Page 1

ENGINE

CONTENTS

ENGINE

3-1

ENGINE COMPONENTS REMOVABLE WITH ENGINE IN PLACE

ENGINE REMOVAL AND INSTALLATION

ENGINE REMOVAL

ENGINE INSTALLATION

ENGINE DISASSEMBLY

ENGINE TOP SIDE

ENGINE BOTTOM SIDE

ENGINE COMPONENTS INSPECTION AND SERVICING

CYLINDER HEAD COVER

CAMSHAFT/CYLINDER HEAD

CYLINDER/PISTON INSPECTION

CONRODICRANKSHAFT

CLUTCH

TRANSMISSION

GEARSHIFT FORK

PRIMARY DRIVE GEAR

STARTER TORQUE LIMITER

STARTER CLUTCH

GEARSHIFT

CRANKCASE

CRANKCASE-CRANKSHAFT BEARING

GENERATOR COVER

CLUTCH COVER

GEARSHIFT COVER

ENGINE REASSEMBLY

ENGINE BOTTOM SIDE

ENGINE TOP SIDE

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

3- 2

3- 3

3- 3

3-10

3-17

3-17

3-24

3-34

3-34

3-35

3-48

3-50

3-54

3-56

3-62

3-63

3-64

3-65

3-66

3-66

3-73

3-77

3-77

3-77

3-78

3-78

3-93

40

Page 2

3- 2

ENGINE

ENGINE COMPONENTS REMOVABLE WITH ENGINE IN PLACE

The parts listed below can be removed and reinstalled without removing the engine from the frame

the page listed in this section for removal and reinstallation instructions

ENGINE LEFT SIDE

.

. Refer to

4

PARTS

Generator rotor

Gearshift

ENGINE RIGHT SIDE

PARTS

Clutch cover

Clutch

Oil pump driven gear

Primary drive gear

Cam drive idle gear/sprocket

Gear position switch

Oil sump filter

Oil pressure switch

Oil jet

ENGINE CENTER

PARTS

Cylinder head cover

Camshaft

Cylinder head (Front)

Cylinder (Front)

Piston (Front)

Cam chain tension adjuster 3-18 and -22

Oil filter

Starter motor

REMOVAL

3-30

3-31

REMOVAL

3-25

3-25

3-28 3-86

3-29 3-83

3-28

3-27

3-28

3-67 3-67

3-68

REMOVAL

3-17 and -20

3-18 and -21

3-19 3-96

3-20 3-95

3-20 3-93

3-24

3-19

INSTALLATION

3-82

3-80

INSTALLATION

3-91

3-86

3-84

3-85

3-85

3-68 and -95

INSTALLATION

3-112

3-106

3-102 and -105

3-93

3-113

4

It

Page 3

~

~

~

~

~

~

~

~

~

ENGINE 3-3

ENGINE REMOVAL AND INSTALLATION

010

1

ENGINE REMOVAL

Before taking the engine out of the frame, wash the engine

using a steam cleaner

in the following steps

removal procedure

•

Remove the under cowling.(C-,-6-5)

•

Drain engine oil

•

Drain engine coolant

•

Remove the seat

. Engine removal is sequentially explained

. Reinstall the engine by reversing the

.

. (=2-14)

. (172-17)

. (=6-7)

6-7)

r

•

Disconnect theObattery lead wire

•

Remove the radiator

•

Lift and support the fuel tank

•

Remove the air cleaner

. (C75-5)

.

(r-

. (174-75)

74-65)

.

r

40

•

Remove the throttle body

.(C-

74-76)

Page 4

~

~

~

~

~

3-4 ENGINE

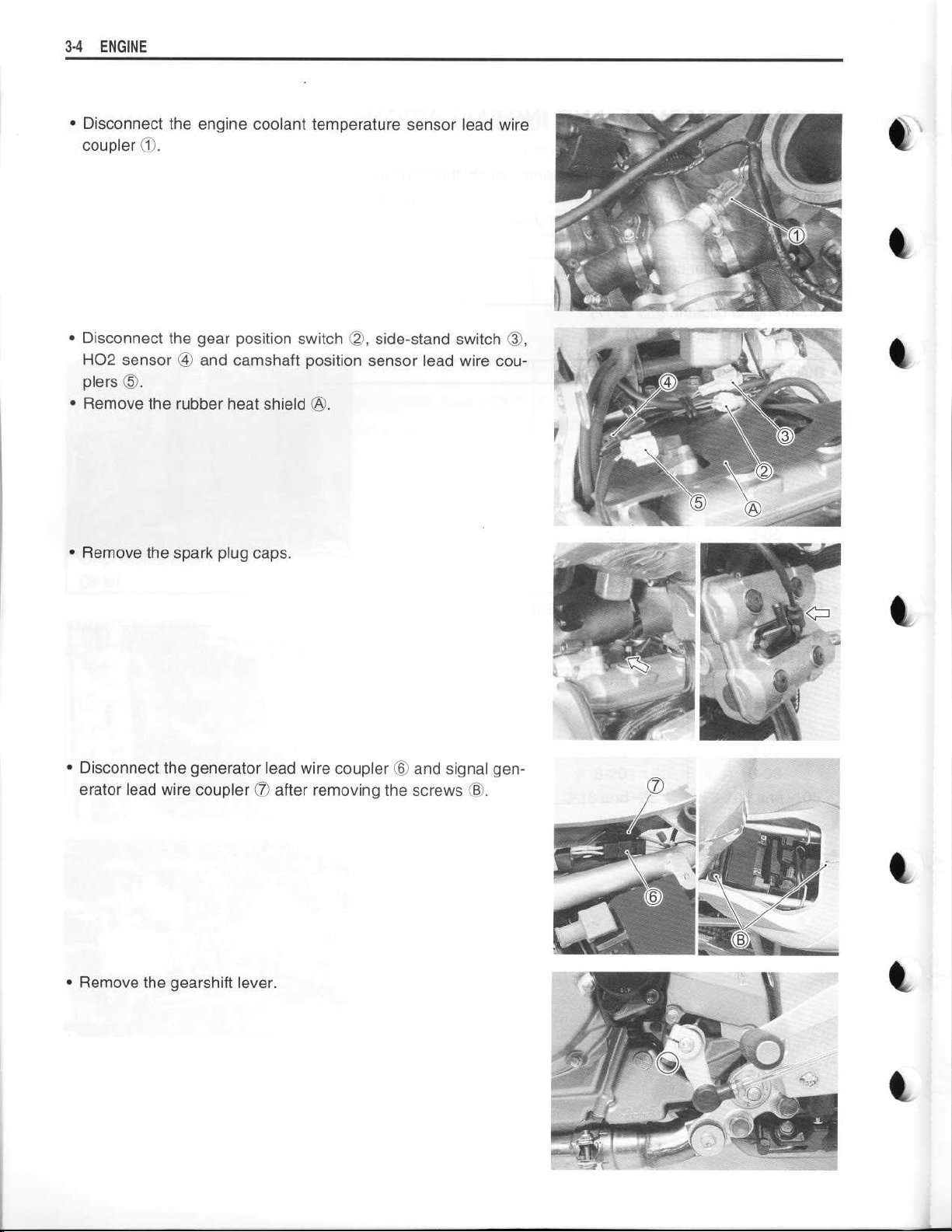

•

Disconnect the engine coolant temperature sensor lead wire

coupler0

•

Disconnect the gear position switch 02

H02 sensor ® and camshaft position sensor lead wire couplers ($

•

Remove the rubber heat shield

.

,

side-stand switch

OO

,

1

.

OO

.

•

Remove the spark plug caps

•

Disconnect the generator lead wire coupler

erator lead wire coupler 07 after removing the screws

•

Remove the gearshift lever

.

0

and signal gen-

.

OO

.

l

Page 5

~

~

~

~

~

~

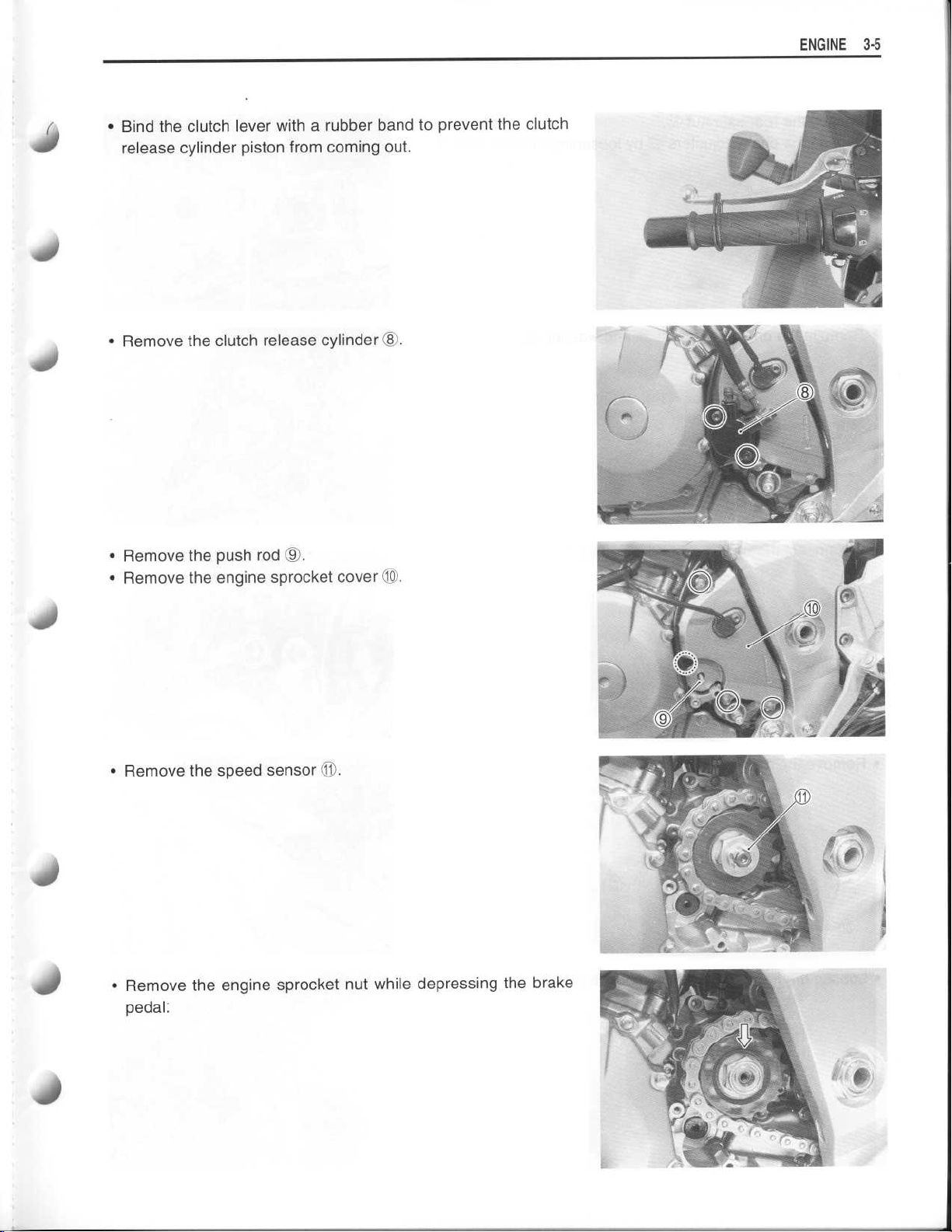

Bind the clutch lever with a rubber band to prevent the clutch

•

release cylinder piston from coming out

Remove the clutch release cylinder ®

•

.

.

ENGINE 3-

5

•

Remove the push rod 09

•

Remove the engine sprocket cover 10

•

Remove the speed sensor 11

Remove the engine sprocket nut while depressing the brake

•

pedal

.

.

.

.

40

Page 6

~

~

~

~

~

~

3-6 ENGINE

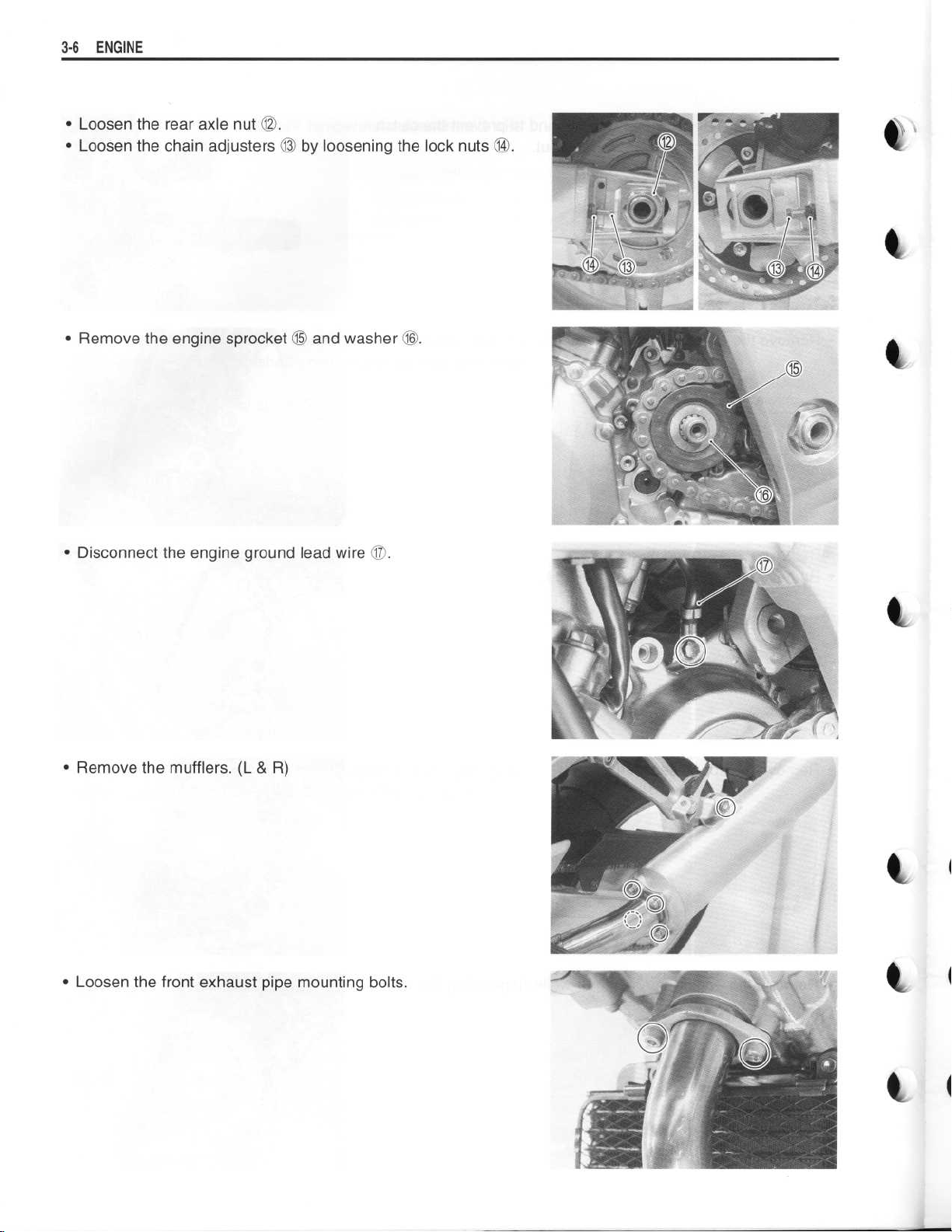

•

Loosen the rear axle nut 1©

•

Loosen the chain adjusters 13 by loosening the lock nuts

.

(W

.

4

•

Remove the engine sprocket 15 and washer i

.

•

Disconnect the engine ground lead wire i

•

Remove the mufflers

•

Loosen the front exhaust pipe mounting bolts

. (L & R)

.

.

l

Page 7

~

~

~

•

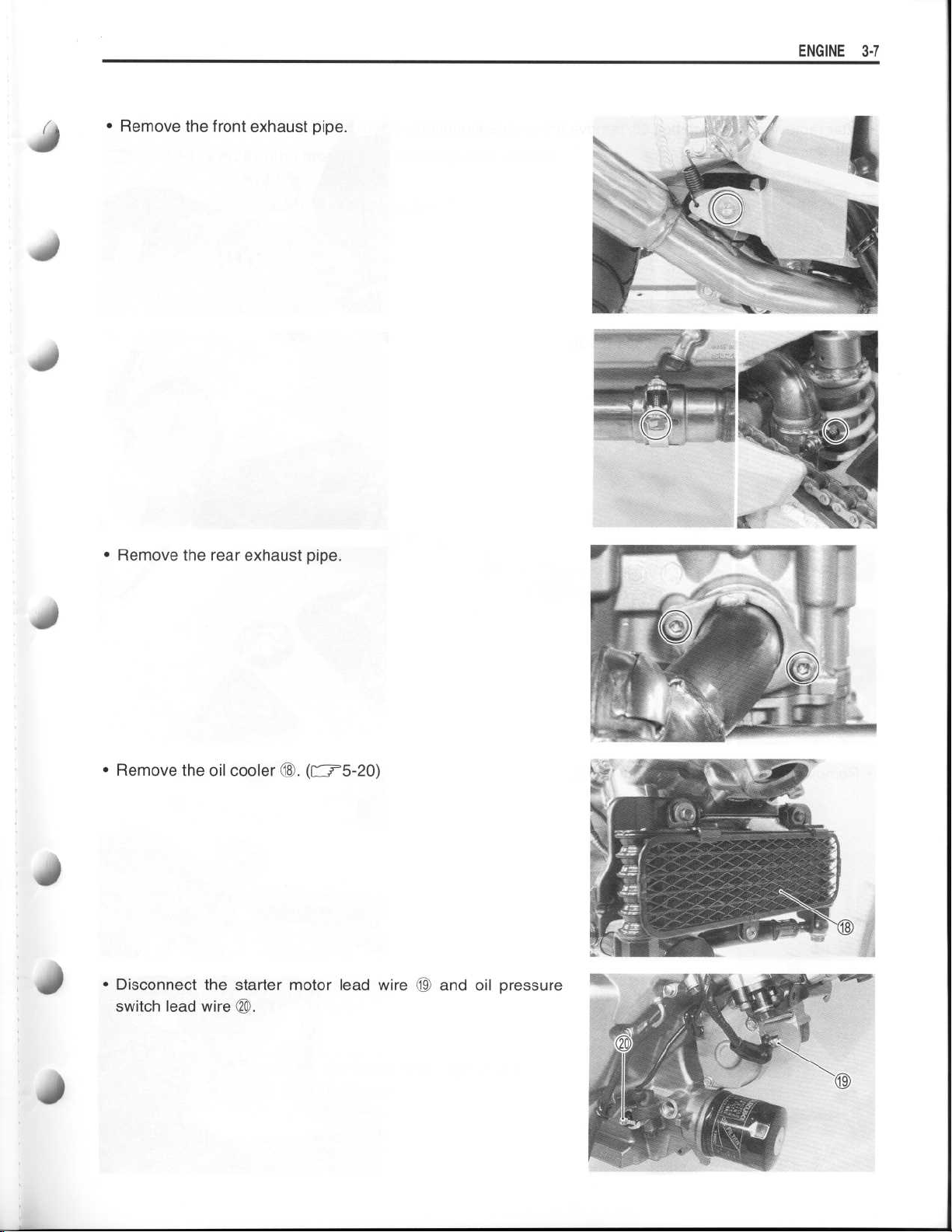

Remove the front exhaust pipe

ENGINE 3-7

.

J

•

Remove the rear exhaust pipe

•

Remove the oil cooler

•

Disconnect the starter motor lead wire 79 and oil pressure

switch lead wire 20

(I

.

.

(f"

.

r5-20)

Page 8

~

~

~

3-8

ENGINE

•

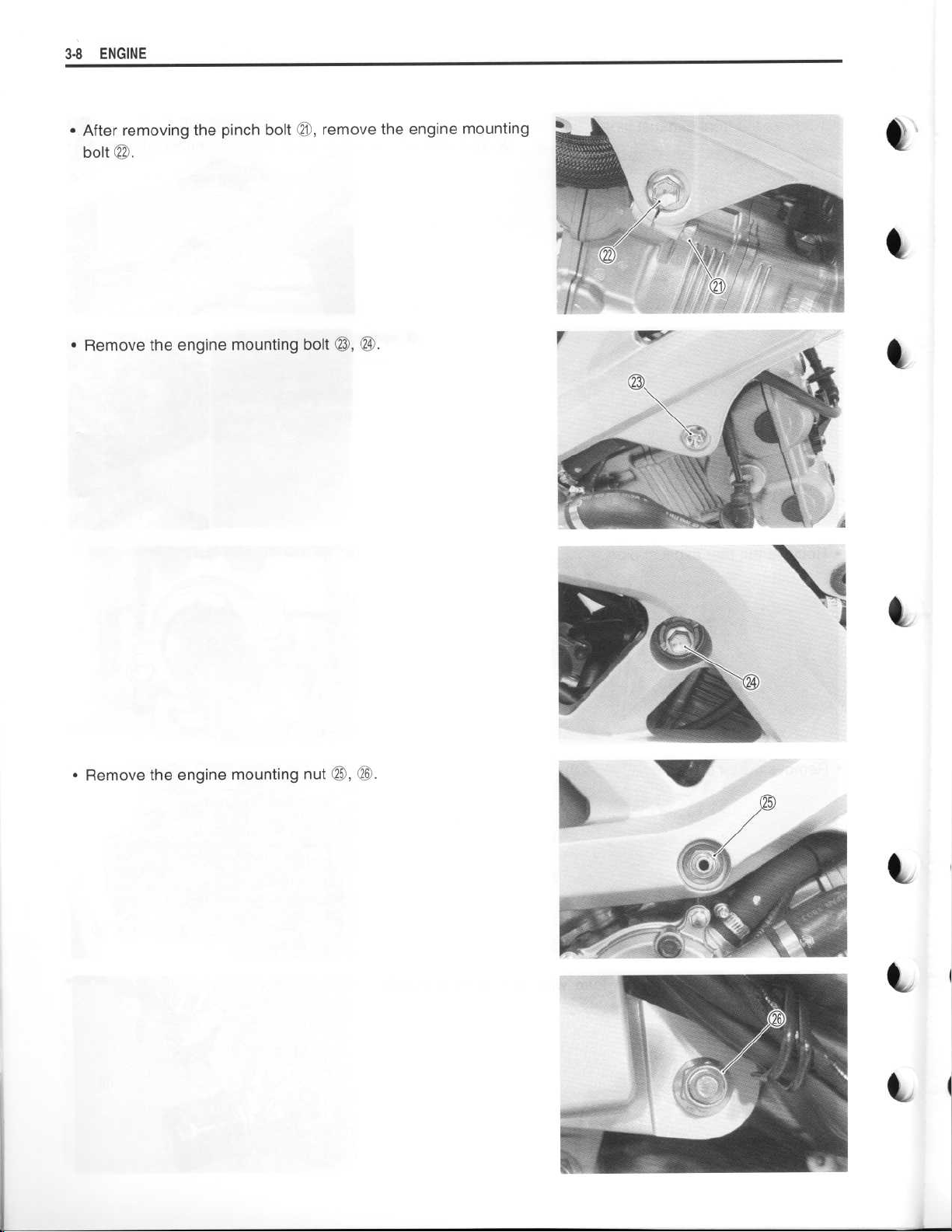

After removing the pinch bolt (3,

bolt

(2

.

Remove the engine mounting bolt 23

•

remove the engine mounting

, (3

.

•

Remove the engine mounting nut

(S,

26

.

I

11

Page 9

~

~

~

~

ENGINE3-9

•

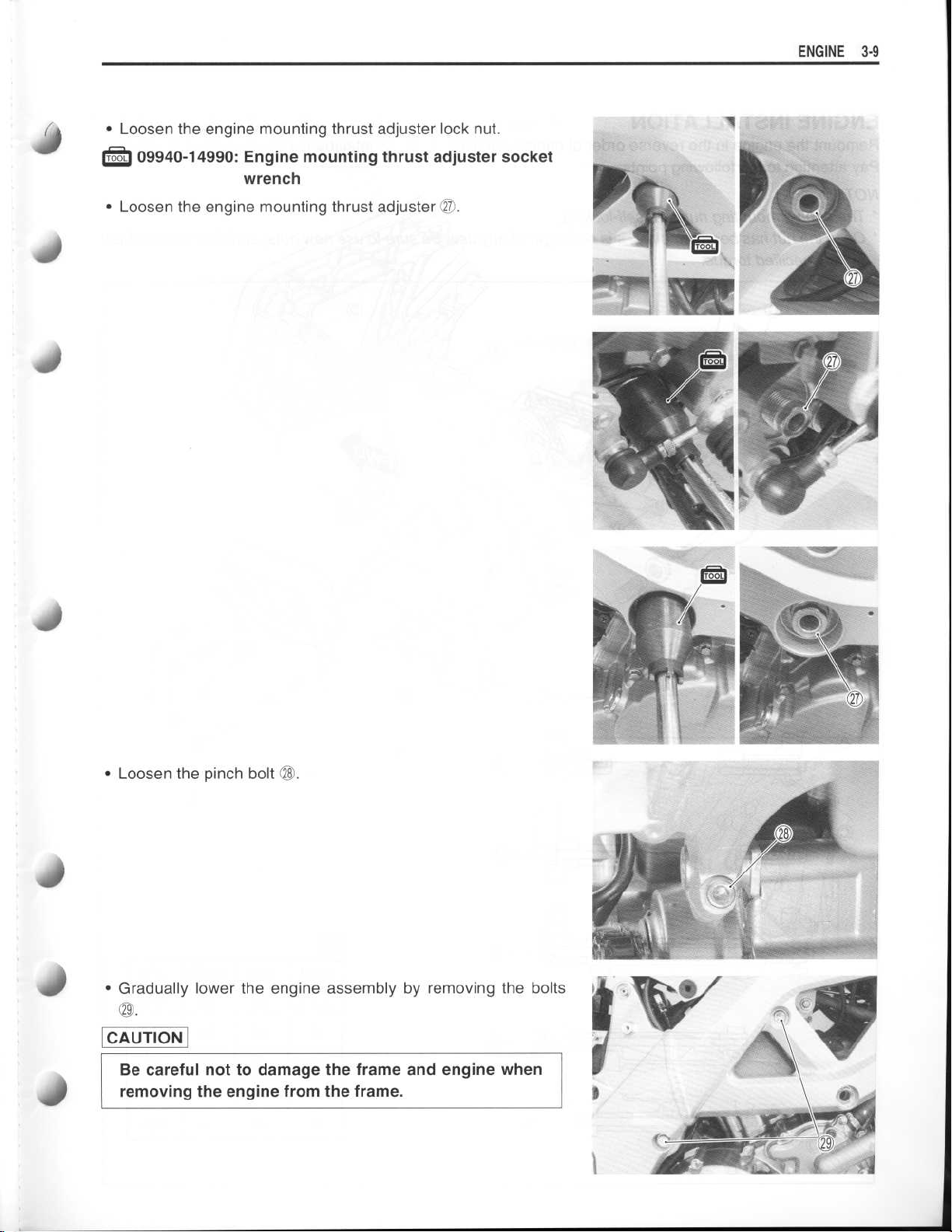

Loosen the engine mounting thrust adjuster lock nut

.

40

09940-14990

•

Loosen the engine mounting thrust adjuster v

: Engine mounting thrust adjuster socket

wrench

.

I'

•

Loosen the pinch bolt 28

•

Gradually lower the engine assembly by removing the bolts

(a

.

CAUTION

Be careful not to damage the frame and engine when

removing the engine from the frame

.

.

Page 10

~

3-10

ENGINE

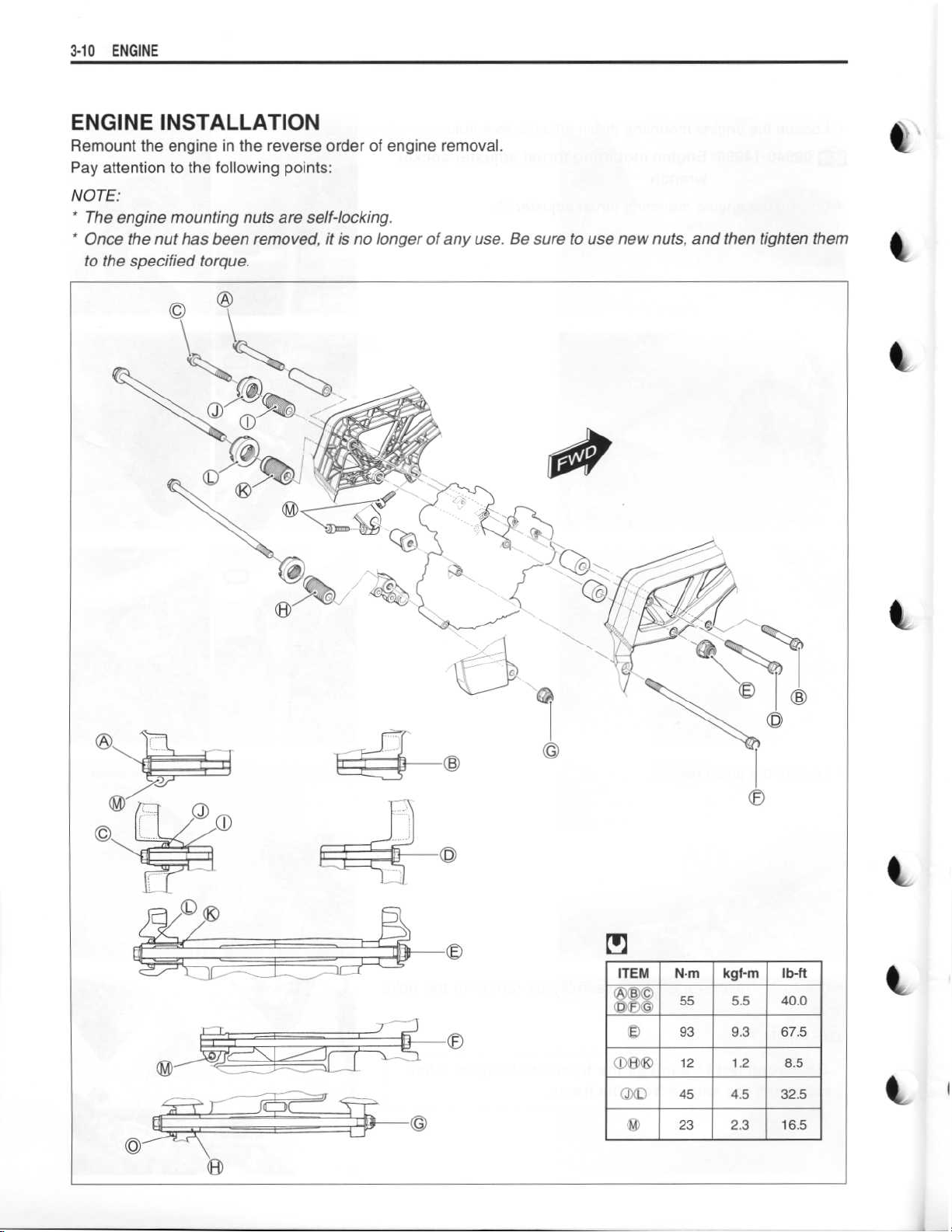

ENGINE INSTALLATION

Remount the engine in the reverse order of engine removal

Pay attention to the following points

NOTE

:

* The engine mounting nuts are self-locking

"

Once the nut has been removed, it is no longer of any use

to the specified torque

.

:

.

.

. Be sure to use new nuts, and then tighten them

r

c

i

A=

' '

ITEM

~©©

OE©

T WK

DJ ©

E

®

N

.m

kgf-m

55 5

®

93 9

12

45

23

1 .2

4

2

.5

.3

.5

.3

lb-ft

40

.0

67

.5

8

.5

32

.5

16

.5

l

Page 11

~

~

•

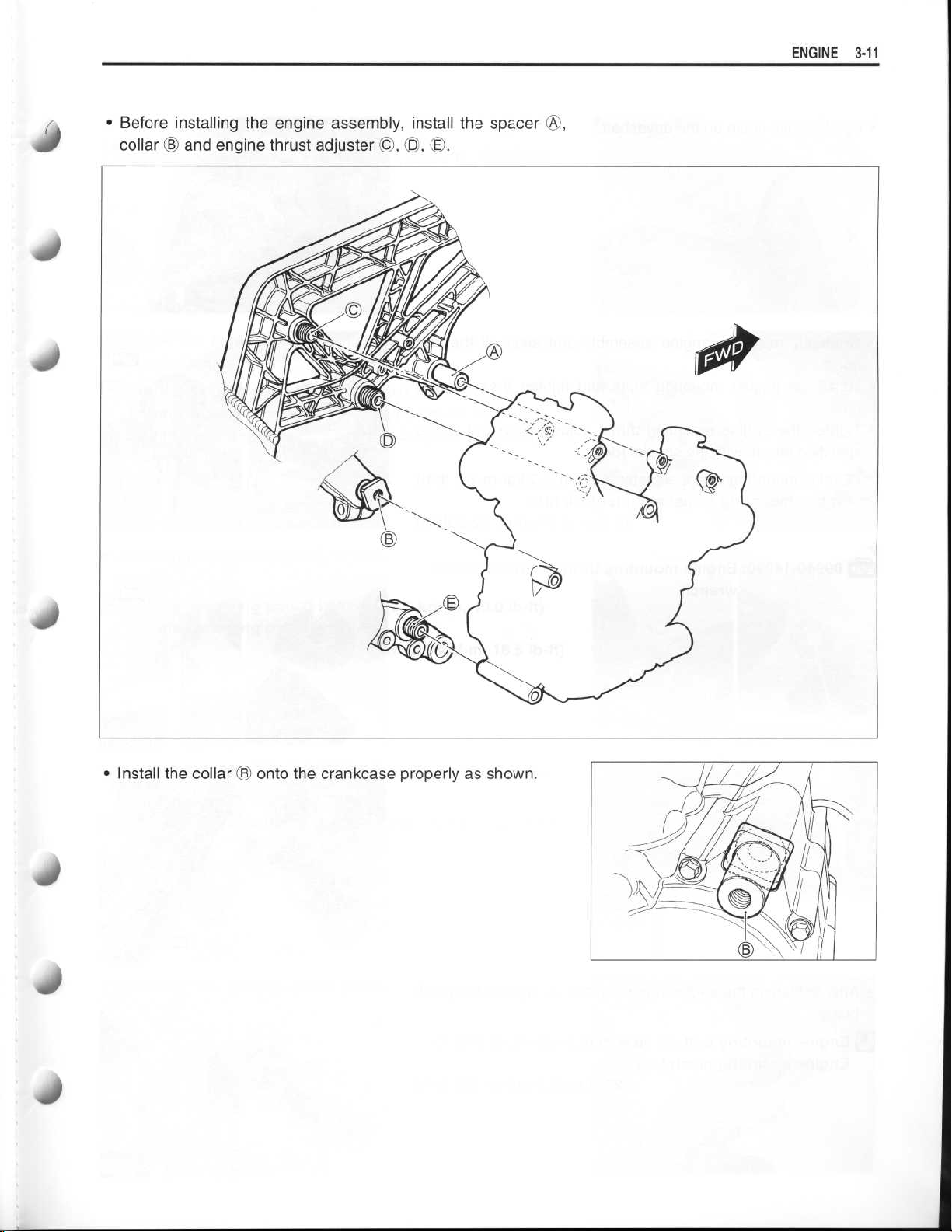

Before installing the engine assembly, install the spacer

collar © and engine thrust adjuster

©, O,

OO

.

OO

,

ENGINE 3-

1 1

to

•

Install the collar © onto the crankcase properly as shown

.

Page 12

~

~

~

~

~

~

~

3

-12 ENGINE

•

Put the drive chain on the driveshaft

Gradually raise the engine assembly and align all the bolt

•

holes

.

Install the engine mounting bolts and tighten them tempo-

•

rarily

.

Tighten the engine mounting thrust adjuster lock nut to the

•

specified torque with the special tool

.

.

Engine mounting thrust adjuster

•

Engine mounting thrust adjuster lock nut

09940-14990

: Engine mounting thrust adjuster socket

wrench

: 12 N

.m (1

45 N

.m (4 .5 kgf-m, 32

.2 kgf-m, 8

:

.5 Ib-ft)

.5 Ib-ft)

•

After tightening the engine mounting bolt

bolt ©

.

Engine mounting bolt

•

Engine mounting pinch bolt

OA

:

55 N

.m (5 .5 kgf-m, 40

©

:

23 N

.m (2

tighten the pinch

A),

.3 kgf-m, 6

.0 Ib-ft)

.5 Ib-ft)

Page 13

~

~

~

~

~

~

~

~

ENGINE 3-13

•

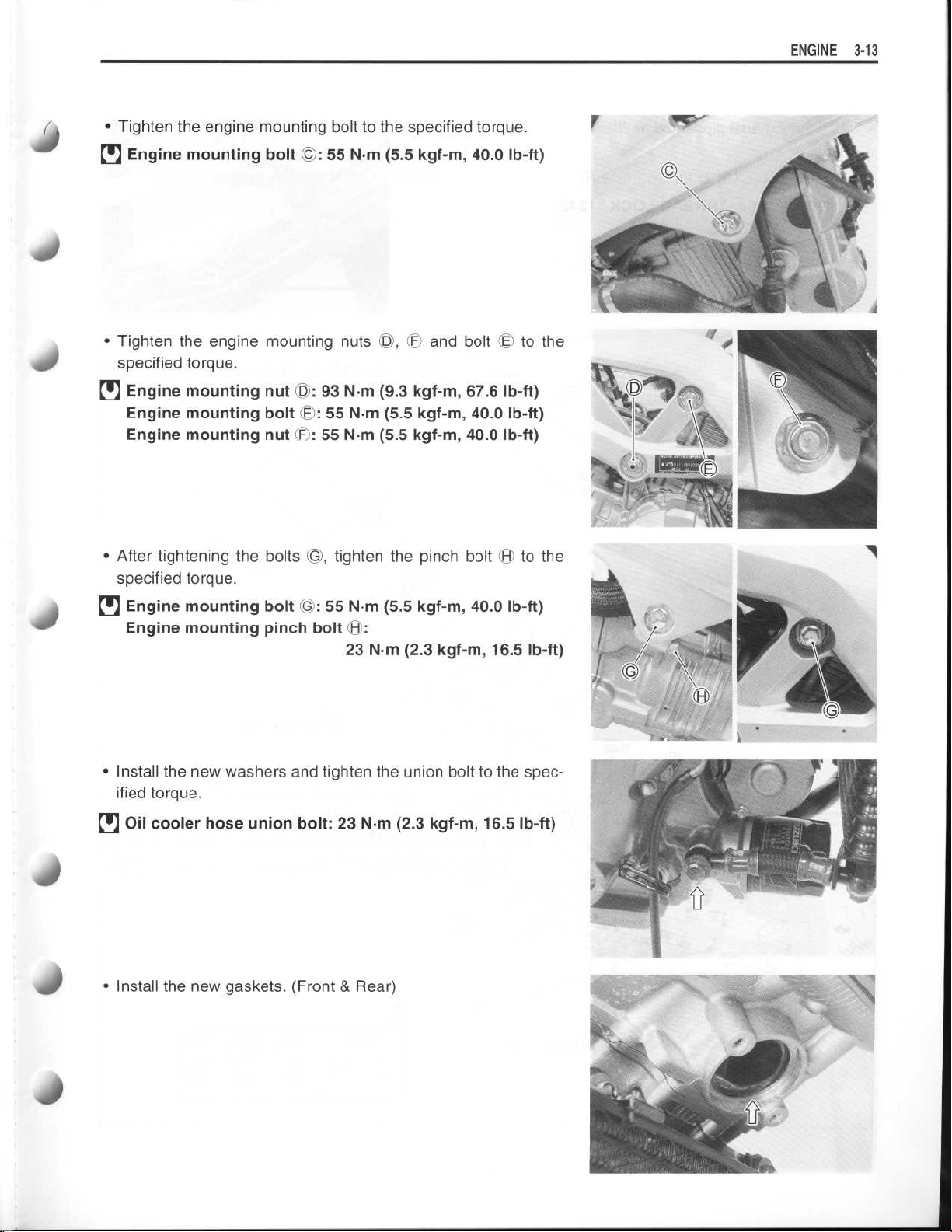

Tighten the engine mounting bolt to the specified torque

.

Engine mounting bolt

•

•

Tighten the engine mounting nuts

specified torque

Engine mounting nut(: 93 N-m (9

•

Engine mounting bolt

Engine mounting nut

•

After tightening the bolts ©, tighten the pinch bolt

specified torque

•

Engine mounting bolt

Engine mounting pinch bolt (L

.

.

OO

(F

©

©

:

55 N

:

55 N

:

55 N

:

55 N

23 N

.m (5

.5 kgf-m, 40

OO ,

OO

.3 kgf-m, 67

.m (5

.5 kgf-m, 40

.m (5

.5 kgf-m, 40

.m (5

.5 kgf-m, 40

.m (2

.0 lb-ft)

and bolt (

.6 lb-ft)

.0 lb-ft)

.0 lb-ft)

.0 lb-ft)

.3 kgf-m, 16

.5 lb-ft)

to the

to the

4

•

Install the new washers and tighten the union bolt to the specified torque

Oil cooler hose union bolt

•

•

Install the new gaskets

.

: 23 N

.m (2

.3 kgf-m, 16

. (Front & Rear)

.5 lb-ft)

Page 14

~

3

-14 ENGINE

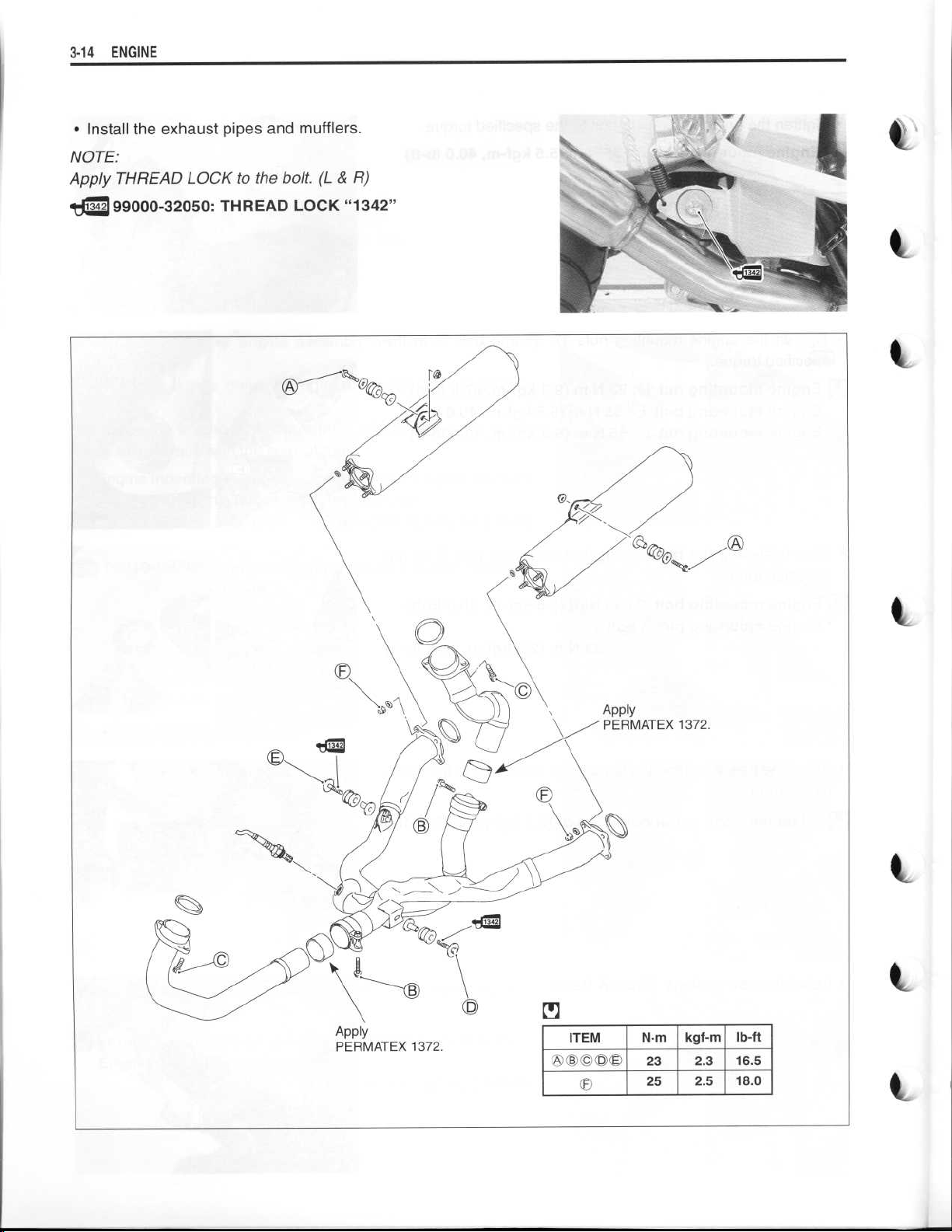

•

Install the exhaust pipes and mufflers

NOTE

:

Apply THREAD LOCK to the bolt

. (L & R)

.

99000-32050

: THREAD LOCK "1342"

I

ITEM

OO©©OO®

N

.m

kgf-m

23

25

lb-ft

2

.3

16

.5

2

.5

18

.0

Page 15

~

~

~

~

~

~

ENGINE 3-15

•

40

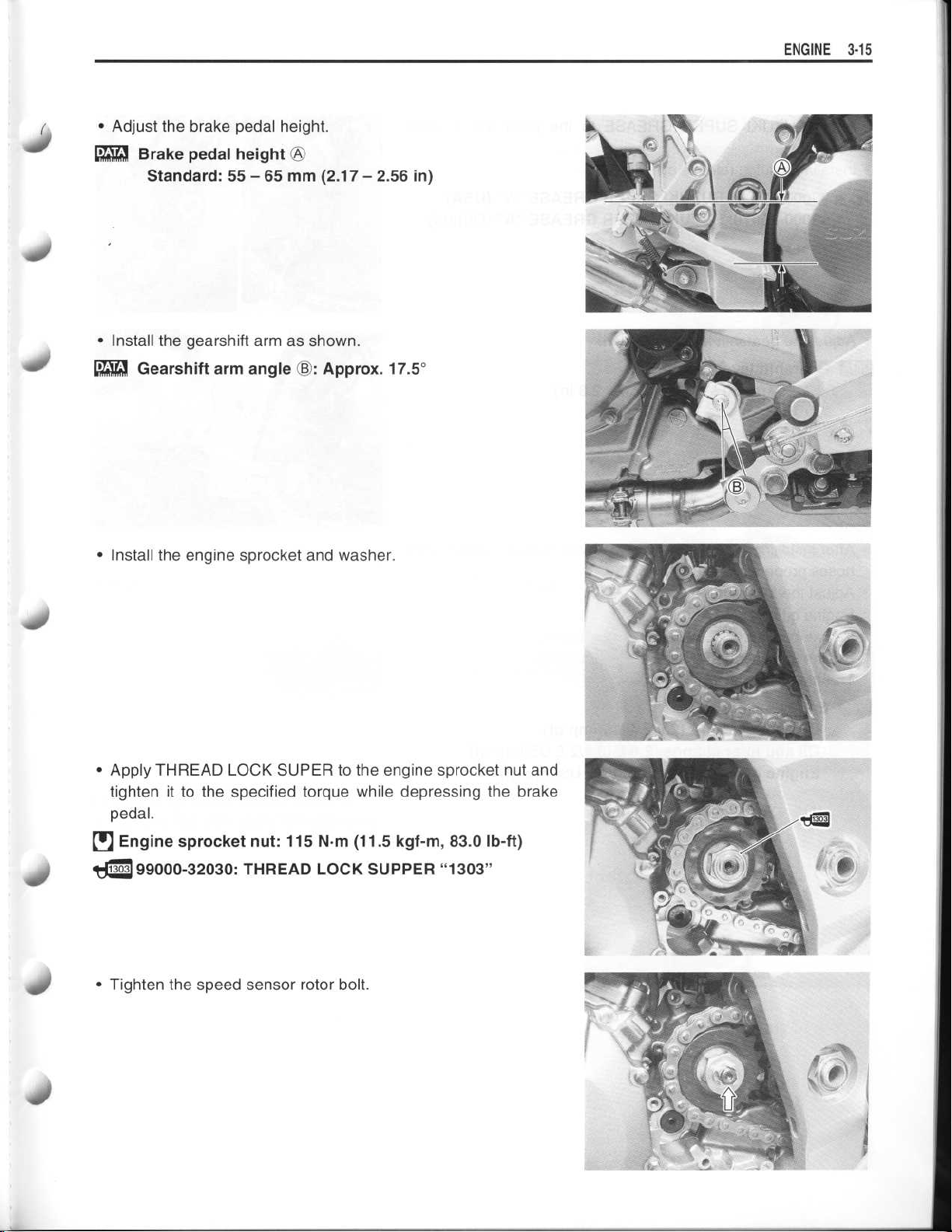

Adjust the brake pedal height

•

Brake pedal height

Standard

•

Install the gearshift arm as shown

•

Gearshift arm angle

: 55 -

65 mm (2

OA

©

.

.17

Approx

:

- 2

.

.56 in)

. 17

.5°

•

Install the engine sprocket and washer

•

Apply THREAD LOCK SUPER to the engine sprocket nut and

tighten it to the specified torque while depressing the brake

pedal

.

Engine sprocket nut

0

99000-32030

•

Tighten the speed sensor rotor bolt

: 115 N

: THREAD LOCK SUPPER "1303"

.m (11

.

.5 kgf-m, 83

.

.0 lb-ft)

40

Page 16

~

~

~

~

~

~

~

~

~

~

~

3

-16 ENGINE

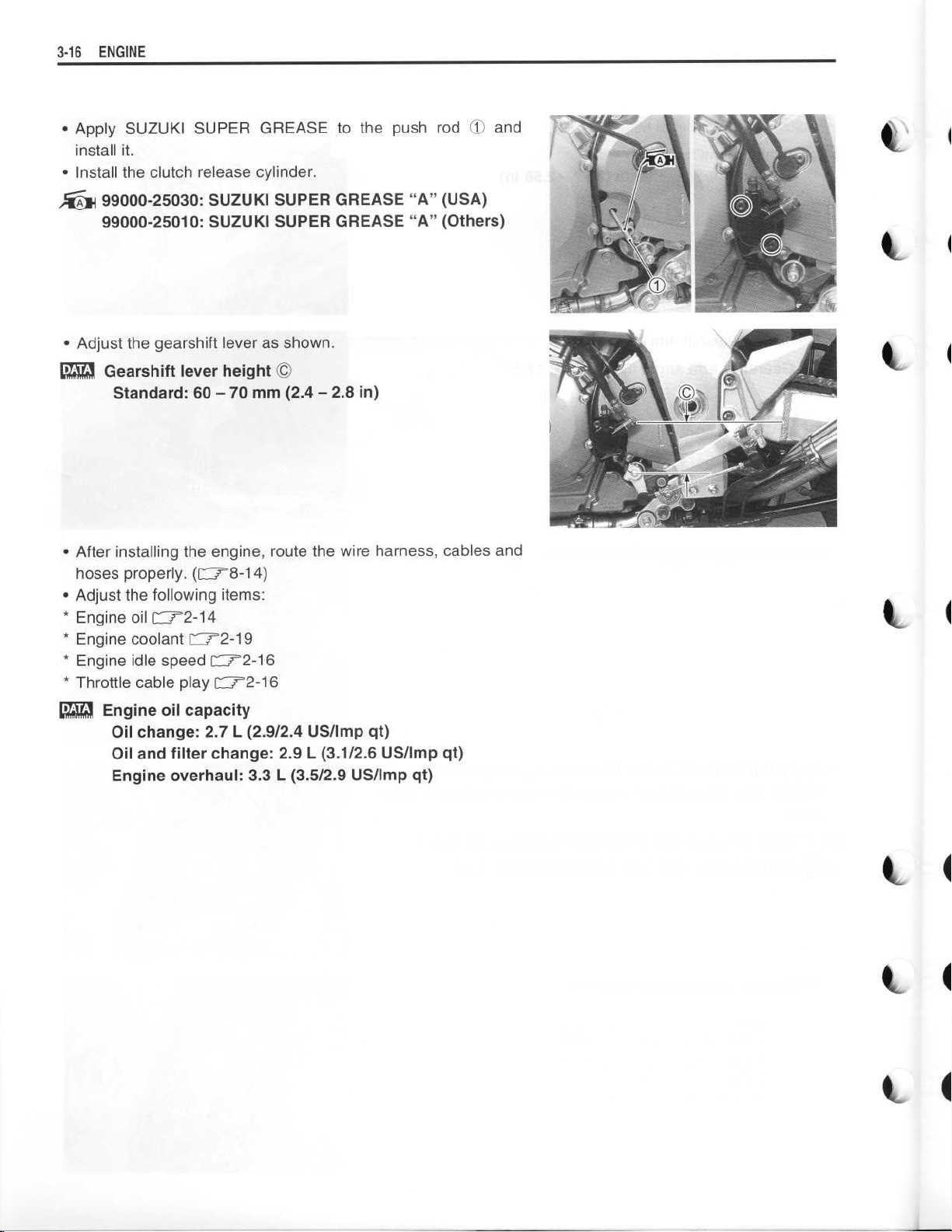

•

Apply SUZUKI SUPER

install it

•

Install the clutch release cylinder

.

GREASE to the push rod 10 and

.

99000-25030

99000-25010

•

Adjust the gearshift lever as shown

•

Gearshift lever height

Standard

•

After installing the engine, route the wire harness, cables and

hoses properly

•

Adjust the following items

•

Engine oil =2-14

•

Engine coolant L7'2-19

•

Engine idle speed C12-16

•

Throttle cable play

•

Engine oil capacity

Oil change

Oil and filter change

Engine overhaul

: SUZUKI SUPER GREASE "A" (USA)

: SUZUKI SUPER GREASE "A" (Others)

.

: 60-70 mm (2.4-

. (Cr8-14)

:

r

-

72-16

: 2

.7 L (2

.9/2

.4 US/Imp qt)

: 2

.9 L (3

: 3

.3 L (3

.8 in)

2

.6 US/Imp qt)

.1/2

.5/2

.9 US/Imp qt)

Page 17

~

~

~

~

ENGINE 3-17

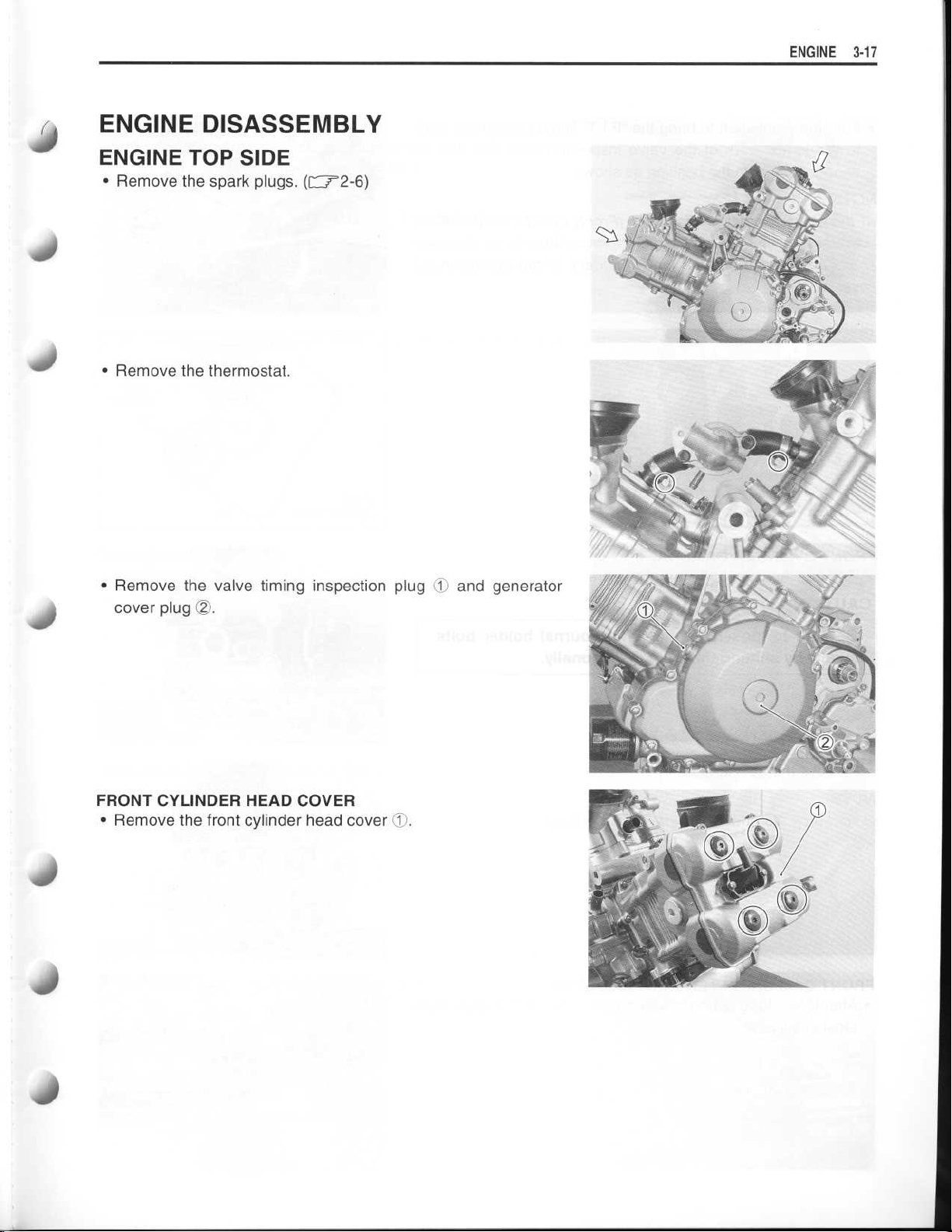

ENGINE DISASSEMBLY

ENGINE TOP SIDE

•

Remove the spark plugs.(

r -

7-2-6)

40

•

Remove the thermostat

.

•

Remove the valve timing inspection plugOand generator

cover plug 02

FRONT CYLINDER HEAD COVER

•

Remove the front cylinder head cover J

.

.

Page 18

~

~

~

3-18 ENGINE

•

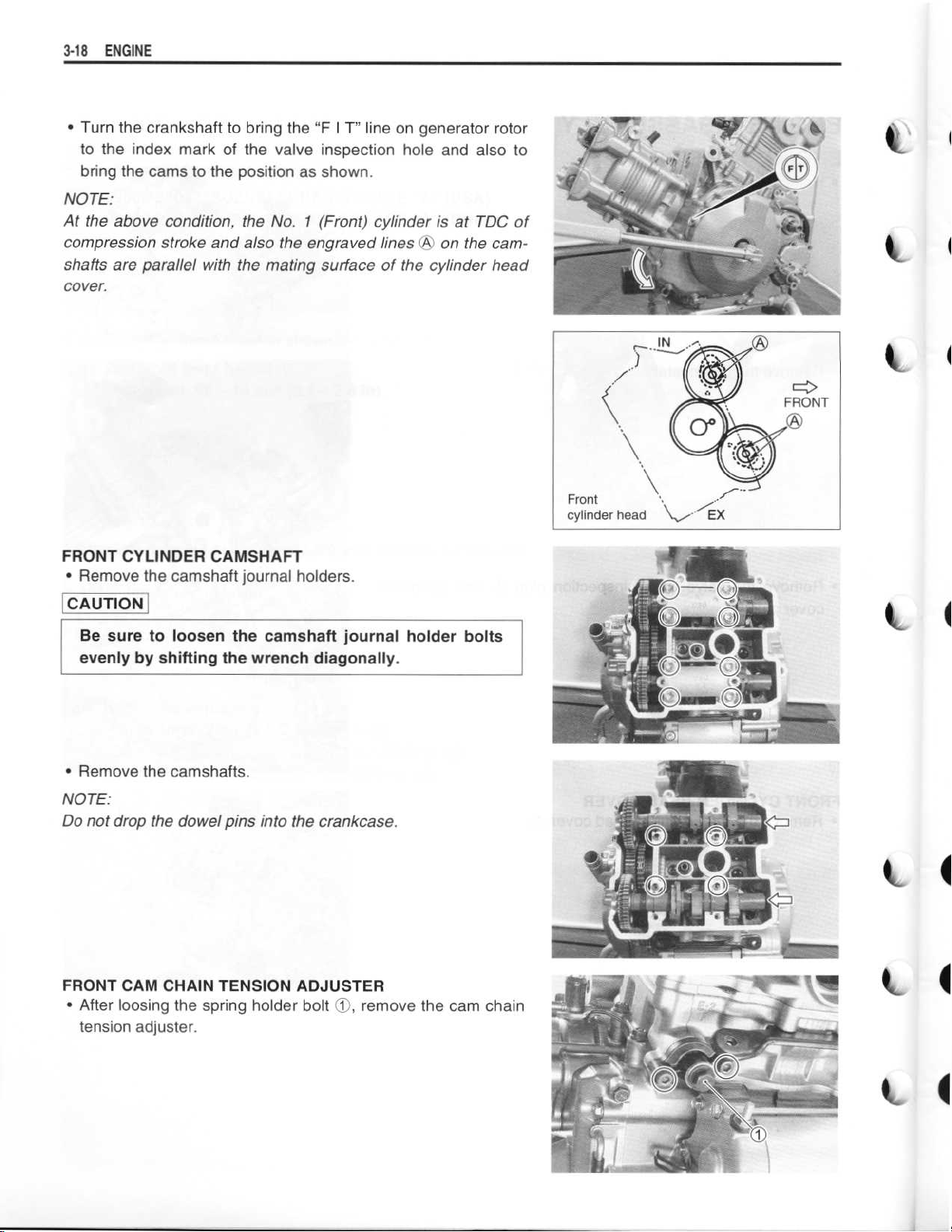

Turn the crankshaft to bring the "F I T" line on generator rotor

to the index mark of the valve inspection hole and also to

bring the cams to the position as shown

NOTE

:

At the above condition, the No

compression stroke and also the engraved lines

shafts are parallel with the mating surface of the cylinder head

cover

.

. 1 (Front) cylinder is at TDC of

.

(

on the cam-

FRONT CYLINDER CAMSHAFT

•

Remove the camshaft journal holders

CAUTION

Be sure to loosen the camshaft journal holder bolts

evenly by shifting the wrench diagonally

•

Remove the camshafts

NOTE

:

Do not drop the dowel pins into the crankcase

FRONT CAM CHAIN TENSION ADJUSTER

•

After loosing the spring holder bolt

tension adjuster

.

.

.

.

.

remove the cam chain

O,

Page 19

~

~

~

~

~

~

~

ENGINE 3-19

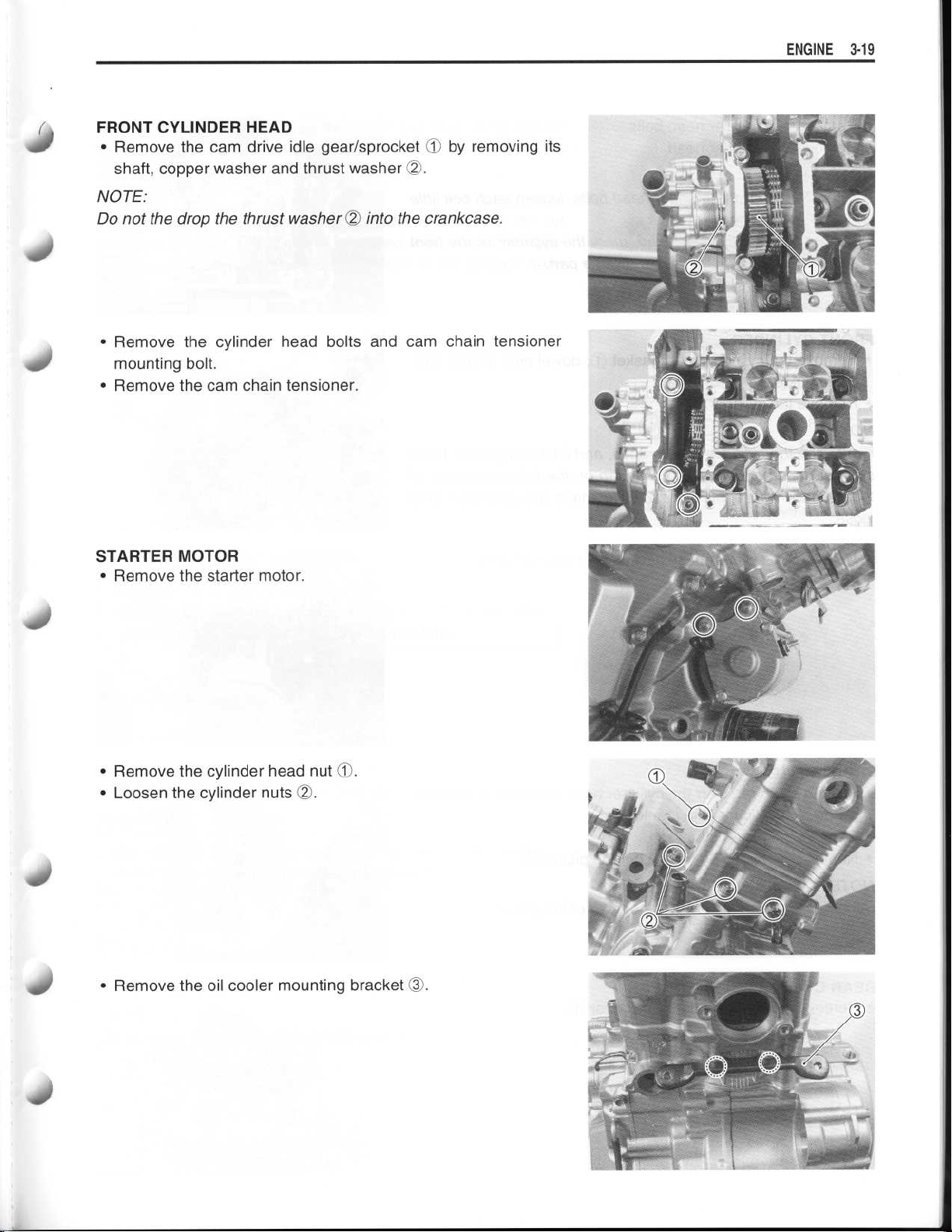

FRONT CYLINDER HEAD

•

Remove the cam drive idle gear/sprocket 90 by removing its

shaft, copper washer and thrust washer

NOTE

:

Do not the drop the thrust washer

OO

OO

.

into the crankcase

.

400

•

Remove the cylinder head bolts and cam chain tensioner

mounting bolt

•

Remove the cam chain tensioner

.

.

STARTER MOTOR

(Z

.

D

.

.

(T

•

Remove the starter motor

•

Remove the cylinder head nut

•

Loosen the cylinder nuts

•

Remove the oil cooler mounting bracket

.

Page 20

~

~

~

~

~

~

~

~

~

3-20 ENGINE

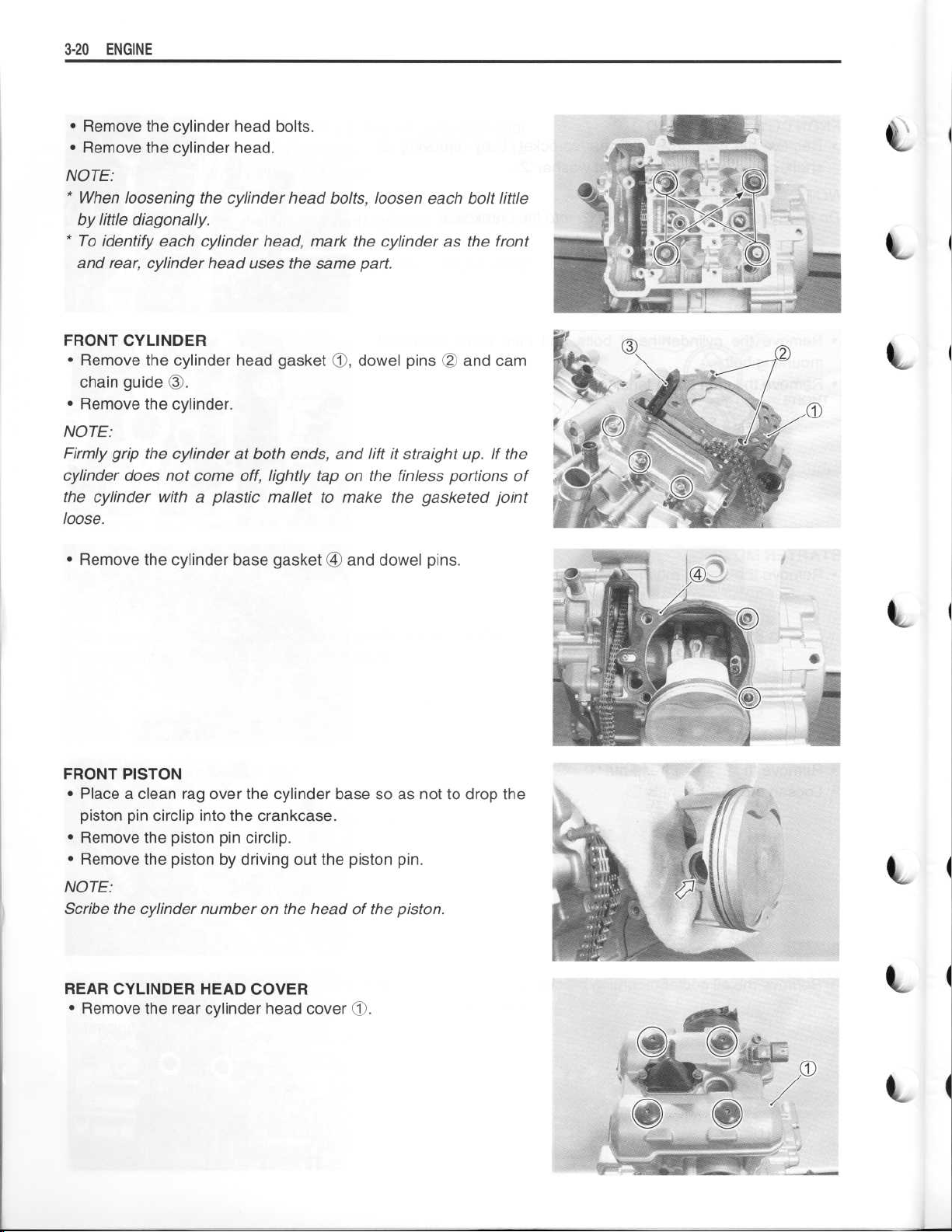

•

Remove the cylinder head bolts

•

Remove the cylinder head

NOTE

:

.

.

* When loosening the cylinder head bolts, loosen each bolt little

by little diagonally

.

* To identify each cylinder head, mark the cylinder as the front

and

rear,

cylinder head uses the same part

.

FRONT CYLINDER

•

Remove the cylinder head gasketO,dowel pinsOOand cam

chain guide (3

•

Remove the cylinder

NOTE

:

Firmly grip

cylinder does not come off, lightly

.

.

the cylinder at both ends, and lift it

tap

on the finless portions of

straight up

.

If the

the cylinder with a plastic mallet to make the gasketed joint

loose

.

•

Remove the cylinder base gasket ® and dowel pins

.

FRONT PISTON

•

Place a clean rag over the cylinder base so as not to drop the

piston pin circlip into the crankcase

•

Remove the piston pin circlip

•

Remove the piston by driving out the piston pin

NOTE

:

Scribe the

cylinder number on the head of the piston

.

.

.

.

REAR CYLINDER HEAD COVER

•

Remove the rear cylinder head cover 90

.

Page 21

~

~

•

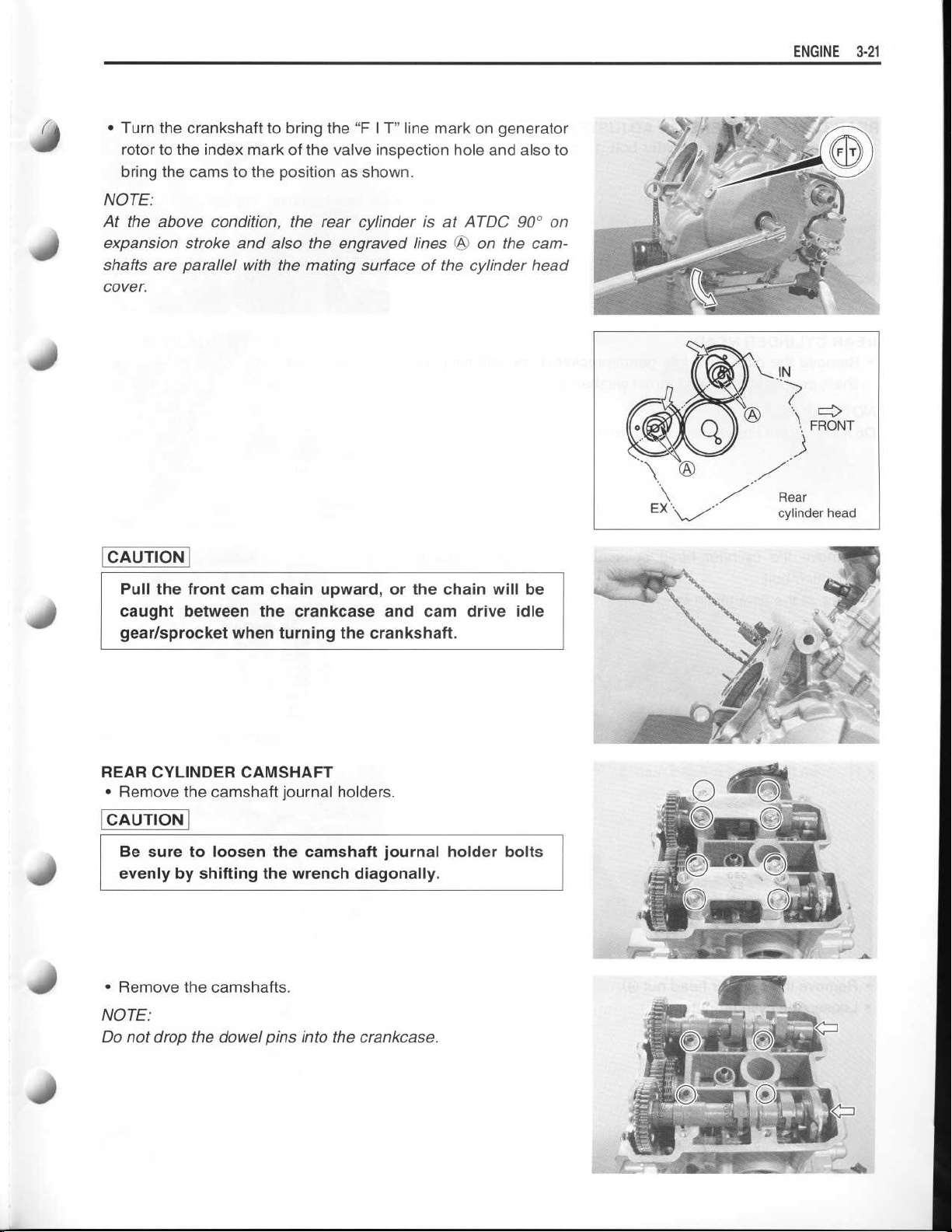

Turn the crankshaft to bring the "F I T" line mark on generator

rotor to the index mark of the valve inspection hole and also to

bring the cams to the position as shown

NOTE

:

At the above condition, the rear cylinder is at ATDC 90° on

expansion stroke and also the engraved lines

shafts are parallel with the mating surface of the cylinder head

cover

.

.

on the cam-

OA

ENGINE

3-21

CAUTION

Pull the front cam chain upward, or the chain will be

caught between the crankcase and cam drive idle

gear/sprocket when turning the crankshaft

REAR CYLINDER CAMSHAFT

•

Remove the camshaft journal holders

CAUTION

Be sure to loosen the camshaft journal holder bolts

evenly by shifting the wrench diagonally

•

Remove the camshafts

.

.

.

.

NOTE

:

Do not drop the dowel pins into the crankcase

.

Page 22

~

~

~

~

~

~

~

3-22 ENGINE

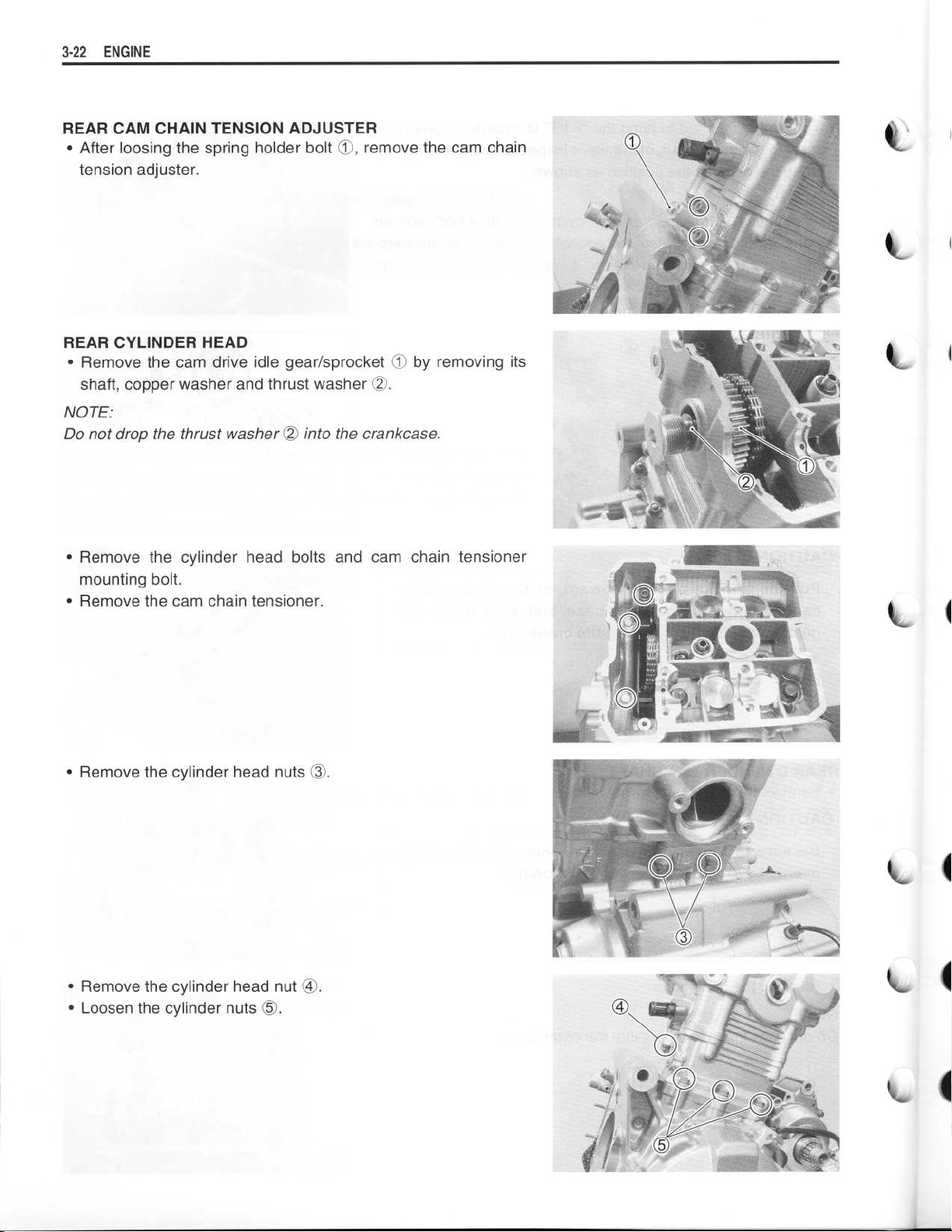

REAR CAM CHAIN TENSION ADJUSTER

After loosing the spring holder bolt t, remove the cam chain

•

tension adjuster

REAR CYLINDER HEAD

•

Remove the cam drive idle gear/sprocket 1O by removing its

shaft, copper washer and thrust washer 02

NOTE

:

Do not drop the thrust washer

•

Remove the cylinder head bolts and cam chain tensioner

mounting bolt

•

Remove the cam chain tensioner

.

.

2

into the crankcase

.

.

.

c

k-

I

•

Remove the cylinder head nuts (O

•

Remove the cylinder head nut ®

•

Loosen the cylinder nuts 05

)-

.

.

~L

4

Page 23

~

~

~

~

~

~

~

~

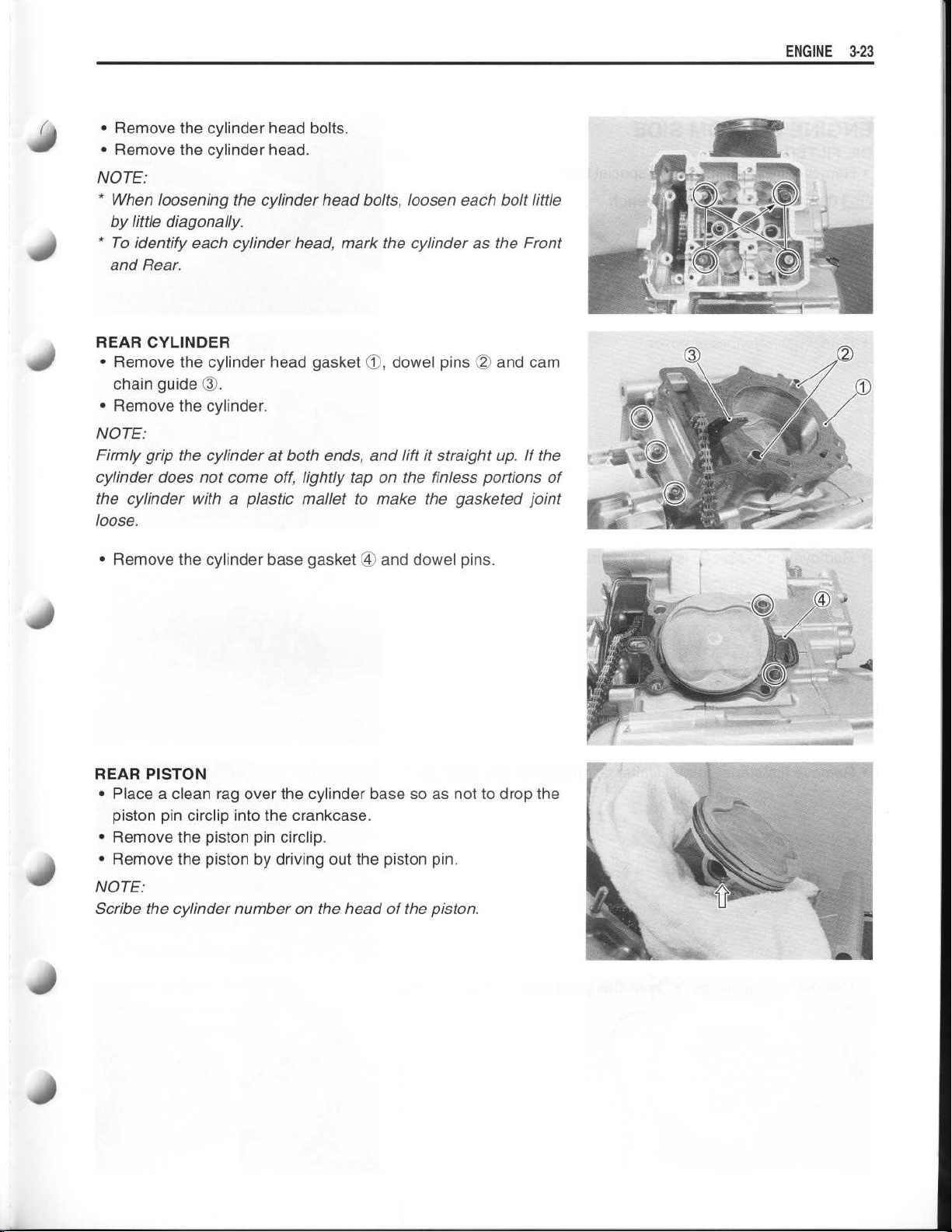

•

Remove the cylinder head bolts

•

Remove the cylinder head

NOTE

:

* When loosening the cylinder head bolts, loosen each bolt little

by little diagonally

* To identify each cylinder head, mark the cylinder as the Front

and Rear

REAR CYLINDER

•

Remove the cylinder head gasket 90, dowel pins 02 and cam

chain guide

•

Remove the cylinder

NOTE

Firmly grip the cylinder at both ends, and lift it straight up

cylinder does not come off, lightly tap on the finless portions of

the cylinder with a plastic mallet to make the gasketed joint

loose

.

:

.

(1

.

.

.

.

.

. If the

ENGINE

3-23

40

•

Remove the cylinder base gasket ® and dowel pins

REAR PISTON

•

Place a clean rag over the cylinder base so as not to drop the

piston pin circlip into the crankcase

•

Remove the piston pin circlip

•

Remove the piston by driving out the piston pin

NOTE

:

Scribe the cylinder number on the head of the piston

.

.

.

.

.

Page 24

~

~

~

~

~

3-24 ENGINE

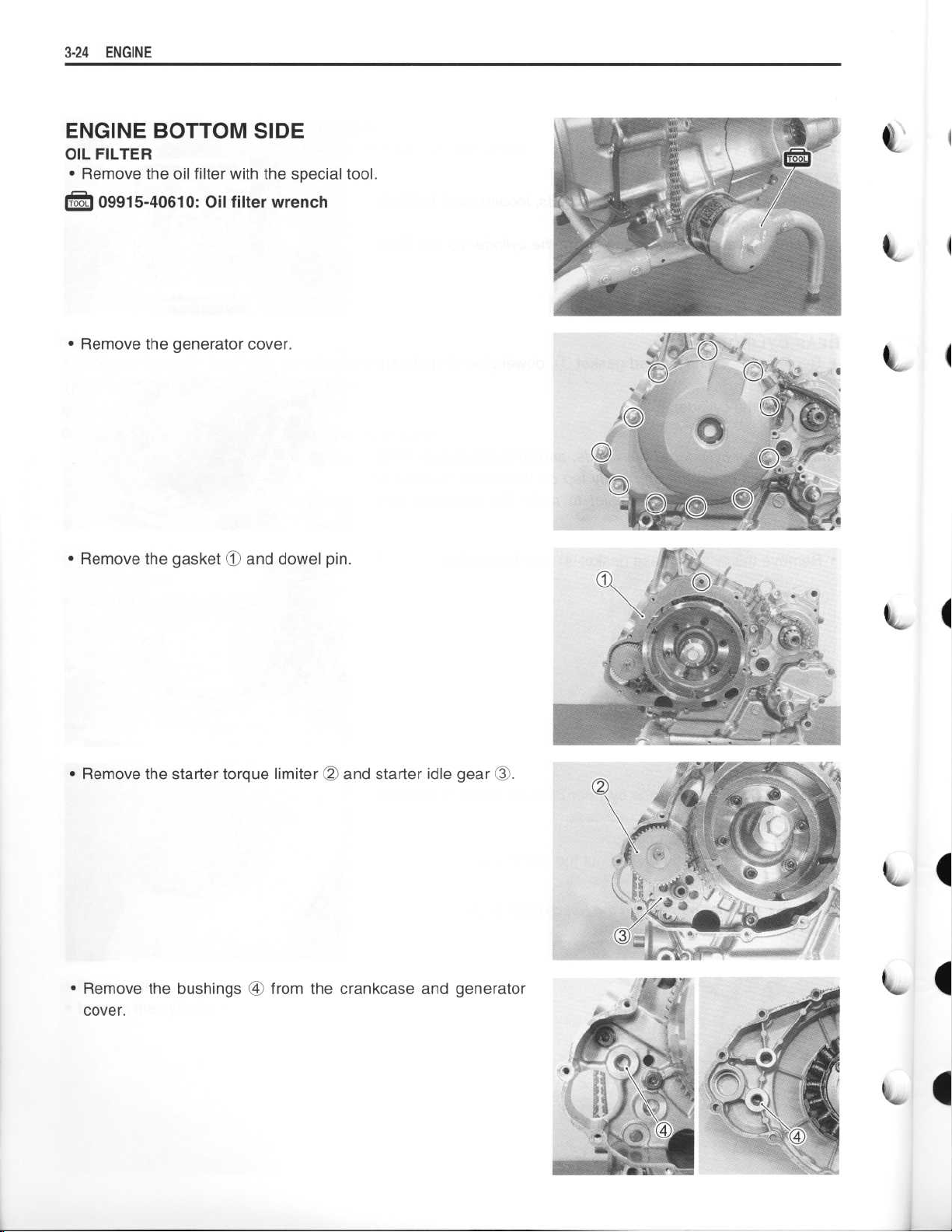

ENGINE BOTTOM SIDE

OIL FILTER

•

Remove the oil filter with the special tool

.

:

09915-40610

•

Remove the generator cover

: Oil filter wrench

.

.

•

Remove the gasket 90 and dowel pin

•

Remove the starter torque limiter

•

Remove the bushings ® from the crankcase and generator

cover

.

.

and starter idle gear 03

O

.

Page 25

~

~

~

~

~

~

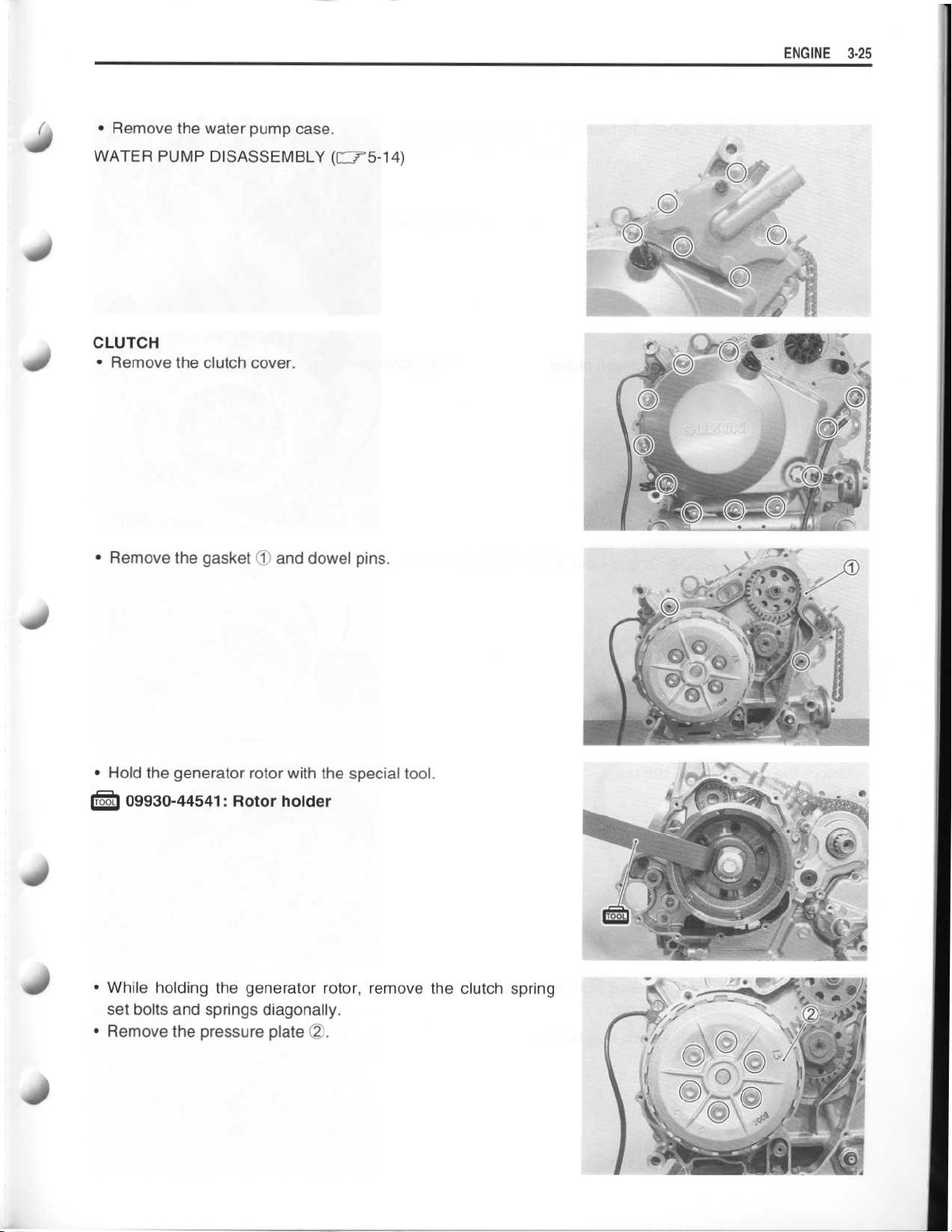

ENGINE 3-25

•

Remove the water pump case

.

40

40

WATER PUMP DISASSEMBLY

CLUTCH

•

Remove the clutch cover

•

Remove the gasketDand dowel pins

(r

r5-14)

.

.

S

490

40

•

Hold the generator rotor with the special tool

09930-44541

•

While holding the generator rotor, remove the clutch spring

set bolts and springs diagonally

•

Remove the pressure plate 02

: Rotor holder

.

.

.

40

Page 26

~

~

~

~

~

~

3

-26 ENGINE

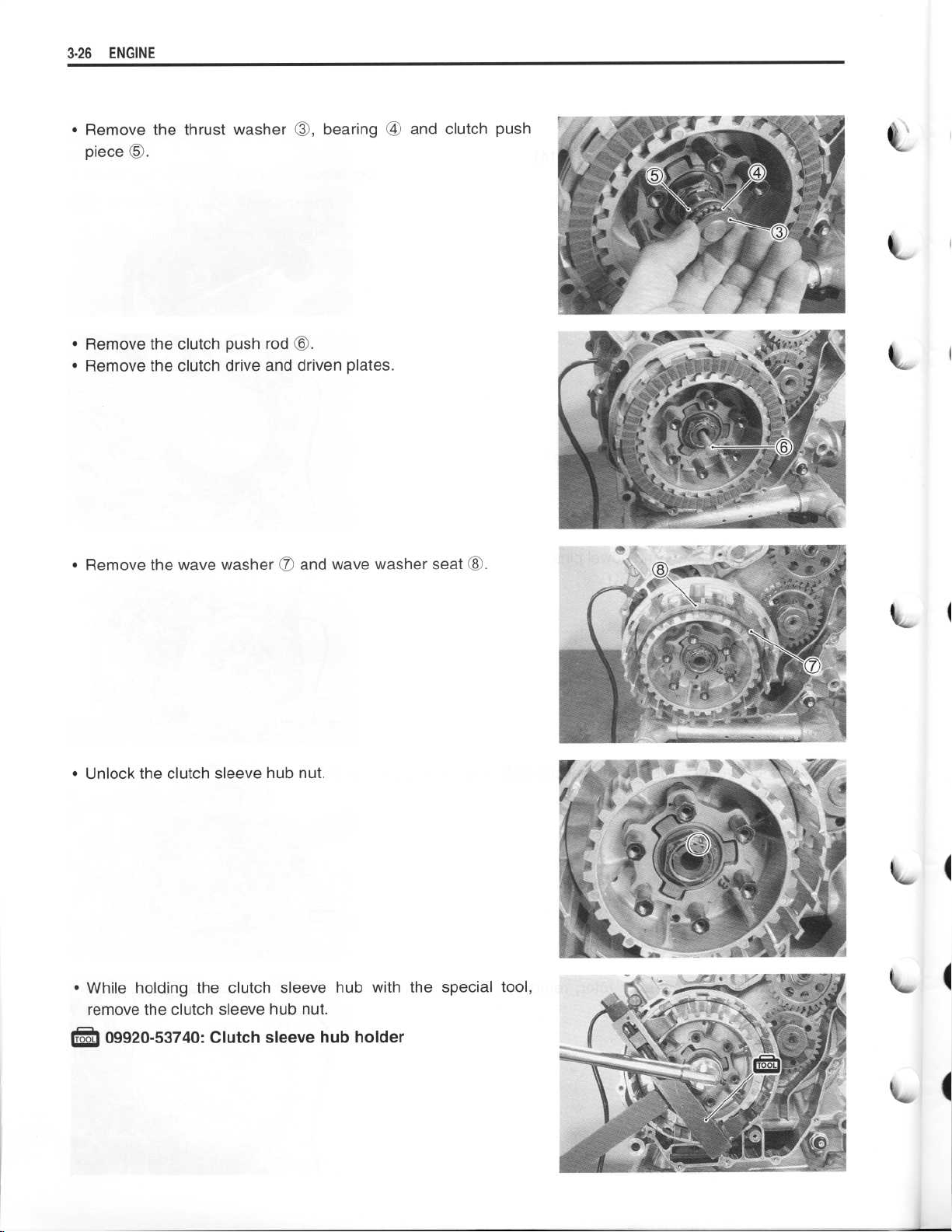

•

Remove the thrust washer ©, bearing ® and clutch push

piece ©

.

I

I

•

Remove the clutch push rod ©

Remove the clutch drive and driven plates

•

.

.

k-

Remove the wave washer (7 and wave washer seat ©

•

•

Unlock the clutch sleeve hub nut

While holding the clutch sleeve hub with the special tool,

•

remove the clutch sleeve hub nut

:

.

09920-53740

: Clutch sleeve hub holder

.

.

.

Page 27

~

~

~

~

~

~

~

ENGINE 3-27

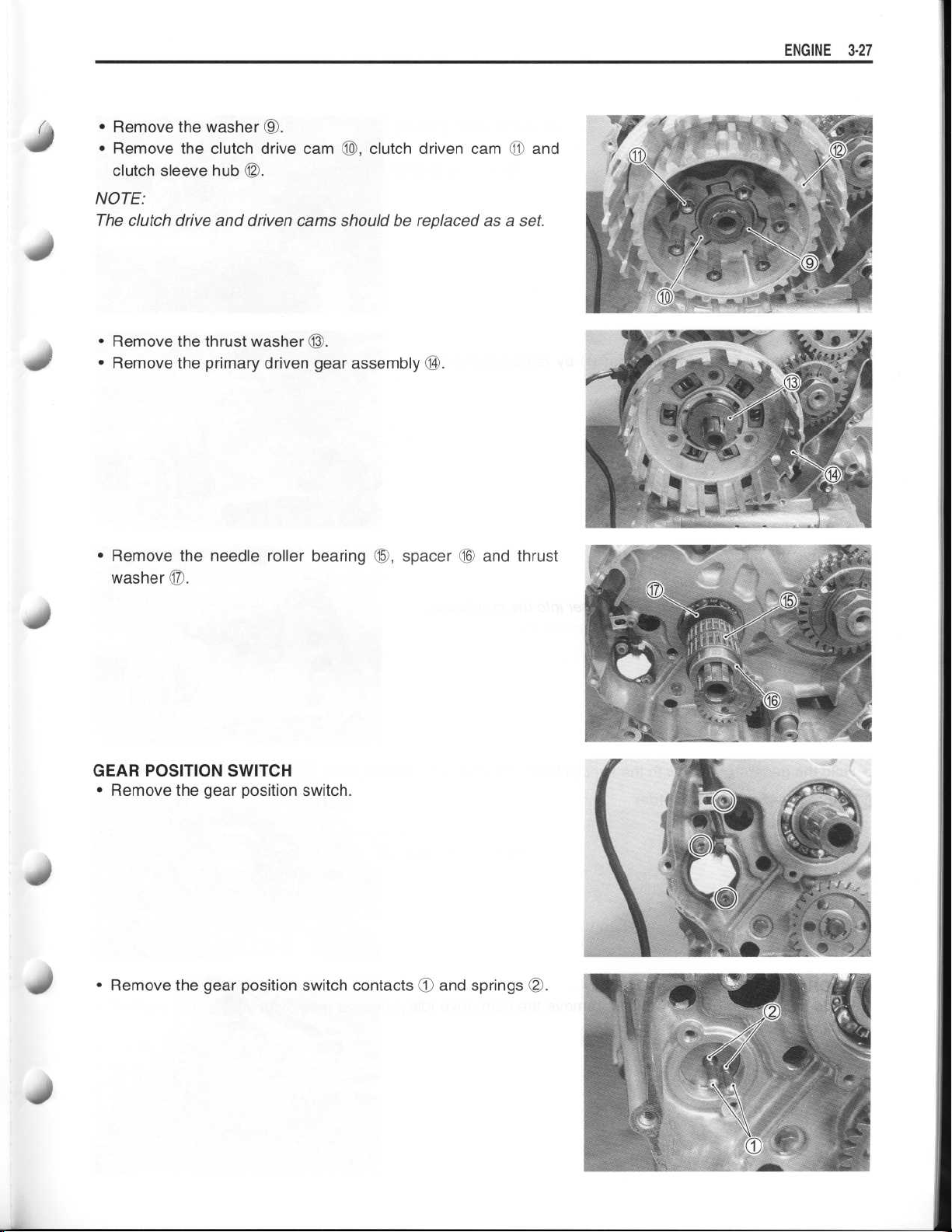

•

40

Remove the washer ©9

•

Remove the clutch drive cam

clutch sleeve hub

NOTE

:

The clutch drive and driven cams should be replaced as a set

•

Remove the thrust washer

•

Remove the primary driven gear assembly 14

(2

.

(2,

clutch driven cam 11 and

.

.

(D

.

.

4-

•

Remove the needle roller bearing 15

washer 17

GEAR POSITION SWITCH

•

Remove the gear position switch

•

Remove the gear position switch contacts ® and springs

.

,

spacer(* and thrust

.

OO

.

Page 28

~

~

~

~

~

3-

2 8

ENGINE

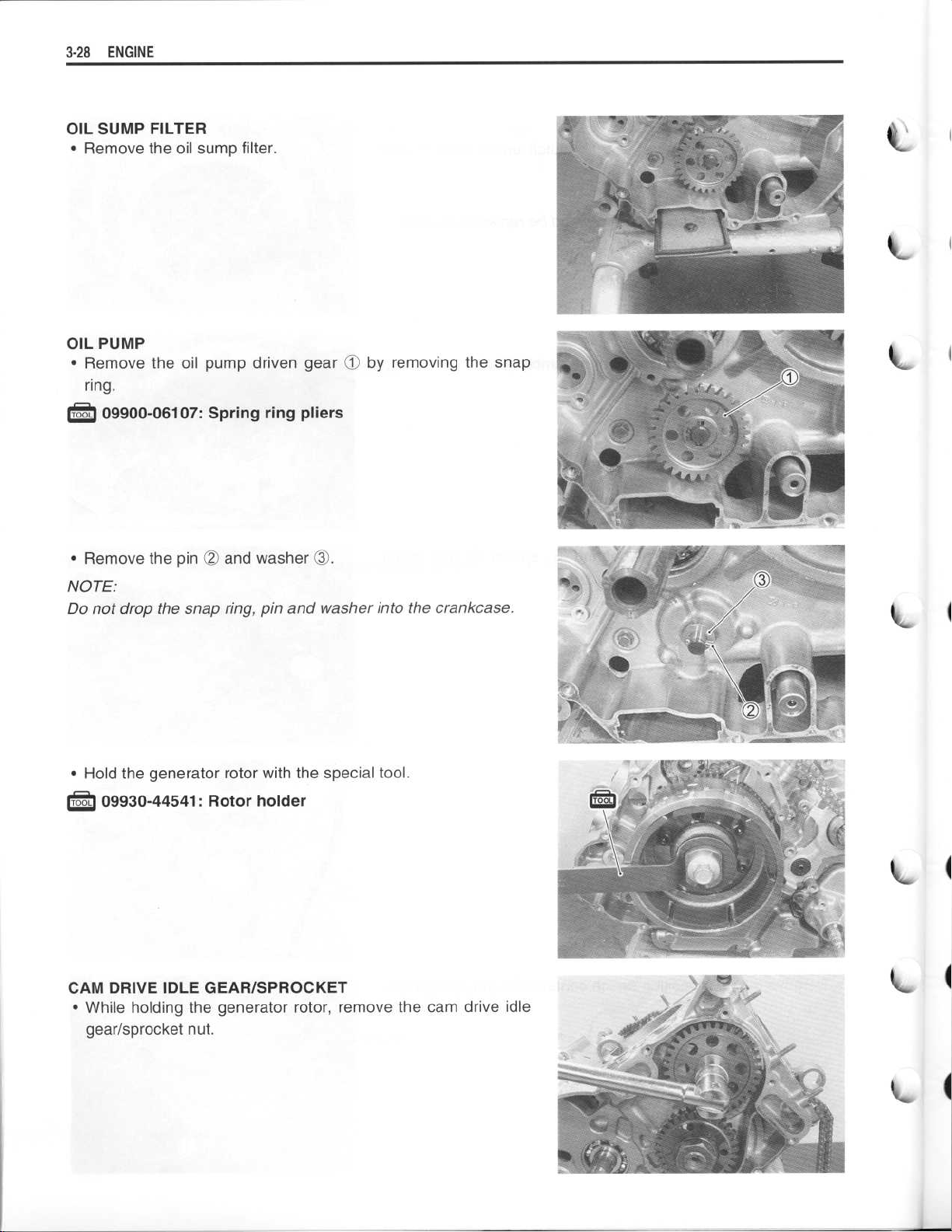

OIL SUMP FILTER

•

Remove the oil sump filter

OIL PUMP

•

Remove the oil pump driven gear 90 by removing the snap

ring

.

. .

09900-06107

: Spring ring pliers

.

•

Remove the pinOOand washer 03

NOTE

:

Do not drop the snap ring, pin and washer into the crankcase

Hold the generator rotor with the special tool

•

09930-44541

CAM DRIVE IDLE GEAR/SPROCKET

•

While holding the generator rotor, remove the cam drive idle

gear/sprocket nut

: Rotor holder

.

.

.

.

Page 29

~

~

~

~

~

~

~

ENGINE 3-29

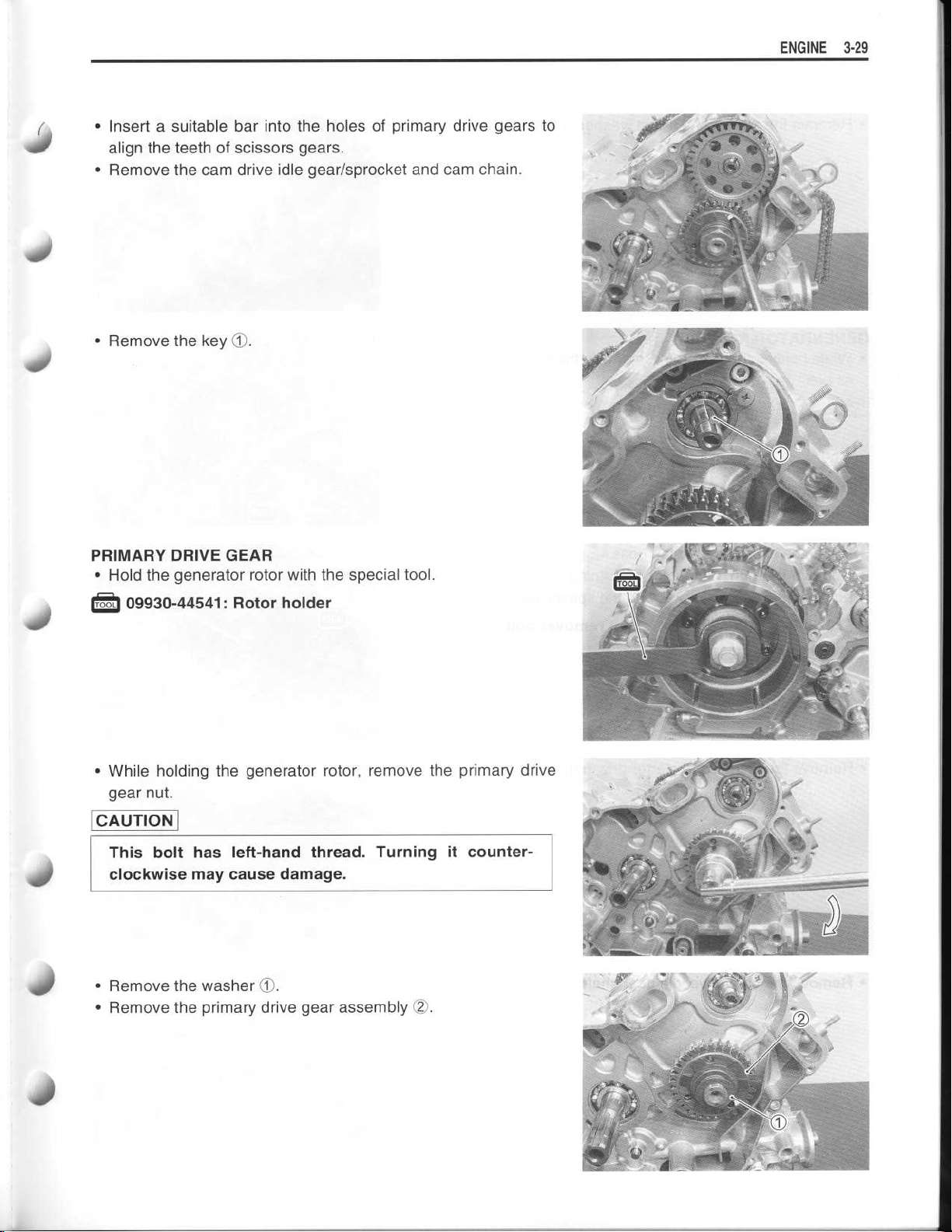

•

Insert a suitable bar into the holes of primary drive gears to

410

align the teeth of scissors gears

•

Remove the cam drive idle gear/sprocket and cam chain

•

Remove the key

O

.

.

.

PRIMARY DRIVE GEAR

•

Hold the generator rotor with the special tool

09930-44541

•

While holding the generator rotor, remove the primary drive

gear nut

CAUTION

This bolt has left-hand thread

clockwise may cause damage

•

Remove the washer ®

•

Remove the primary drive gear assembly

.

: Rotor holder

. Turning it counter-

.

.

0

.

.

9

Page 30

~

~

~

~

~

~

3-30

ENGINE

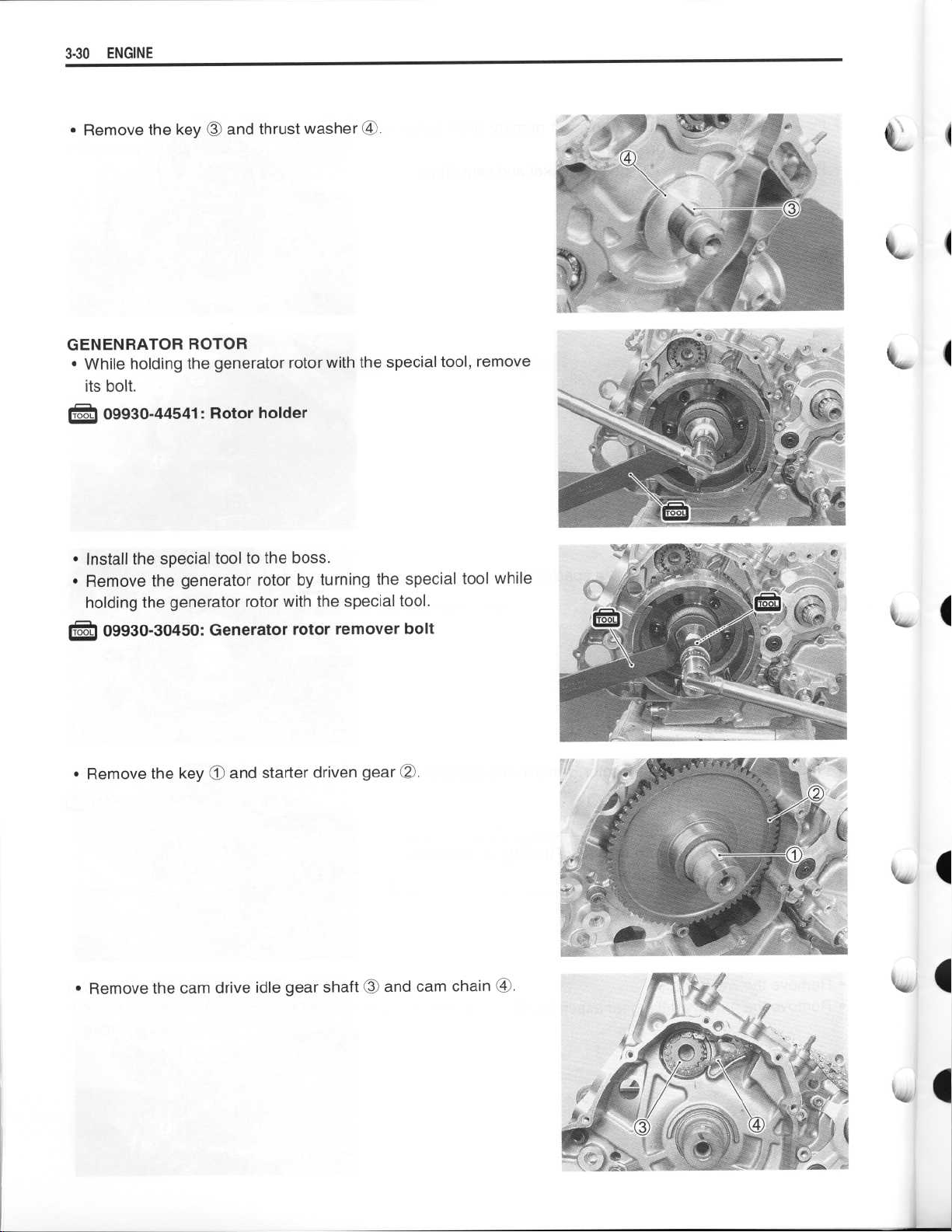

•

Remove the key ® and thrust washer ®

.

GENENRATOR ROTOR

While holding the generator rotor with the special tool, remove

•

its bolt

. .

•

•

.

09930-44541

Install the special tool to the boss

Remove the generator rotor by turning the special tool while

holding the generator rotor with the special tool

09930-30450

: Rotor holder

.

.

: Generator rotor remover bolt

k.

I

Remove the key 1O and starter driven gear E

•

Remove the cam drive idle gear shaft ® and cam chain ®

•

.

.

Page 31

~

~

~

~

~

~

GEARSHIFT

•

Remove the gearshift cover

Remove the gasket 1O and dowel pins

•

•

Draw out the gearshift shaft

.

.

OO

.

ENGINE

3-31

•

Remove the gearshift cam plate ®

•

Remove the gearshift cam stopper ®

Remove the engine sprocket spacer O5

•

.

.

.

Page 32

~

~

~

~

~

~

3-32 ENGINE

•

Remove the crankcase bolts

.

Separator the crankcase into 2 parts, right and left with the

•

crankcase separating tool

09920-13120

NOTE

:

•

Fit the crankcase separating tool, so that the tool arms are in

parallel with the side of crankcase

•

The crankshaft and transmission components should remain

in the left crankcase half

When separating the crankcase, tap the end of the counter-

•

shaft with a plastic hammer

•

Remove the dowel pins

: Crankcase separating tool

.

.

.

.

.

Page 33

~

~

~

ENGINE 3-33

•

Remove

gearshift cam ©

•

Remove the countershaft and driveshaft

•

Remove the crankshaft

the

gearshift

fork

shafts

.

.

©,

gearshift

.

forks

(7)

and

40

Page 34

~

~

~

~

~

~

3-34 ENGINE

ENGINE COMPONENTS INSPECTION AND SERVICING

CYLINDER HEAD COVER

DISASSEMBLY

CAUTION

Be sure to identify each removed part as to its loca-

tion, and lay the parts out in groups designated as

"No

. 1", "No

be restored to the original location during assembly

Remove the camshaft position sensor 10

•

Remove the PAIR reed valve cover

•

. 2" "Exhaust", "Intake", so that each will

.

.

OO

.

INSPECTION

Inspect the PAIR reed valve for the carbon deposit

•

If the carbon deposit is found in the reed valve, replace it with

•

a new one

REASSEMBLY

Apply SUZUKI SUPER GREASE to the O-ring and install it

•

99000-25030

99000-25010

•

Apply THREAD LOCK to the thread and install the PAIR reed

valve cover

.

: SUZUKI SUPER GREASE "A" (USA)

: SUZUKI SUPER GREASE "A" (Others)

.

.

.

99000-32050

: THREAD LOCK "1342"

Page 35

~

ENGINE3-35

CAMSHAFT/CYLINDER HEAD

CAUTION

Be sure to identify each removed part as to its loca-

tion, and lay the parts out in groups designated as

"No

go

. 1", "No

be restored to the original location during assembly

. 2", "Exhaust", "Intake", so that each will

.

CAMSHAFT

All camshafts should be checked for runout and also for wear of

cams and journals if the engine has been noted as giving abnor-

mal noise, vibration or lack power output

. Any of these condi-

tions may be caused by camshafts worn down or distorted to the

service limit

The camshafts can be identified by the engraved letter

1O No

No

OO

No

(3

® No

.

.

. 1 (Front) intake camshaft ("INF" and "I"

. 1 (Front) exhaust camshaft ("EXF" and "E"

. 2 (Rear) intake camshaft ("INR" and "I"

. 2 (Rear) exhaust camshaft ("EXR" and "E"

: Intake)

: Exhaust)

: Intake)

: Exhaust)

CAM WEAR

Worn-down cams are often the cause of mistimed valve opera-

tion resulting in reduced power output

.

The limit of cam wear is specified for both intake and exhaust

cams in terms of cam height

S

micrometer

. Replace camshaft if it wears worn down to the limit

which is to be measured with a

(R,

.

Cam height

Service Limit (IN)

09900-20202

: Micrometer (25 - 50 mm)

(EX)

: 37

.48 mm (1

: 36

.08 mm (1

.476 in)

.420 in)

Page 36

~

~

~

3-36 ENGINE

CAMSHAFT JOURNAL WEAR

Determine whether or not each journal is worn down to the limit

by measuring the oil clearance with the camshaft installed in

place

. Use the plastigaugeOto read the clearance at the widest

portion, which is specified as follows

•

Camshaft journal oil clearance

Service Limit (IN&EX)

:

: 0

.150 mm (0

.0059 in)

09900-22301

09900-22302

NOTE

:

Install camshaft journal holder to their original positions

Tighten the camshaft journal holder bolts evenly and diagonally

to the specified torque

Camshaft journal holder bolt

NOTE

:

Do not rotate the camshaft with the plastigauge in place

Remove the camshaft holders, and read the width of the compressed plastigauge with envelope scale

should be taken at the widest part

: Plastigauge

: Plastigauge

.

: 10 N-m (1

.

.0 kgf-m, 7

. This measurement

.

.0 lb-ft)

.

If the camshaft journal oil clearance measured exceeds the limit,

measure the inside diameter of the camshaft journal holder and

outside diameter of the camshaft journal

or the cylinder head depending upon which one exceeds the

specification

Camshaft journal holder I.D.

•

09900-20602

09900-22403

•

Camshaft journal O.D.

09900-20205

.

Standard (IN&EX)

22

.012 - 22

: Dial gauge (1/1 000 mm, 1 mm)

: Small bore gauge (18 -

Standard (IN&EX)

21

.972 -21.993 mm (0

: Micrometer (0

:

.025 mm (0

:

. Replace the camshaft

.8666 - 0

35 mm)

.8650-0

- 25 mm)

.8671 in)

.8659 in)

Page 37

~

CAMSHAFT RUNOUT

Measure the runout with a dial gauge

the runout exceeds the limit

=

Camshaft runout

Service Limit (IN

09900-20607

09900-20701

09900-21304

: Dial gauge (1/100 mm, 10 mm)

: Magnetic stand

-block (100 mm)

: V

.

&

EX)

: 0

CAM GEAR AND AUTOMATIC-DECOMP

Inspect the cam gear teeth for wear and damage

Inspect the automatic-decomp

tion

.

. for damage and smooth opera-

. Replace the camshaft if

.10 mm (0

.004 in)

.

.

If there are unusual, replace the camshaft assembly and cam

chain as a set

.

CAUTION

ENGINE3.

3 7

Do not attempt to disassemble the cam gears and

automatic-decomp

. assembly

. They are unserviceable

.

CAM CHAIN TENSION ADJUSTER

The cam chain tension adjusters are maintained at the proper

cam chain tension automatically

Unlock the ratchet

if it slides smoothly

(k,

and move the push rod © in place to see

. If any stickiness is noted or ratchet mecha-

.

nism is faulty, replace the cam chain tension adjuster assembly

with a new one

.

90 Front cam chain tension adjuster

(2 Rear cam chain tension adjuster

CAM CHAIN GUIDE AND CAM CHAIN TENSIONER

Check the cam chain guide and tensioner for wear and damage

.

If they are found to be damaged, replace them with the new

ones

4

.

O

Front cam chain tensioner

Rear cam chain tensioner

OO

(3 Front and Rear cam chain guide

Page 38

~

~

~

~

~

3-38 ENGINE

CYLINDER HEAD

Remove the pin 10 and O-ring

•

•

Remove the tappets

hand

.

Using special tools, compress the valve spring and remove

•

two cotter halvesOOfrom the valve stem

.

.

09916-14510

09916-14910

09916-84511

O

: Valve lifter

: Valve lifter attachment

: Tweezers

2

.

and shims ® by fingers or magnetic

.

i

•

Remove the valve spring retainer © and valve spring 07

•

Pull out the valve from the other side

.

.

t

. '

Page 39

~

~

•

Remove the oil seals ® and spring seats

CAUTION

O

.

ENGINE3-39

aI

Do not reuse the removed oil seals

CYLINDER HEAD DISTORTION

Decarbonize the combustion chambers

Check the gasketed surface of the cylinder head for distortion

with a straightedge and thickness gauge, taking a clearance

reading at several places indicated

position of the straightedge exceeds the limit, replace the cylin-

der head

VALVE STEM RUNOUT

Support the valve with "V" blocks, as shown, and check its runty

with a dial gauge

The valve must be replaced if the runout exceeds the limit

.

Cylinder head distortion

Service Limit

09900-20803

: 0

.05 mm (0

: Thickness gauge

.

.

.

. If the largest reading at any

.002 in)

.

40

d

Valve stem runout

Service Limit

09900-20607

09900-20701

09900-21304

VALVE HEAD RADIAL RUNOUT

Place the dial gauge at right angles to the valve head face, and

measure the valve head radial runout

If it measures more than the limit, replace the valve

'~Valve head radial runout

Service Limit

09900-20607

09900-20701

09900-21304

: 0

.05 mm (0

: Dial gauge (1/100 mm)

: Magnetic stand

: V-block (100 mm)

: 0

.03 mm (0

: Dial gauge (1/100 mm)

: Magnetic stand

: V

-block (100 mm)

.002 in)

.

.

.001 in)

Page 40

3-40

ENGINE

VALVE FACE WEAR

Visually inspect each valve for wear of its seating face

any valve with an abnormally worn face

decreases as the wear of the face advances

. The thickness

.

. Replace

OT

Measure the thickness and, if the thickness is found to have

been reduced to the limit, replace it

.

Valve head thickness

Service Limit

09900-20101

: 0

: Vernier calipers

OT

.5 mm (0

.02 in)

VALVE STEM DEFLECTION

Lift the valve about 10 mm (0

.39 in) from the valve seat

.

Measure the valve stem deflection in two directions, "X" and "Y",

perpendicular to each other, by positioning the dial gauge as

shown

. If the deflection measured exceeds the limit, (see below)

then determine whether the valve or the guide should be

replaced with a new one

.

Valve stem deflection (IN&EX)

Service Limit

09900-20607

09900-20701

: 0

.35 mm (0

.014 in)

: Dial gauge (1/100 mm)

: Magnetic stand

VALVE STEM WEAR

If the valve stem is worn down to the limit, as measured with a

micrometer, where the clearance is found to be in excess of the

limit indicated, replace the valve

then replace the guide

recheck the clearance

. After replacing valve or guide, be sure to

.

; if the stem is within the limit,

Valve stem O.D.

Standard (IN):5

09900-20205

NOTE

:

If

valve

(EX):5

: Micrometer (0 - 25 mm)

guides havetobe

.475

- 5

.455

.490 mm (0

- 5

.470 mm (0

.2156-0

.2148-0

.2161 in)

.2154 in)

removed for replacement after

inspecting related parts, carry out the steps shown in valve

guide servicing

.

Page 41

~

~

~

~

~

VALVE GUIDE SERVICING

Using the valve guide remover, drive the valve guide out

•

toward the intake or exhaust camshaft side

.

.

09916-44910

NOTE

:

•

Discard the removed valve guide subassemblies

Only oversized valve guides are available as replacement

•

. (Part No

parts

•

Re-finish the valve guide holes in cylinder head with the

reamer and handle

09916-34580

09916-34542

: Valve guide remover/installer

. 111 15-32E70)

.

: Valve guide reamer

: Reamer handle

.

.

ENGINE3-4

1

S

S

•

Oil the stem hole, too, of each valve guide and drive the guide

into the guide hole with the valve guide installer and attachment

.

09916-44910

09916-53340

CAUTION

Failure to oil the valve guide hole before driving the

new guide into place may result in a damaged guide or

head

.

•

After fitting the valve guides, re-finish their guiding bores with

the reamer

09916-34550

09916-34542

NOTE

:

Insert the reamer from the combustion chamber and always turn

the reamer handle clockwise

VALVE SEAT WIDTH

•

Coat the valve seat uniformly with Prussian blue

and tap the coated seat with the valve face in a rotating man-

ner, in order to obtain a clear impression of the seating con-

tact

. In this operation, use the valve lapper to hold the valve

head

.

: Valve guide remover/installer

: Attachment

. Be sure to clean and oil the guides after reaming

: Valve guide reamer

: Reamer handle

.

. Fit the valve

.

im

Page 42

~

~

3-42 ENGINE

•

The ring-like dye impression left on the valve face must be

continuous without any break

ring, which is the visualized seat "width", must be within the

following specification

L 1

Valve seat width

Standard

. .

09916-10911

If either requirement is not met, correct the seat by servicing is

as follows

VALVE SEAT SERVICING

The valve seats for both intake and exhaust valves are

machined to four different angles

cut 45°

:

.)

: 0

:

.9 -1.1 mm (0

: Valve lapper set

. In addition, the width of the dye

.035-0

. (The seat contact surface is

.043 in)

INTAKE

45

0

60°

15°

30°

NOTE

:

The valve seat contact area must be inspected after each cut

09916-21111

09916-24210

09916-24480

09916-24810

09916-27710

•

Insert the solid pilot with a slight rotation

snugly

•

Using the 45° cutter, descale and clean up the seat with one

or two turns

•

Inspect the seat by the previously described seat width measurement procedure

seat conditioning with the 45° cutter is required

NOTE

:

Cut only the minimum amount necessary from the seat to prevent the possibility of the tappet shim replacement

N-615 or N-626 N-615 or N-626

N-211 N-211

_

N-626

: Valve seat cutter set

: Valve seat cutter (N-615)

: Solid pilot (N-140-5

: Valve seat cutter (N-626)

: Valve seat cutter (N-211)

. Install the 45° cutter, attachment and T-handle

.

. If the seat is pitted or burned, additional

EXHAUST

_

N-615

.

.5)

. Seat the pilot

.

.

.

Page 43

If the contact area is too high on the valve, or if it is too wide, use

the 150/600cutters (for exhaust side) and 30°/60° cutters (for

intake side) to lower and narrow the contact area

.

ENGINE 3-43

1

40

If the contact area is too low or too narrow, use the 45° cutter to

raise and widen the contact area

•

After the desired seat position and width is achieved, use the

.

Contact area too low and too

narrow on face of valve

45° cutter very lightly to clean up any burrs caused by the previous cutting operations

.

CAUTION

DO NOT use lapping compound after the final cut is

made

. The finished valve seat should have a velvety

smooth finish and not a highly polished or shiny fin-

ish

.

This will provide a soft surface for the final seating of

the valve which will occur during the first few seconds

of engine operation

.

40

40

•

Clean and assemble the head and valve components

intake and exhaust ports with gasoline to check for leaks

. Fill the

. If

any leaks occur, inspect the valve seat and face for burrs or

other things that could prevent the valve from sealing

.

A WARNING

Always use extreme caution when handling gasoline

NOTE

:

.

After servicing the valve seats, be sure to check the tappet

.

(r7

clearance after the cylinder head has been reinstalled

2-8)

Page 44

~

3-44 ENGINE

VALVE SPRING

The force of the coil spring keeps the valve seat tight

ened spring results in reduced engine power output, and often

account for the chattering noise coming from the valve mechanism

Check the valve springs for proper strength by measuring their

free length and also by the force required to compress them

the spring length is less than the service limit, or if the force

required to compress the spring does not fall within the range

specified, replace it

(

Valve spring free length (IN&EX)

Service Limit

Valve spring tension (IN & EX)

Standard

.

: 41

.2 mm (1

: 197 - 227 N/35

(20

.1 -23.1 kgf/35

.62 in)

.6 mm

.6 mm, 44.3-51.0 lbs/1

. Weak-

. If

L

.40 in)

09900-20102

CAM DRIVE IDLE GEAR/SPROCKET THRUST CLEARANCE

Install the cam drive idle gear/sprocket

washer (3 and thrust washer ® to each cylinder head

the shaft02to the specified torque

measure the thrust clearance between the cylinder head and the

thrust washer

90

Cam drive idle gear/sprocket thrust clearance

Standard

: Vernier calipers

®

.

: 0

.15 -

.29 mm (0

0

(1),

its shaft

. Use a thickness gauge to

.006

.011 in)

- 0

02,

copper

. Tighten

Cam drive idle gear/sprocket shaft

0

40 N

09900-20803

: Thickness gauge

:

.m (4 .0 kgf-m, 29

.0 lb-ft)

Re

Page 45

~

~

~

~

~

If the thrust clearance exceeds the standard range, adjust the

thrust clearance by the following procedures

•

Remove the thrust washer, and measure its thickness with a

micrometer

•

Change the thrust washer with the other washer if the thrust

clearance is incorrect

•

Perform the thrust clearance measurement described above

once again checking to make sure it is within standard

09900-20205

.

: Micrometer (0

Color/Mark

(Part No

(09181-15182)

Yellow

(09181-15181)

Light blue

(09181-15176)

Light green

(09181-15172)

Brown

(09181-15166)

"J" mark

(09181-15164)

.)

Blue

.

- 25 mm)

Thrust washer thickness E

:

1

.38-1

(0

.054-0.056)

1

.28-1

(0

.050

-0

1

.18-1

(0

.046-0

1

.08-1

(0

.043-0

0

.98-1

(0

.039-0

0

.88-0

(0

.035

- 0

Unit

.42

.32

.052)

.22

.048)

.12

.044)

.02

.040)

.92

.036)

.

: mm (in)

ENGINE

3-45

40

CYLINDER HEAD REASSEMBLY

•

Install the valve spring seats

•

Apply oil to each oil seal, and press-fit them into position with

the valve guide installer

09916-44910

CAUTION

Do not reuse the removed oil seals

•

Insert the valves, with their stems coated with molybdenum oil

solution all around and along the full stem length without any

break

.

CAUTION

When inserting each valve, take care not to damage

the lip of the oil seal

MOLYBDENUM OIL SOLUTION

-a

: Valve guide remover/installer

.

.

.

.

Page 46

~

~

~

~

~

3- 46ENGINE

•

Install the valve spring with the small-pitch portion

cylinder head

Large-pitch portion

©

:

•

Put on the valve spring retainer, and using the valve lifter,

press down the spring, fit the cotter halves to the stem end,

and release the lifter to allow the cotter 1~ to wedge in

between retainer and stem

the cotter fits snugly into the groove © in the stem end

~ •

09916-14510

09916-14910

09916-84511

.

. Be sure that the rounded lip © of

: Valve lifter

: Valve lifter attachment

: Tweezers

OO

.

facing

I

(D C

~

CAUTION

Be sure to restore each spring and valve to their original positions

•

Install the tappet shim and tappet to their original position

NOTE

:

•

Apply engine oil to the shim and tappet before fitting them

•

When seating the tappet shim, be sure the figure printed sur-

face faces the tappet

•

Apply engine oil to the 0-ring and install it

.

.

.

.

.

I

Page 47

~

~

~

~

~

•

Install the pin (

INTAKE PIPE/WATER UNION

•

Remove the intake pipe

.

.

ENGINE

3-47

.0

•

Remove the water union

•

When installing the intake pipe, apply grease to the 0-ring

NOTE

:

"UP" mark faces upward

99000-25030

99000-25010

CAUTION

Use the new 0-ring to prevent air from sucking

through the joint

•

Apply engine coolant to the new 0-ring and install the water

union

.

: SUZUKI SUPER GREASE "A" (USA)

: SUZUKI SUPER GREASE "A" (Others)

.

.

.

.

Page 48

~

~

~

~

3-48

ENGINE

CYLINDER/PISTON INSPECTION

CYLINDER DISTORTION

Check the gasketed surface of the cylinder for distortion with a

straightedge and thickness gauge, taking a clearance reading at

several places as indicated

of the straightedge exceeds the limit, replace the cylinder

•

Cylinder distortion

Service Limit

.

•

09900-20803

CYLINDER BORE

Inspect the cylinder wall for any scratches, nicks or other dam-

. Measure the cylinder bore diameter at six places

age

•

Cylinder bore

Standard

: Thickness gauge

: 98

. If the largest reading at any position

.

.05 mm (0

: 0

.000 - 98

.002 in)

.015 mm (3

.8583 - 3

.8589 in)

.

k.

PISTON DIAMETER

Using a micrometer, measure the piston outside diameter at

10 mm (0

less than the limit, replace the piston

•

.

.

PISTON-TO-CYLINDER CLEARANCE

As a result of the previous measurement, if the piston to cylinder

clearance exceeds the following limit, replace both cylinder and

piston

•

.4 in) from the piston skirt end

Piston diameter

Service Limit

09900-20204

.

Piston to cylinder clearance

Service Limit

: 97

.880 mm (3

: Micrometer (75 - 100 mm)

: 0

.12 mm (0

. If the measurement is

.

.8535 in)

.0047 in)

Page 49

~

~

~

~

~

PISTON RING TO GROOVE CLEARANCE

Using a thickness gauge, measure the side clearances of the

1st and 2nd rings

replace both piston and piston rings

(

Piston ring to groove clearance

Service Limit (1st)

. If any of the clearances exceeds the limit,

.

:

0

(2nd)

.18 mm (0

:0.15 mm (0

.0071 in)

.0059 in)

O

ENGINE 3-

4 9

•

Piston ring groove width

Standard (1st):0

(2nd)

(Oil)

•

Piston ring thickness

Standard (1st):0

(2nd):0

09900-20803

09900-20205

PISTON RING FREE END GAP AND PISTON RING END GAP

Before installing piston rings, measure the free end gap of each

ring using vernier calipers

measure each ring end gap using a thickness gauge

If any ring has an excess end gap, replace the ring

•

Piston ring free end gap

Service Limit (1st):7

: Thickness gauge

: Micrometer (0

.93 - 0

1

.55-1

: 1

.01 - 1

: 2

.51 -2.53 mm

.86

1

.38

.97-0

. Next, fit the ring in the cylinder, and

(2nd):8

.95 mm

(0

.0366-0

.57

mm

(0

.0610

.03 mm

(0

.0398-0

(0

.0988-0

.91 mm (0

- 0

1

.40 mm (0

-

.99 mm (0

- 25 mm)

.0 mm (0

.1 mm (0

.0374 in)

- 0 .0618 in)

.0406 in)

.0996 in)

.034 -0.036 in)

.054-0

.038-0

.

.

.28 in)

.32 in)

O

O3

.055 in)

.039 in)

10

i

H

l

O

li®

1

09900-20101

: Vernier caliper

Page 50

3-50 ENGINE

Piston ring end gap

Service Limit (1st):0

(2nd)

09900-20803

PISTON PIN AND PIN BORE

Using a small bore gauge, measure the piston pin bore inside

diameter, and using a micrometer, measure the piston pin outside diameter . If the difference between these two measure-

ments is more than the limits, replace both piston and piston pin

Piston pin bore I.D.

Service limit

09900-20602

09900-22403

: Thickness gauge

: 22

.030 mm (0

: Dial gauge (1/1 000 mm, 1 mm)

: Small bore gauge (18-35 mm)

.7 mm (0

.7 mm (0

:

0

.03 in)

.03 in)

.

.8673 in)

L

Using a micrometer, measure the piston pin outside diameter at

three positions

Piston pin O.D.

Service Limit

09900-20205

.

: 21

.980 mm (0

: Micrometer (0 -

.8654 in)

25 mm)

CON ROD/CRANKSHAFT

CONROD SMALL END I

Using a small bore gauge, measure the inside diameter of the

conrod small end

Conrod small end I.D.

Service Limit

09900-20602

09900-22403

If the inside diameter of the conrod small end exceeds the limit,

replace the conrod

.

: Dial gauge (1/1 000 mm, 1 mm)

: Small bore gauge (18 -

.

.D

.

: 22

.040 mm (0

.8677 in)

35 mm)

Page 51

~

~

~

~

~

~

~

CONROD BIG END SIDE CLEARANCE

Check the conrod side clearance by using a thickness gauge

the clearance exceeds the limit, replace conrod or crankshaft

•

Conrod big end side clearance

Service Limit

09900-20803

Conrod big end width

[

Standard

•

Crank pin width

Standard

09900-20205

: 0

.50 mm (0

: Thickness gauge

: 21

.95 - 22

.17 -

44

: 44

: Micrometer (0

.020 in)

.00 mm (0

.22 mm (1

- 25 mm)

.864 -0.866 in)

.739-1

.741 in)

. If

.

OWN

ENGINE3-5

1

S

CONROD-CRANK PIN BEARING INSPECTION

•

Loosen the bearing cap bolts, and tap the bearing cap bolt

lightly with plastic hammer to remove the bearing cap

CAUTION

Never reuse the bearing cap bolt

Remove the conrods, and mark them to identify the cylinder

•

position

Inspect the bearing surfaces for any sign of fusion, pitting,

•

burn, or flaws

bearings

CONROD-CRANK PIN BEARING SELECTION

Place plastigauge axially on the crank pin avoiding the oil

•

hole, at TDC or BDC side as shown in the illustration

•

Tighten the bearing cap bolts as the specified manner

.

. If any, replace them with a specified set of

.

.

.

.

.

09900-22301

09900-22302

NOTE

:

Never rotate the crankshaft or conrod when a piece of plastigauge is in the clearance

: Plastigauge

: Plastigauge

.

Page 52

~

~

~

~

3-52 ENGINE

Remove the caps and measure the width of compressed plas-

•

tigauge

taken at the widest part

•

If oil clearance exceeds the service limit, select the specified

bearings from the bearing selection table

•

Check the corresponding conrod I

«2„

•

Check the corresponding crank pin O

"2" or "3" stamped on the left crank web

Bearing selection table

with envelope

Con rod big end oil clearance

Service Limit

scale

.

: 0

.080 mm (0

. This measurement should be

.0031 in)

.D

. code number

.D

.

"1" or

OO,

. code number ©,

.

"1",

Crank pin O.D.

Code

Con rod I

code

[

Conrod big end I.D. specification

. D

.

C

Conrod big end oil clearance

Standard

Code

1

2 Black

: 0

.040 -0.064 mm (0

OO

1

2

1

Green

48

(1

48

(1

I

.D

2 3

Black

Brown

.0016

- 0

. specification

.000-48

.8898

.008 -48.016 mm

.8900 -1.8904 in)

.008 mm

- 1

.8900 in)

Brown

Yellow

.0025 in)

FRONT

Crank pin O.D. specification

Code

©

1

2

3

09900-20202

: Micrometer (25 -

O.D. specification

44

(1

44

(1

44

(1

- 45

.992

.7713

.984

.7710 - 1

.976

.7707

50 mm)

.7717 in)

- 1

- 44

.7713 in)

- 44

- 1

.7710 in)

.000 mm

.992 mm

.984 mm

Page 53

~

~

ENGINE 3-53

Bearing thickness

Color (Part No

Green

(12164-16G00-OAO)

Black

(12164-16G00-OBO)

Brown

(12164-16G00-OCO)

Yellow

(12164-16G00-ODO)

CAUTION

Bearing must be replaced as a set

BEARING ASSEMBLY

When fitting the bearings to the bearing cap and conrod, be

•

sure to fix the stopper part

.)

Thickness

1

.476

- 1

.480 mm

(0

.0581-0

1

.480 -1.484 mm

(0

.0583-0

1

.484-1

(0

.0584-0

1

.488 -1.492 mm

(0

.0586

.

first, and press in the other end

OO

.0583 in)

.0584 in)

.488 mm

.0586 in)

- 0

.0587 in)

0

.

•

Apply molybdenum oil solution to the crank pin and bearing

surface

-9

.

MOLYBDENUM OIL SOLUTION

Page 54

~

~

3-54 ENGINE

•

When fitting the conrods on the crankshaft, make sure that

I.D. codes © of the conrods face each cylinder intake valve

sides

.

NOTE

:

The shape of the conrod is not symmetrially right and left

CAUTION

.

Never reuse the bearing cap bolt

Apply engine oil to the bearing cap bolts

•

Tighten the bearing cap bolts as following two steps

Conrod bearing cap bolt

(Initial):35 N

(Final)

•

Check the conrod movement for smooth turning

.m (3

.5 kgf-m, 25

: After tightening the bolts to the above torque,

tighten them 1/4 of a turn (90

.

.

.5 Ib-ft)

0 )

.

.

.

CLUTCH

CLUTCH DRIVE PLATES

NOTE

:

Wipe off engine oil from the clutch drive plates with a clean rag

Measure the thickness of drive plates with a vernier calipers

each drive plate is not within the standard range, replace it with

a new one

:

.

.

Drive plate thickness

Standard (No

(No

. 2&No

09900-20102

. 1):2

.92 - 3

. 3):3

.72-3

: Vernier calipers

.08 mm (0

.88 mm (0

.115

- 0

.146-0

.121 in)

.153 in)

.

. If

Page 55

~

~

~

ENGINE 3-55

Measure the claw width of drive plates with a vernier calipers

Replace the drive plates found to have worn down to the limit

•

Drive plate claw width (No

Standard (No

(No

. 2&No

09900-20102

CLUTCH DRIVEN PLATES

NOTE

:

Wipe off engine oil from the clutch driven plates with a clean rag

Measure each driven plate for distortion with a thickness gauge

and surface plate

Replace driven plates which exceed the limit

•

Driven plate distortion

Service Limit

09900-20803

CLUTCH SPRING FREE LENGTH

Measure the free length of each coil spring with a vernier calipers, and compare the length with the specified limit

the springs if any spring is not within the limit

•

Clutch spring free length

Service Limit

. 1):13

. 3):13

: Vernier calipers

.

: 0

.10 mm (0

: Thickness gauge

: 26

.7 mm (1

. 1 and No

.85

-13

.90-14

.004 in)

.05 in)

. 2)

.96 mm (0

.00 mm (0

.

.

.545

- 0

.550 in)

.547-0

.551 in)

. Replace all

.

.

.

09900-20102

CLUTCH BEARING

Inspect the clutch release bearing for any abnormality, particu-

larly cracks, to decide whether it can be reused or should be

replaced

Smooth engagement and disengagement of the clutch depends

on the condition of this bearing

NOTE

Thrust washer is located between the pressure plate and the

bearing

j

.

:

.

: Vernier calipers

.

Page 56

~

~

~

~

~

ENGINE

3-56

TRANSMISSION

CONSTRUCTION

1® 1st driven gear

02 5th driven gear

(3

4th driven gear

3rd driven gear

•

•

6th driven gear

•

2nd driven gear

(7 Driveshaft

•

Countershaft

(9 5th drive gear

10 3rd & 4th drive gear

11 6th drive gear

2nd drive gear

•

Page 57

~

~

~

~

ENGINE 3-57

DISASSEMBLY

CAUTION

Be sure to identify each removed part as to its loca-

tion, and lay the parts out in groups designated as

"Drive" and "Driven", so that each will be restored to

40

the original location during assembly

Countershaft

•

Remove the 0-ring 1, 2nd drive gear ( and top drive gear

.

(

CAUTION

.

The removed 0-ring must be replaced with a new one

•

Remove the top drive gear bushing ®, washer ($ and 3rd/4th

drive gears ©

•

Remove the snap ring with the special tool

09900-06107

.

.

: Spring ring pliers

.

•

Remove the 5th drive gear (7 and its bushing ©

.

Page 58

~

~

~

~

~

3-58 ENGINE

Driveshaft

•

Remove the washer 1O and 1 st driven gear

Remove the 1st driven gear bushing 03,washer ® and 5th

•

driven gear O5

.

OO

.

Remove the snap ring with the special tool

•

09900-06107

Remove the washer ®, 4th driven gear 07 and its bushing ®

•

Remove the washer ®, 3rd driven gear 1o and its busing

•

: Spring ring pliers

.

.

(b)

.

Page 59

~

~

~

~

~

~

~

~

~

•

Remove the washer 1©

•

Remove the top driven gear 13 by removing the snap ring

. .

09900-06107

•

Remove the snap ring with the special tool

09900-06107

: Spring ring pliers

: Spring ring pliers

.

(W

.

.

ENGINE 3

.59

•

Remove the 2nd driven gear

REASSEMBLY

Assemble the transfer in the reverse order of disassembly

attention to the following points

NOTE

:

•

Always use new snap rings

•

4

Before installing the gears, coat lightly engine oil to the shafts

and gears

CAUTION

•

Never reuse a snap ring

removed from a shaft, it should be discarded and a

new snap ring must be installed

•

When installing a new snap ring, care must be taken

not to expand the end gap larger than required to slip

the snap ring over the shaft

•

After installing a snap ring, always ensure that it is

completely seated in its groove and securely fitted

.

15 ,

its bushing16and washer

:

.

. After a snap ring has been

.

.

(T

. Pay

.

.

Page 60

3-60

ENGINE

•

When installing a new snap ring, pay attention to the direction

of the snap ring

in the figure

CAUTION

When installing the 3rd and 4th driven gear bushings

on to the driveshaft, align the shaft oil holesOOwith

the bushing oil hole

. Fit it to the side where the thrust is as shown

.

©

.

Page 61

M

w

z

z

w

Page 62

~

~

~

3

-62 ENGINE

GEARSHIFT FORK

GEARSHIFT FORK TO GROOVE CLEARANCE

Using a thickness gauge, check the gearshift fork clearance in

the groove of its gear

The clearance for each gearshift fork plays an important role in

the smoothness and positiveness of the shifting action

•

Shift fork to groove clearance

Service Limit

.

: 0

.50 mm (0

.

.020 in)

09900-20803

09900-20102

If the clearance checked is noted to exceed the limit specified,

replace the fork or its gear, or both

•

Shift fork groove width

Standard

: Thickness gauge

: Vernier calipers

.

: 5

.0 -5.1 mm (0

.197

- 0

.201 in)

•

Shift fork thickness

Standard

: 4.8- 4

.9 mm (0

.189 -0.193 in)

Page 63

~

~

~

~

~

~

~

PRIMARY DRIVE GEAR

PRIMARY DRIVE GEAR INSPECTION

Visually inspect the gear teeth for wear and damage

worn, replace the gear with a new one

PRIMARY DRIVE GEAR DISASSEMBLY

•

Disassemble the primary drive gear by removing the snap

ring

D

.

09900-06107

Snap ring

•

Spring washer

•

03 Scissors gear

Spring

•

~5 Primary drive gear

: Spring ring pliers

.

. If they are

ENGINE 3-

6 3

S

PRIMARY DRIVE GEAR REASSEMBLY

•

Set the springs 1O into the grooves

•

Install the scissors gear

NOTE

:

Align the hole of the primary drive gear with the hole of the scissors gear

•

Install the spring washerOOnot to cover the holes of the

gears

NOTE

The convex side of the washer faces upward

.

.

:

(Z

.

.

.

T

Page 64

~

~

~

~

~

~

3-64 ENGINE

•

Install the snap ring ® completely with the special tool

. .

09900-06107

CAUTION

•

Never reuse a snap ring

•

When installing a new snap ring, care must be taken

not to expand the end gap larger than required to slip

a snap ring over the gear

•

After installing a snap ring, always insure that it is

completely seated in its groove and securely fitted

: Spring ring pliers

.

.

.

.

STARTER TORQUE LIMITER

STARTER TORQUE LIMITER INSPECTION

CAUTION

Do not attempt to disassemble the starter torque lim-

iter

.

The starter torque limiter is available only as an

assembly

•

Check the slip torque with the special tools

Slip torque

09930-73110

09930-73120

•

Set the starter torque limiter to the special tools and vise as

shown in the illustration

•

If the slip torque is not within the specification, replace the

starter torque limiter with a new one

.

Standard

.

: 22

- 45 N-m (2.2-4.5 kgf-m, 16.0-32.5 Ib-ft)

: Starter torque limiter holder

: Starter torque limiter socket

.

.

O

O2

Page 65

~

~

~

~

~

~

~

~

ENGINE 3-65

STARTER CLUTCH

DISASSEMBLY

•

Remove the starter clutch securing bolts by holding the rotor

with the special tool

.

+/

09930-44541

REASSEMBLY

•

Install the starter clutch in the proper direction

NOTE

:

* When installing the starter clutch onto the rotor, face the

flange sideOOof the one way clutch to the rotor

* The arrow mark © must face to the engine side

•

Apply engine oil to the starter clutch

•

Apply THREAD LOCK SUPER to the bolts, and then tighten

them to the specified torque with the special tool

Starter clutch bolt

0

99000-32030

.M

09930-44541

: Rotor holder

.

.

: 25 N

.m (2 .5 kgf-m, 18

: THREAD LOCK SUPER "1303"

: Rotor holder

.0 Ib-ft)

.

.

.

+/

d#

410

INSPECTION

•

Install the starter driven gear to the starter clutch

•

Check that the starter driven gear turns in the opposite direction of the arrow mark © on the rotor while holding the generator rotor

•

If there is anything unusual, replace the one way clutch

Inspect the starter driven gear bushing for any damage

. The gear never turns in the direction of the arrow

.

.

.

.

Page 66

~

~

~

~

~

~

~

~

~

3-66 ENGINE

GEARSHIFT

GEARSHIFT SHAFT/GEARSHIFT ARM DISASSEMBLY

•

Remove the following parts from the gearshift shaft/gearshift

arm 90

•

03 Snap ring

•

O5

.

Washer

Gearshift shaft return spring

© Plate return spring

Washer

07

© Snap ring

Gearshift cam drive plate~© Washer

09900-06107

: Snap ring pliers

GEARSHIFT SHAFT/GEARSHIFT ARM INSPECTION

Check the gearshift shaft/gearshift arm 1~ for wear or bend

.

RETURN SPRINGS INSPECTION

Check the return springs, ® and ©, for damage or fatigue

.

GEARSHIFT SHAFT/GEARSHIFT ARM REASSEMBLY

•

Install the following parts to the gearshift shaft/gearshift arm

1O as shown in the right illustration

(2 Washer

Snap ring

•

Gearshift shaft return spring

•

Gearshift cam drive plate~© Washer

05

. .

09900-06107

NOTE

:

When installing the gearshift shaft return spring ®, position the

stopperOAof the gearshift arm between the shaft return spring

ends

©

.

CRANKCASE

: Snap ring pliers

.

© Plate return spring

Washer

07

© Snap ring

OIL PUMP

•

Remove the oil pump

.

Page 67

~

~

~

~

~

~

~

ENGINE 3-67

oil

•

Rotate the

smoothly

If it does not move smoothly, replace the oil pump assembly

•

CAUTION

.

pump

by

hand

and

check thatitmoves

.

.I`

Do not attempt to disassemble the oil pump assembly

The oil pump is available only as an assembly

•

Install the oil pump

OIL PRESSURE REGULATOR

•

Remove the oil pressure regulator 1~

•

When installing the oil pressure regulator, apply engine oil to

the new O-ring

.

.

.

.

.

if

Check the operation of the oil pressure regulator by pushing on

the piston with a proper bar

replace the oil pressure regulator with a new one

OIL PRESSURE SWITCH

•

Remove the oil pressure switch 10

•

When installing the oil pressure switch, apply SUZUKI BOND

to the thread

©

Oil pressure switch

1207B

99104-31140

.

: SUZUKI BOND "1207B"

. If the piston does not operate,

.

.

: 14 N

.m (1

.4 kgf-m, 10

.0 Ib-ft)

Page 68

~

~

~

~

~

~

3-

6 8

ENGINE

OIL JET

•

Remove the oil gallery plug

•

Remove the oil jet with a suitable bar

.

.

•

Remove the oil jet

•

Check the oil jets for clogging

oil passage with a proper wire or compressed air

•

Fit the new 0-ring to the oil jet

CAUTION

.

. If they are clogged, clean their

.

.

Use the new O-ring to prevent oil leakage

NOTE

:

Apply engine oil to the O-ring when installing the oil jet

•

Install the oil jet with a suitable bar

.

.

.

Page 69

~

~

~

~

~

~

~

ENGINE 3-69

•

Tighten the oil gallery plug to the specified torque

.

Oil gallery plug (M8)

•

•

Apply engine oil to the new O-ring and install it

•

Apply THREAD LOCK to the screw and tighten it to the speci-

fied torque

•

Piston cooling oil nozzle screw

99000-32050

.

:18 N

.m (1

.8 kgf-m, 13

: 8 N

.m (0

: THREAD LOCK "1342"

.0 Ib-ft)

.

.8 kgf-m, 6

.0 lb-ft)

When replacing the gearshift arm stopper bolt, apply

•

THREAD LOCK SUPER to it

Gearshift arm stopper bolt

•

99000-32030

BEARING/OIL SEAL

Rotate the bearing inner race by finger to inspect for abnormal

play, noise and smooth rotation while the bearings are in the

crankcase

Replace the bearing in the following procedure if there is any-

4

thing unusual

.

: THREAD LOCK SUPER "1303"

.

.

: 23 N

.m (2

.3 kgf-m, 16

.5 lb-ft)

Page 70

~

~

~

~

3-70

ENGINE

•

Remove the oil seal retainer

•

Remove the oil seal

CAUTION

.

.

The removed oil seal must be replaced with a new one

•

Remove the oil seal with the special tool

09913-50121

CAUTION

The removed oil seal must be replaced with a new one

•

Remove the bearing retainers

: Oil seal remover

.

.

.

.

Page 71

~

ENGINE 3-71

•

Remove the bearings with the special tool

.

09921-20240

NOTE

:

: Bearing remover set

If there is no abnormal noise, the bearing removal is not necessary

.

•

Install the bearings with the special tool

09913-70210

: Bearing installer set

.

NOTE

:

The sealed side of the driveshaft bearing

must face outside

OO

.

Page 72

~

~

~

~

3-72 ENGINE

•

Install the bearing retainers

NOTE

:

.

When installing the bearing retainers, apply THREAD LOCK to

the screws

Install the oil seals with the special tool

•

Apply SUZUKI SUPER GREASE to the oil seal lip

•

,!j6H

.

09900-32050

09913-70210

99000-25030

99000-25010

: THREAD LOCK "1342"

.

Bearing installer set

:

: SUZUKI SUPER GREASE

: SUZUKI SUPER GREASE

"A"

"A"

.

(USA)

(Others)

•

Install the oil seal retainer

.

Page 73

~

~

~

S

v/r'

CRANKCASE-CRANKSHAFT BEARING

CRANKCASE-CRANKSHAFT BEARING INSPECTION

•

Inspect the crankshaft journal bearings for any damage

any, replace them with a specified set of bearings

•

Inspect the crankshaft journal for any damage

•

Measure the crankshaft journal O

Crankshaft journal O.D.

Standard

: 47

.985 -48.000 mm (1

.D

. with the special tool

.8892

.

.

- 1

.8898 in)

. If

.

ENGINE 3-73

40

09900-20202

CRANKCASE-CRANKSHAFT BEARING SELECTION

Select the specified bearings from the crankcase bore I

The crankcase bore I.D. code

the inside of each crankcase half

Bearing selection table

I

.D

. code O

A

B

C

Bearing thickness

Color (Part No

(12229-06G00-OAO)

(12229-06G00-OBO)

(12229-06G00-0C0)

: Micrometer (25 -

I.D. specification

52

.000-52

(2

.0472-2

52

.006-52

(2

.0475 - 2

52

.012 -52.018 m m

(2

.0477 - 2

.)

Green

Black

Brown

50 mm)

O "A",

"B" or

.

.006 m m

.0475 in)

.012 mm

.0477 in)

.0479 in)

1

(0

1

(0

2

(0

.D . code

"C", is stamped on

Bearing

Green

Black

Brown

Thickness

.996 -1.999 mm

.0786 -0.0787 in)

2

.999

.0787 -0.0788 in)

.002 -2.005 mm

.0788 -0.0789 in)

.002 mm

-

.

Color code

to

CAUTION

Bearing must be replaced as a set

.

Page 74

~

~

3-74

ENGINE

CRANKSHAFT JOURNAL BEARING REPLACEMENT

Use the special tool to replace the crankshaft journal bearings

The replacement procedure is as follows

.

.

09913-60230

Set the special tool as shown to remove the crankshaft journal

•

bearings

NOTE

Remove the crankshaft journal bearings in only one direction,

from inside to outside of each crankcase half

.

:

: Journal bearing remover/installer

:

.

.

Gradually press out the bearing with the special tool by using

•

the hand-press

CAUTION

The removed bearings must be replaced with new

ones

.

NOTE

:

Using the hand-press is recommended to remove the crankshaft

journal bearings

be removed by using with the following special tools

09924-84510

09924-74570

.

. However, the crankshaft journal bearings can

.

: Bearing installer set

: Final drive gear bearing remover/installer

Bearing

Page 75

~

~

~

ENGINE 3-75

• Set the specified crankshaft journal bearings to the special

tool

.

CAUTION

•

Before setting the bearing, apply enough engine oil

to the special tool and bearings

•

When setting the bearing, align the bearing side with

the engraved lineOAand also the bearing edge with

the mating surface of the special tool

.

.

09913-60210

09913-60240

NOTE

:

Journal bearing remover/installer (09913-60240) is included in

Journal bearing remover/installer set (09913-60210)

•

Tighten the special tool bolt to the specified torque

Special tool bolt

0

CAUTION

: Journal bearing remover/installer set or