Page 1

COOLING AND LUBRICATION

COOLING AND LUBRICATION SYSTEM

CONTENTS

SYSTEM 5-1

,of

ENGINE COOLANT

COOLING CIRCUIT

INSPECTION

RADIATOR

RADIATOR RESERVOIR TANK

RADIATOR CAP

WA TER HOSE

INSPECTION

COOLING FAN

REMOVAL AND INSTALLATION

INSPECTION

COOLING FAN THERMO-SWITCH

REMOVAL

INSPECTION

INSTALLATION

ENGINE COOLANT TEMPERATURE SENSOR

REMOVAL

INSPECTION

INS TA LA TION

THERMOSTAT

REMOVAL

INSPECTION

INSTALLATION

WATER PUMP

REMOVAL AND DISASSEMBLY

INSPECTION AND CLEANING

REASSEMBLY AND INSTALLATION

LUBRICATION SYSTEM

OIL PRESSURE

OIL FILTER

OIL PRESSURE REGULATOR

OIL STRAINER

OIL JET

OIL PUMP

~

REMOVAL

INSTALLATION

INSPECTION AND CLEANING

REMOVAL AND INSTALLATION

INSPECTION

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

5- 3

5- 4

5- 4

5- 5

5- 5

5- 6

5- 6

5- 7

5- 7

5- 7

5- 7

5- 7

5- 7

5- 8

5- 8

5- 8

5- 9

5- 9

5- 9

5- 9

~

~

5-10

5-10

5-10

5-11

5-12

5-12

5-12

5-13

5-14

5-14

5-15

5-16

5-19

5-19

5-19

5-19

5-19

5-19

5-19

5

Page 2

COOLING AND LUBRICATION SYSTEM

5-

2

COOLING AND LUBRICATION SYSTEM

CONTENTS

OIL PRESSURE SWITCH

OIL COOLER

REMOVAL

INSTALLATION

INSPECTION AND CLEANING

ENGINE LUBRICATION FLOW CHART

ENGINE LUBRICATION CIRCUIT

~

~

~

~

~

~

~

.

5-19

5-20

5-20

5-21

5-21

5-22

5-23

Page 3

~

~

~

~

~

~

~

5-

COOLING AND LUBRICATION SYSTEM

3

ENGINE COOLANT

At the time of manufacture, the cooling system is filled with a

:50 mixture of distilled water and ethylene glycol anti-freeze

50

This 50

and excellent heat protection, and will protect the cooling system

from freezing at temperatures above -31 °C (-24 °F)

If the motorcycle is to be exposed to temperatures below -31 °C

(-24 °F), this mixing ratio should be increased up to 55 % or

60 % according to the figure

CAUTION

50 % engine coolant including reservoir tank capacity

:50 mixture will provide the optimum corrosion protection

.

.

•

Use a high quality ethylene glycol base anti-freeze,

mixed with distilled water

base anti-freeze and different brands of anti-freeze

•

Do not rut in more than 60%anti-freeze or less than

50 %

. (Refer to the right figure

•

Do not use a radiator anti-leak additive

Anti-freeze

Water

. Do not mix an alcohol

.)

.

1 100 ml (2

1 100 ml (2

.3/1

.9 US/Imp-pt)

.3/1

.9 US/Imp

.pt)

.

.

Anti-freeze

density

50%

55%

60%

(F) (C)

32

-10

14

-20

-4

C

0

Q

O)

C

N

a)

a)

U-

Fig

-30

-22

-40 -40

-58 -50

-60

-76

-70

-94

.1 Engine coolant density-freezing

point curve

Freezing point

-31 °C (-24 °F)

-40 °C (-40 °F)

-55 °C (-67 °F)

0

40

20

60

80

Density (%)

100

04

(°F) (°C)

302 150

284 140

c

Q

266 130

0)

248 120

:0

m

230 110

212 100

0 10

.2 Engine coolant density-boiling

Fig

point curve

WARNING

A

You can be injured by scalding fluid or steam if you open the radiator cap when the engine is

•

. After the engine cools, wrap a thick cloth around cap and carefully remove the cap by

hot

turning it a quarter turn to allow pressure to escape and then turn the cap all the way off

•

The engine must be cool before servicing the cooling system

•

Coolant is farmful

If the comes in contact with skin or eyes, flush with water

•

If swallowed accidentally, induce vomiting and call physician immediately

•

•

Keep it away from children

;

.

.

.

20 30 40

Density (%)

.

(kgf/cm2)

50 60

1

.5

0

.9

a)

0

.5

0)

Z3

0

(7

.

Page 4

~

~

~

~

~

5-4COOLING AND LUBRICATION SYSTEM

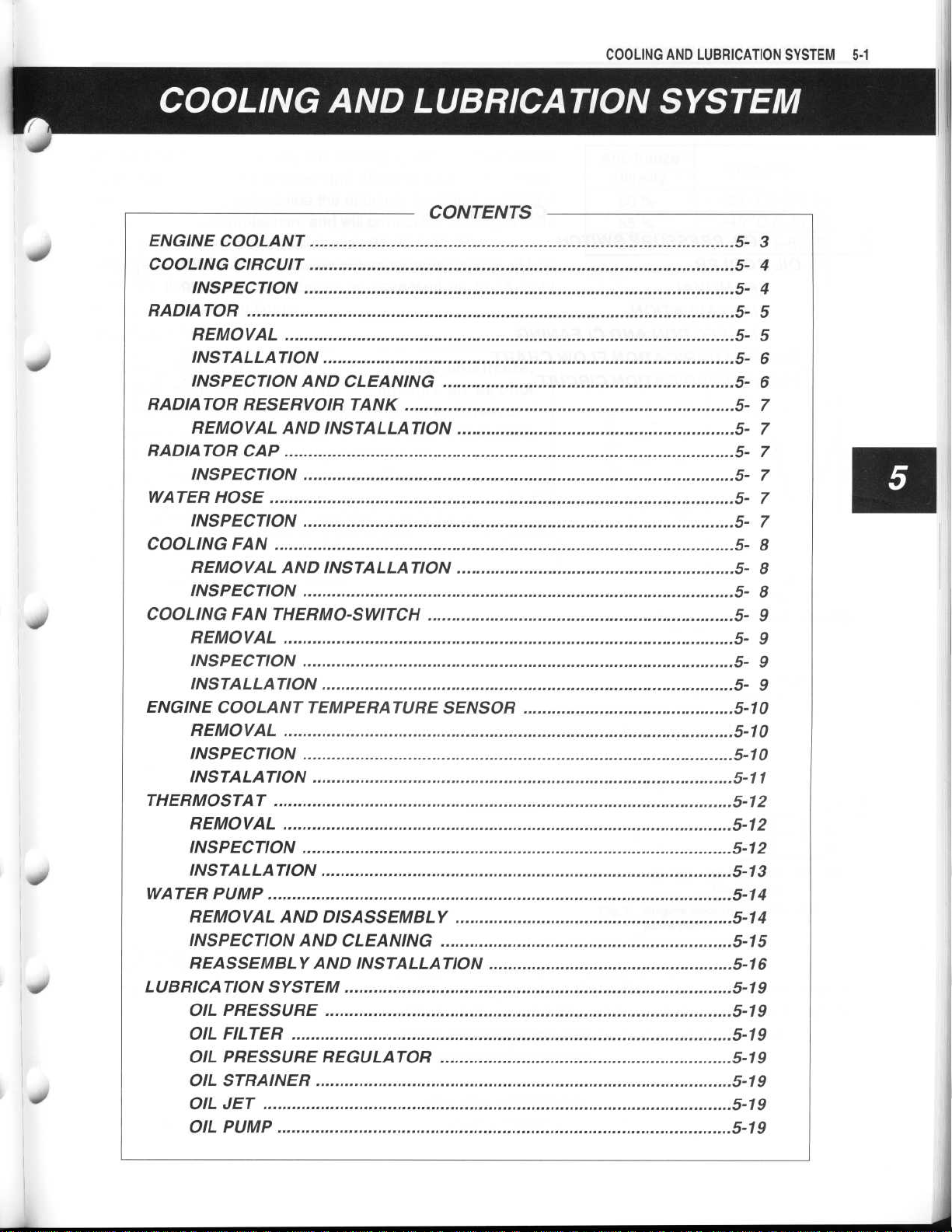

COOLING CIRCUIT

RESERVOIR TANK

RADIATOR

NO

. 1 CYLINDER HEAD

. 1 CYLINDER

NO

THERMOSTAT

NO

. 2 CYLINDER

NO

. 2 CYLINDER HEAD

WATER PUMP

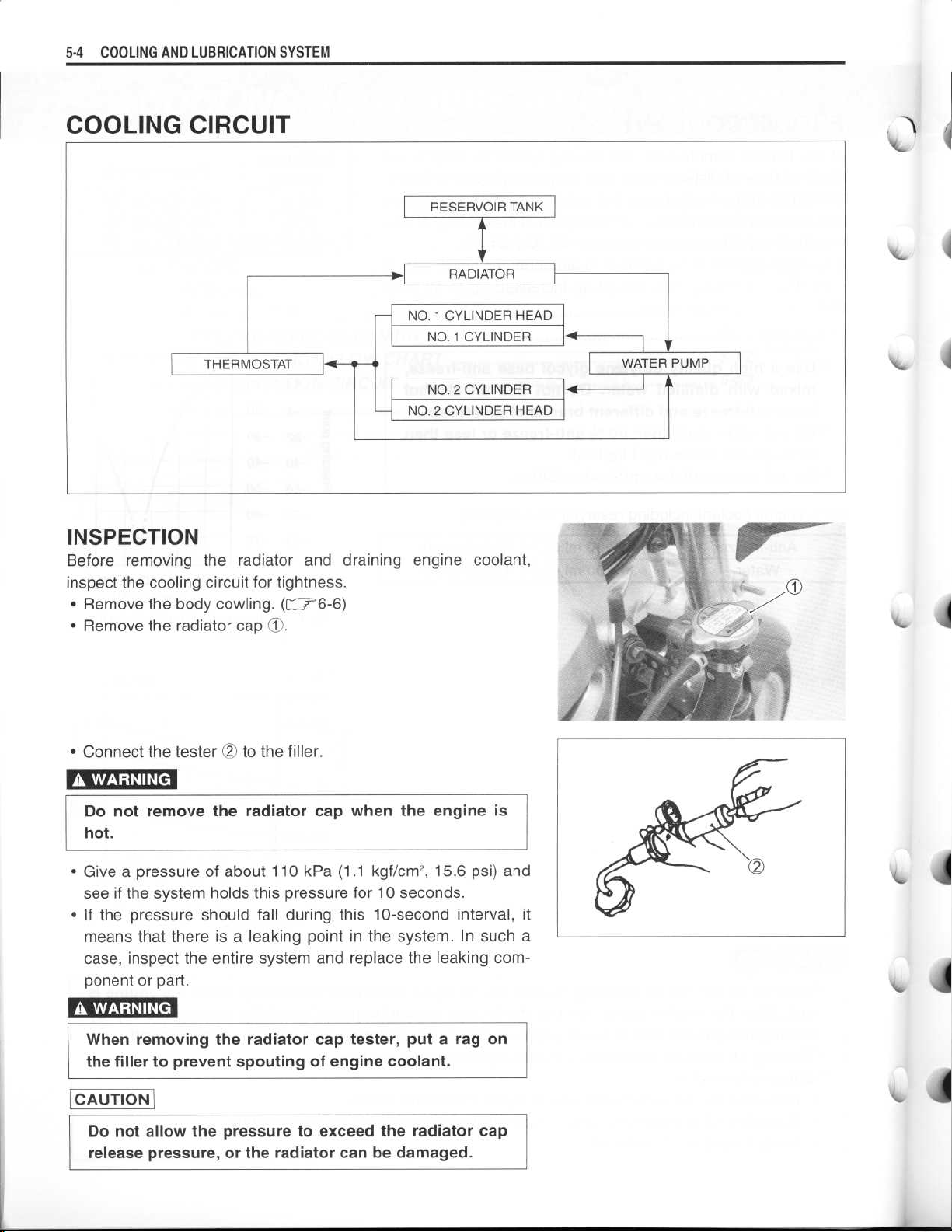

INSPECTION

Before removing the radiator and draining engine coolant,

inspect the cooling circuit for tightness

•

Remove the body cowling

•

Remove the radiator cap ®

Connect the tester 02 to the filler

•

A WARNING

Do not remove the radiator cap when the engine is

hot

.

•

Give a pressure of about 110 kPa (1

see if the system holds this pressure for 10 seconds

If the pressure should fall during this 10-second interval, it

•

means that there is a leaking point in the system

case, inspect the entire system and replace the leaking com-

ponent or part

.

. (=6-6)

.

.

.

.1 kgf/cm

2

,15.6 psi) and

.

. In such a

A WARNING

When removing the radiator cap tester, put a rag on

the filler to prevent spouting of engine coolant

CAUTION

Do not allow the pressure to exceed the radiator cap

release pressure, or the radiator can be damaged

.

.

Page 5

~

~

~

~

~

~

COOLING AND LUBRICATION SYSTEM5-5

I

RADIATOR

40

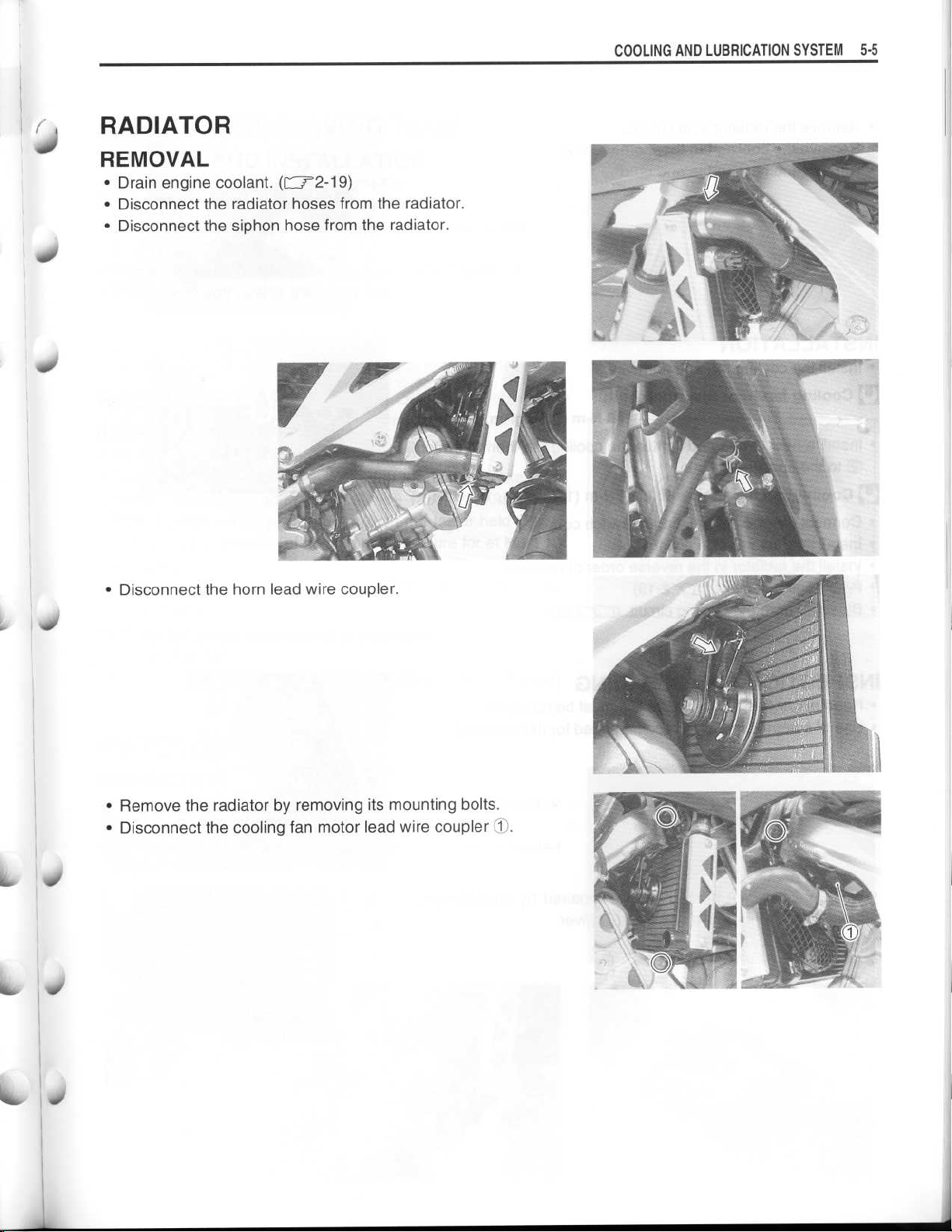

REMOVAL

•

Drain engine coolant.(C-.

Disconnect the radiator hoses from the radiator

•

Disconnect the siphon hose from the radiator

•

7-2-19)

.

.

Disconnect the horn lead wire coupler

•

Remove the radiator by removing its mounting bolts

•

Disconnect the cooling fan motor lead wire coupler 10

•

.

.

.

Page 6

~

~

~

~

~

~

~

~

~

~

~

~

~

~

~

5-6COOLING AND LUBRICATION SYSTEM

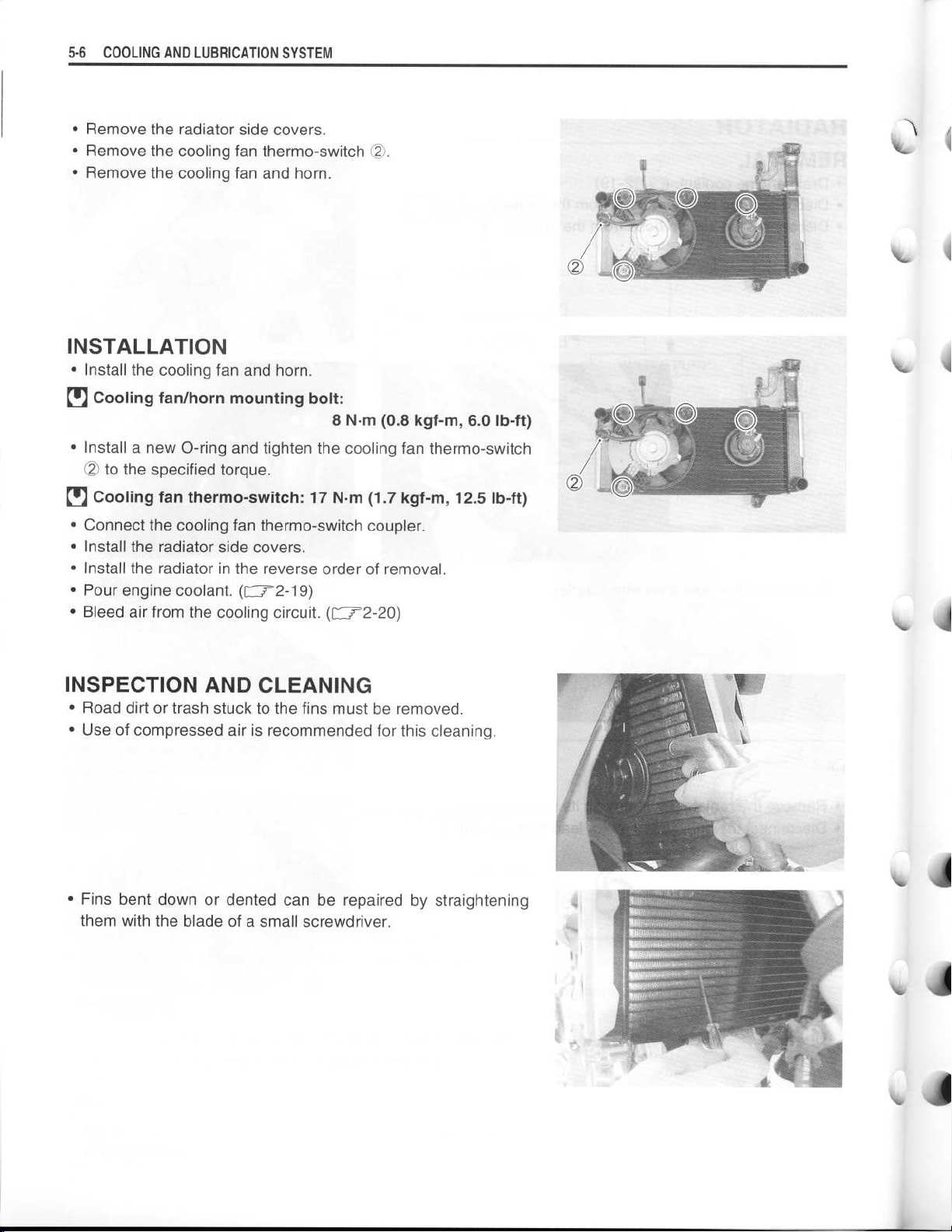

•

Remove the radiator side covers

•

Remove the cooling fan thermo-switch

•

Remove the cooling fan and horn

INSTALLATION

•

Install the cooling fan and horn

Cooling fan/horn mounting bolt

•

•

Install a new 0-ring and tighten the cooling fan thermo-switch

02

to the specified torque

•

Cooling fan thermo-switch

•

Connect the cooling fan thermo-switch coupler

•

Install the radiator side covers

•

Install the radiator in the reverse order of removal

•

Pour engine coolant.(F-

•

Bleed air from the cooling circuit

.

72-19)

.

.

.

:

8 N

: 17 N

.m (1

.

. (CI2-20)

02

.

.m (0

.8 kgf-m, 6

.7 kgf-m, 12

.0 lb-ft)

.5 lb-ft)

.

.

INSPECTION AND CLEANING

•

Road dirt or trash stuck to the fins must be removed

•

Use of compressed air is recommended for this cleaning

•

Fins bent down or dented can be repaired by straightening

them with the blade of a small screwdriver

.

.

.

Page 7

~

~

~

~

~

~

~

~

~

~

~

COOLING AND LUBRICATION SYSTEM5-7

RADIATOR RESERVOIR TANK

REMOVAL AND INSTAL

•

Lift and support the fuel tank

•

Disconnect the siphon hose from the radiator

•

Remove the reservoir tank by removing its mounting bolt

•

Drain engine coolant

•

Install the reservoir tank in the reverse order of removal

•

Fill the reservoir tank to the upper level

.

LA

TION

.(rr4-65)

.

.

.

.

RADIATOR CAP

INSPECTION

•

Fit the cap 90 to the radiator cap tester

•

Build up pressure slowly by operating the tester

that the pressure build-up stops at 95

kgf/cm2,13.5-17

still, the cap is capable of holding that pressure for at least 10

seconds

•

Replace the cap if it is found not to satisfy either of these two

requirements

.

.8 psi) and that, with the tester held stand-

.

(2)

.

-

125 kPa (0

. Make sure

.95

-1.25

Radiator cap valve opening pressure

Standard

95-

:

125 kPa (0

.95-1

.25 kgf/cm

2 ,

13.5-17.8 psi)

WATER HOSE

INSPECTION

•

Any water hose found in a cracked condition or flattened or

water leaked must be replaced

•

Any leakage from the connecting section should be corrected

by proper tightening

.

.

Page 8

~

~

~

~

~

~

~

~

~

5 -8

COOLING AND LUBRICATION SYSTEM

COOLING FAN

REMOVAL AND INSTALLATION

REMOVAL

•

Remove the steering stem lower plate 10

•

Remove the radiator mounting bolts

•

Move the radiator forward

.

.

.

WAN

•

Disconnect the cooling fan motor lead wire couplerOand

cooling fan thermo-switch coupler ®

•

Remove the cooling fan

INSTALLATION

•

Install the cooling fan and radiator in the reverse order of

removal

Cooling fan motor mounting bolt

.

.

8 N

.

:

.m (0

.8 kgf-m, 6

.0 Ib-ft)

INSPECTION

•

Disconnect the cooling fan motor lead wire coupler

•

Test the cooling fan motor for load current with an ammeter

connected as shown in the illustration

•

The voltmeter is for making sure that the battery applies 12 V

to the motor . With the motor with electric motor fan running at

full speed, the ammeter should be indicating not more than 5

amperes

•

If the fan motor does not turn, replace the motor assembly

with a new one

.

.

.

O

.

1

14

NOTE

:

When making above test, it is not necessary to remove the cooling fan

.

Page 9

~

~

~

~

~

~

~

~

~

~

~

COOLING AND LUBRICATION SYSTEM

/

COOLING FAN THERMO-SWITCH

5 -9

REMOVAL

•

Drain engine coolant

•

Disconnect the cooling fan thermo-switch lead wire coupler

10

.

•

Remove the cooling fan thermo-switch (2

. ([72-19)

.

INSPECTION

•

Check the cooling fan thermo-switch closing/opening temperature by testing it at a bench as shown in the figure

the thermo-switch 1) to the circuit tester and place it in oil contained in a pan, which is placed on a stove

•

Heat the oil to raise its temperature slowly and read the column thermometer (2 when the switch closes or opens

Cooling fan thermo-switch operating temperature

Standard (OFF-ON)

(ON-DOFF)

09900-25008

: Multi circuit tester set

: Approx

: Approx

.

. 105 °C (221 °F)

. 100 °C (212 °F)

. Connect

.

020

Tester knob indication

CAUTION

•

Take special care when handling the thermo-switch

It may cause damage if it gets a sharp impact

•

Do not contact the cooling fan thermo-switch

the column thermometer 02 with a pan

: Continuity test (

•)

l))

.

.

(1)

.

and

INSTALLATION

•

Install a new 0-ring 1O

•

Tighten the cooling fan thermo-switch to the specified torque

0

Cooling fan thermo-switch

•

Pour engine coolant

•

Bleed air from the cooling circuit

~

40

.

. (

F-7-2-19)

: 17 N

.

(

r

-

.m (1

.7 kgf-m, 12

7-2-20)

.

.5 lb-ft)

Page 10

~

~

~

~

~

5-10

COOLING AND LUBRICATION SYSTEM

ENGINE COOLANT TEMPERATURE SENSOR

REMOVAL

•

Drain engine coolant.(f

•

Disconnect the engine coolant temperature sensor lead wire

coupler 10

Place a rag under the sensor and remove the engine coolant

•

temperature sensor

INSPECTION

•

Check the engine coolant temperature sensor by testing it at a

bench as shown in the figure

sorOto the circuit tester and place it in oil contained in a pan,

which is placed on a stove

Heat the oil to raise its temperature slowly and read the col-

•

umn thermometer

If the temperature sensor ohmic valve does not change in the

•

proportion indicated, replace it with a new one

Temperature sensor specification

.

OO

OO

2-19)

-

.

. Connect the temperature sen-

.

and the ohmmeter

.

.

Temperature

20 °C (68 °F)

40 °C (104 °F)

60 °C (140 °F)

80 °C (176 °F)

09900-25008

Tester knob indication

o

If the resistance noted to show infinity or too much different

resistance value, replace the temperature sensor with a new

one

.

CAUTION

* Take special care when handling the temperature

sensor

impact

* Do not contact the engine coolant temperature sen-

sor

. It may cause damage if it gets a sharp

.

and the column thermometerOOwith a pan

®

: Multi circuit tester set

: Resistance (0)

Standard resistance

Approx

Approx

Approx

Approx

. 2

.45 kQ

. 1

.15 k4

. 0

.58 kQ

. 0

.32 kQ

.

Page 11

~

~

~

~

INSTALATION

•

Install a new sealing washer

•

Tighten the engine coolant temperature sensor to the specified torque

Engine coolant temperature sensor

0

CAUTION

Take special care when handling the temperature sensor

. It may cause damage if it gets a sharp impact

•

Pour engine coolant.(f-2-19)

•

Bleed air from the cooling circuit

.

(j)

.

18 N

.(C1-2-20)

:

.m (1

.8 kgf-m, 10

.6 Ib-ft)

.

COOLING AND LUBRICATION SYSTEM5-1

1

Page 12

~

~

~

~

~

5

-12

COOLING AND LUBRICATION SYSTEM

THERMOSTAT

REMOVAL

•

Drain engine coolant

•

Place a rag under the thermostat case

•

Remove the thermostat case

•

Remove the thermostat

.

(r

--

r2-19)

O

.

.

.

INSPECTION

Inspect the thermostat pellet for signs of cracking

Test the thermostat at a bench for control action in the following

manner

•

•

•

.

Pass a string through the thermostat as shown in the photo-

graph

.

Immerse the thermostat in water contained in a beaker as

shown in the illustration

in suspension

stove and observe the rising temperature on a thermometer

Read the thermometer just when opening the thermostat

reading, which is the temperature level at which the thermo-

stat valve begins to open, should be within the standard

value

.

Thermostat valve opening temperature

Standard

. Heat the water by placing the beaker on a

: Approx

. Note that the immersed thermostat is

. 88 °C (190 °F)

.

.

. This

Page 13

~

~

~

~

~

~

~

•

Keep on heating the water to raise its temperature

•

Just when the water temperature reaches specified value, the

thermostat valve should have lifted by at least 8

(0

.31 in)

.

Thermostat valve lift

Standard

•

A thermostat failing to satisfy either of the two requirements

(start-to-open temperature and valve lift) must be replaced

: Over 8

.0 mm at 100 °C (Over 0

.

.0 mm

.31 in . at 212 °F)

.

INSTALLATION

•

Install the thermostat

NOTE

:

The jiggle valveOOof the thermostat faces upside

.

.

COOLING AND LUBRICATION SYSTEM5-1

3

•

Install the thermostat case

•

Tighten the thermostat case bolts to the specified torque

Thermostat case bolt

0

•

Pour engine coolant.(f r

•

Bleed air from the cooling circuit.(F-

.

: 10 N

2-19)

.m (1

.0 kgf-m, 7

.0 Ib-ft)

72-20)

.

Page 14

~

~

~

~

~

~

~

~

~

5-14

COOLING AND LUBRICATION SYSTEM

WATER PUMP

REMOVAL AND DISASSEMBLY

NOTE

:

Before draining engine oil and engine coolant, inspect engine oil

and coolant leakage between the water pump and clutch cover

engine oil is leaking, visually inspect the oil seal and O-ring

engine coolant is leaking, visually inspect the mechanical seal and

seal ring

•

•

•

•

•

. (=5-15)

Remove the under cowling

Drain engine coolant.(r72-19)

Drain engine oil

Disconnect the water hoses

Remove the water pump case

. (=2-14)

. (=6-5)

.

.

. If

. If

Remove the clutch cover

•

•

Remove the E-ring from the impeller shaft

Remove the impeller

•

•

Remove the mechanical seal ring C1 and the rubber seal !2D

from the impeller

.

.

.

.

14

Page 15

~

~

~

~

~

~

~

~

1

COOLING AND LUBRICATION SYSTEM 5-

5

Remove the bearings with the special tool and proper bars

•

. .

09921-20240

NOTE

:

If there is no abnormal noise, bearing removal is

CAUTION

The removed bearing must be replaced with a new

one

.

•

Remove the mechanical seal using the special tool

09921-20240

NOTE

:

If there is no abnormal condition, the mechanical seal

not necessary

CAUTION

The removed mechanical seal must be replaced with a

new one

•

Remove the oil seal using a suitable bar

: Bearing remover set

not necessary

.

: Bearing remover set

removal is

.

.

.

.

Em

.

fim

S

NOTE

:

If there is no abnormal condition, the oil seal

essary

.

CAUTION

The removed oil seal must be replaced with a new one

removal is

not nec-

.

INSPECTION AND CLEANING

BEARING

•

Inspect the play of the bearings by hand while they are in the

clutch cover

•

Rotate the inner race by hand to inspect for abnormal noise

and smooth rotation

•

Replace the bearing if there is anything unusual

MECHANICAL SEAL

•

Visually inspect the mechanical seal for damage, with particu-

lar attention given to the sealing face

•

Replace the mechanical seal that shows indications of leakage

. Also replace the seal ring if necessary

.

.

.

.

.

Page 16

~

~

~

~

~

5-16

COOLING AND LUBRICATION SYSTEM

OIL SEAL

•

Visually inspect the oil seal for damage, with particular atten-

tion given to the lip

•

Replace the oil seal that shows indications of leakage

.

.

REASSEMBLY AND INSTALLATION

•

Install the oil seal using the special tool

.

09913-70210

NOTE

:

The stamped mark on the oil seal faces outside

•

Apply a small quantity of the SUZUKI SUPER GREASE to the

oil seal lip

99000-25030

99000-25010

•

Install the new mechanical seal using a suitable size socket

wrench

NOTE

On the new mechanical seal, the sealer A) has been applied

.

:

: Bearing installer set

.

: SUZUKI

: SUZUKI

SUPER GREASE "A" (USA)

SUPER GREASE "A"

.

(Others)

.

Page 17

~

~

~

~

~

~

•

Install the new bearing using the special tool

09913-70210

NOTE

:

The stamped mark on the bearing faces crankcase side

•

Apply SUZUKI SUPER GREASE to the impeller shaft

99000-25030

99000-25010

•

Install the rubber seal 1O into the impeller

•

After wiping off the oily or greasy matter from the mechanical

seal ring, install it into the impeller

NOTE

:

The paint marked sideOOof the mechanical seal ring faces the

impeller

•

.

Install the impeller to the clutch cover

: Bearing installer set

: SUZUKI

: SUZUKI

SUPER GREASE

SUPER GREASE "A"

.

.

.

.

.

"A"

(USA)

(Others)

.

COOLING AND LUBRICATION SYSTEM

EM

5-17

•

Fix the impeller shaft with the E-ring securely

•

Install a new 0-ring

NOTE

:

Apply engine coolant to the O-ring

CAUTION

Use a new O-ring to prevent engine coolant leakage

OO

.

OO

.

.

.

Page 18

~

~

~

~

~

~

~

~

5-18

COOLING AND LUBRICATION SYSTEM

Set the impeller shaft end to the cam drive idle shaft

•

(

T3-91)

r

-

•

Install the clutch cover

©

Clutch cover bolt

•

Install the water pump case

Water pump case bolt

0

•

Connect the water hoses

•

Pour engine oil

•

Pour engine coolant.(r--72-19)

•

Bleed air from the cooling circuit

•

Install the under cowling

. (1I72-14)

.

: 11 N

.

.m (1

.

: 10 N

.

.1 kgf-m, 8

.m (1

.0 kgf-m, 7

. (=2-20)

.0 lb-ft)

.

.3 lb-ft)

Page 19

LUBRICATION SYSTEM

OIL PRESSURE

F-72-32

OIL FILTER

F--72-15

OIL PRESSURE REGULATOR

C-73-67

OIL STRAINER

=3-28 and -85

OIL JET

r -

7'3-68, -69 and -95

OIL PUMP

=3-66 and -67

COOLING AND LUBRICATION SYSTEM 5-19

d/

OIL

PRESSURE SWITCH

C'3-67, 7-29 and -30

nI

Page 20

~

~

~

~

~

~

5-20

COOLING AND LUBRICATION SYSTEM

OIL COOLER

REMOVAL

•

Remove the under cowling.(f'"'6-5)

•

Drain engine oil

•

Disconnect the oil cooler hoses

•

Remove the oil cooler

. (=2-14)

.

.

•

Remove the oil cooler fin guard net

•

Remove the oil hoses

.

.

Page 21

~

~

~

~

~

~

~

~

~

~

COOLING AND LUBRICATION SYSTEM

I

INSTALLATION

•

Install new gasket washers 90

CAUTION

Use new gasket washers to prevent engine oil leak-

age

.

•

Install the oil cooler

•

Tighten the oil cooler mounting bolts (2) to the specified

torque

.

Oil cooler mounting bolt

•

•

Tighten the oil cooler hose union bolts 03 to the specified

torque

.

Oil cooler hose union bolt

•

Install the under cowling

•

.

.

.

: 10 N

: 23 N

.m (1

.m (2

.0 kgf-m, 7

.3 kgf-m, 16

.3 Ib-ft)

.5 lb-ft)

5-21

INSPECTION AND CLEANING

Inspect the oil cooler and hose joints for oil leakage

•

defect are found, replace the oil cooler and oil hoses with the

new ones

•

Road dirt or trash stuck to the fins must be removed

Use of compressed air is recommended for this cleaning

•

Fins bent down or dented can be repaired by straightening

•

them with the blade of a small screwdriver

.

.

. If any

.

.

Page 22

~

~

~

5-

2 2

COOLING AND LUBRICATION SYSTEM

ENGINE LUBRICATION FLOW CHART

#2 CYLINDER

EX

. CAMSHAFT

JOURNALS/

CAM FACES/

SCISSORS GEAR

CAM SPROCKETS AND DRIVE

CHAIN

iii

OIL JET

iii iii

TAPPETS

ik~

CAMSHAFT DRIVE

IDLE GEAR BUSHING

1

CRANKSHAFT LEFT SIDE

JOURNAL BEARING

T

GENERATOR

STARTER

CLUTCH

[REAR]

IN

. CAMSHAFT

JOURNALS/

CAM FACES/

SCISSORS GEAR

#1 PISTON

AND PIS-

TON PIN

#1 PISTON

COOLING

NOZZLE

IN

. CAMSHAFT

JOURNALS/

CAM FACES/

SCISSORS GEAR

iii

#1 AND #2

CYLINDER

WALLS

iii

#1 AND #2 CRANKSHAFT PIN BEARINGS

~i i

iii

#2 CYLINDER

Ali

TAPPETS

A

CAMSHAFT DRIVE

IDLE GEAR BUSHING

#2 PISTON

PIS-

AND

TON PIN

~i i

#2 PISTON

COOLING

NOZZLE

CRANKSHAFT RIGHT SIDE

JOURNAL BEARING

[FRONT]

A"

i l

OIL JET

1

EX

. CAMSHAFT

JOURNALS/

CAM FACES/

SCISSORS GEAR

iii

CAM SPROCK-

ETS AND DRIVE

CHAIN

DRIVESHAFT

iii

LEFT SIDE

BEARING

DRIVESHAFT

GEARS AND

BUSHINGS

iii

I

OIL PUMP

4

OIL SUMP FILTER

~

COUNTERSHAFT

LEFT SIDE

BEARING

COUNTERSHAFT

GEARS AND

BUSHINGS

CLUTCH PLATES

~„

r

OIL PRESSURE

REGULATOR

OIL PAN

OIL JET

BY-PASS

MAIN GALLERY

OIL COOLER

OIL PRESSURE

SWITCH

BY-PASS

OIL FILTER

4

Page 23

COOLING AND LUBRICATION SYSTEM5-2 3

i (

S

./

ENGINE LUBRICATION CIRCUIT

Loading...

Loading...