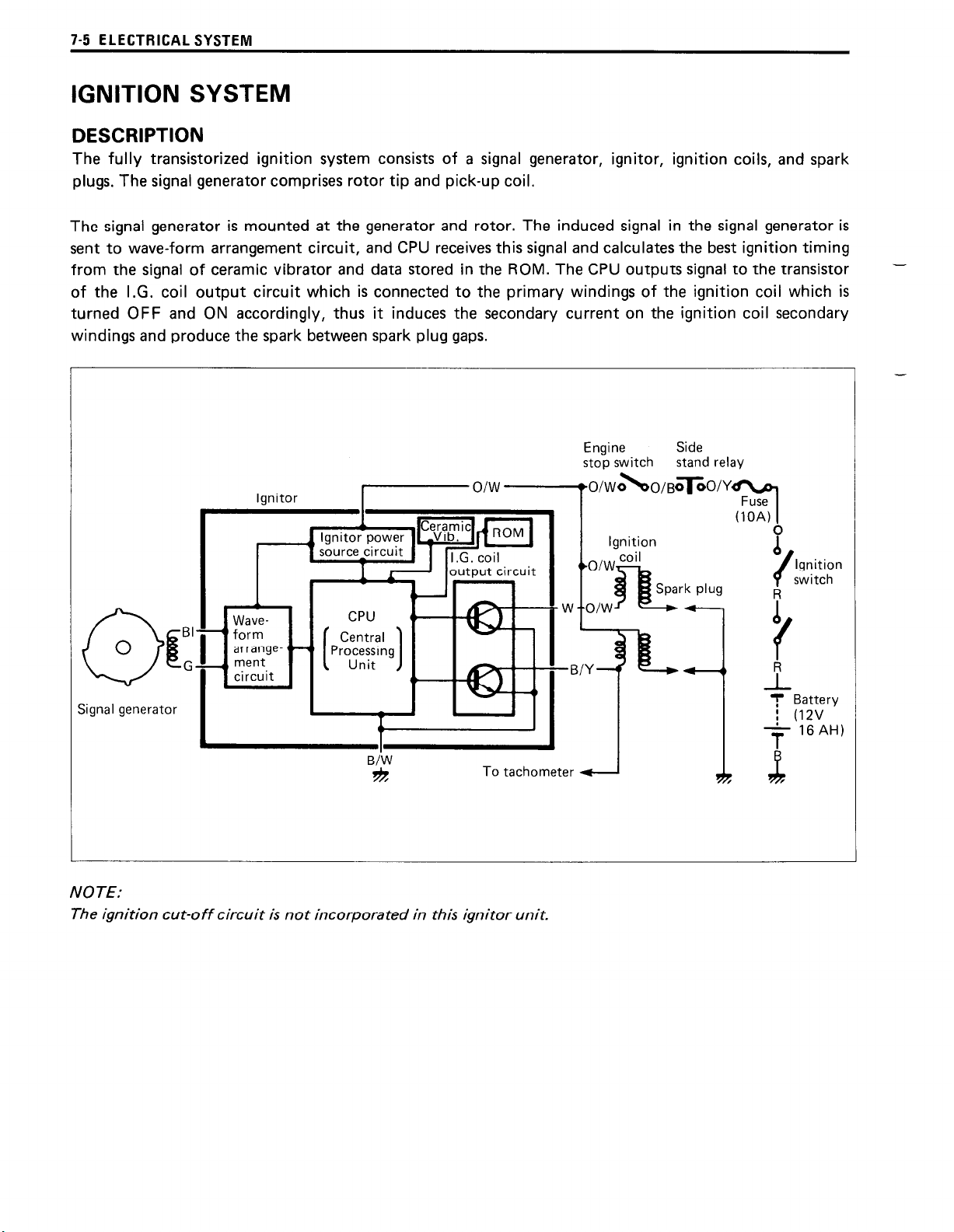

The fully transistorized ignition system consists of a signal generator, ignitor, ignition coils, and spark

plugs. The signal generator comprises rotor tip and pick-up coil.

The signal generator is mounted at the generator and rotor. The induced signal in the signal generator is

sent to wave-form arrangement circuit, and CPU receives this signal and calculates the best ignition timing

from the signal of ceramic vibrator and data stored in the ROM. The CPU outputs signal to the transistor

of the I.G. coil output circuit which is connected to the primary windings of the ignition coil which is

turned OFF and ON accordingly, thus it induces the secondary current on the ignition coil secondary

windings and produce the spark between spark plug gaps.

-

-

lgnitor

70/w-

I

r

B/W

*

,

To tachometer f-

Wave-

&

* ’

form

0

B’

E

G

0

Signal generator

NOTE:

The ignition cut-off circuit is not incorporated in this ignitor unit.

I

+, ment

arrange-

circuit

’ +-I

*

CPU

Central

Processing

Unit

I I,,

Engine

stop switch stand relay

O/WO\O,BO~o/Y~

I

-B/Y-

I

Side

H

ignition

switch

/

R

b

f

iL

T Battery

:

(12V

B 16AH’

I

A

INSPECTION

IGNITION COIL (Checking with Electra Tester)

l

Remove the ignition coils from the frame.

l

Using the electro tester, test each ignition coil for sparking

performance. The test connection is as indicated. Make sure

that the three-needle sparking distance is at least 8 mm.

If no sparking or orange color sparking occurs with this much

gap, then it is defective and must be replaced.

09900-28106 : Electra tester

STD Spark performance : 8 mm (0.3 in)

IGNITION COIL (Checking with Pocket Tester)

l

A SUZUKI pocket tester or an ohmmeter may be used,

instead of the electro tester. In either case, the ignition coil

is to be checked for continuity

ary windings.

Exact ohmic readings are not necessary, but, if the windings

are in sound condition, their continuity will be noted with

these approximate ohmic values.

in both primary and second-

ELECTRICAL SYSTEM 7-6

I

Porn

Select “IG. COIL”

k

09900-25002 :

Pocket tester

Ignition coil resistance

Primary :@tap- 0 tap2-6a

Tester range: (x 1 a)

: &

Secondary

tap - Plug cap 19 - 27 ka

Tester range: (x 1 kR)

SIGNAL GENERATOR (Checking with Pocket Tester)

l

Remove the seat and left frame cover.

l

Measure the resistance between lead wires. If the resistance is

infinity or less than the specification, the signal generator

must be replaced.

09900-25002 : Pocket tester

(For U.S.A. model)

Signal coil resistance : (G - BI)

Approx. 117

Tester range:

R

(x

100 a)

(For the other models)

Signal coil resistance : (G - BI)

Approx. 230

Tester range

n

:

(x 100 a)

Wire color

:

Green

G

BI : Blue

7-7 ELECTRICAL SYSTEM

CAUTION:

When replacing the generator coil, apply a small quantity of

THREAD LOCK “1342” to its mounting bolts and lead wire

guide screws.

99000-32050 : THREAD LOCK “1342”

SPARK PLUG

l

Clean the plug with a wire brush and pin. Use the pin to

remove carbon, taking care not to damage the porcelain.

I

~-of~,o~-,n~

1

model)

1

Clamp

(Only for U.S.A. model)

I

l

Check the gap with a thickness gauge.

Spark plug gap : 0.8 - 0.9 mm (0.031 - 0.035 in)

Recommended spark plug

ND: X24EPR-U9

ND: X22EPR-U9

ND: X27EPR-U9

NGK: DPR8EA-9

NGK: DPR7EA-9

NGK: DPRSEA-9

. . . . .

. . . . .

. . . . .

. . . . . .

. . . . . .

. . . . . .

Standard

Hot type

Cold type

Standard

Hot type

Cold type

NOTE:

“R” type spark plug is installed for some specifications. “R”

type spark plug has a resister located at the ten ter electrode to

prevent radio noise.

Loading...

Loading...