Page 1

D - ADJUSTMENTS

Article Text

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

ARTICLE BEGINNING

Thursday, April 08, 1999 09:26AM

1993 ENGINE PERFORMANCE

Suzuki of America Corp. On-Vehicle Adjustments

Suzuki; Samurai, Sidekick, Swift

ENGINE MECHANICAL

Before performing any on-vehicle adjustments to fuel or

ignition system, ensure engine mechanical condition is okay.

VALVE CLEARANCE

NOTE: Swift DOHC uses hydraulic lifters. No adjustments are

required.

Samurai & Sidekick

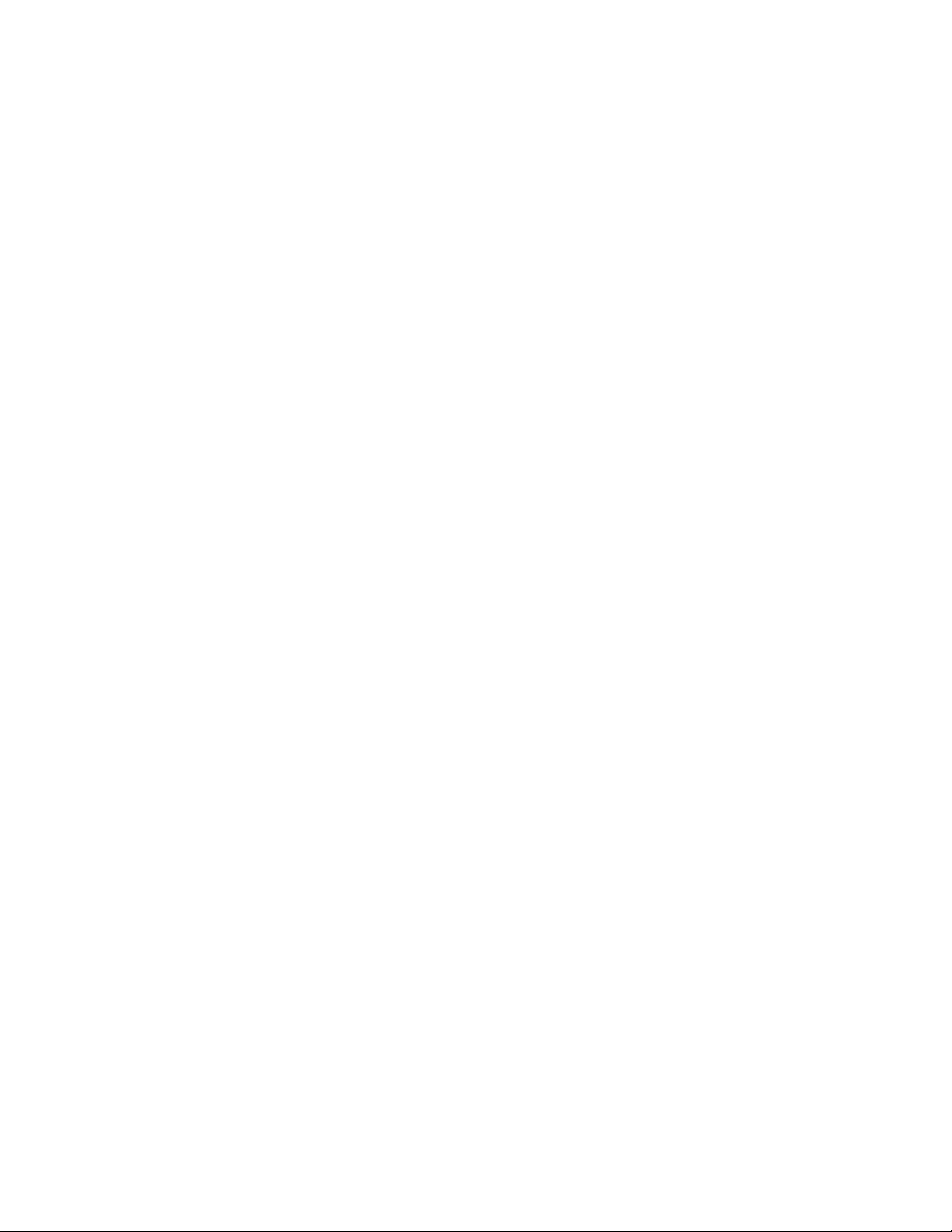

1) Remove valve cover. Rotate engine until zero degree (TDC)

timing mark of timing belt cover is in line with timing mark on

crankshaft pulley. See Fig. 1.

2) Ensure cylinder No. 1 is at TDC on compression stroke.

Remove distributor cap. On Samurai and Sidekick (TBI), ensure rotor is

pointed upward at distributor hold-down bolt and to No. 1 terminal of

distributor cap. On Sidekick (MPI), ensure rotor is at about 1 o’clock

position and pointed to No. 1 terminal of distributor cap. If rotor is

not as described, rotate crankshaft 360 degrees.

3) Measure valve clearance between adjustment screw and valve

stem using shim thickness gauge. Check intake valve clearance of

cylinders No. 1 and 2 and exhaust valve clearance of cylinders No.

1and 3. See VALVE CLEARANCE SPECIFICATIONS table.

4) Turn crankshaft one complete revolution (360 degrees).

Check intake valve clearance of cylinders No. 3 and 4 and exhaust

valve clearance of cylinders No. 2 and 4.

5) Adjust valves by loosening lock nut and turning adjusting

screw until clearance is as specified. After adjusting clearance,

tighten adjusting screw lock nut to 11.0-13.5 ft. lbs. (15-18 N.m) for

Samurai or 90-108 INCH lbs. (10-13 N.m) on Sidekick. On all models,

recheck clearance.

VALVE CLEARANCE SPECIFICATIONS TABLE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application In. (mm)

Samurai, Sidekick (TBI) & Swift SOHC

Engine Cold

Intake ........................................ .005-.007 (.13-.18)

Exhaust ....................................... .006-.008 (.15-.20)

Engine Hot

Intake ........................................ .009-.011 (.23-.28)

Exhaust ....................................... .010-.012 (.25-.30)

Page 2

D - ADJUSTMENTS

Article Text (p. 2)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Sidekick (MPI)

Engine Cold

Intake & Exhaust .............................. .003-.005 (.08-.12)

Engine Hot

Intake & Exhaust .............................. .005-.006 (.12-.16)

Swift DOHC ..................................................... (1)

(1) - Hydraulic valve lash adjusters are used and no adjustment is

required.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Swift SOHC

1) Remove valve cover. Remove right inner fender apron

extension to enable timing marks to be seen. Align crankshaft pulley

timing mark with TDC mark on timing belt cover. See Fig. 1.

2) Remove distributor cap. Ensure rotor is pointing upward

toward distributor hold-down bolt and to No. 1 terminal of distributor

cap. If rotor is not as described, rotate crankshaft 360 degrees.

3) Measure valve clearance between adjustment screw and valve

stem using shim thickness gauge. Check intake valve clearance of

cylinders No. 1 and 2 and exhaust valve clearance of cylinders No.

1and 3. See VALVE CLEARANCE SPECIFICATIONS table. Turn crankshaft one

complete revolution (360 degrees). Check intake valve clearance of

cylinders No. 3 and 4 and exhaust valve clearance of cylinders No. 2

and 4.

4) Adjust valves by loosening lock nut and turning adjusting

screw until clearance is as specified. Hold adjusting screw while

tightening lock nut to 11.0-13.5 ft. lbs. (15-18 N.m). Recheck

clearance.

IGNITION TIMING

NOTE: Verify that increasing engine speed advances ignition timing.

Samurai & Sidekick

1) Ensure transmission is in Neutral or Park and parking

brake is set. Inspect crankshaft pulley timing mark and timing mark

indicator on timing belt cover. See Fig. 1. Clean marks as required.

Start engine, and warm it to normal operating temperature. Turn engine

off with ignition on for 5 seconds. Restart engine. Run engine at 2000

RPM for 5 minutes, and then return it to idle. Turn all accessories

off. Attach timing light to No. 1 spark plug wire. Ensure idle speed

is correct. See IDLE SPEED SPECIFICATIONS table under IDLE SPEED &

MIXTURE.

CAUTION: Driving with jumper wire installed in monitor coupler will

damage catalytic converter.

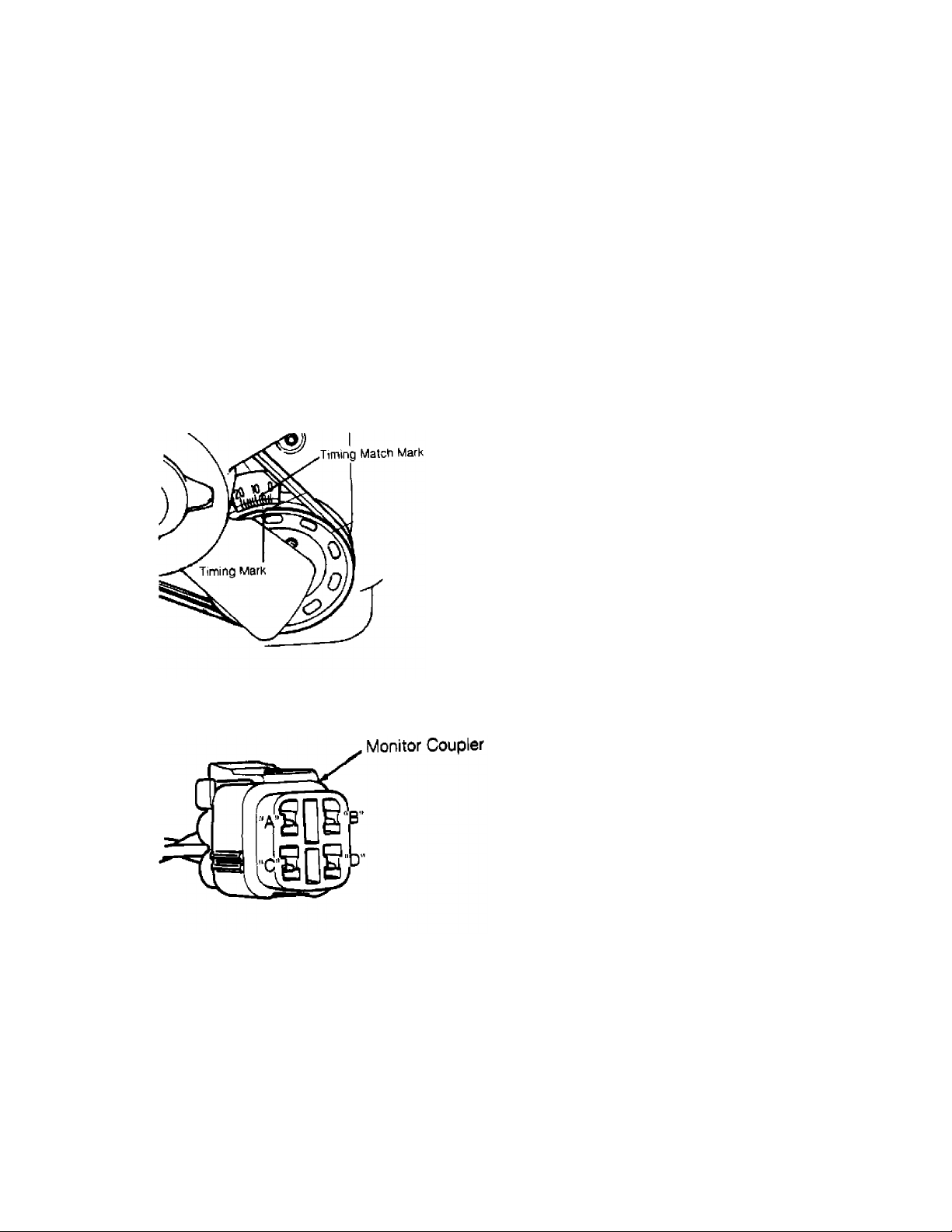

2) Remove protective cap from monitor coupler located next to

battery. Connect jumper wire between terminals "C" (ground) and "D"

(test switch). See Fig. 2. Aim timing light at crankshaft pulley and

timing cover timing marks. If ignition timing is not within

Page 3

D - ADJUSTMENTS

Article Text (p. 3)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

specification, loosen distributor hold-down flange bolts, and rotate

distributor to obtain correct ignition timing. See IGNITION TIMING

table. Tighten distributor hold-down flange bolts, and recheck

ignition timing.

NOTE: With jumper wire installed, timing should be fixed. If

timing varies, terminal "D" is not properly grounded.

3) Remove jumper wire from monitor coupler. Ensure ignition

timing advances as engine speed increases. If ignition timing does not

advance, check TPS, monitor coupler wiring circuit, engine start

signal circuit and ECM.

Fig. 1: Locating Ignition Timing Mark

Courtesy of Suzuki of America Corp.

Fig. 2: Identifying Monitor Coupler Terminals (Samurai & Sidekick)

Courtesy of Suzuki of America Corp.

IGNITION TIMING TABLE (Degrees BTDC @ RPM) (1)

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application Man. Trans. Auto. Trans.

Samurai .................. (2) 7-9 @ 800 ................ Not Used

Sidekick

MPI ..................... (2) 4-6 @ 800 ........... (2) 4-6 @ 800

TBI ..................... (2) 7-9 @ 800 ........... (2) 7-9 @ 800

Swift

Page 4

D - ADJUSTMENTS

Article Text (p. 4)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

DOHC ................. (3) 5-7 @ 800-900 ..... (3) 5-7 @ 800-900

SOHC .................... (3) 4-6 @ 750 ........... (3) 4-6 @ 850

(1) - See Fig. 1 for timing mark location.

(2) - With jumper wire installed between "C" and "D" terminals of

monitor coupler connector, located near battery. See Fig. 2.

(3) - With jumper wire installed between "D" and "E" terminals of

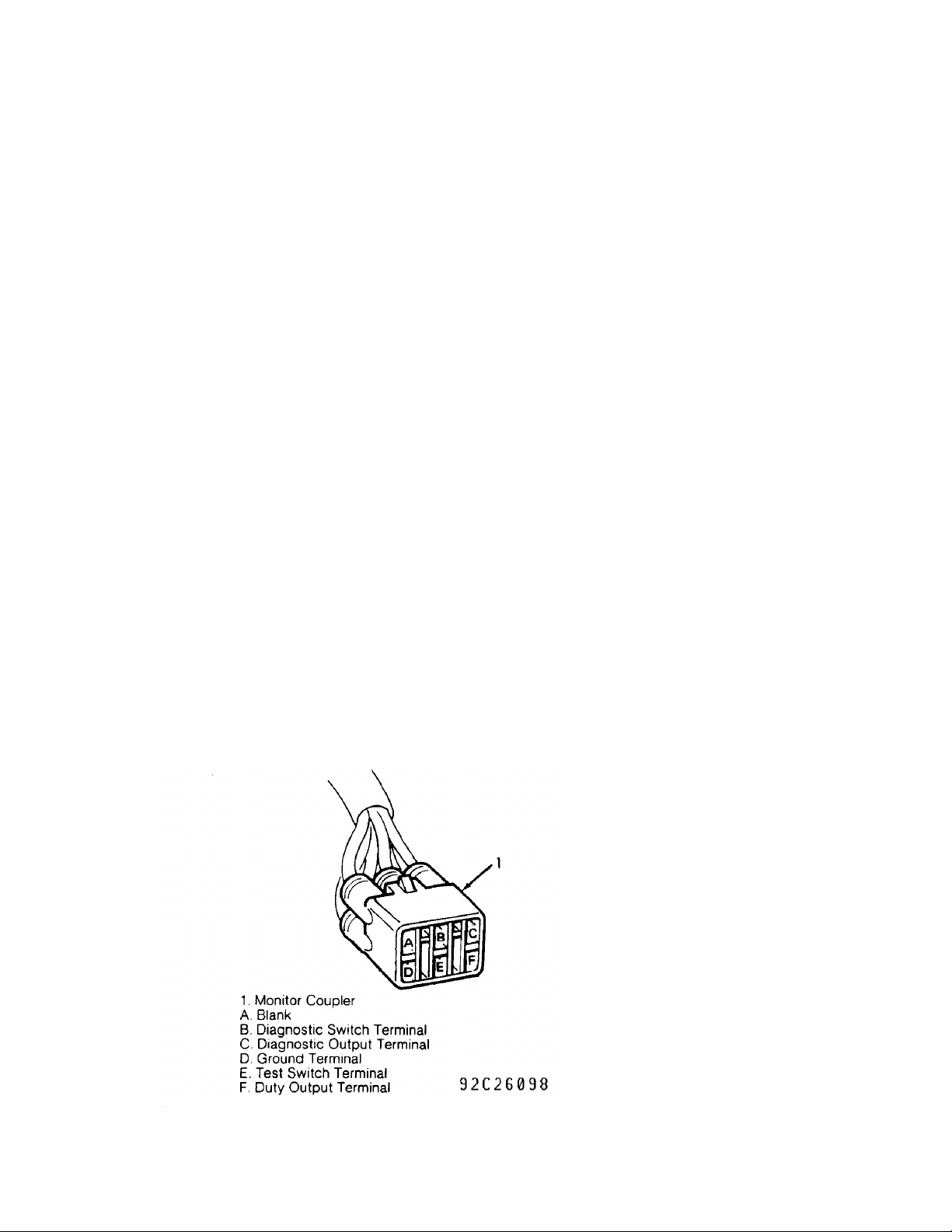

monitor coupler connector, located near ignition coil.

See Fig. 3.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Swift

1) Ensure transmission is in Neutral or Park. Set parking

brake. Inspect crankshaft pulley timing mark and timing mark indicator

on timing belt cover. See Fig. 1. Clean marks as required. Start

engine, and warm it to normal operating temperature. Turn all

accessories off. Attach timing light to No. 1 spark plug wire. Ensure

idle speed is correct. See IDLE SPEED SPECIFICATIONS table under IDLE

SPEED & MIXTURE.

CAUTION: Driving with jumper wire installed in monitor coupler will

damage catalytic converter.

2) Connect terminals "D" (ground) and "E" (test switch) of

monitor coupler. See Fig. 3. Aim timing light at crankshaft pulley and

timing cover timing marks. If ignition timing is not within

specification, loosen distributor hold-down bolt and rotate

distributor to obtain correct ignition timing. See IGNITION TIMING

table. Tighten distributor hold-down bolt, and recheck ignition

timing.

Fig. 3: Identifying Monitor Coupler Terminals (Swift)

Courtesy of Suzuki of America Corp.

Page 5

D - ADJUSTMENTS

Article Text (p. 5)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

PICK-UP COIL AIR GAP

Thursday, April 08, 1999 09:26AM

1) Remove distributor cap and rotor. Using non-magnetic shim

thickness gauge, measure air gap between reluctor tooth and pick-up

coil. See PICK-UP COIL AIR GAP table. If adjustment is required,

loosen pick-up coil plate hold-down screws.

2) Using blade screwdriver, move pick-up coil plate to adjust

air gap to specification. See PICK-UP COIL AIR GAP table. Tighten

screws, and recheck air gap. Ensure no metal particles are on pick-up

coil tooth.

PICK-UP COIL AIR GAP TABLE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application In. (mm)

Samurai ........................................................ (1)

Sidekick ....................................................... (1)

Swift

DOHC (2) ...................................... .008-.012 (.20-.30)

SOHC ................................................... .008 (.20)

(1) - Not adjustable.

(2) - Also referred to as crank angle sensor air gap.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

IDLE SPEED & MIXTURE

NOTE: Mixture is not adjustable. Mixture is controlled by ECM from

various sensor inputs.

COLD (FAST) IDLE

NOTE: Cold start or fast idle speed is not adjustable. Air valve

operation supplies by-pass air for cold starting.

IDLE SPEED

NOTE: DO NOT adjust idle speed in areas above 8200 ft. elevation.

Samurai

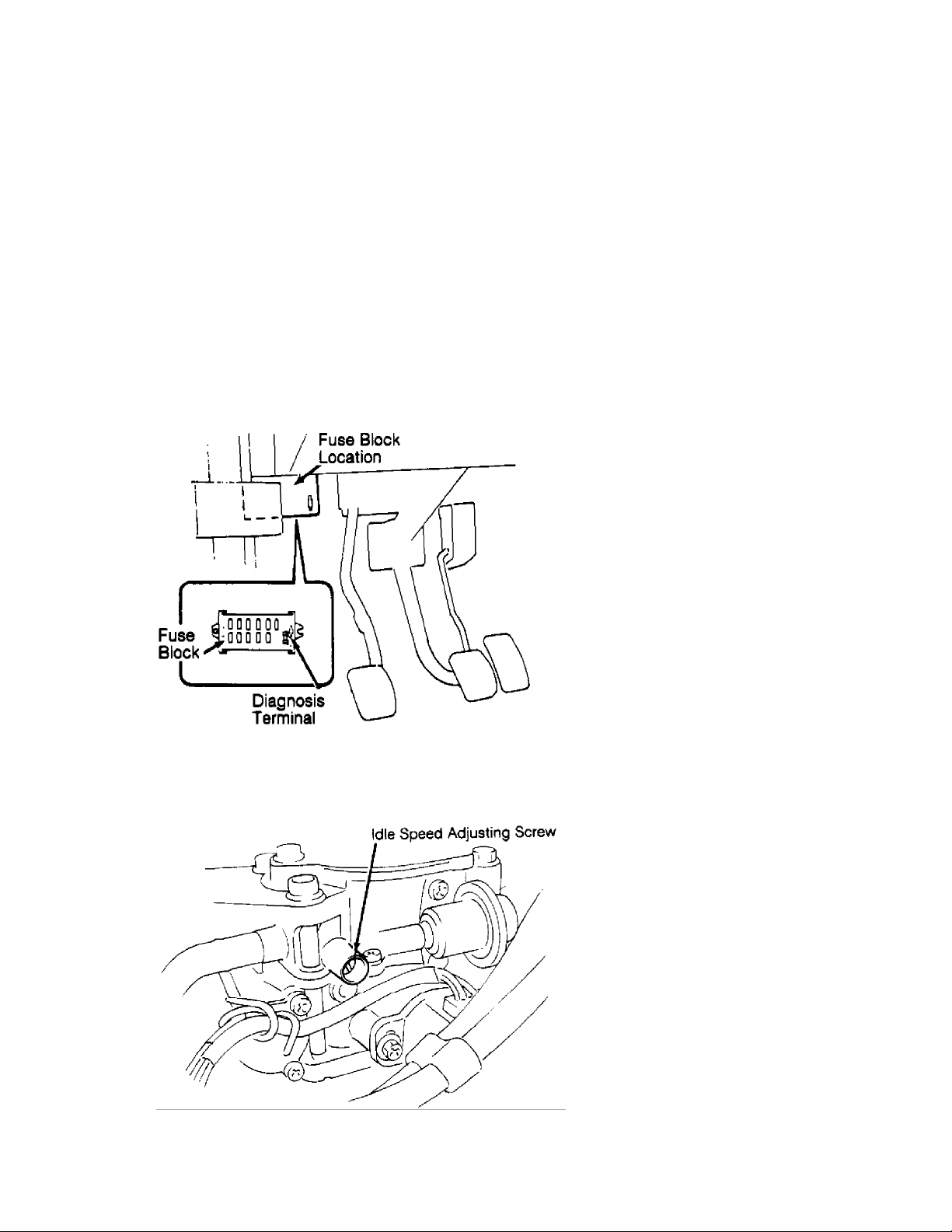

1) Start engine, and warm it to normal operating temperature.

Install spare fuse into diagnosis terminal of fuse box, and ensure

Malfunction Indicator Light (MIL) indicates Code 12. See Fig. 4.

2) Turn engine off. Connect Duty Meter (99963-00006) to

monitor coupler duty check terminal "A" and ground terminal "C". See

Fig. 2. Test connector is located near battery. Turn ignition on, and

wait 5 seconds.

3) Start engine, run it at 2000 RPM for 5 minutes and then

return it to idle. Using duty meter, ensure idle speed and IAC duty

percentage are within specification. See IDLE SPEED SPECIFICATIONS and

IAC DUTY AT SPECIFIED IDLE SPEED tables. If idle speed and/or IAC duty

percentage require adjustment, remove idle speed adjusting screw

Page 6

D - ADJUSTMENTS

Article Text (p. 6)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

protective cap on throttle body. To adjust idle speed, turn adjusting

screw. See Fig. 5.

4) When idle speed and IAC duty percentage are within

specification and vehicle is equipped with A/C, go to step 5). If

vehicle is not equipped with A/C, reinstall idle speed adjusting screw

protective cap to throttle body. Remove duty meter from monitor

coupler, and rein-stall cap. Remove spare fuse from diagnosis terminal

of fuse box.

5) Turn A/C on, and set fan switch to LOW position. Check

idle speed and IAC duty percentage. If idle speed and/or IAC duty

percentage is not within specification, turn A/C VSV adjusting screw

to adjust idle. See Fig. 6.

Fig. 4: Installing Diagnosis Terminal Fuse (Samurai)

Courtesy of Suzuki of America Corp.

Fig. 5: Locating Idle Speed Adjusting Screw (Typical)

Courtesy of Suzuki of America Corp.

Page 7

D - ADJUSTMENTS

Article Text (p. 7)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Fig. 6: Locating A/C VSV Adjusting Screw (Samurai & Sidekick)

Courtesy of Suzuki of America Corp.

IDLE SPEED SPECIFICATIONS TABLE (1)

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application Idle RPM

Samurai

With A/C Off .............................................. 750-850

With A/C On .......................................... (2) 950-1050

Sidekick

With A/C Off .............................................. 750-850

With A/C On .......................................... (3) 950-1050

Swift

DOHC

With A/C Off .............................................. 800-900

With A/C On ........................................... (2) 850-950

SOHC

With A/C Off

Auto. Transaxle .......................................... 800-900

Man. Transaxle ........................................... 700-800

With A/C On

Auto. Transaxle (4) .................................. (2) 800-900

Man. Transaxle (4) .................................... (2)700-800

Auto. & Man. Transaxles (5) .............................. 850-950

(1) - Transaxle or transmission in Neutral or Park.

(2) - A/C idle speed is adjusted by rotating adjusting screw on A/C

Vacuum Switching Valve (VSV).

(3) - With auto. transmission in gear, idle RPM is 750-850.

(4) - When ECM part number ends with "0".

(5) - When ECM part number ends with number other than "0".

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

IAC DUTY AT SPECIFIED IDLE SPEED TABLE (1)

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application Percent

Page 8

D - ADJUSTMENTS

Article Text (p. 8)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Samurai & Sidekick .............................................. 50

Swift

DOHC ........................................................ 30-40

SOHC (2) .................................................... 25-35

(1) - See IDLE SPEED SPECIFICATIONS table.

(2) - With A/C turned off (if equipped).

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Sidekick

1) Start engine, and warm it to operating temperature. Turn

all accessories off. Ensure all fuel and emission control system wire

connectors and hoses are properly connected. Ensure accelerator cable

has free play at throttle body. Ensure ignition timing is correct. See

IGNITION TIMING table under IGNITION TIMING. Ensure air cleaner and

ducts are properly installed and air filter element is in good

condition.

2) Connect service wire between terminals "B" (diagnosis

switch) and "C" (ground) of monitor coupler. See Fig. 2. Ensure MIL

(CHECK ENGINE light) indicates Code 12. Turn engine off, and connect

Duty Meter (99963-00006) to monitor coupler duty terminals "A"

(output) and "C" (ground). Test connector is located near battery.

Connect tachometer.

3) Start engine, and warm it to operating temperature. Ensure

idle speed and IAC duty percentage are within specification. See IDLE

SPEED SPECIFICATIONS and IAC DUTY AT SPECIFIED IDLE SPEED tables. If

idle speed and/or IAC duty percentage require adjustment, remove idle

speed adjusting screw protective cap on throttle body. Turn idle speed

adjusting screw to adjust idle to specification. See Fig. 5.

4) When idle speed and IAC duty percentage are as specified

and vehicle is equipped with A/C, go to next step. If vehicle is not

equipped with A/C, reinstall idle speed adjusting screw protective cap

to throttle body and remove service jumper wire. Remove duty meter

from monitor coupler, and reinstall cap.

5) Turn A/C on, and set fan switch to LOW position. Check

idle speed and IAC duty percentage with A/C on. If idle speed and IAC

duty percentage are not as specified, turn A/C VSV adjusting screw to

adjust idle to specification. See Fig. 6.

NOTE: On Swift, specified values used for this inspection and

adjustment vary depending on type of ECM. Type of ECM can be

identified by last digit of ECM part number. Last digit will

be "0" or a number other than "0".

Swift SOHC

1) Idle speed is controlled by ECM using IAC valve and

requires no adjustments under normal conditions. If conditions require

idle speed to be adjusted, start engine and warm it to operating

temperature. Turn all accessories off. Ensure all fuel and emission

control system wire connectors and hoses are properly connected.

Ensure accelerator cable has free-play, air cleaner and ducts are

properly installed and air filter element is in good condition.

Page 9

D - ADJUSTMENTS

Article Text (p. 9)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

2) Ensure ignition timing is correct. See IGNITION TIMING

table under IGNITION TIMING. Connect terminal "B" (diagnosis switch)

to terminal "D" (ground) using a service wire. See Fig. 3. MIL (CHECK

ENGINE light) should indicate Code 12. Attach duty meter to duty

output terminal "F" and ground terminal "D". Remove idle speed

adjusting screw cap from side of throttle body, just above throttle

lever. Turn idle speed adjusting screw to obtain correct idle speed.

See IDLE SPEED SPECIFICATIONS and IAC DUTY AT SPECIFIED IDLE SPEED

tables. On vehicles without A/C, remove service wire, reinstall

protective cap to throttle body and recheck idle speed.

3) On vehicles equipped with A/C, turn A/C switch to ON

position and set fan switch to HIGH position. With A/C operating

correctly, verify idle speed is 850-950 RPM. If adjustment is

required, turn A/C Vacuum Switching Valve (VSV) adjusting screw as

necessary. See Fig. 7. See IDLE SPEED SPECIFICATIONS table. Remove

service wire, reinstall protective cap to throttle body and recheck

idle speed.

Fig. 7: Identifying Typical Idle Adjustment System (Swift)

Courtesy of Suzuki of America Corp.

Swift DOHC

1) Idle speed is controlled by IAC valve and should not

require adjustment. If idle speed needs to be changed, start engine

and warm it to operating temperature. Turn all accessories off. Ensure

all fuel and emission control system wire connectors and hoses are

properly connected. Ensure accelerator cable has free play. Ensure air

cleaner and ducts are properly installed and air filter element is in

good condition.

2) Ensure ignition timing is correct. See IGNITION TIMING

Page 10

D - ADJUSTMENTS

Article Text (p. 10)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

table under IGNITION TIMING. Connect terminal "B" (diagnosis switch)

to terminal "D" (ground) using a service wire. See Fig. 3. MIL (CHECK

ENGINE light) should indicate Code 12. Attach duty meter to duty

output terminal "F" and ground terminal "D". Remove idle speed

adjusting screw protective cap from top of throttle body. See Fig. 7.

Turn idle speed adjusting screw to obtain correct idle RPM. See IDLE

SPEED SPECIFICATIONS and IAC DUTY AT SPECIFIED IDLE SPEED tables.

3) On vehicles equipped with A/C, turn A/C switch to ON

position and set fan switch to HIGH position. With A/C operating

correctly, verify idle is 850-950 RPM and IAC duty is 30-40 percent.

If adjustment is required, turn A/C Vacuum Switching Valve (VSV)

adjusting screw to obtain correct idle. See IDLE SPEED SPECIFICATIONS

table. Remove service wire, reinstall protective cap to throttle body

and recheck idle speed.

THROTTLE CABLE

Samurai

1) Ensure throttle cable has 0.4-0.6" (10-15 mm) free play.

Hold exposed portion of cable at center and move cable up and down to

measure play. Use lock nut and adjusting nut on cable bracket to

adjust free play. See Fig. 8.

2) If throttle opener rod is pushed back by hand (i.e.,

throttle valve is at idle position), cable free play should be 0.12-0.

20" (3.0-5.0 mm). Use lock nut and adjusting nut on cable bracket to

adjust free play.

Fig. 8: Adj. Typical Acc. Cable Play (Samurai, Sidekick TBI & Swift)

Courtesy of Suzuki of America Corp.

Sidekick (MPI)

1) With throttle valve closed, accelerator pedal play should

be 0.08-0.27" (2.0-7.0 mm). Use lock nut and adjusting nut on cable

bracket to adjust free play. See Fig. 9.

2) With accelerator pedal depressed fully, check clearance

between throttle lever and lever stopper at throttle body. If

clearance is not 0.02-0.07" (0.5-2.0 mm), correct by changing height

of pedal stopper bolt located under accelerator pedal. After throttle

cable adjustment is complete, adjust transmission kickdown cable.

3) Check A/T cable free play. See Fig. 9. If clearance is not

0.03-0.06" (0.8-1.5 mm), use lock nut and adjusting nut on cable

Page 11

Copyright © 1998 Mitchell Repair Information Company, LLC

bracket to adjust free play.

D - ADJUSTMENTS

Article Text (p. 11)

1993 Suzuki Swift

For 111

Thursday, April 08, 1999 09:26AM

Fig. 9: Adjusting Cable Play (Sidekick MPI)

Courtesy of Suzuki of America Corp.

Sidekick (TBI)

1) Ensure cable has 0.4-0.6" (10-15 mm) free play. Hold

exposed portion of cable at center and move cable up and down to

adjust free play. See Fig. 8.

2) After throttle cable adjustment is complete, adjust

transmission kickdown cable. Loosen and back off kickdown lock nut and

adjusting nut considerably. With accelerator pedal fully depressed,

pull on kickdown cable housing to remove cable free play. With free

play removed, ensure clearance between kickdown cable bracket and

upper lock nut is 0.039" (1.00 mm). Adjust upper lock nut as

necessary.

3) Holding upper lock nut position on kickdown cable, release

accelerator pedal. While holding upper lock nut position, securely

tighten lower adjusting nut to bracket.

Swift

Ensure cable has .12-.20" (3.0-5.0 mm) free play. Hold

exposed portion of cable at center and move cable up and down to

measure free play. Use lock nut and adjusting nut on cable bracket to

adjust free play. See Fig. 8.

DASHPOT

Page 12

D - ADJUSTMENTS

Article Text (p. 12)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Swift DOHC

1) Ensure transmission is in Park or Neutral and parking

brake is set. Start engine, and warm it to operating temperature. Turn

all accessories off. Ensure idle speed is within specification. See

IDLE SPEED SPECIFICATIONS table under IDLE SPEED.

2) Operate throttle lever to increase and decrease engine RPM

while noting RPM at which dashpot rod contacts throttle lever. Adjust

dashpot adjusting screw to specified RPM at which dashpot rod should

contact throttle lever. See Figs. 8 and 13. See DASHPOT ADJUSTMENT

table.

DASHPOT ADJUSTMENT TABLE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application (1) RPM

Swift DOHC ............................................... 3000-3400

(1) - Engine speed when throttle lever contacts dashpot rod after

deceleration.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

THROTTLE OPENER

Samurai

1) Ensure transmission is in Neutral or Park. Set parking

brake. Turn ignition on for 5 seconds, and then start engine. Run

engine at 2000 RPM for 5 minutes to warm it to operating temperature.

Return engine to idle speed. Turn all accessories off. Disconnect and

plug vacuum hose from throttle opener on throttle body.

2) Engine speed should increase to 2150-2250 RPM when vacuum

hose is removed from throttle opener. If engine speed is not within

specification, adjust by turning throttle opener adjusting screw. See

Fig. 10. Reconnect vacuum hose when adjustment is within

specification. See THROTTLE OPENER SPECIFICATIONS table.

Sidekick (TBI)

1) Ensure transmission is in Neutral or Park, and set parking

brake. Warm engine to operating temperature. Turn all accessories off.

Disconnect and plug vacuum hose from throttle opener on throttle body.

2) Engine speed should increase to 2100-2300 RPM when vacuum

hose is removed from throttle opener. If engine speed is not within

specification, adjust by turning throttle opener adjusting screw. See

Fig. 10. Reconnect vacuum hose when adjustment is within

specification. See THROTTLE OPENER SPECIFICATIONS table.

THROTTLE OPENER SPECIFICATIONS TABLE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application (1) RPM

Samurai .................................................. 2150-2250

Sidekick TBI ............................................. 2100-2300

Page 13

D - ADJUSTMENTS

Article Text (p. 13)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

(1) - Transaxle or transmission in Neutral or Park with vacuum hose

disconnected and plugged at throttle opener.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Fig. 10: Adjusting Throttle Opener (Samurai & Sidekick TBI)

Courtesy of Suzuki of America Corp.

THROTTLE POSITION SENSOR (TPS)

THROTTLE POSITION SENSOR (TPS) RESISTANCE TABLE

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

Application Ohms

Samurai

Between Terminals "C" & "D"

With .008" (.20 mm) Clearance At Stop Screw ................. 0-550

With .016" (.41 mm) Clearance At Stop Screw .............. Infinity

Between Terminals "A" & "D" ............................. 3500-6500

Between Terminals "B" & "D"

At Idle (1) ................................................ 0-2000

At Wide Open Throttle ............................... (2) 2000-6500

Sidekick (MPI)

Between Terminals "A" & "B"

With .020" (.50 mm) Clearance At Stop Screw ................. 0-500

With .031" (.80 mm) Clearance At Stop Screw .............. Infinity

Between Terminals "A" & "D" ............................. 3500-6500

Between Terminals "A" & "C"

At Idle .................................................. 300-2000

At Wide Open Throttle ............................... (3) 2000-6500

Sidekick (TBI)

Between Terminals "C" & "D"

With .012" (.3 mm) Clearance At Stop Screw .................. 0-500

With .020" (.5 mm) Clearance At Stop Screw ............... Infinity

Between Terminals "A" & "D" ............................. 3500-6500

Page 14

D - ADJUSTMENTS

Article Text (p. 14)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Between Terminals "B" & "D"

At Idle .............................................. (1) 300-2000

At Wide Open Throttle ............................... (2) 2000-6500

Swift (DOHC)

Between Terminals "C" & "D"

With .012" (.30 mm) Clearance At Stop Screw ................. 0-500

With .035" (.89 mm) Clearance At Stop Screw .............. Infinity

Between Terminals "C" & "A" ............................. 3500-6500

Between Terminals "C" & "B"

At Idle .................................................... 0-2000

At Wide Open Throttle ................................... 3500-6500

Swift (SOHC)

Between Terminals "A" & "B"

With .012" (.30 mm) Clearance At Stop Screw ........ Less Than 5000

With .035" (.89 mm) Clearance At Stop Screw .............. Infinity

Between Terminals "A" & "D" ............................. 4370-8130

Between Terminals "A" & "C"

At Idle .................................................. 240-1140

At Wide Open Throttle ................................... 3170-6600

(1) - To obtain idle position, apply 19 in. Hg vacuum to throttle

opener.

(2) - There should be more than 2000 ohms difference between idle and

wide open throttle resistance.

ДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДДД

CAUTION: DO NOT rotate Samurai throttle stop screw to adjust idle.

Throttle stop screw is factory-set, and is used as zero

reference point for all other adjustments.

TPS Inspection (Samurai)

1) Disconnect TPS connector. Using hand vacuum pump, apply 20

in. Hg vacuum to throttle opener to move throttle lever to idle

position. Using ohmmeter, check resistance between upper and lower

terminals of TPS connector with proper shim thickness gauge inserted

between throttle valve lever and stop screw. See Fig. 10. See THROTTLE

POSITION SENSOR (TPS) RESISTANCE table.

2) If TPS inspection results are not within specification,

adjust TPS. Replace TPS if it cannot be adjusted to specification.

TPS Adjustment (Samurai)

1) Disconnect TPS harness connector and throttle opener

vacuum hose. Using hand vacuum pump, apply 20 in. Hg vacuum to

throttle opener to move throttle lever to idle position. Insert .012"

(.30 mm) shim thickness gauge between throttle lever and throttle stop

screw. See Fig. 10.

2) Connect ohmmeter between terminals "C" and "D" of TPS

connector. See Fig. 11. Loosen TPS mounting bolts, and turn TPS fully

clockwise. Turn TPS counterclockwise slowly to find position ohmmeter

reading changes from infinity to zero ohms. Tighten TPS mounting bolts

at that position.

Page 15

D - ADJUSTMENTS

Article Text (p. 15)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Fig. 11: Throttle Pos. Sensor (TPS) Term. ID (Samurai & Sidekick TBI)

Courtesy of Suzuki of America Corp.

3) Ensure continuity does not exist between terminals "C" and

"D" when .016" (0.40 mm) shim thickness gauge is inserted between

throttle lever and throttle stop screw.

4) Ensure continuity exists between terminals "C" and "D"

when .008" (0.20 mm) shim thickness gauge is inserted between throttle

lever and throttle stop screw.

5) If continuity is not as specified in steps 3) and 4), TPS

zero adjustment is incorrect. Start adjustment sequence again. If

results are the same after readjusting, replace TPS. After final

adjustment is completed, reconnect TPS connector and vacuum hose to

throttle opener.

TPS Inspection (Sidekick MPI)

Disconnect negative battery cable. Unplug TPS connector.

Using ohmmeter, check resistance between terminals of TPS connector.

See Fig. 15. If idle switch check is not within specification, adjust

TPS installation angle. See THROTTLE POSITION SENSOR (TPS) RESISTANCE

table. Replace TPS if it cannot be adjusted to specification.

TPS Adjustment (Sidekick MPI)

1) Disconnect negative battery cable. Unplug TPS connector,

and insert .026" (0.65 mm) shim thickness gauge between throttle lever

and throttle stop screw. Loosen TPS mounting screws. Connect ohmmeter

between TPS terminals "A" and "B", and check resistance. See THROTTLE

POSITION SENSOR (TPS) RESISTANCE table.

2) Turn TPS fully counterclockwise, and then turn it

clockwise slowly to locate point where ohmmeter reading changes from

zero to infinity. Holding TPS at that position, tighten TPS mounting

screws snug.

3) Ensure continuity does not exist between terminals "A" and

"B" when 0.037" (0.8 mm) shim thickness gauge is inserted between

throttle lever and throttle stop screw. See Figs. 14 and 15.

4) Ensure continuity exists between terminals "A" and "B"

when 0.020" (0.5 mm) shim thickness gauge is inserted between throttle

lever and throttle stop screw. Tighten TPS mounting screws to 22.8-38.

4 INCH lbs. (2.5-4.5 N.m).

Page 16

D - ADJUSTMENTS

Article Text (p. 16)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

5) If continuity is not as specified in steps 3) and 4), TPS

zero adjustment is incorrect. Start adjustment sequence again. If

results are the same after readjusting, replace TPS. After final

adjustment is completed, reconnect TPS connector.

TPS Inspection (Sidekick TBI)

Disconnect negative battery cable. Disconnect TPS harness

connector. Using ohmmeter, check resistance between each pair of

terminals. See Fig. 11. See THROTTLE POSITION SENSOR (TPS) RESISTANCE

table. If resistances are not as specified, adjust TPS. Recheck

resistance between each pair of terminals. If TPS cannot be adjusted

to obtain correct values, replace TPS.

TPS Adjustment (Sidekick TBI)

1) Disconnect TPS harness connector and throttle opener

vacuum hose. Using hand vacuum pump, apply 19 in. Hg vacuum to

throttle opener to move throttle lever to idle position. Counting

number of turns, loosen idle speed adjusting screw until clearance is

obtained between throttle lever and adjusting screw. Record number of

turns. Connect ohmmeter between terminals "C" and "D". See Fig. 11.

2) Insert .016" (.40 mm) thickness gauge between idle speed

adjusting screw and throttle lever. Loosen TPS mounting screws. Turn

TPS fully clockwise. Slowly rotate TPS counterclockwise to locate

position where ohmmeter readings changes from infinity to zero ohms.

Holding TPS at this position, tighten mounting screws to 30 INCH lbs.

(3.4 N.m.). Repeat TPS INSPECTION (SIDEKICK TBI) to verify correct

adjustment and operation.

3) After verifying adjustment, reconnect TPS harness

connector and throttle opener vacuum hose. Turn idle speed adjusting

screw inward number of turns previously recorded. If necessary,

readjust idle speed. See IDLE SPEED.

CAUTION: DO NOT adjust Swift DOHC throttle stop screw to adjust

idle. Throttle stop screw is factory-set, and is used as

zero reference point for all other adjustments.

TPS Inspection (Swift DOHC)

Unplug TPS connector. Using ohmmeter, check resistance with

selected shim thickness gauges between throttle stop screw and

throttle lever. See Figs. 12 and 13. See THROTTLE POSITION SENSOR

(TPS) RESISTANCE table. If TPS cannot be adjusted to obtain correct

values at terminals "C" and "D", replace TPS.

Page 17

D - ADJUSTMENTS

Article Text (p. 17)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

Fig. 12: Throttle Position Sensor (TPS) Terminal ID (Swift DOHC)

Courtesy of Suzuki of America Corp.

Fig. 13: Inserting Shim Thickness Gauge (Swift DOHC)

Courtesy of Suzuki of America Corp.

TPS Adjustment (Swift DOHC)

1) Unplug TPS connector, and loosen TPS mounting screws.

Place a .025" (.63 mm) shim thickness gauge between throttle lever and

throttle stop screw. See Fig. 13.

2) Connect ohmmeter between terminals "C" and "D". See

Fig. 12. Turn TPS fully clockwise, and then slowly rotate TPS

counterclockwise to locate position at which ohmmeter reading changes

from zero to infinity. Holding TPS at that position, tighten mounting

screws snug.

3) Ensure continuity does not exist between terminals "C" and

"D" when 0.035" (0.90 mm) shim thickness gauge is inserted between

throttle lever and throttle stop screw.

4) Ensure continuity exists between terminals "C" and "D"

when 0.012" (0.30 mm) shim thickness gauge is inserted between

throttle lever and throttle stop screw. Tighten TPS mounting screws to

Page 18

D - ADJUSTMENTS

Article Text (p. 18)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

30 INCH lbs.(3.4 N.m).

5) If continuity is not as specified in steps 3) and 4), TPS

zero adjustment is incorrect. Start adjustment sequence again. If

results are the same after readjusting, replace TPS. After final

adjustment is completed, reconnect TPS connector.

CAUTION: DO NOT adjust Swift SOHC throttle stop screw to adjust

idle. Throttle stop screw is factory-set, and is used as

zero reference point for all other adjustments.

TPS Inspection (Swift SOHC)

Unplug TPS connector. Using ohmmeter, check resistance

between terminals of TPS connector with proper shim thickness gauge

inserted between throttle lever and throttle stop screw. See Figs. 14

and 15. See THROTTLE POSITION SENSOR (TPS) RESISTANCE table.

Fig. 14: Inserting Shim Thickness Gauge (Sidekick MPI & Swift SOHC)

Courtesy of Suzuki of America Corp.

Fig. 15: Throttle Position Sensor (TPS) Term. ID (Swift SOHC

Shown; Sidekick MPI Is Similar)

Courtesy of Suzuki of America Corp.

Page 19

D - ADJUSTMENTS

Article Text (p. 19)

1993 Suzuki Swift

For 111

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, April 08, 1999 09:26AM

TPS Adjustment (Swift SOHC)

1) Unplug TPS connector, and loosen TPS mounting screws.

Insert .024" (.60 mm) shim thickness gauge between throttle lever and

throttle stop screw. Connect ohmmeter between TPS terminals "A" and

"B". See Fig. 15.

2) Turn TPS fully counterclockwise. Turn TPS clockwise to

locate position ohmmeter reading changes from zero to infinity.

Holding TPS at that position, tighten TPS mounting screws snug.

3) Ensure continuity does not exist between terminals "A" and

"B" when 0.035" (0.90 mm) shim thickness gauge is inserted between

throttle lever and throttle stop screw.

4) Ensure continuity exists between terminals "A" and "B"

when 0.012" (0.30 mm) shim thickness gauge is inserted between

throttle lever and throttle stop screw. Tighten TPS mounting screws to

18 INCH lbs.(2.0 N.m).

5) If continuity is not as specified in steps 3) and 4), TPS

zero adjustment is incorrect. Start adjustment sequence again. If

results are the same after readjusting, replace TPS. After final

adjustment is completed, reconnect TPS connector.

POWER STEERING VSV

Disconnect VSV connector, and check resistance between

terminals. If resistance is not 33-39 ohms, replace VSV. If resistance

is 33-39 ohms, disconnect vacuum hoses from 3-way joints. Blow into

top hose. Air should not come out of other hose. With 12 volts and

ground applied to terminals, blow into top hose. Air should pass

through hoses. If results are not as described, replace VSV.

END OF ARTICLE

Loading...

Loading...